Page 1

Leica EG 1160

Paraffin Embedding Center

Instruction manual

Leica EG1160 V4.1 English – 05/2001

Always keep this manual near the instrument!

Read carefully prior to operating the instrument!

Page 2

Page 3

1. Important information

Serial No. .................................................

Year of manufacture .................................................

Manufactured in: Federal Republic of Germany

The information, numerical data, notes and value judgments contained in this manual represent the current

state of scientific knowledge and state-of-the-art technology as we understand it following thorough investigation in this field. We are under no obligation to update the present manual periodically and on an ongoing basis according to the latest technical developments, nor to provide our customers with additional

copies, updates etc. of this manual.

For erroneous statements, drawings, technical illustrations etc. contained in this manual we exclude liability as far as permissible according to the national

legal system applicable in each individual case. In particular, no liability whatsoever is accepted for any financial loss or consequential damage caused by or

related to compliance with statements or other information in this manual.

Statements, drawings, illustrations and other information as regards contents or technical details of the

present manual are not to be considered as warranted

characteristics of our products. These are determined

only by the contract provisions agreed between ourselves and our customers.

Leica Microsystems Nussloch GmbH

Heidelberger Strasse 17-19

D-69226 Nussloch

Germany

Leica reserves the right to change technical specifications as well as manufacturing processes without

prior notice. Only in this way is it possible to continuously improve the technology and manufacturing techniques used in our products.

This document is protected under copyright laws. Any

copyrights of this document are retained by Leica

Microsystems Nussloch GmbH.

Any reproduction of text and illustrations (or of any

parts thereof) by means of print, photocopy, microfiche,

web cam or other methods – including any electronic

systems and media – requires express prior permission in writing by Leica Microsystems Nussloch GmbH.

For the instrument serial number and year of manufacture, please refer to the name plate at the back of

the instrument.

Telephone 0 62 24/143 - 0

Telefax 0 62 24/143 - 200

eMail: histo_info@leica-microsystems.com

Internet: http://www.histo-solutions.com

Leica EG 1160 – Paraffin Embedding Center 3

© Leica Microsystems Nussloch GmbH

Page 4

2. Table of contents

1. Important information..................................................................................................................................... 3

2. Table of contents............................................................................................................................................. 4

3. Installation........................................................................................................................................................ 5

4. Technical data ................................................................................................................................................. 6

5. General description ........................................................................................................................................ 7

6. Safety precautions .......................................................................................................................................... 8

7. Leica EG 1160 – Overview............................................................................................................................ 10

8. Components and features ............................................................................................................................ 12

9. Controls / Display .......................................................................................................................................... 16

10. Operation ........................................................................................................................................................ 17

11. Tissue embedding ......................................................................................................................................... 24

12. Cleaning, maintenance, service................................................................................................................. 26

13. Troubleshooting ............................................................................................................................................ 28

14. Ordering information .................................................................................................................................... 31

15. Warrenty and service ................................................................................................................................... 32

4

Instruction manual V 4.1 – 05/2001

Page 5

The Leica EG 1160 is a compact bench-top unit and can be set up easily. All

components come in a cardboard box. The components that are packed

separately can be attached to the instrument easily (see page 5 "Part list").

