BCL 900i

Barcode Scanner

Original operating instructions

EN 2015/

10 - 50130069

Subject to change

without prior notice

iii

CONTENTS

REFERENCES ......................................................................................................... vii

Reference Documentation ........................................................................................ vii

Support Through the Website ................................................................................... vii

Patents ..................................................................................................................... vii

CONVENTIONS ....................................................................................................... viii

COMPLIANCE ......................................................................................................... viii

Electrical Safety ........................................................................................................viii

Laser Safety ..............................................................................................................viii

Warning and Serial labels .......................................................................................... ix

Power Supply .............................................................................................................. x

CSA Listing ................................................................................................................. x

CE Compliance ........................................................................................................... x

FCC Compliance ........................................................................................................ xi

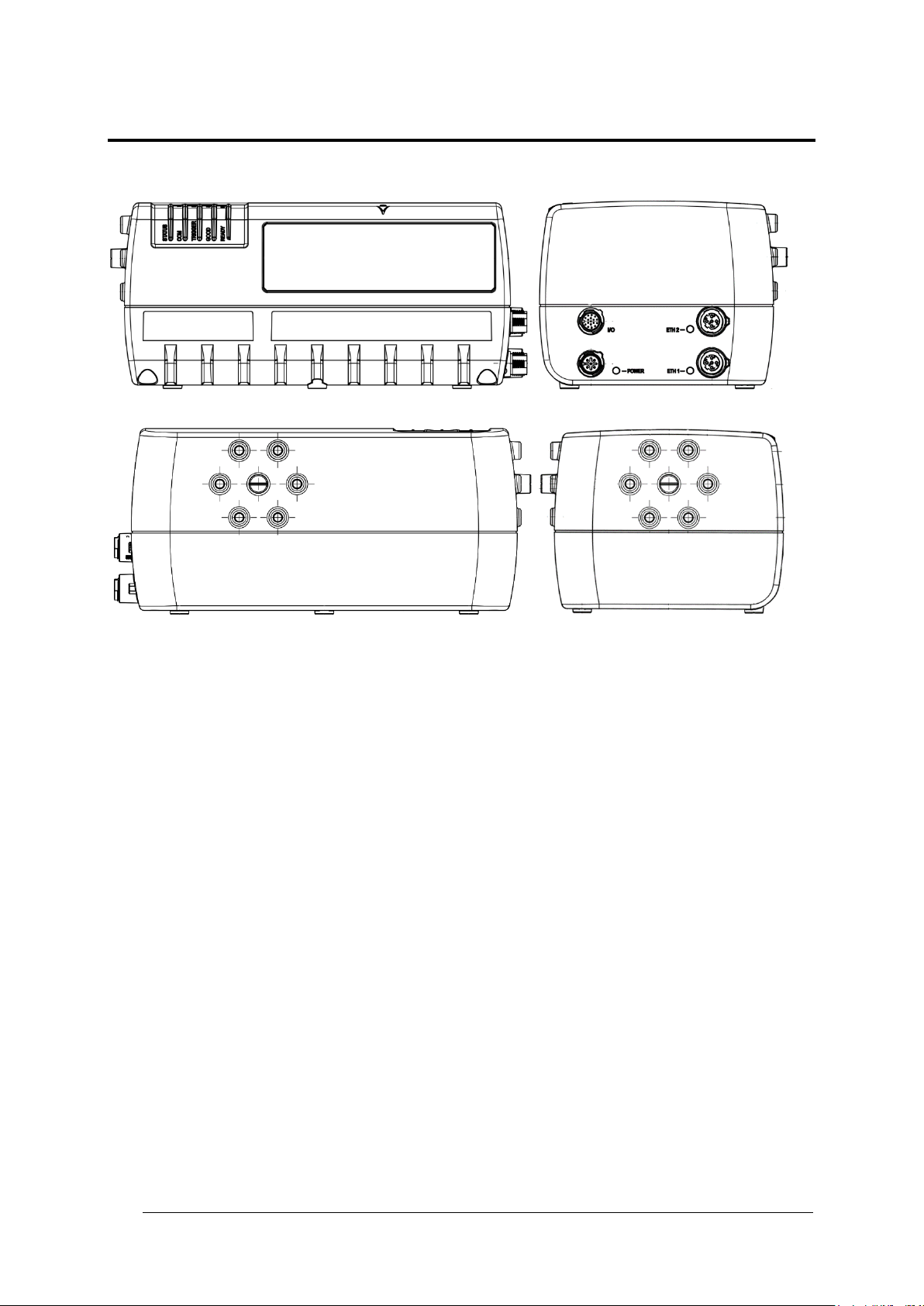

GENERAL VIEW ...................................................................................................... xii

1 INTRODUCTION ........................................................................................................ 1

1.1 Product Description ..................................................................................................... 1

1.2 Applications ................................................................................................................ 1

1.3 Model Description ....................................................................................................... 2

1.4 BCL 900i versions ....................................................................................................... 2

1.5 Human Machine Interface ................................................................ ........................... 3

1.6 Accessories ................................................................................................................ 4

1.7 Photoelectric Sensor ................................................................................................... 5

1.8 Encoder (Tachometer) ................................................................................................ 6

1.9 MA Industrial Connection Box ..................................................................................... 7

1.10 MSC 900 System Controller ........................................................................................ 8

2 MECHANICAL INSTALLATION ................................................................................. 9

2.1 Preparing for Mechanical Installation .......................................................................... 9

2.2 Unpacking Instructions .............................................................................................. 10

2.3 Installation Sequence ................................................................................................ 11

2.4 What You Need to Know About Your Application ...................................................... 12

2.5 Installation ................................................................................................................. 13

2.5.1 Dimensions and Clearances ..................................................................................... 13

2.5.2 Physical Support Requirements ................................................................................ 13

2.5.3 Vibration Limitations .................................................................................................. 13

2.5.4 General Mounting Guidelines .................................................................................... 14

2.5.5 Mounting Structure Considerations ........................................................................... 15

2.5.6 Mounting the Scanner ............................................................................................... 16

2.5.7 Positioning the Scanners .......................................................................................... 19

3 ELECTRICAL INSTALLATION ................................................................................ 20

3.1 Preparing for Electrical Installation ............................................................................ 20

3.2 Connecting a BCL 900i Scanner ............................................................................... 21

3.3 Typical Connection Block Diagrams .......................................................................... 22

3.3.1 Single BCL 900i Barcode Scanner to MA 900 ........................................................... 22

3.3.2 Master/Slave Array with MA 900 ............................................................................... 23

3.3.3 BCL 900i Barcode Scanners in an Array with MSC 900 Master ................................ 24

3.4 General Electrical Installaion guidelines and Precautions ......................................... 26

3.5 BCL 900i Connector Panels ...................................................................................... 27

iv

3.6 Connecting a PC to the BCL 900i.............................................................................. 28

3.7 Power Connector Pin-Out Table ............................................................................... 28

3.8 Power Connections ................................................................................................... 29

3.9 MA 900 Connection Box ........................................................................................... 30

3.9.1 Wiring Into the MA 900 Connection Box .................................................................... 30

3.10 Photoelectric Sensor Connections to MA 900 ........................................................... 32

3.10.1 Photoelectric Sensor (NPN) ...................................................................................... 33

3.10.2 Photoelectric Sensor (PNP) ...................................................................................... 34

3.11 Tachometer Wiring to MA 900 ................................................................................... 35

3.11.1 Encoder/Tachometer Wiring for NPN Output (two models) ....................................... 35

3.11.2 Encoder/Tachometer Wiring for PNP Output (two models) ....................................... 37

3.12 Digital Output Configuration to MA 900 ..................................................................... 39

3.12.1 Unpowered Outputs .................................................................................................. 40

3.12.2 Powered Outputs ...................................................................................................... 41

3.13 Connecting to the MSC 900 System Controller (optional) ......................................... 42

3.14 Check Scanner Installation ....................................................................................... 43

4 USER INTERFACE .................................................................................................. 44

4.1 Getting Started .......................................................................................................... 44

4.1.1 Prerequisites ............................................................................................................. 44

4.1.2 Starting the User Interface ........................................................................................ 45

4.2 User Interface Basics ................................................................................................ 47

4.2.1 BCL 900i User Interface Menu Tree .......................................................................... 47

4.2.2 Entering Text Using the Text Entry Tool .................................................................... 47

4.2.3 Getting Help .............................................................................................................. 48

4.3 Modify Settings ......................................................................................................... 49

4.4 Modify Settings | System Info .................................................................................... 50

4.5 Modify Settings | Global Settings ............................................................................... 53

4.5.1 Modify Settings | Global Settings | Operating Mode .................................................. 54

4.5.2 Modify Settings | Global Settings | Barcode Settings Table ....................................... 69

4.5.3 Modify Settings | Global Settings | Barcode Configuration ......................................... 75

Strip Filter Settings .................................................................................................... 79

Strip Filter Settings .................................................................................................... 84

Strip Filter Settings .................................................................................................... 98

4.5.4 Modify Settings | Global Settings | Serial Ports ......................................................... 99

4.5.5 Modify Settings | Global Settings | Ethernet ............................................................ 103

User Socket n ......................................................................................................... 107

4.5.6 Modify Settings | Global Settings | Messaging ......................................................... 111

4.5.7 Modify Settings | Global Settings | Digital I/O ................................ .......................... 133

4.5.8 Modify Settings | Global Settings | Diagnostics ....................................................... 136

4.5.9 Modify Settings | Global Settings | Energy Saving ................................................... 138

4.5.10 Modify Settings | Global Settings | HMI Settings (Human-Machine Interface) .......... 143

4.6 Device Settings ....................................................................................................... 145

4.6.1 Device Settings | Device Name | Device Info .......................................................... 146

4.6.2 Device Settings | Device Name | Mounting .............................................................. 148

4.6.3 Device Settings | Device Name | Options ................................................................ 150

4.7 Diagnostics ............................................................................................................. 152

4.7.1 Diagnostics | Monitor ............................................................................................... 153

4.7.2 Diagnostics | Read Test .......................................................................................... 155

4.7.3 Diagnostics | Status Viewer ..................................................................................... 156

4.8 Utilities .................................................................................................................... 159

4.8.1 Utilities | Backup or Restore .................................................................................... 159

4.8.2 Utilities | Reboot ...................................................................................................... 161

4.8.3 Utilities | Update Firmware ...................................................................................... 162

v

5 BARCODE SCANNING FEATURES ...................................................................... 164

5.1 First-time Startup .................................................................................................... 164

5.1.1 Default Parameters ................................................................................................. 164

5.1.2 Check Operations using Test Mode ........................................................................ 164

5.2 Basic Installation Procedures with the MA 900 ................................ ........................ 166

5.3 Basic Installation with MSC 900 Controller .............................................................. 169

5.4 LED Indicators ........................................................................................................ 173

