Page 1

HEARTH PRODUCTS

US

Portland

KITS AND ACCESSORIES

P/N 506022-01

REV. A 10/2008

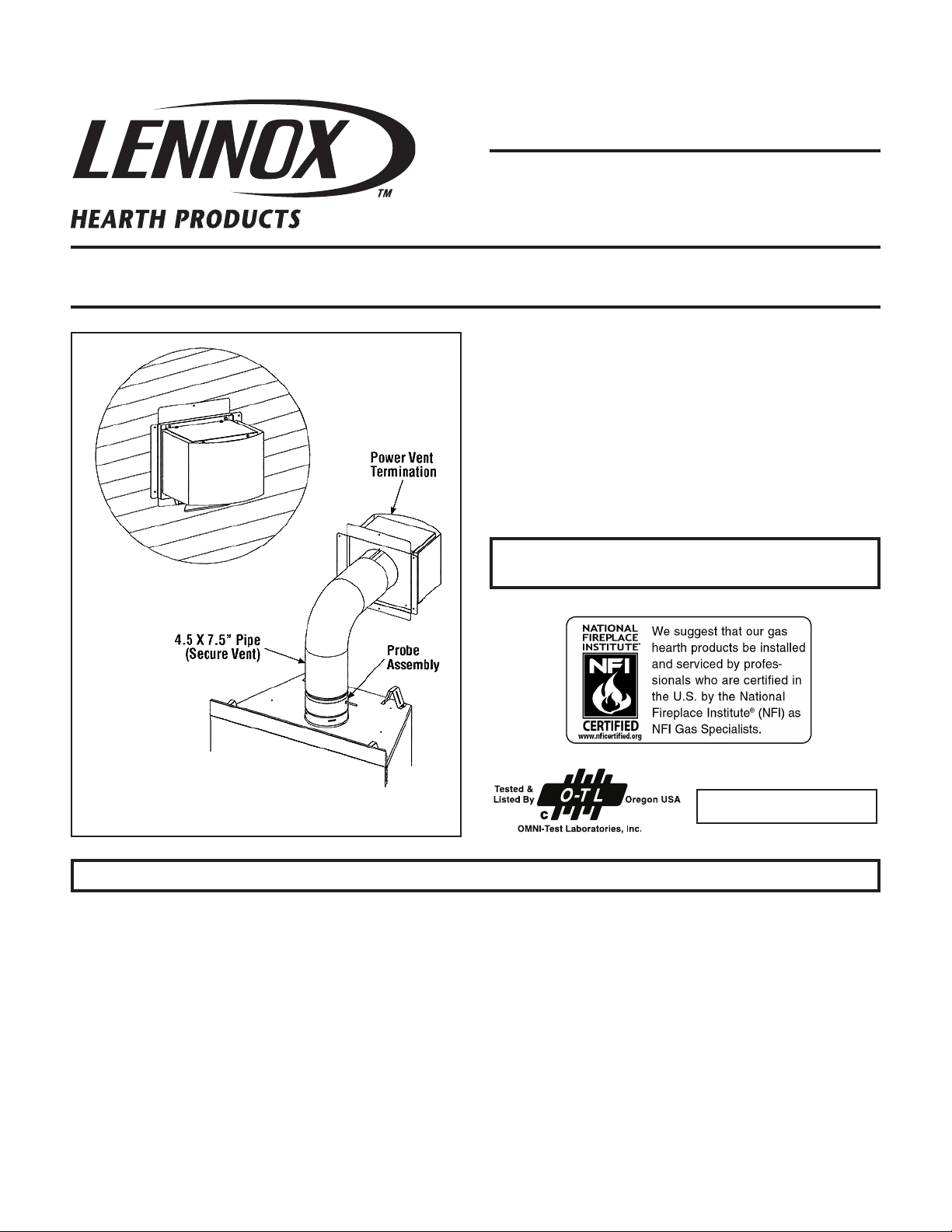

POWER VENT KIT

LPVK-110

INSTALLATION INSTRUCTIONS FOR THE LPVK-110 POWER VENT KIT (CATALOG NO. H7387)

FOR USE WITH DIRECT VENT GAS FIREPLACES

GENERAL INFORMATION

These instructions are supplementary to the Installation and Operating

Instructions supplied with the fireplace and should be kept together.

Refer to the Installation and Operating Instructions for proper gas supply,

safety requirements and operations. Read these instructions in their

entirety before beginning the installation.

