Page 1

Owner's Manual and Instructions

Therma Grow

MODELS OUTPUT (Btuh) FUEL

™

Greenhouse Heaters

HW220 220,000

Available in either

L.P. Gas Vapor

Withdrawal or

Natural Gas

Configurations.

Congratulations!

You have purchased the finest agricultural building heater available.

Your new L.B. White heater incorporates the benefits from the most experienced

manufacturer of heating products using state-of-the-art technology.

We, at L.B. White, thank you for your confidence in our products and

welcome any suggestions or comments you may have...call us, toll-free,

at (800) 345-7200.

ATTENTION ALL USERS

This heater has been tested and evaluated by C.S.A. International, in

accordance with IAS U.S. Requirements for Gas-Fired Greenhouse Heaters,

for use as a direct gas-fired circulating heater for the heating of greenhouses.

If you are considering using this product for any application other than its

intended use, then please contact your fuel gas supplier, or the L.B. White

Co., Inc.

150-27595

Page 2

Page 3

GENERAL HAZARD WARNING

2

■ Failure to comply with the precautions and instructions provided with this heater, can result in:

—Death

— Serious bodily injury or burns

— Property damage or loss from fire or explosion

— Asphyxiation due to lack of adequate air supply or carbon monoxide poisoning

— Electrical shock

■ Read this Owner’s Manual before installing or using this heater.

■ Only properly-trained service people should repair or install this heater.

■ Save this Owner’s Manual for future use and reference.

■ Owner’s Manuals and replacement labels are available at no charge. For assistance, contact

L.B. White at 800-345-7200.

WARNING

■ Proper gas supply pressure must be provided to the inlet of the heater.

■ Refer to dataplate for proper gas supply pressure.

■ Gas pressure in excess of the maximum inlet pressure specified at the heater inlet can cause

fires or explosions.

■ Fires or explosions can lead to serious injury, death, building damage, or loss of plant life.

■ Gas pressure below the minimum inlet pressure specified at the heater inlet may cause

improper combustion.

■ Improper combustion can lead to asphyxiation or carbon monoxide poisoning and therefore

serious injury or death to humans and plant life.

WARNING

Fire and Explosion Hazard

■ Not for home or recreational vehicle use.

■ Installation of this heater in a home or

recreational vehicle may result in a fire or

explosion.

■ Fire or explosions can cause property

damage or loss of life.

Fire and Explosion Hazard

■ Keep solid combustibles a safe distance

away from the heater.

■ Solid combustibles include wood or paper

products, straw, and dust.

■ Do not use the heater in spaces which

contain or may contain volatile or airborne

WARNING

combustibles.

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of

■ Volatile or airborne combustibles include

gasoline, solvents, paint thinner, dust

particles or unknown chemicals.

this or any other appliance.

■ Failure to follow these instructions may

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

result in a fire or explosion.

■ Fire or explosions can lead to property

damage, personal injury or loss of life.

2. Don't touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

Page 4

Table of Contents

3

SECTION PAGE

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Heater Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Installation Instructions

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Air Discharge Diverter Duct . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Indoor Installation Requirements

Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Exhaust Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Hanging the Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Sediment Trap Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Thermostat Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Manual Shut-Off Valve, Hose and Regulator Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . .11

Start-Up Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Shut-Down Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Cleaning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Service Instructions

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Motor & Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Air Proving Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Manual Reset High Limit Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Burner Orifice and Gas Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Gas Pressure Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Igniter and Flame Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Troubleshooting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Electrical Connection and Ladder Diagram

115 Volt Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

230 Volt Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Heater Component Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Parts Identification (Parts List & Schematic) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27 & 28

Warranty Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Replacement Parts and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

General Information

This Owner's Manual includes all options and accessories

commonly used on this heater. However, depending on the

configuration purchased, some options and accessories

may not be included.

When calling for technical service assistance, or for other

specific information, always have model number,

configuration number and serial number available. This

information is contained on the dataplate. The dataplate is

located on the interior of either the burner end or motor end

door.

