Page 1

364933E

Lenze

Antriebstechnik

Technical description

Frequencyinverters

8100ASeries

Page 2

Art.-Nr. 364 933

This technical description is valid for the devices:

Controller type

Enclosure IP20

Hardware version and index

Software version and index

B102_A.1X.6x

B103_A.lx.6x

B104_A.lx.6x

B10S_A.lx.6x

1st edition of:

Date of print:

26.10.1993

08.02.1994

Page 3

Technical description 81 00_ A

1. FEATURES

2 TECHNICAl DATA

2.1 Inverter data

2.2 Manufacturer's certification

3. INSTALLATION AND OPERATION

3.1 Wiring

3.1 .1 Screening

3.1.2 Grounding control electronics

3.2 Radio interference suppression

4. INVERTER CONNECTIONS

4.1 Mains and motor connection

4.1 .1 Mains choke

4.1.2 Fuses

4.1.3 Motor choke

4.2 Operating with brake chopper

4.3 Control connections

4.3.1 Position of the controls for parameter setting.

4.3.2 Opening the cover

4.4 Pulse train input/incremental encoder input X5

4.5 Serial interfaces

5. OPERATIONAND DISPLAY

5.1 Operating unit 810288 (Option)

5.2 Parameter entry

5.3 Display of operating states

6. COMMISSIONING

3

4

4

5

7

8

8

9

10

11

11

11

12

12

13

15

21

22

22

23

25

25

26

27

28

7. PARAMETER SETTING

7. 1 Parameters for initializing

7.2 Operating parameters

7.3 Control parameters

7.4 Display parameters

7.5 General parameters

7.6 Application parameters

8. CODETABlE

8. SURVEllLANCE AND PROTECTIVE FUNCTlONS

8.1 Voltage surveillance

8.2 Current surveillance

8.3 Temperature surveillance

8.4 System surveillance

9. SIGNALFlOW CHART

lenze

29

29

32

39

44

45

46

56

71

71

71

72

72

73

Page 4

2

Technical description 8100_A

SAFETYINFORMATION

The equipment described is intended for use in industrial electrical drive systems.

Thls equlpment can endanger Ilfe through rotatlng machlnery

and high voltages, therefore It Is essential that guards for both

electrlcal and mechanlcal parts are not removed.

The followlng points should be observed for the safety of the personnei:

Only quallfled person ne I familiar wlth the equlpment are permitted to InstalI,

operate and malntaln the devlces.

System documentatlon must be avallable and observed at all tImes.

All non-quallfled personnel are kept at a safe dlstance from the equlpment.

The system must be Installed In accordance wlth local regulations.

A qualified person, is someone who is familiar with all safety notes and established

safety practices, with the installation, operation and maintenance of this equipment

and the hazards involved. For more detailed definitions see IEC 364.

It is recommended that anyone who operates or maintains electrical or mechanical

equipment should have a basic knowledge of First Aid. As aminimum, they should

know where the First Aid equipment is kept and the identity of the official First

Aiders.

These safety notes do not represent a complete list of the steps necessary to ensure

safe operation of the equipment. Ifyou wish further information, please contact your

nearest Lenze representative.

The information in this technical description applies only to the hardware and

software vers ions that are indicated on the cover page. If the version of your

equipment is not listed, then this manual must not be used. Lenze cannot be held

responsible for any malfunction resulting from the above.

The specifications, processes and circuitry described in this manual are for guidance

only and must be adapted to your own specific applications. Lenze does not

guarantee the suitability of the processes and circuitry described in this technical

description for individual applications.

The specifications in this manual describe the features of the products, without

guarantee.

Lenze personnel have carefully checked this manual and the equipment it describes,

but cannot be held responsible for any inaccuracies.

Technlcal alterations reserved.

lenze

Page 5

Technical description 8100_ A

The 8100_A series comprises six frequency inverters covering a power range from

0.25 kW to 2.2 kW.

1. FEATURES

Digital control unit with 16-bit micro processor

Inverter with space pulse width modulation

Continuous load with up to 160% overload

or current limitation up to 120% overload

Inverter outputs protected against short-circuits

Integrated brake transistor, external resistors

Unipolar or bipolar set-value input, also with additional set-value if desired

13-bit resolution of the analog inputs

Set-value input possible via digital frequency input

4 complete parameter sets, can be changed via terminals

Control parameters can be changed ON-UNE

Digital inputs and outputs for 24V-PLC level

8 digital inputs, 5 of them freely assignable

3

4 freely assignable digital outputs, and one relay output

1 freely assignable monitor output for :f:10V or :f:20mA

PTC input for motor temperature surveillance

Process control

Speed control, closed-Ioop control with tachometer or incremental encoder

feedback

Linear or square V/f-characteristic

Linear or S-shaped ramp generator characteristic

Up to 15 JOG set-values, up to 15 additional accel. and decel. times

Chopper frequency can be set from 1.0 kHz to 4.0 kHz

DC bus voltage compensation

DC injection braking

Serial interface RS 232C/RS 485

LCD operating unit 810288 available as option

Lenze

Page 6

4 Technicaldescription8100_A

2 TECHNICAL DATA

2.1 INVERTERDATA

Inverter type

Output power

Rated motor power

(4-po1e)

Mains voltage

Rated mains current

Output voltage

Rated output current

Max. inverter current

without Clamp

with Clamp

Power loss

fd = 50Hz,

Output frequency

Master voltage

I=IN

Master current

Ambient temperature

Enclosure IP20 to DIN 40050

Part no. 356 845 356 846

SN/kVA

PN/W

Vmains

Imains/A

V

IN/A

Imax/A

pv/W

fd

UL

IL

Tu

8101 8102 8103 8104 8105

0.76 1.0 1.3

250 370 550

190...260V

4.5

2.0 2.6 3.4 4.0 7.0 9.5

3.2 4.2 5.4 6.4

2.4 3.1

25

5.0 7.0 9.0

3 x 0

4.1

35

50

o. . .t4 80Hz

0.. .10V or -10V...+10V

0...20mA

4...20mA

o to 45°C

356 848 356 850 356 851 356 852

1.5 2.7 3.6

750

tO% 50. ..60Hz

... Vmains

4.8 8. 4 11. 4

70 90 150

or -20mA.. .+2OmA

or t 4mA.. .t20mA

8106

1500 2200

15 17

11.

2 15.

2

Lenze

Page 7

Technical description 8100_ A

2.2 MANUFACTURER'SCERTIFICATION

The electronic drives listed are called "devices" in terms of industriallanguage, but

they are not ready to use devices or machines in the sense of the "safety regulations

tor devices", the "EMC regulations" or the "EC machine guideline". The final function

is only determined when integrated into the control system of the final user.

The compliance of the user system to the legal regulations applicable remains the

responsibility of the user. The technical descriptions of the Lenze products give

advice and recommendations tor the use of electronic equipment under consideration

ot the standards listed below:

5

Equipping high power plant with

electronic devices

Regulations for the erection ot

power installations

Degrees of protection provided

by enclosures

Creepage distances and clearances

Electrostatic discharge (ESD)

Electrical fast transient interference (burst)

Radio interference suppression ot

electrical appliances and plant

Radio interference suppression of radio

trequency equipment for industrial,scientific,

medical (15M)and similar purposes VDE0871

DINVDE 0160

DIN VDE0100

DIN40050

DINVDE 0110

VDE 0843 part 2 (lEC 801-2)

VDE 0843 part 4 (lEC 801-4)

VDE 0875, part 11 (EN55011)

l.enze

Page 8

6

a

a

c

a

B-

s::.

I

Technical description 8100_Ä

e "'C

0

C\J

.....1

Lenze

B

-----

UIII ih)

I. A.

:.D.::.D.::.D

, """""""tom00000000000

View trom direction ..A ..

8100

1

8101/8102

8103/8104

8105/8106

a b c d

mm mm

162 205 130 190 136

162 205

200 245 165 230 156 5.5 7.5 70 130 4.5

mm mm

130 190

e

mm mm mm mm mm

149 5.5 7.5 60 120 2.8

h k 1

9

7.5 47 107 2.1

5.5

Weight

kg

Lenze

Page 9

Technical description 8100_A

3. INSTALLATION AND OPERATION

Install device vertically with terminals at the bottom.

Ensure a free space of 100 mm at the top and bottom and 50 mm at either side.

Connect the fixing screw of the reference potentiometer to PE.

The inverters must not be connected to mains with an earth-Ieakage current

breaker, without additional measures (e.g. zeroing) (see VDE0160/5.88). In case

of an earth fault, a DC component in the fault current can prevent the release of

the earth leakage current breaker.

Maintain a time of 3 minutes between mains disconnection and reconnection.

