Page 1

KHBETCPCBAUTO

13369406

Ä.Eó'ä

L-force Controls

Communication Manual

PC-based automation

EtherCAT control technology

Commissioning & configuration

L

Page 2

2 L DMS 3.1 EN 01/2011 TD17

Page 3

Control technology | EtherCAT communication manual

Contents

1 About this documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Document history

1.2 Conventions used

1.3 Terminology used

1.4 Notes used

2 Safety instructions

3 The "PC-based automation" system

4 The Lenze control system with EtherCAT

4.1 Brief description of EtherCAT

4.1.1 Features

4.1.2 Structure of the EtherCAT bus system

4.1.3 Communication

4.2 Required hardware components

4.2.1 The industrial PC - the central component

4.2.2 Field devices

4.2.3 EtherCAT product codes

4.2.4 EtherCAT hardware for the industrial PC

4.3 Required engineering tools

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.4 Interaction of the components

4.4.1 The state machine of the Lenze control technology

4.4.2 Communication between engineering PC and field devices

5 Technical data

5.1 General data of the EtherCAT bus

5.2 MC-ETC communication card

5.3 Communication times and drive-specific data

6 Synchronisation with "Distributed clocks"

6.1 Synchronous communication

6.2 Adjusting task cycle time and DC cycle time

6.3 Setting the DC synchronisation with the »EtherCAT Configurator«

6.4 Check of the DC synchronicity

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . 39

DMS 3.1 EN 01/2011 TD17 L 3

Page 4

Control technology | EtherCAT communication manual

7 Commissioning of the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1 Overview of commissioning steps

7.2 Detailed commissioning steps

7.2.1 Planning the bus topology

7.2.2 Installing field devices

7.2.3 Creating a project folder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.2.4 Determining the physical EtherCAT configuration (fieldbus scan)

7.2.5 Configuration in the »Engineer«

7.2.6 Inserting devices available on the fieldbus into the »EtherCAT Configurator«

project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.2.7 Creating the configuration in the »EtherCAT Configurator«

7.2.8 Configuration in the »PLC Designer«

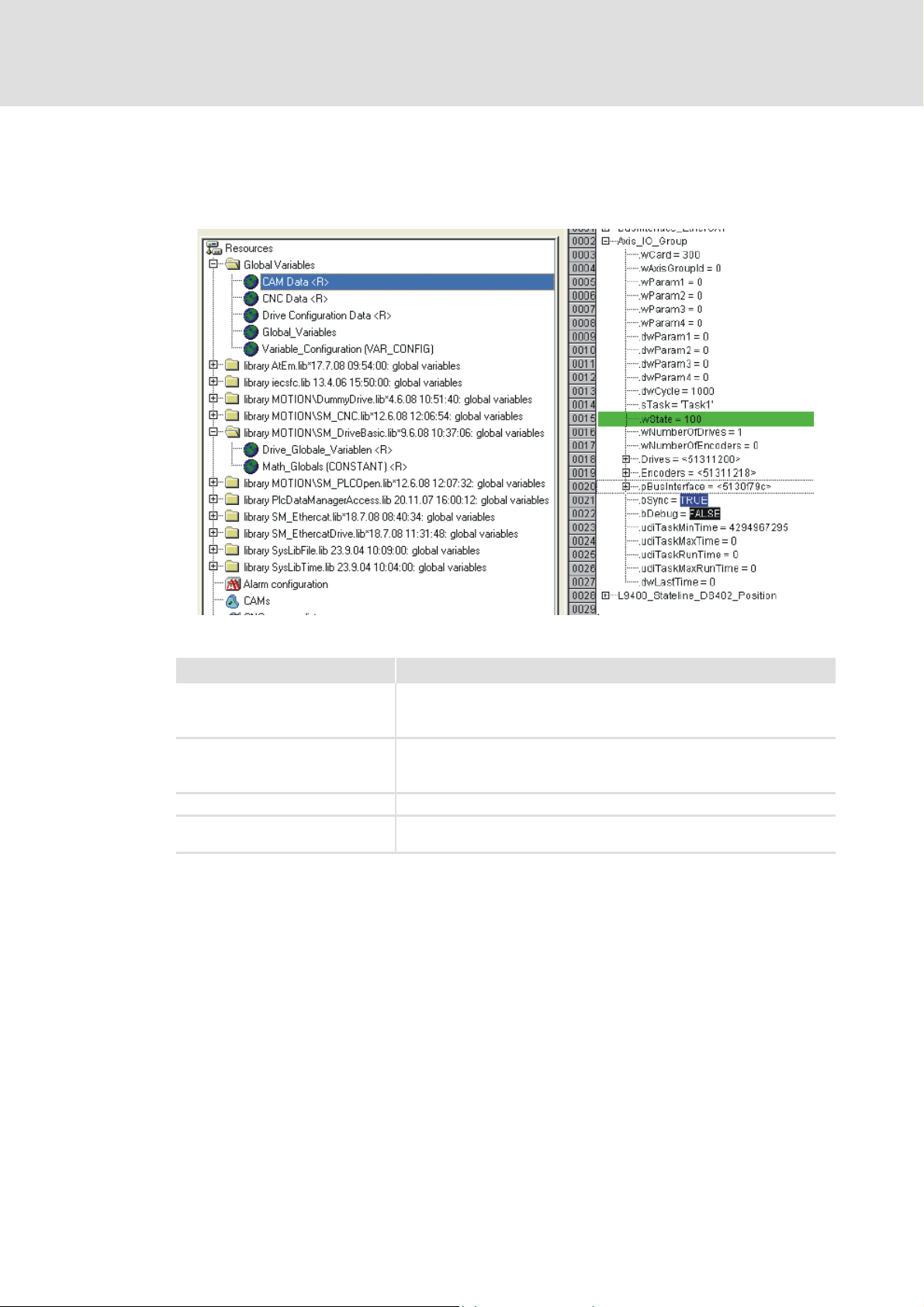

7.3 Checking the system startup

7.3.1 Evaluation of the boot-up error message of the SM_DriveBasic.lib library

7.3.2 Evaluation of the Axis_IO_Group state

7.3.3 Evaluation of the axis state

7.4 Typical commissioning scenarios

7.4.1 Switching on a completely configured system

7.4.2 Switching on a system with an incomplete configuration

7.4.3 Updating the PLC application while the EtherCAT configuration remains

7.4.4 Stopping and starting the PLC while the configuration remains unchanged

unchanged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . 47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

. . . . . . . . . . . . . . . . 56

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

. . . 80

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

. . . . . . . . . . . . . . . . . . 85

. 89

7.5 Detailed overview of the commissioning steps

8 EtherCAT with CANopen or PROFIBUS

8.1 Addressing the PROFIBUS and CANopen stations

8.2 Addressing EtherCAT nodes using CANopen/PROFIBUS nodes

9 EtherCAT function libraries

9.1 Usability

9.2 Function blocks/functions required for a »PLC Designer« project (overview)

9.3 Properties of function blocks

9.4 The EC_T_STATE structure

9.5 Function blocks and functions for master/slave states

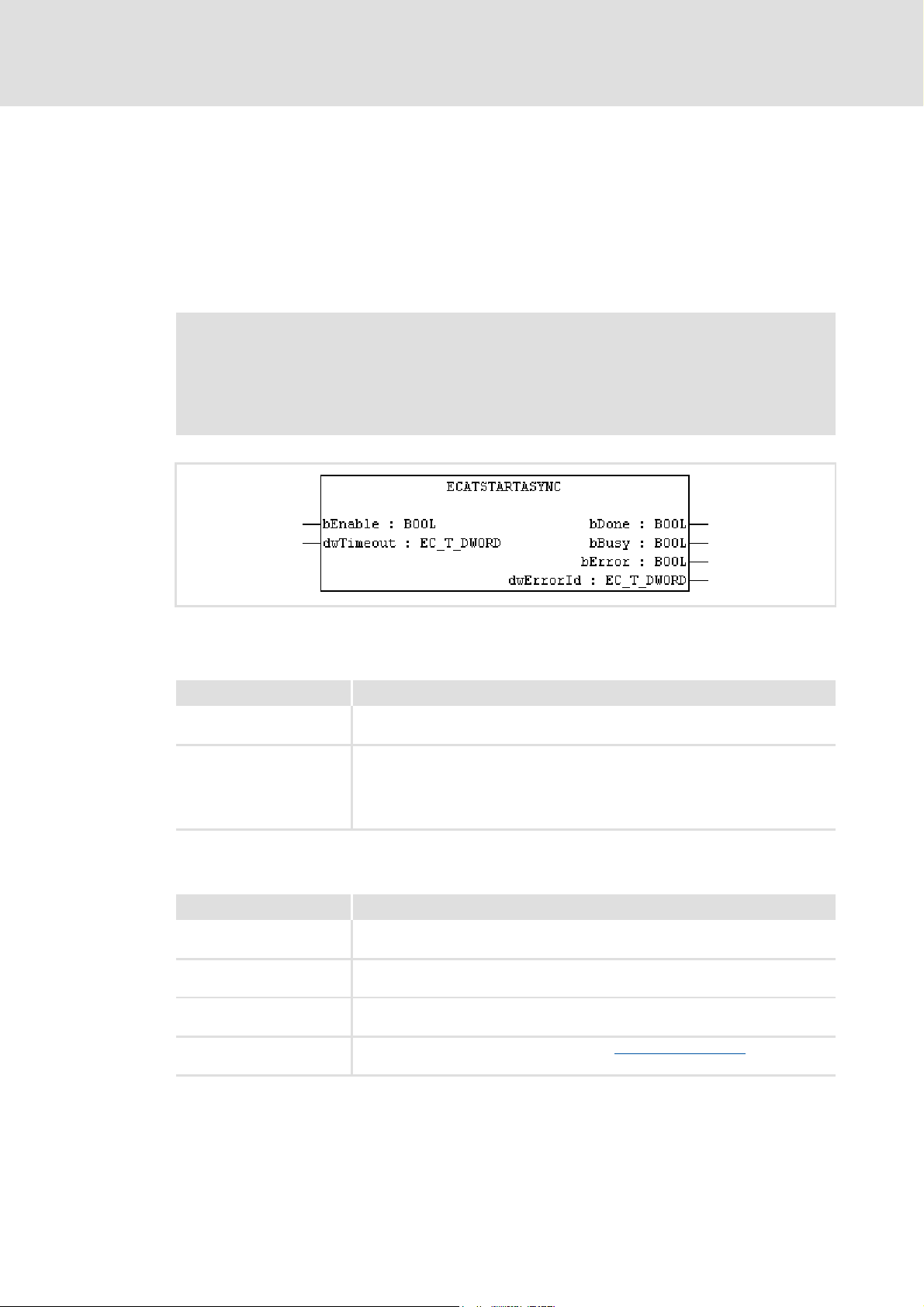

9.5.1 ecatStartAsync (FB)

9.5.2 ecatStopAsync (FB)

9.5.3 ecatSetMasterStateAsync (FB)

9.5.4 ecatSetSlaveStateAsync (FB)

9.5.5 ecatGetMasterState (FUN)

9.5.6 ecatGetSlaveState (FUN)

9.5.7 ecatGetSlaveStateAsync (FB)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

. . . . . . . . . . . . . . . . . . . . . 93

. . . . . . . . 97

4 L DMS 3.1 EN 01/2011 TD17

Page 5

Control technology | EtherCAT communication manual

9.6 Functions for the network management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

9.6.1 ecatMasterIsConfigured (FUN)

9.6.2 ecatGetSlaveId (FUN)

9.6.3 ecatGetSlaveIdAtPosition (FUN)

9.6.4 ecatGetSlaveProp (FUN)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

9.7 Function blocks and functions for diagnosing the network

9.7.1 ecatGetNumConfiguredSlaves (FUN)

9.7.2 ecatGetNumConnectedSlaves (FUN)

9.7.3 ECATDiagnostic (FB)

9.7.4 ResetMasterStatus (FB)

9.7.5 SMC_ETCErrorString (FUN)

9.7.6 L_ECAT_ReadErrCnt (FB)

9.7.7 L_ECAT_ResetErrCnt (FB)

9.7.8 The global EtherCAT master structure ECAT_MASTER

9.8 Function blocks for CANopen over EtherCAT (CoE)

9.8.1 ecatCoeSdoDownloadReq (FB)

9.8.2 ecatCoeSdoUploadReq (FB)

10 Defining the minimum cycle time of the PLC project

10.1 Calculating the total access time to the peripheral devices (T

10.2 Detecting the task utilisation of the application (T

10.2.1 Display of the system utilisation in the »PLC Designer« with the task editor

10.2.2 Detecting the task utilisation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

. . . . . . . . . . . . . . . . . . . . . . . . 112

. . . . . . . . . . . . . . . . . . . . . . 118

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Correction

Task utilisation

). . . . . . . . . . . . . . . . . . . . 126

) . . . . . . . . . . . . . 125

. 126

10.3 Calculating the minimum cycle time

10.4 Optimising the system

11 Diagnostics

11.1 Diagnostics with the »EtherCAT Configurator«

11.2 Diagnostics with the »PLC Designer«

11.3 Diagnostic codes

11.4 Logbook of the IPC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

11.1.1 "Diagnostics" tab

11.1.2 Representation in the online mode

11.2.1 VISU_ETHERCATMaster visualisation template

11.2.2 VISU_ECATDiagnostic visualisation template

11.2.3 The global variable

11.2.4 Error scenario (example)

11.4.1 Displaying the EtherCAT entries of the logbook

11.4.2 Messages in the logbook of the industrial PC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

wState . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

DMS 3.1 EN 01/2011 TD17 L 5

Page 6

Control technology | EtherCAT communication manual

11.5 Error counters of the EtherCAT slaves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

11.5.1 Error types: "Errors" and "Forwarded Errors"

11.5.2 Error counter reset from the application

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

11.6 Error scenarios

11.6.1 Compilation error in »PLC Designer«

11.6.2 EtherCAT bus does not enter the Pre-Operational state

11.6.3 Control unit/PLC does not enter the RUN state

11.6.4 EtherCAT bus does not enter the Operational state

11.6.5 Error during EtherCAT data transmission

11.6.6 Shafts make clicking noises

11.6.7 Shafts do not rotate

11.6.8 Logbook message: "Cannot spawn Remote API Server"

11.6.9 Logbook message: "Ethernet cable not connected"

11.6.10 Logbook message: "Ethernet cable connected"

11.6.11 Logbook messages: "Slave at index X missing" with

"Cyclic command WKC error ..." . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

11.6.12 Logbook message: "Cyclic command WKC error ..."

11.7 System error messages

11.7.1 IPC logbook messages

11.7.2 General error codes (0x00000000

11.7.3 CANOpen over EtherCAT (CoE) SDO error codes

(0x98110040 ... 0x9811005D

11.7.4 Remote API error codes (0x98110181 ... 0x98110196

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

. . . . . . . . . . . . . . . . . . . . 147

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

. . . . . . . . . . . . . . . . . . . . . . . . 148

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

. . . . . . . . . . . . . . . . . . . . . 151

. . . . . . . . . . . . . . . . . . . . . . . . 152

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

. . . . . . . . . . . . . . . . . . . . . . . . . 156

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

, 0x98110001 ... 0x98110038

hex

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

hex

). . . . . . . . . . . . . . . . . . . 163

hex

) . . . . . . 159

hex

11.8 SDO abort codes

12 Parameter reference

12.1 Parameters of the MC-ETC communication card in slot 1

12.2 Interface parameters of the MC-ETC communication card in slot 1

12.3 Parameters of the MC-ETC communication card in slot 2

12.4 Interface parameters of the MC-ETC communication card in slot 2

13 Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

. . . . . . . . . . . . . . . . . . . . . . . . . . 166

. . . . . . . . . . . . . . . . . 167

. . . . . . . . . . . . . . . . . . . . . . . . . . 182

. . . . . . . . . . . . . . . . . 183

6 L DMS 3.1 EN 01/2011 TD17

Page 7

Control technology | EtherCAT communication manual

1 About this documentation

Note!

For industrial PCs of the EL 1xx, EL x8xx, CS x8xx and CPC x8xx series in control

technology release 2.5, EtherCAT is not supported.

This documentation ...

This documentation contains detailed information on how to commission, configure

and diagnose the EtherCAT bus system within the scope of Lenze's control technology.

belongs to the "PC-based automation" manual collection which consists of the

following documentation:

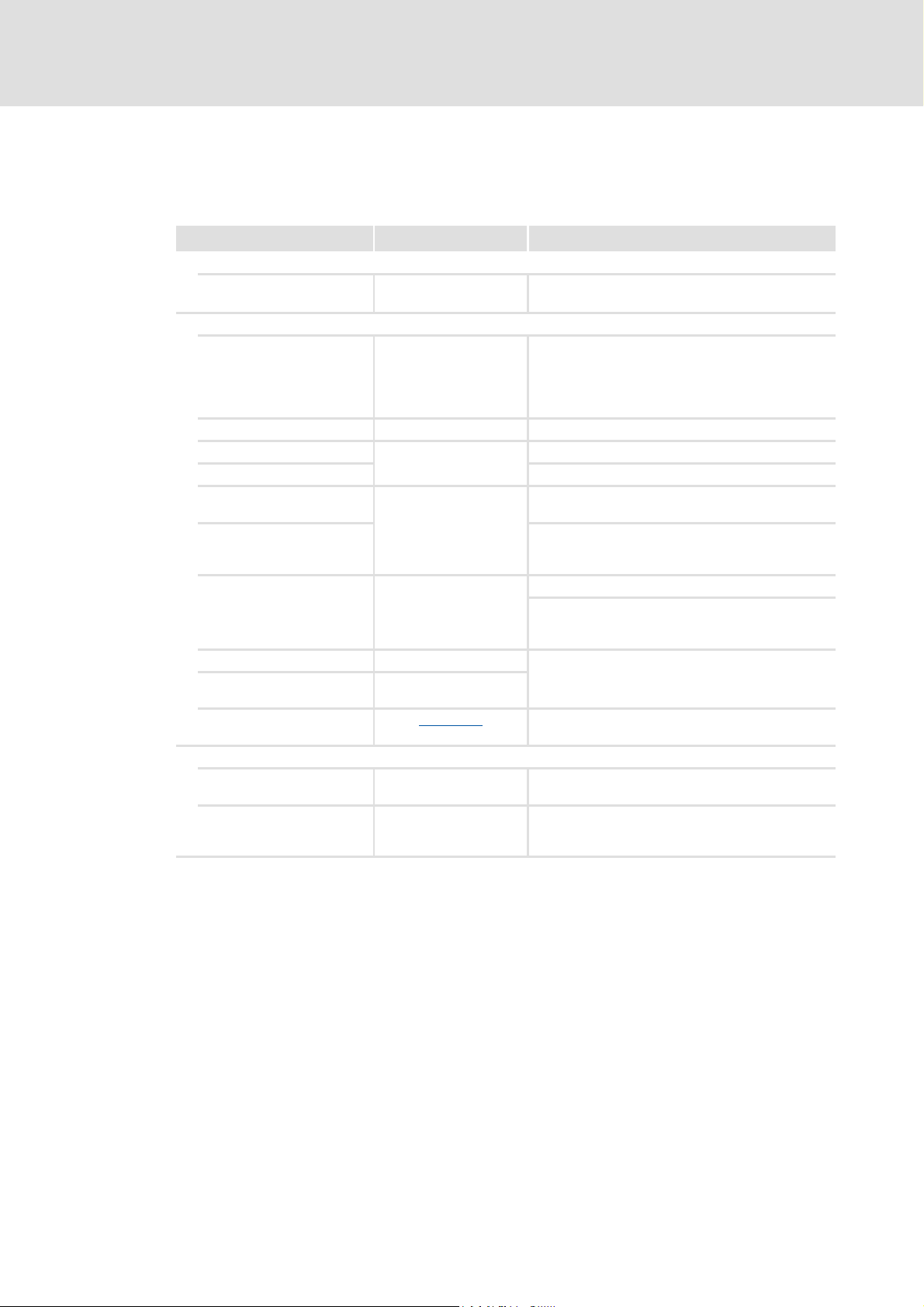

Documentation Subject

System manuals

"PC-based automation"

Communication manuals

"PC-based automation"

(Software) Manual

"PC-based automation"

Operating Instructions

"Embedded Line Panel PC"

Operating Instructions

"Command Station"

Operating Instructions

"Control Cabinet PC"

Operating Instructions

"HMI EL 100"

Further software manuals • »Global Drive Control« (»GDC«)

• Control technology - system structure & configuration

• Control technology - system structure & components

• CANopen control technology

• Control technology PROFIBUS

• EtherCAT control technology

• Industrial PC - parameter setting & configuration

• EL x7xx - built-in panel-PC with TFT display

• CS x7xx - stand-alone operator terminal

• CPC x7xx - control cabinet PC

• EL 1xx - HMI with Windows

• »Engineer«

• »PLC Designer« / »PLC Designer« / »PLC Designer - CANopen for Runtime

• »VisiWinNET® Smart«

About this documentation

® CE

–IPC as gateway - parameter setting & configuration

Systems«

DMS 3.1 EN 01/2011 TD17 L 7

Page 8

Control technology | EtherCAT communication manual

About this documentation

Further technical documentations for Lenze components

More information about Lenze components that can be used together with "PC-based

automation" can be found in the following documents:

Mounting & wiring Legend:

MAs for Inverter Drives 8400 Printed documentation

MAs for Servo Drives 9400 Online help/PDF

MA EPM-Txxx (I/O system IP20) Abbreviations used:

MA EPM-Sxxx (I/O system 1000) SHB System Manual

MA 8200 vector BA Operating Instructions

Wiring according to EMC, 8200 vector MA Mounting Instructions

MAs for the ECS servo system SW Software manual

MA communication card MC-CAN2 KHB Communication manual

MA communication card MC-ETC

MA communication card MC-ETH

MA communication card MC-PBM

MA communication card MC-PBS

MA communication card MC-MPI

MAs for communication modules

Parameter setting, configuration, commissioning

SW Inverter Drive 8400

BaseLine / StateLine / HighLine / TopLine

SW Servo Drive 9400 HighLine / PLC

Commissioning guide 9400 HighLine

SHB I/O system IP20 (EPM-Txxx)

SHB I/O system 1000 (EPM-Sxxx)

SHB 8200 vector

BAs for the ECS servo system

KHBs for communication modules

Programming

SW 9400 function library

Creating a network

KHBs for communication modules

Tip!

