Page 1

Page 2

Contents

Electrical Alignment Instructions

Page

- Technical data ................................................................................ 3

- Playback ......................................................................................... 4

1. Azimuth Adjustment

2. Tape Speed Adjustment

3. Output Level Adjustment

4. DNL Adjustment

- Recording ...................................................................................... 4

1. OSC Frequency Adjustment

2. Bias Trap Adjustment

3. Bias Current Adjustment

4. Dolby Nr. Bias Trap Adjustment

5. Input Sensitivity Adjustment

6. Level Meter Adjustment

7. Record Current Adjustment

8. Peak Indicator Level Adjustment

9. ALC Balance Adjustment

- Electrical Adjustment Procedure .......................................... 5+6

1. DC F.G. Servo Motor

2. RIP Head (Azimuth)

3. Dolby P.C.B.

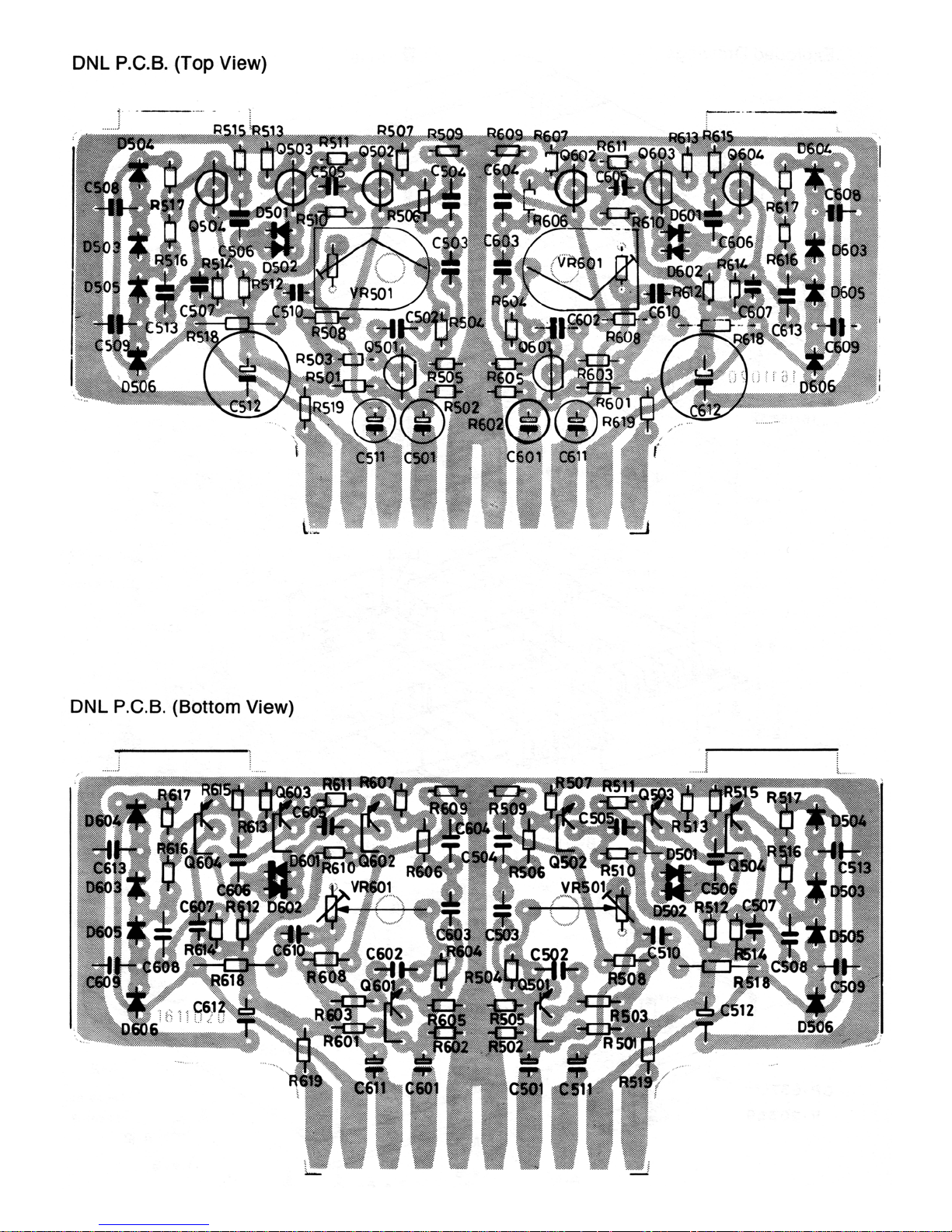

4. DNL P.C.B.

5. Power P.C.B.

6. Pre Amp. P.C.B.

Mechanical Alignment Instructions

Page

- Tape Speed................................. 7

- Wow and Flutter ............................................................................... 7

- Mechanical Adjustment ........................................................ 8 + 9

1. Pinch Roller Pressure Measurement

2. Azimuth, Head Location Adjustment

3. Tape Speed Adjustment Location

Mechanical Parts List ........................................... 10-14

- Take-up Torque ............................................................................... 7

- Fast Forward and Rewind Torque ................................................... 7

- Pinch Roller Pressure ...................................................................... 7

- Tape Speed / Wow and Flutter ........................................................ 7

- Azimuth Head, Alignment ................................................................ 7

Electrical Parts List

............................................ 15-21

Drawings

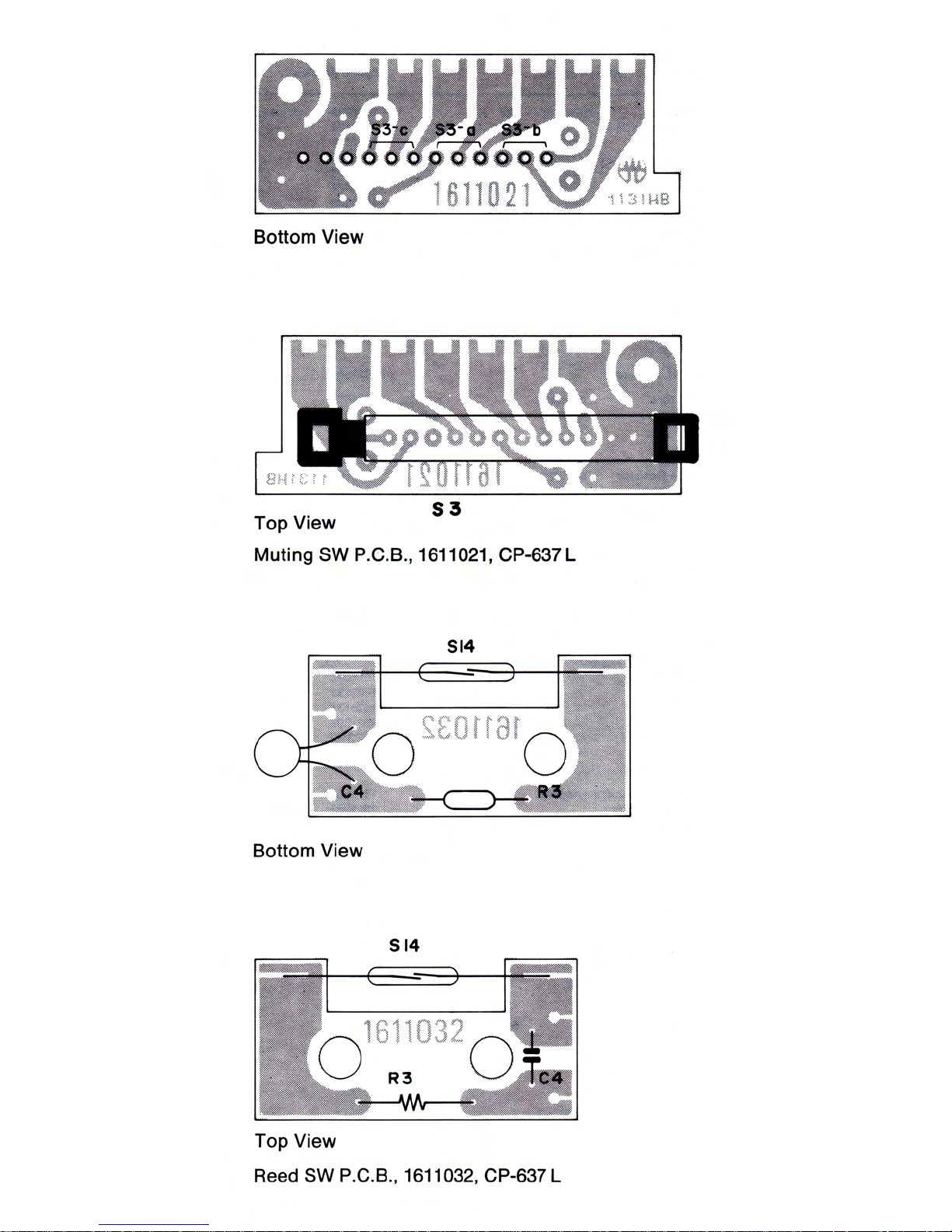

- Muting SW P.C.B. .................... ..................................................... 22

- Reed SW P.C.B. ...................... ..................................................... 22

- Mic Jack P.C.B. ........................ ..................................................... 23

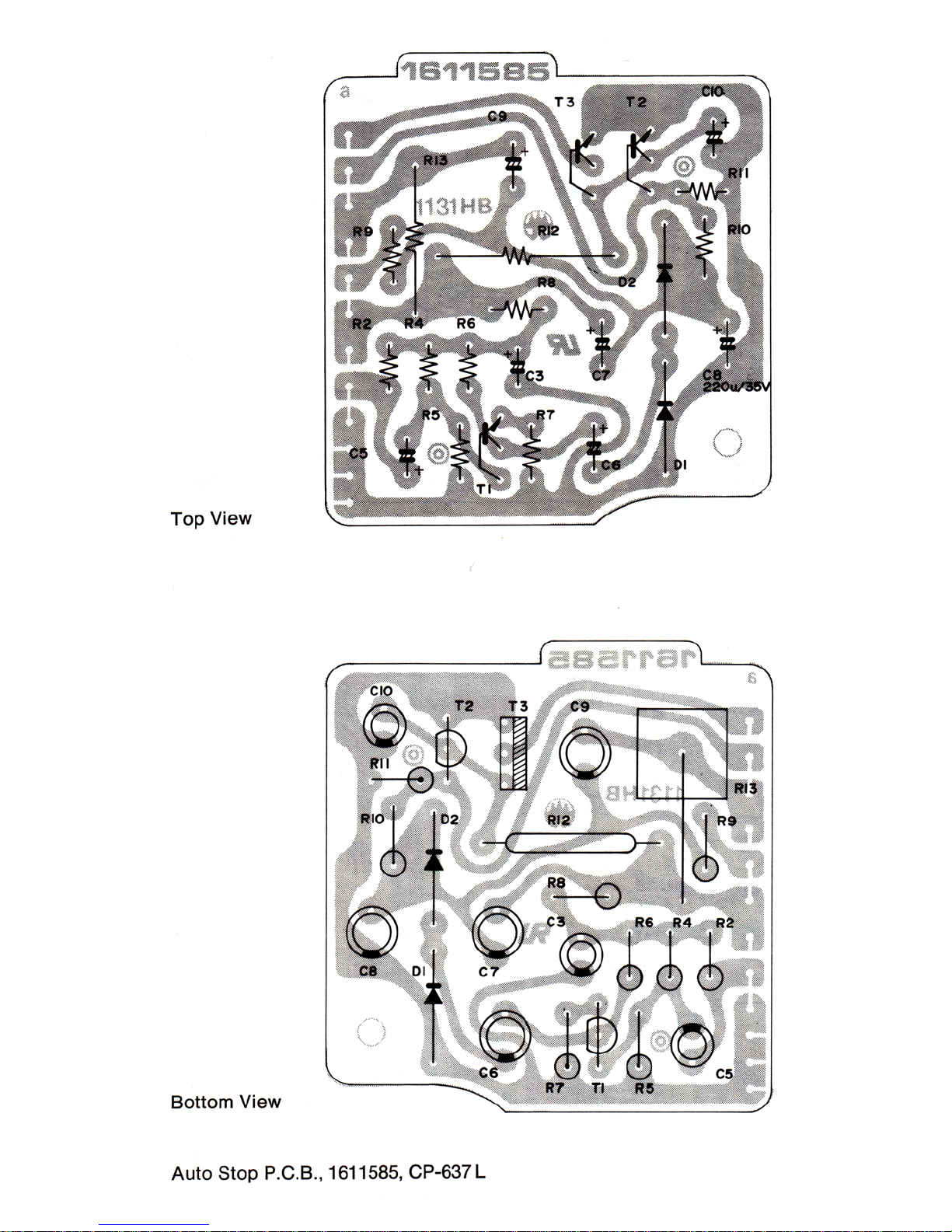

- Auto Stop P.C.B. ...................... ..................................................... 24

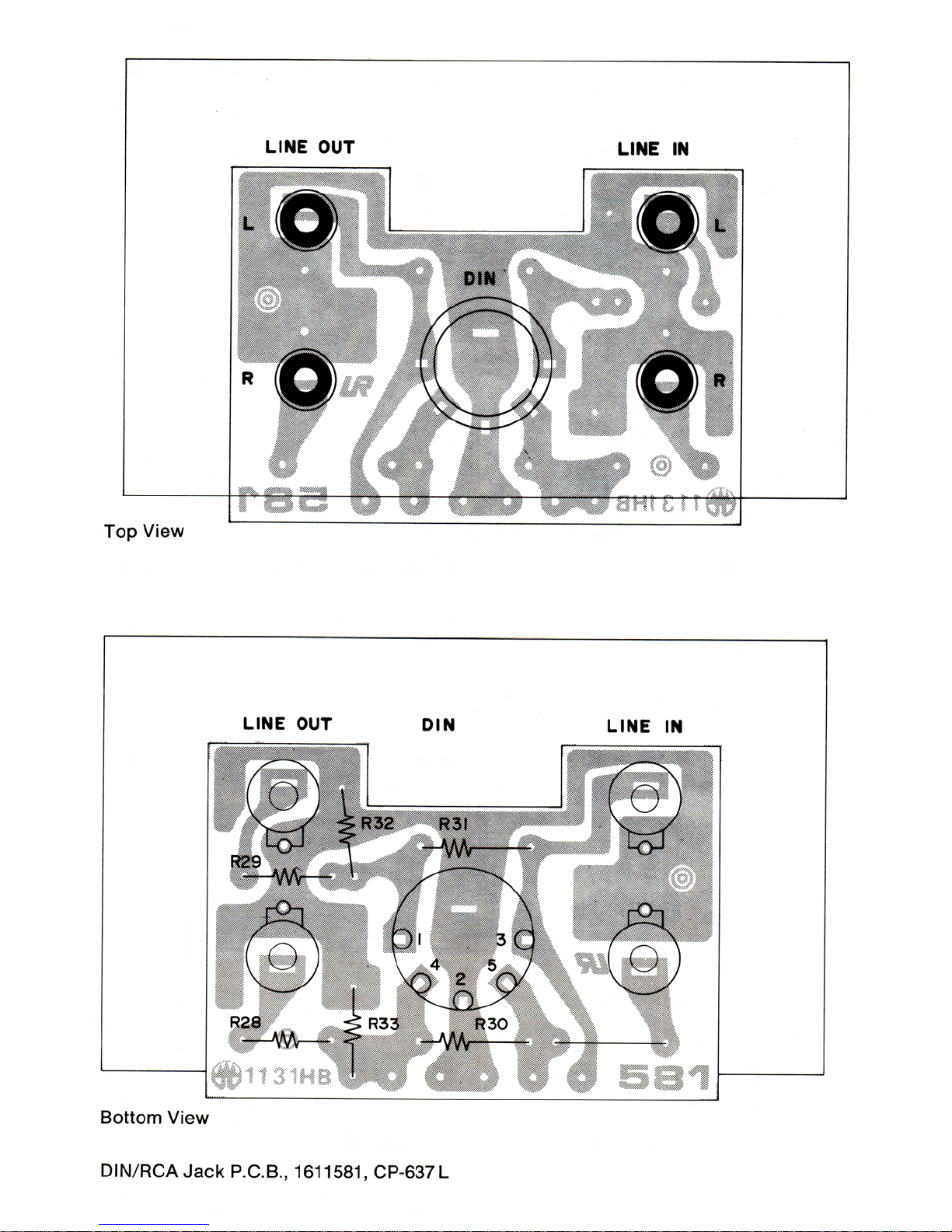

- DIN/RCA Jack P.C.B. ............... ..................................................... 25

