Page 1

EDSTCXN

./Yù

Ä./Yùä

Software manual

ETC Motion Control

L

ETCxCxxx

Operating System NC

l

Page 2

I Tip!

Current documentation and software updates concerning Lenze products can be found

on the Internet in the "Services & Downloads" area under

http://www.Lenze.com

© 2006 Lenze Drive Systems GmbH, Hans−Lenze−Straße 1, D−31855 Aerzen

No part of this documentation may be reproduced or made accessible to third parties without written consent by Lenze Drive

Systems GmbH.

All information given in this documentation has been selected carefully and complies with the hardware and software

described. Nevertheless, deviations cannot be ruled out. We do not take any responsibility or liability for damages which might

possibly occur. Necessary corrections will be included in subsequent editions.

Page 3

Contents i

1 Preface and general information 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 About this Manual 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 For which products is the manual valid? 11 . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Legal regulations 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Getting started 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 System overview 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Examples for an automation system 13 . . . . . . . . . . . . . . . . . . . . .

2.1.2 Layout example for an ETC island 15 . . . . . . . . . . . . . . . . . . . . . . . .

2.1.3 Connecting ETCHx and PC 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Status display 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Commissioning steps (overview) 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Establishing the communication between PC and ETCHx 21 . . . . . . . . . . . .

2.4.1 Starting ETCHx 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 Starting the terminal program "HyperTerminal" and

activating the monitor interface 21 . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.3 Setting the operating mode of the ETCHx 25 . . . . . . . . . . . . . . . . .

2.4.4 Assigning the IP address of the ETCHx 28 . . . . . . . . . . . . . . . . . . . .

2.5 Configuring ETC−MMI and ETC−MMI gateway 30 . . . . . . . . . . . . . . . . . . . . . .

2.6 Installing ETC−MMI 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.1 Building in and installing the ETCPx 31 . . . . . . . . . . . . . . . . . . . . . .

2.7 Starting ETC−MMI 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.1 Switching the language in the ETC−MMI 33 . . . . . . . . . . . . . . . . . .

2.7.2 Establishing a connection between ETC−MMI and ETC 34 . . . . . . .

2.8 Parameterising drives via machine constants 36 . . . . . . . . . . . . . . . . . . . . . .

2.8.1 Overview of the most important machine constants 36 . . . . . . . .

2.8.2 Machine constant file ETCxC.mk 39 . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.3 Notes on loading the MK file into the control system 40 . . . . . . . .

2.8.4 Example for adapting a machine constant file 41 . . . . . . . . . . . . .

2.8.5 Adapting machine constants in the ETC−MMI 42 . . . . . . . . . . . . . .

2.8.6 Checking the parameters of the drives 43 . . . . . . . . . . . . . . . . . . . .

2.8.7 Testing the drives in inching mode 44 . . . . . . . . . . . . . . . . . . . . . . .

2.9 CNC programming according to DIN 66025 45 . . . . . . . . . . . . . . . . . . . . . . .

2.9.1 G−functions 45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9.2 M−functions 46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10 Creating a CNC sample program 47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10.1 Calling the text editor in the ETC−MMI 47 . . . . . . . . . . . . . . . . . . . .

2.10.2 Entering and saving a CNC program 48 . . . . . . . . . . . . . . . . . . . . . .

2.10.3 Loading the CNC program into the control system and

starting it 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10.4 Extending the CNC program 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDSTCXN EN 2.0

l 3

Page 4

Contentsi

2.11 ETC PLC programming with CoDeSys 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11.1 Installing CoDeSys 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11.2 Configuring the control system in the ETC−CoDeSys 51 . . . . . . . . .

2.12 Creating a PLC sample program 60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.1 Required hardware 60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.12.2 Starting and configuring the PLC sample program 61 . . . . . . . . . .

2.12.3 Loading the PLC sample program into the control system 68 . . . .

2.13 Testing CNC and PLC program 72 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.14 PLC keys in the ETC−MMI 75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.14.1 Labelling of the PLC keys in the ETC−MMI 75 . . . . . . . . . . . . . . . . . .

2.14.2 Calling the signals in the PLC 76 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.14.3 Function of the keys 76 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15 Operation via a Lenze−HMI 77 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.15.1 Settings for the connection of a Lenze−HMI H505 77 . . . . . . . . . . .

2.15.2 Functional description HMI505 operation 81 . . . . . . . . . . . . . . . . .

2.16 Updating the firmware of the ETCHx in the "Standalone"

operating mode 83 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.16.1 Calling the boot monitor in the control system 83 . . . . . . . . . . . . .

2.16.2 Querying the version of the firmware 84 . . . . . . . . . . . . . . . . . . . . .

2.16.3 Updating the firmware 84 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 CNC programming 87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Basics 87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 G functions 91 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Overview of G functions 91 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 G functions individual descriptions 94 . . . . . . . . . . . . . . . . . . . . . .

3.3 Formula processor 172 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Arithmetic operations 172 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Block extensions 174 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Parameter assignment P 174 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.2 H functions 175 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.3 M functions 175 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.4 Q functions 177 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.5 S functions 178 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.6 T functions 179 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Data fields 180 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 P field 180 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.2 Q field 189 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l 4

EDSTCXN EN 2.0

Page 5

Contents i

4 Machine constants 190 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Basics 190 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Test settings 192 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 MK_TEST_OHNEMECHANIK 192 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 MK_SPS_DUMMY 192 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Software configuration 193 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 MK_KUNDE 193 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 MK_VOREINSTELLUNG 193 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3 MK_NCPROG_OHNE_KOMMENTARE 194 . . . . . . . . . . . . . . . . . . . . .

4.3.4 MK_NCPROG_NICHT_INS_EEPROM 194 . . . . . . . . . . . . . . . . . . . . . .

4.3.5 MK_METRISCH 194 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.6 MK_CONST_REL_MM 195 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.7 MK_CONST_REL_INCH 195 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.8 MK_KONTURFEHLER 195 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.9 MK_LAH_GRENZWINKEL 196 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.10 MK_RADIUS_B_BEWERTUNG 196 . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.11 MK_EPSILONMM 197 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.12 MK_EPSILONGRAD 197 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.13 MK_OVERRIDEMAX 197 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.14 MK_FEHLERRESTART 197 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.15 MK_S0T0_VERSATZ_ERLAUBT 198 . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.16 MK_S_VERSATZSPERRE 198 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.17 MK_CANOPEN_BAUDRATE 198 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.18 MK_DELTAT 199 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Storage space reservation 200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 MK_SPS_SPEICHERGROESSE 200 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.2 MK_SPS_DATENGROESSE 200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.3 MK_SPV_SPEICHERGROESSE 200 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.4 MK_SPV_SYMBOLANZAHL 201 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.5 MK_HEADERANZAHL 201 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.6 MK_KANALANZAHL 201 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.7 MK_LAH_VORLAUFTIEFE 202 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.8 MK_LAH_RUECKLAUFGRENZE 202 . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.9 MK_PFELD_GROESSE 203 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Configuration of axes − Basics 204 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.1 MK_CANDRIVES 204 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.2 MK_APPLACHSIDX 205 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Configuration of axes − Assignment and evaluation 207 . . . . . . . . . . . . . . . .

4.6.1 MK_CANDRIVES 207 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6.2 MK_APPLACHSIDX 207 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6.3 MK_ACHSENART 208 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDSTCXN EN 2.0

l 5

Page 6

Contentsi

4.7 Configuration of axes − Resolution 209 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.1 MK_IMPULSE 209 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.2 MK_WEG 209 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7.3 MK_MASSSTAB 209 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 Configuration of axes − Operating range 210 . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8.1 MK_GRUNDOFFSET 210 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8.2 MK_SW_ENDS_MINUS, MK_SW_ENDS_PLUS 210 . . . . . . . . . . . . .

4.8.3 MK_SW_ENDS_MIT_RAMPE 210 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8.4 MK_SCHLEPPGENAUHALT 210 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8.5 MK_GENAUHALTZEIT 210 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9 Configuration of axes − Controller settings 211 . . . . . . . . . . . . . . . . . . . . . . . .

4.9.1 MK_T2 211 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10 Configuration of axes − Referencing 212 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10.1 MK_REF_RICHTUNG_UND_FOLGE 212 . . . . . . . . . . . . . . . . . . . . . . .

4.11 Configuration of axes − speed and acceleration 213 . . . . . . . . . . . . . . . . . . . .

4.11.1 MK_MODVMAX 213 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.11.2 MK_VMAX 213 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.11.3 MK_BESCHL, MK_BREMS 213 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.11.4 MK_T_BESCHL 213 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.11.5 MK_VBAHNMAX 214 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.11.6 MK_BAHNBESCHL, MK_BAHNBREMS 214 . . . . . . . . . . . . . . . . . . . . .

4.11.7 MK_T_BAHNBESCHL 214 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.12 Configuration of axes − Correction of axes 215 . . . . . . . . . . . . . . . . . . . . . . . . .

4.12.1 MK_SPINDELUMKEHRSPIEL 215 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.13 Configuration of axes − Handwheels 218 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.13.1 MK_CANDRIVES 218 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.13.2 MK_APPLACHSIDX 218 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.13.3 MK_ACHSENART 218 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.13.4 MK_IMPULSE 218 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.13.5 MK_WEG 218 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.13.6 MK_HANDRADZUORDNUNG 218 . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.13.7 MK_HANDRADFAKTOR 219 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.13.8 MK_HANDRADFILTER 219 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.14 Configuration of axes − Synchronous axes 220 . . . . . . . . . . . . . . . . . . . . . . . . .

4.14.1 MK_ACHSENART 220 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.14.2 MK_SYNCHRONABWEICHUNG 220 . . . . . . . . . . . . . . . . . . . . . . . . . .

4.14.3 MK_SYNCHRONOFFSET 220 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

l 6

EDSTCXN EN 2.0

Page 7

Contents i

4.15 Technology−specific settings 221 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.15.1 MK_MFKT_UPR_TABELLE 221 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.15.2 MK_TECHNOLOGIEDATEN1 ... MK_TECHNOLOGIEDATEN4 221 . . .

4.15.3 MK_MASCH_POLAR_KART 222 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.15.4 MK_KARTESISCH_ACHSNR 222 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.15.5 MK_POLAR_ACHSNR 223 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.15.6 MK_WLK_C_GRENZWINKEL 223 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.15.7 MK_WLK_C_OFFSET 223 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.15.8 MK_WLK_VERWEILZEIT 224 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.15.9 MK_X_WINKEL 224 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.15.10 MK_GEWINDE_VMAX 224 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.15.11 MK_DW224_255 225 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.16 List of machine constants 226 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Interface PLC <−> NC operating system 240 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Definitions 240 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Data block 0 242 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 Data block 1 245 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.3 Data block 2 268 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Extended interface for MMI functions 270 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Data blocks 8 ... 14 270 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Data block 15 273 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 ET −MMI gateway 276 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Installing the ETC−MMI gateway 276 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Starting the ETC−MMI gateway 277 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Configuring the ETC−MMI gateway 278 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 Connection − Setting up connections 278 . . . . . . . . . . . . . . . . . . . . .