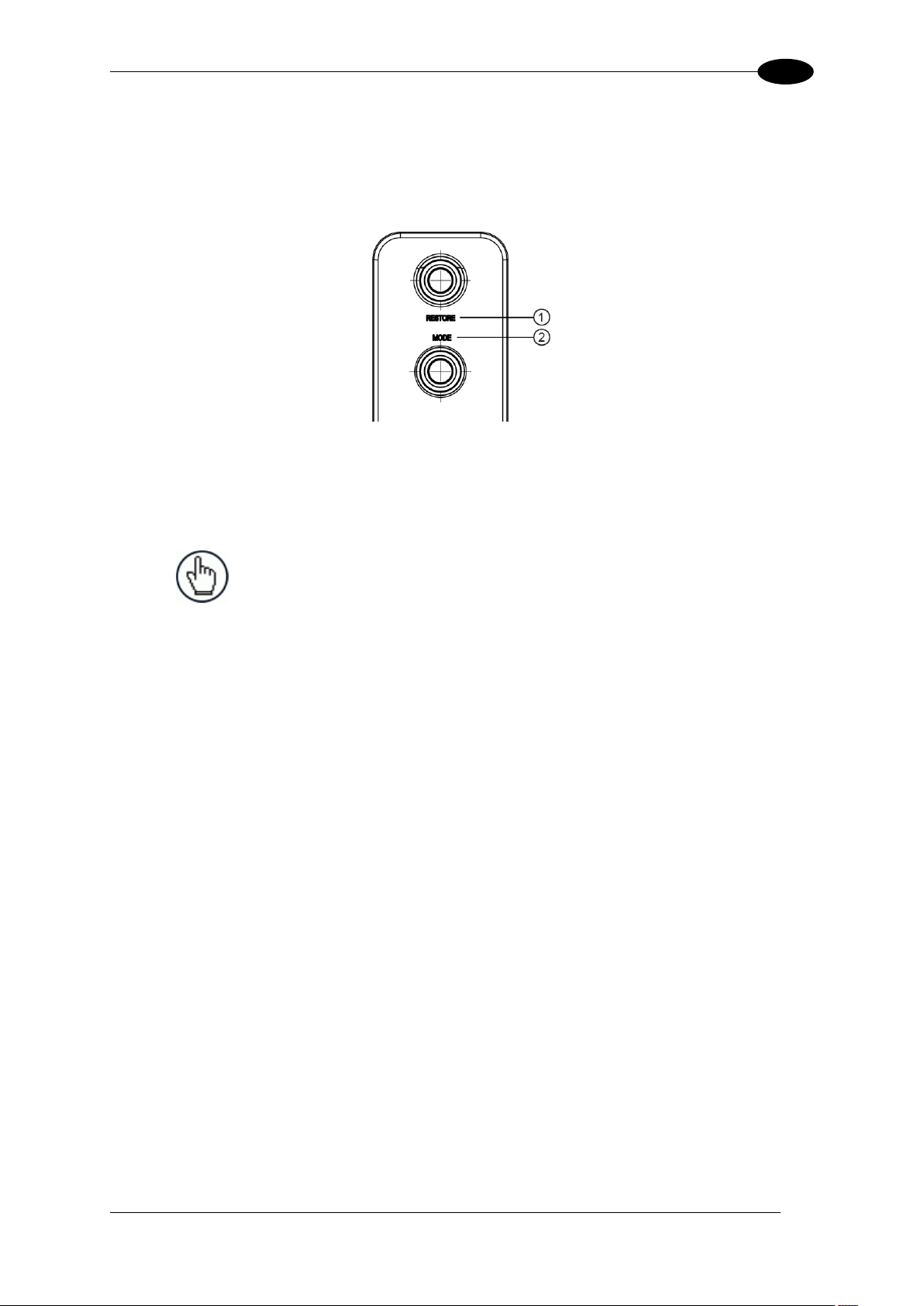

5.5 Control Panel Buttons ............................................................................................. 174

5.5.1 Human Machine Interface ................................................................ ....................... 174

HMI Functions (Mode) ............................................................................................. 174

Test Mode ............................................................................................................... 176

Learn ...................................................................................................................... 176

Setup ................................ ................................................................ ...................... 176

Netconfig ................................................................................................................. 176

5.5.2 Restore Button and Other Functions ....................................................................... 177

5.6 PackTrack™ ........................................................................................................... 178

5.6.1 Using the PackTrack Wizard ................................................................................... 180

5.6.2 Top-Mounted Barcode Scanner Calibration Using PackTrack ................................. 184

5.6.3 Side-Mounted Barcode Scanner Calibration Using PackTrack ................................ 191

5.6.4 Bottom-Mounted Barcode Scanner Calibration Using PackTrack ............................ 198

5.6.5 Verifying PackTrack Calibration .............................................................................. 199

5.7 Replacing an Installed BCL 900i ............................................................................. 202

5.7.1 Replacing a Standalone Scanner Using Restore ..................................................... 202

5.7.2 Replacing a Slave Scanner in an Array/Tunnel Automatically ................................. 203

5.7.3 Replacing a Slave Scanner in an Array/Tunnel Using Restore ................................ 204

5.7.4 Replacing a Master Scanner in an Array/Tunnel Using Restore .............................. 204

5.7.5 Checking the Operation of the Replacement ........................................................... 205

5.8 Typical Layouts ....................................................................................................... 206

5.8.1 Large Synchronized Network Layout ....................................................................... 206

5.9 Code Reconstruction Technology (CRT) ................................................................. 209

5.9.1 Tilt Angle for Code Reconstruction Technology....................................................... 210

5.9.2 Minimum Code Height For Code Reconstruction Technology ................................. 211

5.10 Reading Diagram .................................................................................................... 213

BCL 900i SM 102 .................................................................................................... 214

BCL 900i SN 102 .................................................................................................... 218

6 MAINTENANCE ..................................................................................................... 223

6.1 Overview ................................................................................................ ................. 223

6.2 Maintenance Tasks ................................................................................................. 224

6.2.1 Cleaning the Exit Window ....................................................................................... 225

6.2.2 Cleaning the Photoelectric Sensor .......................................................................... 226

6.2.3 Cleaning the Tachometer ........................................................................................ 227

6.2.4 Tighten Mounting Hardware .................................................................................... 228

6.2.5 Checking Barcode Scanning System Connections .................................................. 228

6.2.6 Verify Barcode Scanner Operation .......................................................................... 228

6.2.7 Verify Photoelectric Sensor Operation .................................................................... 228

6.2.8 Verify Tachometer Operation .................................................................................. 229

7 TROUBLESHOOTING ............................................................................................ 230

7.1 Error Codes and Resolutions .................................................................................. 231

8 TECHNICAL FEATURES ....................................................................................... 237

8.1 Technical Specifications .......................................................................................... 237

INDEX ..................................................................................................................... 240

vi

vii

REFERENCES

REFERENCE DOCUMENTATION

The documentation related to the BCL 900i management is listed below:

MA 900 Connection Box Installation Manuals

MSC 900 Controller Manuals

SUPPORT THROUGH THE WEBSITE

Leuze electronic provides several services as well as technical support through its website.

Log on to www.leuze.de and click on PRODUCTS for further information:

PRODUCTS – STATIONARY BARCODE READERS

Select your product from the links on the Stationary Barcode Readers page. The

product page describes specific Info, Features, Applications, Models, Accessories, and

Downloads including documentation, software drivers, and utility programs.

PATENTS

This product is covered by one or more of the following patents:

Utility patents: EP0789315B1, EP0851376B1, EP0926615B1, EP0959426B9,

EP1217571B1, EP1363228B1, JP4033958B2, JP4376353B2, US5992740, US6177979,

US6347740, US6394352, US6443360, US6527184, US6629639, US6742710

viii

WARNINGS OR CAUTIONS: This symbol identifies a hazard or procedure that, if

incorrectly performed, could cause personal injury or result in equipment damage. It is

also used to bring the user’s attention to details that are considered IMPORTANT.

HIGH VOLTAGE CAUTION: This symbol alerts the user they are about to perform an

action involving, either a dangerous level of voltage, or to warn against an action that

could result in damage to devices or electrical shock.

LASER CAUTION: This symbol alerts the user they are about to perform an action

involving possible exposure to laser light radiation.

ESD CAUTION: This symbol identifies a procedure that requires you take measures to

prevent Electrostatic Discharge (ESD) e.g., use an ESD wrist strap. Circuit boards are

most at risk. Please follow ESD procedures.

NOTES: This symbol draws attention to details or procedures that may be useful in

improving, maintaining, or enhancing the performance of the hardware or software being

discussed.

WARNING: Use of controls or adjustments or performance of

procedures other than those specified herein may result in

exposure to hazardous visible laser light.

CONVENTIONS

COMPLIANCE

ELECTRICAL SAFETY

This product conforms to the applicable requirements contained in the European Standard

for electrical safety EN 60950 at the date of manufacture.

LASER SAFETY

The following information is provided to comply with the rules imposed by international

authorities and refers to the correct use of the BCL 900i barcode scanners.

Standard Regulations

These barcode scanners use low-power laser diodes. Avoid staring at the beam as one

would with any very strong light source, such as the sun.

Take care when installing the laser device to avoid inadvertent laser beam contact with the

eye of an observer, including through reflective surfaces.

This product conforms to the applicable requirements of IEC 60825-1 and complies with 21

CFR 1040.10 except for deviations pursuant to Laser Notice N° 50, date June 24, 2007. The

scanner is classified as a Class 2 laser product according to IEC 60825-1 regulations.

There is a safety device which allows the laser to be switched on only if the motor is rotating

above the threshold for its correct scanning speed.

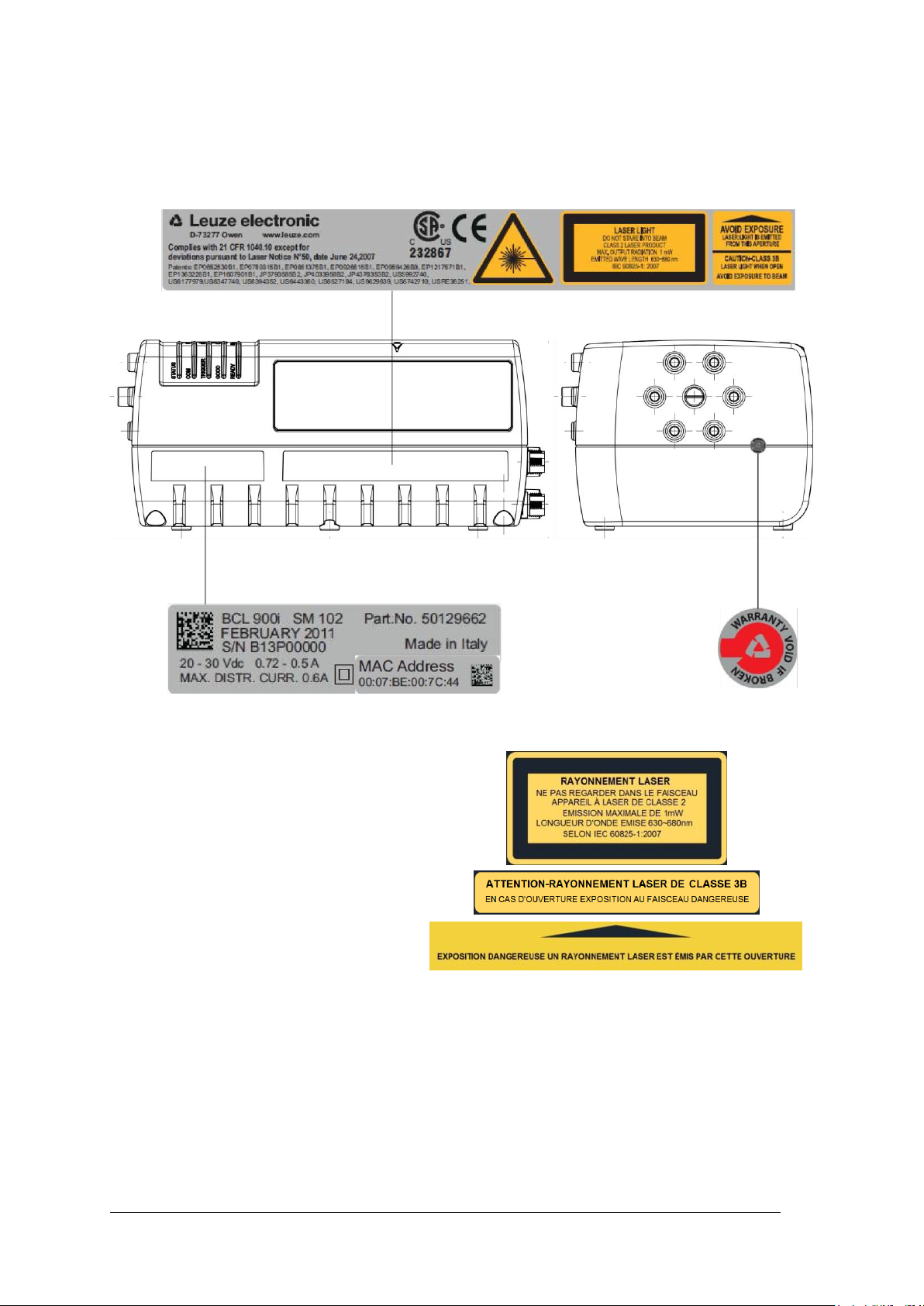

ix

WARNING AND SERIAL LABELS

The Warning Label on the front of the barcode scanner indicates exposure to laser light and

the device classification.

