LeCroy LT344L, LT342L, LT322, LT224, LT344 Service Manual

...

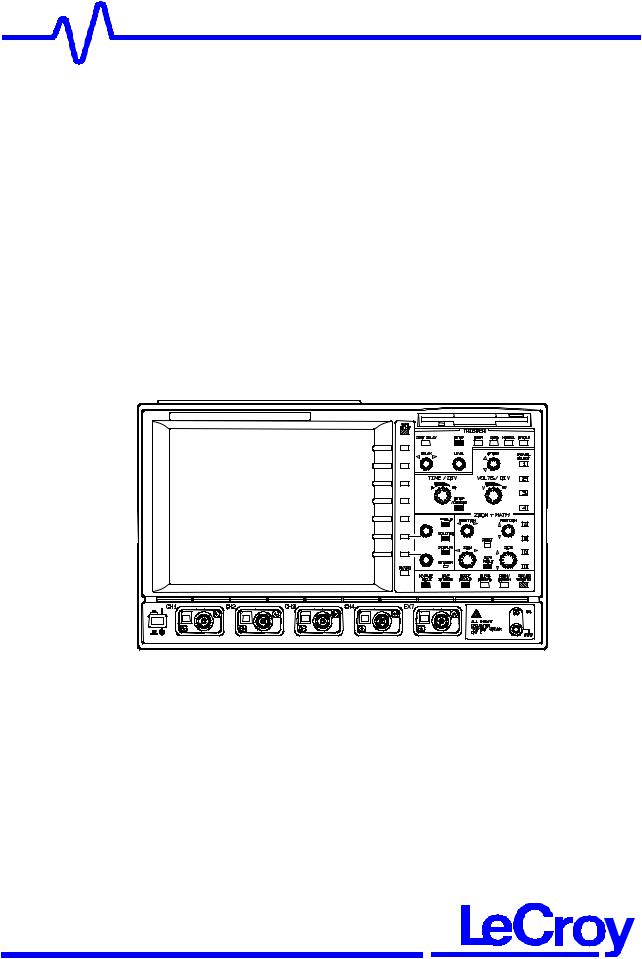

LeCroy waverunner

LT Series

Service Manual

Version A- October 1999

LeCroy Corporate Headquarters

700 Chestnut Ridge Road

Chestnut Ridge, NY 10977-6499

USA

Tel : (914) 425-2000

Fax : (914) 425-8967

http://www.lecroy.com

Copyright © October 1999. LeCroy is a registered trade-mark of LeCroy Corporation. All rights reserved. Information in this publication supersedes all earlier versions. Specifications subject to change.

Read this First

1.Warranty and Product Support

It is recommended that you thoroughly inspect the contents of the oscilloscope packaging immediately upon receipt. Check all contents against the packing list/invoice copy shipped with the instrument. Unless LeCroy is notified promptly of any missing or damaged item, responsibility for its replacement cannot be accepted. Contact your nearest LeCroy Customer Service Center or national distributor immediately (see chapter 2 for contact numbers).

1.1Warranty

LeCroy warrants its oscilloscope products for normal use and operation within specifications for a period of three years from the date of shipment. Calibration each year is recommended to ensure in-spec. performance. Spares, replacement parts and repairs are warranted for 90 days. The instrument's firmware has been thoroughly tested and is thought to be functional, but is supplied without warranty of any kind covering detailed performance. Products not made by LeCroy are covered solely by the warranty of the original equipment manufacturer.

Under the LeCroy warranty, LeCroy will repair or, at its option, replace any product returned within the warranty period to a LeCroy authorized service center. However, this will be done only if the product is determined after examination by LeCroy to be defective due to workmanship or materials, and not to have been caused by misuse, neglect or accident, or by abnormal conditions or operation.

1.2Product Assistance

Note: This warranty replaces all other warranties, expressed or implied, including but not limited to any implied warranty of merchantability, fitness, or adequacy for any particular purpose or use. LeCroy shall not be liable for any special, incidental, or consequential damages, whether in contract or otherwise. The client will be responsible for the transportation and insurance charges for the return of products to the service facility. LeCroy will return all products under warranty with transport prepaid.

Help on installation, calibration, and the use of LeCroy equipment is available from the LeCroy Customer Service Center in your country.

1.3Maintenance Agreements

LeCroy provides a variety of customer support services under Maintenance Agreements. Such agreements give extended warranty and allow clients to budget maintenance costs after the initial three-year warranty has expired. Other services such as installation, training, enhancements and on-site repairs are available through special supplemental support agreements.

1.4Staying Up to Date

LeCroy is dedicated to offering state-of-the-art instruments, by continually refining and improving the performance of LeCroy products. Because of the speed with which physical modifications may be implemented, this manual and related documentation may not agree in every detail with the products they describe. For

Read this First 1-1

example, there might be small discrepancies in the values of components affecting pulse shape, timing or offset, and — infrequently — minor logic changes. However, be assured the scope itself is in full order and incorporates the most up-to-date circuitry. LeCroy frequently updates firmware and software during servicing to improve scope performance, free of charge during warranty. You will be kept informed of such changes, through new or revised manuals and other publications.

Nevertheless, you should retain this, the original manual, for future reference to your scope’s unchanged hardware specifications.

1.5Service and Repair

Please return products requiring maintenance to the Customer Service Department in your country or to an authorized service facility. The customer is responsible for transportation charges to the factory, whereas all in-warranty products will be returned to you with transportation prepaid. Outside the warranty period, you will need to provide us with a purchase order number before we can repair your LeCroy product. You will be billed for parts and labor related to the repair work, and for shipping.

1.6How to return a Product

Contact the nearest LeCroy Service Center or office to find out where to return the product. All returned products should be identified by model and serial number. You should describe the defect or failure, and provide your name and contact number. In the case of a product returned to the factory, a Return Authorization Number (RAN) should be used.

Return shipments should be made prepaid. We cannot accept COD (Cash On Delivery) or Collect Return shipments. We recommend air-freighting.

It is important that the RAN be clearly shown on the outside of the shipping package for prompt redirection to the appropriate LeCroy department.