Manuals and software updates for Lenze products can be found in the download

area at:

http://ww.Lenze.com

8 L DMS 3.1 EN 01/2011 TD17

Page 9

Target group

This documentation is intended for all persons who plan, install, commission and maintain

the networking of devices in the field of control technology.

1.1 Document history

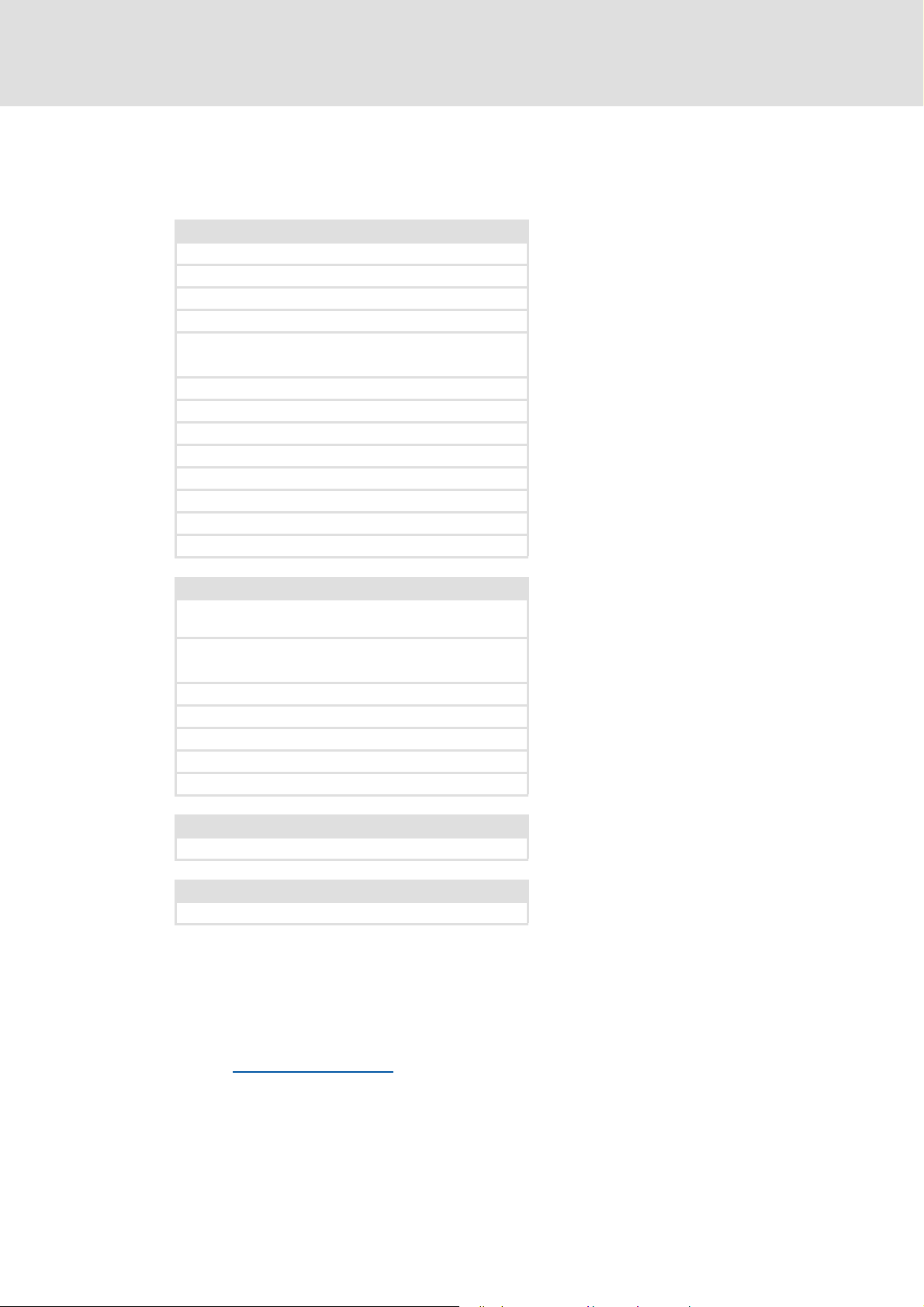

Material no. Version Description

- 1.0 09/2008 TD11

13296253 2.0 05/2009 TD17 General revision

13317335 3.0 10/2009 TD17 General revision

13369406 3.1 01/2011 TD17 • General updates

Your opinion is important to us!

Control technology | EtherCAT communication manual

About this documentation

Document history

First edition

TD17

• Information on control technology release 2.5 has been added.

These instructions were created to the best of our knowledge and belief to give you the

best possible support for handling our product.

If you have suggestions for improvement, please e-mail us to:

feedback-docu@Lenze.de

Thank you for your support.

Your Lenze documentation team

DMS 3.1 EN 01/2011 TD17 L 9

Page 10

Control technology | EtherCAT communication manual

About this documentation

Conventions used

1.2 Conventions used

This documentation uses the following conventions to distinguish between different types

of information:

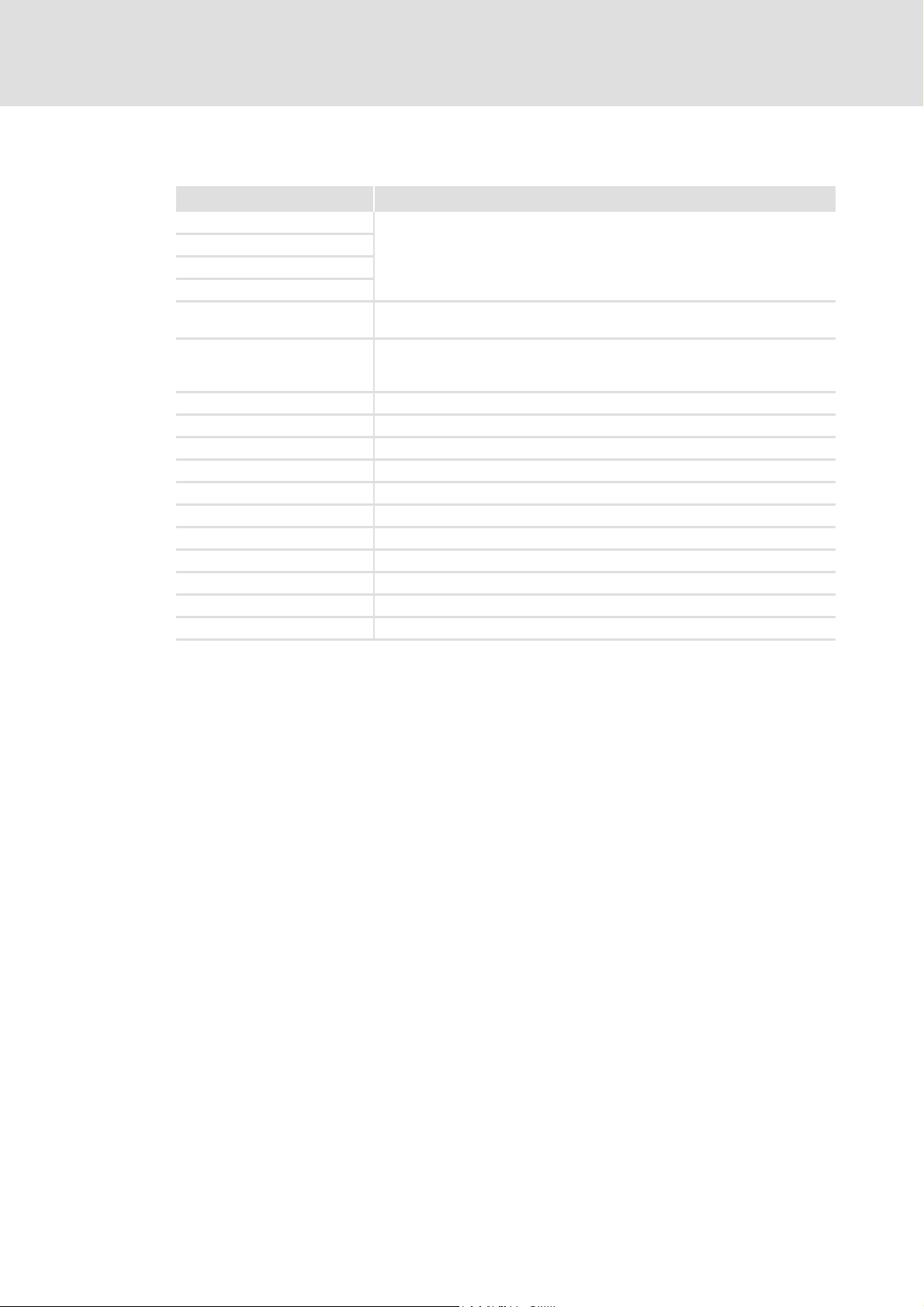

Type of information Writing Examples/notes

Spelling of numbers

Decimal separator Point The decimal point is always used.

For example: 1234.56

Text

Version information Blue text colour All information valid for or from a certain software

Program name » « The Lenze PC software »Engineer«...

Window Italics The Message window... / The Options dialog box...

Variable identifier By setting bEnable to TRUE...

Control element Bold The OK button... / the Copy command... / the

Sequence of menu

commands

Shortcut <Bold> Use <F1> to open the online help.

Program code Courier

Keyword Courier bold

version, is indicated accordingly in this

documentation.

Example: This function extension is available from

software version V3.0!

Characteristics tab... / the Name input field...

If the execution of a function requires several

commands in a row, the individual commands are

separated by an arrow: Select File

If a key combination is required for a command, a "+"

is placed between the key identifiers: With

<Shift>+<ESC>...

IF var1 < var2 THEN

a = a + 1

END IF

Open to ...

Hyperlink Underlined

Symbols

Page reference ( 10) Optically highlighted reference to another page. It is

Step-by-step instructions

Optically highlighted reference to another topic. It is

activated with a mouse-click in this documentation.

activated with a mouse-click in this documentation.

Step-by-step instructions are indicated by a

pictograph.

10 L DMS 3.1 EN 01/2011 TD17

Page 11

1.3 Terminology used

Term Meaning

»Engineer« Lenze engineering tools supporting you during the entire life cycle of a machine

»EtherCAT Configurator«

»Global Drive Control« (GDC)

»PLC Designer«

Code "Container" for one or several parameters used for Lenze Servo Drives parameter

Subcode If a code contains several parameters, they are stored in "subcodes".

IPC Industrial PC

PLC Programmable Logic Controller

AT-EM EtherCAT master

CoE CANopen over EtherCAT

DC Distributed clocks (distributed synchronised clocks)

EoE Ethernet over EtherCAT

FoE File access over EtherCAT

MCF Master configuration file (XML file for EtherCAT bus configuration)

SoE Servo drive profile over EtherCAT

FB Function block (contained in a function library)

FUN Function (contained in a function library)

Control technology | EtherCAT communication manual

About this documentation

Terminology used

- from the planning phase to maintenance.

setting or monitoring.

In the documentation the diagonal slash "/" is used as a separator between the

designation of the code and subcode (e.g. "C00118/3").

DMS 3.1 EN 01/2011 TD17 L 11

Page 12

Control technology | EtherCAT communication manual

About this documentation

Notes used

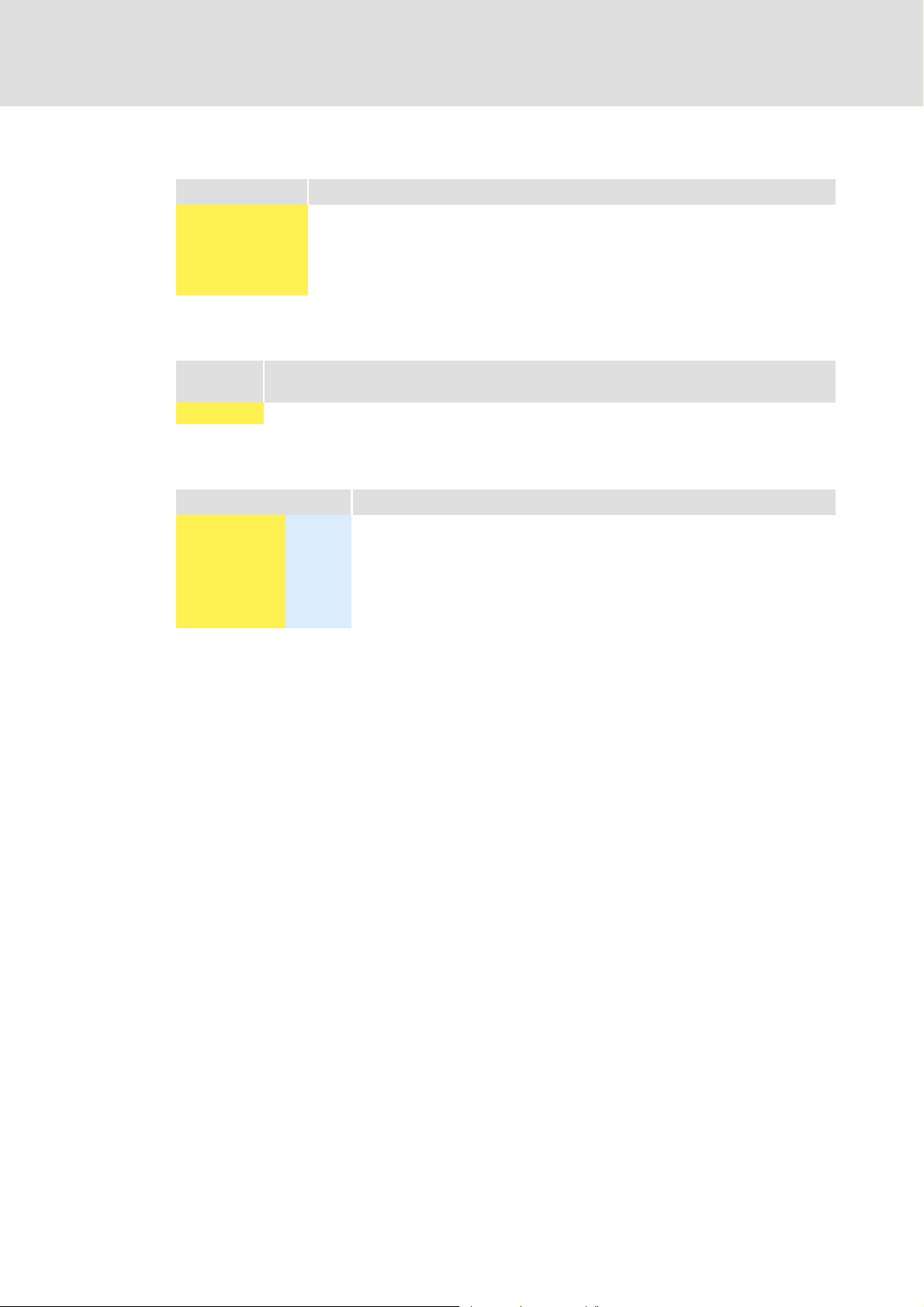

1.4 Notes used

The following signal words and symbols are used in this documentation to indicate

dangers and important information:

Safety instructions

Structure of safety instructions:

Pictograph and signal word!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph Signal word Meaning

Danger! Danger of personal injuries through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Application notes

Pictograph Signal word Meaning

Stop! Danger of property damage

Note! Important note for trouble-free operation

Reference to an imminent danger that may result in death or serious

personal injury if the corresponding measures are not taken.

Reference to an imminent danger that may result in death or serious

personal injury if the corresponding measures are not taken.

Reference to a possible danger that may result in property damage if the

corresponding measures are not taken.

Tip! Useful tip for easy handling

Reference to another documentation

12 L DMS 3.1 EN 01/2011 TD17

Page 13

Control technology | EtherCAT communication manual

2 Safety instructions

Please observe the following safety instructions when you want to commission a controller

or system using an industrial PC.

Read the documentation supplied with the system components thoroughly

before starting to commission the devices and the industrial PC!

The System Manual contains safety instructions which must be observed!

Danger!

According to our present level of knowledge it is not possible to ensure the

absolute freedom from errors of a software.

If necessary, systems with built-in controllers must be provided with additional

monitoring and protective equipment according to relevant safety regulations

(e.g. law on technical equipment, regulations for the prevention of accidents) so

that an impermissible operating status does not endanger persons or facilities.

Safety instructions

During commissioning persons must keep a safe distance from the motor or the

machine parts driven by the motor. Otherwise there would be a risk of injury by

the moving machine parts.

Stop!

If you change parameters in an engineering tool during an existing online

connection to a device, the changes are directly added to the device!

A wrong parameter setting can cause unpredictable motor movements. By

unintentional direction of rotation, too high speed or jerky operation, the driven

machine parts may be damaged!