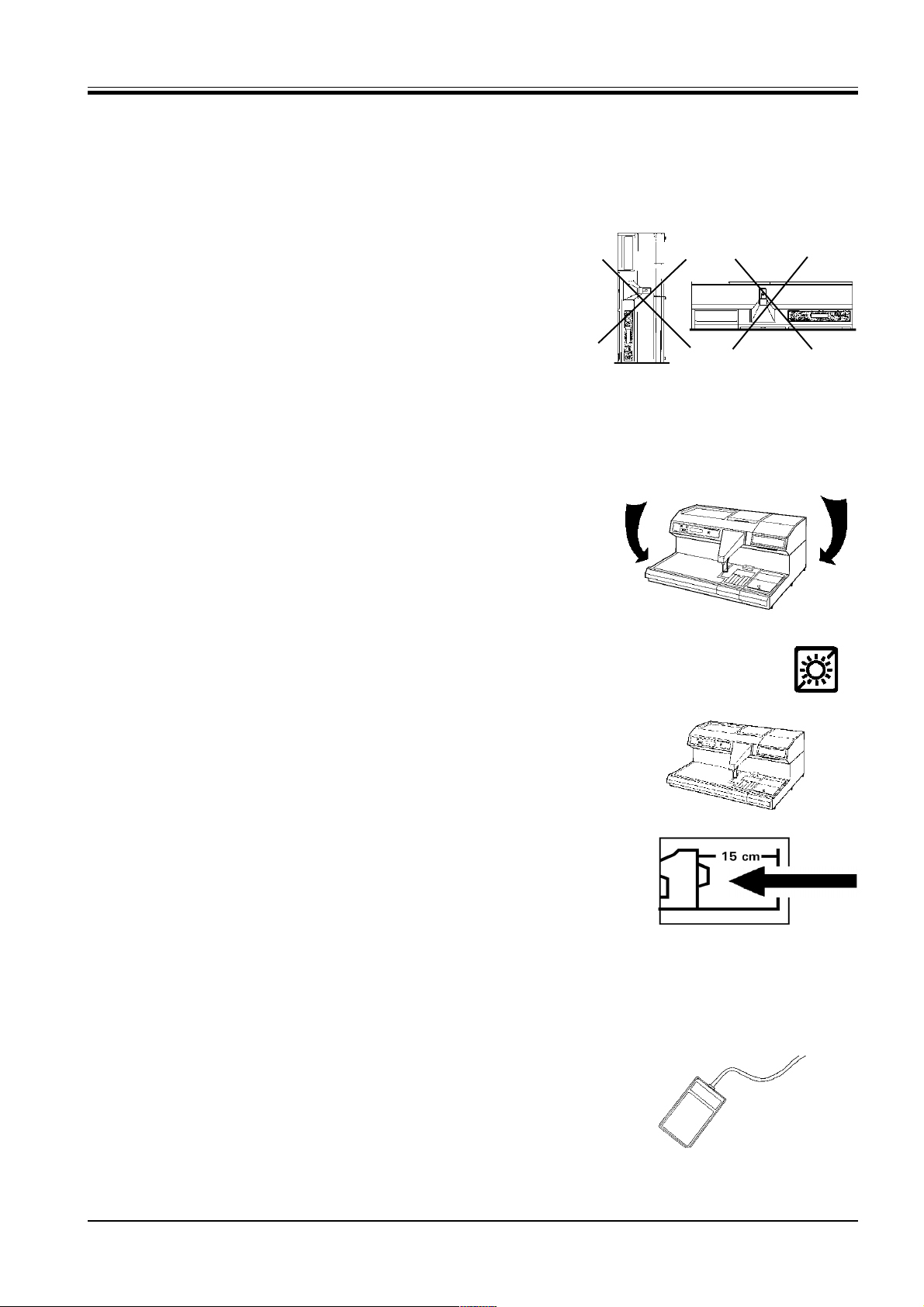

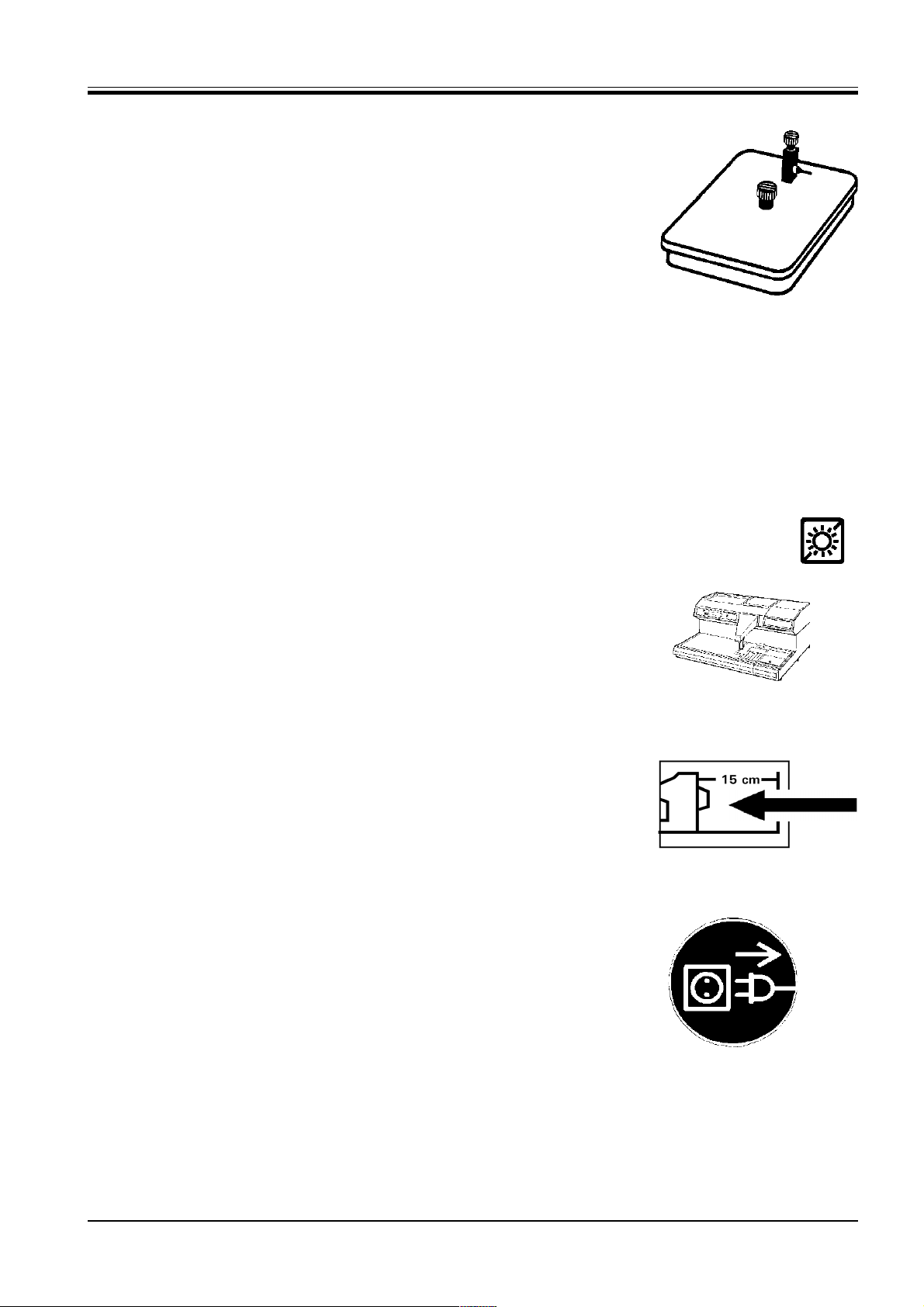

1. Transport and assembly position

The Leica EG 1160 must never - not even for a short while - be positioned as

shown. These positions will inevitably cause damage to the condenser.

Therefore, please check the Tip-N-Tell indicators which are attached to the

package upon receipt.

Should it become necessary to bring the instrument in a position other than

normal, lay the instrument on its back turning it slowly and carefully.

3. Installation

2. Unpacking

The instrument may o n l y be lifted holding it at the sides of the base plate

of the housing. Dot not carry the instrument holding it at the top cover, at the

front handholds of the removable trays or the dispenser. Risk of fracture!

3. Place of installation

The instrument should be set up on a stable, plane laboratory table. Please

ensure that there is no air condition vent nearby.

The location must fulfil the following conditions to ensure that air circulation

is not affected. The back of the instrument must be at least 15 cm away from

the wall. The shipment includes two spacers which must be attached to the

back. Non-compliance with this minimum distance can cause substantial

damage to the instrument and will invalidate the warranty.

4. Power supply

Prior to connecting the instrument to the mains outlet, please ensure that

the power supply specified on the nameplate complies with the local mains

conditions.

5. Foot pedal

The foot pedal is connected to the socket in the right-hand bottom corner on

the back.

Leica EG1160 – Paraffin Embedding Center 5

Page 6

4. Technical data

Power supply: 115 V / 60 Hz

230 V / 50 Hz

Fuses:

115V/60Hz F1, F2 = T5.0 A

230V/50Hz acc. to IEC 127-2

Power consumption: 800 VA

Operating

temperature range: 18°C - 35°C

Cooling system:

Refrigerant: 140 g ±5g R134A

Compressor oil: 150 ccm

EMKARATE RL15S

Temperature control

Dimensions:

(LxDxH) 910 x 575 x 320 mm

Weight: 50 kg

Capacities:

Paraffin reservoir: 3 l

Cassette bath: approx.100 cass.

Heated

recessed area: 8 cassettes

Cold plate: approx. 60 blocks

Programmable parameters:

Temperature

Paraffin reservoir

Mold warmer

Cassette bath

Work surface

Cold plate

Workdays

Daily work times (beginning, end)

Weekday

Time

Operation either manual or via the

foot pedal.

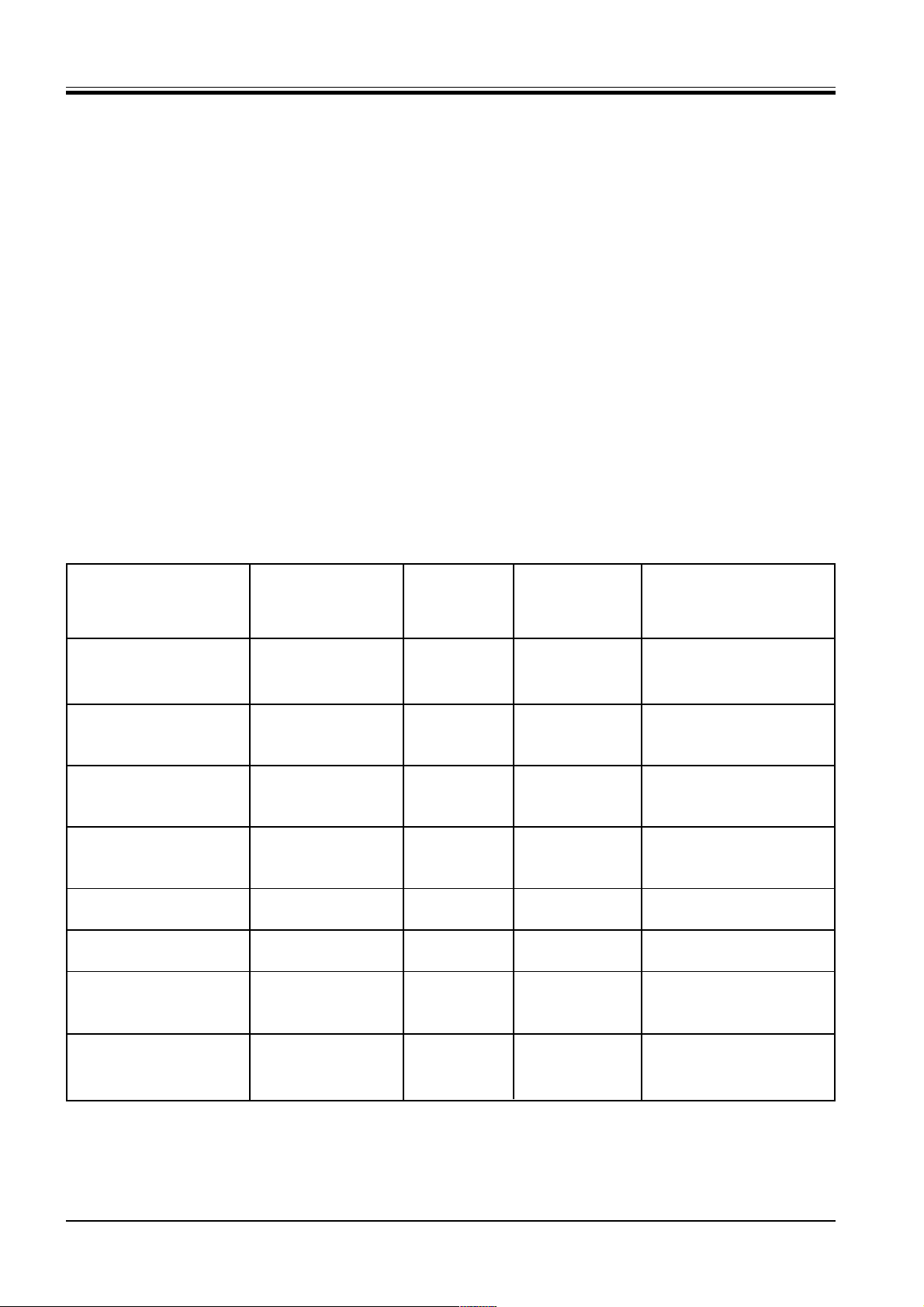

Functional unit Temperature Heated Separate Warm-up time

range separately temperature prior to operation

control

Paraffin reservoir 45 - 70°C, + + 4 h

± 1°C increments

Mold warmer 35 - 70°C + + 1 h

± 1°C increments

Cassette bath 45 - 70°C + + 1.5 h

± 1°C increments

Work area 45 - 70°C + + 1 h

± 1°C increments

Cold plate - 5°C - - 1 h

Forceps holder right 70°C + -

Forceps holder left 70°C + (not basic instrument)

Paraffin dispenser 45 - 70°C + + pump

* at an ambient temperature of 22°C and at an air humidity of 60%

All heated components include overheat protection.

