Page 1

Leica Abbe Mark II

Refractometer

Models 13104800/13104810/

13104940/13104950

Instruction Manual

Gebrauchsanleitung

Manuel d’utilisation

Manual de instrucciones

Page 2

Page 3

1.0 INTRODUCTION.................................................................. 3

2.0 UNPACKING........................................................................ 3

3.0 POWER REQUIREMENTS.................................................. 3

4.0 SET UP .................................................................................. 3

4.1 Equipment Installation........................................................ 3

5.0 CONTROLS............................................................................ 3

5.1 Variable Conditions in Taking Readings .......................... 4

5.2 Calibrating With Distilled Water ...................................... 4

6.0 OPERATING INSTRUCTIONS .......................................... 4

7.0 LEICA ABBE MARK II PLUS REFRACTOMETER............ 5

7.1 Computer Interface............................................................ 5

7.2 Setting the Baud Rate ...................................................... 5

7.3 Printer Interface ................................................................ 5

7.4 Custom Programming........................................................ 5

8.0 REFRACTOMETER USE, TECHNIQUES AND

REFRACTION PRINCIPLES ................................................ 6

8.1 High Index/High Dispersion Samples ............................ 6

9.0 CALIBRATION WITH TEST GLASS.................................. 6

10.0 ILLUMINATOR BULB REPLACEMENT ..............................7

10.1 Fuses .................................................................................... 8

11.0 CARE AND CLEANING ........................................................8

12.0 SERVICING ............................................................................8

13.0 SPECIFICATIONS..................................................................8

13.1 The following specifications refer only to the

LEICA ABBE MARK II PLUS Refractometer.................... 9

Explanattion of Warning Symbols

1.0 INTRODUCTION

NNOOTTEE::

Please read these instructions carefully before attempting

to use the instrument.

This Instruction Manual is designed specifically for the LEICA

ABBE MARK II Refractometer and describes proper set up, use

and routine maintenance of the instrument.

SSeeccttiioonnss 77..00 -- 77..44 aarree

aapppplliiccaabbllee oonnllyy ttoo tthhee LLEEIICCAA AABBBBEE MMAARRKK IIII PPlluuss RReeffrraaccttoommeetteerr..

The LEICA ABBE MARK II Refractometer is a durable bench-top

instrument. It provides efficient, reliable and repeatable readings

in three modes:

• % Solids (

O

Brix)

• % Solids (

O

Brix) temperature compensated or (BX-TC) and

• Refractive index (nD)

The LEICA ABBE MARK II Plus Refractometer can accommodate

a custom program on the % Solids (

O

Brix) scale. This can be ac-

complished with pre-programming or retrofitting at the factory.

2.0 UNPACKING

The LEICA ABBE MARK II Refractometer has been carefully packaged for shipping. Before setting aside the packing materials,

check the box(es) to assure that all items ordered have been

received. Among the accessories in the refractometer box will be:

• a refractive index test glass (Catalog No. 10451)

• a 1/16" ( No. 4) Allen wrench (Catalog No. X30600)

• a bottle of 1- Bromonaphthaline for measuring solids

(Catalog No. 10452)

• a dust cover (Catalog No. 10450-140)

Check the instrument and model number against the original

order before discarding any packing materials. The original

packing materials may be saved for future storage or transportation of the refractometer.

3.0 POWER REQUIREMENTS

Models 13104800/13104940 115~ +/-10%, 50/60 Hz

Models 13104810/13104950 230~ +/-10%, 50/60 Hz

• Input power 25P max

• Indoor use only

• Altitude up to 2000m

• Temperature range 5

O

C to 40OC

• Pollution degree 2

• Installation category 2

• Max relative humidity 80% for temperatures up to 31OC

decreasing linearly to 50% relative humidity at 40OC.

4.0 SET UP

The LEICA ABBE MARK II Refractometer is easy to use.

Very little training is needed to set up and operate the instrument

to obtain temperature and refractive index measurements.

4.1 Equipment Installation

The LEICA ABBE MARK II Retractometer must be used on a hard,

stable and level surface such as a laboratory table or work

bench.

