Page 1

Propane Vapor

Withdrawal

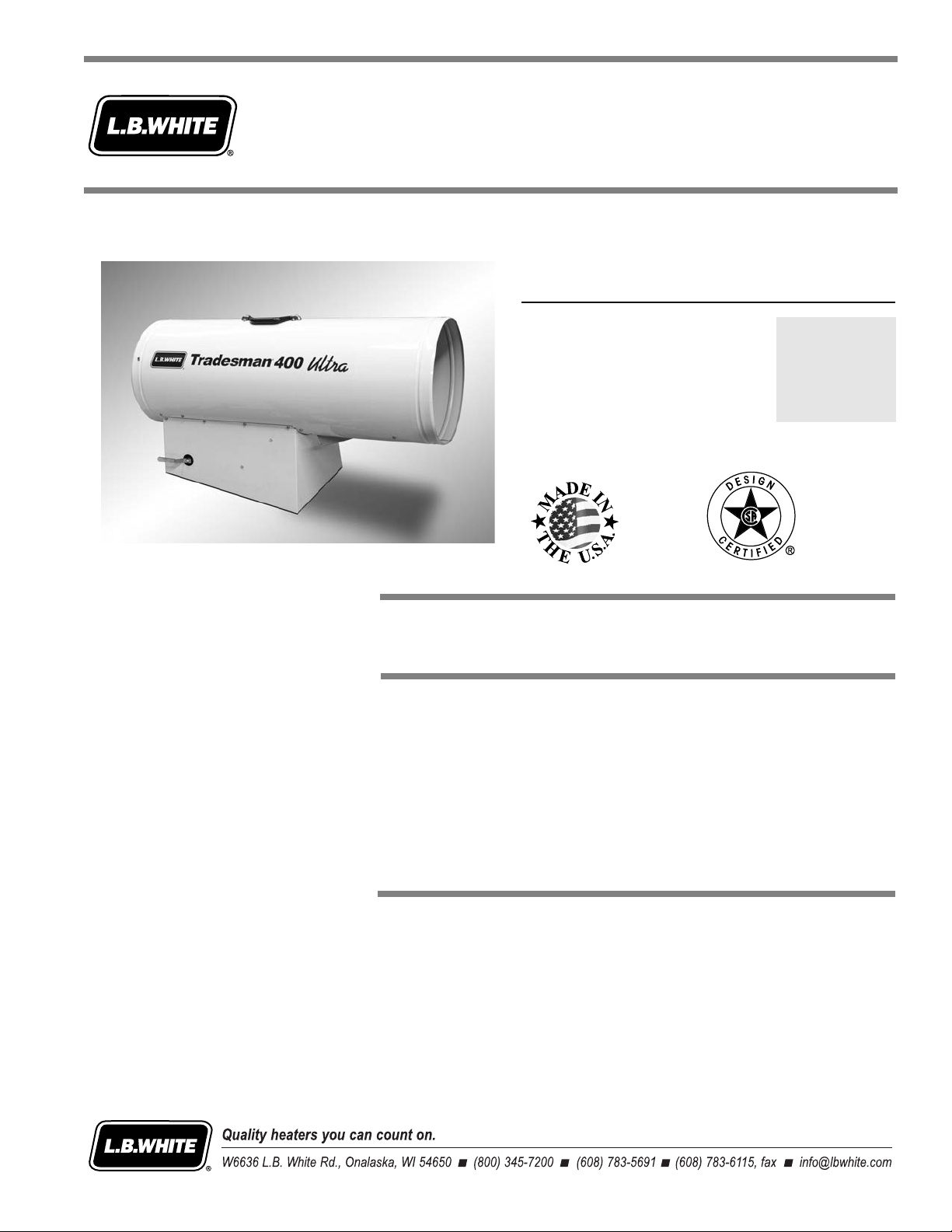

Congratulations!

You have purchased the finest portable forced air construction heater available.

Your new L.B. White heater incorporates the benefits from the most experienced

manufacturer of heating products using state-of-the-art technology.

We, at L.B. White, thank you for your confidence in our products and

welcome any suggestions or comments you may have...call us, toll-free,

at (800) 345-7200.

Owner's Manual and Instructions

Tradesman 400 and Tradesman 400 Ultra Construction Heaters

ATTENTION ALL USERS

This heater has been tested and evaluated by C.S.A. International in accordance with

the requirements of Standard ANSI Z83.7

CSA 2.14 and is listed and approved as a

direct gas-fired forced-air construction heater with application for the temporary

heating of buildings under construction, alteration, or repair. If you are considering

using this product for any application other than its intended use, then please

contact your fuel gas supplier, or the L.B. White Co., Inc.

MODELS OUTPUT (Btuh) FUEL

CP400 400,000

Certification by:

150-27749

Page 2

Page 3

WARNING

Fire and Explosion Hazard

■ Not for home or recreational vehicle use.

■ Installation of this heater in a home or

recreational vehicle may result in a fire or

explosion.

■ Fire or explosions can cause property damage

or loss of life.

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don't touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

WARNING

Fire and Explosion Hazard

■ Keep solid combustibles a safe distance away

from the heater.

■ Solid combustibles include wood, paper, or

plastic products, building materials and dust.

■ Do not use the heater in spaces which contain

or may contain volatile or airborne

combustibles.

■ Volatile or airborne combustibles include

gasoline, solvents, paint thinner, dust

particles or unknown chemicals.

■ Failure to follow these instructions may result

in a fire or explosion.

■ Fire or explosions can lead to property

damage, personal injury or loss of life.

GENERAL HAZARD WARNING

■ Failure to comply with the precautions and instructions provided with this heater, can result in:

— Death

— Serious bodily injury or burns

— Property damage or loss from fire or explosion

— Asphyxiation due to lack of adequate air supply or carbon monoxide poisoning

— Electrical shock

■ Read this Owner’s Manual before installing or using this product.

■ Only properly-trained service people should repair or install this heater.

■ Save this Owner’s Manual for future use and reference.

■ Owner’s Manuals and replacement labels are available at no charge. For assistance, contact L.B.

White at 800-345-7200.

WARNING

■ Proper gas supply pressure must be provided to the inlet of the heater.

■ Refer to data plate for proper gas supply pressure.

■ Gas pressure in excess of the maximum inlet pressure specified at the heater inlet can cause fires

or explosions.

■ Fires or explosions can lead to serious injury, death, or building damage.

■ Gas pressure below the minimum inlet pressure specified at the heater inlet may cause improper

combustion.

■ Improper combustion can lead to asphyxiation or carbon monoxide poisoning and therefore

serious injury or death.