6 Instruction manual V4.0 – 4/98

Page 7

5. General description

Features

1. Paraffin flow rate is pump con

trolled.

2. Paraffin flow rate adjustable in 10

increments

3. Paraffin quantity level indicated

in the display

4. Separate paraffin collecting tray

5. Removable cassette bath

6. Forceps holder on the right (ba

sic instrument) or on the right and

left (not basic instrument)

7. Paraffin dispenser with inte

grated illumination

8. User menu available in 5 lan

guages

9. Fault detection by error

codes in the display

10. Optional accessories: Magni

fier, vacuum attachment, fiber

optical light guide (for connec

tion to the coldlight souces of the

Leica CLS series)

The Leica EG 1160 is a modern tissue embedding center providing all

features required for rapid, convenient and efficient paraffin embedding of tissue including a separately

heated 3-liter capacity paraffin reservoir. Paraffin quantity level shown

on LCD display in two steps. Separately heated paraffin delivery system with integrated filter and pump

ensure a smooth, consistent paraffin flow. The paraffin flow rate is adjustable in 10 increments.

The paraffin outlet nozzle can be operated either manually or via foot

pedal. A non-glare illumination is integrated at the paraffin dispenser

outlet to provide a well lighted work

area.

The separately heated mold warmer

to the right of the paraffin reservoir

is designed to store and heat the

molds prior to embedding.

The work area is divided into three

parts: Cassette storage, working and

embedding area and cold plate. The

cassettes containing the tissue are

stored in a separately heated, removable tray with a capacity of

approx. 100 specimen capsules.

The large work area ensures convenient block removal and easy access

to the cassettes. The forceps holder(s) is/are designed to accommodate three forceps and is/are integrated in the instrument. The heated

recessed area behind the dispenser

handle is designed to keep the par-

affin in the cassette molten. Excess

paraffin can be drained through an

outlet after the removing the stopper.

In front of the paraffin dispenser outlet a refrigeration spot is integrated

in the cold plate ensuring optimal

cooling. The large cold plate provides space for more than 60 embedding molds. A removable tray is located under the work area to collect

excess paraffin drained from the

work area.

The Leica EG 1160 is operated and

programmed via a menu-driven control board. The menu is displayed in

German, English, French, Spanish or

Italian as selected. All operations are

microprocessor-controlled.

Malfunctions are indicated by a numerical error code in the display. A

battery backup prevents loss of all

programmed parameters if a power

failure occurs.

The individual functional units of the

Leica EG 1160 are ergonomically positioned to enable rapid and convenient operation. The instrument may

be operated by qualified personnel

only in accordance with this operating instruction manual.

If used in accordance with the operating instructions and appropriate

maintenance is ensured, the tissue

embedding center will operate

trouble-free and give perfect embedding results for many years.

7Leica EG1160 – Paraffin Embedding Center

Page 8

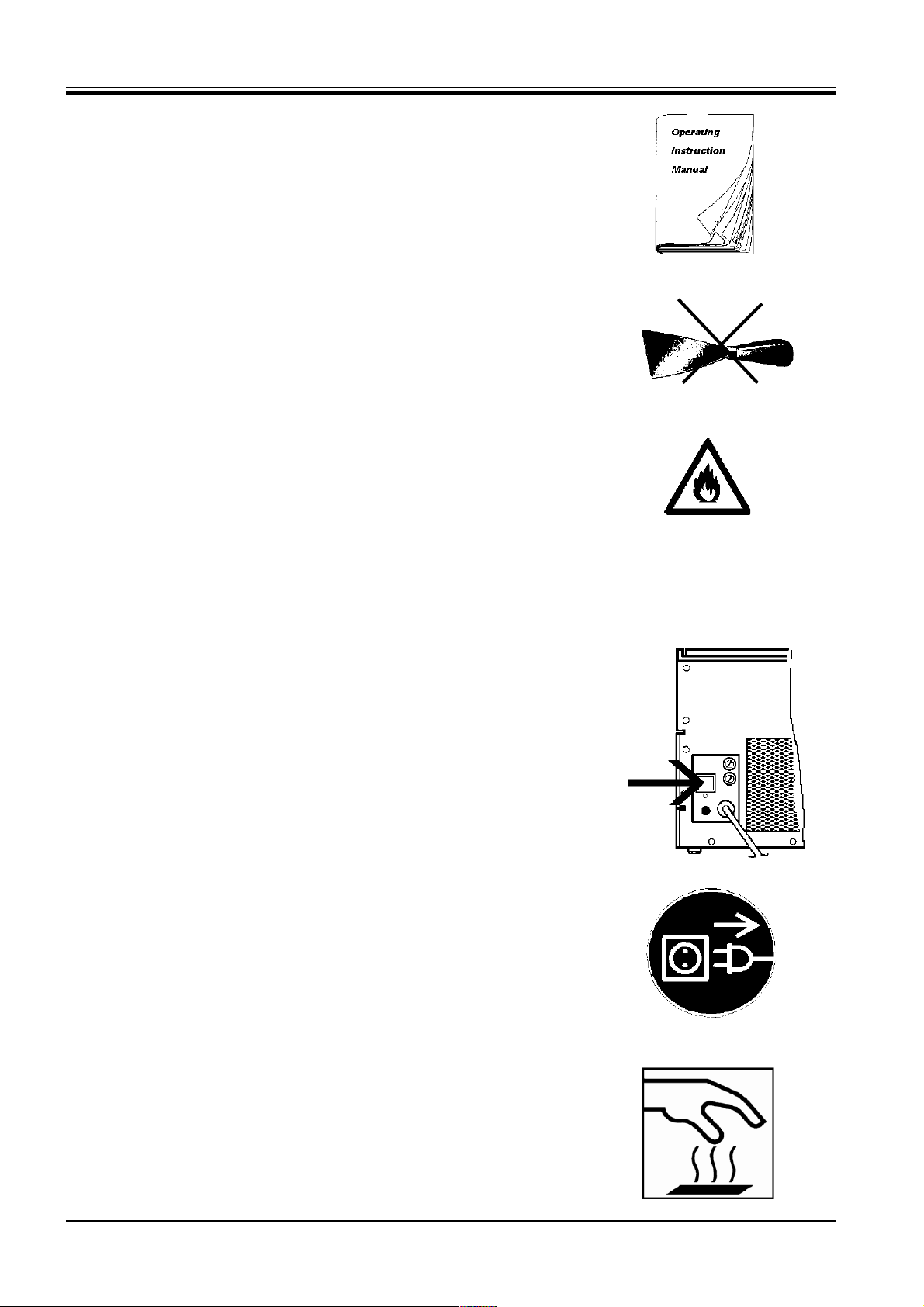

6. Safety precautions

- The instrument may be used by qualified personnel only.

- To avoid any operating mistakes from the beginning, it is necessary to

read the operating instructions to familiarize oneself with the technical

details.

- Paraffin is flammable and should be handled with care. Spillage should

be avoided. Paraffin on the surfaces must not be removed with sharp

tools as it would ruin the coating. It should be avoided to allow xylene to

react on all surfaces.

Caution:

Xylene is a flammable organic solvent. Its flash point is between 27 and

32°C. Xylene vapours are heavier than air and can easily catch fire on

hot surfaces or sparks even over a greater distance.

- Illumination: Before replacing the lamp, the tissue embedding center must

be turned off with the main switch.

- To clean the condenser fins, switch the instrument off with the main

switch and disconnect it from mains.

- To replace the fuses, the power cord must be disconnected from the

power supply. Only fuses that are accessible from outside can be replaced. If you need further information, please contact your local Leica

sales office or dealer.

- When operating, the paraffin reservoir, mold warmer, cassette bath, work

area and forceps holder are all hot.

Caution: Risk of burning!

Note: Combustible and flammable substances must not be stored near

the instrument!

