Page 1

LeCroy WaveStation

LW4001LW400A Series AWG

Remote Programmer’s Manual

August 1996

Rev. C

Page 2

LeCroy

Corporate Headquarters

700 Chestnut Ridge Road

Chestnut Ridge, NY 10977-6499

Tel: (914) 578-6020, FAX: 578-5985

European Headquarters

Mannheimerstrasse 175

D-69123 Heidelberg, Germany

Tel: (49) 6221 840989

FAX: (49) 6221 833827

European Manufacturing

2, rue du Pr6-de-la-Fontaine

P.O. Box 341

1217 Meyrin 1/Geneva, Switzerland

Tel: (41) 22 719 21 11, FAX: 22 782 39

Copyright August 1996, LeCroy. All dghts reserved. Information in this publication supersedes all earlier versions.

Specifications subject to change.

LeCroy® Is a registered trademark of LeCroy Corporation

WaveStation® is a registered trademark of LeCroy Corporation

Centronics® is a registered trademark of Data Computer Corp.

Citizen® is a registered trademark of Citizen America Corp.

Epson® is a registered trademark of Epson Amedca Inc.

Hewlett-Packard® is a registered trademark, and HP

IBM® is a registered trademark, and IBM PC/XT

Business Machines Corporation.

MATHCAD® is a registered trademark of MATHSOFT INC.

MATLAB® is a registered trademark of MATHWORKS

PSPICE® is a registered trademark of MICROSIM Corporation

Smart Trigger

Microsoft®, MS-DOS®, QuickBasic®, Excel® and Windows® are trademarks of Microsoft Corporation.

PCX is a file format developed by ZSoft Corporation for use with PC Paint programs.

Bubble Jet® is a registered trademark of Canon USA, Incorporated.

Apple® and Macintosh® are registered trademarks of Apple Computer, Incorporated.

TM

is a trademark of LeCroy Corporation

TM

is a trademark of Hewlett-Packard, Co.

r",

PC/AT

TM

and PSI2

TM

are trademarks of International

Page 3

TABLE OF CONTENTS I

SECTION 1

GENERAL INFORMATION

Initial Inspection .............................................................................. 1-1

Warranty .........................................................................................

Product Assistance ..........................................................................

Maintenance Agreements ................................................................ 1-2

Service Procedure ........................................................................... 1-2

Return Procedure ............................................................................ 1-2

How to Use This Manual ................................................................. 1-3

Introduction .....................................................................................

What is SCPI ...................................................................................

SECTION 2

ABOUT REMOTE CONTROL

Interface Configuration and Special Commands ............................. 2-1

GPIB Remote Control ...................................................................... 2-1

GPIB Signals and Lines .................................................................. 2-1

Setting the GPIB Address ............................................................... 2-1

GPIB Remote Control and Hardcopy Operation ..............................

Remote Control Operation over GPIB ............................................. 2-2

End or Identity (EOI) Operation ....................................................... 2-2

Hardcopy Operation over GPIB .......................................................

IEEE-488 Standard Messages ........................................................ 2-3

Checking GPIB Communications Using National

Instruments IBIC Program ............................................................. 2-5

Error Code .......................................................................................2-7

1-1

1-1

1-5

1-5

2-2

2-2

SECTION 3

INSTRUMENT MODEL AND SUBSYSTEM HIERARCHY

Remote Command System Model ................................................... 3-1

Introduction to SCPI Command Syntax ........................................... 3-1

Command Subsystems ................................................................... 3-4

Overview of OUTPut Commands .................................................... 3-5

Overview of WAVE Commands ....................................................... 3-5

Overview of FGEN Commands .....................................................

Overview of EQUation Commands ................................................

Overview of DISPlay Commands .................................................. 3-15

Overview of HCOPy Commands ................................................... 3-17

3-11

3-14

Page 4

TABLE OF CONTENTS

Overview of TRIGger Commands .................................................

Overview of MMEMory Commands ...............................................

Overview of PROJect Commands .................................................

Overview of SYSTem Commands .................................................

Overview of STATus Commands .................................................

488.2 Command Commands .........................................................

SECTION 4

STATUS & ERROR REPORTING

Status Register ................................................................................

Status Byte Operation .... . ................................................................

Status Data Structures ....................................................................

Querying the Operational and Questionable Status Register ..........

Event Enable Registers ...................................................................

Status Byte Register Definition ........................................................

Checking Status and Requesting Service .....................................

GPIB Service Request ..................................................................

SECTION 5

WAVEFORM TRANSFERS VIA GPIB

Introduction .....................................................................................

Transferring Waveforms via GPIB .................. . ................................5-1

The Data Interchange Format (DIF) ................................................

Viewing Waveform Data in the DIF File ...........................................

Other Data Formats ........................................................................

3-18

3-19

3-20

3-21

.3-22

3-23

4-1

4-1

4-1

4-3

4-4

4-6

4-12

4-15

5-1

5-2

5-5

5-8

SECTION 6

REMOTE COMMANDS .......................................................................

SECTION 7

REMOTE PROGRAMMING EXAMPLES

Introduction .....................................................................................

Setting Up the Environment for

QuickBASIC Programming ............................................................

The LWGPIB.BAS Program ............................................................

End Or Identify (EOI) Operation ......................................................

Initializing GPIB Communication with the AWG ...............................

Sending a Command to the LW400 Series AWG ............................

6-1

7-1

7-1

7-2

7-9

7-9

7-9

Page 5

I TABLE OFCONTENTS I

Sending a Query, Reading the Response, and

Using Status to Determine When the Operation is Done ...............

Downloading a Waveform .............................................................

Uploading a Waveform DIF File to the AWG ................................. 7-12

INDEX

INDEX OF REMOTE COMMANDS

7-10

7-11

Page 6

I TABLEOF CONTENTS

THIS PAGE LEFT INTENTIONALLY BLANK

Page 7

INITIAL INSPECTION

It is recommended that the shipment be thoroughly inspected

immediately upon delivery to the purchaser. All material in the

container should be checked against the enclosed Packing List.

LeCroy cannot accept responsibility for shortages in comparison

with the Packing List unless notified promptly. If the shipment is

damaged in any way, please contact the Customer Service

Department.

WARRANTY

LeCroy warrants its products to operate within specifications

under normal use for a period of one year from the date of

shipment. Spares, replacement parts and repairs are warranted

for 90 days. The instrument’s firmware is thoroughly tested and

thought to be functional, but is supplied "as is" with no warranty

of any kind covering detailed performance. Products not

manufactured by LeCroy are covered solely by the warranty of

the original equipment manufacturer.

In exercising this warranty, LeCroy will repair or, at its option, replace any product returned to the Customer Service Department

or an authorized service facility within the warranty period,

provided that the warrantor’s examination discloses that the

product is defective due to workmanship or materials and that

the defect has not been caused by misuse, neglect, accident or

abnormal conditions or operation.

The purchaser is responsible for transportation and insurance

charges for the retum of products to the servicing facility. LeCroy

will return all in-warranty products with transportation prepaid.

This warranty is in lieu of all other warranties, expressed or im-

plied, including but not limited to any implied warranty of mer-

chantability, fitness, or adequacy for any particular purpose or

use. LeCroy shall not be liable for any special, incidental, or con-

sequential damages, whether in contract or otherwise.

PRODUCT ASSISTANCE

Answers to questions concerning installation, calibration, and

use of LeCroy equipment are available from the Customer

Service Dept., 700 Chestnut Ridge Road, Chestnut Ridge, New

York 10977-6499, U.S.A., tel. (914)578-6020.

1-1

Page 8

GENERAL INFORMATION

MAINTENANCE

AGREEMENTS

LeCroy offers a selection of customer support services. Maintenance agreements provide extended warranty and allow the

customer to budget maintenance costs after the initial one year

warranty has expired. Other services such as installation,

training, enhancements and on-site repair are available through

specific Supplemental Support Agreements.

UPDATED MANUALS

SERVICE PROCEDURE

LeCroy is committed to providing state-of-the-art instrumentation

and is continually refining and improving the performance of its

products. While physical modifications can be implemented

quite rapidly, the corrected documentation frequently requires

more time to produce. Consequently, this manual may not agree

in every detail with the accompanying product. There may be

small discrepancies in the values of components for the

purposes of pulse shape, timing, offset, etc., and occasionally,

minor logic changes. Where any such inconsistencies exist,

please be assured that the unit is correct and incorporates the

most up-to-date circuitry. In a similar way the firmware may

undergo revision when the instrument is serviced. Should this be

the case, manual updates will be made available as necessary.

Products requiring maintenance should be retumed to the

Customer Service Department or authorized service facility.

LeCroy will repair or replace any product under warranty at no

charge. The customer is responsible for transportation charges

to the factory. All in-warranty products will be returned to the

customer with transportation prepaid.

For all LeCroy products in need of repair after the warranty

period, the customer must provide a Purchase Order Number

before repairs can be initiated. The customer will be billed for

parts and labor for the repair, as well as for shipping.

1-2

Page 9

Introduction

GENERAL INFORMATION

RETURN PROCEDURE

HOW TO USE THIS MANUAL

To determine your nearest authorized service facility, contact the

Customer Service Department or your field office. All products

retumed for repair should be identified by the model and serial

numbers and include a description of the defect or failure, name

and phone number of the user, and, in the case of products

returned to the factory, a Retum Authorization Number (RAN).

The RAN may be obtained by contacting the Customer Service

Department in New York, tel. (914)578-6020. Return shipments

should be made prepaid. LeCroy will not accept C.O.D. or

Collect Return Shipments. Wherever possible, the original

shipping carton should be used. If a substitute carton is used, it

should be rigid and be packed such that the product is

surrounded with a minimum of four inches of excelsior or similar

shock-absorbing material. In addressing the shipment, it is

important that the Return Authorization Number be displayed on

the outside of the container to ensure its prompt routing to the

proper department within LeCroy.

This manual explains the programming protocol for controlling

the LW400/LW400A Series Arbitrary Waveform Generators,

including the LW420,LW420A, LW410 and LW410A, from a

host computer. These models may also be reffered to as the

WaveStation.

Pupose of this manual:

Gain an overview of the instrument remote programming

interface.

Familiarize yourself with the SCPI programming language as

it applies to the LW400/LW40OA.

Provide detailed information on all of the WaveStation

remote commands.

