Page 1

Instructions for Use

VT1200 / VT1200 S

Vibrating-blade

microtome

Leica VT1200/VT1200 S V 1.4 RevC, English - 09/2013

Order No. 14 0481 80101 RevC

Always keep this manual with the instrument.

Read carefully before working with the instrument.

Page 2

Page 3

Note

The information, numerical data, notes and value

judgments contained in this manual represent

the current state of scientific knowledge and

state-of-the-art technology as we understand it

following thorough investigation in this field. We

are under no obligation to update the present

manual periodically and on an ongoing basis according to the latest technical developments, nor

to provide our customers with additional copies,

updates etc. of this manual.

To the extent permitted in accordance with

the national legal system as applicable in each

individual case, we shall not be held liable for

erroneous statements, drawings, technical illustrations etc. contained in this manual. In particular, no liability whatsoever is accepted for any

financial loss or consequential damage caused

by or related to compliance with statements or

other information in this manual.

Statements, drawings, illustrations and other

information as regards contents or technical

details of the present Instructions for Use are not

to be considered as warranted characteristics of

our products.

These are determined only by the contract

provisions agreed between ourselves and our

customers.

Leica reserves the right to change technical

specifications, as well as manufacturing processes, without prior notice. Only in this way is

it possible to continuously improve the technology and manufacturing techniques used in our

products.

This document is protected under copyright laws.

Any copyrights of this document are retained by

Leica Biosystems Nussloch GmbH.

Any reproduction of text and illustrations (or

of any parts thereof) by means of print, photocopy, microfiche, web cam or other methods

– including any electronic systems and media

– requires express prior permission in writing by

Leica Biosystems Nussloch GmbH.

For the instrument serial number and year of

manufacture, please refer to the nameplate on

the back of the instrument.

© Leica Biosystems Nussloch GmbH

Leica Biosystems Nussloch GmbH

Heidelberger Str. 17-19

D-69226 Nussloch

Germany

Phone: +49 62 24 143-0

Fax: +49 62 24 143-268

Internet: http://www.LeicaBiosystems.com

Assembly contracted by Leica Microsystems Ltd. Shanghai

Leica VT1200 / VT1200 S

1

Page 4

Contents

1 Important Information ................................................................................................................4

1.1 Symbols in the text and their meanings .................................................................................... 4

1.2 Qualification of personnel ........................................................................................................... 5

1.3 Intended use/improper use ......................................................................................................... 5

2. Safety ............................................................................................................................................6

2.1 General safety notes .................................................................................................................... 6

2.2 Warnings ........................................................................................................................................ 6

2.3 Transport, unpacking and setting up......................................................................................... 7

3. Instrument characteristics ........................................................................................................8

3.1 Technical data for the VT1200 ................................................................................................... 8

3.1.1 Technical data for the VT1200 S ................................................................................................ 9

3.2 General overview – VT1200/VT1200 S ..................................................................................... 10

3.3 VT1200 Control Panel ................................................................................................................. 12

3.3.1 VT1200 S control panel .............................................................................................................. 13

4. Installation .................................................................................................................................14

4.1 Standard scope of delivery for the VT1200............................................................................. 14

4.1.1 Standard scope of delivery for the VT1200 S ......................................................................... 15

4.2 Packing and setting up the instrument ................................................................................... 16

4.3 Before commissioning the instrument .................................................................................... 17

5. Working with the Instrument ..................................................................................................18

5.1 Description of the typical application ..................................................................................... 18

5.2 Control elements on the VT1200 control panel ...................................................................... 19

5.2.1 Moving the specimen receptacle vertically........................................................................... 19

5.2.2 Fine-adjusting the blade-to-specimen proximity and feeding to the section thickness ..... 20

5.2.3 Moving the blade ........................................................................................................................ 20

5.2.4 Selecting the sectioning parameters ...................................................................................... 21

5.3 Control elements on the VT1200 S control panel .................................................................. 22

5.4 Installing the accessories ......................................................................................................... 32

5.4.1 Installing the ice tray and buffer tray ...................................................................................... 32

5.4.2 Installing the double-walled buffer tray.................................................................................. 33

5.4.3 Preparing a specimen ................................................................................................................ 33

5.4.4 Installing and removing the blade holder ............................................................................... 34

5.4.5 Inserting the blade ...................................................................................................................... 35

5.4.6 Adjusting the clearance angle ................................................................................................. 35

5.5 Routine daily maintenance and switching off the instrument – VT1200/VT1200 S .......... 36

2

Instructions for Use V 1.4 RevC – 09/2013

Page 5

Contents

6. Operating the VibroCheck ...................................................................................................... 37

6.1 Using the VibroCheck with the VT1200 ................................................................................... 37

6.2 Using the VibroCheck with the VT1200 S ................................................................................ 39

7. Malfunctions: Meaning and Troubleshooting .................................................................... 41

7.1 Error messages and troubleshooting ...................................................................................... 41

7.2 Replacing the main fuse ............................................................................................................ 46

8. Cleaning and Maintenance .................................................................................................... 47

8.1 Cleaning the instrument............................................................................................................. 47

9. Ordering Information for Optional Accessories, Consumables and Spare Parts .........48

9.1 Extension accessories for standard specimens .................................................................. 49

9.1.1 Buffer trays .................................................................................................................................. 49

9.1.2 Specimen plate ........................................................................................................................... 50

9.1.3 VibroCheck ................................................................................................................................... 51

9.1.4 Blades ........................................................................................................................................... 52

9.1.5 Microscope, assembly ............................................................................................................... 52

9.1.6 Magnifier, assembly ................................................................................................................... 52

9.1.7 Installing the magnifier support or microscope support .................................................... 53

9.1.8 Fiber-optic illumination, cold light source .............................................................................. 54

9.1.9 Cyanoacrylate adhesive ............................................................................................................ 55

9.1.10 Foot switch .................................................................................................................................. 55

9.1.11 Julabo FL300 – recirculating cooler/chiller ............................................................................ 55

10. Warranty and Service ..............................................................................................................56

11. Decontamination Certificate (Master) ..................................................................................58

Leica VT1200 / VT1200 S

3

Page 6

1 Important Information

1.1 Symbols in the text and their meanings

Warnings

appear in a gray box and are marked by

a warning triangle .

Useful tips,

i.e. important user information, appear

in a gray box and are marked by an .

(5)

(Fig. 5)

Numbers in parentheses refer to item

numbers in illustrations or to the illustrations themselves.

Manufacturer

Date of Manufacture

The CE labeling shows that the product

corresponds to one or more applicable

European directives.

Observe the Instructions for Use

Order No.

Serial number

Environmental protection symbol of

the China RoHS directive.

The number in the symbol indicates

the "Environment-friendly Use Period"

of the product in years.

The symbol is used if a substance

restricted in China is used in excess

of the maximum permitted limit.

The CSA test mark means that a

product has been tested and fulfills

the applicable safety and/or performance standards, including the

relevant standards defined or administered by the American National

Standards Institute (ANSI), Underwriters Laboratories (UL), the Canadian Standards Association (CSA),

the National Sanitation Foundation

International (NSF) and others.

Symbol for labeling electrical and

electronic equipment in accordance

with Section 7 of the German Electrical and Electronic Equipment Act

(ElektroG).

ElektroG is the law on the bringing

into circulation, return and environmentally compatible disposal of electrical and electronic equipment.

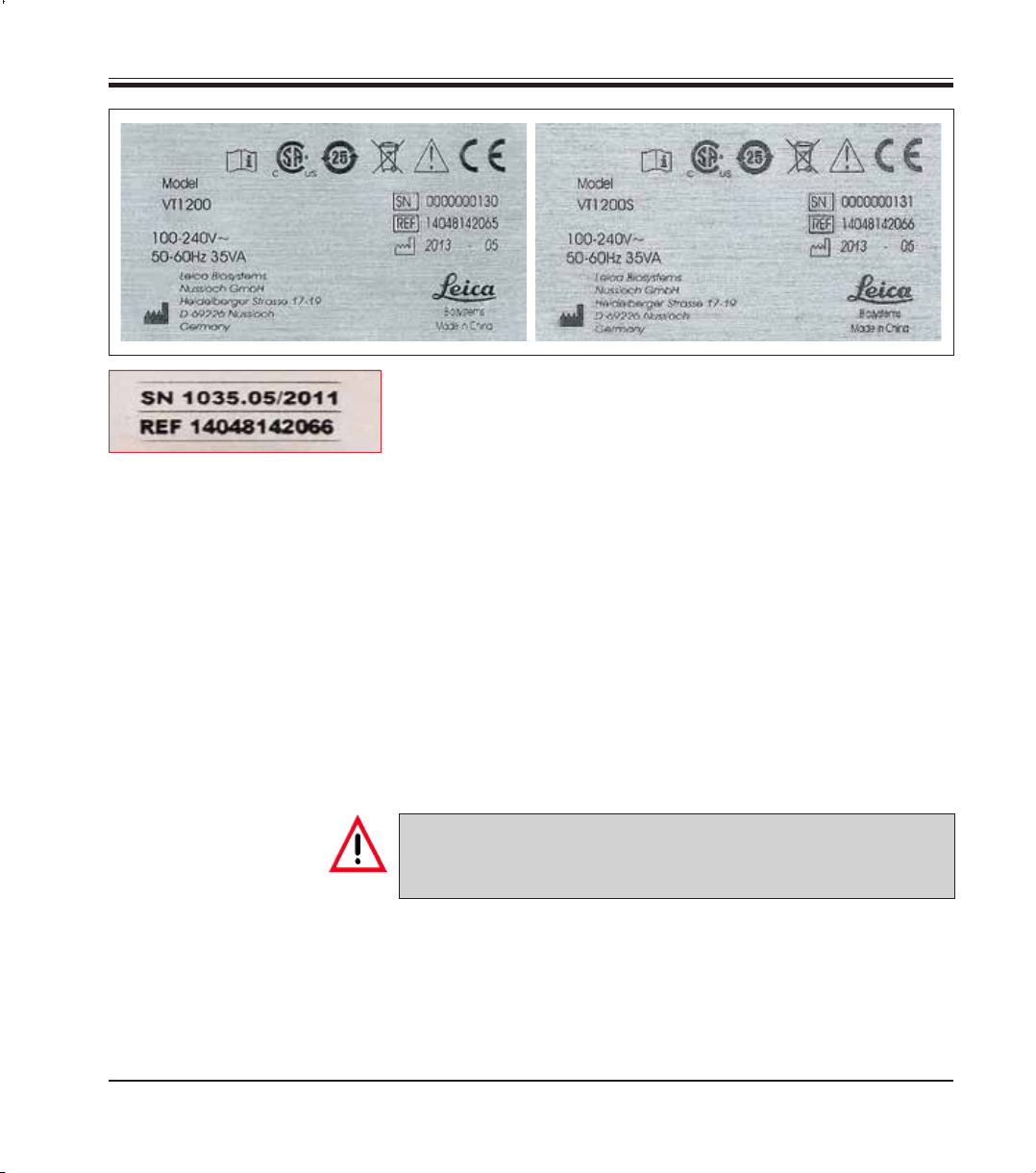

Instrument

model:

4

All information provided in these Instructions for Use applies only to the instrument

type indicated on the title page.