Internal components to limit the switch-on current must cool in order to prevent a

failure of internal or external fuses.

Plug terminals for control and power connections may only be connected or

disconnected when the device is without voltage.

Model 8106_A may only be operated with the specified mains choke.

The motor connected may not be switched via a contactor when the drive is

enabled, except in emergency situations.

Replace defective fuses only with the specified type when the device is switched

off.

7

Warning: The device carries potential up to 30s after mains disconnection.

The cooling air temperature must not exceed 45°C. If the cooling air contains

pollutions (dust, flakes, aggressive gases) which may impair the inverter function,

ensure sufficient protective measures, such as separate air ducts, installation of

filters, periodical cleaning. In ca se of condensation, disconnect the device from

the mains and wait until the visibile humidity has evaporated.

The types 8101_A to 8105_A are designed for a continuous thermal current limit

of 1.2'IN and type 8106_A for 1.0'IN. In case of load changes make sure that

these values are not exceeded, otherwise the temperature trip may become

effective. The effective continuous current is permissible, if leff s 1.2'IN (for

8106_A: leff s 1.0'IN) and the connected motor is not overheated.

Warning: With corresponding settings, this device generates an output frequency

up to 480 Hz. If connected to an unsuitable motor, dangerous overspeed

may result.

ienze

Page 10

8 Technical description 8100_A

3.1 WIRING

3.1.1 SCREENING

The inputs and contral terminals of the device are noise immune without screening of

the connecting cables up to severity class 4 to IEC 801-4.

Additional screening is required, if the device is operated where severity class 4 is

not sufficient, e.g. where power cables and control cables cannot be laid separately.

Caution: Interferences may cause faults in the program, which immediately stop

the operation via a trip fault.

SCREENING OF CONTROL CABLES

In order to avoid signal faults, we recommend to screen analog cabling, wires for

digital frequency input, and for incremental encoder feedback.

To avoid PE-Ioops, connect the screens of the contral cables at one end to PE, either

via

the provided inverter terminals or

via insulated central points, which are connected to PE at one point

(e.g. PE terminals).

via the Sub-D plug X5 (only for digital frequency input or incremental encoder

feedback).

In case of interruptions at terminal boards, relays, fuses etc. keep connections of

control cable screens as short as possible.

For screening of the control wires of the serial LECOMinterface see technical

description LECOMAlB.

SCREENINGOFMOTORCABLESAND BRAKECHOPPERCABLES

Motor cables and cables of the brake resistors are a source of electrical noise and

must be screened if sensitive equipment is close by.

Connect the screen of the motor cable directly to PE, for wires longer than 3m, both

sides, if possible.

lenze

Page 11

Technical description 8100_A

3.1.2 GROUNDING CONTROL ELECTRONICS

Single drives

For computer networks with fixed installation, an additional potential separation

between computer and inverter (e.g. Lenze Converter 2101) is necessary.

Network of several drives

In a drive network, it is necessary to remove the GND-PE connection from every

controller, to avoid GND-Ioops. Carry all GND-cables to external insulated central

points, centralize again from there and connect to PE in the central supply. Make

sure that the voltage between GNDand PE does not exceed 50 V.

In case of a fixed computer installation, mains isolation must also be provided (e.g.

Lenze Converter type 2101).

GND-PE bridge

9

Lenze

GND- PE bridae

o

V60

V61.

-EEffi

F1

u V W RB +UG-

Page 12

10 Technical description 8100_Ä

3.2 RADIO INTERFERENCE SUPPRESSION

For electromagnetic compatibility, local regulations apply which can be maintained

when considering the recommendations given below.

Measures against radio interference suppression depend on the site of the device to

be installed. Within industrial premises, which are not connected to the public low-

voltage supply, the limit va lues to EN 55011, dass A apply. Within residential areas

or industrial premises which are connected to the public low-voltage supply, the limit

values to EN 55011, dass 8 apply.

Radio interference suppression to EN 55011, dass A or 8, can be obtained by the

following measures:

al Mains filter

Type

Mains filter 332 705

8101A - 8104A

- -

8105 A - 8106 A

333 228

partno.

bl Screenings

- Motor ca bles

- Mains cables between filter and device

Cable lenght

,.../ < 10m

~ -

I

I

j

I

~

Filter

M

3 J

....

Three-phase motor

3~6

L1 N PE

Connectionfor radiointerference suppression to EN55011, dass A or 8

lenze

Page 13

Technical description 8100_ A

4. INVERTERCONNECTIONS

4.1 MAINS AND MOTOR CONNECTION

11

*'

Filter

M

3""

"'---"

Three - phase motor

3""'6

.

L1 N PE

Operation without brake chopper

The PE connection can, in addition to the power plug, be bolted to the right terminal

clamp at the front side of the inverter.

8106_ A inverters must only be operated with the correct mains choke.

The power plug may only be connected or disconnected when the device is without

voltage.

*) For screenings see 3.1

Screened cables and mains filters are necessary for radio interference

suppression to EN 55011, class A or B (see 3.2).

4.1.1 MAINSCHOKE

Advantages when using a mains choke:

Compliance with surge strength dass I according to VDE 0160

Reduction of mains feedback

Increasing the inverter life

Reduction of radio interference

Mains chokes are not supplied with the inverter.

Lenze

Page 14

12

Technical description 8100_A

k

+

+

m

f.

o

Type

8101-02 9

8103-04

8105 3.5 14 323331 96 77 84 61 96 86 86 5.8 9

8106

L

mH A

I

part no.

359485 66 67 50 54 69 61 78 4.8 9

5

5 9

1.6 17 323361 96 77 84 61

323330 96

a

mm mm mm mm mm mm mm mm mm

c

b

84 61 96 86 86 5.8 9

77

e f

d

96 86 86 5.8

m n

k

9

4.1.2 FUSES

Types

Mains fuses F1 M12A FF25A FF30A

(internal)

Part no.

Replace defectivefuses only with the specifiedtype when the device isswitched off.

The device carries potential up to 30 seconds after mains disconnectionl

8101 I 8102 I 8103 I 8104

331 113

8105 8106

307 308 321 554

4.1.3 MOTOR CHOKE

A motor choke is only required for large motor cable lengths:

as of 100m for unscreened motor cables

as of 50m for screened motor cables

Type

8101 - 8106

Motor

current

up to 10 A

Inductivity per

100m/50m cab1e 1ength

1.0 mH 357 869

Part no.

lenze

Page 15

Technical description 8100_A

13

4.2 OPERATINGWITHBRAKECHOPPER

When operating three-phase AC motors with static frequency inverters, the motor

feeds back energy to the DC bus when braking, Le. generating. Ifthe DC bus voltage

exceeds a permissible value, the inverter sets trip for the time of overvoltage. The

reason for the overvoltage is that the rate of deceleration is not adapted to the load

inertia. When using a brake chopper, the excessive DC bus voltage is switched

across a resistor which dissipates the regenerated energy as heat until the DC bus

voltage falls below the switching threshold. Therefore short deceleration times with

large inertias are possible.

8100_A series 11

Peak brake power

Maximum permanent

brake power

specified brake

resistor

Threshold voltage

(external)

Operation with brake chopper

8101

8102

300 W

11

11 120 W I 250 W I

. ..1

~i-1

Conlrolvoltage L1 N PE

I

8105

8106

1700 W

450 W

82 0

The PE connection can, in addition to the power plug, be bolted to the right terminal

clamp at the front side of the inverter. 8106_ A inverters must only be operated with

the correct mains choke. The power plug may only be connected or disconnected

when the device is without voltage.

*) For screening see 3.1

Screened cables and mains filters are necessary for radio interference

suppression to EN 55011, class A or B (see 3.2).

lenze

Page 16

14

Brake resistors

Technical description8100_A

R

Ohm kW

82 0 I 450 W 345 394 448 x 47 x 100

2*100 0

470 0

Pn

I

I 100 W 309 163 170 x 33 x 48

Part no.

HxWxD

mm

I 120 W 305 062 170 x 33 x 48

For these brake resistorsapplies:

- maximum permissible braking time:

- maximum permissible duty cycle:

15s

25%

Brake resistorsare not supplied with the inverter.

Overcurrent release

Overcurrent release

Setting

4700/120W

305 062

2000/200W

2x 309 163

820/450W

345 394

*) The setting of the overcurrent release results from the maximum permissible

brake current of the resistor (r.m.s. valuel.

Overcurrent release and base are not supplied with the inverter.

Base for thermal overcurrent release: Part no. 325 701

Warning: In ca se of mains overvoltage (>260 VI, the brake chopper may be

activated. When using resistors without overload protection, the

resistors may burn out. Therefore, only resistors with integrated or

external temperature surveillance may be used. Since the surface of the

brake resistors may heat up to 350°C, the resistors must be built into a

0.5 A 325 692

1.0 A

2.3 A 325 695

*)

part no.

