Page 1

EDSTCXX

./Y2

Ä./Y2ä

Hardware Manual

ETC Motion Control

L

ETCxxxxx

DIN rail modules and PCI card

l

Page 2

© 2006 Lenze Drive Systems GmbH, Hans−Lenze−Straße 1, D−31855 Aerzen

No part of this documentation may be reproduced or made accessible to third parties without written consent by Lenze Drive

Systems GmbH.

All information given in this documentation has been selected carefully and complies with the hardware and software

described. Nevertheless, deviations cannot be ruled out. We do not take any responsibility or liability for damages which might

possibly occur. Necessary corrections will be included in subsequent editions.

Page 3

Contents i

1 Preface and general information 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 About this Manual 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 For which products is the manual valid? 6 . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Legal regulations 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Technical data 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 General data and operating conditions 8 . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Rated data 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Standard device 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Power supply unit 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.3 Bus termination module 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.4 Input module 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.5 Output module 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.6 Analogue module 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Device description 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 System overview 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Examples for an automation system 14 . . . . . . . . . . . . . . . . . . . . .

3.1.2 Layout example for an ETC island 16 . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3 Set node address 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Control in top hat rail design (ETCHx) 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Serial interface 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 CAN interface 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3 Ethernet interface 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.4 Watchdog (WDOG) 25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Control as PCI insert card (ETCPx) 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Serial interface 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 CAN interface 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Configuration and Watchdog 30 . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Module 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Power supply unit 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.2 Bus termination module 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.3 Input module 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.4 Output module 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.5 Analogue module 45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDSTCXX EN 2.0

l 3

Page 4

Contentsi

4 Mechanical installation 47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Control and module for top hat rail mounting (ETCHx) 47 . . . . . . . . . . . . . .

4.1.1 Control ETCHx 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.2 Module ETCHx 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.3 Dismantling of control and module ETCHx 51 . . . . . . . . . . . . . . . . .

4.2 Control in PCI design (ETCPx) 52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Installing the PCI card in the PC 52 . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Electrical installation 53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Installation according to EMC (installation of a CE−typical drive system) 53

5.2 CAN installation instructions 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Cable types for the CAN Bus 56 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Relationship between cable length and transfer rate 56 . . . . . . . .

5.2.3 Stub cables 57 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Initial switch−on 58 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Troubleshooting and fault elimination 59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Status display 59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Error management 62 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Module replacement 64 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Battery replacement 65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Index 68 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l 4

EDSTCXX EN 2.0

Page 5

Preface and general information

1 Preface and general information

The ETC Motion Control as the leading element of automation is together

with the Lenze drive controllers and motors an optimal system solution for

the control of movements.

In the ETC system both compact controls for installation on top hat rails and

PC insert cards are available. In both hardware designs either a NC or a MC

core can be supplied. The programming of the NC is carried out in accordance

with DIN 66025 (G code), that of MC in accordance with PLCOpen. Both

controls also include a PLC with is programmed in accordancd with 61131−3.

The control system is complemented by the corresponding I/O

subassemblies.

The communication with the drives via CAN or to the PC level via Ethernet

TCP/IP is also integrated into the ETC.

About this Manual

1

1.1

1.1 About this Manual

Target group

Contents

Further information

This manual is intended for all those who plan, install, program or

commission the ETC Motion Control System under the "NC" operating

system.

The ETC device manual contains information on the following topics:

ƒ Technical data

ƒ Structure and function of the system components including interface

ƒ Mounting, connecting and maintaining system components

This manual is complemented by the software manuals "MC operating

system" and "NC operating system", which provide important information

for the programmer and commissioner.

I Tip!

description

Current documentation and software updates concerning Lenze

products can be found on the Internet in the "Services &

Downloads" area under

http://www.Lenze.com

EDSTCXX EN 2.0

l

5

Page 6

1

1.2

Preface and general information

For which products is the manual valid?

1.2 For which products is the manual valid?

Standard device

ETC xx 0 xx 1A 10

Product

Version

HM = top hat rail, MC core

PM = PCI insert card, MC core

HC = DIN rail, CNC core

PC = PCI insert card, CNC core

ETCHx0xx

Number of axes

02 = 2 axes

04 = 4 axes

08 = 8 axes

12 = 12 axes

Hardware version

Modules

Software version ETCPx0xx

ETCH xxxx 1A 10

Product

N003 = power supply unit

T000 = bus termination module

I008 = 8 dig. inputs

I016 = 16 dig. inputs

U008 = 8 dig. outputs

U016 = 16 dig. outputs

A022 = 2 analogue inputs and outputs

each

ETCHxxxx

Hardware version

Software version

6

l

EDSTCXX EN 2.0

Page 7

1.3 Legal regulations

Preface and general information

Legal regulations

1

1.3

Marking

Manufacturer

CE conformity

Application as intended

The components of the ETC Motion Control System are clearly marked by the

contents of the nameplate.

Lenze Drive Systems GmbH, Postfach 101352, D−31763 Hameln

Compliant with EC Directive "Electromagnetic compatibility"

Components of the ETC Motion Control System

ƒ must only be operated under the operating conditions described in the

ETC Hardware Manual.

ƒ are not approved for the use in explosive environments.

ƒ comply with the protection requirements of the EC Directive "Low

voltage".

ƒ are no machines in the sense of the EC Directive "Machines".

ƒ are no household appliances, as components they are intended for

industrial use only.

The downstream user is responsible for ensuring that the EC Directives are

complied with in machine use.

Any other use shall be deemed inappropriate!

Liability

Warranty

The information, data and notes in this manual were up to date at the time

of printing. No claims for the modification of systems and components that

have already been supplied may be made on the basis of the specifications,

illustrations and descriptions in this manual.

No liability is accepted by Lenze as to the suitability of any of the procedures

or circuit recommendations included here.

The information in this manual describe the properties of the products

without guaranteeing them. No liability will be accepted for damage or

disturbance caused by:

ƒ ignoring this manual

ƒ unauthorised alterations to the components of the ETC Motion Control

System

ƒ operating errors and incorrect working on or with the ETC Motion

Control System

See terms of sales and delivery of Lenze Drive Systems GmbH.

Report any claims under warranty to Lenze immediately on discovery of the

defect or fault. The warranty is void in all cases where liability cannot be

established.

EDSTCXX EN 2.0

l

7

Page 8

2

2.1

Technical data

General data and operating conditions

2 Technical data

2.1 General data and operating conditions

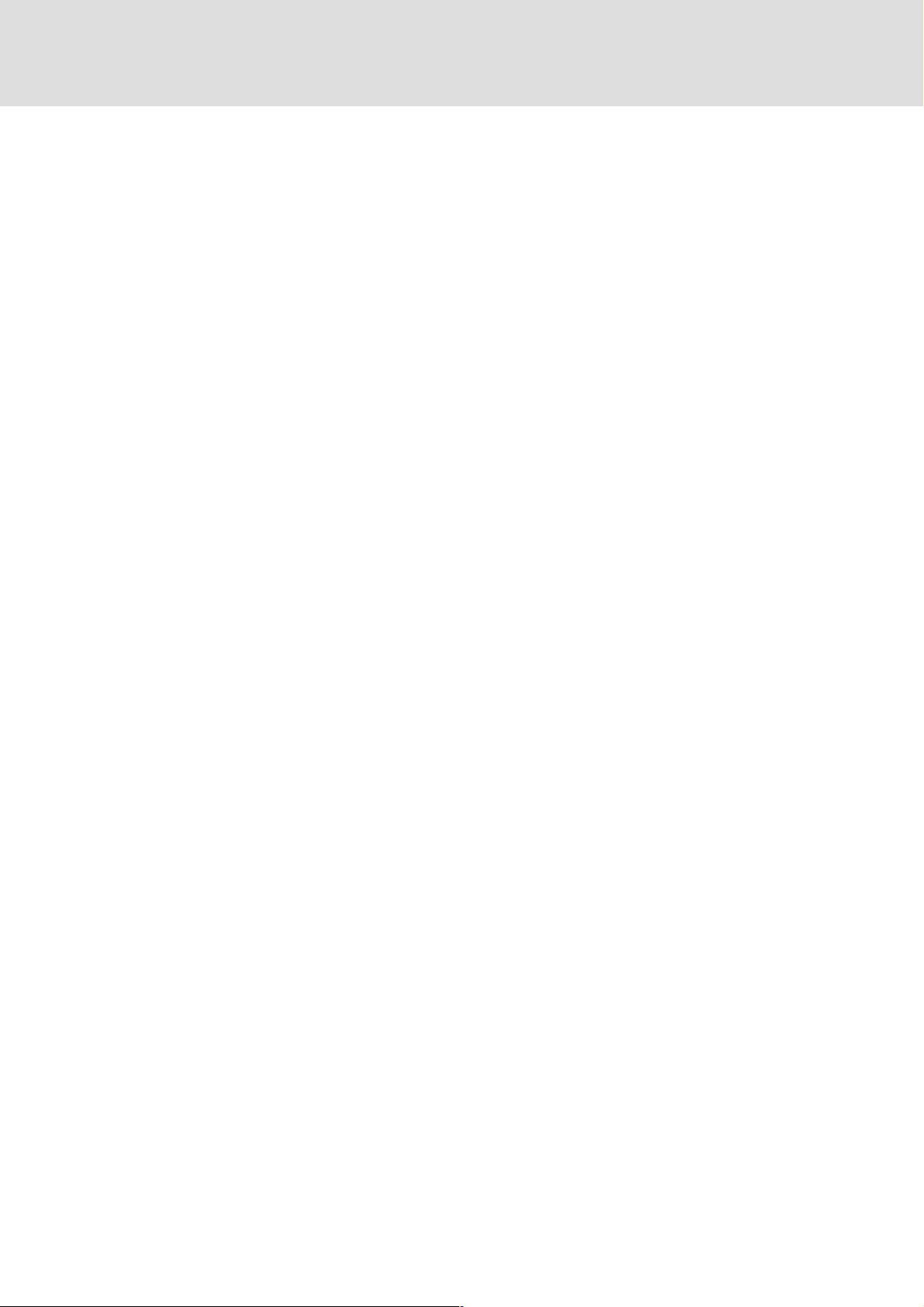

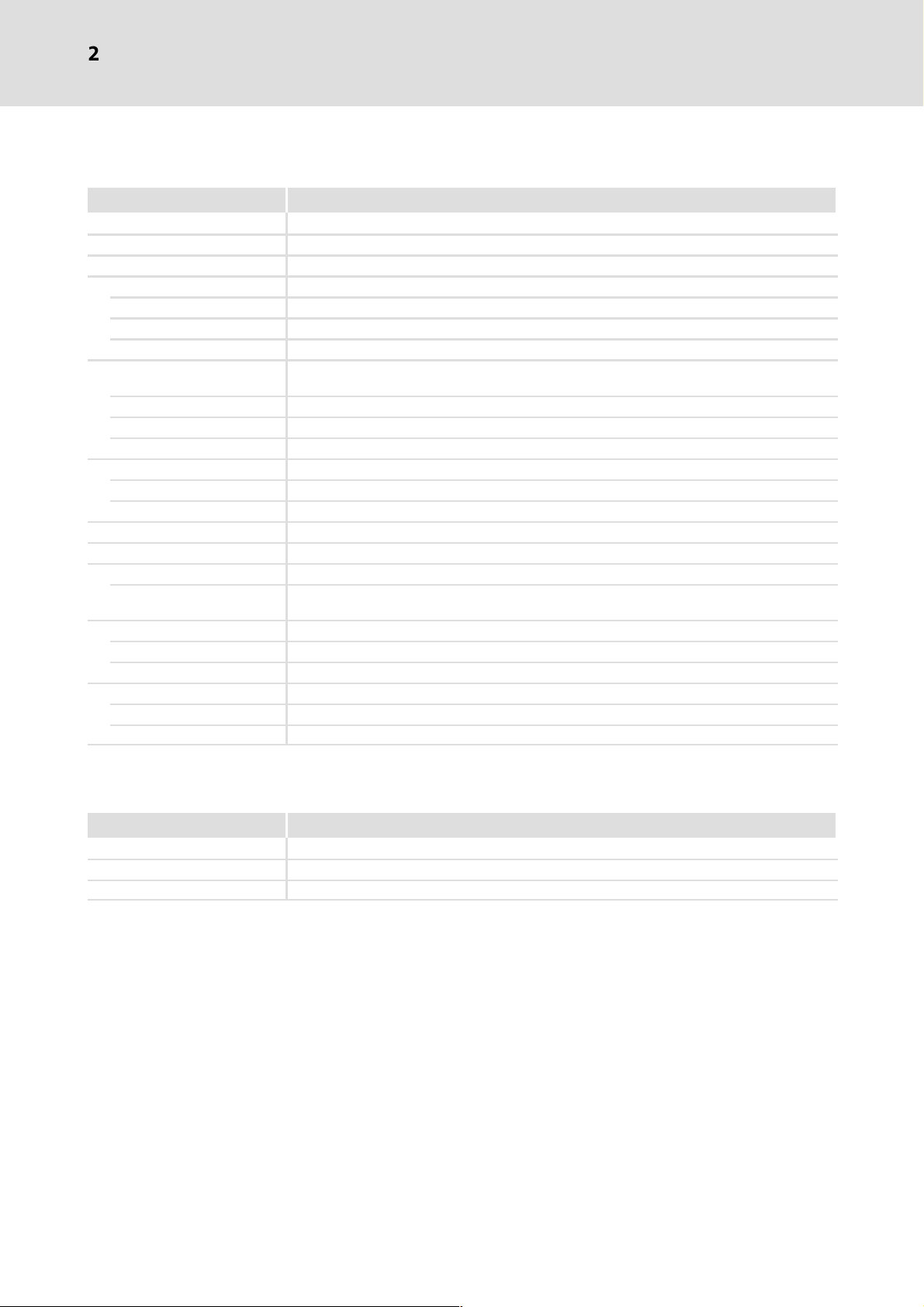

Type

Labelling and approval CE (compliance with the EMC Directive)