A nameplate is attached to the rear side of the instrument. The series and REF numbers are attached to a separate label (Fig. 1a) on the right side of the instrument.

Fig. 1 and 1a are provided as an example only and show a valid nameplate for this

instrument.

Instructions for Use V 1.4 RevC – 09/2013

Page 7

Fig. 1a

1.2 Qualification of personnel

The Leica VT1200 and the VT1200 S may be operated by trained laboratory

personnel only.

All laboratory personnel designated to operate this instrument must read

these Instructions for Use carefully and must be familiar with all technical

features of the instrument before attempting to operate it.

1. Important Information

Fig. 1

1.3 Intended use/improper use

The Leica VT1200 and VT1200 S are used for sectioning in the fields of medicine, biology and industry, and are especially designed for sectioning fixed

or unfixed fresh tissue in buffer.

The instrument must be used exclusively according to the instructions contained in these Instructions for Use.

Any other use of the instrument is considered improper.

Leica VT1200 / VT1200 S

The VT1200/VT1200 S may be used for research purposes only. Sections made using the VT1200/VT1200 S must NOT be used for diagnostics.

5

Page 8

2. Safety

These Instructions for Use includes important information related to the

operating safety and maintenance of the instrument.

The Operating Manual is an important part of the product, and must be

read carefully prior to startup and use and must always be kept near the

instrument.

If additional requirements on accident prevention and environmental protection apply in the country of operation, these Instructions for Use must

be supplemented by appropriate instructions to ensure compliance with

such requirements.

Make sure to read all of these Instructions for Use before you work on or

operate the instrument.

2.1 General safety notes

These instruments have been built and tested in accordance with the safety

regulations for electrical measuring, control, regulating and laboratory

devices.

In order to maintain this condition and to ensure safe operation, the user

must follow the instructions and warnings contained in this operating manual.

2.2 Warnings

6

The current EC Declarations of Conformity can be found on the Internet:

www.LeicaBiosystems.com

The safety devices installed in this instrument by the manufacturer only

constitute the basis for accident prevention. Operating the instrument safely

is, above all, the responsibility of the owner, as well as the designated personnel who operate, service or clean the instrument.

To ensure trouble-free operation of the instrument, make sure to comply

with the following instructions and warnings.

Instructions for Use V 1.4 RevC – 09/2013

Page 9

• Extremely sharp blades pose risk of injury when touched!

• Fresh tissue poses risk of infection!

• Fire hazard from uncovered magnifier! Cover the magnifier during work breaks!

Proper handling

Always be exceptionally careful when handling the blades!

Do not leave open blades lying around after removal.

Always make sure to handle the blade in a way that will not cause you injury.

All appropriate safety precautions must be met to avoid the risk of infection.

Wearing safety gloves, a mask and safety goggles—in accordance with the "Working with Sub-

stances that Pose a Health Risk" guidelines—is absolutely mandatory.

The instrument may be opened by authorized service personnel only.

Always disconnect the power plug before opening the instrument.

Always switch off the instrument using the power switch and disconnect the power plug before

replacing the fuse. The use of fuses other than those installed at the factory is not permitted.

2.3 Transport, unpacking and setting up

2. Safety

The instrument must be set up so that the main power switch on its right side (item 7 in Fig. 14) is

easily accessible at any time.

Because the weight of the instrument is approx. 56 kg, carrying the instrument requires 2 persons

(1 carrying handle per person).

Leica VT1200 / VT1200 S

• Whenunpackingtheinstrument,comparethepartsreceivedwiththe

parts ordered. If the parts received do not match your order, contact the

sales company responsible for your order immediately.

• Beforeconnectingtothepowersupplysystem,pleaseobserve"Technical Data"!

• Neverconnecttheinstrumenttoapowersocketthatdoesnothavea

protective conductor terminal.

7

Page 10

3. Instrument characteristics

3.1 Technical data for the VT1200

General data:

Sectioning frequency (±10 %) ........................................................................................................... 85 Hz (± 10 %)

Amplitude.................................................................................................... from 0 - 3 mm, in 0.05 mm increments

Sectioning speed (± 10 %) ................................................................................................................ 0.01 - 1.5 mm/s

Return speed (± 10 %) ..................................................................................................................................2.5 mm/s

Total vertical specimen stroke .................................................................................................20 mm (motorized)

Cutting range ..............................................................................................................................45 mm (adjustable)

Maximum specimen size:

With standard blade holder ............................................................................................................. 33 x 50 mm

Specimen orientation, rotating .................................................................................................................... 360°

Specimen plate, swiveling ....................................................................................................................... 0 - 10°

Section thickness adjustment .................................................................................. manual, in 1 µm increments

Ambient conditions:

Operating temperature range: ........................................................................................... min. 10 °C - max. 35 °C

Relative humidity: ....................................................................................................................................... max. 60 %

Storage temperature: ................................................................................................................................... 5 - 55 °C

Storage humidity: ............................................................................................................................................. < 60 %

Height: ........................................................................................................................ up to 2000 m above sea level

Electrical data:

Rated voltage range (± 10 %): ....................................................................................................................... 100 V - 240 V

Nominal frequency (±10 %): .................................................................................................................................. 50/60 Hz

Power consumption: ...................................................................................................................................................35 VA

Protective class: ...................................................................................................................................................................I

Power fuse: ...................................................................................................................................................... T 1 A L 250 V

Pollution degree: ..................................................................................................................................................................2

Overvoltage category: ....................................................................................................................................................... II

Electrical overload protection: ..................................................................................................................................... Yes

Internal current limit for the electronics: ................................................................................................................... Yes

Dimensions:

L x W x H: ............................................................................................................................... 600 mm x 250 mm x 230 mm

Height with magnifier support ............................................................................................ 600 mm x 250 mm x 320 mm

Height with microscope: ..................................................................................................... 600 mm x 250 mm x 490 mm

L x W x H control unit (when the bases are folded in): ................................................... 165 mm x 120 mm x 72 mm

Weight:

Without magnifier support and control unit .............................................................................................................56 kg

VT1200 control unit .........................................................................................................................................................1 kg

Magnifier support ...........................................................................................................................................................2 kg

Microscope support with stereomicroscope ............................................................................................................4 kg

8

Instructions for Use V 1.4 RevC – 09/2013

Page 11

3. Instrument Characteristics

3.1.1 Technical data for the VT1200 S

General data:

Sectioning frequency (± 10 %): ...................................................................................................................85 Hz (± 10 %)

Amplitude: ....................................................................................................... from 0 - 3 mm, in increments of 0.05 mm

Sectioning speed (± 10 %): ........................................................................................................................0.01 - 1.5 mm/s

Return speed (± 10 %): .................................................................................... 1.0 - 5 mm/s, in increments of 0.5 mm/s

Total vertical specimen stroke: ......................................................................................................... 20 mm (motorized)

Sectioning range: ..................................................................................................................................................... 45 mm

Sectioning window: .................................................................................................................................. 0.5 mm - 45 mm

Specimen retraction: .............................................................................. 0 - 100 µm (adjustable; can be deactivated)

Maximum specimen size:

with standard blade holder: ..................................................................................................................... 33 x 50 mm

Specimen orientation, rotating: ........................................................................................................................... 360°

Specimen plate, swiveling: ...............................................................................................................................0 - 10°

Sectioning thickness setting: ............................................manual in 1 µm increments or automatic max. 1000 µm

Ambient conditions:

Operating temperature range: .....................................................................................................min. 10 °C - max. 35 °C

Relative humidity: ............................................................................................................................................... max. 60 %

Storage temperature: .............................................................................................................................................5 - 55 °C

Storage humidity: .......................................................................................................................................................< 60 %

Height: .................................................................................................................................up to 2000 m above sea level

Electrical data:

Rated voltage range (± 10 %): ...................................................................................................................... 100 V - 240 V

Nominal frequency (± 10 %): ................................................................................................................................ 50/60 Hz

Power consumption: ..................................................................................................................................................35 VA

Protective class: ..................................................................................................................................................................I

Power fuse: ..................................................................................................................................................... T 1 A L 250 V

Pollution degree: .................................................................................................................................................................2

Overvoltage category: ...................................................................................................................................................... II

Electrical overload protection: .................................................................................................................................... Yes

Internal current limit for the electronics: .................................................................................................................. Yes

Dimensions:

L x W x H: .............................................................................................................................. 600 mm x 250 mm x 230 mm

Height with magnifier: ......................................................................................................... 600 mm x 250 mm x 320 mm

Height with microscope: .................................................................................................... 600 mm x 250 mm x 490 mm

Control unit (when the bases are folded in): ..................................................................... 190 mm x 150 mm x 72 mm

Weight:

Without magnifier support and control unit: ...........................................................................................................56 kg

VT1200 S control unit: ...................................................................................................................................................1 kg

Magnifier support: .........................................................................................................................................................2 kg

Microscope support with stereomicroscope: ..........................................................................................................4 kg