325 693

fire-proofhousing.

The brake chopper output isnot protected against short-circuits.

lenze

Page 17

Technical description 8100_A

4.3

CONTROlCONNECTIONS

--r~ r'---r~-------------------

.,4)1 ,4),_ _,4)

15

2 3 4 7 a 9 1020 21

H!1

Xi

E3 E4 E540K11K14A1A2 A3A4

X3

Assignment of the control terminal block

Freely assignable

digital inputs

Assigned digital

inputs

-10V - reference voltage

."'V - "",.<,. 't...

Bipolarsetvalueinput 8

0...t10V/0...t20mA/

t4...t20mA GND 7 Kll

Bipolar different. input

0...10/30/60/90/120V I 3 I

Bipolar different. input

0.. .t10V

R/QSP 1 221

L/QSP

[m '"

+15V 20

r- --,

22~~1E2111

596062VE9 X5 X6 ~

X4 =

X2 X4

IVE91Incremental encoder supply

[1-;;]

I

60

1591

A3

I 101 I A21

Al'

K14

401

[ 4

[0

Xl X3

I'

D1gIn 1

~

~I I~II 1"1

. -

~

Monitor output

GND

24Vext

6*fd - output

Freely assignable

digital outputs

~

LECDM1

~

- -------

~

~

J

Relay output

]

GND

Free1y assignable

digital inputs

J

I

r

Lenze

Page 18

16

ANALOG INPUTS

Bipolar differential input. terminals 1. 2

X1

-10V ...+10V

Bipolar differential input. terminals 3. 4

51

lI!I1mJl0N

ITDDIOFF

T echnical description 81 00_ A

Use:

Additionalset-value(set-value2)

Input resistance:

168 kO per terminal

Input voltage:

-10V... + 10V

Resolution: 13 bit

Parameter setting:

Configuration: C005

Setting: C025. C026, C027

Tir'Tif: C220, C221

Display: C049

Use:

Actual speed (Tachometer)

Input resistance:

> 100kO per terminal, 47.5kO as load

Input voltage:

The input voltage range can be changed

using S1 on the control module

(For switch position see 4.3.1).

Resolution: 13 bit

X1

~c-_11

@. 1-

UTacho

+

81/1 81/2 81/3 I voltage range

OFF OFF OFF

ON OFF OFF

OFF ON OFF

OFF OFF ON

ON ON ON

*) Factory setting

10...+ 10V

- 30... + 30Y

60. . .+ 60Y

90...+ 90Y

-120. . .+120Y*

Parameter setting:

Configuration: C005

PI controller setting: C029

Setting: C025, C026. C027

Display: C051

Pilot control: C238

Lenze

Page 19

Technical description8100_A

Bipolar set-value input. terminal 8

168K

17

Use:

Set-value 1

Input resistance:

a) 168 kn

b) 250 n for master current

(min. source voltage of the master

current generator for fdmax: 5V)

Parameter setting:

Configuration: C005

Setting: C025, C026, C027

Tir. Tif: C012, C013 and

C100, C101, C103

Set-value: C046, C172

Resolution: 13 bit (-10V...+10V)

r1":' ~J

@I 1+

Umaster

i master

Set-va1ue

input

0.. .10V*

0.. .2OmA -0- -0-

4...20mA -0-

-10...+10V

-20...+20mA -1- -0- ON

;1:4...:t20mA

*) Factory setting

+ 10V/-10V reference voltage. terminals 9, 10

Use: .

Output current:

COOS C034

-0- -0- OFF

-1- -0- OFF

-1- -1- ON

Sl/4

ON

-1- ON

Supply voltage for set-value input

using potentiometer

maximum 7mA

lenze

unipolar set value bipolar set value

Page 20

18

DIGITAL INPUTS AND OUTPUTS

Technical description 8100_A

+ 15V-output, terminal 20

Use:

Output current: maximum 100mA

Digital inputs, terminals 21, 22, 28, E1...E5

Use:

Input resistance: 3.6kQ

Input voltage:

-Assigned digital inputs

Function:

Parameter setting/display:

Auxiliary voltage to

-control the digital inputs

via contacts

-supply of the digital outputs

Terminal contral of the controller

Low signal

High signal = 13V...30V

Terminals 21, 22: Invert set value

Terminals 21, 22: Quick stop (QSP)

Terminal 28: Controller enable (RFR)

Function: C176

Direction of rotation: C041 ,

Quick stop: C042,

tif for QSP: C105

Display RFR: C040

= OV... 5V

-Freely assignable digital inputs

Functions:

freely assignable

Parameter setting:

Functions: C112, C113

Polarity: C114

Priority: C115

Freely assignable digital outputs, terminals AL .A4

external supply: O...30V

Output current: max.50mA

Functions: freely assignable

Parameter setting:

Functions: C116, C117

Polarity: C118

lenze

Page 21

Technical description 8100_A

The assignments of the digital inputs and outputs shown below correspond to the

factory setting. For switchign of the signal cables. only use relays with low-current

contacts. Relays with gold-plated contacts are suitable (part no. 321 351).

Connecting diagram of the digital inputs and outputs

- with external 24V supply

19

RFR TRIP-Reset JOG JOG

TRIP-Set oe inj.braking

without external 24V supply

RFR TRIP-Reset JOG JOG

TRIP-Set oe inj.braking

Lenze

Omin input =output

Omin input =output

Romp-generator

not assigned

Ramp- generator

not assigned

59

Page 22

20

-output using terminal A4

6*fd

Technlcal descrlptlon 8100_A

I

~ 53

digital

tacho (n

(Lenze 322 )

Freely asslgnable relay output, terminals K11, K14

cp--

external supply:

Output current:

Functlon:

Changing to 6-fd-output

using S3: 6-fd-output: S3

output A4: S3 = "1"

Factory setting: S3 = "A"

Use:

isolated contact

external supply: max. 50V

Output current: max. 500mA

Function: freelyassignable

Parameter setting:

Functions: C116, C117

Polarity: C118

Factory setting: Trip fault

0...30V

max. 2mA

6-fd output

= "A"

Monitor output, terminal 62

Use:

Analog output

Parameter setting:

Functions: C111

Setting: C108. C109

Change-over:

S2 ="A": :t10V= :tfdmax

S2 ="1": :t20mA= :tfdmax

Factory setting: S2 =" A"

lenze

Page 23

Technical description 8100_A

21

Supply of Incremental encoder. terminal VE9

X4

incremental encoder

PTC Input X50A/B

X50A ~ ~ X50B

UJ'

Use:

An incremental encoder connected via

X5 for digital frequency input must be

supplied from an external power supply.

The required voltage/power depends on

the type of encoder (TTL-/HTL-encoder).

For pin assignment X5 see 4.4

Use:

Temperature surveillance of the

connected motor using

PTC thermal sensors to DIN44081

and DIN 44082 or thermal switches.

Parameter setting:

Activated by: C119. C120

Display: C067

Acknowledgement: C067. C043

PTC

Lead the connecting cable ot the PTC through the passage on the front side tor the

connection of the control module. plug X50A/B.

4.3.1 POSITION OF THE CONTROLSFOR PARAMETERSETTING

The switches on the control module can be accessed by removing the window.

XSOB

@

~~V105

XSOA@

mrnL

Ulli!l!l!J LI

51

Control module 8102MP

lenze

1'1

o

Page 24

22 Technical description 8100_A

4.3.2 OPENINGTHE COVER

To connect the PTC connecting cables, it may be necessary to remove the cover. For

this proceed as folIows:

-

Disconnect mains voltage and wait at least 30s.

-

Remove control and power terminals

-

Carefully remove the cover, by inserting a screwdriver into the short slots at

the top side of the inverter.

4.4

PULSE TRAIN INPUT/INCREMENTAL ENCODER INPUT X5

The 9-pole Sub-D connector X5 serves as digital frequency input and incremental

encoder input, where two complementary signals shifted by 900 are provided. When

using HTLencoders, it is sufficient to provice signals A and B. The inputs A\ and B\

must then be bridged with + Vcc.

The maximum input frequency is 300 kHz for TTL encoders and 100 kHz'for HTL

encoders.

X5: Pin Name

1

2

3

4

5

6

7

8

9

B

A\

A

+VCC

GND

0\

o

8V2

B\

Input/output

Input

Input

Input

Output

Input

Input

Output

Input

Explanation

2nd pulse train/incremental encoder signal

1st pulse train/incremental encoder signal (invertedl

1st pulse train/incremental encoder signal

Supply voltage term. VE9

Controller reference point term. 60

single-track pulse train signal when C005

single-track pulse train signal when C005 = 16

not used

2nd pulse train/incremental encoder signal (inverted)

=16 (inverted)

For the connection of a signal cable via terminals, a suitable adapter

(part no. 348 922) can be supplied.