ALL WARNINGS AND PRECAUTIONS IN THE INSTALLATION AND

OPERATION MANUAL PROVIDED WITH THE APPLIANCE APPLY TO

THESE INSTRUCTIONS.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

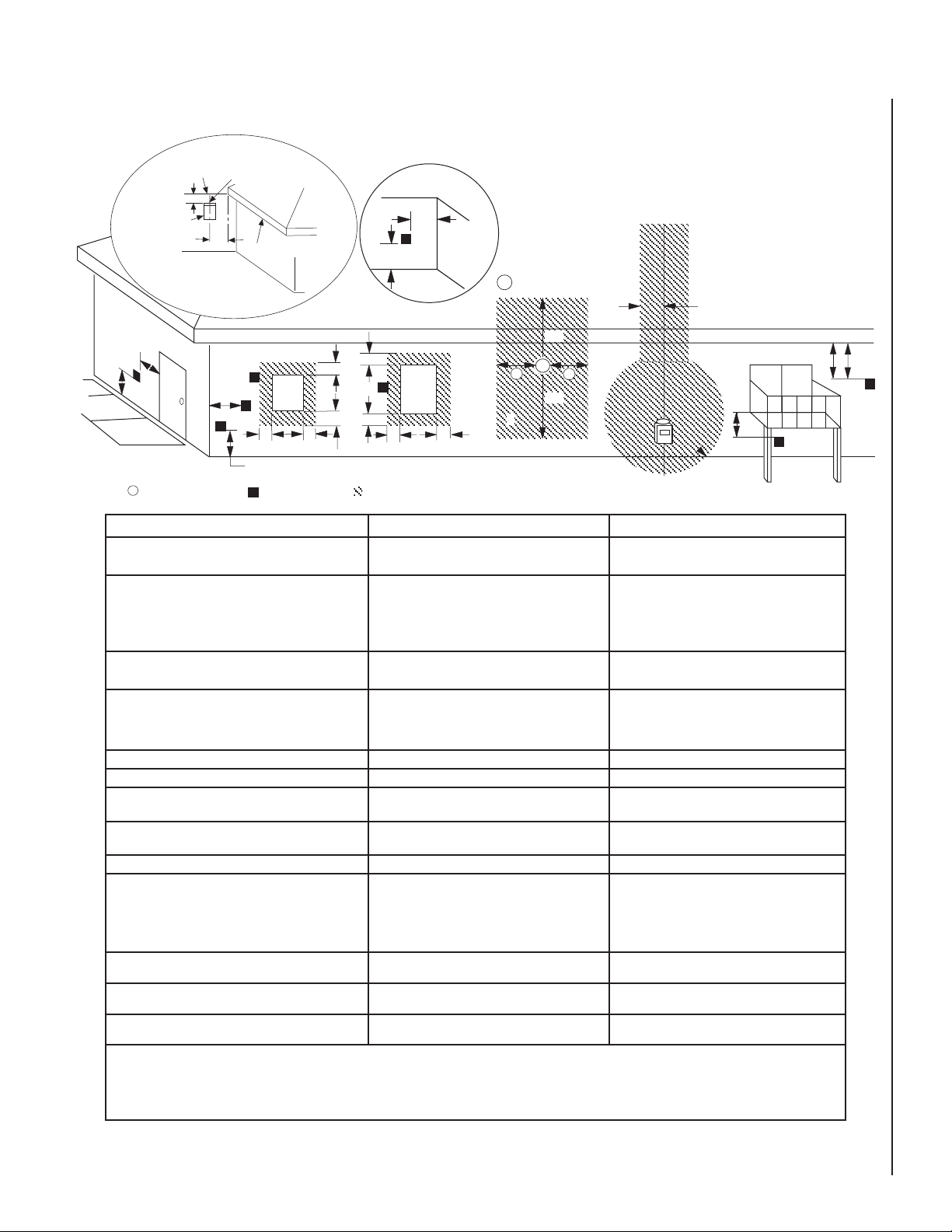

Figure 1 - Power Vent Assembly

OTL Report No. 116-F-39C-5

For Use With Lennox ELDV Fireplaces (Electronic Models) Catalog Numbers: H3950 (35”), H3953” (40”) and H3956 (45”)

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

1

Page 2

INSTALLATION INSTRUCTIONS

Locate the fireplace as per the instructions supplied under the fireplace. Make the following modifications to add the components used with the

Power Vent Kits. This kit can only be used in conjunction with “Direct Vent” series electronic versions of Lennox Fireplaces. This installation must

conform with local codes or, in the absence of local codes, with the Natural Fuel Gas Code, ANSI Z223.1/NFPA 54, or the Natural Gas and Propane

Installation Code, CSA B149.1.

CAUTION: The LPVK-110 Power Vent Kit cannot be used with Millivolt appliances. Use the LPVK-110 only with the Electronically controlled fireplaces listed for its use as shown in this document.

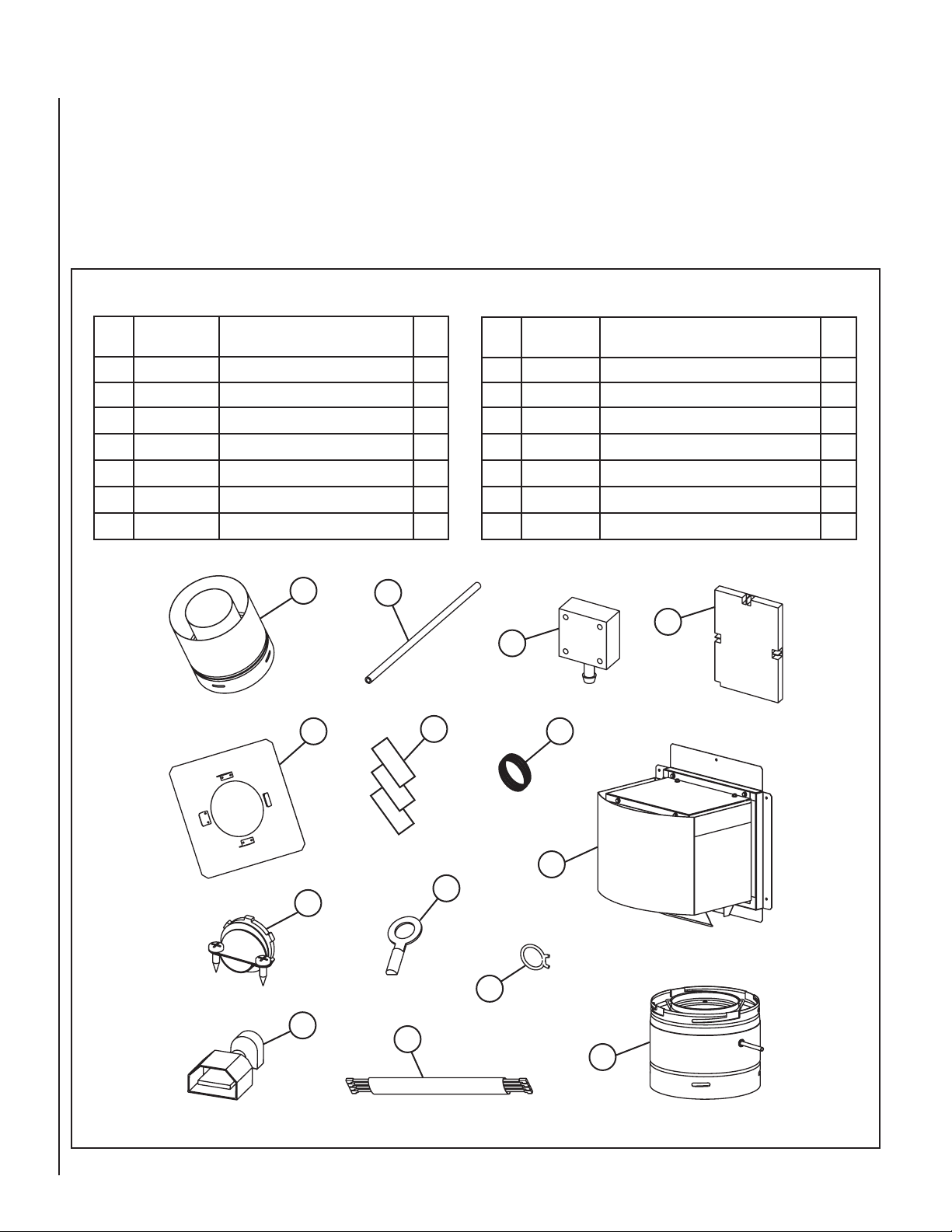

POWER VENT KIT CONTENTS

Item

No.

1 601970-01

Part

Number

Description Qty.

Vacuum Hose 1

2 102019-01 Wiring Harness 1

3 102005-01 Pressure Switch 1

4 102009-01 Control Module 1

5 102010-01 Strain Relief - 3/8” 2

6 102021-01 Ring Terminal - #10 2

7 H7384 Insulated 1/4” Male Terminal 4

12

1

13

14

Item

No.

8 102022-01

Part

Number

Description Qty.