Leica VT1200 / VT1200 S

9

Page 12

3. Instrument characteristics

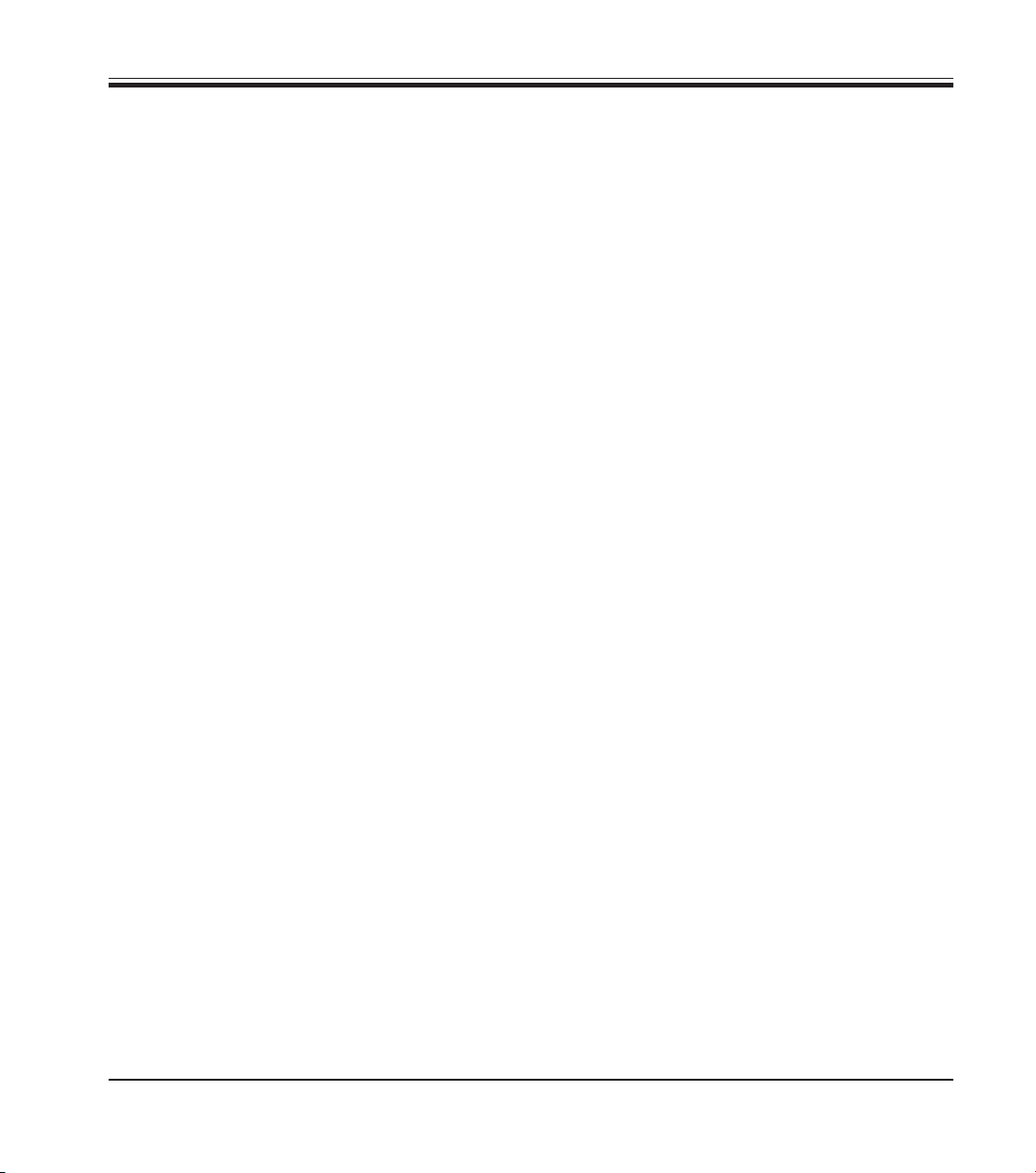

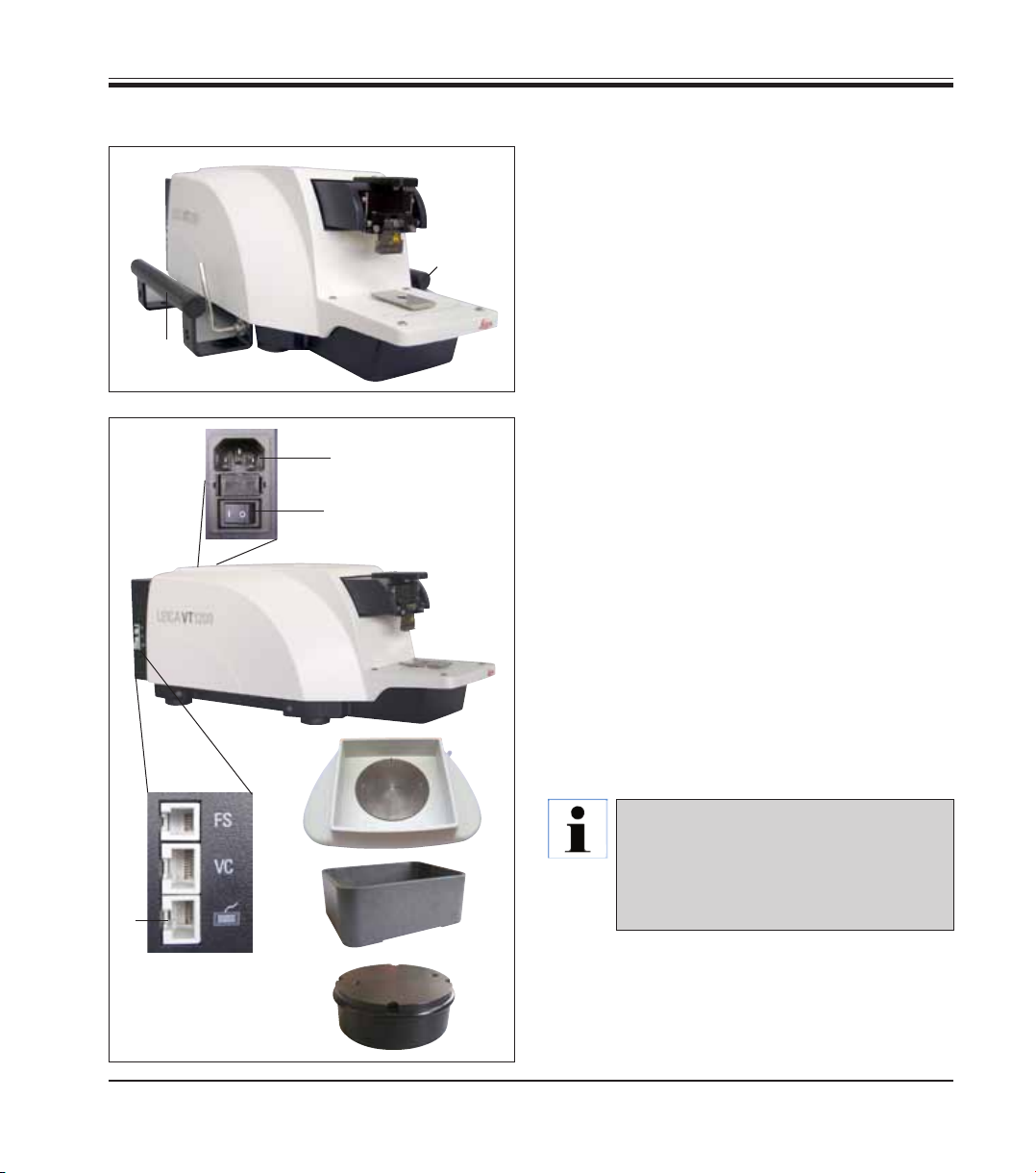

3.2 General overview – VT1200/VT1200 S

Fig. 3, Magnifier

Fiber

optic

light guide

Cold light

source

Fig. 4, Microscope

Fig. 5

Cutting head

Fig. 2, Basic instrument

10

Fig. 6,

Foot switch

Blade holder

Fig. 8,

Control panelm

VT1200 Smm

Fig. 7,

VT1200 control

panel

Instructions for Use V 1.4 RevC – 09/2013

Page 13

Attachments on dovetail receptacle

3. Instrument Characteristics

Ice tray

Buffer tray

Buffer tray,

plastic

Buffer tray,

metal

Specimen plate

for specimens 1 c m

in height

for specimens 2 cm

in height

Double-walled buffer tray

Julabo FL300

(recirculating

cooler/chiller)

