Page 1

Automation Systems

Controller-based

Automation

EtherCAT®

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Communication Manual EN

Ä.O5ôä

13462095

L

Page 2

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 6

1.1 Document history _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 8

1.2 Conventions used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 9

1.3 Terminology used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 10

1.4 Definition of the notes used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

2Safety instructions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 13

3 Controller-based Automation: Central motion control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 14

4 The Lenze automation system with EtherCAT _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 17

4.1 Brief description of EtherCAT _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 17

4.1.1 Structure of the EtherCAT bus system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 18

4.1.2 Communication _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 19

4.1.2.1 The EtherCAT state machine _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 20

4.1.2.2 Addressing of the slaves _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 22

4.1.2.3 Working counter _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 23

4.2 Required hardware components _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 24

4.2.1 Field devices _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 24

4.2.2 The Lenze Controller - the central component _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 25

4.2.3 EtherCAT product codes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 26

4.2.4 The EtherCAT interface of the Lenze Controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 28

4.3 Lenze Engineering tools _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 29

4.4 Interaction of the components _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 30

4.4.1 The state machine of the Lenze control technology _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 30

4.4.2 Communication between the Engineering PC and the field devices _ _ _ _ _ _ _ _ _ _ _ _ 32

4.4.2.1 EtherCAT bus not in operation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 32

4.4.2.2 EtherCAT bus in operation (gateway function) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 33

5 Technical data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 34

5.1 General data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 34

5.2 EtherCAT interface of the Lenze Controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 34

5.3 Communication times and drive-specific data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 35

6 Synchronisation with "Distributed clocks" (DC) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 36

6.1 Synchronous communication _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 37

6.2 Test of DC synchronicity _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 38

2 Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 3

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7 Commissioning of the system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 39

7.1 Sample projects (Application Samples) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 39

7.2 Overview of the commissioning steps _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 40

7.3 Detailed description of the commissioning steps _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 42

7.3.1 Planning the bus topology _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 42

7.3.2 Installing field devices _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 43

7.3.3 Create a project folder _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 43

7.3.4 Commissioning the i700 servo inverter _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 44

7.3.4.1 i700 parameter management in the Controller-based Automation

system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 45

7.3.4.2 i700 parameter management in »EASY Starter« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 49

7.3.4.3 Exchanging i700 parameter sets between »PLC Designer« and

»EASY Starter« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 51

7.3.4.4 Overview of the commissioning steps _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 52

7.3.4.5 Checking the wiring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 53

7.3.4.6 Entering motor and controller settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 54

7.3.4.7 Setting the feedback system for servo control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 57

7.3.4.8 Integrating the L_SMC_AxisBasicControl function block _ _ _ _ _ _ _ _ _ _ _ _ 59

7.3.4.9 Executing manual control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 65

7.3.4.10 Optimising control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 67

7.3.5 Commissioning other Lenze field devices _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 70

7.3.6 Creating a PLC program with a target system (Logic/Motion) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 71

7.3.7 Configuring the communication parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 73

7.3.8 Determining the physical EtherCAT configuration (fieldbus scan) _ _ _ _ _ _ _ _ _ _ _ _ _ 75

7.3.9 Importing missing devices / device description files _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 78

7.3.10 Creating a control configuration (adding field devices) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 79

7.3.11 Creating a task _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 82

7.3.12 Setting a DC synchronisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 87

7.3.13 Setting SoftMotion parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 92

7.3.14 Processing EtherCAT I/O mapping _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 95

7.3.14.1 Entering the settings for PDO mapping _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 96

7.3.14.2 Configuring individual PDO mapping _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 97

7.3.14.3 PDO mapping for logic devices _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 100

7.3.14.4 Using PDO mapping settings from »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 101

7.3.15 Compiling the PLC program code _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 103

7.3.16 Logging in on the controller with the »PLC Designer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 103

7.3.17 Starting the PLC program _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 103

7.3.18 Start parameters of the Servo Drives 9400 HighLine CiA 402 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 103

7.3.19 Optimising the task utilisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 104

7.4 State diagram for commissioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 105

8 Mixed operation - EtherCAT with other bus systems _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 106

8.1 CANopen and EtherCAT _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 107

8.2 PROFIBUS as the logic bus and EtherCAT as a logic bus or motion bus _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 108

8.3 EtherCAT and PROFINET _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 109

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 3

Page 4

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9 Function library L_IODrvEtherCAT.lib _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 110

9.1 Overview of functions and function blocks _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 114

9.2 CoE Interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 115

9.2.1 Reading and writing parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 115

9.2.1.1 Reading parameters (SDO upload) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 116

9.2.1.2 Writing parameters (SDO download) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 120

9.2.2 L_ETC_CoE_SdoRead (FB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 125

9.2.3 L_ETC_CoE_SdoRead4 (FB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 127

9.2.4 L_ETC_CoE_SdoReadEx (FB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 129

9.2.5 L_ETC_CoE_SdoWrite (FB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 131

9.2.6 L_ETC_CoE_SdoWrite4 (FB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 133

9.2.7 L_ETC_CoE_SdoWriteEx (FB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 135

9.3 Device Interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 137

9.3.1 ETCSlave (FB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 137

9.3.2 L_ETC_GetSlave (FUN) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 138

9.3.3 L_ETC_IoControl (FUN) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 139

9.3.4 L_IODrvEtherCAT (FB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 140

9.4 Diagnostic Interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 141

9.4.1 L_ETC_GetEmergency (FB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 141

9.4.2 L_ETC_GetErrorString (FUN) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 143

9.4.3 L_ETC_GetMasterDiagnostic (FB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 144

9.4.4 L_ETC_ReadErrCnt (FB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 145

9.4.5 L_ETC_ResetErrCnt (FB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 146

9.5 FoE interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 147

9.5.1 L_ETC_FoE_Read (FB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 147

9.5.2 L_ETC_FoE_Write (FB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 149

9.6 State Machine Interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 151

9.6.1 L_ETC_GetMasterState (FB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 151

9.6.2 L_ETC_GetSlaveState (FB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 152

9.6.3 L_ETC_SetMasterState (FB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 153

9.6.4 L_ETC_SetSlaveState (FB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 154

9.7 Data types _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 155

9.7.1 L_ETC_COE_EMERGENCY _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 155

9.7.2 L_ETC_COE_EMERGENCY_BUFFER_DATA _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 155

9.7.3 L_ETC_COE_FLAGS _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 155

9.7.4 L_ETC_DIAGNOSTIC _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 156

9.7.5 L_ETC_EVTPARAM_PARAMETERTRANSFER _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 156

9.7.6 L_ETC_ERRORCODE _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 157

9.7.7 L_ETC_IOCTLOPARMS _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 157

9.7.8 L_ETC_LANGUAGE _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 157

9.7.9 L_ETC_SLAVE_PORTS _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 157

9.7.10 L_ETC_PARAMETERTRANSFERSERVICE_CODE _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 158

9.7.11 L_ETC_STATE (EtherCAT status) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 158

4 Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 5

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

10 Restarting the EtherCAT fieldbus _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 159

11 Defining the cycle time of the PLC project _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 160

11.1 Determining the task utilisation of the application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 160

11.2 Optimising the system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 162

12 Diagnostics _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 163

12.1 Diagnostics with the »PLC Designer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 163

12.1.1 Representation in the online mode _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 163

12.1.2 Diagnostic tabs of the EtherCAT master _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 164

12.1.3 Display window for EtherCAT logbook messages _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 165

12.1.4 Visualisation of the function block L_ETC_GetMasterDiagnostic _ _ _ _ _ _ _ _ _ _ _ _ _ _ 166

12.2 Diagnostic codes in the »WebConfig« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 169

12.3 Logbook of the Lenze Controller in the »WebConfig« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 170

12.4 Error counters of the EtherCAT slaves _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 172

12.4.1 Error types "Errors" and "Forwarded Errors" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 172

12.4.2 Error counter reset from the application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 173

12.5 Error scenarios _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 174

12.5.1 The EtherCAT bus does not assume the "Pre-Operational" state. _ _ _ _ _ _ _ _ _ _ _ _ _ _ 175

12.5.2 The EtherCAT bus does not assume the "Operational" state _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 176

12.5.3 Messages: WKC Error / Not all slaves "Operational" / SyncManager Watchdog _ _ _ _ _ _ 177

12.5.4 Error during process data transfer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 178

12.5.5 Message: EtherCAT cable not connected / connected _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 180

12.5.6 Message: Frame Response Error _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 180

12.5.7 Shafts make clicking noises _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 181

12.5.8 Shafts do not rotate _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 182

12.6 System error messages _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 183

12.6.1 General error codes (L_ETC_ERRORCODE) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 183

12.6.2 Lenze Controller logbook messages _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 190

12.6.3 SDO abort codes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 195

13 Parameter reference _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 196

Index _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 201

Your opinion is important to us _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 204

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 5

Page 6

1 About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation

This documentation ...

• contains detailed information about the commissioning, configuration, and diagnostics of the

EtherCAT

• is part of the "Controller-based Automation" manual collection. It consists of the following sets

of documentation:

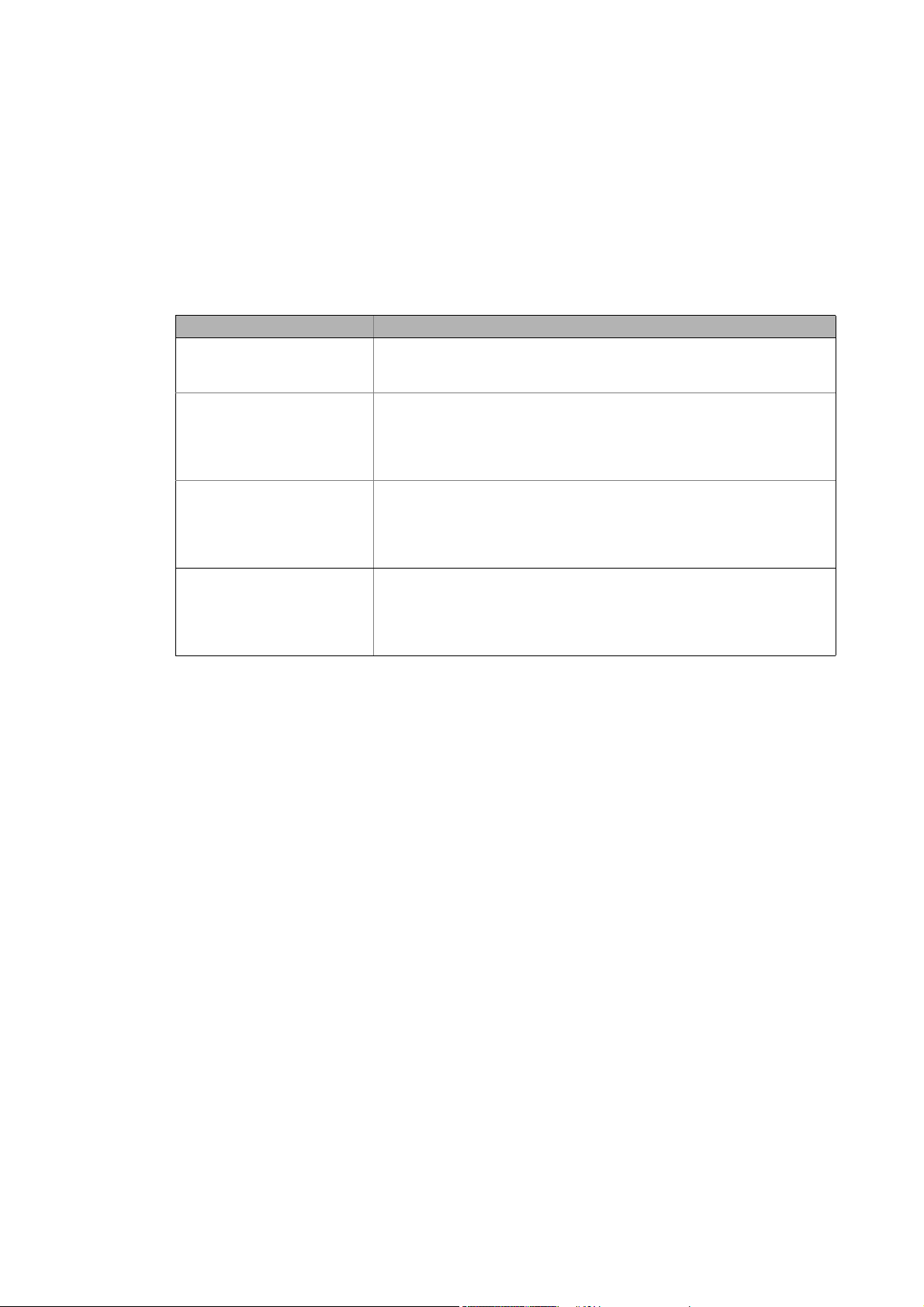

Documentation type Subject

System manuals System overview/sample topologies

Communication manuals

Online helps

Reference manuals

Online helps

Software manuals

Online helps

® bus system as part of the Lenze automation system "Controller-based Automation".