2

Page 4

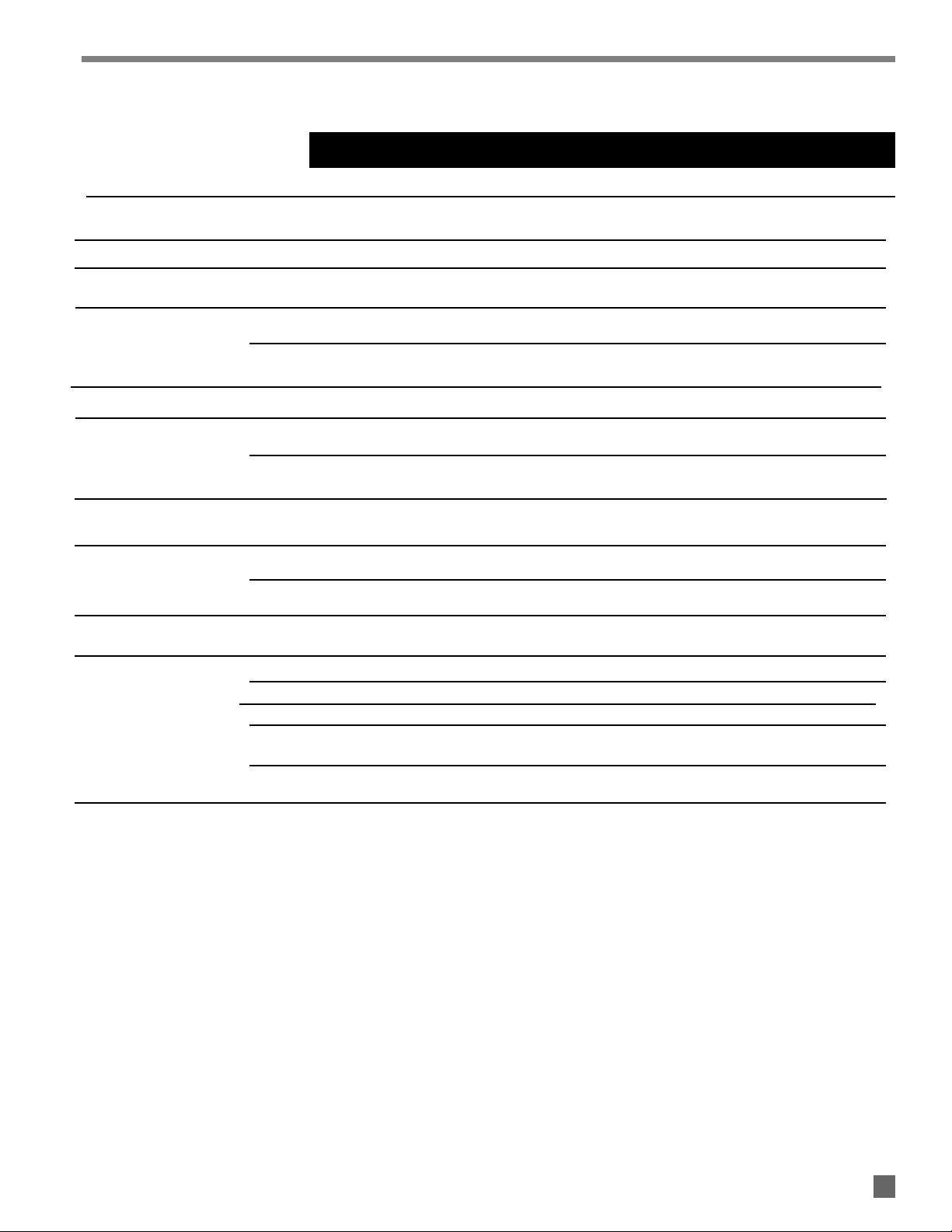

SECTION PAGE

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Heater Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Installation and Assembly Instructions

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Propane Gas Supply Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Handle Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Hose and Regulator Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Connecting Regulator to Propane Gas Supply Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Start-Up Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Shut-Down Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Variable Rate Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Cleaning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Service Instructions

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Motor, Fan, and Air Proving Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Backflash Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Variable Rate Valve and Gas Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Igniter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Burner Orifice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Ignition Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Gas Pressure Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Troubleshooting Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Electrical Connection and Ladder Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Heater Component Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Parts Identification

Parts Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Warranty Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Replacement Parts and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Table of Contents

General Information

This Owner's Manual includes all options and accessories

commonly used on this heater.

When calling for technical service assistance, or for other

specific information, always have model number,

configuration number and serial number available. This

information is contained on the dataplate.

This manual will instruct you in the operation and care of

your unit. Have your qualified installer review this manual

with you so that you fully understand the heater and how it

functions.

The gas supply line installation, installation of the heater,

and repair and servicing of the heater requires continuing

expert training and knowledge of gas heaters and should

not be attempted by anyone who is not so qualified. See

page 6 for definition of the necessary qualifications.

Contact your local L.B. White distributor or the L.B. White

Co., Inc. for assistance, or if you have any questions about

the use of the equipment or its application.

The L.B. White Co., Inc. has a policy of continuous product

improvement. It reserves the right to change specifications

and design without notice.

3

Page 5

Maximum / Minimum Input (BTUH) 400,000/250,000

5.2

5.2

5.2

18.5

4.0

1.5

TOP 7 ft.

SIDES 5 ft.

BACK 5 ft.

BLOWER

OUTLET

GAS SUPPLY

.

.

34 1/4 x 12 5/8 x 21 3/4

1/5 H.P., 3,300 RPM

Sleeve Bearing

CP400

Propane Gas

6 ft., (1.83 m.)

SPECIFICATIONS

Model

Electrical Supply

(Volts/Hz/Phase)

Amp Draw

Dimensions (Inches)

L x W x H

Minimum Safe

Distances From

Nearest

Combustible

Materials

STARTING

CONTINUOUS

OPERATION

Fuel Consumption Per Hour (lbs.)

I

nlet Gas Supply

Pressure Acceptable at

the Gas Connection (PSI)

MAX.

MIN.

15 ft.

115/60/1

Heater Specifications

Fuel Type

Burner Manifold Pressure (PSI)

4

Motor Characteristics

Page 6

Propane gas and natural gas have man-made odorants added specifically for detection of fuel gas leaks.

If a gas leak occurs, you should be able to smell the fuel gas.

THAT’S YOUR SIGNAL TO GO INTO IMMEDIATE ACTION!

■ Do not take any action that could ignite the fuel gas. Do

not operate any electrical switches. Do not pull any

power supply or extension cords. Do not light matches

or any other source of flame. Do not use your

telephone.

■ Get everyone out of the building and away from the area

immediately.

■ Close all propane gas tank or cylinder fuel supply valves,

or the main fuel supply valve located at the meter if you

use natural gas.

■ Propane gas is heavier than air and may settle in low

areas. When you have reason to suspect a propane

leak, keep out of all low areas.

■ Use your neighbor’s phone and call your fuel gas

supplier and your fire department. Do not re-enter the

building or area.

■ Stay out of the building and away from the area until

declared safe by the firefighters and your fuel gas

supplier.

■ FINALLY, let the fuel gas service person and the

firefighters check for escaped gas. Have them air out

the building and area before you return. Properly

trained service people must repair the leak, check for

further leakages, and then relight the appliance for you.

■ Some people cannot smell well. Some people cannot

smell the odor of the man-made chemical added to

propane or natural gas. You must determine if you can

smell the odorant in these fuel gases.

■ Learn to recognize the odor of propane gas and natural

gas. Local propane gas dealers will be more than happy

to give you a scratch and sniff pamphlet. Use it to

become familiar with the fuel gas odor.

■ Smoking can decrease your ability to smell. Being

around an odor for a period of time can affect your

sensitivity to that particular odor.

■ The odorant in propane gas and natural gas is colorless

and the intensity of its odor can fade under some

circumstances.

■ If there is an underground leak, the movement of gas

through the soil can filter the odorant.

■ Propane gas odor may differ in intensity at different

levels. Since propane gas is heavier than air, there may

be more odor at lower levels.

■ Always be sensitive to the slightest gas odor. If you

continue to detect any gas odor, no matter how small,

treat it as a serious leak. Immediately go into action as

discussed previously.