Hose Clamp - 11/32” 2

9 P-8-7102 Snap Bushing 2

10 601957-01 Power Vent Termination 1

11 601978-01 Probe Assembly 1

12 74L61 SV Termination Adapter (SV4.5RCH) 1

13 H2246 Firestop Assembly (Horizontal) 1

14 67L6501 Velcro Strips (2” Lengths) 3

4

3

9

Power Vent Kit Components

2

10

6

5

8

7

2

11

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 3

PREPARE THE FIREPLACE FOR POWER-VENTING

Exterior

Wall

3 Feet

Below Bottom

Of Fireplace

Maximum

SV4.5E90

Elbow

Horizontal / Inclined Run

Power Vent

Termination

Support

Brackets

Building

Support

Framing

Exterior

Wall

Power Vent

Termination

Power Vent

Termination

Fireplace

Firestop/Spacer

Ceiling

Maximum

Vertical Rise

66 Feet

Probe Adapter

(Required)

Probe Adapter

(Required)

Minimum

Vent Run 8’

Horizontal

Probe Adapter

(Required)

SV4.5E90

Elbow

SV4.5L6/12/24/36/48

Vent Sections

SV4.5L6/12/24/36/48

Vent Sections

Firestop/Spacer

Maximum Horizontal

Venting 110’ Max.

Up To 6 Elbows

Fireplace

Floor

5/8” Restrictor

1” Restrictor

Rear Log Bracket

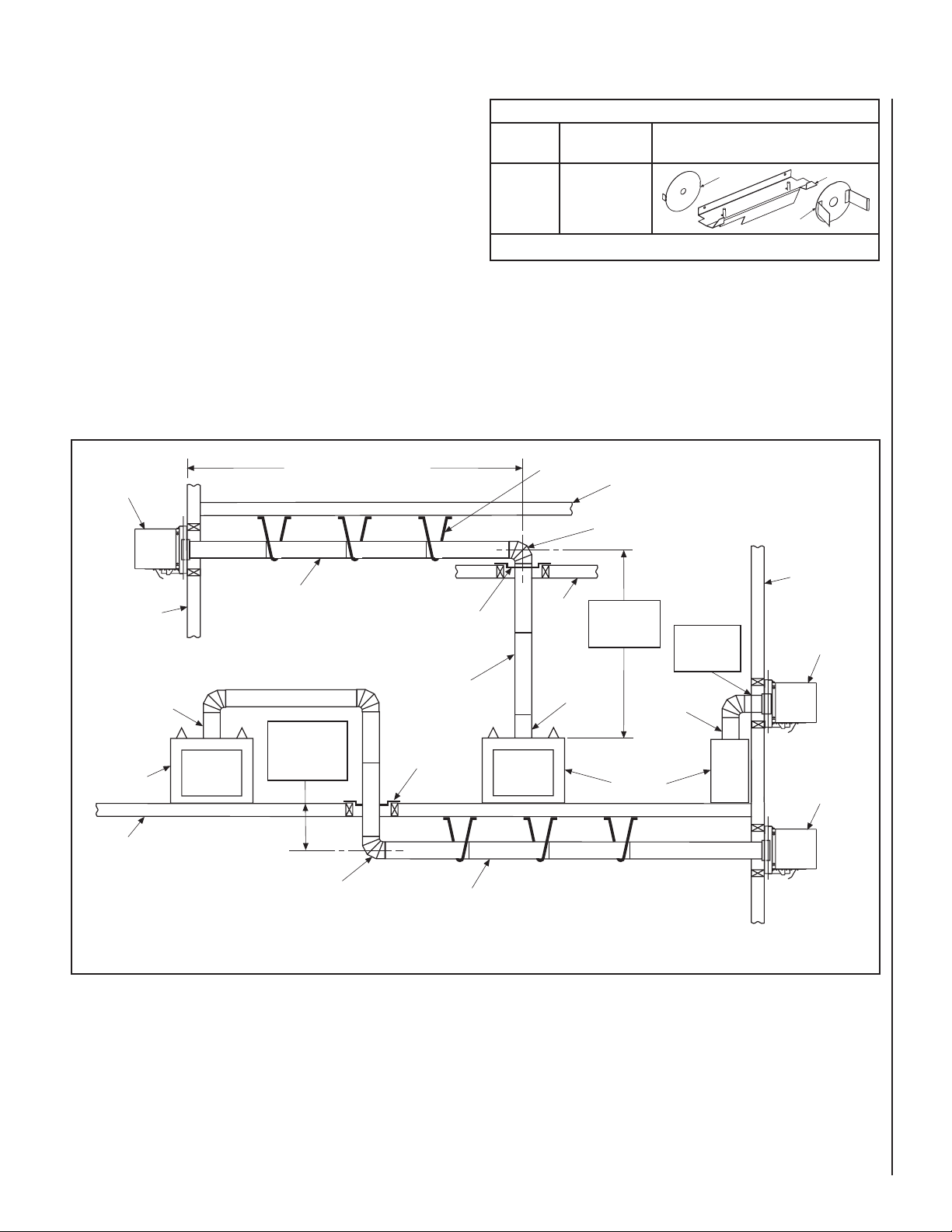

Modify fireplace for acceptance of the power vent kit. Refer to Table 1

and install the appropriate adapter kit. Follow the instructions provided

with the kit to successfully prepare the fireplace for use with power

venting. If no kit is listed, the fireplace will not require modification.

Refer to the fireplace installation instructions for details and information

detailing its compatibility with power venting. If its is not compatible, do

not power-vent the fireplace.

VENTING THE FIREPLACE

Venting Configurations

Maximum vent is 110 feet, plus six 90-degree elbows or twelve 45degree elbows. Minimum horizontal vent length is 8 feet, maximum

vertical rise above the fireplace is 66 feet. The vent can be installed

with any combination or rise and run between appliance and termination, including up to 3 feet below the unit (see Figure 2 ). Ensure

vent pipe is properly supported.

Fireplace

Model

ELDV

Table 1

FIREPLACE ADAPTER KITS (For LPVK-110)

Kit Catalog

Number

Kit Contents

H7407

(ELDV-PVAK)