• Controller-based Automation

• Visualising

Bus systems

• Controller-based Automation EtherCAT®

• Controller-based Automation CANopen®

• Controller-based Automation PROFIBUS®

• Controller-based Automation PROFINET®

Lenze Controller:

• Controller 3200 C

• Controller c300

• Controller p300

• Controller p500

Lenze Engineering Tools:

• »PLC Designer«: Programming

• »Engineer«: Inverter configuration

• »VisiWinNET® Smart«: Visualisation

• »Backup & Restore«: Back up/restore data

6 Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 7

1 About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

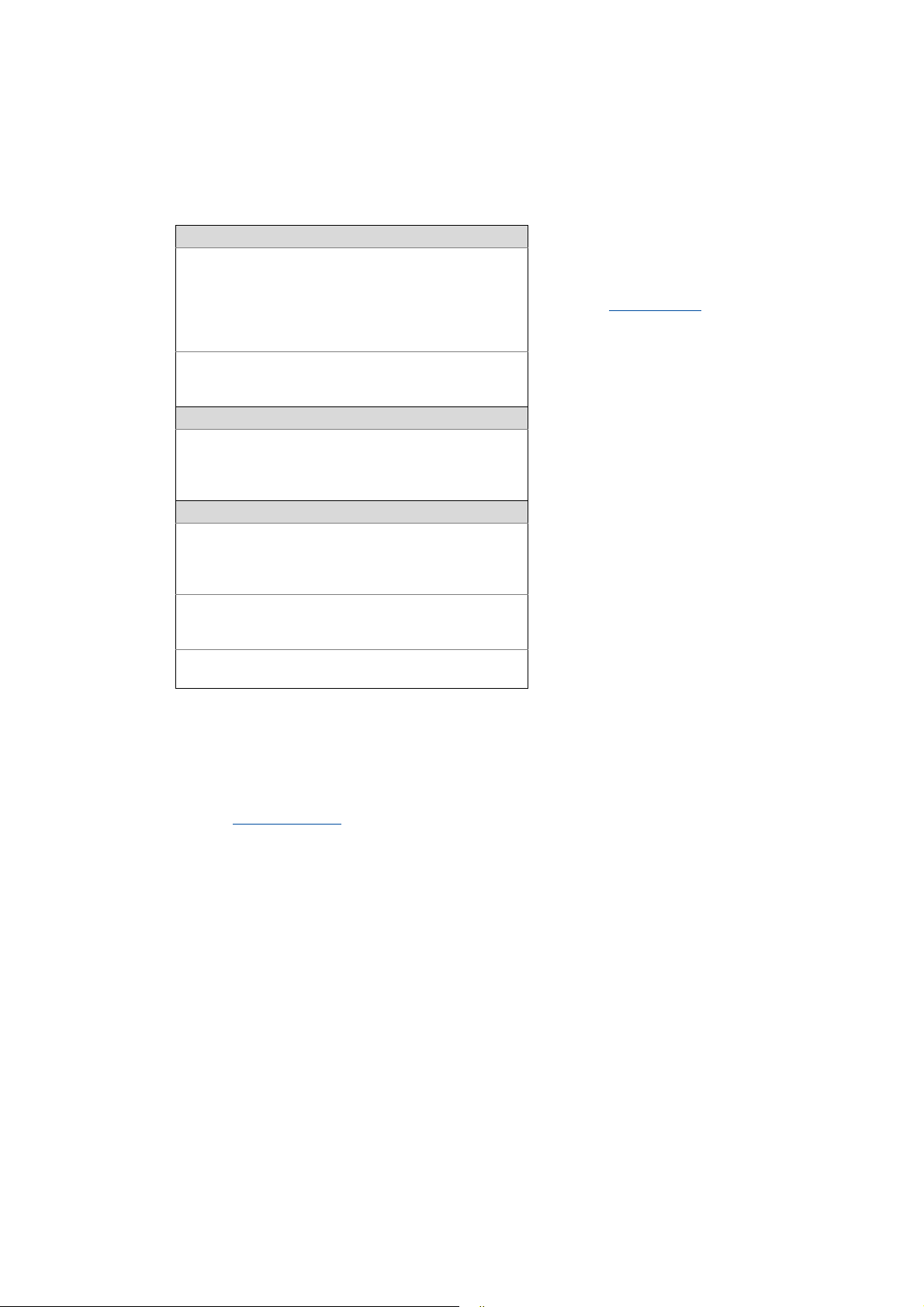

More technical documentation for Lenze components

Further information on Lenze products which can be used in conjunction with Controller-based

Automation can be found in the following sets of documentation:

Mounting & wiring Symbols:

Mounting instructions

• Controller

• Communication cards (MC-xxx)

• I/O system 1000 (EPM-Sxxx)

• Inverter, Servo Drives

•Communication modules

Operating instructions

• Controller

• Servo system ECS (ECSxE, ECSxM)

Sample applications/Using application templates

Online help/software manuals

• Application Sample i700

• Application Samples

• ApplicationTemplate

Parameter setting, configuration, commissioning

Online help/reference manuals

•L-force Controller

• Inverter, Servo Drives

• I/O system 1000 (EPM-Sxxx)

Online help/communication manuals

• Bus systems

•Communication modules

Operating instructions

• Servo system ECS (ECSxE, ECSxM)

Printed documentation

Online help in the Lenze Engineering

Tool (also available as PDF file at

www.lenze.com

.)

Tip!

Current documentation and software updates with regard to Lenze products can be found

in the download area at:

www.lenze.com

Target group

This documentation is intended for persons who plan, install, commission and maintain the

networking of devices as part of the Lenze automation system "Controller-based Automation".

Information on validity

The information provided in this documentation is valid for the Lenze automation system

"Controller-based Automation" from version 3.

Screenshots/application examples

All screenshots in this documentation are application examples. Depending on the firmware

version of the field devices and the software version of the Engineering tools installed (e.g. »PLC

Designer« ), screenshots in this documentation may differ from the representation on the screen.

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 7

Page 8

1 About this documentation

1.1 Document history

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.1 Document history

Version Description

1.0 09/2008 TD17 First edition

2.0 05/2009 TD17 General revision

3.0 10/2009 TD17 General revision

4.0 10/2010 TD17 Commissioning and configuration with the Lenze »PLC Designer« V3.x

4.1 03/2011 TD17 • Special features for the ECS servo system added.

• References to Lenze sample projects for EtherCAT logic field devices (device

application + PLC program) added.

Commissioning of the system

4.2 12/2011 TD17 • Revision on the Lenze automation system"Controller-based Automation",

Release 3.2

•Chapter Function library L_IODrvEtherCAT.lib

5.0 08/2012 TD17 • Revision on the Lenze automation system"Controller-based Automation",

Release 3.3

• Information on the Servo-Inverter i700 added.

• Information on the ECS servo system and »GDC« removed.

6.0 11/2012 TD17 • General corrections

•New layout

6.1 12/2012 TD17 New function block L_ETC_GetEmergency (FB)

system "Controller-based Automation", Release 3.4

6.3 11/2013 TD17 Revision on the Lenze automation system"Controller-based Automation",

release 3.6

6.4 04/2014 TD17 Revision on the Lenze automation system"Controller-based Automation",

release 3.8

( 39)

( 110) updated.

( 141) in the Lenze automation

8

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 9

1 About this documentation

1.2 Conventions used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.2 Conventions used

This documentation uses the following conventions to distinguish different types of information:

Type of information Identification Examples/notes

Numbers

Decimal Normal spelling Example: 1234

Decimal separator Point In general, the decimal point is used.

Example: 1234.56

Hexadecimal 0x[0 ... 9, A ... F] Example: 0x60F4

Binary

• Nibble

Text

Program name » « PC software

Window italics The message window... / The Options dialog box ...

Variable name Setting bEnable to TRUE...

Control element Bold The OK button ... / The Copy command ... / The Properties

Sequence of menu

commands

Shortcut <Bold> Use <F1> to open the online help.

Program code Courier IF var1 < var2 THEN

Keyword Courier bold

Hyperlink Underlined

Icons

Page reference ( 9) Optically highlighted reference to another page. Can be

Step-by-step instructions

0b[0, 1] Example: ’0b0110’

Example: ’0b0110.0100’

Example: Lenze »Engineer«

tab ... / The Name input field ...

If several successive commands are required for

executing a function, the individual commands are

separated from each other by an arrow: Select the

command File

If a key combination is required for a command, a "+" is

placed between the key identifiers: With

<Shift>+<ESC>...

a = a + 1

END IF

Optically highlighted reference to another topic. Can be

activated with a mouse-click in this documentation.

activated with a mouse-click in this documentation.

Step-by-step instructions are marked by a pictograph.

Open to...

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 9

Page 10

1 About this documentation

1.3 Terminology used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.3 Terminology used

Term Meaning

CAN CAN (Controller Area Network) is an asynchronous, serial fieldbus system.

CANopen® is a communication protocol based on CAN. The Lenze system bus (CAN on board)

operates with a subset of this communication protocol.

CANopen® is a registered Community Trade Mark of the CAN User Organisation CiA® (CAN

in Automation e. V.).

Code Parameter for parameterising or monitoring the field device. The term is also referred to as

CoE CANopen over EtherCAT

Controller The controller is the central component of the automation system which controls the Logic

DC Distributed clocks (distributed synchronised clocks)

Engineering PC The Engineering PC and the Engineering tools installed serve to configure and parameterise

Engineering tools Lenze software solutions for simply engineering in all phases:

FB Function block (contained in a function library)

Fieldbus stations Controller (PLC) and inverter integrated in the bus system (EtherCAT)

Field device

FoE File Access over EtherCAT

FUN Function (contained in a function library)

Index Each object has a unique index for addressing purposes.

Inverter Generic term for Lenze frequency inverters, servo inverters

PLC Programmable Logic Controller

Object "Container" for one or more parameters with which you can parameterise or monitor the

"index" in common usage.

and Motion functionalities (by means of the runtime software).

The controller communicates with the field devices via the fieldbus.

the system.

The Engineering PC communicates with the controller via Ethernet.

•»EASY Starter«

• »Engineer«

•»PLC Designer«

•»WebConfig«

•»VisiWinNET®«

•»IPC Backup & Restore«

Lenze Engineering tools

EtherCAT® (Ethernet for Controller and Automation Technology) is an Ethernet-based

fieldbus system which meets the application profile for industrial real-time systems.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff

Automation GmbH, Germany.

In this documentation, the index is shown as a hexadecimal value preceded by "0x", e.g.

"0x1000".

(German designation: SPS - Speicherprogrammierbare Steuerung)

PROFIBUS® (Process Fieldbus) is a common fieldbus system for the automation of machines

and production lines.

PROFIBUS® is a registered trademark and patented technology licensed by the PROFIBUS &

PROFINET International user organisation (PI).

PROFINET® (Process Field Network) is a real-time capable fieldbus system based on Ethernet.

PROFINET® is a registered trademark and patented technology licensed by the PROFIBUS &

PROFINET International (PI) user organisation.

fieldbus node.

( 29)

10

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 11

1 About this documentation

1.3 Terminology used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Term Meaning

Subcode If a code contains several parameters, they are stored in so-called "subcodes".

This manual uses a slash "/" as a separator between code and subcode (e.g. "C00118/3").

In normal usage, the term is also referred to as "Subindex".

Subindex If a code contains several parameters, they are stored in so-called "subindices".

In this documentation, the slash "/" is used as a separator between an index and subindex,

e.g. "0x1018/1".

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 11

Page 12

1 About this documentation

1.4 Definition of the notes used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.4 Definition of the notes used

The following signal words and symbols are used in this documentation to indicate dangers and

important information:

Safety instructions

Layout of the safety instructions:

Pictograph and signal word!

(characterises the type and severity of danger)

Note

(describes the danger and suggests how to prevent dangerous situations)

Pictograph Signal word Meaning

Danger! Danger of personal injury through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of damage to material assets

Refere nce to a n imm inent d ange r that m ay resu lt in deat h or s erious person al injury

if the corresponding measures are not taken.