5

Safety Precautions

FUEL GAS ODOR

ODOR FADING -- NO ODOR DETECTED

ATTENTION -- CRITICAL POINTS TO REMEMBER!

■ Propane gas has a distinctive odor. Learn to recognize

these odors. (Reference Fuel Gas Odor and Odor Fading

sections above.

■

If you have not been properly trained in repair and service

of propane gas then do not attempt to light heater,

perform service or repairs, or make any adjustments to

the heater on the propane gas fuel system.

■ Even if you are not properly trained in the service and

repair of the heater, ALWAYS be consciously aware of

the odors of propane gas and natural gas.

■ A periodic sniff test around the heater or at the heater’s

joints; i.e. hose, connections, etc., is a good safety

practice under any conditions. If you smell even a small

amount of gas, CONTACT YOUR FUEL GAS SUPPLIER

IMMEDIATELY. DO NOT WAIT!

WARNING

■ Do not use this heater for heating human living

quarters.

■ Do not use in unventilated areas.

■ The flow of combustion and ventilation air must not be

obstructed.

■ Proper ventilation air must be provided to support the

combustion air requirements of the heater being used.

■ Lack of proper ventilation air will lead to improper

combustion.

■ Improper combustion can lead to carbon monoxide

poisoning leading to serious injury or death. Symptoms

of carbon monoxide poisoning can include headaches,

dizziness and difficulty in breathing.

Asphyxiation Hazard

Page 7

1. Do not attempt to install, repair, or service this heater

or the gas supply line unless you have continuing

expert training and knowledge of gas heaters.

Qualifications for service and installation of this

equipment are as follows:

a.

To be a qualified gas heater service person, you

must have sufficient training and experience to

handle all aspects of gas-fired heater installation,

service and repair. This includes the task of

installation, troubleshooting, replacement of

defective parts and testing of the heater. You

must be able to place the heater into a continuing

safe and normal operating condition. You must

completely familiarize yourself with each model

heater by reading and complying with the safety

instructions, labels, Owner’s Manual, etc., that is

provided with each heater.

b.

To be a qualified gas installation person, you must

have sufficient training and experience to handle

all aspects of installing, repairing and altering gas

lines, including selecting and installing the proper

equipment, and selecting proper pipe and tank

size to be used. This must be done in accordance

with all local, state and national codes as well as

the manufacturer’s requirements.

c. In the Commonwealth of Massachusetts, this

product must be installed by a gas fitter licensed

by the Commonwealth of Massachusetts.

2. All installations and applications of L.B. White heaters

must meet all relevant local, state and national

codes. Included are L.P. gas, natural gas, electrical,

and safety codes. Your local fuel gas supplier, a local

licensed electrician, the local fire department or

similar government agencies, or your insurance agent

can help you determine code requirements.

Also refer to:

-- ANSI/NFPA 58, latest edition, Standard for

Storage and Handling of Liquefied Petroleum

Gas

-- ANSI Z223.1/NFPA 54, National Fuel Gas

Code

-- ANSI/NFPA 70, National Electrical Code.

3. Adequate ventilation air for combustion must be

provided in accordance with OSHA 29 CFR 1926.154,

Temporary Heating Devices, and ANSI A10.10, Safety

Requirements for Temporary and Portable Space

Heating Devices.

4. We cannot anticipate every use which maybe made

of our heaters. Check with the local fire safety

authority if you have questions about applications.

5. Once the heater has been lit, high surface and

exhaust temperatures can ignite clothing or burn

users who come too close to the heater. When the

heater is in operation, those working around the

heater should never touch the heater or come within

the clearances stated. Use extreme caution when

lighting the heater or adjusting heat levels.

6. Forced air heaters shall not be directed toward any

propane gas container within 20 feet (6.10 meters).

Do not wash the heater. Use only compressed air, a

soft brush or dry cloth to clean the interior of the

heater and it’s components.

7. Use only the regulator supplied with the heater. The

heater must be regulated at all times for proper

operation.

8. For safety, this heater is equipped with an auto reset

backflash switch, and an air proving switch. Never

operate the heater with any safety device that has

been bypassed. Do not operate this heater unless

these features are fully functioning.

9. Do not block air intakes or discharge outlets of the

heater. Doing so may cause improper combustion or

damage to heater components leading to property

damage.

10 The hose assembly shall be visually inspected on a

daily basis after heater relocation and when the

heater is in use. If it is evident there is excessive

abrasion or wear, or if the hose is cut, it must be

replaced prior to the heater being put into operation.

The hose assembly shall be protected from building

materials, and contact with hot surfaces during use.

The hose assembly shall be that specified by the

manufacturer. See parts list.

11. Check for gas leaks and proper function upon heater

installation, when relocating, and after servicing.

Refer to leak check instructions within installation

section of this manual.

12. This heater should be inspected for proper operation

by a qualified service person before each use and at

least annually.

13. Always turn off the gas supply to the heater if the

heater is not going to be used in the heating of the

work space.

14. This heater is equipped with a three-prong

(grounding) plug for your protection against shock

hazard and must be plugged directly into a properly

grounded three-prong receptacle. Failure to use a

properly grounded receptacle can result in electrical

shock, personal injury, or death.

15. If gas flow is interrupted and flame goes out, do not

relight the heater until you are that all gas that may

have accummulated has cleared away. In any event,

do not relight the heater for at least 5 minutes.

16. The heater requires a minimum 500 gallon propane

tank for proper gas supply pressure and operation. A

larger tank may be required depending upon

temperature conditions at the site.

17. When the heater is to be stored indoors, the

connection between the propane gas supply

container and the heater must be disconnected. The

container must be stored in accordance with the

Standard for the Storage and Handling of Liquified

Petroleum Gases, ANSI/NFPA 58.

18. Propane gas supply containers have left handed

threads. Always use the appropriate wrench to make

a connection to tighten or loosen the P.O.L. fitting at

the cylinders’ gas supply valve.

6

Page 8

1. Read all safety precautions and follow L. B. White

recommendations when installing this heater. If

during the installation or relocating of heater, you

suspect that a part is damaged or defective, call a

qualified service agency for repair or replacement.

2. Ensure the heater is properly positioned before use.

The heater must be installed on a level, flat,and

stable surface when in operation and according to

minimum safe distances from combustible materials.

Safe distances are given on the heater dataplate and

on page 4 of this manual.

3. This heater is approved for indoor use only. The

heater shall be installed so it is not directly exposed

to water spray, rain, and /or dripping water.

4. The heater’s gas pressure regulator (with pressure

relief valve) must be protected from adverse weather

conditions (rain, ice, snow) as well as from building

materials (tar, concrete, plaster, etc.) which can affect

safe operation and could result in property damage or

injury.

5. Heaters used in the vicinity of combustible tarpaulins,

canvas, plastics, wind barriers, or similar coverings

shall be located at least 10 feet from the coverings.

The coverings shall be securely fastened to prevent

ignition or upsetting of the heater due to wind action

on the covering or other material.

6. Insure that all accessories that ship with the heater

have been and installed.

7. Check all connections for gas leaks using approved

gas leak detectors. Gas leak testing is performed as

follows:

-- Check all pipe connections, hose connections,

fittings and adapters upstream of the gas

control with approved gas leak detectors.

-- In the event a gas leak is detected, check the

components involved for cleanliness and

proper application of pipe compound before

further tightening.

-- Tighten the gas connections as necessary to

stop the leak.

