Page 1

Convection

Vertical Heaters

Workman Standard Duty

Norseman Heavy Duty

View this manual online at www.lbwhite.com

Attention

Models 320, CV225 and CV100

heaters have been tested and

evaluated by CSA Group in

accordance with Standard ANSI

Z83.7 • CSA 2.14 and are listed

and approved as a direct fi red

vertical convection construction

heaters for use on combustible

fl oors. Model 341 heaters are

tested and evaluated by the

L.B.White and are not approved

for use on combustible fl oors.

All heaters are intended for use

as a portable, temporary heater

for buildings under construction,

alteration, or repair. If you are

considering using this product

for any application other than its

intended use, then please

contact your fuel gas supplier,

or the L.B. White Company, LLC

This manual provides

instruction for all

vertical construction

heaters manufactured by

L.B. White. Information

relating to a specifi c

model or gas confi guration is noted. Unless,

noted, the information

applies to all models.

Owner’s Manual and Instructions

320

200,000 Btu/h*/58.6kW

341

250,000 Btu/h*/73.3kW

CV225

225,000 Btu/h*/65.9kW

CV100

100,000 Btu/h*/29.3kW

*Specifi c models for

US or Canada. Refer

to heater dataplate.

Propane

Vapor

Withdrawal

Natural

Gas

Congratulations!

You have purchased the fi nest convection heater available.

Your new L.B. White heater incorporates the benefi ts from the

most experienced manufacturer of heating products using

state-of-the-art technology.

We, at L.B. White, thank you for your confi dence in our products

and welcome any suggestions or comments you may have...call

us, toll-free, at 1-800-345-7200.

www.lbwhite.com

SCAN THIS

with your smartphone or

visit http://goo.gl/nvneR

SEE ASSEMBLY

INSTRUCTIONS

INSIDE

WORLD PROVIDER - INNOVATIVE HEATING SOLUTIONS

411 Mason Street, Onalaska, WI 54650, USA • 800-345-7200 • 608-783-5691 • 608-783-6115 (fax) • www.lbwhite.com

to view maintenance

videos for L.B.White heaters.*

* Requires an app like QR Droid

for Android or for iPhone

Page 2

2

Vertical Convection Heaters

TABLE OF CONTENTS

Heater Specifi cations ............................................................................................................... 4

General Information ................................................................................................................. 5

Safety Precautions .................................................................................................................. 6

Installation Instructions

General ......................................................................................................................... 10

Burner Installation, Norseman 200 Plus and Norseman 250 ........................................ 12

Hose and Regulator Assembly - Propane Heaters ....................................................... 12

Connecting the Regulator to the Gas Supply

Propane Heaters ................................................................................................ 13

Natural Gas Heaters ........................................................................................... 13

Lighting and Shut Down Instructions

Workman 225 Plus ............................................................................................. 14

Norseman 200 Plus and Norseman 250 ............................................................ 15

Workman 100 Plus Natural Gas ......................................................................... 16

Cleaning Instructions ............................................................................................................... 17

Maintenance Instructions ......................................................................................................... 18

Service Instructions ................................................................................................................. 19

General ......................................................................................................................... 19

Workman 225 Plus ........................................................................................................ 19

Burner Orifi ce and Safety Control Valve ............................................................. 19

Workman 100 Plus Natural Gas.................................................................................... 20

Pilot Orifi ce ......................................................................................................... 20

Burner Orifi ce ..................................................................................................... 20

Safety Control Valve and Gas Regulator ............................................................ 20

Norseman 200 Plus and Norseman 250 ....................................................................... 21

Burner Orifi ce ..................................................................................................... 21

Pilot Orifi ce ......................................................................................................... 21

Safety Control Valve ........................................................................................... 21

Igniter and Electrode (Workman 225 Plus, Norseman 200 Plus, and Workman 100 Plus) . 22

Thermocouple (all models) ........................................................................................... 23

Gas Pressure Checks ................................................................................................... 24

Troubleshooting Information .................................................................................................... 26

Heater Component Function ................................................................................................... 27

Parts Identifi cation

Parts Schematic and Parts List

Workman 225 Plus ............................................................................................. 28

Norseman 200 Plus and Norseman 250 ............................................................ 29/30

Workman 100 Plus Natural Gas ......................................................................... 31

Warranty Policy, Replacement Parts, and Service .................................................................. 33

www.lbwhite.com

Owner’s Manual • Workman & Norseman

Page 3

Vertical Convection Heaters

3

■ FAILURE TO COMPLY WITH THE PRECAUTIONS AND INSTRUCTIONS PROVIDED WITH

THIS HEATER CAN RESULT IN:

— DEATH

— SERIOUS BODILY INJURY OR BURNS

— PROPERTY DAMAGE OR LOSS FROM FIRE OR EXPLOSION

— ASPHYXIATION DUE TO LACK OF ADEQUATE AIR SUPPLY OR CARBON MONOXIDE

POISONING

■ READ THIS OWNER’S MANUAL BEFORE INSTALLING OR USING THIS PRODUCT.

■ ONLY PERSONS WHO CAN READ, UNDERSTAND, AND FOLLOW THE INSTRUCTIONS

SHOULD USE OR SERVICE THIS HEATER.

■ SAVE THIS OWNER’S MANUAL FOR FUTURE USE AND REFERENCE.

■ OWNER’S MANUALS AND REPLACEMENT LABELS ARE AVAILABLE AT NO CHARGE. SEE

WEBSITE, OR FOR ASSISTANCE, CONTACT L.B. WHITE AT 1-800-345-7200.

WARNING

GENERAL HAZARD WARNING

■ PROPER GAS SUPPLY PRESSURE MUST BE PROVIDED TO THE INLET OF THE HEATER.

■ REFER TO DATA PLATE FOR PROPER GAS SUPPLY PRESSURE.

■ GAS PRESSURE IN EXCESS OF THE MAXIMUM INLET PRESSURE SPECIFIED AT THE

HEATER INLET CAN CAUSE FIRES OR EXPLOSIONS.

■ FIRES OR EXPLOSIONS CAN LEAD TO SERIOUS INJURY, DEATH, OR BUILDING

DAMAGE.

■ GAS PRESSURE BELOW THE MINIMUM INLET PRESSURE SPECIFIED AT THE HEATER INLET

MAY CAUSE IMPROPER COMBUSTION.

■ IMPROPER COMBUSTION CAN LEAD TO ASPHYXIATION OR CARBON MONOXIDE POISONING AND THEREFORE SERIOUS INJURY OR DEATH.

WARNING

■ NOT FOR HOME OR RECREATIONAL VEHICLE USE.

■ INSTALLATION OF THIS HEATER IN A HOME OR RECREATIONAL VEHICLE MAY RESULT IN A

FIRE OR EXPLOSION.

■ FIRE OR EXPLOSIONS CAN CAUSE PROPERTY DAMAGE OR LOSS OF LIFE.

FIRE AND EXPLOSION HAZARD

WARNING

FIRE, BURN, INHALATION, AND

EXPLOSION HAZARD

■ KEEP SOLID COMBUSTIBLES A SAFE DISTANCE AWAY FROM THE HEATER.

■ SOLID COMBUSTIBLES INCLUDE WOOD,

PAPER, OR PLASTIC PRODUCTS, BUILDING

MATERIALS AND DUST.

■ DO NOT USE THE HEATER IN SPACES WHICH

CONTAIN OR MAY CONTAIN VOLATILE OR

AIRBORNE COMBUSTIBLES.

■ VOLATILE OR AIRBORNE COMBUSTIBLES

INCLUDE GASOLINE, SOLVENTS, PAINT

THINNER, DUST PARTICLES OR UNKNOWN

CHEMICALS.

■ FAILURE TO FOLLOW THESE INSTRUCTIONS

MAY RESULT IN A FIRE OR EXPLOSION.

■ FIRE OR EXPLOSIONS CAN LEAD TO

PROPERTY DAMAGE, PERSONAL INJURY OR

DEATH.

Owner’s Manual • Workman & Norseman

FOR YOUR SAFETY

Do not store or use gasoline or other fl am-

mable vapors and liquids in the vicinity of this

or any other appliance.

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open fl ame.

4. Immediately call your gas supplier.

WARNING

Cancer and reproductive harm.

See www.P65Warnings.ca.gov.

Page 4

4

Vertical Convection Heaters

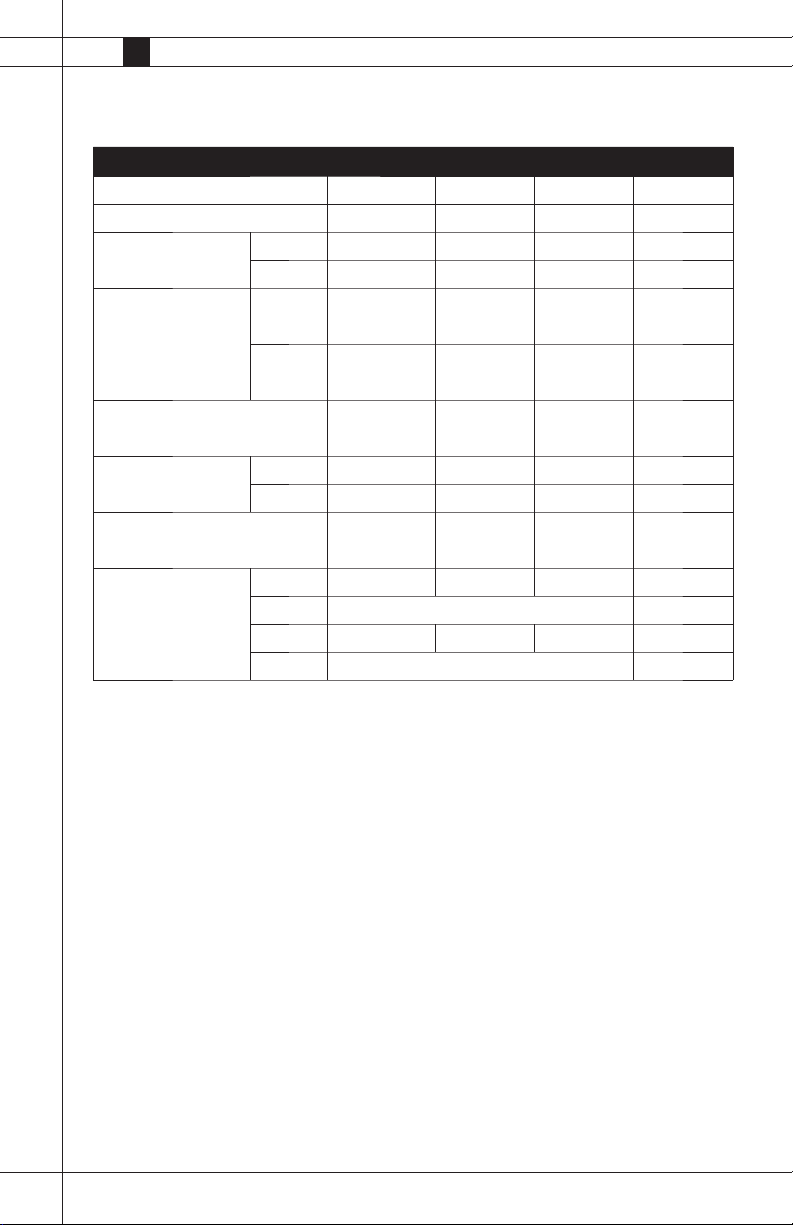

Specifications

Description Model

320 341 CV225 CV100

Fuel Type Propane Gas Propane Gas Propane Gas Natural Gas

Input (Btuh/kW) MAX. 200,000 / 58.6 250,000 / 73.3 225,000 / 65.9 100,000 / 29.3

MIN. N/A N/A 45,000 / 13.2 N/A

Inlet gas supply pressure

acceptable at the gas con-

nection of the heater (see

Footnote 1)

Burner manifold pressure

(see Footnote 1)

Fuel consumption per hour

(see Footnote 2)

Dimensions (Inches/cm)

LxWxH

Minimum safe distances

from nearest combustible

materials (Feet/Meters)

MAX. 23 / 158.6 23 / 158.6 10.2 / 70.3 13.5 / 3.36

MIN. 23 / 158.6 23 / 158.6 10.2 / 70.3 7.0 / 1.74

23 / 158.6 23 / 158.6 10.0 / 68.9 5.1 / 1.27

MAX. 9.28 / 4.21 11.6 / 5.26 10.44 / 4.73 100 / 2.83

MIN. N/A N/A 2.08 / 0.94 N/A

18x13x24/

46x33x61

TOP 5 ft. 10 in. / 1.77 8.0/2.43 5 ft. 10 in. / 1.77 5.0 / 1.52

SIDES 4.0 / 1.2 3.0 / .91

BELOW O See Footnote 3 O O

PROPANE US: 6/1.83 Canada: 10/3.05 N/A

18x13x24/

46x33x61

17x15 x26/

43x38x66

16.5x15x 25/

42x38x64

Footnote 1: Gas pressures: Models 320, 341, and CV225: expressed in PSIG/kPa.

Model CV100: expressed in Inches of Water Column / kPa

Footnote 2: Fuel consumption: Models 320, 341, and CV225: expressed in pounds/kilograms per hour

Model CV100: expressed in cubic feet / cubic meters per hour.

Footnote 3: DO NOT place this heater on any combustible material

www.lbwhite.com

Owner’s Manual • Workman & Norseman

Page 5

General Information

When calling for technical service assistance, or for

other specifi c information, always have model

number, confi guration number and serial number

available. This information is contained on the

dataplate.

This manual will instruct you in the operation and care

of your unit. Have your installer review this manual

with you so that you fully understand the heater and

how it functions.

Contact your local L.B. White distributor or the

L.B. White Company, LLC for assistance, or if you

have any questions about the use of the equipment

or its application.

The L.B. White Company, LLC has a policy of continuous product improvement. It reserves the right to

change specifi cations and design without notice.