6.3.2 Trace – Error logbook 281 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.3 About – Version information 282 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Mmigtway.ini 283 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1 Example of the file "mmigtway.ini" 284 . . . . . . . . . . . . . . . . . . . . . .

6.5 Communication values in the DPR area 285 . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDSTCXN EN 2.0

l 7

Page 8

Contentsi

7 ETC−MMI 286 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Installing ETC−MMI 286 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Starting ETC−MMI 288 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Operating ETC−MMI 289 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 Display elements of the program interface 289 . . . . . . . . . . . . . . . .

7.3.2 Operational controls of the program interface 290 . . . . . . . . . . . . .

7.3.3 Help function 291 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.4 Configuration file 291 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.5 Language switch 291 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.6 Passwords 292 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.7 Notes, warnings, error messages 292 . . . . . . . . . . . . . . . . . . . . . . . .

7.4 "Setup" operating mode 293 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 "Automatic" operating mode 298 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 "Programming" operating mode 302 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.1 ASCI editor 305 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.2 File manager 308 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6.3 Cycle programming 310 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.7 "Diagnostics" operating mode 312 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8 Appendix 321 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 PLC programming 336 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 ETC PLC programming with CoDeSys 336 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 CoDeSys installation 337 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Connecting ETC and PC 338 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8.1 Language file (SPRACHE.TXT) 321 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8.2 Cycle programming 325 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.8.3 Configuration file (DELPHMMI.INI) 327 . . . . . . . . . . . . . . . . . . . . . . .

8.2.1 System requirements for CoDeSys V2.xx 337 . . . . . . . . . . . . . . . . . .

8.2.2 Installing software 337 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.1 V.24 Interface 338 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.2 Ethernet interface (only ETCHx, DIN rail design) 338 . . . . . . . . . . . .

8.3.3 DPR interface (only ETCPx, PCI insert card) 339 . . . . . . . . . . . . . . . . .

8.4 Project planning 340 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.1 Target system setup 340 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.2 Configuring PLC tasks of the ETCxM 340 . . . . . . . . . . . . . . . . . . . . . .

8.4.3 Configuring PLC tasks of the ETCxC 342 . . . . . . . . . . . . . . . . . . . . . .

8.4.4 Configuring I/O modules 343 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.5 Addressing 349 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.6 Remanent variables 350 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.7 Object directory (parameter manager) 350 . . . . . . . . . . . . . . . . . . . .

l 8

EDSTCXN EN 2.0

Page 9

Contents i

8.5 Network variables 353 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.1 Settings in the target system 353 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.2 Settings in the global variable list 354 . . . . . . . . . . . . . . . . . . . . . . . .

8.6 Generate program 355 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7 Interface to the ETC 356 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.1 Data blocks 356 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.2 System variables of the ETCxC 356 . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.3 System variables of the ETCxM 359 . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.4 Using machine constants in the ETCxC 359 . . . . . . . . . . . . . . . . . . .

8.7.5 Using machine constants in the ETCxM 359 . . . . . . . . . . . . . . . . . . .

8.7.6 Parameter field of the ETCxC 359 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.7 Operating data of the ETCxC 360 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.8 Reading error messages for the ETCxM 360 . . . . . . . . . . . . . . . . . . .

8.8 Library 361 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8.1 General functions 361 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8.2 V24 functions 377 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8.3 FILE IO functions 383 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8.4 Memory access functions 393 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8.5 CANopen functions 398 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8.6 CAN functions (only ETCxM) 410 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8.7 MMI communication functions 414 . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8.8 Realtime clock (only ETCxM) 417 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9 Library ServerSDO.lib 418 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9.1 InitServerSdo 418 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Index 419 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDSTCXN EN 2.0

l 9

Page 10

1

1.1

Preface and general information

About this Manual

1 Preface and general information

1.1 About this Manual

Target group

Contents

Further information

This manual is intended for persons who program and commission the ETC

Motion Control System under the "NC" operating system.

The software manual "NC Operating System" contains information on the

following topics:

ƒ Getting started ˘ a chronological description of the commissioning

steps

ƒ CNC programming ˘ working with G functions, formula processor,

block extensions and data fields

ƒ Machine constants ˘ parameterisation of drives

ƒ PLC−ETC interface ˘ data blocks and their functions

ƒ ETC−MMI gateway ˘ communication between Windows applications

and the ETC

ƒ ETC−MMI ˘ integrated development environment for the creation of

CNC programs

ƒ CoDeSys ˘ integrated development environment for the creation of PLC

programs

The ETC Hardware Manual contains information on the following topics:

ƒ Technical data

ƒ Structure and function of the system components including interface

description

ƒ Mounting, connecting and maintaining system components

10

l

EDSTCXN EN 2.0

Page 11

Preface and general information

For which products is the manual valid?

1.2 For which products is the manual valid?

1

1.2

Standard device

ETC xx 0 xx 1A 10

Product

Version

HC = DIN rail, CNC core

PC = PCI plug−in card, CNC core

ETCHC0xx

Number of axes

02 = 2 axes

04 = 4 axes

08 = 8 axes

12 = 12 axes

Hardware version

Modules

Software version ETCPC0xx

ETCH xxxx 1A 10

Product

N003 = power supply unit

T000 = bus termination module

I008 = 8 dig. inputs

I016 = 16 dig. inputs

U008 = 8 dig. outputs

U016 = 16 dig. outputs

A022 = 2 analogue inputs and outputs

each

ETCHxxxx

Hardware version

Software version

EDSTCXN EN 2.0

l

11

Page 12

1

1.3

1.3 Legal regulations

Preface and general information

Legal regulations

Marking

Manufacturer

CE conformity

Application as intended

The components of the ETC Motion Control System are clearly marked by the

contents of the nameplate.

Lenze Drive Systems GmbH, Postfach 101352, D−31763 Hameln

Compliant with EC Directive "Electromagnetic compatibility"

Components of the ETC Motion Control System

ƒ must only be operated under the operating conditions described in the

ETC Hardware Manual.

ƒ are not approved for the use in explosive environments.

ƒ comply with the protection requirements of the EC Directive "Low

voltage".

ƒ are no machines in the sense of the EC Directive "Machines".

ƒ are no household appliances, as components they are intended for

industrial use only.

The downstream user is responsible for ensuring that the EC Directives are

complied with in machine use.

Any other use shall be deemed inappropriate!

Liability

Warranty

The information, data and notes in this manual were up to date at the time

of printing. No claims for the modification of systems and components that

have already been supplied may be made on the basis of the specifications,

illustrations and descriptions in this manual.

No liability is accepted by Lenze as to the suitability of any of the procedures

or circuit recommendations included here.

The information in this manual describe the properties of the products

without guaranteeing them. No liability will be accepted for damage or

disturbance caused by:

ƒ ignoring this manual

ƒ unauthorised alterations to the components of the ETC Motion Control

System

ƒ operating errors and incorrect working on or with the ETC Motion

Control System

See terms of sales and delivery of Lenze Drive Systems GmbH.

Report any claims under warranty to Lenze immediately on discovery of the

defect or fault. The warranty is void in all cases where liability cannot be

established.

12

l

EDSTCXN EN 2.0

Page 13

2 Getting started

This chapter explains the basics of the ETC system and describes the

procedure for realising an automation task.

2.1 System overview

2.1.1 Examples for an automation system

Ethernet

ETCHx

CAN1

Getting started

System overview

Examples for an automation system

ETCHN003

ETC-System Components

2

2.1

2.1.1

ETCHT000

ETCHx / ETCPx

IPC with ETCPx

ECS/MCS-System Drives HMI I/O-System IP20

CAN2

CAN-I/O

ETCM001

The core of the automation system is the ETC control in the top hat rail design

(ETCHx) or as PCI insert card (ETCPx).

The top hat rail design ETCHx is normally used in a so−called ETC island

(¶ 15); it communicates via Ethernet with the applications on the IPC (or

standard PC).

The ETCPC is inserted into the IPC (or standard PC) and communicates with

the applications via the PCI bus.

Both designs have two separate CAN busses:

EDSTCXN EN 2.0

ƒ At CAN1 bus (or also ME bus) the I/O modules and any operating

components are connected. Third party devices must comply with teh

DS401 profile of the CANopen specification.

ƒ The drives (e.g. the ECS compact servo) are connected to the connection

for the Motion CAN bus (CAN2) at the front plate. External drives must

comply with the profile DS402 of the CANopen specification and in

particular support the "Interpolated Position Mode".

l

13

Page 14

2

2.1

2.1.1

Getting started

System overview

Examples for an automation system

To carry out its allocated control function the ETC control needs various

programs which are transferred from the IPC (or standard PC):

ƒ Operating system or firmware of the control (e.g. ETCHC.rsc)

ƒ PLC programs (e.g. SPSDummy.prg)

ƒ CNC programs; i.e. cycle and DIN programs (e.g. 9000.zyk or

Nikolaus.din)

IPC

The ETC control is operated and maintained via the IPC (or standard PC). The

following applications might run on it:

ƒ Windows 2000 or XPoperating system

ƒ Terminal program (e.g. HyperTerminal) for establishing the Ethernet

connection between IPC and ETCHx control and for the configuration of

the ETCHx control via the monitor interface (e.g. firmware update). This

is not required for the ETCPx.

ƒ ETC−MMI gateway as communications program between Windows

applications and the ETC control.

ƒ Lenze ETC−MMI for the configuration, operation and monitoring of the

ETC control and for creating CNC programs.

ƒ CoDeSys development environment for the creation and testing of PLC

programs.

) Note!

An external keyboard is required at the IPC for commissioning. It

is not required for normal operation.