DMS 3.1 EN 01/2011 TD17 L 13

Page 14

Control technology | EtherCAT communication manual

The "PC-based automation" system

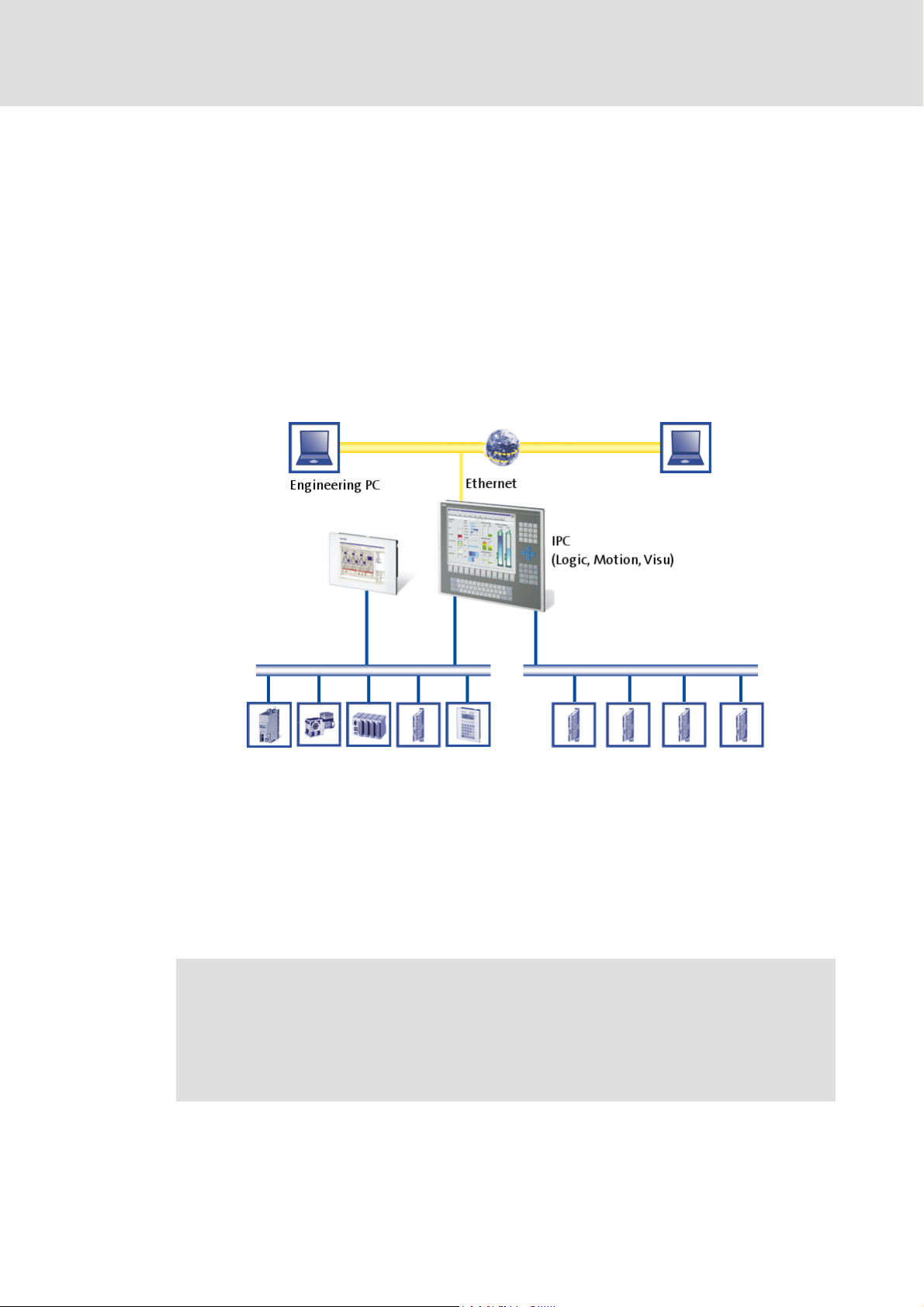

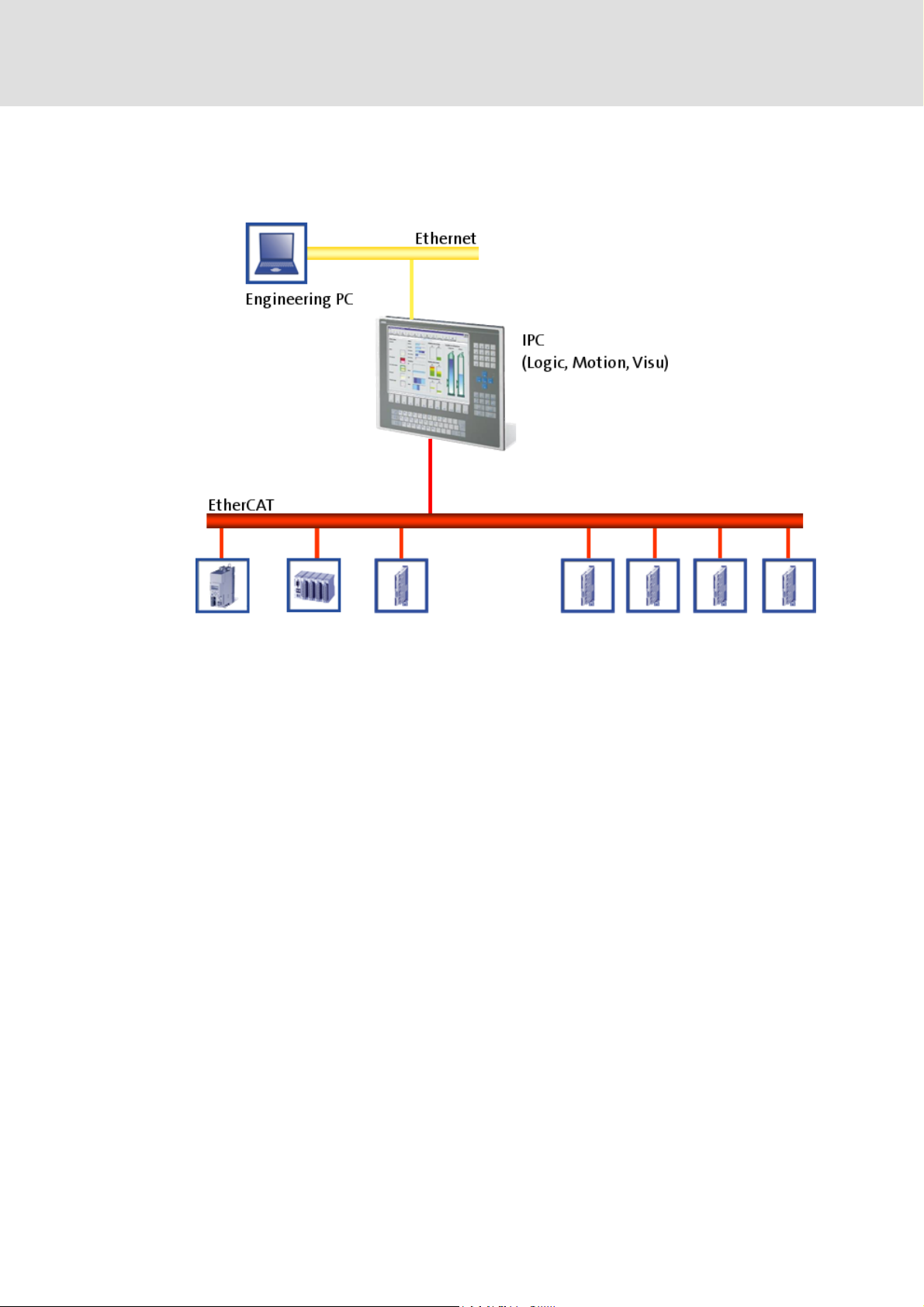

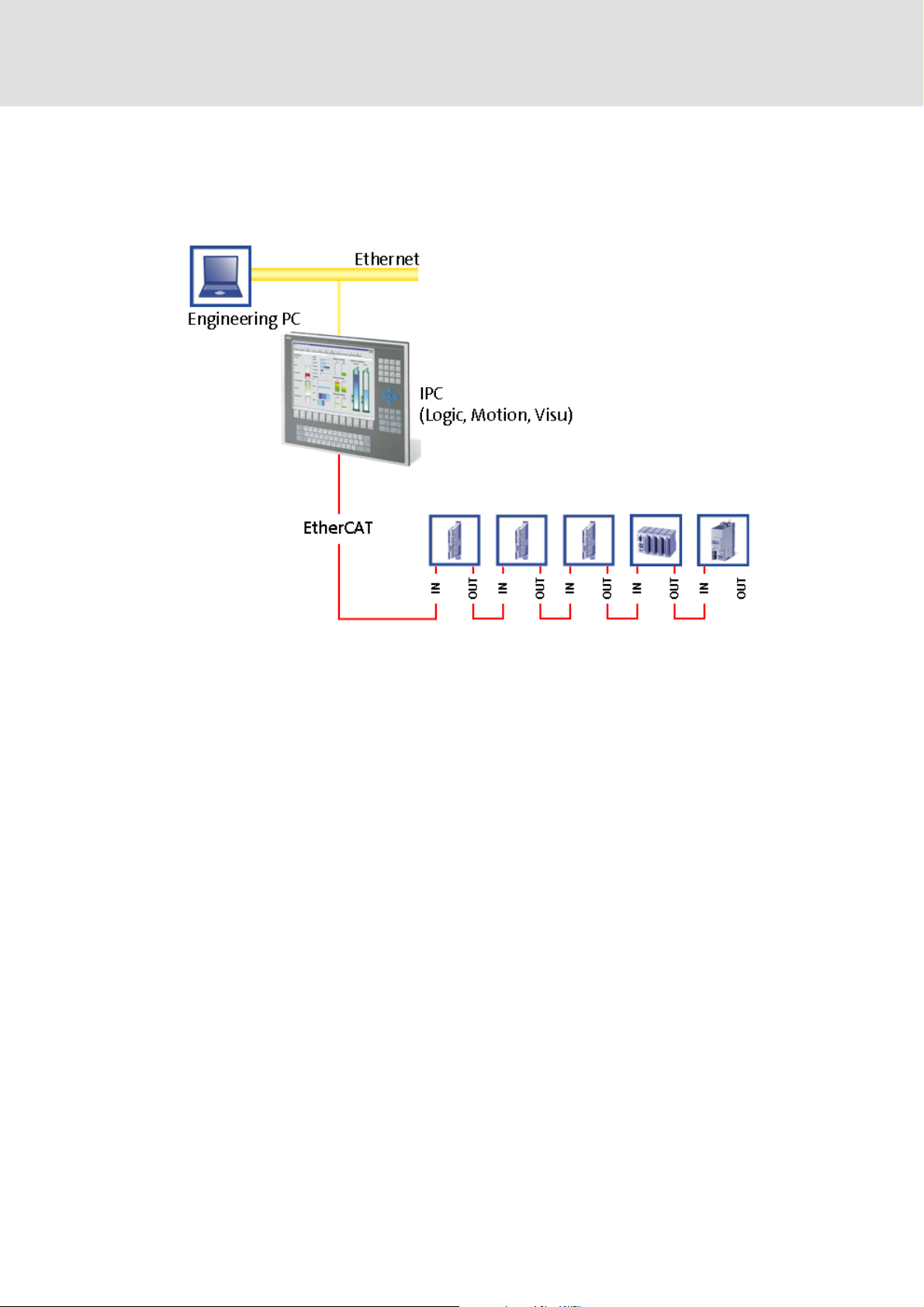

3 The "PC-based automation" system

Industrial PCs (IPCs) are increasingly finding their way into automation technology. With

their scaling characteristics and the possible combination of visualisation and control in

one device, industrial PCs offer clear advantages for many applications.

Lenze industrial PCs are available with the following software equipments:

Industrial PC as component (optional with operating system) without any further

software

Industrial PC as visualisation system

Industrial PC as control and visualisation system

The "PC-based automation" system allows the central control of Logic and Motion systems.

For this purpose, Lenze provides coordinated system components:

Industrial PCs as control and visualisation system

– The IPC is the central component of the PC-based automation which control the

Logic and Motion functionalities by means of the runtime software.

– The IPC communicates with the field devices via the fieldbus.

– The IPCs are available in different designs.

Note!

Moreover, the HMI series EL 1xx PLC belongs to the "PC based automation"

system. These devices differ considerably from the industrial PCs in performance

and various other details. However the devices of the HMI series EL 1xx PLC are

able to fulfil smaller control functions.

14 L DMS 3.1 EN 01/2011 TD17

Page 15

Control technology | EtherCAT communication manual

The "PC-based automation" system

Engineering tools for the Engineering PC

– The Engineering PC communicates with the IPC via Ethernet.

– The different engineering tools are used to configure and parameterise the system.

Fieldbuses

Field devices

DMS 3.1 EN 01/2011 TD17 L 15

Page 16

Control technology | EtherCAT communication manual

The Lenze control system with EtherCAT

Brief description of EtherCAT

4 The Lenze control system with EtherCAT

Note!

For industrial PCs of the EL 1xx, EL x8xx, CS x8xx and CPC x8xx series in control

technology release 2.5, EtherCAT is not supported.

This chapter provides basic information about ...

the EtherCAT bus system;

the structure of the Lenze control system with the EtherCAT bus system;

the Lenze engineering tools required for commissioning.

the interaction of the components.

4.1 Brief description of EtherCAT

Tip!

More detailed information about EtherCAT can be found on the Internet website of

the EtherCAT Technology Group under:

www.EtherCAT.org

4.1.1 Features

EtherCAT is a high-performance bus system based on Ethernet.

Thanks to the integrated synchronisation mechanisms via "distributed clocks",

EtherCAT offers excellent real-time characteristics.

Synchronisation with "Distributed clocks"

EtherCAT provides a higher bandwidth compared to CANopen:

– This enables motion and logic applications to be operated by the same bus.

– The number of the nodes to be controlled is higher.

– The maximally possible bus length is longer.

EtherCAT can access all field devices via a common interface. Therefore, a division into

Logic fieldbus and MotionBus is not required.

( 36)

16 L DMS 3.1 EN 01/2011 TD17

Page 17

Control technology | EtherCAT communication manual

4.1.2 Structure of the EtherCAT bus system

Basic structure

The Lenze control system with EtherCAT

Brief description of EtherCAT

Physical structure

An EtherCAT master can communicate with one or more nodes ("slaves").

Internally, the EtherCAT bus has a ring topology. Since Ethernet cables are provided

with a going and a return conductor within one cable, for the installer the topology

seems to be a line. The last slave closes the ring.

Switches, hubs or other infrastructure components known from the Ethernet standard

must not be used because they impair the real-time performance.

DMS 3.1 EN 01/2011 TD17 L 17

Page 18

Control technology | EtherCAT communication manual

The Lenze control system with EtherCAT

Brief description of EtherCAT

4.1.3 Communication

Compared with the conventional Ethernet, the collision-free transfer of telegrams on the

bus makes EtherCAT a real-time capable bus system.

Communication is always initiated by the EtherCAT master, i.e. the industrial PC. A

telegram sent by the master passes through all EtherCAT slaves. The last slave of the

communication chain sends the telegram back to the EtherCAT master. On the way back,

the telegram is directly sent to the EtherCAT master, without being processed in the slaves.

With EtherCAT, telegram processing completely takes place on the hardware level. The

slaves take the data intended for them from the Ethernet frame and write their data back

to the Ethernet frame. Every datagram can be passed on with a minimum delay.

18 L DMS 3.1 EN 01/2011 TD17

Page 19

Control technology | EtherCAT communication manual

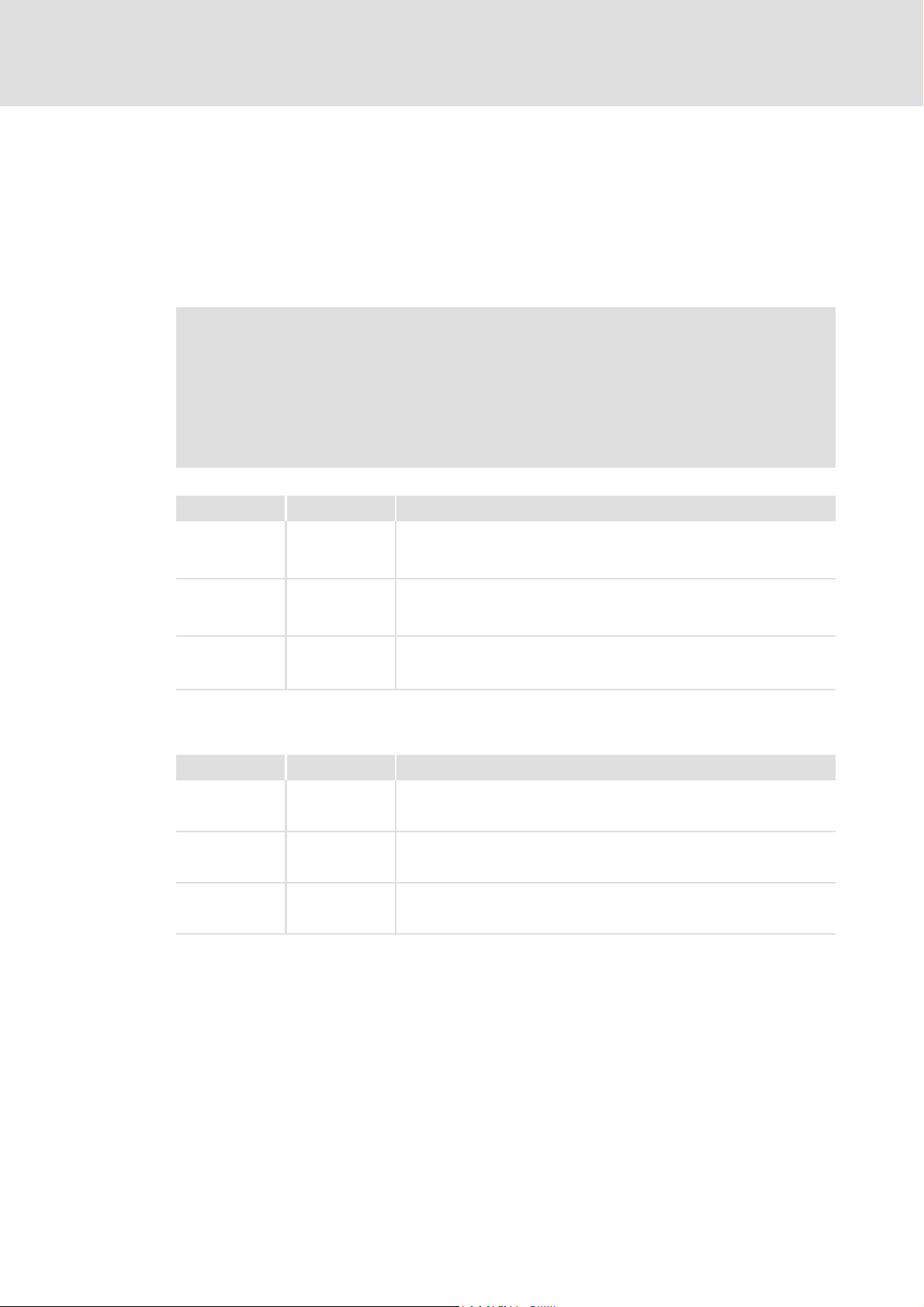

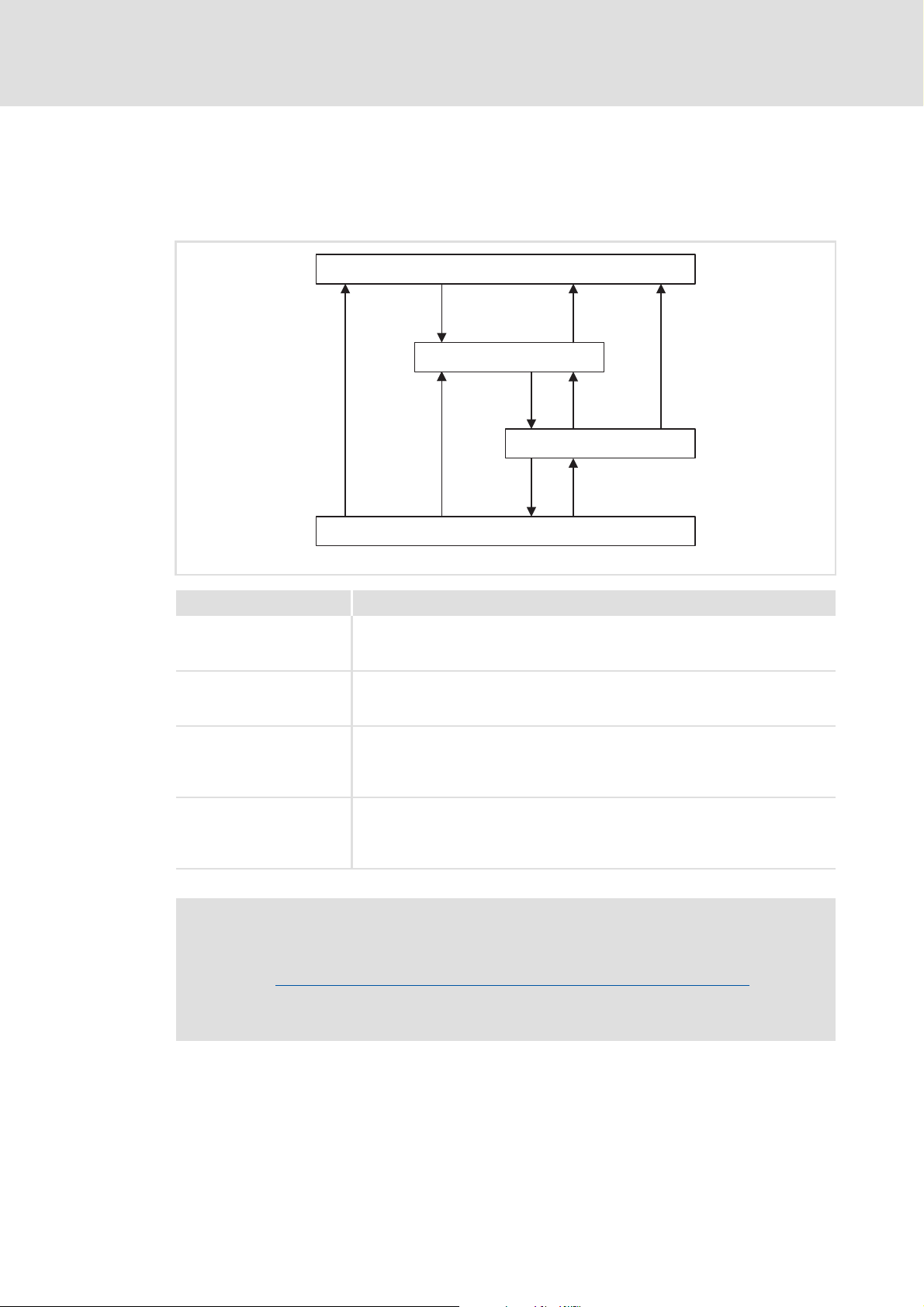

4.1.3.1 The EtherCAT state machine

Before communication via EtherCAT is possible, the bus runs through the EtherCAT state

machine during power-up. The following illustration shows the possible state change from

an EtherCAT slave's point of view:

The Lenze control system with EtherCAT

Brief description of EtherCAT

Init

Pre-Operational

Safe-Operational

Operational

Status Description

Init • Initialisation phase

• No SDO/PDO communication with the slaves

• Device can be detected by fieldbus scan

Pre-Operational • The fieldbus is active.

• SDO communication (mailbox communication) is possible.

• No PDO communication

Safe-Operational • SDO communication (mailbox communication) is possible.

• PDO communication:

–The input data is transmitted to the master and evaluated.

–The output data have the "Safe" state. It is not forwarded to the basic device.

Operational • Normal operation

–SDO communication

–PDO communication

–Fieldbus synchronisation has been successful (if used)

Note!

• Scanning of the EtherCAT fieldbus is possible in all states:

Determining the physical EtherCAT configuration (fieldbus scan)

• SDO communication via the EtherCAT fieldbus is only possible when at least

the Pre-Operational state has been reached.

E94AYCET009

( 47)

DMS 3.1 EN 01/2011 TD17 L 19

Page 20

Control technology | EtherCAT communication manual

The Lenze control system with EtherCAT

Brief description of EtherCAT

4.1.3.2 Addressing of the slaves

The EtherCAT system uses two types of addressing for the slaves:

Auto-increment addressing

Fixed-address addressing

The auto-increment addressing is used by the master during the initialisation phase of the

fieldbus. When the Pre-Operational state has been reached, the master uses the FixedAddress addressing.

Auto-increment addressing

The auto-increment addressing is based on the bus topology. Each slave can be addressed

by means of its physical position within the fieldbus.

Slave 1 = address 0

Slave 2 = address -1

Slave 3 = address -2 etc.

The master transmits a telegram to the slave address. Each slave increments the address

during the telegram cycle. A slave to which a telegram is addressed recognises the

telegram by means of the address 0.

A configuration example is given under:

Determining the physical EtherCAT configuration (fieldbus scan)

Fixed-address addressing

With the fixed-address addressing, the slaves are addressed via the station address

distributed by the master in the start-up phase.

In the EtherCAT bus topology in the »PLC Designer«, the first slave gets the address 1001,

the second slave the address 1002, etc. The EtherCAT addresses cannot be changed.

The EtherCAT address of the master is 0. Master objects with this address can also be

accessed via CoE.

Example

The first slave of a configuration obtains the following addresses:

0 by the auto-increment mode

( 47)

1001 by the fixed addressing mode (default address of the first slave in the »EtherCAT

Configurator«).

20 L DMS 3.1 EN 01/2011 TD17

Page 21

4.1.3.3 Working counter

Each EtherCAT datagram contains a working counter (WKC) which is incremented by each

slave after the data have been processed successfully.

In every cycle, the control unit compares the expected value of the working counter with

the value read back via the fieldbus. If the read-back value is lower than the expected value,

the telegram has not reached all addressed slaves. The control unit recognises this and

signals an error.

The working counter (WKC) can be used as a diagnostics option to check the processing of

the EtherCAT telegrams by the slaves.