1.7What Comes with Your Scope

The following items are shipped together with the standard configuration of this oscilloscope:

∙Front Scope Cover

∙10:1 10 MΩ PP006 Passive Probe — one per channel

∙Two 250 V Fuses, AC Power Cord and Plug

∙Operator’s Manual , Remote Control Manual, Hands-On Guide

∙Performance Certificate or Calibration Certificate, Declaration of Conformity

Note: Wherever possible, please use the original shipping carton. If a substitute carton is used, it should be rigid and packed so that that the product is surrounded by a minimum of four inches or 10 cm of shock-absorbent material.

minimum of four inches or 10 cm of shock-absorbent material.

1-2 Read this First

2.General Information

2.1Product Assistance

Help on installation, calibration, and the use of LeCroy equipment is available from your local LeCroy office, or from LeCroy’s

∙ Customer Care Center, 700 Chestnut Ridge Road, Chestnut Ridge,

New York 10977–6499, U.S.A., tel. (914) 578–6020 |

|

∙ European Service Center, 2, rue du Pré-de-la-Fontaine, 1217 Meyrin 1, |

Geneva |

Switzerland, tel. (41) 22/719 21 11. |

|

∙LeCroy Japan Corporation, Sasazuka Center Bldg – 6th floor, 1-6, 2-Chome, Sasazuka, Shibuya-ku, Tokyo Japan 151-0073, tel. (81) 3 3376 9400

2.2Installation for Safe and Efficient Operation Operating Environment

For safe operation of the instrument to its specifications, ensure that the operating environment is maintained within the following parameters:

Temperature ............. |

5 to 40 °C (41 to 104 °F) rated. |

Humidity.................... |

Maximum relative humidity 80 % RH (non-condensing) for |

|

temperatures up to 31 °C decreasing linearly to 50 % relative |

|

humidity at 40 °C |

Altitude...................... |

< 2000 m (6560 ft) |

The oscilloscope has been qualified to the following EN61010-1 category:

Installation (Overvoltage) Category ........................ |

II |

|

Protection Class......................... |

… ........................ |

I |

Pollution Degree ........................ |

............................ |

2 |

General Information 2-1

Safety Symbols

Where the following symbols or indications appear on the instrument’s front or rear panels, or elsewhere in this manual, they alert the user to an aspect of safety.

.......................... |

CAUTION: Refer to accompanying documents (for Safety- |

|

related information). See elsewhere in this manual wherever |

|

the symbol is present. |

.......................... |

CAUTION: Risk of electric shock |

x........................... |

On (Supply) |

Standby (Supply) |

............................Earth (Ground) Terminal

............................Earth (Ground) Terminal

...................... Alternating Current Only

...................... Alternating Current Only

........................ Chassis Terminal

............................ |

Earth (Ground) Terminal on BNC Connectors |

WARNING................. |

Denotes a hazard. If a WARNING is indicated on the |

|

instrument do not proceed until its conditions are |

|

understood and met. |

WARNING |

|

Any use of this instrument in a manner not specified by the manufacturer

may impair the instrument’s safety protection.

2-2 General Information

The oscilloscope has not been designed to make direct measurements on the human body. Users who connect a LeCroy oscilloscope directly to a person do so at their own risk. Use only indoors.

Power Requirements

The oscilloscope operates from a 100 V to 240V AC power source at 50 Hz to 60 Hz.

No voltage selection is required, since the instrument automatically adapts to the line voltage present.

Fuses

The power supply of the oscilloscope is protected against short-circuit and overload by means of two 6.3 A/250 V AC “T”-rated fuses, located above the mains plug.

Disconnect the power cord before inspecting or replacing a fuse. Open the fuse box by inserting a small screwdriver under the plastic cover and prying it open. For continued fire protection at all line voltages, replace only with fuses of the specified type and rating (see above).

Ground

The oscilloscope has been designed to operate from a single-phase power source, with one of the current-carrying conductors (neutral conductor) at ground (earth) potential. Maintain the ground line to avoid an electric shock.

None of the current-carrying conductors may exceed 250 V rms with respect to ground potential. The oscilloscope is provided with a three-wire electrical cord containing a three-terminal polarized plug for mains voltage and safety ground connection. The plug's ground terminal is connected directly to the frame of the unit. For adequate protection against electrical hazard, this plug must be inserted into a mating outlet containing a safety ground contact.

Cleaning and Maintenance

Maintenance and repairs should be carried out exclusively by a LeCroy technician. Cleaning should be limited to the exterior of the instrument only, using a damp, soft cloth. Do not use chemicals or abrasive elements. Under no circumstances should moisture be allowed to penetrate the disk drive analyzer. To avoid electric shocks, disconnect the instrument from the power supply before cleaning.

CAUTION

CAUTION

Risk of electrical shock: No user-serviceable parts inside. Leave repair to qualified personnel.

General Information 2-3

Power On

Connect the oscilloscope to the power outlet and switch it on using the power On/Standby button, located near the left-hand corner of the instrument below the screen. After the instrument is switched on, auto-calibration is performed and a test of the disk drive analyzer's ADCs and memories is carried out. The full testing procedure takes approximately 10 seconds, after which time a display will appear on the screen.

2-4 General Information

Specifications

Specifications

3.Instrument Architecture Overview

PROCESSORS

The Waverunner central processor (CPU), a PowerPCä microprocessor, performs the oscilloscope’s computations and controls its operation. A range of peripheral interfaces allow you to control remotely, store waveforms and other data, and make hard copies. A support processor constantly monitors the front-panel controls. Waverunner either transfers data to display memory for direct waveform display, or stores it to reference memories, for fast data-processing.

ADCs

Each Waverunner channel has an eight-bit Analog-to-Digital Converter (ADC). The instrument’s ADC architecture is designed to give excellent amplitude and phase correlation, maximum analog-to-digital conversion performance, large record lengths and superior time resolution.

MEMORIES

Waverunner acquisition memories simplify signal acquisition by producing waveform records that allow detailed analysis over large time intervals. There are four memories for temporary storage, and four more for waveform zooming and processing.

RIS

The Waverunner oscilloscope captures and stores repetitive signals at a maximum Random Interleaved Sampling (RIS) rate of 25 GS/s. This advanced digitizing technique enables measurement of repetitive signals with an effective sampling interval of 40 ps, and a measurement resolution of up to 5 ps.

TRIGGER SYSTEM

You can control Waverunner triggering to a highly specialized degree in accordance with waveform characteristics and chosen trigger conditions. The trigger source can be any of the input channels, line (synchronized to scope’s main input supply) or external. The coupling is selected from AC, LF REJect, HF REJect, HF, and DC; the slope from positive and negative. Waverunner SMART Trigger offers a wide range of sophisticated trigger modes matched to special trigger conditions and sets of conditions.