14

l

EDSTCXN EN 2.0

Page 15

Getting started

System overview

Layout example for an ETC island

2

2.1

2.1.2

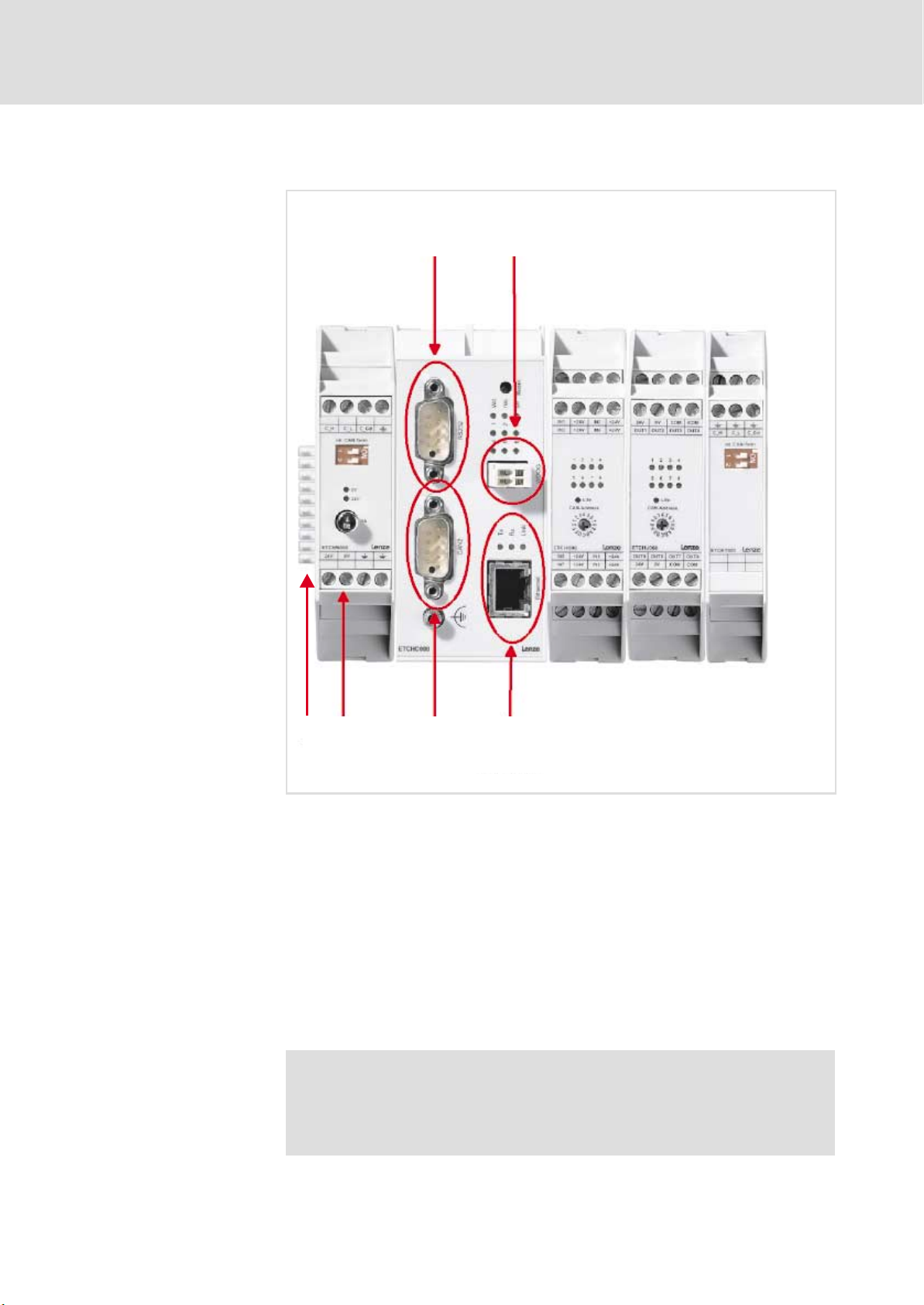

2.1.2 Layout example for an ETC island

ETCHN003

10

ETCHx004

ETCHI016

ETCHI008

ETCHT000

2345

ETCM002

0 Serial interface (RS232)

1 Watchdog (e.g. for emergency stop chain)

2 Ethernet

3 Motion CAN bus (CAN2)

4 24 V supply

5 ME bus (CAN1)

ETCHN003: Power supply unit for the supply of the ETC island and ME bus

connection

ETCHx004: ETC Motion Control for 4 axes (control)

ETCHIxxx: Input module with 16 or 8 digital inputs

ETCHT000: ME bus terminator module

) Note!

To terminate the ME bus DIP switch 1 must be set to ON at both

the power supply unit ETCHN003 and the bus terminator

module ETCHT000.

EDSTCXN EN 2.0

l

15

Page 16

2

2.1

2.1.3

Getting started

System overview

Connecting ETCHx and PC

2.1.3 Connecting ETCHx and PC

Three types of connections are possible between the ETCHx and a PC.

Connection type Cable version Description

Serial connection System cable type EWL 0068

Local connection via Ethernet

(pear−to−pear connection)

Network connection Ethernet patch cable STP Cat5

or a comparable RS232 cable

with double−sided 9−pin

SUB−D socket (for the pin

assignment see ETC Hardware

Manual)

System cable type EWL 0065,

EWL 0066 or EWL 0067

(double−sided RJ45)

(double−sided RJ45)

This connection is only

required for commissioning!

A free COM port at the PC is

connected with the RS232

interface of the ETCHx. The PC

communicates via a terminal

program with the monitor

interface of the ETCHx.

A network card in the PC is

connected with the Ethernet

connection of the ETCHx via a

cross−over cable.

Communication takes place

via the TCP/IP protocol.

The ETCHx is connected to a

separate or existing network

(e.g. Intranet) via an Ethernet

connection. Communication

takes place via the TCP/IP

protocol.

0

0 Connection via serial interface

1 Local TCP/IP connection

2 Network TCP/IP connection

1

2

ETCM004

16

l

EDSTCXN EN 2.0

Page 17

2.2 Status display

Getting started

Status display

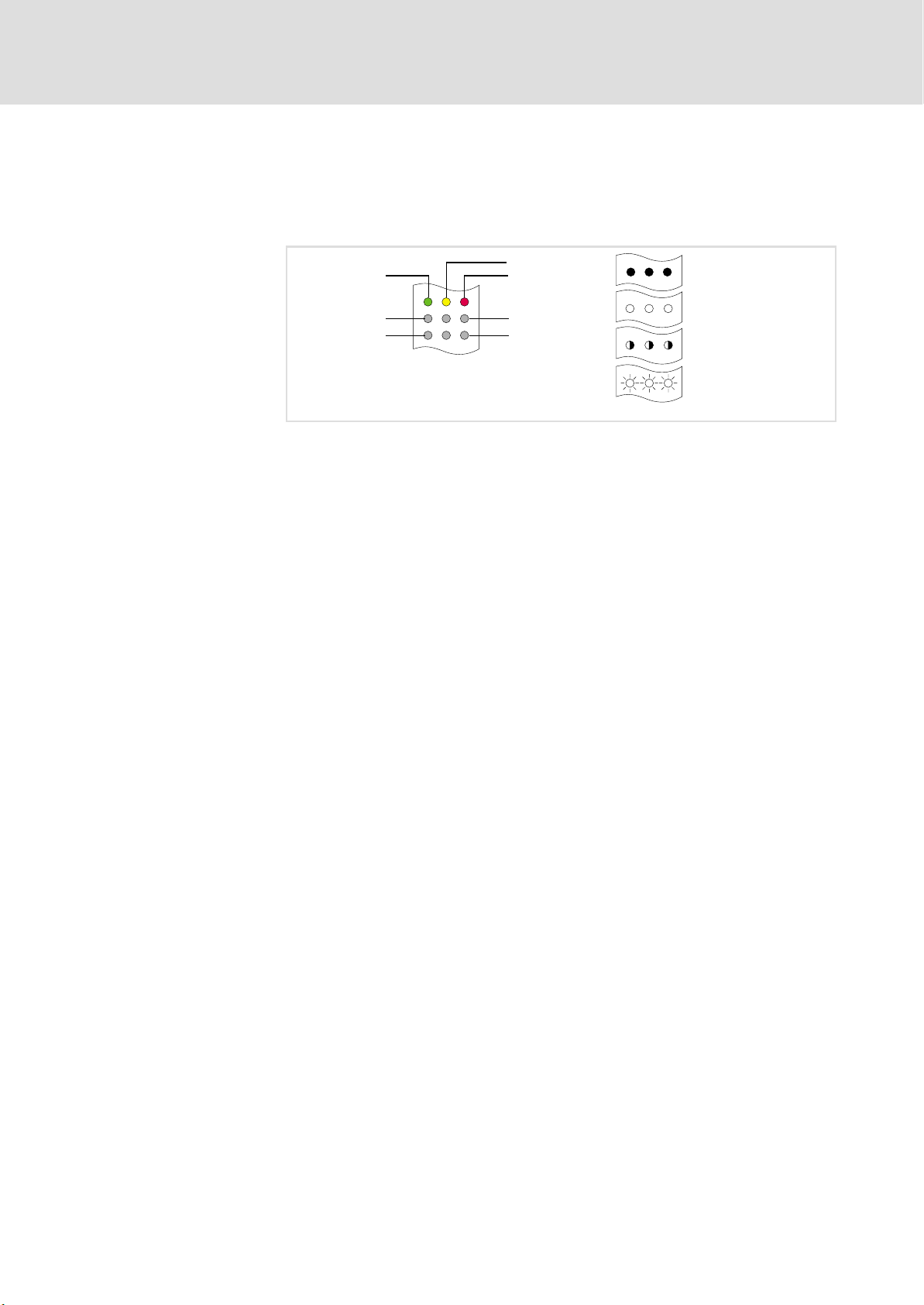

LEDs on the front plate of the ETC report the actual system state. The

meanings of the signals differ in the start−up phase and during operation.

2.2

2

Watchdog (GN)

0 LED on

1 LED off

2 LED any

3 LED flashes

reserved (YE)

Error (RD)

1

4

3

6

0

1

2

3

ETC042

EDSTCXN EN 2.0

l

17

Page 18

2

2.2

Getting started

Status display

Start−up phase

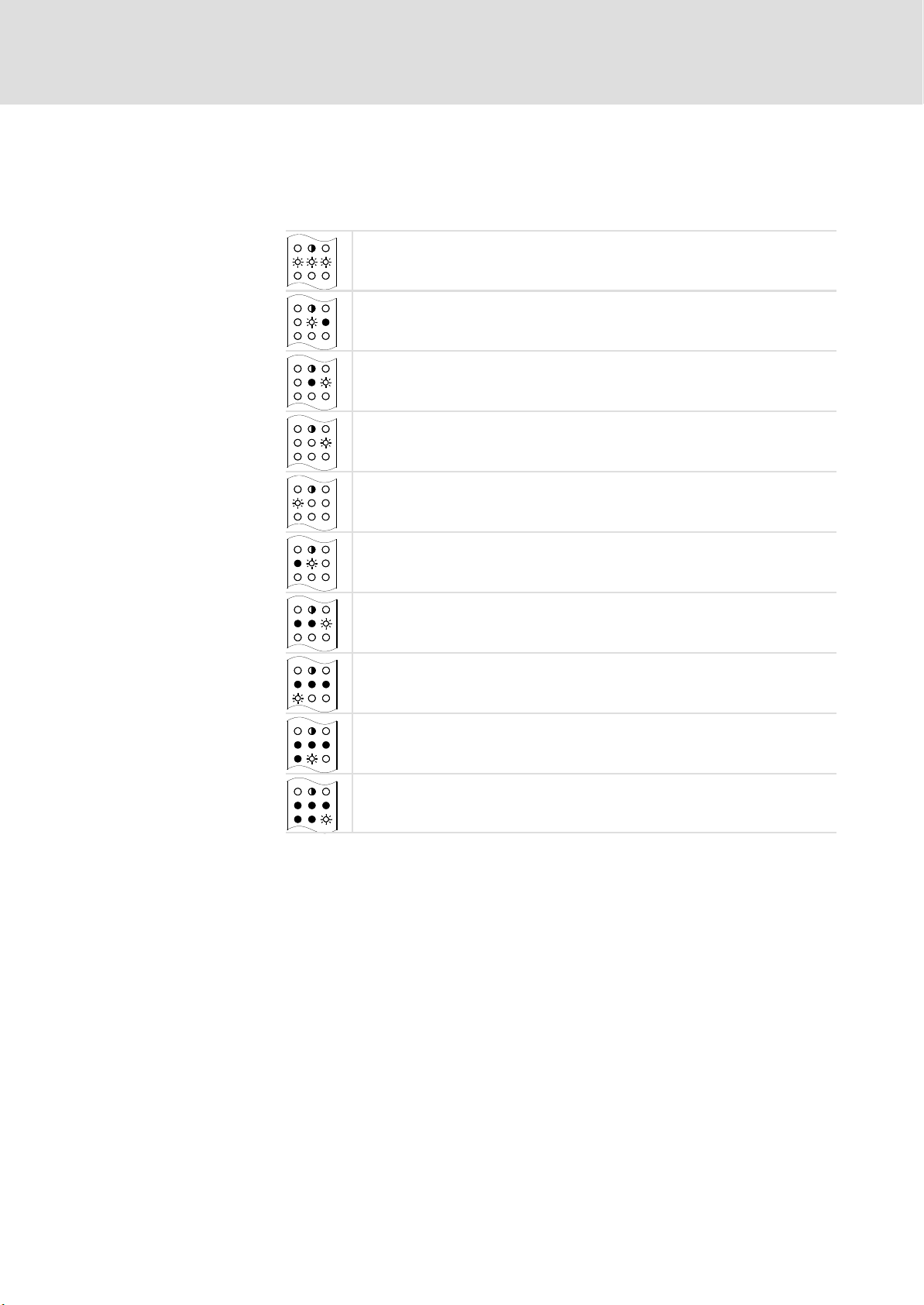

During start−up a RAM test is carried out. After an error−free RAM test the

LEDs 1 ... 6 produce a running indication. Any errors during the boot sequence

will be signalled by the following pattern of flashing and indications.