Climatic conditions

Storage 1 K3 per IEC/EN 60721−3−2

Temperature −20 °C ... +60 °C; D

Transport 2 K3 per IEC/EN 60721−3−2

Temperature −20 °C ... +60 °C; D

Operation

Atmospheric pressure 860 hPa to 1060 hPa

Rel. humidity 8 % ... 80 % (non condensing)

Vibration resistance

Shock (10 ms) max. 5 G

Vibration (5 ... 100 Hz) max. 0.5 G

Noise immunity EN50082−1 = severity 3

Noise emission EN50082−2 = limit value B

Packaging Dustproof packaging

Protection category IP20 IP00

Installation position vertical −

Installation clearances top and bottom 80 mm −

1)

Temperature −0 °C ... +50 °C; D

above 1000 m site altitude permissible temperature reduced by 1 K/300 m

1)

At maximum load, vertical installation and sufficient convection

ETCHx ETCPx

= 20 K/h

max

= 20 K/h

max

3 K3 per IEC/EN 60721−3−2

= 10 K/h

max

8

l

EDSTCXX EN 2.0

Page 9

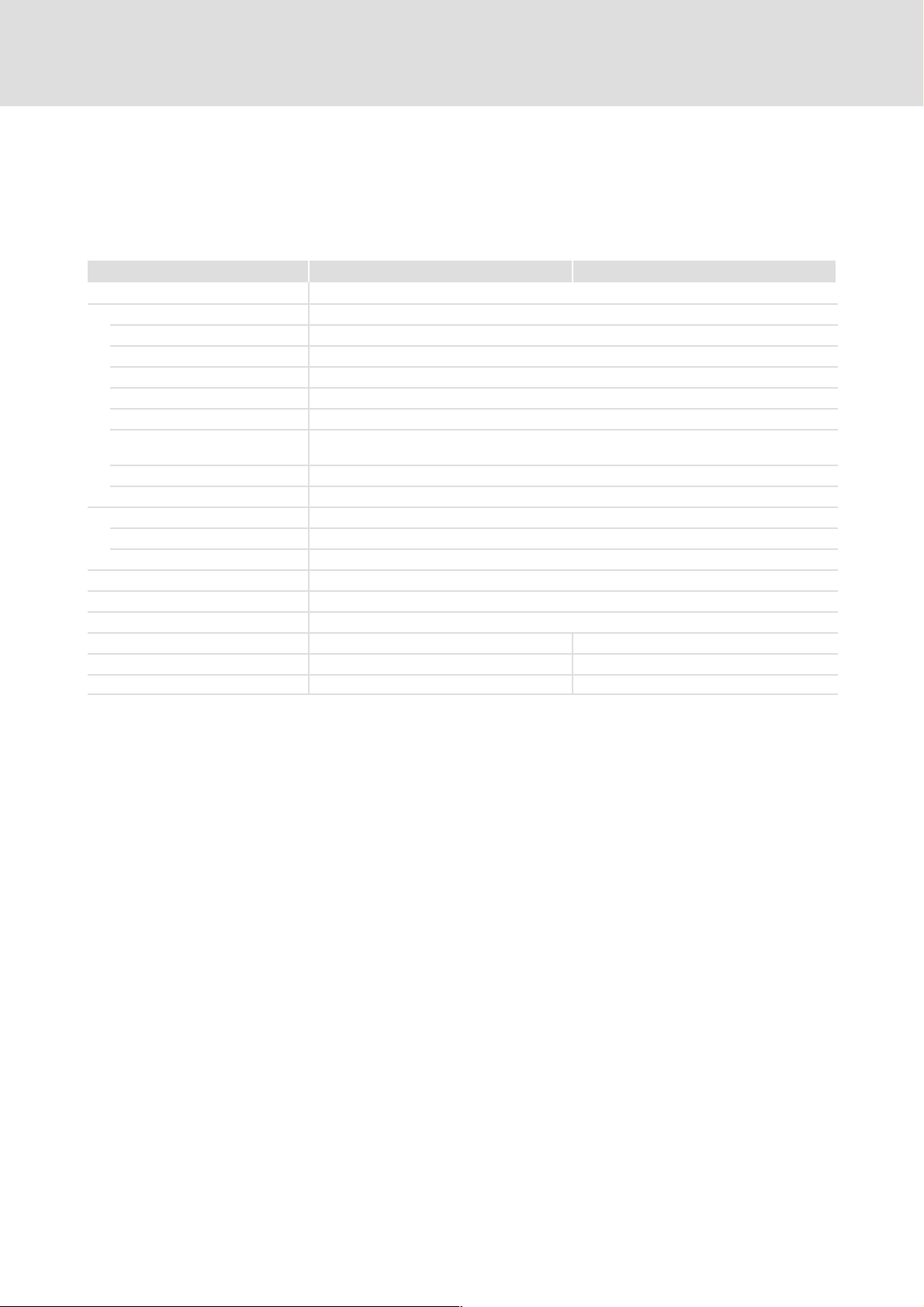

Technical data

Rated data

Standard device

2.2 Rated data

2.2.1 Standard device

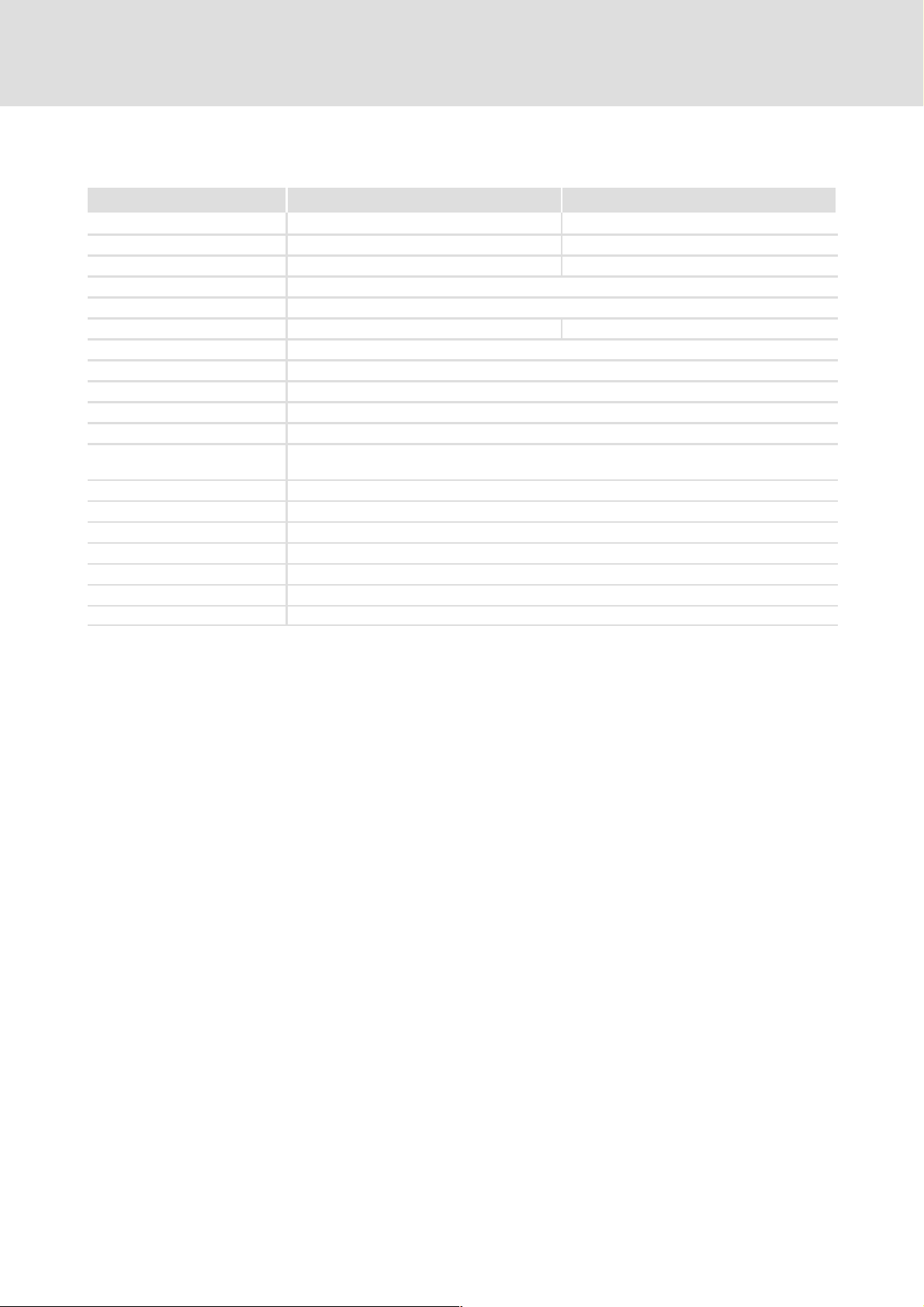

Type ETCHx ETCPx

Use Control (top hat rail design) Control (PCI insert card)

Weight 235 g 300 g

Dimensions (W x H x D) 100 x 45 x 115 mm 130 x 23 x 190 mm

Supply voltages:

Feed (external) typ. 24 V DC

5 V DC output on ME bus typ. 5.0 V, min. 4.75 V, max. 5.25 V DC

24 V DC output on ME bus typ. 24 V, min. 18 V, max. 32 V DC

Power loss max. 3 W

Power recovery up to max. ±32 V possible at the connection terminals

Potential isolation:

to CAN via optocoupler

to process level via optocoupler

Fuse:

24 V DC output on ME bus Front panel fuse

5 V DC output Short−circuit proof via DC/DC converter

Protection:

Feed against polarity reversal

5 V and 24 V supply against short circuit and polarity reversal

2

2.2

2.2.1

EDSTCXX EN 2.0

l

9

Page 10

2

2.2

2.2.2

Technical data

Rated data

Power supply unit

2.2.2 Power supply unit

Type

Use Power supply module

Weight 150 g

Dimensions (H x W x D) 99 mm x 22.5 mm x 114.5 mm

Supply voltages:

Feed (external) typ. 24 V DC

5 V DC output on ME bus typ. 5.0 V DC (4.75 ... 5.25 V DC)

24 V DC output on ME bus typ. 24 V DC (18 ... 32 V DC)

Power cunsumption at max.

output current:

Feed 18 V DC max. 3.2 A

Feed 24 V DC max. 2.9 A

Feed 32 V DC max. 2.7 A

Output current

5 V DC output on ME bus max. 3.0 A

24 V DC output on ME bus max. 2.0 A

Power loss max. 83 W

Power recovery up to max. ±32 V possible at the connection terminals

Potential isolation

between 5 V DC output and

24 V DC input

Fuse:

24 V DC output on ME bus Front panel fuse

5 V DC output Short−circuit proof via DC/DC converter

Protection

Feed against polarity reversal

5 V and 24 V supply against short circuit and polarity reversal

ETCHN003

500 V

2.2.3 Bus termination module

Type

Use Termination module or transfer module for internal CAN Bus (CAN1)