Figure 1: Warning and Device Class Label Location

Produit(s) conforme selon 21CFR

1040.10 sauf des dérogations relatives

à la Laser Notice N° 50, date Juin 24,

2007.

Dans le paquet il y a l’étiquette(s) pour

les pays où le texte d'avertissement en

français sont obligatoires. Le(s) mettre

sur le produit à la place de la version

anglaise.

Figure 2: Exemple d'étiquettes d'avertissement laser

x

WARNING: Disconnect the power supply when installing the device or during

maintenance to avoid unintentional exposure to laser light.

WARNING: There are no user serviceable parts inside the barcode scanner. Service

should only be performed by Leuze electronic trained and certified technicians.

Any violation of the optical parts in particular could result in exposure to Class 3B laser

light.

WARNING: This is a Class A product. In a domestic environment this

product may cause radio interference in which case the user may be

required to take adequate measures.

POWER SUPPLY

This product is intended to be installed by Qualified Personnel only.

This product is intended to be supplied by a UL listed or CSA Certified Power unit with “Class

2” or LPS power source.

CSA LISTING

Certificate: 70002952

3862 13 INFORMATION TECHNOLOGY EQUIPMENT-(CSA 60950-1-07, Second Edition)

3862 93 INFORMATION TECHNOLOGY EQUIPMENT-(UL 60950-1, Second EditionCertified to U.S. Stds)

Unattended scanning system, models BCL 900i-XYWZ rated 20-30 VDC 0.72-0.5 A and 2030 VDC 1-0.7 A

CE COMPLIANCE

xi

FCC COMPLIANCE

Modifications or changes to this equipment without the expressed written approval of Leuze

electronic could void the authority to use the equipment.

This device complies with PART 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference which may cause undesired

operation.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his/her own expense.

