Leica EG 1150 H V2.2 User Manual

Instruction Manual

Leica EG1150H

V2.2 English, Rev. B - 12/2009

Always keep this manual near the instrument.

Read carefully prior to operating the instrument.

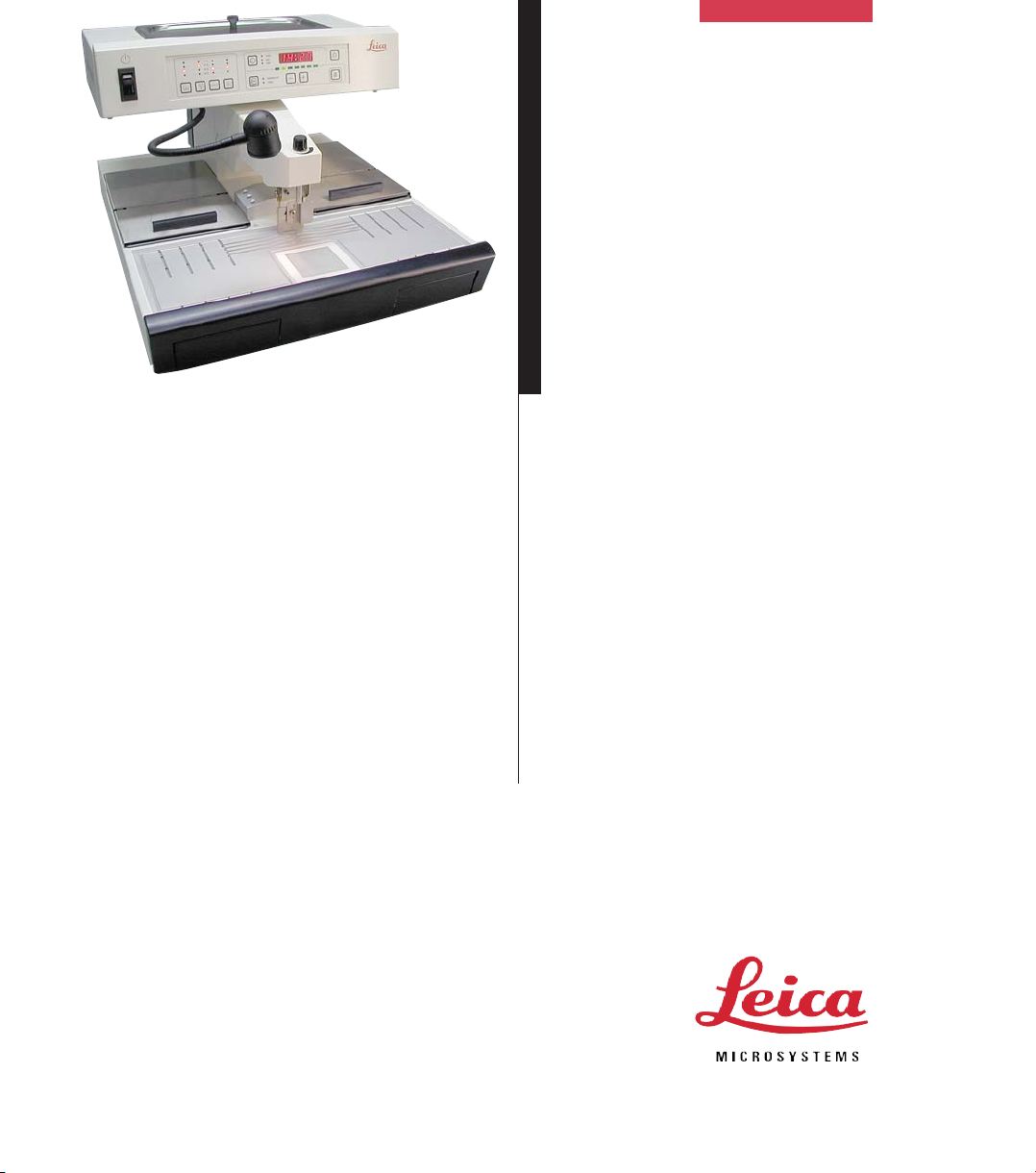

Leica EG1150 H

Paraffin Embedding

Station

IMPORTANT NOTE

The information, numerical data, notes and value judgments contained in this manual represent the current state of scientific knowledge

and state-of-the-art technology as we understand it following thorough investigation in this

field.