Weight 90 g

Dimensions (H x W x D) 99 x 17.5 x 114.5 mm

ETCHT000

10

l

EDSTCXX EN 2.0

Page 11

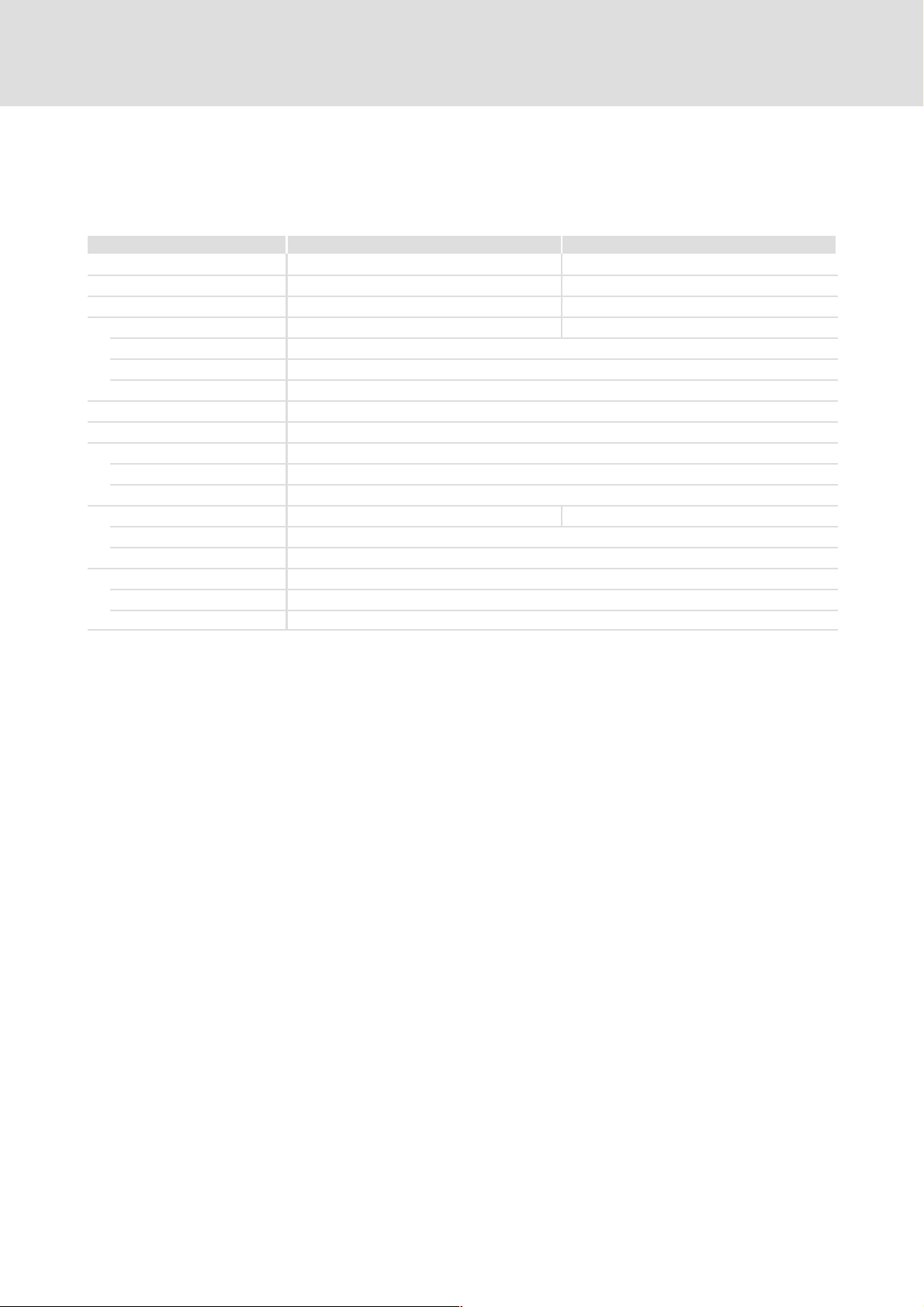

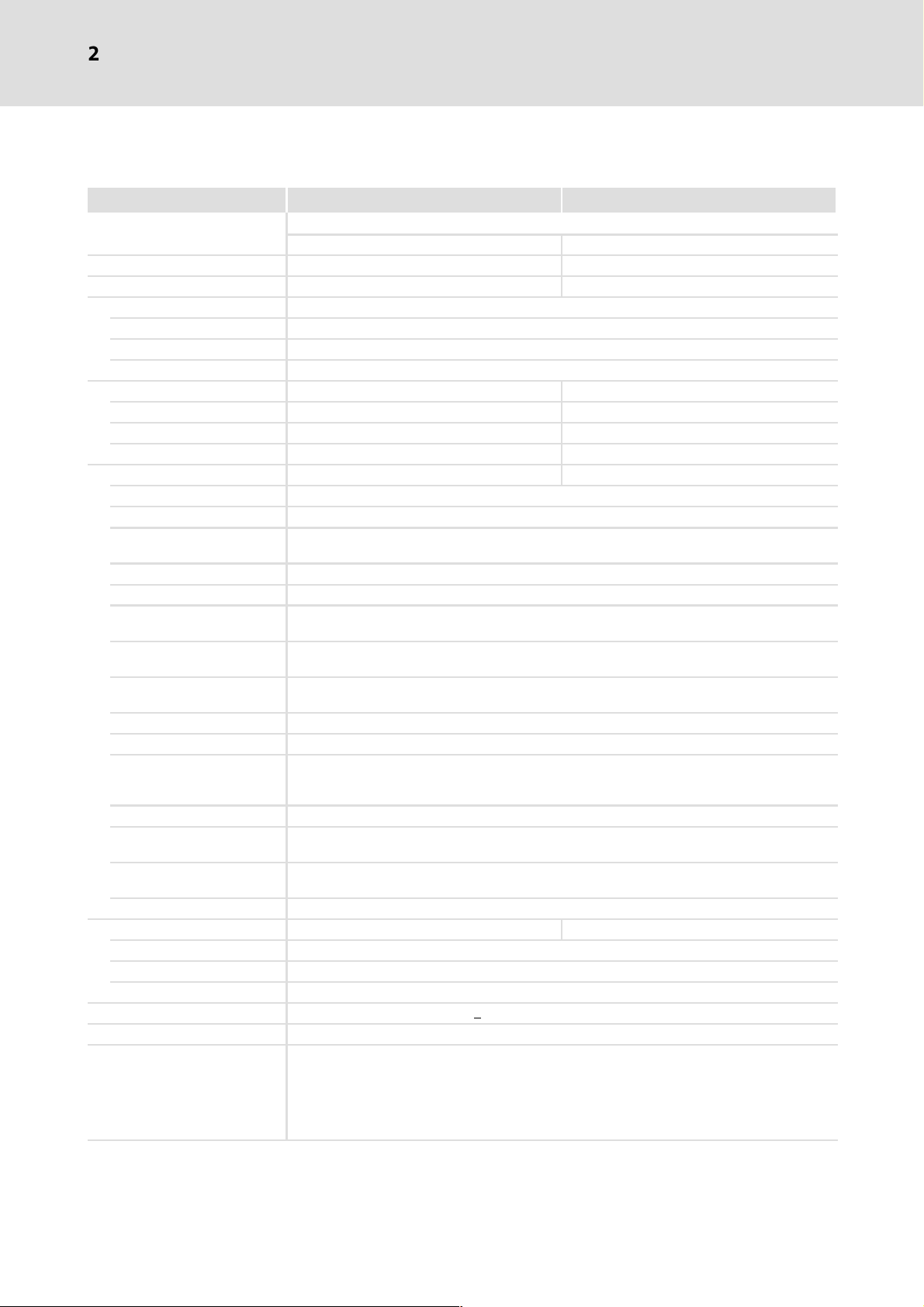

2.2.4 Input module

Technical data

Rated data

Input module

2

2.2

2.2.4

Type ETCHI008

Use 8 channel input module 16 channel input module

Weight 120 g 215 g

Dimensions (H x W x D) 99 x 22.5 x 114.5 mm 99 x 45.0 x 114.5 mm

Switching voltage of the inputs typ. 24 V DC (18 ... 32 V DC) via ME bus

Logical voltage typ. 5V DC ( 4.75 ... 5.25 V DC) via ME bus

Power loss typ. 3.0 W typ. 4.7 W

Input type digital current drawing inputs

Voltages of state "1" 11.0 to 32.0 V DC

Voltages of state "0" −3 to +5 V DC

Min. input current per channel 3 mA

Max. input current per channel 12 mA

Max. switching frequency at the

input

Input indication per input one LED, connected in series to the input terminal

Electrical isolation the inputs are connected via the joint earthing potential

24 V DC PTC thermistor

Logic component SMD time−lag fuse 500 mA

Power recovery up to max. +32 V at one input/output terminal possible

Protection Feed protected against polarity reversal.

Potential isolation 500 V DC (between logic component and input terminal)

approx. 250 Hz

ETCHI016

EDSTCXX EN 2.0

l

11

Page 12

2

2.2

2.2.5

Technical data

Rated data

Output module

2.2.5 Output module

Type ETCHU008

Use

Weight 145 g 215 g

Dimensions (H x W x D) 99 x 22.5 x 114.5 mm 99 x 45.0 x 114.5 mm

Supply voltages:

Supply voltage outputs typ. 24 V DC (18 ... 32 V DC) external feed

Supply voltage control typ. 24 V DC (18 ... 32 V DC) via ME bus

Logical voltage typ. 5.0 V DC (4.75 ... 5.24 V DC) via ME bus

Power loss:

4 outputs switched on typ. 1.0 W −

8 outputs switched on typ. 1.8 W typ. 1.5 W

16 outputs switched on − typ. 3.0 W

Outputs:

Switching voltage typ. 24 V DC (18 ... 32 V DC) external feed

Load characteristic resistive, inductive, capacitive

Continuous current per

channel

Current per channel for 1 sec 700 mA

Voltage drop for switch max. 400 mV at 500 mA

Min. voltage at the output

terminals

Parallel switching of several

outputs

Switching frequency of the

switches

Restart automatically after short circuit (with control present)

Short circuit peak current transient 4.0 A per channel (limited in the switch)

automatic restart current

with sustained short circuit

at output

Output indication on LED per output at the switch output

Initial state witch missing

control switched off by

Intermediate storage of the

control signal

Electrical isolation The output earth conductors are connected to each other

Fuse:

Switch Per 4 outputs each time−lag Microfuse 4 A; optionally pluggable

Switch triggering SMD time−lag fuse 500 mA

Logic component SMD time−lag fuse 500 mA

Power recovery up to max. + 32 V DC at one output terminal possible

Potential isolation 500 V DC (between logic component and input terminal)

Protection l The outputs are protected against overheating, short circuit and polarity reversal up to

±32 V DC.

l Additional fire protection with 4 A fuse. Suppressor diode (36 V) parallel to each switch

output.

l Series diode between switch output and output terminal.

l RESET trigger with drop in logical voltage.

Semiconductor switch against 24 V DC (High Side Switches)

8 channel output module 16 channel output module

max. 500 mA

Supply voltage – 1.0 V (at full load 0.5 A)

possible

max. 250 Hz at resistive load

3.0 A pulsed (with control present) switched off

logical component

no

ETCHU016

12

l

EDSTCXX EN 2.0

Page 13

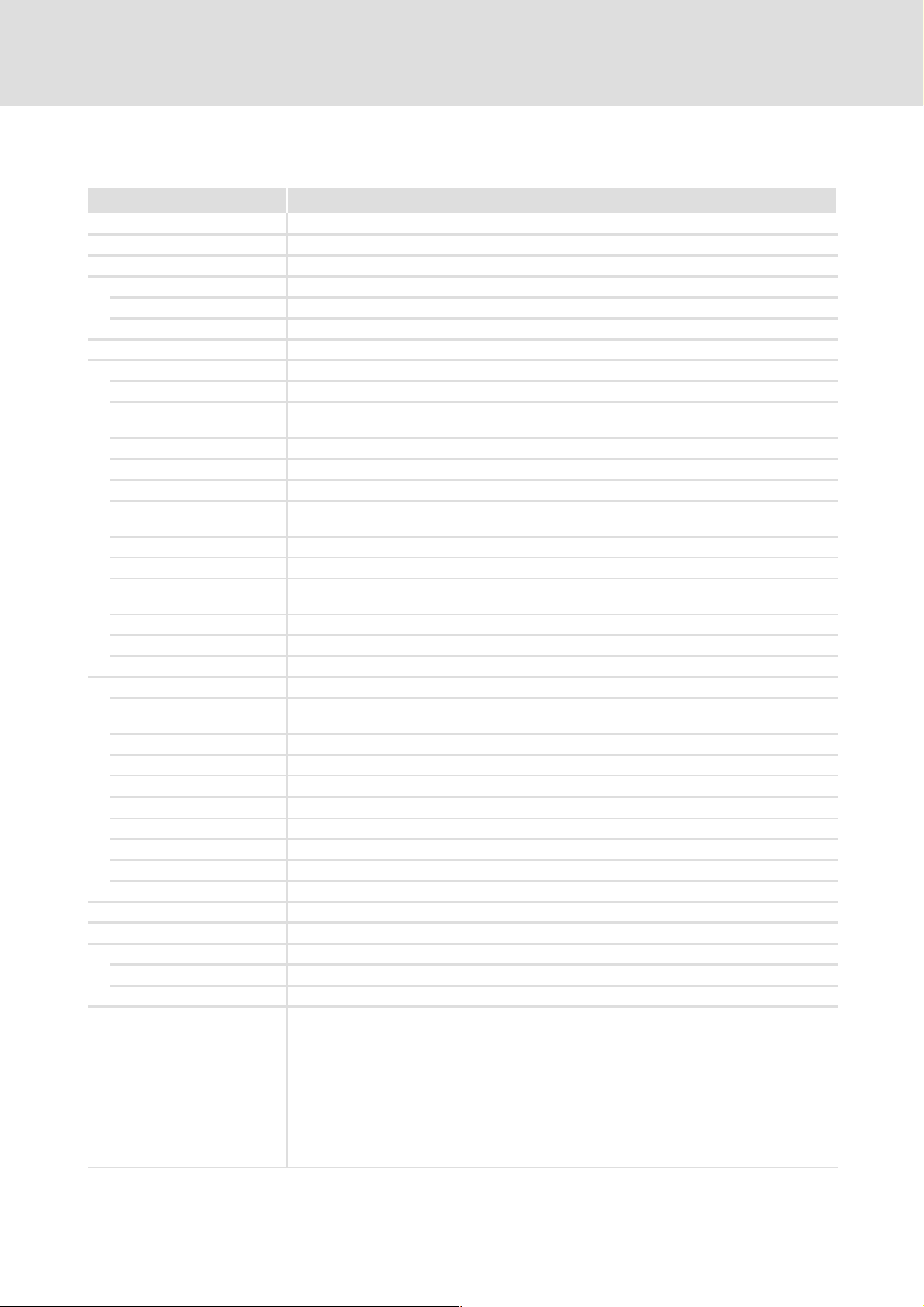

2.2.6 Analogue module

Technical data

Rated data

Analogue module

2

2.2

2.2.6

Type

Use 2 channel analogue input/output module, 0 V or −10 V ... +10 V

Weight 125 g

Dimensions (H x W x D) 99 x 22.5 x 114.5 mm

Supply voltages:

Control voltage (sensor feed) typ. 24 V DC (18 ... 32 V DC) feed via ME bus

Logical voltage typ. 24 V DC (18 ... 32 V DC) feed via ME bus

Power loss max. 6.2 W

Input:

Input impedance > 500 kOhm

Measuring range

(switchable)

Voltage at the input max. 32 V

Resolution 12 Bit

Conversion method successive approximation

Value of the LSB 2.5 mV for measuring range 0 ... 10 V or

5 mV for measuring range −10 V ... +10 V

Inaccuracy max. 50 mV for measuring range 0 ... 10 V or max. 100 mV for measuring range −10 V ... +10 V

Scanning frequency 205 Hz

Filters analogue low−pass filter of 1st degree with a limiting frequency of 30 Hz, digital configurable

Permitted sensor types Active and passive sensors

Sensor feed, sensor current 10 V regulated, max. 10 mA

Permitted connection cables Shielded cables; shield placed before the module

Output:

Output range (switchable) 0 ... 10 V or −10 ... +10 V

max. 0 ... 10.238 V or −10.238 V ... +10.238 V

Output current max. 2 mA

Min. load 5 kOhm

Resolution 12 Bit

Value of the LSB 2.5 mV or 5 mV

Inaccuracy max. 50 mV or 100 mV

Output rate min. 10 ms continually, min. 5 ms continually (digital input filter switched off)

Filters analogue low−pass filter of 1st degree with a limiting frequency of approx. 730 Hz

Permitted connection cables Shielded cables, shield placed before the module

Power recovery max. ±32 V at an input/output terminal

Potential isolation 500 V DC between ME bus and input/output terminals

Fuse:

Logic component SMD time−lag fuse 500 mA

System voltage SMD time−lag fuse 1500 mA

Protection l 24 V system voltage is protected by a definite plug−in direction in the housing.

l 5 V bus voltage is protected by a definite plug−in direction in the housing.

l Sensor supply is protected against short circuit, overcurrent and negative feed

l Current and voltage inputs (optional) are protected against voltages up to 32 V

l Input protection via high resistance voltage dividers

l Protection of the sensor feed via series diodes and active current limitation

l ESD protection via Transil diodes at PE

l Output protection via passive current limitation

l Series and parallel diodes, short−circuit proof

l ESD protection via Transil diodes at PE

ETCHA022

0 ... 10 V or –10 V ... +10 V

low−pass filter

EDSTCXX EN 2.0

l

13

Page 14

3

3.1

3.1.1

Device description

System overview

Examples for an automation system

3 Device description

3.1 System overview

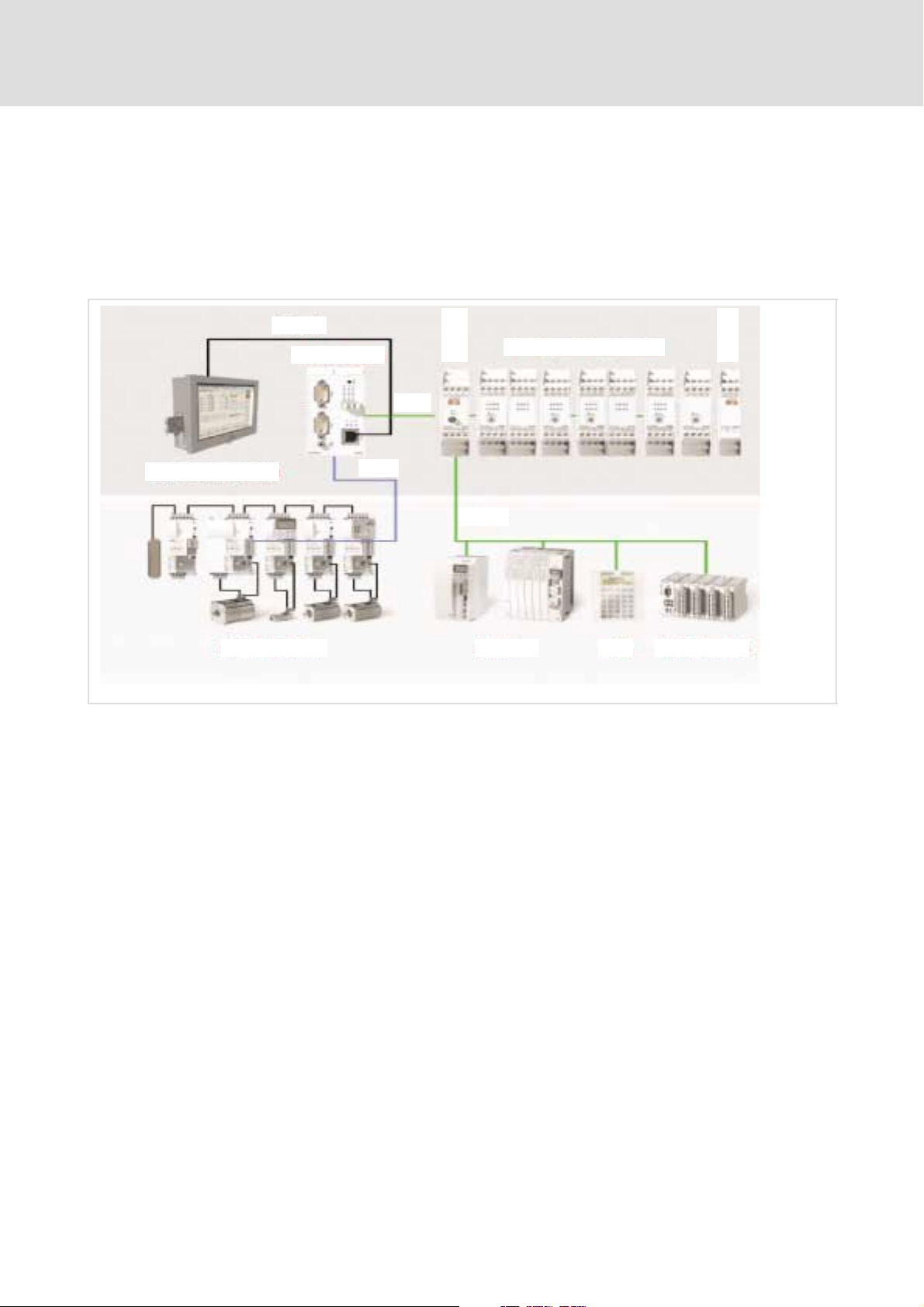

3.1.1 Examples for an automation system

Ethernet

ETCHx

CAN1

ETCHN003

ETC-System Components

ETCHT000

ETCHx / ETCPx

IPC with ETCPx

ECS/MCS-System Drives HMI I/O-System IP20

CAN2

CAN-I/O

ETCM001

The core of the automation system is the ETC control in the top hat rail design

(ETCHx) or as PCI insert card (ETCPx).

The top hat rail design ETCHx is normally used in a so−called ETC island

(¶ 16); it communicates via Ethernet with the applications on the IPC (or

standard PC).

The ETCPC is inserted into the IPC (or standard PC) and communicates with

the applications via the PCI bus.

Both designs have two separate CAN busses:

14

ƒ At CAN1 bus (or also ME bus) the I/O modules and any operating

components are connected. Third party devices must comply with teh

DS401 profile of the CANopen specification.

ƒ The drives (e.g. the ECS compact servo) are connected to the connection

for the Motion CAN bus (CAN2) at the front plate. External drives must

comply with the profile DS402 of the CANopen specification and in

particular support the "Interpolated Position Mode".

l

EDSTCXX EN 2.0

Page 15

Device description

System overview

Examples for an automation system

To carry out its allocated control function the ETC control needs various

programs which are transferred from the IPC (or standard PC):

ƒ Operating system or firmware of the control (e.g. ETCHC.rsc)

ƒ PLC programs (e.g. SPSDummy.prg)

ƒ CNC programs; i.e. cycle and DIN programs (e.g. 9000.zyk or

Nikolaus.din)

3.1

3.1.1

3

IPC

The ETC control is operated and maintained via the IPC (or standard PC). The

following applications might run on it:

ƒ Windows 2000 or XPoperating system

ƒ Terminal program (e.g. HyperTerminal) for establishing the Ethernet

connection between IPC and ETCHx control and for the configuration of

the ETCHx control via the monitor interface (e.g. firmware update). This

is not required for the ETCPx.

ƒ ETC−MMI gateway as communications program between Windows

applications and the ETC control.

ƒ Lenze ETC−MMI for the configuration, operation and monitoring of the

ETC control and for creating CNC programs.

ƒ CoDeSys development environment for the creation and testing of PLC

programs.

) Note!

An external keyboard is required at the IPC for commissioning. It

is not required for normal operation.

EDSTCXX EN 2.0

l

15

Page 16

3

3.1

3.1.2

Device description

System overview

Layout example for an ETC island

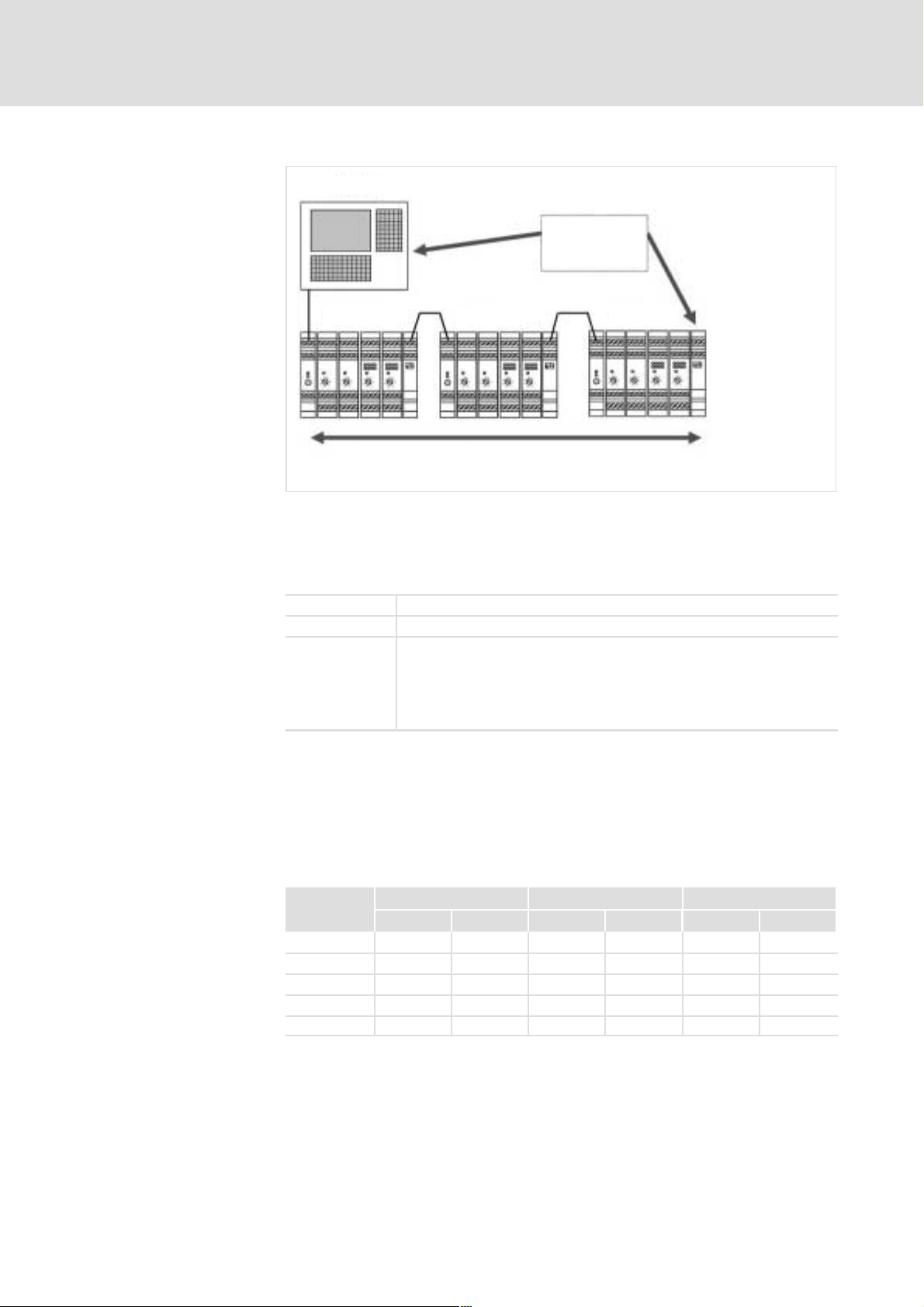

3.1.2 Layout example for an ETC island

ETCHN003

10

ETCHx004

ETCHI016

ETCHI008

ETCHT000

2345

ETCM002

0 Serial interface (RS232)

1 Watchdog (e.g. for emergency stop chain)

2 Ethernet

3 Motion CAN bus (CAN2)

4 24 V supply

5 ME bus (CAN1)

ETCHN003: Power supply unit for the supply of the ETC island and ME bus

connection

ETCHx004: ETC Motion Control for 4 axes (control)

ETCHIxxx: Input module with 16 or 8 digital inputs

ETCHT000: ME bus terminator module

) Note!

To terminate the ME bus DIP switch 1 must be set to ON at both

the power supply unit ETCHN003 and the bus terminator

module ETCHT000.

16

l

EDSTCXX EN 2.0

Page 17

Control

CAN Master

Device description

System overview

Layout example for an ETC island

CAN bus terminated

3

3.1

3.1.2

1. isolated system

max. CAN bus length

2. isolated system 3. isolated system

ETC024

Several ETCHx islands can be connected to form a complete system. Please

note the maximum permissible cable length per CAN level dependent on the

Baud rate (¶ 56). The maximum number of modules in one ETCHx island is

limited by the following constraints.

CAN Bus max. 127 modules

Module address max. 16 modules of the same type

Power supply

unit

In practice the capacity of the power supply unit is the decisive factor for

the maximum number of modules in an island. The current consumption of

the individual modules both via the 24 V and the 5 V supply is relevant and

must be taken into account.

Typically 15 modules can be supplied with one power supply unit

ETCHN003.

The power consumption of the individual modules fromthe 5 V voltage

produced in the power supply unit is shown in the following table.

EDSTCXX EN 2.0

The figure for "typ." refers to the 24 V supply voltage and with a high signal

being present at half the digital inputs and outputs.

The figure for "max." refers to the 32 V supply voltage and an operating state

with maximum power consumption.

Module

ETCHU008 95 mA 180 mA 15 mA 30 mA 30 mA 80 mA

ETCHU016 130 mA 240 mA 25 mA 55 mA 60 mA 160 mA

ETCHI008 70 mA 90 mA 90 mA 105 mA − −

ETCHI016 90 mA 120 mA 145 mA 175 mA − −

ETCHA022 150 mA 160 mA 60 mA 80 mA − −

5 V internal bus 24 V internal bus 24 V external (no load)

typ. max. typ. max. typ. max.