xii

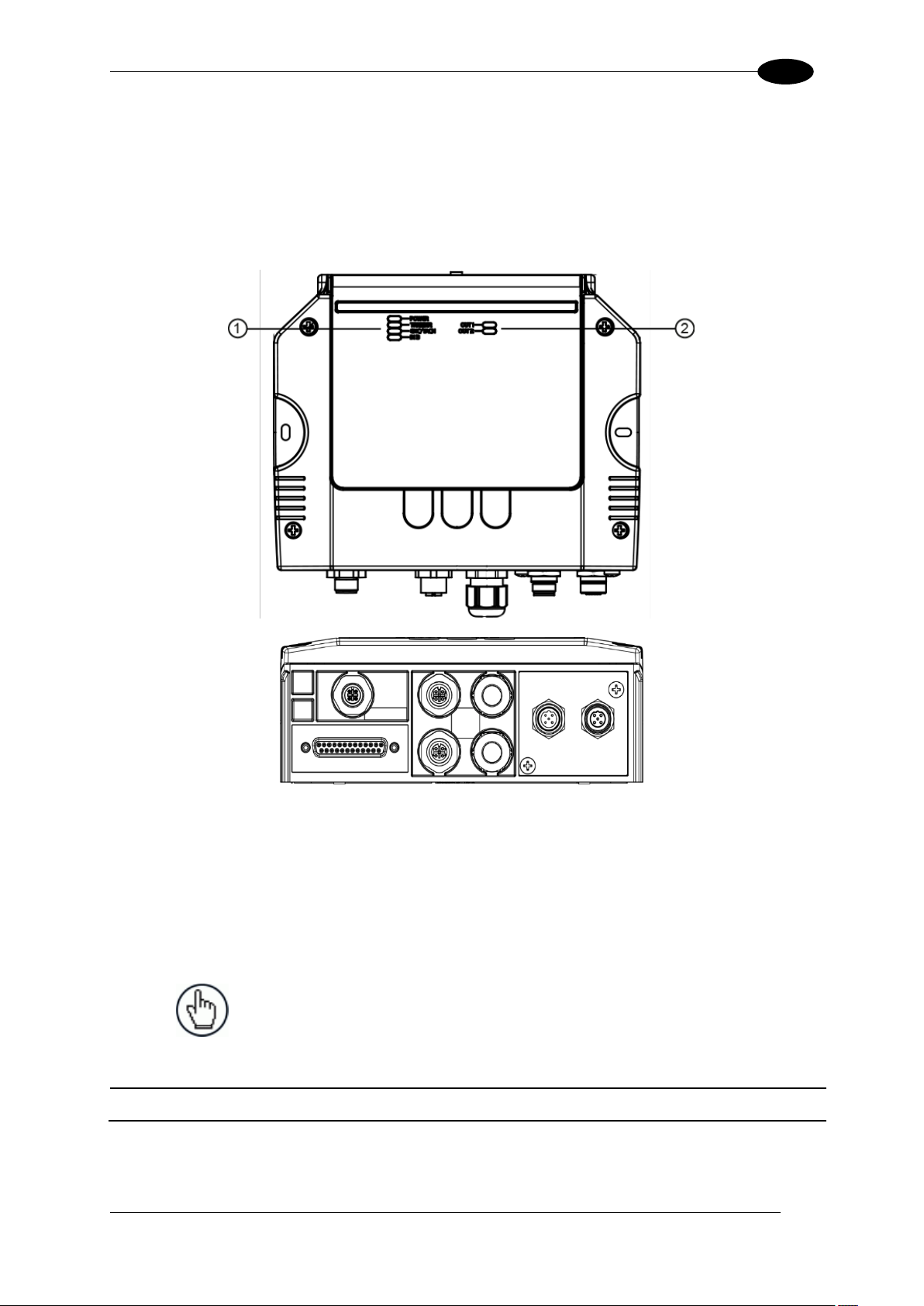

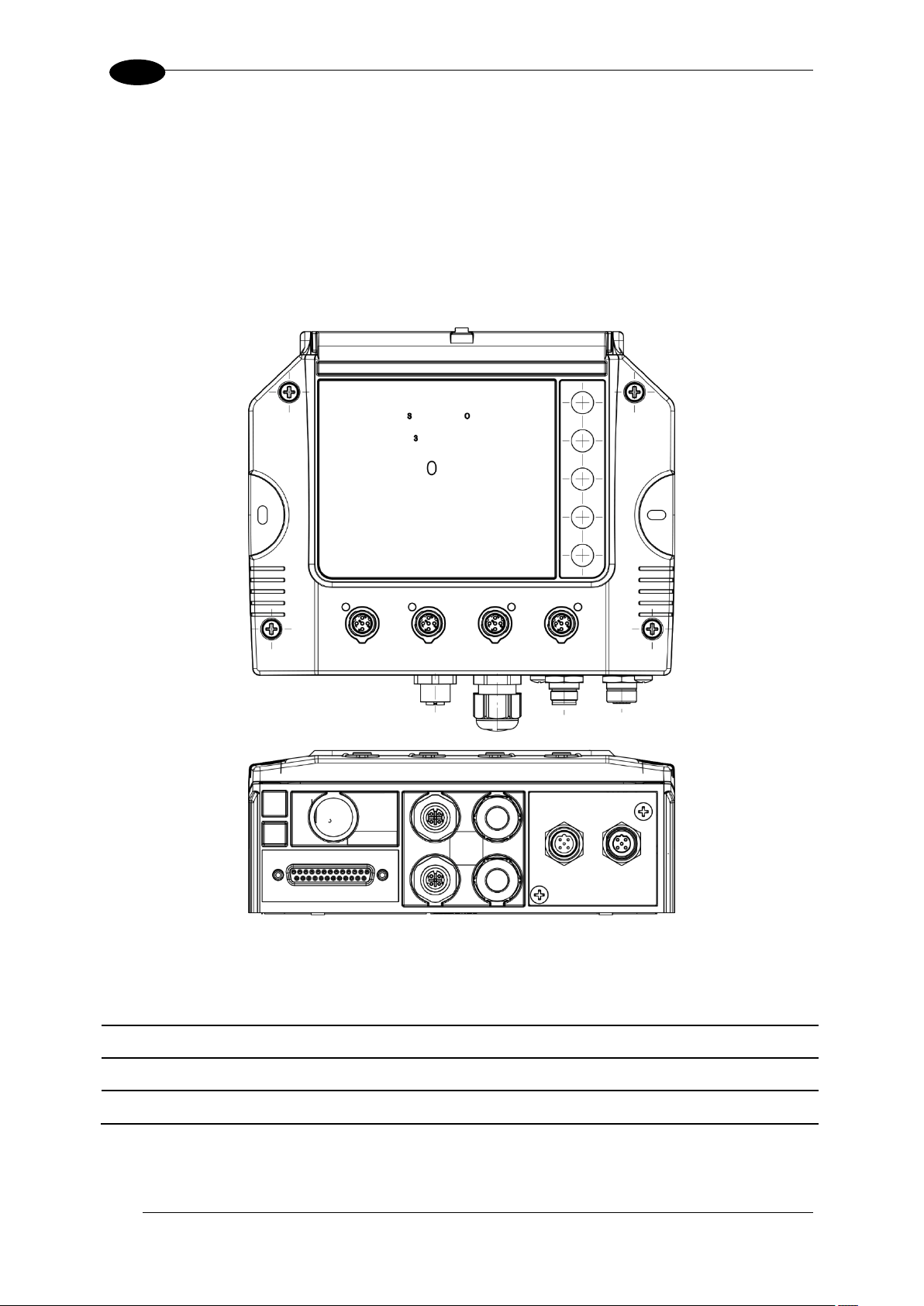

GENERAL VIEW

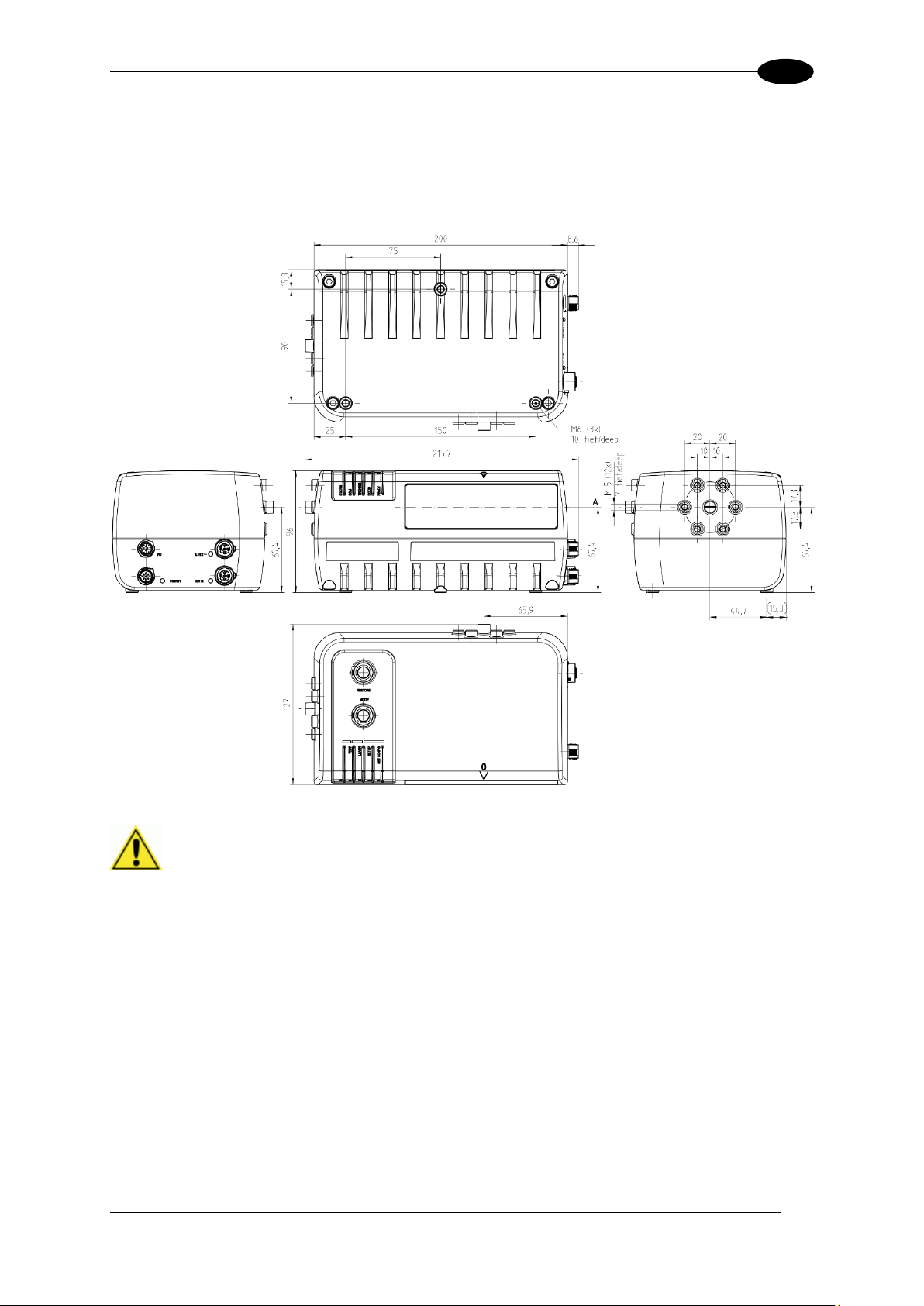

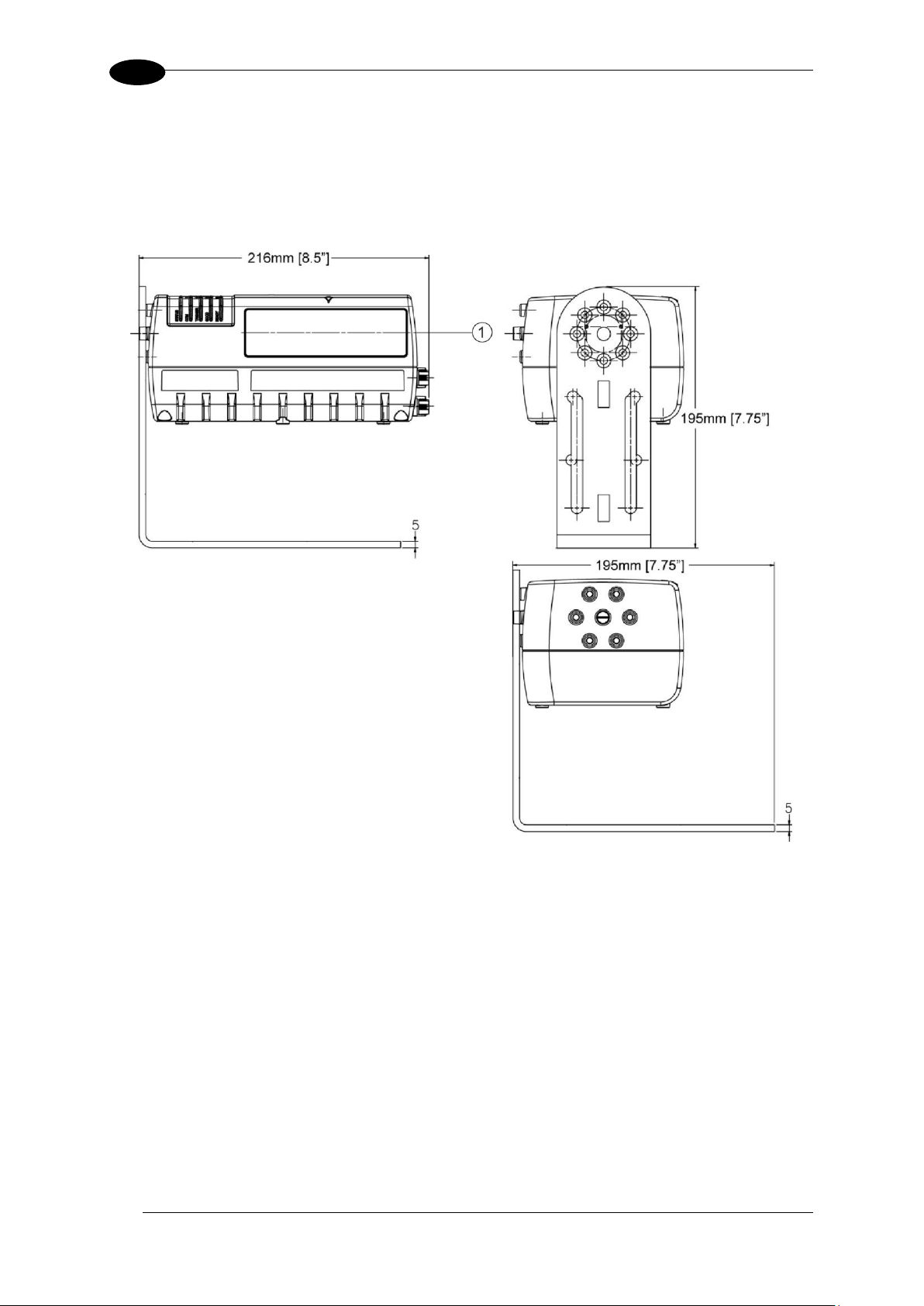

Figure 3: BCL 900i Barcode Scanner Front and Left Side Views

Figure 4: BCL 900i Barcode Scanner Back and Right Side Views

INTRODUCTION

1

1

1 INTRODUCTION

1.1 PRODUCT DESCRIPTION

The BCL 900i barcode scanner complete with decoder is designed to provide an innovative

and high performance solution in omnidirectional reading applications by combining the

following advanced technologies with Leuze electronic solid experience in the material

handling sector.

Some of the main features of the BCL 900i are listed below:

Scanning speed 1000 scans/sec

Reads all popular codes

Supply voltage from 20 to 30 vdc

Test mode to verify the reading features and exact positioning of the scanner without the

need for external tools

Programmable in several different operating modes to suit the most various barcode

reading system requirements

Light source: solid state laser diodes; the light emitted has a wave length between

630~680 nm. For laser safety precautions refer to the “compliance” section at the

beginning of this manual

1.2 APPLICATIONS

The BCL 900i barcode scanners are specifically designed for industrial applications and for

all cases requiring high reading performance such as:

Code Reconstruction Technology (CRT)

Reading of codes covered by plastic film

Reading of codes with a wide depth of field

Reading codes within a wide field of view

Reading of high resolution codes positioned at long distances from the reader

Code reading on fast moving objects

These barcode scanners are designed for both single-reader layouts and multi-reader

layouts. For typical layouts, see section 5.8.

BCL 900i REFERENCE MANUAL

2

1

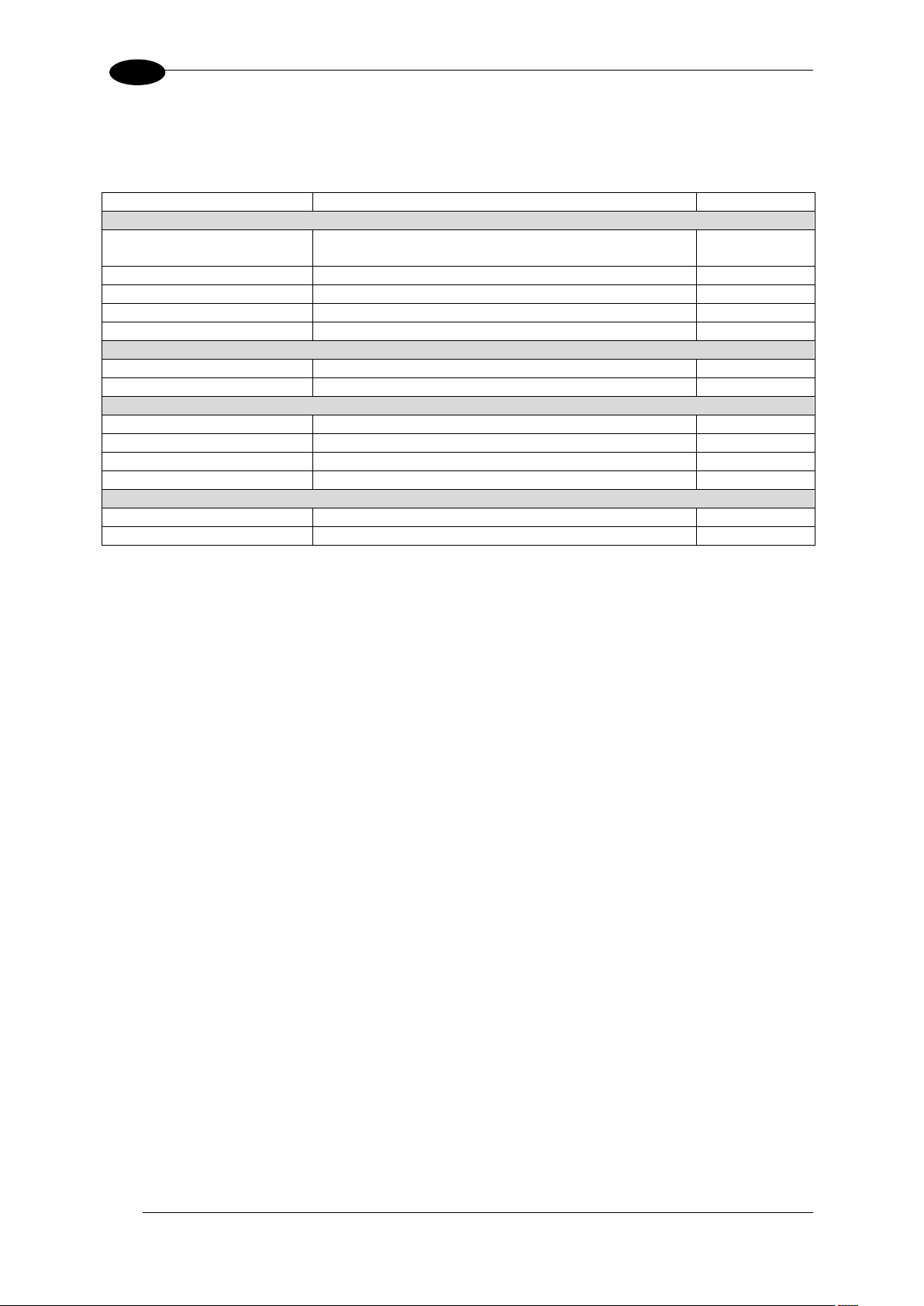

Model

Description

Part Number

BCL 900i SN 102

High Density

50129661

BCL 900i SM 102

Medium Density

50129662

1.3 MODEL DESCRIPTION

The BCL 900i barcode scanner is available in versions that differ depending on the interface

connection, the optical resolution and on the optic version:

1.4 BCL 900i VERSIONS

INTRODUCTION

3

1

RESTORE

MODE

NOTE: Some of these functions may be performed using the User

Interface. See Chapter 4.

1.5 HUMAN MACHINE INTERFACE

The BCL 900i barcode scanner includes two external buttons that make up the HMI interface

and perform specific tasks without the need of connecting to the BCL 900i User Interface.

See 5.5 for functional description.

Figure 5: BCL 900i Interface Buttons

BCL 900i REFERENCE MANUAL

4

1

Name

Description

Part Number

Cables and Terminators

KB 900 - 1000 MSC

Interface Cable 1m length between MA 900 and

MSC 900

50131533

KB 900 - 1000

Cable 1 m length

50131531

KB 900 - 3000

Cable 3 m length

50131529

KB 900 - 5000

Cable 5 m length

50131532

Connection Boxes

MA 900

Connection Box for BCL 900i

50129663

Controllers

MSC 900 - 1000

Controller (Standard)

50129664

MSC 900 - 1100

Controller (Profibus)

50129665

MSC 900 - 1200

Controller Profinet

50129666

Brackets

BT 900

BCL 900i L-shape Mounting Bracket

50131534

1.6 ACCESSORIES

The following accessories are available on request for the BCL 900i barcode scanner.

INTRODUCTION

5

1

1.7 PHOTOELECTRIC SENSOR

The optional Photoelectric Sensor is used in barcode scanner systems to detect the

presence of an item in the scanning area.