8

Instruction manual V 4.1 – 05/2001

Page 9

- When using the optional vacuum attachment, please ensure that, af-

ter infiltration, the vacuum is neutralised very slowly. Therefore, open

the aeration knob very cautiously. Air entering too rapidly could cause

hot paraffin to splash and should therefore be avoided.

- Prior to connecting the instrument to the power supply in the labora-

tory, please make sure that the power supply complies with the values specified on the nameplate. The tissue embedding center should

be connected to a grounded socket only.

6. Safety precautions

- The equipment must not be set up near an air condition vent or should

not be exposed to direct sunlight!

- Full refrigeration capacity is ensured only if the clearance on the back

of the instrument is not less than 15 cm. Therefore, it is necessary to

mount the spacers provided.

- Prior to any maintenance and service action, the tissue embedding

center must be disconnected from the power supply.

Leica EG1160 – Paraffin Embedding Center 9

Page 10

7. Leica EG 1160 – Overview

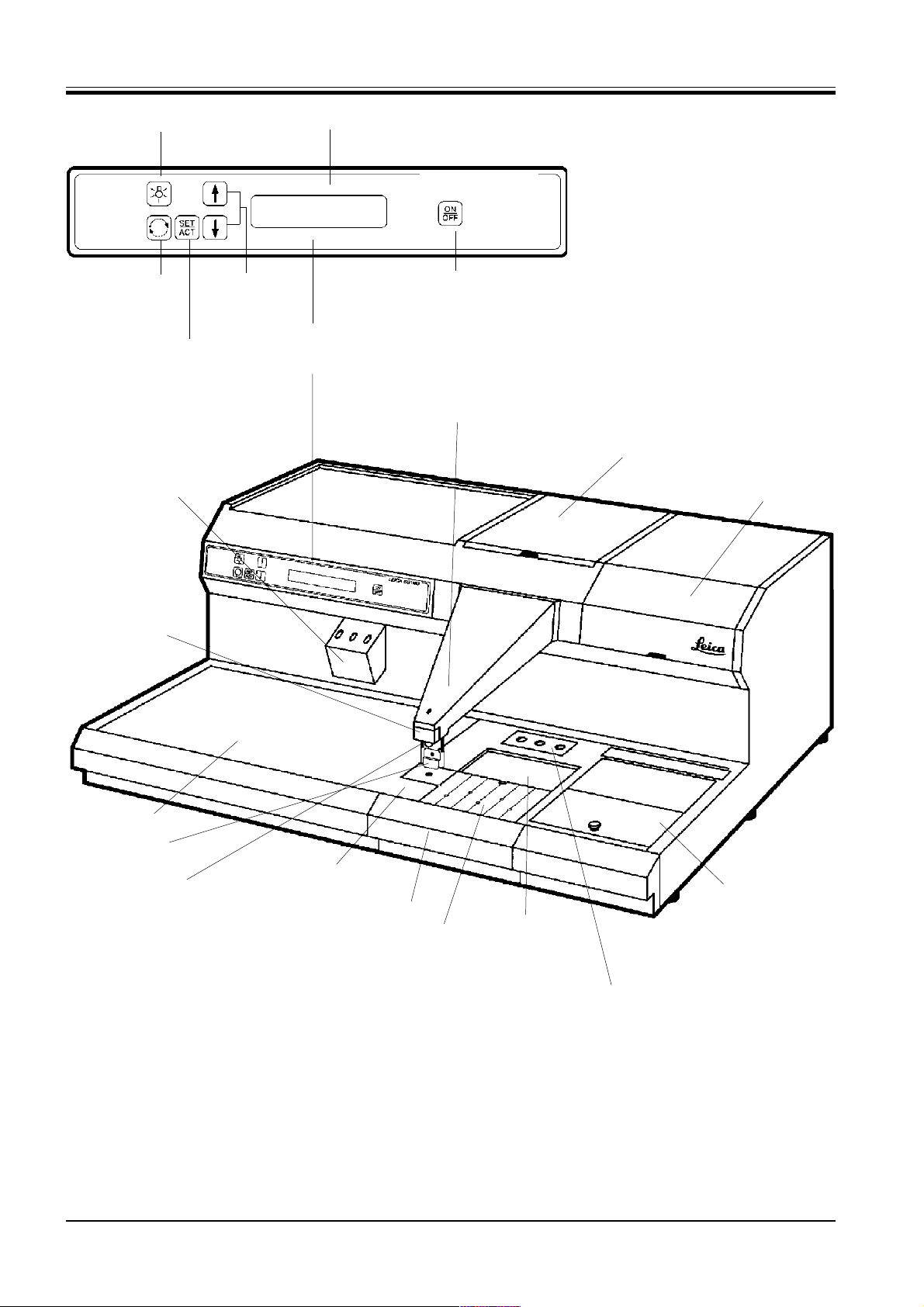

Illumination button (3) LCD display (2)

Leica EG1160

Menu button (4) Arrow UP/DOWN

buttons (6)

SET/ACT button (5)

Forceps holder (11a)*

(only on model with

additional forceps

holder on the left)

Cover cap for

illumination (23)

ON/OFF button (7)

Contol panel (1)

Dispenser

with integrated illumination (8)

Paraffin reservoir (13)

Mold warmer (14)

Cold plate (17)

Dispenser handle

extension clip (29)

Dispenser handle (9)

10

Refrigeration spot (16)

Paraffin collecting tray (18)

Work area (20)

Cassette bath (15)

Heated area for

cassettes (10)

Forceps holder (11)

Instruction manual V 4.1 – 05/2001

Page 11

Fuses

Main switch (21)

Socket for foot

pedal

7. Leica EG 1160 – Overview

Condenser fins

Conection branch (27)

Magnifier (24)

Power

cord

Vacuum attachment (25)

Lid (26)

Spacers

Areation knob (28)

The Leica EG 1160 is a compact benchtop unit. It is available in two different configurations: basic instrument and

model with an additional forceps holders on the left. Both models are shipped in a wooden crate. Please check if

the following accessories are included in the shipment and if they are in perfect condition.

NOTE: If equipment or accessories are found to be damaged, please keep the original packing material and contact

your local sales office immediately.

Piecs Accessory/Component Catalog Number

1 Cassette bath ..................................................................................................................................... 0386 19544

1 Foot pedal ........................................................................................................................................... 0356 08793

2 Spacers ............................................................................................................................................... 0386 24590

1 Set of stoppers (10 pcs.)................................................................................................................... 0386 24782

1 Replacement bulb.............................................................................................................................. 0187 21220

Optional accessories:

1 Magnifier ............................................................................................. 0386 21462

1 Vacuum attachment ..............................................................................................0356 21980

1 Fiber optical light guide ..............................................................................................0386 31352

1 Coldlight source Leica CLS 100 - 100 V, 50/60Hz.....................................................................0502 30213

120 V, 50/60Hz .....................................................................0502 30214

230 V, 50/60Hz .....................................................................0502 30215

240 V, 50/60Hz .....................................................................0502 30216

If you need further accessories, please contact your Leica sales office or dealer using above ordering information.

Leica EG 1160 – Paraffin Embedding Center 11

Page 12

8. Components and features

Paraffin reservoir (13)

The paraffin reservoir can hold up to 3 liters. The paraffin temperature can

be adjusted in a range from 45 to 70°C. The reservoir has an overheat protection in case of a temperature control failure. The paraffin quantity level is

indicated in the display graphically both in the standby and operating condition. The display indicates two levels:

1. Reservoir filling quantity: 1 l - 3 l

2. Reserve: max. 1 l

When the "reserve" diagram is indicated, there is still approximately 1 liter in

the reservoir, so it is not necessary to interrupt work immediately. Nevertheless, it is necessary to refill the paraffin reservoir as soon as possible.

A grid inside the paraffin reservoir provides that only molten paraffin flows

through the dispenser outlet nozzle to ensure troublefree embedding. An

integrated filter at the junction point of dispenser and reservoir prevents

any contamination of molten paraffin.

Each refill of the reservoir can cause the formation of air bubbles that impede a smooth paraffin flow. This can be overcome by pushing the paraffin

dispenser handle until a smooth flow is achieved..

The paraffin flow rate is adjustable in 10 increments (see "Initial operation",

"Controls").

A pump ensures a smooth and precisely controlled paraffin flow. Due to its

special design, the pump is protected against damage by solid or semiliquid

paraffin.