We are under no obligation to update the

present manual periodically and on an ongoing

basis according to the latest technical developments, nor to provide our customers with additional copies, updates etc. of this manual.

For erroneous statements, drawings, technical

illustrations, etc. contained in this manual we

exclude liability as far as permissible according

to the national legal system applicable in each

individual case. In particular, no liability whatsoever is accepted for any financial loss or consequential damage caused by or related to

compliance

in this manual.

Statements, drawings, illustrations and other

information as regards contents or technical

details of the present manual are not to be considered as warranted characteristics of our

products.

with statements or other information

These are determined only by the contract provisions agreed between ourselves and our customers.

Leica reserves the right to change technical

specifications as well as manufacturing processes without prior notice. Only in this way is it

possible to continuously improve the technology and manufacturing techniques used in our

products.

This document is protected under copyright

laws. Any copyrights of this document are

retained by Leica Biosystems Nussloch GmbH.

Any reproduction of text and illustrations (or of

any parts thereof) by means of print, photocopy,

microfiche, web cam or other methods — including any electronic systems and media — requires express prior permission in writing by

Leica Biosystems Nussloch GmbH.

For the instrument serial number and year of

manufacture, please refer to the name plate at

the left side of the instrument.

© Leica Biosystems Nussloch GmbH

Published by:

Leica Biosystems Nussloch GmbH

Heidelberger Str. 17 - 19

D-69226 Nussloch

Germany

Phone: +49 (0)6224 143-0

Fax: +49 (0)6224 143-268

Internet: http://www.leica-microsystems.com

Leica EG1150H – Paraffin Embedding Station

3

Table of contents

1. Important notes .......................................................................................................................................................... 5

1.1 Symbols used in the text and their

meanings .....................................................................................................................................................................5

1.2 Specified use and application ................................................................................................................................. 5

1.3 User group ................................................................................................................................................................... 5

1.4 Instrument type ........................................................................................................................................................... 5

2. Safety .......................................................................................................................................................................... 6

2.1 Safety regulations ...................................................................................................................................................... 6

2.2 Safety instructions ..................................................................................................................................................... 6

2.3 Built-in safety devices ............................................................................................................................................... 8

3. Instrument components and specifications ......................................................................................................... 9

3.1 Specifications ............................................................................................................................................................. 9

3.2 Overview – instrument parts .................................................................................................................................. 10

3.3 Instrument specifications ....................................................................................................................................... 11

4. Commissioning ......................................................................................................................................................... 12

4.1 Unpacking and installation ..................................................................................................................................... 12

4.3 Package contents .................................................................................................................................................... 13

4.2 Location conditions.................................................................................................................................................. 13

4.4 Necessary assembly work ..................................................................................................................................... 14

4.5 Optional accessories ...............................................................................................................................................16

4.6 Electrical connection ..............................................................................................................................................17

5. Operation ...................................................................................................................................................................18

5.1 Instrument parts/functions ..................................................................................................................................... 18

5.2 Switching the instrument on .................................................................................................................................. 23

5.3 Control panel functions ........................................................................................................................................... 24

5.4 Operating modes ...................................................................................................................................................... 25

5.5 Time-program control ............................................................................................................................................. 26

5.6 Instrument heater ..................................................................................................................................................... 28

6. Cleaning and maintenance ....................................................................................................................................30

6.1 Cleaning the instrument .......................................................................................................................................... 30

6.2 Maintenance instructions ......................................................................................................................................31

7. Troubleshooting ....................................................................................................................................................... 32

7.1 Possible faults ...........................................................................................................................................................32

7.2 Replacing the halogen lamp ................................................................................................................................... 35

7.3 Changing a fuse ........................................................................................................................................................36

8. Warranty and service .............................................................................................................................................38