Checksum error in the internal FLASH−PROM. 3 times fast consecutive flashing. The

boot loader is then burned afresh into the internal FLASH−PROM. Occurs always

after a boot loader update.

Error in the last 32 kByte of RAM memory (after an update and writing of the boot

loader to the Flash).

Error in the first 32 kByte ofRAM memory.

Error when extracting the boot loader.

Error during the burning of the boot loader into the FLASH−PROM.

Errors in the RAM memory.

Error in the last 32 kByte ofRAM memory.

No firmware loaded or checksum error in the firmware. After 5 times flashing the

boot monitor is activated.

Error when loading the firmware from the FLASH−PROM. After 5 times flashing the

boot monitor is activated.

Error when starting the firmware.

18

l

EDSTCXN EN 2.0

Page 19

Getting started

Status display

2

2.2

Operation

When the control enters the operating mode after start−up, the following

pattern of flashing and indications applies.

LED Meaning

Watchdog Watchdog, must always illuminate when running.

Reserved Without function

ERROR Flashes after an exception (violation of the control program protection during

runtime, exceeding the permitted variable range, division by zero etc.).

LED 1 Flashes at the clock pulse of the coarse interpolator

LED 2 Flashes at the clock pulse of the interpreter

LED 3 Flashes at the clock pulse of the central control

LED 4 Flashes at the clock pulse of the fine interpolator

LED 5 Flashes with each RS232 interrupt or CAN interrupt

LED 6 Flashes at the clock pulse of the PLC cycle time

) Note!

The "flashing" frequency can be so low with short programs,

that the LEDs appear dark.

EDSTCXN EN 2.0

l

19

Page 20

2

2.3

Getting started

Commissioning steps (overview)

2.3 Commissioning steps (overview)

( Stop!

) Note!

Step ETCHC ETCPC Description See

1X− Connect ETCHC via RS232 cable with PC and start ETCHC. ^ 21

2 X − Start terminal program on the PC (if required, configure in

3 X − If the ETCHC is to be operated in the "with MMI"

4 X − Assign the IP address of the ETCHC. ^ 28

5 X X If required, install ETC−MMI and ETC−MMI Gateway. ^ 31

6 − X Install ETCPC in the PC and install the driver. ^ 31

7 X X Start ETC−MMI and ETC−MMI Gateway. ^ 32

8 X X Establish connection between ETC−MMI and ETCxC. ^ 34

9 X X Parameterise drives via machine constants. ^ 36

10 X X Check parameters of the drives. ^ 43

11 X X Test drives in inching mode. ^ 44

12 X X Create CNC program in the ETC−MMI. ^ 47

13 X X Load CNC program into ETCxC, start and test CNC

14 X X If required, install CoDeSys. ^ 51

15 X X Start and configure CoDeSys. ^ 51

16 X X Create PLC program. ^ 60

17 X X Load PLC program into ETCxC, start and test PLC program. ^ 68

18 X X Test CNC and PLC program. ^ 72

Observe the notes in the chapter "Initital switch−on" of the ETC

Hardware Manual before commissioning the system.

Only build in and install the PCI control variant ETCPx in step 6.

^ 21

advance) and activate monitor interface of the ETCHC.

^ 25

operating mode, replace the firmware file on the ETC by

the file "NetBoot.rsc".

^ 49

program.

20

l

EDSTCXN EN 2.0

Page 21

Establishing the communication between PC and ETCHx

2.4 Establishing the communication between PC and ETCHx

) Note!

The steps described in this chapter only apply to the ETCHx

variant (DIN rail variant); they are not required for the ETCPx

variant (PCI card).

2.4.1 Starting ETCHx

1. Connect the serial interfaces of PC and ETCHx.

For this purpose, use the system cable of type EWL 0068 or a comparable

RS232 cable with double−sided 9−pin D−Sub socket (for the pin

assignment see ETC Hardware Manual).

2. Start the PC.

3. Start the ETCHx by mains connection or initialise the ETCHx by a reset

(press the Reset key on the front panel).

As soon as the ETC firmware has been loaded, the green watchdog LED

lights up at the ETCHx .

Getting started

Starting ETCHx

2

2.4

2.4.1

2.4.2 Starting the terminal program "HyperTerminal" and activating the monitor interface

For the communication between PC and ETCHx, you require a terminal

program. The terminal program "HyperTerminal" is available in every

standard Windows installation.

1. If you have already established a connection with an ETC (i.e. if a

connection is already configured), start the connection via <Start>

Programs W Accessories W Communication W HyperTerminal W

ConnectionName.ht. See next section.

If no connection has been configured yet, start the HyperTerminal via

<Start>

The program queries different settings of the telephone connection

because it is also designed for a modem connection. These settings are

not significant in this context.

2. After you have been prompted, enter a name for the connection (for

example "ETC") and click OK.

W Programs W Accessories W Communication W HyperTerminal.

W

EDSTCXN EN 2.0

l

21

Page 22

2

2.4

2.4.2

Getting started

Establishing the communication between PC and ETCHx

Starting the terminal program "HyperTerminal" and activating the monitor interface

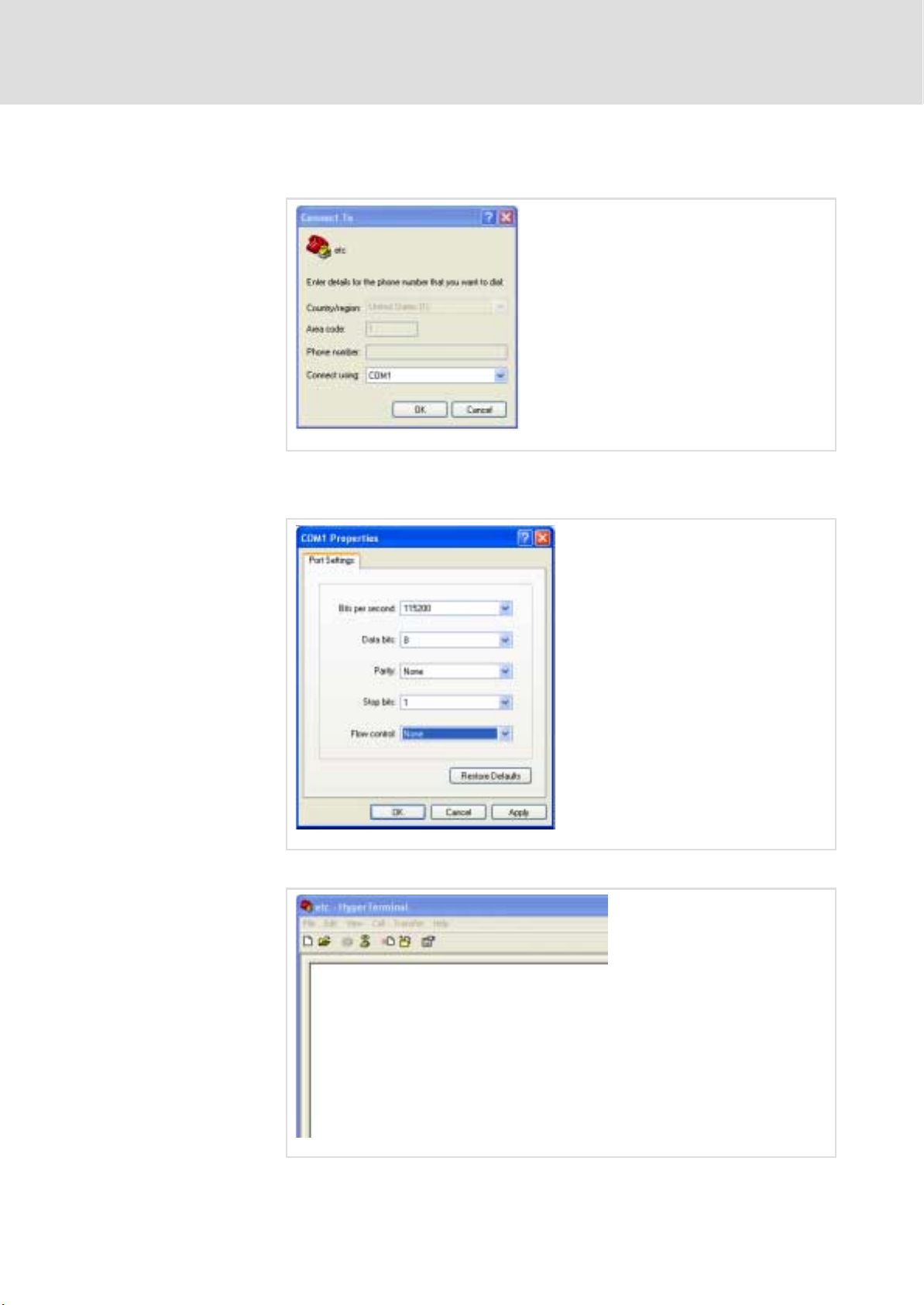

3. In the "Connect to" dialogue, select the PC interface via which you want

to establish the connection (for example "COM1").