Paraffin dispenser with illumination (8)

The dispenser is separately heated and always has the same temperature

as the paraffin reservoir. The dispenser handle (9) is used for manually operating the paraffin flow and is provided with a dispenser handle extension

clip (29). The paraffin flow is released by lightly pushing the mold backward

against the extension clip of the dispenser handle, thus opening the dispenser valve and activating the pump. Releasing the handle, a spring causes

it to return to the start position. Thus, the valve is shut and the pump operation is stopped. When dispensing is controlled with the foot pedal, the dispenser handle is not needed and can be flipped back out of the way. This

provides ample space allowing convenient filling of larger molds.

The homogeneous, diffuse illumination of the embedding area and refrigeration spot provides an optimal view of the embedding process and specimen orientation. The light bulb can be removed after removing the cap (23).

23

9

29

12

Instruction manual V 4.1 – 05/2001

Page 13

Mold warmer (14)

The temperature of the mold warmer is adjustable from 35 to 70°C. The

hinged lid can be locked in position while open.

Cassette bath (15)

The cassette bath temperature is adjustable from 45 to 70°C. The cas–

sette bath can hold more than 100 cassettes. It can be easily removed.

An integrated lid protects against thermal loss and contamination.

Refrigeration spot (16)

The refrigeration spot is integrated in the cold plate thus ensuring consistent, low temperatures. Positioned directly in front of the embedding

area it ensures convenient filling of the molds in optimal ergonomic conditions. The mold containing the sample is filled approximately one third

and placed on the refrigeration spot, where the paraffin starts to solidify

rapidly. In the semiliquid paraffin the sample can be oriented as required.

After orientation, the mold is filled up with paraffin. Note: Care should be

taken that the paraffin does not become too solid during orientation, as

this could cause an inhomogeneous block which would make sectioning

more difficult.

8. Components and features

Cold plate (17)

The cold plate is turned on and off via the menu. The temperature is -5°C.

The rate of cooling at -5°C ensures optimal consistency of the blocks

and minimises the risk of brittleness as a result of too rapid cooling, and

a high level of productivity. The cold plate provides ample space for approximately 60 paraffin blocks. Controlled cooling ensures that the

preselected temperature is accurately maintained. Before starting to

work, the cold plate should be free of paraffin and dry to prevent frost

buildup.

Paraffin collecting tray (18)

A large removable tray is located under the heated work area to collect

excess paraffin drained from the surface. The paraffin that collects in

the tray should not be reused. The tray should be emptied every day.

Leica EG1160 – Paraffin Embedding Center 13

Page 14

8. Components and features

Work area (20)

The temperature of the work area is adjustable from 45°C to 70°C. It includes

the embedding area, forceps holder (11), recessed area for cassettes (10)

and space to remove the lids. The forceps holder (11) is separately heated.

The heated recessed area is designed for approximately eight cassettes.

By closing the drain hole with the stopper provided, it can be utilised as a

paraffin tray. Several grooves and drain holes in the area where the lids are

removed provide that molten paraffin drains rapidly.

Main switch (21)

The main switch - a green toggle switch - is located on the back of the instrument. It is not necessary, however, to turn the instrument off with the

main switch after daily operation.

In daily routine, the tissue embedding center should be switched on and off

with the ON/OFF button on the control panel.

10

11

Note:

If the Leica EG 1160's automatic turn-on feature is used, i. e. if it is programmed to turn on automatically to be ready to operate when the user

arrives, the main switch must be in the ON condition.

Note:

After a power failure, the Leica EG 1160 will not switch on automatically. At

that stage, it is in the standby condition, just like after turning it on with the

main switch, i.e. you have to set it going pushing the ON/OFF switch.

Cooling

Whenever the instrument was disconnected from mains, for example after

a power failure or when it had been turned off with the main switch, it will

take 10 minutes until the condenser of the cooling system is ready to operate.

21

23

Cover cap for illumination (23)

The cover cap for the light bulb is inserted at the front of the paraffin dispenser. For light bulb replacement, the cap is pulled towards the operator.

14

Instruction manual V 4.1 – 05/2001

Page 15

Instrument with additional forceps holder on the left

Forceps holder left (11a)

The instrument configuration with an addional forcesp holder on the left

covers the needs of left-handers in particular. This forceps holder also is

separately heated.

Optional accessories

Magnifier (24)

When correctly mounted, the magnifier can be swung horizontally and

vertically. When correctly adjusted, both the paraffin dispenser outlet

and the refrigeration spot are in focus, thus avoiding frequent readjustment to orient small and delicate biopsies.

8. Components and features

Vacuum attachment (25)

The optional vacuum attachment can be used instead of the cassette

bath, which is a standard accessory. The vacuum lid allows for vacuum

infiltration of the tissue while stored in the wax bath - that means complete infiltration of the tissue in less time.

The vacuum pump (not included) is connected to the connecting branch

(27). Care should be taken that the lid (26) is seated flat on the cassette

bath. The seal of the lid must be free of paraffin to ensure tightness so

that a vacuum can build up. To improve the tightness, the lid should be

pushed on to the cassette bath when the vacuum pump starts to operate.

A vacuum can be generated only if the aeration knob (28) is shut. After

infiltration, the lid cannot be opened immediately. First, the knob (28) has

to be opened slowly to allow normal pressure to establish inside.

Note:

After infiltration, the vacuum should be neutralised very slowly, as air

entering too rapidly could cause hot paraffin to splash and therefore

should be avoided.

28

26

27

Fiber optical light guide

for connection to the coldlight sources of Leica CLS series

To optimally illuminate the dispensing area, a fiber optical light guide

with a cold light source can be used.

Leica EG1160 – Paraffin Embedding Center 15

Page 16

9. Controls / Display

Control panel (1)

The control panel with push buttons and the 2-line display (2) is protected with a PE foil.

Leica EG1160

Push button functions

Depending on the mode of operation - initialisation, programming, operation - some of the push buttons have multiple functions:

Initialisation ACT Mode SET Mode

(Operation) (Programming)

Standby a) Deactivation or reactiv-

ation of the previously

selected temperature

To turn instrument ON: To turn instrument

ACT mode ON/OFF

status line

(= default reading) b) Programming of the

workdays

Language selection Adjustment of the Setting of variable

(only after turning on paraffin flow rate parameters (temperature,

with the main switch day, time)

on the back)

ACT mode SET mode

Illumination Illumination

ON/OFF ON/OFF

Scrolling through Scrolling through

the menu the menu

For details on operation and programming please refer to chapter 10 "Operation".

16

Instruction manual V 4.1 – 05/2001

Page 17

Please ensure that all preparatory steps described in chapter 11 have

6

been completed:

1. Putting the instrument into operation after delivery

Turn the instrument on with the main switch (green toggle switch in

the lower right corner on the back of the instrument) while pushing

the ARROW UP button on the control panel for approx. 2 seconds.

Then push the ON/OFF button. The instrument will then be initialised.

The main switch should always remain in ON position even after daily

work. In daily routine, the tissue embedding center is turned on/off by

pushing the ON/OFF button on the control panel.

Turning on again after several weeks

When the instrument had been switched off with the main switch and

was out of use for several weeks, please pursue the same procedure

as described above.

10. Operation

2. After initialisation, the language selection reads in the display. The

desired language (E, G, F, I, S) can be selected within 10-15 seconds

pushing the ARROW UP/ARROW DOWN buttons. Once the button is

relased the selected language is stored automatically.

3. Approximately 10 seconds after releasing the ARROW button the instrument automatically switches over to the standby. In the standby

condition, the display is not illuminated.

In the lower line of the display reads actual day and actual time as

well as the current paraffin quantity level. The upper line remains

empty.

4. The Leica EG 1160 is put into operation by pushing the ON/OFF button. This button must be held down for approx. 10 seconds. This feature protects against unintended setting into operation. The instrument will then be ready for operation in the ACT mode.

Default reading

I SPEAK ..

ENGLISH

ICH SPRECHE ..

DEUTSCH

23456789012345

TU 13:09

Day Time Quantity

PAR TANK + 58°C

TU 13:11

Push one of the ARROW buttons to display the FLOW RATE reading.

In order to obtain a smooth, bubble-free paraffin flow, the flow rate

should first be set to 100% pushing one of the ARROW buttons. Push

FLOW RATE 100%

TU 13:18

the dispenser handle backward or press the foot pedal until the paraffin flow is smooth and free of bubbles.

The Leica EG 1160 has two modes of operation: the actual operating

mode (ACT) and the programming mode (SET). To change from one

mode to the other, push the ACT/SET button.