Vertical Convection Heaters

5

Owner’s Manual • Workman & Norseman

Page 6

6

Vertical Convection Heaters

Safety Precautions

WARNING

■ Do not use this heater for heating human living quarters.

■ Use of direct-fi red heaters in the construction environment can result in exposure to levels of CO,

CO2, and NO2 considered to be hazardous to health and potentially life threatening.

■ Do not use in unventilated areas.

■ Know the signs of CO and CO2 poisoning

- Headaches, stinging eyes.

- Dizziness, disorientation.

- Diffi culty breathing, feeling of being suffocated.

■ Proper ventilation air exchange (OSHA 29 CFR 1926.57) to support combustions and maintain

acceptable air quality shall be provided in accordance with OSHA 29 CFR part 1926.154, ANSI A10.10

Safety Requirements for Temporary and Portable Space Heating Devices and Equipment used in the

Construction Industry or the Natural Gas and Propane Installation Codes CSA B149.1.

- Periodically monitor levels of CO, CO2, and NO2 existing at the construction site – at the

minimum at the start of the shift and after 4 hours.

- Provide ventilation air exchange, either natural or mechanical, as required to maintain

acceptable indoor air quality.

USA 8-Hr. Time weighted average Canada 8-Hr. Time weighted average

(OSHA 29 CFR 1926.55 App A) WorkSafe BC OHS Guidelines Part 5.1

and Ontario Workplaces Reg 833

CO 50 ppm 25 ppm

CO2 5,000 ppm 5,000 ppm

NO2 3 ppm (Reg 833)

USA – Ceiling Limit Canada STEL (15 minutes Reg 833/1 hr.

(Short Term Exposure Limit = 15 minutes) WSBC) WorkSafe BC OHS Guidelines part

5.1 and Ontario Workplaces Reg 833

CO 100 ppm

CO2 15,000 ppm (WSBC)

30,000 ppm (Reg 833)

NO2 5 ppm 1.0 ppm (WorkSafeBC)

5.0 ppm (Reg 833)

■ Ensure that the fl ow of combustion and ventilation air exchange cannot become obstructed.

■ As the building ‘tightens up” during the construction phases, ventilation may need to be increased.

Air Quality Hazard

www.lbwhite.com

Owner’s Manual • Workman & Norseman

Page 7

Vertical Convection Heaters

Fuel Gas Odor Odor Fading - No

Propane gas and natural gas have man-made odorants added specifi cally for detection of fuel gas leaks.

If a gas leak occurs, you should be able to smell

the fuel gas . THAT’S YOUR SIGNAL TO GO INTO

IMMEDIATE ACTION!

■ Do not take any action that could ignite the fuel

gas. Do not operate any electrical switches. Do not

pull any power supply or extension cords. Do not

light matches or any other source of fl ame. Do not

use your telephone.

■ Get everyone out of the building and away from the

area immediately.

■ Close all fuel supply valves.

■ Propane gas is heavier than air and may settle in

low areas. When you have reason to suspect a

propane leak, keep out of all low areas.

■ Use your neighbor’s phone and call your fuel gassupplier and your fi re department. Do not re-enter

the building or area.

Odor Detected

■ Some people cannot smell well. Some people

cannot smell the odor of the man-made chemical added to propane or natural gas. You must

determine if you can smell the odorant in these

fuel gases.

■ Learn to recognize the odor of propane gas and

natural gas. Local propane gas dealers and your

local natural gas supplier (utility) will be more than

happy to give you a “scratch and sniff” pamphlet.

Use it to become familiar with the fuel gas odor.

■ Smoking can decrease your ability to smell. Being

around an odor for a period of time can affect your

sensitivity to that particular odor.

■ The odorant in propane gas and natural gas is colorless and the intensity of its odor can fade under

some circumstances.

■ If there is an underground leak, the movement of

gas through the soil can fi lter the odorant.

7

■ Stay out of the building and away from the area

until declared safe by the fi refi ghters and your fuel

gas supplier.

■ FINALLY, let the fuel gas service person and the

fi refi ghters check for escaped gas. Have them

air out the building and area before you return.

Properly trained service people must repair the

leak, check for further leakages, and then relight

the heater for you.

Owner’s Manual • Workman & Norseman

■ Propane gas odor may differ in intensity at different

levels. Since propane gas is heavier than air, there

may be more odor at lower levels.

■ Always be sensitive to the slightest gas odor. If you

continue to detect any gas odor, no matter how

small, treat it as a serious leak. Immediately go into

action as discussed previously.

Page 8

8

Vertical Convection Heaters

Attention - Critical

Points to Remember!

WARNING

Burn Hazard

■ High surface and discharge temperatures.

■ Do not touch the heater or come within safe

clearances given on dataplate or owner’s

manual.

■ Use extreme caution when lighting the heater

or adjusting heat levels.

■ Failure to follow this warning can result in

burns or ignition of clothing.

■ Burns cause serious injury or death.

• Propane gas has a distinctive odor. Learn to recognize this odor. (Reference “Fuel Gas Odor” and

“Odor Fading” section above.

• If you have not been properly trained in repair and

service of propane gas fueled heaters, then do not

attempt to light heater, perform service or repairs,

or make any adjustments to the heater on propane

gas fuel system.

• Even if you are not properly trained in the service

and repair of the heater, ALWAYS be consciously

aware of the odor of propane gas and natural gas.

• A periodic sniff test around the heater or at the

heater’s joints; i.e. hose, connections, etc., is a good

safety practice under any conditions. If you smell

even a small amount of gas, CONTACT YOUR

FUEL GAS SUPPLIER IMMEDIATELY.

DO NOT WAIT!

normal operating condition. You must completely

familiarize yourself with each model heater by

reading and complying with the safety instructions,

labels, Owner’s Manual, etc., that is provided with

each heater.

b. To be a qualifi ed gas installation person, you must

have suffi cient training and experience to handle

all aspects of installing, repairing and altering gas

lines, including selecting and installing the proper

equipment, and selecting proper pipe and tank size

to be used. This must be done in accordance with

all local, state and national codes as well as the

manufacturer’s requirements.

c. Norseman 200, Workman 225, Workman 100 NG:

In the Commonwealth of Massachusetts, these

products must be installed by a gas fi tter licensed

by the Commonwealth of Massachusetts.

2. All installations and applications of L.B. White

heaters must meet all relevant local, state and

national codes. Included are L.P. gas, natural gas,

electrical, and safety codes. Your local fuel gas

supplier, a local licensed electrician, the local fi re

department or similar government agencies, or

your insurance agent can help you determine code

requirements.

In the absence of local codes, refer to:

-- ANSI/NFPA 58, latest edition, Standard for Storage

and Handling of Liquefi ed Petroleum Gas

-- ANSI Z223.1/NFPA 54, National Fuel Gas Code

-- CSA B149.1, Natural Gas and Propane Installation

Code.

1. Do not attempt to install, repair, or service this

heater or the gas supply line unless you have

continuing expert training and knowledge of gas

heaters.

Qualifi cations for service and installation of this

equipment are as follows:

a. To be a qualifi ed gas heater service person, you

must have suffi cient training and experience to

handle all aspects of gas-fi red heater installation,

service and repair. This includes the task of installation, troubleshooting, replacement of defective

parts and testing of the heater. You must be able

to place the heater into a continuing safe and

www.lbwhite.com

Owner’s Manual • Workman & Norseman

3. Not for use with duct work.

4. We cannot anticipate every use which may be

made of our heater. Check with your local fi re

safety authority if you have questions about applications.

5. Other standards govern the use of fuel gases and

heat producing products in specifi c applications.

Your local authority can advise you about these.

6. Use only compressed air, soft brush or dry cloth to

clean the interior of the heater and it’s components.

Page 9

Vertical Convection Heaters

9

7. Always use approved pipe thread compound

suitable for use with propane gas on the threaded

connections.

8. Do not block air intakes or discharge outlets of the

heater. Doing so may cause improper combustion or damage to heater components leading to

property damage.

9. The hose assembly shall be visually inspected on

a daily basis after heater relocation and when the

heater is in use. If it is evident there is excessive

abrasion or wear, or if the hose is cut, it must be

replaced prior to the heater being put into operation. The hose assembly shall be protected building materials, and contact with hot surfaces during

use. The replacement hose assembly shall be that

specifi ed by the manufacturer. See parts list.

10. Check for gas leaks and proper function upon

heater installation or when relocating. Refer to

leak check instructions within installation section

of this manual.

11. This heater should be inspected for proper

operation by a qualifi ed service person before

each use and at least annually.

12. Always turn off the gas supply to the heater

when not using the heater.

14. Minimum propane gas supply cylinder size to be

used shall be 100 pounds. When using a cylinder

supply system, the system must be arranged

to provide vapor withdrawal from the operating

cylinder.

15. When the heater is to be stored indoors, the

connection between the propane gas supply

cylinder(s) and the heater must be disconnected

and the cylinder(s) removed from the heater and

stored in accordance with the Standard for Storage and Handling of Liquefi ed Petroleum Gases,

ANSI/NFPA 58, and natural GAs and Propane

installation code, CSA B149.1

16. Propane gas supply containers have left handed

threads. Always use the appropriate wrench to

tighten or loosen the P.O.L. fi tting at the propane

gas containers supply valve. Do not use pliers.

13. If gas fl ow is interrupted and fl ame goes out, do

not relight the heater until you are sure that all

gas that may have accumulated has cleaned

away. In any event, do not relight the heater for

at least 5 minutes.

Owner’s Manual • Workman & Norseman

Page 10

10

Vertical Convection Heaters

General Installation Instructions

WARNING

Can cause property damage, severe injury or death.

1. To avoid dangerous accumulation of fuel gas, turn

off gas supply at the appliance service valve before

starting installation, and perform gas leak test after

completion of installation.

2. Do not force the safety control valve’s button. Use

only your hand to depress the button. Never use

any tools. If the button will not operate by hand, the

control should be replaced by a qualifi ed service

technician. Force or attempted repair may result in

fi re or explosion.

1. Read all safety precautions and follow L.B. White

recommendations when installing this heater. If

during the installation or relocating of heater, you

suspect that a part is damaged or defective, call a

INSTALLATION INSTRUCTIONS

qualifi ed service agency for repair or replacement.

2. Position heater properly before use. Using a

level, ensure the heater is installed on a level,

fl at, horizontal and stable surface when hot or in

operation and according to minimum clearances

from combustible surfaces such as walls, fl oor or

ceilings. Do not place combustible materials within

this zone of clearance. See Specifi cation Page

4 of this manual for minimum safe distances to

combustible materials.

Burn Hazard

WARNING

■ Temperatures at base of the Norseman

250 (model 341) may ignite combustible

materials.

■ Use the Norseman 250 heater on non-combustible materials to avoid a fi re hazard.

Fire Hazard

3. L.P Gas Installation Requirements

■ Ensure all L.P. gas containers are secured and

protected from people, vehicular traffi c and

contact.

■ L.P. gas containers must be located on a

fl at,level, and stable surface.

■ L.P. gas cylinders (100 lb./45kg cylinders/tanks)

must be secured from tip-over.

Contact your local authorities, L.P. gas dealers, or

fi re marshalls for specifi cs dealing with installation

in your area.

4. Position the heater and its gas supply hose so

as to protect heater and its gas supply hose

from traffi c. Protect hoses with a shielding

device of suitable nature to protect the hose

from traffi c and movement or other construction

equipment.

5. The heater shall be installed so it is not directly

exposed to water spray, rain, and /or dripping

water.

6. The heater’s gas pressure regulator (with

pressure relief valve) must be protected from

adverse weather conditions (rain, ice, snow) as

well as from building materials (tar, concrete,

plaster, etc.) which can affect safe operation and

could result in property damage or injury.

7. Heaters used in the vicinity of combustible

tarpaulins, canvas, plastics, wind barriers, or

similar coverings shall be located at least 10

feet (3.05m) from the coverings. The coverings

shall be securely fastened to prevent ignition or

upsetting of the heater due to wind action on the

covering or other material.

■ Per OSHA 1926.154: a heater not suitable for use

on a combustible surface may be used on such

surfaces providing the heater rests on a suitable

heat shielding and insulating material, such as

concrete, of at least 1 inch (2.54cm) thickness. The

insulating material shall extend beyond the heater

2 feet (0.61m) or more in all directions.

www.lbwhite.com

Owner’s Manual • Workman & Norseman

Page 11

Vertical Convection Heaters

11

8. Check all connections for gas leaks using approved gas leak detectors. Gas leak testing is

performed as follows:

WARNING

Fire and Explosion Hazard

■ Do not use open fl ame (matches, torches,

candles, etc.) in checking for gas leaks.

■ Use only approved leak detectors.

■ Failure to follow this warning can lead to fi res

or explosions.

■ Fires or explosions can lead to property damage, personal injury or loss of life.

-- Check all pipe connections, hose connections,

fi ttings and adapters upstream of the gas control

with approved gas leak detectors.

-- In the event a gas leak is detected, check the

components involved for cleanliness and proper

application of pipe compound before further

tightening.

-- Further tighten the gas connections as necessary

to stop the leak.

-- After all connections are checked and any leaks

are stopped, turn on the main burner.

-- Stand clear while the main burner ignites to

prevent injury caused from hidden leaks that could

cause fl ashback.

9. A qualifi ed service agency must inspect the

heater before each use and at least annually.

10. Light according to instructions on heater or

within owner’s manual.

11. Make sure the heater has the proper gas regu-

lator for the application. A regulator must be

connected to the gas supply so that gas pressure at the inlet to the gas valve is regulated

within the range specifi ed on the dataplate at

all times. Contact your gas supplier, or the L.B.

White Co., Inc. if you have any questions.

12. This heater is confi gured for use with propane

vapor withdrawal only. Consult the heater’s dataplate for the gas confi guration of the specifi c

heater. Do not use the heater in an propane

liquid withdrawal system or application. If you

are in doubt, contact the L.B. White Co., Inc.