-- After all connections are checked and any

leaks are stopped, turn on the main burner.

-- Stand clear while the main burner ignites to

prevent injury caused from hidden leaks that

could cause flashback.

-- With the main burner in operation, check all

connections, hose connections, fittings and

joints as well as the gas control valve inlet and

outlet connections with approved gas leak

detectors.

-- If a leak is detected, check the components

involved for cleanliness in the thread areas

and proper application of pipe compound

before further tightening.

-- Tighten the gas connection as necessary to

stop the leak.

-- If necessary, replace the parts or components

involved if the leak cannot be stopped.

-- Ensure all gas leaks have been identified and

repaired before proceeding.

8. A qualified service agency must check for proper

operating gas pressure upon installation of the

heater.

9. Always use pipe thread compund that is resistant to

propane and natural gas on threaded connections.

10. Light according to instructions on heater or within

owner's manual.

11 Make sure the heater has the proper gas regulator for

the application. A regulator must be connected to the

gas supply so that gas pressure at the inlet to the gas

valve is regulated within the range specified on the

dataplate at all times. Contact your gas supplier, or

the L.B. White Co., Inc. if you have any questions.

12. This heater is configured for use for propane gas

vapor withdrawal only. Do not use the heater in an

propane gas liquid withdrawal system or application.

If you are in doubt, contact the L.B. White Co., Inc.

WARNING

Fire and Explosion Hazard

Can cause property damage, severe injury or death

To avoid dangerous accumulation of fuel gas, turn

off gas supply at the heater service valve before

starting installation, and perform gas leak test after

completion of installation.

7

Installation and Assembly Instructions

GENERAL

WARNING

Fire and Explosion Hazard

■ Do not use open flame (matches, torches, candles,

etc.) in checking for gas leaks.

■ Use only approved leak detectors.

■ Failure to follow this warning can lead to fires or

explosions.

■ Fires or explosions can lead to property damage,

personal injury or loss of life.

Page 9

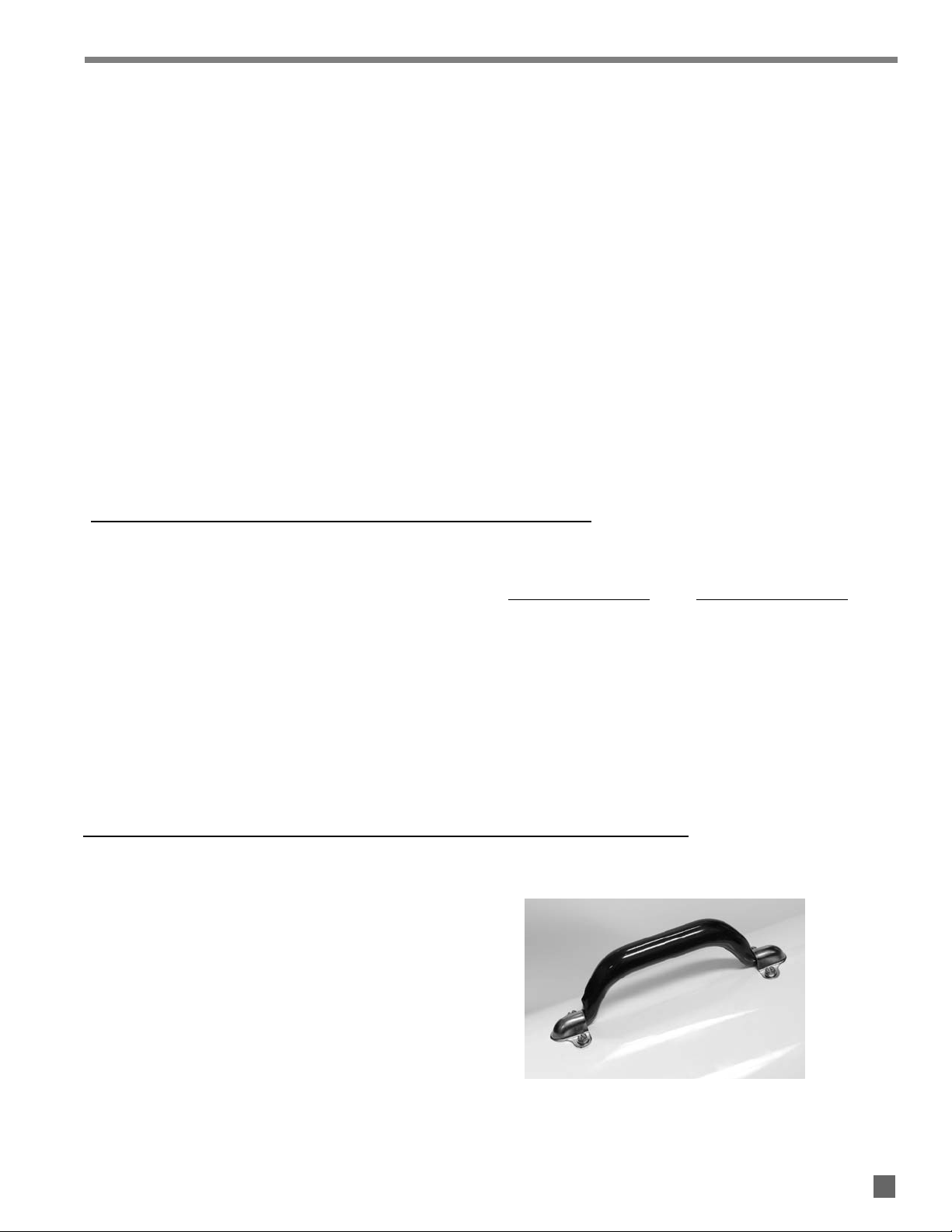

Assemble handle to four holes at barrel top as shown

in Fig.1. Tighten screws securely.

FIG. 1

HANDLE ASSEMBLY

8

13. The heater must be installed so as not to interfere

with or obstruct normal exits, emergency exits, doors

and walkways.

14. Railing, fencing or suitable substitute materials must

be used to keep the heating equipment from any

people using and visiting the structure.

15 . Eventually, like all electrical/mechanical devices, the

thermostat can fail. Thermostat failure may result in

an underheating condition. The thermostat should be

tested to make sure it turns the heater on and off

within a temperature differential of ±3°F.

16. Take time to understand how to operate and maintain

the heater by using this Owner’s Manual. Make sure

you know how to shut off the gas supply to the

building and also to the individual heater. Contact

your fuel gas supplier if you have any questions.

17. Any defects found in performing any of the service or

maintenance procedures must be eliminated and

defective parts replaced immediately. The heater

must be retested by properly qualified service

personnel before placing the heater back into use.

PROPANE GAS SUPPLY SIZING

The vaporization of propane is affected by several factors:

the surface area of the container, the liquid level of

propane, temperature surrounding the container, and the

relative humidity. All of these factors are specific to a site.

Therefore, a degree of experience and judgement is

required to select the proper propane supply.

Although experience is the best guide, the following

recommendations can be used as a starting point. The

table is based on experience in northern climates where

cold weather and high humidity are prevalent in the winter.

If more or less favorable conditions prevail at a specific site,

adjustments can be made on the basis of experience.

Recommended Gas Supply

Propane Supply Tank: Heater(s)/Container(s):

500 gallon 1 heater per tank

1,000 gallon 2 heaters per tank

If more than one gas supply container is used per heater,

the containers must be manifolded together to allow vapor

withdrawal simultaneously from multiple containers.

