Lennox Hearth PI40 User Manual

INSTALLATION AND OPERATION MANUAL

Save These Instructions

For Future Reference

Pellet Insert

Model Winslow™ (PI40)

Pellet-Fired

Fireplace Insert

P/N 775,229M, Rev. C, 11/2008

US

Portland

A French manual is available upon request. Order P/N 775,229CF.

Ce manuel d’installation est disponible en francais, simplement en faire la demande. Numéro de la pièce

775,229CF.

These appliances must be properly installed and operated in order to prevent the possibility

of a house re. Please read this entire manual before installation and use of this pellet

fuel-burning room heater. Failure to follow these instructions could result in property

damage, bodily injury or even death. Contact your local building or re ofcials

to obtain a permit and information on any installation requirements and

inspection requirements in your area.

WARNINGS

•

Hot! Do not touch! The glass and surfaces of this appliance will be

hot during operation and will retain heat for a while after shutting off

the appliance. Severe burns may result.

•

Carefully supervise children in the same room as appliance.

•

Lennox™ pellet-burning appliances are designed for use as a supple-

mental heater. They are not intended for continuous use as a primary

heat source.

Report No. 050-S-14b-2

2

1. DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING

ANOTHER APPLIANCE.

2. Do not connect this appliance to air ducts or any air distribu-

tion system.

3. DO NOT INSTALL A FLUE DAMPER IN THE EXHAUST VENTING

SYSTEM OF THIS UNIT.

4. Do not use class B venting intended for gas appliances as a

chimney or connector pipe on a pellet-fired appliance.

5. The minimum clearances must be maintained for all com-

bustible surfaces and materials including; furniture, carpet,

drapes, clothing, wood, papers, etc. Do not store combustibles

within this clearance space (see Clearances on Page 7).

6. INSTALLATION DISCLAIMER - It is imperative that the exhaust

venting system be installed correctly and sealed gas-tight

(not allowing exhaust to leak). Follow the vent manufacturer's

instructions for proper installation. Since Lennox Hearth

Products has no control over the installation of your fire-

place insert, Lennox Hearth Products grants no warranty,

implied or stated for the installation or maintenance of your

insert, and assumes no responsibility for any consequential

damage(s).

7. Burning any kind of fuel consumes oxygen. If outside air is

not ducted to the appliance, ensure that there is an adequate

source of fresh air available to the room where the appliance

is installed.

8. The appliance will not operate using natural draft, nor without

a power source for the blower and fuel feeding systems.

9. Never use gasoline, gasoline-type lantern fuel, kerosene,

charcoal lighter fluid, or similar liquids to start or “freshen up”

a fire in this heater. Keep all such liquids well away from the

heater while it is in use.

10. The authority having jurisdiction such as municipal build-

ing department, fire department, fire prevention bureau, etc

should be consulted before installation to determine the need

to obtain a permit.

10. APPROVED FUEL: This appliance is designed specifically for

use only with pelletized wood fuels only. This appliance is

designed and approved for the burning of wood residue pellets

with up to 3% ash content. This appliance is NOT approved to

burn cardboard, nut hulls, cherry pits, corn, etc. regardless

if it is in pellet form. Failure to comply with this restriction

will void all warranties and the safety listing of the fireplace

insert. Consult with your Lennox Hearth Products dealer for

more information on approved pellet fuels.

11. These appliances are designed as supplemental heaters.

Therefore, it is advisable to have an alternate heat source

when installed in a dwelling.

12. CONTINUOUS OPERATION: When operated correctly, this

appliance cannot be overfired. Continuous operation at a

maximum burn can, however, shorten the life of the electri-

cal components (blowers, motors, and electronic controls),

and is not recommended. Typical approved operation would

include running at the low to mid range setting with occasional

running on the maximum setting during the coldest periods

of the winter.

DO NOT OVER-FIRE THIS INSERT. Follow all

instructions regarding the proper use of this insert.

13. CAUTION: NEVER PUT FINGERS NEAR AUGER. Pellet fuel is

fed to the UltraGrate™ by a screw auger. This auger is driven

by a high torque motor. The auger is capable of doing seri-

ous harm to fingers. Keep pellets in the hopper at all times

and keep fingers away from auger. The auger can start and

stop automatically at any time while the insert is running.

14.CAUTION: NEVER PUT FINGERS NEAR AUGER. Pellet fuel is

fed to the UltraGrate™ by a screw auger. This auger is driven

by a high torque motor. The auger is capable of doing serious

harm to fingers. Keep pellets in the hopper at all times and

keep fingers away from auger. The auger can start and stop

automatically at any time while the insert is running.

15. FLY ASH BUILD-UP: For all wood pellet fuel-burning heaters,

the combustion gases will contain small particles of fly-ash.

This will vary due to the ash content of the fuel being burned.

Over time, the fly-ash will collect in the exhaust venting

system and restrict the flow of the flue gases. The exhaust

venting system should be inspected regularly and cleaned

as necessary.

16. SOOT FORMATION: Incomplete combustion, such as occurs

during startup, shutdown, or incorrect operation of the room

heater will lead to some soot formation which will collect in

the exhaust venting system. A precautionary inspection on

a regular basis is advisable to determine the necessity of

cleaning. The exhaust venting system should be inspected

regularly and cleaned as necessary.

17. DISPOSING OF ASHES: Any ashes removed from the pellet

fireplace insert must be deposited in a metal container with

a tight-fitting lid. The closed container of ashes should be

placed on a noncombustible floor or on the ground, well

away from all combustible materials, outside of the dwell-

ing pending final disposal. If the ashes are disposed of by

burial in soil or otherwise locally dispersed, they should be

retained in the closed container until all cinders have been

thoroughly cooled.

19. The instructions must be strictly adhered to. Do not use

makeshift methods or compromise in the installation.

20.

Do not abuse the door glass by striking, slamming or similar

trauma. Do not operate the insert with the glass removed,

cracked or broken.

18. SAVE THESE INSTRUCTIONS.

19. See the listing label on the appliance.

IMPORTANT SAFETY AND WARNIING

INFORMATION

READ THIS MANUAL IN ITS ENTIRETY AND UNDER-

STAND THESE RULES TO FOLLOW FOR SAFETY.