AUTOMATIC CALIBRATION

Waverunner automatic calibration ensures an overall vertical accuracy of typically 1 % of full scale. Vertical gain and offset calibration, and horizontal (time) resolution take place each time you change the volts per division setting. Periodic and temperature-dependent auto-calibration ensures long-term stability at the current setting.

Specifications 3-1

DISPLAY SYSTEM

You control the display’s interactive, user-friendly interface using push-buttons and knobs. Display as many as eight different waveforms at once on eight separate grids. The parameters controlling signal capture are simultaneously reported. The Waverunner display presents internal status and measurement results, as well as operational, measurement, and waveform-analysis menus.

The 8.4-inch color flat-panel TFT-LCD screen presents waveforms and data using advanced color management. Overlap-mixing and contrast-enhancement functions ensure that overlapping waveforms remain distinct at all times. Both pre-set and personal color schemes are available.

The Analog Persistence function offers display attributes of an analog instrument with all the advantages of digital technology. The Full Screen function expands waveform grids to fill the entire screen.

A hard copy of the screen can be easily produced by pressing the front-panel PRINT SCREEN button.

INTERFACE AND PANEL SETUPS

Although Waverunner is a truly digital instrument, the front-panel layout and controls are similar to an analog oscilloscope’s. Rapid response and instant representation of waveforms on the high-resolution screen add to this impression. Four front-panel setups can be stored internally and recalled either directly or by remote control, thus ensuring rapid front-panel configuration. When power is switched off, the current front-panel settings are automatically stored for subsequent recall at the next power-on.

REMOTE CONTROL

Waverunner has also been designed for remote control operation in automated testing and computer-aided measurement applications. You control the entire measurement process — including cursor and pulse-parameter settings, dynamic modification of front-panel settings, and display organization — through the rearpanel industry-standard GPIB (IEEE-488) and standard RS-232-C ports. See this manual’s Chapter 12, Use Waverunner with PC, and the Remote Control Manual.

3-2 Specifications

|

BLOCK DIAGRAM: Hi-Z, 50 W Amplifiers + Attenuators |

|

|||

|

|

|

|

Optional Storage |

|

|

Sample |

|

Fast |

Devices |

|

CH1 |

8-Bit ADC(s) |

|

|||

& Hold |

memory |

Floppy Disk |

|||

|

|

||||

|

|

|

|

Interface |

|

CH2 |

Sample |

8-Bit ADC(s) |

Fast |

Centronics |

|

& Hold |

memory |

||||

|

|

||||

|

|

|

|

RS-232-C |

|

External |

|

|

|

|

|

Trigger |

Trigger |

Timebase |

|

GPIB |

|

|

Logic |

|

|

||

|

|

|

|

||

|

|

|

|

Power PC |

|

|

|

|

|

Microprocessor |

|

|

|

|

|

with Integrated |

|

CH3 |

Sample |

8-Bit ADC(s) |

Fast |

Cache Memory |

|

|

|||||

& Hold |

memory |

|

|||

|

|

Front-Panel |

|||

|

|

|

|

||

CH4 |

Sample |

8-Bit ADC(s) |

Fast |

Processor |

|

|

|||||

& Hold |

memory |

|

|||

|

|

Real-Time |

|||

|

|

|

|

||

|

|

|

|

Clock |

|

|

|

|

Display |

Data Memories |

|

|

|

|

Processor |

||

|

|

|

|

||

|

|

|

|

Program Memory |

|

Specifications 3-3

Specifications

MODELS

Waverunner LT342/322 Series: Two channels

Waverunner LT344 Series: Four channels

ACQUISITION SYSTEM

Bandwidth (− 3dB): LT342/LT344/LT322:500 MHz;LT224:200 MHz @ 50 Ω and at probe tip with PP006

Bandwidth Limiter at 25 MHz and 200 MHz can be selected for each channel LT224 is 25MHz.

Input Impedance: 50 Ω ± 1.0 %; 1 MΩ ± 1.0 % // 16 pF typical

Input Coupling: 1 MΩ: AC, DC, GND; 50 Ω: DC, GND

Max Input: 50 Ω: 5 Vrms; 1 MΩ: 400 V max (peak AC <-5 kHz + DC)

Single Shot Sampling Rate: 500 MS/s

Acquisition Memory: LT342/LT344;250 000 points per channel; 1 M points per channel on L modelsLT224/LT322; 100 000

Vertical Resolution: 8 bits

Sensitivity: 2 mV–10 V/div

Offset Range:

Ø2 mV–99 mV/div: ± 1 V

Ø100 mV–0.99 mV/div: ± 10 V

Ø1 V–10 V/div: ± 100 V

ACQUISITION MODES

|

|

|

|

|

MODE |

TIME BASE SETTING |

MAXIMUM RATE |

DESCRIPTION |

|

|

|

|

|

|

Single Shot |

|

|

|

|

|

|

|

|

|

LT342(L)/LT344(L) |

10 ns to 1000 s/div |

500 MS/s |

One ADC per channel |

|

|

|

|

||

LT224/LT322 |

20 ns to 1000 s/div |

200 MS/s |

||

|

||||

|

|

|

|

|

|

|

|

|

|

Repetitive |

|

|

|

|

|

|

|

|

|

LT342(L)/LT344(L) |

1 ns to 5 μsec/div |

25 GS/s |

Random Interleaved |

|

|

|

|

||

LT224/LT322 |

1 ns to 10 μsec/div |

10 GS/s |

Sampling (RIS) |

|

|

||||

|

|

|

|

|

Sequence Mode |

|

|

|

|

|

|

|

|

3-4 Specifications

|

|

|

|

Stores Multiple Events |

|

LT342/LT344 |

2–1000 segments |

500 MS/s |

with time stamp in |

|

segmented acquisition |

|||

|

|

|

|

|

|

|

|

|

memories |

|

LT224/LT322 |

2–400 segments |

200 MS/s |

Stores Multiple Events |

|

|

|

|

with time stamp in |

|

LT342L/LT344L |

2–4000 segments |

500 MS/s |

segmented acquisition |

|

memories |

|||

|

|

|

|

|

|

|

£500 000 pts: |

|

Waveform slowly rolls |

|

Roll Mode |

500 ms–1000s/div |

100 ks/s |

across display when |

|

³ 500 000 pts: |

used with slow time |

||

|

|

|

||

|

|

1 s–1000s/div |

|

bases. |

|

|

|

|

|

TIMEBASE SYSTEM

Timebases: Main and up to four zoom traces simultaneously

Time/Div Range: 1 ns/div to 1000 s/div

Clock Accuracy: £10 ppm

Interpolator Resolution: 5 ps

External Clock: £500 MHz, 50 W, or 1 MW impedance

TRIGGERING SYSTEM

Modes: NORMAL, AUTO, SINGLE and STOP

Sources: Any input channel, External, EXT 10 or line; slope, level and coupling are unique to each source (except line trigger)