ETCHU008/016: Outputs fed externally.

ETCHI008/016: Eingänge intern gespeist.

The ampacity of the cables and plug−in connectors of the internal system bus

is at least 8 A (per cable). The direct plug−in connections between housing

and PCB can accept a load of 3 A.

l

17

Page 18

3

3.1

3.1.3

Device description

System overview

Set node address

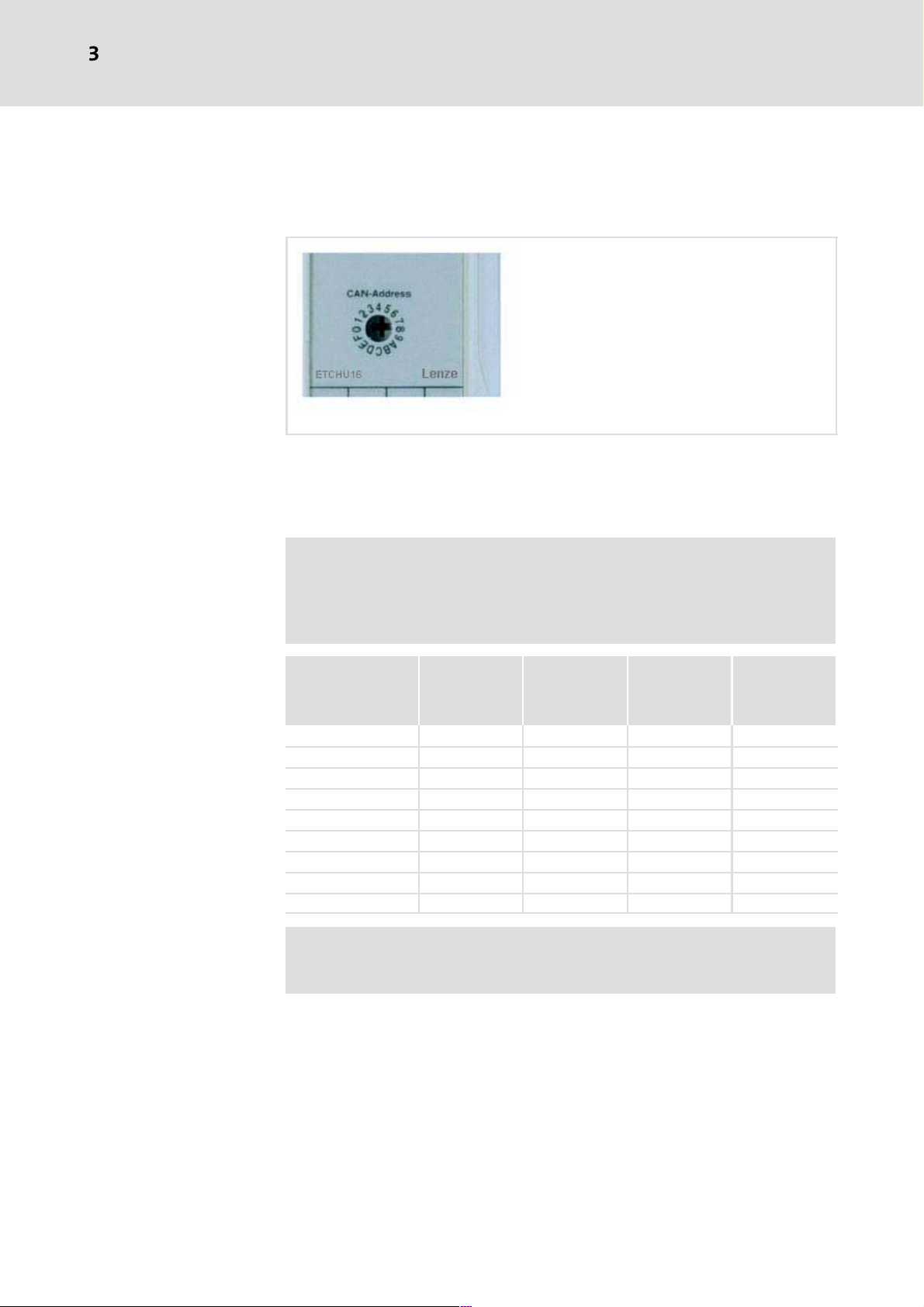

3.1.3 Set node address

Every ETCHx I/O module in a line represents a separate node at CAN1 bus and

must be set up with a unique node address.

ETC025

The node address is set via a front Hex switch (4 low value address bits) and

via permanently wirded bridges within the housing (3 high value address

bits). This means that a maximum of 16 modules are possible within a

module type.

) Note!

Some modules have internal codings switches instead of the

permanently wired bridges for the optional modification of the

high value address bits.

Module type High value

address bits

permanently

wired

CAN Bus Master −− −− 00 0

−− −− −− 01 H…0 FH 1 ... 15

ETCHU 10 H 0…FH 10 H…1 FH 16 ... 31

20 H 0…FH 20 H…2 FH 32 ... 47

ETCHA 30 H 0…FH 30 H…3 FH 48 ... 63

40 H 0…FH 40 H...4 FH 64 ... 79

ETCHI 50 H 0…FH 50 H…5 FH 80 ... 95

60 H 0…FH 60 H ... 6 FH 96 ... 111

70 H 0…FH 70 H ... 7 FH 112 ... 127

Low value

address bits

adjustable at

the front

Adjustable

node address

(hex)

Adjustable

node address

(decimal)

) Note!

All modules at the CAN bus must have a different node address.

18

l

EDSTCXX EN 2.0

Page 19

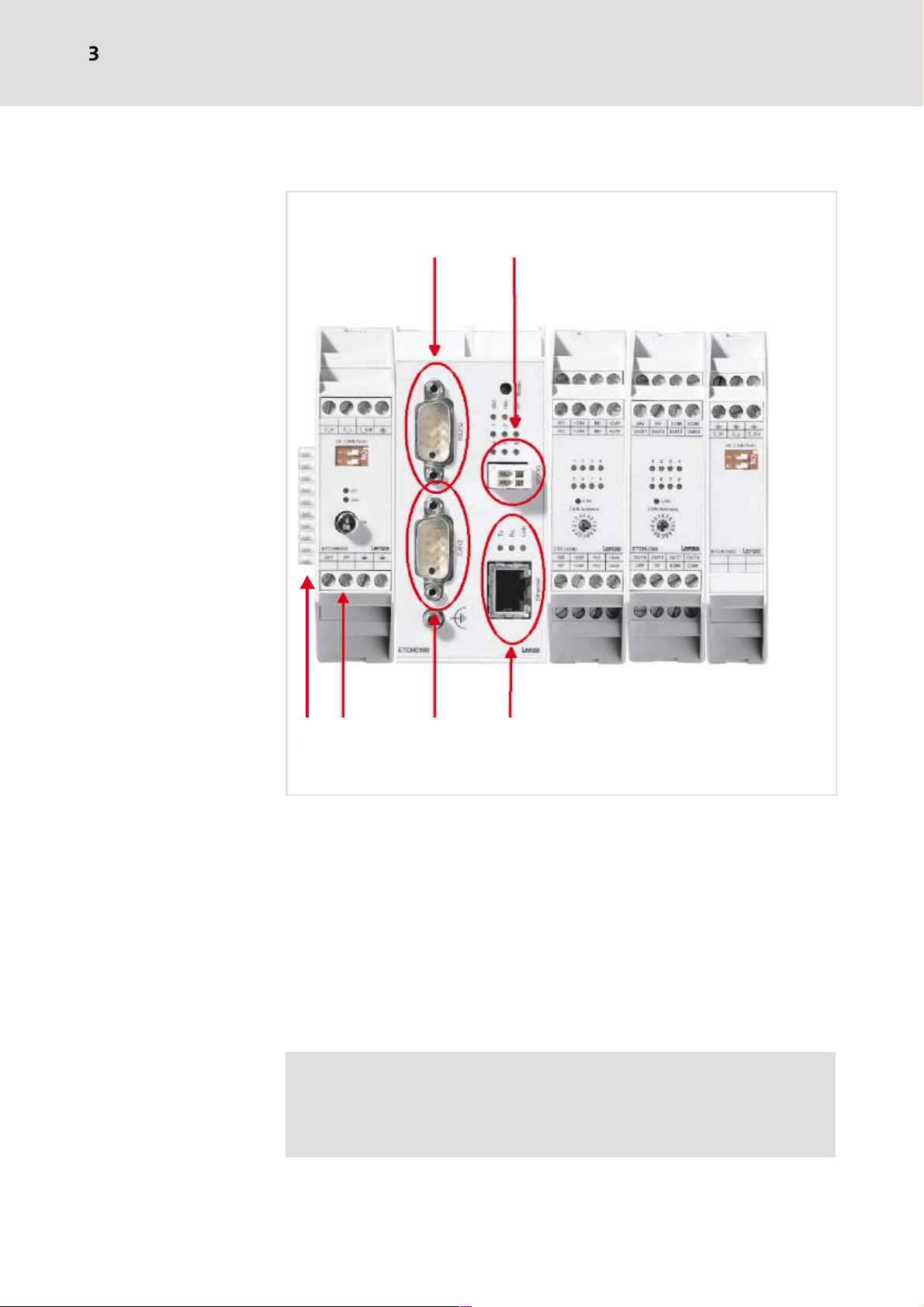

3.2 Control in top hat rail design (ETCHx)

Device description

Control in top hat rail design (ETCHx)

3

3.2

Description

Features

Elements

The ETCHx is a control for top hat rail assembly. Up−to−date communication

interfaces like Ethernet TCP/IP for networking and PC−MMI connection and

dual CANopen for the connection of field bus terminals or digital drive

amplifiers make the ETCHX ideal for use in machines with a distributed

control structure.

The connection to other modules is via the integrated ME bus.

ƒ 32 Bit MPC 555 Microcontroller

ƒ 4 MByte SRAM (with battery buffer; of which 12 KByte are available to

the PLC as remanent variable memory)

ƒ 2 MB Flash PROM

ƒ 2 CAN interfaces, 2 serial interfaces

ƒ 1 Ethernet TCP/IP interface

ƒ Watchdog

Designation Function

0 RS232 1st serial interface

1 ME bus Supply of the connected

4

modules and CAN1 bus for I/O

modules

0

5

2 CAN2 CAN2 bus for drives and

2nd RS232 interface

6

1

2

3 Functional earth (PE)

7

4 reset initialise control

8

5 LED 1 Status indication

3

6 WDOG Watchdog output

7 LED 2 Ethernet communication

8 Ethernet TCP/IP interface

ETC003

The control includes a battery for the SRAM.

The CAN1 interface is only present on the internal "ME bus". It can be

connected either to the power supply unit ETCHN003 or the bus termination

module ETCHT000.

EDSTCXX EN 2.0

l

19

Page 20

3

3.2

Device description

Control in top hat rail design (ETCHx)

Organisation of memory

4 MByte static SRAM (32 Bit RAM) and 2 MB Flash PROM are available.

ETCHC: The firmware has a memory requirement of 1 ... 1.5 MB SRAM and

1 MB Flash PROM. This means that the user has 2.5 ... 3 MB SRAM and 1 MB

Flash PROM available. This is sufficient for e.g. typically 128 NC sentences

(preprocessing buffer), 512 kB PLC program, 128 kB PLC data and 1 MB SPV

memory (DIN program memory).

ETCHM: The firmware has a memory requirement of 1 MB SRAM and 1 MB

Flash PROM. This means that the user has 3 MB SRAM and 1 MB Flash PROM

available. Verfügung. This is sufficient for e.g. typically 2000 kB PLC program

and 1000 kB PLC data.

The memory allocation can be configured by the user.

20

l

EDSTCXX EN 2.0

Page 21

Device description

Control in top hat rail design (ETCHx)

Serial interface

3

3.2

3.2.1

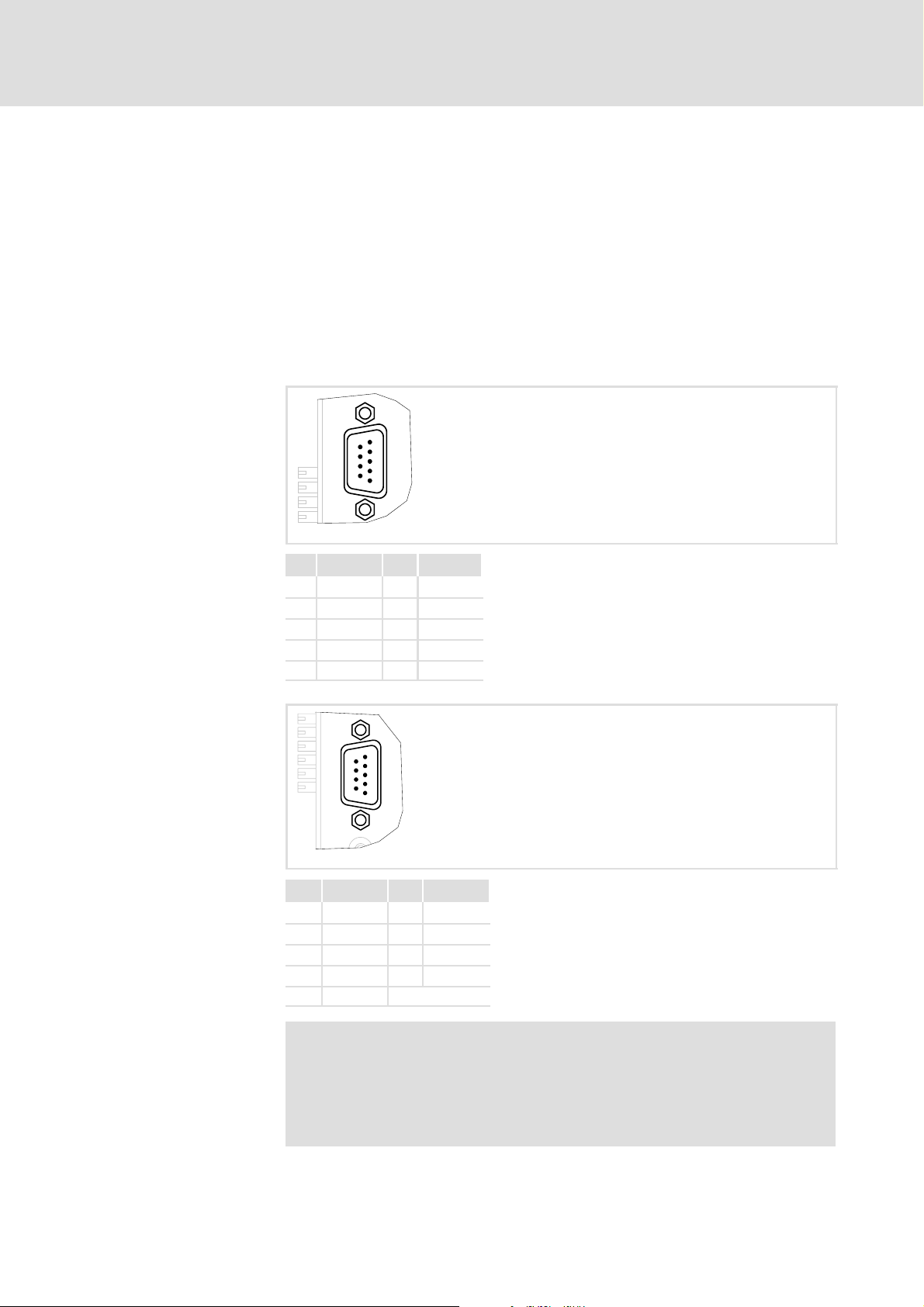

3.2.1 Serial interface

Connector allocation RS 232

(9−pole D−Sub pin)