4

Instruction Manual V 2.2, Rev. B – 12/2009

1. Important notes

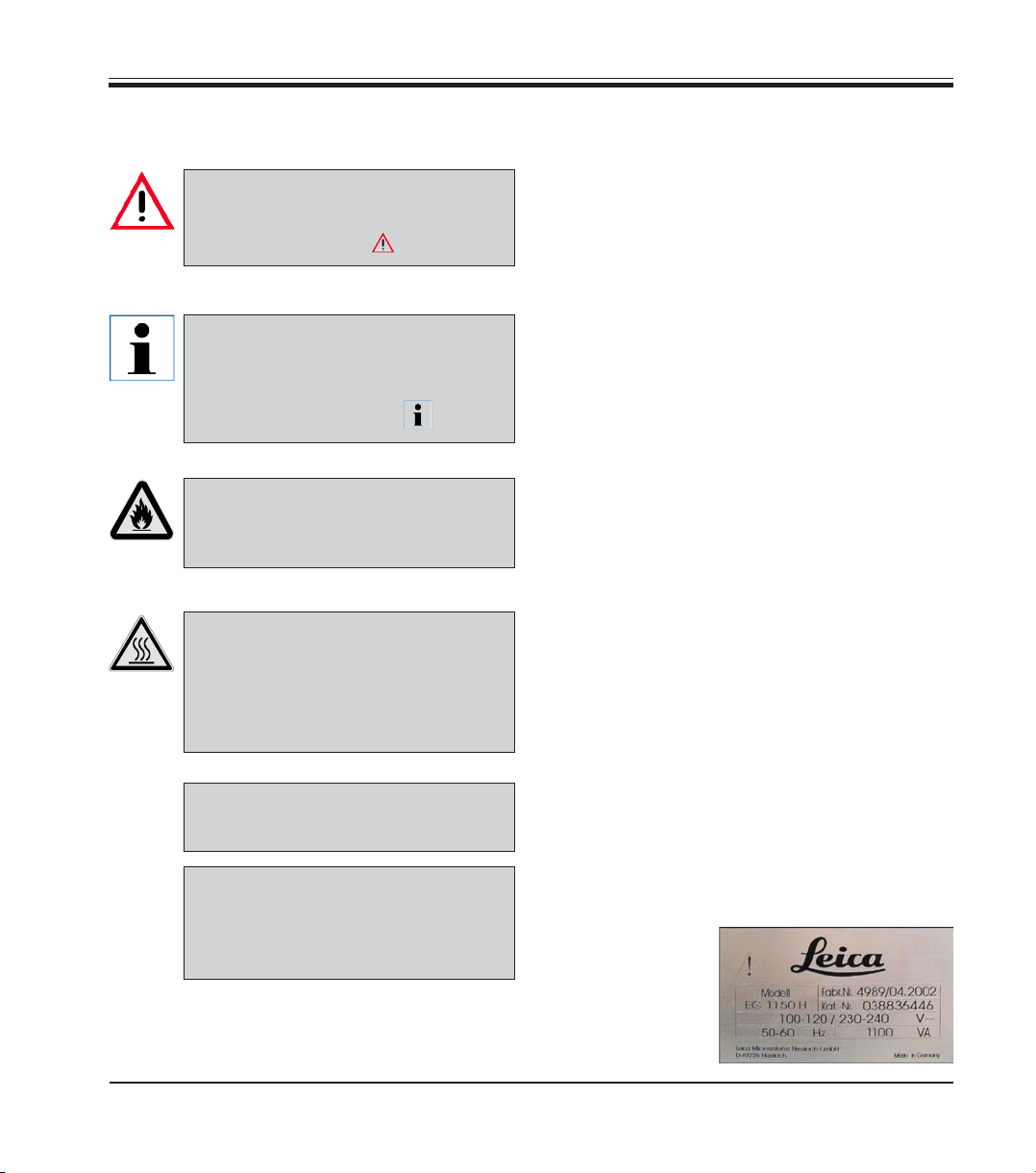

1.1 Symbols used in the text and their

meanings

Warnings and cautions

appear in a gray box and are marked

by a warning triangle

Notes,

i.e. important information for the

user, appear in a gray box and are

marked with the symbol

Solvents and reagents that are inflammable are marked with this

symbol.

This warning symbol indicates the

surfaces on the instrument that are

hot during operation.

Avoid direct contact to prevent risk

of burning.

.

.

1.2 Specified use and application

The Leica EG1150H is a modern paraffin embedding station with microprocessor control.

