Page 1

SHPPLCDREUSESW

13412153

Ä.J6Vä

L-force Controls

Software manual

PC-based Automation

PLC Designer V2.x

Commissioning of Lenze devices (Application Samples)

L

Page 2

Page 3

PLC Designer V2.x| Lenze Application Samples

Contents

Contents

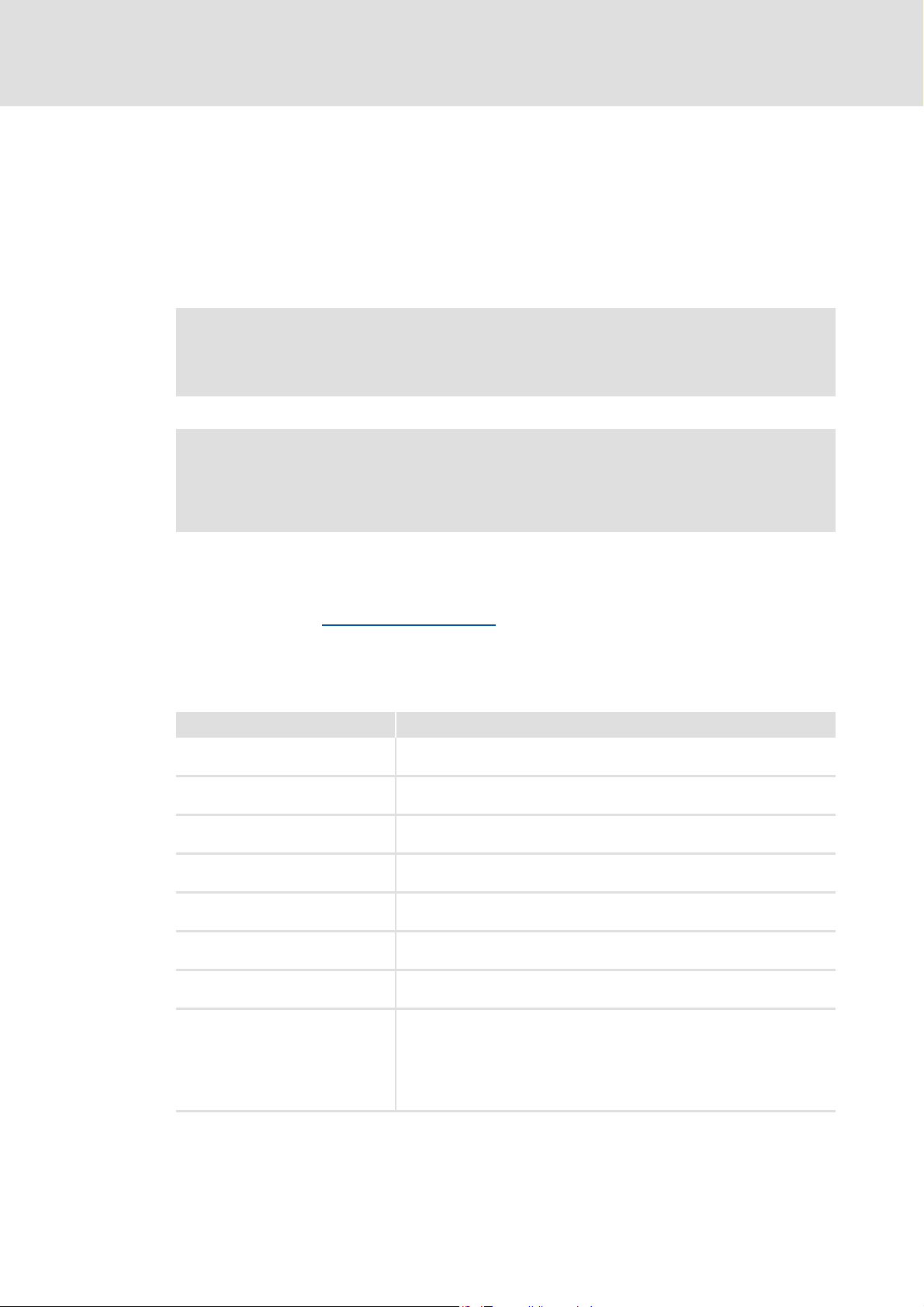

1 About this documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.1 Document history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.2 Trademark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.3 Conventions used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.4 Notes used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3 The "PC-based automation" system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1 System requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2 What is the PLC Designer? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.3 Where can I receive a full version of the PLC Designer? . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3.1 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5 System bus (CAN) / CANopen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.1 CANopen (Logic) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

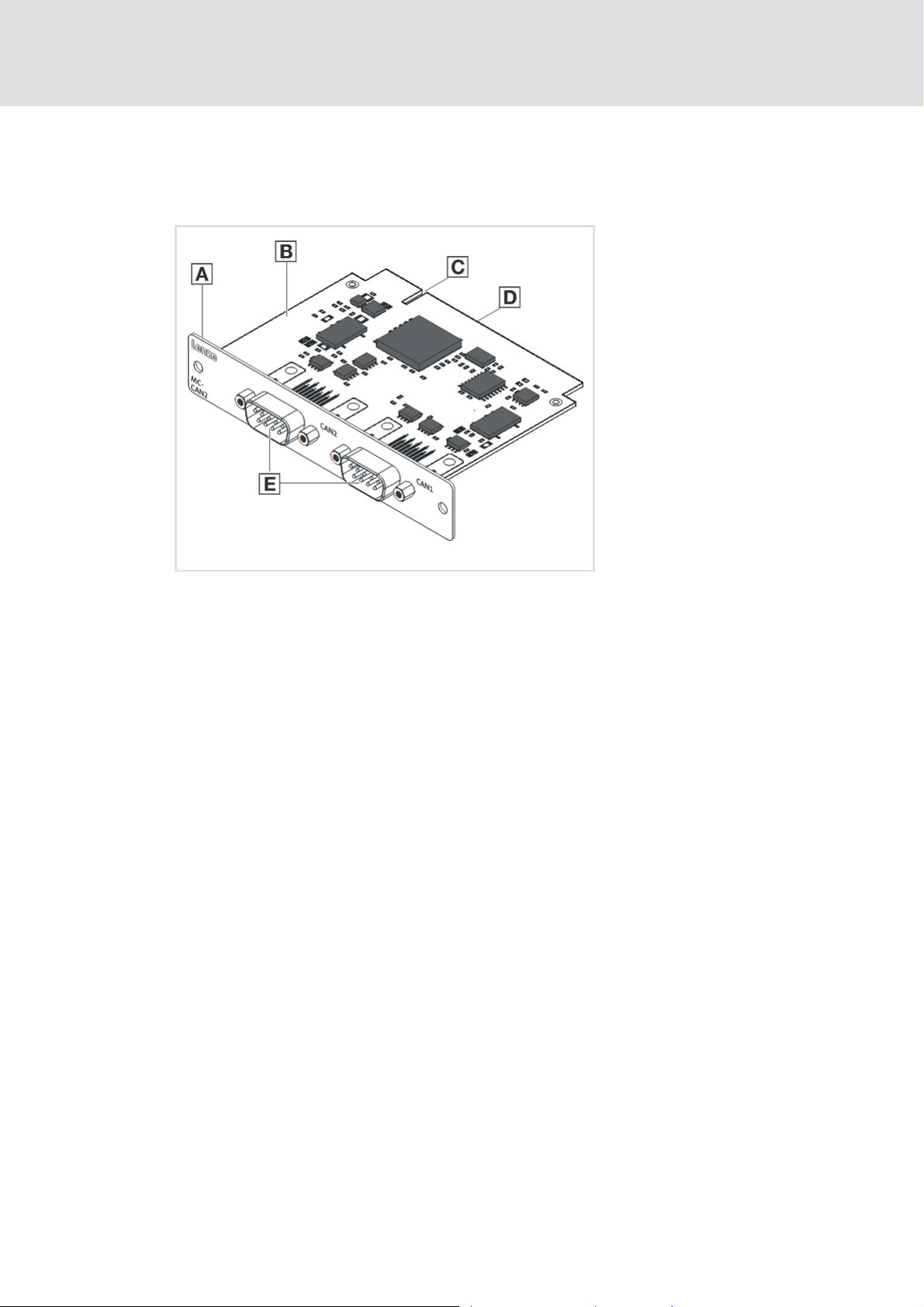

5.2 Communication card MC-CAN2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6 Commissioning the CANopen Logic bus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1 Overview of the commissioning steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2 Commissioning field devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.2.1 Going online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3 Preparing the restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.3.1 Special features of the 9400 Servo Drives HighLine . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3.2 Special features of the 8400 Inverter Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3.3 Commission 8200 vector frequency inverters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3.4 Special features of the ECS servo system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7 Commissioning a sample project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.1 General system structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.2 Wiring the hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.2.1 Configuring the CAN interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.2.2 Configuring an EL1xx Ethernet interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.3 Opening a project in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.3.1 Establishing communication with the Industrial PC or EL1xx . . . . . . . . . . . . . . . 38

7.3.2 Starting the sample project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1.3 EN - 07/2012 L 3

Page 4

PLC Designer V2.x| Lenze Application Samples

Contents

8 Working with the sample projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.1 8400 StateLine - "LAS_40_INTF_Can_84SL_Speed" sample project . . . . . . . . . . . . . . . . . 41