ETCM006

4. Click OK.

5. In the "COMx Properties " dialogue, enter the following data:

ETCM007

6. Click OK.

22

l

ETCM008

EDSTCXN EN 2.0

Page 23

Getting started

Establishing the communication between PC and ETCHx

Starting the terminal program "HyperTerminal" and activating the monitor interface

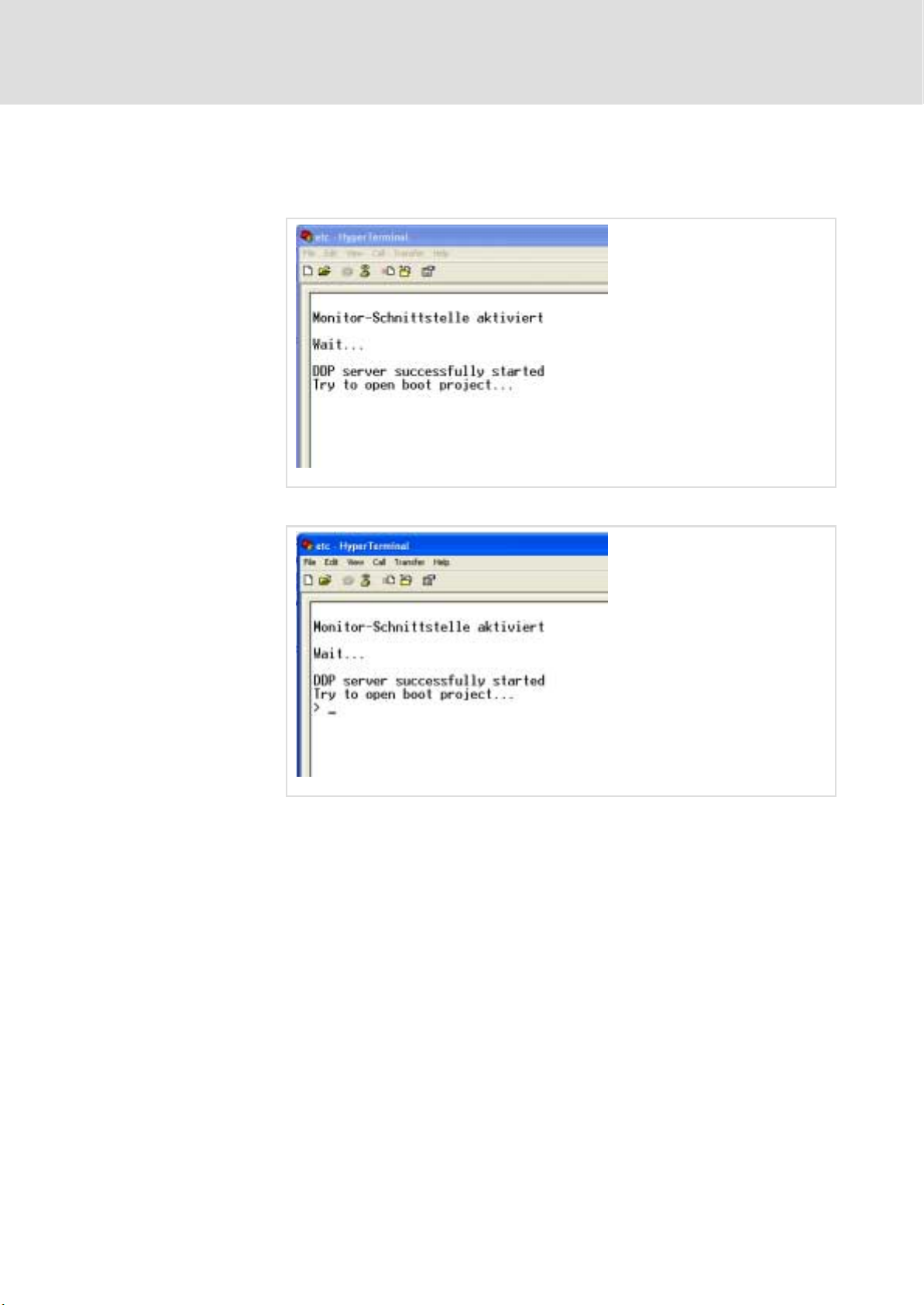

As soon as a connection has been established between the PC and ETC, the

LEDs 1 ... 6 at the ETCHx start to flash circulatingly. The message "Wait Boot

Loader" appears and the following window is displayed:

2

2.4

2.4.2

ETCM009

7. Press the <?> key until the prompt ">" appears.

The monitor interface has been started. You can now send commands to

the ETC via the keyboard.

ETCM010

EDSTCXN EN 2.0

l

23

Page 24

2

2.4

2.4.2

Getting started

Establishing the communication between PC and ETCHx

Starting the terminal program "HyperTerminal" and activating the monitor interface

Important commands of the

monitor program

Fault elimination

Command Meaning

dir [dr:][pattern] Shows the contents of the specified drive. The flashdisk (sd:) is preset, other

possible drives are program storage (ps:), Ram disk (rd:) and floppy disk

(fd:), if existing. As pattern, the usual MS−DOS patterns can be used, e.g.:

*.din

del [dr:][pattern] Deletes the specified files on the specified drive. The flash disk (sd:) is

preset.

cd [dr:] Changes to or shows the currently selected drive. The flash disk (sd:) is

preset.

format dr: Formats the current disk and thus deletes all files on this disk. A disk name

must be specified.

reboot Resets the control system. To activate the boot monitor, the "!" key must be

pressed afterwards until the boot monitor responds (this may take

3−4 seconds).

help Displays the help page with commands of the monitor program.

ver Displays version string

ipconf Configures network parameters for Ethernet interface

hwconf Displays hardware configuration of the control system (CPU type, memory

etc.)

If you cannot establish a connection to the ETCHx by means of the described

procedure, proceed as follows:

1. Check the cabling between PC and ETCHx.

2. Check the connection parameters of the terminal program.

A first test of the cable connection can be performed by means of a bridge

between the pins 2 and 3 at the socket of the cable (control system side):

ƒ Afterwards, the terminal program is called as usual and any letters can

be entered via the keyboard.

ƒ If the entered characters of the keyboard are correctly displayed in the

mask of the terminal program (the characters are sent back by the

bridge as echo), the cable must be checked for exchanged pins (pin2/3),

for short circuit and the connection must be checked for correct

parameter setting.

24

l

EDSTCXN EN 2.0

Page 25

Getting started

Establishing the communication between PC and ETCHx

Setting the operating mode of the ETCHx

2

2.4

2.4.3

2.4.3 Setting the operating mode of the ETCHx

The ETCHx can be operated in two operating modes:

ƒ Variant "Standalone" (delivery variant)

– Directly after the voltage has been applied, the control system loads

the firmware.

– The control system executes a fixed program.

ƒ Variant "with MMI"

– After the voltage has been applied, the control system waits until the

firmware is loaded by a PC via any MMI program (e.g. ETC−MMI).

– Variable user programs can be executed.

Comparison of the operating

modes

Use The control system operates a

User program A fixed program runs in the

Installed firmware on the

control system

Installation of the firmware The firmware is loaded and

Behaviour of the control

system after the voltage has

been applied

LED display after the voltage

has been applied

Starting the firmware Before the start, the firmware

Standalone (delivery) With MMI

machine without further

coupling to a PC.

control system.

Boot loader

firmware

installed in the EEPROM by the

boot loader.

After the voltage has been

applied, the control system

automatically starts with its

firmware.

After the firmware has been

started successfully, the green

watchdog LED lights up.

is loaded from the EEPROM of

the control system into the

RAM and started.

The control system operates a

machine with coupling to a

user interface, which is used

for loading programs and

operating the control system.

Variable user programs can be

loaded into the control

system.

Boot loader

loader

The Loader is loaded and

installed in the EEPROM by the

boot loader.

After the voltage has been

applied, the control system

waits until the firmware is

loaded via the PC.

The successful start of the

loader is indicated by

circulating LEDs (1 ... 6).

The firmware is located on the

PC and is loaded into the RAM

of the control system and

started when the MMI user

interface is started.

After the firmware has been

started successfully, the green

watchdog LED lights up.

Set the "Standalone"

operating mode

EDSTCXN EN 2.0

The "Standalone" operating mode is factory−set.

) Note!

If the ETCHx has already been operated in the "with MMI"

operating mode and is to be reset to the "Standalone" operating

mode, the file "NetBoot.rsc" (loader) must be deleted in the

control system and the firmware file ETCHC_A.rsc (ETCHC) or

ETCPC.rsc (ETCPC) is to be transferred instead. For this purpose,

proceed as described in the following section; the files that are

to be exchanged are the only difference.

l

25

Page 26

2

2.4

2.4.3

Getting started

Establishing the communication between PC and ETCHx

Setting the operating mode of the ETCHx

Set the "With MMI" operating

mode

For the "With MMI" operating mode, the firmware file must be replaced by

the file "NetBoot.rsc" (Loader) on the ETCHx.

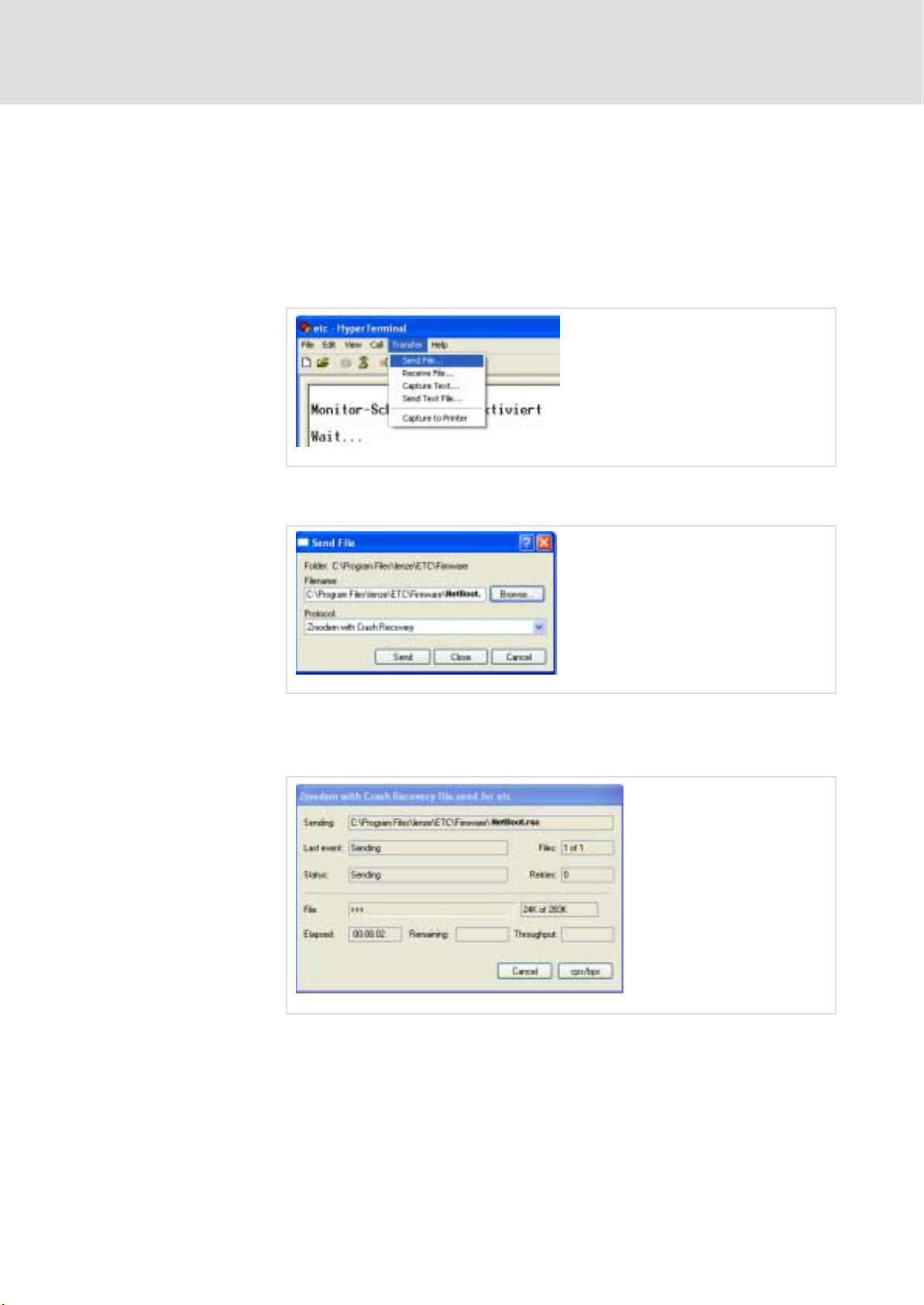

1. To delete the firmware, enter the following in the HyperTerminal: del

sd: etc*.rsc. Afterwards, press the <Enter> key.