It is designed for embedding histological tissue

specimens in molten paraffin for use in pathology laboratories and only for the following tasks:

• Melt solid paraffin for sample embedding

and maintain the molten paraffin at the required temperature.

• Fill the molds, in which the tissue specimens

were placed, with paraffin.

• Heat and maintain the temperatures of embedding cassettes with specimens and

molds as well as the required forceps.

Any other use of the instrument will be

considered as improper use!

1.3 User group

• The Leica EG1150H may only be operated by

qualified personnel.

• The user must read the operating instructions supplied and be familiar with all the instrument’s technical details before any work

on the instrument can be carried out.

(5)

ENTER

Leica EG1150H – Paraffin Embedding Station

Figures in brackets refer to item

numbers in figures.

Function keys that have to be

pressed on the input screen, are displayed in bold type and capital letters.

1.4 Instrument type

All information in this instruction manual applies

only to the instrument type indicated on the title

page.

A name plate with

the serial number

is attached to the

back of the instrument.

5

2. Safety

Be sure to comply with the safety instructions and warnings provided in this chapter.

Be sure to read these instructions, even if you are already familiar with the operation and

use of other Leica products.

2.1 Safety notes

This instruction manual contains important

instructions and information regarding the

operational safety and maintenance of the

instrument.

The instruction manual is an important part of

the product, which must be read carefully prior

to start-up and use and must always be kept

near the instrument.

If additional requirements on accident

prevention and environmental protection exist in the country of operation,

this instruction manual must be

supplemented by appropriate instructions to ensure compliance with such

requirements.

The protective devices on both instrument and accessories may neither be removed nor modified. Only service personnel qualified by Leica may repair the instrument and access the

instrument’s internal components.

This instrument has been built and tested in accordance with the safety regulations for electrical measuring, control, regulating and laboratory devices.

To maintain this condition and ensure safe operation, the user must observe all notes and

warnings contained in this Operating Manual.

For current information about applicable standards, please refer to the

CE declaration for the instrument and

to our Internet site:

http://www.leica-microsystems.com

2.2 Warnings

The safety devices installed in this instrument by the manufacturer only constitute the basis for

accident prevention. Primarily responsible for accident-free operation is above all the owner

of the instrument and, in addition, the designated personnel who operates, services or cleans

the instrument.

To ensure trouble-free operation of the instrument, make sure to comply with the following

instructions and warnings.

6

Instruction Manual V 2.2, Rev B – 12/2009

Safety instructions – safety regulations on the instrument itself

Safety regulations marked with a warning triangle on the instrument itself mean that

when operating or exchanging respective parts of the instrument, the correct operating

steps as described in the instruction manual supplied, must be adhered to. Non-observance can cause accidents, injuries and/or damage to the instrument/accessories.

Certain surfaces of the instrument are hot during operation under normal

conditions. They are marked with this warning sign. Touching these surfaces

can cause burns.

Safety instructions – transport and installation

After unpacking the instrument it may only be transported in an upright position.

Place the instrument on a laboratory table and adjust it to a horizontal position.

The instrument must not be exposed to direct sunlight (window)!

Plug the instrument only into a grounded mains socket. The protective effect may not be

eliminated by an extension cable without a protective grounding conductor.

The instrument automatically recognizes the applied voltage/frequency.

The installation location must be well-ventilated; there should be no ignition sources

there of any kind.

The instrument may not be operated in hazardous locations.

Extreme temperature fluctuations between storage facility and setup site as well as high

humidity may cause condensation to form. In this case, wait at least two hours before

switching on.

2. Safety

Safety instructions – working with the instrument

Paraffin is flammable and should therefore be handled with due care. Do not use sharp

tools to remove solidified paraffin from the work areas, as this may destroy the coating on

the surface. Use the plastic spatula supplied with the instrument.

During operation, the paraffin reservoir, mold warmer, cassette warmer, work area as

well as the forceps holder are hot.

Risk of burning!

Do not store any combustible and flammable substances near the instrument. There is a

fire hazard if work with an exposed flame (e.g. Bunsen burner) is carried out in the direct

vicinity of the instrument (solvent vapors). Therefore a minimum safety distance of 2

meters must be adhered to!

Leica EG1150 H – Paraffin Embedding Station

7

2. Safety

Hazards – servicing and cleaning

Switch off the instrument each time before servicing and pull out the mains plug.