- Power Supply P.C.B. (Bottom View) .............................. 26

- Power Supply P.C.B. (Top View) ................................... 27

- LED P.C.B. ............................... ..................................................... 28

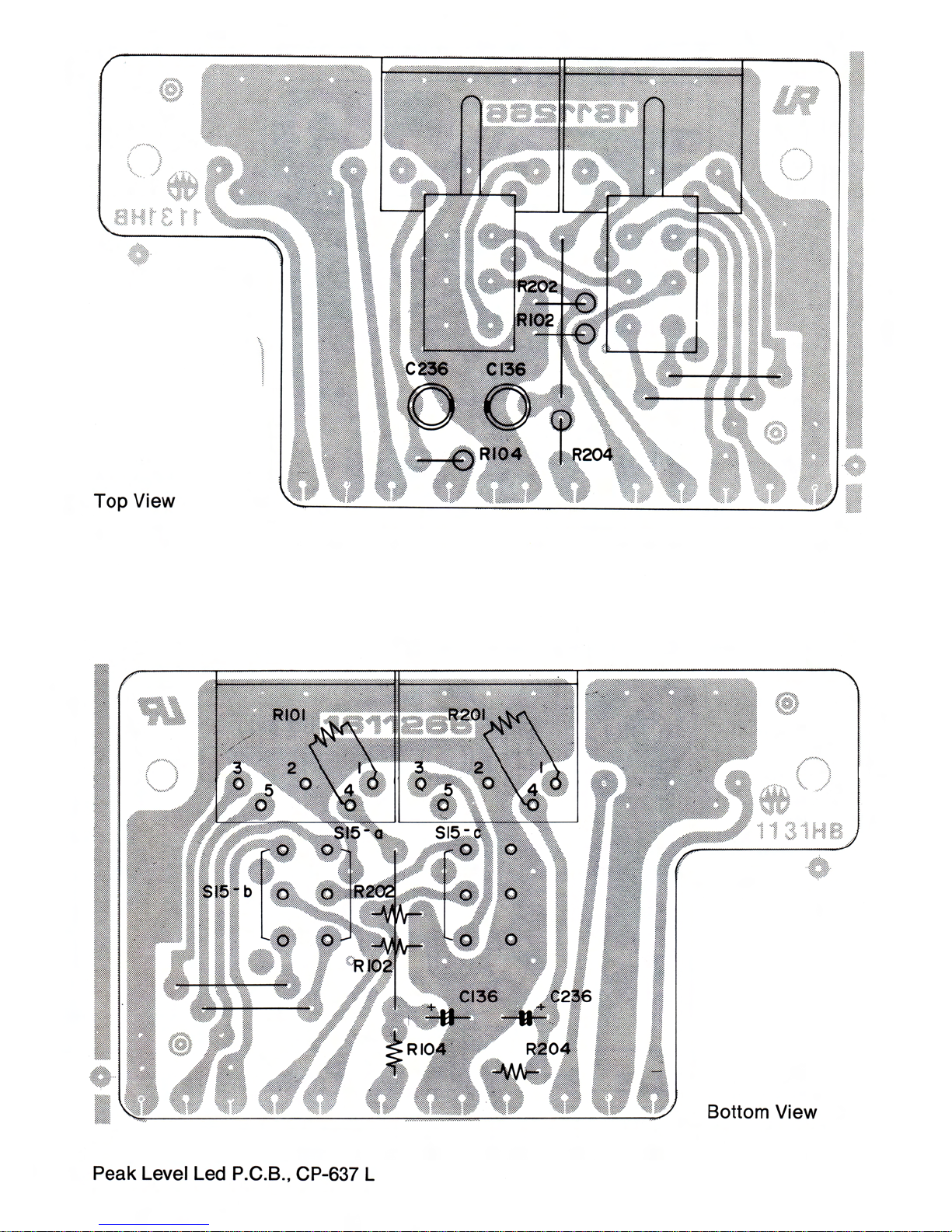

- Peak Level LED P.C.B. ............ ..................................................... 28