13. Take time to understand how to operate and

maintain the heater by using this Owner’s

Manual. Make sure you know how to shut off

the gas supply to the building and also to the

individual heater. Contact your fuel gas supplier

if you have any questions.

14. Any defects found in performing any of the

service or maintenance procedures must

be eliminated and defective parts replaced

immediately. The heater must be retested by

properly qualifi ed service personnel before

placing the heater back into use.

-- With the main burner in operation, check all

connections, hose connections, fi ttings and joints

as well as the gas control valve inlet and outlet

connections with approved gas leak detectors.

-- If a leak is detected, check the components

involved for cleanliness in the thread areas and

proper application of pipe compound before

further tightening.

-- Tighten the gas connection as necessary to stop

the leak.

-- If necessary, replace the parts or components

involved if the leak cannot be stopped.

-- Ensure all gas leaks have been identifi ed and

repaired before proceeding.

Owner’s Manual • Workman & Norseman

15. For indoor use only. Adequate ventilation shall

be provided in accordance with OSHA 29 CFR

1926.154, Safety Requirements for Temporary

and Portable Space Heating Devices and

Equipment, ANSI A10.10, National Fuel Gas

Code, ANSI Z223.1/NFPA54, Liquifi ed Petro-

leum Gas Code, NFPA 58 or the Natural gas

and Propane Installation Code, CAN B149.1,

as appropriate.

Page 12

12

Vertical Convection Heaters

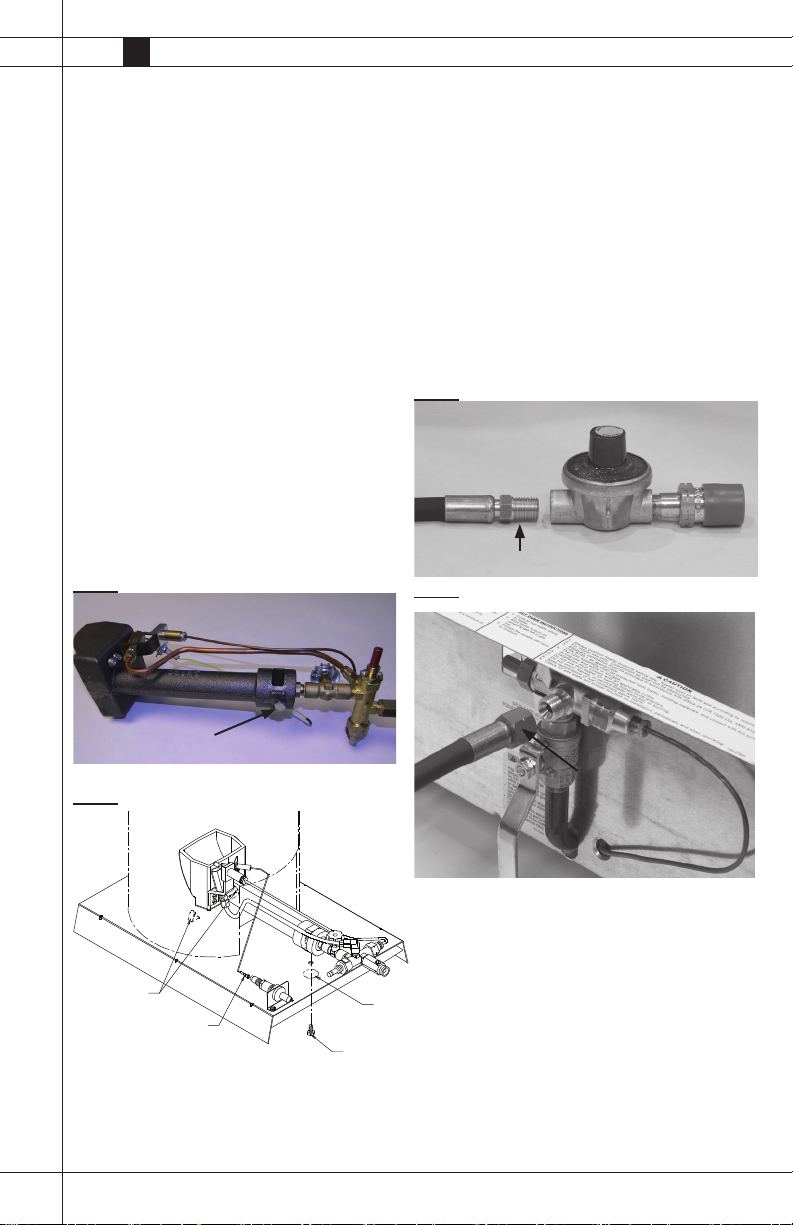

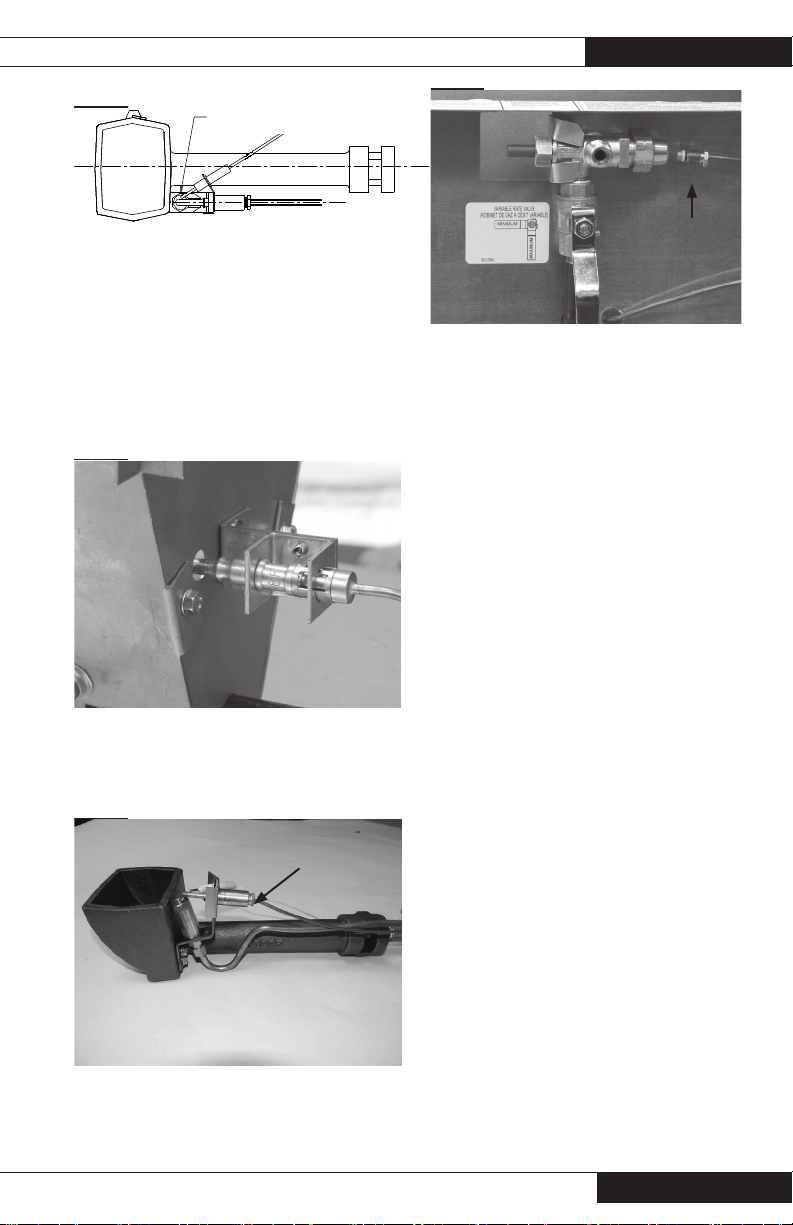

Burner Installation

Norseman 200 Plus and Norseman 250

1. Remove the 7/16 hex head screw from underside

of pre-assembled burner. See Fig. 1.

2. Install the burner assembly into the heater’s case

assembly. See Fig. 2.

a. The burner head must be located between upright

tabs in heater’s base.

b. Align tapped hole in burner casting (previously oc-

cupied by hex head bolt) to mounting hole in base.

c. Using a 7/16 in. nut driver or ratchet with 7/16 in.

socket, securely fasten the burner assembly to the

base using the screw removed in step 1.

3. Norseman 200 heaters: Push female terminal on

electrode wire securely onto male terminal of push

button igniter. See Fig. 2.

FIG. 1

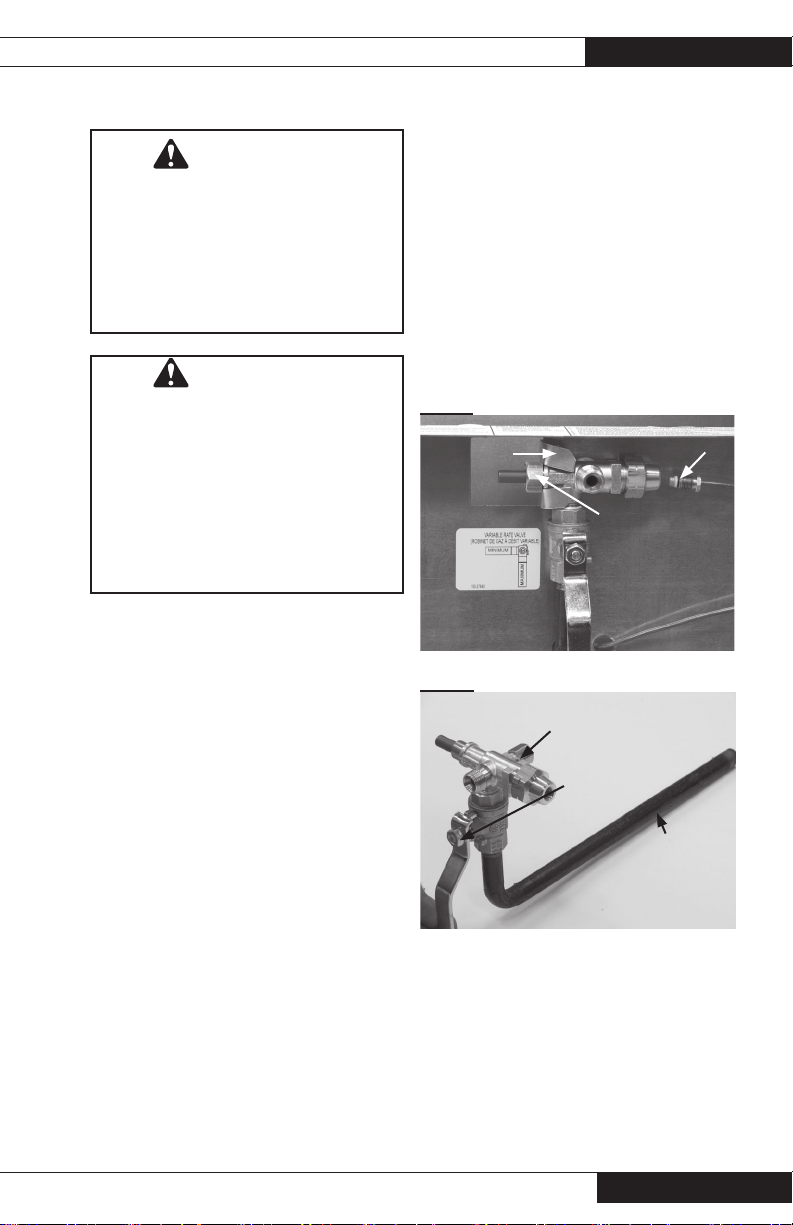

Hose and Regulator

Assembly

Propane Gas Heaters

1. Apply a small amount of pipe thread sealant to

threads of rigid hose connection. Connect this end

to to regulator outlet. See Fig. 3. Tighten securely.

Workman 225 shown.

2. Connect opposite end of hose with nut to safety

control valve of heater. See Fig.4. Tighten securely.

(Workman 225 Plus shown.)

FIG. 3

APPLY SEALANT

FIG. 4

7/16 SCREW

FIG. 2

UPRIGHT

TABS

NORSEMAN 200:

ELECTRODE LEAD

CONNECTED TO

PUSH BUTTON

IGNITER

www.lbwhite.com

Owner’s Manual • Workman & Norseman

NORSEMAN 200:

HOLE IN BAFFLE

PLATE

7/16 IN. BURNER

SCREW

NUT HAS LEFT

HANDED THREADS

NOTE:

Norseman 200 & Norseman

250 heaters use a hose with

swivel nuts at both ends.

• Connect one end to safety

control valve at heater.

• Connect opposite end to

hose adapter at regulator

outlet.