Leica EG1160 – Paraffin Embedding Center 17

Page 18

10. Operation

ACT Mode (Operation)

5. Normal operation of the Leica EG 1160 takes place in the ACT mode. In

this mode, all display readings are actual values.

Starting from the default reading (PAR TANK +XX°C), each step of the 5step menu of the temperature controllable functional units can be displayed to review the actual temperature by scrolling the menu with the

MENU button:

The status line always is the same.

PAR TANK +XX°C

TU 13:11

COLD PLAT +XX°C

TU 13:11

CASS BATH +XX°C

TU 13:12

MOLD TRAY +XX°C

TU 13:12

All display readings both in the ACT and SET (programming) mode auto-

matically return to the ACT default reading after approximately 10 seconds:

5.1 The ILLUMINATION of the work area is switched ON/OFF with the LAMP

button.

5.2The PARAFFIN FLOW RATE is individually adjustable and can be

preselected in the ACT mode with the ARROW buttons in 10% increments.

5.3 Adjustment of the FLOW QUANTITY

The flow quantity for the lowest flow rate (10%) can be adjusted as required. All other flow rate increments will then be recalculated on this

basic adjustment and stored automatically.

1. Set the flow rate to 10% by pushing the ARROW buttons in the ACT mode.

2. On pushing the SET/ACT button the display reads:

3. Operate the pump manually or with the foot pedal and push the ARROW

buttons to readjust the flow quantity for the 10% flow rate. The new values will be stored automatically.

WORK SURF +XX°C

TU 13:12

PAR TANK +XX°C

TU 13:15

FLOW RATE 100%

TU 13:18

FLOW RATE 10%

TU 13:19

Decrease the flow rate

to 10%

ADJUST

FLOW RATE 10%

18

Increase/decrease

the flow rate

Instruction manual V 4.1 – 05/2001

Page 19

ACT Mode (Operation)

5.4 The paraffin flow rate is selectable in 10% incre-

ments:

10 %, 20 %, 30 %, 40 %, 50 %, 60 %, 70 %, 80 %,

90 %, 100 %

The display reading will change with the selected

flow rate. It always reads the percentage flow rate

selected.

10. Operation

Increase/decrease

of the flow rate

FLOW RATE 80%

TU 13:15

How to quit the display reading "FLOW RATE":

1. Approximately 10 seconds after having selected the

flow rate, the display will automatically return to the

ACT default reading.

2. Pushing the MENU button will also lead to the ACT

default reading.

3. Pushing the SET/ACT button will lead to the pro-

gramming mode (SET mode).

Note: If a flow rate of 10% is selected, the SET/ACT

button will lead to the programming mode "ADJUST

FLOW RATE" (see 5.3).

5.5 SWITCHING OFF with the ON/OFF button

By pushing the ON/OFF button, the instrument automatically returns to the standby condition.

FLOW RATE 80%

TU 13:15

FLOW RATE 80 %

TU 13:15

FLOW RATE 80 %

TU 13:15

PAR TANK +XX°C

TU 13:15

10 sec

10 sec

PAR-TANK +XX°C

DI 13:15

PAR-TANK +XX°C

DI 13:15

TEMPERATURWAHL

DI 13:15

TU 13:15

It is not necessary to switch the tissue embedding

center off with the main switch. If switched off with

the main switch, all programmed parameters are

maintained. In this case, however, the program will

not be activated.

In the SET mode, the ON/OFF button has an additional function for the programming of temp–

eratures and workdays (see 6.1, 6.4).

Leica EG 1160 – Paraffin Embedding Center 19

Page 20

10. Operation

SET Mode (Programming)

6. The SET mode is activated by pushing the SET/ACT button. The SET mode

is used for programming only. The programmable parameters are as fol-

lows:

- Paraffin reservoir temperature

- Cold plate temperature

- Cassette bath temperature

- Mold warmer temperature

- Work area temperature

- Actual day

- Actual time

- Planned start time

- Planned finishing time

- Workdays

The instrument is programmed to have all functional units ready to operate at the preselected time on the preselected workdays, i.e. all heated

and refrigerated components are turned on automatically so that they

will have reached the preselected temperatures when the operator starts

working (see chapter 4 "Technical data").

The MENU button is used to scroll through the individual items of the

menu.

Once the last item of the menu ("WORKDAYS ARE .. ") is reached, the first

item ("SET TEMPERATURES: PAR TANK") will be indicated again after

pressing the MENU button.

SET TEMPERATURES

PAR-TANK XX°C

SET TEMPERATURES

COLD PLAT XX°C

SET TEMPERATURES

CASS BATH XX°C

SET TEMPERATURES

MOLD TRAY XX°C

SET TEMPERATURES

WORK SURF XX°C

TODAY IS ...

MO

THE TIME IS ...

10:00 HRS

START WORK AT ...

10:00 HRS

STOP WORK AT ...

16:00 HRS

WORKDAYS

MO YES

20

SET TEMPERATURES

PAR TANK XX°C

etc. ...

Instruction manual V 4.1 – 05/2001

Page 21

SET Mode (Programming)

The ARROW buttons are used to preselect the temperature, time and

days. The speed of the display increases (1-2 step mechanism), the

longer the button is held down.

6.1 TEMPERATURE SETTING

The temperature is preselected with the ARROW buttons. Once the

minimum or maximum value is reached, the indication will stop. The

value displayed when releasing the ARROW button will be stored

automatically, and heating and cooling will be activated accordingly.

The individual temperature settings can be activated or deactivated

with the ON/OFF button.

ON:

The previously entered temperature reads in the display. If the current value is not changed, the microprocessor will adjust the temperature to the displayed value.

OFF:

The temperature control function can be switched off if no specific

temperature is required. The previously entered temperature remains

in the memory but will not be activated.

10. Operation

SET TEMPERATURES

PAR TANK 58°C

SET TEMPERATURES

PAR TANK 58°C

The display reads:

In this case, the default reading is as follows:

6.2 ACTUAL TIME / DAY

Actual time and day are set with the ARROW buttons. An endless

search mechanism provides that the search run restarts from the

beginning automatically after attaining 23:59 or SUN.

The time/day indicated on releasing the ARROW buttons will be stored

automatically.

6.3 BEGINNING AND END OF WORK

The time when you start and stop work is selected with the ARROW

buttons. The endless search mechanism provides that the search run

automatically restarts from the beginning after attaining 23:59. Thus

the instrument will be operational on all days of the week defined as

workdays (see 6.4) at the previously selected time. The time indicated

on releasing the ARROW buttons will be stored automatically.

SET TEMPERATURES

PAR TANK - - - -

PAR TANK - - - FR 11:10

TODAY IS ...

MO

THE TIME IS ...

12:30 HRS

START WORK AT ...

10:00 HRS

STOP WORK AT ...

16:00 HRS

Leica EG1160 – Paraffin Embedding Center 21

Page 22

10. Operation

SET Mode (Programming)

6.4 WORKDAYS

The workdays are selected with the ARROW buttons. Releasing the button, the indicated day will be put in the memory automatically. The ON/

OFF button is used to confirm if the program shall be activated (YES) or

not (NO) the day indicated in the display.

WORKDAYS

MO YES

If the programming of workdays is not desired, i.e. if the user can do

entirely without the automatic turn-on function of the tissue embedding

center, "NO" must be entered for each day of the week.

6.5 How to quit the programming (SET) mode

1. 10 seconds after activation of any of the buttons, the instrument will automatically return to the ACT mode (de-

SET TEMPERATURES

PAR TANK +XX°C

fault reading).

This feature is a protection against unintended programming.

2. Pushing the SET/ACT button will also lead to the ACT

SET TEMPERATURES

PAR TANK +XX°C

mode.

WORKDAYS

MONO

10 sec

PAR TANK +XX°C

TU 15:11

PAR TANK +XX°C

TU 15:11

The flow rate cannot be selected in the SET mode. It can only be

selected in the ACT mode.

AUTOMATIC TURN-ON FEATURE

If this feature is not used, it should be ensured that the tissue embedding center is turned on early enough to allow all components to

reach the appropriate temperatures to avoid unnecessary delays.

Especially the paraffin reservoir heater should be turned on early

enough, as it can take some hours until the wax is molten. The individual warmup times are listed in chapter 4 "Technical data".

22

Instruction manual V 4.1 – 05/2001

Page 23

Main switch + 2 sec

▼

Self test

▼

I SPEAK..