When using cleaners, please comply with the safety instructions of the manufacturer and

the laboratory safety regulations.

Before changing defective fuses, the instrument has to be disconnected from the mains.

Only fuses that are easily accessible may be replaced by the user.

Set the standby switch to “Standby“ (

power cable out of the mains socket.

During operation and cleaning, do not allow any liquid to penetrate inside the instrument

and the transporting arm.

2.3 Built-in safety devices

The instrument is equipped with the following safety features and devices:

Fuses in the heating elements

All resistance mats of the instrument are equipped with overheating fuses,

which switch the heating element off if overheated.

) when replacing the halogen lamp and pull the

Automatic circuit breaker in standby switch

An automatic circuit breaker is located in the standby switch. This circuit

breaker separates the power electronics from the mains power supply in

the event of a short-circuit.

In this case, the standby switch jumps to the position “0“ = Off.

Note that the only way the user has for complete disconnection from the mains supply is

disconnection of the mains plug.

8

Instruction Manual V 2.2, Rev. B – 12/2009

3.1 Specifications

General data

Approvals: The approval symbols relating to this instrument are located

Power voltages: 100-120 V, 50/ 60 Hz

Input: 1100 VA

Class of protection

Degree of pollution1:2

Overvoltage category: II

Operating temperature range: +18 °C to + 40°C

Working temperatures: 55 °C to 70 °C, adjustable in 5 degree (K) increments.

Relative air humidity: maximum 60 %, non-condensing.

1)

according to IEC-1010, UL 3101, EN 61010

Fuses

Standby switch: Circuit breaker manufactured by ETA,

Fine-wire fuses 6.3 x 32 mm: 2x T 2.0 A; 2x T 3.2 A; T2x 4.0 A; T2x 5.0 A; T2x 6.25 A

Fuse type: Co. Schurter: type Fst

3. Instrument components and specifications

on the rear of the instrument next to the nameplate.

230-240 V, 50/ 60 Hz

1

:I

model 3120-F421-P7T1-W01D-5A

Dimensions and weight

Dimensions:

Height: 360 mm

Width: 500 mm

Depth: 640 mm

Weight: approx. 22 kg

Capacities

Paraffin reservoir: approx. 3 l

Cassette warmer: approx. 100 cassettes

Mold warmer: approx. 50 molds

Programmable parameters

Temperature: Paraffin reservoir/dispenser

Time: Working days, current weekday

Leica EG1150 H – Paraffin Embedding Station

(heating-up time = 4h)