Example

10 slaves read/write process data in the Operational status

Expected value of the WKC: 10

A cable break between the 8th and 9th slave causes the master to be unable to access

slave 9 and slave 10:

– Value of the restored WKC: 8

– An error response is initiated in the control.

Control technology | EtherCAT communication manual

The Lenze control system with EtherCAT

Brief description of EtherCAT

DMS 3.1 EN 01/2011 TD17 L 21

Page 22

Control technology | EtherCAT communication manual

The Lenze control system with EtherCAT

Required hardware components

4.2 Required hardware components

4.2.1 The industrial PC - the central component

The industrial PC is the central component in the EtherCAT bus system:

The industrial PC is the EtherCAT master.

The industrial PC acts as EtherCAT gateway to be able to access the field devices from

the engineering PC via Ethernet and EtherCAT.

The devices must be connected in a line. To ensure that the system operates properly,

the physical arrangement of the EtherCAT field devices must comply with the bus

topology created in the »EtherCAT Configurator«.

Each EtherCAT slave has two EtherCAT ports.

– In contrast to Ethernet, one port is assigned as input, the other one as output.

– Input (IN) and output (OUT) must not be reversed!

A bus termination at the last slave is not required since the bus system at the last slave

is terminated automatically.

22 L DMS 3.1 EN 01/2011 TD17

Page 23

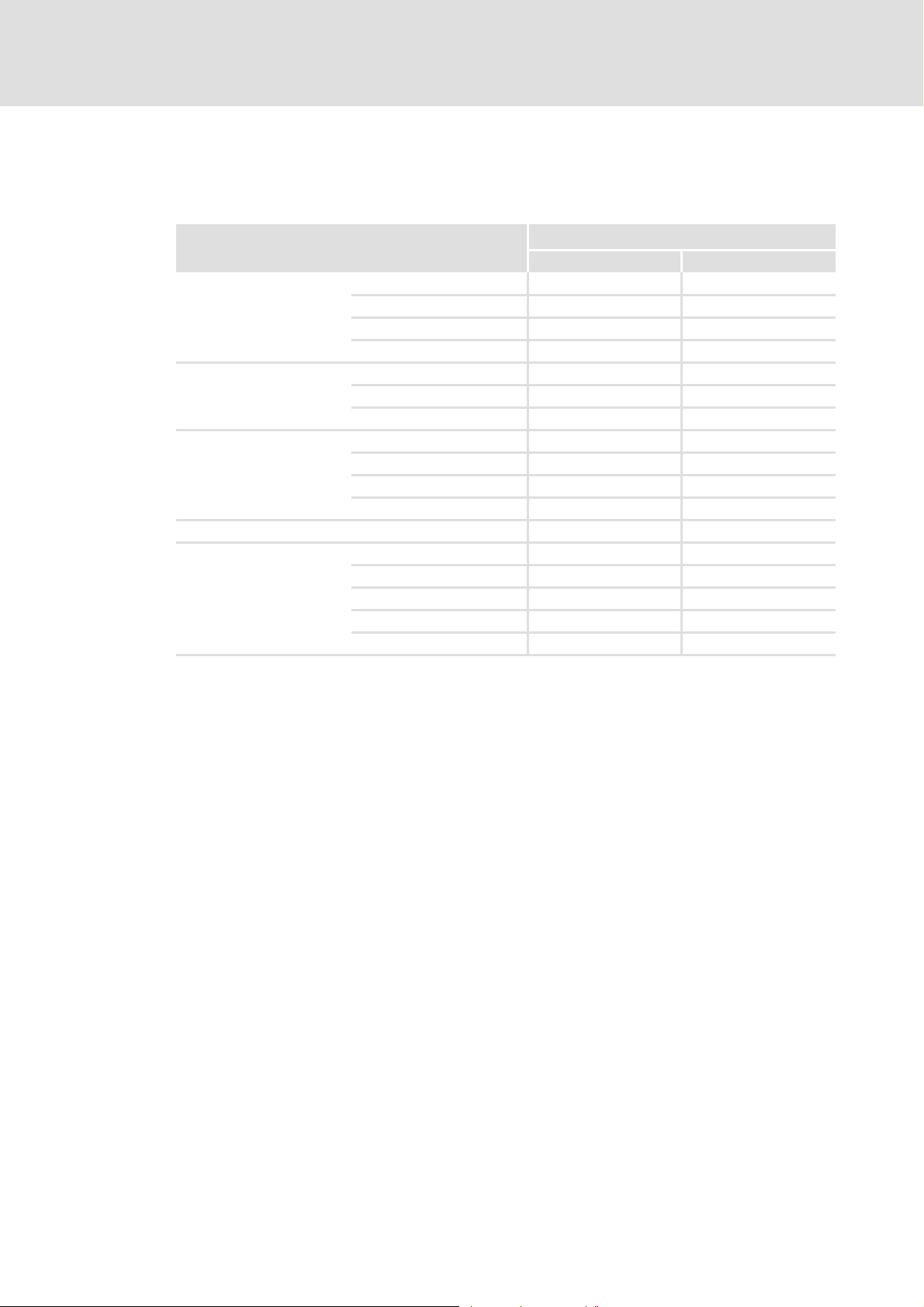

4.2.2 Field devices

The Lenze control system supports the following EtherCAT-capable logic and motion

components:

Field devices EtherCAT bus

Industrial PCs EL x1xx PLC z -

Servo Drives 9400 1) HighLine z

Inverter Drives 8400 2) BaseLine z

I/O system 1000 EPM-Sxxx z

ECS servo system 3) ECSxE z

1) With EtherCAT E94AYCET communication module

2) With EtherCAT E84AYCET communication module

3) With EtherCAT EMF2192IB communication module

Control technology | EtherCAT communication manual

The Lenze control system with EtherCAT

Required hardware components

Logic Motion

EL x7xx zz

CS x7xx zz

CPC x7xx zz

Highline with CiA402 zz

PLC z

StateLine z

HighLine z

TopLine z

ECSxS (Speed & Torque) z

ECSxP (Posi & Shaft) z

ECSxM (Motion) z

ECSxA (Application) z

Field devices of other manufacturers can be integrated as logic nodes if they provide a

standard-compliant EtherCAT device description.

DMS 3.1 EN 01/2011 TD17 L 23

Page 24

Control technology | EtherCAT communication manual

The Lenze control system with EtherCAT

Required hardware components

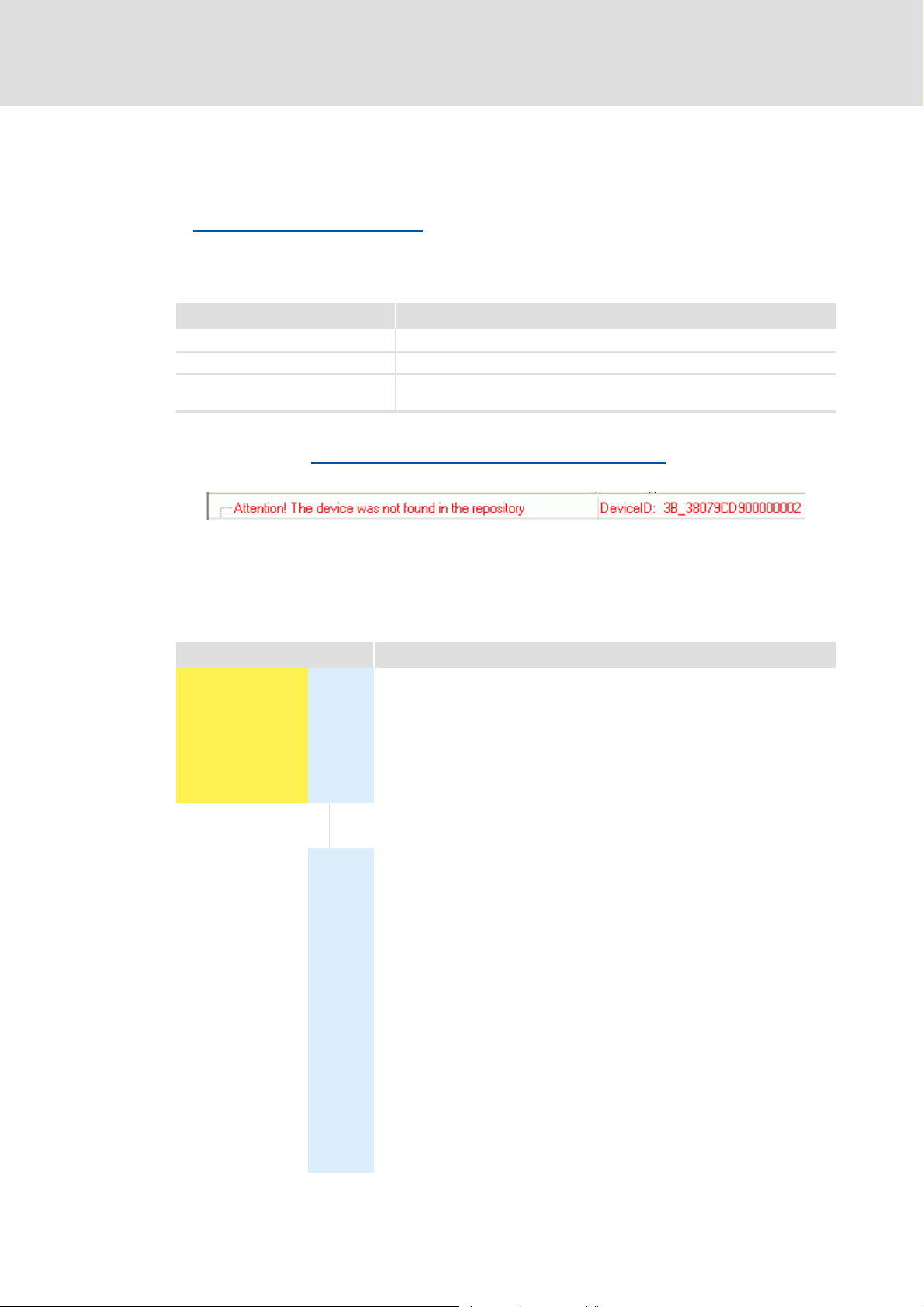

4.2.3 EtherCAT product codes

The product codes serve to assign device descriptions to the corresponding devices. Device

descriptions can be installed via the device repository.

Importing missing field devices

The product codes are part of the device ID.

Structure of the device ID: <Manufacturer ID>_<Productcode><Revision number

Identification Meaning

Manufacturer ID Clear identification for the manufacturer, for Lenze devices: 0x3B

Product code Product code of the product range/the device

Revision number Revision number, consists of Major Revision (CANopen behaviour) and

If, for instance, a device available at the fieldbus witout an installed device description is

detected during a Fieldbus scan with the »EtherCAT Configurator«

the device ID as hexidecimal value is displayed.

( 59)

Minor Revision (device version)

(59

hex

dec

( 47) , a message with

)

In the example, the device description for a Lenze Servo Drive 9400 HighLine, actuator –

speed, is not installed (0x38079CD9

= 940023001

hex

dec

).

Product codes for Servo Drives 9400

Product code [dec] Meaning

9 4 0 0 2 1 x x x Servo Drive 9400 in general

9 4 0 0 2 2 x x x Servo Drive 9400 StateLine

9 4 0 0 2 3 x x x Servo Drive 9400 HighLine

9 4 0 0 2 4 x x x Servo Drive 9400 TopLine

9 4 0 0 2 5 x x x Servo Drive 9400 PLC

9 4 0 0 2 6 x x x Servo Drive 9400 V/R (regenerative power supply module)

Applications:

0 0 0 Empty application

0 0 1 Actuating drive speed

0 0 2 Actuating drive torque

0 0 3 Electronic gearbox

0 0 4 Synchronism with mark synchronisation

0 0 5 Table positioning

0 0 6 Positioning sequence control

0 0 7 PLC application

000

89Reserved

...

...

9

Reserved

1 x x Reserved for device profiles

1 0 1 CiA402

2 x x Reserved for Lenze applications

2 0 1 Regenerative power supply module application

24 L DMS 3.1 EN 01/2011 TD17

Page 25

Control technology | EtherCAT communication manual

Product codes for Inverter Drives 8400

Product code [dec] Meaning

8 4 0 0 2 1 Inverter Drive 8400 BaseLine

8 4 0 0 2 2 Inverter Drive 8400 StateLine

8 4 0 0 2 3 Inverter Drive 8400 HighLine

8 4 0 0 2 4 Inverter Drive 8400 TopLine

Product codes for the I/O system 1000

The Lenze control system with EtherCAT

Required hardware components

Product code

[dec]

1 3 0 0 I/O system EPM-S130

Meaning

Product codes for the ECS servo system

Product code [dec] Meaning

2 1 9 2 0 7 0 0 ECSxA axis module "Application"

2 1 9 2 0 7 0 1 ECSxM axis module "Motion"

2 1 9 2 0 7 0 2 ECSxP axis module "Posi & Shaft"

2 1 9 2 0 7 0 3 ECSxS axis module "Speed & Torque"

2 1 9 2 0 7 1 1 ECSxE power supply module

DMS 3.1 EN 01/2011 TD17 L 25

Page 26

Control technology | EtherCAT communication manual

The Lenze control system with EtherCAT

Required hardware components

4.2.4 EtherCAT hardware for the industrial PC

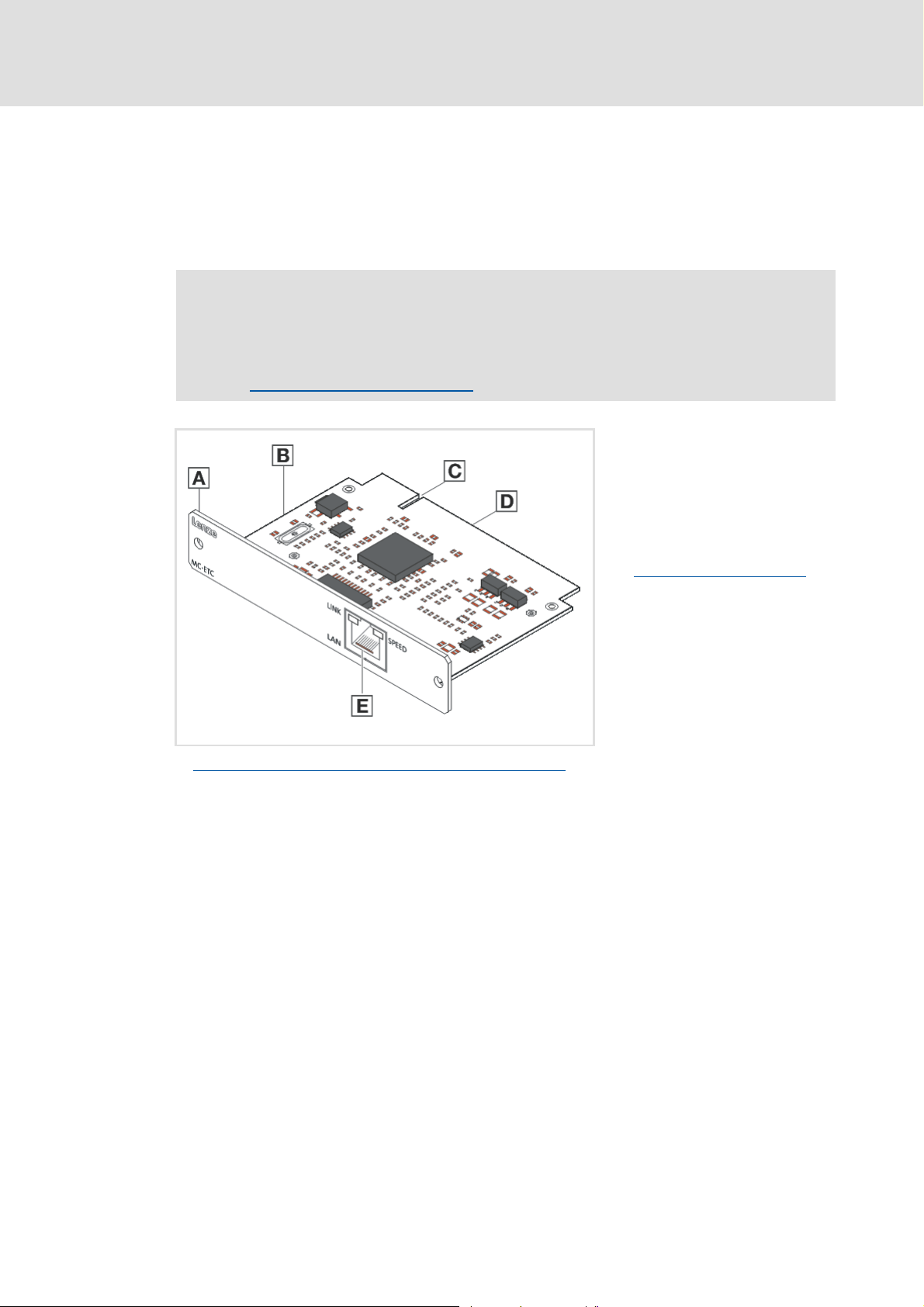

MC-ETC communication card

The MC-ETC communication card is a plug-in card for connecting an industrial PC to an

EtherCAT network.

Note!

In case of a correct connection to the field devices, the LEDs of the

communication card are lit.

Connection RJ45 socket / LEDs

( 34)

A Front panel

B Board

C Coding

D Connection

E EtherCAT connection

Connection RJ45 socket / LEDs

( 34)

MC-ETC-001

Technical data of the

MC-ETC communication card ( 34)

26 L DMS 3.1 EN 01/2011 TD17

Page 27

Control technology | EtherCAT communication manual

The Lenze control system with EtherCAT

Required hardware components

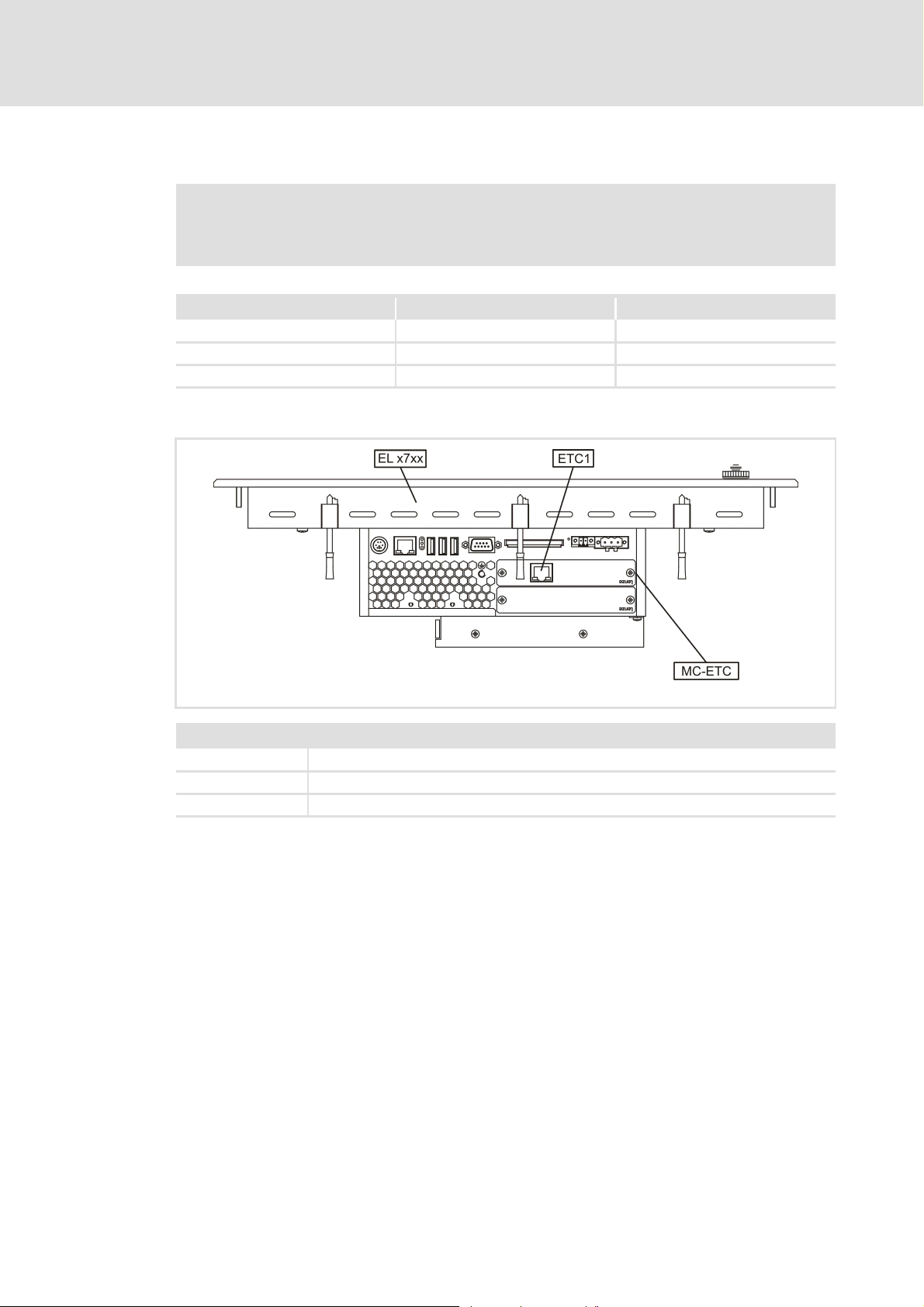

Possible applications

Note!

The industrial PC only supports one communication card MC-ETC!