- PRE P.C.B. (Bottom View) .............................. 29

- PRE P.C.B. (Top View) ................................... 30

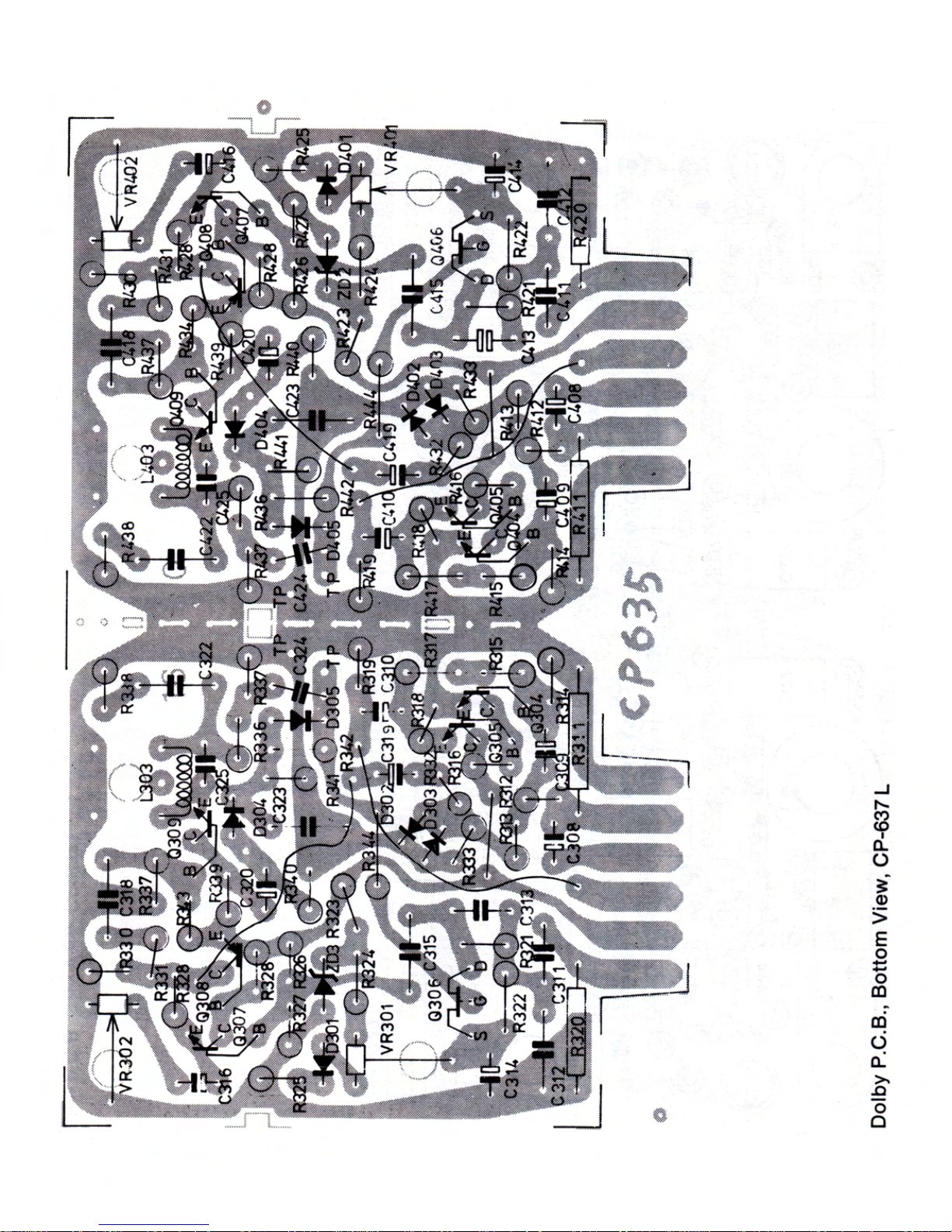

- Dolby P.C.B. (Bottom View) ............................. 31

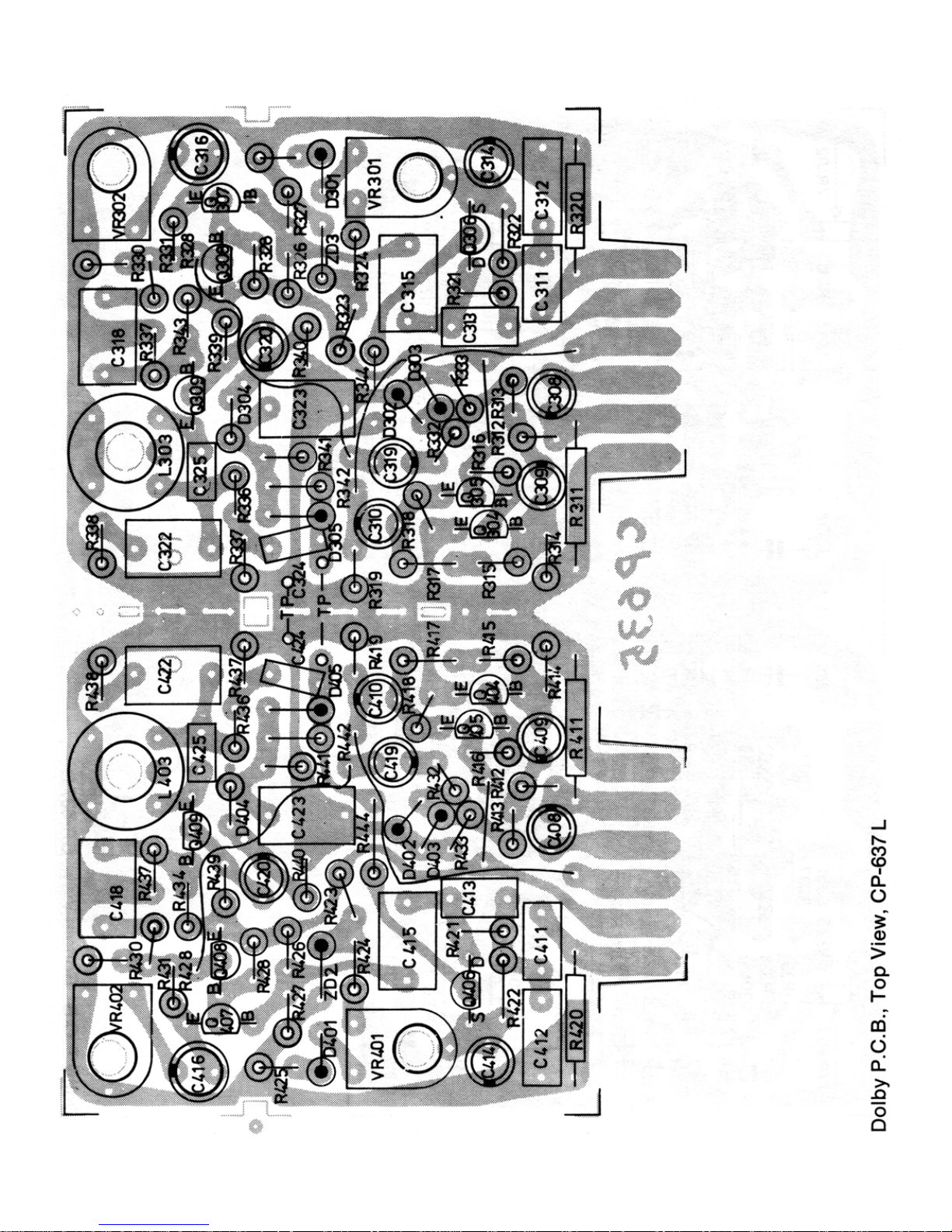

- Dolby P.C.B. (Top View) ................................... 32

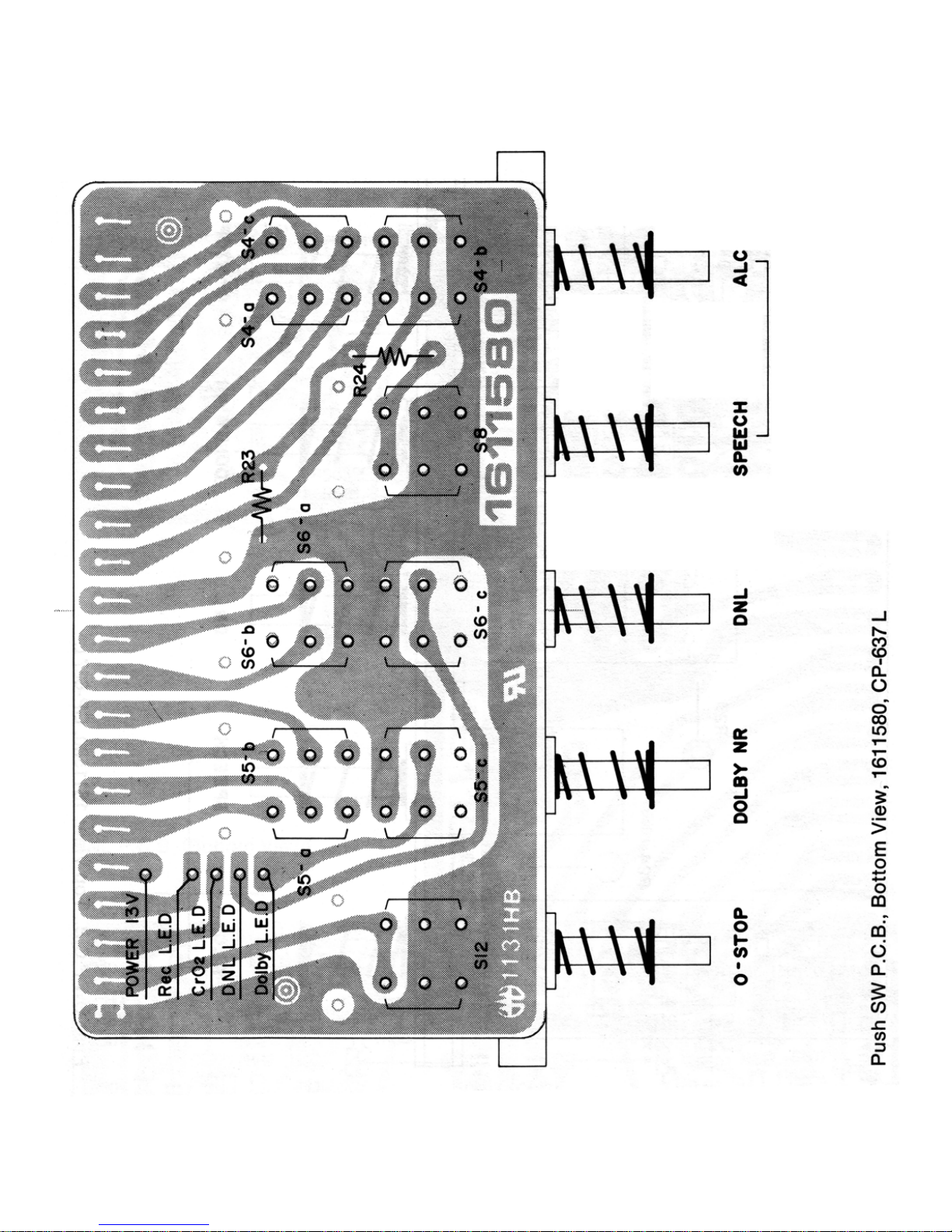

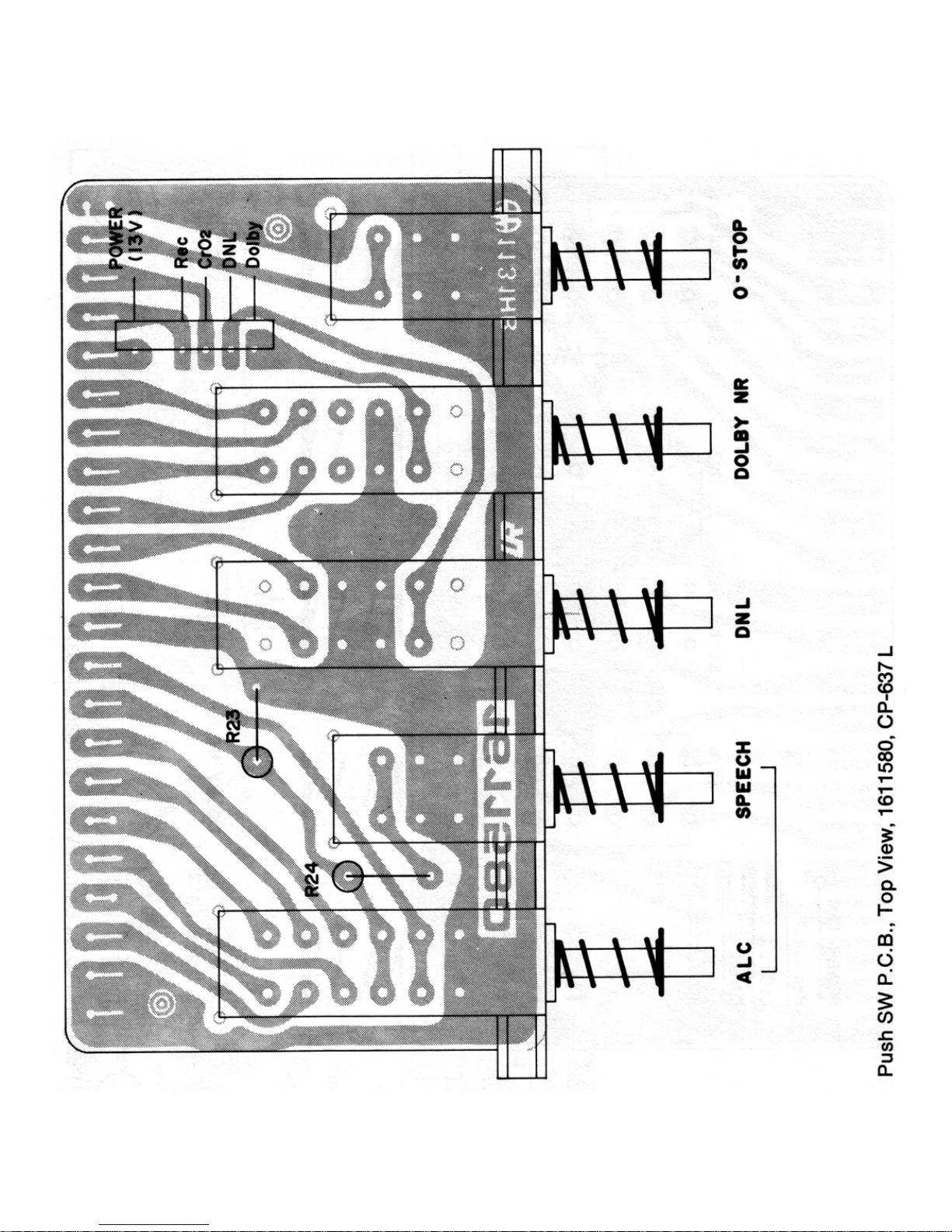

- Push SW P.C.B. (Bottom View) .............................. 33

- Push SW P.C.B. (Top View) ................................... 34

- DNL P.C.B. ............................... ..................................................... 35

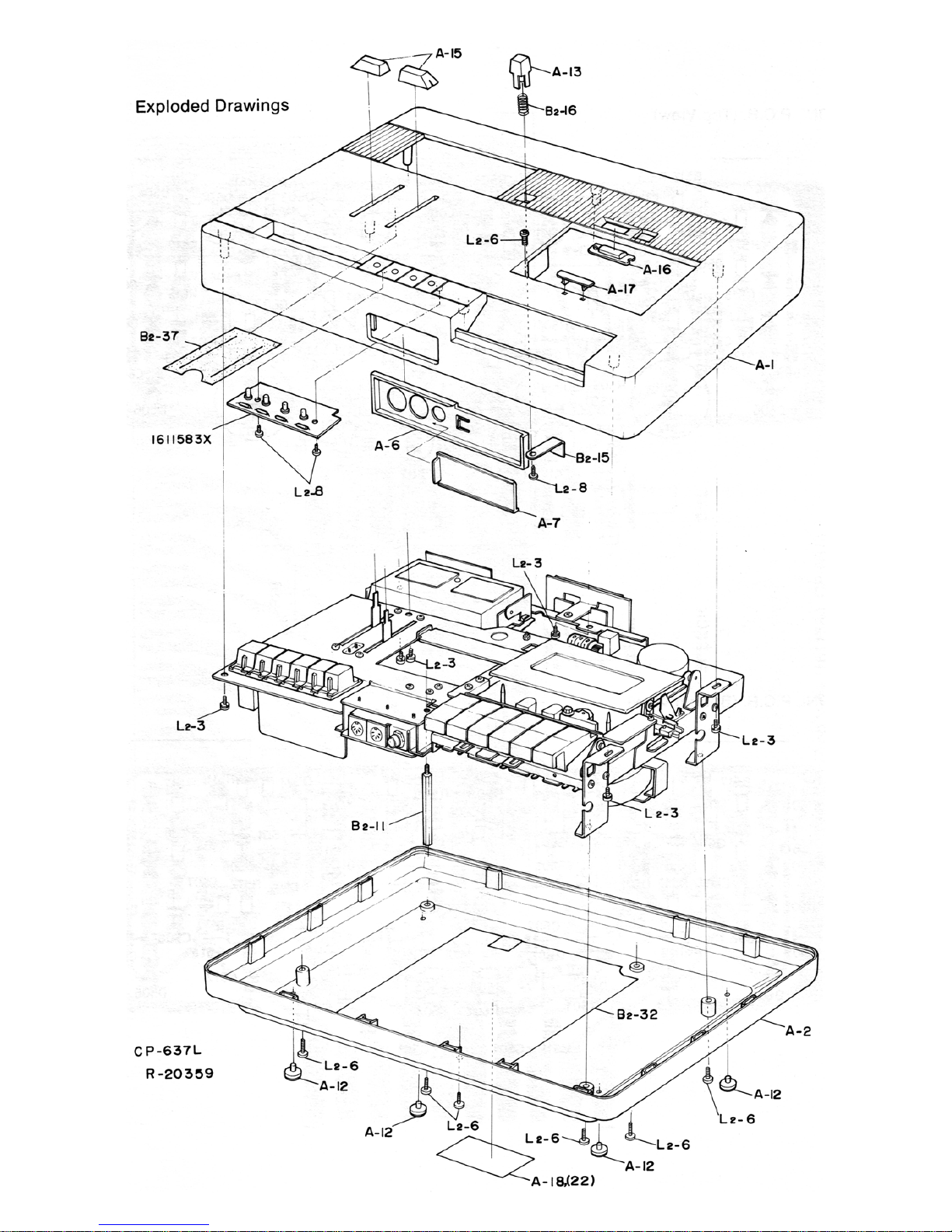

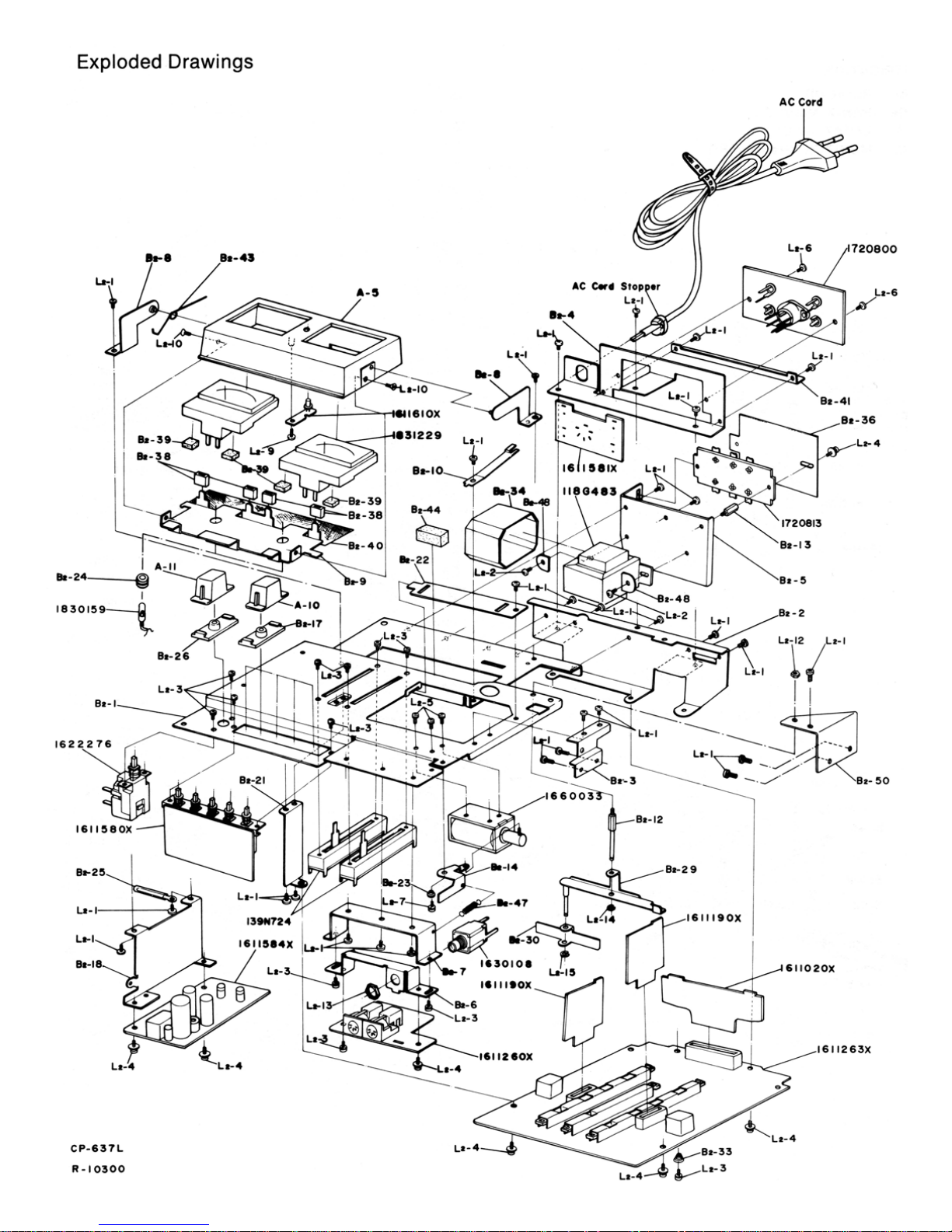

- Exploded drawings ................... ............................................... 36+37