The photoelectric sensor is used in singulated systems where the packages are separated

by an open space between the trailing edge of one package and the leading edge of the

next. The photoelectric sensor, along with the encoder, enables a programmable transmit

point at a defined distance from the sensor. Without the photoelectric sensor, the barcode

scanner can be run in continuous mode. See 4.5.1 Modify Settings | Global Settings |

Operating Mode.

Depending on the application, these devices may need to be configured differently. While the

photoelectric sensor and tachometer work well with belt conveyors, a special configuration is

needed for tilt-tray and cross-belt sorter applications. See section 3.10 for wiring options.

BCL 900i REFERENCE MANUAL

6

1

1.8 ENCODER (TACHOMETER)

The tachometer provides a continuous pulse to the system, which provides feedback on

conveyor speed and transmit point, and can be used to help track the package position along

the length of the conveyor. See section 3.11 for wiring options.

INTRODUCTION

7

1

POWER

TRIGGER

ENC/TACH

IN3

OUT1

OUT2

NOTE: Scanner operation requires a MA 900 Connection Box or

MSC 900 controller.

Industrial Connection Box

MA 900 Connection Box

MA 900 for BCL 900i

50129663

1.9 MA INDUSTRIAL CONNECTION BOX

MA Series are industrial connection boxes that can be used to connect the barcode scanners

to an encoder/tachometer, photoelectric sensor, serial devices, relays, or other peripherals.

The MA 900 includes a Backup Module, which allows easy parameter restore and backup

operations. The Backup Module also provides an easy way to upload existing parameters to

a replacement barcode scanner when necessary. See section 3.9.1 for wiring options.

Figure 6: MA 900 Connection Box

BCL 900i REFERENCE MANUAL

8

1

System Controller

MSC 900 - 1000 System Controller

Standard

50129664

MSC 900 - 1100 System Controller

Profibus

50129665

MSC 900 - 1200 System Controller

Profinet

50129666

1.10 MSC 900 SYSTEM CONTROLLER

The MSC 900 Controller offers all the necessary functions to make the phases of installation,

setup, testing, and maintenance of the omni-directional reading array or tunnel easy and

quick.

The MSC 900 Controller is fully compatible with BCL 900i scanner and its sturdy mechanical

structure makes the MSC 900 Controller the ideal solution for industrial environments. The

Controller allows connection to the Trigger and Encoder/Tachometer. PNP inputs are

available via M12 circular connectors, placed on the lower front panel (see section 3.11).

Figure 7: MSC 900 System Controller

MECHANICAL INSTALLATION

9

2

IMPORTANT: Application-specific drawings and documents provided by

Leuze electronic supersede any contradictory content in this manual.

NOTE: Refer to the Chapter 3 Electrical Installation and Reference

Documentation for details on connecting your barcode scanners to other

devices in the system.

WARNING: Electrical Installation by Qualified Service Technicians Only!

Procedures may involve exposure to high-voltage. A trained and authorized

technician must perform these procedures. Do not attempt to perform any

electrical installation procedures unless you are a trained technician.

IMPORTANT: BCL 900i barcode scanners contain electronics that may be

affected by electrostatic discharge (ESD). To prevent personal injury or

damage to the unit, please follow the safety precautions and warnings found

in the References section at the beginning of this manual. Failure to follow

these precautions may void your warranty.

WARNING: When installing several scanners, take care to position them so

that no laser beam enters the reading window of other scanners. This

condition could occur more frequently for side mounted applications. If these

precautions are not followed, read rate could be negatively affected. To

resolve this problem, it is sufficient to slightly change the inclination and

position of one of the two scanners involved if possible.

2 MECHANICAL INSTALLATION

2.1 PREPARING FOR MECHANICAL INSTALLATION

Before mounting any components, please do the following:

Read all instructions before beginning your installation.

Define and confirm the accuracy of your application’s requirements and structure

position, especially the height of the conveyor from the floor.

Review all installation-specific drawings provided with your equipment.

Review and plan the mechanical installation of all devices used in your application. Be

sure to allow adequate clearance for maintenance.

Review and plan the power requirements for your application.

Check the contents of the shipping cartons against the packing list.

Record all product serial numbers.

BCL 900i REFERENCE MANUAL

10

2

2.2 UNPACKING INSTRUCTIONS

Verify that the BCL 900i barcode scanners and all the parts supplied with the equipment are

present and intact when opening the packaging; the list of parts includes:

BCL 900i reader

L-shape Mounting Bracket BT 900

Mounting screws (two types) and washers

BCL 900i Leaflet with Barcode Sample inside

MECHANICAL INSTALLATION

11

2

NOTE: Everything should be MECHANICALLY INSTALLED before

performing any ELECTRICAL INSTALLATION.

See Chapter 3 Electrical Installation for electrical installation details.

2.3 INSTALLATION SEQUENCE

To complete mechanical installation and setup, you must:

Review the details of your application’s requirements

Erect mounting structure or other supporting structures

Determine and mark the Mounting Bracket location(s)

Mount the bracket to the mounting structure

Mount the BCL 900i to its mounting bracket

Mount the photoelectric sensor to the mounting structure (optional)

Mount the tachometer to the mounting structure (optional)

Mount the MA Connection Box to the mounting structure

Mount the MSC 900 to the mounting structure, if necessary

Complete electrical installation (See Chapter 3)

Align the BCL 900i for proper operation

Configure the BCL 900i (See Chapter 4)

Check BCL 900i operations (See Chapter 5)

BCL 900i REFERENCE MANUAL

12

2

2.4 WHAT YOU NEED TO KNOW ABOUT YOUR APPLICATION

To assure you get optimal performance out of your BCL 900i, it must be installed to meet the

complete needs of your application. Therefore, take the time to learn the details of your

application. The better you know your application, the easier it is to apply the BCL 900i’s

capabilities to meet your application’s requirements.

Below is what you will need to know before you can begin installation:

Conveyor Specifications

Conveyor type: Belt, tilt-tray, cross belt, other?

What is the conveyor width?

What is the conveyor speed?

Does conveyor speed vary or is it constant?

Product Specifications

Are the packages being transported always singulated (not touching) or non-

singulated (possibly touching)?

How many different product sizes may be involved?

Are products justified: toward/away from reader, centered, or variable?

Application Specifications

How will the barcode information be used in your application?

What are your communication requirements?

While it is nearly impossible to cover all application configurations, the next several pages

provide the basics on determining how to mechanically install your BCL 900i. If you need

additional assistance, feel free to contact your sales representative or customer service

(www.leuze.de).

MECHANICAL INSTALLATION

13

2

IMPORTANT: The BCL 900i is a sealed, unventilated unit. Mounting the unit

with 300 mm [12”] of clearance (front, top, and sides) is recommended for

cooling and ease of maintenance.

2.5 INSTALLATION

2.5.1 Dimensions and Clearances

The overall dimensions of the BCL 900i are 216 x 96 x 127 mm [8.5 x 3.8 x 5 in].

2.5.2 Physical Support Requirements

For details on the weight of the barcode scanners, see Chapter 8, Technical Features.

Multiple-head systems may include further details on the physical support requirements with

any application-specific documentation provided.

2.5.3 Vibration Limitations

See Chapter 8, Technical Features.

BCL 900i REFERENCE MANUAL

14

2

2.5.4 General Mounting Guidelines

It is important that you follow these general precautions when installing, setting up, operating,

maintaining, troubleshooting, or replacing any Leuze electronic products, parts or related

equipment.

As you plan and install your BCL 900i barcode scanning system application, be sure to keep

the following guidelines in mind:

All mounting structure assembly and equipment installation can be performed by one

installer.

Determine the proper orientation and position of the barcode scanner.

Leave adequate clearances (approximately 300 mm [12 inches]) for wiring.

Route wires carefully to reduce or minimize electrical noise. When power and

communication wiring must cross, make their intersection perpendicular.

Proper grounding limits the effects of noise due to Electromagnetic Interference (EMI).

MECHANICAL INSTALLATION

15

2

2.5.5 Mounting Structure Considerations

Your first task is to mount your BCL 900i barcode scanner.

Your mounting structure must provide the following capabilities:

It is adjustable enough for you to move your unit to the optimum position for proper

scanning.

It allows a technician access to the barcode scanner while it is mounted.

It must be as vibration free as possible so as not to affect the scanning accuracy.

It is constructed of steel or aluminum.

It provides approximately 300 mm [12 inches] minimum clearance on all sides. This

clearance is necessary to provide proper ventilation, allow access to all panels of the

barcode scanner, and allow room for proper servicing.

BCL 900i REFERENCE MANUAL

16

2

SCAN LINE

2.5.6 Mounting the Scanner

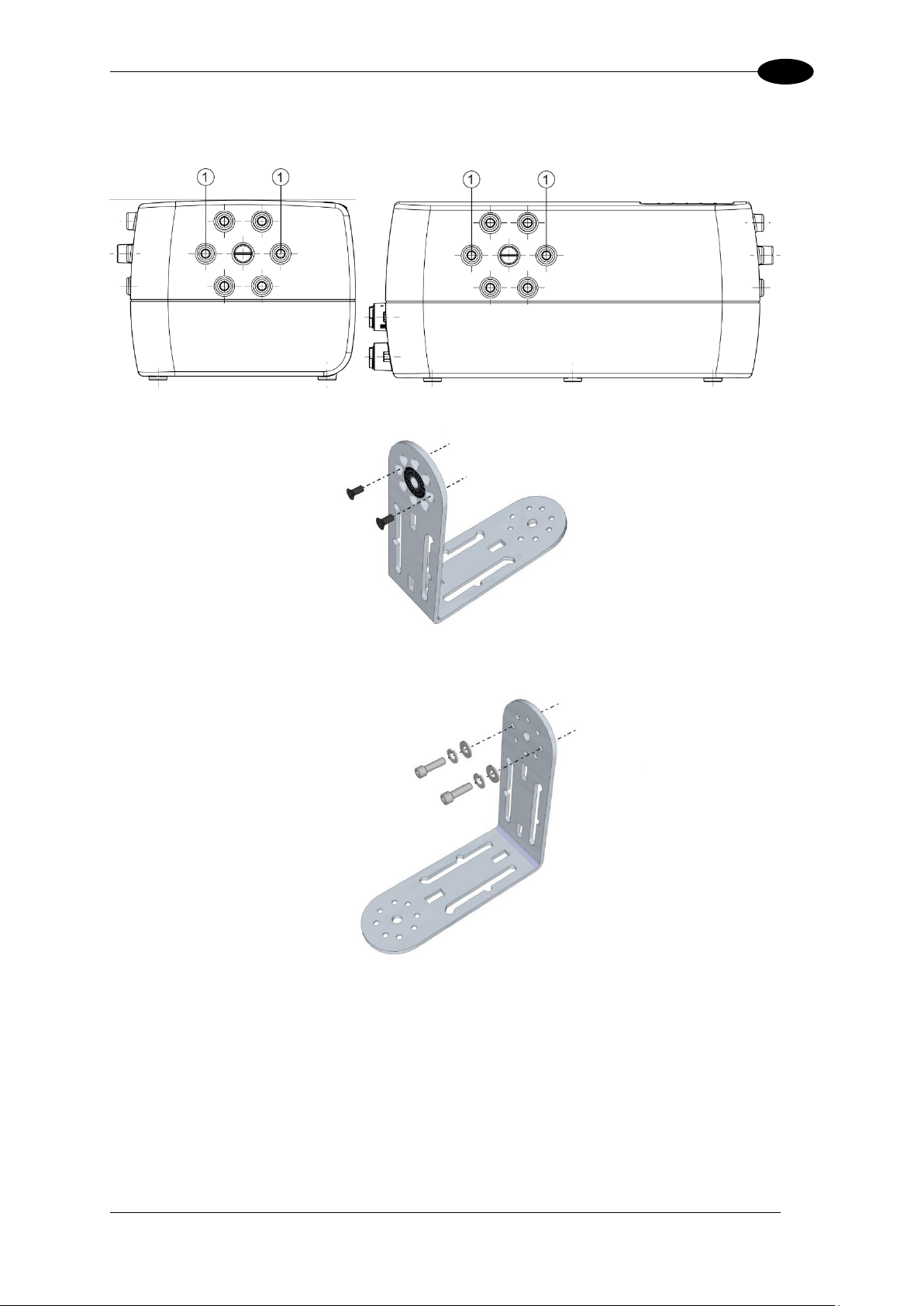

The BCL 900i can be installed to operate in any position. There are 12 screw holes (M6 X 8)

on the sides of the scanner for mounting. The diagram below can be used for installation;

refer to reading diagrams (See 5.10) and any application drawings for correct positioning of

the scanner with respect to the reading zone and scanner orientation.