Refere nce to a n imm inent d ange r that m ay resu lt in deat h or s erious person al injury

if the corresponding measures are not taken.

Reference to a possible danger that may result in damage to material assets if the

corresponding measures are not taken.

Application notes

Pictograph Signal word Meaning

Note! Important note to ensure trouble-free operation

Tip! Useful tip for easy handling

Reference to other documentation

12

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 13

2 Safety instructions

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2 Safety instructions

Observe the following safety instructions if you want to commission an inverter or a system with

the Lenze Controller.

Read the documentation supplied with the system components carefully before you

start commissioning the devices and the Lenze Controller!

The system manual contains safety instructions which must be observed!

Danger!

Risk of injury

There is risk of injury by ...

• unpredictable motor movements (e.g. an unintended direction of rotation, too high

speeds, or jerky movement);

• impermissible operating states during the parameterisation while there is an active

online connection to the device.

Possible consequences

Death or severe injuries

Protective measures

• If required, provide systems with installed inverters with additional monitoring and

protective devices according to the safety regulations valid in each case (e.g. law on

technical equipment, regulations for the prevention of accidents).

• During commissioning, maintain an adequate safety distance to the motor or the

machine parts driven by the motor.

Stop!

Damage or destruction of machine parts

Damage or destruction of machine parts can be caused by ...

• unpredictable motor movements (e.g. an unintended direction of rotation, too high

speeds, or jerky movement);

• impermissible operating states during the parameterisation while there is an active

online connection to the device.

Possible consequences

Damage or destruction of machine parts

Protective measures

If required, provide systems with installed inverters with additional monitoring and

protective devices according to the safety regulations valid in each case (e.g. law on

technical equipment, regulations for the prevention of accidents).

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 13

Page 14

3 Controller-based Automation: Central motion control

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

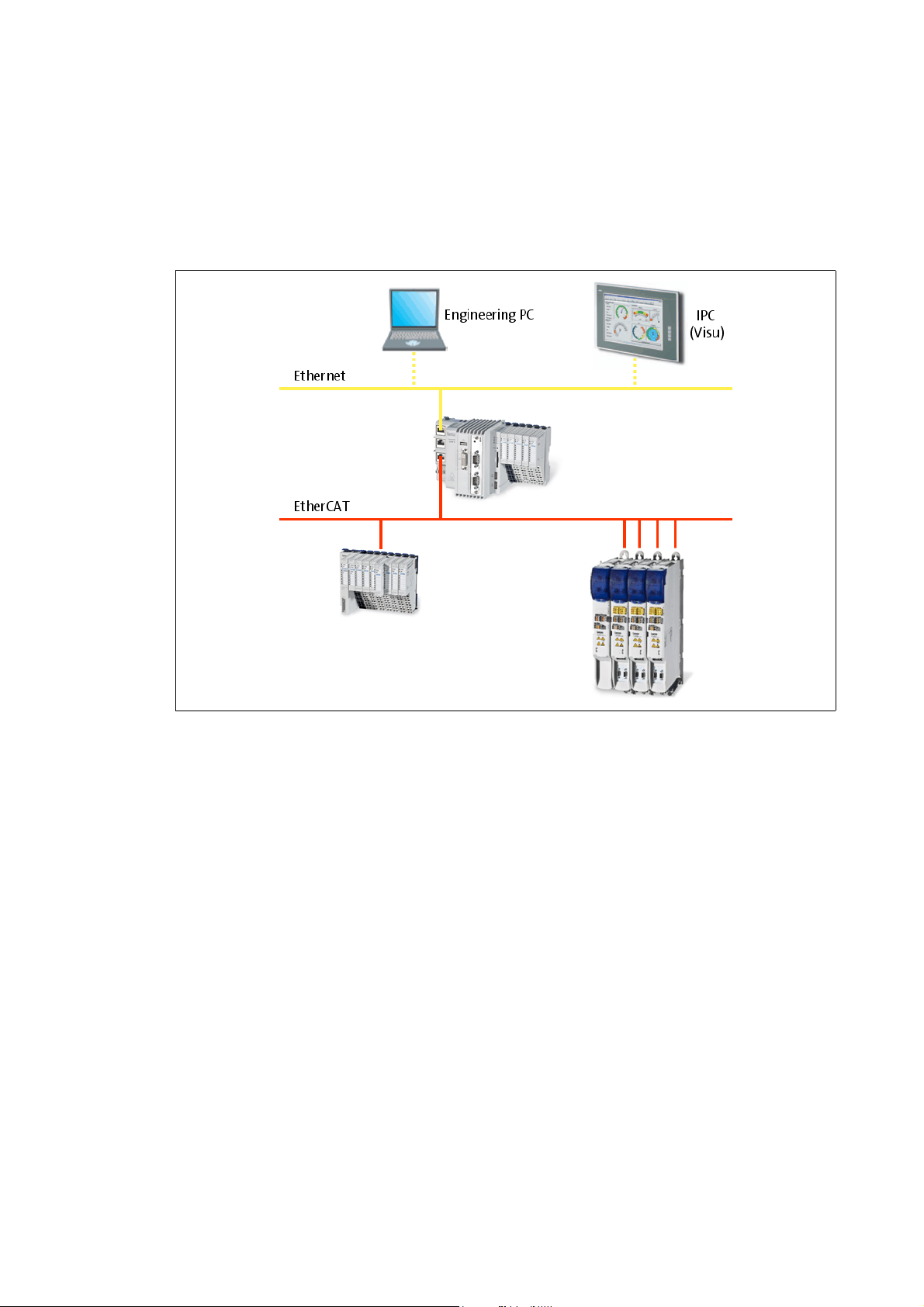

3 Controller-based Automation: Central motion control

The Lenze automation system "Controller-based Automation" serves to create complex automation

solutions with central motion control. Here, the Controller is the control centre of the system.

System structure of the Controller-based Automation: "All from one single source"

[3-1] Example: EtherCAT bus system with a 3231 C controller, a 1000 I/O system and an i700 servo inverter

14 Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 15

3 Controller-based Automation: Central motion control

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Lenze provides especially coordinated system components:

• Engineering software

The Lenze Engineering tools

to parameterise, configure and diagnose the system. The Engineering PC communicates with

the Controller via Ethernet.

•Controller

The Lenze Controller is available as Panel Controller with integrated touch display and as

Cabinet Controller in control cabinet design.

Cabinet Controllers provide a direct coupling of the I/O system 100 via the integrated backplane

bus.

The runtime software of the Lenze Controllers provides the control and/or visualisation of

motion sequences. The following software versions are available:

• "Logic": Sequence control in the Controller, motion control in the inverter

• "Motion": Sequence control and motion control in the Controller, inverter as actuating drive

• "Visu": Optional visualisation of the automation system, can be used separately or in addition

to "Logic" or "Motion"

An external monitor panel/display can be connected to the Cabinet Controller 3231 C/

3241 C.

• Without software: Controller as single component with operating system only

•Bus systems

EtherCAT is a standard "on board" bus system of the Controller-based Automation. EtherCAT

enables the control of all nodes (Motion/Logic) on one common fieldbus.

Optionally, CANopen, PROFIBUS and PROFINET can be used as extended topologies.

The Controllers c300/p300 have a CANopen interface "on board" as well (in addition to

EtherCAT).

• Inverter (e.g. Servo Inverter i700)

( 29) on your Engineering PC (Windows operating system ) serve

"Logic & Motion" runtime software

The "Controller-based Automation" system allows for the central control of devices for Logic and

Motion applications. The runtime software runs on the Controller.

In case of Logic applications, the sequence control is carried out in the Controller and the motion

control is carried out in the inverter.

In case of Motion applications , the sequence control and motion control are carried out in the

Controller. The inverter is used as actuating drive.

• Motion applications make special demands on the cycle time and real-time capability of the bus

system between the Controller and the subordinate fieldbus nodes.

• this is for instance the case if the field devices, for example, are to move in a synchronised way

or if position setpoints are to be transmitted.

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 15

Page 16

3 Controller-based Automation: Central motion control

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

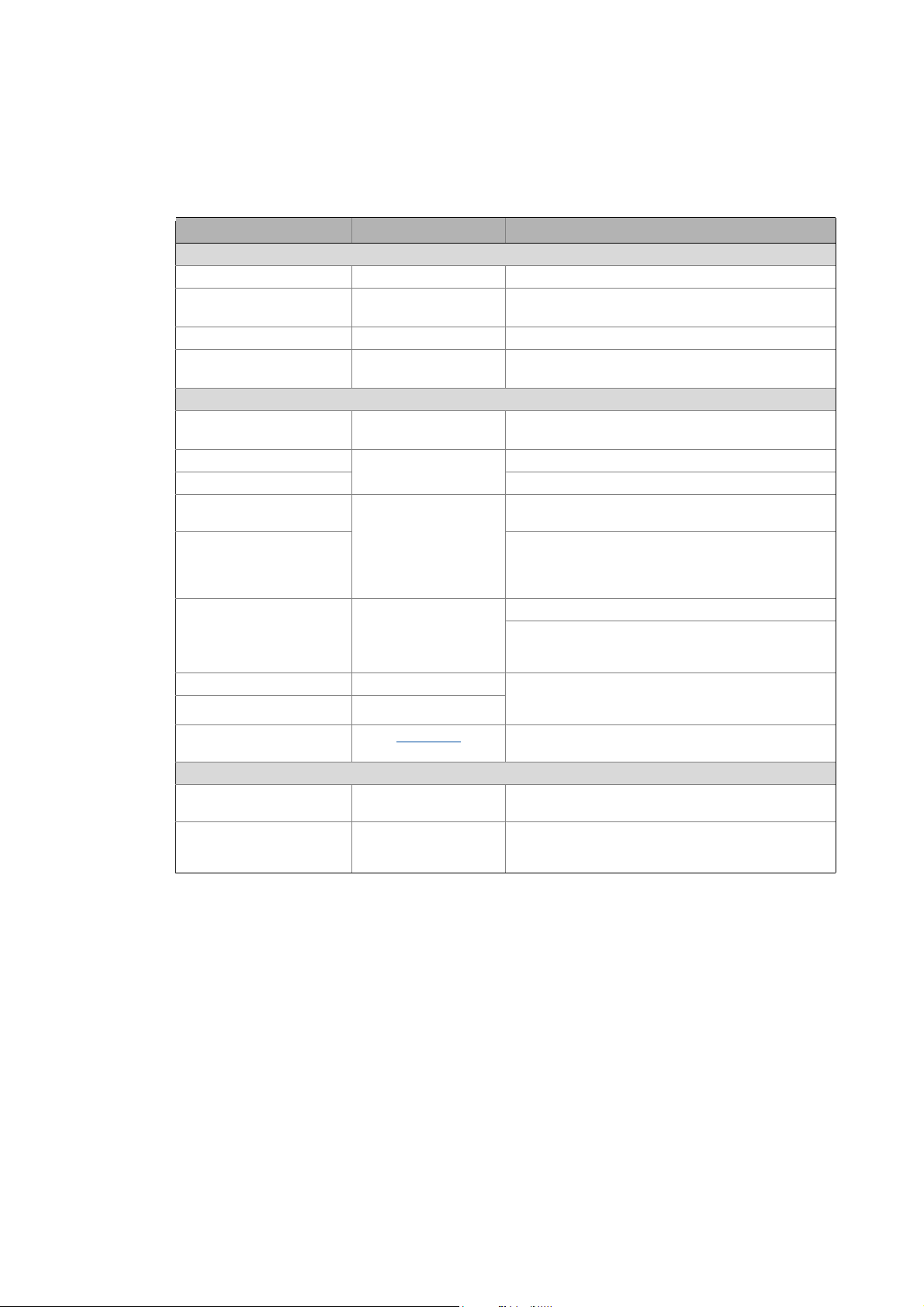

Fieldbus communication

The Lenze Controllers have different interfaces for fieldbus communication:

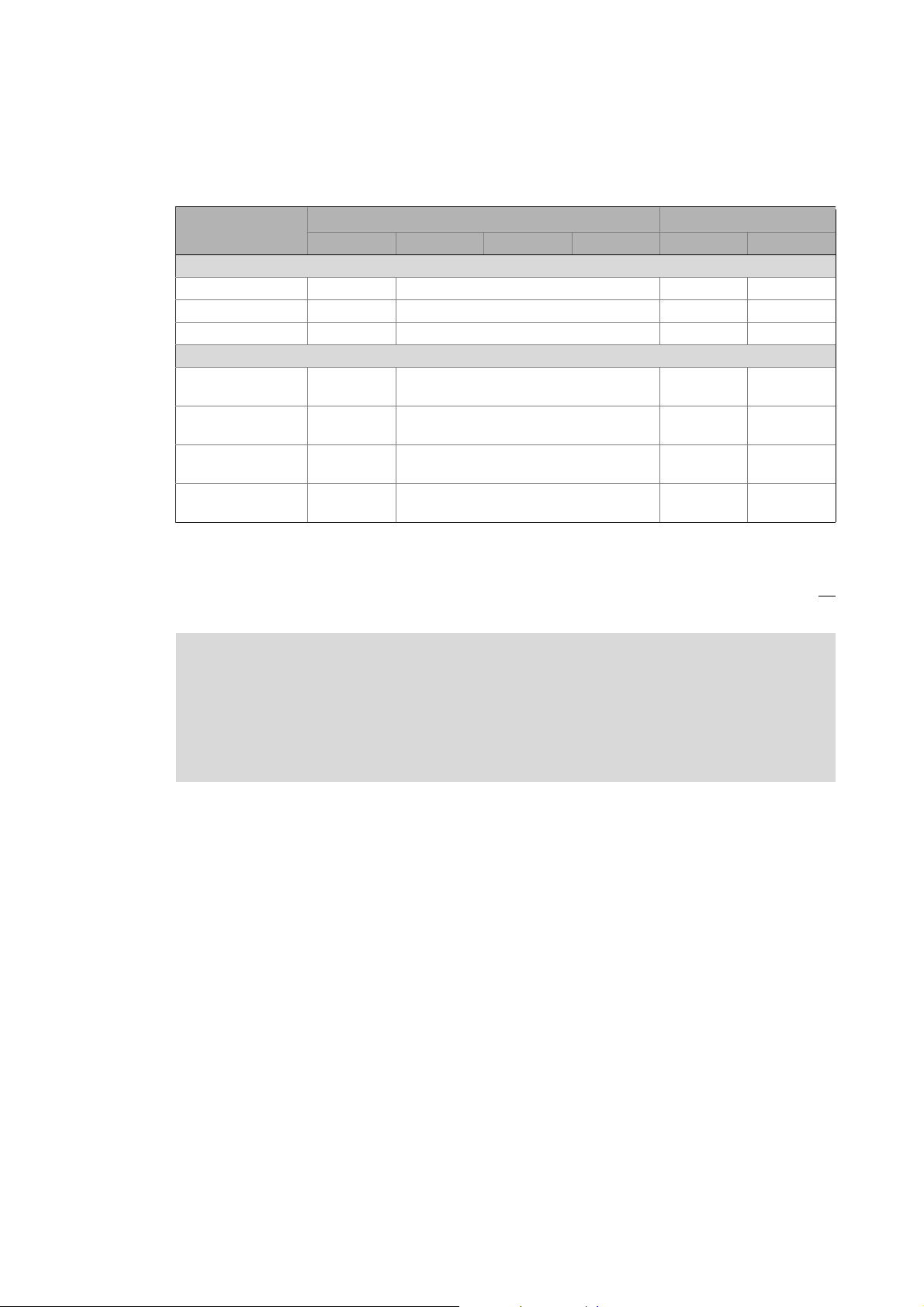

Area Cabinet Controller Panel Controller

c300 3221 C 3231 C 3241 C p300 p500

Interfaces (on board)

Ethernet1212

EtherCAT 1

CANopen 1

Optional interfaces (communication cards)

CANopen

MC-CAN2

PROFIBUS master

MC-PBM

PROFIBUS slave

MC-PBS

PROFINET device

MC-PND

1)

2)

- -

- -

- -

- -

11

-1

1)

2)

1

-

1) In preparation

2) Only the CAN master functionality is supported.

The Ethernet interface serves to connect the Engineering PC or to create line topologies (no

integrated switch for Controller c300/p300).

More information on the bus systems and configuration can be found in the

communication manuals:

• Controller-based Automation EtherCAT®

• Controller-based Automation CANopen®

• Controller-based Automation PROFIBUS®

• Controller-based Automation PROFINET®

16 Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 17

4 The Lenze automation system with EtherCAT

4.1 Brief description of EtherCAT

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4 The Lenze automation system with EtherCAT

This chapter provides basic information about ...

• the structure of the Lenze automation system using the EtherCAT bus system;

• the Lenze Engineering tools required for commissioning;

• the interaction of the components.

4.1 Brief description of EtherCAT

Tip!

Detailed information on EtherCAT is provided on the Internet website of the EtherCAT

Technology Group:

www.ethercat.org

Product features

• EtherCAT is a high-performance bus system based on Ethernet.

• Due to its integrated synchronisation mechanisms based on "distributed clocks", EtherCAT

possesses outstanding real time characteristics.

Synchronisation with "Distributed clocks" (DC)

• EtherCAT provides a higher bandwidth compared to CANopen:

• This enables motion and logic applications to be operated by the same fieldbus.

• The number of the nodes to be controlled is higher.

• The maximally possible bus length is longer.

• EtherCAT can access all field devices via a common interface. Therefore, unlike for the Lenze

CANopen control technology, a division into Logic bus and Motion bus is not required.

• The "Modular Device Profile for IPC" (MDP) is based on the "Modular Device Profile Specification"

of the EtherCAT Technology Group. All (software and hardware) components of the Lenze

Controller or Embedded PC are divided into modules. The list of the modules available is

generated dynamically, depending on the physically available components. The Lenze I/O

system 1000 with the EPM-S130 head end supports the "Modular Device Profile".

( 36)

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 17

Page 18

4 The Lenze automation system with EtherCAT

4.1 Brief description of EtherCAT

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.1.1 Structure of the EtherCAT bus system

Basic structure

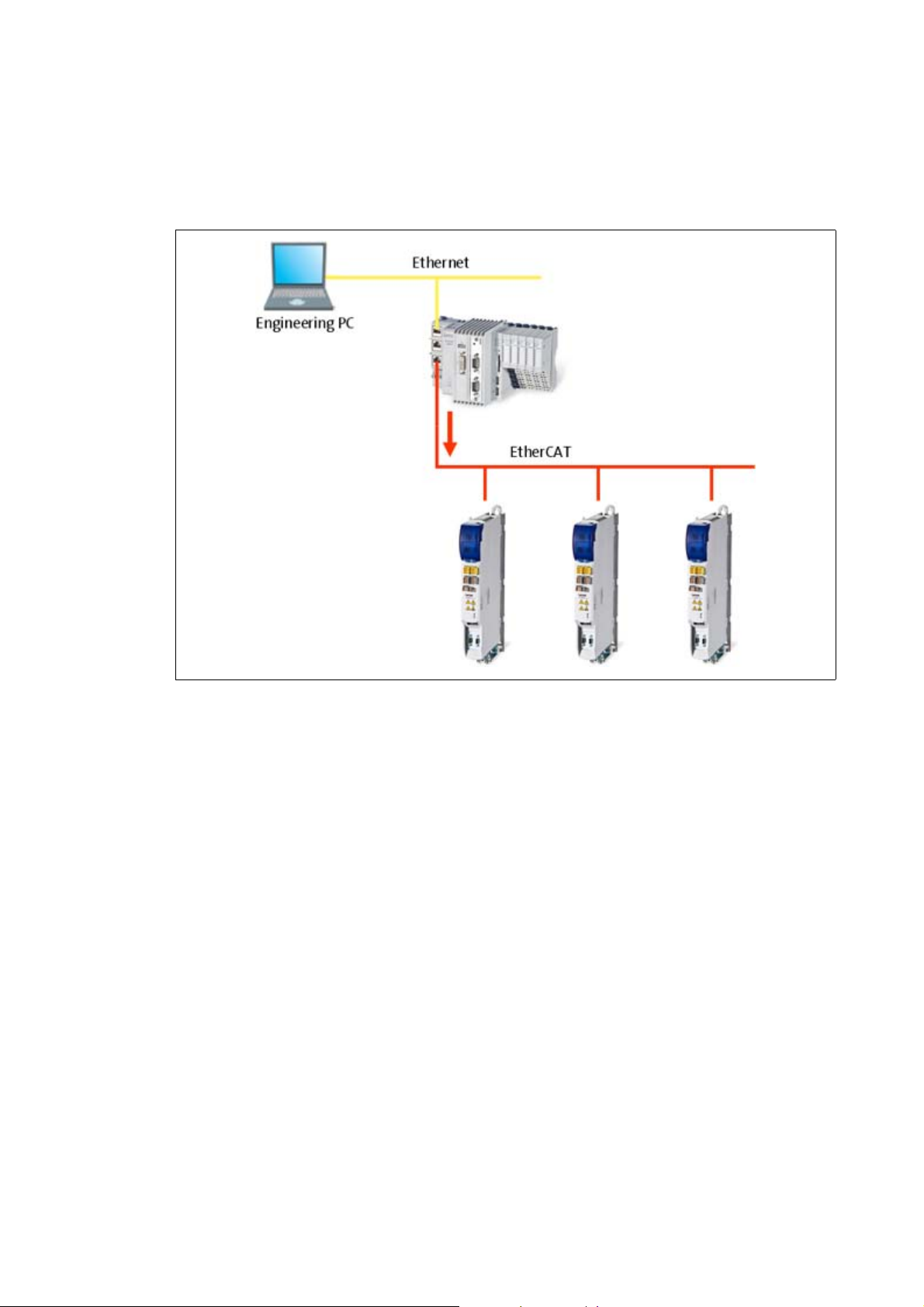

[4-1] Example: EtherCAT bus system with 3231 C controller and i700 servo inverter

Physical structure

An EtherCAT master can communicate with one or more nodes (slaves).

Internally, the EtherCAT bus has a ring topology. Since Ethernet cables are provided with a feed

conductor and a return conductor within one cable, for the installer the topology seems to be a line.

The last slave closes the ring.

Switches, hubs, or other infrastructure components known from the Ethernet standard must not be

used because they impair the real-time performance.

18

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 19

4 The Lenze automation system with EtherCAT

4.1 Brief description of EtherCAT

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.1.2 Communication

Compared with conventional Ethernet, the collision-free transfer of telegrams on the fieldbus

makes EtherCAT a real-time capable bus system.

Communication is always initiated by the EtherCAT master, i.e. the Lenze Controller. A telegram

sent by the master passes through all EtherCAT slaves. The last slave of the communication chain

sends the telegram back to the EtherCAT master. On the way back, the telegram is directly sent to

the EtherCAT master, without being processed in the slaves.

When EtherCAT is used, data are transferred in so-called "EtherCAT frames". The fieldbus nodes

only remove the data intended for them and do so while the EtherCAT frame is passing through the

device. Output data are inserted into the frame at the same time. Read and write access is always

carried out on a small section of the overall EtherCAT frame – the datagrams. This means that a

frame does not have to be received completely before it is processed. Each datagram is passed on

with minimal delay.

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 19

Page 20

4 The Lenze automation system with EtherCAT

Operational

Pre-Operational

Init

Safe-Operational

4.1 Brief description of EtherCAT

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.1.2.1 The EtherCAT state machine

Before communication via EtherCAT is possible, the fieldbus is scanned by the EtherCAT state

machine when the installation is being powered up. The following illustration shows the possible

status changes from the point of view of an EtherCAT slave.

E94AYCET009

[4-2] EtherCAT state machine

State Description

Init • Initialisation phase

• No SDO/PDO communication with the slaves

• Device can be detected by fieldbus scan

Pre-operational • The fieldbus is active.

• SDO communication (mailbox communication) is possible.

• No PDO communication

Safe-operational • SDO communication (mailbox communication) is possible.

• PDO communication:

• The input data in the process image are updated.

• The output data from the process image are not transferred to the slaves.

Operational Normal operation

• SDO communication

• PDO communication

• Fieldbus synchronisation has been successful (if used)

Note!

• A fieldbus scan is possible in any EtherCAT state.

Determining the physical EtherCAT configuration (fieldbus scan)

• The SDO communication via the EtherCAT bus is only possible if at least the "PreOperational" state has been reached.

• Only in the transitional phases between states can bus nodes be in different states.

( 75)

20

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 21

4 The Lenze automation system with EtherCAT

4.1 Brief description of EtherCAT

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

AL Status Code

Possible errors during transitions between states are entered in the EtherCAT register "AL Status

Code" (address 0x0134:0x0135).