Specimen plate

for specimens 1 c m

in height

for specimens 2 cm

in height

VibroCheck

Fig. 9

Blades for the blade holder

Sapphire blade

Directional

Cyanoacrylate adhesive

Leica VT1200 / VT1200 S

Directional

Cyanoacrylate adhesive

11

Page 14

3. Instrument characteristics

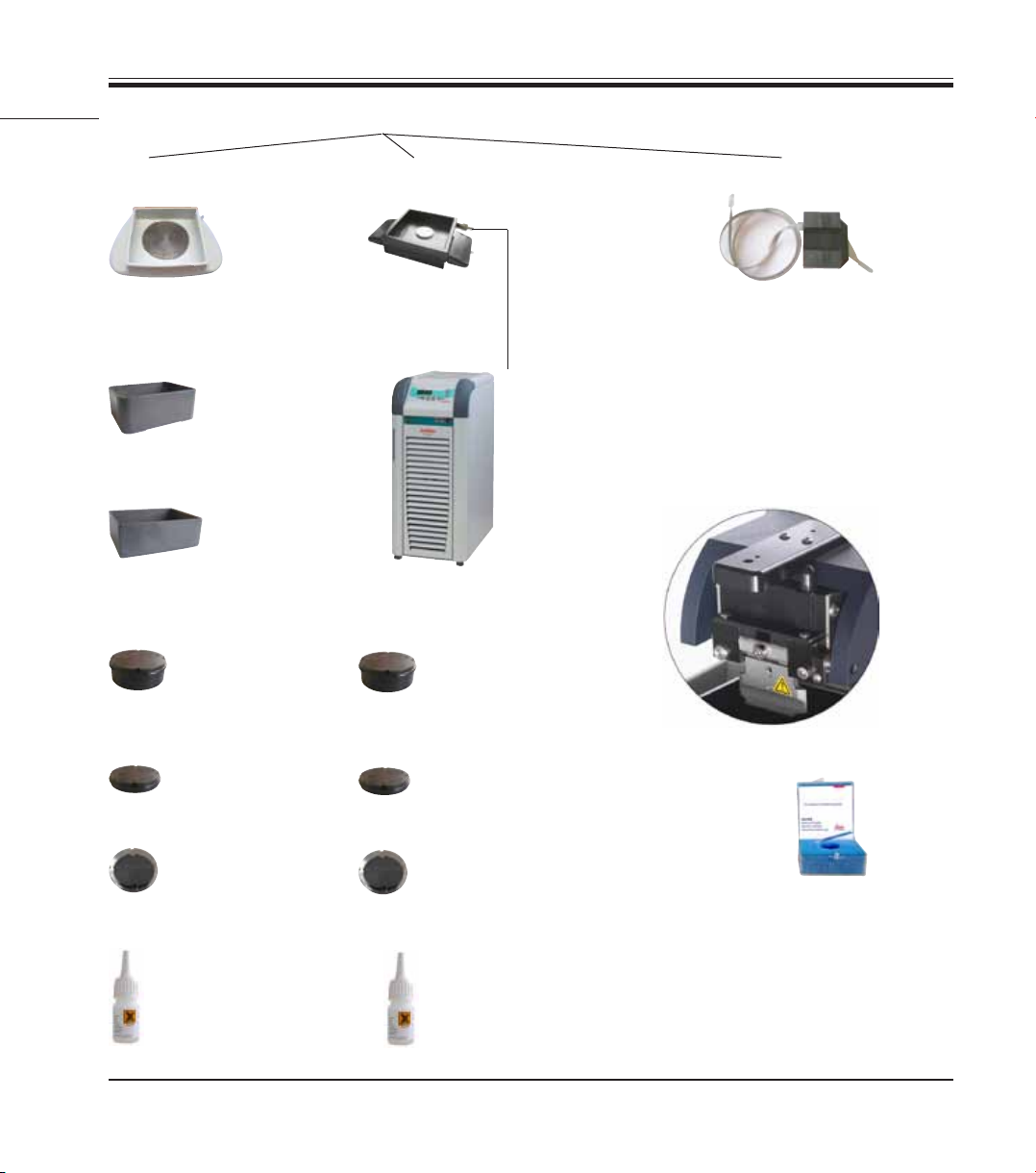

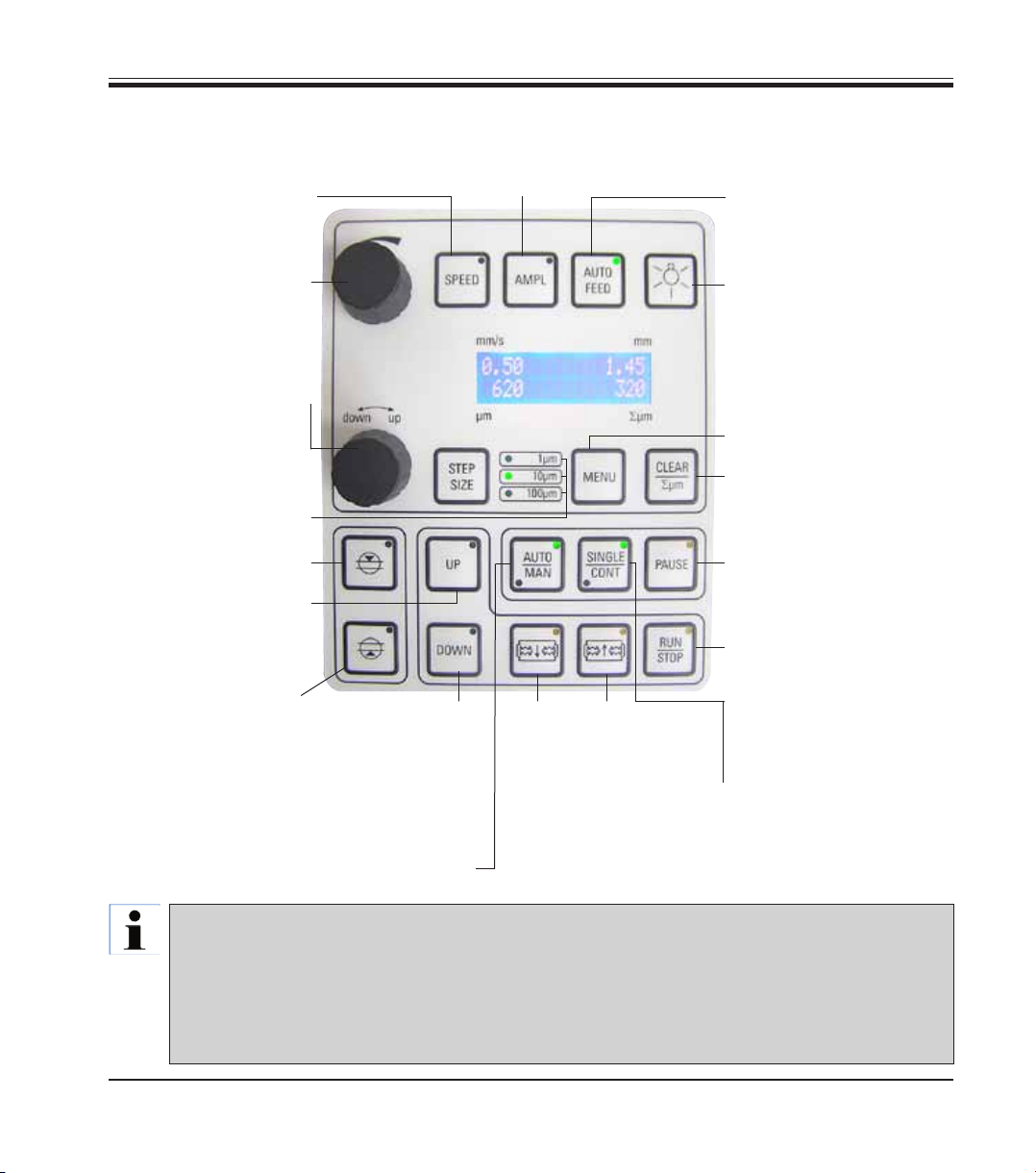

3.3 VT1200 Control Panel

LED display for blade feed

rate and amplitude

Setting dial 1, for blade feed

rate and amplitude

LED display for section

thickness and

section thickness totalizing

Setting dial 2, for section

thickness and moving the

specimens vertically

Selection of the step size,

1 µm,10 µm or

Quickly moves the speci-

men upwards (press the

button until the desired

Quickly moves the specimen

downwards (press once to

adjust to the lowest position)

(for approx. 3 sec.) to save a

frequently used feed value

(pressing it more than once

feeds by the saved section

thickness multiple times).

100 µm steps

position is reached)

Press this button

Moves the blade to-

wards the specimen

Caution: Keep it pressed down until the desired

position is reached. When the end position is

reached, the LED lights up.

LED for feed rate

LED on, for enabled ampli-

1

2

Moves the blade away

from the specimen

tude adjustment

Toggles between SPEED (blade

feed rate) and AMPL (amplitude)

Section thickness

Sets the current specimen

position between 0 (lower) and

20,000 µm (upper) or - after zero,

totals the section thicknesses

Pressing this button toggles

between µm and ∑µm (actively illuminated).

Resets the totalized section

thickness display ∑µm to zero.

Immediately starts or stops

the sectioning process

ON/OFF lamp

Fig. 10

12

The Leica VT1200 is a semiautomatic microtome with a vibrating blade. Before each cut, a manual feed to the desired section thickness must be carried out using the setting dial for section

thickness. The VT1200 does not include an automatic specimen retraction; however, retraction

can be performed manually.

Instructions for Use V 1.4 RevC – 09/2013

Page 15

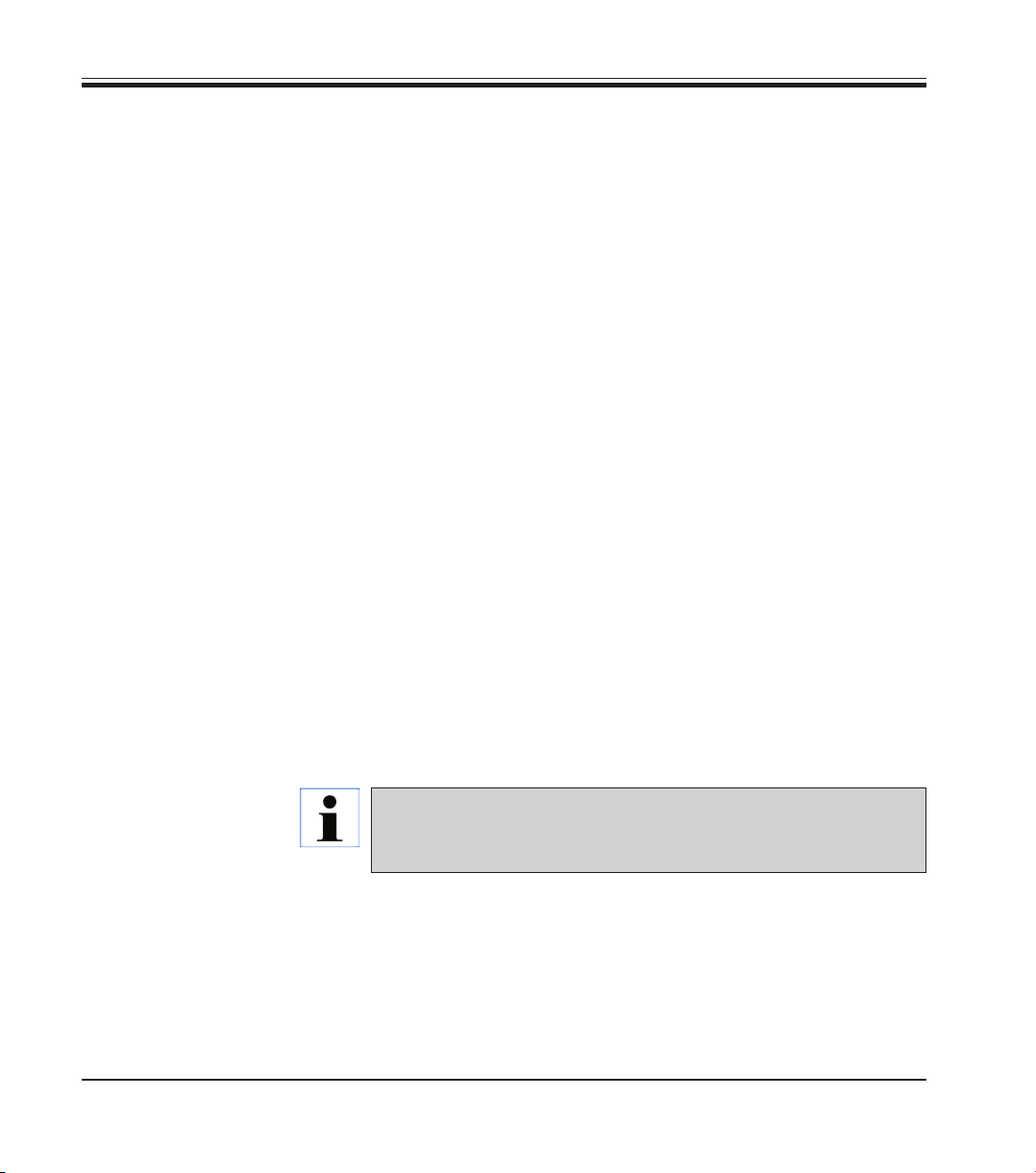

3.3.1 VT1200 S control panel

Sets the blade feed rate.