WARNING

Do not attempt to alter or modify the construction of

the appliance or its components. Any modification

or alteration may void the warranty, certification

and listings of this unit.

WARNING

Improper installation, adjustment, alteration, ser-

vice or maintenance can cause injury or property

damage. Refer to this manual. For assistance or

additional information consult a qualified installer,

service agency or the gas supplier.

3

CONGRATULATIONS!

When you purchased your new pellet stove, you joined the ranks of

thousands of individuals whose answer to their home heating needs,

aesthetics, efficiency and our environment. We extend our continued

support to help you achieve the maximum benefit and enjoyment avail-

able from your new pellet stove.

It is our goal at Lennox Hearth Products to provide you, our valued

customer, with an appliance that will ensure you years of trouble free

warmth and pleasure.

Thank you for selecting a Lennox Hearth Products stove as the answer

to your home supplemental heating needs.

TABLE OF CONTENTS

Important Safety Warnings ................................................... Page.2

Using this Manual ................................................................. Page 3

Planning Your Installation ..................................................... Page 4

Selecting a Location .............................................................. Page 4

Features and Specifications .................................................. Page.5

Insert Dimensions ................................................................. Page.6

Minimum Fireplace Size ........................................................ Page.6

Clearances to Combustibles .................................................. Page.7

Hearth Protection .................................................................. Page.7

Installation ....................................................................... Page.8-17

Control Board Installation.......................................... Page.8

Venting ...................................................................... Page.8

Vent Termination Requirements ................................ Page.8

Vent Termination Locations .......................................

Page 9

Insert Leveling......................................................... Page.10

Surround Installation............................................... Page.10

Mobile Home Installations ....................................... Page.11

Outside Air Installations .......................................... Page.12

Thermostat installation ............................................ Page.12

Door Trim Installation Instructions .........................

Page.12

Door Grill Installation Instructions .........................

Page.14

Brick Panel Installation Instructions ........................

Page.15

Log Set Installation Instructions ............................ Page.17

Operation ....................................................................... Page.14-19

Control Board .......................................................... Page.18

Filling the Hopper .................................................... Page.18

Lighting ................................................................... Page.18

Manual Operation .................................................... Page.18

Thermostat Operation ............................................. Page.18

Shut Down .............................................................. Page.19

Paint Curing ............................................................ Page.19

Convection Blower Operation .................................. Page.19

Operating Sounds ................................................... Page.19

Pellet Fuel ................................................................ Page.19

Corn Fuel ................................................................. Page.19

Cautions .................................................................. Page.19

Cleaning and Maintenance ............................................. Page.20-23

Burn Pot Cleaning ................................................... Page.20

Cleaning Glass......................................................... Page.20

Cleaning Heat Exchanger ......................................... Page.20

Cleaning Flue Gas Passageways .............................. Page.20

Cleaning Combustion Blower .................................. Page.21

Cleaning Vent Pipe .................................................. Page.21

Removing Ash from the Firebox .............................. Page.21

Cleaning Convection Blower .................................... Page.22

Adjustable Hopper ................................................... Page.22

Cleaning “Proof of Fire” Switch ...............................

Page 22

Front Door Opening and Removal ........................... Page.23

Side Door Removal ................................................. Page.23

Component Location and Functions ............................... Page.24-25

Igniter...................................................................... Page.24

Vacuum Switch ....................................................... Page.24

Auger and Auger Motor .......................................... Page.24

Over Temperature Snap Switch ............................... Page.24

Proof of Fire Snap Switch........................................ Page.24

Convection Blower Snap Switch .............................. Page.24

Draft Adjuster .......................................................... Page.25

Wiring Diagram ....................................................... Page.25

Diagnostic Codes ................................................................ Page.26

Troubleshooting .................................................................. Page.26

Replacement Parts .............................................................. Page.27

Accessories ......................................................................... Page.28

Heat Kit Instructions .......................................................... Page.29

Pellet Insert ZC Kit Assembly Instructions .......................... Page 30

ZC Framing Dimensions for

Combustible Hearth /Floor ........................................... Page.33

ZC Framing Dimensions for Non-

Combustible Hearth /Floor ........................................... Page.34

Product Reference Information ........................................... Page.36

USING THIS MANUAL

Please read and carefully follow all of the instructions found in this

manual. Please pay special attention to the safety instructions provided

in this manual.

PRODUCT IS SUBJECT TO CHANGE WITHOUT NOTICE

4

PLANNING YOUR INSTALLATION

WARNING

Check all local building and safety codes before

installation. The installation instructions and appro-

priate code requirements must be followed exactly

and without compromise. Alterations to the stove are

not allowed. Do not connect the stove to a chimney

system serving another stove, appliance, or any air

distribution duct. Failure to follow these instructions

will void the manufacturers warranty.

The installation of this appliance must conform to local codes and appli-

cable state and federal requirements. Familiarity with these requirements

before installation is essential. Important considerations to discuss with

local building officials include:

1.

Applicable codes (i.e. Uniform Mechanical Code, State or Regional

Codes).

Electrical codes:

In USA, NEC, ANSI/NFPA 70 – Latest Edition

In Canada, CSA C22.1 – Latest Edition

Power Supply Requirements

The power cord must be plugged into a standard, 120 volt, 60 Hz grounded

electrical outlet. The power supply cord must be routed to avoid contact

with any of the hot or sharp exterior surface areas of the stove. When

installed in a manufactured home, the appliance must be electrically

grounded to the steel chassis (see Mobile Home Installations on Page

11, for additional requirements). These requirements must be met unless

otherwise specified by state or local authorities.

Electrical

• The fireplace insert requires 120 volts AC for operation.

• Maximum wattage is 700.

• Igniter wattage is 400.

• Normal operating wattage is 300.

Electrical Generator Operation

Your Winslow™ PI40 insert can be powered with a gas driven electrical

gererator. However, the generator’s electrical regulator may not be compat-

ible with the insert’s electronics. The higher the quality of the gererator,

the greater the chance that it is compatible with the insert.

Questions To Ask Local Building Official

A correct installation is critical and imperative for reducing fire hazards and

perilous conditions that can arise when wood pellet burning appliances

are improperly installed. The installer must follow all of the manufactur-

ers’ instructions.