AL Status Code

[hex]

0x0000 No error

0x0011 Invalid status change requested

0x0012 Unknown status requested

0x0013 "Bootstrap" status is not supported

0x0016 Invalid mailbox configuration "Pre-operational"

0x001A Synchronisation error

0x001B Sync manager watchdog

0x001D Invalid output data configuration

0x001E Invalid input data configuration

0x002B Invalid input and output data

0x0030 Invalid configuration of DC synchronisation

0x9001 Firmware watchdog error

0x9002 Mapping error

Description

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 21

Page 22

4 The Lenze automation system with EtherCAT

4.1 Brief description of EtherCAT

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.1.2.2 Addressing of the slaves

The EtherCAT system uses two types of addressing for the slaves:

Auto-increment addressing

The auto-increment addressing is used by the master during the initialisation phase of the fieldbus.

When the "Pre-Operational" state has been reached, the master uses the Fixed-Address addressing.

Fixed-address addressing

With the fixed-address addressing, the slaves are addressed via the station address distributed by

the master during the start-up phase.

In the EtherCAT bus topology in »PLC Designer«, the first slave is given the address ’1001’, the

second the address ’1002’ and so on. The EtherCAT addresses cannot be changed.

The EtherCAT address of the master is ’0’. Access to master objects with the address ’0’ is possible.

Example

The first slave of a configuration is given the following addresses ...

• ’0’ due to the automatic incrementation procedure;

• ’1001’ due to the fixed addressing procedure.

22

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 23

4 The Lenze automation system with EtherCAT

4.1 Brief description of EtherCAT

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.1.2.3 Working counter

Each EtherCAT datagram contains a working counter (WKC) which is incremented by each slave

after the data have been processed successfully.

The working counter (WKC) can be used as a diagnostics option to check the processing of the

EtherCAT telegrams by the slaves.

In each cycle, the Lenze Controller compares the expected value of the working counter with the

value read back via the fieldbus. If the read-back value is smaller than the expected value, not all

addressed slaves have been reached. The controller detects this and reports an error.

Messages: WKC Error / Not all slaves "Operational" / SyncManager Watchdog

Example

• 10 slaves read/write process data in the "Operational" state

Expected value of the WKC: 10

• A cable break between the 8th and 9th slave causes the master to be unable to access slave 9

and slave 10:

• Value of the restored WKC: 8

• An error response is initiated in the Lenze Controller.

• The EtherCAT bus changes to the state "Pre-Operational".

( 177)

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 23

Page 24

4 The Lenze automation system with EtherCAT

4.2 Required hardware components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2 Required hardware components

4.2.1 Field devices

The Lenze automation system supports the following EtherCAT-capable logic and motion

components:

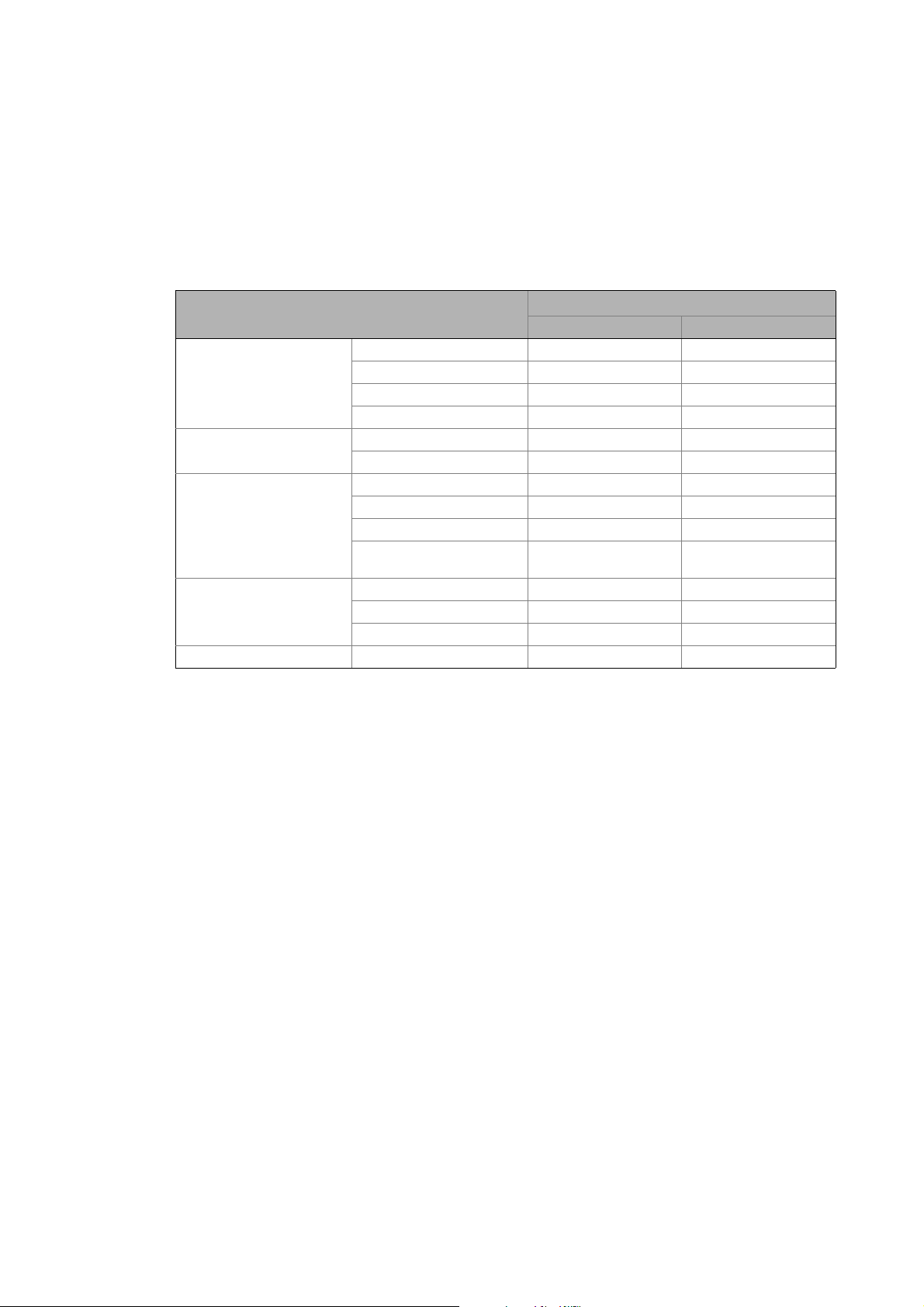

Field devices EtherCAT

Logic Motion

Controller Controller 32xx C

Controller c300

Controller p300

Controller p500

i700 servo inverter Single axis

Double axis

Servo Drives 9400 1) HighLine

Highline with CiA402

PLC

Regenerative power supply

module

Inverter Drives 8400 2) StateLine

HighLine

TopLine

I/O-System 1000 EPM-Sxxx

1) With EtherCAT E94AYCET communication module

2) With EtherCAT E84AYCET communication module

Field devices of other manufacturers can be integrated as Logic nodes if they provide a standardcompliant EtherCAT device description.

24

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 25

4 The Lenze automation system with EtherCAT

4.2 Required hardware components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2.2 The Lenze Controller - the central component

[4-3] Example: EtherCAT bus system with 3231 C controller as gateway and i700 servo inverter

The Lenze Controller is the central component in the EtherCAT bus system:

• The controller is the EtherCAT master.

• The Lenze Controllers have an EtherCAT interface "on-board".

• The controller acts as an EtherCAT gateway in order to enable access to the field devices from

the Engineering PC via Ethernet and EtherCAT.

• The devices are interconnected successively in line. For correct operation, it is nec essary that th e

physical sequence of the EtherCAT field devices matches the bus topology created in »PLC

Designer«.

Otherwise the system will not become "Operational". (An error message indicates which slave

(product code) is expected at what position.)

• Each EtherCAT slave has two EtherCAT ports.

In contrast to Ethernet, one port is assigned as input, the other one as output.

The inputs (IN) and outputs (OUT) must be correctly wired to each other

• A bus termination at the last slave is not required since the bus system at the last slave is

terminated automatically.

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 25

Page 26

4 The Lenze automation system with EtherCAT

4.2 Required hardware components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

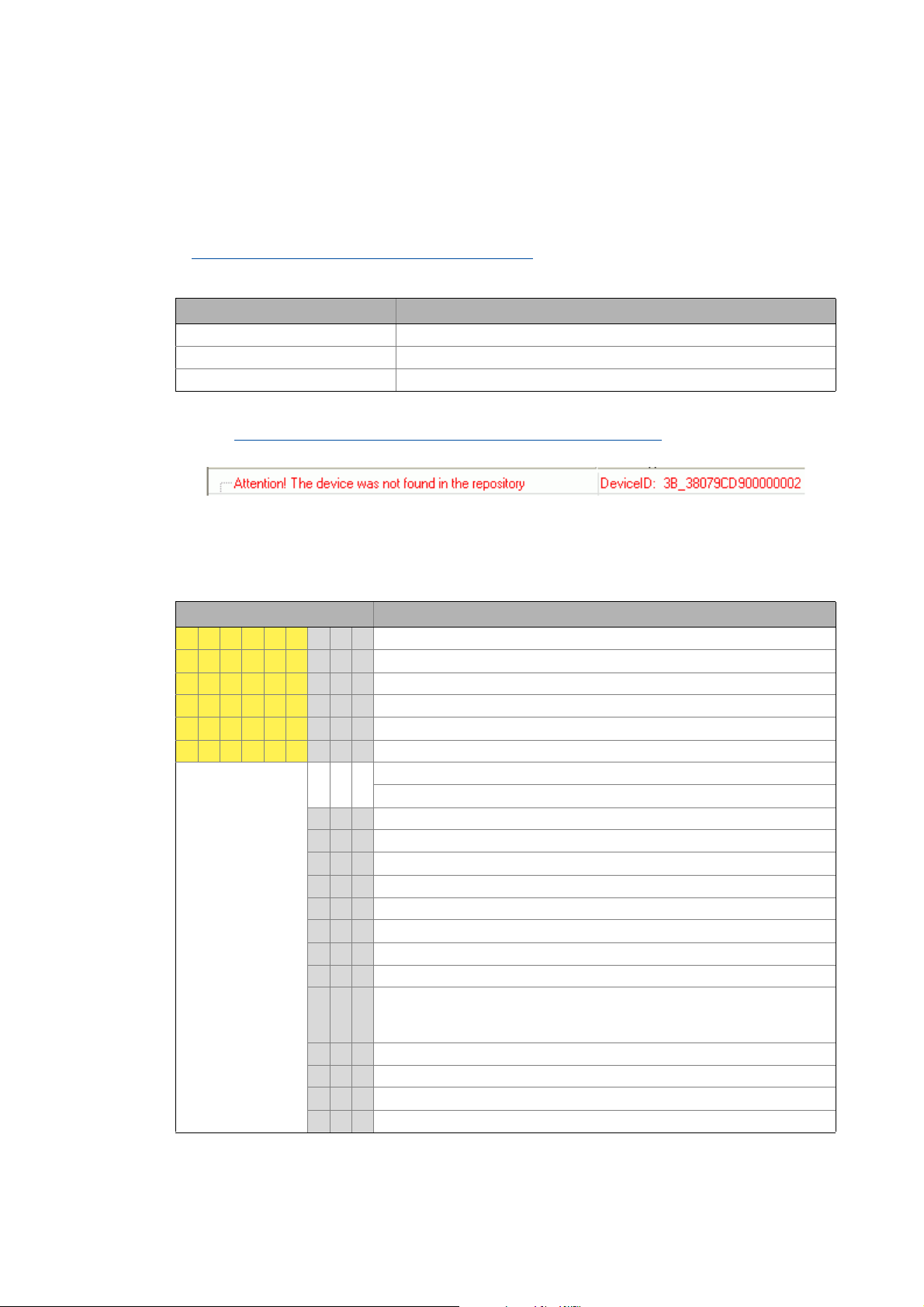

4.2.3 EtherCAT product codes

Device descriptions can be assigned to the corresponding devices with the help of the product

codes. In »PLC Designer«, you can install device descriptions with the menu command Tools

Device repository....

Importing missing devices / device description files

Structure of the device ID: <Manufacturer ID>_<Productcode><Revision number

Identification Meaning

Manufacturer ID Unique identification for the manufacturer, for Lenze devices: 0x3B

Product code Product code of the product range/the device

Revision number Revision number

If, for instance, a device available at the fieldbus without an installed device description is detected

during a Determining the physical EtherCAT configuration (fieldbus scan)

device ID as hexadecimal value is displayed:

( 78)

(59)

( 75) a message with the

In this example, the device description for a Lenze Servo Drive 9400 HighLine, actuating drive speed, is not installed (0x38079CD9 = 940023001).