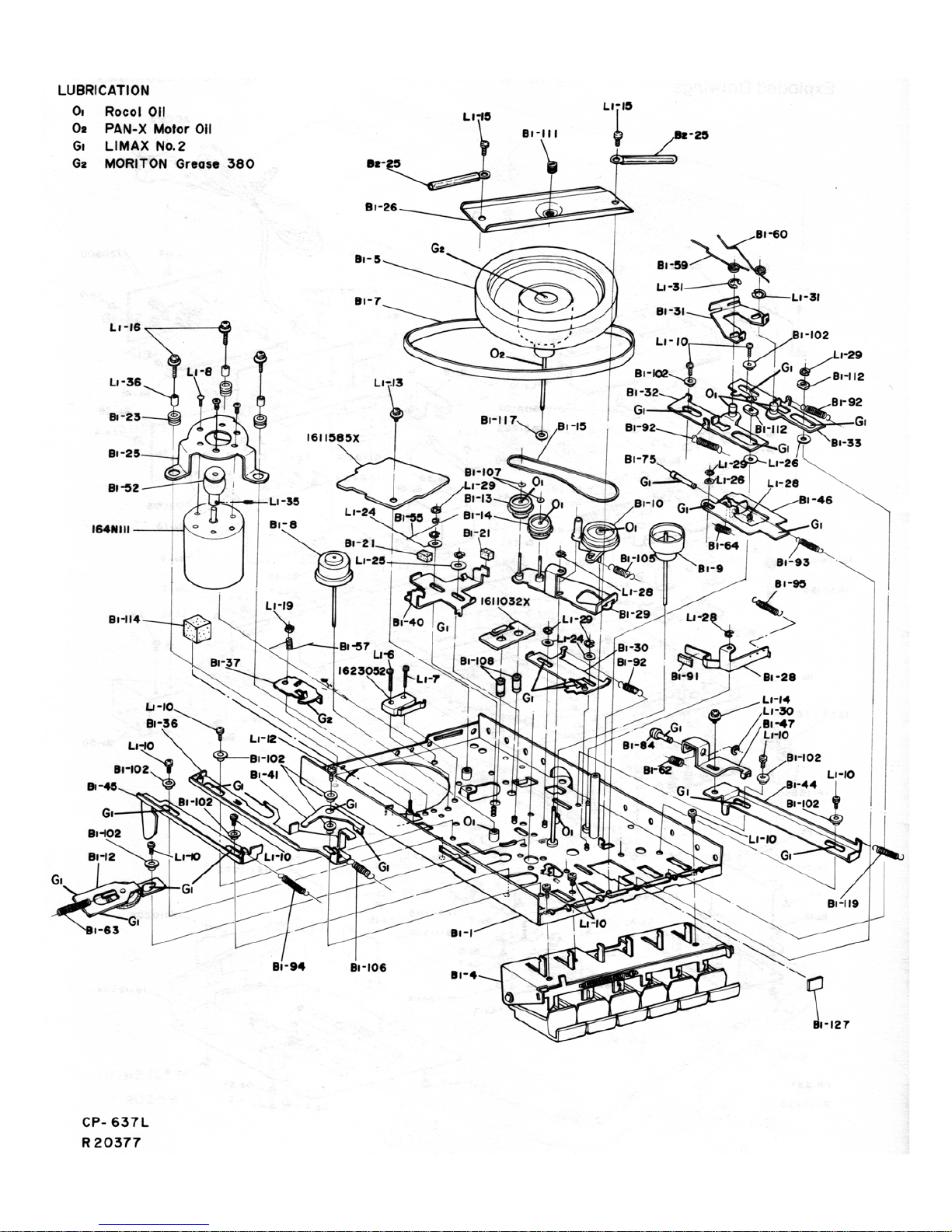

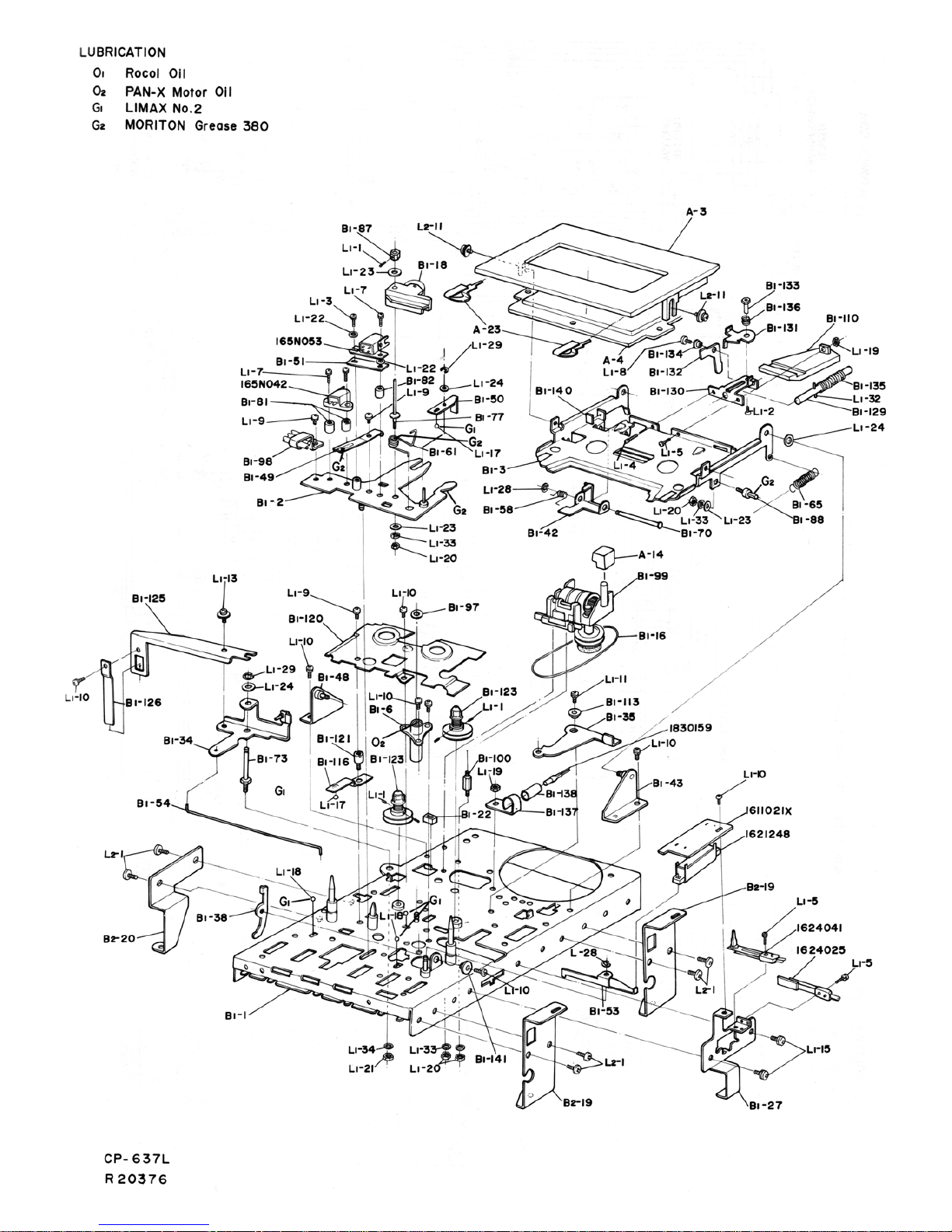

- Exploded and Lubrication drawings ......................................... 38+39

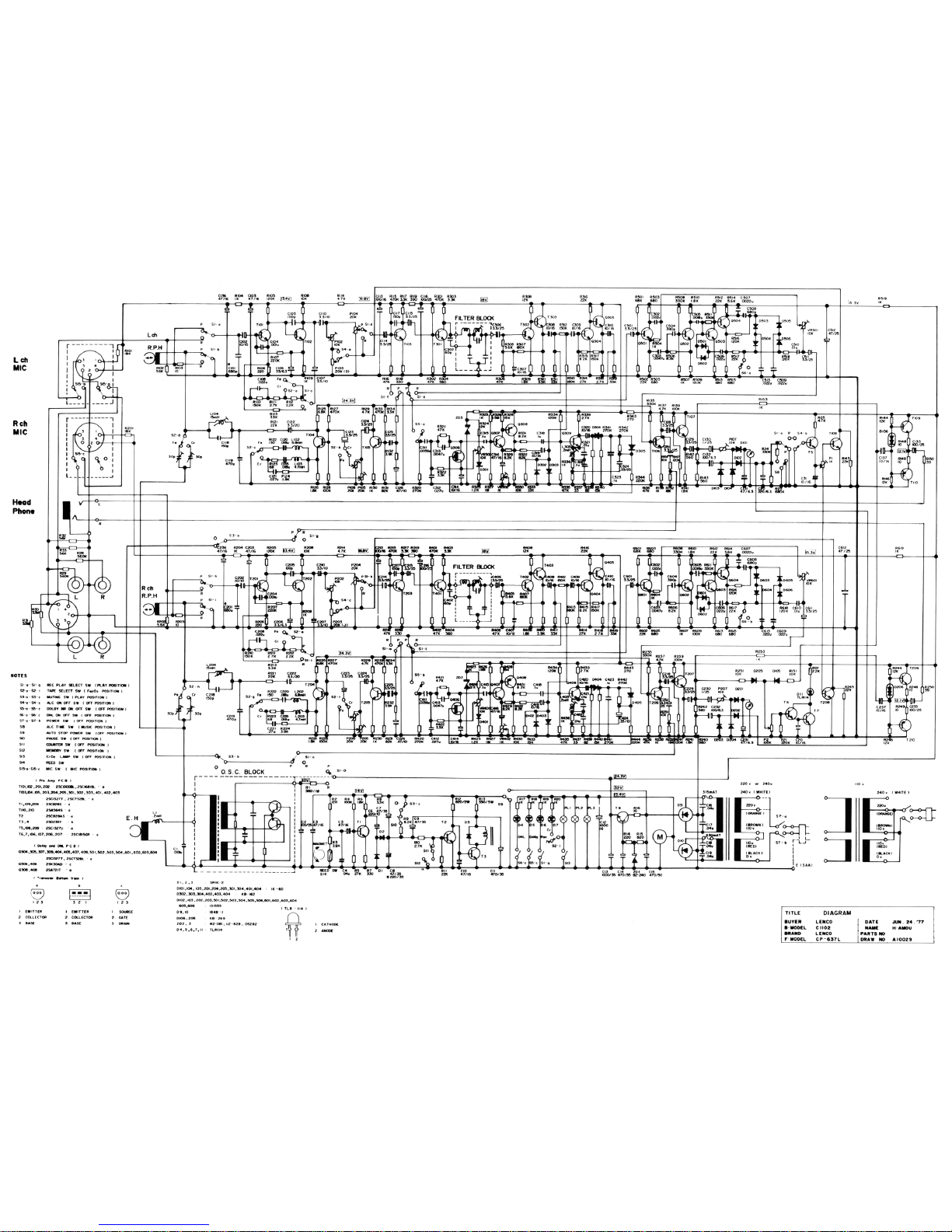

Wiring Diagram.......................... 40

Electrical Circuit Diagram ................................ ......... 40

Page 3

Technical data

Mains voltage:

220 V, can be resoldered for 110 V (Europe)

240 V (UK)

117 V (USA, ANP, Canada)

Mains frequency:

50 - 60 Hz

Power requirement:

0 W

Motors:

1 DC-motor with servo control

Cassettes:

Compact cassette:

Chrome dioxide BASF CrO

2

C 60 C 401 R

Standard TEAC MTT-502

Tape speed:

4.76 cm/s

Fast forward and rewind:

<75 s with C 60 cassette

Erase and bias frequency:

105 kHz

Level meter:

2 VU-meter

1 Peak Level Indicator

Dolby Level at

± 3 dB

Inputs: (for Dolby level)

1. Microphone input with DIN plug for low-impedance

microphones

Sensitivity: 330 µV imped. about 5.6 kOhms

Max. input voltage: 33 mV

Electret microphones: + 5 V max. 0.5 mA

2. Input DIN plug connections 1 + 4

Sensitivity: 0.33 mV impedance: 5.6 kOhms

(0.06 mVikOhm)

Max. input voltage: 33 mV

3. Line input PHONO plug

Sensitivity: 33 mV impedance: 560 kOhms

Max. input voltage: 3.3 V

4. Phono Input (DIN) DIN Plug connection 3+5

Sensitivity: 200 mV impedance: 3.3 mOhms

Outputs: (for Dolby level)

1. DIN plug, pin 3+5: 1000 mV impedance: 15 kOhms

2. LINE output (PHONO): 1000 mV impedance: 15 kOhms

3. Headphone output: 200 mV impedance: 8 kOhms

Harmonic distortion (333 Hz): (for 0 dB VU)

Standard cassette:

< 2.0 %

Ferri chrome cassette: < 2.0 %

Frequency response with: 20 dB VU

Standard cassette: 30-15000 Hz ± 3 dB

Ferri chrome cassette: 30-16000 Hz ± 3 dB

Wow + Flutter:

to WRMS < 0.06 % to DIN 45507 weighted

< ± 0.14 %

Drift: < ± 1.5 %

Signal/noise ratio: (DIN 45500)

(Reference 3 % third harmonic distortion)

Standard cassette: 53 dB 58 dB

Ferri chrome cassette: 54 dB 60 dB

without Dolby with Dolby

Cross talk: (1000 Hz)

with two track recording in opposite directions: > 60 dB with

stereo recording:

> 35 dB

Erase attenuation: (1000 Hz, full modulation Cr02 tape) >

62dB

Weight:

5.5 kg

Dimensions:

268 x 424 x 107 mm

Page 4

Alignment Instructions

Playback

1. Azimuth Adjustment

Connect a scope or VTVM to the right channel PRE-AMP OUTPUT

jack. Insert a test tape (TEAC MTT-114, 115) into the unit. Adjust the

Azimuth adjusting screw for maximum output into the right channel.

(See figure 1 R/P HEAD.)

2. Tape Speed Adjustment

Connect scope, VTVM and FREQUENCY COUNTER to the right

channel PRE-AMP OUTPUT jack. Insert a Test Tape (MTT-111 3

kHz) into the unit. Adjust the tape speed adjusting screw for a 3 kHz

value in the frequency counter. (See fig. 1 DC F.G. Servo Motor.)

3. Output Level Adjustment

Connect scope and VTVM to the TP-2 and Ground (L-ch and R-ch).

Insert a test tape MTT-150 (Dolby level calibration tape 200 nwb/m)

into the unit. Adjust the P 104 (left) and P 204 (right) for a 580 mV

reading.

4. DNL adjustment

Connect a scope to the PRE-AMP OUTPUT jack. Set the unit for a

PLAY function, then depress the PAUSE button, DNL switch, ON.

Adjust the VR 501 (L-ch), VR 601 (R-ch) so that the level of high

frequency noise is at a minimum on the scope. (See fig. 1, DNL

P.C.B.)

Recording

1. OSC Frequency Adjustment

Connect the scope and frequency counter to the terminals of the

erase head. Set the unit for recording. Adjust L 1 so that there is an

OSC frequency value of 105 kHz on the frequency counter. (See fig.