Page 13

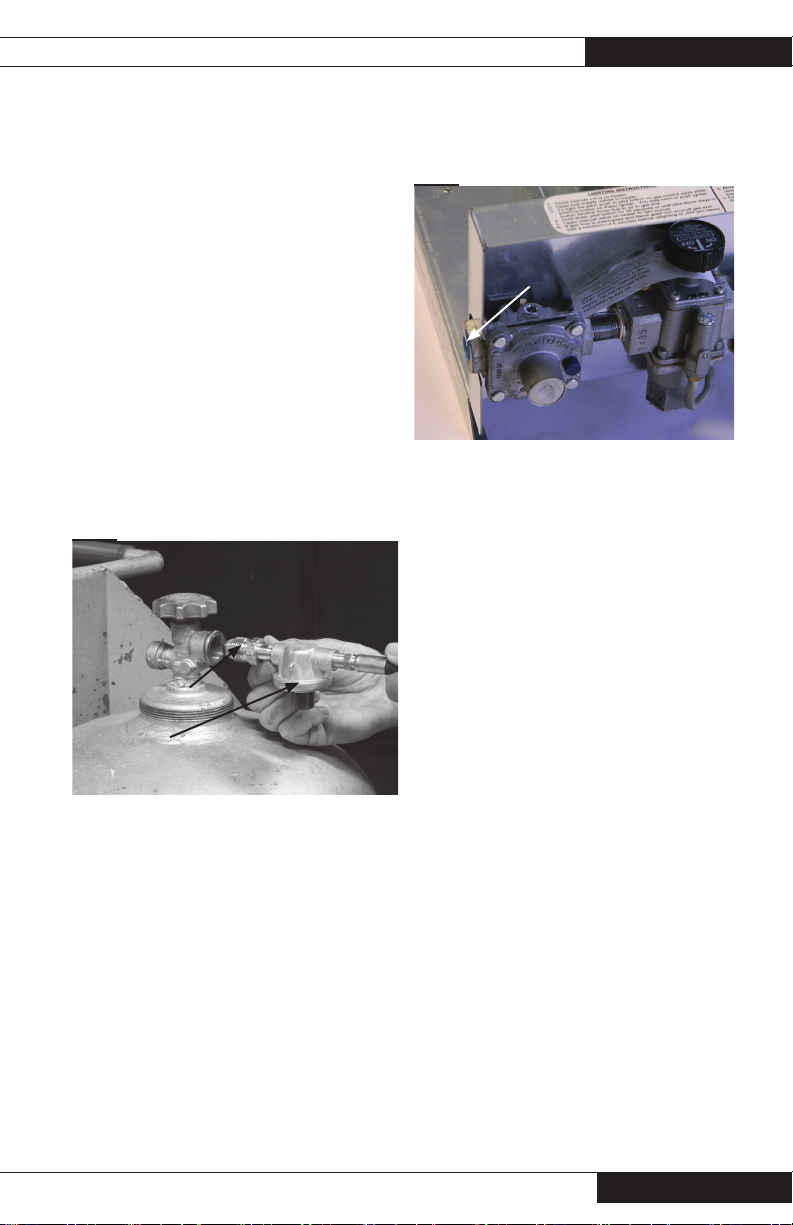

Connecting Regulator to

Gas Supply

Vertical Convection Heaters

13

Propane Gas Heaters (Workman 225

Plus, Norseman 200 Plus and Norseman

250)

1. Remove protective cap from POL fi tting. Do not

discard cap. Position regulator as shown to protect

its vent, or install protective cover over the regulator

and cylinder valve.

2. Insert POL fi tting into propane supply valve. See

Fig.5. Thread nut on fi tting counterclockwise into

propane supply valve. Tighten nut securely with a

wrench.

-- When storing or transporting the heater, ensure the

cap is pushed onto the POL fi tting to prevent dam-

age or dirt entry into regulator.

FIG. 5

POL FITTING

REGULATOR VENT DOWN

FIG. 6

GAS INLET

OF HEATER

Natural Gas Heaters (Workman 100 Plus

Natural Gas)

-- Connect the appropriate gas supply line to the inlet

of the regulator located on the heater. See Fig. 6.

This regulator takes an inlet pressure of 13.5 In.W.C.

(3.36 kPa) maximum or a minimum inlet pressure of

7.0 inches W.C. (1.74 kPa) The regulator reduces

the inlet pressure down to 5.1 In. W.C. (1.27 kPa)

for operation.

For inlet pressures exceeding 13.5 In.

W.C. (3.36 kPa), an additional regulator

will be needed upstream of the heater’s

regulator to reduce the higher pressure to

the required inlet pressure.

Owner’s Manual • Workman & Norseman

Page 14

14

Vertical Convection Heaters

Lighting Instructions

Workman 225 Plus

WARNING

Burn Hazard

■ Before lighting, ensure the variable heat valve

on heater is positioned to the minimum heat

output setting. See Fig. 7.

■ Failure to do so will result in the main burner

igniting at full heat output.

■ Serious injury or death due to burns may

occur.

1. Slowly open the propane gas supply container valve.

(This prevents lockup of the excess fl ow check valve

internal to the regulator’s POL fi tting.)

2. Fully depress the button on the safety control valve

while pushing the igniter button. The burner will light.

See Fig. 7.

FIG. 7

BUTTON ON

SAFETY VALVE

SET VARIABLE

RATE VALVE TO

MINIMUM POSITION

BEFORE LIGHTING

IGNITER BUTTON

FIG. 8

MAXIMUM HEAT

Shut-Down Instructions

1. Close the propane gas supply container valve.

2. Allow the heater to burn off any fuel gas remaining in

the gas supply line.

3. Position the variable rate valve to its minimum heat

position.

4. Disconnect the heater from its gas supply.

■ On new installations it may take a short time for gas

to purge out any air before the burner lights.

3. Keep the valve button depressed for about 30 seconds to allow the thermocouple to warm up.

4. Release the safety control valve button.

5. Once the burner is lit, the variable rate valve can be

positioned to any setting from minimum to maximum

heat. See Fig. 8

www.lbwhite.com

Owner’s Manual • Workman & Norseman

Page 15

Vertical Convection Heaters

15

Lighting Instructions

Norseman 200 Plus and Norseman 250

WARNING

Burn Hazard

■ Before lighting, ensure the manual main

burner valve is completely closed. See Fig. 9

■ Failure to do so will result in the main burner

igniting at full heat output.

■ Serious injury or death due to burns may

occur.

1. Slowly open the propane gas container valve.

(This prevents lockup of the excess fl ow check valve

internal to the regulator’s POL fi tting.)

2. Norseman 200 Plus:

Fully depress the button on the pilot safety control valve

while pushing the igniter button.

Norseman 250:

Apply a fl ame to the pilot assembly. Then depress the

button on the safety control valve to light the pilot.

■ On new installations it may take a short time for gas to

purge out any air before the pilot lights and stays lit.

3. Once the pilot fl ame is lit, keep the pilot button de-

pressed for about 30 seconds to allow the thermocouple

to warm up.

Shut-Down Instructions

A. To properly shut heater down after normal use, or

when further use is anticipated:

-- Close the manual main burner valve on heater.

The pilot will stay lit.

B. To properly shut heater down for storage, or when

further use is not anticipated:

1. Close propane gas supply container valve. Allow

heater to burn off remaining gas in its hose.

2. Close manual main burner valve on heater.

3. Disconnect the heater from its gas supply.

4. Release the safety control valve button.

5. Slowly open the manual main burner valve located

between the pilot safety control and burner.

FIG. 9

MAIN BURNER VALVE

PILOT ASSEMBLY

IGNITER BUTTON

Owner’s Manual • Workman & Norseman

PILOT BUTTON

Page 16

16

Vertical Convection Heaters

Lighting Instructions

Workman 100 Plus Natural Gas

1. Follow the instructions on the knob of the safety control

valve knob to light:

-- Turn the knob counter- clockwise (CCW) from OFF to

the PILOT position.

-- Fully depress the knob while repetitively pushing the

igniter’s button.

-- Keep the knob depressed in the PILOT position for

about 30 seconds to allow the thermocouple to warm up.

■ On new installations it may take a short time for gas to

purge out any air before the pilot lights and stays lit.

-- Release the knob on the safety control valve.

-- Turn the knob counterclockwise to ON. The main burner

will light.

FIG. 10

CONTROL

VALVE KNOB

Shut-Down Instructions

A. To properly shut heater down after normal use, or

when further use is anticipated:

-- Turn the knob on the pilot safety control valve to the

PILOT position. The main burner will shut off but

the pilot light will remain lit.

B. To properly shut heater down for storage, or when

further use is not anticipated:

1. Close the fuel supply valve.

2. Allow the heater to burn off any fuel gas remaining

on the gas supply line.

3. Slightly depress the safety control valve’s knob and

turn the knob clockwise to OFF position.

4. Disconnect the heater from its gas supply.

IGNITER BUTTON

www.lbwhite.com

Owner’s Manual • Workman & Norseman

Page 17

Cleaning Instructions

Vertical Convection Heaters

17

WARNING

Fire, Burn, and Explosion Hazard

■ This heater contains mechanical components

used in the gas management and safety

systems.

■ Such components may become inoperative or

fail due to dust, dirt, wear or aging.

■ Periodic cleaning and inspection as well as

proper maintenance are essential to avoid

serious injury or damage

1. Before cleaning, close all gas supply valves.

2. The heater should have dirt or dust removed

periodically:

a. Before each use give the heater a general

cleaning using compressed air, a soft brush, or

dry rag, on its case and internal components.

b. At least once a year, give the heater a

thorough cleaning. At this time, brush and/or

blow off the burner and related components.

WARNING

Do not use a pressure washer, water or liquid

cleaning solution on any gas controls. Use of a

pressure washer, water, or liquid cleaning solution on the control components can cause severe

personal injury or property damage due to water

and/or liquids:

* On gas control valves causing corrosion which

can result in gas leaks and fi re or explosion from

the leak.

Clean all components of the heater with

pressurized air, a dry brush or a dry cloth.

Owner’s Manual • Workman & Norseman

Page 18

18

Vertical Convection Heaters

Maintenance Instructions

BEFORE EACH USE:

1. Ensure the area surrounding the heater is free

and clear from combustible materials, gasoline, and other fl ammable vapors and liquids.

2. Inspect the gas hose. Replace the gas hose

immediately if nicks or cuts are found.

3. For heaters with a push button igniter, make

sure the wire from the igniter to the electrode

is in good condition, without any nicks or cuts.

Replace the electrode (comes with wire) if

defects are found.

4. Check for gas leaks using approved leak

detectors.

5. Review all heater markings (i.e. warnings,

start-up, shut-down, etc.) at the time of maintenance for legibility. Make sure none are cut,

torn, or otherwise damaged. Any damaged

markings must be replaced immediately by

contacting the L.B. White Co., Inc. Dataplates,

start-up and shut-down instructions and warnings are available at no cost.

6. Ensure the proper regulator is matched to

the heater being used. Regulators are set to

different pressures, depending on the design

requirements of the heater. Mis-matching of

the regualtor to the improper heater can result

in over or under fi ring of the heater, resulting

in soot, high levels of carbon monoxide, or

damage to the heater and surrounding area. If

in doubt, contact L.B. White Co.

ANNUALLY:

1. Regulators can wear out and function improperly. Have your gas supplier check the date

codes on all regulators installed and check

delivery pressures to the appliance to make sure

that the regulator is reliable.

7. Inspect the regulator to make sure the regulator vent is not blocked. Debris, insects, insect

nests, tar, snow, or ice on a regulator can

block vents and cause excess pressure at the

heater.

www.lbwhite.com

Owner’s Manual • Workman & Norseman

Page 19

Service Instructions

WARNING

Burn Hazard

■ Heater surfaces are hot for a period of time after

the heater has been shut down.

■ Allow the heater to cool before performing

service, maintenance, or cleaning.

■ Failure to follow this warning will result in burns

causing injury.