Coupling Modes: DC(DC to 250MHz/LT224; DC to 200MHz), AC(Applox.7.5Hz to 250MHz/LT224; Approx.7.5Hz to 200MHz), HF(to 500MHz/LT224 not have), HFREJ, LFREJ (reject frequency 50 kHz typical)

Pre-Trigger Recording: 0–100 % of horizontal time scale

Post Trigger Delay: 0–10 000 divisions

Holdoff by Time or Events: Up to 20 s or from 1 to 99 999 999 events

Internal Trigger Range: ±5 div

Maximum Trigger Frequency: Up to 500 MHz with HF coupling

External Trigger Input: ±0.5 V, ±5 V with Ext 10; max input same as input channels

SMART TRIGGER TYPES

Signal or pulse width: Triggers on glitches down to 2 ns(LT224 is 3ns). Pulse widths are selectable between < 2.5 ns to 20 s.

Signal interval: Triggers on intervals selectable between 10 ns and 20 s.

Specifications 3-5

TV: Triggers on line (up to 1500) and field 1 or 2 (odd or even) for PAL (SECAM), NTSC, or non-standard video.

State/Edge qualified: Triggers on any input source only if a given state (or transition) has occurred on another source. Delay between sources is selectable by time or number of events.

Dropout: Triggers if the input signal drops out for longer than a selected time out between 25 ns and 20 s.

AUTOSETUP

Automatically sets timebase, trigger, and sensitivity to display a wide range of repetitive signals.

Vertical Find: Automatically sets sensitivity for the selected input signal

PROBES

Model PP006: PP006 with auto-detect: 10:1, 10 MΩ; one probe per channel

Probe System: ProBus Intelligent Probe System supports active, high-voltage, current, and differential probes, and differential amplifiers

COLOR WAVEFORM DISPLAY

Type: Color 8.4-inch flat-panel TFT-LCD with VGA, 640 x 480 resolution

Screen Saver: Display blanks after 10 minutes

Real Time Clock: Date, hours, minutes, and seconds displayed with waveform

Number of Traces: Maximum eight on LT344/LT224 Series, six on LT342/LT322 Series; simultaneously display channel, zoom, memory, and math traces

Grid Styles: Single, Dual, Quad, Octal, XY, Single+XY, Dual+XY; Full Screen gives enlarged view of each style

Waveform Display Styles: Sample dots joined or dots only — regular or bold

ANALOG PERSISTENCE DISPLAY

Analog Persistence and Color Graded Persistence: Variable saturation levels; stores each trace’s persistence data in memory

Trace Display: Opaque or transparent overlap

ZOOM EXPANSION TRACES

Style: Display up to four zoom traces

Vertical Zoom: Up to 5x expansion, 50x with averaging

Horizontal Zoom: Expand to 2 pts/div, magnify to 50 000x

Autoscroll: Automatically scan and display a captured signal

RAPID SIGNAL PROCESSING

Processor: Power PC 603eTM

3-6 Specifications

|

LT342/LT322 |

|

LT344/LT224 |

|

LT342L |

|

|

LT344L |

|

2.1.1 16 Mbytes |

|

2.1.2 16 Mbytes |

|

2.1.3 32 Mbytes |

2.1.4 |

32 Mbytes |

|

|

|

|

|

|

|

|

|

|

|

64 MBYTE SYSTEM MEMORY OPTIONAL FOR ALL MODELS |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INTERNAL WAVEFORM MEMORY

Waveform: M1, M2, M3, M4; memory length equal to acquisition memory

Zoom and Math: A, B, C, D; memory length equal to acquisition memory

Memories M1–4 and A–D store full-length waveforms with 16 bits/data point

SETUP STORAGE

For front panel and instrument status: Four non-volatile memories and floppy drive are standard; hard drive and memory card are optional

MATH TOOLS

Simultaneously perform up to four math processing functions; traces can be chained together to perform math on math. Standard functions: add, subtract, multiply, divide, negate, identity, summation, averaging to 1000 sweeps, ERES low-pass digital filters for 11-bit vertical resolution, FFT of 50 kpoint waveforms, Extrema for displaying envelope roof and floor, physical units, rescale (with units), sin x/x, resample (deskew).

MEASURE TOOLS

Cursor Measurements:

ØRelative Time: Two arrow-style cursors measure time and voltage differences relative to each other with a resolution of ± 0.05 % full scale.

ØRelative Amplitude (Voltage): Two horizontal bars measure voltage differences at

± 0.2 % fs resolution.

ØAbsolute Time: Cross-hair marker measures time relative to trigger and voltage with respect to ground.

ØAbsolute Amplitude (Voltage): A horizontal reference line cursor measures voltage with respect to ground.

Automated Measurements: Display any five parameters together with their average, high, low and standard deviations.

Pass/Fail: Test any five parameters against selectable thresholds. Limit testing is performed using masks created on the scope or on a PC. Setup a pass or fail condition to initiate actions such as hardcopy output, save waveform to memory, GPIB SRQ, or pulse out.

EXTENDED MATH AND MEASUREMENTS OPTION

Adds math and advanced measurements for general-purpose applications. Math Tools is expanded to include all standard math plus integration, derivative, log and exponential (base e and base 10), square, square root, absolute value, plus data log when using the trend function.

Specifications 3-7

WAVEANALYZER OPTION

Adds math processing to include FFTs of 1 Mpoint waveforms, power spectrum density, spectrum averaging, waveform averaging to one million sweeps, continuous averaging, waveform histograms, and histogram parameters. Includes the Extended Math and Measurement option.