1 Power P.C.B.)

2. Bias Trap Adjustment

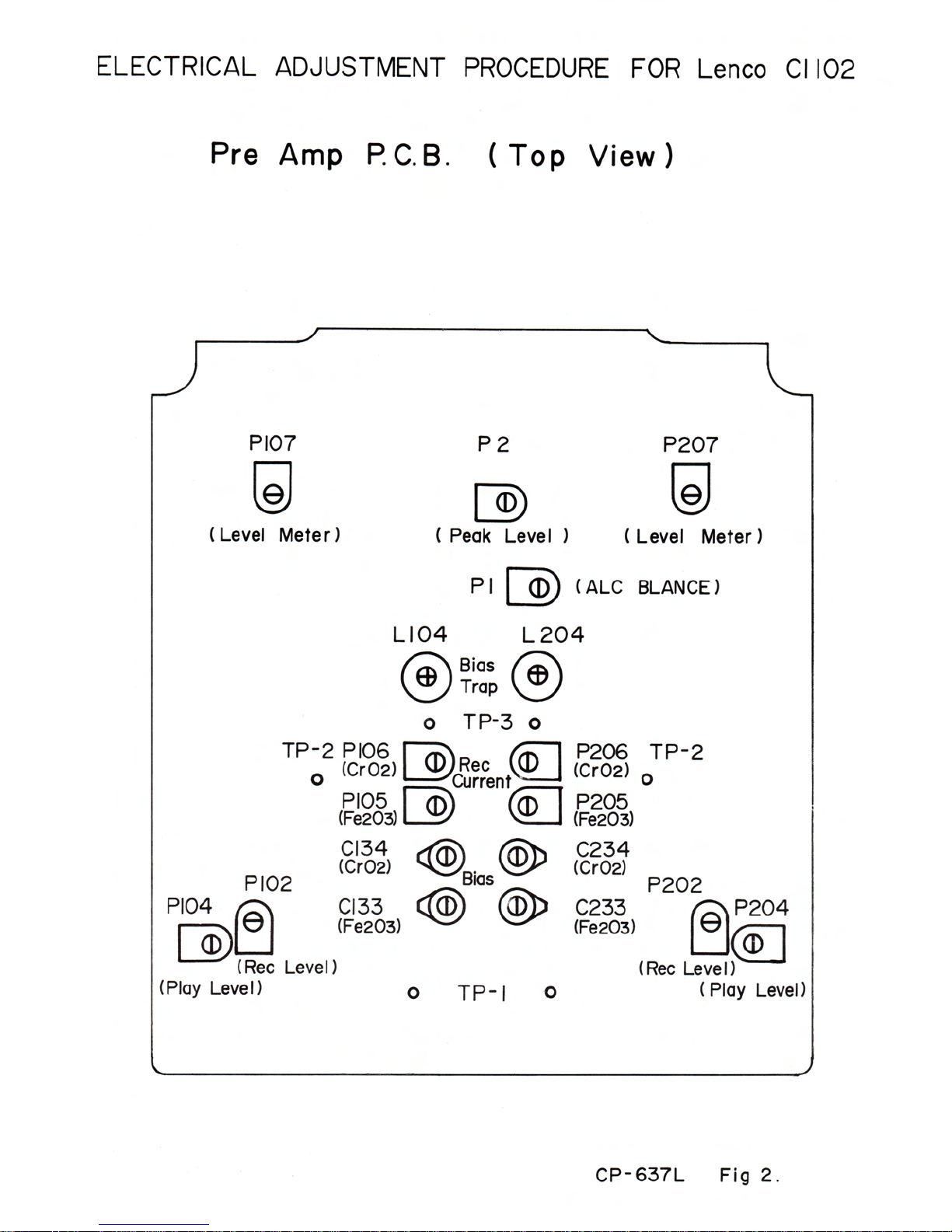

Connect the scope and VTVM to the TP-3 and Ground. (See fig. 2.)

Set the unit for recording. Adjust the L 104 (L-ch) and L 204 (R-ch) so

that the level on the VTVT is at a minimum. (See fig. 2.)

3. Bias Current Adjustment AF

Generator

333 Hz

1 kHz

0 dB - 1 V

Attenuator 95 dB Unit

Mic. Input L

R

V.T.V.M.

Scope

Connection should be made as above. Set the unit for recording. For

Fe 203, adjust C 133 (L-ch), C 233 (R-ch) to flat level at between 333

Hz and 10 kHz. For Cr02, adjust C 134 (L-ch), C 234 (R-ch) to flat

level at between 333 Hz and 12,5 kHz. (See figure 2.)

4. Dolby NR Bias Trap Adjustment

Connect the VTVM and scope to the test point pin on the Dolby

P.C.B. (See figure 1).

Set the unit for recording. Dolby NR switch "ON" position. Adjust L

303 (L-ch), L 403 (R-ch) for the minimum indication on the VTVM.

5. Input Sensitivity Adjustment AF

Generator

333 Hz

0 dB - 1 V

Attenuator

-70 dB Unit

DIN Input

L

R

TP-2

V.T.V.M.

Scope

Connection should be made as above. Set the unit for recording.

Record level controls (P 103, P 203) set at maximum. Adjust P 102

(L-ch), P 202 (R-ch) for 580 mV reading at TP 2 (L-ch, R-ch). (See

figure 2.)

6. Level Meter Adjustment

Connection should be made as for ADJUSTMENT 5. When

ADJUSTMENT 5 has been completed (580 mV rading at TP a),

adjust P 107 (L-ch), P 207 (R-ch) for +3 VU reading on level meters

(L-ch, R-ch). (See figure 2.)

7. Record Current Adjustment

Connection should be made as in ADJUSTMENT 5. Feed -70 dB

(333 Hz) into the DIN input. Set the record level controls (103/203) to

maximum.

Make a recording (use blank tape) then playback what has been

recorded and adjust P 105 (L-ch), P 205 (R-ch) for Fe 203 Tape, P

106 (L-ch), P 206 (R-ch) for Cr02 Tape so that the output at TP 2 has

a value of 580 mV. (See figure 2.)

8. Peak Indicator Level Adjustment

Set the unit for recording. Feed -68.5 dB (1 kHz) into the DIN input

Left and Right channels.

Adjust P 2 until the peak level indicator lights up. (See fig. 2).

AF Generator

1 kHz

0 dB = 1 V

Attenuator

-68.5 dB (1 kHz)

DIN Input

L

R

Unit

9. ALC Balance Adjustment

Disconnect R 1 (or cut the foil pattern) so that the Bias OSC is

stopped. Set the ALC switch to the "ON" position and keep the unit

set at recording. Feed -50 dB (1 kHz) signal into the DIN input Left

and Right channels. Adjust P 1 so that the value of the level meter on

Left and Right channel will be the same. (See figure 2 ALC

BALANCE).

AF Generator

1 kHz

0 dB = 1 V

Attenuator -50 dB

(1 kHz) Unit

DIN Input

L

R

Page 5

Page 6

Page 7

Mechanical Checks and Adjustments

Model C 1102

Note:

All the mechanical checks and alignments should be

done with the upper and bottom cabinet assembly (A-1 and A-

2) removed.

Take-up Torque

(Spec. 30-60 g/cm)

1.

Load the torque meter cassette.

2.

Set the unit in the play mode and read the value on the dial

scale. The meter should indicate a torque of 30 to 60 g/cm.

3.

If the torque range is out of the specified limit, clean the

driving surface of the take-up reel base shaft assembly (B

1-8) and tape-up pulley assembly (B 1-12) with pure

alcohol.

4.

If the above cleaning proves ineffective for a correct tor

que alignment, replace the take-up reel base shaft as

sembly.

5.

First, remove the reel table assembly (B 1-12), then pull

out the take-up reel base shaft assembly. After putting a

drop of oil on the reel shaft (B 1-17), insert the new part

and then fit the reel assembly onto it's shaft. Finally tighten

two set screws (L 1-1).

Fast-Forward and Rewind Torque

(Spec. 65-120 g/cm)

1. Load the torque meter cassette.

2. Set the unit at F.F. or REWIND mode and read the value on

the dial scale. The meter should indicate a torque of 65 to

120 g/cm.

3. If the value is outside the specified range, clean the driving

surface of the fast forward pulley A assembly (B 1-14), fast

forward pulley B (B 1-13) and C (B 1-14).

4. If the above cleaning operation is ineffective for a torque

alignment replace the fast forward pulley A assembly.

5. To replace, first remove the fast forward and rewind arm A

assembly (B 1-29).

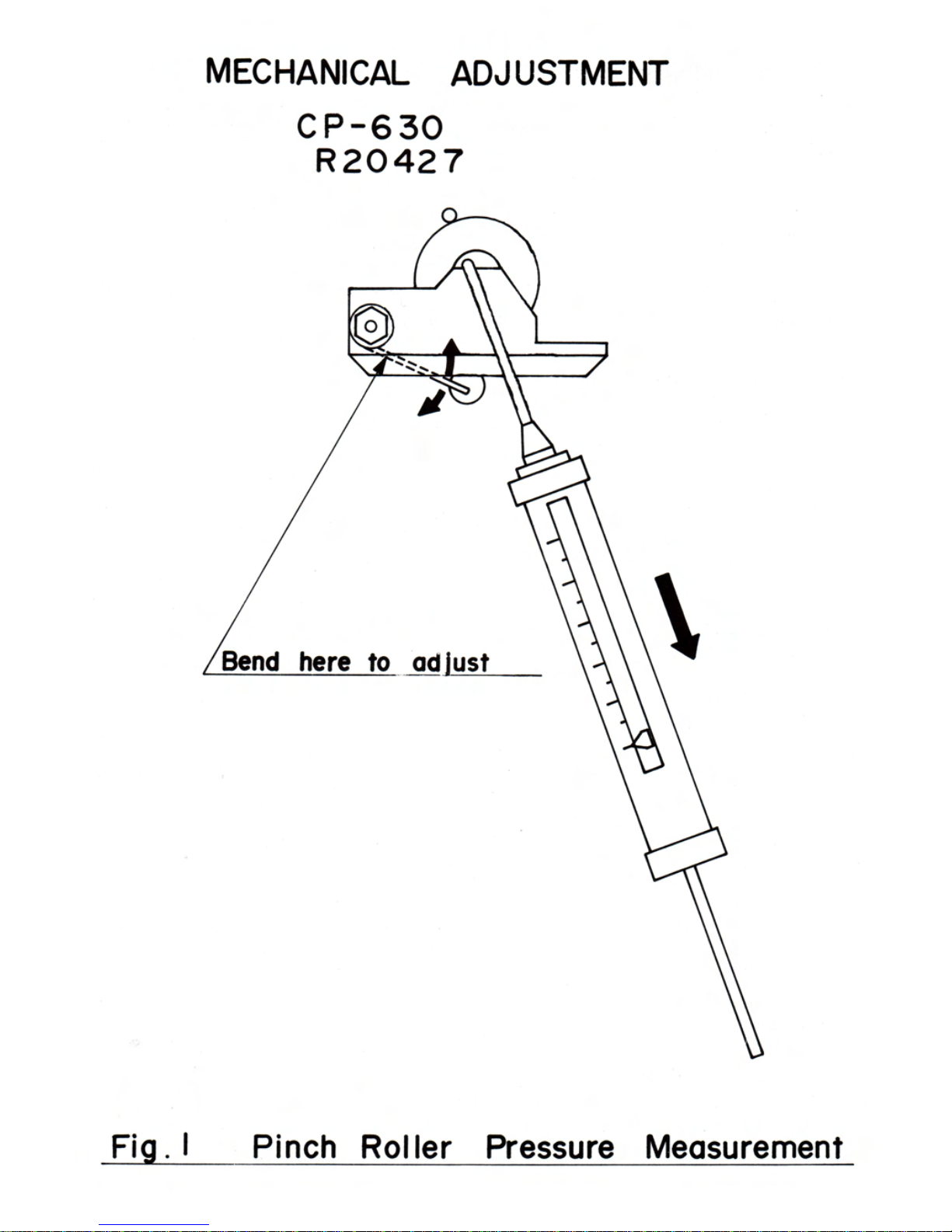

Pinch Roller Pressure

1. Place the unit in the play mode (but without a loaded tape).

2. Attach the spring scale to the edge of the pinch roller as

sembly (B 1-18) as shown (fig. 1).

3. Gently draw the pinch roller assembly away from the capstan

shaft (in a direction parallel to a line that inter cepts the

centre of the capstan shaft and the pinch roller) until the

capstan shaft and the pinch roller are completely separated.

4. Gradually lessen the pressure until the pinch roller just begins

to rotate. The scale should then read approximately 500-650

g/cm.

5. If the scale reading is outside the above range, replace the

pinch roller spring (B 1-61) or adjust the spring arm as shown.

6. After the replacement, install the pinch roller adjusting nut (B

1-87) with 1 mm vertical clearance. Check whether the pinch

roller is vertical to the capstan.

Tape Speed / WOW and Flutter

Note:

Before commencing the following alignments, make

sure that all parts in the tape path, particularly the capstan,

pinch roller and head, are cleaned with pure alcohol.

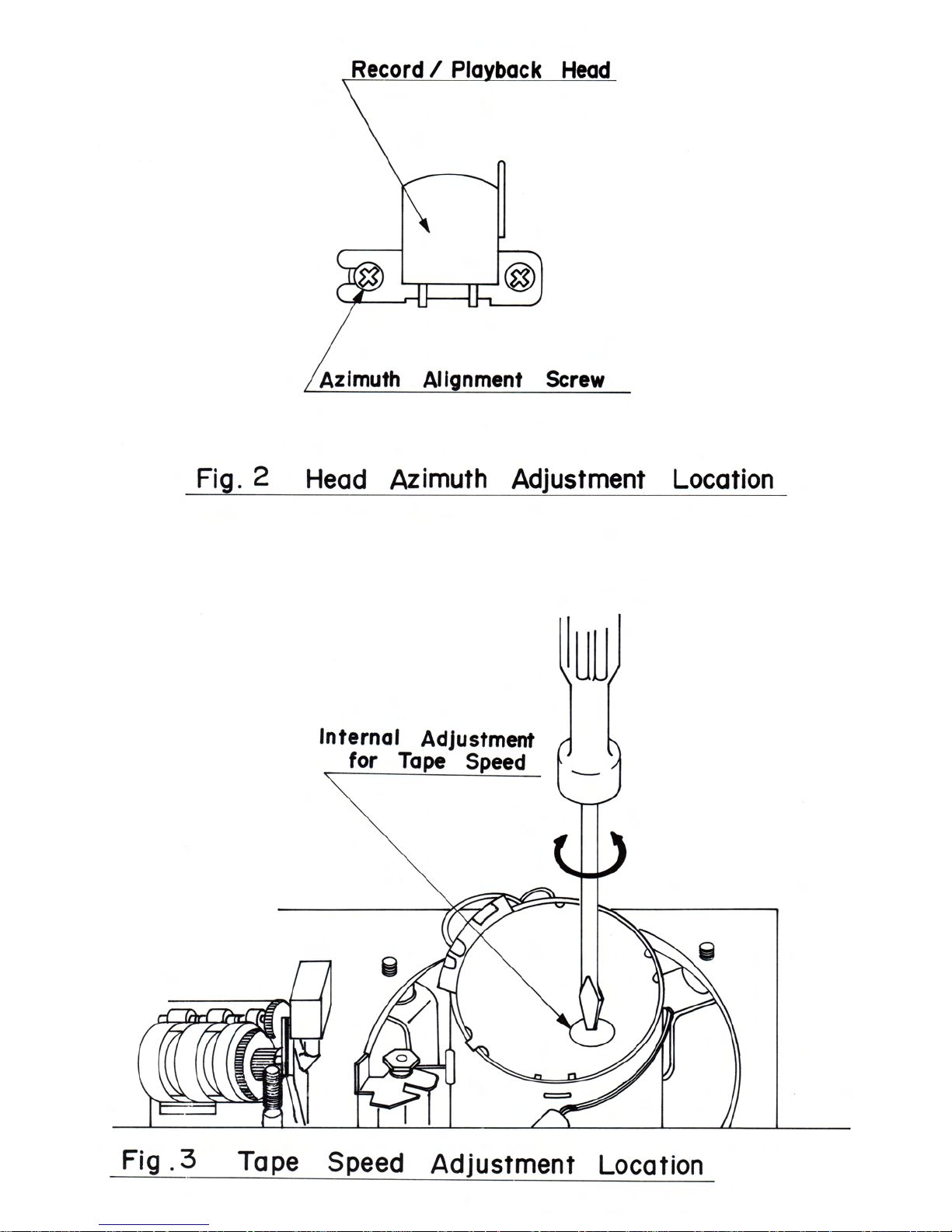

Head Azimuth Alignment

1. Connect the AC vacuum tube voltage meter to both chan

nels of the "Line-out".