The subassembly features two serial interfaces of the RS232 standard. The

signals of the first serial interface are connected to the RS232 plug

connector, and those of the second interface to the free contacts of the CAN2

plug connector. There are no hardware handshake signals for the second

interface.

The PLC programming environment and that of the internal monitors is

operated with 115 kBaud via the "RS232 connector. A client−specific PLC

program can control both interfaces.

1

6

RS232

9

5

ETC029

Pin Signal Pin Signal

1nc 6 DSR

2 RxD 7 RTS

3 TxD 8 CTS

4 DTR 9 nc

5 GND

Connector allocation (9−pole

D−Sub pin)

1

6

CAN2

9

5

Pin Signal Pin Signal

1 RxD 2 6

2 7

3 8 TxD 2

4 GND 9

5

) Note!

Use shielded cables and connector shells from metal or

metallised plastic for connecting the serial interfaces. The cable

shield must be connected conductively to both sides of the

connector shell.

ETC030

EDSTCXX EN 2.0

l

21

Page 22

3

3.2

3.2.2

Device description

Control in top hat rail design (ETCHx)

CAN interface

3.2.2 CAN interface

CAN2 (drives)

Connector allocation (9−pole

D−Sub pin)

Drives approved by Lenze can be connected to the CAN2 interface.

The CAN2 interface is connected to the 9−pole D−Sub connector with

standard connector allocation via the CAN driver (electrically isolated). The

isolation voltage to the computer is 500 V.

The CAN2 bus must be terminated in the connector with a 120 Ohm resistor.

A Can high−speed interface is implemetned in accordance with the ISO/DIS

11898 standard. The ETCHx is implemented as CAN Master.

1

6

CAN2

9

5

ETC030

Pin Signal Pin Signal

1 6 GND

2 CAN_L 7 CAN_H

3 GND 8

4 9 nc

5 Shield

ME bus with CAN1 (I/O)

Devices can be connected to the CAN1 bus which are triggered via the PLC

and support the CANopen profile DS 301. The bus lines can be picked up

directly at the bus connection if required.

The CAN1 interface is connected to the ME bus via CAN driver with electrical

connection to the PC. If the ETCHx is used at the CAN bus start or end, the bus

must be terminated with a terminating resistor of 120 Ohm (DIP switch on

the power supply unit ETCHN003 or the bus termination module ETCHT000).

To connect a block of interconnected modules to other CAN statiions the

CAN bus signals are directed to the upper terminals in the power supply

module ETCHN003 and the bus terminator module ETCHT000.

22

l

EDSTCXX EN 2.0

Page 23

Connector allocation for ME

bus with CAN1 (Phoenix

Mini−Combicon)

ME

Pin Signal Pin Signal

1 GND 5 V 6 CAN_H

2 GND 5 V 7 CAN_L

3 +5 V 8 PE

4 +5 V 9 +24 V

5 CAN_Gnd 10 GND 24 V

Device description

Control in top hat rail design (ETCHx)

CAN interface

3

3.2

3.2.2

ETC010

) Note!

The physical connection can be checked at any point of the CAN

bus using an Ohmmeter. All supply voltages must be switched

off for the measurement.

The measured resistance between the signals CAN_H and CAN_L

must be approx. 60 Ohm. The resistance between CAN_L and

GND and btetween CAN_H and GND must be "infinitely" large.

Other values can be measured as a result of a short circuit in the

signals or a reversal of the connections.

CiA−DS−102−1 and CiA DR−303−1 describes the plug−in connectors

and cables used and the supported bit rates.

EDSTCXX EN 2.0

l

23

Page 24

3

3.2

3.2.3

Device description

Control in top hat rail design (ETCHx)

Ethernet interface

3.2.3 Ethernet interface

The interface is used to connect a PC terminal or to integrate the control

within a network. It is designed as a RJ45 plug−in connector. The cabling type

is 10 BASE−T.

Connector allocation (8−pole

RJ45 connector)

Tx

Rx

Link

Ethernet

Pin Signal Pin Signal

1 TxD+ 6 RxD−

2 TxD− 7 nc

3 RxD+ 8 nc

4 nc

5 nc

ETC036

The LEDs on the front plate indicate the following states:

Tx, Rx Data transfer via the interface

LNK Result of the internal 10 BASE−T Link Integrity Test. It illuminates as soon as

an Ethernet connection has been established.

) Note!

If a point−to−point connection between control and PC terminal

is being set up, a "cross−over" cable must be used.

24

l

EDSTCXX EN 2.0

Page 25

3.2.4 Watchdog (WDOG)

The Watchdog circuit is used to monitor the processor and switches the

linked outputs off as soon as they are no longer triggered.

2

WDOG

Device description

Control in top hat rail design (ETCHx)

Watchdog (WDOG)

3

3.2

3.2.4

1

Pin Signal

1 +24 V

2 out (max. 100 mA)

Conductor cross section: max 0.5 mm

2

ETC039

A Watchdog signal can be picked off from the WDOG connector. For this a

+24 V voltage must be connected to Pin 1. Unless the Watchdog has been

released, the voltage is connected through to Pin 2.

EDSTCXX EN 2.0

l

25

Page 26

3

3.3

Device description

Control as PCI insert card (ETCPx)

3.3 Control as PCI insert card (ETCPx)

Description

Features

Elements

The ETCPC includes the coupling to the PC via a PCI bus plug−in connector and

the complete MC or NC core plus a PlC computer core.

ƒ 32 Bit MPC 555 Microcontroller

ƒ 4 MByte SRAM (with battery buffer; of which 12 KByte are available to

the PLC as remanent variable memory)

ƒ 256 MB Flash PROM

ƒ 2 CAN interfaces, 2 serial interfaces

ƒ Watchdog

Designation Function

0 P1 1st Serial interface (RS232)

1 P2 2nd Serial interface (RS232)

5

2 J3 Lenze Service interface

3 J4 Lenze Service interface

6

4 J5 Lenze Service interface

0

1

4

3

2

:

5 Battery for SRAM

9

8

6 P7 Lenze Service interface

7 P5 Lenze Service interface

8 P6 CAN 2 (drives)

7

9 LEDs Status indication

Organisation of memory

P4 CAN 1 (I/O)

:

ETC004

4 MByte static SRAM (32 Bit RAM) and 256 kB Flash PROM are available. The

firmware has a memory requirement of 1 MB SRAM.

The firmware is read from the hard drive and written to the SRAM. This

means the user has 3 MB SRAM and 256 kB Flash available.

The memory allocation can be configured by the user.

26

l

EDSTCXX EN 2.0

Page 27

3.3.1 Serial interface

Device description

Control as PCI insert card (ETCPx)

Serial interface

The subassembly features two serial interfaces of RS232 standard. The can

be used for operating the PLC development environment, as monitor

interfaces and as client−specific PLC interface.

The signals are directed to 10−pole pin contact strips P1 and P2 and can be

connected via ribbon cables to the D−Sub plug connectors fitted to the card

slots or the PC housing openings.

The PLC programming environment can be operated at P1 with 115 kBaud

or via P2 with 38 kBaud. The monitor is actuated via P1.

A client−specific PLC program can operate both interfaces.

A standard null modem cable can be used to connect a PC. The handshake

cables (RTS, CTS) must be wired.

3.3

3.3.1

) Note!

Use shielded cables and connector shells from metal or

metallised plastic for connecting the serial interfaces. The cable

shield must be connected conductively to both sides of the

connector shell.

3

Connector allocation P1 and

P2 (10−pole pin contact strip)

P1 P2

2

2

10

1

9

Pin Signal Pin Signal

1nc6 CTS

2 DSR 7 DTR

3 RxD 8 nc

4 RTS 9 GND

5 TxD 10 nc

10

1

9

ETC032

EDSTCXX EN 2.0

l

27

Page 28

3

3.3

3.3.1

Connector allocation P2, user

interface(9−pole D−Sub pin)

Device description

Control as PCI insert card (ETCPx)

Serial interface

ETC033

Pin Signal Pin Signal

1nc6 nc

2 RxD 7 nc

3 TxD 8 nc

4 nc 9 nc

5 GND

Connector allocation P1,

monitor program (10−pole pin

contact strip)

ETC034

Pin Signal Pin Signal

1nc6 nc

2 nc 7 nc

3 TxD 8 nc

4 nc 9 GND

5 RxD 10 nc

Via the plug connector P1 the content of the DPR can be read and written to

using a monitor program. It also allows for a data backup of the system

parameters from the DPR to the Parameter EEPROM.

The interface for the monitor program requires the following settings:

Baud rate 9600

Data bits 8

Stop bits 1

Parity no

28

The monitor program only uses ASCII characters; CR, LF, BS, XON and XOFF

are used as control characters.

l

EDSTCXX EN 2.0

Page 29

3.3.2 CAN interface

Connector allocation P4 and

P6, CAN interface (9−pole

D−Sub pin)

Device description

Control as PCI insert card (ETCPx)

CAN interface

The two CAN Controllers are directed via CAN drivers to 9−pole D−Sub plug−in

connectors with standard connector allocation (electrically isolated).

Because theETCPx has only one plug−in connector per CAN channel, the

subassembly must either be connected to one of the two bus ends or it must

be integrated with the bus line using an adapter cable or node connector

(e.g. ERbic by ERNI).

If the ETCPx is positioned at the CAN bus start or end, a terminating resistor

can be added on the board via the jumpbers J7 and J10.

A CAN high−speed interface in accordance with the ISO/DIS 11898 standard

has been implemented. The ETCPCx is implemented as a CAN Master.

The CAN interface is electrically isolated from the computer. The isolation

voltage to the computer is 500 V.

3.3

3.3.2

3

CAN interface P4

P4

P6

Pin Signal Pin Signal

1 Reserved 6 Ground

2 CAN−Low 7 CAN−High

3 Ground 8 Reserved

4 Reserved 9 +U

5 Shield

P4

P6

ETC035

P4 allows for devices to be connected which are triggered by the PLC and

support the CANopen profile DS 301.

A maximum of 60 nodes can be connected electrically to the interface.

EDSTCXX EN 2.0

l

29

Page 30

3

3.3

3.3.3

Device description

Control as PCI insert card (ETCPx)

Configuration and Watchdog

CAN interface P6

P6 is a drive interface for the connection of drives which have been approved

by Lenze. Dependent on the control design up to 12 axes can be controlled.

) Note!

The physical connection can be checked at any point of the CAN

bus using an Ohmmeter. All supply voltages must be switched

off for the measurement.

The measured resistance between the signals CAN_H and CAN_L

must be approx. 60 Ohm. The resistance between CAN_L and

GND and btetween CAN_H and GND must be "infinitely" large.

Other values can be measured as a result of a short circuit in the

signals or a reversal of the connections.

CiA−DS−102−1 and CiA DR−303−1 describes the plug−in connectors

and cables used and the supported bit rates.

3.3.3 Configuration and Watchdog

J7

J38

J10

Jumper

J7 Terminating resistor CAN 1 closed

J10 Terminating resistor CAN 2 closed

J11 RESET PCI bus acts on ETCPx closed

J38 Wachtdog bridged

Function Standard settings

CAUTION! Attach J38 only for commissioning and test

J11

open

ETC037

30

l

EDSTCXX EN 2.0

Page 31

Device description

Control as PCI insert card (ETCPx)

Configuration and Watchdog

3

3.3

3.3.3

Watchdog OK signal

Jumper allocation J5, Serial

expansion bus (14−pole pin

contact strip)

The watchdog circuit is used to check the processor and switches off the

linked outputs as soon as they are no longer triggered.

The Watchdog OK signal is connected to Pin 10 of the pin contact strip J5. For

external use this signal must be edited via the corresponding drivers and an

electrical isolation.

The jumper J38 is to be used for test purposes. It releases the WDOG signal

constantly irrespective of the Watchdog. The Watchdog OK signal is

indicated by the illumination of an LED in the status display.

J5

214

113

ETC038

Pin Signal

1 GND

10 IO_WDOG

) Note!