8.1.1 Components used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.1.2 Short overview of the functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.1.2.1 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.1.2.2 Open the »Engineer« project & go online. . . . . . . . . . . . . . . . . . . . . . . . 43

8.1.3 Program structure in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.1.3.1 Control configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.1.3.2 Program organisation units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.1.4 Operation via the visualisations in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . 48

8.1.4.1 Information/home page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.1.4.2 Automatic mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.1.4.3 Manual mode ("Manual jog") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.1.4.4 Service mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.1.4.5 Parameter transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.1.4.6 CAN diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.1.5 Interface assignment in the »Engineer« . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.2 8400 HighLine - "LAS_40_INTF_Can_84HL_TabPos" sample project . . . . . . . . . . . . . . . . 61

8.2.1 Components used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.2.2 Short overview of the functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.2.3 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.2.3.1 Open the »Engineer« project & go online. . . . . . . . . . . . . . . . . . . . . . . . 63

8.2.4 Program structure in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.2.4.1 Control configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.2.4.2 Program organisation units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.2.5 Operation via the visualisations in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . 69

8.2.5.1 Information/home page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.2.5.2 Automatic mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.2.5.3 Manual mode ("Manual jog") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

8.2.5.4 Service mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

8.2.5.5 Homing mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8.2.5.6 Parameter transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

8.2.5.7 CAN diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.2.6 Interface assignment in the »Engineer« . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4 L 1.3 EN - 07/2012

Page 5

PLC Designer V2.x| Lenze Application Samples

Contents

8.3 9400 HighLine - "LAS_40_INTF_Can_94HL_Speed" sample project . . . . . . . . . . . . . . . . . 83

8.3.1 Components used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8.3.2 Short overview of the functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

8.3.2.1 Open the »Engineer« project & go online. . . . . . . . . . . . . . . . . . . . . . . . 85

8.3.3 Program structure in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8.3.3.1 Control configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8.3.3.2 Program organisation units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

8.3.4 Operation via the visualisations in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . 90

8.3.4.1 Information/home page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

8.3.4.2 Automatic mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

8.3.4.3 Manual mode ("Manual jog") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.3.4.4 Service mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

8.3.4.5 Parameter transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

8.3.4.6 CAN diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

8.3.5 Interface assignment in the »Engineer« . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

8.4 9400 HighLine - "LAS_40_INTF_Can_94HL_TabPos" sample project . . . . . . . . . . . . . . . . 102

8.4.1 Components used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

8.4.2 Short overview of the functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

8.4.2.1 Open the »Engineer« project & go online. . . . . . . . . . . . . . . . . . . . . . . . 104

8.4.3 Program structure in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.4.3.1 Control configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.4.3.2 Program organisation units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

8.4.4 Operation via the visualisations in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . 110

8.4.4.1 Information/home page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

8.4.4.2 Automatic mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

8.4.4.3 Manual mode ("Manual jog") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

8.4.4.4 Service mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

8.4.4.5 Homing mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

8.4.4.6 Parameter transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

8.4.4.7 CAN diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

8.4.5 Interface assignment in the »Engineer« . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

1.3 EN - 07/2012 L 5

Page 6

PLC Designer V2.x| Lenze Application Samples

Contents

8.5 ECS servo system - "LAS_40_INTF_Can_ECSPosShaft" sample project . . . . . . . . . . . . . . 125

8.5.1 Components used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

8.5.2 Short overview of the functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

8.5.3 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

8.5.4 Open the »Global Drive Control« project & go online . . . . . . . . . . . . . . . . . . . . . . 127

8.5.5 Program structure in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

8.5.5.1 Control configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

8.5.5.2 Program organisation units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

8.5.6 Operation via the visualisations in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . 135

8.5.6.1 Information/home page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

8.5.6.2 Automatic mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

8.5.6.3 Manual mode ("Manual jog") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

8.5.6.4 Service mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

8.5.6.5 Homing mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

8.5.6.6 Parameter transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

8.5.6.7 CAN diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

8.5.7 Interface assignment in the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

8.6 8200 vector - "LAS_40_INTF_Can_82_Speed" sample project . . . . . . . . . . . . . . . . . . . . . . 148

8.6.1 Components used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

8.6.2 Short overview of the functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

8.6.3 Open the »Global Drive Control« project & go online . . . . . . . . . . . . . . . . . . . . . . 149

8.6.4 Program structure in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

8.6.5 Operation via the visualisations in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . 155

8.6.6 Interface assignment in the »Global Drive Control«. . . . . . . . . . . . . . . . . . . . . . . . 165

8.6.2.1 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

8.6.4.1 Control configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

8.6.4.2 Program organisation units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

8.6.5.1 Information/home page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

8.6.5.2 Automatic mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

8.6.5.3 Manual mode ("Manual jog") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

8.6.5.4 Service mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

8.6.5.5 Parameter transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

8.6.5.6 CAN diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

6 L 1.3 EN - 07/2012

Page 7

PLC Designer V2.x| Lenze Application Samples

Contents

8.7 9300 servo - "LAS_40_INTF_Can_93_Speed" sample project . . . . . . . . . . . . . . . . . . . . . . . 167

8.7.1 Components used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

8.7.2 Short overview of the functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

8.7.2.1 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

8.7.3 Open the »Global Drive Control« project & go online . . . . . . . . . . . . . . . . . . . . . . 169

8.7.4 Program structure in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

8.7.4.1 Control configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

8.7.4.2 Program organisation units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

8.7.5 Operation via the visualisations in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . 175

8.7.5.1 Information/home page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

8.7.5.2 Automatic mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

8.7.5.3 Manual mode ("Manual jog") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

8.7.5.4 Service mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

8.7.5.5 Parameter transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

8.7.5.6 CAN diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

8.7.6 Interface assignment in the »Global Drive Control«. . . . . . . . . . . . . . . . . . . . . . . . 185

8.8 9300 - "LAS_40_INTF_Can_93_EP" sample project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

8.8.1 Components used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

8.8.2 Short overview of the functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

8.8.2.1 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

8.8.3 Open the »Global Drive Control« project & go online . . . . . . . . . . . . . . . . . . . . . . 190

8.8.4 Program structure in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

8.8.4.1 Control configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

8.8.4.2 Program organisation units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

8.8.5 Operation via the visualisations in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . 197

8.8.5.1 Information/home page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

8.8.5.2 Automatic mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

8.8.5.3 Manual mode ("Manual jog") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

8.8.5.4 Service mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

8.8.5.5 Homing mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

8.8.5.6 Parameter transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

8.8.5.7 CAN diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

8.8.6 Interface assignment in the »Global Drive Control«. . . . . . . . . . . . . . . . . . . . . . . . 209

1.3 EN - 07/2012 L 7

Page 8

PLC Designer V2.x| Lenze Application Samples

Contents

8.9 ECS/9400/8400 - "LAS_40_INTF_84SL_Speed_94HL_Speed_ECSPosShaft" sample project

212

8.9.1 Components used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

8.9.2 Short overview of the functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

8.9.2.1 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

8.9.2.2 Program structure in the »PLC Designer« . . . . . . . . . . . . . . . . . . . . . . . . 214

8.9.2.3 Program organisation units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

8.9.3 Operation via the visualisations in the »PLC Designer«. . . . . . . . . . . . . . . . . . . . . 218

8.9.3.1 Information/home page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

8.9.3.2 Automatic mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

8.9.3.3 Manual mode ("Manual jog") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

8.9.3.4 Service mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

8.9.3.5 "Homing ECS" mode (homing) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