2. Use a test tape (in which 10,000 Hz signal is recorded).

3. To achieve the maximum reading on the AC VTVM adjust the

azimuth alignment screw (fig. 2).

4. After the adjustment, fix the screw with lacquer.

Tape Speed

(Spec. 3000 Hz ± 45 Hz)

1. Connect the frequency counter to both channels of the lineout.

2. Set the EQ switch to normal position, then load and play a

TEAC MTT-111 test tape in which a 3000 Hz signal is

recorded.

3. Adjust the control located at the top of the meter for a reading

of 3000 Hz ± 5 Hz on the frequency counter (fig. 3). (This

tape speed alignment should be done after approx. 30

seconds operating time).

4. Then, verify the reading on the frequency counter as being

within the specified range 3000 Hz±45 Hz at the beginning,

middle and near the end of the tape.

Wow and Flutter

(Spec. DIN weighted: within ± 0.2% at record and playback)

Note: When using these methods, obtain the maximum wow and

flutter value, by repeated play, stop or pause mode of operation.

This operation ls necessary to make sure that the wow and

flutter value between record and playback will not create a false

reading.

1. Connect the oscillator to the line-in of the unit, and the wow

and flutter meter to either channel of the line-out.

2. Set line or record controls of the unit to obtain the optimum

input level.

3. Load a test tape (BASF C 60) and set the BASF/EQ

switches to the normal position.

4. Apply and record a 3000 Hz signal.

5. Record and play the recorded section.

6. Read the value on the wow and flutter meter. The wow and

flutter value should be within ± 0.2 %, DIN max.

7. If the measured value is out of specification, check the takeup torque and pinch roller pressure, and see that the capstan

or belt is not stretched or oily.

8. If the above checks prove ineffective, repair or replace the

pinch roller assembly (B 1-6), motor and any other defective

parts.

9. When the capstan assembly must be replaced, make sure it

is weil oiled. Re-adjust the end clearance by adjusting the

thrust-screw (B 1-111) until the clearance is between 0.15-0.3

mm.

Page 8

Page 9

Page 10

!

Parts List

CP-637 L (Lenco C 1102)

Mechanical Parts

Reference No.

Descrlption

Lenco Part No.

Quantity

Unlt Price

A-1

Cabinet Assembly, Top

21C7384X

1

Consists of following:

A-1 Cabinet, Top

21C7384

1

A-16 Window, Tapecounter

21W7472

1

B 2-37 Cover, Volume Control

24W7808

1

A-2

Cabinet Assembly, Bottom

21C7386X

1

Consists of following:

A-2 Cabinet, Bottom

21C7386

1

A-12 Rubber, Foot

21W7299

4

B 2-32 Paper, Shield

24W7641

1

A-3

Door Assembly, Cassette

21C7392X

1

Consists of following:

A-3 Door, Cassette

21C7392

1

A-4 Window, Cassette

2107088

1

A-23 Spring, Cassette Setting

23W9627

2

A-5

Box, VU Meter

21C7389

1

A-6

Cover, Microphone Jack

21C7390

1

A-7

Door, Microphone Jack

21C7391

1

A-10

Button, Push Switch

21N7597

5

A-11

Button, Power Switch

21N7598

1

A-13

Button, VU Meter Box

21N7602

1

A-14

Button, Tapecounter

21N7603

1

A-15

Knob, Volume Control

21N7604

2

A-17

Decoration Plate, Azimuth Hole

21W7473

1

A-18

Plate, Rating (220 V, 50 Hz)

23M7885

1

A-22

Plate, Rating (240 V, 50 Hz)

23M7890

1

B 1-1

Chassis Assembly

23S7191X

1

Consists of following:

B 1-1 Chassis, Mechanism

23S7191

1

B 1-17 Metal, Reel Shaft

22R7051

2

B 1-56 Stay, Auto Stop PC Board

25W8271

1

B 1-67 Stay, Flywheel Holder

25W7723

1

B 1-71 Shaft, Pause Lever B

25W7718

1

B 1-74 Stay, Basic

25W8172

2

B 1-83 Shaft, Head Chassis Guide

25W7713

2

B 1-85 Stay, Basic

25W7709

1

B 1-86 Shaft, Guide

25W7710

5

B 1-89 Shaft, Fast Forward Arm

25W7719

2

B 1-104 Shaft, Tape Changing Spring

25W7737

1

B 1-2

Plate Assembly, Head Base

23W8776X

1

Consists of following:

B 1-2 Chassis, Head

23W8776

1

B 1-76 Stay, Pinch Roller Arm

25W7712

1

B 1-79 Stay, Head Adjusting Spring

25W7720

1

B 1-83 Shaft, Head Chassis Guide

25W7713

1

B 1-3

Plate Assembly, Cassette Lifting

23W9940X

1

Consists of following:

B 1-3 Plate, Cassette Lifting

23W9940

1

A-19 Sheet A

24W7508

1

A-20 Sheet B

24W7509

1

B 1-140 Spacer

24W7443

1

B 1-4

Pushbutton Assembly

27N7060

1

B 1-5

Capstan Assembly

27W7060

1

Note:

Page 11

!

Reference No.

Descrlption

Lenco Part No.

Quantity

Unlt Prlce

B 1-6

Metal, Capstan

22H7050

1

B 1-7

Belt, Capstan

21V7068

1

B 1-8

Shaft Assembly, Take-up Reel Base

27W7061

1

B 1-9

Shaft Assembly, Supply Reel Base

27W7062

1

B 1-10

Pulley A Assembly, Fast Forward

27W7063X

1

Consists of following:

B 1-10 Pulley A, Fast Forward

27W7063

1

B 1-24 Arm, Fast Forward Pulley

21W7204

1

B 1-78 Shaft, Fast Forward Pulley

25W7683

1

B 1-101 Washer

24W7369

1

L 1-27 E-Ring Ø 1.5

EEU0015

1

B 1-12

Pulley Assembly, Take-up

21W7327X

1

Consist of following

B 1-12 Puliey, Take-up

21W7327

1

B 1-39 Arm, Take-up Pulley

23W8774

1

B 1-68 Shaft, Take-up Pulley

25W7681

1

L 1-27 E-Ring Ø 1.5

EEU0015

1 B 1-13

Pulley B, Fast Forward

27W7064

1

B 1-14

Pulley C, Fast Forward

27W7065

1

B 1-15

Belt, Fast Forward

21W7104

1

B 1-16

Belt, Counter

21V7040

1

B 1-18

Pinch Roller Assembly

21W7203X

1

Consist of following

B 1-18 Arm, Pinch Roller

21W7203

1

B 1-19 Pinch Rolier

27W7071

1

B 1-66 Shaft, Pinch-Roller

25W7741

1

B 1-21

Rubber, Brake

21W7201

2

B 1-22

Cushion, Door

21W7199

1

B 1-23

Cushion, Motor

21W7236

3

B 1-25

Holder, Motor

23X7262

1

B 1-26

Bracket A, Flywheel

23W8783

1

B 1-27

Bracket B, Flywheel

23W8765

1

B 1-28

Arm Assembly, Back Tension

23W8778X

1

Consists of following:

B 1-28 Arm, Back Tension

23W8778

1

B 1-91 Felt. Back Tension

24W7360

1

B 1-29

Arm A Assembly, Fast Forward and Rewind

23W8794X

1

Consists of following:

B 1-29 Arm A, Fast Forward and Rewind

23W8794

1

B 1-69 Shaft, Fast Forward Pulley B

25W7682

2

B 1-30

Arm B Assembly, Fast Forward and Rewind

23W8793X

1

Consists of following:

B 1-30 Arm B, Fast Forward and Rewind

23W8793

1

B 1-103 Shaft, Fast Forward and Rewind Arm B

25W7733

1

B 1-31

Arm C, Fast Forward and Rewind

23W8792

1

B 1-32

Arm Assembly, Fast Forward

23W8791X

1

Consists of following:

B 1-32 Arm, Fast Forward

23W8791

1

B 1-72 Shaft, Fast Forward and Rewind Arm C

25W7721

1

B 1-33

Arm Assembly, Rewind

23W8790X

1

Consists of following:

B 1-33 Arm, Rewind

23W8790

1

B 1-72 Shaft, Fast Forward and Rewind Arm C

25W7721

1

B 1-34

Arm A Assembly, Tape Changing

23W9954X

1

Consists of following

B 1-34 Arm A, Tape Changing

23W9954

1

B 1-96 Stop Pin

25W8169

1

Note:

Page 12

!

Reference No.

Description

Lenco Part No.

Quantity

Unit Price

B 1-35

Arm B, Tape Changing

23W8785

1

B 1-36

Lever A Assembly, Pause

23W8782X

1

Consists of following:

B 1-36 Lever A, Pause

23W8782

1

B 1-90 Shaft, Pause Lever A

25W7708

1 B 1-37

Lever B, Pause

23W8795

1

B 1-38

Lever C, Pause

23W8781

1

B 1-40

Arm, Brake

23W8773

1

B 1-41

Plate, Lock Release

23W9698

1

B 1-42

Plate, Record Prevention

23W8779

1

B 1-43

Angle B Assembly, Door

23W9749X

1

Consist of following

B 1-43 Angle B, Door

23W9749

1

B 1-80 Shaft B, Door

25W7946

1 B 1-44

Arm A, Record

23W8771

1

B 1-45

Lever B, Eject

23W9753

1

B 1-46

Arm, Head Chassis

23W8775

1

B 1-47

Arm B, Record

23W8770

1

B 1-48

Angle Assembly, Door

23W8777X

1

Consist of following

B 1-48 Angle, Door

23W8777

1

B 1-11 Shaft, Door

25W7704

1

B 1-49

Spring A, Head Chassis Holding

23W8789

1

B 1-50

Spring B, Head Chassis Holding

23W8788

1

B 1-51

Spring, R/P Head

23W8796

1

B 1-52

Pulley, Motor

25R7082

1

B 1-53

Spring, Slide Switch Changing

23W8772

1

B 1-54

Spoke, Switch Changing

26W7359

1

B 1-55

Spring, Brake Arm

26W7487

1

B 1-57

Spring, Pause Lever B

26W7249

1

B 1-58

Spring, Record Prevention Plate

26W7246

1

B 1-59

Spring, Fast Forward

26W7250

1

B 1-60

Spring, Rewind

26W7251

1

B 1-61

Spring, Pinch Roller

26W7244

1

B 1-62

Spring A, Push Shaft

26W7254

1

B 1-63

Spring, Take-up Pulley Arm

26W7245

1

B 1-64

Spring B, Push Shaft

26W7253

1

B 1-65

Spring, Door

26W7248

1

B 1-70

Shaft, Record Prevention Plate

25W7707

1

B 1-73

Shaft, Tape Changing Arm A

25W7715

1

B 1-75

Shaft, Head Chassis Pushing

25W7711

1

B 1-77

Shaft 8, Pinch Roller Arm

25W8004

1

B 1-81

Stay, Erase Head

25W7706

2

B 1-82

Stay, R/P Head

25W7705

1

B 1-84

Shaft, Record Arm B

25W7714

1

B 1-87

Nut B, Pinch Roller Adjusting

25W8005

1

B 1-88

Shaft, Eject Lever B

25W7717

1

B 1-92

Coil Spring A

26W7258

3

B 1-93

Coil Spring B

23W7259

1

B 1-94

Coil Spring C

26W7292

1

B 1-95

Spring, Back Tension Arm

23W7261

1

B 1-97

Washer, Oil Stopper

24W7370

1

B 1-98

Cramp, Shield Wire

23W8848

1

B 1-99

Counter Assembly

1670017X

1

Consists of following:

B 1-99 Counter

1670017

1

B 1-124 Washer

24W7505

1

Magnet Ring

1790100

1

B 1-100

Stay, Counter

25W7961

1

B 1-102

2 H pipe

25W7241

10

B 1-105

Coil Spring D

26W7265

1

B 1-106

Coil Spring E

26W7266

1

B 1-107

Washer B

24W7653

2

B 1-108

Cushion, Rubber

21W7210

2

B 1-110

Window, Tape Lighting

21 U7100

1

Note:

Page 13

!

Reference No.

Descrlption

Lenco Part No.

Quantity

Unit Price

B 1-111

Screw, Thrust

25W7132

1

B 1-112

Roller B, Guide

25W8000

2

B 1-113

Guide, Tape Changing Arm B

25W7595

1

B 1-114

Stay, Pause Lever B

21W7220

1

B 1-116

Spring C, Head Chassis Holding

23W8900

1

B 1-117

Washer, Thrust

24W7228

1

B 1-119

Spring, Record Arm A

26W7333

1

B 1-120

Cover, Chassis

23W9966

1

B 1-121

Stay, Chassis Cover

25W7781

1

B 1-123

Reel Table Assembly

27W7082

2

B 1-125

Arm C, Tape Changing

23W9425

1

B 1-126

Spring, Tape Changing

23W8800

1

B 1-127

Spacer, Head Chassis

23W9555

1

B 1-129

Bar, Eject

21W7253

1

B 1-130

Holder, Eject Bar

23W9086

1

B 1-131

Plate, Eject Bar Locking

23W9763

1

B 1-132

Plate, Lock Release

23W9764

1

B 1-133

Pipe, Locking Plate

25W7829

1

B 1-134

Pipe, Lock Release Plate

25W7830

1

B 1-135

Spring, Eject Bar

23W7315

1

B 1-136

Spring, Eject Bar Locking

23W7316

1

B 1-137

Holder, Lamp

23W9624

1

B 1-138

Cover, Lamp

21W7351

1

B 1-141

Pipe, Pause Lever C

25W8064

1

B 2-1

Chassis

23X7296

1

B 2-2

Joint A

23X7295

1

B 2-3

Joint B Assembly

23X7298X

1

Consists of following:

B 2-3 Joint B

23X7298

1

B 2-49 Spacer

25W0744

1

B 2-4

Bracket, Pin Jack

23X7301

1

B 2-5

Bracket, Transformer

23X7302

1

B 2-6

Holder, Microphone Jack

23X7290

1

B 2-7

Bracket, Microphone Jack

23X7291

1

B 2-8

Holder Assembly, VU Meter Box

23X7292X

2

Consists of following:

B 2-8 Holder, VU Meter Box

23X7292

2

B 2-42 Pin, VU Meter Box

25W7777

2

B 2-9

Plate Assembly, VU Meter

23X7293X

1

Consists of following:

B 2-9 Plate, VU Meter

23X7293

1

B 2-40 Cover, VU Meter Box

24T7258

1 B 2-10

Spring, VU Meter Box Locking

23X7294

1

B 2-11

Stay, Bottom Cabinet Holding

25W8281

1

B 2-12

Shaft, Record Arm C

25W8282

1

B 2-13

Stay, Terminal Board

25W8283

1

B 2-14

Lever, Auto Stop

23X7299

1

B 2-15

Arm, Meter Box Lifting

23X7300

1

B 2-16

Spring, Meter Box Lifting Button

26W7537

1

B 2-17

Holder, Push Switch Button

21W7311

5

B 2-18

Bracket, Power PCB

23W9560

1

B 2-19

Bracket, Mechanism Chassis

23W8734

2

B 2-20

Bracket B, Record/Playback PC Board

23W9413

1

B 2-21

Bracket C, Record/Playback PC Board

23W9419

1

B 2-22

Plate, PC Board

23W9566

1

B 2-23

Pipe, Auto Stop Lever

25W7518

1

B 2-24

Holder, Lamp

21W8502

2

B 2-25

Retainer, Wire

23W1046

3

B 2-26

Holder, Power Switch Button

21W7312

1

B 2-29

Lever C Assembly, Record

23W9423X

1

Consists of following:

B 2-29 Lever C, Record

23W9423

1

B 2-31 Shaft, Record Lever D

25W7959

1

Note:

Page 14

!