The phase position of the input signal provides the direction of rotation of the drive.

A

Ä

----, I I

B

---.J

B

CCW rotation

I I I I

I

I I I r

I I I

I

...

CW rotation

r-

L-

I

If the additional reference is not required for digital frequency input, a fault may be

caused by an offset error of the analog input terminals 1, 2. This fault can be

eliminated setting the amplification factor to zero (C25 = 1, C27 = 0).

Caution! When the controller is enabled, a system cable which is only connected

to the digital frequency input X5, may suffer interference such that the

drive may start or reverse unintentionally (only for configuration

C005

= -2- and enabled controller).

lenze

Page 25

Technical description 8100_ A

PULSE TRAIN INPUT

23

With digital frequency input (C005) the set-value 1 is provided as absolute frequency

via X5, Le. the internal frequency set-value is directly proportional to the frequency

of the input signals. The conversion factor results from the settings under C026 and

C027.

encoder adjustment (C027)

fdset [Hz] = fmaster [Hz] .

encoder constant (C026)

When calculating the frequency reference fdset. an error up to 1% of fdmaxis

possible.

4.5 SERIAL INTERFACES

The inverters of the 8100_A series can communicate via the serial interface LECOM1

(X6) with superimposed hosts (PLC or PC). The LECOM1 interface (connector X6) is

used to process the

connect devices

(LECOM-B). The interface is suitable for parameter setting, surveillance, diagnosis

and simple control tasks.

The common RS 232 C interface, simple point-to-point connection with a maximum

LECOM-A/B-protocol. The LECOM1-interface can also be used to

to the RS 232C standard (LECOM-A)or to the standard RS485

cable length of 15 m can be achieved. Almost every personal computer (PC) or other

master system has this interface. For several drives and greater distance, the RS485

interface must be used. Only two wires are used to enable the communication of up

to 31 controllers via a distance of maximum 1200 m. Alternatively, the connections

can also be done via optical fibres. Further information can be obtained from the

technical description LECOM LI.

The LECOM A/B-protocol is based on the 1745 ISO standard and supports up to 90

controllers. It recognizes faults and therefore avoids the transmission of faulty data.

Lenze

Page 26

24

Technical description 8100_A

Features of the serial interface

-

Pin assianment:

1 + VCC15

RxD

2

TxD

3

4 DTR

5 GND

6 DSR

7

T/R (AI

8

T/R (B)

9 + VCC5

Output

Input Data receiving line RS232C

Output

Output Sending control RS232C

Input

Output/Input

Output/Input

Output Supply voltage +5V

Supply voltage + 15 V/50mA

Data sending line RS232C

Controller reference potential. term. 60

(unused)

RS485

RS485

For simple connection of the RS485 interface via terminals, a suitable adapter (part

no. 348921) can be supplied.

Baud rate: can be changed from 1200 Baud to 9600 Baud

Protocol: LECOM

There are additionalcodes, which can only be accessed via LECOM(seecode

table 7.7).

Further information about the serial communication can be obtained from the

technical description LECOMAlB.

lenze

Page 27

Technical description 8100_A

25

5. OPERATIONG AND DISPLAY

5.1 OPERATING UNIT 810288 (OPTION)

The two-line LCD operating unit 8102BB (part no. 347642) can be installed as

option. This operating and display unit is used to set the parameters of the frequency

inverters directly at the device. The operating unit is not supplied with the inverter.

Plugging and removing of the operating unit is only possible when the controller is

switched off.

Display

I

Lenze 8100

Inverter

RDY 0

Imax 0

IMP 0

Healthy (LED green)

clamp current reached (LED red)

Pulse inhibit (LED yellow)

Keys

Key functions

Key

PRG

SH + PRG

.. Increase displayed value

.. + SH

.

. + SH

STP

SH + STP Enable controller

Function

Change between code and parameter level

To confirm parameter change

Increase displayed value fast

Reduce displayed value

Reduce displayed value fast

Inhibit controller

Display

Position of arrow marks the activated level Icode-/parameter level)

Code.

C 0 5 0

f d A c

Parameter. . Unit

....

t u

t Explanatory text for each code and

parameter

a 1

o . 0

v a 1 u e

H z

Example

lenze

Page 28

26 Technical description 8100_A

5.2 PARAMETERENTRY

According to the selected code, parameters are entered in three different ways.

when the operating unit 8102BB is used.

al Immediate entry

The device immediately accepts the set parameters.

bl Entry after pressing SH + PRG

The device only accepts the set parameters after pressing SH + PRG. First

press the SH key and then the PRG key.

cl Entry with controller inhibited

The device only accepts the set parameters with the controller inhibited and after

pressing SH + PRG.

The way of parameter entry can be obtained from the information given in the code

table (see 7.71. If the setting is accepted, "m" is displayed for about 1s in the

display (except for parameters with immediate entryl.

Mains connection Code level

Set code using

Ä and .

Parameter level

Set parameter using

Ä and .

..

press

PRG

..

Press PRG

or SH+PRG

Please note: The inverter is factory-set for a parameter setting via the LECOM

interface. To enter the parameters via the keys of the operating unit 8102 BB, the

operating mode C001 must be changed first.

lenze

Page 29

Technical description 8100_A

5.3 DISPLAY OF OPERATING STATES

The one-line LED display in the window of the inverter allows fast information about

the operating state of the frequency inverter type 8100_A.

Display of actual frequency:

The field frequency is less than 2% of fmax (C011)

27

ip

~

... is between 2% and 48% of fmax (C011)

... is between 48% and 52% of fmax (C011)

ISI

...is between 52% and 98% of fmax (C011)

... is higher than 98% of fmax (C011)

Fault indications and surveillance messages see code table 7.7 (Code C067).

In case of controller inhibit. the decimal point in the LEDis flashing.

Lenze

Page 30

28

6. COMMISSIONING

The inverters of the 8100 _A series are factory-set so that a suitable four-pole three-

phase standard motor with 230V rated voltage and 50Hz rated frequency can be

operated without any further settings. If adjustments are required, the inverter

parameters must be set via the LECOM interface or the optional operating unit

8102BB (see 7.).

All common three-phase motors can be used, which have an insulating phase

separation (paper between the windings).

To run the drive, you only need to the following:

Direction of rotation

For the factory-set terminal configuration apply a voltage between 13 and 30V either

across terminal 21 for CW rotation or

across terminal 22 for CCW rotation

Reference potential is terminal 40.

Controller enable

To enable the controller, apply a voltage between 13 and 30 V across terminal 28

(RFR).This also applies for operation via the LECOMinterface or via the operating

unit 8102BB (see 7.3.1).

Input of set-value

The motor speed is varied via the set-value input; in factory setting, this is given by

an analog signal via terminals 7 and 8 (see 4.3). For a digital set-value input, change

the operating mode (see 7.1.2) and for digital frequency input change the

configuration (see 7.1.6).

Technical description 8100_ A

lenze

Page 31

Technical description 8100_A

29

7. PARAMETERSETTING

7.1 PARAMETERS FOR INITIALlZING

7.1.1 CODESETCOOO

Under coca you can select the standard code set, the extended code set, or activate

a "read-only-access" for the standard code set and activate the password protection

under C94.

Code coca can only be changed using the keys on the operating unit 810288, not

using the LECOM interface. When using the LECOM interface, all parameters can be

accessed, independently of coca.

7.1.2 OPERATINGMODE C001

Depending on the selected operating mode, the control signals are entered via the

control terminals, the operating unit 810288 or the serial LECOM interface. Also the

parameter setting depends on the operating mode, either via the operating unit or the

LECOM interfaces.

7.1.3 LOAD PARAMETER SET C002

Operation via keypad or interface:

The parameter sets are changed or loaded via C002.

Operation via terminal contral:

The parameter sets can also be changed and loaded via the digitalinput terminals

E1...E5. Here C002 serves as display which parameter set is active.