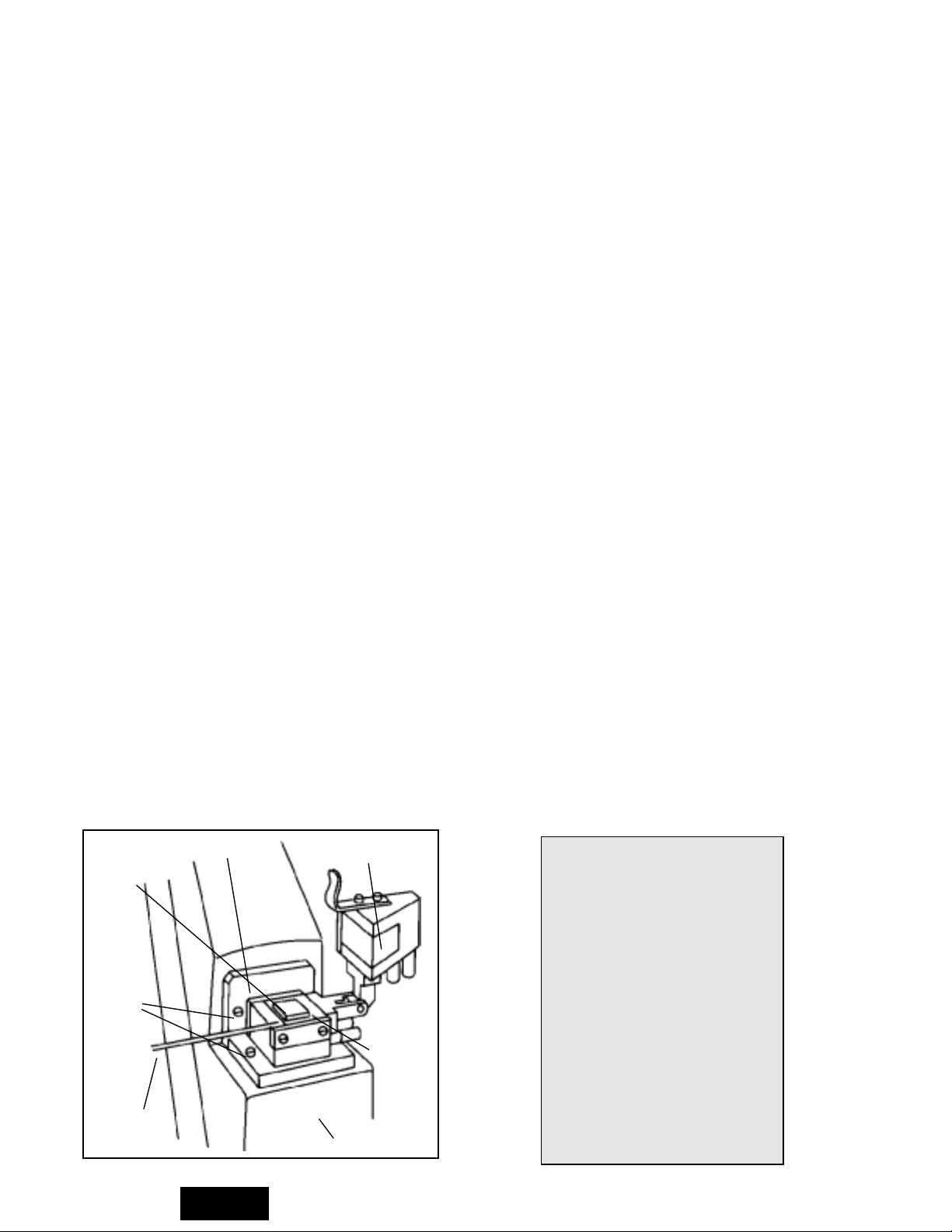

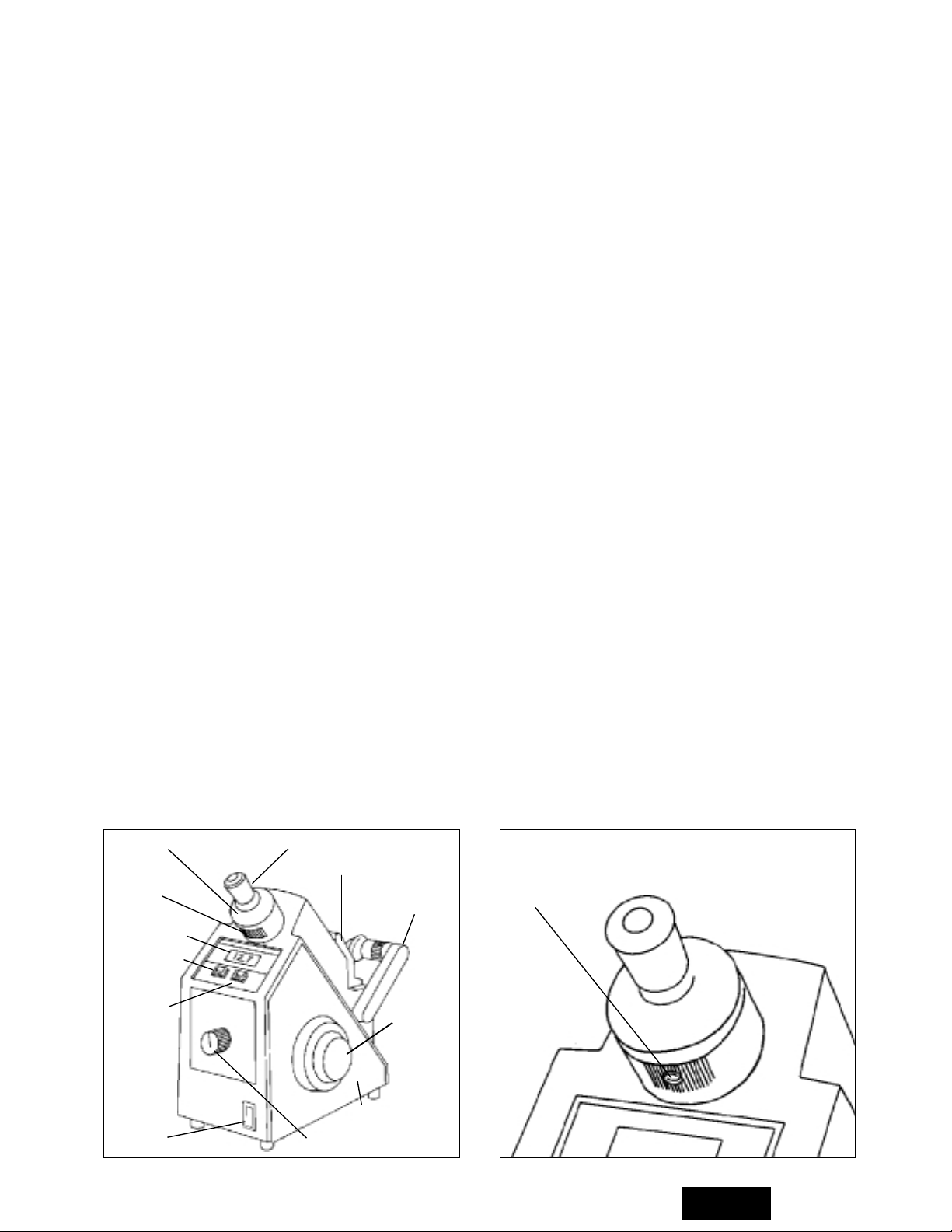

5.0 CONTROLS

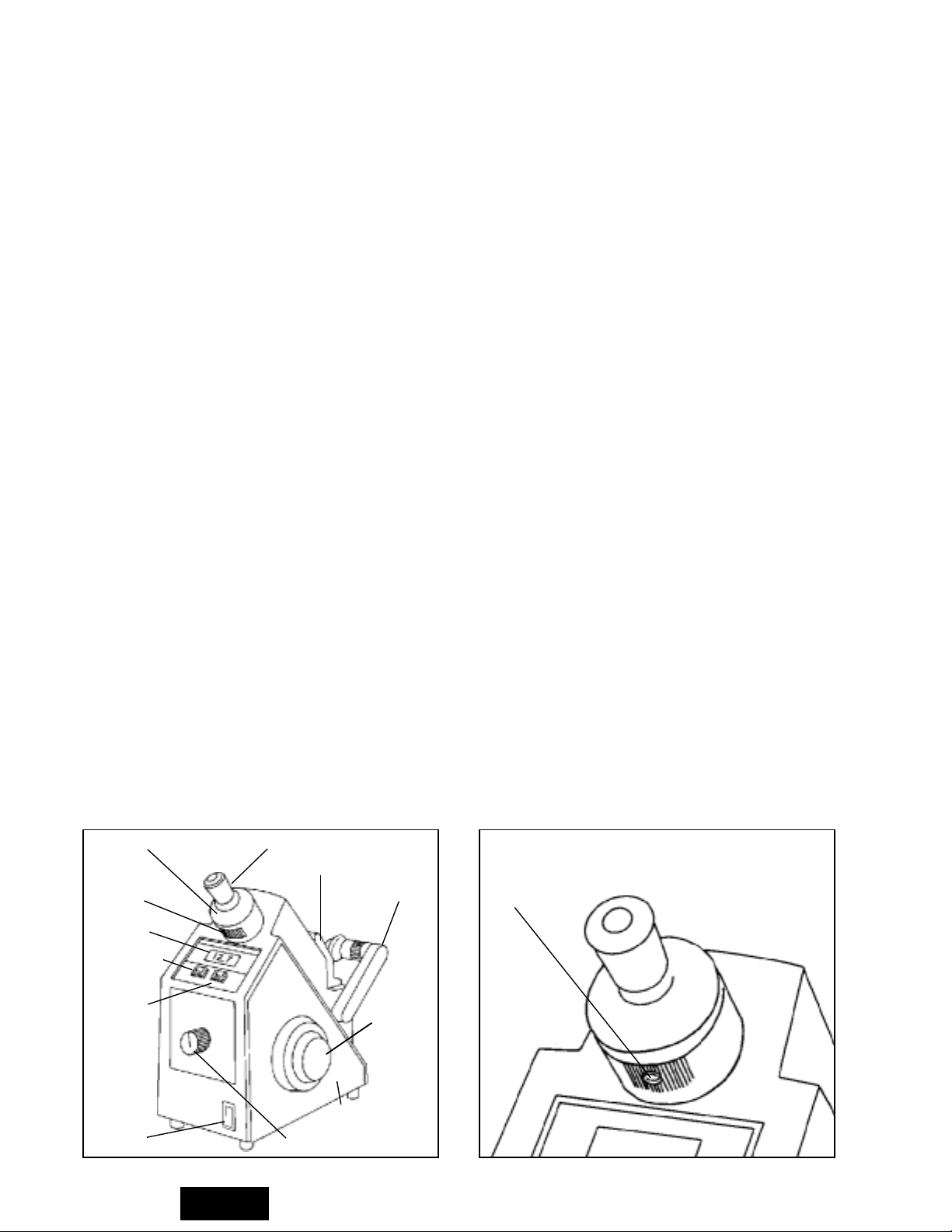

THE LEICA ABBE MARK II Refractometer controls are identified

in Figure 1.

NNOOTTEE::

The mode selector switch no longer functions as the

on/off switch. The ON/OFF switch is located on the lower left

front cover of the instrument above the Leica logo.

PPoowweerr SSwwiittcchh::

The Power Switch is located in the lower right corner of the front

panel (Figure 1). | = on 0 = off

English

Leica ABBE MARK II Refractometer

Instruction Manual

Contents

5X20 250mA T/250V (Type 10480/10494)

CAUTIONN:

Risk of electric shock

CAUTIONN:

(Refer to accompanying documents)

!

CAAUTION:

As a safety precaution, the power cord

has been grounded to the instrument base. Never use a

2-prong adapter between the power cord and the power

source; it will render the grounding feature ineffective.

CAAUTION:

Use of this equipment other than in the manner specified in this manual may result in reduction of

safety protection.

!

3

Page 4

TThhee mmooddee sseelleeccttoorr sswwiittcchh iiss uusseedd ttoo sseelleecctt mmeeaassuurreemmeenntt mmooddeess::

TThhee mmooddeess aarree::

• % Solids-TC - Temperature Compensated % Solids as Sucrose

(

O

Brix) per International Commission for Uniform Methods of

Sugar Analysis Refractive Index Tables.

•nD- Refractive Index

• % Solids - Non-Temperature Compensated % Solids as Sucrose

The reticle adjustment access hole permits vertical adjustment

of the crosshair during calibration procedures.

Depress the read display button to obtain measurement values.

Depressing the temperature display button will provide

a reading of the prism temperature.

Readings are shown digitally in the display window.

5.1 Variable Conditions in Taking Readings

Distilled water readings above 20OC can be obtained in the

refractive index % Solids-TC mode, assuming the instrument is

properly calibrated. Correct readings cannot be obtained in the

non-temperature compensated % Solids mode when the water

sample temperature is above or below 20

O

C. Refractive index (nD)

readings for distilled water can be obtained from 0OC to 80OC (see

Chart 1 for values between 18-30OC).

Refractive index is inversely proportional to temperature. As

temperature increases, the solution density decreases and the

refractive index or % Solids reading will decrease. As temperature decreases the solution density will increase and the

refractive index (% Solids) will increase. The % Solids-TC mode

automatically corrects the reading for temperature based on

the temperature coefficient of sucrose in solution. This coefficient is typical of most aqueous solutions.

5.2 Calibrating With Distilled Water

To calibrate:

1. Place a distilled water sample on the measuring prism surface

and let it stand undisturbed for 3-5 minutes to obtain temperature

stability. Turn the mode selector switch to the refractive index

(nD) position.

2. Focus the eyepiece until the crosshair clearly appears.

3. Rotate the adjustment control clockwise until the shadow line

nearly meets the crosshair. Use the dispersion correction wheel

to obtain the sharpest possible color-free shadow line. Adjust the

shadow line to meet the crosshair. Press the Read button and

record the n

D

value, then press the temperature button and

record the temperature.

4. If the instrument is properly calibrated, the reading will be

1.3330 less 0.0001 for each degree above 20OC or plus 0.0001 for

each degree below 20

O

C.

If the instrument is not calibrated, determine the proper reading

(Chart 1) and rotate the adjustment control and depress the READ

display button until the display reads correctly. (The shadow line

will no longer intersect the crosshair on the reticle.)

5. Insert a 1/16" Allen wrench into the reticle adjustment

access hole (Figure 2) located in the dispersion correction wheel.

Turn the wrench to bring the crosshair into proper position on the

shadow line.

NNOOTTEE::

The final movement made with the adjustment

correction control wheel should always be in a clockwise direction. The shadow line will move upward.

6. Turn the mode selector to the BX-TC position. Press the READ

button. An LED reading of 000.0 or 0.1 is normal. If a negative sign

and a decimal point appear, no reading can be given.

Go on to the next step.

If a “No Reading” condition persists after repeated READ

attempts, rotate the adjustment control until the display reads

000.0 or 0.1. Only a very slight adjustment will be necessary.

Readjust the reticle crosshair to the shadow line.

The display should now read 000.0.

Repeat the steps until the display reads 000.0.

6.0 OPERATING INSTRUCTIONS

To begin operation:

1. Open the prism assembly cover (Figure 4) and remove the

protective lens tissue. Clean the measuring prism surface with

alcohol and then distilled water. Wipe with a clean soft cloth or

lens tissue, but do not wipe the measuring prism surface while

it is dry. Any residue left on the prism can affect the accuracy

of readings.

2. Turn the mode selector to the desired mode position.

3. Apply a sample solution to the measuring prism surface using a

glass dropper. Close the prism cover and position the illumination

arm so that the exposed face of the upper prism is fully illuminated.

4. Turn the dispersion correction wheel so that the crosshair

adjustment access hole is at the six o’clock position.

English

Dispersion Correction Wheel

Adjustable Eyepiece

Reticle Adjustment

Access Hole

Display Window

Read Display Button

Temp. Display

Button

Power Switch

Mode Selector

Prism Surface

Illuminator Arm

Adjustment

Control

Right Panel Cover

Reticle Adjustment

Access Hole

FFiigguurree 11

FFiigguurree 22

4

Page 5

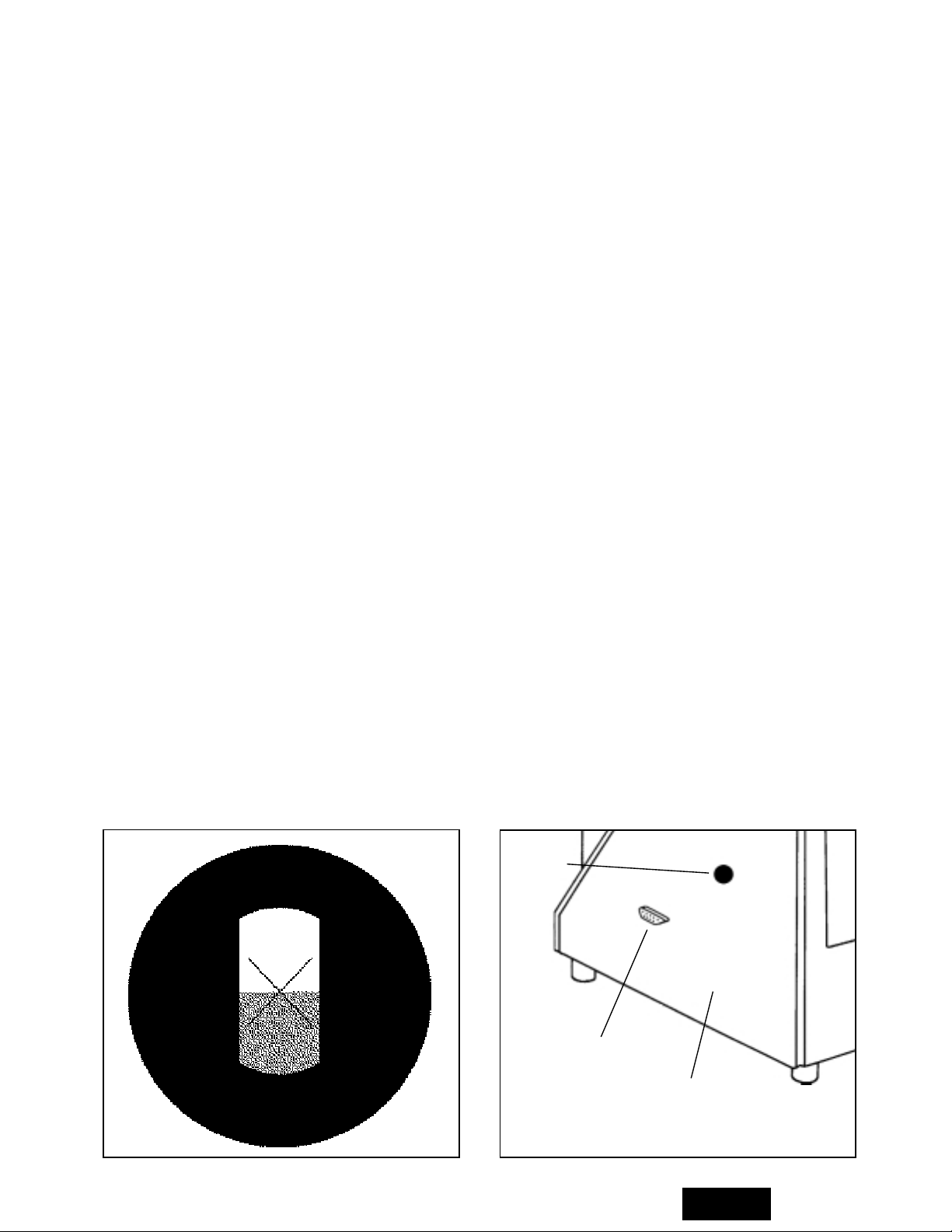

5. Rotate the adjustment control counterclockwise to position the

shadow line at the bottom of the field of view.

6. Rotate the eyepiece to bring the crosshair into focus.

7. Move the shadow line to the crosshair reticle with the coarse

adjustment control.

8. Rotate the dispersion correction wheel to eliminate any red or

green color at the edge of the shadow line.

9. Turn the adjustment control to center the shadow line to the

crosshair. The shadow line must be perfectly centered to obtain

an accurate reading (Figure 3a).

10. Depress the READ button. The value of the test sample will be

digitally indicated in the display window. Depressing the TEMP

button will activate a temperature sensing device located in the

measuring prism. The display will digitally indicate the actual

temperature of the measuring prism and sample.

NNOOTTEE::

If the LEICA ABBE MARK II Refractometer is to be used in

an environment where foreign materials may contaminate the

display buttons, use the splash guard accessory (Catalog No.

13104590). It will prevent instrument damage and possible instrument failure.

7.0 LEICA ABBE MARK II PLUS

REFRACTOMETER

NNOOTTEE::

Sections 7.0 through 7.4 are applicable only for the LEICA

ABBE MARK II Plus Refractometer - Model 13104940/13104950.

The LEICA ABBE MARK II Refractometer provides computer

interface, custom programming and printer interface capabilities.