Vertical Convection Heaters

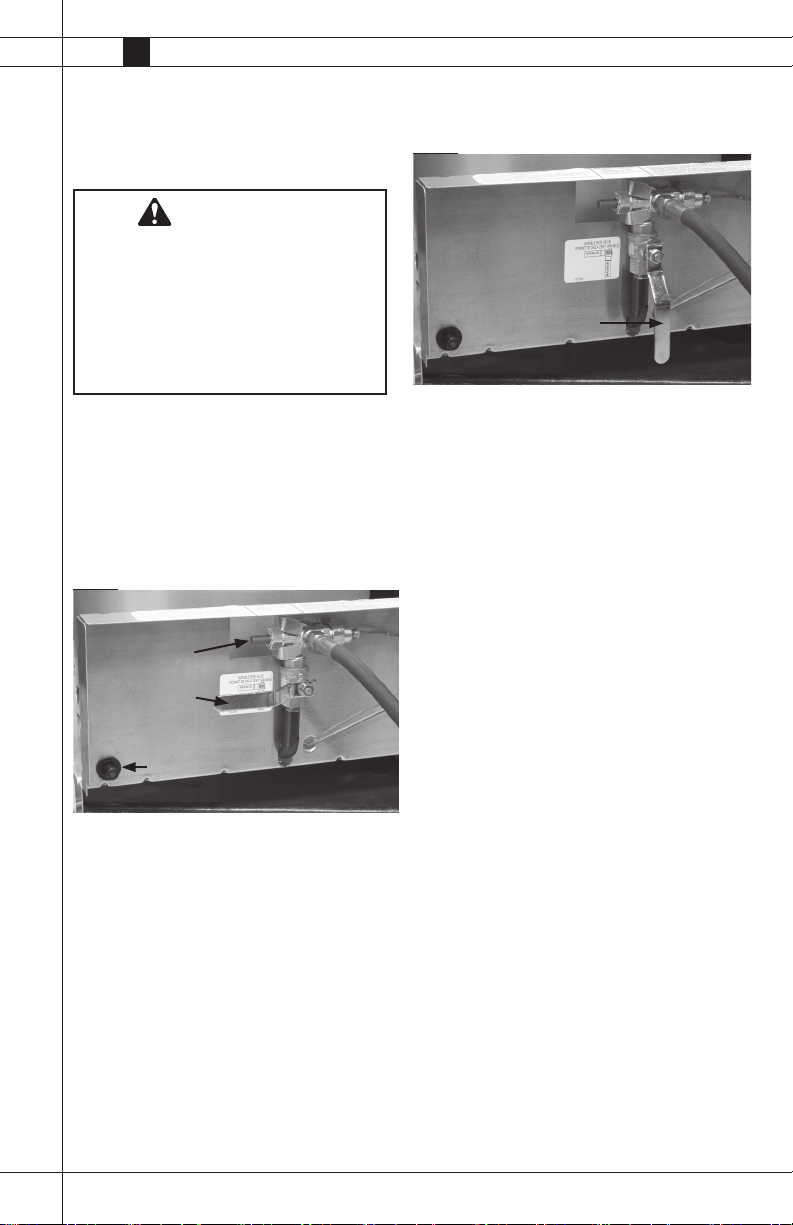

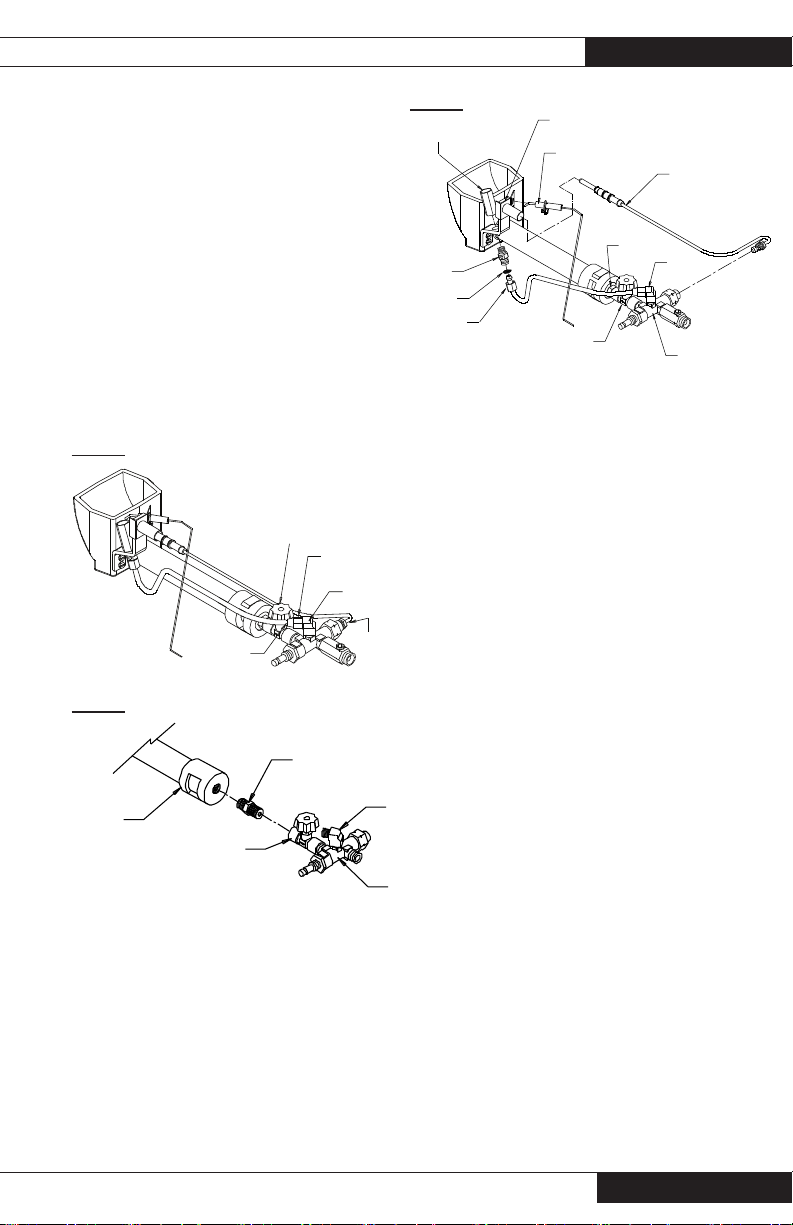

WORKMAN 225 PLUS

Burner Manifold/ Orifi ce and Safety

Control valve. See Figs. 11 and 12.

1. Straighten the mounting bracket tabs and remove

thermocouple from safety control valve.

2. Remove the jam nut securing the safety control valve

to its mounting bracket.

3. Pull the safety control with manifold from heater.

19

WARNING

Fire and Explosion Hazard

■ Do not disassemble or attempt to repair any

heater components or gas train components

such as gas valves, or gas hoses.

■ All component parts must be replaced if defects

are found.

■ Failure to follow this warning will result in fi re or

explosions, causing property damage, injury, or

death.

1. Close the fuel supply valve to the heater before

servicing.

2. Disconnect the thermocouple from the safety

control valve when servicing either the pilot safety

control valve or the burner orifi ce.

3. Workman 225 Plus and Workman 100

Plus NG: Remove the heater’s barrel for access

to burner related components.

Norseman 200 Plus and Norseman

250: Remove the 7/16 in. burner retaining screw

from underside of case and pull the burner from

the case when servicing burner components.

4. Disconnect the gas hose if needed for the service

procedure.

4. Replace or clean components as needed.

FIG. 11

BRACKET

FIG. 12

THERMOCOUPLE

JAM NUT

SAFETY VALVE

VARIABLE

RATE

VALV E

ORIFICE

MANIFOLD

5. For reassembly, reverse the respective service

procedure. Ensure gas connections are tightened

securely and leak checked before lighting the

heater.

6. Clean the heater’s orifi ce with compressed air or

a soft, dry rag. Do not use fi les, drills, etc., which

may enlarge the holes, causing combustion problems or burner fl ame extending outside of the case

barrel. Replace the component if its holes cannot

be cleaned properly.

Owner’s Manual • Workman & Norseman

Page 20

20

Vertical Convection Heaters

WORKMAN 100 PLUS NATURAL GAS

Pilot Orifi ce

1. Remove the thermocouple from the mounting bracket

and loosen the pilot line’ compression fi tting. Care-

fully reposition the pilot line away from the pilot

orifi ce.

2. Remove the screws that secure the burner head to

the heater’s base. See Fig. 13.

3. Slide the burner head off of the base to expose the

pilot and burner orifi ces.

FIG. 13

THERMOCOUPLE

BURNER

HEAD

PILOT HEAD

PILOT ORIFICE

SCREWS

PILOT TUBE

COMPRESSION FITTING

4. Once the burner head has been moved away, use

appropriate wrenches to hold the pilot head in place

while removing the pilot orifi ce.

Safety Control Valve & Gas Regulator:

1. Remove the two hex head screws that secure the

regulator to the upright panel on the heater. See Fig. 15.

FIG. 15

SCREWS

2. Loosen the pilot tube’s compression fi tting at the safety

control valve and carefully reposition the pilot tube away

from the safety control valve. See Fig. 16.

FIG. 16

SAFETY CONTROL

VALV E

Burner Orifi ce:

-- Follow steps 1 through 3 above. Hold the pipe nipple

between the safety control valve and the burner

orifi ce with a pipe wrench while removing the burner

orifi ce with a suitable open end or adjustable wrench.

See Fig. 14 for location of pipe nipple and burner

orifi ce.

FIG. 14

BURNER ORIFICE

PIPE NIPPLE

SCREWS

www.lbwhite.com

Owner’s Manual • Workman & Norseman

REGULATOR

PILOT TUBE

COMPRESSION FITTING

3. Loosen the thermcouple connector nut at the safety

control valve.

4. Pull the complete regulator/safety control valve/burner

orifi ce assembly from the heater. Disassemble as

needed for valve replacement.

Page 21

Vertical Convection Heaters

21

NORSEMAN 200 PLUS AND

NORSEMAN 250

Burner Orifi ce (See Fig. 17)

1. Disconnect compression nut from brass elbow and

thermocouple from pilot control valve.

2. Carefully reposition pilot line and thermocouple away

from safety control valve.

3. Disassemble the following:

-- Pilot control with manual valve from burner orifi ce

-- Burner orifi ce from burner casting.

4. Clean the burner orifi ce.

FIG. 17

BURNER VALVE

PILOT LINE

COMPRESSION

NUT

ELBOW

THERMOCOUPLE

FIG. 19

PILOT HEAD

PILOT

ORIFICE

SCREEN

COMPRESSION

NUT

BRACKET ASSEMBLY

ELECTRODE

BURNER ORIFICE

VALVE

Safety Control Valve (See Fig. 18)

1. Remove pilot line from safety control valve.

2. Remove thermocouple at safety control.

3. Loosen safety control from manual burner

valve.

THERMOCOUPLE

ELBOW

VALVE

FIG. 18

BURNER ORIFICE

BURNER

VALV E

Pilot Orifi ce (See Fig. 19.)

1. Loosen compression nut at pilot orifi ce and carefully

reposition pilot tube away from the orifi ce.

2. Remove pilot orifi ce from pilot head and screen from

orifi ce inlet.

3. Ensure orifi ce hole is not plugged.

Owner’s Manual • Workman & Norseman

ELBOW

VALV E

Page 22

22

Vertical Convection Heaters

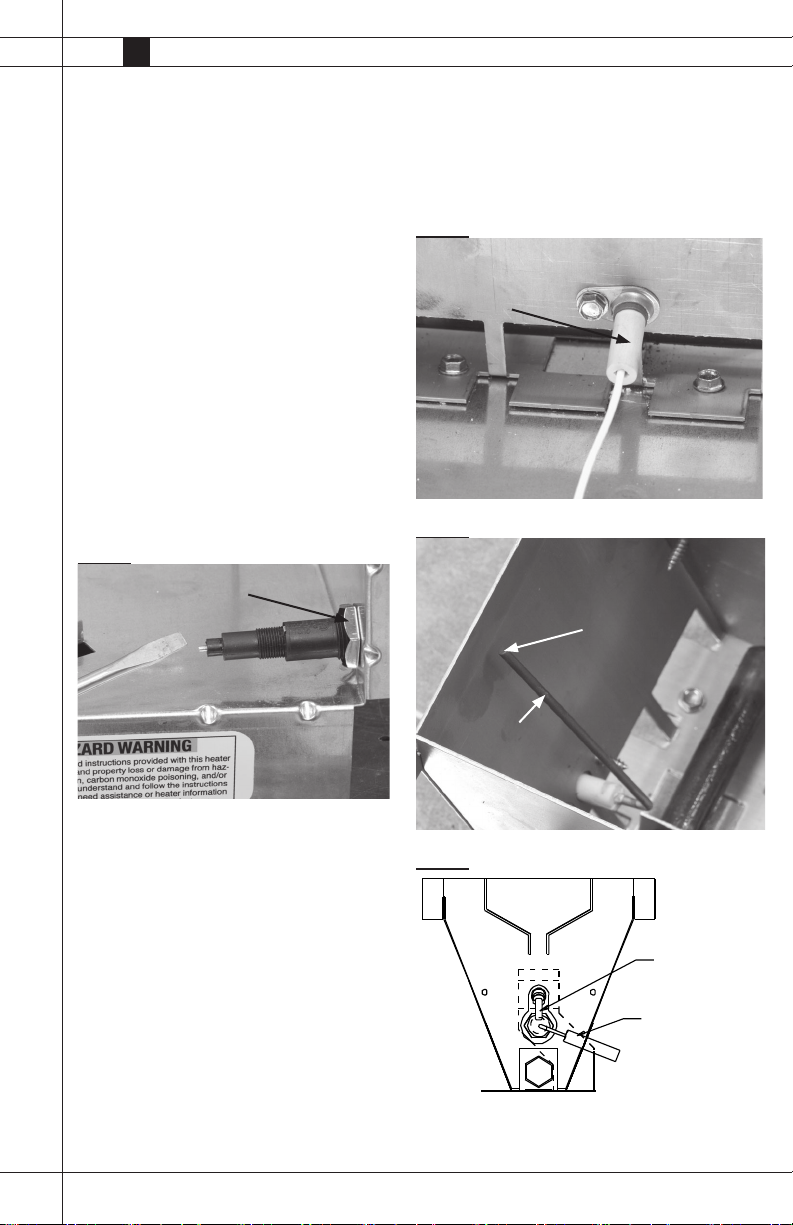

IGNITER AND ELECTRODE

Workman 225 Plus, Norseman 200 Plus,

and Workman 100 Plus NG

Servicing of the igniter and electrode is needed

when a spark is not observed at the electrode when

pushing the igniter button. This may happen with hard

use over a long period of time, or due to dust and dirt

accumulation.

If you do not see a spark being generated at the

electrode check the following areas:

A. Igniter

1. Remove the wire from the push button igniter.

2. Position a screwdriver tip about 1/8 in. from igniter.

See Fig. 20.

3. Holding the screwdriver by its handle, push the

igniter’s button several times. If spark is not seen,

replace the igniter. If spark is observed, proceed to

electrode servicing.

FIG. 20

REMOVE NUT TO

REPLACE IGNITER

Workman 225 Plus: See Fig. 22

Workman 100 Plus Natural Gas: See Fig. 23

Norseman 200 Plus: See Fig. 24, page 22.

Clean the electrode with emery cloth or steel wool.

FIG. 21

INSULATOR

FIG. 22

TIP G AP: 5/32 I N.

B. Electrode

1. Ensure the wire between the electrode and the

igniter is securely connected.

2. Verify that the electrode’s insulator body is not

cracked and that the electrode rod does not move

within its the body. See Fig. 21. If it does, replace

the electrode.

3. Check the wire for nicks, cuts, or mars. Nicks or

cuts will prevent a spark from being generated at

the electrode tip. Replace the electrode if necessary. The electrode ships with the wire.

4. Electrode tip gap can vary depending on model of

heater. Ensure proper position.

www.lbwhite.com

Owner’s Manual • Workman & Norseman

FIG. 23

CLEAN - USE

EMERY CLOTH

THERMOCOUPLE

ELECTRODE ON CENTER

LINE OF PILOT ORIFICE

Page 23

FIG. 24

1/16 INSIDE EDGE OF PILOT HEAD

TO SIDE OF ELECTRODE

THERMOCOUPLE - ALL MODELS

The thermocouple may need replacement if the burner

goes out after allowing the thermocouple to heat up for

an extended period of time.

1. Workman 225 Plus and Workman 100

Plus Natural Gas: Pull back on the thermocouple

to disengage its mounting clip from the support

bracket. See Fig. 25, Workman 225 Plus shown.

FIG. 25

Vertical Convection Heaters

FIG. 27

■ For thermocouples using a mounting clip, ensure

the thermocouple is completely pushed into its

bracket when replacing. Failure to do so may

cause burner outage.

■ When connecting the thermocouple to the safety

control valve, thread the thermocouple fi nger tight

to the valve, then snug it in with a wrench.

To determine if the thermocouple is defective:

Connect an ohm meter between the ends of the

thermocouple.