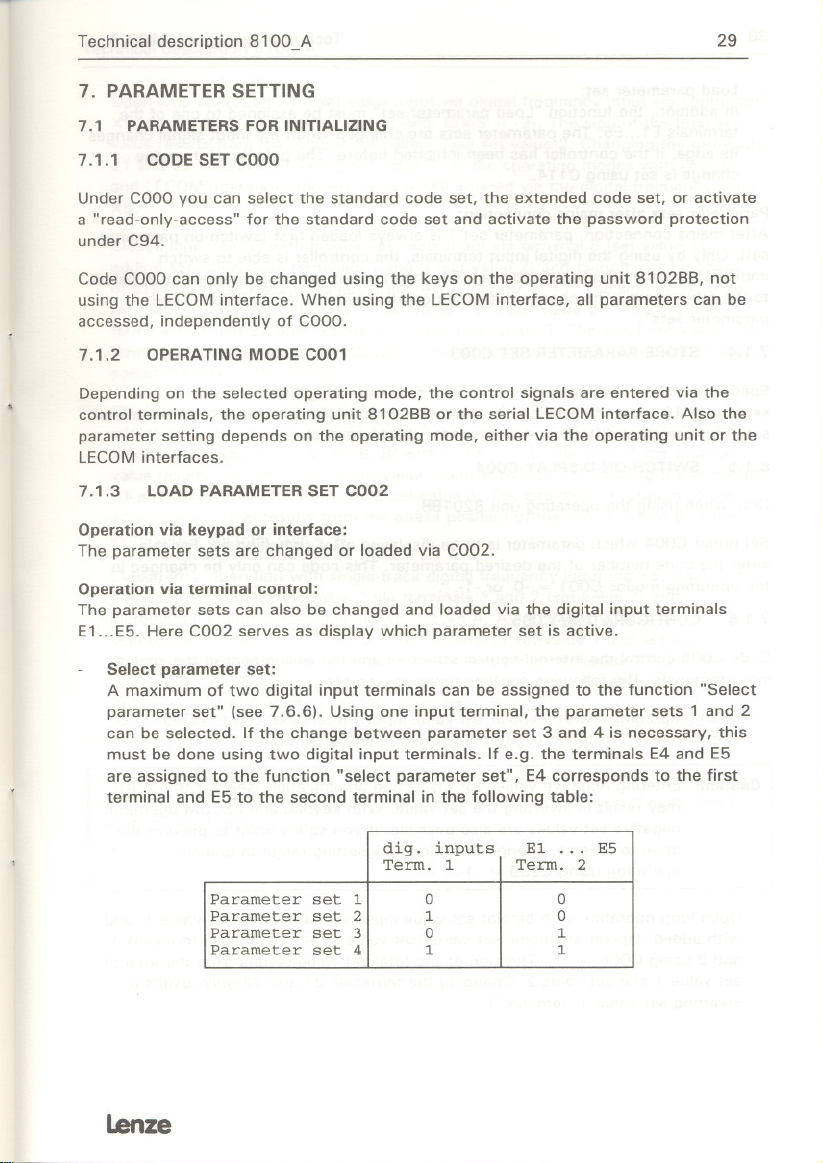

Select parameter set:

A maximum

parameter set" (see 7.6.6). Using one input terminal,the parameter sets

can be selected.Ifthe change between parameter set 3 and 4 is necessary, this

of two digitalinput terminalscan be assigned to the function "Select

1 and 2

must bedoneusing two digitalinput terminals.Ife.g.the terminals E4 and E5

are assigned to thefunction"select parameter set", E4 corresponds to the first

terminal and E5 to the second terminal in the following table:

.. . ES

El

Term.

2

0

0

Parameter set 1

Parameter set 2

Parameter set 3

dig. inputs

Term. 1

0

1

0 1

Parameter set 4 1 1

lenze

Page 32

30

load parameter set:

In addition, the function "load parameter set" must be assigned to one of the

terminals E1...E5. The parameter sets are changed when the input signal changes

its edge, if the controller has been inhibited before. The polarity of the edge

change is set using C114.

Parameter sets after mains connection:

After mains connection, parameter set 1 is always loaded first (switch-on parameter

set). Only by using the digital input terminals, the controller is able to switch

immediately to another parameter set. For this, the desired parameter set must be set

to the table above. The change is then automatie, without the function "load

parameter sets".

7.1 .4 STORE PARAMETERSET C003

Specific parameter sets must be stored permanently using C003, otherwise your

settings will be lost after mains disconnection or after changing to another parameter

set. Four complete different parameter sets can be stored.

8.1.5 SWITCH-ON DISPLAYC004

Only when using the operating unit 8201 BB.

Set under C004 which parameter is to be displayed after switching-on. For this,

enter the code number of the desired parameter. This code can only be changed in

the operating modes C001

7.1.6 CONFIGURATIONC005

= -0- or -1-.

Technical description 8100_A

Code C005 control the internal control structure and the assignment of the analog

input terminals. The following configurations can be set:

Open-Ioop control with unipolar set-value input via terminal 8 with C005

The direction of rotation is determined by terminals 21, 22.

Caution! Entering negative values for offset and amplification (see 7.2.9/7.2.10)

may result in inverting the set-value. With keypad and LECOMoperation,

negative set-values are also possible. If you safely want to prevent the

drive to reverse, change the frequency setting range to unipolar

operation using C239 = -1-.

Open-Ioop operation with bipolar set-value input via terminal 8 (set-value 1) and

with added, bipolar additional set-value (set-value 2) via the control terminals 1

and 2 using C005 = -1-. The sign of the total set-value results from the total of

set-value 1 and set-value 2. Chan ging the terminals 21 and 22 only results in

inverting set-value 1, terminal 8.

= -0-.

Lenze

Page 33

Technical description 8100_ A

Open-Ioop operation with set-value input via digital frequency input via connector

X5, tracks A, AI, B, BI (set-value 1) with C005 = -2-. The sign of the total set-

value results from the total of set-value 1 and set-value 2. Changing the terminals

21 and 22 results in inverting set-value 1. In the operating modes with keypad

and LECOMoperation, the set-value is still entered via the digital frequency input

X5.

Closed-Ioop control with bipolar set-value input via terminal 8 (set-value 1),

adding set-value 2 via terminals 1 and 2 (set-value 2) and tachometer feedback

of the actual value via terminals 3 and 4 with C005

set-value results from the total of set-value 1 and set-value 2. Changing the

terminals 21 and 22 only results in inverting set-value 1. The input voltage at the

terminals 3 and 4 has to be adapted to the tachometer voltage by means of the

switch S1 (see 4.3).

Closed-Ioop control with bipolar set-value input via terminal 8 (set-value 1),

adding set-value 2 via terminals 1 and 2 (set-value 2) and incremental encoder

feedback via X5, tracks A, AI, B, BI with C005 = 13. The sign of the total set-

value results from the total of set-value 1 and set-value 2. Changing the terminals

21 and 22 only results in inverting set-value 1. The direction of rotation of the

actual-value signal results from the phase position of the tracks A and B of the

= 11. The sign of the total

incrementalencoder (see4.4).

Closed-Ioop operation with single-track digital frequency input via X5, track 0, 01

(set-value 1), adding set-value 2 via terminals 1 and 2 (set-value 2) and

incremental encoder feedback via X5, tracks A, AI, B, BI with C005 = 16. The

sign of the total set-value results from the total of set-value 1 and set-value 2.

The sign of set-value 1 is determined by the input from terminals 21, 22. The

direction of rotation of the actual value signal results from the phase position of

the tracks A and B of the incremental encoder (see 4.4).

31

The setting of the PI controller is described under C029.

The set- and actual value inputs can be adjusted if there should be an o11set and gain

error (see 7.2.9/7.2.10). For configurations with additional set-value always check

input terminals 1 and 2.

lenze

Page 34

32 Technical description 8100_A

7.1.7 CONTROLMODEC006

Either Trip or Clamp can be selected as control modes.

In the control mode Trip, the inverter is inhibited, when 160% of the rated current is

exceeded. A fault indicationis displayed (see8). High torque can be obtained for a

short time in this mode.

In the control mode Clamp the motor current is limited to 120% of the rated current.

(Imat' S 1.2 IN)due to permanent peak current limitation. In case of shock load, the

controller will not set trip. The output signal Imax (in case of factory setting terminal

A2) is set, as soon as the peak current limitation cuts in. The red LEDflashes if the

LCD keypad 8120 is used.

Caution: If the motor is stalled, it may overheat in the control mode "Clamp".

7.1.8 LECOM1 ADDRESSC009

For the communication via the LECOM1interface, set the controller address under

code C009 (see4.5).

7.2 OPERATING PARAMETERS

7.2.1 MINIMUM FIELD FREQUENCY fdmin C010

MAXIMUMFIELD FREQUENCY fdmax C011

The set-value setting

accelerates to the minimum speed fdmin after controller enable.

is determined via fdmin and fdmax' With zero set-value the drive

fdminis only effective with analog set-value input and unipolar set-value

(C005 = -0-). fdmaxis a reference value for the setting of the acceleration and

deceleration times Tir and Tif.

With absolute set-value input, e.g. via the LECOMinterface or JOG values, fdmaxis a

limit value.

The chopper frequency of the output voltage set under C018, influences the

effective maximum field frequency. For example, the field frequency with

C018 = -0- (fCh = 1.0 kHz) is limited to 120 Hz (see 7.2.7).