ENGLISH

▼

MO 12:30

Flow chart

Select the desired language within 10-15 seconds

Standby

Status line

ACT

▼▼ ▼

10 sec PAR TANK XX°C

▲

10 sec

▲

10 sec

▲

10 sec MOLD TRAY XX°C

10 sec WORK SURF XX°C

▲ ▲

Status line

COLD PLAT XX°C

Status line

CASS BATH XX°C

Status line

Status line

Status line

▼

▼

SET

SET TEMPERATURES 10 sec

▼

PAR TANK XX°C

▼

SET TEMPERATURES 10 sec

COLD PLAT XX°C

▼

SET TEMPERATURES 10 sec

CASS BATH XX°C

▼

SET TEMPERATURES 10 sec

MOLD TRAY XX°C

▼

SET TEMPERATURES 10 sec

WORK SURF XX°C

▼

TODAY IS ... 10 sec

MO

▲ ▲ ▲ ▲ ▲ ▲▲ ▲ ▲

▼

▼

THE TIME IS ... 10 sec

Illumination ON/OFF

ON/OFF (Standby)

10 ... 100%

FLOW RATE 10%

Status line

▲

START WORK AT ... 10 sec

STOP WORK AT ... 10 sec

WORKDAYS 10 sec

MO YES

AJUST

FLOW RATE 10%

12:30 HRS

10:00 HRS

▲

16:00 HRS

10 sec

Illumination ON/OFF

Activation of temperature control

Activation of workdays

Leica EG 1160 – Paraffin Embedding Center 23

▼

Page 24

11. Tissue embedding

The paraffin reservoir is filled with

wax pellets (e.g. Leica HISTO–WAX).

The level of the molten wax should

reach up to 2-3 cm under the upper

edge of the reservoir.

When the symbol for "paraffin tank

on reserve" is displayed, there is still

approximately 1 litre left. However,

the paraffin reservoir should be refilled immediately at that stage.

The set temperature for the paraffin

reservoir should be set to a value

between the melting point and the

maximum value indicated by the

manufacturer of the paraffin that is

used.

Once all functional units have

reached the preselected temperatures and the wax in the paraffin reservoir is completely molten, tissue

embedding can begin.

Note:

Overheating of the molten wax must

be avoided as important components

can be damaged resulting in damage

to the sample.

1. The embedding cassettes containing the dehydrated and infiltrated tissue sample are transferred to the

cassette bath ( approx. 100 cassettes), which is filled with molten

wax to prevent the solidification of

the wax.

The cassette bath temperature is

optimally maintained constant when

it is filled with molten paraffin.

If the cassette bath is not filled with

wax, it should not be filled with cassettes up to the top edge, as a film

could form on the cassettes at the

top reducing the quality of the embedding.

By use of the optional vacuum attachment for the cassette bath, the

tissue can be infiltrated under

vacuum. The vacuum is generated

by a vacuum pump that is connected

to the connecting branch on top of

the vacuum lid. The seal of the lid

must be free of paraffin to be seated

flat on the cassette bath to allow for

the vacuum to build up. To improve

the tightness, the lid should briefly be

pushed on to the cassette bath when

the vacuum pump is turned on. After

infiltration, the lid cannot be opened

immediately. The aeration knob has

first to be opened slowly (!) to allow

for pressure equalisation inside.

2. The embedding molds are placed

in the mold warmer.

Note:

Overheating of the molds must be

avoided as this could cause problems when removing the block from

the mold.

The molds should be clean and dry.

First, the molds should be treated

with xylene, then with soap solution

and finally rinsed with distilled water and dried.

3. Take three to four cassettes out of

the cassette bath and, depending on

the work method, either place them

on the work area to allow liquid paraffin to drop and immediately remove

them from the mold, or transfer them

to the heated recessed area filled

with molten wax for intermediate

storage to prevent immediate solidification of the infiltrated specimen.

This applies in particular to small biopsies. If the heated recessed area

is not filled with wax, it provides additional space on the work area.

4. Select an appropriate embedding

mold, place it under the dispenser

outlet nozzle and fill it with paraffin

as required:

a. using the foot pedal

b. manually, by pushing the paraf-

fin dispenser handle

c. when filling larger molds, the dis-

penser handle can be retracted,

thus providing enough clearance

under the paraffin outlet nozzle.

The flow is adjustable in 10 increments.

24 Instruction manual V4.0 – 4/98

Page 25

11. Tissue embedding

5. Open the cassette and transfer the

sample to the mold using warm forceps.

6. The mold is placed on the refrigeration spot for a moment. The tissue is oriented with forceps as required. Within a few seconds, the

clear consistency of the wax will

change.

Small tissue specimens can be oriented by slowly pushing the mold

from the embedding spot to the refrigeration spot. As the wax solidifies

very slowly in the transition area, the

tissue can be removed from the forceps without any risk that the sample

sticks to the tip of forceps. (If the wax

becomes solid too rapidly, the forceps will stick to the tissue).

Note: Please avoid a film to form on

the surface of the paraffin. This

would create two phases in the finished block which could cause fissures inside as a result of which the

block could break during sectioning.

7. After orientation of the specimen,

the half filled mold is retrans–ferred

to the embedding spot. After positioning a cassette base or an embedding ring, the mold is filled up with

paraffin.

When not using cassettes or embedding rings, the mold should be filled

up to the top edge.

Note: Do not overfill the mold to avoid

contaminating the cassette base or

embedding ring outside as this could

result in the insufficient clamping in

the specimen holder of the microtome.

8. Place the mold on the cold plate.

The wax will become entirely solid

within a short time. Finally, the paraffin block including the specimen

can be easily removed from the

mold.

All steps should be performed without delays to ensure that the wax

homogeneously solidifies in the mold

to prevent the formation of layers,

which could affect the sectioning

results.

Please note that the removable tray

where excess paraffin is drained

should be emptied at regular intervals to ensure that liquid paraffin

drains easily and the removable tray

does not stick to the guides.

Caution! The tray can be hot!

Excess paraffin collected in the removable tray should not be reused,

as it would be contaminated.

9. On termination of embedding, the

Leica EG 1160 should be turned off

pushing the ON/OFF button. Condensation water on the cold plate should

be wiped off and liquid paraffin removed from the work area with soaking paper. For further information on

cleaning and maintenance, please

refer to chapter 12.

Note: The tissue embedding center

need not be turned off with the green

main switch on the back. If it is programmed to automatically turn on in

advance, it must not be switched off

with the main switch.

When the automatic turn-on feature

is not used, please make sure that

the instrument is turned on early

enough to allow the individual components to reach the required temperatures. This applies particularly

to the heater of the paraffin reservoir, as it can take several hours until the solid wax is entirely molten.

The warmup times of the indivi–dual

components are listed in chapter 4

"Technical data".

25Leica EG1160 – Paraffin Embedding Center

Page 26

12. Cleaning, maintenance, service

Regular cleaning and maintenance will keep your Leica EG 1160 in good

operating condition for many years.

1. General instructions: Paraffin

- Paraffin is flammable and therefore must be handled with care. Avoid

spillage of liquid paraffin.

- All Leica EG 1160 components that come into contact with paraffin and

the interior of the instrument are carefully sealed to prevent wax from

entering. Nevertheless, if paraffin is spilled, it should always be removed

carefully.

- The paraffin reservoir and cassette bath, if required, should be filled with

care. Avoid overfilling!

- The wax in the cassette bath and heated recessed area must be exchanged every day to avoid contamination.

- Solid wax particles on the surface of the work area must not be removed

with sharp tools, as this could damage the finish. A soft plastic spatula is

ideal for wax removal. Alternatively, solid paraffin can be lifted off easily

by lightly warming it.

- The surfaces of the work area of the Leica EG 1160 are made of aluminium with polyester epoxy finish. The control board is covered with a

PE film. The base of the housing is a polyester epoxy coated steel plate.

All seams are sealed with a specific fungicidal silicone.

All materials are easy to clean with common laboratory detergents, which

are appropriate for paraffin removal. Do not allow organic solvents to

react for a longer period. Apply varnish protection occasionally.

Caution:

Xylene must not be used for cleaning. Although xylene is an ideal wax solvent, its flash point ranges between 27 and 32°C. Xylene vapours are heavier

than air and can catch fire even if the source of heat is at a larger distance.

Therefore, it is not appropriate for cleaning hot or potentially hot surfaces.

Risk of fire!

26

Instruction manual V 4.1 – 05/2001

Page 27

12. Cleaning, maintenance, service

2. Cleaning of paraffin reservoir, filter and dispenser outlet

The grid separating solid from liquid wax and the filter can be removed

from the paraffin reservoir for cleaning. The reservoir is cleaned inside

with a paper tissue.