Manifold system shall be in accordance with NFPA 58.

Page 10

1. Thread rigid end of hose into gas inlet of heater.

Tighten securely. See Fig.2.

FIG. 2

2. Thread hose adapter to regulator outlet and tighten

securely. Connect end of hose with nut to hose

adapter. Tighten hose nut securely. See Fig 3.

FIG. 3

HOSE AND REGULATOR ASSEMBLY

9

1. At the inlet of the regulator is a male nut and stem

called a POL. Remove the cap from the POL but do

not discard it. Insert POL stem into the valve on the

tank. Thread the nut counterclockwise into the tank

valve. Tighten the nut securely with a wrench. See

Fig. 4.

2. Slowly open the tank valve. This will prevent lock-up

of the excess flow valve within POL stem.

3. Check all connections with approved leak detector.

Do not use flame to check for leaks. A fire or

explosion may result.

4. When storing or transporting the heater, ensure the

cap is pushed back onto the POL fitting to protect the

fitting from damage and prevent entry of dirt.

FIG. 4

CONNECTING PROPANE REGULATOR TO PROPANE GAS TANK

POL NUT

AND STEM

Page 11

Start-Up Instructions

1. Connect the heater’s electrical cord to an approved

electrical outlet.

2. Open the gas supply valve. For LP heaters, this is

located on the tank.

3. Set thermostat on heater to a setting above room

temperature. The heater will start and the burner will

ignite.

■ It is normal for air to be trapped in gas hose on new

installations. You may need to recycle the heater

before air is finally purged from the line and ignition

takes place.

4. Do not exceed input rating provided on dataplate or

manufacturer’s recommended burner manifold

pressure for size orifice used. Ensure that the

primary air supply to heater is open and free of dust,

dirt and debris for complete, proper combustion.

If the heater is to be shut down for cleaning, maintenance,

or repair, follow steps 1-4. Otherwise turn the thermostat to

a lower setting.

1. Close the gas supply valve.

2. Allow the heater to burn off any fuel gas remaining in

the gas supply line.

3. Set the thermostat to its lowest setting.

4. Disconnect the heater from its gas and electrical

supplies.

Shut-Down Instructions

1410

Variable Rate Valve

This heater includes a variable rate valve for

adjusting the heat output from low to high heat, or

anywhere in-between. See Figs. 5.

FIG. 5

Page 12

1. The area surrounding the heater shall be kept clear

and free from combustible materials, gasoline, and

other flammable vapors and liquids.

2. Have your gas supplier check all gas piping annually

for leaks or restrictions in gas lines.

3. Regulators must be periodically inspected to make

sure the regulator vents are not blocked. Debris,

insects, insect nests, snow, or ice on a regulator can

block vents and cause excess pressure at the heater.

4. Regulators can wear out and function improperly.

Have your gas supplier check the date codes on all

regulators installed and check delivery pressures to

the heater to make sure that the regulator is reliable.

5. Check all wiring, associated terminals, and electrical

components within the heater for corrosion, frayed or

cut insulation, tight connections, etc. Repair or

replace as necessary.

6. Review all heater markings (i.e. wiring diagram,

warnings, start-up, shut-down, troubleshooting, etc.)

at the time of maintenance for legibility. Make sure

none are cut, torn, or otherwise damaged. Any

damaged markings must be replaced immediately by

contacting the L.B. White Co., Inc. Dataplates, startup and shut-down instructions and warnings are

available at no cost. A nominal charge will be applied

for wiring diagrams.

Maintenance Instructions

1. Before cleaning, shut off all gas supply valves and

disconnect electrical supply.

2. The heater should have dirt or dust removed

periodically:

NOTE: Before each use clean the heater using

compressed air or a soft brush or dry rag on

its case and internal components. At this

time, dust off the motor case to prevent

the

motor from over-heating. Also ensure the fan

blade is free of material build-up.

WARNING

Do not use a pressure washer, water, or liquid cleaning

solution on any gas controls. Use of a pressure washer,

water, or liquid cleaning solution on the control

components can cause severe personal injury or

property damage due to water and/or liquids:

■ In electrical components, and wires causing electrical

shock or equipment failure.

■ On gas control valves causing corrosion which can

result in gas leaks and fire or explosion from the leak.

Clean all components of the heater with pressurized air,

a dry brush, or a dry cloth.

Cleaning Instructions

WARNING

Fire, Burn, and Explosion Hazard

■ This heater contains electrical and mechanical components in the gas management, and safety systems.

■ Such components may become inoperative or fail due to dust, dirt, wear and aging.

■ Periodic cleaning and inspection as well as proper maintenance are essential to avoid serious injury or property

damage.

1411

Page 13

1. Remove fan guard and screws securing the motor

mount to the heater’s barrel. See Fig 6.

2. Lift motor/fan assembly from heater.

FIG. 6

Motor

-- Remove both screws and strap securing the motor.

Air Proving Switch

-- Remove screw securing switch bracket to motor mount.

-- On reassembly, ensure tab on switch bracket is located in

positioning hole adjacent to screw hole.

Fan

-- Loosen set screw at hub.

-- Pull fan from shaft.

-- Ensure fan is flush on shaft end, and set screw is

positioned over flat of motor shaft before tightening

FIG. 7

Service Instructions

1. Close the fuel supply valve to the heater and

disconnect the electrical supply before servicing

unless necessary for your service procedure.

2. Remove the heater’s bottom base or side panel for

access to electrical components and connections.

3 Disconnect the appropriate electrical leads for the

component being replaced.

4. Remove the fan guard and motor/fan assembly for

access to upper barrel components.

5. The auto reset backflash, and thermostat can be

tested by disconnecting the leads at the component,

and placing a jumper connecting the leads together.:

-- Reconnect the electrical supply and open fuel

supply valves.

-- If the heater lights, the component is defective

and must be replaced.

-- Do not leave the jumper on or operate the heater if

the part is defective. Replace the part immediately.

-- An alternate method for checking the components

is to perform a continuity check..

6. The air proving switch must not be jumpered. If

jumpered, the ignition control will not allow heater

operation. Test the air proving switch for continuity.

If defective, replace the switch

7. For reassembly, reverse the respective service

procedure. Ensure gas connections are tightened

securely.

8. After servicing, start the heater to ensure proper

operation and check for gas leaks.

9. Clean the heater’s orifice with compressed air or a

soft, dry rag. Do not use files, drills, broaches, etc. to

clean the orifice. Doing so may enlarge the hole,

causing combustion or ignition problems. Replace

the orifice if it cannot be cleaned properly.

WARNING

Burn Hazard

■ Some heater surfaces are hot for a period of time

after the heater has been shut down.

■ Allow the heater to cool before performing service,

maintenance, or cleaning.

■ Failure to follow this warning will result in burns

causing injury.

WARNING

Fire and Explosion Hazard

■ Do not disassemble or attempt to repair any heater

components or gas train components.

■ All component parts must be replaced if defects are

found.

■ Failure to follow this warning will result in fire or

explosions, causing property damage, injury, or death.

GENERAL

MOTOR , FAN, AND AIR PROVING SWITCH

1412

SET SCREW

REMOVE

SCREWS

STRAP

AIR PROVING

SWITCH

REMOVE ON

BOTH SIDES

FAN END OF

HEATER

Page 14

To replace the switch, remove the screws, spacers

and nuts holding the switch to the burner plate. See

Fig. 8 and 9..