WARNING

Electrical grounding instructions: This appliance is

equipped with a three-prong (grounding) plug for

your protection against shock hazard and should

be plugged directly into a properly grounded three-

prong receptacle. Do not cut or remove the ground-

ing prong from this plug. Do not route power cord

under or in front of appliance.

Surge Protectors - A surge protector is recommended to ensure the

stove’s electrical components are not damaged due to a surge in the

electrical supply. Only high quality protectors should be used - cheap

ones do not provide the protection needed.

Smoke Detectors - Since there are always several potential sources of

fire in any home, we recommend installing smoke detectors. If possible,

install the smoke detector in a hallway adjacent to the room (to reduce

the possibility of occasional false activation from the heat produced

by these appliances). If your local code requires a smoke detector be

installed within the same room, you must follow the requirements of

your local code. Check with your local building department for require-

ments in your area.

Installation / Maintenance Standards - National Fire Protection Associa-

tion – The primary NFPA standard that refers to installation and main-

tenance of pellet appliances and venting is NFPA 211 – Latest Edition:

Chimneys, Fireplaces, Vents, and Solid Fuel appliances.

The design of your home and where you place your stove will determine

its value as a source of heat. This type of appliance depends primarily on

air circulation (convection) to disperse its heat, and therefore, a central

location is often best. There are other practical considerations, which

must be considered before a final selection of locations is made.

• Existing Chimneys

• Pellet Fuel Storage

• Aesthetic Considerations

• Roof Design (rafter locations & roof pitch)

• Room Traffic

• Proximity to Combustibles

• Electrical Wiring

SELECTING A LOCATION

CAUTION

The body of these appliances are very heavy. The

use of a heavy duty escalara (stair step hand truck)

is recommended for lifting the appliance body.

NEGATIVE PRESSURE WARNING

This appliance is not designed to be operated in a negative pressure. Very

airtight homes with large kitchen exhaust fans, or homes with furnace

cold air returns located in close proximity to the stove may create nega-

tive pressure in the same room as the heating appliance. This can create

dangerous condition, drawing combustion by-products into the home. Be

sure your home has adequate makeup air to eliminate negative pressures

caused by the above-mentioned sources. Outside air connected to the

appliance probably will not resolve such a problem as the stove is not the

source of negative pressure. Lennox Hearth Products accepts no liability

for damages resulting from negative pressures described here.

Ventilation Requirements - Provide adequate air for combustion. The

fresh air requirements of this appliance must be met within the space where

it will be installed. Ventilation is essential when using a solid-fuel-burning

heater. In well insulated and weather tight homes, it may inhibit the rate

the exhaust flows through the venting system (caused by a shortage of

air in the home). The lack of air is caused by many common household

appliances which exhaust air from the home (such as a furnace, heat

pump, air conditioner, clothes dryer, exhaust fans, fireplaces, and other

fuel burning appliances). Also, the combustion process of this heater

uses oxygen from inside the dwelling. If the available fresh air delivery

in the dwelling is insufficient to support the demands of these appli-

ances, problems can result (i.e. excessive negative pressure will result

in performance problems. To correct this problem it may help to open

a window (preferably on the windward side of the house) or install an

outside combustion air duct to the appliance.

2. Local amendments

3. Is a permit required - cost. You may wish to contact your insurance

company to ask if they require this.

4. If outside combustion air is required

5. Rooms where the installation is not allowed

FEATURES AND SPECIFICATIONS

Wood pellets manufactured to the pellet fuels institute (P.F.I.) certification

standard are available in two grades, Standard and Premium. The primary

difference between the two is the ash content of the pellets.

The P.F.I. specification for standard grade and premium grade residential

pellet fuel is as follows:

• CHLORIDES (Salt): Less than 300 p.p.m. to avoid insert and vent

rusting.

• BULK DENSITY: 40 lb. / Cu. Ft. minimum

• MOISTURE CONTENT: 8% maximum

• ASH CONTENT: < 3% maximum (standard grade) < 1% maximum

(premium grade)

• FINES: 0.5% maximum through a 1/8” screen

5

Installation Options

• Residential

• Vented vertical and horizontal (see venting instructions)

• Manufactured home and mobile home

• Thermostat or manual operation

• Bedrooms

Heating

• Max. feed rate is 4.5 pounds/hour or 37,500 BTU/hour

• Min. feed rate is 1.8 pounds/hour or 15,120 BTU/hour

Venting

This fireplace insert is approved for venting with Type L and Type PL

pellet vent pipe or listed pellet flex liner. We recommend the use of

venting products manufactured by Security Chimneys International.

The flue collar on the fireplace insert accepts 3” diameter pipe. The vent

pipe can be installed vertically or horizontally (see Venting section for

recommended installations).

The combustion air for this fireplace insert is drawn through a pipe at

the lower rear of the fireplace insert. For mobile home installations a 2”

ID flex line or pipe can be attached to the fireplace insert’s air intake to

draw air from outside the house.

Note: When installing this stove at altitudes of 4000 feet and above, we

suggest the use of 4” pellet vent.

Thermostat

This fireplace insert can be operated manually or with a thermostat.

Lighting

This fireplace insert is equipped with an electric self ignitor for ease of

ignition.

Fuel Specifications

This insert is designed to burn wood pellet fuel. In addition, a corn/wood

pellet mixture, with a maximum of 50 percent corn can be burned. Burning

any other fuel that is not approved for use with this appliance will void the

appliance warranty. IMPORTANT: The corn/wood mix needs to be mixed

evenly before being put in the Winslow™ pellet insert hopper.

Wood Pellet Specifications: This appliance has been designed to burn

wood residue pellets with up to 3% ash content. Dirty fuel will adversely

affect the performance of the insert. Any questions regarding pellet fuel

can be answered at the Pellet Fuels Institute (PFI), www.pelletheat.org.

• BTU CONTENT: There are a number of variations in pellet fuels that are

not included in PFI standards. For example, BTU (heat value) content

may range from just under 8,000 to almost 9,000 Btu, depending

upon species and region of the country and other variables.

Corn Specifications: Use only clean-shelled corn with a moisture content

less than 15% and approximate fuel value of 7000 BTU/lb (16,200 kJ/kg).