Caution! fdmax is an internal scaling value. Therefore, larger changes via the

LECOMinterface, may only be done when the controlleris inhibited.

Lenze

Page 35

Technical description 8100_A

33

7.2.2 ACCLERATIONTIMETIR C012

DECELERATIONTIME TIF C013

Acceleration and deceleration refer to a change of the field frequency from zero to

fdmax.

The times Tir and Tif can be calculated as folIows:

fd 1Hz

fdmax

fd 2

fdl

.-.,," I !"'.- Tir = tir

0

Tif = tif

fdmax

Here, tir and tif are the desired times for the change between fd1 and fd2 and Tir

and Tif the values to be set under C012, C013.

7.2.3 VIf CHARACTERISTIC

A linear or square motor voltage characteristic can be set under C014. Square

characteristics are preferably used for pump and biower drives.

7.2.4 VIf NOMINALFREQUENCYfdN

The slope of the VIf characteristic is set using the VIf nominal frequency. It is

calculated from the rated motor voltage and the rated motor frequency as folio

ws:

230 V

fdN [HZ]

. fN Motor [Hz]

UN Motor [V]

The settings of the VIf nominal frequency for the most common mains and motor

combinations can be obtained from the table below. Please note that the maximum

output voltage of the inverter can only be as high as the mains supply voltage.

UNMotor fNMotor fdN

[V] [Hz] [Hz]

230 50

220

230 60 60.0

240 50

50

50.0

52.3

47.9

Lenze

Page 36

34 Technical description 8100_A

Caution! During commissioning always check that the no-load current does not

exceed the rated motor current. If necessary, the current consumption

during idle running can be reduced by increasing the VIf nominal

frequency and therefore the VIf characteristic.

7.2.5 VOLTAGEBOOST UminC016

The Umin parameter must be adapted to the asynchronous motor used, otherwise

the motor may be damaged due to overheat. We can say from experience that self-

ventilated standard asynchronous motors of insulation class Bcan be operated with

their rated current in the lower frequency range (fd=0...25Hz) for a short time.

Adapt the Uminparameter as foliows:

- Connect r.m.s current meter to one motor phase

-Run the motor without load at fd = 5Hz

- Set Umin:

a) For short-time operation in the lower frequency range, set Uminsuch that the

motor current does not exceed its rated value (lMotor:s INMotor)

b) For continuous operation in the lower frequency range, set Uminsuch that the

motor current does not exceed 80% of its rated value (lMotor :s 0,8 . IN Motor) or

use a force-ventilated motor or a motor with higher insulation class and set Umin

as under a).

An internal compensation of the DC bus voltage compensates for changes in the

mains voltage so that these must not be considered when setting the VIf rated

frequency.

7.2.6 RESPONSETHRESHOLD QMIN C017

The amin signal shows if the field frequency (in open-Ioop operation) or the actual

value of the PI-controller (in closed-Ioop operation) is smaller than or equal to the

frequency set under CO17. The amin signal can be assigned to a digital output

terminal using codes C116, C117.

Lenze

Page 37

Technical description 8100_ A

7.2.7 CHOPPING FREQUENCY FCH C018

The desired chopping frequency of the output voltage can be set under C018.

Note: The chopping frequencies limitthe effective maximum field frequency

fdmax.

35

C018 fCH

-0- 1.0 120

-1-

-2-

-3- 3.3 480

I

-4-

-5- 4.0 480

I

kHz Hz

1.5 180

2.0 240

3.6 480

eff. fdmax

.

7.2.8 RESPONSETHRESHOLD AUTO DC INJECTION BRAKING C019

DC injection braking is activated when the actual frequency is less than the

frequency set under C019. When setting 0.0 Hz, this function is not active.

The amount of the stand still voltage can be set under C036, the time of the DC

injectionbrakingcan be set under C107.

7.2.9 PRESELECTION OF ENCODER C025

Errors which may occur in the encoder or in the transmission path, can be

compensated by adjusting the set- and actual value inputs.

The analog inputs can be adjusted, if offset and gain are required.

For the pulse train/incremental encoder input X5, a gain setting is provided. For

open-Ioop operation with digital frequency input (C005

loop operation with incremental encoder feedback (C005 = -13-) the input X5 is

adjusted under C025

and incremental encoder feedback (C005

= -10-. In closed-Ioop operation with digital frequency input

= -16-) the adjustment for single-track

digital frequency input (via X5, track 0, Oll is done by C025 = -11- and the

adjustment of two-pulse incremental encoder feedback (via X5, tracks A, AI, B, BI) is

done by C025 = -10-

= -2-) and for the closed-

First select the encoder under C025, then make the adjustment under C026, C027

for the selected input.

lenze

Page 38

36

Technical description 8100_A

7.2.10 ENCODERCONSTANT C026

A constant deviation in the encoder signal (offset) can be adjusted under C026. A

gain error can be corrected under C027.

For configurations with set-value 2 (see 7.1.61. the input via terminals 1 and 2 must

always be checked.

Select the incremental encoder type for the adjustment of X5 using C026. Different

encoder constants can be adapted using C027.

For digital frequency input, make the adjustment as described under 4.4.

7.2.11 AUTOMATIC ADJUSTMENT FOR THE ACTUAL VALUE OF THE

Code C029 is used to make an automatic adjustment of the feebdback.

Preparing the adjustment:

Before adjusting the speed controller, observe the setting of the encoder constants.

ENCODERADJUSTMENT C027

PI-CONTROLLER

Analog actual value: If you use an analog tachometer signal, adjust the maximum

tachometer voltage to be expected. You can determine this tachometer voltage

fram the rated tachometer voltage and the maximum motor speed. Set the

corresponding switch combination of S1 on the contral module, as shown in

chapter 4.3.

Digital actual value: If you use an incremental encoder as actual speed detector,

select the incremental encoder input under C025 = -10- and then enter the

encoder constant under C026.

Automatic gain adjustment of actual value

Conditions:

Operate the drive in idle running.

The set-value must be at least 10% of the maximum field frequency.

Set the influence of the PI-controller under C074 to zero.

Activation of the automatic adjustment:

Select a configuration with closed-Ioop control under C005.

Enable the controller and wait for the acceleration time to elapse.

Activate the automatic adjustment with C029

adjustment by "ok". After this procedure, the gain of the actual value

feedback is set automatically.

Set the influence of the PI-controller under code C074 such that the

maximum possible slip, mostly stall slip, is compensated (e.g. 10%).

-feedback

= -1-. The inverter confirms the

lenze

Page 39

Technical description 8100_ A

Manual adjustment

If for technical reasons, automatie adjustment in no-load operation is not possible or

sufficiently precise, you can enter the adjustment factor by hand following

measurement of the variable to be controlled:

Select a configuration with closed-Ioop control under C005.

The set-value must be least 10% of the maximum field frequency.

Enable the controller and wait for the acceleration time to elapse.

Increase the influence of the PI-controller with C074 to the maximum possible

slip (stall slip, approx. 10%)

Gain (C070) and response time (C071) should be in factory-setting.

If the drive oscillates, reduce the gain (C070) until the drive runs smoothly.

Measure the motor shaft speed using a speed meter.

Calculate the value for the encoder adjustment and adjust und er C027:

37

Actual speed

Encoder adjustment (C027)

desired speed

Dynamic adjustment (C070. C071)

This adjustment is necessary following both automatie and manual adjustment. By

means of the dynamic adjustment the PI-controller is adapted to different inertias:

Increase the gain of the PI-controller with C070 until the drive starts to

oscillate. Then, reduce this value by approx. 10%

If no oscillation occurs with a gain of about 10, halve the setting time in code

C071 and repeat the gain adjustment procedure.

If the system oscillates throughout the entire range, increase the setting time

(C071) until the drive runs smoothly.

Save the settings with C003.

Additional functions

For special applications, some auxiliary functions for the PI controller can be used.

Actual speed value of the PI controller: see C051

Monitor signals of the PIcontroller: see C111

* old value C027

Lenze

Page 40

38

Technical description 8100_ A

Output actual value

Frequency pilot contral: see C238

Frequency setting range: see C239

Input integral component = 0

Using this function the integral component of the PI controller can be reset to zero.

You can activate this auxiliary function by one of the freely assignable inputs with

C113.

This function is useful, for example in applications where a drive is to be brought to

standstill with zero set-value and is to remain stationary and ready for operation

without controller inhibit. Blanking out the I-component prevents the motor from

drifting. If the drive is mechanically braked at set-value zero, blanking out the 1-

component prevents the drive from jerking when the brakes are released.

Output actual value

The digital output function actual value = 0 indicates that the drive is stationary.

The range in which the function is active is provided with a fixed window of 0.5%

referenced to fdmax.