Product codes for Servo Drives 9400

Product code [dec] Meaning

9 4 0 0 2 1 x x x Servo Drive 9400 in general

9 4 0 0 2 2 x x x Servo Drive 9400 StateLine

9 4 0 0 2 3 x x x Servo Drive 9400 HighLine

9 4 0 0 2 4 x x x Servo Drive 9400 TopLine

9 4 0 0 2 5 x x x Servo Drive 9400 PLC

9 4 0 0 2 6 x x x Servo Drive 9400 V/R (regenerative power supply module)

Applications:

0 0 0 Empty application

0 0 1 Actuating drive - speed

0 0 2 Actuating drive - torque

0 0 3 Electronic gearbox

0 0 4 Synchronism with mark synchronisation

0 0 5 Table positioning

0 0 6 Positioning sequence control

0 0 7 PLC application

000

89Reserved

...

...

9

Reserved

1 x x Reserved for device profiles

1 0 1 CiA402

2 x x Reserved for Lenze applications

2 0 1 Regenerative power supply module application

26

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 27

4 The Lenze automation system with EtherCAT

4.2 Required hardware components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Product codes for Inverter Drives 8400

Product code [dec] Meaning

8 4 0 0 2 2 Inverter Drive 8400 StateLine

8 4 0 0 2 3 Inverter Drive 8400 HighLine

8 4 0 0 2 4 Inverter Drive 8400 TopLine

Product codes for i700 servo inverter

Product code [hex] Meaning

1 7 6 2 0 6 6 4 3 3 Single axis

1 7 6 2 0 6 6 4 3 4Double axis

Product codes for the I/O system 1000

Product code

[dec]

1 3 0 0 I/O system EPM-S130

Meaning

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 27

Page 28

4 The Lenze automation system with EtherCAT

4.2 Required hardware components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.2.4 The EtherCAT interface of the Lenze Controller

The EtherCAT interface links the controller to an EtherCAT network.

Note!

In the case of a correct connection to the field devices, the LEDs of the EtherCAT interface

are lit.

EtherCAT interface of the Lenze Controller

Example

( 34)

ETC1: EtherCAT network connection

[4-4] EtherCAT interface at the 3231 C controller

28

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 29

4 The Lenze automation system with EtherCAT

4.3 Lenze Engineering tools

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.3 Lenze Engineering tools

The Lenze Engineering tools enable the configuration and operation of controller-based Lenze

automation systems according to individual requirements.

Use the corresponding Engineering tool applicable to the field device.

»EASY Navigator«: Starting the suitable Engineering tool

The Lenze Engineering software consists of the Engineering tools optimised for the respective

Engineering stage.

The »EASY Navigator« represents the Lenze Engineering tools installed on the Engineering PC. Start

the desired Engineering tool via the corresponding button:

The »EASY Navigator« ...

• simplifies orientation for selecting the suitable Engineering tool;

• allows for the simple start of the required Engineering tool (depending on the application):

What would you like to do? Button Engineering tool

Programming

• Program the controller

• Parameterise/commission the Servo-Inverter i700

• Parameterise the I/O system 1000

Parameterising/configuring the inverter

• Parameterising and configuring the automation/drive

system

• Parameterising Inverter Drives 8400/Servo Drives 9400

Visualising

• Visualising the applications of the automation system

• Creating the visualisation/user interfaces

Online diagnostics

• Easy online diagnostics of the controllers (from »EASY

Starter« V1.2) and other Lenze devices

Online parameterisation

• Online parameterisation/commissioning of Lenze

devices

• Direct online parameterisation when the online

connection to the Lenze devices is active.

»PLC Designer«

»Engineer«

»VisiWinNET«

»EASY Starter«

(reading parameters)

»EASY Starter«

(reading/writing

parameters)

Further Engineering tools that are not called via the »EASY Navigator« are:

• »WebConfig« (web-based parameterisation, configuration, and online diagnostics)

• »Backup & Restore« (data backup/recovery, software update).

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 29

Page 30

4 The Lenze automation system with EtherCAT

4.4 Interaction of the components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.4 Interaction of the components

4.4.1 The state machine of the Lenze control technology

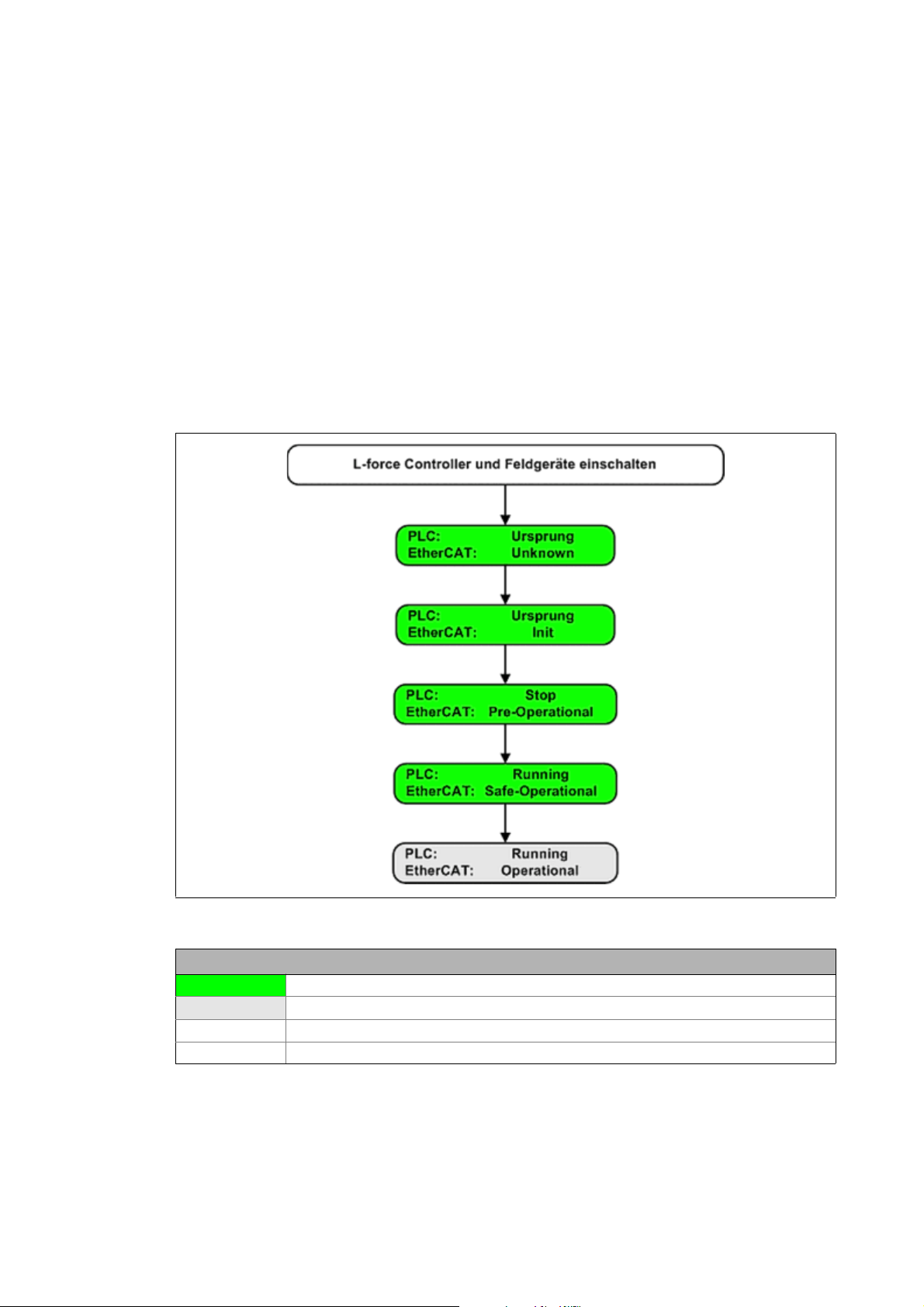

In the Lenze control technology, the states of the PLC and the EtherCAT bus are coupled. The PLC

controls the fieldbus.

After switch-on, the system automatically powers up if the following conditions are fulfilled:

• There is an executable PLC boot project on the controller (»PLC Designer« project).

• The slaves that are on the fieldbus and have been configured in »PLC Designer« are accessible.

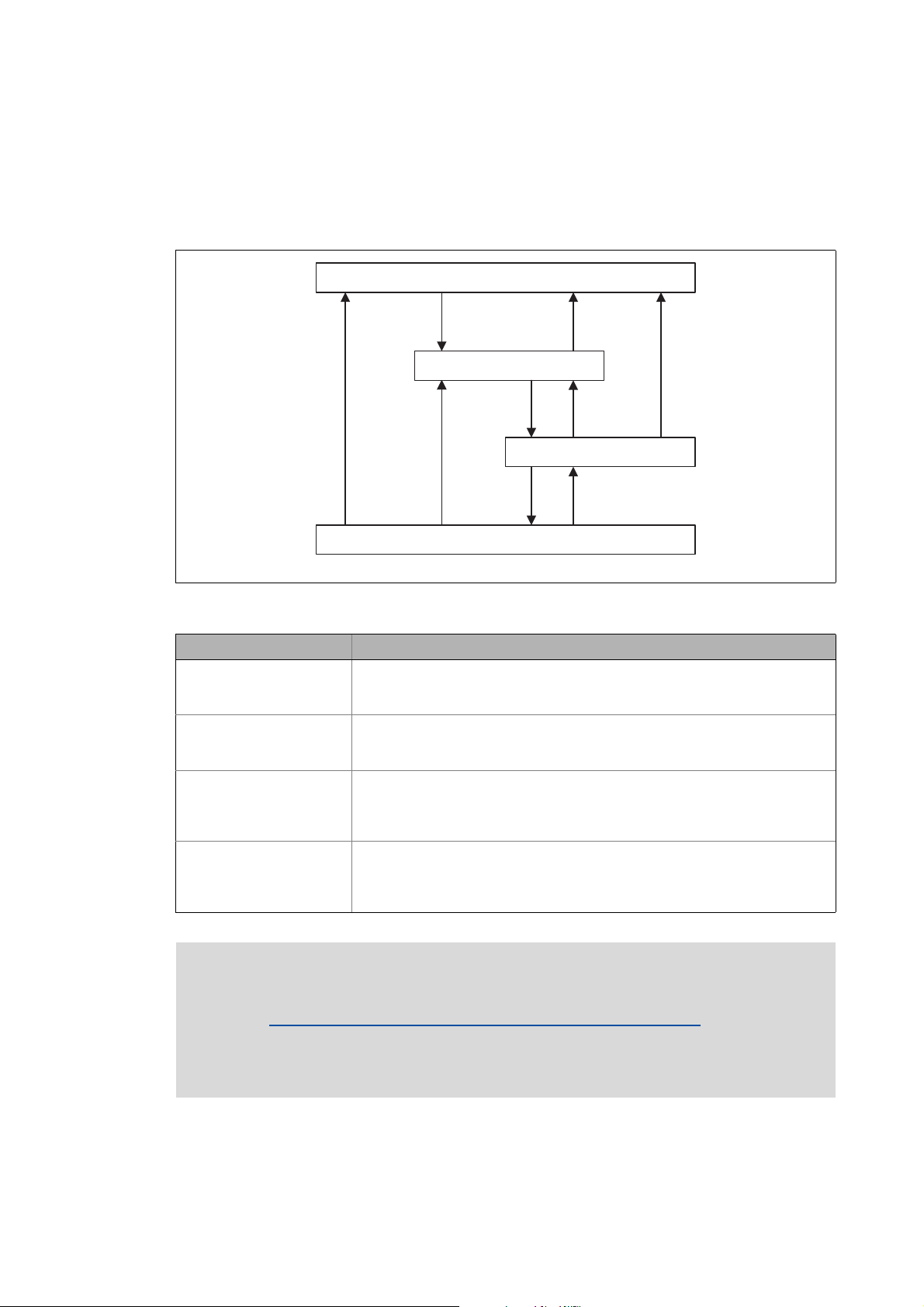

The following illustration shows the linkage of the states in the state machine of the Lenze control

technology when the conditions for the automatic acceleration of the system are fulfilled (boot

project with EtherCAT configuration):

[4-5] States in the Lenze control technology

Legend

Transitional state, automatic change to next state

Stationary state, change to next state by external actions

PLC State of the PLC

EtherCAT State of the EtherCAT bus

30

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 31

4 The Lenze automation system with EtherCAT

4.4 Interaction of the components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Explanation of the transitions during system start

While a state is passed through, different tests are carried out (e.g. it is tested whether the physical

topology complies with the configuration). If the tests are successful, the system automatically

changes to the next state.

State What happens? What is tested?