SPECIAL APPLICATION SOLUTIONS

Jitter and Timing Analysis (JTA): Precision cycle-to-cycle timing measurements with enhanced accuracy, histograms on persistence traces, persistence to waveform tracing and full statistical analysis.

PowerMeasureä : A complete solution for the power conversion engineer. Includes timing deskew of voltage and current, and rescale to electrical units.

INTERFACE

Remote Control: Full control via GPIB and RS-232-C

Floppy Drive: Internal, DOS-format, 3.5" high-density

PC Card Slot: Supports memory and hard drive cards

External Monitor Port: 15-pin D-Type VGA-compatible

Centronics Port: Parallel printer interface

Internal graphics printer (optional): 25 mm/s max, 112 mm paper width; provides hardcopy output in <10 seconds

OUTPUTS

Calibrator signal: 500 Hz–1 MHz square wave, − 1.0 to +1.0, test point, and ground lug on front panel

Control signals: Choice of trigger ready, trigger out, or Pass/Fail status; TTL levels into 1 MΩ at rear panel BNC (output resistance 300 Ω ± 10 %)

GENERAL

GENERAL

Operating Conditions: Temperature 5–40°C; humidity 80 % non-condensing at 40°C; altitude ≤2000 m

Shock and Vibration: Conforms to MIL-PRF-28800P; Class C

Power Requirements: 90–132 V AC and 180–250 V AC; 45–66 Hz; maximum power dissipation 150 VA–230 VA, depending on model

Certifications: CE, UL and cUL

Dimensions (HWD): 210 mm x 350 mm x 300 mm (8.3" x 13.8" x 11.8"); height excludes scope feet

Weight: 8 kg (18 lbs)

Warranty and Calibration: Three years; calibration recommended yearly

3-8 Specifications

Theory of

of Operation

Operation

4.Theory of Operation

4.1Processor Board

MPC603e Processor

The PowerPC603e on the processor board is a 4-bit RISC processor having 2x32Kbyte cache and features high speed processing and quick memory access. The processor is designed to operate with an internal clock which is several times the external bus clock cycles and is used under the 32bit mode.

The board consists of two circuit-blocks:

•The 32bit block, that contains the main PowerPC processor, dynamic RAM modules, VGA interface, Super-I/O and main board interface.

•The 8bit block, which incorporates all peripherals and other interfaces for outer connections.

These two circuit-blocks are connected through MC68150 (dynamic bus sizer).

Power Supply

The board requires two power sources (Vcc and +12V). +12V source is used for OP-amp and small-peripheral operation.

The processor requires 3.3V, and all other logic devices are operated by the +5V source. All of the signals are TTL compatible.

The processor allows +5V input signals and does not require logic level conversion. An OP-amp and MOSFET transistor consist of 3.3V power source. The reference voltage is taken through the voltage-resistor divider network across +5V power source.

32bit Peripherals

There are six devices hooked on the processor’s 32bit data bus:

•VGA video controller

•DRAM system

•bus sizer, an interface to 8bit circuit-block

•DMA controller

•Super-I/O

•MAIN board

Theory of Operation 4-1

CPU’s Block Diagram

CPU:PowerPC 603e

DRAM:2X128MB max

DMAC:71071

Super I/O

RS232C, Parallel, Floppy Disk

MAIN Board I/F

VGA:65545

BUS Sizer:MC68150

Flash PROM: 2MBmax

32bit BUS

NVRAM:128KB

Real Time Clock

Interrupt Controller

Front Panel I/F

GP-IB

Internal Printer I/F

Small Peripherals

PCMCIA type I/II/III

Other Control Ports

8bit BUS

4-2 Theory of Operation

DRAM

The DRAM circuit consists of one or two SIMM modules, constituting from 16MB to a maximum of 128 MB. The SIMM modules to be supported are only of EDO types. The DRAM control circuit is built with one piece each of CPLD and GAL, and several gate ICs.

The DRAMC (IC13) located on the main control circuit, generates all types of bus cycle timing(normal R/W, 2-beat/8-beat bursts of R/W), refresh cycles, and DMA cycles. It also generates signals for automatic increment of column-addresses to be used in burst transfer mode. Furthermore, the DRAMC has a register for setting one or two SIMMs and determining SIMM size (whether it is less than 32MB or more than 64MB), in order to adjust the memory mapping so as not to have gaps in memory mapping according with the memory capacity.

The CAS (IC14) distributes signals for column address selection to the CAS signal circuits of each SIMM chip. CAS is selected by the size of memory access (1, 2, 3, and 4 bytes), accessing start-address, and type of bus cycles (normal, burst, refresh and DMA).

Two multiplexers (IC9 and IC10) switch the address lines of odd and even addresses to be connected with the address lines of each SIMM. The other multiplexer (IC11) switches low order address bits, i.e., routing them either directly to the processor or to the low order address generated in DRAMC.

Normal Access Timing

This is the simplest access possible: the processor puts an address onto the address bus and reads or writes the required data out of or to the DRAM which corresponds with the bus.

The bus width is 32bits, or 4bytes wide, and the CPU performs to read or write operations (of one through four bytes) which are chained in a bus cycle.

Burst Access Timing

A burst access, on the 603e configured with 32bit device operation, performs either two or eight successive reads in DRAM (2-beat or 8-beat burst access). The idea is to put the beginning of an address onto the address bus and read/write data out of or to DRAM every clock cycle, without incrementing the address required by the processor (this is to be achieved by the external logic circuit). Using EDO-DRAM enables to read and write every 30ns of clocks similarly as with one or two SIMMs. The 8-beat access is indicated by an active “low” of NTBST signals and a 32bit access signal (SIZ2..0=011), and the 2-beat access is indicated by an active “high” of NTBST signals and an access size of 64 bits (SIZ2..0=100).

Refresh Timing

The 32 KHz clock from the RTC chip is used to generate the timing to refresh DRAM. Without this clock, the DRAM would not be refreshed and all the data in it would be erased out. DRAMC detects the rising edge and the falling edge of this 32KHz clock. At the each edge, it generates the CAS before RAS refreshes the cycles.

The arbitration logics between other accesses (bus cycle with the processor and DMA cycle) and refresh cycles reside in the DRAMC.

DMA Timing

The DMA access can be used for data transfer to and from floppy disks.

Theory of Operation 4-3

The data is transferred in between the I/O and DRAMs by simultaneously accessing the desired addresses in the Super I/O and DRAMs.