2. To transfer the Loader to the ETC, activate the menu item Transfer

W

Send File in the HyperTerminal.

ETCM021

3. Specify the path to the file "NetBoot.rsc" and select the protocol

"Zmodem with Crach Recovery".

ETCM022

4. Click on Send.

While the file is being loaded into the control system, the following figure

is displayed. On the ETC front plate, the LEDs 1 ... 6 flash circulatingly.

ETCM023

26

l

EDSTCXN EN 2.0

Page 27

Getting started

Establishing the communication between PC and ETCHx

Setting the operating mode of the ETCHx

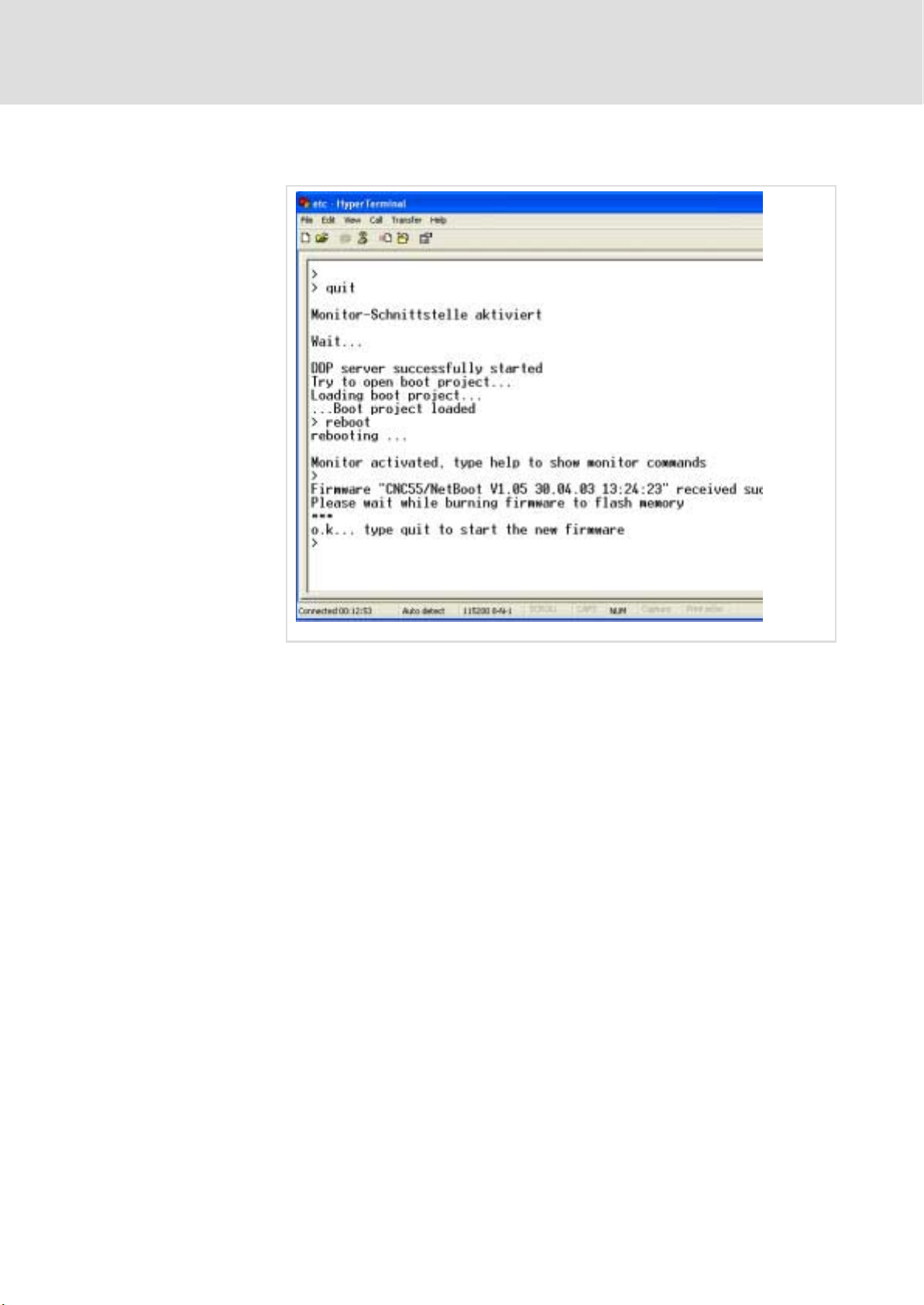

After loading is complete, the following figure is displayed:

2

2.4

2.4.3

The control system waits until the firmware is loaded from the PC; on the

ETC front plate, the LEDs 1 ... 6 flash circulatingly.

5. In the HyperTerminal window, enter quit and confirm the command

with <Enter> .

The firmware starts. On the ETC front plate, the green watchdog LED

lights up.

ETCN007

EDSTCXN EN 2.0

l

27

Page 28

2

2.4

2.4.4

Getting started

Establishing the communication between PC and ETCHx

Assigning the IP address of the ETCHx

2.4.4 Assigning the IP address of the ETCHx

For communication via a network or a local Ethernet cable, the ETCHx

requires a unambiguous IP address (with subnet mask) that matches the

other nodes. When the control system is delivered, it has a specific, but

random IP address.

The IP address of the ETCHx is assigned via the monitor interface (as

described in the following). This IP address is requested when connections

are established in the ETC−MMI Gateway (¶ 34).

Specify the IP address according to the following general rules for IP

addresses:

Separate (local) network

segment

If the control system and PC are connected with a local network segment or

via a direct Ethernet connection (without Internet/Intranet connection),

assign IP addresses of class B or class C to the two network stations.

ƒ Addresses of class B are in the range from 128.0.0.0 to

191.255.255.255. The corresponding subnet mask is 255.255.0.0

(default).

ƒ Addresses of class C are in the range from 192.0.0.0 to

223.255.255.255. The corresponding subnet mask is 255.255.255.0

(default).

Existing network segment

The gateway address is not relevant here. You can enter a free IP address of

the subnetwork (not 0.0.0.0).

Example IP address Subnet

This address must be assigned to the ETCHC and

specified as connection parameter in the ETC−MMI

Gateway ^ 34:

This address must be specified in the network

connection of the PC (TCP/IP settings):

181.16.1.10

181.16.1.11 255.255.0.0 181.16.1.1

mask

255.255.0.0 181.16.1.1

Gateway

address

) Note!

Do not use any leading zeros in the IP addresses. Otherwise, the

IP address will be interpreted as octa decimal number.

If ETCHx and PC are to be connected with an existing network segment, the

addresses and the subnet mask must be assigned by the network

administrator.

) Note!

If the Ethernet adapter supports 100Base−T technology, "Auto

Select" or "10Base−T" must be set for the "Media Type" property.

28

l

EDSTCXN EN 2.0

Page 29

Getting started

Establishing the communication between PC and ETCHx

Assigning the IP address of the ETCHx

2

2.4

2.4.4

MAC address

Assigning an IP address

Like any other device with Ethernet controller, the ETCHx receives an

unchangeable and worldwide unique physical Ethernet address, also called

MAC ID (Media Access Control Identity), from the manufacturer. It can be

used for addressing on the hardware level. The address has a fixed length of

6 bytes (48 bits) and contains an address type, an identification of the

manufacturer and a serial number.

MAC−ID of the ETC: 00:05:7e:xx:xx:xx (with xx:xx:xx = serial number).

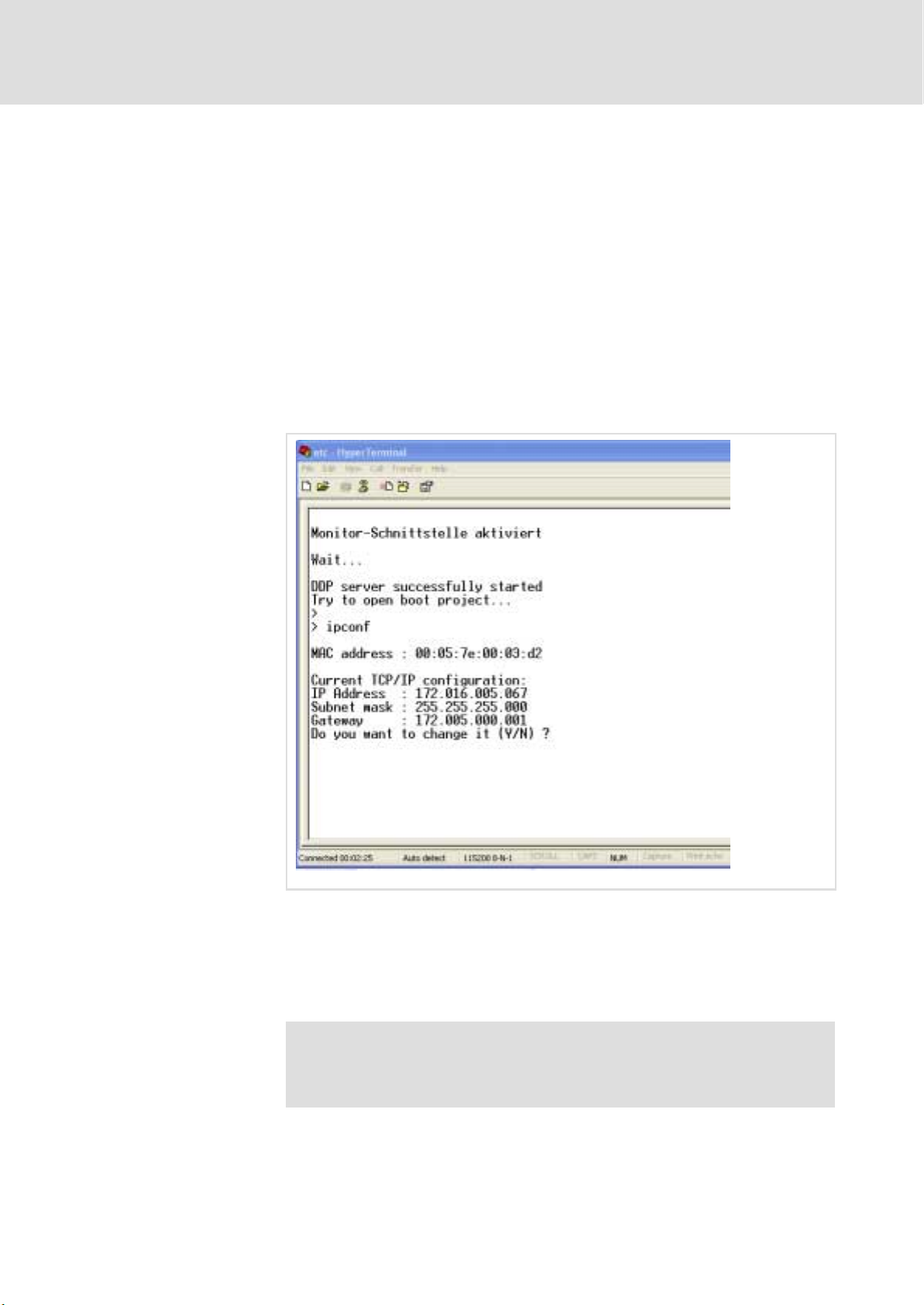

The IP address of the ETCHx is specified via the monitor interface.