This characteristic can be used for example in cases where the I-component has to

be blanked out.

The signal actual value

7.2.12 MASTERCURRENTC034

If the analog set-value must be entered as master current via terminal 8, adjust the

setting range under C034 as folIows:

= set-value: see C240

= 0

= 0 can be assigned to a digital output terminal using C117.

0...20mA: C034

4...20mA: C034

= -0-

= -1-

T0 change from master voltage to master current, using switch 51/4 on the control

module. For the position of the switch see 4.3.

Master voltage/potentiometer: 51/4

Master current: 51/4

Factory setting: 51/4 = OFF

= OFF

= ON

7.2.13 BRAKEVOLTAGEC036

The brake voltage is used to set the DCcomponent flowing in the motor. For

activation of the DC brake see C048 (see 7.3.7).

lenze

Page 41

Technical description 8100_ A

39

7.2.14

The JOG frequency set-va lues are set using the codes C038 and C039. First, enter

PRESELECTION OF JOG REFERENCEC038

REFERENCE39

the JOG set-value under C038. This JOG set-value can be assigned a frequency

under C039. If e.g. -2- has been selected under C038, you can enter the frequency

for JOG 2 under C039.

JOG set-values which are larger than fdmax are limited internally to fdmax'

To activate the JOG set-values see 7.3.5. For activated JOG set-value, set-value 2 is

switched

7.3 CONTROL PARAMETERS

off.

Depending on the operating mode C001 (see 7.1.2). the control parameters are

changed via the control terminals, the operating unit 810288 or via the LECOM

interface.Forterminalcontrol, the followingcodes serve as displays. If keypad or

LECOMcontrol is selected, the codes serve as operating parameters.

7.3.1 CONTROLLER ENABLE C040

Controller enable

Independently of the operating mode C001, the controller must be enabled by

applyinga voltage between 13 and 30 V across terminal28. When using the

operating unit 810288, the controller can always be inhibited using the STP key and

be enabled by pressing SH + STP.

Inthe operating mode

and enabled additionally using

LECOM operation (C001 = -3-). the controller can be inhibited

C040 = -1- (via the LECOM interface)

The controller can only be enabled via those input channels, which were used to

inhibit the controller:

- Terminal 28

-CodeC040 (inthe operating modes keypad and LECOMoperation)

- Stop key

-Trip fault indication

If, for example, the controller has been inhibited

it can only be enabled via C040 = -1-.

Controller enable after mains connection

The controller is enabled after mains connection,

across terminal 28.

enabled. in addition

Only in the operating mode C001 = -3-, the controller must be

via LECOM interface (C040 = -1-).

in LECOM operation via C040 = -0-,

if a voltage of 13 ... 30 V is applied

lenze

Page 42

40

Controller enable after chan ging the operating mode C001

The operating mode can only be changed if the controller is inhibited first. The

controller can only be enabled by the input channel, which has been used to inhibit

the controller.

Controller enable when chan ging the parameter sets C002

Before changing the parameter sets, the controller must be inhibited. Loading another

parameter set causes the controller to be initialized again. It then acts as after mains

connection.

Caution! When changing the parameter sets or loading factory setting, the drive

may accelerate if it has not been inhibited via terminal 28 first.

Technical description 8100_ A

7.3.2 INVERTSET-VALUEC041

Codes C041 and C042 are provided for the functions:

Depending on the operating mode C001, the codes have a direct effect on the

functions or display the state of the control terminals 21 and 22. Also, in case of

terminal control, the function of the terminals 21 and 22 can be changed using C176

(see 7.6.191.

Quick stop function

By activating quick stop, the drive is decelerated along the pre-set deceleration ramp

with C105. When reaching fd

Uminset with C016

In addition. a DC brake can be activated via C019 using a holding time to be set with

C107. After the holding time, the inverter changes its output voltage to OV.

Keypad

For keypad or LECOM operation (C001 = -1-, -3-1. the set-value is inverted with

C041 and quick stop is activated with C042. The terminals 21 and 22 are always

active in these operating modes.

QUICKSTOPC042

Invert set-value and

Activate quick stop

=0 Hz, the output voltage corresponds to the value

(see 7.2.51.

or LECOM operation:

lenze

Page 43

Technical description 8100_Ä

Terminal control:

With terminal contral (C001 = -0-, -2-) the momentary state of the terminals 21 and

22 according to the terminal configuration C176 is detected and displayed in C041

and C042.

Terminals functions with C176=-0-

term. 21

term. 22

High

Low

Low Low . x -

Disp. CD41

Low

High

Disp. C042

- 0 -

- ,- . 0 - Set-value inverted

Meanin9

. D - Set-value not inverted

.1.

Quick stop active

41

If a voltage between 13 and 30V (High signal) is applied across terminals 21 and 22

both, the direction of rotation is provided by the terminal signal, which was active

first. If a HIGHsignal is applied to both terminals before mains connection, the

controller activates "quick stop".

Terminal function with C176

term. 21 term. 22

High

Low Low

Low . 0 - - x - Set-vaLue not inverted

x

High

x Low - x .

=-,-

. 0 -

Meaning

Quick stop active

Quick stop not active

Disp. C041 Disp. C042

- 1 - - x . Set-value inverted

- x - - 1.

Warningl With C176 = -1- in case of wire breakage at terminal 21, the drive may

change its direction of rotation.

7.3.3 TRIP RESETWITH LECOMC043

Code C043 is used to reset a fault. For this, enter C043 = -0-.

Code C043 can only be reached via the LECOMinterface.

7.3.4 PROCESS CONTROLC044

Inthe operating modes keypad or LECOMoperation, the process is switched on or

off using C044. In case of terminal control, the process control can be assigned to

one of the digital inputs E1...E5. Here C044 is used to display whether the process

contral is active.

iBnze

Page 44

42

The process control sequence determines the main set-value and the Ti time of the

corresponding ramp function generator in a sequence and time which can be

programmed. The process control comprises a maximum of eight steps. Each step

can be assigned the following parameters (see 7.6.20):

- one frequency set-value (using C211)

- one pair of acceleration and deceleration times (using C212)

- the duration (using C213)

Technical description 8100_A

-the following step (using C214)

If the process control is activated, each step which has been reached is displayed

under C160. Each step can also be output as a signal via one of the freely

programmable digital output terminals using C117.

The process control is interrupted and reset on step 1 by one of the following

actions:

-controller inhibit

- quick stop

- trip fault indication

After having cancelled the interruption, the controller starts with step 1, unless the

process control is inhibited first. Over- or undervoltage indications do not influence

the process contro!.

Functions, which may influence the main reference, such as

-invert set-value

- ramp function generator input

- ramp function generator stop

- DC injection braking

are available during the process contro!. For example, the time of the momentary

step continues while the DC brake is activated. During the process control, set-value

(C049) is set to zero. The deceleration time set under C221 remains active.

7.3.5 ENABLEJOG SET-VALUEC045

Terminal control:

According to the assignment of the JOG set-values to the digital input terminals, the

JOG enable results from the binary coding of the input terminals (see 7.6.6).

This function can be assigned to a maximum of four digital inputs. Therefore, 1, 3, 7

or 15 binary coded JOG-set-values are possible when assigned.

= zero

lenze

Page 45

T echnical description 8100_ A

If, for example, the terminals E1, E3, E4 and E5 are assigned for the JOG enable, E1

corresponds to the first terminal, E3 to the second terminal, E4 to the third terminal

and E5 to the forth terminal in the following table:

43

digital input terminals

1st term. 2nd term.

Set-value 1

JOG 1

JOG 2 active

In case of operation via keypad or LECOM interface, activate the desired JOG set-

value using C045.

active

...

JOG 15 active 1

0 0

1 0 0 0

0

1 0

1 1

EI ... ES

3rd term. 4th term.

0 0

0

1

7.3.6 SET-VALUE1 C046

Code C046 shows the momentary set-value 1. In case of operation via keypad or

LECOM interface, set the set-value using C046.

The input or display can be relative in %fdmax or absolute in Hz. You can change

between these two modes using C 172.

7.3.7 DC BRAKINGC048

The DC injection braking is activated as folio ws:

incase of terminal control via the digitalinput terminals (toassign the function to

one of the digitalinput terminals

braking active or not active.

of operation via keypad 8102BB or LECOMinterface (see 7.1.2) using

incase

see 7.6.6). C048 shows here: DC injection

C048 = -1-

automatically,ifthe fieldfrequency fallsbelow the Auto DC treshold

(see 7.2.8) (no display in C048).

The amount of the holding voltage

is set with C036 (see 7.2.13) and the time of

activation with C107 (see 7.6.3).

Caution! Long-term operation of the DC brake may result in overheating the

motor.

Lenze

Page 46

44

7.4 DISPLAY PARAMETERS

Display parameters can only be read.