This manual will instruct you in the operation and care of

your unit. Have your qualified installer review this manual

with you so that you fully understand the heater and how it

functions.

The gas supply line installation, installation of the heater,

and repair and servicing of the heater requires continuing

expert training and knowledge of gas heaters and should

not be attempted by anyone who is not so qualified. See

page 6 for definition of the necessary qualifications. A

detailed Installation and Service Guide is available, at no

charge, to qualified personnel by contacting the local

L.B. White distributor, dealer or the L.B. White Company.

Contact your local L.B. White distributor or the L.B. White

Co., Inc. for assistance, or if you have any questions about

the use of the equipment or its application.

The L.B. White Co., Inc. has a policy of continuous product

improvement. It reserves the right to change specifications

and design without notice.

Page 5

4

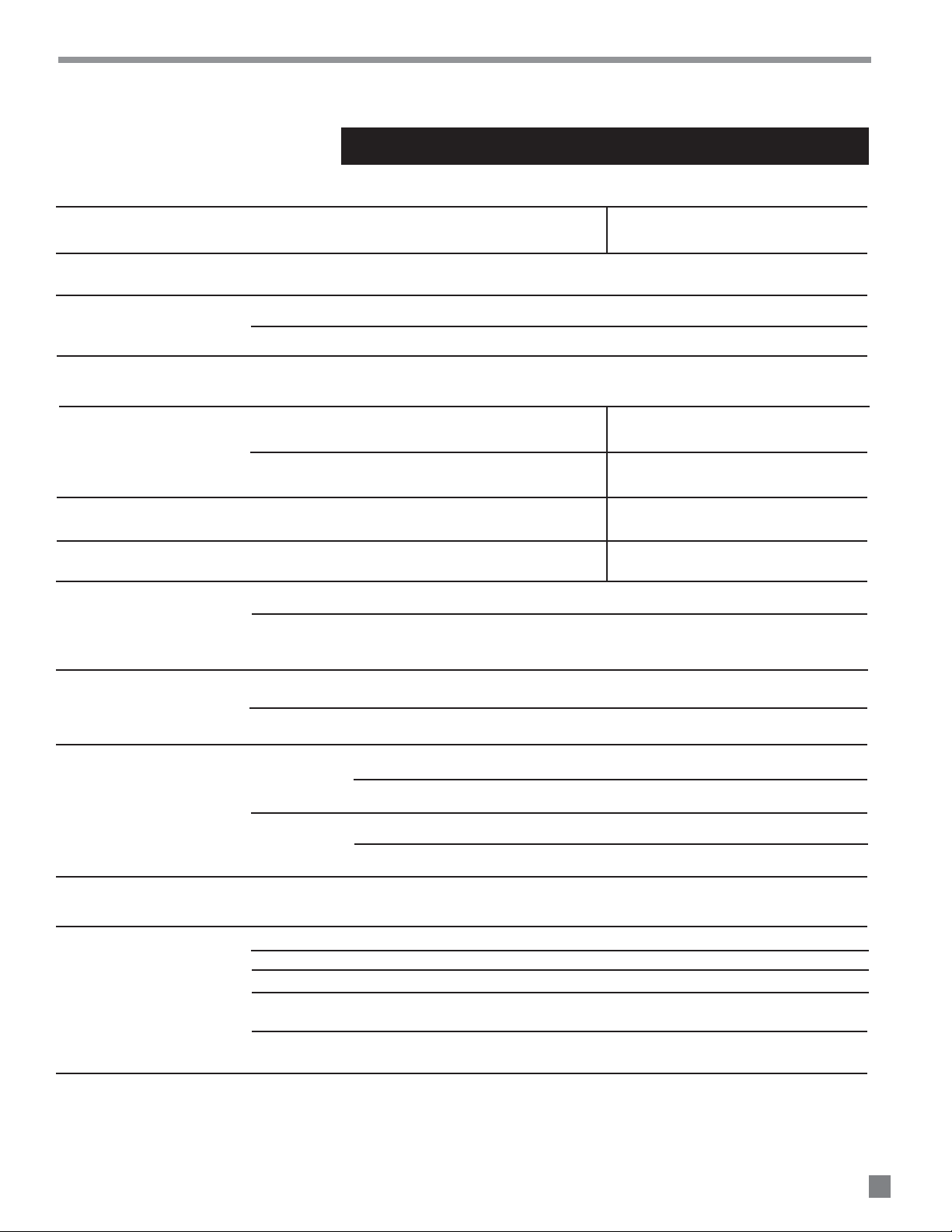

Heater Specifications

SPECIFICATIONS

HW220

Model

Propane Natural

Gas Gas

Maximum Input (BTUH) 220,000

Indoor Mounting Air

Exchange Requirements

Outdoor Mounting Air

Exchange Requirements

Inlet Gas Supply

Pressure Acceptable at

the Inlet of the Heater

for Purpose of Input

Adjustment (In. W.C.)

Burner Manifold

Pressure (In. W.C.)

Fuel Consumption Per

Hour

Motor Characteristics

EXHAUST FAN 550 CFM

(1)

SHUTTERED AIR INLET 220 sq. in.

SHUTTERED

(1)

EXHAUST OUTLET

MAX. 13.5 11.0

MIN. 11.0 7.0

5.0 3.1

10.19 lbs. 220 cu. ft.

100 sq. in.

Ball Bearing

1/2 H.P.

1,100 RPM

Electrical Supply

(Volts/Hz/Phase)

115 VOLT MOTOR

STARTING

Amp Draw

CONTINUOUS

OPERATION

Dimensions (inches)

L x W x H

TOP 1 ft.

SIDES 1 ft.

Minimum Safe

Distances From Nearest

Combustible Materials