8.9.3.6 Parameter transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

8.9.3.7 CAN diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

8.9.4 Interface assignment in the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

9 Adding other components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

9.1 Copying and inserting nodes of the same series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

9.1.1 Establishing the connection between the visualisation and the FB. . . . . . . . . . 229

9.2 Inserting further subelements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

9.3 Copying and inserting different nodes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

10 Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

10.1 What to do if the PLC is not running? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

10.1.1 The PLC was exited on the target system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

10.1.2 No download of the PLC program to the target system possible . . . . . . . . . . . . 232

10.2 What to do if the CAN bus is not running/CAN nodes do not respond? . . . . . . . . . . . . . 233

10.3 What to do if the motor does not rotate? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

11 The L_S84_Drive8400.lib library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

11.1 L_S84_ActuatorSpeedBL - actuation of the 8400 BaseLine controller . . . . . . . . . . . . . . . 235

11.1.1 Structure of S84_DriveControl_8400BL - actuation to the controller . . . . . . . . 236

11.1.2 Structure of S84_DriveStatus_8400BL - status of the controller . . . . . . . . . . . . 237

11.2 L_S84_ActuatorSpeedSL - actuation of the 8400 StateLine controller. . . . . . . . . . . . . . . 238

11.2.1 Structure of S84_DriveControl_8400 - actuation to the controller . . . . . . . . . . 239

11.2.2 Structure of S84_DriveStatus_8400 - status of the controller. . . . . . . . . . . . . . . 240

11.3 L_S84_GetVersion - transfer of the version. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

11.4 L_S84_ReadErrorCode - read out error status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

11.5 L_S84_SDOList84SL - parameter list for 8400 StateLine controller. . . . . . . . . . . . . . . . . . 242

8 L 1.3 EN - 07/2012

Page 9

PLC Designer V2.x| Lenze Application Samples

Contents

11.6 L_S84_TablePositioningHL - profile data record management . . . . . . . . . . . . . . . . . . . . . 243

11.6.1 Structure of S84_DriveControl_8400HL_TablePositioning - actuation to the drive

244

11.6.2 Structure of S84_DriveStatus_8400HL_TablePositioning - status of the controller

245

12 The L_S94_Drive9400.lib library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

12.1 L_S94_ActuatorSpeed - actuation of the 9400 HighLine controller . . . . . . . . . . . . . . . . . 246

12.1.1 Structure of S94_DriveControl_ActSpeed - actuation to the 9400 controller. 247

12.1.2 Structure of S94_DriveStatus_ActSpeed - status of the controller . . . . . . . . . . 248

12.2 L_S94_GetVersion - transfer of the version. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

12.3 L_S94_ReadErrorCode - read out error status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

12.4 L_S94_TablePositioning - table positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

12.4.1 Structure of S94_DriveControl_TablePositioning - actuation to the controller 252

12.4.2 Structure of S94_DriveStatus_TablePositioning - status of the controller . . . 253

13 The L_SCS_DriveECS.lib library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

13.1 L_SCS_ActuatorSpeed - actuation of the ECS servo system. . . . . . . . . . . . . . . . . . . . . . . . . 255

13.1.1 Structure of SCS_DriveControl_Speed - control for the drive . . . . . . . . . . . . . . . 256

13.1.2 Structure of SCS_DriveStatus_Speed - status of the controller. . . . . . . . . . . . . . 257

13.2 L_SCS_GetVersion - transfer of the version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

13.3 L_SCS_PosiShaft - actuation of the ECS servo system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

13.3.1 Structure of SCS_DriveControl_PosiShaft - control for the drive . . . . . . . . . . . . 259

13.3.2 Structure of SCS_DriveStatus_PosiShaft - status of the controller . . . . . . . . . . 260

13.3.2.1 Process data from the axis module (status words and actual values) 261

13.3.2.2 Monitor data words from the controller (tx_par1 and tx_par2) . . . 262

13.4 L_SCS_SupplyModule - actuation of the ECS servo system power supply module . . . 263

13.4.1 Structure of SCS_Control_Supply - actuation to the ECS controller power supply

module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

13.4.2 Structure of SCS_Status_Supply - status of the controller . . . . . . . . . . . . . . . . . . 265

13.4.3 L_SCS_ReadErrorCode - read out error status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

14 The L_S8V_Drive82Vector.lib library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

14.1 L_S8V_ActuatorSpeed - actuation of the 8200 vector controller. . . . . . . . . . . . . . . . . . . . 267

14.1.1 Actuation to the controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

14.1.2 Status of the controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

14.2 L_S8V_ReadErrorCode - read out error status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

14.3 L_S8V_SDOList. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

1.3 EN - 07/2012 L 9

Page 10

PLC Designer V2.x| Lenze Application Samples

Contents

15 The L_S8S_Drive82SMD.lib library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

15.1 L_S8S_ActuatorSpeed - actuation of the 8400 SMD controller . . . . . . . . . . . . . . . . . . . . . 272

15.1.1 Structure S8S_DriveControl - actuation to the controller . . . . . . . . . . . . . . . . . . . 273

15.1.2 Structure S8S_DriveStatus - status of the controller . . . . . . . . . . . . . . . . . . . . . . . 274

15.2 L_S8S_SDOList . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

16 The L_S93_Drive9300.lib library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

16.1 L_S93_ActuatorSpeed - control the 9300 Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

16.1.1 Structure of 93_DriveControl_Speed - actuation to the controller . . . . . . . . . . 277

16.1.2 Structure of 93_DriveStatus_Speed - status of the controller. . . . . . . . . . . . . . . 278

16.2 L_S93_Positioning - control the 9300 Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

16.2.1 Structure of S93_DriveControl_93xxEP - actuation to the 9300 EP controller 280

16.2.2 Structure of S93_DriveStatus_93xxEP - status of the 9300 EP controller . . . . 281

16.3 L_S93_ReadErrorCode - read out error status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

17 The L_SCB_CANBasic.lib library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

17.1 L_SCB_Actuator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

17.2 L_SCB_CanStatus - node inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

17.3 L_SCB_GetNodeDataRxPDO1 - read out data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

17.4 L_SCB_GetNodeDataRxPDO2 - read out data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

17.5 L_SCB_GetNodeState - node inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

17.6 L_SCB_GetStateOptional - check with regard to "OptionalDevice" . . . . . . . . . . . . . . . . . 287

17.7 L_SCB_GetVersion - transfer of the version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

17.8 L_SCB_ParRead - read parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

17.9 L_SCB_ParRead_String - "String"-read parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

17.10 L_SCB_ParWrite - write parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

17.11 L_SCB_PutNodeDataTxPDO1 - data transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

17.12 L_SCB_PutNodeDataTxPDO2 - data transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

17.13 L_SCB_SDO_Converter - conversion block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

17.13.1 SCB_ParameterData . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

17.14 L_SCB_SDO_ListSize10 - parameter list (length: 10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

17.15 L_SCB_SDO_ListSize25 - parameter list (length: 25) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

17.16 L_SCB_SDO_ListSize50 - parameter list (length: 50) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

17.17 L_SCB_StartNode - restart CAN nodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

17.18 L_SCB_StatusSingleNode - read out bus status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

17.18.1 SCB_StateCanMaster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

17.18.2 Structure of SCB_CanNodeDiagnose -. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

17.19 L_SCB_SDO_TransferTable - transfer parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

10 L 1.3 EN - 07/2012

Page 11

PLC Designer V2.x| Lenze Application Samples

Contents

18 The L_SDC_DataConversion.lib library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

18.1 L_SDC_2BytesToWord - type converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

18.2 L_SDC_2WordsToDWord - type converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

18.3 L_SDC_4BytesToDWord - type converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

18.4 L_SDC_BitsToByte - bit multiplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

18.5 L_SDC_BitsToDWord - bit multiplexer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

18.6 L_SDC_BitsToWord - bit multiplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

18.7 L_SDC_ByteToBits - bit demultiplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

18.8 L_SDC_GetBitOfByte - conversion block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 306

18.9 L_SDC_DWordToBits - bit demultiplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

18.10 L_SDC_DWordTo2Words - type converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

18.11 L_SDC_DWordTo4Bytes - type converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

18.12 L_SDC_GetBitOfDWord - conversion block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

18.13 L_SDC_GetBitOfWord - conversion block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

18.14 L_SDC_GetVersion - transfer of the version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

18.15 L_SDC_ResetBitOfByte - conversion block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 310

18.16 L_SDC_ResetBitOfDWord - conversion block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

18.17 L_SDC_ResetBitOfWord - conversion block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

18.18 L_SDC_SetBitOfByte - bit operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

18.19 L_SDC_SetBitOfDWord - bit operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

18.20 L_SDC_SetBitOfWord - bit operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

18.21 L_SDC_WordTo2Bytes - type converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

18.22 L_SDC_WordToBits - bit demultiplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

19 The L_SEC_ErrorCode.lib library. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

19.1 L_SEC_GetVersion - transfer of the version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

19.2 L_SEC_InfoErrorCode - read out error status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

20 The L_SSC_Scaling.lib library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

20.1 L_SSC_AccToUnit - conversion block (for 9400 device series). . . . . . . . . . . . . . . . . . . . . . . 316

20.2 L_SSC_GetAxisData - read out machine parameters from axis data . . . . . . . . . . . . . . . . 317

20.3 L_SSC_GetPosition - conversion block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

20.4 L_SSC_GetSpeed - conversion block (for 9400 device series) . . . . . . . . . . . . . . . . . . . . . . . 319

20.5 L_SSC_GetVersion - transfer of the version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

20.6 L_SSC_Norm_aToNorm_n - signal converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

20.7 L_SSC_Norm_nToNorm_a - signal converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

1.3 EN - 07/2012 L 11

Page 12

PLC Designer V2.x| Lenze Application Samples

Contents

20.8 L_SSC_Norm_nToSpeed_s - signal converter (for 9400 device series). . . . . . . . . . . . . . . 321

20.8.1 SSC_Axis_logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

20.9 L_SSC_PosToUnit - conversion block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

20.10 L_SSC_Speed_nToNorm_r - signal converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 323

20.11 L_SSC_Speed_rToNorm_n - signal converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

20.12 L_SSC_Speed_sToNorm_n - signal converter (for 9400 device series). . . . . . . . . . . . . . . 324

20.13 L_SSC_Speed_sToSpeed_v - signal converter (for 9400 device series). . . . . . . . . . . . . . . 324

20.14 L_SSC_Speed_vToSpeed_s - signal converter (for 9400 device series). . . . . . . . . . . . . . . 325

20.15 L_SSC_SetAxisData - machine parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

20.16 L_SSC_SetPosition - position conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327

20.17 L_SSC_SetSpeed - speed conversion (for 9400 device series) . . . . . . . . . . . . . . . . . . . . . . . 328

20.18 L_SSC_SpeedToUnit - conversion block (for 9400 device series) . . . . . . . . . . . . . . . . . . . . 329

20.19 L_SSC_TaskCycle - read in task time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

20.20 L_SSC_UnitToAcc - conversion block (for 9400 device series). . . . . . . . . . . . . . . . . . . . . . . 330

20.21 L_SSC_UnitToPos - conversion block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

20.22 L_SSC_UnitToSpeed - conversion block (for 9400 device series) . . . . . . . . . . . . . . . . . . . . 332

21 Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 333

Your opinion is important to us. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

12 L 1.3 EN - 07/2012

Page 13

PLC Designer V2.x| Lenze Application Samples

About this documentation

1 About this documentation

This documentation describes the first commissioning steps of a Lenze automation system

on the basis of a simple example application. The automation system used consists of a PLC

for the control technology and drive components connected (via a bus system).