Reference No.

Description

Lenco Part No.

Quantity

Unit Price

B 2-30

Lever 0, Record

23W9564

1

B 2-33

Spring, Earth

26W7227

1

B 2-34

Shield, Transformer

23W9562

2

B 2-36

Plate, Insulation

24W7807

1

B 2-38

Cushion, Stopper

21W7013

4

B 2-39

Cushion, VU Meter

24W7805

4

B 2-41

Plate, Shelter

23X7303

1

B 2-43

Spring, Meter 80x Lifting

26W7242

1

B 2-44

Cushion, Meter 80x

24W7389

1

B 2-47

Spring, Auto Stop Lever

26W7439

1

B 2-48

Washer, Transformer

23W0255

2

B 2-50

Joint C

23X7426

1 L 1-1

Siotted Socket Setscrew M 2 X 3

SSI2003

5

L 1-2

Flat Countersunk Head Screw M 2 X 5

SDM1205

1

L 1-35

Siotted Socket Setscrew M 2.6 X 4

SSI2604

1

L 1-3

Pan Head Screw M 2 X 8

SPM1208

1

L 1-4

Pan Head SEMS Screw M 2 X 5

CPM1205

1

L 1-5

Pan Head SEMS Screw M 2 X 8

CPM1208

3

L 1-6

Pan Head SEMS Screw M 2 X 10

CPM1210

1

L 1-7

Pan Head SEMS Screw M 2 X 12

CPM1212

4

L 1-8

Pan Head Screw M 2.6 X 3

SPM1903

4

L 1-9

Pan Head SEMS Screw M 2.6 X 4

CPM1904

3

L 1-10

Pan Head SEMS Screw M 2.6 X 6

CPM1906

19

L 1-11

Pan Head SEMS Screw M 2.6 X 8

CPM1908

1

L 1-12

Pan Head SEMS Screw M 2.6 X 10

CPM1910

1

L 1-13

Pan Head W SEMS Screw M 2.6 X 6

FPM1906

2

L 1-14

Pan Head W SEMS Screw M 3 X 6

FPM3306

1

L 1-15

Pan Head SEMS Screw M 3 X 6

CPM3306

4

L 1-16

Pan Head W SEMS Screw M 3 X 12

FPM3312

3

Steel Ball Ø 2.5

80S0025

2

L 1-18

Steel Ball Ø 3

80S0030

3

L 1-19

Nut M 2

NHM0020

3

L 1-20

Nut M 2.6

NHM0026

4

L 1-21

Nut M 3

NHM0030

1

L 1-22

Flat Washer M 2 (0.4 t X Ø 5)

WP82054

2

L 1-23

Flat Washer M 2.6 (0.5 t X Ø 7.5)

WP89075

3

L 1-24

Flat Washer M 3.5 (0.5 t X Ø 7)

WP8C075

9

L 1-25

Flat Washer Ø 4 X Ø 10X 0.8 t

1

L 1-26

Flat Washer M 4 (0.5 t X Ø 10)

WP84103

3

L 1-28

E-Ring Ø 2

EEU0020

5 L 1-29

E-Ring Ø 2.5

EEU0025

10

L 1-30

E-Ring Ø 3

EEU0030

1

L 1-31

E-Ring Ø 4

EEU0040

2

L 1-32

Spring Pin Ø 1.6 X 12

PSK1612

1

L 1-33

Spring Washer M 2.6

WSM9056

4

L 1-34

Spring Washer M 3

WSM3067

1

L 1-36

Spacer Ø 3 X Ø 4 X 7

G003070

3 L 2-1

Tapping Screw (Tap-Tite C Type) M 3 X 6

36

L 2-2

Tapping Screw (Tape-Tite C Type) M 3 X 8

2

L 2-3

Pan Head SEMS Screw M 3 X 6

CPM3306

18

L 2-4

Pan Head W SEMS Screw M 3 X 6

FPM3306

7

L 2-5

Pan Head SEMS Screw M 3 X 5

CPM3305

3

L 2-6

8inding Head Screw M 3 X 8

S8K3308

9

L 2-7

Pan Head SEMS Screw M 2.6 X 6

CPM1906

1

L 2-8

Pan Head Tapping Screw M 2.6 X 6

3

L 2-9

Tapping Screw M 3 X 8

SLM3308

1

L 2-10

Flat Countersunk Head Screw M 2.6 X 6

SDK1906

2

L 2-11

Pan Head W SEMS Screw M 2.6 X 6

FPK1906

2

L 2-12

Nut M 3

NHM0030

1

L 2-13

Nut M 12

NHM0120

1

L 2-14

E-Ring Ø 3

1

L 2-15

E-Ring Ø 2.5

1

Note:

Page 15

!

Electrical Parts

Reference No.

Description

Lenco Part No.

Quantity

Unlt Price

Record/Playback Head

165N053

1

Erase Head

165N042

1

Level Meter

1831229

2

Power Transformer

118G483

1

AC Cord (COMMON-type)

1750277

1

AC Cord (BASEC-type)

1750280

1

AC Cord (SAA-type)

1750283

1

AC Cord Stopper (COMMON-type)

SR-4N-4

1

AC Cord Stopper (BASEC-type)

SR-5N-4

1

AC Cord Stopper (SAA-type)

SR-6W-1

1

DC FG-Servo Motor

164N111

1

S 1

Slide Switch (12-Circuit)

1621210, 1621259,

2

1621345

S 2

Slide Switch ( 9-Circuit)

1621318,1621237,

1

1621344

S 3

Slide Switch ( 4-Circuit)

1621248,1621341

1

S 4, 5, 6, 12

Push Switch (5-function- common)

1622298

1

Power Switch

1622276

1

Micro Switch

1623052

1

Leaf Switch

1624025

1

Leaf Switch

1624041

1

S 14

Reed Switch

1623133,1623136

1

S 15

Push Switch (2-Circuit)

1622195,1622174

2

P.C.B. Connector 10 P

172M459

1

P.C.B. Connector 6 P

172M584

2

Connector (5 P-3.5 mm)

172M606

1

Connector (3 P-3.5 mm)

172M604

13

Connector (5 P-2.5 mm) L-type

172M854

1

Connector Socket (5 P-3.5 mm)

172M870, 172M590

1

Connector Socket (3 P-3.5 mm)

172M588, 172M868 13

Connector Socket (5 P-2.5 mm)

172M862

1

P 103, 203

Slide Resistor 20 K (D)

139N724

2

DIN/RCA Jack Board

1720800

1

Terminal Board

1720813

1

DIN/RCA Jack P.C.B.

1611581

1

MIC Jack P.C.B.

1611266

1

Pre-Amplifier P.C.B.

1611263B

1

Dolby P.C.B.

1611190

1

DNL P.C.B.

1611020

1

Auto Stop P.C.B.

1611585

1

Push Switch P.C.B.

1611580

1

LED P.C.B. (4-function-common)

1611583

1

Peak Level LED P.C.B.

1611610

1

Power P.C.B.

1611584

1

Muting P.C.B.

1611021

1

Reed Switch P.C.B.

1611032

1

PL 1, 2, 3

Pilot Lamp

1830159

3

Solenoid Coil

1660033

1

Head Phone Jack (6.3 mm)

1630108

1

DIN Jack (P.C.B.-type)

1720401, 172C401

2

O.S.C. Block

1810074

1

Filter Block

1810098

2

Magnet Ring

1790100

1

Fuse (315 mAT)

1790095

1

Fuse (630 mAT)

1790098

1

L 102, 202

Semi-fixed Inductance 6.8 mH

1170100

2

L 103, 203

Semi-fixed Inductance 4.7 mH (J)

1170135

2

L 104, 204

Semi-fixed Inductance 15 mH

1170078

2

L 1, 303, 403

Semi-fixed Inductance 200 µH

1170069

3

Trimmer Capacitor

1280057

4

VR 302, 402

Semi-fixed Resistor (8 mm) 1 K

138N026

3

P102, 202

Semi-fixed Resistor (8 mm) 10 K

138N271

8

107, 207

VR 501, 601

301, 401

Page 16

!

Reference No.

Description

Lenco Part No.

Quantity

Unit Price

P 104, 204, 105

Semi-fixed Resistor (8 mm) 20 K

138N028

6

205,106,206

P2

Semi-fixed Resistor (8 mm) 100 K

138N004

1

MIC Jack P.C.B. Assembly

1611266X

MIC Jack P.C.B.

1611266

1

R 101, 201

Carbon Resistor

18 K

1337183

2

R102,202

Carbon Resistor

5.6 K

1337562

2

R 104, 204

Carbon Resistor

1

K

1337102

2

1622195

S 15

Push Switch (2-Circuit)

1622174

1

DIN/RCA Jack P.C.B. Assembly

1611581X

DIN/RCA Jack P.C.B.

1611581

1

R 28, 29

Carbon Resistor

560 K

W (J)

1346564

2

R 30, 31

Carbon Resistor

3.3 M

1321335

2

R 32, 33

Carbon Resistor

56

K

W (J)

1346563

2

DIN/RCA Jack Board

1720800

1

Peak Level P.C.B. Assembly

1611610X

Peak Level P.C.B.

1611610

1

011

Light Emitting Diode

TLR-114

1

Pre-Amplifier P.C.B. Assembly

1611263BX

Pre-Amplifier P.C.B.

1611263B

1

Filter Block

1810098

2

T 5

Transistor

2SC1327U

1

T 6,7

Transistor

2SC1815GR

2

T 10, 201

Transistor

2SC1000BL

4

102, 202

2SC1681BL

T 103, 203

Transistor

2SC1327T

6

104, 204

2SC732BL

105, 205

T 106, 206

Transistor

2SC1815GR

4

107, 207

T 108, 208

Transistor

2SC1327U

2

T 109, 209

Transistor

2SC828S

2

T 110, 210

Transistor

2SA564S

2

T 301, 401

Transistor

2SC1327T

6

302, 402

2SC732BL

303, 403

P 1

Semi-fixed Resistor

(8 mm)

1 K

138N026

1

P 2

Semi-fixed Resistor

(8 mm) 100 K

138N004

1

P 103, 203

Slide Resistor

20 K (0)

139N724

2

P 104, 204

Semi-fixed Resistor

(8 mm) 20 K

138N028

6

105, 205

106, 206

P 107, 207

Semi-fixed Resistor

(8mm)

10 K

138N271

2

L 102, 202

Semi-fixed Inductance

6.8 mH

1170100

2

L 103, 203

Semi-fixed Inductance

4.7 mH (J)

1170135

2

L 104, 204

Semi-fixed Inductance

15

mH

1170078

2

PL 1, 2, 3

Pilot Lamp

1830159

3

D 101, 201

Diode

1K-60

2

D 102, 202

Diode

1S1555

4

103, 203

D 104, 204

Diode

1K-60

4

105, 205

D 106, 206

Diode

KB-269

2

R 21

Carbon Resistor

220

K

1337224

2

R 22

Carbon Resistor

2.2 K

1337222

2

R 23

Carbon Resistor

680

K

1337684

2

R 24

Carbon Resistor

330

K

1337334

2

Note:

Page 17

!

Reference No.

Description

Lenco Part No.

Quantity

Unit Prlce

R 25

Carbon Resistor

4.7 K 1337472

2

R 103, 203

Carbon Resistor

10

1337100

2

R 105, 205

Carbon Resistor

120 K 1337124

2

R 106, 206

Carbon Resistor

220

1337221

2

R 107, 207

Carbon Resistor

220 K 1337224

2

R 108, 208

Carbon Resistor

10 K 1337103

2

R 109, 209

Carbon Resistor

1 K 1337102

2

R 110, 210

Carbon Resistor

150 K 1337154

2

R 111, 211

Carbon Resistor

2.7 K

1337272

2

R 112, 212

Carbon Resistor

2.2 K

1337222

2

R 113, 213

Carbon Resistor

3.3 K

1337332

2

R 114, 214

Carbon Resistor

4.7 K

1337472

2

R 115, 215

Carbon Resistor

470 K 1337474

2

R 116, 216

Carbon Resistor

47 K 1337473

2

R 117, 217

Carbon Resistor

3.3K

1337332

2

R 118, 218

Carbon Resistor

330

1337331

2

R 119, 219

Carbon Resistor

390

1337391

2

R 121, 221

Carbon Resistor

22 K 1337223

2

R 122, 222

Carbon Resistor

150

1337151

2

R 123, 223

Carbon Resistor

68

1337680

2

R 124, 224

Carbon Resistor

3.9 K 1337392

2

R 125, 225

Carbon Resistor

6.8 K

1337682

2

R 126, 226

Carbon Resistor

1.8 K

1337182

2

R 127, 227

Carbon Resistor

470 K 1337474

2

R 128, 228

Carbon Resistor

100 K 1337104

2

R 129, 229

Carbon Resistor

4.7 K

1337472

2

R 130, 230

Carbon Resistor

1 K 1337102

2

R 131, 231

Carbon Resistor

82 K 1337823

2

R 132, 232

Carbon Resistor

3.9 K

1337392

2

R 133, 233

Carbon Resistor

470 K 1337474

2

R 134, 234

Carbon Resistor

3.3 K

1337332

2

R 135, 235

Carbon Resistor

330 K 1337334

2

R 136, 236

Carbon Resistor

47 K 1337473

2

R 137, 237

Carbon Resistor

4.7 K

1337472

2

R 138, 238

Carbon Resistor

1 K 1337102

2

R 139, 239

Carbon Resistor

100 K 1337104

2

R 141, 241

Carbon Resistor

1.8 K

1337182

2

R 142, 242

Carbon Resistor

560

1337561

4

143, 243

R 144, 244

Carbon Resistor

12 K 1337123

2

R 145, 245

Carbon Resistor

22 K 1337223

2

R 146, 246

Carbon Resistor

12 K 1337123

2

R 147, 247

Carbon Resistor

120 K 1337124

2

R 148, 248

Carbon Resistor

10

1337100

2

R 149, 249

Carbon Resistor

10

1337100

2

R 150, 250

Carbon Resistor

39

1337390

2

R 151, 251

Carbon Resistor

10 K 1337102

2

R 152, 252

Carbon Resistor

18 K 1337183

2

R 153, 253

Carbon Resistor

1 K 1337102

2

R 301,401

Carbon Resistor

470

K 1337474

2

R 302, 402

Carbon Resistor

47

K 1337473

2

R 303, 403

Carbon Resistor

3.3 K

1337332

2

R 304, 404

Carbon Resistor

560

1337561

2

R 305, 405

Carbon Resistor

5.6 K

1337562

2

R 306, 406

Carbon Resistor

47 K 1337473

2

R 307, 407

Carbon Resistor

180 K 1337184

2

R 308, 408

Carbon Resistor

12 K 1337123

2

R 309, 409

Carbon Resistor

1.8 K

1337182

2

R 310, 410

Carbon Resistor

3.9 K

1337392

2

R 343, 443

Carbon Resistor

270

1337271

2

C 101, 201

Styrol Capacitor

680 p

1230681

2

C 102, 202

Tantal Electrolytic Capacitor

10 µ/10

1224106

2

C 103, 203

Electrolytic Capacitor

47 µ/16

1203476

2

C 104, 204

Myler Capacitor

0.001 µ (K)

1250102

2

C 105, 205

Ceramic Capacitor

100 p

1203101

2

C 106, 206

Electrolytic Capacitor

33 µ/6.3

1201336

2

Note:

Page 18

!