The instrument becomes the LEICA ABBE MARK II Plus Refractometer (Model 13104940/13104950) with the addition of the

RS232 port. The LEICA ABBE MARK II Plus can be ordered as:

• an original purchase

• a factory upgrade or

• a retrofit to an existing LEICA ABBE MARK II Refractometer.

7.1 Computer Interface

Turn on the LEICA ABBE MARK II Plus Refractometer with the

switch located on the instrument’s front panel. When the refractometer is first turned on, the software version (

e.g.,

1.6) will

appear in the read display for a few seconds. The refractometer

is ready to use when this message disappears.

By interfacing the LEICA ABBE MARK II Plus to a computer,

sample reading results can be transferred to IBM-PC compatible data-handling software programs with communications

capabilities (

e.g.,

Microsoft Works®, Framework II™ and

ProComm®)

1

. Software can be used to store, graph, analyze and

print data. Leica also offers LEICA ABBE MARK II Plus Refractometer interface software (MARKPLUS) specifically designed for

use with the instrument.

The MARKPLUS software allows the instrument user to reprogram the % Solids scales from the default "Brix" (% Solids) scale

to a user defined scale.

7.2 Setting the baud rate

The baud rate of the LEICA ABBE MARK II Plus is set to 9600. To

change the baud rate remove the cap on the left side of the

instrument (Figure 3b). Turn the instrument on and using the

eraser end of a pencil press the post switch which is centered in

the hole. The display will show the current baud rate. To change

the rate press the read button on the front of the instrument panel

until the appropriate baud rate is displayed. Choose the baud rate

from the following options: 300, 1200, 2400, 4800, 9600. Once the

appropriate baud rate is displayed press the switch again. Turn

off the instrument and replace the cap. The new baud rate will be

permanently retained in the instrument memory.

7.3 Printer Interface

The LEICA ABBE MARK II Plus Refractometer can be interfaced

to a serial port printer for printed data results using the 9-pin

RS232 output. A parallel port printer may be used with a serial to

parallel converter.

7.4 Custom Programming

LEICA ABBE MARK II Plus Refractometer interface software

(MARKPLUS) may be configured for customized calibration

curves and temperature compensation. (The standard LEICA

ABBE MARK II Refractometer corrects to 20OC only.) However,

MARKPLUS must be configured for each specific application or

custom programming. Leica’s MARKPLUS is designed to accept

a Table of Refractive Index, Temperature and Concentration values and then generate custom scale data for instrument programming. Data is entered from a text file. Contact your Leica

representative for more information.

English

FFiigguurree 33aa FFiigguurree 33bb

Baud Rate

Adjustment

RS232 Port

Left Panel Cover

5

Page 6

8.0REFRACTOMETER USE, TECHNIQUES

AND REFRACTION PRINCIPLES

Refractive Index measurements taken on the LEICA ABBE MARK

II and LEICA ABBE MARK II Plus Refractometers are affected by

temperature. Different values can be obtained when the same

sample is measured at different temperatures. For example: as

the temperature of a sugar solution sample rises, its density and

refractive index decrease. This causes an apparent decrease in

concentration when using the non-temperature compensated %

Solids mode. The % Solids-TC (Temperature Compensated) mode

automatically corrects the reading to the correct value at 20

O

C.

For every 1OC change in temperature, an aqueous solution containing sugar will change readings by approximately 0.08%. This

is the average value for samples of 0 to 85% at 15OC to 45OC. As

temperature rises the % Solids reading decreases. As temperature decreases, the % Solids reading increases.

The LEICA ABBE MARK II Refractometer temperature will rise

approximately 1OC every 10 minutes for 1 hour until it stabilizes.

An instrument that has been turned on for more than 1 hour in a

20OC room could read 26OC. The rise in temperature is principally

due to heat generated by the power transformer inside the

instrument housing.

The sample placed on the measuring prism surface of a LEICA

ABBE MARK II Refractometer that has been turned on for more

than an hour in a 20OC environment will assume the temperature

of the prism (

i.e.,

approximately 26OC). Although the sample is

now warmer and would indicate a lower concentration when

measured in the uncompensated Brix mode, the BX-TC mode

automatically compensates for the temperature difference and

displays the concentration of the solution as if its temperature

were 20OC. Without compensation for the 6Orise, the readout of a

70% solution would be 0.5% less (6OC x 0.08%) or 69.5%.

The measuring prism surface temperature can be lowered

by running cooling fluid through the water jackets in the prism

housing. However, the heat generated inside the instrument

housing still affects the prism temperature. For this reason it is

necessary to run fluid slightly below the desired temperature. A

thermometer placed in the fluid line may measure several

degrees below the actual displayed temperature of the measuring prism surface displayed when the temperature button is

pressed. The opposite is true if the prism temperature has to be

elevated above the ambient temperature.

The fluid circulation system allows the prism to be adjusted

for temperatures up to 80

O

C. This may be necessary when using

samples that solidify at lower temperatures.

Measuring viscous samples, such as high Brix sugar syrups, may

be more difficult than measuring products with lower total dissolved solids.

Stir the sample on the measuring prism surface with a rubber

spatula or an angled piece of clear plastic tubing. Completely

cover the surface making sure all the air pockets between the

sample and the measuring prism surface are removed.

For removing carbonation from carbonated soft drink samples,

open and close the prism cover two or three times after loading.

Doing this provides the best possible reading line and the best way

to judge where the shadow line intersects the crosshair reticle.

NNOOTTEE::

Remember the accuracy of the instrument is only as good

as the clarity of the shadow line.

8.1 High Index/High Dispersion Samples

High refractive index samples with high dispersion properties may require

additional use of Catalog #13K30650 589nm bandpass filter accessory. This

accessory will insure that the shadowline will be sharp for these samples.

9.0 CALIBRATION WITH TEST GLASS

Refer to Chart 1, Refractive Index of Triple Distilled Water at

Various Temperatures to compare the refractive index reading

with the calibrated temperature reading.

To calibrate the LEICA ABBE MARK II Refractometer use:

• a refractive index test glass (Catalog No. 13104510)

• a bottle of 1- Bromonaphthaline (Catalog No. 13104520)

• a 1/16" (No. 4) Allen wrench (Catalog No. 13X30600)

• lens tissue

The refractive index test glass is imprinted with the refractive

index scale. The bottom and front surfaces of the glass are polished. It is important that these surfaces are very clean when

beginning calibration procedures.

TToo ccaalliibbrraattee::

1. Turn the “Mode” selector switch to the refractive index position.

2. Apply a single drop of 1-Bromonaphthaline to the surface of

the measuring prism surface.

3. Place the refractive index test glass on the measuring prism

surface with the imprinted side facing up. Position the polished

end of the test glass toward the illuminator - about 1/8" (2mm)

from the edge (Figure 4).

4. Align the illuminator so that the light is directed onto the polished face of the test glass. Cover the illuminator lens with lens

tissue to diffuse the light.

5. Adjust the illuminator arm, dispersion correction wheel, eyepiece and adjustment control so that the shadowline is centered,

in focus, free of color. This is the same procedure used with a

English

Back Plate

Test Glass

Test Glass Position

1/8” [2mm] from edge)

Base Plate

Measuring

Prism

Fastening

Screws

Illuminating Prism

CChhaarrtt 11:: RReeffrraaccttiivvee IInnddeexx ooff TTrriippllee

DDiissttiilllleedd WWaatteerr aatt VVaarriioouuss TTeemmppeerraattuurreess

TTeemmpp OOCC RReeffrraaccttiivvee IInnddeexx

18 1.3332

19 1.3331

20 1.3330

21 1.3329

22 1.3328

23 1.3327

24 1.3326

25 1.3325

26 1.3324

27 1.3323

28 1.3322

29 1.3321

30 1.3319

Source: Molar Refraction of Organic Compounds

FFiigguurree 44

6

Page 7

liquid sample.

6. Depress the READ button and record the digital reading which

appears in the display window.

If the reading differs from the value printed on the test glass by

more than ±0.0001, repeat the measurement several times.

Clean the measuring prism and test glass surfaces with alcohol,

followed by water after each test.

If an error persists, make the following adjustment:

7. Turn the shadow line adjustment control slightly and depress

the READ button. Repeat this procedure until the display agrees

with the test glass value.

The shadowline will now be above or below the center of the

crosshair reticle.

8. Insert the Allen wrench through the reticle access hole in the dispersion correction wheel. Adjust the reticle until the shadow line

passes through the center of the crosshair (Figure 2 & Figure 3a).

The instrument is now calibrated.

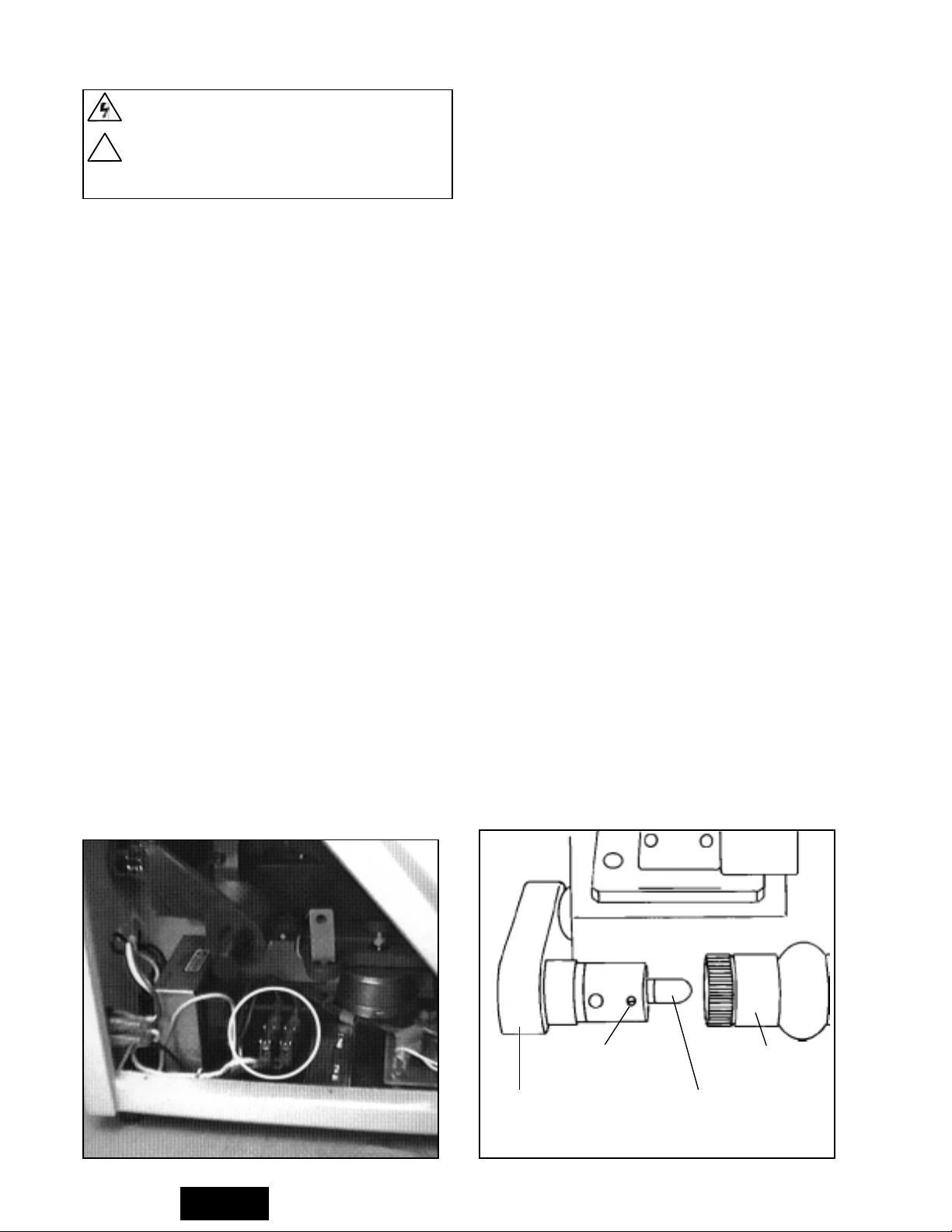

10.0 ILLUMINATOR BULB REPLACEMENT

The illuminator bulb can be replaced by removing the condenser

sleeve (Figure 6). Always use the suggested replacement bulb

(Catalog No. 13104620, pkg. of 3) for maximum efficiency and

safety. After inserting a new bulb, the socket can be adjusted to

center the light on the measuring prism with the condenser

sleeve in place. If necessary, push down on the spring-loaded

condenser sleeve lock pin and slide back and forth until the pin

snaps into place.