7.4.1 DISPLAYSET-VALUE2 C049

C049 shows the momentary set-value 2 (in % fdmax). Independently of the

operating mode. set-value 2 is always provided via the control terminals 1, 2, and

not via the LECOMinterface or the keypad 810288.

With suitable configuration (see 7.1.6) set-value 2 is added internally to set-value 1

(C046). The total is limited internally to :I::fdmax'

7.4.2 OUTPUT FREQUENCYC050

C050 shows the actual running frequency in Hz.

7.4.3 ACTUALVALUEOF PI-CONTROLLER

Code C051 shows the actual value of the PI-controller. Depending on the display of

set-value 1 (C046). you can select with C172 a scaled display (in % fdmax)or an

absolute display (in Hz).

In open-Ioop control, "0" is shown with C051.

7.4.4 MOTORVOLTAGEC052

C052 shows the actual output voltage and therefore the motor voltage in Volts.

Technical description 8100_A

Caution! Even when the display shows "OV". the motor terminals may carry

voltage. 8efore working on the motor side. always disconnect the

controller from mains and wait at least 30 seconds.

7.4.5 DC BUSVOLTAGEC053

CO53 shows the actual DC bus voltage in Volts.

7.4.6 TRIP FAULT INDICATIONC0067

Code C067 displays a momentary fault (see 8). The fault can also be reset under this

code.

Reset faults are saved in the history butter and can be read using the LECOM

interface with codes C161 to C168. When using the operating unit 810288. they

can be displayed by pressing the . key. A maximum of eight fault indications can

be read; the last fault is displayed first. then the one before and so on.

Lenze

Page 47

Technicaldescription8100_A

7.5 GENERALPARAMETERS

45

7.5.1 OPERATINGSTATUSC068

CONTROLLERSTATUSC069

The codes C068 and C069 contain information about the controller and operating

status. They can only be read via the LECOM interface.

C068 Display of the operating status

Bit no.

Signal

Bit no. 7 4

15

TRIP

Signal

*)

Bit no. 14: nset = nactual

C069 Display of the controller status

Bit no.

Signal

Bit 6 is not used.

Further information can be obtained from the technical description "LECOM AlB".

7 6 5 4 3

RFR

14 13

*)

IMAX

Communication fault

xxxx RESET

12 11

QSP

IMP

3

10

R/L

Operating fault

2 1

AUTO REMOT PCHG CALARM

9 8

QMIN

RFR

o

BALARM

7.5.2 GAINOFPICONTROLLERC070

RESPONSETIMEOFPI CONTROLLERC071

INFLUENCEOFPI CONTROLLERC074

0

With codes C070. C071 and C074 the PI-controller is adjusted. The procedure for

this is described in 7.2.11.

7.5.3 RATEDMOTORPOWERC081

The power of the connected motor can be set with C081. This setting is required. to

adapt the smooth running of the motor with low field frequencies.

7.5.4 CONTROLLERTYPEC093

With C093. the controller type 810x is displayed. Code C093 can only be read via

the LECOM interface.

ienze

Page 48

46 Technical description 8100_ A

7.5.5 USER PASSWORD C094

If a password is entered with C094, the code set under COOO(see 7.1.11 can only

be changed if the password has been entered.

If you do not need a password, enter C094 = -0-.

7.5.6 LANGUAGEC09S

With code C098 you can enter the language of the display texts on the option al

operating unit 810288. German, English, and French language are possible.

7.5.7 SOFTWAREVERSIONC099

C099 shows the software version.

7.6 APPLlCATION PARAMETERS

7.6.1 PRESELECTION ADDITIONAL RAMP TIME C100

Apart from the acceleration and deceleration times set under C012 and C013, 15

ADDITIONAL ACCELERATION TIME C101

ADDITIONAL DECELERATION TIME C103

additionalvalues can be programmedfor the main set-value (seesignal flow chartl.

First, preselect the desired pair of ramp times using C100, then enter the value for

the additional acceleration time using C101 or the additional deceleration time using

C103.

If, e.g. -2- has been selected in C102, enter the value for the additional deceleration

time Tif2 in C103.

The additional acceleration and deceleration times refer to a change of the field

frequency from 0 to fdmax and can be calculated as described under 7.2.2.

To activate the additional acceleration and deceleration times see

7.6.2 DECELERATIONTIME FORQUICKSTOPC105

If the quick stop function (see 7.3.21 is activated, the drive is decelerated with a

special deceleration time. This deceleration time must be set using C105.

7.6.12.

lenze

Page 49

Technical description 8100_A

7.6.3 HOLDING TIME FOR DC INJECTION BRAKING C107

The time of the OC injection braking can be set using C107. When setting 999s

under C107, the holding time is not limited. After the holding time, the inverter

switches its output voltage to OV.

To activate the OC brake see 7.3.7.

47

Caution! Long-term operation of the OC brake may result in overheating the

motor.

7.6.4 AMPLlFICATION

OFFSET OF MONITOR OUTPUT C109

OF MONITOR OUTPUT C108

To adapt analog output signals, e.g. to extern al displays, C108 and C109 are used to

set the amplificationand otfset of the monitor output terminal 62.

These settings remain active when the function of the monitor output is changed.

7.6.5 MONITOR SIGNAL C111

The monitor output terminal 62 can be assigned to the signals which are selected

under C111 and can be operated as voltage output (:t 10V) or as current output

(:t 20mA). The function is changed by 52 on the control mode (see 4.3).

The following scaling of the output signals is factory-set:

for frequencies: +fdmax corresponds to VMonitor

-fdmax corresponds to VMonitor

for voltages:

1000 V corresponds to VMonitor

o V corresponds to VMonitor

To adapt the display element, otfset and gain can be adjusted. (see 7.6.4).

+ 10V/+20mA

-10V/-20mA

+ 10V/+20mA

+ OV/+OmA

Lenze

Page 50

48 Technical description 8100_A

7.6.6 PRESELECTION OF FREELY PROGRAMMABLE DIGITAL INPUT C112

The digital inputs E1 to E5 can be assigned to the various functions to be selected in

C113. For this, first select the input to be assigned using code C112. Iffor example

the digital input E2 is preselected with C112 = -2-, the function "Trip-Set" can be

assigned to the terminal using C113

Allfunctions can only be assigned once. To activate the JOG references and the

additional Ti times, up to four terminals can be used. In addition, the polarity and the

priority can be changed using C114 and C115

7.6.7 POLARITYOF DIGITALINPUT

Using

inputs E1 to E5.

C115 is used to determine whether the preselected input terminal with its function is

always active or, is switched off depending on the operating mode (see 7.1.1 I. If a

digital input terminal

the terminal terminal signal overwrites an information entered via the keypad or the

LECOMinterface.

Caution: The settings of polarity and priority refer to the selected signal. They are

FUNCTION OF FREELY PROGRAMMABLE DIGITAL INPUT C113

= -4-.

(see 7.6.71.

PRIORITYOF DIGITALINPUT

C114, you can choose whether HIGHor LOWsignalsare active for the digital

is assigned a priority (terminal always activel with C115 = -1-,

lost when the function of the terminalis changed, i.e. with every new

assignment the factory settings are activated.

The factory setting of the polarity for "Trip-Set" (C113 = -4-1is not safe against

wire breakage.

lenze

Page 51

Technical description 8100_A

49

7.6.8 PRESELECTION OF FREELY PROGRAMMABLE DIGITAL OUTPUT C116

The digital outputs Al to A4 and the relay output can be assigned with the functions

which are selected under Cl17. For this, first select the output to be assigned using

Cl16. If for example the digital output A2 is selected with Cl16

assign the indication "healthy" to the terminal using Cl17 = -4-.

Everyfunction can only be assigned once. The relay output terminals Kll, K14 can

be assigned like the digital output terminals Al to A4.

Inaddition, the assigned function can be changed in its polariy using Cl18.

With its factory setting, the digital output terminal A4 is assigned to the signal 6*fd.

Ifyou want to use A4 as a digital output, switch 52 on the control module must be

set to "A". In this case, the default setting for A4 is "Actual value = 0".

FUNCTION OF FREELY PROGRAMMABLE DIGITAL OUTPUT C117

= -2-, you can

Lenze

Page 52

50 Technical description 8100_A

7.6.9 POLARITYOF DIGITALOUTPUTC118

The functions assigned to the digital outputs A1 to A4 can change between HIGH

active and LOW active.

Caution: The setting of the polarity refers to the selected signal. It is lost when

the function of the terminal is changed, i.e. with every new assignment,

the factory-setting is activated.

7.6.10

The surveillance functions "external fault" and "PTC motor protection fault" can be

activated or deactivated using C120. In addition, you may select between a warning