Do not attempt to burn corn with higher moisture content or burn lesser

grade fuels. Do not burn other types of agricultural pellets or by-products

(alfalfa, cherry pits, olive pits, nut shells, etc.) as they are not permitted

to be burned in these appliances.

Weight - 270 pounds

Hopper Capacity

55 pounds (adjustable down to 40 pounds to fit into small fireplaces)

Listing Information

The Winslow™ PI40 insert is safety listed with the following agencies:

• OMNI-Test Laboratories, Inc., Portland Oregon to ASTM E 1509

• US EPA List of Approved Wood Heating Appliances

• Colorado Approved Pellet Stoves

Appearance Options

The Winslow PI40 insert can be ordered with the following door trims, grills,

surround (flange) assemblies, log set and brick panel options :

Door Trim Kits Grill Kits

Black 79038 Black 79000

Gold 79034 Gold 79001

Nickel 79037 Nickel 79002

Brush Nickel 79035 Brush Nickel 79022

Black Nickel 79036 Black Nickel 79039

Surround Kits

29” Ht. x 41” Wd. Black Trim 79004

29” Ht. x 48” Wd. Black Trim 79005

33” Ht. x 41” Wd. Black Trim 79006

33” Ht. x 48” Wd. Black Trim 79007

32” ZC Surround Kit *

29” Ht. x 41” Wd. x 3” Deep 79032

* This black surround kit positions the insert 3” forward so that it will

allow the insert to fit into a fireplace with a narrower width in the front

(32” min.). Note: No trim kits are available for this kit at this time.

Surround Trim Kits

Trim/Black 29” Ht. x 41” Wd. H5143

Trim/Black 29” Ht. x 48” Wd. H5145

Trim/Black 33” Ht. x 41” Wd. H5144

Trim/Black 33” Ht. x 48” Wd. H5146

Trim/Gold 29” Ht. x 41” Wd. 75036

Trim/Gold 29” Ht. x 48” Wd. 75038

Trim/Gold 33” Ht. x 41” Wd. 75040

Trim/Gold 33” Ht. x 48” Wd. 75042

Trim/Nickel 29” Ht. x 41” Wd. 75037

Trim/Nickel 29” Ht. x 48” Wd. 75039

Trim/Nickel 33” Ht. x 41” Wd. 75041

Trim/Nickel 33” Ht. x 48” Wd. 75043

Log Set

H5142

Brick Panel Kit

79030

CAUTION

THE USE OF UNAPPROVED, DIRTY, WET AND/OR

HIGH SALT CONTENT FUEL WILL VOID THE WAR-

RANTY!

6

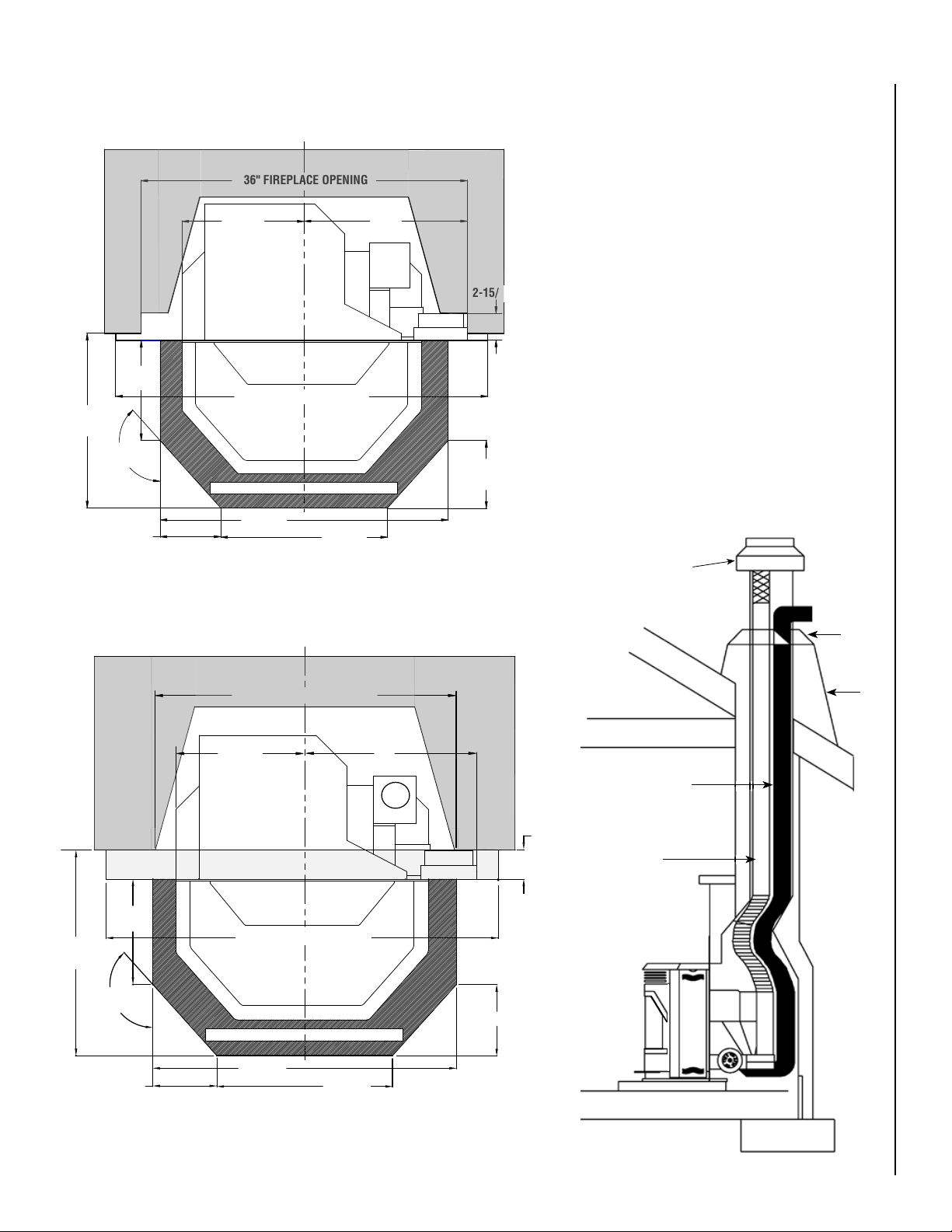

Front View

Figures 3 and 5

shows the minimum sized fireplace required for the

Winslow™ PI40 insert when any of the four non-extended surround

sizes are used.