1-3

Page 10

GENERAL INFORMATION

The following sections are contained in this manual:

Section I

Section 2

Section 3

Section 4

Section 5

Section 6

Introduction

Gives a brief history of remote control interfaces and protocols

and explains the advantages of the SCPI command language

and how it is used in the WaveStation.

About Remote Control

Explains how to operate the WaveStation remotely across the

GPIB bus.

Instrument Model and Subsystem Hierarchy

Presents the function representation of the instrument as viewed

from the remote control interface, often referred to as the

instrument Model. Describes the command hierarchy and

introduces basic SCPI syntax and subsystems. Provides an

overview of the command hierarchy and how it relates to the

arbitrary waveform generator functional sections.

Statue and Error Reporting

Describes in detail the Status and Error reporting system.

Waveform Transfers via GPIB

Explains the format for transferring waveforms between an

extemal device and the WAVESTATION via GPIB.

Remote Commands

Provides a detailed command reference, including command

syntax and purpose.

Section 7

1-4

Remote Programming Example

Page 11

Introduction

Introduction

GENERAL INFORMATION

The remote control interface consists of hardware, the GPIB

port, as well as a software protocol. The hardware interfaces are

described in your user manual for the instrument. The software

protocol is described in this manual and builds upon the rapidly

emerging industry standard SCPI (Standard Commands For

Programmable Instruments).

What is SCPI

SCPI is a remote command language for test and

measurement instruments. It was developed by a consortium of

test and measurement instrument manufacturers and is

intended to provide a consistent programming language for

instrument control and data transfer.

IEEE-488 (GPIB) was adopted as a standard remote control

interface in 1975. The standard specified system

interconnections and communication protocols which provided a

universal hardware interface for integrating multiple instruments

into a test system. The original standard put instruments on a

common bus, but each instrument manufacturer used a

proprietary command set. Every time a user added a new

instrument to the bus, he had to leam another set of, often

enigmatic, commands. Updates to the standard in 1987, led to

IEEE-488.1 and 488.2 which further refined the standard but still

fell short of ensuring a common command syntax beyond a few

mandated "common commands". In 1990, the Standard

Commands for Programmable Instruments (SCPI) consortium

developed a system of common remote commands.

Although SCPI was originally defined for GPIB, it has now

spread well beyond that interface and is being used to support a

wide range of hardware interfaces. For example SCPI has

became a major element in the implementation of VXl based

systems.

The SCPI command language standardizes command syntax

and structure used in remote control of test and measurement

instrumentation and is being rapidly adopted by leaders in test &

measurement instrumentation. This allows the user to learn a

single set of remote commands for instruments which are

supplied by different manufacturers. Because the functionality of

instruments can vary widely, and because new instruments and

measurement techniques are constantly being developed, the

SCPI standard makes provision for new commands to be added

1-5

Page 12

GENERAL INFORMATION

as needed. Because LW400 has many unique features (for

example, waveform formats), LeCroy has enhanced the SCPI

language to provide access to these advanced capabilities.

SCPI benefits the user by providing a single command set for

integrating multiple instruments into a test system. The greatest

benefit occurs on the second or subsequent system integration

programs, where the user does not leam yet another command

language.

This manual will provide you with all the information you require

to control your LW400 using the SCPI programming language.

Because SCPI is an industry standard and not specific to

LeCroy, details on the generic standard are available in industry

standard SCPI manuals.

1-6

Page 13

2

ABOUTREMOTECONTROL I

I

Interface Configuration

and Special Commands

GPIB Remote Control

Controller

The WaveStation can be operated remotely from an instrument

controller or computer across the GPIB bus and commands

sent over GPIB can set or read any WaveStation front panel

instruction.

The GPIB bus can interconnect many instruments to allow

communication with one another over shared cables. The GPIB bus

uses a bit-parallel, byte-serial format. A device connected to the

GPIB is either a talker, listener, or controller. Although some

devices can change roles, a device can perform just one role at a

time.

Talker

Listener

Governs the operation of the bus. A controller, usually a computer,

normally sends program messages to devices and receives

responses from them. One controller task is to decide which device

is the talker and which is a listener(s). The controller may assign

itself to be the talker at one time, and a listener at other times. If

devices on the bus never change their roles, a controller is not

required.

Places messages or data on the GPIB bus for

transmission to other devices. Only one device on

the network can be the talker.

Receives data or commands over the bus. Several

listeners may be active at one time.

GPIB Signals and Lines

Setting the GPIB Address

The GPIB bus has 16 signal lines and eight ground lines. Eight of

the 16 signal lines form a bi-directional data bus which transfers data

and commands. The remaining eight signal lines control the bus

operation. Three lines are for handshaking signals which

synchronize data transmission. The remaining five lines are

management lines which control the flow of information across the

bus and take special action.

The GPIB address is set in the System Sub-menu, accessed

through the Project and Preference menu. From the front panel

press the Project key. Press the soft keys adjacent to the

Preferences and then system entries on the menus to enter the

system menu. Press the soft key adjacent to the GPIB entry on the

2-1

Page 14

ABOUT REMOTE CONTROL

menu to enter the GPIB setup menu. Turn the rotary to select the

GPIB address.

The factory default setting for the GPIB address is 1.

GPIB Remote Control and

Hardcopy Operation

Remote Control Operation

over GPIB

The WaveStation can communicate across the GPIB bus as a talker

or as a listener with a remote host controller (computer). For this

talker/listener remote control operation, the WaveStation conforms to

the guidelines specified by IEEE 488. The hardcopy output can also

communicate across GPIB in one of two ways. First, if the hardcopy

port is the same as the remote control port, then a remote hardcopy

command sends the output to the remote host as a query response.

Second, if the hardcopy port is different from the remote control port

or the local hardcopy key is pressed (Hardcopy Execute), then the

WaveStation enters talk only mode and does not expect any

controller present on the bus.

Talk/Listen The WaveStation enters this mode whenever a command is

received via the GPIB bus. In this mode, the Wavestation can both

receive commands and setups from the remote host computer

(controller) and send data and measurement results.

End or Identify (EOI)

Operation Except where specifically noted, all commands to and from the

WaveStation are terminated by asserting the EOI signal line

simultaneously with the last byte transmitted. No other command

terminators are required.

Hardcopy Operation over GPIB

Talk Only

2-2

The WaveStation enters this mode whenever the hardcopy

destination is set to GPIB and the Hardcopy Execute soft key is

pressed. Talk only is a special GPIB mode where there is no

controller allowed on the bus; the WaveStation is the only talker and

all connected devices must be listeners (i.e., printers/plotters must be

in Listen Only mode).

Page 15

I ABOUTREMOTE CONTROL

I

Talk/Listen

IEEE-488 Standard

Messages

Serial Poll Function

If hardcopy destination is GPIB and then sending the HCOPy

command over the GPIB bus will cause the WaveStation to send the

hardcopy output to the host computer as a response message. In

this mode, the WaveStation will wait to be addressed to talk before

sending the hardcopy data. The host computer then has three

options in generating the hardcopy:

The host computer may read the data into internal memory and

1)

then send the data to a printer/plotter.

The host computer may send the HCOPy remote command and

2)

then address the printer to listener and the WaveStation to talk

and read the data from the WaveStation. As the data is read into

the computer, it is also printed to the printer which is a listener.

The host computer may send the HCOPy remote command and

3)

then address the printer/plotter to listen, the WaveStation to talk,

and the controller to go into stand-by mode waiting for EOI.

This section explains how the WaveStation reacts to the Standard

488.2 messages.

The WaveStation implements a full Serial Poll Interface Function:

1. It can assert the SRQ (Service Request) control line.

It will respond with the current serial poll byte or STB when

2.

addressed to Talk and after the Serial Poll Enable interface

message is received.

After transmitting its status message, the WaveStation stops

3.

asserting the SRQ line and clears its intemal status byte.

Receiving the Trigger

Message

Interface Clear

The WaveStation responds to the Trigger message [*’I’RG

command] by triggering the output waveform. It is executed after all

previously received commands have been processed.

The Interface Clear message (asserting IFC line) is an asynchronous

control line that causes all bus activity to halt. When the WaveStation

receives the IFC message, it becomes unaddressed, stops talking or

listening, and will not participate in future bus transactions until

readdressed to talk or listen.

2-3

Page 16

4BOUT REMOTE CONTROL

~

Device Clear

(Selective or Universal)

Go to Local, Go to

Remote, Go to

Remote with Lockout

Local

The WaveStation will respond to a Selective Device Clear or a

the WaveStation first be addressed to listen, followed by the

the input buffer, the output queue, and the message available (MAV)

status bit to be cleared.

The WaveStation can operate in Local or Remote mode. In Local

the host computer will also be processed. In Remote mode, the

Universal Device Clear interface message. The former requires that

Selective Device Clear message. The latter does not require that the

instrument be previously addressed to listen. Device Clear causes

mode, all front panel controls are operational and commands from

WaveStation operates under computer control and no front panel

controls are operational except the Local soft key (if enabled). The

WaveStation always powers on in Local mode).

Note: The WaveStation processes all messages regardless of

being in Remote or Local modes.

The WaveStation switches to Remote mode (with Local soft key

enabled) when the WaveStation receives a command with the

REN line asserted. All instrument settings remain unchanged

during local-to-remote transitions. The WaveStation screen

indicates that Remote mode is enabled by the appearance of the

Local soft key. No other front panel controls operate.

2-4

If the WaveStation is under remote control and the Local soft key

is pressed, the instrument interrupts program control and returns

to local control. Data and/or settings cannot be changed locally.

Caution:. In Local Lockout state, all front panel keys and knobs

are disabled. Once Remote with Local Lockout is set using the

"RWLS" or "LLO" commands it can only be cleared when the

WaveStation is put into Local mode by sending the "LOC"

command or readdressing the WaveStation with REN

deasserted.

Page 17

I ABOUTREMOTECONTROLI

Checking GPIB

Communications Using

National Instruments IBIC

Program

This quick checkout requires a computer with a National Instrument

GPIB card and the National Instruments IBIC program supplied by

National Instruments with the purchase of a GPIB card. This quick

checkout also assumes that the GPIB card is already installed in the

computer and has passed all test successfully. For help installing or

configuring the National Instruments GPIB card please contact

National Instruments at (800) IEEE-488 or (512) 794-0100.

These example instructions are for an IBM-PC or compatible

computer. The method for other computers is very similar.

Change to the National Instruments GPIB-PC subdirectory with

the command:

CD \GPIB-PC

Start the IBIC program by with the command:

IBIC

Tell the IBIC program the address of the WaveStation (we

assume address 1) with the command:

IBFIND DEV1

Send the identify command to the WaveStation with the

command:

IBWRT "*IDN?"