Figure 2 Typical Power Vent Routing

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

3

Page 4

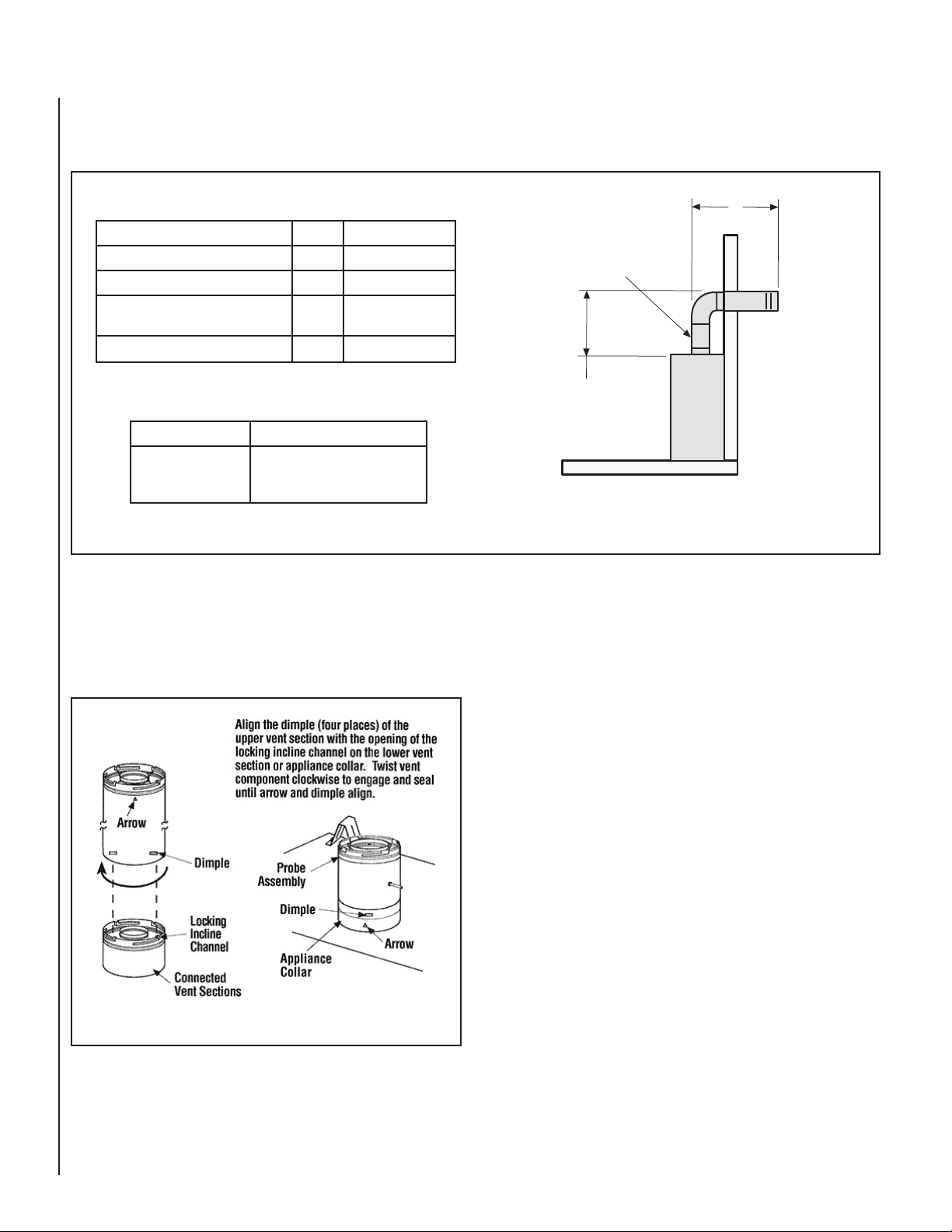

VENT CLEARANCES

A

(See Chart)

B

Probe Assembly

(Required)

Refer to the charts and illustration in Figure 3 for vent clearances for the LPVK-110 Power Vent Kit.

POWER VENT VENTING CHART

Maximmum Number Of Elbows - 6

Maximum Feet Of Run

Minimum Horizontal Run B 8 feet

Minimum Vertical Run A

Maximum Vertical Rise A

MINIMUM CLEARANCES TO COMBUSTIBLES

Vertical Vent Pipe 1.0 in. (25.4 mm)

Horizontal Vent

Pipe

Figure 3

A + B 110 feet

Probe Assembly

And Elbows

66 feet

Top - 3.0 in. (76.2 mm)

Sides - 1.0 in. (25.4 mm)

Bottom - 1.0 in. (25.4 mm)

All other clearances are as per the appliance Installation Instructions

INSTALL PROBE ASSEMBLY ON THE FIREPLACE

• Attach the probe assembly to appliance. The probe assembly (# 11

from Parts List) is of the same design as the unitized concentric pipe

components of the SV4.5 Secure-Vent System, featuring positive twist

lock connections (see Figure 4 ).

Figure 4

CAUTION: The probe assembly must be installed directly to the appliance collar. Install the probe assembly first before connecting any

other vent components to the fireplace.

All of the appliances that can be installed with this power vent kit, are

fitted with collars having locking inclined channels. The dimpled end of

the probe assembly fits over the appliance collar to create the positive

twist lock connection.

To attach the probe assembly to the appliance collar, align the dimpled

end over the collar, adjusting the radial alignment until the four locking

dimples are aligned with the inlet of the four inclined channels on the

collar (refer to Figure 4 ). Push the probe assembly against the collar

until it fully engages, then twist the probe assembly clockwise, running

the dimples down and along the incline channels until they seat at the

end of the channels. The unitized design of the probe assembly components will engage and seal both the inner and outer pipe without the

need for sealant or screws.

• Attach vent components to the probe assembly. Other vent sections

may be added to the previously installed probe assembly in accordance

with the requirements of the fireplace installation instructions and the

vent charts provided in the instructions.

4

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 5

EXTERIOR HORIZONTAL VENT TERMINATION CLEARANCE REQUIREMENTS

F

C

Fixed

Closed

Window

Operable

Window

B

B

A

B

H

M

I

= Vent Terminal = Area where Terminal is not Permitted

= Air Supply Inlet

X

D

3 ft.

3 ft.

A

A

A

= 9” in U.S.

= 12” in Canada

V

L

B

J

X

E

V

A

G

Inside

Corner Detail

B

C

C

C

*18”

Ventilated Soffit

Horizontal

Termination

Detail D

Exterior Wall

Center Line

of Termination

18”

Inside Corner

* See Item D in the Text Below.