Care should be taken that the reservoir is contaminated. Any dirt inside

should be removed prior to removing the grid and the filter.

3. Cleaning the forceps holder

The forceps holder, in particular, is frequently a source of contamination

and is susceptible to dirt. Therefore it should be cleaned thoroughly.

Caution:

The forceps holder is heated separately and thus very hot (approx. 70°C

or 80°C) during operation.

4. The paraffin drained to the paraffin collection tray should be emptied

regularly to ensure that excess paraffin can drain to the tray and prevent

the removable tray from sticking to guide.

5. Illumination of the dispenser outlet

Prior to exchanging the light bulb, the Leica EG 1160 must be turned off

with the green main switch on the back. Remove the cap at the front end

of the dispenser. The light bulb can be removed pulling it toward the user.

The replacement bulb is inserted by lightly pushing it between the contacts.

6. Fuses

See "Technical data". Replacement fuses must meet the specifications

of the manufacturer. Otherwise, this could invalidate the warranty!

Leica EG1160 – Paraffin Embedding Center 27

Page 28

13. Troubleshooting

Whenever a malfunction occurs, please ensure that it is not the result of an operating mistake.

The list below includes the most frequent operating errors.

Equipment malfunctions are indicated as error messages (error codes 1 to 13) in the LCD display. If such an error

code is displayed, please contact your local Leica service center.

FUNCTIONAL UNIT SYMPTOM CAUSE ACTION

Initial operation Instrument does not turn Main switch (on the back) Turn on main switch

on not in ON position

ON/OFF button pushed Hold down ON/OFF

not long enough button for some

seconds

Paraffin reservoir Paraffin quantity level indic- Paraffin not entirely Wait until the wax is

ation does not correspond molten molten completely;

to the actual quantity then check again.

Paraffin does not melt Selected temperature Increase temperature

too low? of paraffin reservoir

Heater not activated? Check if paraffin

reservoir heater is

activated

Temperature readout Wrong temperature Check temperature

incorrect selected? setting and

or activation

no heating

Instrument failure Technical service

Paraffin dispenser No paraffin flow Paraffin not entirely Check the consistency

molten of the wax in the reser

voir

and wait for some time

if necessary

28

Foot pedal not properly Check foot pedal

connected connection

Instruction manual V 4.1 – 05/2001

Page 29

13. Troubleshooting

FUNCTIONAL UNIT SYMPTOM CAUSE ACTION

Paraffin dispenser No paraffin flow Foot pedal / dispenser Technical service

valve switch failure

Paraffin drops when valve Valve / pump failures Technical service

closed

No heating Heater (paraffin reservoir) Activate heater (paraffin

not activated reservoir)

Heater failure Technical service

No illumination Lamp defective Replace lamp

Inhomogeneous paraffin Air bubbles in dispenser Push dispenser handle

flow (e.g. air bubbles) at the start for a while until flow is

homogeneous

Pump failure Technical service

Mold warmer Wrong temperature Wrong temperature Check temperature

Cassette bath indication selected setting

Work area

No heating Heater not activated Activate heater

Heater failure Technical service

Vacuum attachment No vacuum buildup. Lid not properly Check if lid is properly

tional accessory) Vacuum deteriorates too positioned (oppositioned

rapidly

Seal of lid contaminated Check seal

Aeration knob open Check knob

adjustment

Seal untight Technical service

Forceps holder No heating Heater failure Technical service

Leica EG 1160 – Paraffin Embedding Center 29

Page 30

13. Troubleshooting

FUNCTIONAL UNIT SYMPTOM CAUSE ACTION

Cold plate Insufficient cooling Ambient temperature too Check temperature

high? at lower ambient

temperature

Leak in cooling system? Technical service

Air supply to compressor Clean condenser fins

insufficient? (Technical service)

Compressor does not Compressor failure Technical service

start

Compressor stops after Compressor failure Technical service

short operation

Compressor stops after Compressor failure Technical service

short operation and

restarts after a short while

Telephone number of your local sales office:

30

Instruction manual V 4.1 – 05/2001

Page 31

14. Ordering information

Catalog Number

Leica EG 1160 Paraffin embedding center

Basic instrument 115 V/60 Hz........................................................................0386 30527

230 V/50 Hz........................................................................0386 30528

Model with additional forceps holder on the left 115 V/60 Hz ........................................................................0386 30351

230 V/50 Hz........................................................................0386 30352

Additional cassette bath ............................................................................................0386 19544

Magnifier ............................................................................................0386 21462

Replacement bulb ............................................................................................0187 21220

Vacuum attachment ............................................................................................0386 21980

Stoppers (pack of 10) ............................................................................................0386 24782

Fiber optical light guide without coldlight source ............................................................................................0386 31352

Coldlight source Leica CLS 100 - 100 V, 50/60Hz...................................................................0502 30213

120 V, 50/60Hz...................................................................0502 30214

230 V, 50/60Hz...................................................................0502 30215

240 V, 50/60Hz...................................................................0502 30216

Embedding cassettes without lid, 250 pcs, white ............................................................................................0394 12312

" grey....................................................................................0394 08972

" yellow ................................................................................0394 08974

" red......................................................................................0394 08976

" green .................................................................................0394 08978

" blue ....................................................................................0394 08980

Lids for cassettes, 250 pcs, white .................................................................................0394 12315

" grey....................................................................................0394 08982

" red......................................................................................0394 08986

" green .................................................................................0394 08988

" blue ....................................................................................0394 08990

Biopsy cassettes, 250 pcs, white .................................................................................0394 08966

Lids for biopsy cassettes, 250 pcs, white .................................................................................0394 08970

Deep lids for cassettes for samples up to 12 mm high, 250 pcs, white .............................................................0394 12767

Embedding rings, 1000 pcs, white..................................................................................0386 12392

Embedding molds for samples up to 7 x 7 x 5 mm ......................................................................0386 12302

" 15 x 15 x 5 mm .................................................................. 0386 12303

" 24 x 24 x 5 mm .................................................................. 0386 12304

" 30 x 24 x 5 mm .................................................................. 0386 12305

" 37 x 24 x 5 mm .................................................................. 0386 12306

Embedding molds, deep version, for samples up to 24 x 24 x 12 mm ................................................................ 0386 12860

" 37 x 24 x 12 mm ................................................................0386 12861

Marker pencil for marking of cassettes and embedding rings ..........................................................................0386 12300

Filing box for convenient storage of cassettes, lids, molds and embedding rings .........................................0394 12398

Plastic storage cabinet with 4 drawers for cassettes or rings ......................................................................... 0386 12393

Embedding frames, size 1, 56 x 40 x 26 mm (adjustable) .....................................................................................0339 06427

Embedding frames, size 2, 34 x 26 x 18 mm (adjustable) .....................................................................................0339 06432

Base plate for Catalog No. 0339 06427 or Catalog No. 0339 06432.....................................................................0339 06438

Paraflex embedding mold for 8 samples 25 x 25 x 25 mm each .........................................................................0339 10963

Paraflex embedding mold for 4 samples 40 x 40 x 30 mm each .........................................................................0339 10961

Embedding mold for plastics, flexible but stable in form, 8 recesses 25 mm ø,

4 of which with gate for specimen orientation, 19 mm deep ..............................................................................0379 12698

Embedding medium JUNG-Histowax, 1 bag = 2.5 kg ...........................................................................................0374 08585

Large bag (25 kg) ............................................................................................0374 14374

Leica EG 1160 – Paraffin Embedding Center 31

Page 32

15. Warrenty and service

Warranty

Leica Microsystems Nussloch GmbH guarantees that the contractual product delivered

has been subjected to a comprehensive quality control procedure based on the Leica inhouse testing standards, and that the product is faultless and complies with all technical

specifications and/or agreed characteristics warranted.

The scope of the warranty is based on the content of the concluded agreement. The

warranty terms of your Leica sales organization or the organization from which you have

purchased the contractual product shall apply exclusively.

Technical service information

If you require technical service or replacement parts, please contact your Leica sales

representative or dealer who sold the product.

Please provide the following information:

• Model name and serial number of the instrument.

• Location of the instrument and name of the person to contact.

• Reason for the service call.

• Date of delivery.

Decommissioning and disposal

The instrument or parts of the instrument must be disposed of in compliance with the

local laws.

32

Instruction manual V 4.1 – 05/2001

Loading...

Loading...