FIG. 8

FIG. 9

TESTING

The switch should be tested annually.

1. Remove the switch assembly. Apply a small,soft flame

to the sensing disk of the switch. See Fig. 10. Be

careful not to melt the switch’s plastic housing when

conducting this test.

2. Within a short time, you should hear the contacts of

the switch opening.

3. Allow the switch to cool. The switch contacts will

close. Check for electrical continuity across the switch

terminals to ensure contacts have closed.

FIG. 10

AUTO RESET BACKFLASH SWITCH

1413

1. Loosen the compression nut at the outlet of the

variable rate valve. See Fig.11

2. Remove both screws securing the valve bracket to

the heater panel.

3. Remove the valve assembly from the heater and

replace components as needed.

FIG. 11

VARIABLE RATE VALVE AND GAS CONTROL VALVE

SCREWS

SWITCH

SCREWS

COMPRESSION

NUT

VARIABLE RATE VALVE

GAS CONTROL VALVE

NUTS AND SPACERS

Page 15

MAINTENANCE

1. Using a small wire brush, reach down the barrel of

the heater and brush the igniter electrode. Ensure

buildup is removed.

2. Test the igniter. With the gas supply shut off, turn

the heater on. If there is not a spark, or a weak

spark is evident, either check the gap of the igniter

electrode or replace the igniter. Gap should be 3/16

in. See Fig.12. If a spark jumps between the

electrodes, the igniter is functioning properly.

.FIG. 12

REPLACEMENT

1. Disconnect the igniton cable from the igniter. See

Fig.13.

2. Remove the igniter mounting screw and nut. See

Figs. 13 and 14.

FIG. 13

FIG. 14

1. Loosen the compression nut at the burner orifice.

Remove the bowed retaining clip. See Fig. 15.

FIG. 15

2. Reach down the barrel of the heater and pull the

orifice from the burner plate.

3. Inspect the orifice and clean any plugged holes.

Replace it if necessary. The replacement orifice will

include retaining clips.

4. Ensure the orifice is installed so the arrow on its face

is directed upward. See Fig.16. This ensures proper

alignment of smaller orifice hole to the igniter for sure

ignition. See Fig.17.

FIG. 16

FIG. 17

IGNITER

14

BURNER ORIFICE

IGNITER

CABLE

NUT

COMPRESSION NUT

BOWED

RETAINING

CLIP

SCREW

3/16 in.

SMALLER HOLE ALIGNED TO

IGNITER GAP

Page 16

1. Open the clip holding the thermostat bulb to the

motor mount.

2. Remove knob and thermostat mounting screws.

3. Guide the thermostat bulb through the bushing.

4. Remove thermostat from heater

FIG. 18

THERMOSTAT

IGNITION CONTROL

1415

1. Disconnect the LED wire harness from the circuit

board, if applicable.

2. Disconnect the ignition cable and remove the nuts

securing the control to the side of the heater’s base..

See Fig.19.

3. When replacing, use care to prevent damage to the

controller’s components.

FIG. 19

BUSHING

NUT

LED WIRE

HARNESS

SCREWS

CLIP

IGNITION CABLE

Page 17

■ The following explains a typical procedure to be

followed in checking gas pressures.

■ The gas pressures will vary depending upon fuel type.

■ Consult the dataplate on the heater or page 4 in this

manual for specific pressures to be used in conjunction

with this procedure.

■ Gas pressure measured at the gas control valve will

verify proper inlet and burner manifold pressures.

A. Preparation

1. Obtain a pressure gauge capable of reading up to

minimum 10 PSIG.

2. Disconnect the heater from the electrical supply and

close the valve on the LP tank.

B. Gauge Installation

1. Remove the pressure tap plug on the gas regulator.

See Fig. 20.

FIG. 20

2. Install the gauge. See Fig.21. Reconnect the

electrical supply, open the fuel supply valve, and

start the heater

FIG. 21

C. Reading Pressures

1. With the heater operating, the pressure gauge must

read the pressures specified on the dataplate

2. Does the reading at the gas control valve agree with

that specified on the dataplate? If so, then no

further checking is required. Proceed to section D.

3. If the pressures do not agree with that specified on

the dataplate, then the regulator controlling gas

pressure to the heater requires adjustment or

replacment.

D. Completion

1. Once the proper pressure has been confirmed

and/or properly set, close the fuel supply to the

heater and allow the heater to burn off any gas

remaining in the gas supply line.

2. Disconnect the heater from its electrical supply.

3. Remove the gauge.

4. Install pressure tap plug and tighten securely

5. Open the fuel supply and start the heater. Check for

gas leaks at the plug Set heater’s thermostat to

desired temperature.

GAS PRESSURE CHECKS

16

PLUG

Page 18

READ THIS ENTIRE SECTION BEFORE BEGINNING

TO TROUBLESHOOT PROBLEMS.

The following troubleshooting guide provides systematic

procedures for isolating equipment problems. This guide is

intended for use by a QUALIFIED GAS HEATER SERVICE

PERSON. DO NOT ATTEMPT TO SERVICE THESE HEATERS

UNLESS YOU HAVE BEEN PROPERLY TRAINED.

TEST EQUIPMENT REQUIRED

The following pieces of test equipment will be required to

troubleshoot this system with minimal time and effort.

• Digital Multimeter - for measuring AC voltage and

resistance.

• Low Pressure Gauge - for checking inlet and outlet

pressures at the gas control valve against dataplate

rating.

Refer to the system operation sequence in this section to

gain an understanding as to how the equipment operates

during a call for heat. Understanding the sequence of

operation is important as it relates to problem solving.

Heater models labeled Tradesman Ultra have a red light

located at the fan end of the heater. The light will flash a

specific pattern depending upon the problem which is

diagnosed. If the light is flashing, the flash pattern will be

followed by a pause and then a repeat of the flash pattern

until the problem is corrected. Use the light to help

diagnose the problem.

Heater models labeled Tradesman do not have the

diagnostic red light.

Troubleshooting Flow Charts are provided to eliminate

problems. To use the flow charts effectively, you must first

identify the problem.

Before beginning::

■ Inspect heater for apparent damage.

■ Check all wiring for loose connections and worn

insulation.

Tradesman Ultra Diagnostic Heaters Page

Red light is steady on. No flash pattern. . . . . . . . . . . . . . 18

Red light light is not on.. . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Red light is flashing:

A. One Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

B. Two Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

C. Three Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

D. Four Times. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

D. Five Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Tradesman Non - Diagnostic Heters Page

Fan Does Not Run, Heater Does Not Light. . . . . . . . . . . . 22

Fan Runs, Heater Does Not Light . . . . . . . . . . . . . . . . . . . 23

Heater Lights, But Does Not Stay Lit. . . . . . . . . . . . . . . . . 24

Components should be replaced only after each step has

been completed and replacement is suggested in the flow

chart. Refer to the Servicing sections as necessary to

obtain information on disassembly and replacement

procedures of the component once the problem is identified

by the flow chart.

DIRECT IGNITION OPERATION SEQUENCE:

-- Voltage is sent to the thermostat.

-- Thermostat calls for heat.

-- Thermostat sends voltage to ignition control.

-- Red light is illuminated.( Diagnostic Heaters Only).

-- Ignition control module performs self safety check.

-- Internal components are tested.

-- Air proving circuit is checked.

-- Ignition control module begins ignition trial sequence.

-- Ignition control module sends 115 volts to air proving .

switch.