V

V

V

V

V

V

V

*noitallatsnInaidanaC **noitallatsnISU

,hcrop,adnarev,edargevobaecnaraelC=A

.ynoclabro,kced .ynoclabro,kced

.ynoclabro,kced

.ynoclabro,kced .ynoclabro,kced

*)mc03(sehcni21 **)mc03(sehcni21

ebyamtahtroodrowodniwotecnaraelC=B

.denepo .denepo

.denepo

.denepo .denepo

secnailpparof)mc51(ni6

)mc03(ni21,)Wk3(hutB000,01< )mc03(ni21,)Wk3(hutB000,01<

)mc03(ni21,)Wk3(hutB000,01<

)mc03(ni21,)Wk3(hutB000,01< )mc03(ni21,)Wk3(hutB000,01<

dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof

dna)Wk3(hutB000,01>secnailpparof

dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof

)mc19(sehcni63,)Wk03(hutB000,001< )mc19(sehcni63,)Wk03(hutB000,001<

)mc19(sehcni63,)Wk03(hutB000,001<

)mc19(sehcni63,)Wk03(hutB000,001< )mc19(sehcni63,)Wk03(hutB000,001<

*)Wk03(hutB000,001>secnailpparof *)Wk03(hutB000,001>secnailpparof

*)Wk03(hutB000,001>secnailpparof

*)Wk03(hutB000,001>secnailpparof *)Wk03(hutB000,001>secnailpparof

secnailpparof)mc51(ni6

)mc32(ni9,)Wk3(hutB000,01< )mc32(ni9,)Wk3(hutB000,01<

)mc32(ni9,)Wk3(hutB000,01<

)mc32(ni9,)Wk3(hutB000,01< )mc32(ni9,)Wk3(hutB000,01<

dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof

dna)Wk3(hutB000,01>secnailpparof

dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof

)mc03(sehcni21,)Wk51(hutB000,05< )mc03(sehcni21,)Wk51(hutB000,05<

)mc03(sehcni21,)Wk51(hutB000,05<

)mc03(sehcni21,)Wk51(hutB000,05< )mc03(sehcni21,)Wk51(hutB000,05<

**)Wk51(hutB000,05>secnailpparof **)Wk51(hutB000,05>secnailpparof

**)Wk51(hutB000,05>secnailpparof

**)Wk51(hutB000,05>secnailpparof **)Wk51(hutB000,05>secnailpparof

wodniwdesolcyltnenamrepotecnaraelC=C tneverpotdednemmocer)mm503("21

noitasnednocwodniw noitasnednocwodniw

noitasnednocwodniw

noitasnednocwodniw noitasnednocwodniw

tneverpotdednemmocer)mm922("9

noitasnednocwodniw noitasnednocwodniw

noitasnednocwodniw

noitasnednocwodniw noitasnednocwodniw

tiffosdetalitnevotecnaraelclacitreV=D

latnozirohanihtiwlanimretehtevobadetacol latnozirohanihtiwlanimretehtevobadetacol

latnozirohanihtiwlanimretehtevobadetacol

latnozirohanihtiwlanimretehtevobadetacol latnozirohanihtiwlanimretehtevobadetacol

retnecehtmorf)mm854(sehcni81foecnatsid retnecehtmorf)mm854(sehcni81foecnatsid

retnecehtmorf)mm854(sehcni81foecnatsid

retnecehtmorf)mm854(sehcni81foecnatsid retnecehtmorf)mm854(sehcni81foecnatsid

lanimretehtfoenil lanimretehtfoenil

lanimretehtfoenil

lanimretehtfoenil lanimretehtfoenil

)mm854("81 )mm854("81

tiffosdetalitnevnuotecnaraelC=E )mm503("21 )mm503("21

renrocedistuootecnaraelC=F muminim)mc7.21("5 muminim)mc7.21("5

renrocedisniotecnaraelC=G

"42 "42

enilretnecfoedisnihcaeotecnaraelC=H

ylbmessarotaluger/retemevobadednetxe ylbmessarotaluger/retemevobadednetxe

ylbmessarotaluger/retemevobadednetxe

ylbmessarotaluger/retemevobadednetxe ylbmessarotaluger/retemevobadednetxe

teef51fothgiehanihtiw)mc19(teef3

*ylbmessarotaluger/retemehtevoba *ylbmessarotaluger/retemehtevoba

*ylbmessarotaluger/retemehtevoba

*ylbmessarotaluger/retemehtevoba *ylbmessarotaluger/retemehtevoba

teef51fothgiehanihtiw)mc19(teef3

**ylbmessarotaluger/retemehtevoba **ylbmessarotaluger/retemehtevoba

**ylbmessarotaluger/retemehtevoba

**ylbmessarotaluger/retemehtevoba **ylbmessarotaluger/retemehtevoba

teltuotnevrotalugerecivresotecnaraelC=I *)mc19(teef3 **)mc19(teef3

telniylppusrialacinahcemnonotecnaraelC=J

ynaottelnirianoitsubmocehtrognidliubot ynaottelnirianoitsubmocehtrognidliubot

ynaottelnirianoitsubmocehtrognidliubot

ynaottelnirianoitsubmocehtrognidliubot ynaottelnirianoitsubmocehtrognidliubot

ecnailpparehto ecnailpparehto

ecnailpparehto

ecnailpparehto ecnailpparehto

secnailpparof)mc51(ni6

)mc03(ni21,)Wk3(hutB000,01< )mc03(ni21,)Wk3(hutB000,01<

)mc03(ni21,)Wk3(hutB000,01<

)mc03(ni21,)Wk3(hutB000,01< )mc03(ni21,)Wk3(hutB000,01<

dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof

dna)Wk3(hutB000,01>secnailpparof

dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof

)mc19(sehcni63,)Wk03(hutB000,001< )mc19(sehcni63,)Wk03(hutB000,001<

)mc19(sehcni63,)Wk03(hutB000,001<

)mc19(sehcni63,)Wk03(hutB000,001< )mc19(sehcni63,)Wk03(hutB000,001<

*)Wk03(hutB000,001>secnailpparof *)Wk03(hutB000,001>secnailpparof

*)Wk03(hutB000,001>secnailpparof

*)Wk03(hutB000,001>secnailpparof *)Wk03(hutB000,001>secnailpparof

secnailpparof)mc51(ni6

)mc32(ni9,)Wk3(hutB000,01< )mc32(ni9,)Wk3(hutB000,01<

)mc32(ni9,)Wk3(hutB000,01<

)mc32(ni9,)Wk3(hutB000,01< )mc32(ni9,)Wk3(hutB000,01<

dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof

dna)Wk3(hutB000,01>secnailpparof

dna)Wk3(hutB000,01>secnailpparof dna)Wk3(hutB000,01>secnailpparof

)mc03(sehcni21,)Wk51(hutB000,05< )mc03(sehcni21,)Wk51(hutB000,05<

)mc03(sehcni21,)Wk51(hutB000,05<

)mc03(sehcni21,)Wk51(hutB000,05< )mc03(sehcni21,)Wk51(hutB000,05<

**)Wk51(hutB000,05>secnailpparof **)Wk51(hutB000,05>secnailpparof

**)Wk51(hutB000,05>secnailpparof

**)Wk51(hutB000,05>secnailpparof **)Wk51(hutB000,05>secnailpparof

telniylppusrialacinahcemaotecnaraelC=K *)m38.1(teef6 )m3(teef01nihtiwfievoba)mc19(teef3

**yllatnoziroh **yllatnoziroh

**yllatnoziroh

**yllatnoziroh **yllatnoziroh

devaproklawedisdevapevobaecnaraelC=L

ytreporpcilbupnodetacolyawevid ytreporpcilbupnodetacolyawevid

ytreporpcilbupnodetacolyawevid

ytreporpcilbupnodetacolyawevid ytreporpcilbupnodetacolyawevid

‡)m31.2(teef7 ‡)m31.2(teef7

rokced,hcrop,adnarevrednuecnaraelC=M

ynoclab ynoclab

ynoclab

ynoclab ynoclab

‡*)mc03(sehcni21 ‡)mc03(sehcni21

.edoCnoitallatsnIenaporPdnAsaGlanoitaN1.941B-ASCtnerrucehthtiwecnadroccanI*

.sedoCsaGleuFlanoitaN45APFN/1.322ZSISNAtnerucehthtiwecnadroccanI** .sedoCsaGleuFlanoitaN45APFN/1.322ZSISNAtnerucehthtiwecnadroccanI**