-- A good thermocouple will show some level of

resistance from end to end.

23

NUT

2. Norseman 200 Plus and Norseman 250:

Use a wrench and loosen the attachment nut at the pilot assembly. See Fig 26, Norseman 200 Plus shown.

FIG. 26

NUT

3. Loosen the thermocouple connector nut which is

threaded into the safety control valve. See Fig. 27,

Workman 225 Plus shown. Remove the thermocouple.

Owner’s Manual • Workman & Norseman

-- A defective thermocouple will show an open

circuit on the ohm meter

Page 24

24

Vertical Convection Heaters

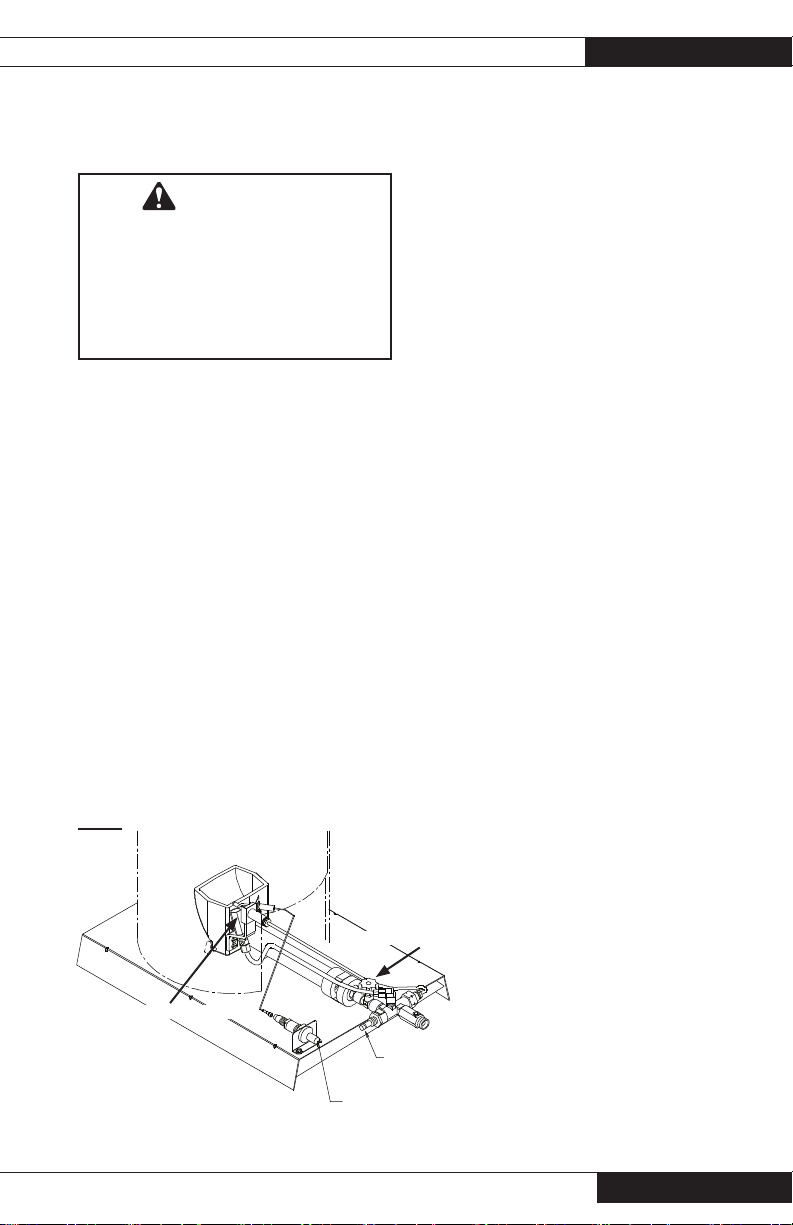

GAS PRESSURE CHECKS

■ This procedure is to be done once a year prior to the

heating season, anytime the heater is moved from one job

location to the next, or after servicing the heater.

MATERIALS REQUIRED

See the list of materials required as follows, depending on

the heater to be checked. Secure these materials through

local purchase.

Quantity Description

1 High Pressure Gas Gauge capable of reading

up to 30 PSIG (Use for Workman 225,

Norseman 200, and Norseman 250 heaters)

OR

Low pressure gauge capable of reading up to

35 inches water column (Use for Workman 100

Plus natural gas ONLY)

1 1/8 in. black iron street ell. (Required for

Workman 225 Plus heaters ONLY)

1 1/4 in. x 2 in. pipe nipple (Required for

Norseman 250 heaters ONLY.)

1 1/4 in. black iron tee (Required for

Norseman 250 heaters ONLY)

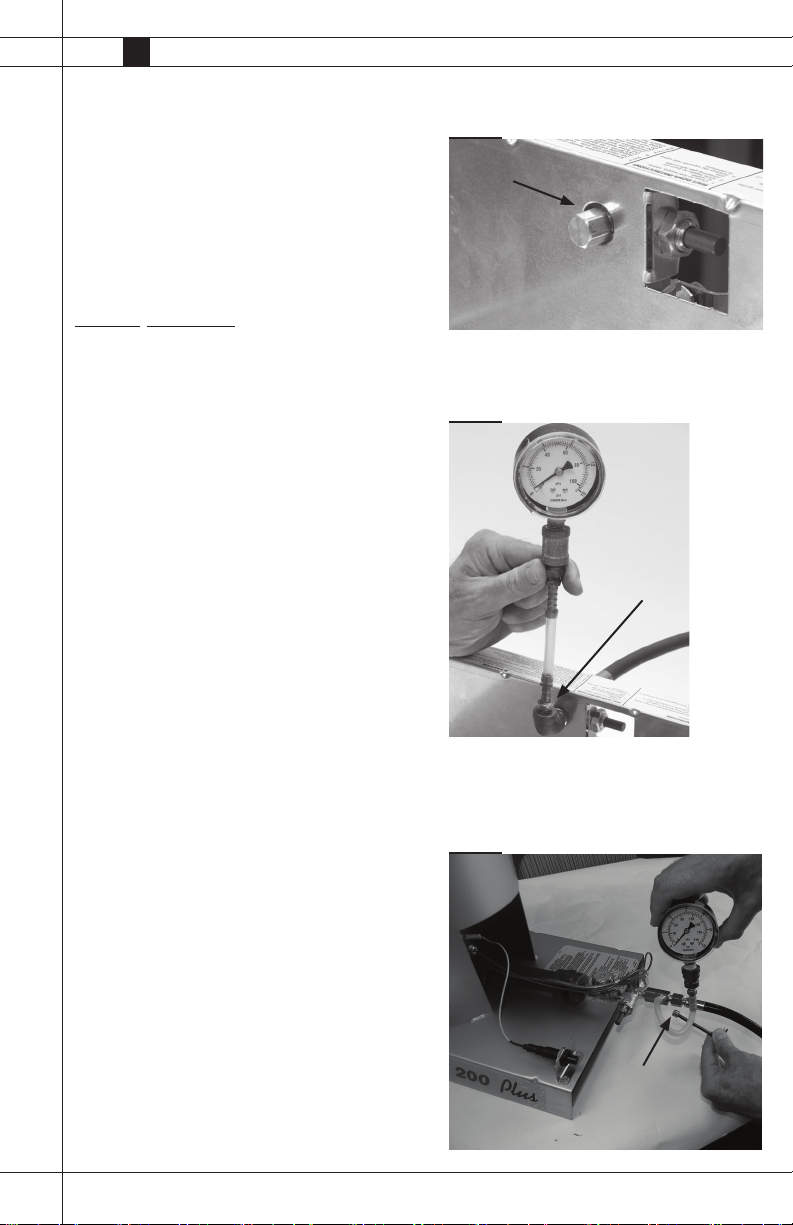

A. PREPARATION- ALL HEATERS

1. Close fuel supply valve at propane gas supply

container.

FIG. 28

CAP

2. Install a 1/8 in. street ell and pressure gauge at this

point. See Fig. 29.

FIG. 29

1/8 IN

STREET

ELL

2. Allow heater to burn off gas remaining in it’s gas

supply lin e.

3. Allow heater to cool.

4. Workman 225 Plus: Position the variable heat valve

to its lowest setting.

Norseman 200 Plus and Norseman 250: Close

the manual main burner valve.

Workman 100 Plus Natural Gas: Position the

knob on the safety control valve to OFF.

B. GAUGE INSTALLATION

Workman 225 Plus:

1. Using an wrench, remove the cap from the safety control

valve as shown in Fig. 28.

www.lbwhite.com

Owner’s Manual • Workman & Norseman

Norseman 200 Plus:

1. Using a 3/16 in. allen wrench, remove the hex plug

from valve inlet. See Fig. 30.

FIG. 30

PLUG

Page 25

Vertical Convection Heaters

25

2. Attach the pressure gauge to this point.

3. Open fuel supply valve to heater.

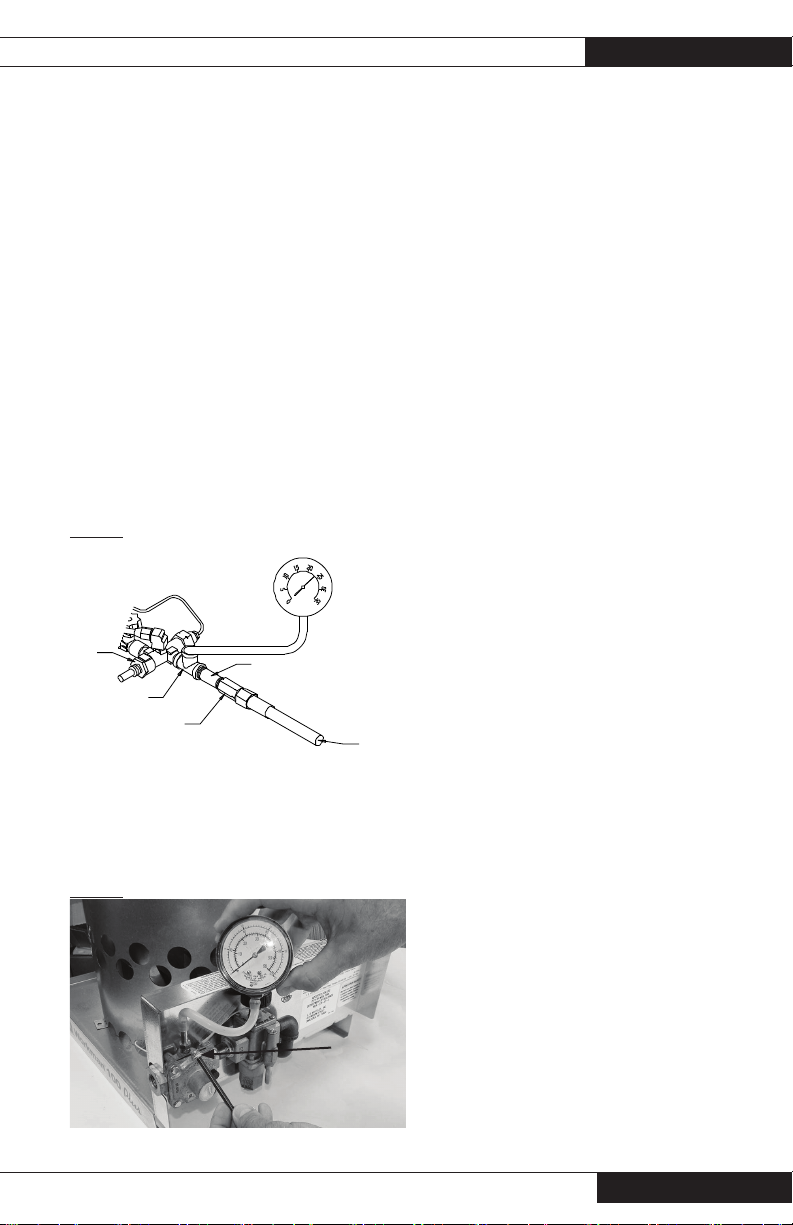

Norseman 250

1. Remove hose adapter from inlet of pilot safety control

valve.

2. Connect the following materials together in the order

as given and tighten securely. See Fig. 31.

-- Tee to inlet of pilot safety control.

-- Nipple to tee.

-- Hose adapter (as removed earlier) to nipple.

-- Gas hose to hose adapter.

3. Connect gauge to tee.

4. Open fuel supply valve to heater.

FIG. 31

HIGH PRESSURE GAUGE

PILOT

CONTROL

VALVE

TEE

HOSE ADAPTER

(FROM PILOT VALVE INLET)

NIPPLE

HOSE

2. Attach the low pressure (0-35 in. water column)

gas gauge to this location.

3. Open the fuel; supply valve to the heater.

C. READING PRESSURES

1. Light the heater. With the heater operating, the

pressure gauge should read the pressure specifi ed

on the dataplate or in the specifi cation section of

this owner’s manual.

2. Does the pressure reading at the inlet of the safety

control agree with that given on the dataplate? If

so, no further checking or adjustment is required.

Proceed to section D.

3. If the inlet pressures do not agree with that specifi ed on the dataplate, then check the following:

-- Improper regulator for heater.

-- Regulator out of adjustment.

(Replace if necessary).

-- Blockage in gas hose.

-- Insuffi cient size or quantity of propane gas

supply containers.

D. COMPLETION

1. Once the proper pressure has been confi rmed,

close fuel supply valves.

2. Allow heater to burn off fuel remaining in gas

supply line.

Workman 100 Plus Natural Gas:

1. Using a 3/16 in. allen wrench, remove the pressure tap

plug at the top on the regulator located on the heater.

See Fig. 32.

FIG. 32

PLUG

Owner’s Manual • Workman & Norseman

3. Norseman 250: Remove gauge, hose adapter,

nipple, and tee. Reconnect hose adapter to inlet of

safety control valve and hose to hose adapter.

Workman 225 Plus: Remove gauge and

street ell. Reconnect cap to safety control

valve.