-- Ignition control sends 115 volts to motor

-- Motor starts.

-- Air proving switch closes and 115 volts are returned to the

ignition control module.

-- Ignition control module sends high voltage to the igniter

electrode.

-- Igniter sparks.

-- Ignition control module sends 115 volts to the gas control

valve through the backflash switch.

-- Gas control valve opens.

-- Ignition occurs.

-- Igniter continues to spark until flame proving

occurs.

-- Ignition spark is cut off.

-- Gas valve stays open.

-- Room warms to desired temperature.

-- Thermostat is satisfied.

-- Heater shuts down.

-- Process starts again on a call for heat.

IGNITION FAILURE SEQUENCE:

-- Trial for ignition takes approximately 10 seconds.

-- If ignition module does not sense a flame within the ignition

trial, the module goes into safety lockout (3 flash pattern.)

-- Gas valve closes.

-- Ignition spark shuts off.

-- Fan motor stops.

-- To retry for ignition, the systems must be reset:

-- Turn the thermostat down and then up to call for

heat

or unplug heater and plug it back in or

-- Position selector switch to off and then back to

on.

17

Troubleshooting Information

WARNING

■ This heater can start at any time.

■ Troubleshooting this system may require operating the

unit with voltage present and gas on. Be careful when

working on the heater.

■ Failure to follow this warning may result in property

damage, personal injury or death.

Page 19

Red Light Constant On

LED light

not on

Normal Operation

Does fan

motor run?

Yes

Yes

Does heater

light?

LED light

defective

Replace LED

Is thermostat

set above room

temperature?

Set thermostat

above room

temperature.

Is proper voltage

supplied to

heater power

cord?

Check extension cords and

circuit breakers. Repair

extension cord, reset breaker,

or call qualified electrician.

No

18

Problem

Defective

Ignition

Control

Does thermostat

receive proper

voltage from

power cord?

Does thermostat

send proper

voltage to

ignition control?

Check for proper voltage

delivered from thermostat to

circuit board.

If electrical connections are

good, replace thermostat.

Yes Yes

Yes

No

No

No

No

Page 20

TRADESMAN ULTRA HEATER

19

Problem

LED Flashing

Is air proving

switch shorted?

(Check continuity on

air proving switch in

open and closed

positions).

Yes

If air proving switch is jumered,

remove jumper and retest.

If switch exhibits short, replace the

switch.

One Time

Air proving switch

contacts are closed

before fan motor starts.

\.

Is air proving switch

stuck closed?

Check continuity.

Is air proving switch

binding?

Repair.

No

No

Replace air proving switch

Yes

Yes

Page 21

Two Times

Indicates lack of air

proving in fan

section (Flash

pattern begins

within 90 seconds

after condition

Occurs).

Do air proving switch

contacts close?

Check continuity.

Remove dirt.

repair or

replace fan.

Is fan binding, or

bent, or caked

with dirt?

No

Is Fan loose On

motor shaft?

Tighten fan blade set screw

Is proper voltage

supplied to motor

from ignition

control?

Defective

motor

Does ignition

control send voltage

to air proving

switch?

Is

ignition control

receiving proper

voltage?

No

Is

proper voltage

supplied to heater

power cord?

Defective

ignition

control.

Defective air proving

switch.

20

Is switch binding?

Repair.

Problem

Does fan motor

run?

No

Yes

Check circuit breakers,

and any extension

cords if used.Contact a

qualified electrician

No

Defective ignition

control

Remove

blockage

Are there

blockages at air

inlet of heater?

No

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Page 22

Three Times

Indicates ignition

failure.The ignition

control is in safety

lockout..

Is proper fuel

supplied to heater

inlet?

Connect proper

gas supply to

heater. Open all

gas shutoff valves.

Is proper gas

pressure supplied

to heater?

Provide proper gas

supply pressure to

heater. Refer to

dataplate. If LP gas is

used, ensure LP

container is full.

Is backflash

switch tripped?

Check

continuity

If switch is tripped,

determine cause.

Check for obstruction at

discharge outlet of heater,

and low voltage from power

supply, orn improper

oversized burner orifice.

Is Ignitor

properly

gapped?

Is proper

voltage

supplied to

gas valve?

Defective gas

valve.

Check igniter gap

Regap to .10 in.

Defective wires or

connections. If good,

replace ignition control.

Does ignitor

spark?

Is igniter high voltage

lead securely

connected?

Reposition

Igniter.

(See Service

Instructions)

Connect high

voltage lead

21

Five Times

If control module does not reset, then replace the it (Internal

board fault.)

If module resets, then have qualified electrician check power

source for power quality problems. (Frequency, line noise, line

spikes, loose connections, too small wire gauge.)

Flame sense related problems. Check for

cracked or dirty flame sensor, improperly

positioned sensor, or poor flame sense ground.

Four Times

Rapid On/Off

cycling of the

burner.

Does gas

solenoid valve open?

Problem

Is the heater

properly

grounded?

No

Ensure all

Grounds are

Connected.

Determine if ignitor receives high voltage:

-- Disconnect ignition lead from ignition control.

-- Position a screwdriver tip about 3/16 inch away

from ignition control where lead was connected .

-- WITH GAS OFF, start the heater.

-- If no spark is seen, replace the igntion control.

-- If spark is seen, reconnect igntion lead to control.

-- Disconnect the lead at the ignitor.

-- Hold the lead about 3/16 in. from a grounded

section of the heater.

-- WITH GAS OFF, start the heater.

-- If no spark is observed, replace the ignition lead.

-- If spark is observed, replace the ignitor.

Is ignitor gap

positioned

toward burner

orifice?

No

No

No

No

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Page 23

TRADESMAN HEATER

Fan Motor Does

Not Run,

Heater Does

Not Light.

Is proper voltage

supplied to

heater?

Provide proper

voltage to heater.

Check breajer and

extension cords.

No

Is

thermostat

set above room

temperature?

Set thermostat

above room

temperature

Is proper

voltage

supplied to

thermostat?

Check power cord

and electrical supply.

Is proper

voltage supplied

to ignition

control?

Defective thermostat.

Is voltage

supplied to air

proving switch

from the

ignition

control?

Defective Ignition

Control.

Does fan motor

start?

Check for voltage from ignition

control to fan motor. If motor

receives voltage but does not

start, replace the motor.

If motor does not receive voltage

from the ignition control, replace

the ignition control.

Are air proving

switch contacts

stuck closed?

Check continuity. If

binding switch. Repair

as needed or replace

air proving switch.

22

Problem

Yes

Yes

YesYes

Yes

Yes

Yes

NoNo

No

No

No

Page 24

Fan Runs,

Heater Does

Not Light.

Do air proving

switch contacts

close?

Open fuel supply

vaves .

Check continuity

of switch.Ensure

switch arm is not

binding. Repair

or replace air

proving switch.

Provide proper

gas pressure to

heater inlet.

Check continuity across

switch. If contacts are

open determine cause.

Check for:

proper voltage, blockages

at air inlets or outlet, loose

fan, or low fan speed.

If good, repalce backflash

switch.

Are all fuel

supply valves

open?

Is proper

gas pressure

supplied?

Are the

backflash switch

contacts

closed.?

Does gas

solenoid valve open?

Is proper

voltage

supplied to

valve?

Defective wires or

connections. If good,

replace ignition control.

Defective

valve.

Does ignitor

spark?

Is high voltage

lead securely

connected to

ignition control

and ignitor?