With the hopper at its largest size (as shipped from the factory), the

fireplace needs to be a minimum of 22-1/2” (572 mm) high. When the

hopper is adjusted to its smallest size (see “Adjustable Hopper”), the

fireplace needs to be a minimum of 19” (483 mm) high.

Side View

Control

Board

Side

Surround

Panel

2-1/2” Minimum Screen Pocket is Needed for the Control

Board (not applicable if P/N 79032 ZC Surround Kit is used*)

15-1/2”

(394mm)

15”

(381mm)

23” (584mm)

Minimum

36” (914mm)

Minimum*

Figure 1

Figure 2

Existing 8” Flue

Flex Pipe

Exhaust Collar

8-3/4”

(222mm)

Min.

W/Hopper Extension 21-13/16” (554mm)

W/O Hopper Extension 18-5/16” (465mm)

15”

(381mm)

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

15-1/4”

(387mm)

19”

(483mm)

29-3/4”

(756mm)

14-3/8”

(365mm)

26-1/4”

(667mm)

23-3/8”

(594mm)

26”

(660mm)

Figure 3

Figure 4

Figure 5

INSERT DIMENSIONS

MINIMUM FIREPLACE SIZE

* This fireplace insert can fit into a fireplace with a narrower width in the front

(32” min. instead of 36” min.) when the 3” Deep ZC Surround Kit is used (P/N

79032). See Figure 11C on Page 11 for more information. Please take note

that because the appliance will be positioned in a more forward position on

the existing hearth, additional floor protection may need to be added to the

front of the appliance (see Figure 7).

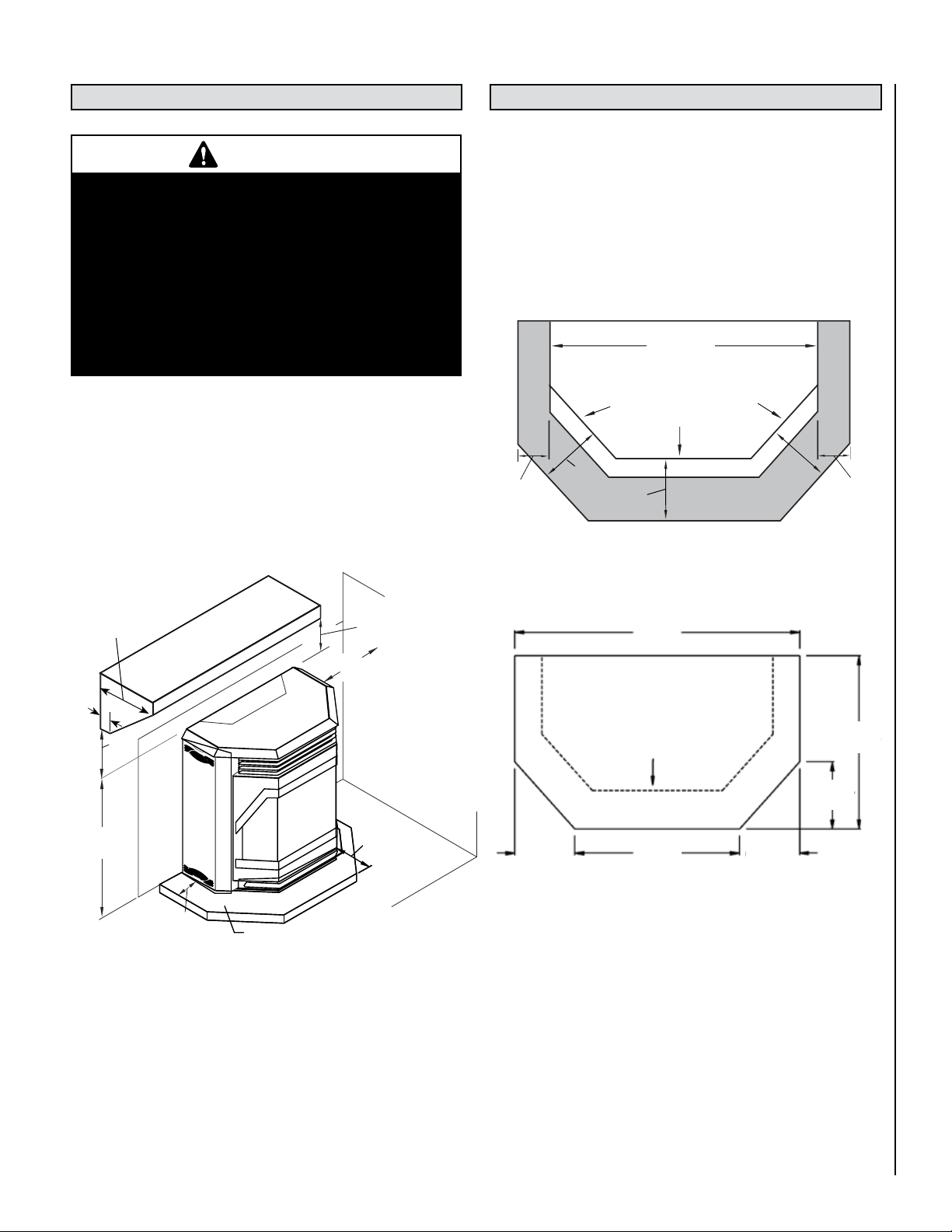

7

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Mantel

Floor Protection

Combustible

Wa

ll

6”

(152mm)

9-1/2”

(241mm)

7-1/2”

(191mm)

10”

(254mm)

Max.

6”

(152mm)

23-3/8”

(594mm)

3”

(76mm)

1-1/2”

(38mm)

The floor protector must be a non-combustible material extending

beneath the insert from the surround panels forward and to the front

and sides as shown in Figure 7. Important, if anything other than a

masonry hearth is used in the installation you must use the Heat Kit

(Cat. No. 79024).

Minimum Size Floor Protection

Outline of Insert Base

Zero Clearance Kit and Heat Kit Installation

The Winslow™ PI40 insert has a Zero Clearance Kit (Cat. No. 79025) and

a Heat Kit (Cat. No. 79024) approved for new construction or remodel

installations. See Zero Clearance and Heat kit installation instructions at

the back of this manual for requirements. Both kits have been tested and

approved through OMNI Testing Laboratories Inc.