Select the values using set-

ting dial 1.

Setting dial 1, for blade

feed rate (SPEED),

AMPLitude or section

thickness for automatic

mode (AUTO FEED)

Sets the amplitude.

Select the values using

setting dial 1.

3. Instrument Characteristics

Possible in automatic sectioning

mode only. Select the desired section thickness for the automatic

feed using setting dial 1.

ON/OFF lamp

Setting dial 2, for section

thickness and moving the

specimens vertically

Selection of the step size,

1 µm, 10 µm or 100 µm steps

First cutting window edge,

LED illuminates when the

window edge is set

Moves the specimen up-

wards (as long as the button

is pressed). When the up-

permost position is reached,

the LED lights up.

Second cutting window

edge, LED illuminates when

the window edge is set

Fig. 11

Toggles between automatic (AUTO) and

semiautomatic (MAN) sectioning mode

The Leica VT1200 S is a fully automatic microtome with vibrating blade. It can be operated in automatic as well as

semiautomatic sectioning mode.

In semiautomatic sectioning mode, a manual feed to the desired section thickness must be carried out before

each cut. There is no automatic specimen retraction in this mode; however, retraction can be performed manually.

In automatic mode, an automatic feed (AUTO FEED) to the selected section thickness is carried out before each

cut, and the specimen is lowered to the desired retraction value after each cut to prevent the specimen surface

and the blade from coming into contact while the blade is being retracted.

Moves the speci-

men into the lowest

position, (LED is

illuminated when the

lowest position is

reached)

Moves the

blade towards

the specimen

Caution: Keep it pressed

down until the desired position is reached. When the

end position is reached, the

LED lights up.

Moves the blade

away from the

specimen

Toggles in and out of the

menu. Memory for 8 parameter sets.

Sets the totalized section

thickness display åµm to "0".

Interrupts the sectioning

process in automatic mode.

Pressing the button again

reactivates the sectioning

process.

Starts or stops the sectioning process. In semiautomatic

mode, the sectioning process

stops immediately; in automatic

mode, the sectioning process is

finished completely.

Toggling between single

stroke (SINGLE) and continuous stroke (CONT) in automatic

mode is possible. In semiautomatic mode, only single stroke

(SINGLE) is possible.

Leica VT1200 / VT1200 S

13

Page 16

4. Installation

4.1 Standard scope of delivery for the VT1200

VT1200 basic instrument ............................................................... 14 0481 42065

1 control panel ................................................................................ 14 0481 43395

1 toolset:

- 1 Allen key, size 3.0 ................................................................. 14 0194 04764

- 1 Allen key, size 6.0 ................................................................. 14 0222 04141

- 1 cryo-manipulator .................................................................. 14 0462 28930

- 1 replacement fuse T 1 A ....................................................... 14 6943 01000

1 set of power cables:

- 1 power cable "D" .................................................................... 14 0411 13558

- 1 power cable "USA-C-J" ....................................................... 14 0411 13559

- 1 power cable "UK" ST/BU F-5A ............................................ 14 0411 27822

1 dust cover (basic instrument), small ......................................... 14 0212 43742

1 bottle of cyanoacrylate adhesive, contents 10 gr. .................. 14 0371 27414

1 Instructions for Use for Leica VT1200/VT1200 S...................... 14 0481 80101

1 language CD .................................................................................. 14 0481 80200

14

VT1200 configuration ....................................................................... 14 912000001

The above scope of delivery, plus:

Ice tray, assembly ........................................................................... 14 0481 42010

Buffer tray (metal), assembly ........................................................ 14 0481 42084

When ordering additional accessories, compare the parts received

with the parts ordered. If the parts received do not match your order,

contact the sales company responsible for your order immediately.

Instructions for Use V 1.4 RevC – 09/2013

Page 17

4.1.1 Standard scope of delivery for the VT1200 S

VT1200 S basic instrument ............................................................. 14 0481 42066

1 control panel ................................................................................ 14 0481 43396

1 toolset:

- 1 Allen key, size 3.0 ................................................................. 14 0194 04764

- 1 Allen key, size 6.0 ................................................................. 14 0222 04141

- 1 cryo-manipulator .................................................................. 14 0462 28930

- 1 replacement fuse T 1A ........................................................ 14 6943 01000

1 set of power cables:

- 1 power cable "D" .................................................................... 14 0411 13558

- 1 power cable "USA-C-J" ....................................................... 14 0411 13559

- 1 power cable "UK" ST/BU F-5A ............................................ 14 0411 27822

1 dust cover (basic instrument), small ......................................... 14 0212 43742

1 bottle of cyanoacrylate adhesive, contents 10 gr. .................. 14 0371 27414

1 Instructions for Use for Leica VT1200/VT1200 S...................... 14 0481 80101

1 language CD .................................................................................. 14 0481 80200

4. Installation

Leica VT1200 / VT1200 S

VT1200 S configuration ...................................................................14 91200S001

The above scope of delivery, plus:

Ice tray, assembly ........................................................................... 14 0481 42010

Buffer tray (metal), assembly ........................................................ 14 0481 42084

When ordering additional accessories, compare the parts received

with the parts ordered. If the parts received do not match your order,

contact the sales company responsible for your order immediately.

15

Page 18

4. Installation

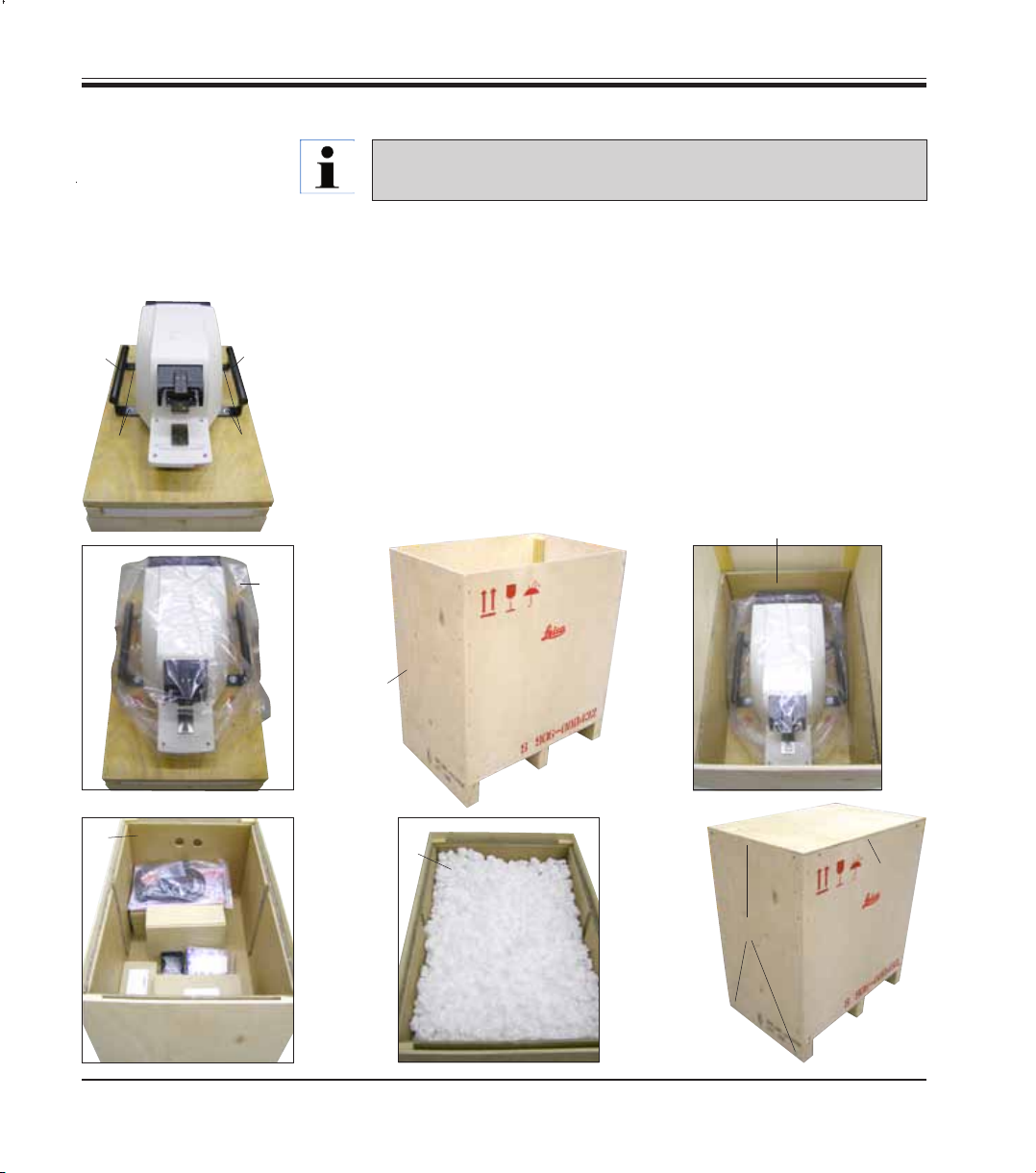

4.2 Packing and setting up the instrument

Ensure that the instrument is standing on a work surface that is as free

of vibrations as possible.

Before each transport, the handles must be screwed onto the instrument using the

provided screws (see Fig. 13). Check to ensure that the handles are firmly in place

and will hold reliably!

Packing the instrument

1. Have 2 people grab the instrument by the transport handles (1), place it

1

2

1

2

3

on the wooden pallet and screw it to the pallet using the 4 size 6 Allen

screws (2).

2. Pull the transparent protective hood (3) over the instrument. Place the

wooden box (4) on the baseplate. Insert the inner carton ring (5).

3. Insert the accessories box (6 – contains accessories) and fill it with

packing material (7).

4. Attach the cover (8) and screw it into place using 8 Phillips screws (9).

5

16

4

6

7

8

9

Instructions for Use V 1.4 RevC – 09/2013

9

Fig. 12

Page 19

4.3 Before commissioning the instrument

1

1

Fig. 13

2

7 (AN)

4

4. Installation

Once the instrument is in its final location, unscrew the transport handles (1) from the instrument using the size 6 Allen key provided and

store them, along with the screws, in a safe

place.

1. Set the power switch (7) on the right side of

the instrument to OFF ().

2. Make sure the power cable is correctly connected in the power socket (2) on the right side

of the instrument.

3. Connect the control panel to the socket (3).

4. Install the ice tray (4).

5. Install the buffer tray (5).

6. Install any optional. accessories, such as the

magnifier, microscope, foot switch, etc. according to p. 49.