Read the id of the WaveStation with the command:

IBRD 100

2-5

Page 18

ABOUT REMOTE CONTROL I

I

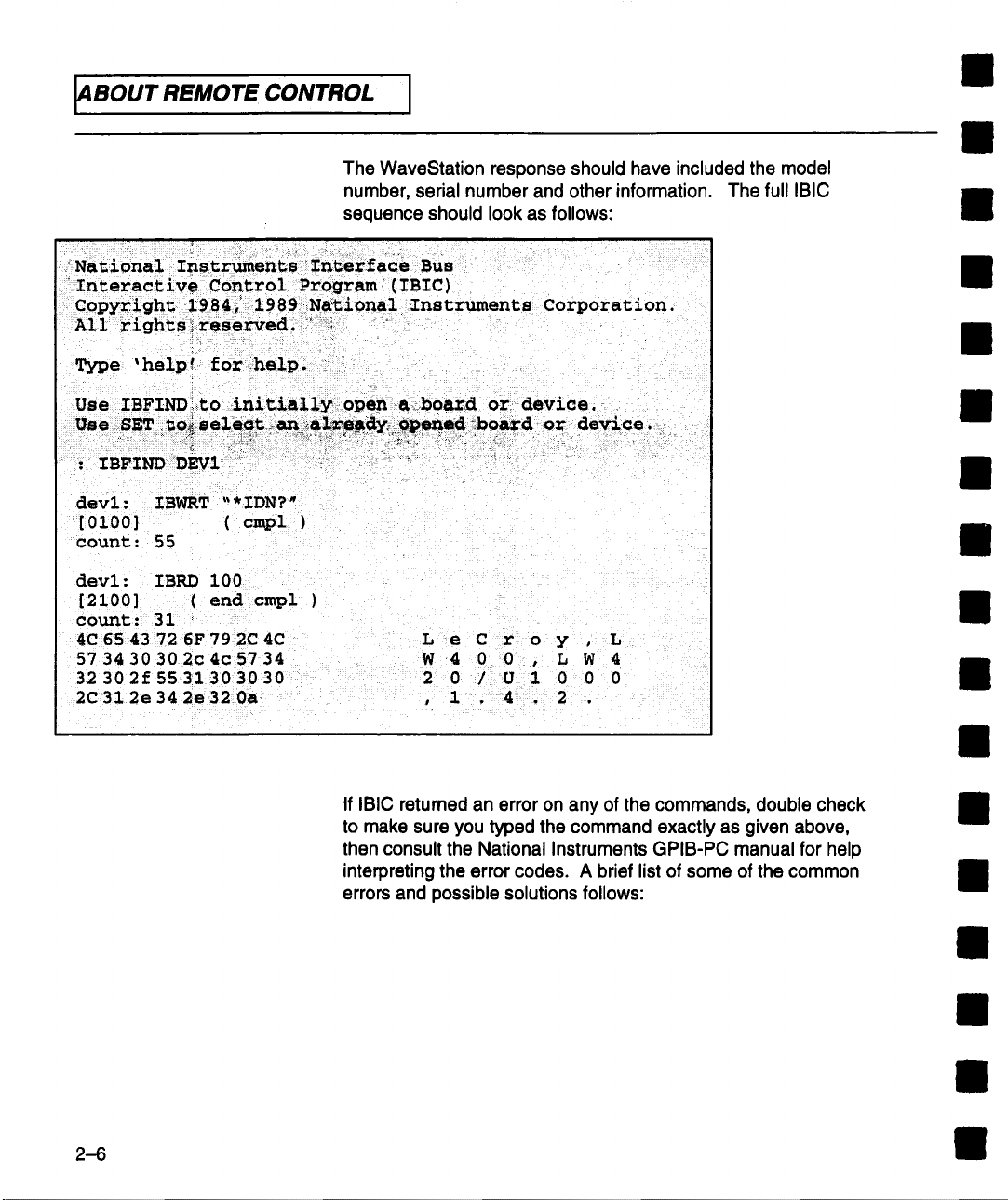

The WaveStation response should have included the model

number, serial number and other information. The full IBIC

sequence should look as follows:

National Imstruments Interface BUS

Interactive Control Program (IBIC)

Type ’ help ! for help.

: IBFIND DEVI ,

devl: IBWRT ’~* IDN?"

[0100]

count: 55

devl: IBRD 100

[2100] ( end cmpl )

count: 31

4C 65 43 72 6F 79 2C 4C

57 34 30 302c4c5734

32 302f 55 31 3030 30

2C31 2e34 2e32 0a

( cmpl

L e C r o y , L

W 4 0 0. L W 4

2 0 / U 1 0 0 0

, 1 , 4 . 2 .

2-6

If IBIC retumed an error on any of the commands, double check

to make sure you typed the command exactly as given above,

then consult the National Instruments GPIB-PC manual for help

interpreting the error codes. A brief list of some of the common

errors and possible solutions follows:

Page 19

I ABOUT REMOTECONTROL I

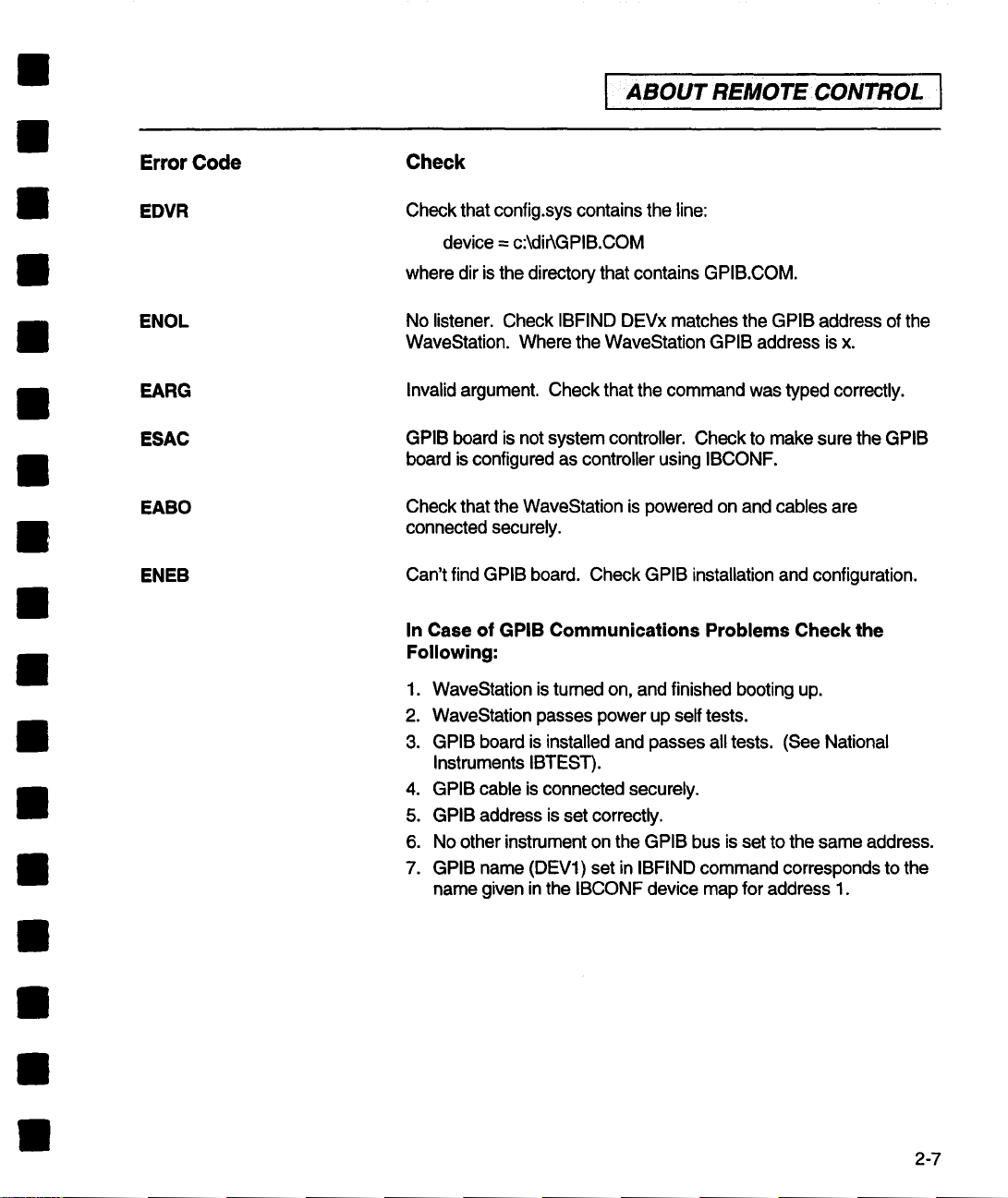

Error Code

EDVR

ENOL

EARG

ESAC

EABO

ENEB

Check

Check that config.sys contains the line:

device = c:\dirkGPIB.COM

where dir is the directory that contains GPIB.COM.

No listener. Check IBFIND DEVx matches the GPIB address of the

WaveStation. Where the WaveStation GPIB address is x.

Invalid argument. Check that the command was typed correctly.

GPIB board is not system controller. Check to make sure the GPIB

board is configured as controller using IBCONF.

Check that the WaveStation is powered on and cables are

connected securely.

Can’t find GPIB board. Check GPIB installation and configuration.

In Case of GPIB Communications Problems Check the

Following:

1. WaveStation is tumed on, and finished booting up.

2. WaveStation passes power up self tests.

GPIB board is installed and passes all tests. (See National

3.

Instruments IBTEST).

4. GPIB cable is connected securely.

GPIB address is set correctly.

5.

6. No other instrument on the GPIB bus is set to the same address.

7. GPIB name (DEV1) set in IBFIND command corresponds to the

name given in the IBCONF device map for address 1.

2-7

Page 20

4BOUT REMOTE CONTROL

~

This page left intentionally blank

2--8

Page 21

3

I

¯ 1

INSTRUMENT MODEL AND

I SUBSYSTEM

HIERARCHY

Remote Command

System Model

PROJect

It is important to understand the remote control subsystem

hierarchy in order to rapidly locate the desired command

and associated message you require. Figure 1 shows the

functional block diagram of the arbitrary waveform

generator as viewed by the remote programming interface.

The structure of the instrument subsystems is closely

related to this block diagram.