DAANGER

: The glass envelope of the bulb may be extremely

hot. Do not attempt to change the bulb before it is completely

cooled or without wearing protection.

WAARNING

: Unplug the refractometer power cord before

attempting to replace the illuminator bulb.

English

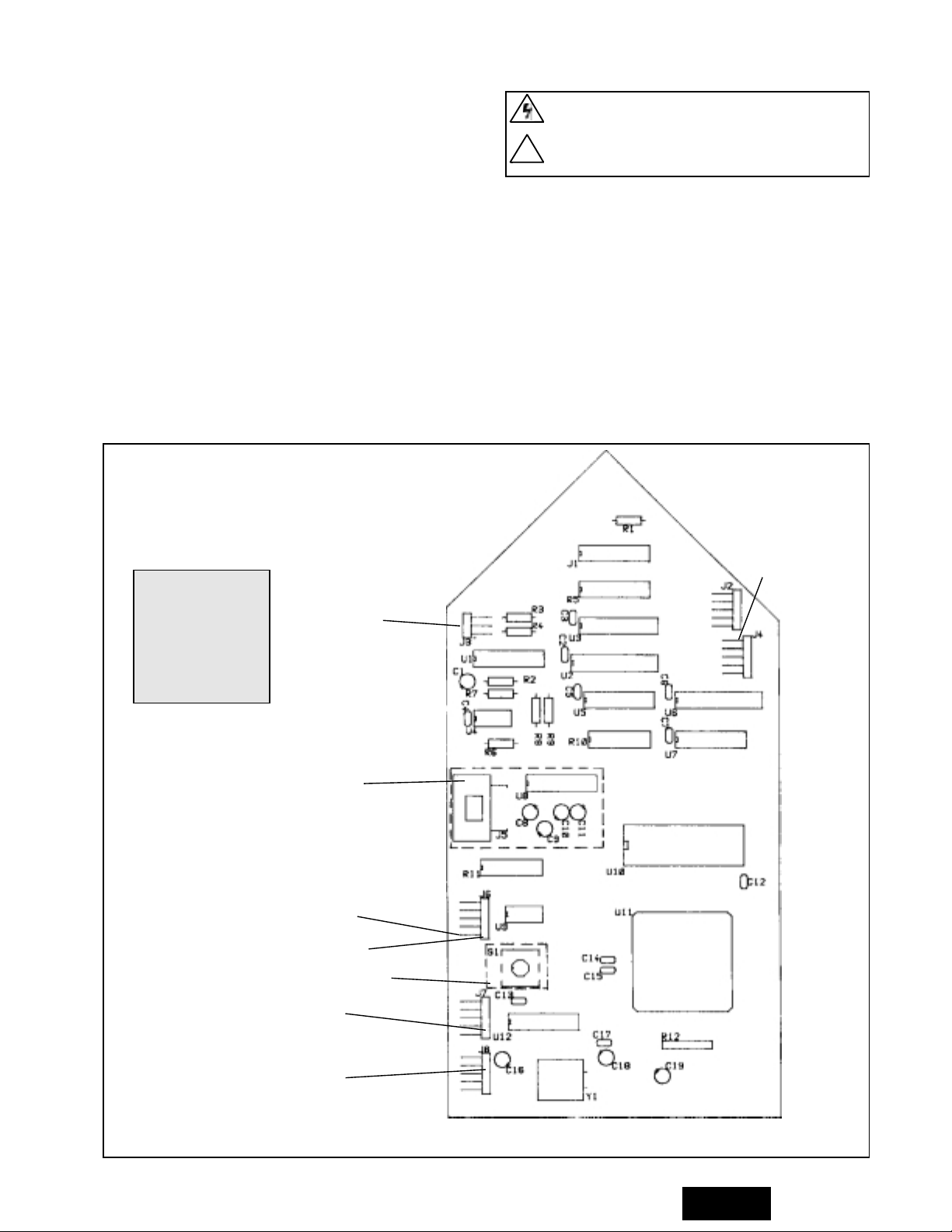

Main Control Board

(November 1992)

WWiirriinngg KKeeyy CCoolloorr CCooddee

W = White

B = Black

G = Green

O = Orange

R = Red

y = Yellow

11331100449944--992244

Not Used

Thermistor Plug

RS232 Plug

(active on 13104940, 13104950)

Not Used

Limit Switch

Baud Rate Switch

Power

Motor

FFiigguurree 55

!

7

Page 8

10.1 Fuses

The LEICA ABBE MARK II Refractometer electrical circuitry is

protected by two (2) fuses. To replace the fuses turn the Adjustment Control Knob (Figure 1) two turns clockwise. This raises the

elevator assembly to provide clear access to the fuses. Remove

the adjustment control knob with a 1/8” Allen wrench. Remove

the two Phillips head screws which hold the right panel cover to

the bottom of the instrument housing. Slide the panel cover down

as far as possible to facilitate its removal. With the right panel

cover removed the fuses will be visible on the bottom plate of the

instrument (Figure 5b). Replace the fuses and reassemble.

11.0 CARE AND CLEANING

The LEICA ABBE MARK II Refractometer is a precision optical instrument designed for years of trouble-free operation. The interior design has been carefully constructed for protection from dust

or spills. The exterior is painted with a durable enamel. The stainless steel refractive prism assembly is sealed with corrosionresistant epoxy.

The use of strong solvents such as N, N-Dimethylformamide or N,

N-Dimethylacetamide, cresols, phenols and other tar acids or

strong acetic solutions should be avoided. Materials such as

Tetrahydrofuran or some lacquer thinners and their components

can deteriorate the prism seal over a long period of time or when

applied in elevated temperatures.

An accumulation of dust, solvents or sample, particularly on the

prism assembly, may eventually penetrate the refractometer and

affect accuracy or accelerate wear.

When the instrument is not in use, the measuring prism assembly

should be kept closed with a folded sheet of lens tissue between

the prisms. The prism surfaces should be cleaned with distilled

water, methanol or an appropriate solvent immediately after

each sample is used.

Warm distilled water is recommended for removing sugar

residues and methanol for oil-based samples. The prism may be

wiped with lens cleaning tissue, but it should not be wiped with

a hard, dry cloth. After wiping the sample from the prism, rinse

the prism again with distilled water.

NNOOTTEE::

Do not wipe the measuring prism surface dry and do not

wipe it with anything if it is dry. Do not contact the prism or the

surrounding seal with metal or with sharp or pointed objects.

The glass parts of the prism assembly are relatively hard and

have excellent resistance to staining. Strong acids or bases

should not be measured with this instrument, nor used as cleaning agents.

To clean the eyepiece, snap out the rubber insert at the end of

the adjustable eyepiece tube. Clean the lens with a cotton swab

or lens tissue lightly dampened with acetone or methanol.

Replace the rubber insert.

12.0 SERVICING

The LEICA ABBE MARK II and LEICA ABBE MARK II Plus

Refractometers should be serviced or repaired by factorytrained service and repair technicians. If operating difficulty is

experienced contact Leica’s Refractometer Customer Service

Department at 716-686-3000 or fax 716-686-3085. Outside the

United States contact your local Leica representative.

13.0 SPECIFICATIONS

LLEEIICCAA AABBBBEE MMAARRKK IIII RReeffrraaccttoommeetteerr MMooddeell 1133110044880000//1133110044881100

LLEEIICCAA AABBBBEE MMAARRKK IIII PPlluuss RReeffrraaccttoommeetteerr

MMooddeell 1133110044994400//1133110044995500

DDiissppllaayy

Direct reading LED

MMooddeess ooff OOppeerraattiioonn

Refractive index (nD),

%Solids (OBrix) and

temperature compensated

Brix - BX-TC

MMooddeess RRaannggee

nn

D

1.3200-1.7000

BBrriixx

0-95

BBXX--TTCC aatt 2200

O

0-95

TTeemmppeerraattuurree OCC

15º-50ºC

PPoowweerr RReeqquuiirreemmeennttss

Model 13104800 115V/60Hz

Model 13104810 230/50Hz

Model 13104940 115V/50-60Hz

Model 13104950 230V/50-60Hz

Illuminator Arm

Socket Adjustment

Screw

Illuminator Bulb

Revolving Condenser

Sleeve

FFiigguurree 55bb FFiigguurree 66

Warning:

Unplug the Refractometer Power Cord before attempt-

ing to check or replace fuses.

CAAUTION:

Replacement of fuses is not user serviceable. Fuses

must be replaced by qualified service personnel. The fuse shall

be replaced only with the same size, type and rating.

!

English

8

Page 9

EElleeccttrriiccaall AApppprroovvaallss

UL listed, CSA certified,

VDE listed, CE

Accuracy ±0.0001n

D

±0.1% Solids (OBrix)- 0.0 95% ±0.1 on custom scale

TTeemmppeerraattuurree CCoommppeennssaattiioonn

Default mode corrects

%Solids scale readings

taken at 15OC to 50OC to a

datum temperature of

20OC; Mark II Plus

Custom Mode corrects to

user specified data

TTeemmppeerraattuurree MMeeaassuurreemmeenntt

Thermistor mounted in

prism assembly

TTeemmppeerraattuurree CCoommppeennssaattiioonn

±0.1OC

AAccccuurraaccyy

SSaammppllee TTyyppeess

Transparent or

translucent liquids and solids

DDiimmeennssiioonnss

6"W x 10.5"L x 14"H

(152mm x 262mm x 356mm)

WWeeiigghhtt

(net) 16lbs (7.3kg)

SSaammppllee TTeemmppeerraattuurree

Fittings on prism assembly

CCoonnttrrooll

for connecting temperature

controlled water circulator

PPrriissmm AAsssseemmbbllyy

Stainless steel, glass sealed

with solvent-resistant epoxy

OOppttiiccaall CCoommppeennssaattiioonn

Dual amici prism compensator for sharp shadow-lines

and 589nm (Sodium D line)

illumination

All models have passed RF Interference Testing, Class A

13.1 The following specifications refer only

to the LEICA ABBE MARK II Plus

Refractometer

DDiissppllaayy

Direct digital readout of

refractive index or

concentration (% solids or

custom scale) and

temperature

DDeeffaauulltt MMooddeess

1. Refractive Index 1.3200 to 1.7000n

D

2. % Solids (OBrix) 0.0 to 95.0%

3. % Solids (

O

Brix) temperature compensated 0.0 to 95.0%

Default % Solids (OBrix) scales (0.0-85.0%) based 1974

I.C.U.M.S.A. Tables (% Sugar vs. nDat 20OC)

CCuussttoomm MMooddeess

• 1. 0.0 to 999.9 readout of concentration. User inputs concentration vs. refractive index data

• 2. 0.0 to 999.9 Temperature Compensated readout of concentration

vs. refractive index vs. temperature data Custom Mode data are

input using Leica software program (IBM PC compatible)

IInntteerrffaaccee

RS232 Serial

CCoommmmuunniiccaattiioonn

User selectable Baud rate,

300, 1200, 2400, 4800,

9600 bps - 8 data bits, one

stop bit, no parity, Baud

rate factory set at 9600.

ASCII output with tab

separators

CCoonnnneeccttiioonn

DB9 Female

PPiinn AAssssiiggnnmmeennttss

2 output, 3 input, 5

ground

English

9

Page 10

LEICA ABBE MARK II Refraktometer

Gebrauchsanleitung

Inhaltsverzeichnis

1.0 Einleitung ............................................................................ 10

2.0 Auspacken des GerätES....................................................10

3.0 NetZspannung...................................................................... 10

4.0 AuFSTELLen des GerätES.................................................. 10

4.1 Ausrüstung Installation...................................................... 10

5.0 Bedienungselemente.......................................................... 10

5.1 Messungsvariabeln ............................................................ 11

5.2 Kalibrieren des Instruments mit Destilliertem Wasser 11

6.0 Bedienungsanleitung ........................................................ 11

7.0 LEICA ABBE MARK II Plus Refraktometer.................... 12

7.1 Computer-Interface .......................................................... 12

7.2 Einstellung der Übertragungsgeschwindigkeit............ 12

7.3 Druckerschnittstelle .......................................................... 12

7.4 Benutzerspezifisches Programmieren .......................... 12

8.0 Der Einsatz des Refraktometers. ....................................13

Techniken und Grundsätze der Refraktion

8.1 Hoher Brechungsidex/Hohes Dispersion Muster........ 13

9.0 Kalibrieren mit Testglas .................................................... 13

10.0 Auswechseln der Lampe....................................................15

10.1 Auswechseln der Sicherung .......................................... 15

11.0 Pflege und Reinigung ..........................................................15

12.0 Wartung..................................................................................16

13.0 Technische Daten................................................................16

13.1 Die nachfolgenden Angaben beziehen sich auss-

chließlich auf das LEICA ABBE MARK II Plus Refraktometer 16

Erläuterung für Warnungs Symbole

1.0 EINLEITUNG

AACCHHTTUUNNGG!!