(1) Air inlets and exhaust outlets must be electromechanically operated and electrically interlocked with the

heater to prevent heater operation if air inlet and exhaust outlet do not open when heating is required.

BACK 1 ft.

BLOWER

OUTLET

GAS Propane Gas Supply — 6 ft. (1.83 m)

SUPPLY Natural Gas Supply — N/A

230 VOLT MOTOR

115 VOLT MOTOR

230 VOLT MOTOR

115/60/1

230/60/1

17.1

6.7

6.2

2.6

35 x 25 x 30

6 ft. (1.83 m)

4

Page 6

5

LP gas and natural gas have man-made odorants added specifically for detection of fuel gas leaks.

If a

gas leak occurs, you should be able to smell the fuel gas.

THAT’S YOUR SIGNAL TO GO INTO IMMEDI

ATE ACTION !

FINALLY,

WARNING

Asphyxiation Hazard

Some people cannot smell well. Some people cannot

smell the odor of the man-made chemical added to

propane or natural gas. You must determine if you can

smell the odorant in these fuel gases.

The odorant in propane gas and natural gas is colorless

and the intensity of its odor can fade under some

circumstances.

Always be sensitive to the slightest gas odor.

Safety Precautions

■ Do not use this heater for heating human living

quarters.

■ Do not use in areas without proper air exchange. See

air exchange requirements on page 4 or on heater’s

dataplate.

■ Exhaust fans, supply air inlets, or exhaust fan outlets

must not be obstructed.

■ Proper air exchange must be provided for either indoor

or outdoor mount installations.

FUEL GAS ODOR

■ Do not take any action that could ignite the fuel gas. Do

not operate any electrical switches. Do not pull any

power supply or extension cords. Do not light matches

or any other source of flame. Do not use your

telephone.

■ Get everyone out of the building and away from the area

immediately.

■ Close all propane gas tank or cylinder fuel supply

valves, or the main fuel supply valve located at the

meter if you use natural gas.