MMEMory

TRIGger

f

FGENera±or

EQUation

> BUTPu± I>

4,

]]ISPtay

I

HCIqpy

I

Figure I

Introduction to SCPI

Command Syntax SCPI commands are English language based ASCII text strings.

The SCPI command set is based on a hierarchical model of a

generic instrument. The instrument is broken down into major

system elements like OUTPUT, DISPLAY, etc. The command

follows a path from major functional elements down through

3-1

Page 22

’

Instrument Model and

Subsystem l-llerarchy

subsystems, to specific functions within the subsystem. For

example to turn on Channel l°s 1 MHz output bandwidth limit

filter the command would be:

OUTPutl:FILTer: FREQuency 1E6

The command is shown in its long (or verbose) form. As with all

commands described in this manual, the uppemase letters

indicate the characters required to represent the short form of

the command. Note that SCPI instruments are not case

sensitive, the use of capitalization in this manual is only intended

to show the difference between the long and short forms of the

command.

Note also that the short form and long form are the only

acceptable forms of a command. So, for "frequency" we can

send "freq" or "frequency" but not "frequ", for example. The

short form is the first four letters, unless the fourth is a vowel, in

which case the short form is the first three letters.

3-2

Keywords are separated by colons, while arguments use a

space as a delimiter. Multiple commands can be included in a

single multi-element command by using a semi-colon to

separate each element. Multiple elements within the same

command may be abbreviated if each element is within the

same subsystem. The second element in a multi-element

command must be preceded with a colon if it is not within the

same subsystem. Commands enclosed in square brackets

indicate default subsystems. For example, OUTPutl:STAte ON

is equivalent to OUTPut1 ON.

Page 23

Instrument Model and

Subsystem Hierarchy I

These are four valid WaveStation commands under two different

subsystems. The WAVE and OUTPut subsystems.

WAVE:SELECT chl - Enable channel 1 editor

WAVE:OPEN "new_wave" - Select waveform new_wave

OUTPut1 :FILTer:FREQuency 1 E6 - Enables the Channel 1

MHz Bandwidth filter

OUTPut1 on - Enables channel 1 output

The above commands may be sent to the WaveStation one

command at a time or they may be combined into a single multi-

element command. Following are valid forms for a multi-element

command. Each element in the command is separated by semi-

colon.

WAVE:SELECT chl ;OPEN "new_wave"

OUTPut1 :FILTer:FREQuency 1E6;:OUTPutl on

Note that when commands are combined using the semicolon

they must be at the same level in the command hierarchy. So

the second line, in the example above, cannot contain just the

argument "on", it requires that the keyword :OUTPut1 be

included. An alternative form of the combined command places

the commands in hierarchical order and doesn’t require a re-

statement of the keyword:

I

OUTPut1 on; FILTer:FREQuency 1E6

A complete discussion of SCPI command structure is contained

in "SCPI 1993, Volume 1:Syntax and Style" available from the

SCPI Consortium.

The English nature of SCPI commands often means that a

command can directly be mapped to a corresponding menu

control. Where standard commands are not available in the

1993 SCPI standard, LeCroy has extended the language to

facilitate control of the instrument. Extensions to the language

use command names and arguments that adhere to the

terminology used in the menu system wherever possible.

3-3

Page 24

Instrument Model and

I

Subsystem Hierarchy

Command Subsystems

OUTPut Subsystem

This section provides a comprehensive overview of the SCPI

command subsystems. All command keywords are shown. This

section is intended to assist the user in rapidly locating the

command form required to carry out AWG actions or query

settings and values. Commands with only a query form are

shown with a ’?’ as a suffix. Command arguments are not

described in detail in this section. Refer to Section 6 of this

manual for details of command arguments and for additional

information on the commands.

The OUTPut subsystem provides control of the output

channel(s), additive noise, and low pass filter bandwidth

selections.

Because the instrument may have two channels, the OUTPut

subsystem is controlled using OUTPut1 or OUTPut2 in order to

uniquely control each of the arbitrary waveform generator’s

outputs. In this manual, the numeric suffix to the OUTPut

subsystem is shown in general form using a # character i.e.,

OUTPut#:NOISe controls the noise output of either channel.

3-4

Page 25

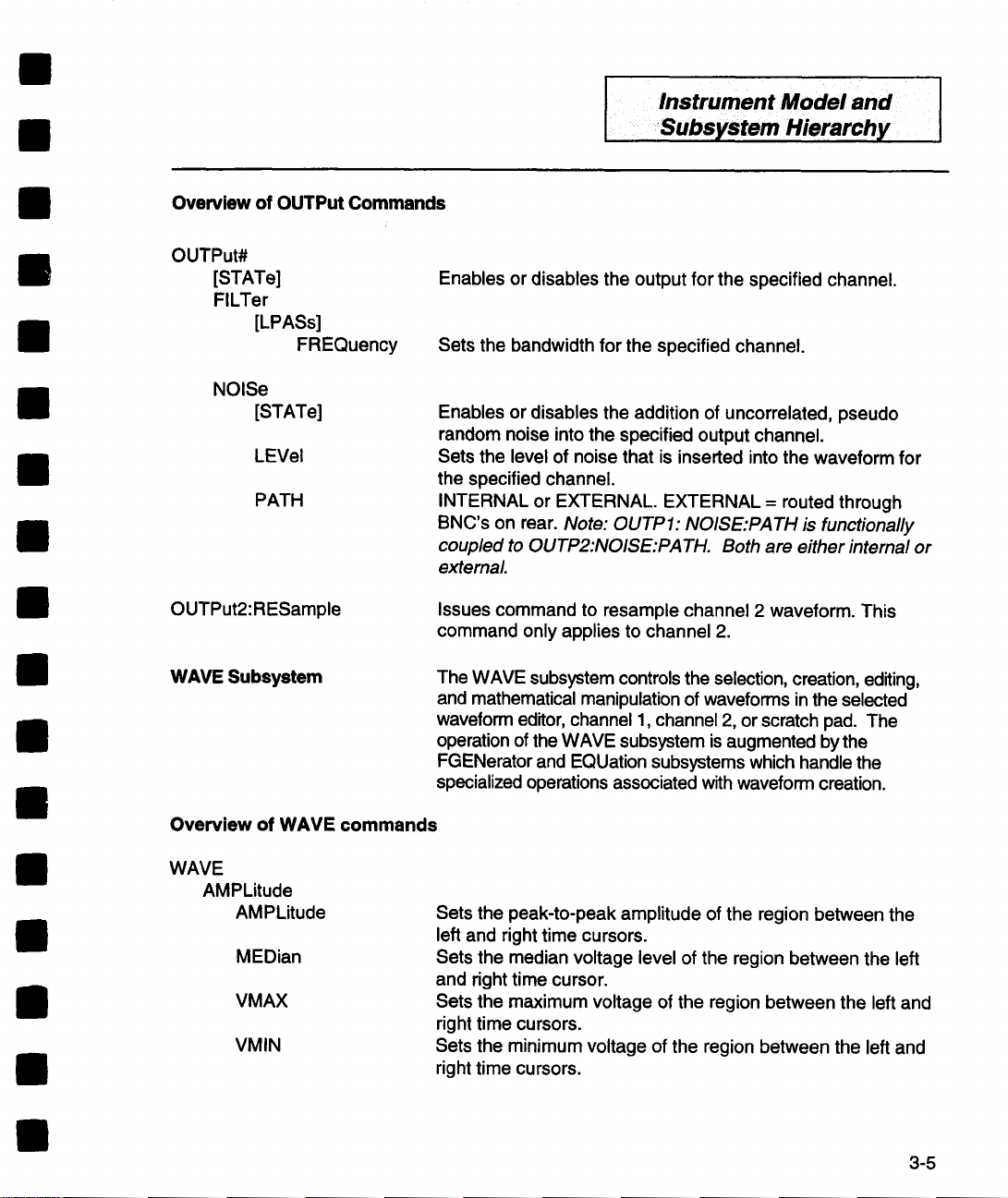

Overview of OUTPut Commands

OUTPut#

[STATe]

FILTer

[LPASs]

FREQuency

NOISe

[STATe]

LEVel

PATH

Enables or disables the output for the specified channel.

Sets the bandwidth for the specified channel.

Enables or disables the addition of uncorrelated, pseudo

random noise into the specified output channel.

Sets the level of noise that is inserted into the waveform for

the specified channel.

INTERNAL or EXTERNAL. EXTERNAL = routed through

BNC’s on rear. Note: OUTPI : NOISE:PATH is functionally

coupled to OUTP2:NOISE:PA TH. Both are either internal or

external

InstrumentModeland

I

Subsystem Hierarchy I

I

OUTPut2:RESample

WAVE Subsystem

Overview of WAVE commands

WAVE

AMPLitude

AMPLitude

MEDian

VMAX

VMIN

Issues command to resample channel 2 waveform. This

command only applies to channel 2.

The WAVE subsystem controls the selection, creation, editing,

and mathematical manipulation of waveforms in the selected

waveform editor, channel 1, channel 2, or scratch pad. The

operation of the WAVE subsystem is augmented by the

FGENerator and EQUation subsystems which handle the

specialized operations associated with waveform creation.

Sets the peak-to-peak amplitude of the region between the

left and right time cursors.

Sets the median voltage level of the region between the left

and right time cursor.

Sets the maximum voltage of the region between the left and

right time cursors.

Sets the minimum voltage of the region between the left and

right time cursors.