The Watchdog signal is a standard TTL output. This output must

not be taken directly from the PC but must be edited via

corresponding drivers and electrical isolation.

EDSTCXX EN 2.0

l

31

Page 32

3

3.4

3.4.1

3.4 Module

3.4.1 Power supply unit

Device description

Module

Power supply unit

Description

Features

The module ETCHN003 is used for the power supply of an ETC island and

transfer module for the CAN bus with multiline system structure.

ƒ Input voltage 18 ... 30 V DC

ƒ Output voltage 5 V DC (max. 3 A) and 24 V DC (max. 2 A)

ƒ Short−circuit and undervoltage protection

ƒ CAN−BUS In

ƒ Bus terminator can be added

ƒ Transfer module for multiline module structure

) Note!

ƒ Only one power supply unit is possible per ME bus. The

attachment of serveral power supply units (parallel

connection) to one ME bus is not permitted.

ƒ The module is protected against short circuit and reverse

polarity. During a short circuit or overloading of the internal

24 V supply on the ME bus the power supply is interrupted.

ƒ The 5 V supply is protected by the internal protective circuit of

the DC/DC converter.

ƒ Each external connection is protected up to an electric

strength of +32 V. This protection effective for a faulty

connection of the module and only if the supply cable includes

a circuit braker 6 A Type B which will trigger, if necessary.

32

l

EDSTCXX EN 2.0

Page 33

Elements

9 ... 12

S1, S2

Device description

Module

Power supply unit

3

3.4

3.4.1

ME

LED 5 V, LED 24 V

F1

1 ... 4

Terminal Designation Meaning Comment

1 +24 V Voltage supply

2 0 V Reference potential

9 C_H CAN High

10 C_L CAN Low

11 C_Gd CAN signal earth

12, 3, 4 CAN shield potential, shielding Terminals bridged

S1 Switch for CAN bus termination On = termination with

F1 Fuse Plug−in Microfuse 5 A,

LED 5 V

LED 24 V

ME ME bus

Live LED 5 V and 24 V Illuminate if voltage is

To extend the ME bus

to external modules

internally

120 Ohm between C_H

and C_L

125 V (manufacturer

Wickmann No.

303−1500−042); pull to

replace

adequate

ETC007

EDSTCXX EN 2.0

l

33

Page 34

3

3.4

3.4.1

Device description

Module

Power supply unit

ME bus

Control and power supply unit are connected to each other via the ME bus

connector. The power supply unit is connected to the left of the control.

ME

ETC010

Pin Signal Pin Signal

1 GND 5 V 6 CAN_H

2 GND 5 V 7 CAN_L

3 +5 V 8 PE

4 +5 V 9 +24 V

5 CAN_Gnd 10 GND 24 V

Block diagram

2

0

0 front terminals

1 ME bus

1

ETC006

34

l

EDSTCXX EN 2.0

Page 35

Device description

Module

Bus termination module

3

3.4

3.4.2

3.4.2 Bus termination module

Description

The module ETCHT000 is used as a bus terminator for the internal CAN bus

or as a transfer module for a multiline system structure.

CAN terminator module: DIP switch 1 = ON

CAN transfer module: DIP switch 1 = Off

Elements

ME

13 ... 15

9 ... 11

S1, S2

Terminal Designation Signal Comment

9 C_H CAN High

10 C_L CAN Low

11 C_Gd CAN signal earth

13 ... 15 CAN shield potential, shielding Terminals bridged

S1 Switch for CAN bus termination On = termination with

S2 Without function

ME ME bus

To extend the ME bus

to external modules

internally

120 Ohm between C_H

and C_L

ETC011

EDSTCXX EN 2.0

l

35

Page 36

3

3.4

3.4.2

Block diagram

Device description

Module

Bus termination module

Klemmen

Klemmen

01

frontseitig

frontseitig

0 front terminals

1 ME bus

Signale

Signale

Klemmen

ME-Bus

ME-Bus

frontseitig

ETC012

36

l

EDSTCXX EN 2.0

Page 37

Device description

Module

Input module

3

3.4

3.4.3

3.4.3 Input module

Description

Features

Elements ETCHI008

The input modules ETCI008 (8 inputs) and ETCI016 (16 inputs) for the

connection of potential−free contacts (make−contacts) switch an available

24 V DC voltage to the respective input.

ƒ 8 or 16 digital inputs

ƒ 8 or 16 control LEDs

ƒ 2 cable connection for 24 V DC input signals

– decoupled via optocoupler

ƒ Module address selectable via rotary switch

13 ... 16

9 ... 12

LED1

ME

LED2

S1

1 ... 4

5 ... 8

Terminal Designation Meaning Comment

13, 15, 9, 11,

1, 3, 5, 7

14, 16, 10, 12,

2, 4, 6, 8

IN1 ... IN8 8 digital inputs 24V

+24 V Encoder supply 24 V Terminals bridged

internally

LED1 Input LED Illuminates if signal is

present

LED2 Live LED Illuminates if no fault

is present

S1 Switch for CAN node address ^ 18

ME ME bus

ETC013

EDSTCXX EN 2.0

l

37

Page 38

3

3.4

3.4.3

Block diagram ETCHI008

Device description

Module

Input module

Signale

Klemmen

Klemmen

01

frontseitig

frontseitig

0 front terminals

1 ME bus

Signale

Klemmen

ME-Bus

ME-Bus

frontseitig

etc015

38

l

EDSTCXX EN 2.0

Page 39

Elements ETCHI016

Device description

Module

Input module

3

3.4

3.4.3

29 ... 3213 ... 16

25 ... 289 ... 12

LED1

ME

LED2

S1

17 ... 201 ... 4

21 ... 245 ... 8

ETC014

Terminal Designation Meaning Comment

13, 15, 9,

11, 1, 3, 5,

7, 29, 31,

25, 27,

17, 19,

21, 23

14, 16,

10, 12, 2,

4, 6, 8, 30,

32, 26,

28, 18,

20, 22, 24

IN1 ... IN16 16 digital inputs24V

+24 V Encoder supply 24 V Terminals bridged

internally

LED1 Input LED Illuminates if signal is

present

LED2 Live LED Illuminates if no fault is

present

S1 Switch for CAN node address ^ 18

ME ME bus

EDSTCXX EN 2.0

l

39

Page 40

3

3.4

3.4.3

Block diagram ETCHI016

Device description

Module

Input module

etc016

0 front terminals

1 ME bus

40

l

EDSTCXX EN 2.0

Page 41

Device description

Module

Output module

3

3.4

3.4.4

3.4.4 Output module

Description

Features

Elements ETCHU008

The output modules ETCU008 (8 outputs) and ETCU016 (16 outputs) provide

the digital signal from the control to the process level. The digital outputs are

supplied via an external voltage source (24 V DC).

ƒ 8 or 16 digital outputs

ƒ 8 or 16 control LEDs

ƒ 2 cable connection

– High active switching, I= 0.5 A per channel (short−circuit proof)

– decoupled via optocoupler

ƒ Module address selectable via rotary switch

13 ... 16

9 ... 12

LED1

ME

LED2

S1

1 ... 4

5 ... 8

Terminal Designation Meaning Comment

9, 10, 11,

12, 1, 2, 3,

4

13, 5 +24 V Encoder supply 24 V

14, 6 0 V Reference potential for encoder

15, 16, 7,8COM Reference potential for load Terminals bridged

OUT1 ... OUT8 8 digital outputs 24V

Terminals bridged

internally

supply

internally with 0 V

LED1 Output LED Illuminates if signal is

present

LED2 Live LED Illuminates if no fault is

present

S1 Switch for CAN node address ^ 18

etc017

EDSTCXX EN 2.0

l

41

Page 42

3

3.4

3.4.4

Block diagram ETCHU008

Device description

Module

Output module

etc019

0 front terminals

1 ME bus

2 Fuse

3 2 fuses (Microfuse 4 A) for 4 outputs each

42

l

EDSTCXX EN 2.0

Page 43

Elements ETCHU016

ME

29 ... 3213 ... 16

25 ... 289 ... 12

LED1

LED2

S1

17 ... 201 ... 4

21 ... 245 ... 8

Device description

Module

Output module

3

3.4

3.4.4

etc018

Terminal Designation Meaning Comment

9, 10, 11,

12, 1, 2, 3,

4, 25, 26,

27, 28,

17, 18,

19, 20

13, 5, 29,21+24 V Encoder supply 24 V

14, 6, 30,220 V Reference potential for encoder

15, 16, 7,

8, 31, 32,

23, 24

OUT1 ... OUT16 16 digital outputs24V

Terminals bridged

internally

supply

COM Reference potential for load Terminals bridged

internally with 0 V

LED1 Output LED Illuminates if signal is

present

LED2 Live LED Illuminates if no fault is

present

S1 Switch for CAN node address ^ 18

EDSTCXX EN 2.0

l

43

Page 44

3

3.4

3.4.4

Block diagram ETCHU016

Device description

Module

Output module

3

2

3

2

01

etc020

0 front terminals

1 ME bus

2 Fuse

3 2 fuses (Microfuse 4 A) for 4 outputs each

44

l

EDSTCXX EN 2.0

Page 45

Device description

Module

Analogue module

3

3.4

3.4.5

3.4.5 Analogue module

Description

The analogue module ETCHA022 is a mixed analogue input and output

module.

Features

ƒ 2 analogue inputs and outputs, resolution 12 Bit, 0 ... 10 V or ±10 V

ƒ Module address selectable via rotary switch

Elements

ME

13 ... 16

9 ... 12

LED2

S1

1 ... 4

Terminal Designation Meaning Comment

14, 10 IN1, IN2 2 analogue inputs 0 ... 10 V or ±10 V

1, 3 OUT1, OUT2 2 analogue outputs 0 ... 10 V or ±10 V

13, 9 +V1, +V2 Sensor supply 24 V

15, 11, 2,4COM Reference potential for sensor

supply

16, 12 Shielding

LED1 Live LED Illuminates if no fault is

S1 Switch for CAN node address ^ 18

Terminals bridged

internally

present(programmable)

ETC021

EDSTCXX EN 2.0

l

45

Page 46

3

3.4

3.4.5

Block diagram

Device description

Module

Analogue module

2

12 Bit A/D

3

12 Bit A/D

0

0 front terminals

1 ME bus

2 Fuse

3 Switch−over voltage range (0 ... 10 V, −10 V ... +10 V)

1

ETC022

46

l

EDSTCXX EN 2.0

Page 47

Mechanical installation

Control and module for top hat rail mounting (ETCHx)

4 Mechanical installation

4.1 Control and module for top hat rail mounting (ETCHx)

The modules of the ETCHx series are housings for top hat rail installation

which are connected together. All modules of the ETCHx series feature

modular ME bus housings and can be clipped directly onto a carrier rail TS35

with a maximum dimension of 7.5 or 15 mm as per European standard EN

50022.

This installation is simple and space−saving. The individual modules are

positioned and connected safely in the housing base using the integrated

10−pole cross−connectors. The power supply of the module control

electronics and the transfer of the bus signals takes place via the cross

connector.

All modules of the ETCHx series have the same construction (with differing

widths), thus keeping the planning costs very low.

4

4.1

EDSTCXX EN 2.0

l

47

Page 48

4

4.1

Mechanical installation

Control and module for top hat rail mounting (ETCHx)

Ventilation

The natural convection of the ambient air is sufficient for operating the

subassemblies. An adequate entry of the air underneath the device and

unobstructed exit above must always be ensured.

For installation in sealed housings the heat loss arising must be dissipated

through the housing surfaces! If this cannot be guaranteed, a forced airflow

is mandatory.

When used at greater heights (> 1000 m above sea level) the reduced air

pressure (< 900 hPa) requires a reduction in the permitted ambient

temperature of 1 K per 300 m.

The system is supplied as an open installation component. Suitable

measures must be taken at the installation location to protect the

component from dust. For most applications a regularly serviced filter in the

incoming air of the installation location is sufficient. With conductive dust

or in aggressive ambient air the use of a sealed cooling circuit using heat

exchangers or an air conditioned switch cabinet are required.

The installation position must be vertical to ensure adequate ventilation.

A clearance of at leats 80 mm above and below the module should be

retained; for vertically orientated rows of modules the distance between the

carrier rails should be 180 mm.

0 Cable channel

0

180 mm

ETC025

48

l

EDSTCXX EN 2.0

Page 49

Mechanical installation

Control and module for top hat rail mounting (ETCHx)

Control ETCHx

4

4.1

4.1.1

4.1.1 Control ETCHx

ETC026

EDSTCXX EN 2.0

l

49

Page 50

4

4.1

4.1.2

4.1.2 Module ETCHx

Mechanical installation

Control and module for top hat rail mounting (ETCHx)

Module ETCHx

ETC027

50

l

EDSTCXX EN 2.0

Page 51

Control and module for top hat rail mounting (ETCHx)

Dismantling of control and module ETCHx

4.1.3 Dismantling of control and module ETCHx

Mechanical installation

4

4.1

4.1.3

ETC028

EDSTCXX EN 2.0

l

51

Page 52

4

4.2

4.2.1

4.2 Control in PCI design (ETCPx)

4.2.1 Installing the PCI card in the PC

Mechanical installation

Control in PCI design (ETCPx)

Installing the PCI card in the PC

( Stop!

Only install the PCI control variant ETCPx after installing the

ETC−MMI and before starting the ETC−MMIs.

{ Danger!

Dangerous electrical voltage!

Dangerous electrical voltage may be present at the components

and connections of the PC.

Potential consequences:

ƒ Death or severe injury when making contact with components

or connections.

Protective measures:

ƒ Disconnect the PC and all connected devices from the mains

before opening the housing.

( Stop!

Electrostatically sensitive components!

ƒ The PCI card ETCPX0XX contains sensitive electronic

components which may be damaged by electrostatic

discharge if the card is touched.