■ Propane gas is heavier than air and may settle in low

areas. When you have reason to suspect a propane

leak, keep out of all low areas.

■ Refer to the specification section and installation

instructions of the heater’s Owner’s Manual, heater

dataplate, or contact the L.B. White Company to

determine air exchange requirements of the heater.

■ Lack of proper air exchange will lead to improper

combustion.

■ Improper combustion can lead to carbon monoxide

poisoning in humans leading to serious injury or death.

Symptoms of carbon monoxide poisoning can include

headaches, dizziness and difficulty in breathing.

■ Natural gas is lighter than air and can collect around

rafters or ceilings.

■ Use your neighbor’s phone and call your fuel gas

supplier and your fire department. Do not re-enter the

building or area.

■ Stay out of the building and away from the area until

declared safe by the firefighters and your fuel gas

supplier.

■

firefighters check for escaped gas. Have them air out

the building and area before you return. Properly

trained service people must repair the leak, check for

further leakages, and then relight the appliance for you.

let the fuel gas service person and the

ODOR FADING -- NO ODOR DETECTED

■

■ Learn to recognize the odor of propane gas and natural

gas. Local propane gas dealers and your local natural

gas supplier (utility) will be more than happy to give you

a scratch and sniff pamphlet. Use it to become familiar

with the fuel gas odor.

■ Smoking can decrease your ability to smell. Being

around an odor for a period of time can affect your

sensitivity to that particular odor.

■

■ If there is an underground leak, the movement of gas

through the soil can filter the odorant.

■ Propane gas odor may differ in intensity at different

levels. Since propane gas is heavier than air, there may

be more odor at lower levels.

■

continue to detect any gas odor, no matter how small,

treat it as a serious leak. Immediately go into action as

discussed previously.

ATTENTION -- CRITICAL POINTS TO REMEMBER!

■ Propane gas and natural gas have a distinctive odor.

Learn to recognize these odors. (Reference Fuel Gas

Odor and Odor Fading sections above.

■

If you have not been properly trained in repair and service

of propane gas and natural gas fueled heaters, then do

not attempt to light heater, perform service or repairs, or

make any adjustments to the heater on propane gas or

natural gas fuel system.

5

■ Even if you are not properly trained in the service and

repair of the heater, ALWAYS be consciously aware of

the odors of propane gas and natural gas.

■ A periodic sniff test around the heater or at the heater’s

joints; i.e. hose, connections, etc., is a good safety

practice under any conditions. If you smell even a small

amount of gas, CONTACT YOUR FUEL GAS SUPPLIER

IMMEDIATELY. DO NOT WAIT!

If you

Page 7

1. Do not attempt to install, repair, or service this heater

6

or the gas supply line unless you have continuing

expert training and knowledge of gas heaters.

Qualifications for service and installation of this

equipment are as follows:

a.

To be a qualified gas heater service person, you

must have sufficient training and experience to

handle all aspects of gas-fired heater installation,

service and repair. This includes the task of

installation, troubleshooting, replacement of

defective parts and testing of the heater. You

must be able to place the heater into a continuing

safe and normal operating condition. You must

completely familiarize yourself with each model

heater by reading and complying with the safety

instructions, labels, Owner’s Manual, etc., that is

provided with each heater.

b.

To be a qualified gas installation person, you must

have sufficient training and experience to handle

all aspects of installing, repairing and altering gas

lines, including selecting and installing the proper

equipment, and selecting proper pipe and tank

size to be used. This must be done in accordance

with all local, state and national codes as well as

the manufacturer’s requirements.

2. All installations and applications of L.B. White heaters

must meet all relevant local, state and national

codes. Included are L.P. gas, natural gas, electrical,

and safety codes. Your local fuel gas supplier, a local

licensed electrician, the local fire department or

similar government agencies, or your insurance agent

can help you determine code requirements.Refer to

the following:

6. Do not operate the heater with its door open.

7. Do not locate fuel gas containers or fuel supply

hoses anywhere near the blower outlet of the heater.