3-5

Page 26

Instrument Model and

I

Subsystem Hierarchy

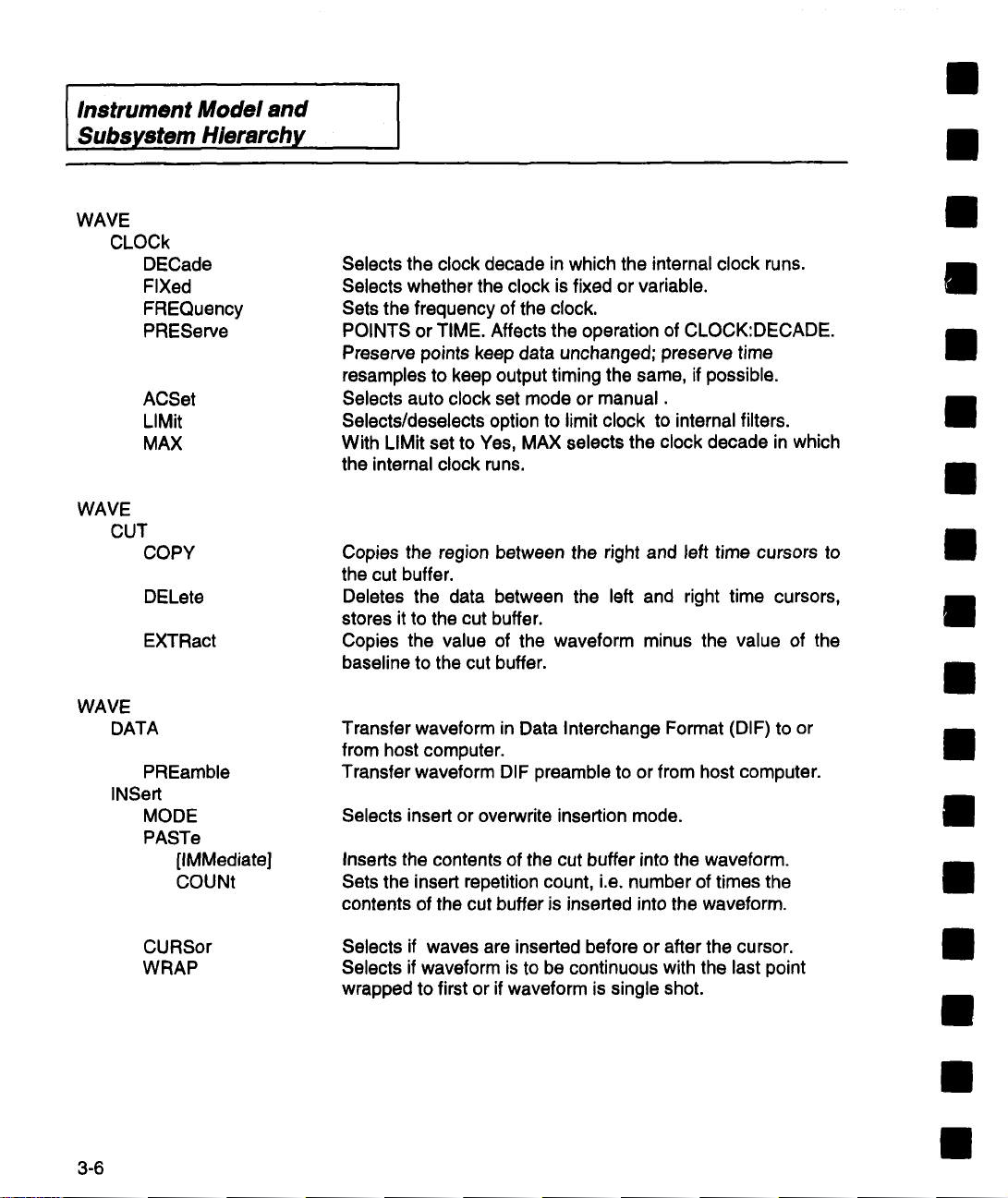

WAVE

CLOCk

DECade

FiXed

FREQuency

PREServe

ACSet

LIMit

MAX

WAVE

CUT

COPY

DELete

EXTRact

Selects the clock decade in which the internal clock runs.

Selects whether the clock is fixed or variable.

Sets the frequency of the clock.

POINTS or TIME. Affects the operation of CLOCK:DECADE.

Preserve points keep data unchanged; preserve time

resamples to keep output timing the same, if possible.

Selects auto clock set mode or manual.

Selects/deselects option to limit clock to internal filters.

With LIMit set to Yes, MAX selects the clock decade in which

the internal clock runs.

Copies the region between the right and left time cursors to

the cut buffer.

Deletes the data between the left and right time cursors,

stores it to the cut buffer.

Copies the value of the waveform minus the value of the

baseline to the cut buffer.

WAVE

DATA

INSert

3-6

PREamble

MODE

PASTe

[IMMediate]

COUNt

CURSor

WRAP

Transfer waveform in Data Interchange Format (DIF) to

from host computer.

Transfer waveform DIF preamble to or from host computer.

Selects insert or overwrite insertion mode.

Inserts the contents of the cut buffer into the waveform.

Sets the insert repetition count, i.e, number of times the

contents of the cut buffer is inserted into the waveform.

Selects if waves are inserted before or after the cursor.

Selects if waveform is to be continuous with the last point

wrapped to first or if waveform is single shot.

Page 27

WAVE

INSert

SCOPe

[IMMediate]

ADDRess

BWLimit

CONTrol

PREServe

SOURce

TYPE

SHAPe

DC

PULSe

RAMP

DURation

LEVel

AMPLitude

BASE

CYCLes

ETIMe

PERiod

TDELay

WIDTh

AMPLitude

CYCLes

FREQuency

INVert

OFFSet

SPOSition

Instrument Model and I

I

Subsystem Hierarchy I

Downloads the data from the specified digital oscilloscope

(DSO).

Sets the GPIB address of the source DSO.

Select option to check for and correct waveform

discontinuities or to not check or correct discontinuities.

Selects the GPIB request control mode for DSO transfers.

Sets how the data from the digital oscilloscope is preserved.

The data can be preserved in time or by points.

Selects waveform source from available DSO traces.

Selects DSO type (model),

Set the time duration (length) of the inserted DC function.

Set the voltage level of the inserted DC function.

Sets the base to top amplitude of the standard wave pulse.

Sets the base voltage level of the pulse.

Sets the number of pulse cycles inserted into the waveform.

The 10%-90% transition time of the rising and falling edges

of the standard wave pulse.

Sets the period (1/frequency) of the standard wave pulse.

Sets time delay from the beginning of the waveform and the

beginning of the first edge of the pulse.

Sets the half amplitude width of the standard wave pulse.

Sets the peak-to-peak amplitude of the standard wave ramp.

Sets the number of cycles of the standard wave ramp

inserted into the waveform.

Sets the frequency of the standard wave ramp.

Controls the polarity of the ramp’s slope, i.e. rising or falling.

Sets the voltage of the zero degree phase of the ramp."

Sets the start position of the ramp in percentage of the ramp

amplitude.

3-7

Page 28

lnstrument Model and

l

Subsystem l-llerarchy

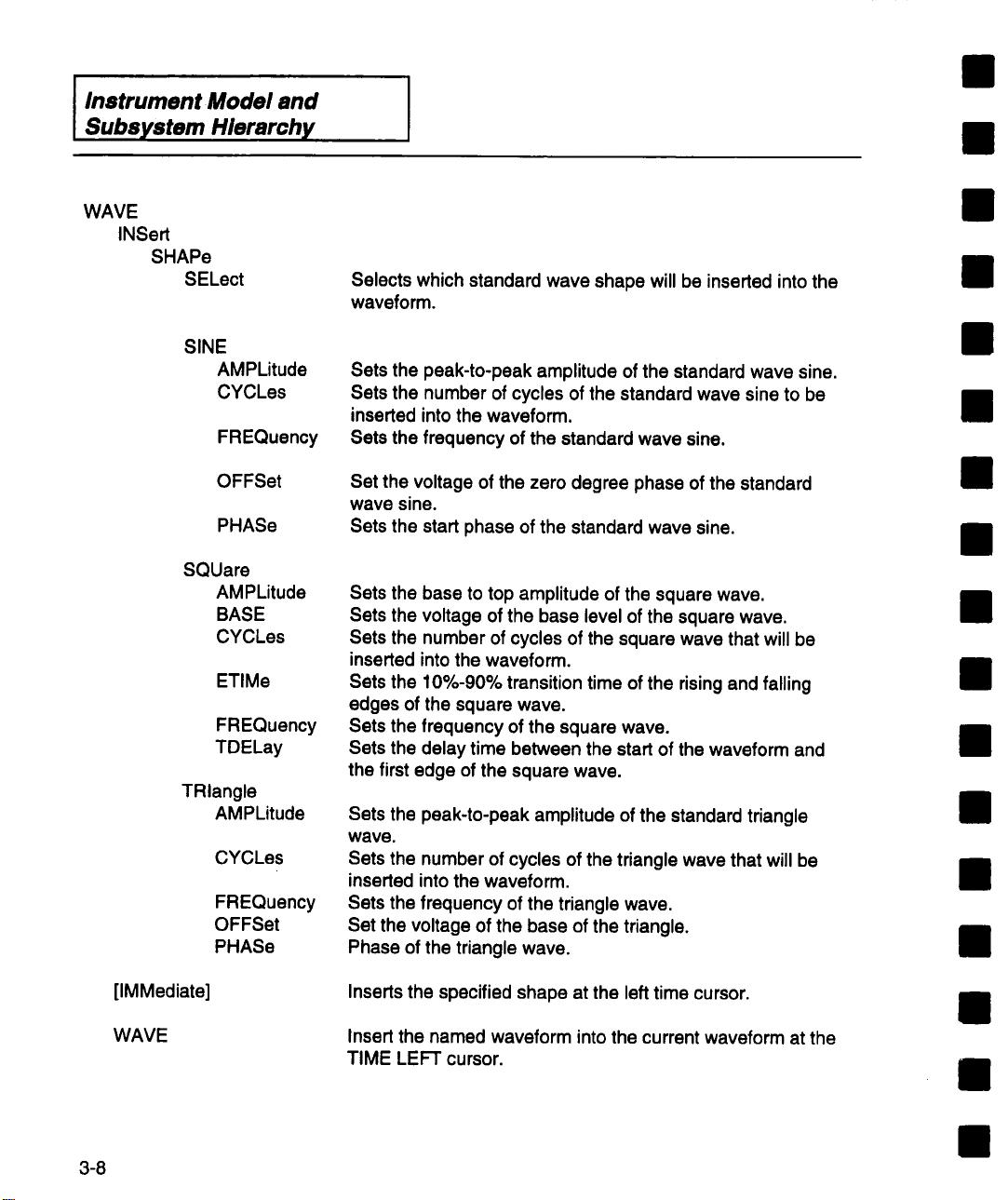

WAVE

INSert

SHAPe

SELect

SINE

AMPLitude

CYCLes

FREQuency

Selects which standard wave shape will be inserted into the

wave form.

Sets the peak-to-peak amplitude of the standard wave sine.

Sets the number of cycles of the standard wave sine to be

inserted into the waveform.

Sets the frequency of the standard wave sine.

SQUare

TRiangle

[IMMediate]

OFFSet

PHASe

AMPLitude

BASE

CYCLes

ETIMe

FREQuency

TDELay

AMPLitude

CYCLes

FREQuency

OFFSet

PHASe

Set the voltage of the zero degree phase of the standard

wave sine.