Industrial PC Can be combined with CANopen Communication card for CANopen

EL x7xx yes MC-CAN2

CS x7xx no

CPC 2700 yes MC-CAN2

Example: Industrial PC EL x7xx with MC-ETC

Legend

EL x7xx Industrial PC of the EL x7xx series

ETC1 EtherCAT network connection

MC-ETC MC-ETC communication card

MC-ETC_ELx7xx

DMS 3.1 EN 01/2011 TD17 L 27

Page 28

Control technology | EtherCAT communication manual

The Lenze control system with EtherCAT

Required engineering tools

4.3 Required engineering tools

The engineering tools required for configuration and parameter setting are installed on

the engineering PC.

»Engineer«, »EtherCAT Configurator« and »PLC Designer« are engineering PC tools

which are independent of each other.

The EtherCAT bus, the industrial PC and the EtherCAT-capable field devices are

configured with the engineering tools highlighted in grey.

28 L DMS 3.1 EN 01/2011 TD17

Page 29

Control technology | EtherCAT communication manual

The Lenze control system with EtherCAT

Required engineering tools

Brief description of the engineering tools

L-force »Engineer«

With the »Engineer«, you can ...

parameterise, configure and diagnose ...

– Servo Drives 9400;

– Inverter Drives 8400;

– the I/O system 1000.

access the supported field devices via the gateway function of the industrial PC.

»Global Drive Control« ((GDC))

With (GDC) you can ...

parameterise, configure and diagnose controllers which are not supported by the

»Engineer« (e.g. devices of the ECS servo system).

access the supported field devices via the gateway function of the industrial PC (not

with PROFIBUS).

L-force »PLC Designer«

The »PLC Designer« is needed to ...

create the control program for the industrial PC;

transfer the PLC projects to the industrial PC.

DMS 3.1 EN 01/2011 TD17 L 29

Page 30

Control technology | EtherCAT communication manual

The Lenze control system with EtherCAT

Interaction of the components

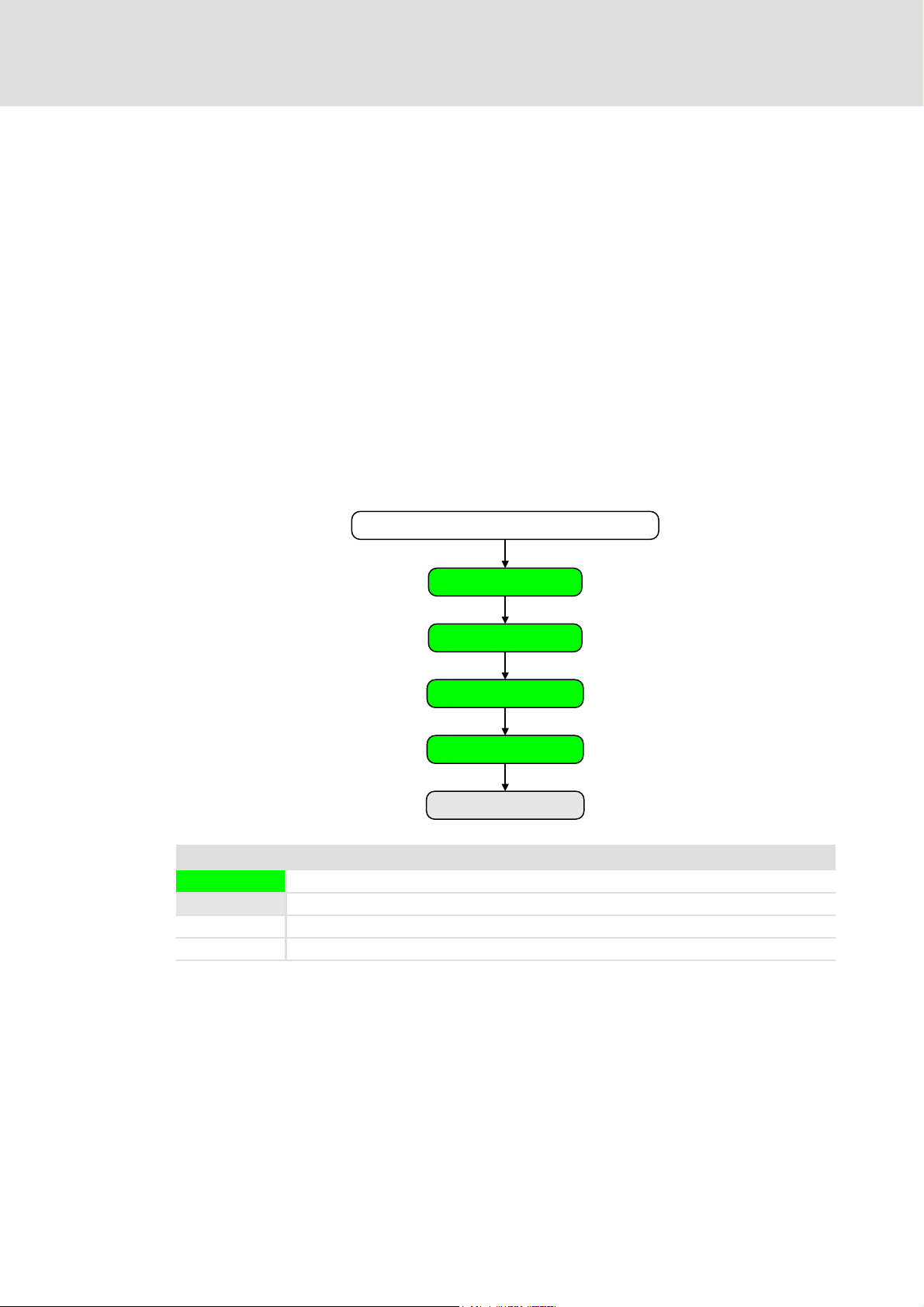

4.4 Interaction of the components

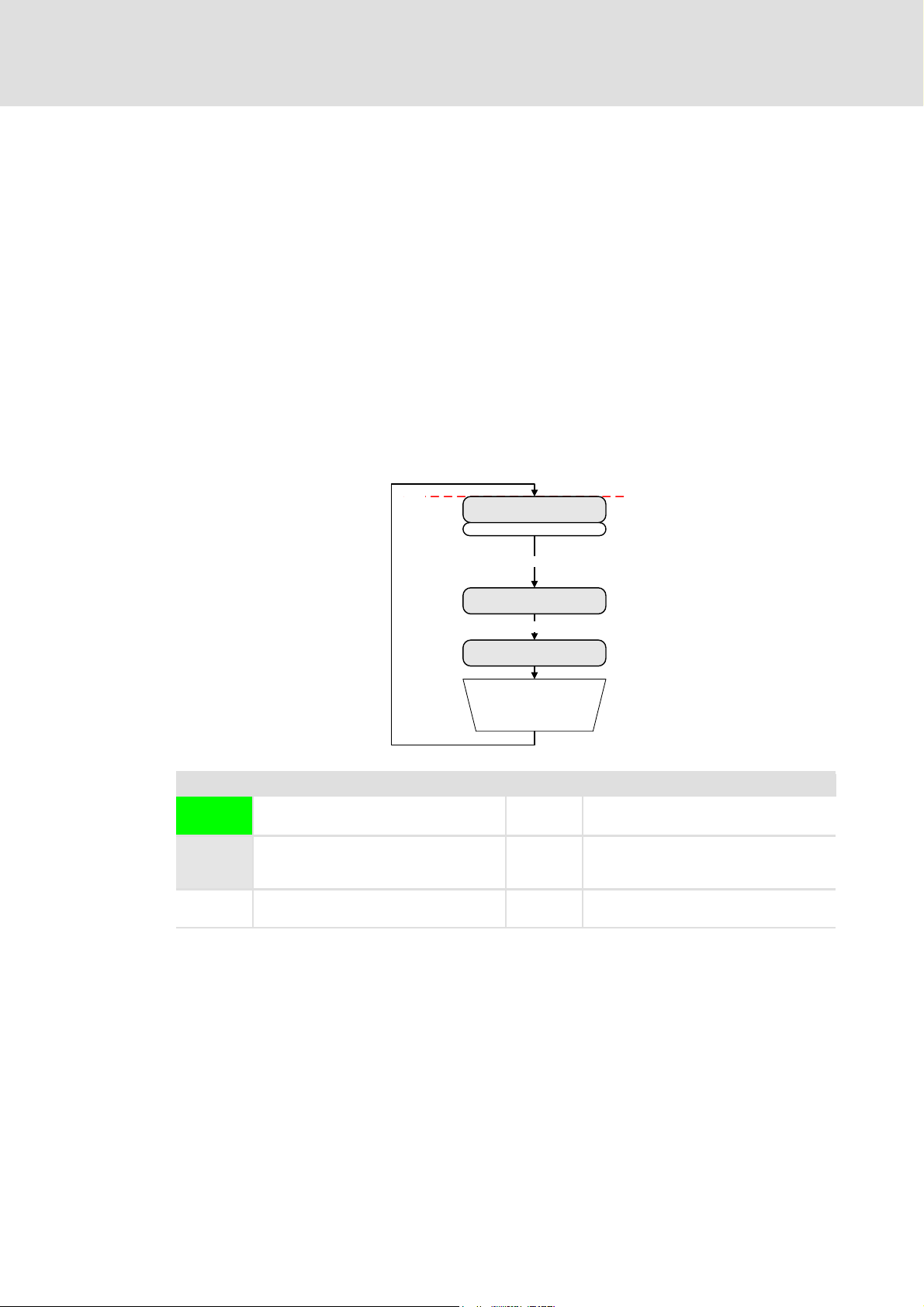

4.4.1 The state machine of the Lenze control technology

In the Lenze control technology, the states of the PLC and the EtherCAT fieldbuses are

coupled. The PLC controls the fieldbus.

After switch-on the system automatically powers up if the following conditions are

fulfilled:

The IPC is provided with the configuration file for the EtherCAT master (master-XML

file), the contents of which corresponds to the real bus topology.

The IPC is provided with an executable PLC boot project.

The slaves at the fieldbus can be accessed.

The following illustration shows the linkage of the states in the state machine of the Lenze

control technology when the conditions for the automatic acceleration of the system are

fulfilled (boot project with EtherCAT BusInterface and EtherCAT master configuration):

Switch on industrial PC and field devices

PLC: Original

EtherCAT: Unknown

PLC: Original

EtherCAT: Init

PLC: Original

EtherCAT: Pre-Operational

PLC: Running

EtherCAT: Safe-Operational

PLC: Running

EtherCAT: Operational

Legend

Transitional state, automatic change to next state

Stationary state, change to next state by external actions

PLC State of the PLC

EtherCAT State of the EtherCAT fieldbus

30 L DMS 3.1 EN 01/2011 TD17

Page 31

Control technology | EtherCAT communication manual

The Lenze control system with EtherCAT

Interaction of the components

Explanation of the transitions during system start

While a state is passed through, different tests are carried out (e.g. it is tested whether the

physical topology complies with the configuration). If the tests are successful, the system

automatically changes to the next state.

Status What happens? What is tested?

PLC EtherCAT

Origin Unknown The system starts. Is a master XML file available?

Origin Init EtherCAT is initialised.

Master XML file is imported.

Bus scan is executed

Origin Pre-Operational EtherCAT is active.

SDO communication is possible.

Running Safe-Operational The PLC program is being loaded.

The PLC is running.

The inputs are transferred, the

outputs are still in a safe state.

Running Operational The system is running.

Does the imported master XML

comply with the result of the bus

scan?

Is an executable boot project

available?

Are all inputs ok and initialised?

Detailed information about the possible bus states and the required commissioning steps

can be found here:

Commissioning of the system

( 42)

DMS 3.1 EN 01/2011 TD17 L 31

Page 32

Control technology | EtherCAT communication manual

The Lenze control system with EtherCAT

Interaction of the components

4.4.2 Communication between engineering PC and field devices

For commissioning of the field devices, an online connection is required between the

engineering PC and the corresponding field device. Depending on the state of the EtherCAT

bus, there are two options:

EtherCAT bus not in operation

EtherCAT bus in operation (gateway function) ( 33)

4.4.2.1 EtherCAT bus not in operation

You can communicate serially or via CANopen.

Condition:

Serial communication:

– You require the E94AZCUS diagnostic adapter.

– Field device and engineering PC (USB interface) must be connected via the diagnostic

adapter.

Communication via CANopen

– You required the EMF2177IB USB system bus adapter .

– Field devices and the engineering PC are connected via the system bus adapter -

either via a point-to-point connection or via the bus system.

Advantage:

Quick option of communication without commissioning of the EtherCAT bus.

( 32)

Disadvantage:

You require additional hardware.

Tip!

As soon as the fieldbus has been commissioned and at least achieved the PreOperational state, this communication path comes second. We recommend to

commission the EtherCAT bus as soon as possible to be able to use the gateway

function.

32 L DMS 3.1 EN 01/2011 TD17

Page 33

Control technology | EtherCAT communication manual

4.4.2.2 EtherCAT bus in operation (gateway function)

You directly communicate via EtherCAT and use the industrial PC as gateway.

Note!

A PLC program does not need to run to be able to use the gateway function.

The Lenze control system with EtherCAT

Interaction of the components

Condition

The bus configuration has been created using the »PLC Designer« and corresponds to

the hardware configuration.

The bus configuration has been loaded onto the industrial PC using the »PLC Designer«

and is active.

The fieldbus state is at least Pre-Operational.

Advantage:

You do not require any additional hardware.

The entire communication (process data, parameter data, and diagnostic data) are

transferred at the same time using a single bus connection.

DMS 3.1 EN 01/2011 TD17 L 33

Page 34

Control technology | EtherCAT communication manual

Technical data

General data of the EtherCAT bus

5 Technical data

5.1 General data of the EtherCAT bus

Field Values

Communication medium S/FTP (Screened Foiled Twisted Pair, ISO/IEC 11801 or EN 50173), CAT5e

Network topology Line

Number of nodes Max. 65535 ( in the entire network )

Max. cable length 100 m between two nodes

Baud rate 100 Mbit/s

EtherCAT module Direct mode

Communication profile CoE (CANopen over EtherCAT)

Synchronisation Distributed clocks

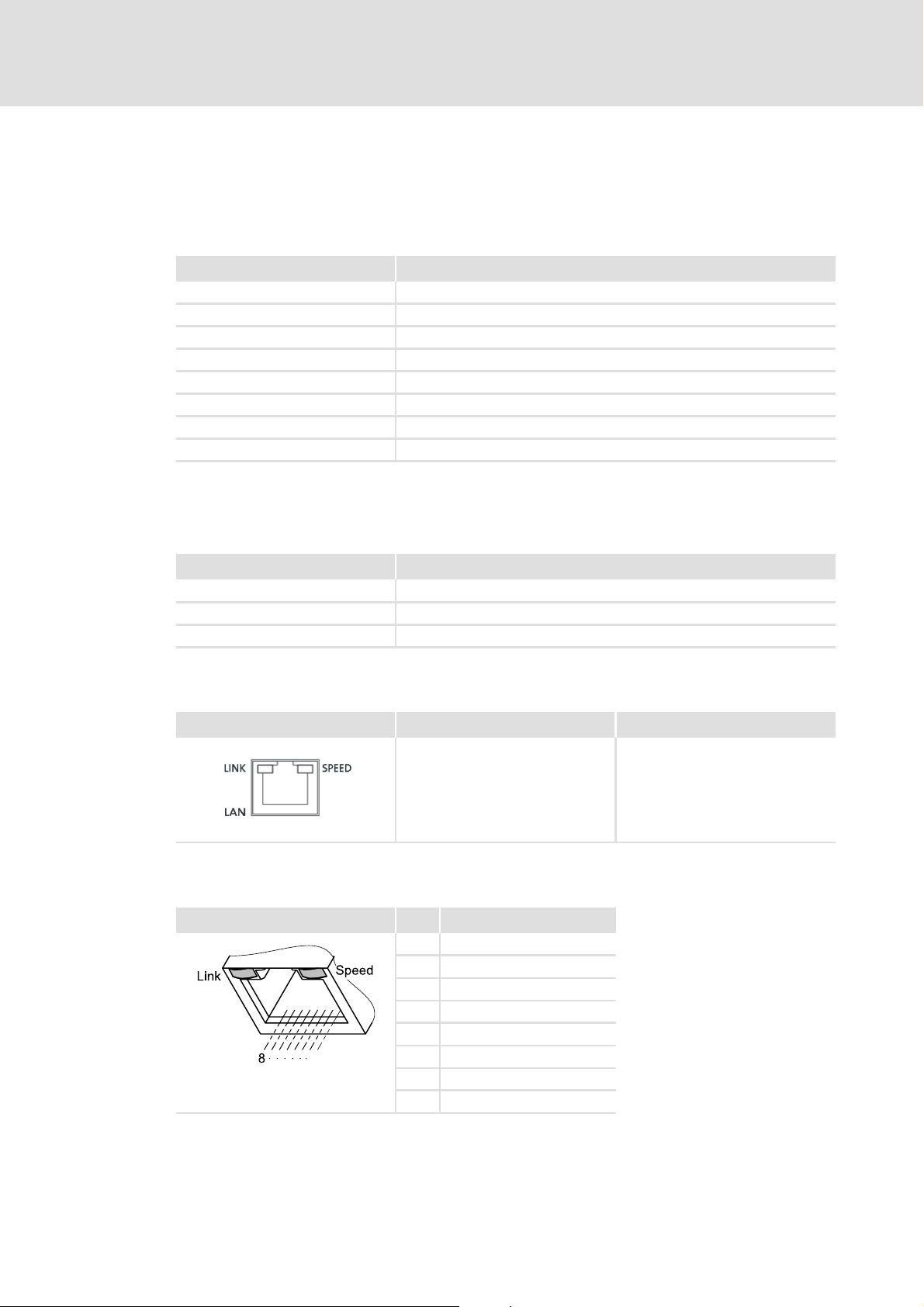

5.2 MC-ETC communication card

Field Values

Possible baud rate 100 Mbit/s

Type within the network Master

Connection RJ45 socket in accordance with EN 50173

Connection RJ45 socket / LEDs

View Description Cable type

Pin assignment

RJ45 socket Pin Assignment

1

MC-ETH-001

E94YCEP018

EtherCAT connection

•LED "Link":

–On: connection ok

–Blinking: data exchange

• LED "Speed":

–Green: 100 MBit/s

1Tx +

2Tx -

3Rx +

4-

5-

6Rx -

7-

8-

•CAT5e S/FTP network cable

(recommended) in accordance

with ISO/IEC 11801 or EN 50173

• Cable length: max. 100 m

34 L DMS 3.1 EN 01/2011 TD17

Page 35

Control technology | EtherCAT communication manual

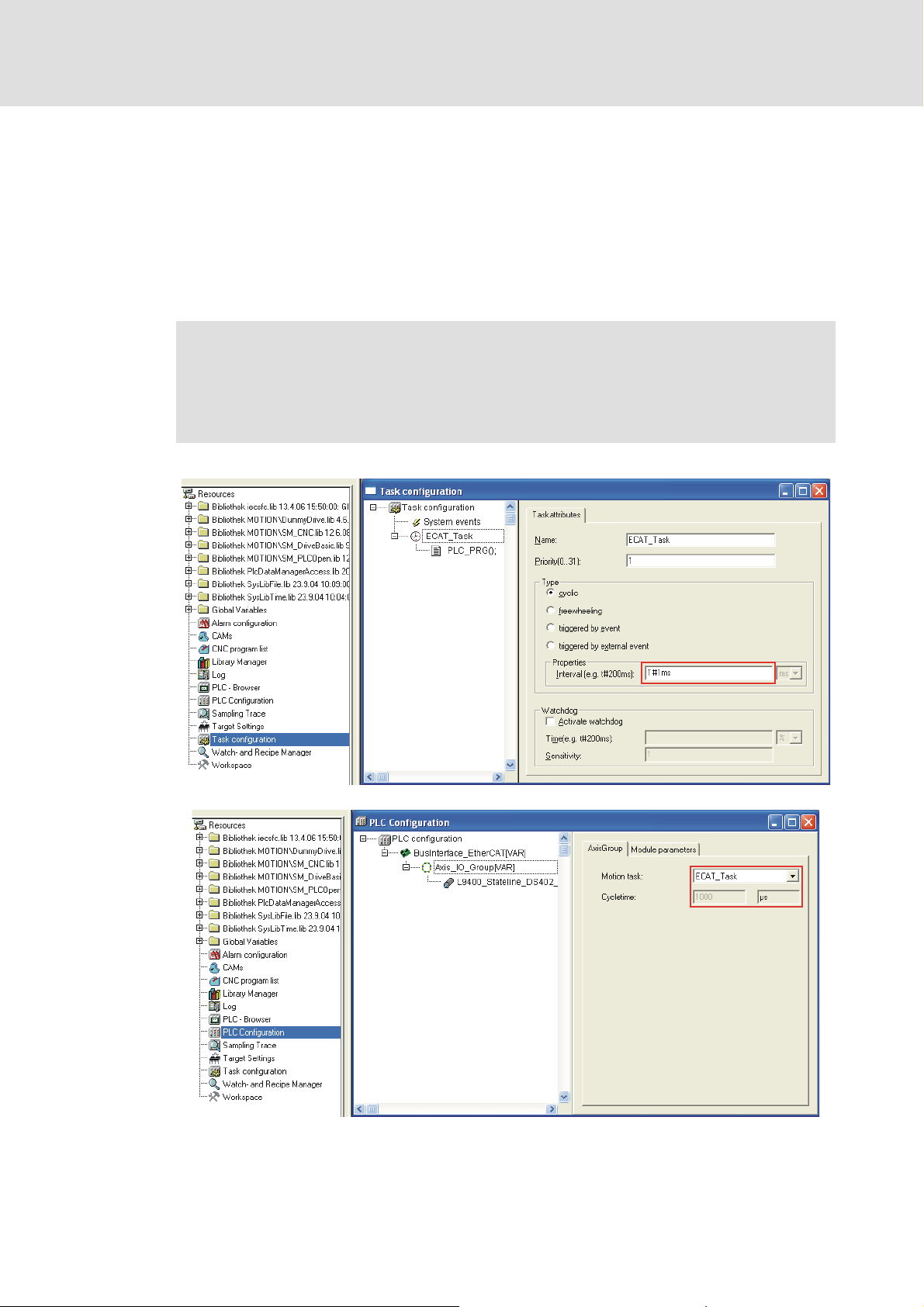

5.3 Communication times and drive-specific data

Field Values

User data per frame 1344 bytes

Process data words (PZD) for Servo

Drives 9400 HighLine

Parameter data (SDO) transfer Max. 128 bytes

Permissible EtherCAT cycle times 1 … 10 ms

Max. number of Servo Drives 9400

HighLine per frame

Total signal runtime for a cycle time

of 1ms

Drive

Control Drive

Runtime of the setpoints

Control

Drive

Runtime of the actual values

Drive

Control

Cross communication Not possible

Cycle synchronisation with locked

PLL (jitter)

max. 32 words (64 bytes)

User data of the frame (1344 bytes) divided by the process data length

resulting from setpoints and actual values of the drives:

• for 32 Tx/Rx bytes: 1344 bytes / 64 bytes = 21 drives

• for 16 Tx/Rx bytes: 1344 bytes / 32 bytes = 42 drives

5 ms

2 ms

3ms

+/-1 μs

Technical data

Communication times and drive-specific data

DMS 3.1 EN 01/2011 TD17 L 35

Page 36

Control technology | EtherCAT communication manual

Synchronisation with "Distributed clocks"

6 Synchronisation with "Distributed clocks"

The "Distributed clocks" (DC) function enables an exact time adjustment for applications

where several auxiliary axes carry out a coordinated movement at the same time. The data

is accepted synchronously with the PLC program. With the DC synchronisation, all slaves

are synchronised with a reference clock, called the "DC master".