Figure 8: BCL 900i mounting dimensions with BT 900

MECHANICAL INSTALLATION

17

2

Mounting position

The BT 900 included with the BCL 900i scanner allows it to be installed in the most suitable

position for your application. The BT 900 is mounted to the scanner as shown below:

Figure 9: BCL 900i BT 900 assembly with countersunk screws

Figure 10: BCL 900i BT 900 assembly with cap screws, lock washers, and flat washers

BCL 900i REFERENCE MANUAL

18

2

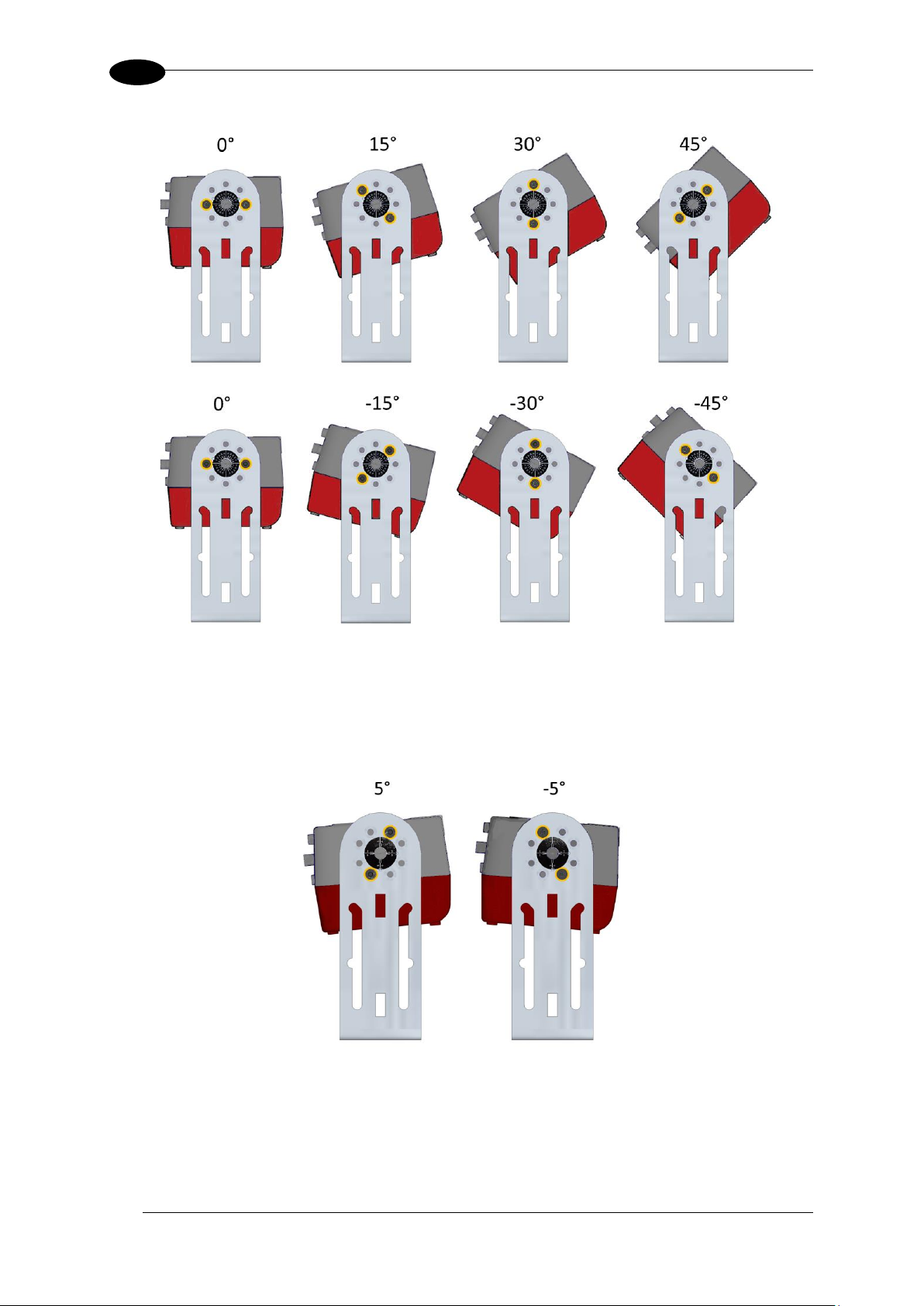

Figure 11: BCL 900i mounting angles

If the BCL 900i needs to be mounted at a 5-degree angle or within 5-degrees of the angles

shown in Figure 11: BCL 900i mounting angles (+/- 5, +/-25, or +/-35-degrees), mount it to

the opposite end of the BT 900 as shown below:

Figure 12: BCL 900i 5-degree mounting option

MECHANICAL INSTALLATION

19

2

α

Tilt βPitch

γ

Skew

2.5.7 Positioning the Scanners

The BCL 900i barcode scanners are able to decode barcode labels at a variety of angles;

however significant angular distortion may degrade reading performance.

When mounting the scanners, take into consideration these three ideal label position angles:

Pitch 0°, Skew 0° to 45° and Tilt 0°.

Follow the suggestions for the best orientation:

Figure 13: Tilt, Pitch, and Skew

BCL 900i REFERENCE MANUAL

20

3

IMPORTANT: The content of this manual may be superseded by any

customer-specific documentation provided by Leuze electronic. Before

proceeding with any installation procedures, be sure to review ALL

documentation, especially content that contains details specific to your

installation.

NOTE: Everything should be MECHANICALLY INSTALLED before

performing any ELECTRICAL INSTALLATION. See Chapter 2 for

mechanical installation details.

Most BCL 900i applications are shipped with the MA Connection Box and

all the necessary cabling required to electrically install the system. If your

system requires custom-length cables or other special wiring,

documentation specific to these requirements has been provided in your

shipment. This special documentation supersedes any contradictory content

in this manual.

NOTE: To reduce the possibility of damage to the unit, check all cabling

between the scanner and other devices for accuracy.

WARNING: Electrical Installation by Qualified Service Technicians Only!

Procedures may involve exposure to high-voltage. A trained and authorized

technician must perform these procedures. Do not attempt to perform any

electrical installation procedures unless you are a trained technician.

IMPORTANT: The BCL 900i barcode scanners contain electronics that may

be affected by electrostatic discharge (ESD). To prevent personal injury or

damage to the unit, please follow the safety precautions and warnings found

in the References section at the beginning of this manual. Failure to follow

these precautions may void your warranty.

3 ELECTRICAL INSTALLATION

3.1 PREPARING FOR ELECTRICAL INSTALLATION

Before mounting any components, please do the following:

Read all instructions before beginning your installation.

Observe all electrical safety requirements discussed in the Introduction to this manual.

Define and confirm the accuracy of your application’s requirements.

Review all installation-specific drawings.

Review and plan the power requirements for your application.

Review and plan the communications requirements for your application.

ELECTRICAL INSTALLATION

21

3

3.2 CONNECTING A BCL 900i SCANNER

To install a BCL 900i barcode scanner, follow this sequence:

Complete mechanical installation (See Chapter 2.)

Complete electrical installation (See wiring illustrations provided in this chapter.)

Observe all electrical safety requirements outlined in this chapter.

Ground the mounting structure to protective earth (PE) ground.

If used, wire the photoelectric sensor (or other trigger) to the MA 900 Connection

Box/MSC 900.

Wire the tachometer to the MA 900 Connection Box/MSC 900 (if used).

Wire serial ports to the MA 900 Connection Box/MSC 900 if needed.

Connect the M12 end of the Ethernet cable to the scanner’s HOST port and network

switch as required by your application.

Connect the scanner to its power supply.

Connect the power supply to the power source.

Setup / check scanner operations (See Chapter 5.)

BCL 900i REFERENCE MANUAL

22

3

MA 900

Backup Module

Photoelectric sensor

Enoder/Tachometer

Digital Output(s)

Setup PC

Host

PWR

17 Pin M12 Connector

RS232 or RS422FD Host

25 Pin D-Connector

3.3 TYPICAL CONNECTION BLOCK DIAGRAMS

3.3.1 Single BCL 900i Barcode Scanner to MA 900

Figure 14: Single BCL 900i to MA 900

ELECTRICAL INSTALLATION

23

3

MA 900

Stack Light or Diverter

Host (Serial)

Host (Fieldbus)

Setup PC

Ethernet

Slave

ETH2

ETH1

PWR

Up to 32 Scanners

Host (Ethernet)

Master

17 Pin M12 to 25 Pin D

25 Pin D-Connector

Encoder/Tachometer

Photoelectric Sensor

3.3.2 Master/Slave Array with MA 900

Figure 15: Master/Slave Array (Tunnel) with MA 900

BCL 900i REFERENCE MANUAL

24

3

Master MSC 900 Controller

Ethernet CFG

Setup PC

Ethernet HOST

Host (Ethernet)

EBC (Internal Scanner Network)

Slave

ETH1

PWR

Up to 31 Scanners

ETH2

Encoder/Tachometer

Photoelectric Sensor

3.3.3 BCL 900i Barcode Scanners in an Array with MSC 900 Master

In an array (tunnel) using the MSC 900 Controller, the chain of scanners completes a circle

from and to the MSC 900 Controller via ETH1 and ETH2. In this scenario, if one scanner

fails, communication from the other scanners to the MSC 900 Controller is not interrupted.

Figure 16: BCL 900i Array (Tunnel) with MSC 900

ELECTRICAL INSTALLATION

25

3

Master MSC 900 Controller

Ethernet CFG

Setup PC

Ethernet HOST

Host (Ethernet)

EBC

Slave

ETH1

PWR

Up to 31 Scanners

Ethernet

ETH2

Host (Fieldbus)

Host (Serial)

Stack Light or Diverter

Encoder/Tachometer

Photoelectric Sensor

MA 900

Figure 17: BCL 900i Array (Tunnel) to MSC 900 (alternate with MA 900)

BCL 900i REFERENCE MANUAL

26

3

IMPORTANT: When planning your installation wiring, remember all power

connections must be quick-disconnect. For PERMANENTLY CONNECTED

EQUIPMENT a readily accessible disconnect device must be incorporated

in the building installation wiring. For PLUGGABLE EQUIPMENT the

socket-outlet must be installed near the equipment and must be easily

accessible

WARNING: To assure no ESD damage will occur, be sure to observe the

precautions outlined in the Introduction to this manual.

IMPORTANT: Ground the mounting structure to safety ground (protective

earth ground (PE)). See wiring recommendations for safety ground.

3.4 GENERAL ELECTRICAL INSTALLAION GUIDELINES AND

PRECAUTIONS

It is important that you follow these general precautions when installing, setting up, operating,

maintaining, troubleshooting or replacing any Leuze electronic products, parts or related

equipment.

As you plan and install your scanner(s), be sure to keep the following guidelines in mind:

Determine the scanner is in the proper location as outlined in Chapter 2.

Leave adequate clearances (approximately 300 mm [12 inches]) for wiring.

Route wires carefully to reduce or minimize electrical noise.

ELECTRICAL INSTALLATION

27

3

I/O (Connects directly to the 25-pin D type connector on the MA Connection Box)

POWER

ETH 2 (Setup or EBC scanner network)

ETH 1 (Host or EBC scanner network)

3.5 BCL 900i CONNECTOR PANELS

After completing mechanical installation, use this section to properly wire your scanners for

optimal performance in your application. BCL 900i wiring connections are made to the

connector panel and through the MA Connection Box (connected to the I/O port of the

scanner). In most applications, the cable connections to the scanner will include:

Figure 18: BCL 900i Connector Panel

Route wiring from the scanner’s connector panel through the wiring channels (if available) on

the Leuze electronic mounting structure when interconnecting cables to other devices.