Mold warmer, cassette warmer, work area

Working times (start, end), time

9

3. Instrument components and specifications

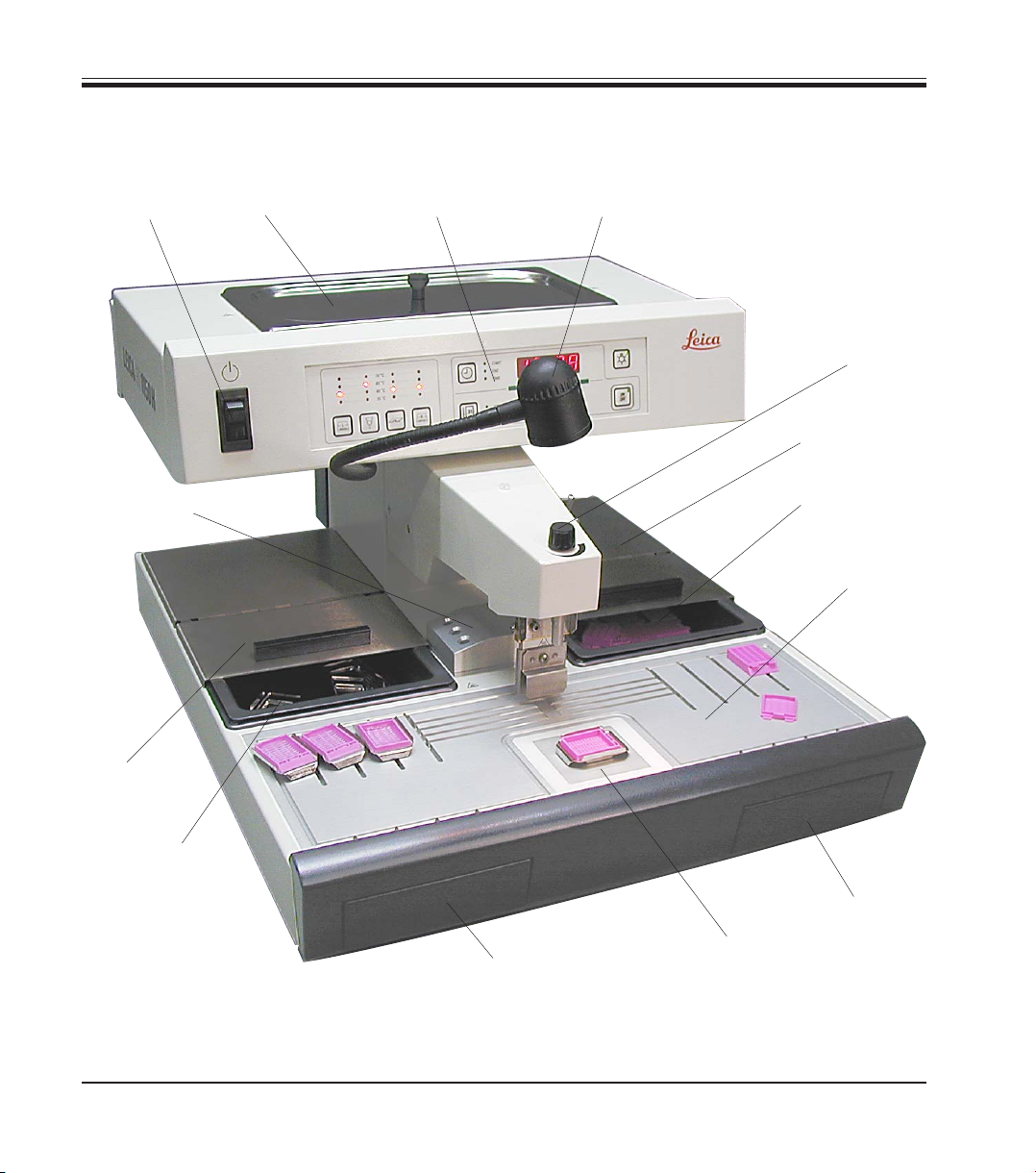

3.2 Overview – instrument parts

Standby

switch

Forceps holder

Paraffin reservoir

with lid

Control panel

Work area illumination

Dispenser

Cassette warmer

lid

Cassette warmer

Work area

Mold warmer

lid

Mold warmer

10

Paraffin collection tray

left

Instruction Manual V 2.2, Rev. B – 12/2009

Paraffin collection

tray right

Refrigeration spot

Fig. 1

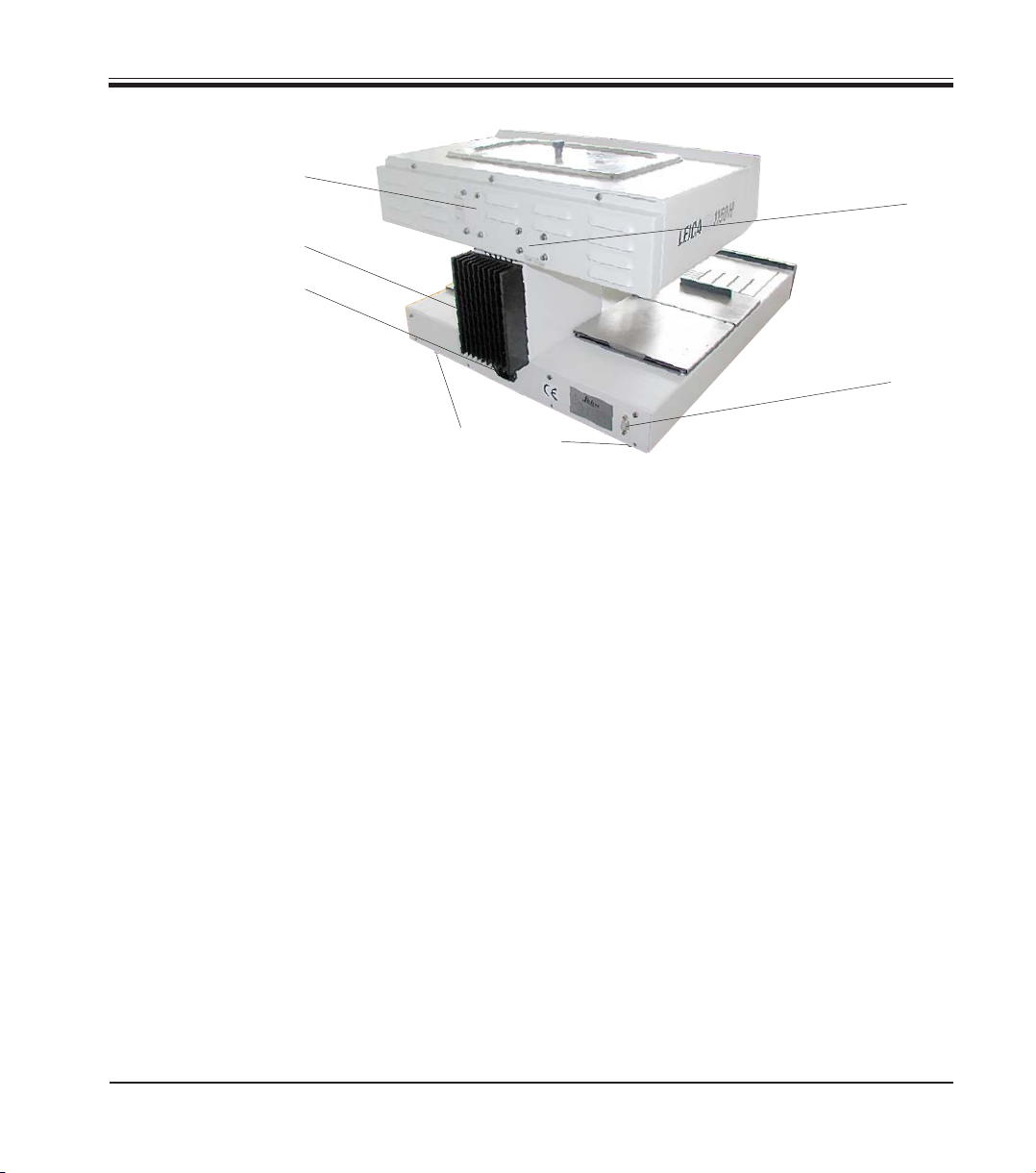

Instrument rear view

3. Instrument components and specifications

Secondary fuses F1-F3

Heat sink

Port for power cord

3.3 Instrument specifications

• Paraffin reservoir with a capacity of 3 liters.

• The paraffin flow is activated by means of a height-adjustable,

pivotable clip – activated either manually by the mold or a foot switch

(optional).

• Controllable flow rate.

• Removable, heatable (indirectly, via the work surface) paraffin collection trays.

• Spacious, easy-to-clean, heated work area, with integrated refrigeration spot, also for extra large cassettes (‘Super Mega Cassettes’) with

paraffin flow system.

• Warmers for cassettes and/or molds with sliding lid, removable and interchangeable.

• Removable, heated forceps holder for 6 forceps, accessible from both

sides.

• Optimum illumination of the work surface by individually adjustable

halogen lamp.

• Temperature range of cassette and mold warmer, work area and paraffin reservoir adjustable from 55°C to 70°C.

• Permanent temperature display for all the work areas.

• The beginning and end of the work time and work days can be programmed.