Note!

• Motion applications always require DC synchronisation.

• DC synchronisation can also be used for Logic applications.

• Some slaves do not support the DC functionality.

– To be able to use the DC function, the first slave connected to the EtherCAT

master (IPC) must be DC-master-capable.

– In the arrangement of the slaves following then, DC-capable and non-DC-

capable devices can be mixed.

• The first EtherCAT node connected to the IPC must

provides the other EtherCAT nodes (including the IPC) with the exact time.

be the DC master which

The settings for the DC synchronisation are made with the »EtherCAT Configurator«.

Adjusting task cycle time and DC cycle time

( 38)

Setting the DC synchronisation with the »EtherCAT Configurator« ( 39)

36 L DMS 3.1 EN 01/2011 TD17

Page 37

Control technology | EtherCAT communication manual

6.1 Synchronous communication

The DC synchronisation provides for a phase-synchronous operation of master and slaves:

Within one bus cycle the setpoints are accepted and the actual values are detected in the

fieldbus at exactly the same time.

If the control (IPC) is synchronous to the distributed clocks, the data (actual values)

collected by the slave are assigned to the master at the end of the bus cycle and data from

the master (setpoints) are sent to the slaves for processing.

When the next DC synchronisation event occurs, the data are accepted.

Note!

State change and DC synchronisation for Servo Drives 9400 HighLine

During the state change from Operational to Pre-Operational, the DC

synchronisation is deactivated (C13883/C14883 = 0).

Synchronisation with "Distributed clocks"

Synchronous communication

In order to re-activate the sync pulses adjust your PLC program in the following

way:

• Call the function block ResetAxisGroup.

– In this way, the EtherCAT fieldbus is reinitialised.

– The DC synchronisation is active again (C13883/C14883 = 1).

DMS 3.1 EN 01/2011 TD17 L 37

Page 38

Control technology | EtherCAT communication manual

Synchronisation with "Distributed clocks"

Adjusting task cycle time and DC cycle time

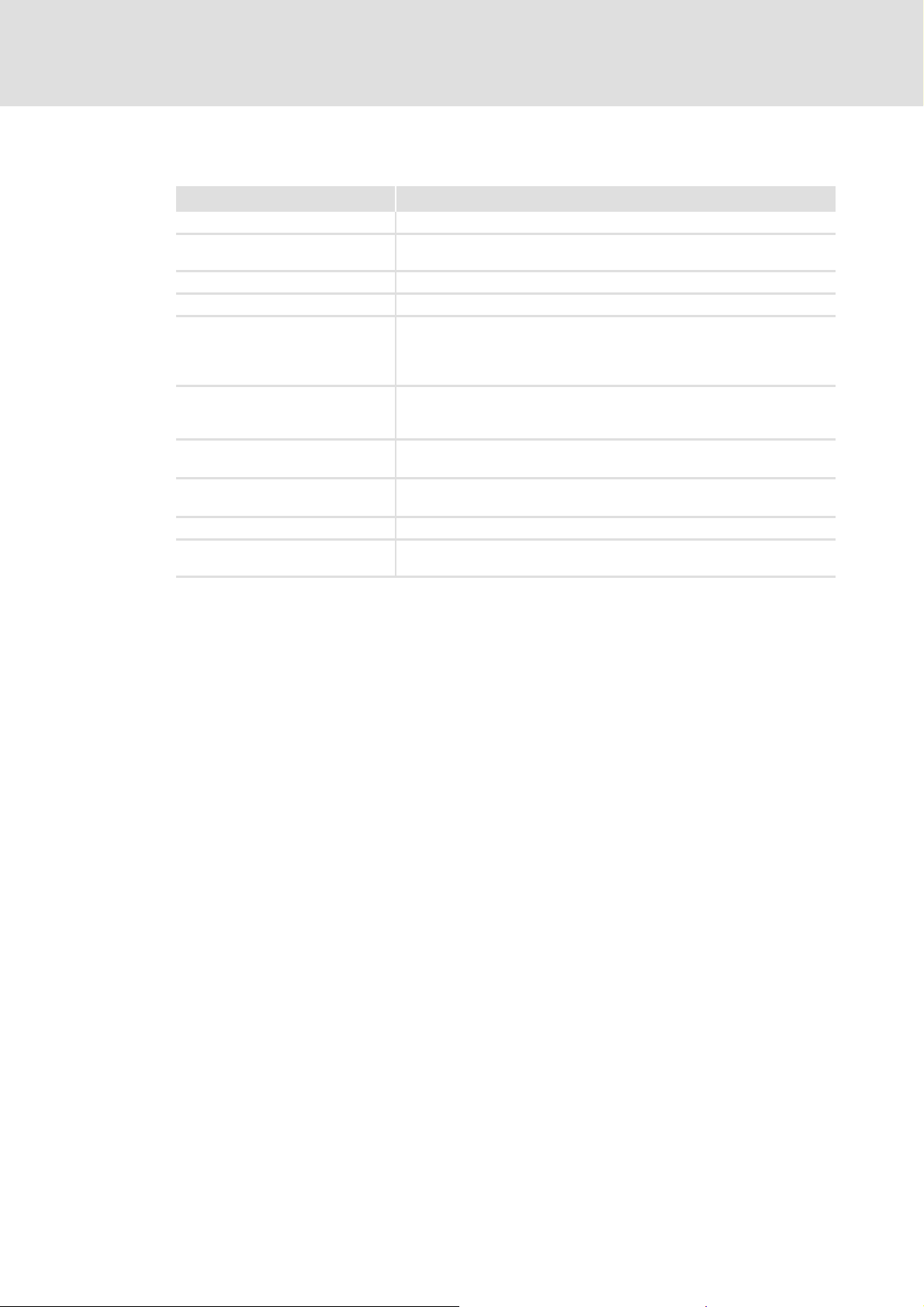

6.2 Adjusting task cycle time and DC cycle time

The industrial PC is the fieldbus master in the EtherCAT network. The clock pulse of the

EtherCAT bus system is determined by the cycle time of the task which is assigned to the

drives (slaves) in the »PLC Designer«.

The task settings in the »PLC Designer« only support integer millisecond cycles and the

smallest possible bus cycle is 1 millisecond. This cycle time can be defined via the task

configuration of the »PLC Designer«.

Note!

• The DC cycle time to be set in the »EtherCAT Configurator« must comply with

EtherCAT task cycle time set in the »PLC Designer«.

• Select the cycle times, according to the technical data, between 1 and 10 ms.

38 L DMS 3.1 EN 01/2011 TD17

Page 39

Control technology | EtherCAT communication manual

Synchronisation with "Distributed clocks"

Setting the DC synchronisation with the »EtherCAT Configurator«

6.3 Setting the DC synchronisation with the »EtherCAT Configurator«

Note!

The manual configuration of the slave DC features requires a detailed

knowledge of EtherCAT and the field device. Thus, DC settings should only be

made by experts.

A faulty configuration can cause maloperation and negative influences on the

system.

How to set the DC synchronisation:

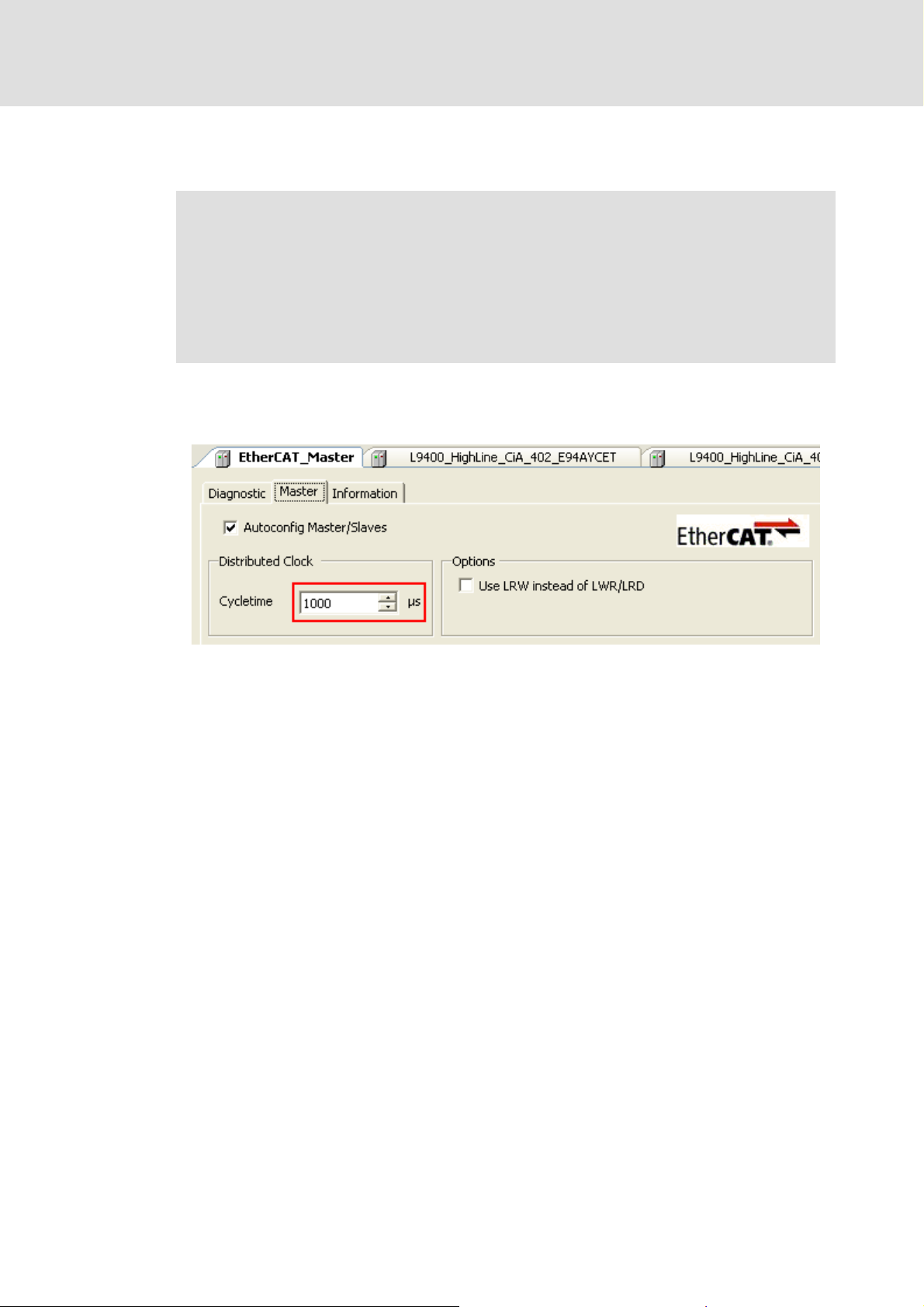

1. Set the Distributed clocks (DC) cycle time at the EtherCAT Master:

• The DC cycle time to be set in the »EtherCAT Configurator« must comply with

the EtherCAT task cycle time set in the »PLC Designer«.

• Select the cycle times, according to the technical data, between 1 and 10 ms.

• The (basic) cycle time set here is valid for all Logic and Motion nodes

synchronised by distributed clocks.

• For field devices with communication modules (e.g. Servo Drives 9400 or

Inverter Drives 8400), a synchronisation source must be selected via code

C01120. If the DC setting and the selection of the sync source differ from each

other (C01120 = MXI1 and "DC nused"), the devices cannot be set to the

Operational state.

•For Servo Drives 9400, code C13892/C14892 = 1 must be set (process data

mode = "deterministic mode").

DMS 3.1 EN 01/2011 TD17 L 39

Page 40

Control technology | EtherCAT communication manual

Synchronisation with "Distributed clocks"

Setting the DC synchronisation with the »EtherCAT Configurator«

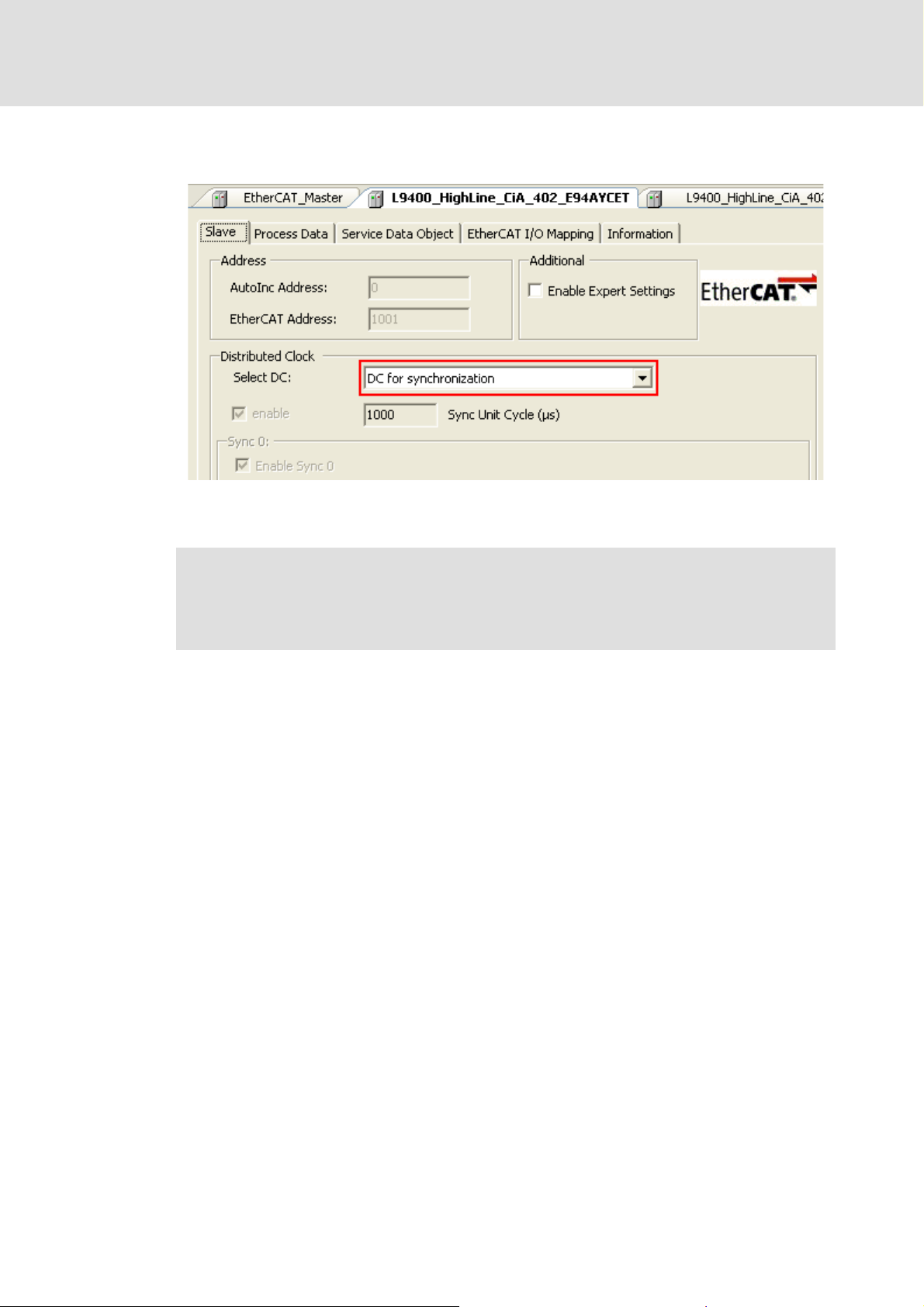

2. Activate the DC functionality for the first slave (DC master) connected to the bus

master (select "DC for synchronization"):

3. Also activate the DC functionality (select "DC for synchronization") for all other

slave devices which are to use the DC synchronisation.

Note!

Maintain all other basic DC settings for the slaves to ensure a correct DC

synchronisation.

40 L DMS 3.1 EN 01/2011 TD17

Page 41

Control technology | EtherCAT communication manual

6.4 Check of the DC synchronicity

The DC synchronicity can only be checked in the Operational bus state.

Synchronisation with "Distributed clocks"

Check of the DC synchronicity

You can check the DC synchronicity via the "ECAT DC: Status" parameter (code C1082/1

C1582/1

bEC_NOTIFY_DC_SLV_SYNC.

) or via the Notifications ( 120) bEC_NOTIFY_DC_STATUS and

/

DMS 3.1 EN 01/2011 TD17 L 41

Page 42

Control technology | EtherCAT communication manual

Commissioning of the system

7 Commissioning of the system

This chapter provides information about how to commission the Lenze control system

with EtherCAT.

Commissioning of the system requires the following Lenze engineering tools:

»EtherCAT Configurator«

»PLC Designer«

»Engineer«

An overview of the commissioning steps is given in the next section Overview of

commissioning steps ( 43). Follow the instructions of these sections step by step in order

to commission your system.

At the end of this chapter you will find a chart showing a Detailed overview of the

commissioning steps ( 90) with regard to the different Lenze engineering tools.