Sets the start phase of the standard wave sine.

Sets the base to top amplitude of the square wave.

Sets the voltage of the base level of the square wave.

Sets the number of cycles of the square wave that will be

inserted into the waveform,

Sets the 10%-90% transition time of the rising and falling

edges of the square wave.

Sets the frequency of the square wave.

Sets the delay time between the start of the waveform and

the first edge of the square wave.

Sets the peak-to-peak amplitude of the standard triangle

wave.

Sets the number of cycles of the triangle wave that will be

inserted into the waveform.

Sets the frequency of the triangle wave.

Set the voltage of the base of the triangle.

Phase of the triangle wave.

Inserts the specified shape at the left time cursor.

3-8

WAVE

Insert the named waveform into the current waveform at the

TIME LEF’r cursor.

Page 29

WAVE

MARKer

MATH

CLOCk

FIRSt

FREQuency

EDGE

DEFault

NDEFined

TIME

[STATE]

LEVel

TYPE

COUPling

IMMediate

SOURce2

[OPERation]

Instrument Model and

I

Subsystem Hierarchy

Sets the time at which the first edge of the clock marker

begins. WAVE:MARKer:TYPE must be set to CLOCk.

Sets the frequency of the marker clock.

WAVE:MARKer:TYPE must be set to CLOCk."

Sets default edge marker.

Query only. Number of edges defined.

Sets the time at which STATE will act.

Low or High.

Sets the voltage level of the marker to TTL or ECL levels.

Selects either a clock marker or an edge marker.

AC or DC, used only for INTEGRATION. If DC, integration of

a constant non-zero voltage becomes a ramp.

Performs the math function specified by

WAVE:MATH[:OPERation] on the current waveform and

WAVE:SOURce2 (if applicable) on the region between the

left and right time cursors. The result is placed into the

current waveform.

Name of the "other" waveform for two waveform operations

such as ADD, SUBTRACT, MULTIPLY DIVIDE.

Specifies which math operation will be performed by

WAVE:MATH :lMMedate. Operation can be SMOOTH, ADD,

SUBTract, MULTiply, DIVide, INTegrate DIFFerentiate

CONVolve.

NEW

OPEN

REGion

LEFT

RIGHt

Creates a new waveform with the name specified by the

argument.

Opens a waveform from the current project.

Set the position of the left time cursor.

Set the position of the right time cursor. This command

requires time cursors not to be in the track mode.

3-9

Page 30

Instrument Model and

Subsystem Hierarchy

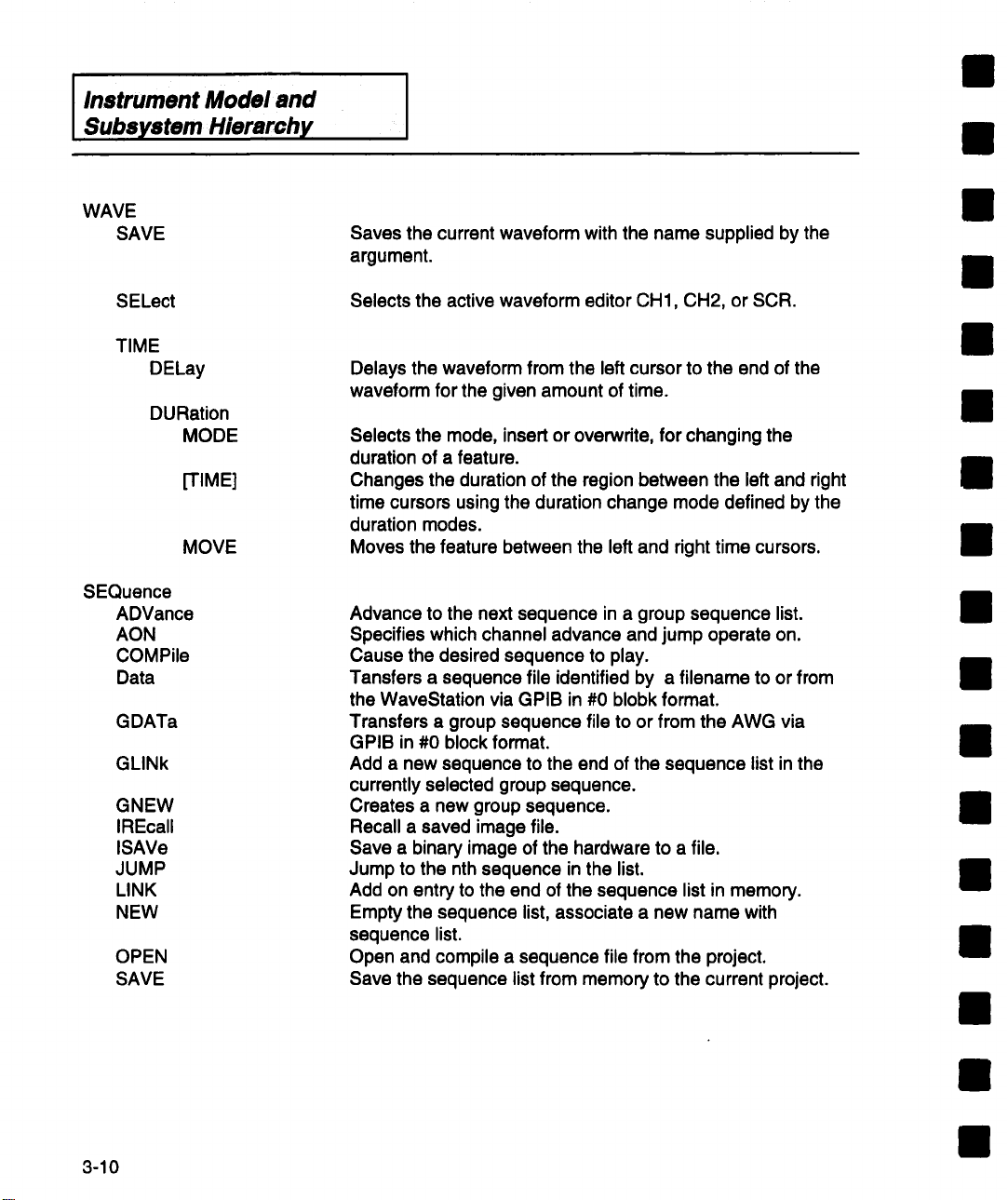

WAVE

SAVE

Saves the current waveform with the name supplied by the

argument.

SELect

TIME

DELay

DURation

SEQuence

ADVance

AON

COMPile

Data

GDATa

GLINk

GNEW

IREcall

ISAVe

JUMP

LINK

NEW

OPEN

SAVE

MODE

[TIME]

MOVE

Selects the active waveform editor CH1, CH2, or SCR.

Delays the waveform from the left cursor to the end of the

waveform for the given amount of time.

Selects the mode, insert or overwrite, for changing the

duration of a feature.

Changes the duration of the region between the left and right

time cursors using the duration change mode defined by the

duration modes.

Moves the feature between the left and right time cursors.

Advance to the next sequence in a group sequence list.

Specifies which channel advance and jump operate on.

Cause the desired sequence to play.

Tansfers a sequence file identified by a filename to or from

the WaveStation via GPIB in #0 blobk format.

Transfers a group sequence file to or from the AWG via

GPIB in #0 block format.

Add a new sequence to the end of the sequence list in the

currently selected group sequence.

Creates a new group sequence.

Recall a saved image file.

Save a binary image of the hardware to a file.

Jump to the nth sequence in the list.

Add on entry to the end of the sequence list in memory.

Empty the sequence list, associate a new name with

sequence list.

Open and compile a sequence file from the project.

Save the sequence list from memory to the current project.

3-10

Page 31

Instrument Model and

I

Subsystem Hierarchy I

FGENerator Subsystem

Overview of FGEN Commands

FGENerator#

DC

LEVel

MULTitone

AMPLitude

NTONes

OFFSet

TONE#

RAMPlitude

[FREQuency]

PULSe

AMPLitude

BASE

ETIMe

PERiod

SWEep

SPACing

STARt

STOP

TIME

[STATe]

The WaveStation’s standard function generator mode is

controlled by the FGENerator subsystem. Any of the seven

standard waveforms, sine, triangle, square, ramp, pulse,

multitone, and DC can be specified. Key parameters such as

frequency, amplitude, offset, and start phase can be controlled

directly. Additionally, the frequency of the sine, triangle, square,

ramp and pulse waveforms can be swept linearly or

logarithmically.

Set the DC voltage level for the specified channel’s function

generator (either I or 2).

Sets the peak-to-peak amplitude of the multitone function in

the specified channel’s function generator (either 1 or 2).

Sets the number of tones to be calculated for the multitone function.

Set the voltage of the zero degree phase of the multitone

waveform.

Sets the relative amplitude of the current tone in the

multitone waveform.

Set the frequency of the current tone in the multitone

waveform.

Sets the base to top amplitude of the pulse in the specified

channel’s function generator (either 1 or 2).

Sets the voltage of the base level of the pulse waveform in

the specified channel’s function generator (either 1 or 2).

Sets the 10%-90% edge time of both the rising and falling

edges of the pulse waveform.

Sets the period (1/frequency) of the pulse in the specified

channel’s function generator (either 1 or 2).

Selects the type of sweep (either linear or log) in the

specified channel’s function generator (either 1 or 2).

Sets the start frequency of the sweep.

Sets the stop frequency of the sweep.

Sets the sweep duration.

Turns the sweep on or off.

3-11

Page 32

Instrument Model and

I

Subsystem Hierarchy

FGENerator#

PULSe

TDELay

WIDTh

RAMP

AMPLitude

FREQuency

INVert

OFFSet

SPOSition

SWEep

STARt

STOP

TIME

[STATe]

Sets the amount of time between the beginning of the

waveform and the beginning of the first edge of the pulse.

Sets 1he width of the pulse from 50% up the rising edge to

50% down the falling edge.

Sets the peak-to-peak amplitude of the ramp in the specified

channel’s function generator (either 1 or 2).

Sets the frequency of the ramp.

Controls whether the ramp is rising or falling.

Set the median voltage of the ramp waveform.

Sets the start position of the ramp in percentage of the

ramp’s peak-to-peak amplitude.

Sets the start frequency of the sweep.

Sets the stop frequency of the sweep.

Sets the sweep duration.

Turns the sweep on or off.