Reference No.

Description

Lenco Part No.

Quantity

Unit Price

C 107, 207

Tantal Electrolytic Capacitor

3.3 µ/10

1224335

2

C 108, 208

Myler Capacitor

0.022 µ (J)

1254223

2

C 110, 210

Tantal Electrolytic Capacitor

3.3 µ/10

1224335

2

C 113, 213

Electrolytic Capacitor

100 µ/16

1203107

2

C 114, 214

Tantal Electrolytic Capacitor

3.3 µ/10

1224335

2

C 115, 215

Electrolytic Capacitor

3.3 µ/25

1204335

2

C 116, 216

Electrolytic Capacitor

100 µ/25

1204107

2

C 117, 217

Ceramic Capacitor

150 p

12D3151

4

118, 218

C 119, 219

Ceramic Capacitor

470 p

12D3471

2

C 120, 220

Myler Capacitor

0.018 µ (J)

1254183

2

C 121, 221

Myler Capacitor

0.027 µ (J)

1254273

2

C 122, 222

Tantal Electrolytic Capacitor

3.3 µ/25

1225335

2

C 123, 223

Electrolytic Capacitor

3.3 µ/25

1204335

2

C 124, 224

Electrolytic Capacitor

3.3 µ/25

1204335

4

125, 225

C 126, 226

Aluminium Solid Element Capacitor 0.47 µ/10

1211474

2

C 128, 228

Electrolytic Capacitor

3.3 µ/25

1204335

4

129, 229

C 130, 230

Electrolytic Capacitor

1 µ/25

1204105

2

C 131, 231

Electrolytic Capacitor

47 µ/6.3

1201476

2

C 132, 232

Electrolytic Capacitor

100 µ/6.3

1201107

2

C 133, 233

Electrolytic Capacitor

100 µ/25

1204107

2

C 137, 237

Electrolytic Capacitor

10 µ/16

1203106

2

C 151, 251

Electrolytic Capacitor

3.3 µ/25

1204335

2

C 302, 402

Ceramic Capacitor

60 p

12D3600

2

C 306, 406

Electrolytic Capacitor

3.3 µ/25

1204335

2

C 307, 407

Electrolytic Capacitor

10 µ/16

1203106

2

C 20

Electrolytic Capacitor

10 µ/16

1203106

2

C 30

Electrolytic Capacitor

220 µ/6.3

1201227

2

C 31

Electrolytic Capacitor

10 µ/16

1203106

2

Dolby P.C.B. Assembly

1611190X

Dolby P.C.B.

1611190

1

Q 304, 404

Transistor

2SC732BL

2

2SC1327T

Q 305, 405

Transistor

2SC732BL

2

2SC1327T

Q 306, 406

Transistor

2SK30AD

2

Q 307, 407

Transistor

2SC732BL

2

2SC1327T

Q 308, 408

Transistor

2SA721T

2

Q 309, 409

Transistor

2SC732BL

2

2SC1327T

D 301, 401

Diode

1 K-60

2

D 302, 402

Diode

KB-162

8

D 303, 403

D 304, 404

D 305, 405

VR 301, 401

Semi-fixed Resistor

(8 mm) 10 K

138N271

2

VR 302, 402

Semi-fixed Resistor

(8 mm) 1 K

138N026

2

ZD 2,3

Zener Diode

WZ-018

2

UZ-82B

2

05Z82

2

L 303, 403

Semi-fixed Inductance

0.2 mH

117D069

2

R 311, 411

Carbon Resistor

33 K 1321333

2

R 312, 412

Carbon Resistor (Precision)

150

K/ W

1330052

2

R 313, 413

Carbon Resistor (Precision)

180

K/ W

1330053

2

R 314, 414

Carbon Resistor

27 K 1337273

2

R 315, 415

Carbon Resistor

8.2 K

1337822

2

R 316, 416

Carbon Resistor

22 K 1337223

2

R 317, 417

Carbon Resistor (Precision)

150

K/ W

1330052

2

R 318, 418

Carbon Resistor

2.7 K

1337272

2

R 319, 419

Carbon Resistor

33 K 1337333

2

R 320, 420

Carbon Resistor

270 K 1321274

2

Note:

Page 19

!

Reference No.

Descrlptlon

Lenco Part No.

Quantlty

Unlt Prlce

R 321, 421

Carbon Resistor

47 K 1337473

2

R 322, 422

Carbon Resistor (Precision)

3.3 K / W

1330051

2

R 323, 423

Carbon Resistor

1 K 1337102

2

R 324, 424

Carbon Resistor

12 K 1337123

2

R 325, 425

Carbon Resistor

1.2 K

1337122

2

R 326, 426

Carbon Resistor

1.5 M

1337155

2

R 327, 427

Carbon Resistor

1 M 1337105

2

R 328, 428

Carbon Resistor

15 K 1337153

2

R 329, 429

Carbon Resistor

8.2 K

1337822

2

R 330, 430

Carbon Resistor

10 K 1337103

2

R 331, 431

Carbon Resistor

8.2 K

1337822

4

332, 432

R 333, 433

Carbon Resistor

33

K

1337333

2

R 334, 434

Carbon Resistor

120 K 1337124

2

R 335, 435

Carbon Resistor

47 K 1337473

2

R 336, 436

Carbon Resistor

1 K 1337102

2

R 337, 437

Carbon Resistor

33

1337330

2

R 338, 438

Carbon Resistor

82

1337820

2

R 339, 439

Carbon Resistor

2.7 K

1337272

2

R 340, 440

Carbon Resistor

15 K 1337153

2

R 341, 441

Carbon Resistor

270 K 1337274

2

R 342, 442

Carbon Resistor

270 K 1337274

2

R 344, 444

Carbon Resistor

220 K 1337224

2

C 308, 408

Electrolytic Capacitor

10 µ/16

1203106

6

309, 409

310, 410

C 311, 411

Precision Film Capacitor

0.0056 µ

1220124

2

C 312, 412

Precision Film Capacitor

0.027 µ

1220123

2

C 313, 413

Precision Film Capacitor

0.0047 µ

1220125

2

C 314, 414

Electrolytic Capacitor

10 µ/16

1203106

2

C 315, 415

Myler Capacitor

0.1 µ (K)

1250104

2

C 316, 416

Electrolytic Capacitor

47 µ/16

1203476

2

C 318, 418

Myler Capacitor

0.1 µ (K)

1250104

2

C 319, 419

Electrolytic Capacitor

10 µ/16

1203106

4

320, 420

C 321, 421

Myler Capacitor

0.01 µ (K)

1250103

2

C 322, 422

Myler Capacitor

0.1 µ

(J) 1254104

2

C 323, 423

Myler Capacitor

0.1 µ (K)

1250104

2

C 324, 424

Alminium Solid Element Capacitor

0.33 µ/10

1211334

2

Auto Stop P.C.B. Assembly

1611585X

Auto Stop P.C.B.

1611585

1

T 1

Transistor

2SC828S

1

T 2

Transistor

2SC828AS

1

T 3

Transistor

2SD235Y

1

D 1, 2

Diode

SR1K-2

2

R 2

Carbon Resistor

12 K 1337123

1

R 4

Carbon Resistor

100 K 1337104

1

R 5

Carbon Resistor

27 K 1337273

1

R 6

Carbon Resistor

1.8 K

1337182

1

R 7

Carbon Resistor

330

1337331

1

R 8

Carbon Resistor

3.3 K

1337332

1

R 9

Carbon Resistor

8.2 K

1337822

1

R 10

Carbon Resistor

2.7 K

1337272

1

R 11

Carbon Resistor

22 K 1337223

1

R 12

Metal Oxide Resistor

820/2 W

1340821

1

R 13

Cement Resistor

330/5 W

1330055

1

1330056

C 3, 5

Electrolytic Capacitor

47 µ/16

1203476

2

C 6

Electrolytic Capacitor

220 µ/10

1202227

1

C 7

Electrolytic Capacitor

47 µ/35

1200476

1

C 8

Electrolytic Capacitor

220 µ/35

1200227

1

C 9

Electrolytic Capacitor

47 µ/35

1200476

1

C 10

Electrolytic Capacitor

47 µ/16

1203476

1

C 11

Electrolytic Capacitor

470 µ/35

1200477

1

Note:

Page 20

!

Reference No.

Descrlption

Lenco Part No.

Quantity

Unlt Prlce

DNL P.C.B. Assembly

1611020X

DNL P.C.B.

1611020

1

Q 501, 601

Transistor

28C1327T

8

502, 602

28C732BL

503, 603

504, 604

D 501, 601

Diode

181555

12

502, 602

503, 603

504, 604

505, 605

506, 606

VR 501, 601

Semi-fixed Resistor

10 K 138N271

2

R 501, 601

Carbon Resistor

68 K 1337683

2

R 502, 602

Carbon Resistor

22 K 1337223

2

R 503, 603

Carbon Resistor

680

1337681

2

R 504, 604

Carbon Resistor

1 K 1337102

2 R 505, 605

Carbon Resistor

680 1337681

2

R 506, 606

Carbon Resistor

8.2 K

1337822

2

R 507, 607

Carbon Resistor

1 K 1337102

2

R 508, 608

Carbon Resistor

330 K 1337334

2

R 509, 609

Carbon Resistor

100 K 1337104

2

R 510, 610

Carbon Resistor

1.8 K

1337182

2

R 511, 611

Carbon Resistor

330 K 1337334

2

R 512, 612

Carbon Resistor

22 K 1337223

2

R 513, 613

Carbon Resistor

680

1337681

2

R 514, 614

Carbon Resistor

5.6K

1337562

2

R 515, 615

Carbon Resistor

680

1337681

2

R 516, 616

Carbon Resistor

120 K 1337124

2

Note:

Page 21

!

Reference No.

Description

Lenco Part No.

Quantity

Unit Price

R 517, 617

Carbon Resistor

22 K 1337223

2

R 518, 618

Carbon Resistor

120 K 1337124

2

R 519, 619

Carbon Resistor

1 K 1337102

2

C 501, 601

Electrolytic Capacitor

3.3 µ/25

1204335

2

C 502, 602

Myler Capacitor

0.022 µ (K)

1250223

2

C 503, 603

Myler Capacitor

0.0047 µ (K)

1250472

2

C 504, 604

Styrol Capacitor

390 p (J)

1230390

2

C 505, 605

Myler Capacitor

0.0018 µ (K)

1250182

2

C 506, 606

Myler Capacitor

0.022 µ (K)

1250223

2

C 507, 607

Myler Capacitor

0.0022 µ (K)

1250222

2

C 508, 608

Styrol Capacitor

680 p

1230681

2

C 509, 609

Myler Capacitor

0.022 µ (K)

1250223

2

C 510, 610

Myler Capacitor

0.01 µ (K)

1250103

2

C 511, 611

Electrolytic Capacitor

3.3 µ/25

1204335

2

C 512, 612

Electrolytic Capacitor

47 µ/25

1204476

2

C 513, 613

Myler Capacitor

0.022 µ (K)

1250223

2

Power P.C.B. Assembly

1611584X

Power P.C.B.

1611584

1

OSC Block

1810074

1

T 4

Transistor

2SD235Y

1

D 9, 10

Diode

1 B4B-1

2

ZD 1

Zener Diode

BZ-240

1

R 1

Metal Oxide Resistor

560/1 W

1334561

1

R 14

Carbon Resistor

220

1337221

1

R 15

Carbon Resistor

820

1337821

1

R 16

Metal Oxide Resistor

10/1 W

1344100

1

C 1

Styrol Capacitor

1000 p (J)

1231102

1

C 2

Electrolytic Capacitor

100 µ/25

1204107

1

C 12

Electrolytic Capacitor

1000 µ/16

1203108

1

C 13

Electrolytic Capacitor

1000 µ/35

1200108

1

C 14

Electrolytic Capacitor

470 µ/35

1200477

1

C 15

Electrolytic Capacitor

470 µ/50

1221477

1

C 16, 17, 18, 19

Ceramic Capacitor

0.04 µ 1203402

4

Reed Switch P.C.B. Assembly

1611032X

Reed Switch P.C.B.

1611032

1

S 14

Reed Switch

1623133

1

1623136

R 3

Carbon Resistor

3.9 K

1321392

1

C 4

Ceramic Capacitor

0.04 µ 1203402

1

LED P.C.B. (4-function) Assembly

1611583X

LED P.C.B. (4-function)

1611583

1

D 4, 5, 6, 7

Light Emitting Diode

TLR-114

4

R 17, 18, 19, 20

Carbon Resistor

1/K 1321102

4

Mutting P.C.B. Assembly

1611021X

Muting P.C.B.

1611021

1

S 3

Slide Switch (4-circuit)

1621248

1

Push Switch P.C.B. Assembly

1611580X

Push Switch P.C.B.

1611580

1

Push Switch (5-function)

1622298

1

R 23

Carbon Resistor

680 K

1337684

1

R 24

Carbon Resistor

330 K

1337334

1

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Loading...

Loading...