42 L DMS 3.1 EN 01/2011 TD17

Page 43

Control technology | EtherCAT communication manual

7.1 Overview of commissioning steps

Commissioning of the system

Overview of commissioning steps

DMS 3.1 EN 01/2011 TD17 L 43

Page 44

Control technology | EtherCAT communication manual

Commissioning of the system

Overview of commissioning steps

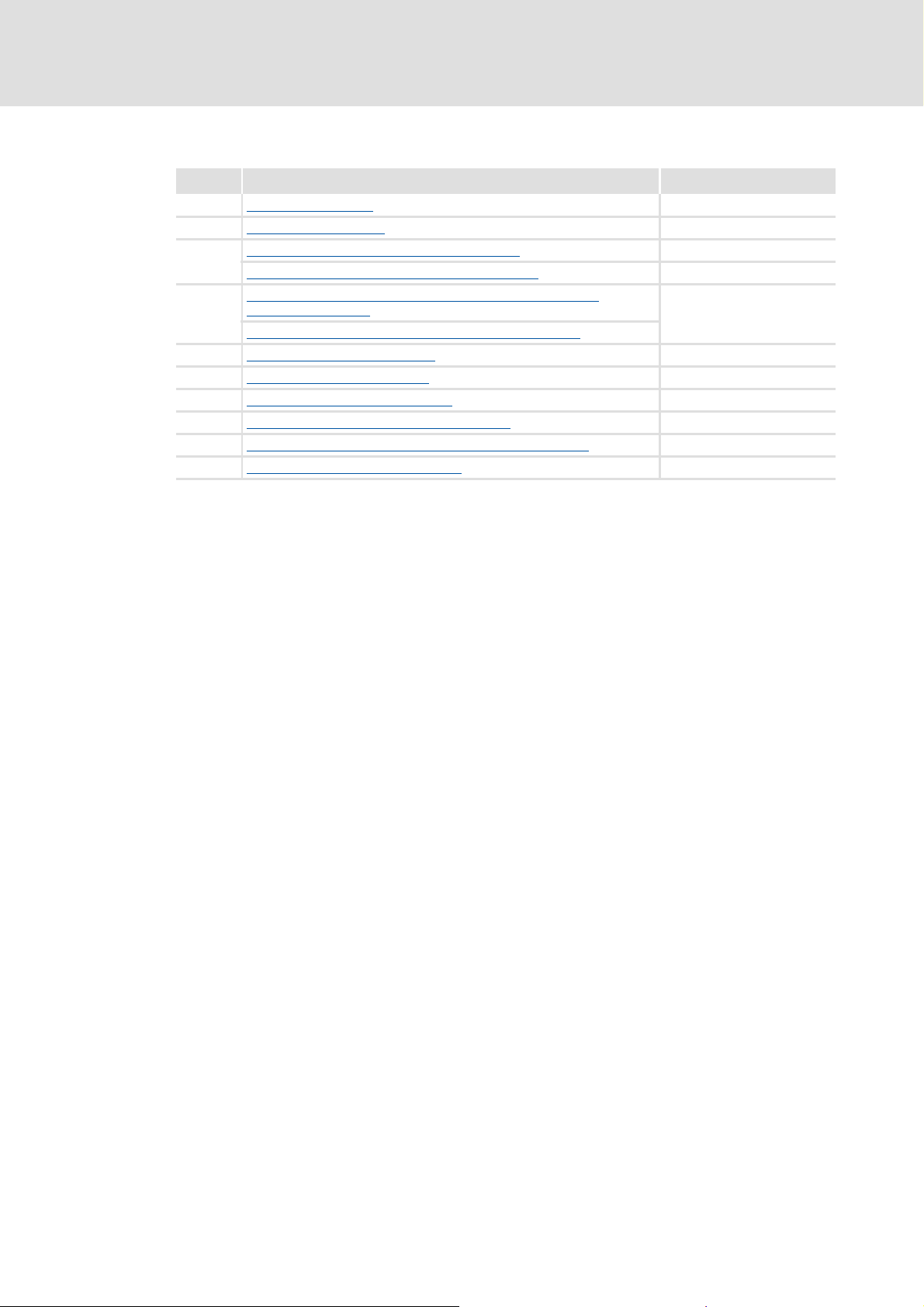

The main commissioning steps are listed in the following table:

Step Activity Software used

1. Installing field devices

2. Creating a project folder

3. Fieldbus scan with the »EtherCAT Configurator«

Fieldbus scan with the »scandf« command line tool

4. Inserting devices available on the fieldbus into the »EtherCAT

Configurator« project ( 55)

Creating the configuration in the »EtherCAT Configurator«

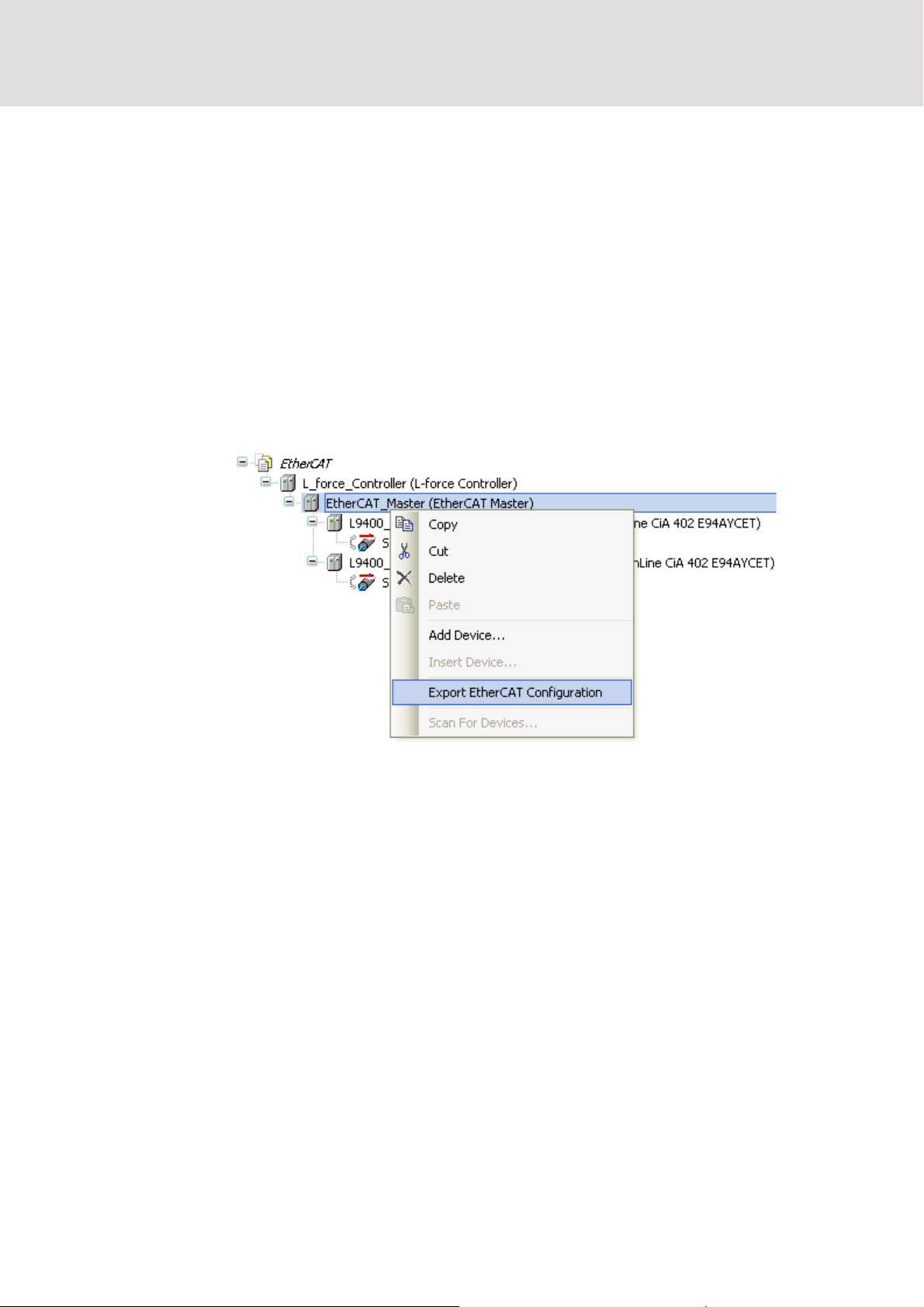

5. Export of EtherCAT configuration

6. Configuration in the »Engineer«

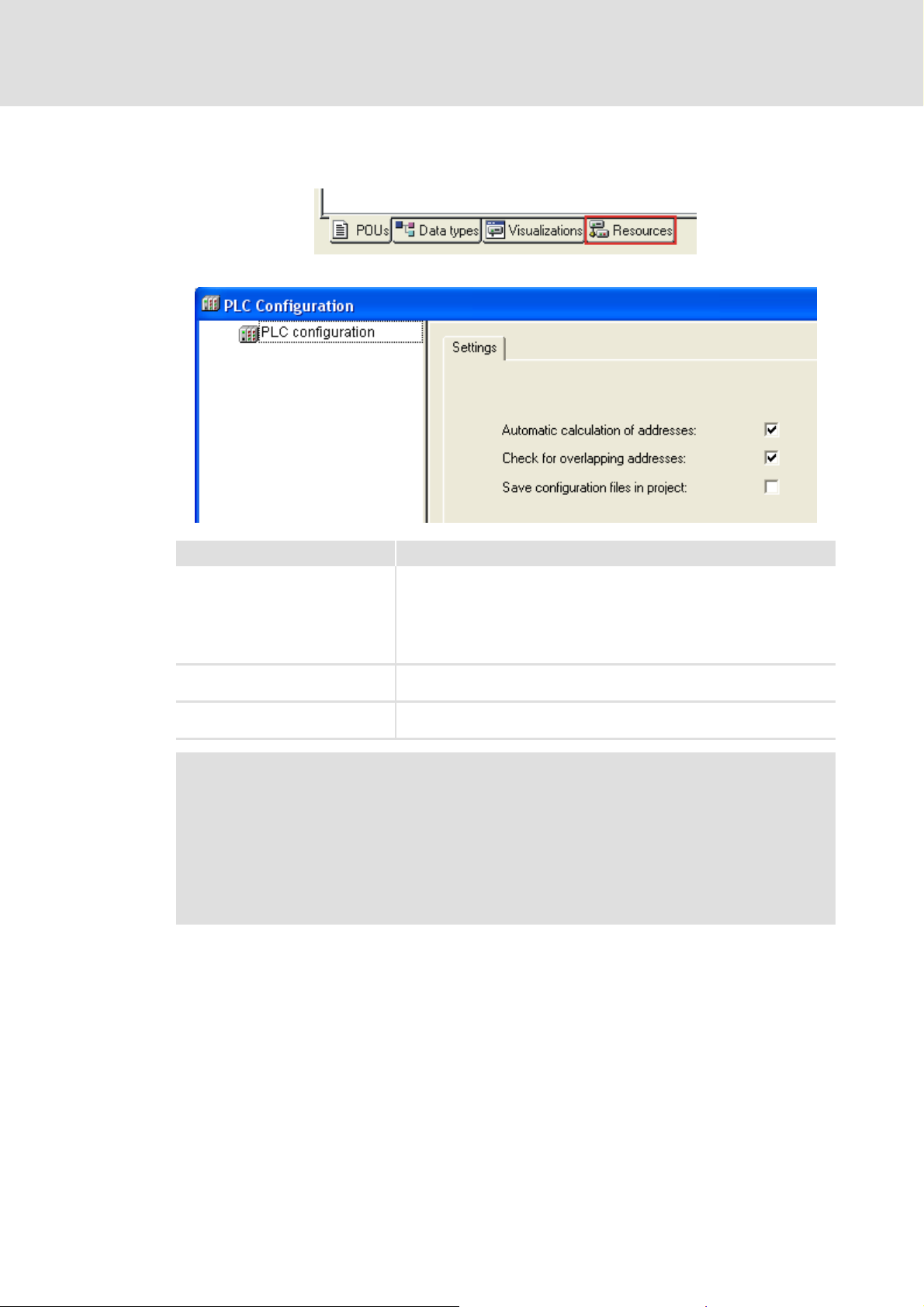

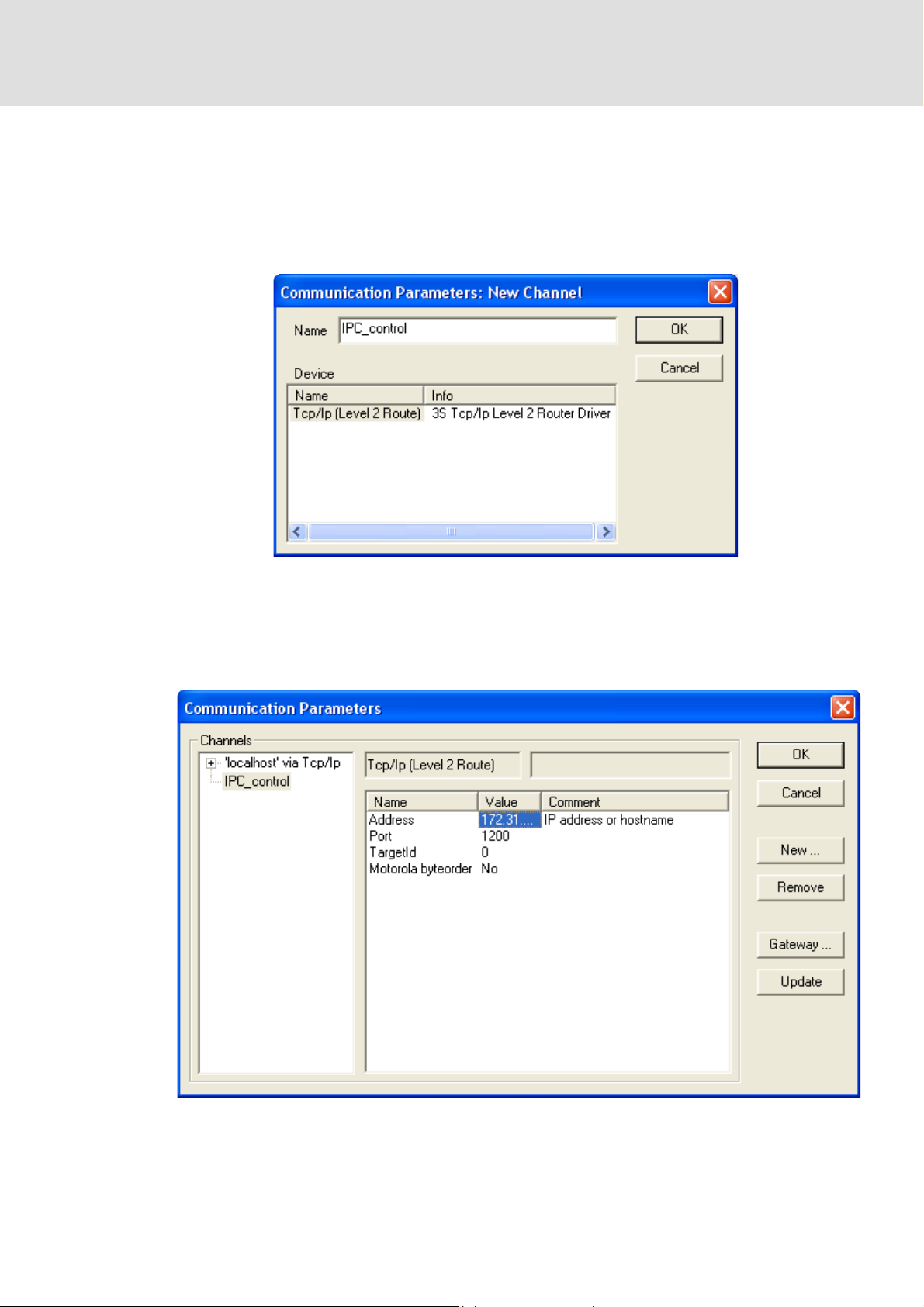

8. Configuration in the »PLC Designer«

9. Loading the control configuration onto the IPC

10. Loading the master configuration onto the EtherCAT master

11. Loading and starting the PLC program

( 45)

( 46)

( 47) »EtherCAT Configurator«

( 51) Command line tool »scandf«

( 56)

( 67) »EtherCAT Configurator«

( 54) »Engineer«

( 68) »PLC Designer«

( 78) »PLC Designer«

( 79) »PLC Designer«

( 79) »PLC Designer«

»EtherCAT Configurator«

44 L DMS 3.1 EN 01/2011 TD17

Page 45

Control technology | EtherCAT communication manual

7.2 Detailed commissioning steps

In the following sections, the individual commissioning steps are described.

More detailed information about how to work with the Lenze engineering tools

can be found in the corresponding manuals and online helps.

7.2.1 Planning the bus topology

Before you start to set up an EtherCAT network, first create a plan of your EtherCAT bus.

Brief description of EtherCAT

How to plan the bus topology for your configuration:

1. Create an overview of the planned EtherCAT network with all field devices to be

integrated.

Commissioning of the system

Detailed commissioning steps

( 16)

2. Start with the industrial PC.

3. Add the other field devices below.

4. You have to distinguish between the following two cases:

• Operation without synchronisation via distributed clocks:

DC synchronisation is not required if exclusively Logic field devices are to be

operated on the network. The sequence of the field device interface connections

on the bus can freely be selected.

• Operation with synchronisation via distributed clocks:

DC synchronisation is required if Motion and Logic field devices are to be

operated on the network. The first node connected to the control IPC must be

capable of being a DC master. The sequence of the other Logic and Motion field

device interface connections can freely be selected.

7.2.2 Installing field devices

For the installation of a field device, follow the mounting instructions for the respective

device.

Note!

• The EtherCAT interfaces of all devices must be wired according to the planned

topology. The inputs (IN) and outputs (OUT) must not be reversed because

otherwise the topology changes.

Communication

• The structure of the EtherCAT configuration must be identical with the order

of the devices in the »EtherCAT Configurator«.

• The master automatically assigns the node addresses to the slaves.

Therefore, a manual address assignment is not required.

DMS 3.1 EN 01/2011 TD17 L 45

( 18).

Page 46

Control technology | EtherCAT communication manual

Commissioning of the system

Detailed commissioning steps

7.2.3 Creating a project folder

Create a project folder on the engineering PC.

Use this project folder to store the below data generated in the different project

configuration steps:

The project file created in the »EtherCAT Configurator«

The configuration files exported from the »EtherCAT Configurator«:

– ECAT_PLC_CFG_1.XML

– ECAT_MASTER_1.XML

The project data created in the »Engineer«

The project file created in the »PLC Designer«

Tip!

Create a separate project folder for every EtherCAT configuration and store the

project and configuration files in this folder.

46 L DMS 3.1 EN 01/2011 TD17

Page 47

Control technology | EtherCAT communication manual

Commissioning of the system

Detailed commissioning steps

7.2.4 Determining the physical EtherCAT configuration (fieldbus scan)

You can execute a fieldbus scan with the »EtherCAT Configurator« on the IPC in order to

check the physical EtherCAT configuration. Alternatively, the command line tool »scandf«

( 51) is also available on the IPC.

Note!

• Scanning of the EtherCAT fieldbus is also possible without an appropriate

EtherCAT configuration.

• Communication to field devices via the EtherCAT fieldbus is only possible if at

least the Pre-Operational state has been reached.

7.2.4.1 Fieldbus scan with the »EtherCAT Configurator«

The »EtherCAT Configurator« offers the possibility to execute an online search for devices

which are connected to the EtherCAT fieldbus.

In order to search for devices you must first establish an online connection of the

»EtherCAT Configurator« with the industrial PC.

How to execute a fieldbus scan with the »EtherCAT Configurator«:

1. Enter the IP address of the industrial PC:

• Select the L-force Controller by double-clicking in the device tree:

• Enter the IP address of the industrial PC which should serve as control unit of the

configuration into the Online access configuration dialog box in the Master

configuration area:

DMS 3.1 EN 01/2011 TD17 L 47

Page 48

Control technology | EtherCAT communication manual

Commissioning of the system

Detailed commissioning steps

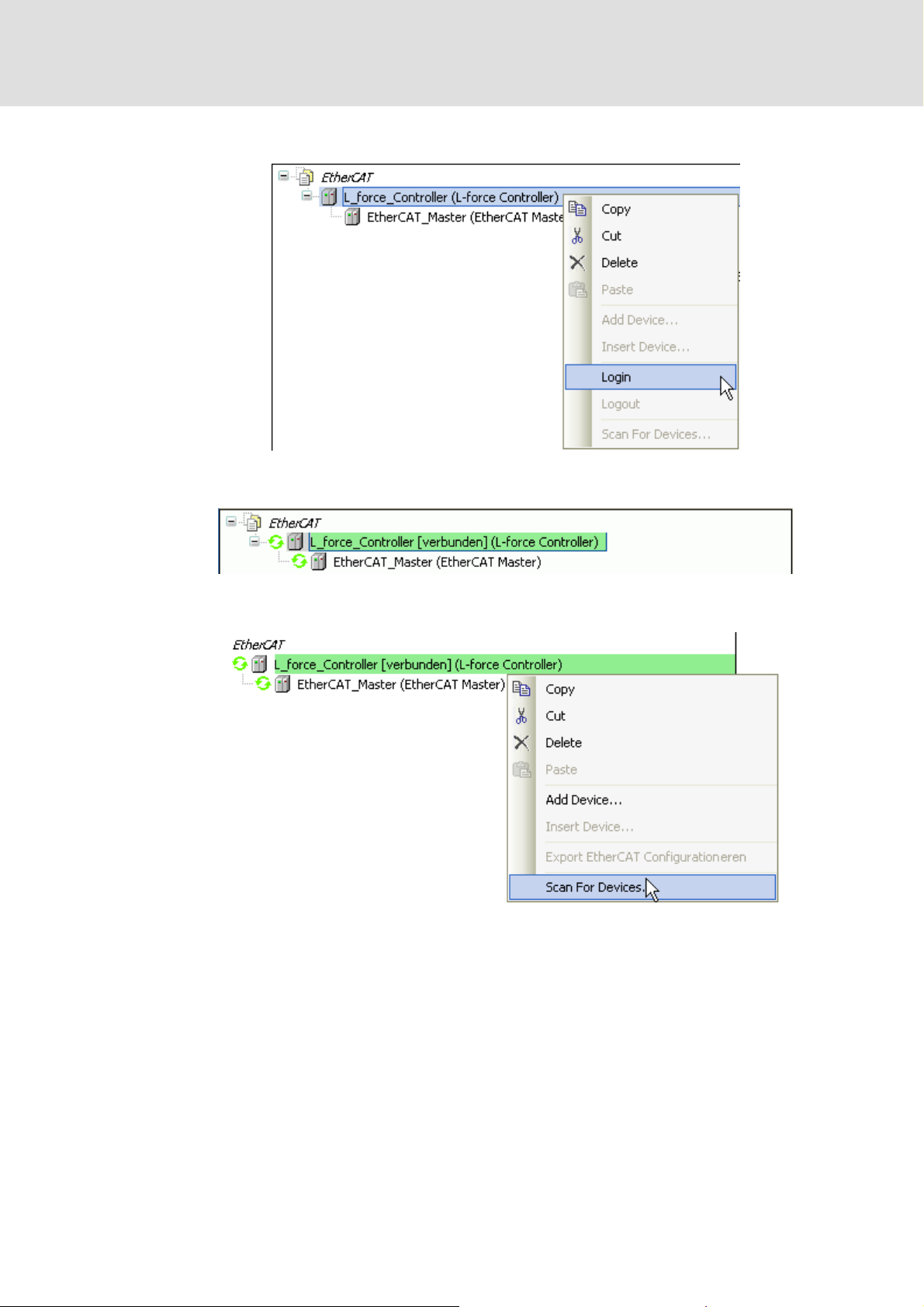

2. Execute the Login command in the context menu of the L-force Controller:

After a successful login, the L-force Controller (the industrial PC) is connected to the

engineering PC:

3. After a successful login, execute the Start Search command in the context menu of

the L-force Controller :