Vor Inbetriebnahme des Geräts, lesen Sie diese

Anleitung bitte sorgfältig durch.

Diese Gebrauchsanleitung wurde eigens für das LEICA ABBE

MARK II Refraktometer geschrieben und beschreibt die richtige

Aufstellung, Benutzung und routinemäßige Wartung des Geräts.

Abschnitte 7.0 bis 7.4 beziehen sich ausschließlich auf das LEICA

ABBE MARK II Plus Refraktometer.

Das LEICA ABBE MARK II Refraktometer ist ein robustes

Tischgerät. Es liefert zuverlässig wiederholbare Meßergebnisse

in drei Modi:

• % Feststoffe (ºBrix)

• % Feststoffe (ºBrix ) Temperaturausgeglichen oder (BX-TC) und

• Brechungsindex (nD)

Das LEICA ABBE MARK II Plus Refraktometer kann durch ein

anwendungsspezifisches Programm für die % Feststoffe (ºBrix)Skala erweitert werden. Dies kann durch Vorprogrammierung

oder Nachrüstung in der Fabrik geschehen.

2.0 AUSPACKUNG DES GERÄTES

Für den Transport wurde das LEICA ABBE MARK II

Refraktometer sehr sorgfältig verpackt. Bevor Sie das

Verpackungsmaterial wegwerfen, kontrollieren Sie den Karton

bzw. die Kartons, um sicherzustellen, daß alle bestellten Teile

vorhanden sind. Zu dem Zubehör im Refraktometer-Karton

gehören:

• ein Brechzahl-Testglas (Kat.-Nr. 10451)

• ein 1/16" (Nr. 4) Sechskantstift-Schlüssel (Kat.-Nr. X30600)

• eine Flasche 1- Bromonaphthalin für Feststoffmessungen

(Kat.-Nr. 10452)

• ein Staubschutz (Kat.-Nr. 10450-140)

Vergleichen Sie das Gerät und die Typ-Nr. mit der Bestellung,

bevor Sie irgendwelche Verpackungsmaterialien wegwerfen.

Das Verpackungsmaterial kann auch zwecks künftiger Lagerung

bzw. Transport des Geräts aufgehoben werden.

3.0 NETZSPANNUNG

Netzspannung und Typ 13104800/13104940 120V ~ ±10% - 60Hz

Bereich Frequenz Typ 13104810/13104950 240V ~ ±10% - 50Hz

Stromaufnahme 25P Max

Bereich der Umweltbedingungen

• Höhe nicht über 2000m

• nicht für den Einsatz im Freien

• Temperaturen von 5ºC bis 40ºC

• maximale relative Feuchte - 80% bei Temperaturen bis zu 31º,

linear absteigend bis 50% relative Feuchte bei 40ºC

• Installationskategorie II (Kategorie Überspannung)

• Verschmutzungsgrad 2

4.0 AUFSTELLEN DES GERÄTES

Das LEICA ABBE MARK II Refraktometer is sehr benutzerfreundlich. Fast keine Einarbeitung ist notwendig, um das Gerät

aufzustellen und zu bedienen; somit sind Temperatur- und

Brechzahlmessungen sehr leicht zu erhalten.

4.1 Ausrüstung Installation

Das LEICA ABBE MARK II Refraktometer muß an einer harten

und ebenen Fläche z.B eine Werkbank oder Tisch aufgestellt

werden.

5.0 BEDIENUNGSELEMENTE

Die Bedienungselemente des LEICA ABBE MARK II

Refraktometers sind in Abb. 1 dargestellt.

Der an der Vorderseite des Geräts angebrachte Wahlschalter für

den Betriebsmodus dient nicht mehr als Ein- und Ausschalter.

EEiinn//AAuusssscchhaalltteerr::

Der Ein/Ausschalter ist an der rechten, unteren Ecke der

Vorderseite des Gerätes (Abb. 1). |=Ein 0=Aus

Deutsch

5X20 100mA T/250V (Typ 1310481/1310495)

VVOORRSSIICCHHTT::

Risiko von elektrischem Schock

VVOORRSSIICCHHTT::

Bitte verweisen sie zu begleitenden

Dokumente

!

VVOORRSSIICCHHTT::

Als Sicherheitsmaßnahme ist der Fuß

des Mikroskops über ein dreipoliges Netzkabel mit

einem Schutzleiter versehen. Verwenden Sie nie

einen zweipoligen Adapter zwischen dem

Neztkabel und der Steckdose; dies würde zum

Verlust des Schutzeffektes führen.

!

10

Page 11

DDeerr WWaahhllsscchhaalltteerr wwiirrdd bbeennuuttzztt uumm ddeenn BBeettrriibbssmmoodduuss

eeiinnzzuusstteelllleenn::

DDiiee MMooddii ssiinndd::

• % Feststoffe-TC - TC Temperatur ausgeglichen % Feststoffe

als Rohzucker (ºBrix) nach der Internationalen Kommission für

gleiche Verfahren der Zucker Prüfung, Brechindex Tabellen.

• nD - Brechindex

• % Feststoff - Nicht Temperatur ausgeglichen % Feststoffe als

Rohzucker.

5.1 Messungsvariabeln

Bei Temperaturen über 20° C kann destilliertes Wasser im

Brechungsindex % Feststoffe-TC-Modus gemessen werden,

vorausgesetzt, das Instrument wurde richtig kalibriert. Genaue

Meßwerte sind im % Feststoffe-Modus ohne

Temperaturausgleich nicht möglich, wenn die Wasserprobe von

20° C abweicht. Bei destilliertem Wasser kann eine

Brechzahlmessung (nD) von 0° C bis 80° C vorgenommen werden

(siehe Tabelle 1 auf Seite 10 für Werte zwischen 18-30° C).

Der Brechungsindex steht im umgekehrten Verhältnis zur

Temperatur. Bei steigenden Temperaturen sinkt die

Lösungsdichte und damit auch der Brechungsindex oder %

Feststoffe-Meßwert. Bei sinkender Temperatur steigen dagegen

die Lösungsdichte und der Brechungsindex (% Feststoffe). Der

% Feststoffe-TC- Modus gleicht den Meßwert auf Grund des

Temperatur-Koeffizients für Zuckerlösungen aus. Dieser

Koeffizient gilt für die meisten wasserhaltigen Lösungen.

5.2 Kalibrieren des Instruments mit destilliertem Wasser

Um das Refraktometer zu kalibrieren:

1. Geben Sie etwas destilliertes Wasser als Probe auf die

Oberfläche des Meßprismas und warten Sie 3 - 5 Minuten ab, um

eine stabile Temperatur zu erreichen. Wählen Sie mit dem

Wahlschalter den Brechzahlmodus (nD).

2. Schärfen Sie das Okular solange ein, bis das Fadenkreuz deut-

lich erscheint.

3. Drehen Sie das Einstellrad im Uhrzeigersinn so lange, bis die

Schattenlinie das Fadenkreuz fast berührt. Rotieren Sie das Dispersions-Korrekturrad bis eine möglichst scharfe und farbenfreie

Schattenlinie erreicht ist. Dann stellen Sie die Schattenlinie so

ein, daß sie mit dem Fadenkreuz in Berührung kommt. Drücken

Sie zuerst die Meßtaste und verzeichnen Sie den n

D

Wert, dann

die Temperaturtaste drücken und den Temperatur Wert verzeichnen.

4. Wenn das Gerät richtig kalibriert wurde, beträgt der Meßwert

1,3330 minus 0,0001 pro Grad über 20ºC bzw. plus 0,0001 pro Grad

unter 20ºC.

Wenn das Gerät nicht kalibriert wurde, ermitteln Sie nach

Tabelle 1 den richtigen Meßwert. Rotieren Sie das Einstellrad

und drücken Sie die Meßtaste solange, bis die Anzeige stimmt.

(Die Schattenlinie entfernt sich dabei vom Fadenkreuz auf der

Meßplatte.)

5. Führen Sie einen 1/16" Sechskant-Stiftschlüssel in das

Fadenkreuz-Einstell-Loch im Dispersions-Korrekturrad (Abb. 2).

Drehen Sie den Schlüssel, bis das Fadenkreuz an der

Schattenlinie liegt.

AACCHHTTUUNNGG!!

Die letzte Drehung des Einstellrads soll immer im

Uhrzeigersinnn erfolgen. Die Schattenlinie bewegt sich dabei

nach oben.

6. Drehen Sie den Modus-Umschalter auf die Stellung BX-TC.

Drücken Sie die Meß-Taste. Ein angezeigter Wert von 0000.0

oder 0.1 ist normal. Beim Erscheinen eines Minuszeichens und

eines Dezimalpunkts ist keine Meßwertanzeige möglich.

Gehen Sie zum nächsten Schritt über.

Wenn die Fehleranzeige auch nach wiederholten Meßversuchen

andauert, drehen Sie das Einstellrad solange, bis 000.0 oder 0.1

erscheint. Dazu bedarf es nur einer geringfügigen Verstellung.

Bringen Sie das Fadenkreuz erneut auf die Schattenlinie.

Das Anzeigefeld soll jetzt 000.0 zeigen.

Wiederholen Sie diese Schritte solange, bis die Anzeige 000.0

beträgt.

6.0 BEDIENUNGSANLEITUNG

Inbetriebnahme des Gerätes:

1. Öffnen Sie den Prismadeckel (Abb. 4) und entfernen Sie das

Linsen-Schutztuch. Reinigen Sie das Meßprisma mit Alkohol und

dann mit destilliertem Wasser. Wischen Sie es dann mit einem

weichen fuselfreien Tuch oder einem Linsenreinigungstuch ab,

aber ohne dabei die Oberfläche des Prismas ganz trocken zu

wischen, da eventuell auf dem Meßprisma verbleibende

Reststoffe die Meß-Leistung beeinträchtigen können.

2. Wählen Sie den erwünschten Modus mit dem ModusUmschalter.

3. Geben Sie eine Flüssigkeitsprobe auf die Oberfläche des

Meßprismas. Benutzen Sie dazu eine Glaspipette. Schließen Sie

den Prismadeckel und richten Sie den Beleuchter-Schwenkarm

so aus, daß die freie Fläche des oberen Prismas voll beleuchtet

ist.

4. Drehen Sie das Dispersions-Korrekturrad bis das

Fadenkreuzeinstellloch direkt nach unten zeigt.

Dispersions-Korrekturrad

Verstellbares Okular

Fadenkreuz-EinstellLoch

Meßwert-und

Temperaturanzeige

Temperatur-Taste

Temperatur-Taste

Taste

Wahlschalter

Prisma-Oberfläche

Beleuchter-

Schwenkarm

Einstrellrad

Rechte Außeuseite

AAbbbb.. 11

Fadenkreuz-Einstell Loc

AAbbbb.. 22

Deutsch

11

Page 12

5. Drehen Sie das Einstellrad gegen den Uhrzeigersinn, bis die

Schattenlinie ganz unten im Blickfeld liegt.

6. Schärfen Sie durch Drehen des Okulars auf das Fadenkreuz

ein.

7. Bringen Sie die Schattenlinie durch Drehen des

Grobeinstellrads an die Fadenkreuzplatte.

8 Drehen Sie das Dispersions-Korrekturrad, bis jeglicher rote

oder grüne Farbstich am Rand der Schattenlinie verschwindet.

9. Zentrieren Sie die Schattenlinie am Fadenkreuz durch Drehen

das Einstellrades. Um einen genauen Meßwert zu erhalten, muß

die Schattenlinie genau am Fadenkreuz zentriert sein (Abb. 3a).

10. Drücken Sie die Meßtaste. Der Meßwert für die

Testflüssigkeit erscheint digital im Anzeigefeld. Durch

Betätigung der Temperaturtaste wird ein Temperatursensor im

Meßprisma aktiviert. Die tatsächliche Temperatur des

Meßprismas und der Probe wird digital angezeigt.

AACCHHTTUUNNGG!!

Wird der LEICA ABBE MARK II Refraktometer in einer

Umgebung benutzt, in der Fremdkörper die Anzeigetasten verunreinigen könnten, ist der als Zubehör erhältliche Spritzschutz

(Kat.-Nr. 10459) zu benützen. Dieser schützt das Gerät vor

Beschädigung und eventuellem Geräteausfall.

7.0 LEICA ABBE MARK II PLUS

REFRAKTOMETER

AACCHHTTUUNNGG!!