The addresses A0 to A25 (as well as lower addresses up to 64MB on the memory map) can be accessed through the DMA controller. Since the Super I/O is directly connected to its 8bit to 32bit bus without passing through the bus sizer, data transfer can be done only to and from memory areas in which addresses are divided by intervals of 4bytes each.

Memory Mapping

When the main switch is on, the internal software automatically sets the system’s memory size to the largest capacity available with the SIMM mounted (2 pieces of 128 MB SIMM size). It also checks whether all the addresses are perennial or not to prevent having "holes" in the address space. Through this operation, available memory capacity in the SIMM mounted is correctly judged and the capacity information is stored again into the DRAMC register. Thus, all the address spaces are assured for perennial address continuation.

VGA controller

The VGA controller chip 65545(IC29) contains the logic circuits to decode its own addresses. It generates all the video signals (RGB, H/V, and all control lines to drive the flat panel), and controls its associated 1 MB video DRAM (to read, write and refresh).

The total of video DRAMs mounted are two pieces of 2MB (but 512KB each of the DRAM only are used).

All timings are extracted from the 16MHz bus clock; therefore, no external crystal or time-base is required. The horizontal and vertical synchronization signals are sent to the external video connector (a half pitch, D-SUB15 pin connector is used).

The 65545 chip can support several bus interfaces (PCI, ISA, VL, etc), the system employs it for VL-bus applications with the mode of 256-color palette operations. The controller has an 18bit color palette and can display 256 colors out of the available 260,000. However, the liquid crystal panel can only use 12-bit color data, and color display is limited to 256 out of 4,096 colors (the color data will be extended to 18bits in the future).

The power supply circuit for the liquid crystal panel has a MOSFET switch that turns the power for the LCD with the reset signal, since the LCD needs to minimize its start-up time.

Super-I/O

This device controls RS-232Cs, floppy disks, and parallel port operations. The controller has its own time-base with a 24MHz crystal. RS-232C can be used by simply connecting the MAX232 buffer (IC31) to it. Since the Super I/O chip has a 16-byte buffer, high speed data transfer is easily carried out.

A 2HD disk drive can be directly connected to the system without any external components other than a piece of pull-up resistor; it can be operated in either interruption mode or DMA mode.

The parallel interface is also activated without other external components other than a piece of pull-up resistor, for the use of 2-way communication.

This IC chip has an IDE interface function in it, but this board does not support the function.

4-4 Theory of Operation

Bus Control

The DEC32 (IC17) performs decoding operations for the circuits (32bit circuit block) which are directly connected to the processor (except the DRAM).( The DRAMC performs decoding operations for the DRAMs).

The RW32 (IC76) generates the control signals of read/write for the devices associated with the DMA, and the byte enable signals (NBE0-3) for the VGA controller.

When the bus cycle starts, 603e must terminate the bus cycle by returning signals after acknowledging each of the data and addresses, from the outside. The ACK32 (IC19) is used to generate the acknowledgement signals.

The ARBT (IC18) has logics for arbitration between the DMA and processor accessing, and performs forced termination of the bus operation when the bus cycle can not be finished within a defined time.

The ACK8 (IC21) has logics for generation of the acknowledgement signals and read write strobe signals in the 8bit peripheral circuit block.

The DEC8 (IC22) has logics for decoding 8bit peripheral circuits, and a certain circuit involved in the address latch operation.

Bus Sizer

The MPC603e processor does not support dynamic bus sizing, which is performed with the 68K processor family. Each 8bit of a 32bit bus is fixed or assigned with the lower addresses, or 0 through 3 bits. Therefore, if an 8bit device were directly connected to the bus, this device would be seen in 4byte steps each in the memory map area. To avoid this, the 8bit-bus peripheral unit shall be connected to the 32bitbus through the bus sizer, MC68150 (IC15). The bus sizer divides one bus cycle for accessing 32 bit-bus of the processor into four cycles each of 8bit accessing cycle, and/or assigns 8bit-bus data to a corresponding 8bits within the 32bits.

8bit Peripherals

The following devices are listed as 8bit data bus units:

•PCMCIA Interface

•Flash PROM

•NVRAM

•RTC

•Interrupt Controller

•GPIB Interface

•Small-peripherals Interface

•Internal printer Interface

•Front-Panel I/F

•Other registers and ports

PCMCIA, type I/II/III interface

This interface consists mainly of buffers for both data and address busses.

The CARD (IC71) generates the control signals both for memory card mode and I/O card mode.

The IC65 (D-F/F) holds control bits for the signals resetting the card, switching between the data area and the attribute area, and switching the card’s modes. All bits in the register are reset to zero when the _RESET signal goes to active low,

Theory of Operation 4-5

which means that their state is also guaranteed at power-up.

The IC66 and the IC67 invert the most significant address bits of the memory card whenever the SWAP jumper is plugged in, so that the first bytes are always allocated to “FFF00000”, regardless of the size of the memory card. This allows to boot directly from the PCMCIA memory card used.

Flash PROM

Two pieces of the Intel’s 29F008-compatible 1MB PROMs (IC45 and 46) are used to operate in the 8-bit bus mode. These ICs do not require any programming voltage to write.

From a hardware point of view, a flash PROM is regarded the same as an EPROM in read mode.

To erase or write to memory, commands are written into the data bus. Writing and erasing must be performed over monitoring the status-signals (RY/#BY) on the port (IC49).

The program may be seen to start from the Flash PROM. The Flash PROM is, however, not regarded as the program or its program area even when start-up (even when the screen appears) is completed, because the program must be processed in the DRAM after transferring the program content from the Flash PROM into the DRAM.

NVRAM

This memory chip is powered from the VCCO in the RTC. When the main power is set to off, the required power for the NVRAM is fed through the lithium battery installed. When the power is set to on, it is powered from the VCC.

The #CS1 signals are also controlled through the RTC. When the main power is set to off, the RTC sets the chip select to the “high” level through a pull-up resistor to place the SRAM a power-down mode to prevent any accidental overwriting.

RTC

The DS1689 real time clock has several functions:

•Keeping the time-of-day and current-date information while power is off.

•Generating 32KHz clock for DRAM refreshment.

•Giving 128Hz of periodic interrupt signals to force bus accessing from the processor and allowing periodic updating of the time display.