7. Use the power switch (7) to switch on the

instrument.

3

Fig. 14

Leica VT1200 / VT1200 S

To make it easier to insert the specimen, adjust the specimen receptacle to

its lowest position, and adjust the blade

5

6

holder to its rearmost position during

the first reference run.

17

Page 20

5. Working with the Instrument

5.1 Description of the typical application

The Leica VT1200 / VT1200 S is a microtome with a vibrating blade and is

predominately used for sectioning fixed and unfixed specimens during

neurological research.

• Tosimplifytheprocessofinsertingthespecimen, you can quickly move the specimen receptacle to the lowest position by pressing the

DOWN button.

• To preparehigh-quality sections,especially

for unfixed tissue, Leica suggests using the

optional VibroCheck measuring instrument to

determine the height amplitude of the blade

after each blade change, and then to minimize

it using the setting screw on the blade holder.

To perform the aforementioned process, install

the VibroCheck instrument (see p. 37 for the

VT1200 or p. 39 for the VT1200 S), install the

blade and adjust the clearance angle to the

desired position. Then take the measurement

and make the appropriate adjustments to the

placement of the blade holder.

Remove the VibroCheck according to the in-

structions, and turn the blade 90° toward the

top to ensure that the ice tray and buffer tray

can be installed safely.

• Insertthebuffertrayintotheicetrayandcover

it with the lid. Fill the ice tray with crushed ice.

• Removethecoverandfillthebuffertraywith

pre-cooled physiological buffer.

• Pushthe icetray and buffertray onto the

dovetail guide and clamp them down.

• Usecyanoacrylate adhesive toadhere the

specimen to the specimen plate and use a

manipulator to place it in the buffer tray. Insert

the hose for gassing the buffer into the hose

clamp.

• UsetheUP button to lift the specimen to the

sectioning level of the blade quickly. Fineadjusting the blade-to-specimen proximity can

be performed using the desired step size 1, 10

or 100 µm.

• Advancethebladetowardthespecimenusing

the "Blade forward" key.

• Aftersectioningthespecimen,usethesetting

dial to feed to the desired section thickness

using the selected step size (1, 10 or 100 µm).

This raises the specimen receptacle to the

desired value.

• Startthesectioningprocessbypressingthe

RUN/STOP key. The process can be stopped

again by pressing this key after the cut has

been completed. Use the "Blade back" key to

move the blade in front of the specimen. Select

the section thickness for the next cut and start

the sectioning process again.

• Aftercompletingthe sectioning process,

remove the blade, dispose of the specimen

receptacle by pushing the DOWN key into its

lowest position, and unclamp, empty and clean

out the ice tray and buffer tray.

18

Instructions for Use V 1.4 RevC – 09/2013

Page 21

5.2 Control elements on the VT1200 control panel

Caution: To practice the key functions, always make sure there are

no blades installed! Do not install the blades until you are familiar

with all of the key functions.

When the instrument is switched on, to make it easier to insert a specimen,

the specimen receptacle automatically moves into the lowest position (the

LED in the DOWN key lights up) and the blade holder moves into the rear-

Switch on the

instrument.

1 = on 0 = off

most position (the LED in "Blade away" from the specimen lights up).

The parameters last used before switching off the instrument: The blade

feed rate (SPEED), selected amplitude (AMPL) and section thickness saved

by the MEMO key are called up again.

The LED illumination is switched on automatically. You can switch it off

using the ON/OFF key (lamp symbol).

5.2.1 Moving the specimen receptacle vertically

When the DOWN key is pressed, the specimen receptacle automatically

moves quickly into the lowest position. (The LED in the DOWN key lights up

when the lower end position is reached.) The ∑µm display is set to "0". If

the DOWN key is pressed a second time while the specimen receptacle is

moving downwards, the specimen receptacle comes to a stop. The current

position appears on the ∑µm display (lowest position = 0). The ∑µm display

does not change while the specimen receptacle is in motion.

5. Working with the Instrument

Leica VT1200 / VT1200 S

When the UP key is pressed and held, the specimen receptacle moves

quickly upwards into the desired position. After the UP key has been released, the current position of the specimen receptacle appears on the ∑µm

display. If the specimen receptacle reaches the upper end position, the LED

in the UP key lights up (uppermost position = 20,000 µm). The ∑µm display

does not change while the specimen receptacle is in motion.

You can reset the display for the current position of the specimen holder to

zero at any point using the CLEAR /∑µm key. The section thicknesses are

then added in the ∑µm display.

19

Page 22

5. Working with the Instrument

5.2.2 Fine-adjusting the blade-to-specimen proximity and feeding to the section thickness

The rotary knob 2 for moving the specimen receptacle vertically can be

used both for fine-adjusting the blade-to-specimen proximity and for adjusting the desired section thicknesses. The step size: 1, 10 or 100 µm can be

selected by pressing the STEP SIZE key.

Turning the setting dial clockwise carries out the desired feed; turning the

setting dial counterclockwise lowers the specimen (minus sign). The value

appears in the lower display when "µm" is selected. After each sectioning

process has been completed, the µm display is set to zero.

Save a commonly used section thickness by adjusting the setting dial for

the section thickness and pressing the MEMO key for 3 seconds. An audible

signal confirms that the value has been accepted.

Feed to the saved value by quickly pressing the MEMO key. Pressing the

MEMO multiple times feeds to the value multiple times.

Neither negative values nor a section thickness of over 1000 µm are

permitted. If an attempt is made to save impermissible values, an audible warning signal sounds three times and the last (permissible)

value is retained.

5.2.3 Moving the blade

Blade

forward back

20

The "Blade forward" and "Blade back" keys have to be held down until the

desired position is reached. The blade feed rate is 2.5 mm/s. When each end

point has been reached, the corresponding LED lights up in the key.

Instructions for Use V 1.4 RevC – 09/2013

Page 23

5.2.4 Selecting the sectioning parameters

SPEED: Blade feed rate – upper display – LED mm/s. The desired blade feed

rate can be adjusted from 0.01 to 1.5 mm/s using rotary knob 1:

0.01 – 0.1 in 0. 01 mm/s increments,

0.10 – 0.5 in 0.02 mm/s increments,

0.50 – 1.5 in 0.10 mm/s increments.

AMPL: upper display – LED mm: Display of the amplitude in mm:

from 0 - 3 mm in 0.05 mm increments

Starts the sectioning process

Starts the sectioning process using the selected amplitude and blade feed

rate. You can start the sectioning process by pressing the RUN/STOP key

a second time, or you can stop the process immediately by pressing the

"Blade back" or "Blade forward" key. The µm display is then reset to "0".

To start a new sectioning process, use the "Blade back" key to move the

blade to the beginning of the specimen, set the desired section thickness

and restart the sectioning process.

5. Working with the Instrument

Leica VT1200 / VT1200 S

21

Page 24

5. Working with the Instrument

5.3 Control elements on the VT1200 S control panel

The Leica VT1200 S is a fully automatic microtome with a vibrating blade

that can be operated in semiautomatic or automatic sectioning mode.

Key / setting dial Semiautomatic sectioning mode Automatic sectioning mode

Switch on the instrument.

1 = on 0 = off

When the instrument is switched

on, to make it easier to insert a

specimen, the specimen receptacle automatically moves into

the lowest position (the LED in the

DOWN key lights up) and the blade

holder moves into the rearmost

position (the LED in "Blade away"

from the specimen lights up).

If semiautomatic sectioning

mode was selected before the

instrument was last switched

off, the following saved parameters are called up again once it

is switched back on:

• Bladefeedrate(SPEED),

• Selectedamplitude(AMPL)

The LED illumination is switched

on automatically. You can switch

it off using the ON/OFF key.

ditto

• Bladefeedrate(SPEED),

• Selectedamplitude(AMPL)

• Savedsectionthickness(AUTO

FEED)

ditto

22

The LED MAN is active.

semiautomatic sectioning mode

is enabled.

The LED AUTO is active.

The automatic sectioning mode

is enabled.

Instructions for Use V 1.4 RevC – 09/2013

Page 25

5. Working with the Instrument

Key / setting dial Semiautomatic sectioning mode Automatic sectioning mode

Toggling from AUTO to

MAN

In semiautomatic sectioning

mode, before each cut, a manual

feed to the desired section thickness must be carried out using

the setting dial for section thickness.

There is no automatic specimen

retraction in this mode; however, retraction can be performed

manually.

The following key functions are

disabled in semiautomatic mode:

• Settingcuttingwindowedges

• Selecting the continuous

stroke (CONT)

• Selectingthesectionthickness

for the automatic feed (AUTO

FEED)

• PAUSE

not active.

In automatic mode, the selected

section thickness feed (AUTO

FEED) is carried out along the 1st

selected cutting window edge

automatically before each cut. To

prevent the specimen surface and

the blade from coming into contact while the blade is being retracted, the specimen is lowered

by the desired retraction value

along the 2nd cutting window

edge after each complete cut.

Toggling from MAN to

AUTO

Leica VT1200 / VT1200 S

An audible warning signal sounds

when these keys are pressed.

The following functions keys become enabled again in automatic

mode:

• Cuttingwindow edges that

have already been set

• Sectionthickness(AUTO FEED)

and continuous stroke (CONT)

23

Page 26

5. Working with the Instrument

Key / setting dial Semiautomatic sectioning mode Automatic sectioning mode

1

The blade feed rate can be ad-

ditto

justed from 0.01 to

1.5 mm/s:

0.01 - 0.1 in 0.01 mm/s increments,

0.10 - 0.5 in 0.02 mm/s increments,

0.50 - 1.5 in 0.10 mm/s increments.

1

Adjusting the amplitude from

ditto

0 to 3 mm in 0.05 mm increments

1

Not possible. Setting the section thickness for

automatic mode - max. 1000 µm.

24

Display for the current specimen holder position (lowest position = 0 µm, uppermost position =

20,000 µm.)

You can reset the display to

"0" at any point by pressing the

CLEAR/∑ µm key. The section

thicknesses are then added in the

∑µm display.

ditto

Instructions for Use V 1.4 RevC – 09/2013

Page 27

5. Working with the Instrument

Key / setting dial Semiautomatic sectioning mode Automatic sectioning mode

The rotary knob for moving the

ditto

specimen receptacle vertically

2

can be used for fine-adjusting

the blade-to-specimen proximity.

Turning the setting dial clockwise

moves the specimen up into the

desired proximity; turning the setting dial counterclockwise lowers

the specimen (minus sign).