3-12

SELect

SINE

AMPLitude

FREQuency

OFFSet

PHASe

SWEep

SPACing

STARt

STOP

TIME

[STATe]

Selects which function the specified channel’s function

generator outputs. The available functions are: SINE,

TRiangle, SQUare, RAMP, PULSe, MULTitone, and DC.

Sets the peak-to-peak amplitude of the sine wave in the

specified channel’s function generator (either 1 or 2).

Sets the frequency of the sine wave.

Sets the voltage of the zero degree phase of the sine

waveform.

Sets the start phase of the sine wave.

Selects the sweep type (either linear or log).

Sets the start frequency of the sweep.

Sets the stop frequency of the sweep.

Sets the sweep duration.

Turns the sweep on or off.

Page 33

FG ENerator#

SQUare

AMPLitude

BASE

ETIMe

FREQuency

SWEep

SPACing

STARt

STOP

TIME

[STATe]

TDELay

TRiangle

AMPLitude

FREQuency

OFFSet

PHASe

SPACing

SWEep

STARt

STOP

TIME

[STATe]

InstrumentModel and

Subsystem Hierarchy I

I

Sets the peak-to-peak amplitude of the square wave in the

specified channel’s function generator (either I or 2).

Sets the voltage of the base level of the square wave.

Sets the 10%-90% edge time of both the rising and falling

edges of the square wave.

Sets the frequency of the square wave.

Selects the sweep type (either linear or log).

Sets the start frequency of the sweep.

Sets the stop frequency of the sweep.

Sets the sweep duration.

Turns the sweep on or off.

Sets the amount of time between the start of the waveform

and the first edge of the square wave. Useful in single trigger

mode; in continuous this time lowers the frequency.

Sets the peak-to-peak amplitude of the triangle wave in the

specified channel’s function generator (either 1 or 2).

Sets the frequency of the triangle wave.

Sets the median voltage of the triangle waveform.

Sets the start phase of the triangle wave.

Selects the sweep type (either linear or log).

Sets the start frequency of the sweep.

Sets the stop frequency of the sweep.

Sets the sweep duration.

Turns the sweep on or off.

[STATe]

Turns the function generator on or off in the specified

channel (either I or 2).

3-13

Page 34

Instrument Model and

I

Subsystem, Hierarchy

EQUation Subsystem The equation subsystem is used to enter, select, save, and

recall equations which describe waveforms mathematically. It is

also used to calculate the waveform sample values based on

the equation.

Overview of EQUation Commands

EQUation

CALCulate

DATA

DEFine

DURation

LINE

NEW

OPEN

SAVE

Calculates the currently specified equation line for the preset

duration and inserts it into the current waveform at the left

cursor position using the current insert mode.

Transfers all the lines of the equation sheet as a "#0" block.

#0 is an indefinite length block of data terminated with EOI.

Defined in IEEE 488.2.

Defines an equation for the current equation line. The

equation line may be up to 50 characters in length and must

be surrounded by quotes. Valid functions are: SIN, COS,

SQRT, PULSE, STEP, LN, LOG, ABS, EXP and TAN. Valid

operators are: +, -, *,/, (,), "","", = and ^. Valid variable

names are X1 through X16. Valid arguments are T, PI,

NOISE, and GNOISE.

Sets the time span over which the equation will be

calculated.

Selects an equation line from the current equation sheet.

Creates a new equation sheet.

Opens an existing equation sheet.

Saves the current equation sheet.

3-14

Page 35

InstrumentM°deland

I

Subsystem Hierarchy I

DISPlay Subsystem The DISPlay subsystem controls the selection and

presentation of text, graphics and waveform information. In

addition, the cursor system is controlled by this subsystem.

Overview of DiSPlay Commands

DISPlay

ANNotation

DATE[:STATe]

LOGO[:STATe]

PARameter[:STATe]

[ALL]

SSAVe Allows the automatic screen saver to be enabled or disabled.

[WINDow]

TRACe

ALL

COLor

CURSors

TIME

DELTa

LEFT

RIGHt

SALL

TEND

TGRid

TRACk

[STATe]

VOLTage

BOTTom

DELTa

TGRid

Allows the time/date annotation field to be switched on or off.

Allows the Company Logo to be switched on or off.

Turns the parameters readouts on or off.

For SCPI compatibility. Same as "Logo".

Displays the whole waveform on the screen.

Sets the trace intensity. Setting the intensity for one trace

will set the same intensity for all traces.

Change the delta time between the time cursors. This

command only has effect if the cursors are in the track mode.

Set the position of the left time cursor.

Set the position of the right time cursor. This command only

has effect if the cursor track mode is off.

Select All selects the entire waveform by placing the left

cursor at time zero and the right cursor at the end of the

waveform.

Places both cursors at the end of the waveform.

Moves both time cursors so they are on the display.

Enables or disables time cursor tracking.

Turns the time cursors on or off.

Set the position of the bottom voltage cursor.

Change the delta voltage between the voltage cursors. This

command only has effect if the voltage cursors are in the

track mode.

Moves both voltage cursors so they are on the display.

~

[

3-15

Page 36

lnstrument Model and

I

Subsystem Hierarchy

DISPlay

[WINDow]

TRACe

VOLTage

TOP

TRACk

[STATe]

GRATicule

COLor

GRID

[STATe]

TYPE

TRACe

X[:SCALe]

CENTer

PDIVision

TCURsors

Y[:SCALe]

PDIVision

RLEVel

Sets the position of the top voltage cursor. This command

only has effect if track is off.

Enables or disables voltage cursor tracking.

Turns the voltage cursors on or off.

Set the display intensity for the grid.

Select or query the grid style. The grid may be a full grid

(ON), no grid (OFF), or set to a cross hair (CHAir).

Selects the type of grid to display. Single, dual, SXY, XY.

Sets the time at the horizontal center of the grid.

Sets the horizontal time per division of the grid.

Displays the portion of the waveform between the time

cursors with the left cursor one division from the left edge of

the grid and the right cursor one division from the right edge

of the grid.

Sets the vertical volts per division of the grid.

Sets the voltage at the vertical center of the grid.

3-16

ZPRevious

Restores the zoom settings to the previous time and voltage

zoom settings.

Page 37

Instrument Model and I

I

HCOPy Subsystem The HCOpy subsystem provides control over printing and

output of screen graphics form the WaveStation.

Overview of HCOPy Commands

HCOPy

AUToincr

FILename

INDex

TARGet

GRAPhics

DESTination

FORMat

PRINter

DESTination

FFEed

MODel

QUALity

SIZE

Enables automatic increment of the filename index when a

hardcopy is stored to a file.

Set or query the current hardcopy file name.

Set the hardcopy filename index number. The index may

range from 0 to 999.

Set the destination for the hardcopy graphics file.

Set the hardcopy graphics file format.

Set the destination of the hardcopy printer data. The

destination may be the GPIB or Centronics port, or it may be

the floppy disk drive where a file in printer format will be

stored.

Set whether a form feed is automatically generated following

a hardcopy.

Set the specified printer model.

Set the print quality, draft or proof. This setting is not

available for all supported printers.

Set the size of the hardcopy, notebook or presentation.

Subsystem Hierarchy

TYPE

[IMMediate]

Sets the hardcopy format. Hardcopies may be formatted to

provide data suitable for printers or graphics files.

Begin a hardcopy.

3-17

Page 38

lnstrument Model and

l

Subsystem l-llerarchy

TRIGger Subsystem

Overview of TRIGger Commends

INITiate [:IMMediate]

TRIGger[:SEQuence]

BCOunt

DELay

LEVel

MODE

SLOPe

SOURce

The trigger subsystem is used to control the Trigger section

of the AWG. This includes controls for triggering such as

level, mode, source and slope.

Triggers the system, equivalent to the IEEE 488.2 command

*TRG.

Sets the burst count or number of repetitions of the waveform

that will be output after a trigger is received in burst mode.

Sets the delay from trigger to start of output of the waveform.

Sets the trigger level in volts.

Sets the trigger mode. The trigger mode may set to

CONTinuous, SINGle, BURSt, or GATE.

Sets the trigger slope.

Sets the trigger source. The trigger source may internal or

external.

3-18

Page 39

InstrumentModel and

Subsystem Hierarchy

MMEMory Subsystem

Overview of MMEMory Commands

MMEMory

CATalog

EQUation

IMAGe?

SEQuence

WAVeform

[ALL]

DATA

PREamble

DELete

EQUation

IMAGe

PROJect

SEQuence

[WAVe form]

The MMEMory (mass memory) subsystem provides support

for the extensive hard disk storage capability of the

WaveStation.

Returns a list of all equations in the current project.

Returns a listing of image files located in the current project

Retums a list of all sequences in the current project.

Returns a list of all waveforms in the current project.

Returns a list of all objects in the current project.

Upload or download the waveform named in the associated

argument. Waveforms are stored in DIF format.

Upload or download the header of the waveform named in

the associated argument.

Deletes the named equation.

Deletes the named image.

Deletes the named project.

Deletes the named sequence.

Deletes the named waveform.

3-19

Page 40

Instrument Model and

I

Subsystem Hierarchy

PROJect Subsystem

Overview of PROJect Commands

PROJect

NEW

OPEN

SAVE

The project subsystem is used to create, open, and save

individual user work areas called projects.

Creates a new project with the specified name. The current

project is closed and the new project is created.

Opens the specified project if it exists (no action is taken if it

doesn’t exist) and closes current project.

Saves the current project.

3-20

Page 41

Instrument Model and

I

Subsystem Hierarchy

SYSTem Subsystem

Overview of SYSTem Commands

SYSTem

CLOCk

EREFerence

COMMunicate

GPIB[:SELF]

ADDRess Sets the GPIB address of the AWG.

ERRor?

HELP

SYNTax?

VERSion?

Provides controls not specific to the vertical, horizontal,

trigger, or measurement subsystems.

Sets whether the system uses the internal clock reference or

an external 10 MHz clock reference.

Query the last three system errors. The result of the query is

the error number followed by the error text for each of the

last three system errors.

Finds out the arguments for and full form of a header.

Example, SYST:HELP:SYNTAX? "WAVE:OPEN".

Returns SCPI version number for which instrument complies.

CALibration Subsystem

CALibration[:ALL]?

Performs an Internal calibration and returns a status code

indicating if the calibration was successful:

0 = Calibration successful

1 = Calibration failed

3-21

Page 42

lnstrument Model and

l

Subsystem Hierarchy

STATus Subsystem

Overview of STATus Commends

STATus

OPERation

CONDition?