.sedoCsaGleuFlanoitaN45APFN/1.322ZSISNAtnerucehthtiwecnadroccanI**

.sedoCsaGleuFlanoitaN45APFN/1.322ZSISNAtnerucehthtiwecnadroccanI** .sedoCsaGleuFlanoitaN45APFN/1.322ZSISNAtnerucehthtiwecnadroccanI**

sevresdnasgnillewdylimafelgnisowtneewtebdetacolsihcihwyawevirddevaproklawedisaevobayltceridetanimrettonllahstnevA‡ sevresdnasgnillewdylimafelgnisowtneewtebdetacolsihcihwyawevirddevaproklawedisaevobayltceridetanimrettonllahstnevA‡

sevresdnasgnillewdylimafelgnisowtneewtebdetacolsihcihwyawevirddevaproklawedisaevobayltceridetanimrettonllahstnevA‡

sevresdnasgnillewdylimafelgnisowtneewtebdetacolsihcihwyawevirddevaproklawedisaevobayltceridetanimrettonllahstnevA‡ sevresdnasgnillewdylimafelgnisowtneewtebdetacolsihcihwyawevirddevaproklawedisaevobayltceridetanimrettonllahstnevA‡

.sgnillewdhtob .sgnillewdhtob

.sgnillewdhtob

.sgnillewdhtob .sgnillewdhtob

:roolfehthtaenebsedis2muminimanonepoyllufsiynoclabrokced,hcrop,adnarevfidettimrepylnO‡* :roolfehthtaenebsedis2muminimanonepoyllufsiynoclabrokced,hcrop,adnarevfidettimrepylnO‡*

:roolfehthtaenebsedis2muminimanonepoyllufsiynoclabrokced,hcrop,adnarevfidettimrepylnO‡*

:roolfehthtaenebsedis2muminimanonepoyllufsiynoclabrokced,hcrop,adnarevfidettimrepylnO‡* :roolfehthtaenebsedis2muminimanonepoyllufsiynoclabrokced,hcrop,adnarevfidettimrepylnO‡*

Figure 5

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

5

Page 6

BEGIN VENTING

PROBE (11)

HOSE CLAMP (8)

VACUUM HOSE (1)

• Install the strain relief (#5) on the termination as shown in Figure 9.

Horizontal (Outside Wall) Termination System

NOTE: The LPVK-110 Power Vent system can only be terminated

horizontally.

Various horizontal venting configurations are possible for use with

these power vent kit. Secure Vent pipe are used in these applications.

Refer to Figures 2, 3 and Tables in Figure 3 which summarizes each

system’s minimum and maximum vertical and horizontal length values

that can be used to design and install the vent components in a variety

of applications.

Horizontal vent systems terminate through an outside wall. Building

Codes limit or prohibit terminating in specific areas. Refer to local codes

and Figure 5 for location guidelines.

• Plan and execute the vent run -

Analyze the vent routing and determine the types and quantities of sections and elbows required. Vent sections are available in net lengths of

4-1/2” (114 mm), 10-1/2” (267 mm), 22-1/2” (572 mm), 34-1/2” (876

mm) and 46-1/2” (1181 mm). Plan the vent lengths so that a joint

does not occur at the intersection of ceiling or roof joists. Elbows are

available in 90° and 45° configurations. Make allowances for elbows

as indicated in the appliance installation instructions.

Maintain a minimum 1” (25 mm) clearance to combustibles on the

vertical sections. Clearances for the horizontal runs are; 3” (76 mm)

on top, 1” (25 mm) on sides, and 1” (25 mm) at the bottom.

• Refer to Figure 10 to connect the three wires of the Romex cable to

the termination. Ensure the ground ring terminal is grounded beneath

a structural screw as shown. Attach the junction box cover (#22) to the

termination with the three screws previously removed.

• Route 14 gauge AWG grounded Romex wiring (not provided). Ensure

the wiring is safety plated to prevent damage by framing nails and finish drywall screws. Route the wire into the lower control compartment

and cut to length before installing the terminals. Install provided wiring

hardware (# 6,7) on the ends of the Romex wire.

Fireplace (J-Box) Wiring

(Refer to appliance Installation

Instructions For Directions)

Strain Relief (5)

Snap

Bushing (9)

Install Vacuum Hose

• Refer to Figure 6 and remove the knockouts located where the strain

relief (#5) and snap bushing (#9) are to be installed, at the lower right

hand side.

• Install the snap bushing (#9) in the hole provided on the fireplace for

the vacuum hose (refer to Figure 6 ).

• Route the vacuum hose (#1), taking caution to not kink and/or damage

the hose (refer to Figure 6 ). Route the hose from the probe assembly

(#11) location to the appliance control compartment, through the snap

bushing previously installed. Ensure enough material is available at

either end to allow hook up. Ensure the hose is safety plated throughout

its run to prevent damage by framing nails and finish drywall screws.

Secure the vacuum hose (#1) to the probe (#11) with the hose clamp

(#8). Refer to Figure 7.

Route Wiring

NOTE: Electrical wiring must be performed by a qualified electrician.

• Install the strain relief (#5) in the hole provided on the fireplace for

the electrical wiring (refer to Figure 6 ).

• Remove the junction box cover (#22) from the termination by removing three screws (refer to Figure 8 ).

Figure 6

Figure 7

14 Gauge

Grounded Romex

Vacuum Hose (1)

6

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 7

BLACK & WHITE

GROUND WIRE

ROMEX

6

7

(BOTTOM OF TERMINATION)

Junction Box Cover (22)

• Refer to Figure 10 and install the electrical hardware on the ends of

the Romex wiring. Male terminals (#7) on the Black and White wires,

and ring terminals (#6) on the ground wire.

Figure 10

Termination Wiring

Figure 8

(BACK OF TERMINATION)

Strain Relief (5)

Romex Wire

Figure 11

Strain Relief (5)

Ground Wire Lug (6)Male Terminals (7)

Figure 9

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

7

Page 8

Installing Power Vent Termination

Siding

Stucco

1-1 /4" Maximu m Recess of

the Squa re Term ina tion into

Exteri or Finishing Material

Exterior Surface of

Framing

5 in. to 9-1/4 in.

(127 to 235 mm)**

Exterior Surface of Siding

Interior Surface of

Finished Wall

Maximum wall thickness

10 in.(254 mm)**

Power Vent

Termination

Maximum Extent of Vent Run

Sections Relative to Exterior

Surface of Framing

Last Vent Section.