Abschnitte 7.0 bis 7.4 beziehen sich ausschließlich

auf das LEICA ABBE MARK II Plus Refraktometer - Typ

13104940/13104950.

Das LEICA ABBE MARK II Refraktometer kann mit ComputerInterface, anwenderspezifischischer Software und einer

Druckerschnittstelle erweitert werden.

Wenn das Gerät durch ein RS232 Anschluß erweitert wird, wird

es zum LEICA ABBE MARK II Plus Refraktometer (Typ

13104940/13104950). Das LEICA ABBE MARK II Plus ist erhältlich

als:

• Neukauf

• werksseitige Aufrüstung

• Nachrüstung eines bestehenden LEICA ABBE MARK II

Refraktometers.

7.1 Computer-Interface

Schalten Sie das LEICA ABBE MARK II Plus Refraktometer mit

dem Wahlschalter an der Vorderseite des Geräts ein. Bei der

Ersteinschaltung wird die Software-Version (z.B. 1.0) einige

Sekunden im Anzeigefeld sichtbar. Das Refraktometer ist

gebrauchsfertig, wenn diese Meldung verschwindet.

Durch die Verbindung des LEICA ABBE MARK II Plus mit einem

Computer über ein Flachbandkabel, können Meßergebnisse an

IBM-kompatibel EDV-Programme mit

Datenübertragungsfähigkeiten (z.B. Microsoft Works

®

, Framework II™ und ProComm®) 1 weitergegeben werden. Software

kann zur Speicherung, grafischen Darstellung, Auswertung und

Ausdruck der Daten eingesetzt werden. Von Leica ist ein

Software-Programm erhältlich - die LEICA ABBE MARK II Plus

Refraktometer Interface Software (MARKPLUS) - die speziell für

dieses Gerät entwickelt wurde.

Mit der MARKPLUS-Software kann der Benutzer die %

Feststoffe-Skalen von der voreingestellten “Brix” (% Feststoffe)

Skala auf eine anwenderspezifische Skala umprogrammieren.

7.2 Einstellung der Übertragungsgeschwindigkeit

Der LEICA ABBE MARK II Plus Refraktometer wird mit einer

eingestellten Übertragungsgeschwindigkeit von 9600 Baud

geliefert. Um die Übertragungsgeschwindigkeit zu ändern, entfernen Sie die Kappe an der linken seite des Gerätes (Zusatz Blatt

3b). In der Öffnung befindet sich der Druckschalter. Das Gerät

einschalten, und auf den Druckschalter drücken, mit dem

Radiergummiende eines Bleistifts. Drücken Sie die Meßtaste

vorne am Gerät so lange, bis Ihre Wahl erscheint (z.B. 300, 1200,

2400, 4800, oder 9600). Wenn die erwünschte Baudrate erscheint,

drücken Sie den Schalter noch einmal.

Schalten Sie dann das Gerät aus, und die Kappe wieder einstellen. Die neue Übertragungsgeschwindigkeit wird in dem

Gerätespeicher behalten.

7.3 Druckerschnittstelle

Der LEICA ABBE MARK II Plus Refraktometer kann auch an eine

serielle Druckerschnittstelle angeschlossen werden, um einen

Ausdruck der Daten zu erhalten. Dazu dient der 9-polige RS232

Ausgang an der Seite des Instruments. Ein Drucker mit

Parallelschnittstelle kann über ein Seriell-Parallel-Übergangsstück angeschlossen werden.

7.4 Benutzerspezifisches Programmieren

Die Software für den LEICA ABBE MARK II Plus Refraktometer

(MARKPLUS) kann für kundenspezifische Kalibrationskurven und

Temperaturausgleich struktiert werden. (Serienmäßig berichtigt

der LEICA ABBE MARK II Plus Refraktometer die Temperatur nur

bis 20°C.) Die MARKPLUS-Software muß jedoch den jeweiligen

kundenspezifischen Anwendung angepaßt werden. Der Zweck

des Leica MARKPLUS-Softwareprogramms liegt darin, eine

Tabelle der Brechzahl-, Temperatur- und Konzentrationswerte

AAbbbb.. 33aa

AAbbbb.. 33bb

Baud Rate

Einstellung

RS232 Port

Linke Seitenwand

Deutsch

12

Page 13

als Eingabe zu akzeptieren, um daraus Daten für eine anwendungsspezifische Skala zwecks Instrument-Programmierung zu

generieren. Die Daten werden aus einer Text-Datei importiert.

Weitere Einzelheiten erhalten Sie von Ihrem LeicaVertragshändler.

8.0 DER EINSATZ DES REFRAKTOMETERS.

TECHNIKEN UND GRUNDSÄTZE DER

REFRAKTION

Die mit dem LEICA ABBE MARK II und dem LEICA ABBE MARK II

Plus Refraktometern erzielten Brechzahl-Meßergebnisse sind

temperaturabhängig. Dies kann zu unterschiedlichen

Meßergebnissen führen, wenn dieselbe Probe bei verschiedenen Temperaturen gemessen wird. Z. B., wenn die Temperatur

einer Zuckerlösung steigt, sinken die Lösungsdichte und damit

auch der Brechungsindex. Dies führt zu einem scheinbar geringeren Konzentrationsmeßwert beim % Feststoffe-Modus ohne

Temperaturausgleich. Beim % Feststoffe-TC-Verfahren (mit

Temperaturausgleich) wird der Meßwert automatisch in einen

Wert korrigiert, der einer Messung bei 20°C entspricht.

Bei jedem Temperaturwechsel von 1°C ändert sich der Wert für

eine Wasser-Zuckerlösung um ca. 0,08 %. Dieser

Durchschnittswert gilt für Proben von 0 bis 85% bei 15°C bis 45°C.

Bei steigender Temperatur sinkt der % Feststoffe-Meßwert. Bei

sinkender Temperatur steigt der % Feststoffe-Meßwert.

Bis die Temperatur des LEICA ABBE MARK II Refraktometers

stabilisiert, steigt sie eine Stunde lang um ca. 1ºC pro 10 Minuten.

Ein Gerät, das in einem Arbeitsraum mit einer

Umgebungstemperatur von 20ºC vor über einer Stunde

eingeschaltet wurde, könnte eine Temperatur von 26ºC

annehmen. Dieser Temperaturanstieg ist hauptsächlich auf die

Wärme des im Gerätegehäuse eingebauten Netztrafos zurückzuführen.

Die auf die Meßprismafläche eines schon über einer Stunde

eingeschalteten LEICA ABBE MARK II Refraktometers gelegte

Probe nimmt die Temperatur des Prismas (d.h. ca. 26ºC) an.

Obwohl die Probe jetzt wärmer ist und im nichtkompensierten

Brix-Modus eine niedrigere Konzentration anzeigen würde, gleicht der BX-TC Modus den Temperaturunterschied automatisch

aus und zeigt die Lösungskonzentration so an, als wäre ihre

Temperatur 20ºC. Ohne Temperaturausgleich würde der

Temperaturanstieg von 6ºC zu einem 0.5% (6ºC x 0,08%) geringeren Meßwert einer 70% Lösung führen, welche einer

Abweichung von 69,5% entspricht.

Die Temperatur der Prisma-Oberfläche kann herabgesetzt werden, indem man ein Kühlmittel durch die Wassermäntel im

Prismagehäuse fließen läßt. Dabei wird die Temperatur des

Prismas trotzdem weiterhin von der im Gerätegehäuse erzeugten

Wärme beeinflußt. Aus diesem Grund muß die Kühlflüssigkeit

etwas unter der erwünschten Temperatur liegen. Ein in das

fließende Kühlmittel eingetauchtes Thermometer könnte einen

Wert anzeigen, der einige Grad unter der bei Betätigung der

Temperaturtaste eigentlich angezeigten MeßprismaOberflächentemperatur liegt. Das Gegenteil gilt, wenn die

Prismatemperatur über die Umgebungstemperatur gebracht

werden muß.

Das Flüssigkeits-Kreislaufsystem ermöglicht die Einstellung des

Prismas für Temperaturen bis 80ºC. Dies könnte bei solchen

Proben notwendig sein, die bei niedrigeren Temperaturen erstarren.

Das Messen von zähflüssigen Proben, wie Zuckersirup mit

hohem Brix-Wert, kann schwieriger sein als das Messen von

Produkten mit einer niedrigeren Menge von völlig aufgelösten

Feststoffen.

Rühren Sie die Probe auf dem Meßprisma mit einem

Gummispachtel oder einem abgewinkelten Kunststoffröhrchen

um. Sorgen Sie für eine vollständige Abdeckung der PrismaOberfläche und stellen Sie sicher, daß keine Luftblasen zwischen

der Probe und dem Meßprisma verbleiben.

Um die Kohlensäure aus kohlensäurehaltigen Getränken zu entfernen, wird der Prismadeckel nach der Probeaufnahme zweioder dreimal auf- und zugeklappt. Dieses Verfahren gibt die bestmögliche Grenzlinie und die deutlichste Abbildung der

Schattenlinie an der Fadenkreuzplatte.

WWIICCHHTTIIGG::

Beachten Sie, daß die Leistung des Geräts abhängig

ist von der Abbildungschärfe der Schattenlinie.

8.1 Hoher Brechungsidex/Hohes Dispersion Muster

Muster mit hohen Brechungsindex und hoher Dispersion benötigen als Zubehör Kat.-Nr. K3065 589mm Dispersions filter. Dieses

Zubehör versichert eine scharfe Schattenlinie für das Muster.

9.0 KALIBRIEREN MIT TESTGLAS

Vergleichen Sie anhand von Tabelle 1 Brechzahl von dreifach

destilliertem Wasser bei verschiedenen Temperaturen (S. 7), den

Brechzahl-Meßwert mit dem kalibrierten Temperatur-Meßwert.

Um das LEICA ABBE MARK II Refraktometer zu kalibrieren,

benutzen Sie:

• ein Brechzahl-Testglas (Kat.-Nr. 10451)

• eine Flasche 1- Bromonaphthalin (Kat.-Nr. 10452)

• einen 1/16" (Nr. 4) Sechskantstift-Schlüssel (Kat.-Nr. X30600)

• ein Linsen-Reinigungstuch

Rückplatte

Testglas

Testglas-Position

(1/8" [2mm] von der

Kante)

Grundplatte

Meßprisma

Fixierschrauben

Beleuchtungsprisma

FFiigguurree 44

TTaabbeellllee 11:: BBrreecchhzzaahhll vvoonn ddrreeiiffaacchh ddeessttiill--

lliieerrtteemm WWaasssseerr bbeeii vveerrsscchhiieeddeenneenn

TTeemmppeerraattuurreenn

TTeemmpp ººCC BBrreecchhzzaahhll

18 1,3332

19 1,3331

20 1,3330

21 1,3329

22 1,3328

23 1,3327

24 1,3326

25 1,3325

26 1,3324

27 1,3323

28 1,3322

29 1,3321

30 1,3319

Quelle: Molare Refraktion von organischen

Verbindungen

Deutsch

13

Page 14

Die Brechungsindex-Skala ist aufgedruckt auf dem BrechzahlTestglas. Die Vorder- und Unterflächen des Glases sind

feingeschliffen. Diese Oberflächen müssen vor dem Kalibrieren

schmutzfrei sein.

KKaalliibbrriieerrvvoorrggaanngg::

1. Wahlschalter auf Brechzahl-Stellung schalten.

2. Einen Tropfen 1-Bromonaphthalin auf die Oberfläche des

Meßprismas geben.

3. Das Brechzahl-Testglas auf das Meßprisma mit der aufdruckten Seite nach oben legen. Die geschliffene Kante soll auf den

Beleuchter zeigen und ca. 2 mm vom Rand sein (Abb. 4).

4. Stellen Sie den Beleuchter so ein, daß das Licht direkt auf die

geschliffene Glasfläche fällt. Decken Sie die Beleuchter-Linse

mit dem Linsentuch zu, um das Licht zu dämpfen.

5. Stellen Sie Beleuchter-Schwenkarm, DispersionsKorrekturrad, Okular und Einstellrad so ein, daß die Schattenlinie

zentriert, scharf und farbenfrei erscheint. Verfahren Sie dazu

genau wie bei einer Flüssigkeitssprobe.

6. Drücken Sie die Meßtaste und registrieren Sie den im

Anzeigefeld dargestellten Meßwert.

Sollte der Wert von dem auf dem Testglas aufgedruckten

Meßwert um mehr als ±0,0001 abweichen, den Vorgang

mehrmals wiederholen. Nach jedem Testvorgang die

Oberflächen des Meßprismas und des Testglases mit ÄthylAlkohol und danach mit Wasser reinigen.