•Providing a unique ID that identifies the origination of scope ID.

•Feeding the power and the chip select signal to the NVRAM.

The chip generates timing clocks necessary for time keeping and driving all other circuits by connecting to 32.768KHz crystal. A few discrete components around it leave the chip powered, when the system is set to off, by the backup lithium battery while the rest of the board is not powered, and charge the battery when the power is on again.

Accesses from the processor are done through the circuit for the bus separation, for addresses and data are multiplexed.

The unique ID was already written in the RTC by the manufacturer, since every different value must be stored in each chip.

Interrupt Controller

4-6 Theory of Operation

In order to prioritize and control several interrupt sources, it is necessary to use an IC of uPD71059. It scans eight interrupt signals and sends a unique interrupt signal to the processor when an (unmasked) interrupt signal appears.

Interrupt levels are assigned as follows:

level 0 |

(lowest priority) FDC |

level 1 |

small peripherals |

level 2 |

RS232C |

level 3 |

GP-IB |

level 4 |

PCMCIA(I/O card mode) |

level 5 |

real time clock |

level 6 |

the MAIN board |

level 7 |

(highest priority) unused |

The priority in the above can be changed by the software.

Small Peripheral Interface

This 8-bit interface is intended to allow external expansion of the board in addition to the processor board.

The tri-state buffers drive the address and control lines, and bi-directional buffers drive data lines.

The address decoding is processed on each expanded peripheral board. Since the acknowledgement toward each access is also returned by the expanded board, there is no restriction to the amount of wait-states.

The bus clock runs at 16MHz, and a reset line reinitializes the boards as does in the CPU.

Four interrupt lines are also included in this interface, so that interrupt-driven boards can be used.

Front Panel

The front panel is accessed by serial read/write signals passing through the IC47 and IC48.

The CPU board can be reset by resetting the 3 buttons on the front panel. This function becomes effective by setting a bit of IC52 for enabling.

Both LED and BEEP are activated by serial writing. LED and BEEP are initialized off by the resetting operation.

Theory of Operation 4-7

Reset Circuit

The power supply is monitored by the IC4 chip. Whenever the Vcc goes below 4.5V (even for a very short time), a reset pulse, in which the width is determined by the C6’s capacity, is generated.

Resetting 3 buttons on the front panel also causes to generate the reset pulse as did in the IC4 when the supply power voltage fell too low.

Bus Error Generation

The 603e expects NTA and NAACK signals for the acknowledgement to the current bus cycle, and inserts wait states during the period NTA and NAACK are kept at “high” levels (any of external devices have not caused to lower the levels). As long as any of the devices does not return the acknowledgement, the bus is to be kept forever in this wait-condition. Then, an external circuit may be required to generate a bus-error signal to break the pending cycle after a given time-out.

The bus error is generated by pulling the NTEA pin of the CPU down to “low”. This is the job done by the GAL (ARBT:IC18) which counts the number of wait-states that have already passed through the counter (IC25). An external 8bit counter (IC18) extends the count to 128 wait-cycles with the 8MHz clock (125ns x128 =16us) before triggering the bus error. With this operation, the system can successfully force the terminate of the current cycle.

Some devices, such as the VGA video controller, have their own logic to generate bus error. Therefore, any access operation for such devices is not entirely related to this circuit.

GPIB Interface

The NEC 7210-compatible device, NAT7210, is employed as the controller, and the TI’s conventional drivers, 75160 and 75161, are also used as the receivers.

Internal Printer Interface

Printer control is the same as for the normal Centronics interface. This circuit consists of buffers only.

Relation of I/O Structure to the associated GALs and CPLDs

The following block-diagram describes the flow in the decoder and the relationships between the acknowledgement to be returned to the CPU and GALs/CPLDs. Three-line boxes are GALs and CPLDs, and one-line boxes indicate other ICs and function blocks.

•DEC32 is the main decoder that performs the decoding operation for five devices. In this operation, however, decoding of the DRAM is excluded.

•DRAMC performs decoding of the DRAM and controls all access operations.

•CAS selects memory chips in the SIMMs according to sizes and addresses of DMA accessing.

•DEC8 is the main decoder in the 8bit-bus area, and does the decoding for three devices.

•CARD generates control signals to access PCMCIA.

•ACK32 generates ACK signals which inform the processor of the completion of bus cycle. The signals are made from the defined time after accessing each device or from the acknowledgement signal which is returned by each device.

•ACK8 informs the termination of the bus which completed within the defined time

4-8 Theory of Operation

after accessing 8bit devices. Regarding the PCMCIA and small peripherals, however, the termination can be delayed by giving an external wait signal.

The GALs which are not shown in this block-diagram are the ARBT and RW32.

•ARBT does the bus arbitration during the DMA’s execution. It also generates a bus error when the bus cycle passes over the defined time.

•RW32 controls both the RW signals when the DMA is executed and the byteenable signals for the VGA controller.

Block Diagram representing relations between I/O Decoding and Acknowledgement

VG |

|

DMA |

|

SuperI/ |

|

MAIN |

|

DRA |

CA

DEC |

DRAM |

From CPU

To CPU (Ack)

ACK32 |

BUS sizer |

DEC8 |

ACK8 |

Wa |

Wa |

PCMC  CAR

CAR

Decod

Decod

Flash

71059 GP-IB NVRAM RTC Small Peripherals

Theory of Operation 4-9

4.2Main Board

Introduction

The main board is divided into the following sections: Front End

A/D Converter & Memory Trigger

Timebase DC Generator

Calibrator & Internal Calibration signal Signal output

Main Board Control

4.2.1Front End

The front end processes an analog signal for ADC and trigger, consists of High impedance buffer, amplifier HFE428, and trigger comparator HTR420.

The main functions of the Front end without the amplifier HFE428 and HTR420 are:

•Four channels operation, calibration with Software control.

• Input protection (clamp + thermal detection) and coupling (AC, DC, 1MΩ , 50Ω ).

•Attenuator by 10 & by 100.

•Offset control.

•Offset control of ± 1V and CAL control of ± 1.4V.

• Detection of 50Ω over loading.

•Input of signal for calibration.