1. In the HyperTerminal, enter the command ipconf and confirm the

command with <Enter>.

The MAC−ID and the current address setting of the ETCHx are displayed.

ETCM011

2. Press the <Y> key and change the settings. Follow the instructions of

the monitor interface.

Select an IP address according to the rules specified at the beginning of

the section.

The HyperTerminal program can now be quit.

) Note!

Note down the IP address because it must be specified when

creating connections in the ETC−MMI Gateway (¶ 34).

EDSTCXN EN 2.0

l

29

Page 30

2

2.5

2.5 Configuring ETC−MMI and ETC−MMI gateway

Getting started

Configuring ETC−MMI and ETC−MMI gateway

The program "ETC−MMI" is used for the following tasks:

ƒ Configuring the control system

ƒ Operating and monitoring the control system

ƒ Maintenance of the control system and error diagnosis

The MMI gateway is the communications program between Windows

applications and ETC control systems. Different applications such as MMIs,

configuration tools or OPC servers can establish connections to one or more

control systems at the same time.

The gateway implements all required mechanisms for access control, error

handling and diagnostics and supports control−specific hardware drivers

and communication protocols. By means of the configuration tools, new

connections can be added and existing connections can be edited.

The ETC−MMI Gateway is installed during the installation of the Lenze

ETC−MMIs. It can also be installed as a separate application. In this case, it is

available as communication channel for other applications.

, For further information, please refer to the chapters "ETC−MMI

Gateway" (¶ 276) and "ETC−MMI" (¶ 286).

30

l

EDSTCXN EN 2.0

Page 31

2.6 Installing ETC−MMI

( Stop!

) Note!

1. In Windows File Explorer, open the program "setup.exe" on the

2. Follow the instructions of the installation program. The following will

Getting started

Installing ETC−MMI

Building in and installing the ETCPx

Only install the PCI control variant ETCPx after installing the

ETC−MMI and before starting the ETC−MMIs.

The ETC−MMI Gateway is installed during the installation of the

Lenze ETC−MMIs

ETC−MMI installation CD.

be requested:

– Demo or standard installation

– Control type (ETCHC or ETCPC)

– IP address of the ETCHC (¶ 28) or index of the ETCPC (indexes of the

PCI cards are in the range 0 ... 9 and are automatically assigned by the

driver. The first ETCPx has the index 0).

In the start bar, the entry "Lenze ETC−MMI" is created. It can be used to

start the application.

2.6

2.6.1

2

3. For an ETCHC: Check that the TCP/IP protocols are installed in the

network properties (Start

For an ETCPC: Install the ETCPC plug−in card in the PC. Observe the notes

in the ETC Hardware Manual.

2.6.1 Building in and installing the ETCPx

1. If you use an ETCPx plug−in card as control system, install it in the PC

now. Please observe the notes in the ETC Hardware Manual.

2. Start the PC and open the BIOS settings.

For Phoenix BIOS: set Advanced\Plug & Play O/S to [NO].

For other BIOS, check the corresponding entry, e.g. PNP OS on [NO].

After the start of the operating system, the hardware wizard detects the

new hardware and queries the driver.

3. Install the ETCPx driver from the ETC−MMI CD (...\wdm2000\ETCPC.inf)

4. Restart the PC.

W Settings W Control Panel W Network).

EDSTCXN EN 2.0

l

31

Page 32

2

2.7

2.7 Starting ETC−MMI

Getting started

Starting ETC−MMI

1. Start the ETC−MMI via <Start>

The ETC−MMI Gateway is automatically started. The application can be

seen on the task bar:

W Programs W Lenze W ETC

ETCN011

ETCN001

) Note!

It can be defined which operating mode is displayed when the

user interface is started. (¶ 327).

For a detailed description of the MMIs, refer to chapter

"ETC−MMI" (¶ 286).

For a detailed description of the MMI gateways, refer to chapter

"ETC−MMI Gateway" (¶ 276).

32

l

EDSTCXN EN 2.0

Page 33

Switching the language in the ETC−MMI

2.7.1 Switching the language in the ETC−MMI

1. In the ETC MMI window, press <F12> (diagnostics).

The MMI window opens in the "Diagnostics" operating mode.

2. In the ETC−MMI diagnostics window, press <F8> (MMI−config.).

The window "delphmmi.ini" opens (¶ 283).

Getting started

Starting ETC−MMI

2

2.7

2.7.1

3. Specify the language in the line Language:

German: "Lenze"

English: "Lenze_gb"

4. Close the window with <Enter>.

5. Quit and restart the ETC−MMI.

EETCN095

EDSTCXN EN 2.0

l

33

Page 34

2

2.7

2.7.2

Getting started

Starting ETC−MMI

Establishing a connection between ETC−MMI and ETC

2.7.2 Establishing a connection between ETC−MMI and ETC

1. On the task bar, click on the ETC−MMI Gateway icon.

A menu opens.

Settings: Start configuration interface.

About: Display version and manufacturer information.

Exit: Close gateway (if there are active connections to an application, a

warning is displayed).

ETCN001

ETCN002

2. Click on Settings.

ETCN003

Connections: List of the already configured connections. A green LED next

to the connection name indicates an active connection, via which the

messages and/or cyclic data are transferred. Via the Settings button, you

can edit the communication parameters of the selected connection

(¶ 278).

Trace: In the case of faults in the communication, you can activate trace

logs on this tab (¶ 281).

About: Display version and manufacturer information.

34

l

EDSTCXN EN 2.0

Page 35

Getting started

Starting ETC−MMI

Establishing a connection between ETC−MMI and ETC

3. To create a new connection, click on Add on the "Connection" tab.

4. Specify a name for the connection.

To enable an application to communicate with a control system via the

ETC−MMI Gateway, each connection must be assigned an unambiguous

name. You can choose any name. Assign e.g. consistent names "ETC0",

"ETC1" ... or application−specific names "ramp", "laser control" etc. A

name can contain up to 31 ASCII characters ("A ... Z", "a ... z" , "0 ... 9").

2

2.7

2.7.2

ETCN004

5. Select a connection type:

ƒ UDP connection for ETCHx control systems

Ethernet communication via DPR/UDP/IP protocol.

ƒ PCI connection for ETCPx control systems

DPR communication via a WDM driver (ETCPC.sys, in the scope of supply

of the ETCPC).

6. Enter a communication parameter in the "IP address" field:

ƒ ETCHC = IP address (¶ 28)

ƒ ETCPC = Index of the PCI cards (indexes of the PCI cards are in the range

0 ... 9 and are automatically assigned by the driver. The first ETCPx has

the index 0).

7. Close the dialogue via OK.

Your entries are saved in the file "mmigtway.ini" (¶ 283). If a connection

with the same parameters already exists, the error "Gateway cannot

change the parameter" is reported.

EDSTCXN EN 2.0

l

35

Page 36

2

2.8

2.8.1

Getting started

Parameterising drives via machine constants

Overview of the most important machine constants

2.8 Parameterising drives via machine constants

The properties of the drives must be parameterised both in the drive itself

and in the control system.

In the control system, the properties are assigned via machine constants

(MCs). A machine constant consists of a keyword and the corresponding

values; for example "MK_VMAX 20".

The machine constants are saved on the PC in a text file with the extension

.mk (e.g. ETCHC.mk for the ETCHC) and are loaded into the control system via

the ETC−MMI. The machine constants can be changed after loading via a

dialogue in the ETC−MMI.

2.8.1 Overview of the most important machine constants

The machine constants listed in the following are mandatory for the

operation of the drive. In relation to the drives, they are only a subset of the

required parameterisation. For a detailed description of all machine

constants, refer to chapter "Machine constants" (¶ 190).

Test setting

( Stop!

The control system only initialises the drives via its machine

constants and determines path−related parameters. The

control−related parameters, the safety functions of the drives

and the parameters of the reference run must be parameterised

in the drive itself by means of the GDC (Global Drive Control).

MC keyword No. of

values

MK_TEST_OHNEMECHANIK 1 0, 1 0: "Achsrechner" ("Axis computer") of

MK_SPS_DUMMY 1 0, 1, −1 0: with integrated PLC function

Values Meaning

the NC firmware works and considers

the actual position counter of the

drive.

1: "Achsrechner" ("Axis computer") of

the NC firmware works, but simulates

the actual position counter of the drive

(actual position = desired position for

the test of the NC function without

mechanics).

1: without integrated PLC function

−1: without integrated PLC function,

releases are reset

36

l

EDSTCXN EN 2.0

Page 37

Getting started

Parameterising drives via machine constants

Overview of the most important machine constants

2

2.8

2.8.1

Hardware configuration

MC keyword No. of

values

MK_CANDRIVES 12 −1, 0 ... 11 Assignment of the axis number 0 ... 11 to

MK_APPLACHSIDX 18 −1, 0 ... 11 Assignment of the axis number 0 ... 11 to

MK_ACHSENART 12

Values Meaning

the CAN node address in the order of the

CAN node address 1 ... 12

−1: No axis number is assigned to the

node address

0 ... 11: An axis number is assigned to the

node address

the axis description in the order of the

axis description X ,Y, Z, C, U, V, W, A, B, u,

v, w, x, y, z, a, b, c

−1: No axis number is assigned to the axis

description

0 ... 11: An axis number is assigned to the

axis description

Assignment of the axis type to the axis

number in the order of the axis number 0

... 11

Bit 0 Axis type

xxxxxxx0 Linear axis

xxxxxxx1

xxxxxx0x Observe HW limit switch

xxxxxx1x

xxxx00xx Normal axis

xxxx01xx

xxxx10xx Measurement axis

xxxx11xx

xx00xxxx Rotation axis with absolute

xx01xxxx

xx11xxxx Modulo 360° axis − shortest distance

x0xxxxxx Normal axis

x1xxxxxx

0xxxxxxx Normal axis

1xxxxxxx

Rotation axis

Bit 1 Limit switch

Ignore HW limit switch

Bit 3/2 Axis type

Spindle

Spindle and measurement axis

Bit 5/4 Only for xxxxxxx1,

rotation axis

positioning

Modulo 360° axis − sign indicates the

direction

is travelled (ETCHC only)

Bit 6 Gantry axis

Gantry axis (synchronous axis with

mechanical coupling)