The explanation of the procedure includes the installation of the integrated development

environment, the »PLC Designer«, and the diagnostics of the application.

Read the mounting instructions supplied with the controller first before you start

working!

The mounting instructions contain safety instructions which must be observed!

Note!

This documentation supplements the software manuals of the »PLC Designer«

and »Engineer«.

Tip!

Information and tools regarding the Lenze products can be found in the download

area under: http://www.Lenze.com

This manual is part of the "PC-based Automation" manual collection. The manual

collection consists of the following parts:

Documentation Subject

System manuals

"PC-based Automation"

Communication manuals

"PC-based Automation"

(Software) manual

"PC-based Automation"

Operating instructions

"Embedded Line Panel PC"

Operating instructions

"Command Station"

Operating instructions

"Control Cabinet PC"

Operating instructions

"HMI EL 100"

More software manuals • »Global Drive Control« (»GDC«)

• Control technology - System structure & configuration

• Visualisation - System structure & components

• CANopen control technology

• PROFIBUS control technology

• Industrial PC - Parameter setting & configuration

• EL x8xx - built-in panel PC with TFT display

• CS x8xx - stand-alone operator terminal

• CPC x8xx - control cabinet PC

• EL 1xx - HMI with Windows

–IPC as gateway - Parameter setting & configuration

• »Engineer«

• »PLC Designer« / »PLC Designer - SoftMotion« / »PLC Designer - CANopen

for Runtime Systems«

• »VisiWinNET® Smart«

® CE

13 L 1.3 EN - 07/2012

Page 14

PLC Designer V2.x| Lenze Application Samples

About this documentation

Information on the use of the IPCs beyond the control technology can be found in

the system manuals tailored to the application case.

1.3 EN - 07/2012 L 14

Page 15

PLC Designer V2.x| Lenze Application Samples

About this documentation

Further technical documentation on Lenze components

More information on Lenze components that can be used together with "PC-based

automation" can be found in the following documentation:

Mounting & wiring Legend:

MAs for Inverter Drives 8400 Printed documentation

MAs for Servo Drives 9400 Online help/PDF

MA EPM-Txxx (I/O system IP20) Abbreviations used:

MA EPM-Sxxx (I/O system 1000) SHB System manual

MA 8200 vector BA Operating instructions

8200 vector wiring according to EMC MA Mounting instructions

MAs for the ECS servo system SW Software manual

MA MC-CAN2 communication card KHB Communication manual

MA MC-ETC communication card

MA MC-ETH communication card

MA MC-PBM communication card

MA MC-PBS communication card

MA MC-MPI communication card

MAs for communication modules

Parameterisation, configuration, commissioning

SW Inverter Drives 8400

BaseLine / StateLine / HighLine / TopLine

SW Servo Drive 9400 HighLine / PLC Í This documentation contains further

9400 HighLine commissioning guidelines

SHB I/O system IP20 (EPM-Txxx)

SHB I/O system 1000 (EPM-Sxxx)

SHB 8200 vector Í This documentation contains further

BAs for the ECS servo system Í This documentation contains further

KHBs for the communication modules

Programming

SW 9400 function library

Establishing a network

KHBs for the communication modules

Í This documentation contains further

information when using the sample projects

information when using the sample projects

information when using the sample projects

information when using the sample projects

Target group

The documentation addresses to persons who plan, install, commission, and maintain the

networking of devices in the field of control technology.

15 L 1.3 EN - 07/2012

Page 16

PLC Designer V2.x| Lenze Application Samples

About this documentation

Information regarding the validity

The information provided in this documentation applies to the AppSamples_100 with the

following Lenze software:

Software From software version

»PLC Designer« 2.3.x

»Engineer« 2.12

»Global Drive Control« 4.11

1.3 EN - 07/2012 L 16

Page 17

1.1 Document history

Version Description

1.1 11/2010 TD11 First edition

1.2 03/2011 TD11 Further sample projects supplemented:

1.3 06/2012 TD11 Amended by general notes on the use of FBs.

1.2 Trademark

Microsoft, Windows, and Windows NT are either registered trademarks or trademarks of

the Microsoft Corporation in the USA and/or other countries.

PLC Designer V2.x| Lenze Application Samples

About this documentation

Document history

• 8200 vector

• 9300 Speed

• 9300 EP

• Multiproject ECS/ 8400 StateLine/9400 HighLine

Adobe and Reader are either registered trademarks or trademarks of Adobe Systems

Incorporated in the USA and/or other countries.

All other brand names mentioned in this documentation are trademarks of their respective

owners.

1.3 EN - 07/2012 L 17

Page 18

PLC Designer V2.x| Lenze Application Samples

About this documentation

Conventions used

1.3 Conventions used

This documentation uses the following conventions to distinguish between different types

of information:

Type of information Display Examples/notes

Numbers

Decimal separator Point The decimal point is generally used.

Text

Version information Text colour blue All pieces of information that only apply to or from a

Program name » « The Lenze PC software »PLC Designer«

Window Italics The Message window... / The Options ... dialog box

Variable name By setting bEnable to TRUE...

Control element Bold The OK... button / The Copy... command / The

Sequence of menu

commands

Shortcut <Bold> Use <F1> to open the online help.

Program code Courier

Keyword Courier bold

Example: 1234.56

certain controller software version are identified

accordingly in this documentation.

Example: This function extension is available as from

software version V3.0!

Properties... tab / The Name ... input field

If the execution of a function requires several

commands in a row, the individual commands are

separated by an arrow: Select File

If a key combination is required for a command, a "+"

is placed between the key identifiers: With

<Shift>+<ESC>...

IF var1 < var2 THEN

a = a + 1

END IF

Open to...

Hyperlink Underlined

Symbols

Page reference ( 18) Optically highlighted reference to another page. It is

Step-by-step instructions

Optically highlighted reference to another topic. It is

activated with a mouse-click in this documentation.

activated with a mouse-click in this documentation.

Step-by-step instructions are marked by a

pictograph.

18 L 1.3 EN - 07/2012

Page 19

1.4 Notes used

The following signal words and icons are used in this documentation to indicate dangers

and important information:

Safety instructions

Structure of safety instructions:

Pictograph and signal word!

(characterises the type and severity of danger)

Note

(explains the danger and how to avoid it)

Pictograph Signal word Meaning

PLC Designer V2.x| Lenze Application Samples

About this documentation

Notes used

Danger! Danger of personal injuries through dangerous electrical voltage

Reference to an imminent danger that may result in death or serious

personal

injury unless the corresponding measures are taken.

Danger! Danger of personal injury through a general source of danger

Reference to an imminent danger that may result in death or serious

personal

injury unless the corresponding measures are taken.

Stop! Danger of damage to material assets

Indicates a potential danger that may lead to material damage unless the

corresponding measures are taken.

Application notes

Pictograph Signal word Meaning

Note! Important note for trouble-free operation

Tip! Useful tip for easy handling

Reference to other documents

1.3 EN - 07/2012 L 19

Page 20

PLC Designer V2.x| Lenze Application Samples

Safety instructions

2 Safety instructions

Please observe the following safety instructions when you want to commission a controller

or system using the »Engineer«.

Read the documentation supplied with the controller or the individual

components of the system carefully before you start to commission the devices

with the »Engineer«!

The device documentation contains safety instructions which must be

observed!

Danger!

According to our present level of knowledge it is not possible to ensure the

absolute freedom from errors of a software.

If necessary, systems with built-in controllers must be provided with additional

monitoring and protective equipment according to relevant safety regulations

(e.g. law on technical equipment, regulations for the prevention of accidents), so

that an impermissible operating status does not endanger persons or facilities.

During commissioning persons must keep a safe distance from the motor or the

machine parts driven by the motor. Otherwise there would be a risk of injury by

the moving machine parts.

Stop!

If you change parameters in the »Engineer« during an online connection to the

device is established, the changes are directly accepted in the device!

A wrong parameter setting can cause unpredictable motor movements. By

unintentional direction of rotation, too high speed or jerky operation, the driven

machine parts may be damaged!