BCL 900i REFERENCE MANUAL

28

3

NOTE: ETH2 is the Setup port, ETH1 is the HOST port.

NOTE: A laptop can only communicate to a scanner that is connected to a MA

Connection Box or MSC 900 Controller.

NOTE: Parameters for tunnel are set up in MASTER scanner (or MSC 900

Controller) only.

NOTE: When using a BCL 900i barcode scanner, no power supply is

required for the MA 900 Connection Box. All power and some

communication options are fed to the MA 900 through the scanner’s 17-pin

I/O connector to the MA 900 25-pin connector using the cable provided.

24V - - - 4A MAX

POWER Input

Unit Connector (shown)

Mating cable connector

5-PIN M12-TYPE MALE

5-PIN M12-TYPE FEMALE

MALE 5-PIN M12-TYPE

Pin

Function

1

+24 VDC

2

n/c 3 dc return

4

n/c

5

protective earth (chassis)

3.6 CONNECTING A PC TO THE BCL 900I

During initial setup, a PC (laptop) may be connected to the BCL 900i with a M12 to RJ45

cable. Screw the M12 connector to the ETH 2 port of the scanner and plug the RJ45 into the

Ethernet port of your PC. If the ETH 2 port is in use, ETH 1 port can be used. For information

on connect to the User Interface, see Chapter 4.

3.7 POWER CONNECTOR PIN-OUT TABLE

A recommended power supply and cabling is available with the BCL 900i (and MSC 900

Controller). However, if your installation requires custom power supply wiring, the pin-outs of

the unit power connector are provided below for your convenience.

ELECTRICAL INSTALLATION

29

3

IMPORTANT: When planning your installation wiring, remember all power

connections must be quick-disconnect.

CAUTION: While performing the following wiring connection procedures, be

sure to follow all safety procedures regarding high-voltage as outlined in the

Introduction to this manual. No power should be applied to any device until

all wiring is completed and checked for accuracy.

IMPORTANT: The socket-outlet must be installed near the scanner. The

outlet must be a readily accessible disconnect device.

GROUND: Ground the scanner to safety ground (protective earth ground

(PE)). See wiring recommendations for safety ground.

3.8 POWER CONNECTIONS

The MA Connection Boxes provide flexible connectivity to a range of I/O devices as well as

serial hosting. The BCL 900i connects to the MA via its I/O port using a single 17-pin M12 to

25-pin D cable. The MA Connection Box also provides space for an optional Backup Module

(recommended) for parameter storage, allowing quick replacement and configuration of the

scanners.

In a system with multiple scanners and other devices required in a scanning array (tunnel),

an MSC 900 Controller serves as the system Master and provides communications between

devices and to the Host. Complete installation information for the MSC 900 Controller is

available in the MSC 900 System Controller Reference Manual available at www.leuze.de.

BCL 900i REFERENCE MANUAL

30

3

POWER

TRIGGER

ENC/TACH

IN3

DEVICE CHASSIS GROUNDING

Earth

GND

AUX

OUT1

OUT2

BACKUP/RESTORE MODULE

IO4 +/- RESERVED FOR MSC 900

O3 +/- RESERVED FOR MSC 900

RESERVED

FIELDBUS BOARD IP65

FIELDBUS BOARD STD

WARNING: DO NOT connect a separate power source to the MA 900

Connection Box. The MA 900 receives its power through its connection to

the BCL 900i Barcode Scanner. Connecting a separate power source will

be detrimental to the system operation.

IMPORTANT: DISCONNECT POWER from the scanning system and

MA 900 before wiring any components.

3.9 MA 900 CONNECTION BOX

Complete installation information for the connection box is available in the MA 900

Installation Manual available at www.leuze.de. A simple drawing of the interior of the box is

shown below.

Figure 19: MA 900 Interior

3.9.1 Wiring Into the MA 900 Connection Box

ELECTRICAL INSTALLATION

31

3

Loose-lead cables must pass through the water-tight seals in the base of the MA 900

Connection Box. Insert the cables allowing enough slack for the individual wires to reach the

appropriate pin block connectors. Securely tighten the water-tight seals after the cables have

been inserted.

Insulation on individual wires should be removed to expose 13 mm [0.5 inch] of bare metal

before inserting into the pin block.

BCL 900i REFERENCE MANUAL

32

3

NOTE: To confirm the photoelectric sensor is functioning properly, watch

the TRIG LED while the photoelectric sensor’s beam is blocked. The Leuze

electronic photoelectric sensor also includes a status LED.

3.10 PHOTOELECTRIC SENSOR CONNECTIONS TO MA 900

Barcode scanning applications may use a Leuze electronic photoelectric sensor as a trigger

device. The photoelectric sensor is wired directly into the MA 900 terminal.

If your application uses a trigger other than the one specified by Leuze electronic, follow the

appropriate wiring diagram to assure proper wiring.

The following diagrams illustrate standard recommended wiring of the Photoelectric Sensor

to the MA 900 terminal block.

ELECTRICAL INSTALLATION

33

3

Jumper

Photoelectric Sensor

3.10.1 Photoelectric Sensor (NPN)

Figure 20: Photoelectric Sensor Wiring (NPN Output)

34

3

Jumper

Photoelectric Sensor

3.10.2 Photoelectric Sensor (PNP)

BCL 900i REFERENCE MANUAL

Figure 21: Photoelectric Sensor Wiring (PNP Output)

ELECTRICAL INSTALLATION

35

3

Jumper

Bare (Shield)

Encoder/Tachometer

NOTE: Some tachometers may

have a different color coding:

(+V)

(Signal)

(Ground) Black or Orange/White

3.11 TACHOMETER WIRING TO MA 900

Omni applications over a conveyor belt use an accessory tachometer and mounting kit. The

following diagrams illustrate standard recommended wiring of an encoder to the MA 900

terminal block.

3.11.1 Encoder/Tachometer Wiring for NPN Output (two models)

Red or White/Orange

White or White/Blue

Figure 22: Encoder/Tachometer Wiring (NPN Output)

BCL 900i REFERENCE MANUAL

36

3

Jumper

Bare (Shield)

Encoder/Tachometer

Figure 23: Encoder/Tachometer Wiring (NPN Output)

ELECTRICAL INSTALLATION

37

3

Jumper

Bare (Shield)

Encoder/Tachometer

NOTE: Some tachometers may

have a different color coding:

Red (+V)

White (signal)

Black (ground) or Orange/White

3.11.2 Encoder/Tachometer Wiring for PNP Output (two models)

or White/Orange

or White/Blue

Figure 24: Encoder/Tachometer Wiring (PNP Output)

BCL 900i REFERENCE MANUAL

38

3

Jumper

Bare (Shield)

Encoder/Tachometer

Figure 25: Encoder/Tachometer Wiring (PNP Output)

ELECTRICAL INSTALLATION

39

3

Outputs 1 - 3

Figure 26: OUTPUTS Block

Maximum Voltage 30 V

Collector Current (pulse) 130 mA Max.

Collector Current (continuous) 40 mA Max.

Saturation Voltage (VCE) 1 V at 10 mA Max.

Maximum Power Dissipation 90 mW at 50°C (Ambient

temperature)

3.12 DIGITAL OUTPUT CONFIGURATION TO MA 900

The MA 900 includes an OUTPUTS block for wiring relays as needed for external

accessories. The User Interface Modify Settings | Digital I/O window includes options for

outputs 1 and 2 with Primary and Secondary Activation Event options including Complete

Read, Partial Read, No Read, Trigger On, Trigger Off, Multiple Read, Right/Match, and

Wrong/No Match.

Schematics for Isolated and Non-Isolated digital outputs are provided below.

40

3

Sink

Source

NPN

PNP

3.12.1 Unpowered Outputs

BCL 900i REFERENCE MANUAL

Figure 27: Unpowered Outputs

ELECTRICAL INSTALLATION

41

3

Sink

Source

NPN

PNP

3.12.2 Powered Outputs

Figure 28: Powered Outputs

BCL 900i REFERENCE MANUAL

42

3

CFG (Configuration via laptop Ethernet cable)

HOST

ETH 1 (EBC scanner network)

ETH 2 (EBC scanner network)

POWER

ENC (PNP Encoder/Tachometer)

Water-tight connectors

TRG (PNP Trigger/Photoelectric Sensor)

I/O (Connects directly to the 25-pin D type connector on the MA Connection Box)

3.13 CONNECTING TO THE MSC 900 SYSTEM CONTROLLER

(OPTIONAL)

In larger scanning arrays (scanning tunnels), an MSC 900 controller can act as the system

master and support up to 31 slave BCL 900i barcode scanners in an Ethernet-based

connection loop (EBC). MSC 900 wiring connections are made to the front and bottom

connector panels. In most applications, the cable connections to the scanner will include:

Figure 29: MSC 900 Bottom Panel Connectors

Complete installation information for the MSC 900 Controller is available in the MSC 900

System Controller Reference Manual available at www.leuze.de.

ELECTRICAL INSTALLATION

43

3

3.14 CHECK SCANNER INSTALLATION

After completing the installation of your barcode scanner, confirm that the barcode scanners,

MA Connection Box and/or MSC 900 Controller have been properly installed mechanically

and electrically. Use the Installation Sequence at the beginning of this chapter and your

application specifications to check your installation.

BCL 900i REFERENCE MANUAL

44

4

Computer

Laptop

Browser

Internet Explorer 11 (or later)

Firefox 30 (or later)

Chrome 36 (or later)

Java

Java version 8 (or later)

NOTE: If the Diagnostic | Monitor page does not run, you may

need to create an exception in the Java Control Panel.

To do this:

If the Diagnostic | Monitor page does not run, you may need to

create an exception in the Java Control Panel.

To do this:

1. Click the Start/Home button and type Configure Java in

the search field. Select the Java Control Panel from the

search results. The Java Control Panel opens.

2. Click the Security Tab to open it.

3. Under Exception Site List, click Edit Site List… The

Exception Site List window opens.

4. Click Add.

5. Enter the IP Address for the system/scanner in the field

provided as follows: http://10.27.154.125/ (but matching

your system’s IP Address)

6. Click OK. The Monitor page should now load. 0.

4 USER INTERFACE

4.1 GETTING STARTED

The BCL 900i barcode scanners are designed for ease-of-setup. The BCL 900i User

Interface is a browser-based application you will use to define operating parameters, monitor

read quality, construct output messages, and view diagnostics. The User Interface enables

you to easily configure, fine-tune, and monitor your scanner’s operation.

This User Interface provides ease-of-use for any operator level.

4.1.1 Prerequisites

Before setting up your barcode scanner you will need the following:

USER INTERFACE

45

4

NOTE: Before starting up or testing the scanner, it must be connected to

a MA 900 Connection Box (see section 3.9.1) or an MSC 900

Controller (see section 3.13) depending on the system configuration.

NOTE: The default setup IP address for all BCL 900i units is:

192.168.3.100 (setup) and 172.27.101.220 (Host).

4.1.2 Starting the User Interface

To access the User Interface:

1. Connect your computer to the scanner’s ETH 2 port using the KB ET-xxxx RJ45

ETHERNET CABLE or M12-TO-RJ45F. If the ETH 2 port is taken, ETH 1 can be used.

2. Turn on your computer.

3. If you are connecting to a stand-alone unit (not connected to an in-house network), you

must configure your PC’s IP Address to be in the same network as the scanner’s (or if

used, controller’s) IP Address.

To change your PC’s IP Address:

a. From the desktop, click the Start button, and then select Control Panel.

b. Type adapter in the search box, and then from the results, under Network and

Sharing Center, click View network connections.

c. Right-click Local Area Connection, and then select Properties.

d. Select the Networking tab. Under This connection uses the following items,

click Internet Protocol Version 4 (TCP/IPv4), and then click Properties.

e. Select Use the following IP address.

f. In the IP address field, type the first 3 octets of the IP address of the reader/controller

unit.

g. For the last octet, type a number that differs from the last octet in the

reader/controller’s IP address. The actual number used is not important as long as it

does not match that of the reader/controller.