Norseman 200 Plus, Workman 100

Plus Natural Gas: Install pressure tap plug

on heaters.

4. Tighten all connections securely. Open the fuel

supply valve and check for gas leaks with appropriate leak detectors.

5. Light the heater and check for proper operation.

Page 26

26

Vertical Convection Heaters

Troubleshooting

PROBLEM CAUSE CURE

1. Burner or pilot will not light.

2. Burner or pilot lights but will

not stay lit when safety

control button is released.

* Propane gas container is empty.

* Fuel supply valves closed.

* Excess fl ow valve in P.O.L. fi tting on propane

regulator is closed.

* Safety control button not fully pushed in.

* Burner or pilot orifi ce is plugged.

* Restriction in gas hose.

* Air in gas line.

* Safety control valve is defective.

* Defective spark igniter or electrode.

* Restriction in gas hose.

* Insuffi ent time allowed for thermocouple to

heat up.

* Loose thermocouple.

* Defective thermocouple.

* Orifi ce is plugged

* Defective safety control valve.

* Improper gas pressure

* Fill container.

* Open fuel supply valves.

* Close propane container valve. Wait 5 min-

utes and open container’s valve slowly.

* Push in button completely.

* Clean or replace orifi ce.

* Remove hose from heater and blow out with

compressed air or replace if necessary.

* Push in safety control valve’s pilot button

(normally 15 -20 seconds is suffi cient) on

control of gas valve to purge air from line

(usually necessary at time of installation).

NOTE: Heaters with push button

Piezo Igniter: Make sure you

are pushing the Piezo igniter button

during this time to prevent gas

accumulation.

* Replace safety control valve.

* Refer to the igniter and electrode service

instruction section for problems associated

with these parts.

* See remedy for same cause in Problem #1

* Hold in control button for 30 seconds to allow

proper warm up.

* Tighten thermocouple at gas control. Make

sure it is securely pushed into its bracket.

Tighten fi nger tight and snug the contact nut

with an appropriate wrench.

* Replace the thermocouple

* See remedy for same in Problem #1

* Replace safety control valve.

* Set pressure according to pressure on

dataplate.

3. Burner fl ame lifting off

burner.

4. Heater not delivering maximum heat output.

5. Electrode does not

provide spark

* Fuel pressure set too high.

* Blockages in burner orifi ce or at primary air

inlets of burner.

* Gas supply valves not fully open.

* Burner orifi ce plugged.

* Low fuel supply pressure.

* WORKMAN 225 PLUS: Variable rate valve

not positioned to maximum

* NORSEMAN 200 OR NORSEMAN 250:

Main burner valve not fully open.

* Improper spark gap.

* Defective electrode or electrode lead.

* Defective push button igniter.

www.lbwhite.com

Owner’s Manual • Workman & Norseman

* Set pressure according to pressure on

dataplate

* Clean area with soft brush, dry cloth, or

compressed air.

* Open valves completely.

* Clean burner orifi ce with compressed air or

replace.

* Consult propane gas supplier. Cylinder or

tank needs replacement or refi ll. Regulator

needs adjustment. Check for use of proper

regulation and fuel gas.

* Position the valve to maximum

* Open the manual main burner valve

completely.

* Set spark gap to instructions.

* Replace electrode.

* Replace igniter

Page 27

Vertical Convection Heaters

Heater Component Function

27

BARREL w/ TOP (CASE)

Upright sheet metal case component. Acts as a

chimney to distribute heat to surrounding area.

BASE

Sheet metal case platform used to support and

stabilize burner and barrel assemblies.

BURNER

Component at which combustion of fuel gases

takes place.

BURNER ORIFICE

Metering device used to feed gas to burner at a

specifi c rate, with the appropriate pressure.

ELECTRODE

Ignites gas by spark. Receives spark voltage from

piezo igniter.

GAS HOSE

Flexible connector used to convey gas from supply

line or cylinder to heater.

PIEZO IGNITER

Generates ignition voltage when igniter button is

pushed. This voltage is sent to electrode to provide

spark.

PILOT LIGHT ORIFICE

A metering device used to supply gas for the dual

purpose of igniting the main burner and heating the

thermocouple.

THERMOCOUPLE

A thermoelectric device that converts heat directly into electrical energy. Works in conjunction

with electromagnet in gas control valve thereby

assisting in maintaining gas supply for the pilot

light.

VARIABLE RATE VALVE

A manually adjsuted valve that allows the user to

operate the heater from its lowest to highest heat

output, or anywhere in-between.

PILOT TUBE

Formed copper tube used to convey gas from the

safety control valve to the pilot light orifi ce.

REGULATOR

The heart of any gas supply installation. Used to

deliver a working pressure to the appliance under

varying conditions in tank pressure.

SAFETY CONTROL VALVE

A gas control valve which is held open by electrical

power supplied by the thermocouple and which

closes automatically to shut off the fl ow of gas to

the main burner when fl ame is extinguished or is

too small to heat the thermocouple.