6”

(152mm)

6”

(152mm)

3”

(76mm)

3”

(76mm)

6”

(152mm)

Insert Base

Firebox Front Edge

Floor Protection

31-3/4”

(807mm)

7-7/16”

(189mm)

19-1/4”

(489mm)

6-11/16”

(170mm)

6-11/16”

(170mm)

18-3/8”

(467mm)

Hearth Protection

(shaded gray)

Figure 6

Figure 7

Figure 8

CLEARANCES TO COMBUSTIBLES

INSTALL VENT AT CLEARANCES SPECIFIED BY THE VENT

MANUFACTURER.

Important: The control board attaches to the back of the right

side surround panel. Therefore, the width of the fireplace firebox

needs to be 36” (914 mm) wide at the front if the insert with control

board is to slide into the firebox. Extended surround panels are

available to accommodate narrower fireboxes.

IMPORTANT

• Minimum clearances specified may not allow

for ease of operation and maintenance (please

take this in to account when planning the instal

-

lation).

• Recommended clearance zone from the front

of the appliance to combustibles is 4 feet mini

-

mum.

• Clearances to combustibles for the appliance

can only be reduced by means approved by the

regulatory authority.

HEARTH PROTECTION

8

Control Board Installation

The Winslow PI40 insert is shipped with the control board wrapped and

placed behind the firebox. To install the control board, unwrap it and

the right side surround panel found in the surround kit. There are four

prongs protruding from the surround. Place the two slots in the bottom

and the two holes in the top of the control board over the four prongs

on the surround panel. Install the surround panels following the instruc-

tions on Page 10.

Venting

This fireplace insert is approved for venting with Type L and Type PL

pellet vent pipe (listed to UL 641 and ULC S609) or listed pellet flex liner

(2100HT [degree F.] liner listed to UL 1777 or ULC S635). We recom-

mend the use of venting products manufactured by Security Chimneys

International. The insert’s flue collar is 3” in diameter. The insert’s com-

bustion blower pressurizes and pushes flue gases out the pellet pipe. All

pipe joints should be locked together or screwed with three screws if the

pipe does not have a locking system. The pipe joints can be sealed with

high temperature silicone if there is a possibility of flue gases leaking

into the living area. The pipe should be fastened with three screws to the

insert’s flue collar. The longer the run of pipe and the more elbows used,

the greater the resistance to the flow of flue gases. Four inch diameter

pellet pipe is recommended for pipe runs greater than 15 feet or when a

number of elbows are used. A 3-4” increaser can be used to connect the

4” pipe to the 3” flue collar. The outside air pipe may run up the chimney,

horizontally, or down provided the structural integrity of the fireplace and

chimney system are maintained. DO NOT INSTALL A FLUE DAMPER IN

THE EXHAUST VENTING SYSTEM OF THIS UNIT. DO NOT CONNECT THIS

UNIT TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE.

Vent Termination Requirements:

If the insert is not vented vertically, the following apply:

1. Do not terminate the vent in any enclosed or semi-enclosed areas

such as a carport, garage, attic, crawlspace, narrow walkway, closely

fenced area, under a sundeck or porch, or any location that can build

up a concentration of fumes such as stairwells, covered breezeway,

etc.

2. Vent surfaces can become hot enough to cause burns if touched.

Non-combustible shielding or guards may be required.

3. Termination must exhaust above the inlet elevation. It is recommended

that at least five feet of vertical pipe be installed outside when the

insert is vented directly through a wall. This will create a natural draft

to prevent the possibility of smoke or odor during appliance shut

down or power failure and avoid exposing people or shrubs to high

temperatures.

4. The vent should terminate no less than four feet below, no less than

four feet horizontally from, and no less than one foot above doors

and windows, or gravity/ventilation air inlets into the building.

5. The distance between the bottom of termination and grade should be

12” minimum. The distance between the bottom of the termination

and a public walkway should be a minimum of seven feet.

6. Locate the vent termination at least two feet away from combustible

materials such as shrubs, plants, grass, fences, roof overhangs, and

adjacent buildings.