Secondary fuses

F4-F5

Port for

foot switch

Sliding elements

Fig. 2

Leica EG1150 H – Paraffin Embedding Station

11

4. Commissioning

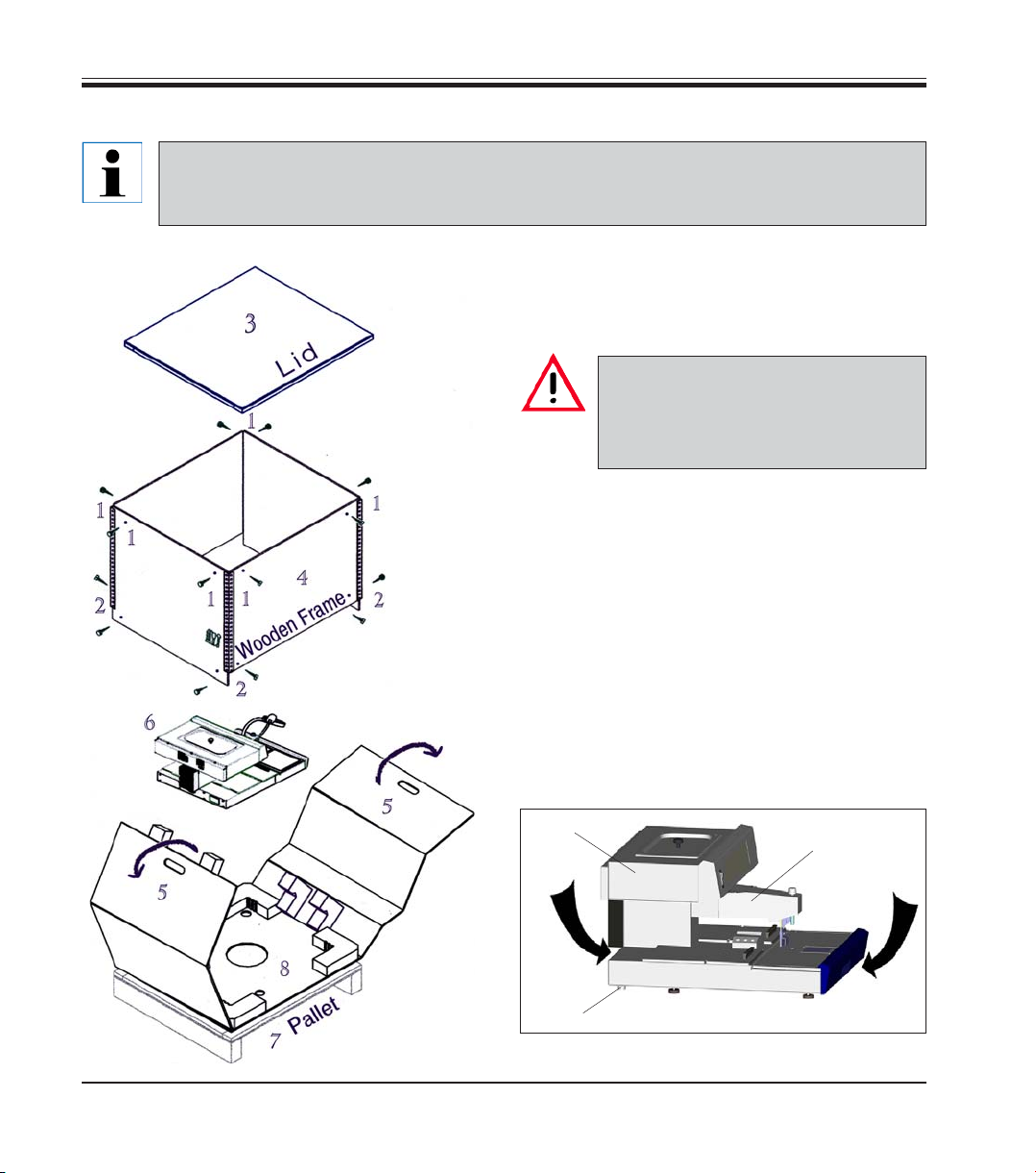

4.1 Unpacking and installation

The unpacking instructions are attached to the outside of the transport crate. Fig. 3

shows the design of the original packaging.

The numbers indicate the sequence of disassembling and reassembling.

• To lift up the instrument (6), hold it at the

front and rear of the base plate (Fig. 4) and

lift it from the foam padding (8).

Important!

Lifting the instrument by the dispenser (10) or paraffin reservoir (11)

can cause serious damage.

• After unpacking the instrument it should only

be transported in a horizontal position.

• Two slide faces (9) at the rear of the base

plate help to reposition the instrument on the

table. To reposition, slightly lift the instrument at the front of the base plate and slide

it on the slide faces.

• The instrument should be set up in such a

way that the air circulation is not affected. A

smooth operation is ensured only when the

instrument is set at a minimum distance of

15 cm from walls and furniture.

12

Fig. 3

11

10

9

Fig. 4

Instruction Manual V 2.2, Rev B – 12/2009

Loading...

Loading...