Connect High Voltage

Lead

Is ignitor

properly

gapped?

Check igniter gap

Regap to .10 in.

Isi ignitor gap

positioned

toward burner

orifice?

Reposition igniter.

(See Service Instructions)

23

TRADESMAN HEATER

Problem

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

NoNo

No

Determine if ignitor receives high voltage:

-- Disconnect ignition lead from ignition control.

-- Position a screwdriver tip about 3/16 inch away

from ignition control where lead was connected .

-- WITH GAS OFF, start the heater.

-- If no spark is seen, replace the igntion control.

-- If spark is seen, reconnect igntion lead to control.

-- Disconnect the lead at the ignitor.

-- Hold the lead about 3/16 in. from a grounded

section of the heater.

-- WITH GAS OFF, start the heater.

-- If no spark is observed, replace the ignition lead.

-- If spark is observed, replace the ignitor.

Page 25

Heater lights

bt will Not stay

lit.

Yes

Is proper

voltage

supplied to

heater?

Is igniter clean?

Is

high voltage

lead securely

connected?

Defective ignition

control.

Check electrical

supply. If extension

cords are used,

eensure proper

wire gauge.

Clean and

check gap.

Replace igniter

if needed.

No

Connect high

voltage lead?

24

TRADESMAN HEATER

Problem

Is proper fuel

supplied to heater

inlet?

Connect proper

gas supply to

heater. Open all

gas shutoff valves.

No

Is proper gas

pressure supplied

to heater?

Provide proper gas

supply pressure to

heater. Refer to

dataplate. If LP gas is

used, ensure LP

container is full.

No

Is the heater

properly

grounded?

No

Ensure all

grounds are

connected.

Yes

Is

ignitor

cracked?

No

Repalce ignitor.

Yes

Yes

Yes

Yes Yes

No

No

Page 26

Electrical Connection and Ladder Diagrams

25

TRADESMAN 400

TRADESMAN 400 ULTRA

Page 27

Heater Component Function

Air Proving Switch

Safety device used to insure that the proper air flow is being

achieved before the gas valve is opened.

Back Flash Switch

Safety device wired into the control system which is used to

break an electrical circuit to the gas control valve in event of

overheat situation.

Burner

Component used to channel gas and provide an area at

which the fuel may ignite.

Burner Orifice

Brass metering device used to feed gas to burner at a

specific rate.

Combustion Chamber

Metal chamber within the heater that provides an area

where burner gas mixes with combustion air, thereby

providing heat.

Direct Spark Ignition Control Module

Electronic printed circuit board which sends and receives

voltages to various controls in an automatic ignition system.

An important safety feature of the control board is that it will

shut down the entire heater, thereby stopping the flow of

fuel gas if burner flame goes out.

Fan

Component used in conjunction with the motor to pull the

fresh air into the heater and blow it into room for heating

Gas Control Solenoid Valve

House an electromagnet which is energized by voltage and

opens to allow passage of gas to the burner orifice.

Gas Hose

Flexible connector used to convey gas from supply line in

building to heater.

Heat Chamber

Metal fire box within the heater that provides an area where

burner flame mixes with combustion air, thereby providing

heat.

Igniter

Ignition device used on automatic direct spark ignition

control systems. Ignites gas by spark.

Igniter Wire

Cable used to provide high voltage to the igniter and also a

pathway for flame sense current.

Motor

Electric device used to force preheated air through the

heater and to circulate heat within a certain area. Converts

electrical energy into mechanical energy.

Regulator

Mechanical device used in gas distribution systems to

reduce a higher inlet pressure to a preset lower pressure.

The regulator is responsible to supply a steady outlet

pressure to the heater(s) despite changes in inlet pressure,

heater demand and weather conditions.

Thermostat

Electrical device used as an automatic “on/off” switch

which will respond to changes in temperature in a certain

area.

26

Page 28

27

PARTS SCHEMATIC

Parts Identification

Page 29

28

Part Number

Tradesman 400 Tradesman 400

Item

Description ULTRA

1 Regulator with POL 572586

2 Hose, fixed X swivel, 3/8 in. x 10 ft. 21841

3 Adaptor, hose, 3/8 in. 572580

4 Knob, thermostat 572514

5 Power cord 571356

6 Lens, LED ----- 571333

7 Air proving switch with bracket 572566

8 Motor 571280

9 Motor mount 572567

10 Fan blade 572569

11 Solenoid Valve w/ bracket 572568

12 Thermostat with knob 571119

13 Variable rate valve 572551

14 Manifold tube with fittings 572570

15 Ignition control 571344

16 Igniion cable, high voltage 571263

17 Igniter 20312

18 Backflash switch with hardware 572571

19 Combustion chamber with backflash, orifice, and igniter 572573

20 Orifice with retaining rings 572572

21 Handle w/ screws 571522

22 Upper barrel assembly with fan guard 572565

23 Side panel 572574

24 Case,bottom assembly with labels 572556 572553

25 Base 572560 572559

26 Fan guard 572564

27 Boot,capacitor 571407

28 Capacitor 571406

29 Bracket w/screw 571405

30 Wire harness,complete (not illustrated) 572557

Parts Identification

PARTS LIST

Page 30

Contact your local L.B. White dealer for replacement parts

and service or call the L.B. White Co., Inc. at (800) 3457200 for assistance. Be sure that you have your heater

model number and configuration number when calling.

L.B. White Co., Inc. warrants that the component parts of its

heater are free from defects in material and workmanship,

when properly installed, operated, and maintained in

accordance with the Owner’s Manual safety guides and

labels contained with each unit. If, within 12 months from

the date of purchase by the end user, any component is

found to be defective, L.B. White Co., Inc. will at its option,

repair or replace the defective part or heater, with a new

part or heater, F.O.B., Onalaska, Wisconsin.

A warranty card on file at L.B. White will automatically

qualify the heater and its component parts for warranty

consideration. If a warranty card is not on file, a copy of the

bill of sale will be required to establish warranty

qualification. If neither is available, the warranty period will

be 12 months from date of shipment from L B. White.

Warranty Policy

Replacement Parts and Service

EQUIPMENT

PARTS

L.B. White Co., Inc. warrants that replacement parts

purchased from the company and used on the appropriate

L. B. White heater are free from defects both in material and

workmanship for 12 months from the date of purchase by

the end user. Warranty is automatic if a component is found

defective within 12 months of the date code marked on the

part. If the defect occurs more than 12 months later than

the date code but within 12 months from the date of

purchase by the end user, a copy of a bill of sale will be

required to establish warranty qualification.

The warranty set forth above is the exclusive warranty

provided by L.B. White, and all other warranties, including

any implied warranties or merchantability or fitness for a

particular purpose, are expressly disclaimed. In the event

any implied warranty is not hereby effectively disclaimed

due to operation of law, such implied warranty is limited in

duration to the duration of the applicable warranty stated

above. The remedies set forth above are the sole and

exclusive remedies available hereunder. L.B. White will not

be liable for any incidental or consequential damages

directly or indirectly related to the sale, handling or use of

the heater, and in any event L.B. White's liability in

connection with the heater, including for claims based on

negligence or strict liability, is limited to the purchase price.

Some states do not allow limitations on how long an implied

warranty lasts, so the above limitation may not apply to you.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above

limitation or exclusion may not apply to you. This warranty

gives you specific legal rights, and you may also have other

rights which vary from state to state.

29

Loading...

Loading...