Use Telescopic Vent

Section (SV4.5LA),

If Necessary

Adapter

SV4.5RCH

Venting Connection and Exterior Wall Recessing

of the Power Vent Horizontal Termination

*Use silicone caulking to

seal the top and sides of

the termination, up to the

underlayment, stucco, or

masonry wall surface.

**For thicknesses greater

than 10”, see Appliance

Installation Instructions.

Power Vent

Termination

*Caulk

*Caulk

Firestop/Spacer (SV4.5HF) shown

on the exterior side of the wall. It

may also be installed on the

interior side.

Power Vent

Termination

7"

(178)

5-1/8"

(130 mm)

12-1/8"

(308 mm)

Note: Centerline of Vent Piping is

NOT the Same as the Centerline of

the Frame Opening.

6 to 48 inch Vent Section,

Telescopic vent section,

Elbow or Appliance Collar

See Appliance Installation

Instructions for Min. Distance

to Base of Appliance.

Base of Appliance

3"

(76 mm)

1"

(25.4 mm)

Adapter

SV4.5RCH

10-1/2"

(267 mm)

• Assemble vent run to exterior wall - If not

previously measured, locate the center of the

vent on the exterior wall. Prepare an opening

as described in the appliance installation

instructions. Assemble the vent system to a

point where the terminus of the last section

is within 8 inches of the outside wall surface

where the power vent is to be mounted (refer

to Figure 12 ).

If the terminus of the last section is not within

this distance, use the telescopic vent section

SV4.5LA, as the last vent section. For wall thicknesses greater than that shown in Figure 12,

refer to the appliance Installation Instructions

for the additional venting components needed

(in addition to the termination and adapter) for

a particular range of wall thicknesses.

• Attach termination adapter - Attach the

adapter (adapter - SV4.5RCH - provided with the

power vent kit - #12) to the vent section telescoping vent section, or elbow or appliance collar, as

shown in Figure 13 in the same manner as any

SV4.5 vent component.

Figure 12

• Install Firestop/Spacer at exterior wall -

Install SV4.5HF Firestop/Spacer (#13), provided

with the power vent kit, over the opening at the

exterior side of the framing, long side up, with

the 3 inch spacer clearance at the top as shown

in Figure 13, and nail into place.

(The Firestop/Spacer may also be installed over

the opening at the interior side of the framing).

• Install the Power Vent termination (#10)

- For the last step, from outside the exterior

wall, slide the collars of the termination onto

the adapter (the outer inside the outer and the

inner outside the inner) until the termination

seats against the exterior wall surface to which

it will be attached. Orient the housing of the

termination with the arrow pointed upwards.

Secure the termination to the exterior wall.

The termination must not be recessed into the

exterior wall or siding by more that the 1-1/4”

(32 mm) as shown in Figure 12.

The Power Vent termination has been designed to perform in a wide range of weather conditions. Our terminations meet or exceed

industry standards.

When selecting the location of your termination, do not place the termination where water from eaves and adjoining roof lines may

create a heavy flow of cascading water onto the terminations. If the termination must be placed where the possibility of cascading

water exists, it is the responsibility of the builder to direct the water away from the termination cap by using gutters or other means.

Take care to carefully follow the Installation Instructions for the termination, including the use of silicone caulking where required.

8

Figure 13 Installing Power Vent Horizontal Termination

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 9

Connecting The Power Vent To The Fireplace Control System

• Disconnect and remove the battery pack. See Figures 15 and 16.

Remove any control compartment cover or access plates and set aside.

Ensure power is off to the fireplace.

Connecting To Battery Backed-up Dexen Systems

Refer to the general components layout shown in Figure 14.

Control Module System Power Cord

On/Off Switch Pressure Switch (3) Power Outlets Control Module Power Cord

• Disconnect system power transformer (3V) from power outlet. Refer

to Figure 14.

• Disconnect 2 brown wires from the On/Off switch.

• Reconnect 2 brown wires to the control module (#4). See Figure 17.

System Power Transformer

4 Wire Harness (2)Vacuum Hose (1)

Figure 14 General System Layout (Firebox Floor Removed For Clarity)

Bundle Disconnected Wire (Do Not Re-use)

Battery Pack (Remove) Disconnect Here

Figure 15

Figure 16

Control Module (4)

Disconnected Battery Pack

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

9

Page 10

• Position the pressure switch (#3) on the fireplace cabinet bottom.

Refer to Figure 14 and Figure 18. Secure in position using Velcro strips

(#4) provided. Install vacuum hose to the pressure switch. Secure with

hose clamp (#8).

Two Brown Wires

From On/Off Switch

Wires To DV

Termnation

Termination

Ground

• Connect control module (#4) (To Power Vent) to the power wire

for the power vent termination. Remove the paint plug from the

fireplace corner post to expose the bare metal at the grounding point

and connect the PV (Romex ground wire) ground with the Control

Module ground wire to the grounding point with the screw provided.

See Figure 19.

• Connect the control module (#4) power plug to the power socket.

(See Figure 19 ).

• Refer to Figure 14 and ensure all components are properly placed.

Ensure the ON/Off switch is secure and the pressure switch is in place.

Ensure the fireplace blower (if used) is installed and connected to

the power socket.

• Place the control module (#4) into position. Secure in position using Velcro strips provided. See Figure 20 and refer to Figure 14.

Control Module Power Plug

Control Module Ground

Figure 17

• Connect four-wire harness (#2) to the control module (#4) (Figure

17 ) at T-STAT (Red) and V-SWITCH (Black). Connect the other end

of the four-wire harness to the unit/wall On/Off switch and pressure

switch (#3) (Figure 18 ), black to the pressure switch, red to the

On/Off switch.

Control Module (4)

System Power Cord

Two 1/4” Wires

(Red)

Two 3/16” Wires

(Black)

Figure 19

Power Vent

Ground

Ground

Point

Control Module Ground

Control Module (4)

Power Supply

Transformer

On/Off Switch

(Wall)

Four-Wire

Harness (2)

Pressure

Switch (3)

Figure 18

• Connect the transformer (3V) to the control module system power.

(Refer to Figure 18 ).