20 L 1.3 EN - 07/2012

Page 21

PLC Designer V2.x| Lenze Application Samples

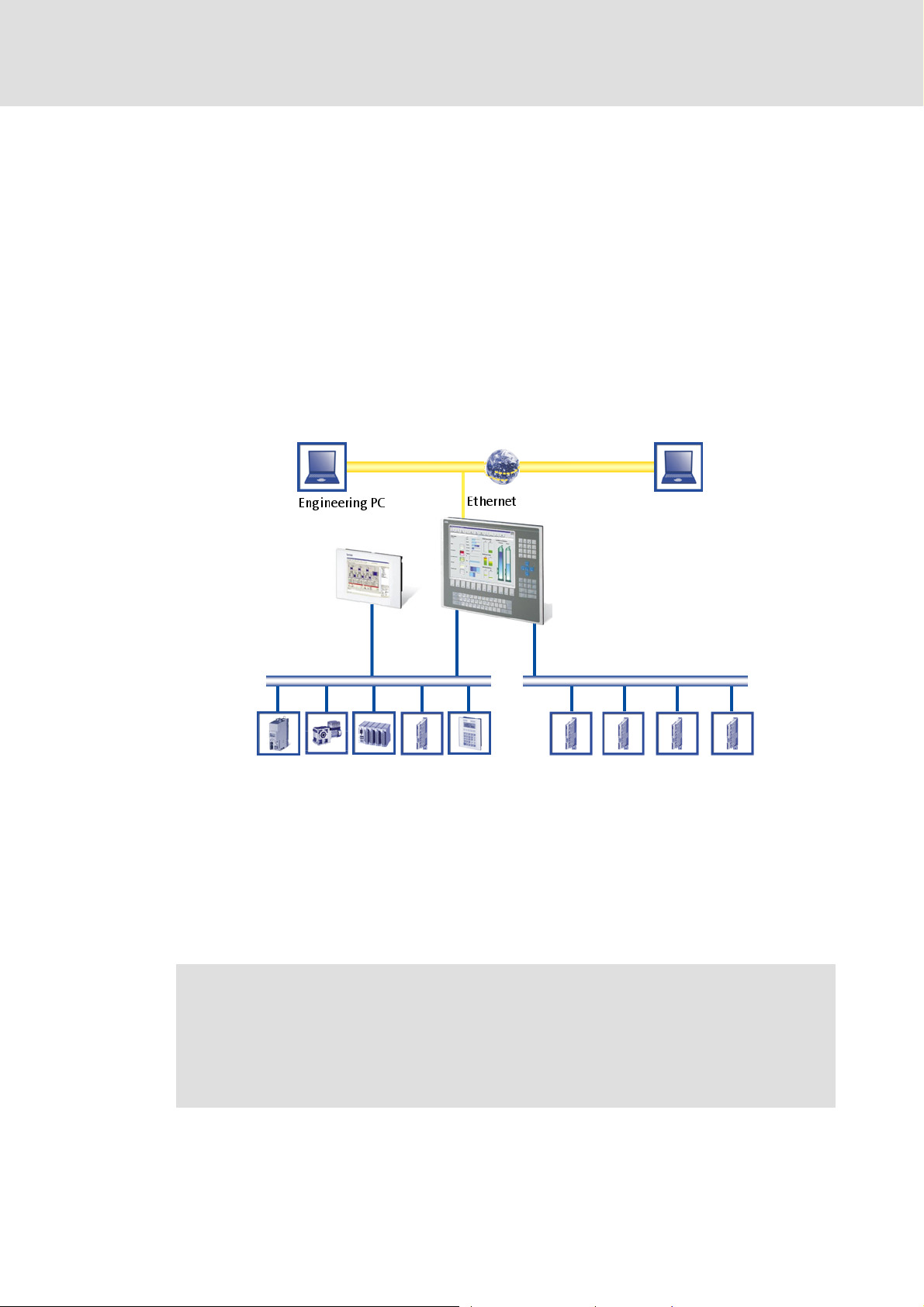

3 The "PC-based automation" system

Industrial PCs (IPCs) become more and more important in the field of automation

technology. Due to their scaling options and various combinations of visualisation and

control on one device, Industrial PCs provide clear advantages for many applications.

Lenze Industrial PCs are available in the following software equipments:

Industrial PC as component (optional with operating system) without any further

software

Industrial PC as visualisation system

Industrial PC as control and visualisation system

The "PC-based automation" system enables the centralised control of Logic and Motion

systems.

The "PC-based automation" system

For this purpose, Lenze provide coordinated system components:

Industrial PCs as control and visualisation system

– The IPC is the central component of the PC-based automation which controls the

Logic and Motion functionalities by means of the runtime software.

– The IPC communicates with the field devices via the fieldbus.

– The IPCs are available in different designs.

Note!

The "PC-based automation" system furthermore contains the EL 1xx PLC HMI

series. These devices clearly differ from the Industrial PCs with regard to the

performance and various other details. Nevertheless the devices of the

EL 1xx PLC HMI series are able to perform smaller control functions.

1.3 EN - 07/2012 L 21

Page 22

PLC Designer V2.x| Lenze Application Samples

The "PC-based automation" system

Engineering tools for the Engineering PC

– The Engineering PC communicates with the IPC via Ethernet.

– Use the various Engineering tools to configure and parameterise the system.

Fieldbuses

Field devices

22 L 1.3 EN - 07/2012

Page 23

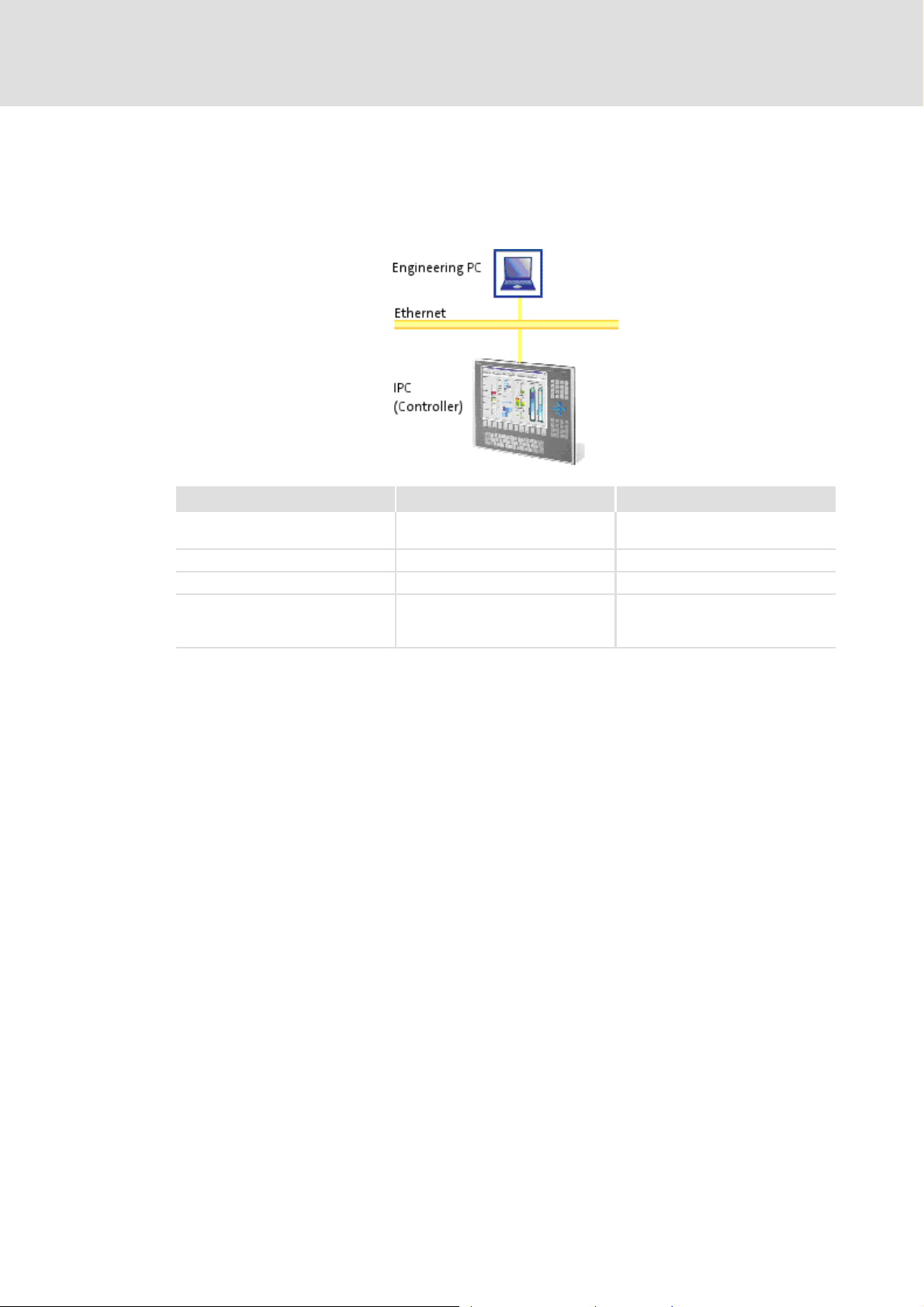

4 Requirements

4.1 System requirements

PLC Designer V2.x| Lenze Application Samples

Requirements

System requirements

Hardware PC/notebook Industrial PC with PLC (Logic) from

Operating system Windows XP Windows CE

Lenze software required »PLC Designer« V2.2.4.x L-force Logic

Further requirements • 100 MB of free hard disk memory • CAN bus system

4.2 What is the PLC Designer?

The »PLC Designer« is a Lenze engineering software for programming the PLC of the Lenze

Industrial PC.