48 L DMS 3.1 EN 01/2011 TD17

Page 49

Control technology | EtherCAT communication manual

Commissioning of the system

Detailed commissioning steps

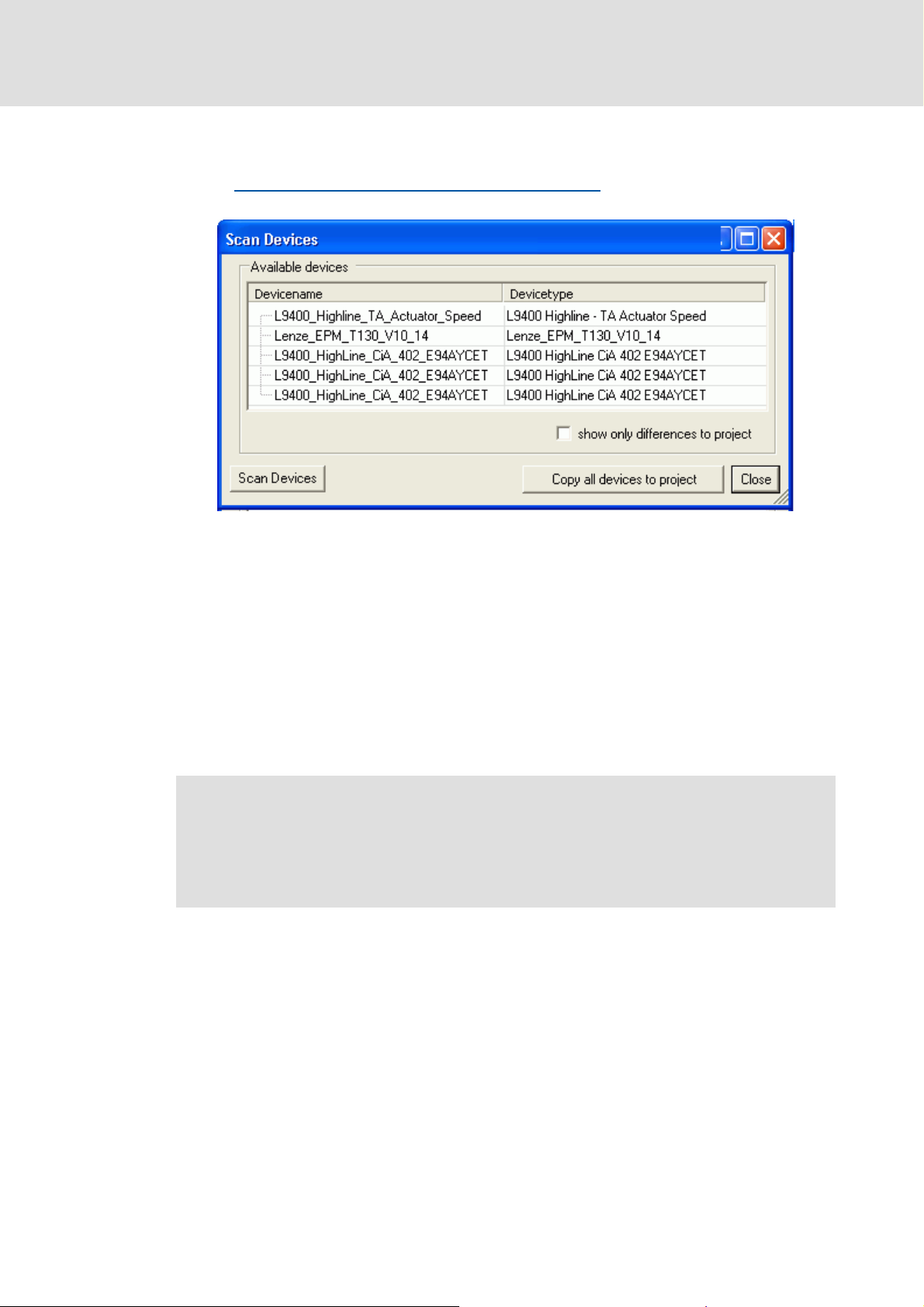

The »EtherCAT Configurator« determines the EtherCAT nodes available at the

fieldbus. In the Start Search dialog box, the devices are listed according to the

physical order at the fieldbus:

Further information on the Start Search dialog box can be found here:

Inserting devices available on the fieldbus into the »EtherCAT Configurator«

project ( 55)

DMS 3.1 EN 01/2011 TD17 L 49

Page 50

Control technology | EtherCAT communication manual

Commissioning of the system

Detailed commissioning steps

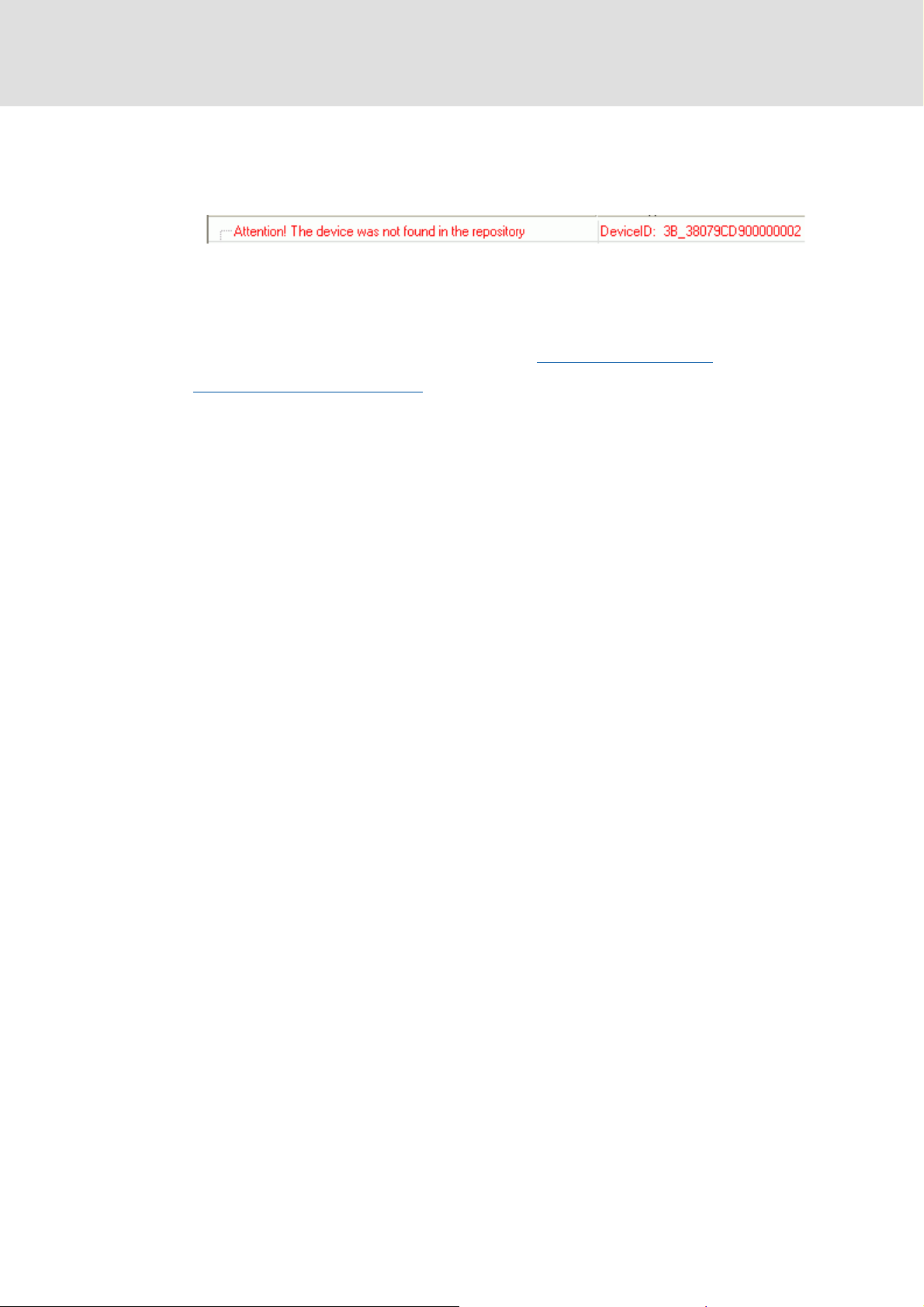

Missing device descriptions

If a device available at the fieldbus is not present in the device repository, an error message

within the Start Search dialog box will inform you about it:

The device cannot be interpolated into the project as the corresponding device

description has not been installed.

In order to install the device in the device repository, the corresponding device

description file from the manufacturer is required. The device identification (device ID)

can be helpful to identify the device (see also EtherCAT product codes

( 24)).

Importing missing field devices

( 59)

50 L DMS 3.1 EN 01/2011 TD17

Page 51

Control technology | EtherCAT communication manual

7.2.4.2 Fieldbus scan with the »scandf« command line tool

Fieldbus scanning command

Command: scanfd <interface> /option

The interface for the EtherCAT slaves to be scanned on the fieldbus is called ECAT.

Option Output on the console

/i Determine available interfaces

/t Display device information for every network node.

/f Display additional device parameters for every device if available.

/n Suppress prompt before execution of the fieldbus scan.

How to carry out a fieldbus scan:

1. Establish a Telnet connection to the IPC.

Commissioning of the system

Detailed commissioning steps

More detailed information is provided in the documentation for the IPC.

2. Call scanfd.exe via the command line box of the IPC to scan the fieldbus.

3. Determine the available interfaces of the IPC:

• Enter scanfd /i.

Output example:

The fieldbus scanner displays the available interfaces:

• ECAT for the EtherCAT-capable field devices,

• CAN1 and CAN2 for the CAN field devices.

DMS 3.1 EN 01/2011 TD17 L 51

Page 52

Control technology | EtherCAT communication manual

Commissioning of the system

Detailed commissioning steps

4. Determine the field devices physically available at the ECAT

interface:

• scanfd ecat /t /f /n

Output example:

After executing the scanfd.exe file, the console displays the result of the fieldbus

scan. The first output line contains the number (x) of slaves found on the fieldbus:

x devices at interface ´ecat´!

The further output lines provide informationen on each slave:

52 L DMS 3.1 EN 01/2011 TD17

Page 53

Control technology | EtherCAT communication manual

Commissioning of the system

Detailed commissioning steps

Information about the field devices

The individual slaves are generally listed according to the auto-increment addressing

scheme in their physically order.

The first slave connected to the master has the node address 0. The second slave has

the negative node address -1. The other slaves have negative node addresses (-n)

corresponding to their positions on the fieldbus.

Information Function

DeviceID Node address of the slave:

• Display of the auto-increment address.

• The first slave has the node address 0.

Vendor Name of the manufacturer

ProductCode Product designation in hexadecimal format

(see also EtherCAT product codes

Examples:

#x38079cd9: Lenze Servo Drive 9400 HighLine TA speed acuating drive

#x38079d3d: Lenze Servo Drive 9400 HighLine CiA402

RevisionNumber Version number in hexadecimal format

SerialNumber Serial number in hexadecimal format

( 24))

Troubleshooting

If the fieldbus scan does not find any field devices at the selected interface, the following

error message appears:

How to check the physical configuration:

1. Analyse the messages in the Logbook of the IPC

( 142)

2. Check the wiring.

( 140). IPC logbook messages

DMS 3.1 EN 01/2011 TD17 L 53

Page 54

Control technology | EtherCAT communication manual

Commissioning of the system

Detailed commissioning steps

7.2.5 Configuration in the »Engineer«

The »Engineer« is used to configure and parameterise the Lenze field devices connected to

the EtherCAT bus.

Note!

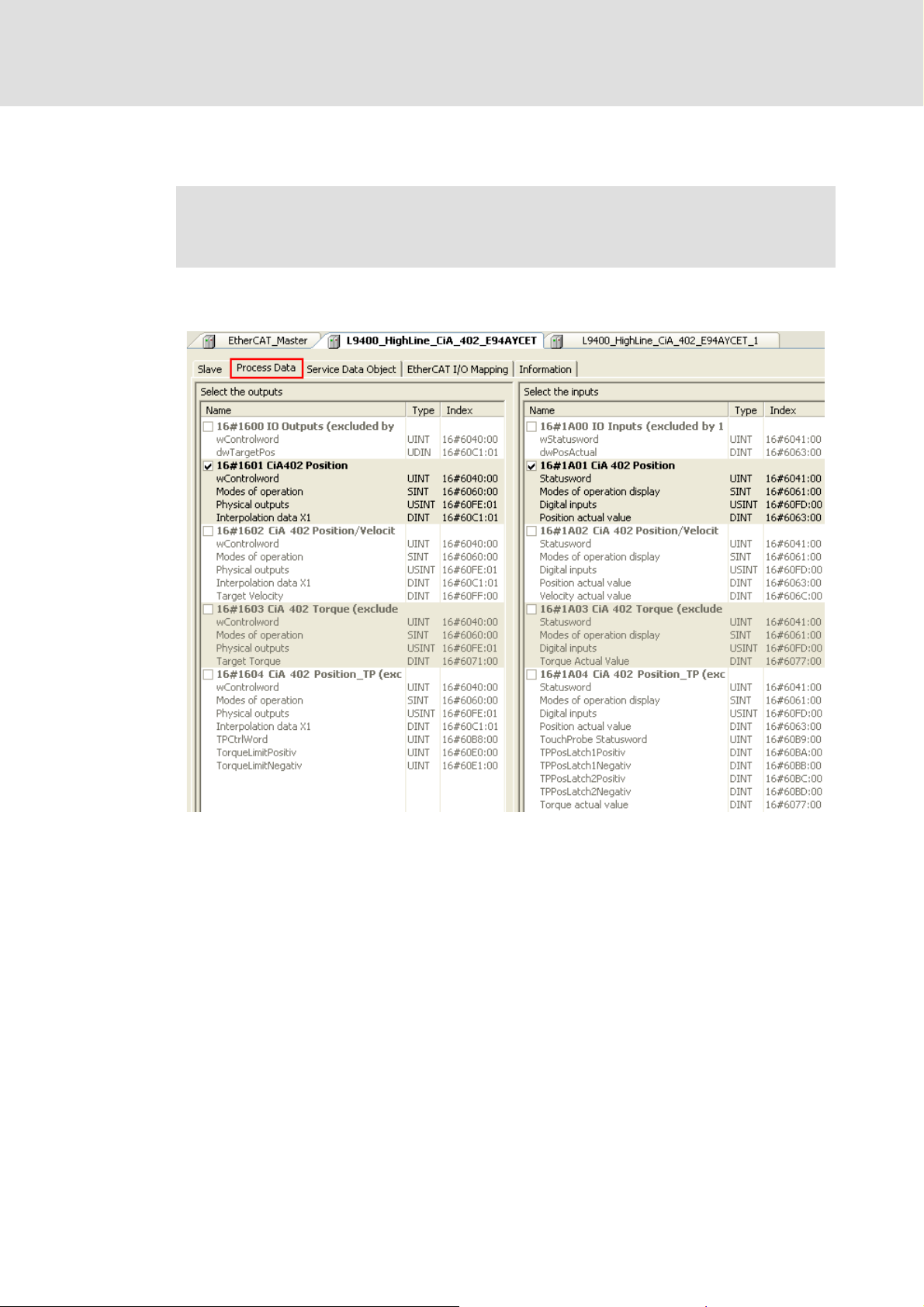

PDO mapping settings

The mapping required for a cross communication must be created in the

»EtherCAT Configurator«/»PLC Designer«.

During start-up of the PLC, the complete configuration/PDO mapping is written

into the EtherCAT slaves. Mapping entries, e.g. from the »Engineer«, are not

overwritten.

Executing PDO mapping

Editing the EtherCAT I/O image ( 66)

( 65)

How to configure the drives in the »Engineer«:

1. Create a new »Engineer« project or open an already existing project.

2. Insert the Lenze field devices in the device tree and select the hardware

configuration of the axes.

For Servo Drives 9400:

• Select inverter.

• Select motor.

• Select modules.

3. Assign an application to the field devices and set the drive parameters.

4. Save the »Engineer« project to the project folder.

54 L DMS 3.1 EN 01/2011 TD17

Page 55

Control technology | EtherCAT communication manual

Commissioning of the system

Detailed commissioning steps

7.2.6 Inserting devices available on the fieldbus into the »EtherCAT Configurator« project

After a Fieldbus scan with the »EtherCAT Configurator«

listed according to their physical order at the fieldbus in the Start Search dialog box:

Here you can...

assign individual unique device names in the Device name column. Observe the

IEC 61131 syntax (no spaces and leading digits in variable names)!

select individual devices in the Device name column and copy them into your

»EtherCAT Configurator« project:

– Activate the Copy into project button.

–The Copy into project button will only appear if one or more devices are selected.

( 47) the EtherCAT nodes are

copy all available devices into your »EtherCAT Configurator« project.

– Activate the Copy all devices into project button.

Note!

We recommend to copy all devices into the project.

After pasting you must check if the order of the devices in the project

corresponds to the physical order in the network.

( 55)

DMS 3.1 EN 01/2011 TD17 L 55

Page 56

Control technology | EtherCAT communication manual

Commissioning of the system

Detailed commissioning steps

7.2.7 Creating the configuration in the »EtherCAT Configurator«

The »EtherCAT Configurator« is used to set up the EtherCAT configuration. During this

process, the ECAT_PLC_CFG_1.XML and ECAT_MASTER_1.XML configuration files are

created.

These files...

illustrate the physical structure of the EtherCAT configuration;

contain synchronisation settings, SoftMotion parameter values (only of SoftMotion

nodes) and the variable mapping of the EtherCAT nodes.

At a later time, you have to

import the ECAT_PLC_CFG_1.XML file into the control configuration using the »PLC

Designer«.

write the ECAT_MASTER_1.XML file to the IPC.

Note!

• The order of the EtherCAT slaves in the device tree must correspond to the

physical order of the EtherCAT configuration.

• In order that the system works properly, end terminals must not be used

when setting up the system configuration in the device tree.

• For the integration of external devices, the »EtherCAT Configurator« only

Observe the following conditions before you lay out a topology in the »Engineer«:

SoftMotion operation is only possible with Servo Drives 9400 Highline CiA402.

The »EtherCAT Configurator« supports Lenze EtherCAT slaves and EtherCAT devices of

other manufacturers. The integration of third-party devices requires the respective

manufacturer's device descriptions.

Importing missing field devices

supports device descriptions meeting the standards.

• Select the cycle times, according to the technical data, from 1 ... 10 ms. The

cycle times are carried out by the configurations in the »EtherCAT

Configurator« and »PLC Designer«.

( 59)

56 L DMS 3.1 EN 01/2011 TD17

Page 57

Control technology | EtherCAT communication manual

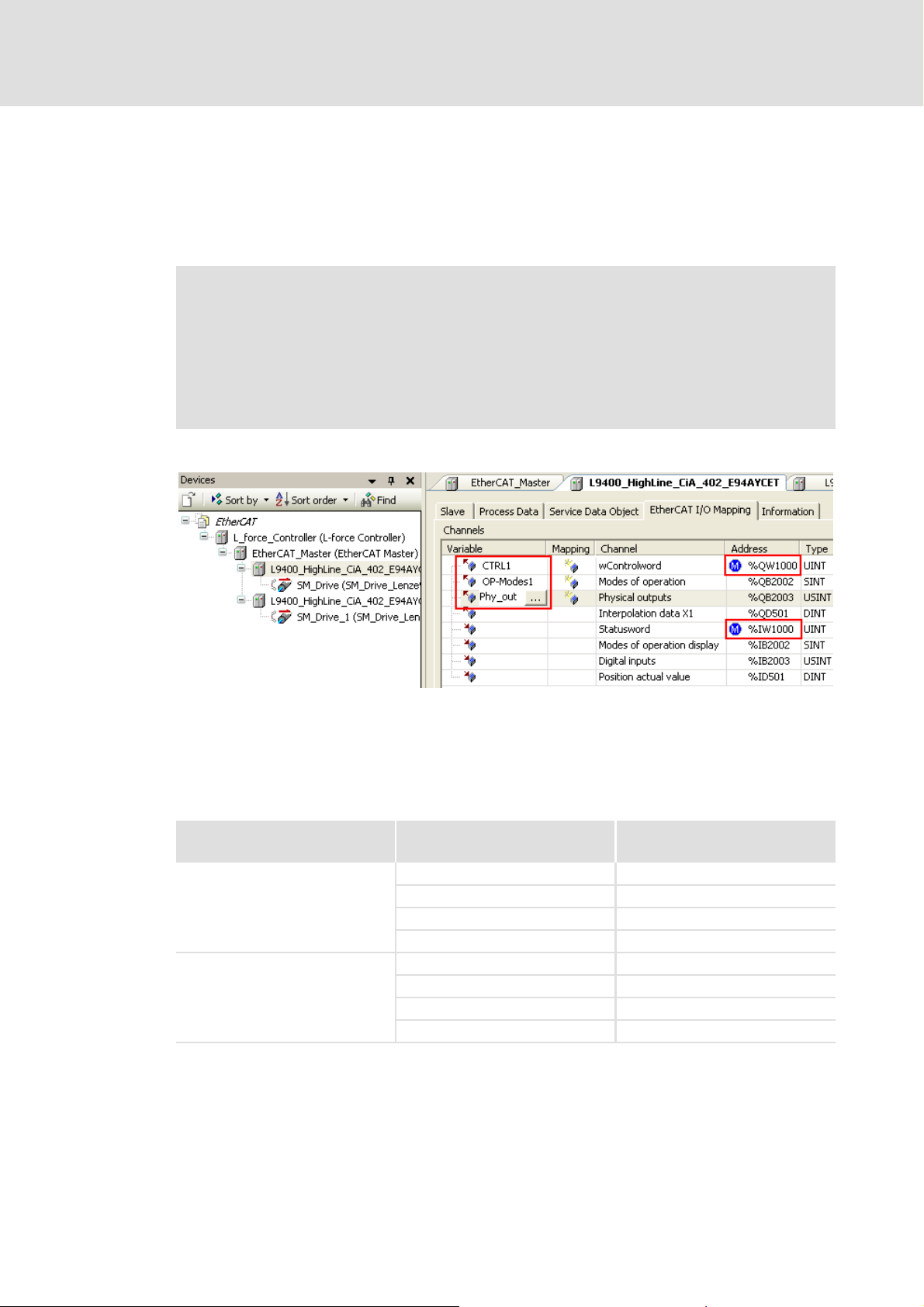

7.2.7.1 Setting up the EtherCAT configuration in the device tree

Note!

The order of the devices in the »EtherCAT Configurator« must correspond with