Owner’s Manual • Workman & Norseman

Page 28

28

Vertical Convection Heaters

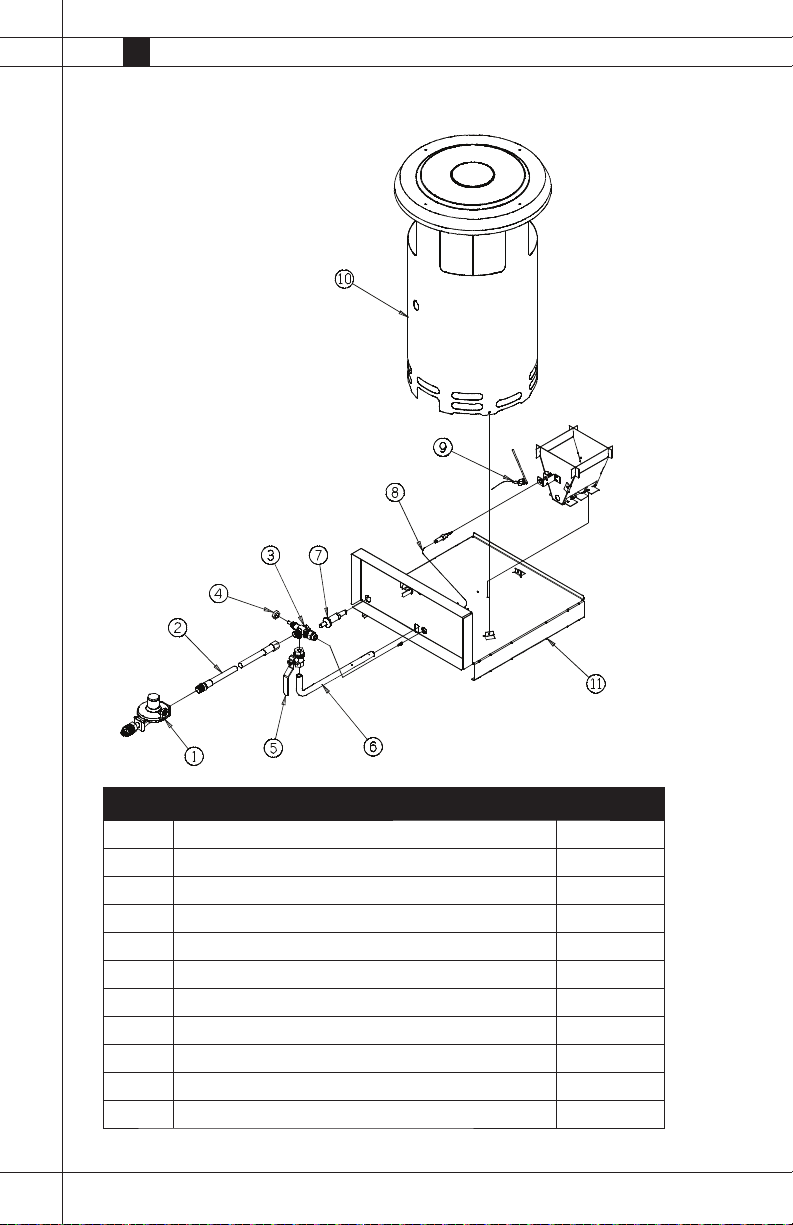

Service Parts Identification Schematic

Workman 225 Plus

Item Description Part Number

1 Regulator w/POL Fit ting 550-23463

2 Hose, 1/4 in. / 15 ft. (4.6 m) 550-20708

3 Valve, Safety Control 572506

4 Nut, Jam 572587

5 Valve, Variable Rate 572507

6Orifi ce Manifold 572508

7 Igniter, Piezo 570434

8Thermocouple 571030

9Electrode 572509

10 Barrel w/Top 57250 5

11 B ase 57 2510

www.lbwhite.com

Owner’s Manual • Workman & Norseman

Page 29

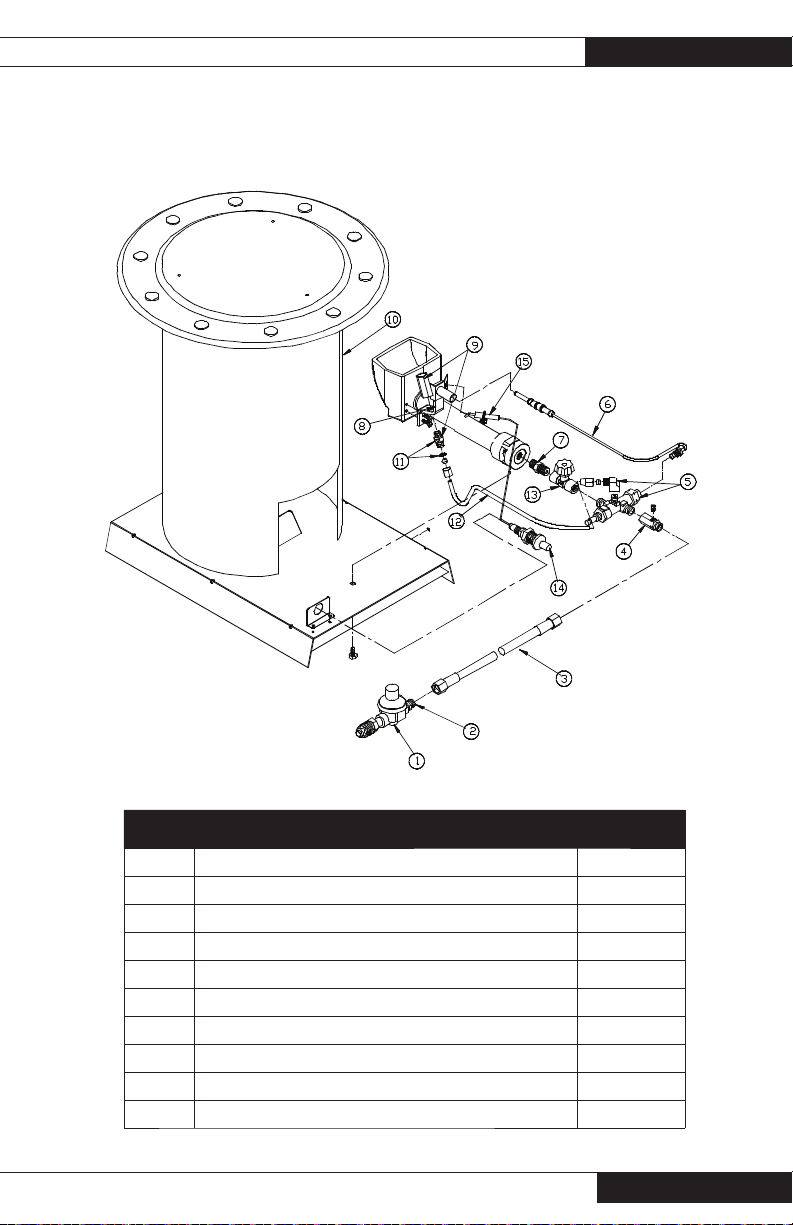

Vertical Convection Heaters

Service Parts Identification Schematic

Norseman 200 Plus and Norseman 250

29

Item Description Part Number

1 Regulator w/POL and Hose Adapter 550-21788

2 Adapter, Hose 500-25790

3 Hose, 1/4 in. x 15 ft. (4.6m) 550 -2050 0

4 Adapter, Hose, w/ Pressure Tap Plug 500-23633

5 Valve, Pilot Safety 500-20356

6Thermocouple 571823

7Orifi ce Burner (Norseman 20 0 Plus) 571582

(Norseman 250) 571573

8 Bracket, Pilot (Nor seman 20 0) 571584

(Norseman 250) 571574

Owner’s Manual • Workman & Norseman

Page 30

30

Vertical Convection Heaters

9 Head, Pilot w Orifi ce 571048

10 Case, Assembly w Labels (Norseman 200 Plus) 500-23373

(Norseman 250) 500-22338

11 O ri fi ce, Pilot w/Screen 571577

12 Tube, Pilot w/Nuts & Sleeves 520529

13 Valve, Man ual Burner 570963

14 Igniter (Norseman 20 0 Plus) 570434

15 Electrode w/Wire (Norseman 200 Plus) 571068

www.lbwhite.com

Owner’s Manual • Workman & Norseman

Page 31

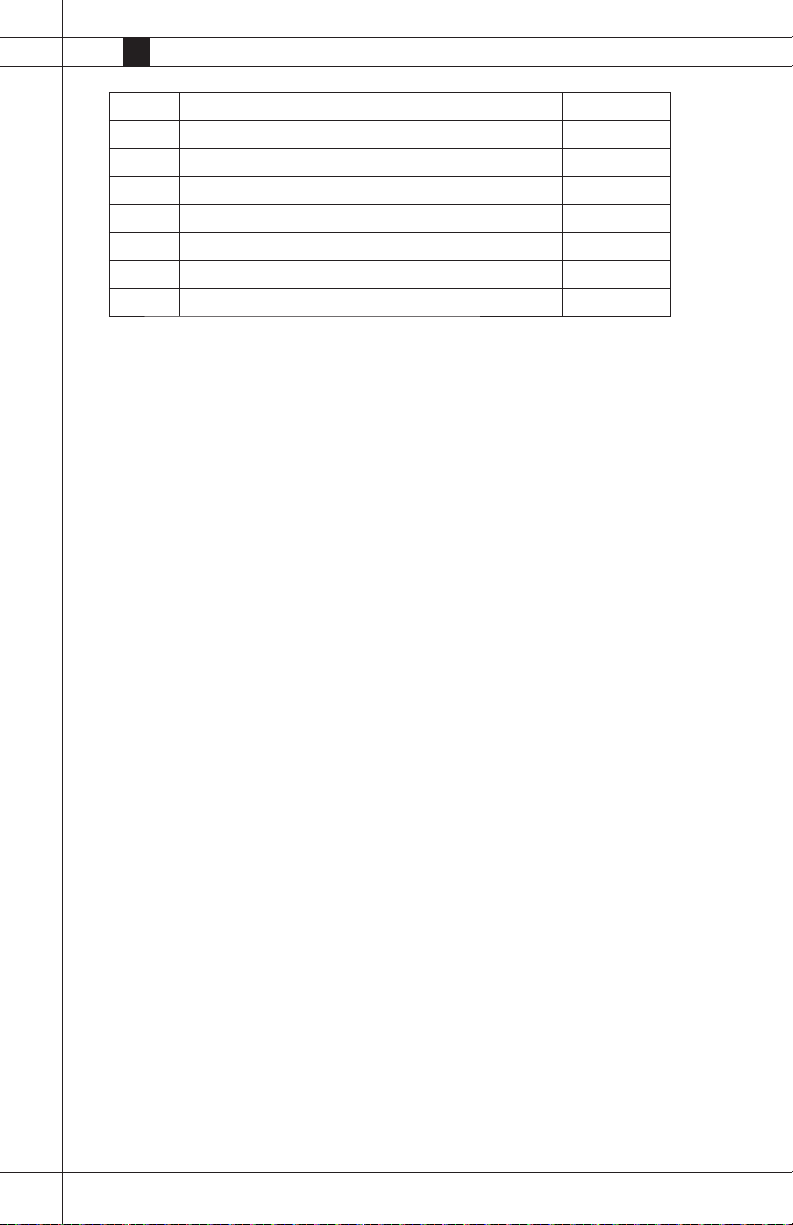

Vertical Convection Heaters

Service Parts Identification Schematic

Workman 100 Plus Natural Gas

8

6

4

1

7

31

11

10

9

2

3

5

12

Item Description Part Number

1 Regulator, Natural Gas 571528

2 Valve, Pilot Safety Control w/Thermocouple 571558

3Igniter w/Nut 570434

4Knob 573265

5 Tube, Pilot w/Nuts and Sleeves 571515

6Thermocouple 573713

7Orifi ce, Pilot 571557

8Bracket 571022

9Orifi ce, Burner 571580

10 Electrode 571068

11 B ar rel w/ Top 5715 05

12 Base 571592

Owner’s Manual • Workman & Norseman

Page 32

32

Vertical Convection Heaters

www.lbwhite.com

Owner’s Manual • Workman & Norseman

Page 33

Warranty Policy

HEATER

L.B. White Company, LLC warrants that the component parts of its heater are free from defects in

material and workmanship, when properly installed,

operated, and maintained in accordance with the

Installation and Maintenance Instructions, safety

guides and labels contained with each unit. If, within

24 months from the date of purchase by the end user,

any component is found to be defective,

L.B. White Company, LLC will at its option, repair

or replace the defective part or heater, with a new

part or heater, F.O.B., Onalaska, Wisconsin.

Registering your product online with L.B.White will

automatically qualify a unit and its component parts

for warranty consideration. If a product has not been

registered with L.B.White, a copy of the bill of sale

will be required to establish warranty qualifi cation.

If neither is available, the warranty period will be 12

months from date of shipment from L B. White.

PARTS

L.B. White Company, LLC warrants that replacement

parts purchased from the company and used on the

appropriate L. B. White equipment are free from defects both in material and workmanship for 12 months

from the date of purchase by the end user. Warranty

is automatic if a component is found defective within

12 months of the date code marked on the part. If the

defect occurs more than 12 months later

than the date code but within 12 months from the

date of purchase by the end user, a copy of a bill of

sale will be required to establish warranty qualifi ca-

tion.

such implied warranty is limited in duration to the duration

of the applicable warranty stated above. The remedies set

forth above are the sole and exclusive remedies available

hereunder. L.B. White will not be liable for any incidental

or consequential damages directly or indirectly related

to the sale, handling or use of the equipment, and in any

event L.B. White’s liability inconnection with the equipment,

including for claims based on negligence or strict liability, is

limited to the purchase price.

Some states do not allow limitations on how long an implied

warranty lasts, so the above limitation may not apply to you.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above

limitation or exclusion may not apply to you. This warranty

gives you specifi c legal rights, and you may also have other

rights which vary from state to state.

To register your product and ensure full warranty, go to

http://www.lbwhite.com/customer_care_center/product-registration/. Please have the serial number(s) and model(s)

handy for the products you are registering.

Service

Contact your local L.B. White dealer for replacement parts

and service. You may also call the L.B. White Company,

LLC at 1-800-345-7200, for assistance, or email us at

customerservice@lbwhite.com.

Be sure that you have your heater model number and

confi guration number when calling.

The warranty set forth above is the exclusive warranty provided by L.B. White, and all other warranties,

including any implied warranties or merchantability

or fi tness for a particular purpose, are expressly

disclaimed. In the event any implied warranty is not

hereby effectively disclaimed due to operation of law,

WORLD PROVIDER - INNOVATIVE

HEATING SOLUTIONS

411 Mason Street, Onalaska, WI 54650

800-345-7200 • 608-783-5691

608-783-6115 (fax)

www.lbwhite.com

150-130968 REV.B

Page 34

Manual del usuario e instrucciones

Calefactores

de convección

verticales

Workman Estándar

Norseman para Servicio Pesado

Para ver este manual en línea, visite www.lbwhite.com

Atención

Los calefactores de los modelos 320,

CV225 y CV100 han sido probados

y evaluados por CSA Group de

conformidad con la norma ANSI

Z83.7 • CSA 2.14 y están clasicados

y aprobados como calefactores de

convección verticales con encendido

directo para usar en edicios en

construcción en pisos combustibles.

Los calefactores del modelo 341 han

sido probados y evaluados por L.B.

White y no están aprobados para

usar en pisos combustibles. Todos

los calefactores están diseñados para

la calefacción transitoria portátil de

edicios en construcción, en renovación o en reparación. Si considera

usar este producto para cualquier

aplicación no contemplada en sus

usos previstos, por favor contáctese

con su proveedor de gas combustible

o con L.B. White Company, LLC

En el presente manual se

brindan instrucciones para

todos los calefactores de

convección verticales fabricados por

L.B. White. La información

relacionada con un modelo

o una conguración de gas

en particular está identi-

cada. La información se

aplica a todos los modelos

a menos que se indique lo

contrario.

¡Felicitaciones!

Usted acaba de comprar el mejor calefactor de convección.

Su nuevo calefactor L.B. White incorpora los benecios del fabricante de productos de calefacción más experimentado que emplea

tecnología de avanzada.

En L.B. White, le agradecemos la conanza depositada en nuestros

productos y serán bien recibidos los comentarios y sugerencias que

pueda tener… llámenos sin cargo al 1-800-345-7200.

320

341

CV225

CV100

200.000 Btu/h*/58.6kW

250.000 Btu/h*/73.3kW

225.000 Btu/h*/65.9kW

100.000 Btu/h*/29.3kW

*Modelos especícos

para EE. UU. o Canadá.

Consulte la placa de

datos del calefactor.

Recuperación

del vapor de

propano

Gas natural

www.lbwhite.com

CONSULTE LAS

INSTRUCCIONES

DE ARMADO

EN EL INTERIOR

PROVEEDOR MUNDIAL - SOLUCIONES DE CALEFACCIÓN INNOVADORAS

411 Mason Street, Onalaska, WI 54650, Estados Unidos • 800-345-7200 • 608-783-5691 • 608-783-6115 (fax) • www.lbwhite.com

ESCANEE ESTE

CÓDIGO

con su teléfono inteligente o

visite http://goo.gl/nvneR

para ver los videos de mantenimiento

para calefactores L.B. White.*

* Necesita una aplicación como QR

Droid para Android o para iPhone

Page 35

2

Calefactores de convección verticales

ÍNDICE

Especicaciones del calefactor ............................................................................................... 4

Información general ................................................................................................................. 5

Precauciones de seguridad ..................................................................................................... 6

Instrucciones de instalación

Información general ..................................................................................................... 10

Instalación del quemador, Norseman 200 Plus y Norseman 250 ................................. 12

Conjunto de manguera y regulador - Calefactores a gas propano ............................... 12

Conexión del regulador al suministro de gas

Calefactores a gas propano ............................................................................... 13

Calefactores a gas natural.................................................................................. 13

Instrucciones de encendido y apagado

Workman 225 Plus ............................................................................................. 14

Norseman 200 Plus y Norseman 250................................................................. 15

Workman 100 Plus Gas Natural ......................................................................... 16

Instrucciones de limpieza ........................................................................................................ 17

Instrucciones de mantenimiento .............................................................................................. 18

Instrucciones de servicio ......................................................................................................... 19

General ......................................................................................................................... 19

Workman 225 Plus ........................................................................................................ 19

Oricio del quemador y válvula de control de seguridad .................................... 19

Workman 100 Plus Gas Natural.................................................................................... 20

Oricio del piloto ................................................................................................. 20

Oricio del quemador ......................................................................................... 20

Válvula de control de seguridad y regulador de gas .......................................... 20

Norseman 200 Plus y Norseman 250 ........................................................................... 21

Oricio del quemador ......................................................................................... 21

Oricio del piloto ................................................................................................. 21

Válvula de control de seguridad ......................................................................... 21

Encendedor y electrodo (Workman 225 Plus, Norseman 200 Plus

y Workman 100 Plus) .................................................................................................... 22

Termocupla (todos los modelos) ................................................................................... 23

Vericaciones de la presión de gas .............................................................................. 24

Resolución de problemas ........................................................................................................ 26

Función de los componentes del calefactor ............................................................................ 27

Identicación de piezas

Esquema de partes y lista de partes

Workman 225 Plus ............................................................................................. 28

Norseman 200 Plus y Norseman 250................................................................. 29/30

Workman 100 Plus Gas Natural ......................................................................... 31/32

Política de garantía, piezas de repuesto y mantenimiento ...................................................... 33

www.lbwhite.com

Manual del usuario • Workman y Norseman

Page 36

Calefactores de convección verticales

3

■ SI NO SE CONTEMPLAN LAS PRECAUCIONES E INSTRUCCIONES SUMINISTRADAS CON ESTE CALEFACTOR, SE PUEDE PROVOCAR:

— LA MUERTE

— QUEMADURAS O LESIONES GRAVES

— DAÑOS O PÉRDIDAS MATERIALES POR INCENDIO O EXPLOSIÓN

— ASFIXIA DEBIDO A LA FALTA DE UN SUMINISTRO DE AIRE ADECUADO O ENVENENAMIENTO POR

MONÓXIDO DE CARBONO

■ LEA DETENIDAMENTE ESTE MANUAL DEL USUARIO ANTES DE INSTALAR O DE USAR ESTE PRODUCTO.

■ ESTE CALEFACTOR DEBE SER UTILIZADO O MANTENIDO EXCLUSIVAMENTE POR PERSONAS QUE

PUEDAN LEER, COMPRENDER Y SEGUIR LAS INSTRUCCIONES.

■ GUARDE ESTE MANUAL DEL USUARIO PARA CONSULTAR Y USAR EN EL FUTURO.

■ LOS MANUALES DEL USUARIO Y LAS ETIQUETAS DE REPUESTO ESTÁN DISPONIBLES SIN COSTO.

CONSULTE EL SITIO WEB O CONTÁCTESE CON L.B. WHITE AL 1-800-345-7200 PARA SOLICITAR AYUDA.

ADVERTENCIA

ADVERTENCIA GENERAL

■ DEBERÁ PROVEERSE UNA PRESIÓN DE SUMINISTRO DE GAS APROPIADA A LA ENTRADA DEL CALEFACTOR.

■ CONSULTE LA PLACA DE DATOS PARA OBTENER INFORMACIÓN SOBRE LA PRESIÓN DE SUMINISTRO DE

GAS ADECUADA.

■ LA PRESIÓN DE GAS QUE SUPERE LA PRESIÓN DE ENTRADA MÁXIMA ESPECIFICADA EN LA ENTRADA

DEL CALEFACTOR PUEDE PROVOCAR INCENDIOS O EXPLOSIONES.

■ LOS INCENDIOS O LAS EXPLOSIONES PUEDEN CAUSAR LESIONES GRAVES, LA MUERTE O DAÑOS AL

EDIFICIO.

■ LA PRESIÓN DE GAS POR DEBAJO DE LA PRESIÓN DE ENTRADA MÍNIMA ESPECIFICADA EN LA ENTRADA

DEL CALEFACTOR PUEDE OCASIONAR UNA COMBUSTIÓN INADECUADA.

■ UNA COMBUSTIÓN INADECUADA PUEDE CAUSAR ASFIXIA O ENVENENAMIENTO POR MONÓXIDO DE

CARBONO, Y ASÍ OCASIONAR LESIONES GRAVES O LA MUERTE.

ADVERTENCIA

■ NO LO USE EN UNA CASA O EN VEHÍCULOS RECREATIVOS.

■ LA INSTALACIÓN DE ESTE CALEFACTOR EN UNA CASA O EN UN VEHÍCULO RECREATIVO PUEDE RESULTAR EN UN INCENDIO O UNA EXPLOSIÓN.