Bit 7 Handwheel

Handwheel

Software configuration

EDSTCXN EN 2.0

MC keyword No. of

values

MK_CANOPEN_BAUDRATE 2 0,

MK_DELTAT 1 Rough interpolation cycle in [ms]

Values Meaning

1st parameter for CAN1

10... 1000

2nd parameter for CAN1

0: no device connected

>0: baud rate for CAN−Open in kB

l

37

Page 38

2

2.8

2.8.1

Getting started

Parameterising drives via machine constants

Overview of the most important machine constants

Setting of the axes

Axis−related limit values

Path−related limit values

MC keyword No. of

values

MK_IMPULSE 12 Number of impulses per [MK_WEG]

MK_WEG 12 Distance in [mm] or [degree] which

MC keyword No. of

values

MK_MODVMAX 12 Modal axis speed (manual traversing)

MK_VMAX 12 Max. axis speed [m/min] or [U/min] in

MK_BESCHL 12 Acceleration ramp [m/s2] or [U/s2] in

MK_BREMS 12 Deceleration ramp [m/sec2] or [U/s2] in

MK_T_BESCHL 12 Damping time constant for acceleration

MC keyword No. of

values

MK_VBAHNMAX 1 Max. material speed [m/min]

MK_BAHNBESCHL 1 Acceleration ramp [m/s2]

MK_BAHNBREMS 1 Deceleration ramp [m/s2]

MK_T_BAHNBESCHL 1 Dampening time constant for

Values Meaning

(after the quadruplication!) in the order

of the axis number 0 ... 11

corresponds to the value of

[MK_IMPULSE] in the axis computer in

the order of the axis number 0 ... 11

Values Meaning

[m/min] or [U/min] in the order of the

axis number 0 ... 11

the order of the axis number 0 ... 11

order of the axis number 0 ... 11

the order of the axis number 0 ... 11

and deceleration ramps [ms] in the order

of the axis number 0 ... 11

Values Meaning

deceleration and acceleration ramps [ms]

38

l

EDSTCXN EN 2.0

Page 39

2.8.2 Machine constant file ETCxC.mk

In the control variant "With MMI", the file ETCxC.mk is loaded into the

control system ETCxC when the ETC−MMI is started. In the "Standalone"

variant, it is detected that the machine constants have already been loaded.

The following example of machine constants is an excerpt from the file

ETCxC.mk with preset machine constants, which must be adapted for the

specific application.

Getting started

Parameterising drives via machine constants

Machine constant file ETCxC.mk

2

2.8

2.8.2

Test setting

Hardware configuration

Software configuration

Setting of the axes

Axis−related limit values

MC keyword No. of

values

MK_TEST_OHNEMECHANIK 1 0

MK_SPS_DUMMY 1 0

MC keyword No. of

values

MK_CANDRIVES 12 0, 1, 2, 3, −1, −1, −1, −1, −1, −1, −1, −1

MK_APPLACHSIDX 18 0, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 13, 14, 15, 16, 17

MK_ACHSENART 12 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0

MC keyword No. of

values

MK_CANOPEN_BAUDRATE 2 500, 1000

MK_DELTAT 1 2

MC keyword No. of

values

MK_IMPULSE 12 65536, 65536, 65536, 65536, 65536, 65536,

MK_WEG 12 10, 10, 10, 10, 10, 10, 10, 10, 10, 10, 10, 10

MC keyword No. of

values

MK_MODVMAX 12 10, 10, 10, 10, 10, 10, 10, 10, 10, 10, 10, 10

MK_VMAX 12 20, 20, 20, 20, 20, 20, 20, 20, 20, 20, 20, 20

MK_BESCHL 12 2, 2, 2, 2, 2, 2, 2, 2, 2, 2, 2, 2

MK_BREMS 12 2, 2, 2, 2, 2, 2, 2, 2, 2, 2, 2, 2

MK_T_BESCHL 12 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0

Values

Values

Values

Values

65536, 65536, 65536, 65536, 65536, 65536

Values

Path−related limit values

EDSTCXN EN 2.0

MC keyword No. of

values

MK_VBAHNMAX 1 20

MK_BAHNBESCHL 1 2

MK_BAHNBREMS 1 2

MK_T_BAHNBESCHL 1 0

Values

l

39

Page 40

2

2.8

2.8.3

2.8.3 Notes on loading the MK file into the control system

Getting started

Parameterising drives via machine constants

Notes on loading the MK file into the control system

Make sure that the number of parameters in the file of machine constants

corresponds to the number of axes (12) in the operating system of the

control system.

When the machine constant file is loaded into the control system, 3 cases are

possible:

ƒ The number of parameters in the file equals the maximum number in

the operating system.

The parameters overwrite the saved machine constants in the control

system.

ƒ The number of parameters in the file is greater than the maximum

number in the operating system.

The parameters overwrite the saved machine constants in the control

system up to the maximum number. An error message is generated for

each parameter of the file that is not adopted.

ƒ The number of parameters in the file is smaller than the maximum

number in the operating system.

The parameters overwrite the saved machine constants in the control

systems. The missing machine constants up to the maximum number are

completed by the entries that already exist in the control system.

) Note!

If the control system is in an error status (display in the ETC−MMI

in the SETUP operating mode: "NCR: ERROR"), the loaded

machine constants are not adopted in the control system.

The machine constants have only been adopted correctly when

the control state "Idle" (display in the ETC−MMI in the SETUP

operating mode: "NCR: STEHT" ("NCR: STANDS")) is reached.

40

l

EDSTCXN EN 2.0

Page 41

Parameterising drives via machine constants

Example for adapting a machine constant file

2.8.4 Example for adapting a machine constant file

The drive configuration has 3 drives with the following properties:

Axis number 0 1 1

CAN node address 8 7 3

CAN baud rate 500 kB

Axis description c X (X’)

Axis type Rotation axis Linear axis with

Resolution pulses 65536 65536 like drive 2

The machine constant file must look as follows:

Getting started

Drive 1 Drive 2 Drive 3

handwheel

Gantry axis for

drive 2 with the

same properties

2

2.8

2.8.4

Test setting

Hardware configuration

Software configuration

Setting of the axes

Explanation

MC keyword No. of

values

MK_TEST_OHNEMECHANIK 1 0

MK_SPS_DUMMY 1 0

MC keyword No.of

values

MK_CANDRIVES 12 −1, −1, 1, −1, −1, −1, 1, 0, −1, −1, −1, −1

MK_APPLACHSIDX 18 1, −1, −1, 0, −1, −1, −1, −1, −1, −1, −1, −1, −1, −1, −1, −1, −1,

MK_ACHSENART 12 1, 192, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0

MC keyword No. of

values

MK_CANOPEN_BAUDRATE 2 500, 1000

MC keyword No. of

values

MK_IMPULSE 12 65536, 65536, 65536, 65536, 65536, 65536,

Values

Values

−1

Values

Values

65536, 65536, 65536, 65536, 65536, 65536

To define a synchronous axes, the same axis number is entered at 2 CAN note

addresses in MK_CANDRIVES. This creates a forced coupling of the axes of

the two CAN node addresses. The CAN axis with the lower node address

automatically is the master axis, the axis with the higher node address and

the same axis number is the slave axis (synchronous axis).

EDSTCXN EN 2.0

The gantry axis (X’, in MK_ACHSENART) is a special case of the synchronous

axes. It is a mechanical forced coupling of 2 axes. Thus, the gantry axis is not

entered as an axis of its own in MK_CANDRIVES, but as a reference to the X

axis.

l

41

Page 42

2

2.8

2.8.5

2.8.5 Adapting machine constants in the ETC−MMI

Getting started

Parameterising drives via machine constants

Adapting machine constants in the ETC−MMI

1. In the ETC MMI window, press <F12> (diagnostics).

The MMI window opens in the "Diagnostics" operating mode.

2. Press <F6> (machine const.).

3. Press F6 (Change current MCs) again.

The current machine constants are loaded.

01

4

0: Available machine constants

1: Date and version of the NC firmware

2: Value of the selected machine constant

3: Accept changed value

4: Short description of the selected machine constant

2

3

EETCN095

42

4. In the field of the available machine constants 0, select the machine

constant that you want to adapt.

5. To change the value of the selected machine constant, press the

<Space bar> and enter the new value in the field 2.

6. To accept the value, press the key 3.

7. After you have made all changes, press <Enter>.

The changes are transferred to the ETC and updated in the MK file.

l

EDSTCXN EN 2.0

Page 43

Test setting

Getting started

Parameterising drives via machine constants

Checking the parameters of the drives

2.8

2.8.6

) Note!

Basically, the operation of the CNC program is also possible:

ƒ without connected mechanics and drives.

This is achieved by setting the machine constant

MK_TEST_OHNEMECHANIK=1.

ƒ without a PLC program.

This is achieved by setting the machine constant

MK_SPS_DUMMY=1.

For the following tests with mechanics, the above−mentioned machine

constants must be set as follows:

2

MC keyword No. of

MK_TEST_OHNEMECHANIK 1 0

MK_SPS_DUMMY 1 1

2.8.6 Checking the parameters of the drives

After the machine constants have been adapted, the connected drives can

be checked via their tolerance margin in the diagnostics.

1. In the ETC MMI window, press <F12> (diagnostics).

The MMI window opens in the "Diagnostics" operating mode.

values

Values

EDSTCXN EN 2.0

ETCN012

Correctly parameterised drives show an alternating tolerance margin

around the zero point.

l

43

Page 44

2

2.8

2.8.7

2.8.7 Testing the drives in inching mode

Getting started

Parameterising drives via machine constants

Testing the drives in inching mode

After the machine constants have been adapted, the drives must be tested

in inching mode. Check whether the configured drives behave according to

the specifications.

1. In the ETC MMI window, press <F9> (setup).

The MMI window opens in the "Setup" operating mode.

2. Press <F2> (Manual travel).

3. In the submenu, press <F1> (Modal travel).

An individual drive is selected. The selected drive is indicated by the

setpoint with a green background.

ETCN011

4. In the submenu, alternately press <S3> (Travel +) and <S4>(Travel −).

In inching mode, the selected drive rotates in positive or negative

direction.

5. To change the speed of the drive, press <S6> (Override +) or <S7>

(Override −).

6. To select the next axis for traversing, press <S5> (axis).

The green setpoint display switches.

44

l

EDSTCXN EN 2.0

Page 45

CNC programming according to DIN 66025

2.9 CNC programming according to DIN 66025

The following description of functions according to DIN 66025 is an excerpt

from the chapter "CNC programming" (¶ 87).

2.9.1 G−functions

G−functions define geometric preparatory functions for the operation of the

axes. On principle, a DIN block with a G−function has the following structure:

The letter "G" follows the number of the G−function. This is followed by the

parameters, which consist of a letter and the corresponding value.

G (number) [parameter (value)] [parameter (value)] ...

The following shows some examples of G−functions:

Getting started

G−functions

2

2.9

2.9.1

g Meaning Parameter Example with parameter and

00 Linear interpolation, high

rate

01 Linear interpolation

02 Circular interpolation,

clockwise

03 Circular interpolation,

counterclockwise

17 Plane selection XY for

circular interpolation

18 Plane selection XZ for

circular interpolation