The main functions of HFE428 are:

Amplitude normalization for the ADC system : at the BNC the dynamic range is 16 mV to 80V FS (full scale) and the ADC/TRIG system input is 500 mV differential. Fine adjustment of gain and variable control

Band width limiter of 25MHz, 200MHz

Main function of HFE420 are:

Generation of trigger signal (analog input and digital output) with comparator Setting of trigger level (TRIG,VALIDATE)

Setting of trigger coupling (DC,AC,LFREJ,HFREJ,HF) Setting of slope (+,-,WINDOW)

Block diagram 1

4-10 Theory of Operation

Control

Relay control

The relay of the attenuator is set by selecting the input coupling and the gain as shown in the table below.

RL1, 2 and 5 are driven with +5V/0V, and RL3, 4 is driven with +5V/-5V.

Input coupling

Control port |

Relay |

GND |

1M,DC |

1M,AC |

50,DC |

|

|

|

|

|

|

GND/*MES |

RL2 |

H |

L |

L |

L |

1M/*50 |

RL1 |

H |

H |

H |

L |

AC/*DC |

RL5 |

H |

L |

H |

L |

1/*10 |

RL3 |

H |

X |

X |

X |

1/*100 |

RL4 |

L |

X |

X |

X |

Switch of attenuator

Control port |

Relay |

2mV-99mV |

100mV-0.99V |

1V-10V |

|

|

|

|

|

1/*10 |

RL3 |

H |

L |

L |

1/*100 |

RL4 |

H |

H |

L |

Divide gain

The gain ratio in each block and input range is a table below.

At the BNC the dynamic range is 16 mV to 80V FS (full scale) and the output is 500 mV differential (HAD626 input).

|

|

|

|

|

|

Range V/div |

|

|

|

|

||

Block |

2mV |

5mV |

10mV |

20mV |

50mV |

100mV |

200mV |

500mV |

1V |

2V |

5V |

10V |

ATT 1/*10 |

1 |

1 |

1 |

1 |

1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

0.1 |

ATT 1/*100 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

0.1 |

0.1 |

0.1 |

0.1 |

HFE428 |

31.25 |

12.5 |

6.25 |

3.125 |

1.25 |

6.25 |

3.125 |

1.25 |

6.25 |

3.125 |

1.25 |

0.625 |

Total(ratio) |

31.25 |

12.5 |

6.25 |

3.125 |

1.25 |

0.625 |

0.3125 |

0.125 |

0.0625 |

0.03125 |

0.0125 |

0.00625 |

Analog control voltage

Circuit name |

signal level |

Signal name |

CHx OFFSET |

+/-4V |

Offset control signal |

CHx GAIN |

0 to +4V |

HFE428 gain control signal |

CHx TRIG LVL1 |

+/-4V |

Trigger level control signal |

CHx TRIG LVL2 |

+/-4V |

Trigger level control signal for smart trigger/window |

CHx HYST |

0 to +4V |

Trigger hysteresis control signal |

INT CAL |

0 to +600mV |

Signal each CH commonness for calibration |

Over load detection

When the input impedance is set to 50 ohm, the over load is detected because of the protection of the terminating resistance.

Over load signal CHx OVLD is produced by detecting temperature of resistance, xR85 for the load and xR87 for ambient.

It is necessary to measure a standard value when there is no input signal in order to detect the over load accurately.

The over load is detected by monitoring the difference between this standard value and

Theory of Operation 4-11

CHX OVLD.

Calibration

The front end executes the calibration of GAIN, BALANCE when the panel setups and the ambient temperature change, so guarantees the accuracy.

Block figure 2 shows the supply of the reference voltage INT CAL. The calibration executes with INT CAL of standard DC voltage.

The INT CAL is all CH common signal and standard DC voltage of the maximum +/- 600mV.

The INT CAL is attenuated to 1/10 in +/-60mV or less.

The CAL OUT signal of DC-1MHz is independent with an internal calibration. The signal can be monitored with an external terminal by switching the internal calibration signal.

Block diagram 2

4-12 Theory of Operation

4.2.2A/D Converter & Memory

Introduction

The analog to digital converter system does the signal conversion to 8bit, using the following circuits:

HAD626

Chip on board MCM (Multi Chip Module).

Hybrid Acquisition Module containing both track & hold amplifier and 8bit ADC. Differential signal input. (Nominal 500mVpp full scale.)

Differential ECL clock input. (up to 500M S/s.)

Differential ECL compatible data outputs and memory clock.

ECL compatible serial interface for internal ADC gain and offset control.

HMM436

Chip on board MCM.

Hybrid Memory Module containing MAM424.

Maximum buffer length is up to maximum 1Mbytes per channel.

MAM424 (Monolithic Access Memory) captures 8bit data at maximum rate of 500Mbytes/s.

Internal memory consists of a 2Mbit SRAM. (up to 250kbytes per channel.) HMM436 (LTXXX) : one MAM424 per channel.

HMM436L (LTXXXL): four MAM424’s per channel. Parallel interface for reading data and writing registers.

Theory of Operation 4-13

4.2.3 Trigger

Introduction

The trigger system includes the following circuits:

HTR420

Chip on board MCM.

Hybrid TRigger module designed for a trigger conditioning in DSO.

Differential signal input. (Nominal 500mVpp full scale.)

Dual threshold inputs controlled by DC generator output.

Selectable filtering of input signal. (DC, AC, HF REJ, LF REJ)

Frequency divider by four. (HF)

Dual differential ECL outputs. (Trigger signal and qualifier signal)

Single ended analog output for TV trigger.

Serial interface for the internal settings.

TV trigger

This circuit is able to trigger on different TV line number standards. TV trigger uses a commercial chip (LM1881).

LM1881 generates composite sync output, vertical sync output and odd/even output.

MST412(Edge qualified function) triggers on video signal using the outputs of LM1881.

LINE trigger

This circuit makes LINE trigger signal from AC line signal of Power Board. Polarity of line trigger.

MST412

Trigger functions (Standard trigger, Hold off, Pulse width, Interval, State qualified, Edge qualified, Drop out) are made in Monolithic Smart Trigger.

Dual differential ECL inputs. (Trigger signal and qualifier signal) Differential ECL clock input.

Differential ECL trigger output. Parallel interface for writing resisters.

400MHz OSC

generates the 400MHz clock for MST412. ECL single ended output.

The clock frequency of oscillator is adjustable by analog signal from 8bit DAC.

The clock stops for Standard trigger, Hold off by events, TV trigger and LINE trigger.

4-14 Theory of Operation

Loading...

Loading...