Properties

Five different editors for the programming languages standardised in the IEC 61131-3,

and a very powerful CFC editor are provided. They serve to create individual programs,

and to trigger the functions of our L-force Logic & Motion runtime software.

By means of the integrated visualisation the processes are shown, in order to obtain all

important pieces of information at a glance during commissioning.

Engineering PC IPC (controller)

firmware V2.0

• CAN nodes (depending on the

respective example application)

1.3 EN - 07/2012 L 23

Page 24

PLC Designer V2.x| Lenze Application Samples

Requirements

Where can I receive a full version of the PLC Designer?

4.3 Where can I receive a full version of the PLC Designer?

The »PLC Designer« is provided for download in the Lenze Application Knowledge Base

(AKB) :

http://akb.lenze.de/akb/infopool.nsf/html/Frame-Softwaredownload

The AKB is a product- and application-oriented collection of information provided by Lenze.

Alternatively you can install the »PLC Designer« from the CD supplied with the

Industrial PC.

4.3.1 Installation

How to install the »PLC Designer«:

1. Select »PLC Designer« to save the full version as a packed ZIP file on your PC

(Engineering PC).

• Unpack the ZIP file PlcDesigner_V2.3.x.zip on your PC (file size approximately

45MB).

• The ZIP file contains an installation file.

or

Start the PLCDesigner_V2.3..x.exe installation file from the CD supplied with the

Industrial PC.

2. Start the EXE file and follow the installation instructions

3. After the installation the »PLC Designer« can be started.

Further information and basics regarding the »PLC Designer« can be found in the

following documentation:

PLC Designer software manual

The manual is available on the CD supplied or on the Internet.

If the »PLC Designer« is already installed, carry out an update of the version available or

install the full version parallel to the version available.

Installing the target systems

Furthermore the »PLC Designer« target setup has to be installed, containing the

information required for controlling the target systems.

For the installation, proceed like for the installation of the »PLC Designer«.

24 L 1.3 EN - 07/2012

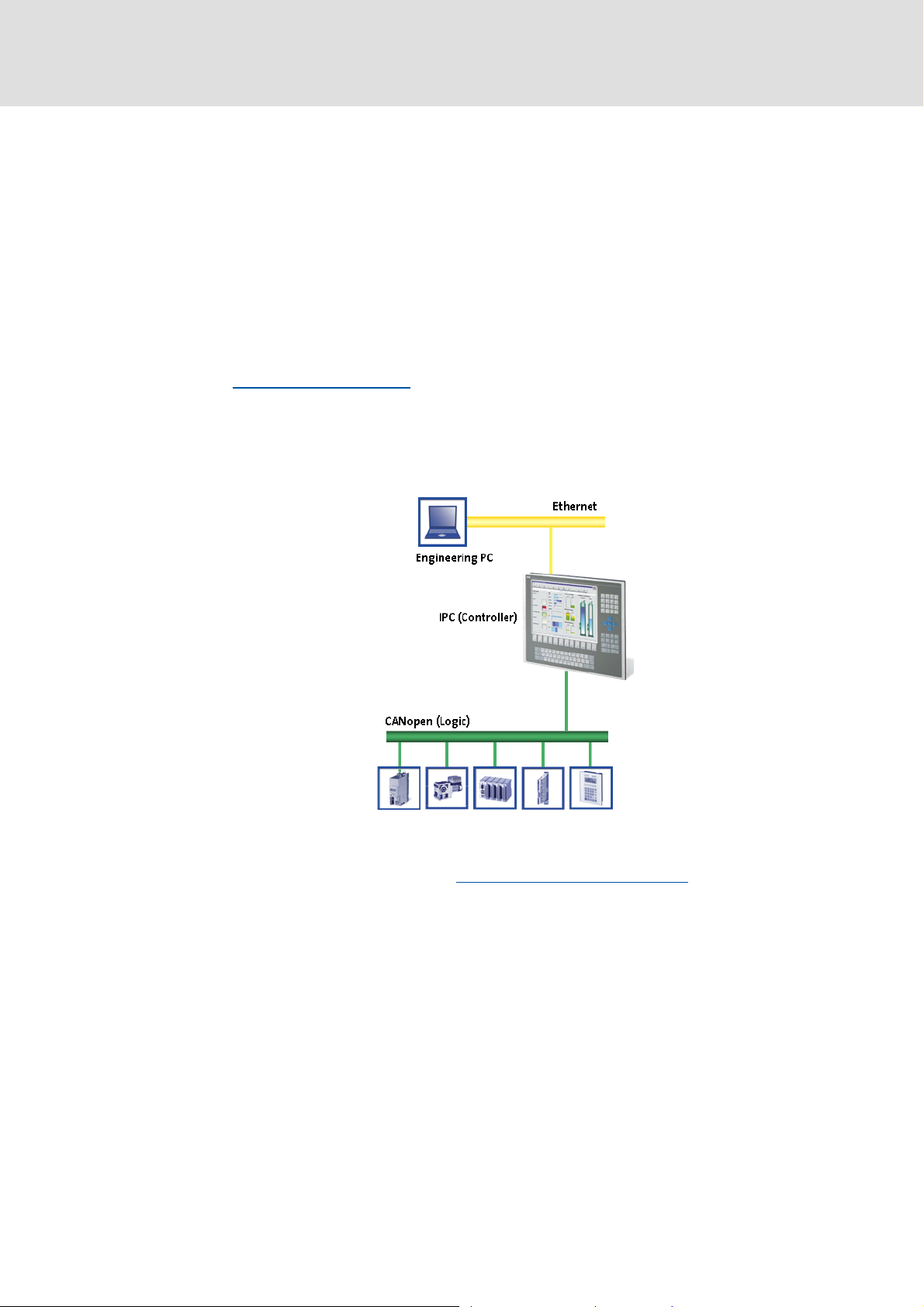

Page 25

PLC Designer V2.x| Lenze Application Samples

5 System bus (CAN) / CANopen

Lenze device series 8400, 9400, 9300, and ECS have an on-board system bus (CAN)

connection. The protocol used there is a subset of CANopen. Thus the devices are not

CANopen-compliant but can be driven by a CANopen-compatible control system under "Lforce Controls" - also in connection with other CANopen-compatible nodes.

Tip!

Detailed information on the system bus (CAN) can be found on the website of the

CAN User Organization CiA (CAN in Automation):

System bus (CAN) / CANopen

CANopen (Logic)

http://www.can-cia.org

5.1 CANopen (Logic)

A variety of different field devices can be connected to the CAN Logic line.

To create a CANopen bus line, use the Communication card MC-CAN2

CANopen (Logic)

The Logic bus line is used to operate controllers which...

carry out simple movements,

do not have a Motion functionality,

are controlled via PLC functionalities only.

The Lenze sample projects are available for the most common system configurations in

each case with selected field devices.

1.3 EN - 07/2012 L 25

( 26).

Page 26

PLC Designer V2.x| Lenze Application Samples

System bus (CAN) / CANopen

Communication card MC-CAN2

5.2 Communication card MC-CAN2

The MC-CAN2 communication card serves to connect an L-force Controller to the CAN bus

system CAN. The card provides two independent bus lines.

A Front panel

B Board

C Coding

D Connection

E CAN connection (CAN 2 /CAN 1)

MC-CAN2-001

26 L 1.3 EN - 07/2012

Page 27

PLC Designer V2.x| Lenze Application Samples

6 Commissioning the CANopen Logic bus

This chapter provides information on commissioning the CANopen Logic field devices in

the Lenze control system.

Depending on the field devices used, the following Lenze engineering tools are required:

»PLC Designer«

»Engineer«

»Global Drive Control« (GDC)

Tip!

For the application of further fieldbus systems, further Engineering software may

be required. Further information can be found in the corresponding

communication manuals.