Example: If the barcode scanner’s IP Address is 192.168.3.100, set your PC’s IP

Address to 192.168.3.101.

h. In the Subnet mask field, type 255.255.255.0

i. In the Default gateway field, type 0.0.0.0

j. Click Okay.

4. Open a web browser and enter the IP address for the BCL 900i. If the correct IP address

is entered, the BCL 900i Log On window will appear.

BCL 900i REFERENCE MANUAL

46

4

5. Enter the Password (default is LEUZE) for your system in the fields provided.

6. Select a language from those available in the Language drop-down list.

7. Select METRIC or IMPERIAL from the Units drop-down list.

8. Click Log On. 0.

If the password is valid, the application enables all functions available to the user and

displays the System Info window.

If the password is not valid, the application displays a results box with the message,

“Incorrect Password.” Click OK to return to the Log On window and enter the correct

user name and password. I you don’t know the password, contact your system manager.

To log out of the User Interface:

Click at the upper right corner of the User Interface window to Log Out. When logged

out, the Log On window will appear.

USER INTERFACE

47

4

NOTE: The Text Entry Tool is needed to enter unprintable/untypable

characters. For example, <CR> is a single character presented as a

string for more easily reading.

The character must be entered with the tool, if typed normally it will be

recognized as a string and not as a single character.

4.2 USER INTERFACE BASICS

4.2.1 BCL 900i User Interface Menu Tree

The functions that you can select are displayed in a menu tree on the left–hand side of the

reader/controller User Interface. The function list is organized much like the hierarchy of a file

system, where you can expand items that are preceded by a box ( ) to further sub–levels

until you find a function of interest.

Sub–levels appear indented below the items from which they are expanded. Clicking the box

again will collapse that branch of the menu. You can expand no further when an item is not

preceded by a box.

The reader/controller User Interface menu tree appears with no items expanded. Click the

folders to display the active window for the setup function and/or expand the folders to view

any additional setup features.

4.2.2 Entering Text Using the Text Entry Tool

In cases where text needs to be entered to create message headers, trailer, custom

messages, or for other reasons, the Text Entry Tool pencil icon “ ” will be displayed.

Click to open the Text Entry Tool.

You can enter text in the text field by typing, or click on the character buttons to create your

message. Select the Extended Characters check box to reveal a new set of control

characters.

Click Submit to save your text to the origin window text field, or click Cancel to return to

origin window without transferring text.

BCL 900i REFERENCE MANUAL

48

4

4.2.3 Getting Help

The complete help for the BCL 900i User Interface is available in this manual.

To access the complete help system:

Select Utilities | Help in the User Interface menu tree.

USER INTERFACE

49

4

4.3 MODIFY SETTINGS

Use the Modify Settings Menu Tree selections during initial setup to configure your scanning

system. If necessary, you can later make modifications to the configuration using the same

menu selections.

BCL 900i REFERENCE MANUAL

50

4

Field Name

Action/Definition

System Info

System

Description

Enter a name to identify this scanning system in the text field.

Role

Select Standalone or Master from the drop-down list. Standalone (not

controllers) indicates a scan point with a single barcode scanner. Master

indicates that the system is made up of more than one barcode scanner in a

master and slave configuration.

NOTE: The MSC 900 Controller will always be

shown as Master and cannot be changed.

Enable

Automatic Slave

Replace

There are two way to replace a defective scanner:

If the check box is not selected: The replacement will be done only pressing

the RESTORE (see section 4.8.1) key on the scanner or using the Edit dropdown.

If the check box is selected: The replacement will be completely automatic.

This will work also as Hot-Automatic-Replacement without turning the system

power off and on.

4.4 MODIFY SETTINGS | SYSTEM INFO

Use System Info to identify and name the scanning system (whether it includes one scanner

or an array), indicate Master or Standalone systems, discover the scanners included in the

system, and distribute software from the Master scanner to Slave scanners in the system.

To view and edit system information:

1. In the tree menu under Modify Settings, click System Info. The System Info window

opens.

2. Enter the appropriate information in the form as described below:

USER INTERFACE

51

4

Master Tools

Discover

Scanners

Click Discover Scanners to automatically find all of the scanners in an array. The

discovered scanners will be listed in the Device Information portion of the

window. This step is only done during initial configuration and is not a

troubleshooting option.

Distribute

Software

Click Distribute Software to send the current software residing on the master

scanner to all of the slave scanners listed in the Device Information section of

the window.

Device Information

Status

Green = No errors and ready to read

Gray = Unit not connected (unit not seen by master)

Red = Error. If you click on the red circle it will take you to the status viewer page

for more info on the error

Model

Displays an image of the scanner/controller model

Dev

Displays the system designation for the device

MAC Address

Displays the MAC Address (Media Access Control Address) for the device

Software version

Displays the device installed software version.

Description

Enter a user-defined description of the device.

ID

Click ID to visually identify a scanner in an array/tunnel. When clicked, all the

scanner lasers will turn off except for the selected scanner, whose laser will blink

for 20 seconds.

Edit

Select to Remove, Reassign, Add, or Replace from the Edit drop-down list to

complete the following actions:

Remove: When selected, you can select the scanner to remove from the

Dev/MAC Address drop-down list. Click OK to remove the selected scanner

from the system.

Reassign: When selected, the Dev column of the selected slave scanner

(selected with ID) presents a drop-down list of Dev numbers. Select a

different number to reassign the scanner.

Add: This is an option under the Edit drop-down list in the Unconfigured

Devices section of the screen. Click OK to add the selected device to the

system.

BCL 900i REFERENCE MANUAL

52

4

Replace: This is an option under the Edit drop-down list in the

Unconfigured Devices section of the screen. When selected, you can select

from a list of slave scanners (Those with a gray indicator, meaning the unit is

not connected) in the system using MAC Address and Dev drop-down lists.

Click OK to replace the selected scanner with the Unconfigured Device.

3. When you have finished making changes, click Update to save or click Reset to revert to

the previously saved values. 0.

USER INTERFACE

53

4

4.5 MODIFY SETTINGS | GLOBAL SETTINGS

Use the Global Settings menu tree selections during initial setup to configure your BCL 900i

Barcode Scanning System. Global settings are applied to the system Master, and then

distributed by the Master Scanner to the Slave devices. If necessary, you can later make

modifications to the global system settings using the same menu selections.

BCL 900i REFERENCE MANUAL

54

4

4.5.1 Modify Settings | Global Settings | Operating Mode

Use Operating Mode to select an operating mode and configure that modes related

parameters. The three operating modes available are On Line, Continuous, and

PackTrack, and the available settings differ depending on the operating mode selected.

To edit the system Operating Mode:

1. In the tree menu under Modify Settings, navigate to Global Settings | Operating

Mode. The Operating Mode window opens.

USER INTERFACE

55

4

Operating Mode

Select On Line, Continuous, or PackTrack from the Operating Mode

Selection drop-down list.

On Line

Select 1 Input Used, 2 Inputs Used, or Serial from the On Line Options dropdown list. Each selection has a different set of parameters as described below. In

this operating mode, the reading phase is defined as the time between the Phase

ON and Phase OFF events. The Phase events can be signals coming from one

or two external presence sensors connected to the scanner inputs or serial

start/stop strings sent from the host over the serial interface or Ethernet input.

Reading Phase

External Trigger active

External Trigger inactive

1 Input Used

The reading phase takes place during the active phase of the

presence sensor, when the scanner tries to acquire and correctly

decode the code. If the operation is successful, the barcode

characters are transmitted on the serial interface or Ethernet input

in the format defined by the current configuration and the right

output event is raised at the end of the photoelectric sensor’s active

phase. If a code cannot be decoded, a no read message is sent

and the no read event is raised at the end of the photoelectric

sensor’s active phase.

Trigger Source

Start Input

Number

Select the Input Number from the selections

available in the drop-down list.

This option defines the numbered input that will

start the trigger cycle.

2. Enter the appropriate information in the form as described below:

BCL 900i REFERENCE MANUAL

56

4

Start Input

Active Level

Select Active Open or Active Closed from the

drop-down list.

Active Open: The input is active when

there is no current flowing through IN

pins. The input from the trigger source is

normally closed. The scanner goes into

trigger mode when the input source is

opened.

Active Closed: The input is active when

current flows through IN pins. The input

from the trigger source is normally

opened. The scanner goes into trigger

mode when the input source is closed.

Reading Phase

Timeout

Select the check box to define a timeout for the

On Line Serial mode and the On Line 1 Input

mode.

Timeout (ms)

Enter a timeout in milliseconds (from 40 to 15000

ms) in the field provided. The Timeout represents

the period of time for the reading phase.

Timeout

Counting

From

Select Start or Stop from the drop-down list.

When Start is selected, the Timeout

used to determine the reading phase will

begin from the Start Input or Serial Start

String (normal operation)

When Stop is selected, the Timeout

used to determine the reading phase will

begin from the Stop Input or Serial Stop

String (effectively extending the reading

phase).

Verifier Settings

Verifier Enable

Select the check box to enable the Code Verifier

operating mode.

Verifier Code

Click to activate the Text Entry Tool and create

the string text used as the match code to the

decoded codes. Use characters from NUL (00H)

to ~ (7EH). Click Submit to save your text to the

origin window text field, or click Cancel to return

to origin window without transferring text.

Store Input

Select an option from the drop-down list to define

the number of the input used to automatically

store the verifier code. This input must be

activated before the reading phase starts, the

verifier code must be read and then after the end

of the reading phase the input must be

deactivated.

USER INTERFACE

57

4

Active Level

Select Active Open or Active Closed from the

drop-down list to choose the active state of the

input.

Active Open: The input is active when

there is no current flowing through IN

pins. The input from the verify mode

source is normally closed. The scanner

goes into trigger mode when the input

source is opened.

Active Closed: The input is active when

current flows through IN pins. The input

from the verify mode source is normally

opened. The scanner goes into trigger

mode when the input source is closed.

Wrong Code

Tx

Select the check box to enable the transmission

of the Wrong Code (Non-Valid Code).

Wrong String

Tx

Select the check box to enable the transmission

of the Wrong String (Non-Valid String) message.

Wrong String

(max. 128

chars)

Enter a text string to be sent in case of a

mismatch (wrong code read/non-valid code).

Beam Shutter Settings

Beam Shutter

Select Disabled, Triggered, or Enabled from the

drop-down list. The Beam Shutter turns the laser

off. The Beam Shutter option can be used to

increase the overall laser diode life when used in

high ambient temperature applications (over

35° C); reduce power consumption; and to turn off

the laser for safety purposes.

Disabled: The laser is always on.

Triggered: The laser is turned off as soon

as the code(s) are read or when the

reading phase ends. The laser is turned

on again when the next reading phase

starts.

Enabled: The laser is always off and all

operations are suspended.

2 Inputs

Used

The reading phase is defined by 2 inputs. It starts when the Start

Input is activated and stops when the Stop Input is deactivated

(unless the Extended Phase is enabled).

Trigger Source

Extended

Phase

Available only for the On Line/2 Inputs option. If

checked, it allows the Stop Input to end the

reading phase only if the Start Input is also

deactivated.

BCL 900i REFERENCE MANUAL

58

4

Start Input

Number

Select an input from the drop-down list to define

the number of the input starting the reading

phase.

Start Input

Active Level

Select Active Open or Active Closed from the

drop-down list.

Active Open: The input is active when

there is no current flowing through IN

pins. The input from the trigger source is

normally closed. The scanner goes into

trigger mode when the input source is

opened.

Active Closed: The input is active when

current flows through IN pins. The input

from the trigger source is normally

opened. The scanner goes into trigger

mode when the input source is closed.

Stop Input

Number

Select an input from the drop-down list to define

the input ending the reading phase.

Stop Input

Active Level

Select Active Open or Active Closed from the

drop-down list to define the active state of the

input.

Active Open: The input is active when

there is no current flowing through IN

pins. The input from the trigger source is

normally closed. The scanner goes into

trigger mode when the input source is

opened.

Active Closed: The input is active when

current flows through IN pins. The input

from the trigger source is normally

opened. The scanner goes into trigger