Sollte der Meßfehler weiterhin bestehen, folgendermaßen

vorgehen:

7. Das Schattenlinien-Einstellrad minimal drehen und dann die

Meßtaste drücken. Den Vorgang solange wiederholen, bis die

Anzeige mit dem aufgedruckten Wert auf dem Testglas übereinstimmt.

Die Schattenlinie befindet sich jetzt oberhalb oder unterhalb der

Mitte des Fadenkreuzes.

8. Führen Sie den Sechskantstift-Schlüssel durch das Loch im

Dispersions-Korrekturrad und zentrieren Sie die Schattenlinie an

der Mitte des Fadenkreuzes durch Verstellen der

Fadenkreuzplatte (Abb. 2 & Abb. 3a.).

Das Gerät ist jetzt kalibriert.

11331100449944--992244

HHaauuppttppllaattiinnee

((NNoovveemmbbeerr 11999922))

DDrraahhttffaarrbbeenn

W = weiß

B = schwarz

G = grün

O = orange

R = rot

Y = gelb

ohne Funktion

Thermistor-Stecker

RS232-Stecker

(aktiv bei 13104940,

13104950)

ohne Funktion

Endschalter

Baudrate-Schalter

Netz

Motor

FFiigguurree 55

Deutsch

14

Page 15

10.0 AUSWECHSELN DER BELEUCHTERLAMPE

Beleuchter-Lampe durch Entfernen der Kondensor-Fassung

auswechseln (Abb. 6). Um maximale Sicherheit und beste

Leistung zu gewährleisten, verwenden Sie immer nur die empfohlene Ersatzlampe (Katalog-Nr. 10462, 3-er Packung). Nach

Auswechseln der Lampe kann die Lampenfassung bei wieder

aufgesetzter Kondensorfassung besser positioniert werden, um

das Licht zum Meßprisma hin zu zentrieren. Falls notwendig,

drücken Sie auf den Federhalterungsstift und schieben Sie

diesen solange hin und her, bis der Stift einrastet.

10.1 Sicherungen

Der LEICA ABBE MARK II Refraktometers elektische Kreislauf ist

gesichert mit zwei (2) Sicherungen. Um die Sicherungen zu ersetzen, drehen Sie das Einstellrad im Uhrzeigersinn. Das bringt das

Hebewerk nach oben und gibt freien Zugang zu den

Sicherungen. Entfernen Sie das Einstellrad mit einen 1/8 Zoll

Sechskantschlüssel. Entfernen Sie die zwei Kreuzschlitz

Schrauben mit welchen der rechtseitige Deckel am

Gerätgehäuse befestigt ist. Gleiten Sie den Deckel nach unten so

weit wie möglich um ihn zu entfernen, die Sicherungen werden

sichtbar auf der unteren Geräteplatte (Abb. 5b). Erstezen Sie die

Sicherungen und montieren Sie die Teile in umgekehrter Reihe.

11.0 WARTUNG UND PFLEGE

Das LEICA ABBE MARK II Refraktometer ist ein optisches

Präzisionsinstrument und ist gebaut für den langjährigen

störungsfreien Einsatz. Die besondere Konstruktion schützt das

Innenleben des Geräts vor Staub und Eindringen von Flüssigkeit.

Das Gehäuse ist mit einer äußerst widerstandsfähigen EmailSchicht lackiert. Die Brechprisma-Einheit aus Edelstahl ist mit

einem korrosionsfesten Epoxyharz abgedichtet.

Starke Lösungsmittel wie N, N-Dimethylformamid oder N, NDimethylazetamid, Kresol, Phenol oder sonstige starke Teeroder Azetsäuren sind zu vermeiden. Tetrahydrofuran und einige

Verdünner sowie ihre Bestandteile können über einen langen

Zeitraum hinweg oder durch Anwendung bei höheren

Temperaturen zu einer Verschlechterung der Prisma-Abdichtung

führen.

Ablagerungen von Staub, Lösemitteln oder Proberesten, vor

allem auf der Prisma-Einheit, können u. U. in das Refraktometer

eindringen und somit die Leistung beeinträchtigen oder zu

erhöhtem Verschleiß führen.

Bei Nichtgebrauch soll die Meßprisma-Einheit geschlossen

bleiben und ein gefaltetes Linsentuch zwischen die Prismen

gelegt werden. Die Prisma-Oberflächen sollen sofort nach jedem

Gebrauch mit destilliertem Wasser, Methanol oder einem

geeigneten Lösemittel gereinigt werden.

Es wird empfohlen, warmes destilliertes Wasser für das

Entfernen von Zuckerresten, bzw. Methanol bei Proben auf Ölbasis zu benutzen. Das Prismas kann mit einem

Linsenreinigungstuch saubergewischt werden, aber nicht mit

einem harten, trockenen Tuch. Wenn das Prisma frei von

Proberesten ist, nochmals mit destilliertem Wasser abspülen.

AACCHHTTUUNNGG::

Die Meßprisma-Oberfläche nicht trockenwischen

und nicht im trockenen Zustand putzen! Das Prisma und dessen

umliegende Abdichtung darf nicht mit Metallteilen oder scharfen

bzw. spitzen Gegenständen in Berührung kommen.

Die Glasteile der Prisma-Einheit sind verhältnismäßig hart und

äußerst fleckenunempfindlich. Starke Säuren oder Basen jedoch

sollen weder mit diesem Instrument gemessen noch als

Reinigungsmittel benutzt werden.

Um das Okular zu reinigen, entfernen Sie den Gummi-Einsatz am

Ende des verstellbaren Okulartubus. Reinigen Sie die Linse mit

einem mit Azeton oder Methanol angefeuchteten Wattestäbchen

oder Linsenreinigungstuch. Gummi-Einsatz wieder aufsetzen.

VVOORRSSIICCHHTT

! Das Glas der Lampe könnte sehr heiß sein.

Erst nach vollständiger Abkühlung der Lampe; bzw:

unter Anwendung von Schutzhandschuhen die Lampe

auswechseln!

AACCHHTTUUNNGG

! Vor Auswechslung der Lampe Netzstecker

ziehen!

!

AACCHHTTUUNNGG

! Auswechseln der Sicherung – Dieser Teil ist

nicht vom Benutzer auszuwechseln. Die Wartung ist nur

durch einen fachkundigen Wartungstechniker

vorzunehmen. Die Sicherung darf nur mit einer Sicherung

desselben Typs und Nennwerts ersetzt werden.

AACCHHTTUUNNGG

! Vor dem Sicherungswechsel, bitte den

Stecker Ziehen.

!

Beleuchter

Schwenkarm

LampenfassungEinstellschraube

Beleuchtungslampe

Drehbare

Kondensorfassung

AAbbbb.. 55bb AAbbbb.. 66

Deutsch

15

Page 16

12.0 WARTUNG

Wartung und Reparatur des LEICA ABBE MARK II bzw. LEICA

ABBE MARK II Plus Refraktometers sollen nur durch im Werk

ausgebildete Wartungs- und Reparaturtechniker vorgenommen

werden. Bei Funktionsstörungen setzen Sie sich bitte in

Verbindung mit dem Leica Kundendienst unter der Rufnummer

716-686-3000 oder Fax 716-686-3085. Außerhalb der Vereinigten

Staaten setzen Sie sich mit Ihrem jeweiligen Leica

Vertragshändler in Verbindung.

13.0 TECHNISCHE DATEN

LLEEIICCAA AABBBBEE MMAARRKK IIII RReeffrraakkttoommeetteerr

TTyypp 1133110044880000//1133110044881100//1133110044994400//1133110044995500

AAnnzzeeiiggeeaarrtt

Tischrefraktometer mit

direkt ablesbarer

Digitalanzeige

BBeettrriieebbssmmooddii

Brechungsindex (nD),

% Feststoffe (ºBrix)

und % Feststoffe

(ºBrix) oder mit

Temperaturausgleich

(BX-TC)

MMoodduuss BBeerreeiicchh

nn

DD

1,32000 - 1,7000

BBrriixx

0 - 95

BBXX--TTCC bbeeii 2200ººCC

0 - 95

TTeemmppeerraattuurr ººCC

15º - 50ºC

NNeettzzssppaannnnuunngg

Typ 13104800 115V/50-60 Hz

Typ 13104810 230V/50-60 Hz

Typ 13104940 115V/50-60 Hz

Typ 13104950 230V/50-60 Hz

GGeennaauuiiggkkeeiitt ((RRMMSS--WWeerrttee))

n

D

± 0,0001 R1

% Feststoffe ºBrix)

± 0,1% BX-TC

± 0,2ºC (stabilisiert)

eelleekkttrr.. ZZuullaassssuunnggeenn

UL zugelassen, CSA geprüft,

CE geprüft. Sämtliche

Modelle sind geprüft und

entsprechen den HF-

Störungsvorschriften Klasse

A.

TTeemmppeerraattuurraauussgglleeiicchh

Im Standardmodus

werden die Meßwerte

der % Feststoffe- (ºBrix)Skala bei 15º bis

50ºC auf eine

Bezugstemperatur von

20ºC berichtigt; im

benutzerspezifischen

Modus erfolgt die

Temperaturberichtigung

nach den Vorgaben des

Benutzers.

TTeemmppeerraattuurrmmeessssuunngg

Einbau-Thermistor in der

Prisma-Einheit

GGeennaauuiiggkkeeiitt ddeess

TTeemmppeerraattuurraauussgglleeiicchhss

± 0,1ºC

PPrroobbeennttyyppeenn

durchsichtige oder

lichtdurchlässige

Flüssigkeiten und Festkörper

AAbbmmeessssuunnggeenn

152 mm (B) x 262 mm

(L) x 356 mm

(H) (6" x 10,5" x 14")

NNeettttooggeewwiicchhtt

7,3 kg (16 lbs.)

PPrroobbeenntteemmppeerraattuurr--

Prisma-Einheit ist mit

Aufnahmestutzen für

kontrolle ein KühlwasserSystems ausgestattet

PPrriissmmaa--EEiinnhheeiitt

Edelstahl und Glas, mit

Lösemittelfestem

Epoxy-Harz versiegelt

OOppttiisscchhee KKoorrrreekkttuurr

zweifacher AmiciPrismenkompensator

für scharfe Schattenlinien

und 589nm (Natrium D-Line)

Beleuchtung

13.1 Die nachfolgenden Angaben beziehen sich

ausschließlich auf das LEICA ABBE MARK II Plus

Refraktometer

AAnnzzeeiiggee

direkt ablesbare

Digitalanzeige des

Brechungsindex oder

der Konzentration

(% Feststoffe oder

kundenspezifische

Skala) sowie der

Temperatur

SSttaannddaarrddmmoodduuss BBeerreeiicchh

Brechungsindex 1,3210 bis 1,700 n

D

% Feststoffe (ºBrix) 0,0 bis 95,0%

% Feststoffe (ºBrix) mit Temperaturausgleich 0,0 bis 95,0%

Standardskalen für % Feststoffe (ºBrix) (0,0 - 95,0%) basieren auf

1974 er ICUMSA-Tabellen (% Zucker vs. nDbei 20ºC).

bbeennuuttzzeerrssppeezziiffiisscchhee MMooddii

• Konzentrations-Anzeige von 0,0 bis 999,9

Benutzereingaben-Konzentration vs. Brechzahldaten

• temperaturberichtigte Konzentrations-Anzeige von 0,0 bis 999.9

Konzentration vs. Brechzahl vs. Temperaturdaten

Benutzerspezifische Daten werden über das Leica InterfaceSoftwareprogramm MARKPLUS (IBM PC-kompatibel) erfaßt.

SScchhnniittttsstteellllee

RS232 serielle Schnittstelle

DDaatteennüübbeerrttrraagguunngg

benutzerdefinierbare

Baudraten: 300, 1200,

2400, 4800, 9600 Bps, 8

Datenbits, ein Stopp-Bit,

keine Parität, werksmäßig

voreingestellte Baudrate

9600. ASCII-Ausgabe mit

Tabs

AAnnsscchhlluußß

DB9-Buchse

PPiinn--BBeelleegguunngg

2 Senden, 3 Empfangen, 5

Masse

Deutsch

16

Page 17

17

Francais

Réfractomètre LEICA ABBE MARK II

Manuel d'utilisation

Table des matières

EExplication des symbboles d'avertissements

1. INTRODUCTION

RREEMMAARRQQUUEE::

Lire ces instructions avec soin avant d'utiliser l'in-

strument.

Ce manuel d'utilisation est conçu spécifiquement pour le réfractomètre LEICA ABBE MARK II et décrit la configuration, l'utilisation

et l'entretien de l'instrument. Les sections de 7.0 à 7.4 se rapportent

uniquement au réfractomètre LEICA ABBE MARK II Plus.