Commissioning the CANopen Logic bus

Overview of the commissioning steps

6.1 Overview of the commissioning steps

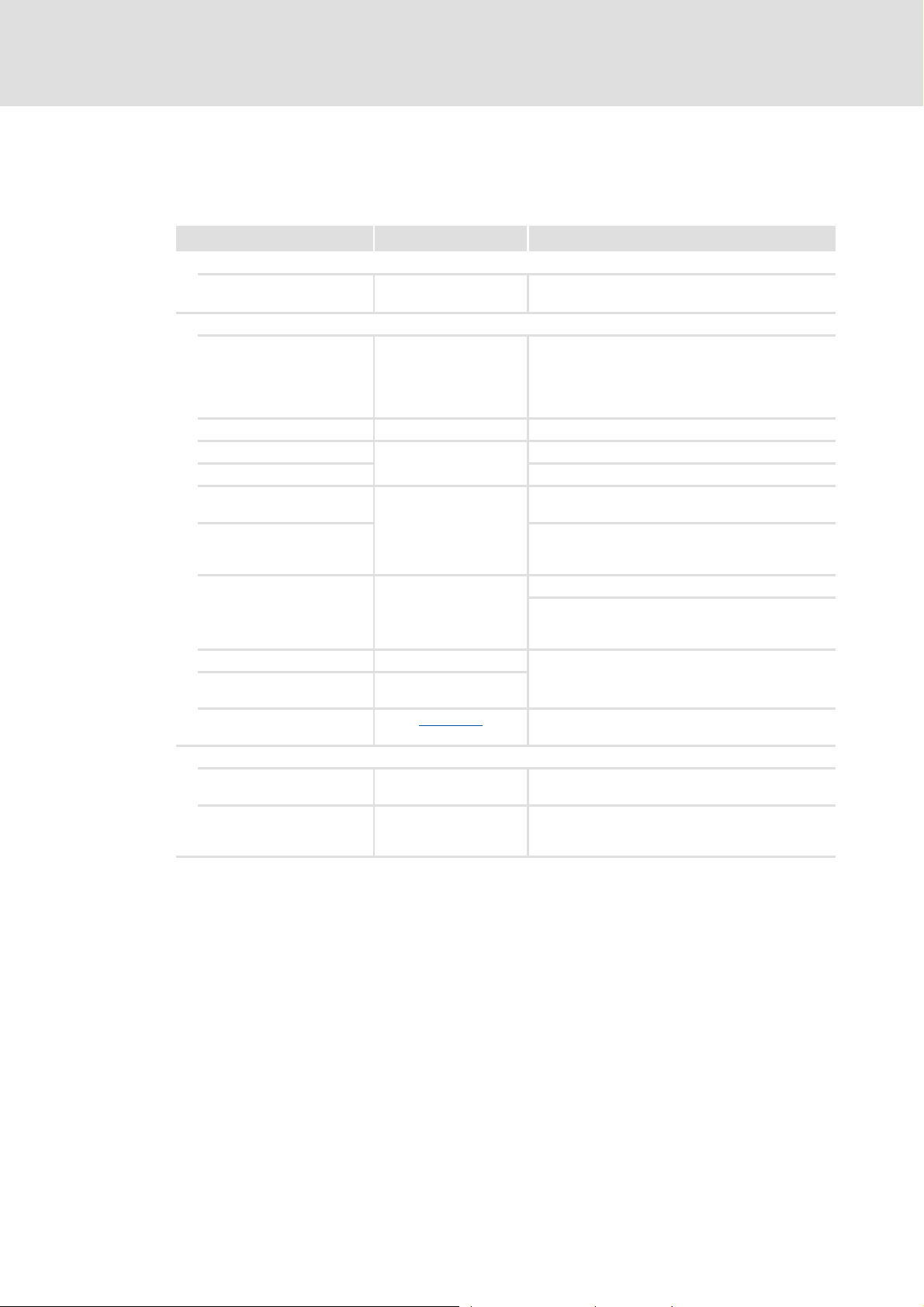

Step Action Lenze software to be used

1. Open sample project

Commissioning field devices

Going online

Preparing the restart

2. Open sample project »PLC Designer«

In the following the individual commissioning steps are described. Follow the given stepby-step instructions to commission your system.

( 29)

( 28)

( 30)

More detailed information about how to work with the Lenze engineering tools

can be found in the corresponding manuals and online helps.

»Engineer« or

»Global Drive Control«

(depending on the used

device)

1.3 EN - 07/2012 L 27

Page 28

PLC Designer V2.x| Lenze Application Samples

Commissioning the CANopen Logic bus

Commissioning field devices

6.2 Commissioning field devices

Parameterise the field devices connected to the CANopen Logic bus either with the

»Engineer« or with the »GDC«, depending on the device.

The configuration of the CAN parameters takes place in the »PLC Designer«.

For this, observe the information in the ...

• documentation for the field devices;

• documentation for the »Engineer« / »GDC«, and »PLC Designer«.

Tip!

We recommend to commission each field device individually and then open the

suitable PLC program.

28 L 1.3 EN - 07/2012

Page 29

6.2.1 Going online

Field device Going online with Connection via

Industrial PC »Engineer« or

Inverter Drive 8400 StateLine /

HighLine

9400 Servo Drive HighLine »Engineer« • IPC as gateway

ECS servo system (ECSxE/S/P/M/A) »Global Drive Control« • IPC as gateway

8200 vector »Global Drive Control« • IPC as gateway

9300 »Global Drive Control« • IPC as gateway

1) CANopen only with system bus adapter EMF2177IB (if required, observe standard device specifications!)

PLC Designer V2.x| Lenze Application Samples

Commissioning the CANopen Logic bus

Commissioning field devices

Ethernet

»WebConfig«

»Engineer« • IPC as gateway

• CAN device interface

• Diagnostic adapter

• Ethernet module E94AYCEN

• CANopen module E94AYCCA

• CAN device interface

• CANopen module EMF2178IB

• CAN device interface 1)

• CAN module CAN PT/

E82ZAFCC010

• CAN device interface 1)

• CAN device interface 1)

Note!

Lenze recommend to use the connection type "IPC as gateway".

Depending on the device and connection type used, detailed information about

establishing a connection and "going online" can be found in the following

documents:

• (Software) manual/online help "PC-based automation"

Industrial PC - Parameter setting & Configuration

• Software manual/online help "PC based automation"

IPC as gateway - Parameter setting & Configuration

• Software manual/online help »Global Drive Control«

IPC as gateway - Parameter setting & Configuration

• Software manual/online help L-force »Engineer«

1.3 EN - 07/2012 L 29

Page 30

PLC Designer V2.x| Lenze Application Samples

Commissioning the CANopen Logic bus

Preparing the restart

6.3 Preparing the restart

In the control technology system you can use the control to transmit the entire parameter

setting via SDO initialisation to the field devices when the machine is switched on.

In accordance with DS301, the control always initialises the CAN parameters of the field

devices. Moreover, it can initialise further parameters. The values for this must be stored in

the control configuration under the Service Data Objects tab.

Usually, the control only transmits those SDO projects for which you have stored another

value than the standard value. The control does not

values in the field device. Thus, not all parameters changed there may be set correctly.

If you want to have a factory adjustment carried out in the field device before SDO

initialisation, go to the Parameter tab and set a checkmark at "Reset Node".

Note!

When a node is reset, the parameter setting in the field device which you have

made with the »Engineer« or the »Global Drive Control« gets lost. In this case,

you have to transmit all parameter values manually to the Service Data Objects

tab. This only makes sense when commissioning is completed and all

parameters are optimised. If you change something afterwards via the

»Engineer« or the »Global Drive Control« you have to maintain it again in the PLC

program.

compare these values with the existing

The Service Data Objects tab contains the codes which are written in the EDS file. The EDS

file contains all writable codes.

30 L 1.3 EN - 07/2012

Page 31

PLC Designer V2.x| Lenze Application Samples

6.3.1 Special features of the 9400 Servo Drives HighLine

Servo Drives 9400 are not purely parameterisable devices. They require an application

download, where several files are transmitted to the memory module.

To put a Servo Drive 9400 into operation, you can:

plug on the memory module.

transmit the application using the »Engineer«. For this, you must keep the original

»Engineer« project.

transmit the application using the L-force »Loader«. For this, you must export and keep

the required files from the »Engineer« project:

Commissioning the CANopen Logic bus

Preparing the restart

1.3 EN - 07/2012 L 31

Page 32

PLC Designer V2.x| Lenze Application Samples

Commissioning the CANopen Logic bus

Preparing the restart

6.3.2 Special features of the 8400 Inverter Drives

Inverter Drives 8400 are purely parameterisable devices.

To put an Inverter Drive 8400 into operation, you can transmit the application using the

»Engineer«. For this, you must keep the original »Engineer« project.

6.3.3 Commission 8200 vector frequency inverters

Connect the CANopen (E82ZAFUCxxx) fieldbus function module for CAN

communication.

CAN settings must be made in the »PLC Designer« because the transmission of the

settings to the 8200 vector frequency inverter is carried out from the control system.

6.3.4 Special features of the ECS servo system

In the ECS servo system, each device has a parameter memory which is only created

once when the parameter setting is created via the »Global Drive Control«. This is the

difference to CANopen devices where the parameterisation is written into the field

device at each system start.

The EMF2221IB card module serves to read parameters saved on an SD card or

SmartMedia card into every ECS device.

When using ECS devices, you cannot set all codes/parameters via the Service Data

Objects tab as the EDS files do not contain all codes/parameters.

32 L 1.3 EN - 07/2012

Page 33

PLC Designer V2.x| Lenze Application Samples

7 Commissioning a sample project

This chapter describes the commissioning of a sample project by means of examples. The

following requirements have to be met, so that the respective sample project can be used.

7.1 General system structure

The Lenze project examples are based on the following system structure.

An Industrial PC (Logic) or an EL1xx (Logic) is the central control section of the system

configuration.

Commissioning a sample project

General system structure

[7-1] System structure with an Industrial PC (Logic)

[7-2] System structure with an EL1xx (Logic)

1.3 EN - 07/2012 L 33

Page 34

PLC Designer V2.x| Lenze Application Samples

Commissioning a sample project

Wiring the hardware

7.2 Wiring the hardware

Before you can work with the project, the hardware has to be connected to each other. The

sample projects are configured so that the motors rotate if a controller is used as CAN

node.

Connect the desired IPC (Industrial PC to PLC, or an EL1xx to a PLC) with the CAN nodes.