PLC EtherCAT

Origin Unknown The system starts. EtherCAT configuration available?

Origin Init EtherCAT is initialised (a fieldbus

scan is carried out).

Stop Pre-operational • EtherCAT is active.

• SDO communication is possible.

Running Safe-operational • The PLC program is being loaded.

• The PLC is running.

• The input data in the process

image are updated.

• The output data from the process

image are not transferred to the

slaves.

Running Operational The system is running.

Does the EtherCAT configuration

match the results of the fieldbus

scan?

If the tests are not successful, the fieldbus changes to the next state. Corresponding remedial

measures are described in the chapter "Error scenarios

" ( 174).

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 31

Page 32

4 The Lenze automation system with EtherCAT

4.4 Interaction of the components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.4.2 Communication between the Engineering PC and the field devices

For commissioning of the field devices, an online connection is required between the Engineering

PC and the corresponding field device. Depending on the state of the EtherCAT bus, there are two

options:

EtherCAT bus not in operation

EtherCAT bus in operation (gateway function) ( 33)

4.4.2.1 EtherCAT bus not in operation

You can communicate serially or via CANopen.

( 32)

Note!

For the i700 servo inverter, there is no possibility of communication in this case.

Condition:

Serial communication:

• You require the E94AZCUS diagnostic adapter.

• The field device and Engineering PC (USB interface) must be connected via the diagnostic

adapter.

Communication via CANopen

• You required the EMF2177IB USB system bus adapter .

• The field devices and the Engineering PC are connected via the system bus adapter - either via a

point-to-point connection or via the bus system.

Advantage:

Quick option of communication without commissioning of the EtherCAT bus.

Disadvantage:

You require additional hardware.

Tip!

As soon as the fieldbus has been commissioned and is at least in the "Pre-Operational"

state, this communication channel is of secondary importance. We recommend that the

EtherCAT bus be commissioned as early as possible in order to enable use of the gateway

function.

32

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 33

4 The Lenze automation system with EtherCAT

4.4 Interaction of the components

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4.4.2.2 EtherCAT bus in operation (gateway function)

You communicate directly via EtherCAT and use the controller as a gateway.

Note!

A PLC program does not need to run to be able to use the gateway function.

[4-6] Example: EtherCAT bus system with 3231 C controller as gateway and i700 servo inverter

Condition:

• The EtherCAT configuration has been created with »PLC Designer« to match the hardware

configuration.

• The EtherCAT configuration has been loaded and activated on the controller with »PLC

Designer«.

• The EtherCAT bus is at least in the "Pre-Operational" state.

Advantage:

• You do not require any additional hardware.

• The process data, parameter data and diagnostic data are transferred via a single bus

connection at the same time.

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 33

Page 34

5Technical data

1

5.1 General data

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5 Technical data

5.1 General data

Area Values

Higher-level network protocol EtherCAT device protocol

Communication medium / cable

type

Network topology Line

Type within the network Master

Number of nodes Max. 65535 ( in the entire network )

Max. cable length 100 m between two stations

Baud rate 100 Mbps

Supported communication profiles CoE (CANopen over EtherCAT)

Synchronisation Distributed clocks

S/FTP (Screened Foiled Twisted Pair, ISO/IEC 11801 or EN 50173), CAT5e

Standard Ethernet (acc. to IEEE 802.3), 100Base-TX (Fast Ethernet)

FoE (File Access over EtherCAT)

5.2 EtherCAT interface of the Lenze Controller

RJ45 socket Pin Assignment LEDs

E94YCEP018

1 Tx + LED "Link" (green):

2Tx -

3 Rx + LED "Speed" (yellow):

4-

5-

6Rx -

7-

8-

On: connection OK

Blinking: Active data exchange

34

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 35

5Technical data

5.3 Communication times and drive-specific data

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.3 Communication times and drive-specific data

Area Values

User data per frame 1344 bytes

Process data words (PCD) Depending on the inverter used

(see documentation of the inverter)

Parameter data (SDO) transfer Max. 128 bytes

Permissible EtherCAT cycle times 1 … 10 ms

Max. number of drives per frame User data of the frame (1344 bytes) divided by the process data length

Cross communication Not possible

Cycle synchronisation with locked

PLL (Jitter)

Instant of transmission for the

EtherCAT frame (for setting, see

Optimising the task utilisation

( 104))

Total signal runtime for a cycle time

of 1 ms

controller drive

Drive

Runtime of the setpoints

Controller

Runtime of the actual values

Drive

drive

controller

resulting from setpoints and actual values of the drives:

• for 32 Tx/Rx bytes: 1344 bytes / 64 bytes = 21 drives

• for 16 Tx/Rx bytes: 1344 bytes / 32 bytes = 42 drives

+/-1 μs

The EtherCAT frame is sent at the

beginning of the bus cycle task.

4 ms 3 ms

2 ms 1 ms

1 ms 1 ms

The EtherCAT frame is sent at the end

of the bus cycle task.

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 35

Page 36

6 Synchronisation with "Distributed clocks" (DC)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6 Synchronisation with "Distributed clocks" (DC)

The "Distributed clocks" (DC) functionality enables exact time synchronisation for applications in

which several axes perform a coordinated movement simultaneously. Data are incorporated

synchronously with the PLC program. During DC synchronisation, all slaves are synchronised with a

reference clock, the so-called "DC master".

Note!

• DC synchronisation is absolutely required for Motion applications.

• DC synchronisation can also be used for Logic applications.

• Not all slaves support the DC functionality.

• In order to be able to use the DC functionality, the first slave connected to the

EtherCAT master (Lenze Controller) must have DC master capability. The other slaves

can be connected in a mixed arrangement, either DC capable or non-DC-capable.

• The first EtherCAT slave after the Lenze Controller must

supplies the other EtherCAT nodes (incl. controller) with the exact time.

be the DC master that

[6-1] Example: EtherCAT bus system with 3231 C controller and i700 servo inverter

The settings for the DC synchronisation are made with the »PLC Designer«.

Setting a DC synchronisation

( 87)

36 Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 37

6 Synchronisation with "Distributed clocks" (DC)

6.1 Synchronous communication

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.1 Synchronous communication

The DC synchronisation provides for a phase-synchronous operation of master and slaves:

Within one bus cycle the setpoints are accepted and the actual values are detected in the fieldbus

at exactly the same time.

If the Lenze Controller (master) is in synch with the distributed clocks, the data (actual values)

acquired by the slave are sent to the master at the end of the bus cycle and data from the master

(setpoint values) are sent to the slaves for processing. .

When the next DC synchronisation event occurs, the data are accepted.

Note!

• The DC synchronisation is only carried out in the "Operational" state.

• After an "Out-of-sync" occurrence, the EtherCAT master synchronises the slaves.

Successful synchronisation is indicated by means of the "In-Sync" message (see

Diagnostic tabs of the EtherCAT master

( 164)).

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 37

Page 38

6 Synchronisation with "Distributed clocks" (DC)

6.2 Test of DC synchronicity

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

6.2 Test of DC synchronicity

DC synchronicity is only available in the "Operational" state.

Test of DC synchronicity in »PLC Designer«

•EtherCAT master: Diagnostic Master tab

"DC In-Sync" is set (TRUE) if the DC master and all DC slaves have been synchronised.

Diagnostic tabs of the EtherCAT master

• Function block L_ETC_GetMasterDiagnostic (FB)

L_ETC_GetMasterDiagnostic ( 166)

"DC In-Sync" is set (TRUE) at the oDiagnostic.xDC_InSync output if the DC master AND all DC

slaves are synchronised.

( 164)

( 144) / Visualisation of the function block

• Function block L_IODrvEtherCAT (FB)

"DC In-Sync" is set (TRUE) at the xDistributedClockInSync output if all DC slaves are synchronised.

Test of DC synchronicity in »WebConfig«:

In the code C281/5

Diagnostic codes in the »WebConfig«

, "DC In-Sync" is set (TRUE) if all DC slaves have been synchronised.

( 140)

( 169)

38

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 39

7 Commissioning of the system

7.1 Sample projects (Application Samples)

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7 Commissioning of the system

This chapter provides information on how to commission the Lenze automation system with

EtherCAT.

Depending on the field devices used, the following Lenze Engineering tools

• »EASY Starter«

• »Engineer«

•»PLC Designer«

7.1 Sample projects (Application Samples)

There already exist sample projects (device application + PLC program) for commissioning of Lenze

inverters.

The Lenze sample projects can be found in the MS Windows start menu under:

Start All programs Lenze AppSamples ...

( 29) are required:

The Lenze sample projects can also be opened in the »PLC Designer« via the menu command File

New project..., or using <Ctrl>+<N>.

Detailed information on the sample projects can be found in the following

documentation:

• SW_ApplicationSample_i700_(PLC Designer V3)_Vx-y_DE/EN.pdf

• SW_ApplicationSamples_(Controller-based)_Vx-y_DE/EN.pdf

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 39

Page 40

7 Commissioning of the system

7.2 Overview of the commissioning steps

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

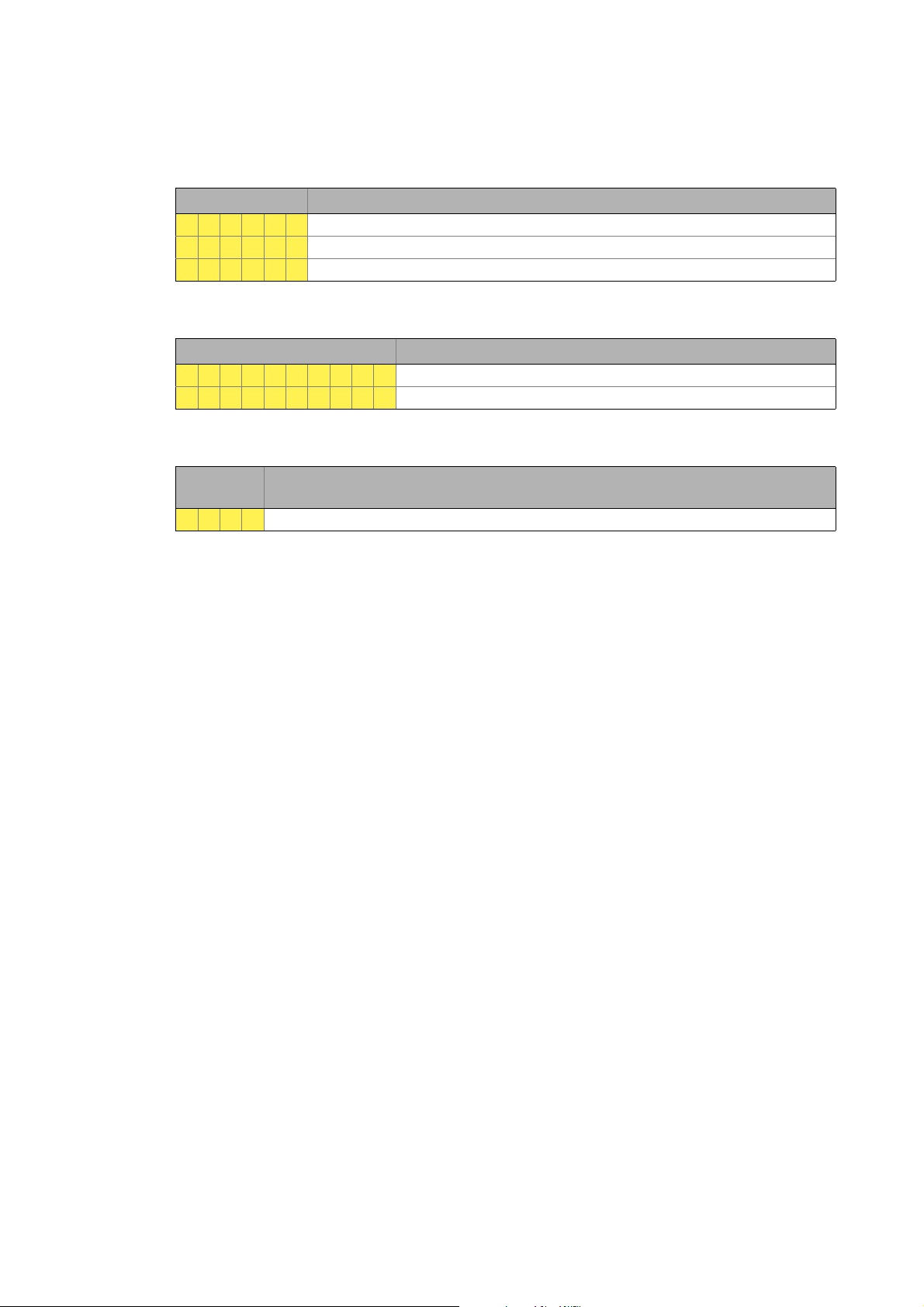

7.2 Overview of the commissioning steps

In the following illustration, the individual commissioning steps and their processing order are

summarised. Detailed information on the individual processing steps can be found in the chapter

Detailed description of the commissioning steps

( 42).