Le réfractomètre LEICA ABBE MARK II est un instrument résistant, à utiliser sur un comptoir. Il fournit des relevés, efficaces,

fiables et répétables en trois modes :

• % solides (° Brix)

• % solides (° Brix) à température compensée ou (BX-TC) et

• Indice de réfraction (nD)

Le réfractomètre LEICA ABBE MARK II peut accommoder un pro-

gramme personnalisé sur l'échelle de % de solides (° Brix), ce

qui peut être accompli par pré-programmation ou par montage

en usine.

2.0 DÉBALLAGE

Le réfractomètre LEICA ABBE MARK II a été soigneusement

emballé pour l'expédition. Avant de jeter le matériel d'emballage,

vérifier si tous les articles sont présents. Liste des accessoires

dans la boîte du réfractomètre :

• verre pour essai d'indice de réfraction (n° de réf. 10451)

• clé hexagonale de 1/16 po (n° de réf. X30600)

• bouteille de 1-bromonaphtaline pour mesurer les solides (n° de

réf. 10452)

• protège poussière (n° de réf. 10450-140)

Vérifier si l'instrument et le numéro du modèle correspondent au

bordereau de commande avant de jeter les matériaux d'emballage. Les matériaux d'emballage d'origine peuvent servir à

ranger ou à transporter le réfractomètre.

3.0 PUISSANCE NÉCESSAIRE

Modèle 13104800/13104940 115~ +/-10 %, 50/60 Hz

Modèle 13104810/13104950 230~ +/-10 %, 50/60 Hz

• Puissance d'entrée 25 P max

• Utilisation à l'intérieur uniquement

• Altitude jusqu'à 2 000 m

• Plage de température de 5 °C à 40 °C

• Degré de pollution 2

• Catégorie d'installation 2

•Humidité relative max 80 % pour des températures allant jusqu'à

31 °C diminuant linéairement jusqu'à une humidité relative de 50

% à 40°C.

4.0 CONFIGURATION

Le réfractomètre LEICA ABBE MARK II est facile à utiliser et ne

demande que peut d'entraînement pour le configurer et l'utiliser

afin d'obtenir les mesures de température et d'indice de réfraction.

4.1 Installation de l'instrument

Le réfractomètre LEICA ABBE MARK II doit être installé sur une

surface solide, stable et horizontale, telle qu'une table ou un

comptoir de laboratoire.

5 x20 250 mA T/250 V (Type 13104800/13104940)

MMIISSEE EENN GGAARRDDEE ::

Risque d'électrocution

MMIISSEE EENN GGAARRDDEE ::

(Voir les documents accompagnant

l'instrument)

!

1.0 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.0 DÉBALLAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.0 PUISSANCE NÉCESSAIRE . . . . . . . . . . . . . . . . . . . . . . . 17

4.0 CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Installation de l'instrument . . . . . . . . . . . . . . . . . . . . . . . 17

5.0 COMMANDES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1 Conditions variables de prises de relevés . . . . . . . . . . 18

5.2 Calibrage avec de l'eau distillée . . . . . . . . . . . . . . . . . . 18

6.0 MODE D'EMPLOI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.0 RÉFRACTOMÈTRE LEICA ABBE MARK II PLUS . . . . . . 19

7.1 Interface pour ordinateur . . . . . . . . . . . . . . . . . . . . . . . . 20

7.2 Établissement de la vitesse de transmission . . . . . . . . 20

7.3 Interface pour imprimante . . . . . . . . . . . . . . . . . . . . . . . 20

8.0 UTILISATION DU RÉFRACTOMÈTRE, TECHNQIUES ET . . .

PRINCIPES DE RÉFRACTION . . . . . . . . . . . . . . . . . . . . . 20

8.1 Échantillons d'indice élevé et à haute dispersion . . . . 22

9.0 CALIBRAGE AVEC UN VERRE POUR ESSAI . . . . . . . . . . 22

10.0 REMPLACEMENT DE LA LAMPE DE L'ILLUMINATEUR .23

10.1 Fusibles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

11.0 ENTRETIEN ET NETTOYAGE . . . . . . . . . . . . . . . . . . . . . . 23

12. 0 RÉPARATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

13.0 SPÉCIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

13.1 Les spécifications suivantes se rapportent uniquement au

réfractomètre LEICA ABBE MARK II PLUS . . . . . . . . . . . . . . 24

MISE EN GAARDE:

Par mesure de sécurité, le cordon d'alimentation a été mis à la terre à la base de l'instrument.

Ne jamais utiliser d'adaptateur à 2 broches entre le cordon d'alimentation et la source d'alimentation parce que

la protection de mise à la terre sera inefficace.

MISE EN GAARDE:

L'utilisation de cet instrument d'une

manière différente de celle indiquée dans ce manuel

peut réduire la protection de sécurité.

!

Page 18

5.0 COMMANDES

Les commandes du réfractomètre LEICA ABBE MARK II sont

indiquées sur la figure 1.

RREEMMAARRQQUUEE ::

Le sélecteur de mode ne fonctionne plus pour

allumer et éteindre l'instrument. L'interrupteur MARCHE/ARRÊT

se trouve sur le couvercle avant de l'instrument, au-dessus du

logotype Leica.

IInntteerrrruupptteeuurr ::

L'interrupteur se trouve au coin inférieur droit du panneau avant

(figure 1) | = marche 0 = arrêt

LLee sséélleecctteeuurr ddee mmooddee sseerrtt àà sséélleeccttiioonnnneerr lleess mmooddeess ddee mmeessuurree

qquuii ssoonntt ::

• % solides-TC - % de solides à température compensée comme

le sucrose (° Brix) selon la Commission internationale pour les

méthodes uniformes des tableaux d'indice de réfraction pour

l'analyse du sucre.

•n

D

- indice de réfraction

• % solides - % de solides sans compensation de température

comme le sucrose

L'orifice d'accès d'ajustement du réticule permet de régler verticalement le viseur pendant les procédures de calibrage.

Appuyer sur le bouton d'affichage READ (relevé) pour obtenir les

valeurs des mesures.

Appuyer sur le bouton d'affichage TEMP (température) pour

obtenir le relevé de la température du prisme.

Les relevés sont indiqués numériquement sur la fenêtre d'affichage.

5.1 Conditions variables de prises de relevés

Les relevés de l'eau distillée au dessus de 20 °C peuvent être

obtenus en mode % de solides avec température compensée, si

l'instrument est calibré correctement. Des relevés corrects ne

peuvent pas être obtenus en mode % de solides sans température compensée si la température de l'échantillon d'eau est

supérieure ou inférieure à 20 °C. Les relevés de l'indice de

réfraction (n

D

) pour l'eau distillée peuvent être obtenus de 0 °C à

80 °C (voir le tableau 1, page 10 pour les valeurs entre 18 et 30°C).

L'indice de réfraction est inversement proportionnel à la tem-

pérature. Lorsque la température s'élève, la densité de la solution diminue et l'indice de réfraction ou le relevé du % de solides

diminue. Lorsque la température s'abaisse, la densité de la solution augmente et l'indice de réfraction (% de solides) augmente.

Le mode % solides-TC corrige automatiquement le relevé pour la

température basée sur le coefficient de température du sucrose

en solution, Ce coefficient est typique de la plupart des solutions

aqueuses.

5.2 Calibrage avec de l'eau distillée

Pour calibrer :

1. Déposer un échantillon d'eau distillée sur la surface du prisme

de mesure et le laisser reposer pendant 3 à 5 minutes pour que

sa température se stabilise. Tourner le sélecteur de mode à la

position de l'indice de réfraction (nD).

2. Ajuster l'oculaire pour faire apparaître clairement le viseur.

3. Tourner la commande de réglage dans le sens des aiguilles

d'une montre jusqu'à ce que la ligne d'ombre rencontre presque

le viseur. Utiliser la roulette de correction de dispersion pour

obtenir la ligne d'ombre la plus nette possible sans qu'elle ait de

couleur. Ajuster la ligne d'ombre pour qu'elle rencontre le viseur.

Appuyer sur le bouton de relevé et noter la valeur de nD, puis

appuyer sur le bouton de température et noter la température.

4. Si l'instrument est calibré correctement, le relevé sera de

1,3330 moins 0,0001 pour chaque degré au-dessus de 20°C ou

plus 0,0001 pour chaque degré au-dessous de 20°C.

Si l'instrument n'est pas calibré, déterminer le relevé correct

(tableau 1), tourner le commande de réglage et appuyer sur le bouton d'affichage de relevé jusqu'à ce que l'affichage soit correct. (la

ligne d'ombre n'intersectera plus le viseur sur le réticule.)

5. Introduire une clé hexagonale de 1/16 po dans l'orifice d'accès

d'ajustement du réticule (Figure 2) situé dans la roulette de correction de dispersion. Tourner la clé pour amener le viseur à la

position correcte sur la ligne d'ombre.

RREEMMAARRQQUUEE::

Le mouvement final fait avec la roulette de com-

Francais

Roulette de correction de

dispersion

Oculaire ajustable

Orifice d'accès d'ajustement du réticule

Fenêtre d'affichage

Bouton d'affichage

de relevé

Bouton d'affichage

de temp.

Interrupteur

Sélecteur de mode

Surface du prisme

Bras de l'illuminateur

Commande de

réglage

Couvre panneau droit

Orifice d'accès d'ajustement

du réticule

FFiigguurree 11

FFiigguurree 22

18

Page 19

Francais

19

mande de correction de réglage doit toujours se faire dans le

sens des aiguilles d'une montre. La ligne d'ombre se déplacera

vers le haut.

6. Tourner le sélecteur de mode à la position BX-TC. Appuyer sur

le bouton de relevé. Un relevé de 000,0 ou 0,1 est normal. Si un

signe négatif et un point décimal apparaissent, aucun relevé de

ne peut être donné.

Passer à l'étape suivante

Si la condition « No reading » (aucun relevé) continue après

plusieurs essais de prise de relevé, faire tourner la commande de

réglage jusqu'à ce que l'affichage indique 000,0 ou 0,1. Il suffira

de faire un très léger réglage. Réajuster le viseur jusqu'à la ligne

d'ombre.

L'affichage doit indiquer maintenant 000,0.

Répéter les étapes jusqu'à ce que l'affichage indique 000,0.

6.0 MODE D'EMPLOI

1. Ouvrir le couvercle de l'assemblage du prisme (Figure 4) et

retirer le tissu de protection de la lentille. Nettoyer la surface du

prisme de mesure avec de l'alcool, puis avec de l'eau distillée.

Essuyer avec un chiffon doux propre ou un tissu pour lentille,

mais ne pas essuyer la surface du prisme de mesure si elle est

déjà sèche. Tout résidu laissé sur le prisme peut affecter la précision des relevés.

2. Tourner le sélecteur de mode à la position de mode désiré.

3. À l'aide d'un compte-goutte en verre, déposer un peu de solution de l'échantillon sur la surface du prisme de mesure. Fermer

le couvercle du prisme et positionner le bras d'éclairage de

manière à éclairer complètement la face exposée du prisme

supérieur.

4. Tourner la roue de correction de dispersion pour que l'orifice

d'accès au réglage du viseur soit à la position de 6 heures.

5. Tourner la commande de réglage dans le sens inverse des

aiguilles d'une montre pour positionner la ligne d'ombre au bas

du champ de vision.

6. Tourner l'oculaire pour faire apparaître clairement le viseur.

7. Amener la ligne d'ombre jusqu'au viseur avec la commande de

réglage grossier.

8. Tourner la roulette de correction de dispersion pour éliminer la

couleur rouge ou verte au bord de la ligne d'ombre.

9. Tourner la commande de réglage pour centrer la ligne d'ombre

sur le viseur. La ligne d'ombre doit être parfaitement centrée

pour obtenir un relevé précis (Figure 4).

10. Appuyer sur le bouton READ. La valeur de l'échantillon d'essai doit être indiquée numériquement dans la fenêtre d'affichage.

Appuyer sur le bouton TEMP pour activer le détecteur de température se trouvant dans le prisme de mesure. L'affichage indiquera numériquement la température réelle du prisme de mesure

et de l'échantillon.

RREEMMAARRQQUUEE::

Si le réfractomètre LEICA ABBE MARK II est utilisé

dans un endroit où des matières étrangères peuvent venir en

contact avec les boutons d'affichage, utiliser l'accessoire contre

les éclaboussures (n° de réf. 13104590) pour ne pas endommager

l'instrument et ne pas le mettre hors service.

7.0 RÉFRACTOMÈTRE LEICA ABBE MARK II

PLUS

RREEMMAARRQQUUEE::