The step size: 1, 10 or 100 µm can

be selected by pressing the STEP

SIZE key.

After the setting dial is turned

clockwise or counterclockwise,

the specimen receptacle position

is updated in the ∑µm display.

In semiautomatic mode, the de-

Not possible.

sired section thickness is selected using the setting dial.

The selected section thickness

appears in the µm display and the

current specimen receptacle position appears in the ∑µm display.

After each sectioning process

has been completed, the µm display is set to "0".

Leica VT1200 / VT1200 S

When the DOWN key is pressed,

the specimen receptacle automatically moves quickly into the

lowest position. (The LED in the

DOWN key lights up when the

lower end position is reached.)

The ∑µm display is set to "0".

ditto

25

Page 28

5. Working with the Instrument

Key / setting dial Semiautomatic sectioning mode Automatic sectioning mode

If the DOWN key is pressed a

second time while the specimen

receptacle is moving downwards,

the specimen receptacle comes

to a stop and the current position appears on the ∑µm display

(lowest position = 0, uppermost

position = 20,000 µm). The ∑µm

display does not change while the

specimen receptacle is in motion.

When the UP key is pressed and

held down, the specimen receptacle moves quickly upwards into

the desired position. After the UP

key has been released, the current position of the specimen receptacle appears on the ∑µm display. If the specimen receptacle

reaches the upper end position,

the LED in the UP key lights up

(uppermost position = 20,000 µm).

The ∑µm display does not change

while the specimen receptacle is

in motion.

ditto

ditto

Blade forward

Blade back

26

The "Blade forward" and "Blade

back" keys have to be held down

until the desired position is

reached. The blade feed rate can

be set in the menu: 1 – 5 mm/s,

in increments of 0.5 mm/s. Each

time an end point is reached, the

corresponding LED lights up in

the key.

ditto

Instructions for Use V 1.4 RevC – 09/2013

Page 29

5. Working with the Instrument

Key / setting dial Semiautomatic sectioning mode Automatic sectioning mode

General information about

the cutting window

Activated cutting window edges can be deactivated

by pressing the corresponding key for approx. three

seconds.

Not possible. The horizontal cutting path can be

reduced to the specimen size. The

two cutting window edges can be

adjusted and changed indepen-

dently. Holding the key down for

a longer duration (audible warning signal) sets the beginning or

end (depending on the key) of the

cutting window to the maximum

value. Smallest possible sectioning window: 0.5 mm . If a window

smaller than 0.5 mm is set or the

user reverses the beginning and

end, the last entered value is accepted and the previous value is set

to the maximum value. The cutting

window is not saved when the instrument is switched off; however,

it is retained when you switch from

automatic mode (AUTO) to semiautomatic mode (MAN).

Leica VT1200 / VT1200 S

Not possible. Advance the blade toward the

specimen using the "Blade for-

ward" key. Press the "1st cutting

window edge" key until the LED in

the key lights up.

Not possible.

Advance the blade to the end of the

specimen using the "Blade forward"

key and press "2nd cutting window

edge" until the LED in the key lights up.

27

Page 30

5. Working with the Instrument

Key / setting dial Semiautomatic sectioning mode Automatic sectioning mode

Only single stroke (SINGLE) is possible. If an attempt is made to switch

to continuous stroke (CONT), an

audible warning signal sounds.

Starts the sectioning process

using the selected amplitude

(AMPL) and blade feed rate

(SPEED). Pressing the RUN/STOP

key a second time stops the sectioning process immediately.

The µm display is then reset to "0". The programmed section thick-

Toggles between single (SINGLE)

and continuous stroke (CONT).

The corresponding LED lights up

to indicate the current selection.

Starts the sectioning process using the selected section thickness

(AUTO FEED) amplitude (AMPL)

and the blade feed rate (SPEED).

If single stroke (SINGLE) is selected, only one sectioning process is

carried out. – If continuous stroke

(CONT) is selected, a continuous

sectioning process takes place.

Pressing the RUN/STOP key a

second time stops the sectioning

process that is in progress. The

blade moves to the 1st cutting

window edge and stays there.

ness (AUTO FEED) appears in the

µm display continuously.

28

Not possible. A sectioning process in progress

can be interrupted immediately

by pressing the PAUSE key and

restarted by pressing the PAUSE

key again. If PAUSE has been

pressed to interrupt a sectioning process, pressing the RUN /

STOP key or the "Blade forward"

or "Blade back" keys discontinues

the sectioning process.

Instructions for Use V 1.4 RevC – 09/2013

Page 31

5. Working with the Instrument

Key / setting dial Semiautomatic sectioning mode Automatic sectioning mode

Press the MENU key

ditto

8 sets of user parameters can be

1

saved;

Current user selection – User

1: turn rotary knob 2 clockwise,

2

then press Menu again.

The blade feed rate (SPEED) can

1

be set from 0 to 1.5 mm/s using

rotary knob 1.

2

Rotary knob 2

1

The amplitude (AMPL) can be set

to 0 - 3 mm using rotary knob 1.

2

1

2

The values can be selected; however, automatic feed is not possible in semiautomatic sectioning mode. If the AUTO FEED key is pressed, one feed motion takes place according to

the value programmed in automatic mode. If the key is pressed more than once, several feed

motions take place.

Leica VT1200 / VT1200 S

Rotary knob 2

The automatic section thickness

feed (AUTO FEED) can be adjusted using predefined step sizes

(1, 10 or 100 µm) max. 1000 µm using rotary knob 1.

29

Page 32

5. Working with the Instrument

Key / setting dial Semiautomatic sectioning mode Automatic sectioning mode

Rotary knob 2

1

Mode: Choice between AUTO

and MAN with rotary knob 1; for

semiautomatic sectioning mode,

2

MAN must be selected.

Rotary knob 2

1

Stroke type (CUT): Only single

stroke (SINGLE) can be selected

using rotary knob 1. If continuous

2

stroke (CONT) is selected, an au-

Rotary knob 2

Mode: Choice between AUTO and

MAN with rotary knob 1; for the

automatic sectioning mode, AUTO

must be selected.

Rotary knob 2

Stroke type (CUT): Choice between single stroke (SINGLE) and

continuous stroke (CONT) with

rotary knob 1.

dible warning signal sounds.

1

Specimen retraction (RETRACT)

cannot be set.

Rotary knob 2

Rotary knob 2

The specimen retraction (RETRACT) can be set from 0 to

100 µm in 10 µm increments using

2

Value cannot be

changed. NO automatic

retraction is possible in

semiautomatic sectioning mode.

rotary knob 1.

30

Rotary knob 2

The LED illumination can be adjusted to 5 different levels of

brightness using rotary knob 1.

ditto

Instructions for Use V 1.4 RevC – 09/2013

Page 33

5. Working with the Instrument

Key / setting dial Semiautomatic sectioning mode Automatic sectioning mode

Rotary knob 2

1

The feed rate (FOR/REV) for the

"Blade forward" and the "Blade

ditto

back" keys can be set between

1 and 5 mm/s in 0.5 mm/s incre-

2

1

ments with rotary knob 1.

Rotary knob 2

Switches the vibration movement

ditto

(FOR/VIB) of the "Blade forward"

key either on or off using rotary

2

1

knob 1.

Rotary knob 2

Key acknowledgment (BEEP) on

ditto

or off with rotary knob 1.

2

Save the parameter and leave by

ditto

pressing the menu MENU key.

If you want to call up the parameters of a certain user (for example, user 3), press the Menu

key and select user 3. Then confirm by pressing the Menu key 2x. The parameters stored under

user3 are now enabled.

Leica VT1200 / VT1200 S

Leaving the menu and

saving the parameter is

possible at any point in

the menu.

31

Page 34

5. Working with the Instrument

5.4 Installing the accessories

3

5.4.1 Installing the ice tray and buffer tray

• Alever(2), which needs to be pushed forward,

is located on the underside of the ice tray (1).

• Nowpushthetrayontothedovetailholder(3)

from the front. Clamp it down by pushing the

lever (2, Fig. 28) towards the rear.

2

Ice tray

Underside

The ice tray can be placed on the stage

1

separately for preparation.

• Pushthebuffertray(5) in as far as it will go

(small pins (4) guide it at the side and front).

It is held in place by three strong magnets,

which are integrated into the bottom of the

2

4

Fig. 15

buffer tray.

• Coverthebuffertray(5) with a Plexiglas lid (6).

• Nowfilltheicetraywithcrushedice.

• Coverthe buffer trayand fill itwith cooled

buffer solution.

6

To remove the buffer tray from the ice

tray, pull on the rounded edges carefully

(7). They help to remove the tray, as they

5

7

Fig. 16

are not magnetic.

32

Instructions for Use V 1.4 RevC – 09/2013

Page 35

5.4.2 Installing the double-walled buffer tray

11

Fig. 17

11

2

5. Working with the Instrument

Clamps for holding the gassing hose for the buffer in the proper position can be added to the

double-walled buffer tray.

When using the double-walled buffer

tray, the recirculating cooler/chiller

must be installed PRIOR TO working

with specimens.

Connect hoses (2, in the scope of delivery of the

double-walled buffer tray) to the empty buffer

tray (bottom of Fig. 17). Access is easier if you

make the left connection first. To do this, pull

back the closure coupling (11), fit the hose until

it engages audibly, and then make the right-hand

connection.

5.4.3 Preparing a specimen

6

Fig. 18

Leica VT1200 / VT1200 S

• Fixthespecimentothespecimenplateusing

the cyanoacrylate (included in the standard

scope of delivery).

• Screwthemanipulator(6) onto the specimen

plate, place it in the buffer tray and adjust it to

the desired position.

• Thespecimenplateisheldinplaceinthebuf-

fer tray magnetically.

33

Page 36

5. Working with the Instrument

5.4.4 Installing and removing the blade holder

7

9

8

Always remove the blade BEFORE installing or removing the blade holder!

For quality and service reasons, the

blade holder (7) is available as a complete unit only.

• Before the blade holdercan be replaced,it

must be brought into a 45° inclined position.

To do so, insert the size 3 Allen key sideways

into the blade holder through the hole (8) and

rotate it 45° clockwise.

Turning the screw (9) counterclockwise

releases the blade holder, allowing it to be

replaced.

• Theinstallationiscarriedoutinreverseorder.

34

Cleaning the blade holder

To clean the blade holder after removal, spray

it with alcohol. It can then be wiped down with

7

a piece of cellulose and placed on a cellulose

towel to dry completely.