Connect the devices (Industrial PC, controllers, motors) with the corresponding voltage

supply

Further information on the electrical connections can be found in the

documentation supplied. Please read the mounting instructions supplied with

the controller first before you start working!

The mounting instructions contain safety instructions which must be observed!

Connect the components with a CAN bus cable.

– For this, use the CAN1 interface in the case of the Industrial PC. The CAN2 interface

is not required for the sample project.

– In the case of the EL100 there only is one CAN interface to be connected with the

components.

34 L 1.3 EN - 07/2012

Page 35

7.2.1 Configuring the CAN interface

For the configuration of the CAN interface the different hardware

(Industrial PC and EL1xx) is to be observed.

Industrial PC

In the case of the Industrial PC you configure the CAN bus using the »PLC Designer«.

EL1xx

In the case of the EL1xx, the device, and additionally the CAN bus must be configured

in the »PLC Designer«.

How to proceed in the case of the EL1xx:

1. On the EL 1xx, click StartSettingsControl PanelFieldbus

2. Configure the CAN interface in the following dialog window:

PLC Designer V2.x| Lenze Application Samples

Commissioning a sample project

Wiring the hardware

EL 1xx CAN device node: node address

of the EL 1xx within a CAN network.

Baud rate: transmission speed of the

fieldbus. The baud rate must be

identical for each fieldbus node within

a network.

According to the baud rate, the

fieldbus parameters are set.

3. Click the Save button to save the settings.

Since the »PLC Designer« accesses the Industrial PC or the EL1xx via Ethernet, connect the

Industrial PC or the EL1xx device to your Engineering PC via a network cable.

Note!

• During initial commissioning, observe the following predefined IP addresses:

– Engineering PC: 192.168.5.100

– Industrial PC: 192.168.5.99

• The network setting for the EL1xx is set to DHCP and has to be set to a fixed

IP address first, so that communication is possible.

1.3 EN - 07/2012 L 35

Page 36

PLC Designer V2.x| Lenze Application Samples

Commissioning a sample project

Wiring the hardware

7.2.2 Configuring an EL1xx Ethernet interface

How to configure the EL1xxx:

1. Click StartSettingsNetwork and Dial-up Connections for the EL 1xx.

2. Click the Dm9CE1 connection and configure the network interface:

3. Click the button to save the settings.

Note!

Changes carried out are not written into the registry automatically; in the case

of a restart, they are lost.

In order to save changes permanently...

•Click Start Settings Control PanelRegistry on the EL1xxx.

• Click the Save button to save the settings.

Further information can be found in the following documentation:

• EL 1xx - HMI with Windows® CE

• Industrial PC - Parameter setting & configuration

36 L 1.3 EN - 07/2012

Page 37

PLC Designer V2.x| Lenze Application Samples

7.3 Opening a project in the »PLC Designer«

The project contains all objects of a control program.

A project is saved in a file. The file name complies with the project name.

In the case of a standard installation you start the »PLC Designer« at the Engineering PC

via:

StartLenzePLC Designer V2.3.xPLC Designer

After starting the »PLC Designer«, a project can be loaded under FileOpen.

Commissioning a sample project

Opening a project in the »PLC Designer«

• Project files can be identified by the ending *.pro.

• Select the *.pro file type from the selection list to display the project files

available.

1.3 EN - 07/2012 L 37

Page 38

PLC Designer V2.x| Lenze Application Samples

Commissioning a sample project

Opening a project in the »PLC Designer«

7.3.1 Establishing communication with the Industrial PC or EL1xx

In the sample project communication between the devices of the system configuration has

already been established. It is reasonable to check communication before the project is

transferred to a PLC device.

How to check communication:

1. Open the Online menu in the menu bar and select the Communication parameters

menu item there.

2. In the "Communication parameters" dialog window the corresponding parameters

can be edited:

• In the Channels field, the name of the respective channel can be viewed.

Highlight the desired channel to display the associated data in the dialog area

on the right.

7.3.2 Starting the sample project

Transfer the sample project to the PLC device first to then start it.

How to start the sample project:

1. Open the Online menu in the menu bar and select the Log in menu item there.

• Confirm the following query on whether the program is to be saved with Yes.

• The project is transferred to the device.

2. Start the program on the HMI.

•Open the Online menu in the menu bar and select the Start menu item there.

The project will start on the HMI.

38 L 1.3 EN - 07/2012

Page 39

PLC Designer V2.x| Lenze Application Samples

Tip!

If the project is to be loaded automatically after a restart of the device, you can

install it as "Boot project".

How to install the project as boot project:

1. Open the Online menu in the menu bar

2. Select the Create boot project command.

• A dialog window is opened, displaying the files created.

3. Click OK to close the dialog window.

Commissioning a sample project

Opening a project in the »PLC Designer«

1.3 EN - 07/2012 L 39

Page 40

PLC Designer V2.x| Lenze Application Samples

Working with the sample projects

8 Working with the sample projects

The ready-configured sample projects are to facilitate the work with the Lenze

components for you. They include established system configurations representing typical

application cases. The objective is to obtain an executable Lenze automation system by

using low effort.

Depending on the application case, the sample projects can be optionally extended, and

thus they have to be adapted to the requirements in each case.

Where do I find the sample projects?

After a successful installation of the Lenze sample projects they can be found under:

ProgramsLenzeAppSamplesAppSamples_0100

Tip!

The»Engineer«sample projects are archived in ZIP format to allow you to send

them for instance by e-mail.

The »Engineer« supports project saving (FileSave archive) and project opening

(FileOpen archive) in ZIP format.

Structure of the sample projects

Each sample project consists of:

– Ready-configured project data in the »Engineer« or »Global Drive Control«(»GDC«)

(depending on the device used)

– Program code and visualisation in the »PLC Designer«. The following modes are

possible: automatic, manual (manual jog), service, homing (optional).

Mode Description

Automatic In the automatic mode a sequence runs over an infinite loop.

Manual In manual mode, the controller can be actuated by setting the individual

Service The service mode serves to adjust the controller.

Homing (available depending on the

device)

control bits manually (Jog1, Jog2, QSP, ErrorReset...). Like this, the controller

can be actuated in manual mode, for instance for cleaning or changing the

tools.

In the homing mode the drive is referenced.

40 L 1.3 EN - 07/2012

Page 41

PLC Designer V2.x| Lenze Application Samples

Working with the sample projects

8400 StateLine - "LAS_40_INTF_Can_84SL_Speed" sample project

8.1 8400 StateLine - "LAS_40_INTF_Can_84SL_Speed" sample project

Further information on the function libraries used in this project can be found in

the following section:

The L_S84_Drive8400.lib library

Standard procedure

How to commission the controller:

1. Commission 8400 Stateline. Commissioning

2. Load the project "LAS_40_INTF_Can_84SL_Speed.zip" to the controller using the Lforce »Engineer«. Open the »Engineer« project & go online

3. Open the "LAS_40_INTF_Can_84SL_Speed.pro" sample project in the »PLC

Designer«. Program structure in the »PLC Designer«

4. Load the project to the IPC/EL 1xx and go online.

8.1.1 Components used

( 235)

( 42)

( 43)

( 45)

[8-1] System configuration with EL x800 CAN master (ID=0, connection at CAN1) and 8400 StateLine (CAN node ID=5)

Industrial PC Field device

Hardware EL x800 8400 StateLine

Operating system IPC software from version Logic

7.02.x (release 2.2.x)

Lenze software required »PLC Designer« from version 20.3

L-force »Engineer« from version 2.12

Further requirements • CAN master ID = 0

• Connection to interface CAN 1

• Logic CAN 500kB

1.3 EN - 07/2012 L 41

From firmware V5.1

• CAN node ID = 5

• Motor: SDSGAI056-22

Page 42

PLC Designer V2.x| Lenze Application Samples

Working with the sample projects

8400 StateLine - "LAS_40_INTF_Can_84SL_Speed" sample project

8.1.2 Short overview of the functions

Mode Description

Automatic In the automatic mode a sequence runs over an infinite loop.

Selection:

•Travel for three seconds at speed1,

•then for five seconds at speed2,

• Start with speed1 again.

Manual In manual mode, the controller can be actuated by setting the individual

Service The service mode serves to adjust the controller.

8.1.2.1 Commissioning

control bits manually (Jog1, Jog2, QSP, ErrorReset...). Like this, the controller

can be actuated in manual mode, for instance for cleaning or changing the

tools.

Selection:

• Travel in positive direction for one second,

•Stop for one second,

• Travel in negative direction for one second.

Read the mounting instructions supplied with the controller first before you start

working!

The mounting instructions contain safety instructions which must be observed!

1. Wire the power connections

– Use the mounting instructions supplied with the controller to correctly use the

power connections according to the requirements of your device.

2. Wire the control terminals

3. Connect USB diagnostic adapter.

4. Switch on the voltage supply of the controller.

– Connect mains voltage.

When the green LED "DRV-RDY" is blinking and the red LED "DRV-ERR" is off, the controller

is ready to start and you can continue with the commissioning.

42 L 1.3 EN - 07/2012

Page 43

PLC Designer V2.x| Lenze Application Samples

8400 StateLine - "LAS_40_INTF_Can_84SL_Speed" sample project

8.1.2.2 Open the »Engineer« project & go online

Detailed infomation on the general handling of the »Engineer« can be found in