Page 1

Module Linking:

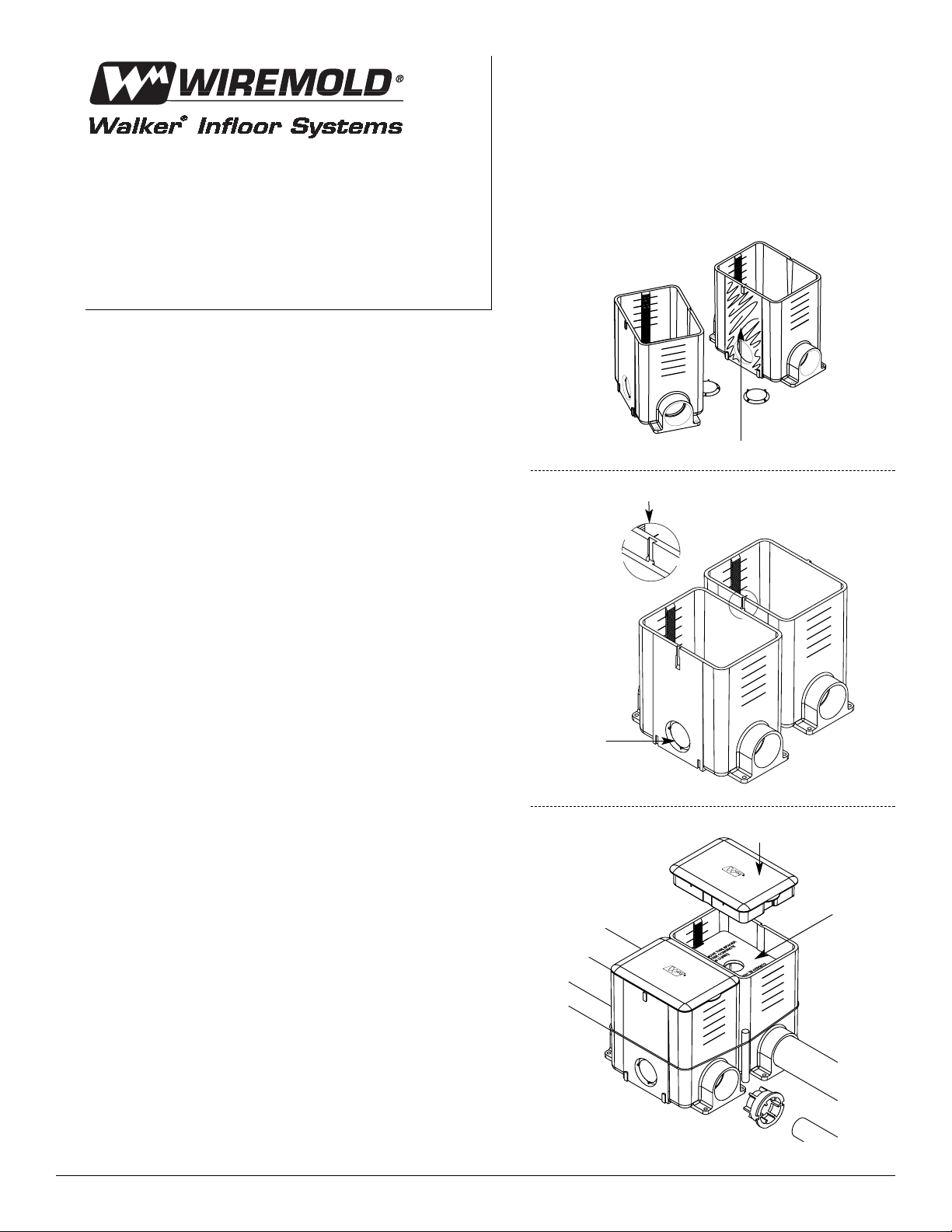

1. Multiple services or compartments may be obtained

by ganging together up to three single-gang units

(Cat. No. 880MP).

2. For multiple compartment installations which require

pass-through between mating modules, you must

remove the knockout section on adjacent surfaces.

To do this, break away with a hammer making sure

you remove knockouts which will be facing one

another after linking the assembly (see Figure 1).

Knockout tabs are intended for passage

between boxes only. They are not designed

for the attachment of conduit fittings.

3. To assemble the modular units, first apply solvent

cement around the flat mating surfaces of the

adjacent walls and “dovetail” slots (see Figure 1).

Engage the “dovetails” and slide the units together

until seated (see Figure 2).

Concrete Preparation:

4. Cement conduit closure plugs to unused ports

or use conduit reducers if reduction is required.

Knockout must be removed from closure plug

for use on 1/2" trade size conduit (see Figure 3).

5. Secure the box assembly to prevent floating

during concrete pour. For above grade, screw

or nail the assembly to the concrete form. For

on-grade applications, drive stakes or rebar next

to the box and secure with wire. Make sure the

stakes are below the 3 1/2" [89mm] min. screed

line (see Figure 3).

6. Cut conduit to length and cement to ports/reducers.

7. Make sure the box spacer and mud cap are in

place prior to pouring concrete. The interior

spacer and cap prevent any movement of the

box walls during the pour.

8. Pour concrete to desired depth using graduated

markings on the box exterior as a guide.

Modulink™Nonmetallic

Modular Floor Box

Cat. Nos. 880MP and 880MPA

INSTALLATION INSTRUCTIONS

Installation Instruction No.: 1A0145 R2 – Updated December 2002

Walker®electrical systems conform to and should be properly

grounded in compliance with requirements of the current National

Electrical Code or codes administered by local authorities.

All electrical products may present a possible shock or fire hazard

if improperly installed or used. Walker electrical products bear the

mark as UL Listed and/or Classified and should be installed in

conformance with current local and/or the National Electrical

Code. Look for listing and/or classification mark on product label.

Figure 2

Figure 1

Figure 3

Knockout Tab

Concrete Cover

Dovetail Slot Detail

Box Spacer

Cement

Page 2

Floor Finishing and Activation:

9. After concrete has cured, saw off the

remainder of the box(es) at floor level

using a wood saw and remove the box

spacer. If the final floor covering is a

thicker than 5/16" [7.9mm], leave enough

of the box protruding above the floor to

compensate (see Figure 4).

10. Wire fill capacity is determined by reading

the first legible volume calibration along

the interior of the box.

11. A cover plate adapter (Cat. No. 880MPA)

is required for each gang or compartment

of the activation. The adapter is installed

by pushing it into the box opening until

firmly seated. The ratchet teeth along

the box interior will retain the adapter

without the use of screws or glue.

12. Bend radius control for fiber optic

communication activations is maintained

by wrapping the cable around the storage

loop on the underside of the cover

adapter prior to installation

(see Figure 5).

13. Attach the trim flange (sold separately)

using four #8-32 screws supplied with trim

flange (see Figure 6).

14. Complete the installation by attaching

the appropriate cover plate option.

Figure 4

Figure 5

Figure 6

Fiber Storage Loop

The Wiremold Company

U.S. and International:

60 Woodlawn Street • West Hartford, CT 06110

1-800-621-0049 • FAX 860-232-2062 • Outside U.S.: 860-233-6251

Canada:

850 Gartshore Street • Fergus, Ontario N1M 2W8

1-800-741-7957 • FAX 519-843-5980

IA0145R2 1202

© Copyright 2002 The Wiremold Company All Rights Reserved

Loading...

Loading...