INSTALLATION

9

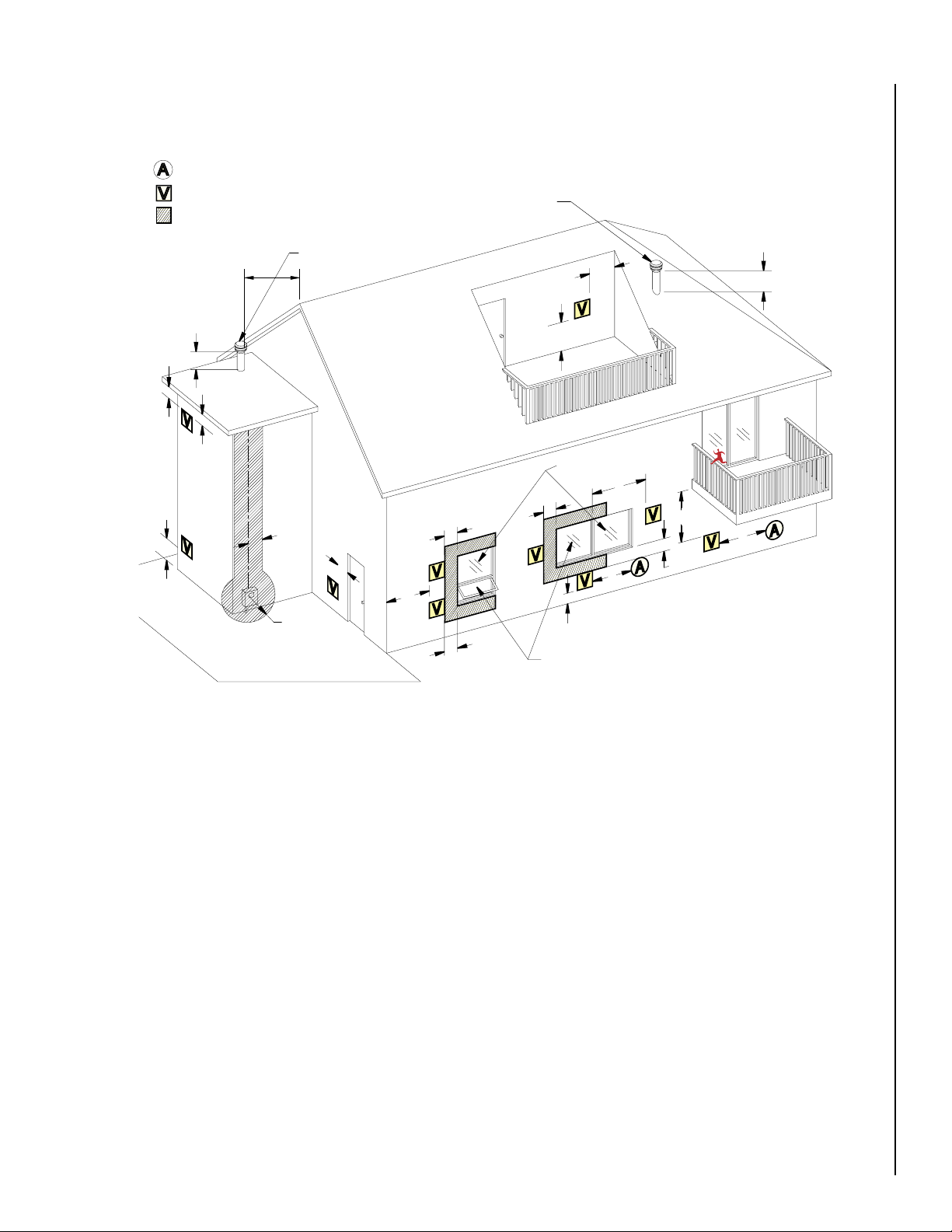

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

A = Clearance above grade, veranda, porch, deck, or balcony (min.

12”/30cm)

B = Clearance to window or door that may be opened (min. 12”/30cm

above - 48”/1.2m below and to the side)

C = Clearance to permanently closed window *(min. 12”/30cm)

D = Vertical clearance to ventilated soffit located above the terminal

within a horizontal distance of *(min. 24”/60cm) from the center-

line of the terminal (min. 22”/55cm) check with local code.

E = Clearance to unventilated soffit *(min. 12”/30cm)

F = Clearance to outside corner *(min. 12”/30cm)

G = Clearance to inside corner *(min. 12”/30cm)

H = Not to be installed above a meter/regulator assembly within *(min.

36”/90cm) horizontally from the centerline of the regulator.

J = Clearance to service regulator vent outlet *(min. 72”/1.8m)

K = Clearance to non-mechanical air supply inlet to building or the

combustion air inlet to any other appliance *(min. 48”/1.2m)

L = Clearance to a mechanical air supply inlet *(min. 120”/3.1m)

M = **Clearance above paved sidewalk or a paved driveway located on

public property *(min. 84”/2.1m)

N = ***Clearance under veranda, porch, deck, or balcony (min.

12”/30cm)

Note:

* Local codes or regulations may require different clearances.

** A vent shall not terminate directly above a sidewalk or paved

driveway which is located between two single family dwellings

and serves both dwellings.

*** Only permitted if veranda, porch, deck, or balcony is fully open on

a minimum of two sides beneath the floor.

Vent Terminal

Area Where Terminal Is Not Permitted

(From Eave)

Vertical Terminal

Vertical Terminal

Fixed Closed

Able To Open

A

A

B

B

B

B

C

D

E

F

G

H

J

K

L

M

N

24”

(610mm)

B

Air Supply Inlet

24”

(610mm)