ENABle

[EVENt]?

PRESet

The status Subsystem is used to control the status reporting

registers. This includes the 488.2 specified condition, event

and enable registers as well as the SCPI defined

QUEStionable and OPERation registers. There are two

event status registers, the Status Byte Register (STB) and

the Standard Event Status Register (ESR) within the

WaveStation. There are also two dual purpose (event and

condition) registers: the OPERation Status Register and the

QUEStionable Status Register. Finally there is an

Error/Event queue that records the last error. For full

information on the Status Registers, please refer to Section 4

of this manual.

Query the Operation Status Condition Register.

Enable bits in the Operation Status Event Register that will

be summarized in the Status Byte Register.

Query the contents of the Operation Status Event register.

Clear all status registers and clear all enable registers. Sets

enable registers to the same as power on conditions.

QUEStionable

CONDition?

ENABle

[EVENt]?

3-22

Query the Questionable Status Condition Register.

Enable bits in the Questionable Status Event Register that

will be summarized in the Status Byte Register.

Query the Questionable Status Event Register.

Page 43

lnstrumentModel and I

I

Subsystem Hierarchy I

488.2 common Commands

*CAL?

*CLS

*ESE

*ESR?

*IDN?

*LRN?

*OPC?

*OPC

*PCB

In addition to the SCPI subsystems, 488.2 mandatory are

supported by the WaveStation. Following is a brief listing of

the standard 488.2 commands. The 488.2 commands work

in combination with the SCPI commands to provide full

control of the WaveStation.

Performs a system calibration and returns a status code

indicating if the calibration was successful:

0 = Calibration successful

1 = Calibration failed

Clears all status registers.

Enable bits in the Event Status Register.

Reads and clears the contents of the Event Status Register.

Identifies the instrument. The response indicates the

manufacturer, the model, the serial number and the software

revision level.

Read the current instrument setup.

When overlapped operations are complete place a "1’ into

the output queue.

When overlapped operations are complete assert the OPC

bit in the EVENT STATUS register.

Identifies the address to pass control back to when the

WaveStation is about to be given control of the GPIB bus.

*RST

*SRE

*STB?

*TRG

*TST

*WAI

Sets all settings (1/O and Scope setup) to their default values.

Enable bits in the Service Request Enable mask.

Read the contents of the main status byte.

Same as the manual button on the Trigger menu.

Performs selftest and returns a status code indicating if

selftest was successful: 0 = success.

WAIT for completion of overlapped operations before parsing

more commands. The operations under WAVE:TIME, and

SEQ:COMP.LC are overlapped operations.

3-23

Page 44

Instrument Model and

I

Subsystem Hierarchy

This page left intentionally blank

3-24

Page 45

4

STATUS&ERROR

I

REPORTING t

I

Status Register

Status Byte Operation

Status Data Structures

Register Model

A set of status registers allows the user to quickly determine the

AWG’s internal processing status at any time. The status registers

as well as the status and event reporting system adhere to the SCPI

recommendations.

The WaveStation continually updates its status to report the latest

events, conditions, and settings.

Changes are summarized by designated bits in the Status Byte

register (STB). The seventh bit, RQS, is asserted whenever any

other bits in the STB are reported as set and their corresponding

enable bits are set. Also, whenever the RQS bit is set, the GPIB bus

SRQ line is automatically asserted.

In general, an asserted bit in the main status byte (STB) reflects,

summarizes, a change in a corresponding status register or queue

(i.e. Standard Event Status Register, Questionable Status Register,

Operation Status Register, or Error/Event Queue).

Two types of status structures, the Register (individual bits) and the

Queue (encoded number), are used in the WaveStation.

In the Register Model individual bits identify a specific WaveStation

condition or event.

Queue Model

Altematively, each bit could act as a summary bit for an associated

status register. Using bits in one status register to indicate changes

in other registers allows for a layered status description. This layering

of detail enables the controller to limit the amount of information it

receives. The Status Byte Register, Standard Event Status Register,

Questionable Status Register, and Operation Status Register all use

the register model status structure.

The Queue Model is a single register which contains an encoded

number. For example, this number may be an error code which

corresponds to an error condition.

4-1

Page 46

I Status & Error Reporting

Event Recording IEEE-488.2 allows two ways to record an event and the WaveStation

Condition Registers Condition Registers are updated continually and are not cleared

I

The WaveStation’s Error/Event Queue is the only register in the

WaveStation employing the queue model. The Error/Event Queue

can hold one error code. When read, the queue reports the most

recent error code, and clears itself.

When the queue is cleared (empty), the corresponding bit in the

Status Byte Register will be cleared. Conversely, when the queue

contains an error code, the corresponding bit in the Status Byte

Register will be set.

registers are implemented as both condition and event registers to

provide full functionality. The names of the condition and event

registers are the same. Only the commands to query the event and

condition registers differ.

when read. If a condition was true but is no longer true the

corresponding bit in the condition register will be false. The

WaveStation has only two condition registers, the Questionable

Status Register and the Operational Status Register. These two

registers also function as event registers. Whether the condition or

event register is queried depends on the form of the query used.

Event Registers Event Registers capture changes in conditions. They are not cleared

until they are read, even if the condition which caused the event no

longer exists. All registers in the WaveStation function as event

registers. The Questionable Status Register and Operational Status

Register function as both event and condition registers depending on

how they are queried. Each bit in an Event Register either

summarizes an event register, or reports a condition or event in the

WaveStation. A bit is set to true (1) when the summary, condition,

event changes from false (0) to true (1) and will remain set until

cleared using the *CLS command or by reading the register.

4-2

Page 47

I Status & Error Reporting I

Querying the Operational

and Questionable Status

Register

Since the Operational Status Register and the Questionable

Status Register can be both condition and event registers

depending on the query form the query form is very important.

To read the Operational and Questionable Event Registers

use the following commands:

STATus:OPERation? - Read Operation Status Event Register.

STATus:QUEStionable? - Read Questionable Status Event Register.

To read the Operation and Questionable Condition Registers use the

following commands:

STATus:OPERation:CONDition? - Read Operation Status Condition

Register.

STATus:QUEStionable:CONDition? - Read Questionable Status

Condition Register.

The following example illustrates how the condition and event

registers can retum different values.

The waiting for trigger status is shown in bit 5 of the Operation Status

register. (The bit meaning of each bit in each register is documented

later in this section.)

While the WaveStation is waiting for a trigger, the commands

STATus:OPERation? and STATus:OPERation:CONDition? retum

the same value for bit 5. Both commands retum true (32) because

the WaveStation is waiting for a trigger.

If both commands are issued again, while the WaveStation is still

waiting for a trigger, the results will be different. The command

STATus:OPERation? will return false (0) because it was cleared

when the event register was read with the command above. The

command STATus:OPERation:CONDition? will retum true (1)

4--3

Page 48

I Status & Error Reporting

because it was not cleared when read and the WaveStation is still

waiting for a trigger.

When the waveform is being generated, the command

STATus:OPERation? will retum false (0) because the event register

was read and cleared the first time the command was sent. The

command STATus:OPERation:CONDition? will return false (0)

because the WaveStation is not waiting for a trigger..

If the WaveStation was waiting for a trigger, receives a trigger and

we send the query STATus:OPERation? While the waveform is

being generated, then this query will return true (32) because the

event of waiting for trigger has occurred since the event register was

last cleared. The query STATus:OPERation:COND? Will retum

false (0) because the WaveStation is not currently waiting for

trigger.

Event Enable Registers

The WaveStation registers are arranged in a tree like structure. The

Status Byte Register is the root of the structure and branches out to

summarize the Standard Event Status Register, the Operation

Status Registers, the Questionable Status Register, and the

Error/Event Queue. Coupled with each event register is an Enable

Register. The Enable Registers determine which if any bits of the

associated Event Register will be summarized in the Status Byte

Register.

Each bit in an event enable register is "AND’ed" with its

corresponding bit in its associated status event register. If the result

of the AND operation is a one (true) the summary bit will be set in the

Status Byte Register.

All event registers are edge sensitive, meaning they are set when the

status changes state. The SCPI standard allows for choosing the

edge of interest (positive going or negative going), but this capability

is not implemented in the WaveStation. The WaveStation will set

the bit in the status register to true (1) whenever the status changes

from false (0) to true (1). Event register bits are set on a positive

going transition.

4-4

Page 49

I Status & Error Reporting I

The status registers and enable registers are associated as follows:

Status Byte Register

Standard Event Status Register

Operation Status Register

Questionable Status Register

Service Request Enable Register

Event Status Enable Register

Operation Status Enable Register

Questionable Status Enable

Register

The following commands are used to set the value of the enable

registers:

*SRE

*ESE

STATus:OPERation: ENABle

STATus:QUEStionable:ENABle

Service Request Enable Register

Event Status Enable Register

Operation Status Enable Register

Questionable Status Enable

Register

The enable registers for the Operation Status Register and the

Questionable Status Register are 15 bits wide with each bit

selecting a different condition or event. The enable registers for

the Service Request Register and the Event Status Register are

7 bits wide with each bit selecting a different condition or event.

The bit positions for the enable register match the bit positions

for the status registers and have the same names. While the

Operation Status Register and the Questionable Status Register

can function as both event and condition registers, only the

results of the event register are AND’ed with the enable register

to set the summary bit in the Status Byte Register.

The value of the Enable registers may also be changed to a

preset value with the STATus:PREset command.

STATus:PREset clears the Operation and Questionable Enable

registers. Refer to command details for STATus:PREset for the

further information. During power-on the enable registers are

set to their STATus:PREset states. The *RST and *CLS

commands have no effect on the enable registers.

4--5

Page 50

I Status & Error Reporting

Status Byte Register

Definition

Status Byte Register

Definition

Bit#

7 (MSB)

6

5

4

3

2

1

0 (LSa)

The main Status Byte register (STB) reflects instrument status at the

time it is read. The register is read when the system controller

(remote computer) polls the WaveStation with the *STB? command

or with a serial poll. Bits in the STB summarize all the other status

registers.

The STB is read with the command *STB? or by serial polling the

WaveStation. The Status Byte Registers enable register is set with

*SRE n. The Status Byte Enable Register is read w#h *$RE?. (Note:

n is the sum of the decimal bit weights of all bits that are true.)

The *STB? query does not alter any bits in the status byte. Only

the *CLS command can clear the status byte, except for the MAV

Message Available but which depends on the state of the output

queue.