Protective measures:

ƒ Divert electrostatic charges using suitable measures (e.g. wrist

earthing strip, antistatic work surface).

1. Switch off the PC.

2. Remove the housing cover from the PC.

3. Remove the cover of an available PCI slot.

4. Check the configuration of the jumpers on the ETC insert card.

5. Gently press the PCI card ETCPX0XX evenly into its slot.

Ensure that the PCI card does not touch any adjacent components.

6. Attach the PCI card with the screw which was previously used to attach

the cover.

7. Close the PC housing cover.

52

l

EDSTCXX EN 2.0

Page 53

Electrical installation

Installation according to EMC (installation of a CE−typical drive system)

5 Electrical installation

5.1 Installation according to EMC (installation of a CE−typical drive system)

5

5.1

General notes

Layout

ƒ The electromagnetic compatibility of the ETC Motion Control depends

on the type and diligence of the installation. Pay particular attention

to:

– Layout

– Shielding

– Earthing

ƒ If the installation differs, the system must be checked for compliance

with the EMC limits in order to evaluate the conformity with the EMC

directive. This applies e.g. to the use of unshielded cables

ƒ The responsibility for complying with the EMC directive is with the end

user.

ƒ If you observe the following measures, you can assume that no EMC

problems will arise and the EMC directive or EMC legislation will be

complied with.

ƒ If devices are operated near the system which do not meet the CE

requirements for noise immunity in EN 61000−4−2, these devices could

be electromagnetically interfered with by the ETC ETC Motion Control

System.

ƒ Make contact between top hat rail and earthed mounting plate:

– Mounting plates with electrically conducting surfaces (zinc plated or

stainless steel) permit a continuous contact.

– Painted plates are not suitable for EMC compliant installation.

EDSTCXX EN 2.0

ƒ If you use several mounting plates:

– Connect mounting plates to each other over a large surface (e.g.

using copper strips).

ƒ When laying cables ensure the physical separation of signal and

network cables.

ƒ Lay the cables as close as possible to the reference potential. Freely

suspended cables act like aerials.

l

53

Page 54

5

5.1

Electrical installation

Installation according to EMC (installation of a CE−typical drive system)

Shielding

Earthing

ƒ Only use cables with braided shields.

ƒ The cover density of the shield should exceed 80%.

ƒ For data cables for the serial coupling always use metallic or metallised

connectors. Attach the shield of the data cable to the connector

housing.

ƒ Use metal cable clamps to attach the braided shields.

ƒ Connect the shield to the shield rail in the switch cabinet.

ƒ Connect shields of analogue control cables on one side only (either at

the sensor or as near as possible to the input of the analogue module).

ƒ Earth all metallic conducting components using suitable cables from a

central earthing point (PE rail).

ƒ Observe the minimum cross−sections defined in the safety instructions:

– For EMC it is not the cable cross−section which matters, but the

surface of the cable and the contact area.

54

l

EDSTCXX EN 2.0

Page 55

5.2 CAN installation instructions

The connection of the incoming connection cable depends on the module

and is carried out e.g. at the front via a 9−pole D−Sub socket.

Electrical installation

CAN installation instructions

5

5.2

Connection cables for CAN

connection

Connection cables for CAN connection

Reserved*

CAN low

Ground

Reserved*

1

6

9

5

Ground*

CAN high

Reserved*

1

2

3

4

5

Shield

6

7

8

99

**

* These signals are optional.

** Metal or metallised plastic housings must be used. The shield must be

connected to the housing on both sides. The contact is achived vie the

metal collars of the fixed components which have protective earth

potentials on both sides.

1

Reserved*

2

CAN low

3

Ground

4

Reserved*

5

Shield

6

Ground*

CAN high

7

8

Reserved*

+U*+U*

1

6

9

5

ETC040

The figure above shows the complete assignment for the CAN bus cable.

The minimum assignment for the cable of a functioning CAN bus is the

connection of pins Pins 2, 3, 7.

The data cables must be designed as paired shielded cables and must be

pysically separated from energy supply cables. Where this is not possible the

use of double−shielded cables is recommended. The inside shield runs

insulated from the outside shield and is connected to an earth connection

(e.g. Ground *).

) Note!

The physical connection can be checked at any point of the CAN

bus using an Ohmmeter. All supply voltages must be switched

off prior to the measurement.

The measured resistance between the signals CAN_H and CAN_L

must be approx. 60 Ohm. The resistance between CAN_L and

GND and btetween CAN_H and GND must be "infinitely" large.

Other values can be measured as a result of a short circuit in the

signals or a reversal of the connections.

CiA−DS−102−1 and CiA DR−303−1 describes the plug−in connectors

and cables used and the supported bit rates.

EDSTCXX EN 2.0

l

55

Page 56

5

5.2

5.2.1

5.2.1 Cable types for the CAN Bus

Electrical installation

CAN installation instructions

Cable types for the CAN Bus

Cable type suitable for the CAN bus:

ƒ LÜTZE, Type Superflex Bus PUR 2x2x0.25 mm@, up to 1 MBit/s

ƒ BELDEN, Type YR−29832, up to 1 MBit/s

Of course, cables of other manufacturers having similar characterstics can

also be used.

The two ends of the bus cables must be terminated with the surge

impedance of the cable. Up to 1 MHz this is usually 120 Ohm (0.25 W) for

twisted pair cables.

Various modules of the ETCHx series already feature this resistor. The

termination module ETCHT000 has been specifically designed for

terminating a CAN bus connection.

Alternatively, the termination can be made using a plug−in connector with

integrated terminating resistance (between the signals CAN high and CAN

low), which is plugged into the available CAN connection at the two furthest

modules.

5.2.2 Relationship between cable length and transfer rate

The maximum transfer rate depends on the delay periods on the sender and

receiver sides (incl. optocouplers), the accuracy of the oscillators and the bus

length (=cable length).

The following table provides an overview for networking Lenze CAN

subassemblies which cable lengths should not be exceeded for a specific

transfer rate. The figures apply to a twisted pair data cable terminated at

both ends and with a runtime of 10 ns/m:

Transfer rate Maximum cable length

1 MBit / s 15 m

500 kBit / s 50 m

56

l

EDSTCXX EN 2.0

Page 57

5.2.3 Stub cables

Electrical installation

CAN installation instructions

Stub cables

Stub cables are permitted. Their maximum length at 125 kB/s must not

exceed 1 m (or 30 cm for 1 Mbit/s) per stub cable.

With several stub cables the total of the stub cable lengths must not exceed

30 m (for 500 kbit/s).

The sub cable connections are made in the terminal box parallel to the CAN

bus. Sub cables are not terminated with a resistor.

Control

CAN Master

CAN bus

terminated

clamping box

1. isolated system

2. isolated system 4. isolated syst.

5.2

5.2.3

5

branch line max. 1 m

3. isolated system

CAN bus not

terminated

ETC041

EDSTCXX EN 2.0

l

57

Page 58

5

5.3

5.3 Initial switch−on

Electrical installation

Initial switch−on

Prior to switching on the main switch always ensure that

ƒ the layout is in accordance with the guidelines of VDE 0100, 0110, 0113

and 0160,

ƒ the protective earth and the supply voltage have been wired correctly,

ƒ not cables with too high a voltage (e.g. 230 V AC) have been wired to

terminals whose inputs or outputs are not specified for this voltage,

ƒ the signal reference conductor cannot be live when connecting earthed

devices or sensors,

ƒ all assemblies have been set up correctly,

ƒ all power circuits of actuators, which could cause injury or damage,

have been switched off,

ƒ the EMERGENCY STOP circuits work properly even during a control

malfunction,

ƒ all plug−in connections have been plugged in properly and, if necessary,

locked.

58

l

EDSTCXX EN 2.0

Page 59

Troubleshooting and fault elimination

6 Troubleshooting and fault elimination

6.1 Status display

LEDs on the front plate of the ETC report the actual system state. The

meanings of the signals differ in the start−up phase and during operation.

Status display

6

6.1

Watchdog (GN)

0 LED on

1 LED off

2 LED any

3 LED flashes

reserved (YE)

Error (RD)

1

4

3

6

0

1

2

3

ETC042

EDSTCXX EN 2.0

l 59

Page 60

6

6.1

Troubleshooting and fault elimination

Status display

Start−up phase

During start−up a RAM test is carried out. After an error−free RAM test the

LEDs 1 ... 6 produce a running indication. Any errors during the boot sequence

will be signalled by the following pattern of flashing and indications.

Checksum error in the internal FLASH−PROM. 3 times fast consecutive flashing. The

boot loader is then burned afresh into the internal FLASH−PROM. Occurs always

after a boot loader update.

Error in the last 32 kByte of RAM memory (after an update and writing of the boot

loader to the Flash).

Error in the first 32 kByte ofRAM memory.

Error when extracting the boot loader.

Error during the burning of the boot loader into the FLASH−PROM.

Errors in the RAM memory.

Error in the last 32 kByte ofRAM memory.

No firmware loaded or checksum error in the firmware. After 5 times flashing the

boot monitor is activated.

Error when loading the firmware from the FLASH−PROM. After 5 times flashing the

boot monitor is activated.

Error when starting the firmware.

l 60

EDSTCXX EN 2.0

Page 61

Troubleshooting and fault elimination

Status display

6

6.1

Operation

When the control enters the operating mode after start−up, the following

pattern of flashing and indications applies.

LED Meaning

Watchdog Watchdog, must always illuminate when running.

Reserved Without function

ERROR Flashes after an exception (violation of the control program protection during

runtime, exceeding the permitted variable range, division by zero etc.).

LED 1 Flashes at the clock pulse of the coarse interpolator

LED 2 Flashes at the clock pulse of the interpreter

LED 3 Flashes at the clock pulse of the central control

LED 4 Flashes at the clock pulse of the fine interpolator

LED 5 Flashes with each RS232 interrupt or CAN interrupt

LED 6 Flashes at the clock pulse of the PLC cycle time

) Note!

The "flashing" frequency can be so low with short programs, that

the LEDs appear dark.

EDSTCXX EN 2.0

l 61

Page 62

6

6.2

Troubleshooting and fault elimination

Error management

6.2 Error management

ETCHN003

ETCHT000

ETCHI008/ETCHI016

Problem Potential cause Remedy

LED 24 V at the power supply

unit does not illuminate

LED 5 V at the power supply

unit does not illuminate

CAN bus does not work

properly

Problem Potential cause Remedy

CAN bus is not continued in

the module

CAN bus does not work

properly

Problem Potential cause Remedy

Module does not work

Live LED does not illuminate

Live LED illuminates, no input

LED, in spite of signal

24 V signal present, input LED

illuminates, but signal is

processed as 0

Brief input signal is not

detected

24 V power supply at the

power supply unit missing

Internal short circuit in the

module

Internal short circuit in the

module

Switch position S1 wrong Check switch position S1

Internal short circuit in the

module

Switch position S1 wrong Check switch position S1

ME bus contacts incorrect

24 V power supply at the

power supply unit missing

Internal module fault Replace module

Internal 24 V short circuit, PTC

has triggered

Live LED is programmed

differently

Signal not present Check signal at module

Input parameterised with

inverse logic

Debouncing active Check parameterisation

Check 24 V supply

Check fuse

Check or replace module

Check or replace module

Check fuse

Check or replace module

Check module

Check 24 V supply

Remove short circuit, wait a

few seconds

Check parameterisation

Check parameterisation

ETCHU008/ETCHU016

62

Problem Potential cause Remedy

Module does not work

Live LED does not illuminate

Live LED illuminates, no

output LED in spite of signal

24V voltage present, output is

0, output LED does not

illuminate, but signal is

present

ME bus contacts incorrect

24 V power supply at the

power supply unit missing

Internal module fault Replace module

Internal 24 V short circuit, fuse

has triggered

Live LED is programmed

differently

Signal not present Check signal at module

Input parameterised via CAN

bus as inverse logic

Check module

Check 24 V supply

Replace module

Check parameterisation

Check parameterisation

l

EDSTCXX EN 2.0

Page 63

Troubleshooting and fault elimination

Error management

6

6.2

ETCHA022

Problem Potential cause Remedy

Module does not work

Live LED does not illuminate Live LED is programmed

Current is not detected

correctly

ME bus contacts incorrect

24 V power supply at the

power supply unit missing

Internal module fault Replace module

differently

Wrong parameterisation Check parameterisation and

Wrong sensor supply Measure the supply voltage of

PTC fuse has triggered Check sensor for short circuit

Check module

Check 24 V supply

Check parameterisation

calibration

the sensor

EDSTCXX EN 2.0

l

63

Page 64

6

6.3

6.3 Module replacement

Troubleshooting and fault elimination

Module replacement

In case of a fault the complete module electronics are replaced. For this all

connected cables must first be removed and the voltage disconnected.

As the individual modules are connected to the internal ME bus via a

connector, the affected module must be separated from any modules

connected to the left or right prior to removal.

The affected module is then removed from the carrier rail with a

corresponding tool by lifting it out from the clip at the bottom of the module.

ETC028

64

l

EDSTCXX EN 2.0

Page 65

6.4 Battery replacement

The battery life is dependent on the network operating time and the

ambient temperature. The typcial service life at 23° C ambient temperature

is approx. 7 years; in the worst case scenario (extremely high or low

temperatures) the battery lasts approx. 0.5 years. A safe operation is ensured

through the continuous monitoring of the remaining battery capacity. The

necessary replacement of the battery is indicated by the control.

During battery replacement the supply voltage for the CMOS−RAM is

provided by a special capacitor. To prevent a data loss in the RAM the battery

replacement should be completed within 15 minutes (time between the

removal of the old battery and insertion of a new battery).

( Stop!

Troubleshooting and fault elimination

Battery replacement

The battery is replaced in the deenergised state. The control or

PC must be disconnected from the mains.

When using tools (screwdriver, tweezers) care should be taken