Figure 9

Vent Termination Locations

10

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

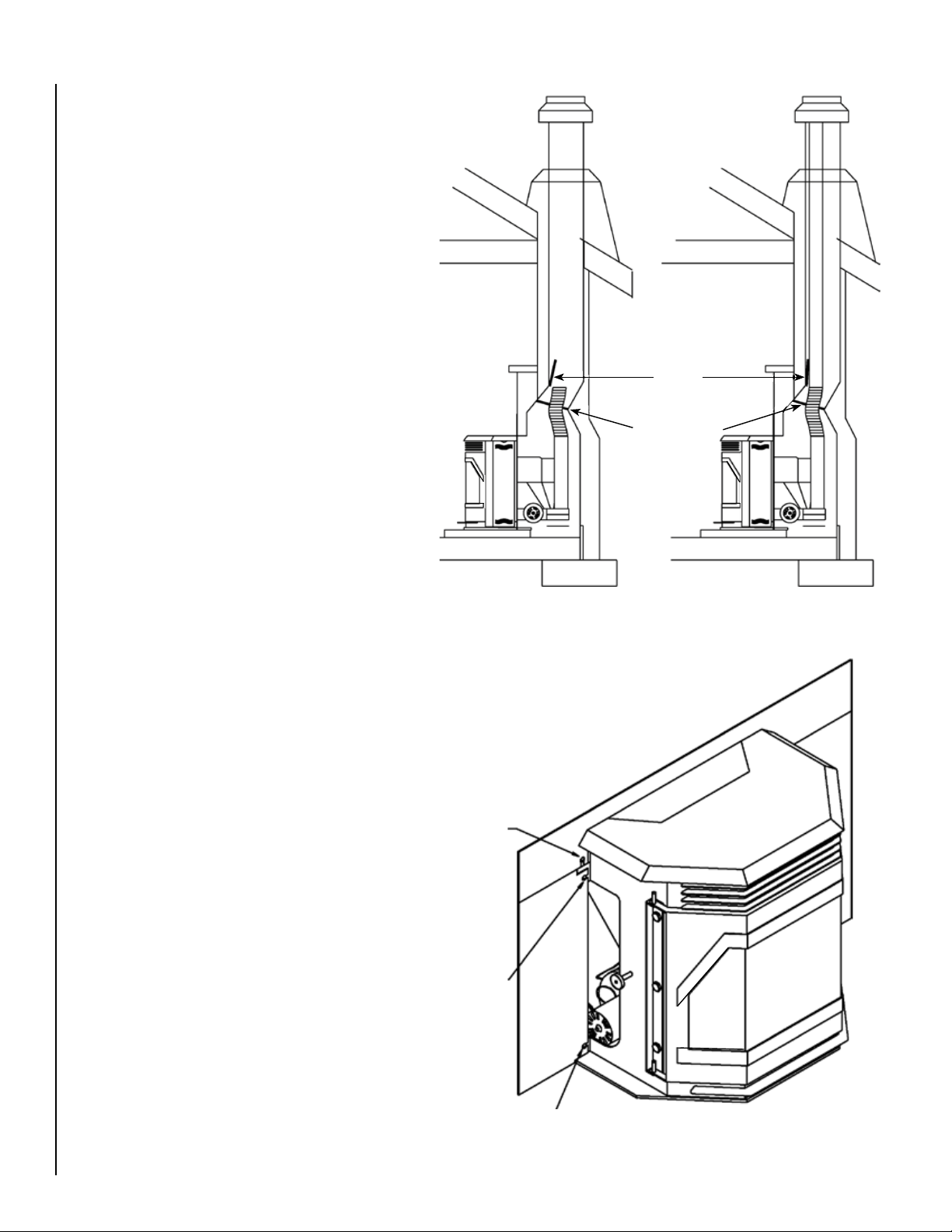

*The block off panel should be

air tight to ensure smoke does

not enter the house and to help

establish chimney draft when the

pipe does not terminate at the top

of the chimney.

Damper

Block Off Panel*

The recommended pipe installation is running the pellet pipe

from the insert all the way to the top of the chimney. However,

the pipe may terminate inside the chimney above the damper if

the chimney is sealed below the pellet pipe termination with a

block off panel (see Figure 10). The insert can also be vented

horizontally out the back of the fireplace, but a listed pellet pipe

thimble must be used if the pipe goes through a combustible wall

and the structural integrity of the fireplace and chimney system

must be maintained.

Insert Leveling

Inside the firebox is a bag of hardware with four 4”x 3/8” carriage

bolts. If the insert needs to be leveled, install one of these bolts

(from the bottom side) in the nuts at the left and right rear of the

base of the insert. Open the front door and remove the bolts screwed

into the nuts at the left and right front of the firebox floor.

From the bottom outside of the insert, install the remaining two

carriage bolts in the nuts from which the bolts were just removed.

A zero clearance front support is available to fill the space between

the insert and hearth.

Surround (Flange) Installation

To install the surround panels:

1. Remove the side doors (see Page 23

) to access the surround

mounting brackets. Remove the speed nuts from the parts bag

found in the firebox. Install the six speed nuts (with the flat

surface forward) on the six surround mounting bracket holes,

three on each side of the insert. A flat-bladed screwdriver may

help in installing the nuts. See the expanded view in Figure

11A.

2. Screw the six 1/4” truss head screws partially into the speed

nuts (see A in Figure 11A).

3. The side surround panel with the small access door for the

control board goes on the right side of the insert (see Figures

11B and 11C

). Slide the slots in the side surround panels and

top surround panels behind the heads of the truss screws.

Tighten all six truss screws after shifting surround panels to

eliminate space between the side and top surround panels.

4. Install two spring clips approximately five inches from each

end of each of the three trim pieces. The spring clips should be

installed in the channel of the trim with the curved portion of

the clip to the front toward the rounded surface of the trim.

5. Place the longest trim piece with the rounded surface out along

the edge of the top surround panel with the spring clips slightly

behind the surround panel. Pull the trim forward, compressing

the spring clips, and slide the trim down onto the surround.

6. Insert the elbowed retainer in the mitred end of the side trim

pieces and fasten with flat screwdriver. Insert the other end

of the retainer in the end of the already installed top surround

trim and slide side trim onto the edge of the side surround

compressing the spring clips in the process. Repeat the same

steps for the other side trim. Fasten the elbowed retainer

securely in the top surround making a nice mitred corner.

Speed Nut

Expanded View

A

A

A

Figure 10

Figure 11A

11

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Cap

Flashing

Outside Air Pipe

Listed Pellet Pipe or

Flex Liner

Storm Collar

Figure 12

CONTROL BOARD

36" FIREPLACE OPENING

18"

13-1/2"

FIREPLACE OPENING C/L

19-1/4"

18-3/8"

HEARTH / FLOOR PROTECTION

31-3/4"

11"

7-7/16"

6-11/16"

138°

41" SURROUND WIDTH

2-15/16"

Figure 11B

Mobile Home Installations

The following steps are required for installation of the Winslow™

PI40 insert in mobile homes. See Figure 12.

1. Connecting the Winslow PI40 insert to outside combustion

air is optional, except in mobile home installations and when

required by local building codes. The insert’s air intake will

accept 2” ID pipe to accommodate outside air installations.

The air intake on the exterior of the home should always

be located substantially below the flue termination and

terminate with a cover to keep out weather and pests.

2. The insert must be fastened to the hearth/floor using lag

screws. The screws can be inserted through the holes in

the base located behind the side doors. If the hearth is

concrete or masonry, use proper lag bolts and methods

designed for anchoring to masonry or concrete.

3. The insert must be grounded with a #8 or larger copper

wire.

WARNING: DO NOT INSTALL THIS INSERT IN A SLEEP-

ING ROOM IN A MANUFACTURED HOME.

CAUTION: THE STRUCTURAL INTEGRITY OF THE

MANUFACTURED HOME FLOOR, WALL, AND CEIL-

ING/ROOF MUST BE MAINTAINED.

CONTROL

BOARD

18"

13-1/2"

FIREPLACE OPENING C/L

21-1/2"

18-3/8"

HEARTH/FLOOR PROTECTION

31-3/4"

11"

7-7/16"

6-11/16"

138°

3"

41" SURROUND WIDTH

32" FIREPLACE OPENING

DEEP

SURROUND

Figure 11C

Fireplace Installation Using Standard Surround Kits

(P/N 79004, 79005, 79006 and 79007)

Fireplace Installation Using 3 Inch Deep ZC Surround Kit

(P/N 79032 *)

* This black surround kit positions the insert 3” forward so that it will allow the insert to fit

into a fireplace with a narrower width in the front (32” min.). Note: No trim kits are avail-

able for this kit at this time. See instruction sheet P/N 506033-05 for more information.

Termination Cap

Loading...

Loading...