10

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Figure 20

Page 11

OPTIONAL

BLOWER SWITCH

JUNCTION BOX

EXHAUST

GR

120 VAC

BK

W

W

BK

R

OPTIONAL BLOWER

14-AWG

BLACK

BLACK

RED

RED

VACUUM

SWITCH

EXHAUST BOWER

CONTROL MODULE

THERMOSTAT OR

WALL SWITCH

BROWN

BROWN

TRANSFORMER 3V

IGNITOR MODULE 3V

BLACK (IGNITOR)

BLACK (SENSOR)

SPARK TO PILOT IGNITOR

ORANGE (THTP)

BLACK (TP)

GREEN (TH)

GAS VALVE

PILOT

IN

IN

POWER VENT WIRING DIAGRAM

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

11

Page 12

POWER VENT OPERATING INSTRUCTIONS

16.17

(411 mm)

15.92

(404 mm)

10.00

(254 mm)

11.19

(284 mm)

13.50

(343 mm)

Top View

Front View

Power Vent Control Sequences

Turn On

1. Turn On The Thermostat Or On/Off Switch.

2. Blower Should Start Immediately.

3. Ignitor Starts Sparking And Pilot Will Light.

4. Burner Should Light After A Few Seconds.

5. Fireplace Should Run Continuously Until Thermostat Or On/Off Switch Is Turned Off.

Turn Off

1. Turn Off The Thermostat Or On/Off Switch.

2. Burner And Pilot Should Be Off Immediately.

3. Blower Will Continue To Run For About 90 Seconds And Then The Blower Will Stop.

Note: Dimensions Are In Inches (mm)

POWER VENT SPECIFICATIONS

12

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 13

TROUBLESHOOTING THE POWER VENT SYSTEM

Important: Service must be performed by a qualified installer, service agency or your gas supplier.

BEFORE COMMENCING TO TROUBLESHOOT THE UNIT:

1. Check if there is power to the unit (fireplace).

2. Check if there is gas to the unit (fireplace).

3. The igniter module in the fireplace is equipped with a lockout device, which will put the unit into a lockout condition. Follow the steps in the

chart below to reset the control: Turn the On/Off switch to the Off position, or turn the thermostat to the Off position.

4. If this is the first time that the unit has been fired, check the wiring of the unit against the wiring diagram before commencing troubleshooting.

START

Power Vent Motor

Is Working?

Yes

On/Off Switch Or Wall Thermostat “On”?

No

Is There 120V Power To The Fireplace?

Are All Wiring Connections Tight?

(Turn Off Power Before Checking)

Is There 120V Power

Yes

To The Motor?

No

Yes

Replace Blower

Replace Control Module

Does The Pilot

Spark?

Yes

Pilot Burner

Lights?

Yes

Does Spark

Stop When Pilot

Lights?

Yes

Does Main Burner

Light?

Yes

No No

Yes

Is The Lead To The

Spark Electrode

Attached Or Arcing

To Ground? Is The

Electrode Cracked?

No

No

No

No

Is Pilot Gas Line

Blocked? Is Pilot

Orifice Blocked?

No

Does Pilot Flame

Cover The Flame

Rod?

No

Check Pilot For Obstruction.

Check Gas Pressure.

Adjust Pilot Flame.

Is There 1V Power

At Terminal 1 (MV)

During Spark Cycle?

No

Yes

Is The Pressure

Switch Closed?

Yes

Replace Control

Module

Replace Ignition Module

Yes

Yes

Replace Pilot

Replace Ignition Module

Is The Flame Rod Corroded?

Is The Pilot Hood Corroded?

Is Flame Rod Insulator Cracked?

Is Wire To Flame Rod Damaged?

Are Wires To Valve

Loose Or Corroded?

Replace Ignition Module

Is There Blockage In The Vent?

Is There Water/Dirt In The Hose From

The Blower To The Pressure Switch?

Are the Hose Connections Loose?

Is The Hose Cracked?

WARNING: Never Jump The Pressure

Switch Out Of This System. Property

Damage, Injury Or Death May Result.

No

Replace Ignition Module

No

Is There Manifold Pressure?

No

Replace Gas Valve

No

Yes

Replace Pressure

Switch

Check Position Of

Pilot. Is Orifice

Blocked?

System Runs

Continuously

Until Switched

Off?

No

Is The Correct Size Of Orifice Restrictor Insalled In The Power Vent?

Does The Pilot Flame Cover The Flame Rod?

Is The Sensor Wire In Good Condition?

Is There Continuity To Ground From The Piloy Burner?

Yes

Does Pressure Switch Open During Operation?

No

Replace Ignition Module

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Replace Control Module

Yes

Replace Pressure Switch

No

Is Vent Partially Blocked?

Is There Water/Dirt In Hose To Pressure Switch?

Are Hose Connections Loose?

Is The Hose Cracked?

No

Does System Run

Continue?

No

Replace Ignition

Modiule

13

Page 14

POWER VENT REPLACEMENT PARTS

25

19

20

18

17

16

15

9

4

26

23

24

22

1

5

21

8

6

2

7

3

Item

Part Number Description Qty.

1 H7383

2 H7369

3 H7366

4 H7367

5 H7368

6 H7370

7 H7384

8 H7371

9 P-8-7102

15 H7372

Vacuum Hose 1

Wire Harness

Pressure Switch

Control Module

Strain Relief - 3/8”

Ring Terminal - #10

Insulated 1/4” Male Terminal

Hose Clamp - 11/32”

Snap Bushing

Base Assembly (Power Vent)

Item Part Number

16 H7378

1

1

1

2

2

4

2

1

1

17 H7382

18 H7365

19 H7375

20 H7373

21 H7374

22 H7377

23 H7379

24 H7380

25 H7376

26 H7381

Kicker Assembly

Blower Gasket

Blower Assembly

Wrapper - Top

Wrapper

Wrapper - Bottom

J-Box

Diverter - Front

Diverter - Back

Wrapper Cover

Wire Mesh

Description

Qty.

1

1

1

1

1

1

1

1

1

1

1

14

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

Page 15

LISTED VENT COMPONENTS

The Power Vent Kit (LPVK-110) is designed and listed for use with Security Chimneys® SV4.5 Secure-Vent™ direct-vent systems. The following

list details the SV4.5 components are available for use in developing vent runs for the power vent system.

SECURE VENT COMPONENTS

Catalog Number

Model Number Description

77L70 SV4.5L6 6” Pipe Length

77L71 SV4.5L12 12” Pipe Length

77L72 SV4.5L24 24” Pipe Length

77L73 SV4.5L36 36” Pipe Length

77L74 SV4.5L48 48” Pipe Length

77L75 SV4.5LA 6” Pipe, Adjustable

77L76 SV4.5E45 Swivel 45° Elbow

77L77 SV4.5E90 Swivel 90° Elbow

96K92 SV4.5SP Support Plate

96K93 SV4.5SU Universal Support

H5816 SV4.5TWSK10 Through Wall Shield Kit

H3907 SV4.5RSA Attic Insulation Shield

H2247 SV4.5VF Firestop, Vertical (10 Pack)

H2246 SV4.5HF Firestop, Horizontal (10 Pack)

NOTE: This list is not complete, but is representative of components

most frequently used. Refer to Lennox Hearth Products catalog sheets

and individual fireplace installation instructions for a complete listing of

SV4.5 vent components listed for use in venting of this product.

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

15

Page 16

The manufacturer reserves the right to make changes at any time, without notice, in design, materials, specifications, prices and also to discontinue colors, styles and products.

Consult your local distributor for fireplace code information.

Printed in U.S.A. © 2008 by LHP

P/N 506022-01 REV. A 10/2008

16

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

1110 West Taft Avenue

Orange, CA 92865

Loading...

Loading...