40

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 41

7 Commissioning of the system

7.2 Overview of the commissioning steps

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

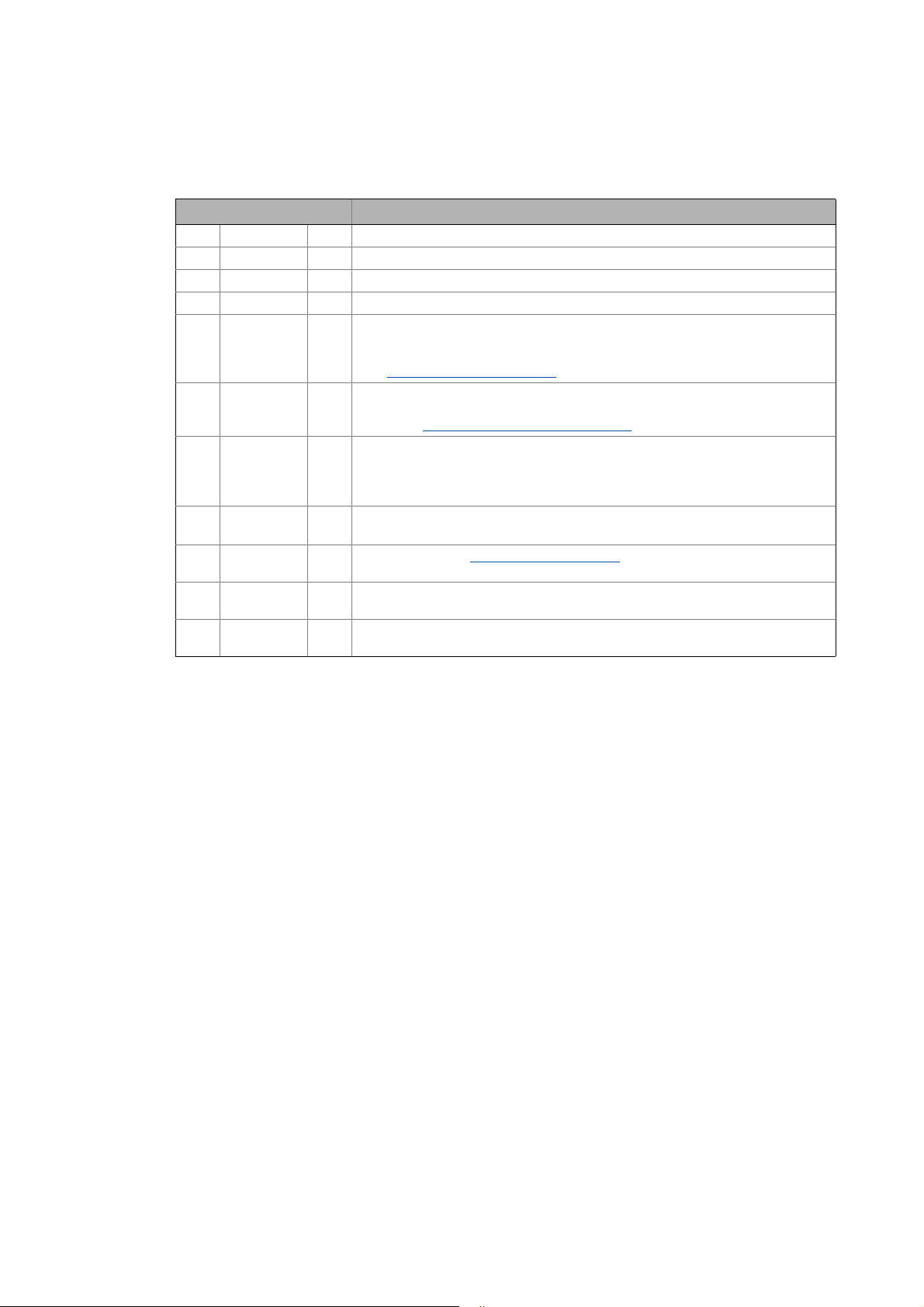

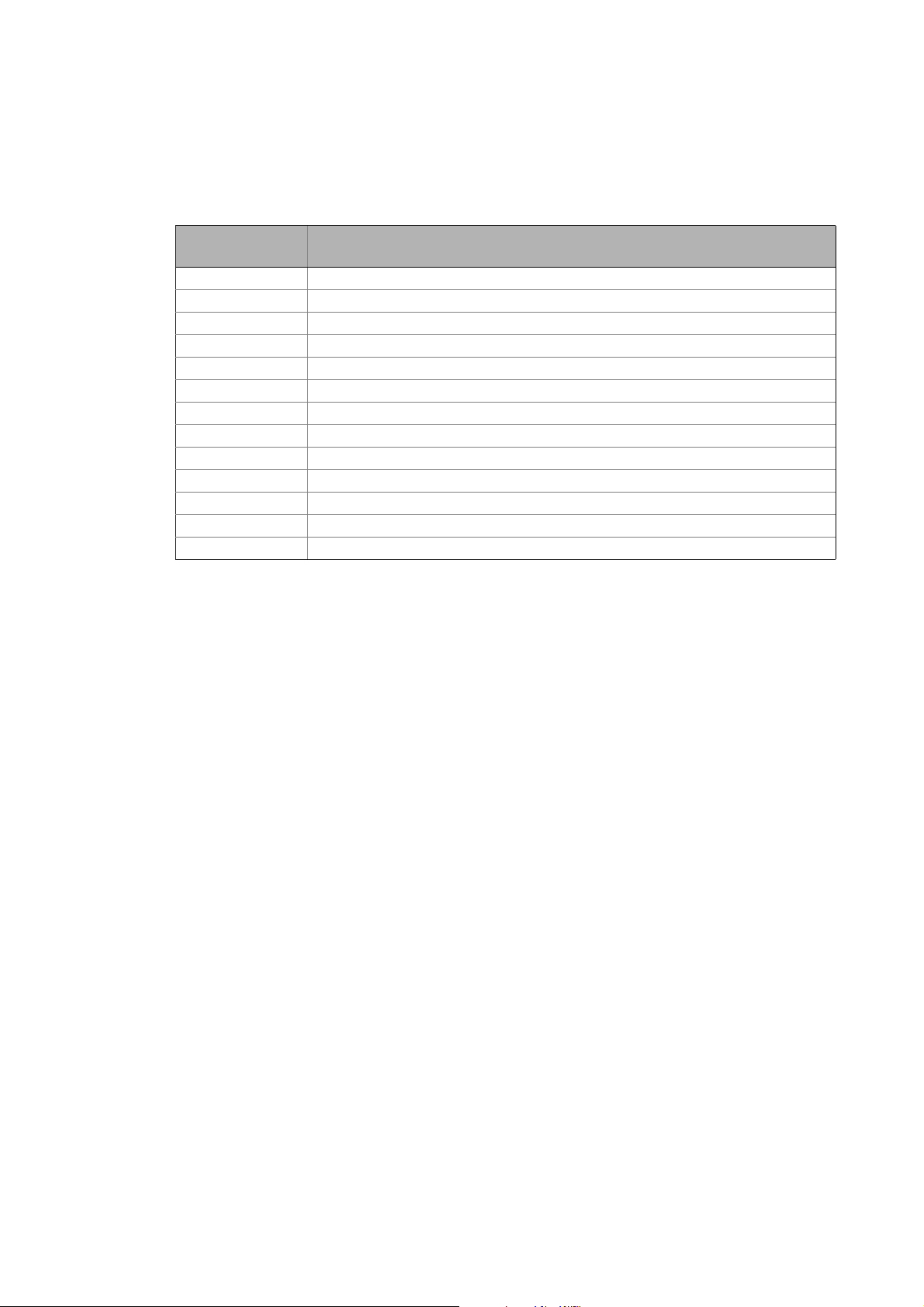

The main commissioning steps are listed in the following table:

Step Activity Lenze software to be

1. Installing field devices

2. Create a project folder

3. Commissioning the i700 servo inverter

Commissioning other Lenze field devices

4. Creating a PLC program with a target system (Logic/Motion)

5. Configuring the communication parameters

6. Determining the physical EtherCAT configuration (fieldbus scan)

If necessary Importing missing devices / device description files

7. Creating a control configuration (adding field devices)

8. Creating a task

9. Setting a DC synchronisation

10. Setting SoftMotion parameters

Only required for drives with Motion functionality.

11. Processing EtherCAT I/O mapping

Only required for drives that solely have the master functionality (logic bus).

12. Compiling the PLC program code

13. Logging in on the controller with the »PLC Designer«

With the log-in, the fieldbus configuration and the PLC program are loaded into

the Controller.

14. Starting the PLC program

( 43)

( 43)

( 44) »PLC Designer«

( 70) »Engineer« /

( 71) »PLC Designer«

( 73)

( 75)

( 78)

( 79)

( 82)

( 87)

( 92)

( 95)

( 103)

( 103)

( 103)

used

»EASY Starter«

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 41

Page 42

7 Commissioning of the system

7.3 Detailed description of the commissioning steps

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.3 Detailed description of the commissioning steps

In the following sections, the individual commissioning steps are described.

Follow the instructions of these sections step by step in order to commission your system.

For more details on how to use the Lenze engineering tools, please refer to the

corresponding software manuals and the online help systems.

7.3.1 Planning the bus topology

Before you set up an EtherCAT network, draw up a plan of the network.

How to plan the bus topology for your configuration

1. Create an overview screen of the planned EtherCAT network with all the field devices to be

integrated into the network.

2. Start with the Lenze Controller (master).

3. Add the other field devices (slaves) below.

The following cases are distinguished:

• Operation without

DC synchronisation is mostly not required if exclusively Logic field devices are to be

operated on the network. The sequence of the field devices on the fieldbus can be freely

selected.

• Operation with

DC synchronisation is required if Motion and Logic field devices are to be operated on the

network. The first node connected to the Lenze Controller must be capable of being a DC

master. The sequence of the other Logic and Motion field device interface connections at

the fieldbus can be freely selected.

synchronisation via distributed clocks:

synchronisation via distributed clocks:

42

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 43

7 Commissioning of the system

7.3 Detailed description of the commissioning steps

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.3.2 Installing field devices

For the installation of a field device, follow the mounting instructions for the respective device.

Note!

• In the case of all field devices, the EtherCAT interfaces must be wired in accordance

with the preceding topology planning. Make sure that the inputs (IN) and outputs

(OUT) are not mixed up with each other; otherwise, the topology changes.

Communication

• The physical sequence of the field devices in the EtherCAT network must match the

EtherCAT configuration created in »PLC Designer«.

• The master automatically assigns the node addresses to the slaves. Therefore, a

manual address assignment is not required.

7.3.3 Create a project folder

( 19)

Create a project folder on the Engineering PC.

Use this project folder to store the data generated in the following different project configuration

steps:

• Project data created in the »Engineer« or »EASY Starter«

• Project data created in »PLC Designer«

Tip!

Create a separate project folder for every EtherCAT configuration and store the project files.

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17 43

Page 44

7 Commissioning of the system

7.3 Detailed description of the commissioning steps

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.3.4 Commissioning the i700 servo inverter

This chapter tells you how to commission the Servo-Inverter i700 in the Lenze automation system

with the help of »PLC Designer«.

For speed commissioning, the Servo-Inverter i700 provides diverse functions for automatic

calculation and setting of parameters.

Danger!

Severe personal injury and damage to the machine/installation

Activate the controller inhibit before you set the parameters for the Servo-Inverter i700

as uncontrolled movements can lead to severe personal injury and damage to the

machine/installation.

Note!

You can also set the parameters for the Servo-Inverter i700 online. To do this, you must

first configure EtherCAT communication.

Setting parameters online is possible from the EtherCAT state "Pre-Operational"

onwards.

Reference manual/online help for the i700 servo inverter

Here, you can find detailed information on all parameters/Objects (object dictionary),

functions and error messages of the i700 servo inverter.

Tip!

There already exist sample projects (device application + PLC program) for commissioning

of the i700 servo inverter.

Sample projects (Application Samples)

( 39)

44

Lenze · Controller-based Automation · EtherCAT® Communication Manual · DMS 6.4 EN · 04/2014 · TD17

Page 45

7 Commissioning of the system

7.3 Detailed description of the commissioning steps