Fig. 19

Instructions for Use V 1.4 RevC – 09/2013

Page 37

5. Working with the Instrument

5.4.5 Inserting the blade

8

10

11

9

Fig. 21

5.4.6 Adjusting the clearance angle

Fig. 20

The blade holder can be used for razor

blades, injector blades and sapphire

blades (universal blade holder).

• Inserta size 3Allen key sidewaysinto the

blade holder through the hole (8) and rotate it

90° clockwise.

Clamp the blade as follows:

• Inserttheprovidedsize3Allenkeyfromthetop

through the opening (10) into the blade holder

(11) and open the blade holder (BH).

• Holdtheentirerazorblade(9) (not separated)

on the left and right with both hands and insert

it into the blade holder. Hook in the blade over

bottom pressure plate (see Fig. 21).

• ClampdowntheBHbyturningthesize3Allen

key clockwise until hand-tight.

The clamping screw (11) on the blade

holder must not be tightened too much!

Now return the blade holder to the cutting position.

• Todo so, insertasize 3 Allenkeysideways

into the blade holder through the hole (8) and

rotate approx. 90° counterclockwise.

For more information about adjusting the clearance angle, see Fig. 22.

• Inserta size 3Allen key sidewaysinto the

blade holder through the hole (8) and rotate it

to the desired clearance angle mark.

12 - 15° 13 - 18° 14 - 21°

12 13 14Fig. 22

Leica VT1200 / VT1200 S

For 15°, the effective clearance angle is "0".

The most commonly used setting is 18°

(13).

35

Page 38

5. Working with the Instrument

5.5 Routine daily maintenance and switching off the instrument – VT1200/VT1200 S

After all daily procedures have been finished, perform the following:

• Switchoffthemainswitchonthesideoftheinstrument.

• Placethemagnifiercoveronthemagnifier.

• Removethebladefromthebladeholderanddisposeofitsafely.

• Pulltheicetrayandbuffertrayoffofthedovetailguideandplacethem

on the stage.

• Removeandemptyoutthebuffertray.Disposeofthecontentsofthe

buffer tray properly.

• Removethespecimenplateandlayitflatonthestage.

• Removethespecimenusingasingle-sidedbladeandremoveanycya-

noacrylate adhesive residue from the specimen plate.

36

Caution! The contents of the ice tray can become contaminated if

buffer solution is spilled over it.

Instructions for Use V 1.4 RevC – 09/2013

Page 39

6.1 Using the VibroCheck with the VT1200

The following instructions must be adhered to exactly. Noncompliance can cause

serious damage to the instrument.

We recommend using the VibroCheck after each blade change to check the

optimum position of the blade and minimize the vertical vibration.

Foot switch for VT

(2) - VibroCheck

Control panel for VT

Fig. 23

3

6. Operating the VibroCheck

Prior to assembly, the dovetail guide (3) is

brought down to the lowest position using the

DOWN key!

1. The user installs the VibroCheck: Push the VC

along the dovetail guide (3) to behind the mark

on the baseplate of the instrument (rear stop)

and clamp it down using the lever (15). Insert

the blade and clamp tightly. Return the blade

to the cutting position (see Fig. 20).

2. Plug the connecting plug of the VibroCheck

(VC) into the socket (2 ) on the left side panel.

Short red flash of LED on VC --> control panel

acknowledges VC. LED then remains red. The

LED in the DOWN key flashes green.

Leica VT1200 / VT1200 S

Fig. 24

15

Fig. 25

3. The user presses the DOWN key. The VC

moves to the bottom position, after that the

blade moves to the rearmost position—the

LED in the RUN/STOP key flashes. Short red

flash of LED on VC --> it then remains red.

4. The user presses the RUN/STOP key: First, the

blade moves forward (into the position exactly

above the VibroCheck), then the VC moves into

a position in which the blade partially covers

the light barrier. (If the VC does not receive

any signal via the light barrier, the operation

is canceled and DOWN is enabled.)

LED on VC flashes green - RUN/STOP flashes

yellow.

37

Page 40

6. Operating the VibroCheck

18a

1

When LED on VC is green and LED in RUN/

STOP is yellow, the blade starts to vibrate with

the amplitude set. Speed = 0, amplitude can be

changed at any time.

On the (5-digit) display, the deviation in height

amplitude is shown in µm (e.g. 0.9 µm). This value

can be either positive or negative. The display

can be switched using the µm/∑µm key. Then a

number appears (e.g. 0.4). This means clockwise

rotation by a turn of 0.4 ("+" see 18a) – (Neg. op-

2

Fig. 26

erational sign means counterclockwise rotation

– see 18a.) If the value is "0", no improvement of

the height amplitude is possible.

17

5. Press the STOP key. Using a size 3 Allen key,

unscrew the clamping screw (16) only slightly,

pull off the cap (17) by pulling it upwards (keep

it in a safe place) and turn the adjusting screw

(18) by the corresponding value (here, a turn of

0.4) clockwise (in the "+" direction, 18a) using a

18

size 3 Allen key. Tighten the clamping screw (16)

clockwise.

6. Press the RUN key, check the value, repeat

steps 5-7 if necessary.

38

18

16

If the display shows ∑µm (2) "0" (optimal) and the value in µm (1) is unacceptably high, the blade must be replaced.

Fig. 27

7. If the measured value is accepted, press

DOWN (flashes green). VC moves to lowest

position - blade is moved to the rear. LED on

VC illuminates red again (LED on RUN/STOP

is off).

8. The instrument now expects the VibroCheck

to be removed. To do so, disconnect the USB

plug connection of the VC to the basic instrument and pull the VC off of the dovetail guide.

LED in DOWN key continues to flash – wait

until LED in DOWN button goes out.

The normal operating status is now restored.

Instructions for Use V 1.4 RevC – 09/2013

Page 41

6. Operating the VibroCheck

6.2 Using the VibroCheck with the VT1200 S

The following instructions must be adhered to exactly. Noncompliance can cause serious damage to the instrument.

We recommend using the VibroCheck after each blade change for checking the optimum position of the blade and important sectioning parameters.

Prior to assembly, the dovetail guide (3) is

Foot switch for VT

VibroCheck

Control panel for VT

Fig. 28

3

15

Fig. 29

Fig. 30

Fig. 31

brought down to the lowest position using the

DOWN key!

1. The user installs the VibroCheck: Push the VC

along the dovetail guide (3) to behind the mark

on the baseplate of the instrument (rear stop)

and clamp it down using the lever (15). Insert

the blade and clamp tightly. Return the blade

to the cutting position (see Fig. 19).

2. Plug the connecting plug of the VibroCheck

(VC) into the corresponding socket on the left

side panel. Short red flash of LED on VC --> it

then remains red. Control panel detects VC

(see Fig. 30). The LED in the DOWN key flashes

green.

3. The user presses the DOWN key. The VC

moves to the bottom position, in addition to that

the blade moves to the rearmost position—the

LED in the RUN/STOP key flashes. Short red

flash of LED on VC --> it then remains red.

4. The user presses the RUN/STOP key: First, the

blade moves forward (into the position exactly

above the VibroCheck), then the VC moves

into a position in which the blade partially

covers the light barrier. LED on VC flashes

green - RUN/STOP flashes yellow. Control

panel shows: "VIBRO search" (see Fig. 30). A

search can last up to 1 minute. When LED on

VC is green and LED in RUN/STOP is yellow,

the blade starts to vibrate.

Leica VT1200 / VT1200 S

39

Page 42

6. Operating the VibroCheck

21

18a

18

Fig. 32

17

The deviation of the height amplitude is shown

on the display in µm (1). This value can be ei-

ther positive or negative. A number (e.g. –0.3)

appears in the ∑µm display (2). This means a

counterclockwise rotation (because of the "-")

by a turn of 0.3 and reduces the height amplitude to a minimum. (If there is no operation

sign, the rotation is in a clockwise direction

"+".) If the value is "0", no improvement of the

height amplitude is possible.

5. Press the STOP key. Unscrew the clamping

screw (16) only slightly using the size 3 Allen

key, pull the cap (17) up and off (keep it in a

safe place) and turn the adjusting screw (18)

counterclockwise (the "-" direction, 18a) by a

turn of 0.3 using the size 3 Allen key. Tighten

the clamping screw (16) clockwise.

6. Press the RUN key, check the value, repeat

steps 5-7 if necessary.

40

18

If the display shows ∑µm (2) "0" (optimal) and the value in µm (1) is unacceptably high, the blade must be replaced.

7. If the measured value is accepted, press

DOWN (flashes green). VC moves to lowest

position - blade is moved to the rear. Control

16

Fig. 33

panel of the VT shows: "VIBRO END". The LED

on the VC is again illuminated in red.

8. The instrument now expects the VibroCheck

to be removed. To do so, disconnect the USB

plug connection of the VC to the basic instrument and pull the VC off of the dovetail guide.

LED in DOWN key continues to flash – wait

until LED in DOWN button goes out.

The normal operating status is now restored.

Fig. 34

Instructions for Use V 1.4 RevC – 09/2013

Page 43

7. Malfunctions: Meaning and Troubleshooting

7.1 Error messages and troubleshooting

Error No. / INF

Error Troubleshooting Comment

No.

Error 01 - Wrong control panel

(VT1200 or VT1200 S)

Error 21 - Head does not swing into

place.

Error 22 - Timeout while initializing

the x-axis. (Timeout)

Error 23 - DC motor of x-axis does

not rotate (during initialization or in normal operation)

Error 24 - "X-Start" limit switch is

not reached.

Error 25 - "X-Start" limit switch can-

not be moved away from.

Error 26 - "X-Stop" limit switch is not

reached.

- Use the correct control

panel for the instrument.

1. Check to see if an amplitude value has been

selected.

2. Try to make the head

swing into place by gently

striking it with your hand.

3. If head does not swing

into place, inform service.

- Inform service!

- Inform service!

- Inform service!

- Inform service!

- Inform service!

- Using an incorrect control

panel does not harm the

instrument, but no functions whatsoever are

available.

After all error messages, the instrument MUST be switched off, then on again using the main

switch.

Leica VT1200 / VT1200 S

41

Page 44

7. Malfunctions: Meaning and Troubleshooting

Error No. /

Error Troubleshooting Comment

INF No.

Error 27 - "Bottom" limit switch of

the Z-axis is not reached

during initialization or

operation.

Error 28 - The "top" limit switch of

the Z-axis is not reached.

Error 31 - Both X sensors activated

(during initialization or in

normal operation)

Error 32 - Both Z sensors activated

(during initialization or in

normal operation)

- Check whether an obstacle is blocking the