8. Do not block air intakes or discharge outlets of the

appliance. Doing so may cause improper combustion

or damage to heater components leading to property

damage or plant loss.

9. The hose assembly shall be visually inspected on an

annual basis. If it is evident there is excessive

abrasion or wear, or if the hose is cut, it must be

replaced prior to the heater being put into operation.

The hose assembly shall be protected from animals,

building materials, and contact with hot surfaces

during use. The hose assembly shall be that

specified by the manufacturer. See parts list.

10. Check for gas leaks and proper function upon heater

installation, before building repopulation or when

relocating.

11. This heater should be inspected for proper operation

by a qualified service person before building

repopulation and at least annually.

12. Always turn off the gas supply to the heater if the

heater is not going to be used.

13. Heaters requiring 230 volts electrical supply must

have electrical wiring consisting of two hot leads, a

neutral lead, and a ground lead. All GreenGro

heaters, regardless of voltage, must be properly

connected to a grounded electrical supply. Failure

to use a grounded electrical supply can result in

electrical shock, serious injury, or death.

-- ANSI/NFPA 58, latest edition, Standard for

Storage and Handling of Liquefied Petroleum

Gas and/or

-- ANSI Z223.1/NFPA 54, National Fuel Gas

Code

-- ANSI/NFPA 70, National Electrical Code.

3. Do not move, handle, or service heater while in

operation or connected to a power or fuel supply.

4. This heater may be installed in areas subject to

washdown. This heater may only be washed on the

external case assembly—see Cleaning Instructions.

Do not wash the interior of the heater. Use only

compressed air, soft brush or dry cloth to clean the

interior of the heater and it’s components. After

external washdown, do not operate this heater until it

is completely dry. In any event, do not operate the

heater for at least one hour after external washdown.

5. For safety, this heater is equipped with a manual

reset high-limit switch and an air proving switch.

Never operate this heater with any safety device that

has been bypassed. Do not operate this heater

unless all of these features are fully functioning.

14. Direct ignition heaters will make up to three trials for

ignition. If ignition is not achieved, the control system

will lock out the gas control valve. If gas is smelled

after system lock out has occurred, immediately close

all fuel supply valves. Do not relight until you are sure

that all gas that may have accumulated has cleared

away. In any event, do not relight for at least 5

minutes.

15. In a hanging type installation, rigid pipe or copper

tubing coupled directly to the heater may cause gas

leaks during movement, and therefore must not be

used. Use only gas hose assemblies that are rated

and approved for L.P. gas and natural gas in a

hanging type of installation.

16. Installations not using the gas hose supplied with this

appliance must connect dimensionally using

American National Standard Wrought Steel and

Wrought Iron Pipe B36/10-1970. (Aluminum piping

or tubing shall not be used.) Copper tubing when

used for conveying natural gas, shall be internally

tinned or equivalently treated to resist sulphur.

6

Page 8

Indoor Mounted Heater:

Outdoor Mounted Heater:

7

Installation Instructions

WARNING

Fire and Explosion Hazard

GENERAL

Direct fired heaters discharge combustion by-products with

the heated air in to the area being heated. These include

CO, CO2, NO, NO2, and Ethylene. These gases can result in

harm to the worker or the plants.

This greenhouse heater has been specifically developed for

very low levels of these combustion by-products. However,

it is necessary to have an exchange of air within the

greenhouse to avoid accumulation of these gases to a

harmful level over an extended period of operating time.

Greenhouses have a natural air leakage factor. This natural

leakage is influenced by the design and physical condition

of the greenhouse as well as wind conditions and other

factors. This natural leakage factor can not be relied upon

as being sufficient to provide the necessary air exchange

within the greenhouse. Proper installation of the GreenGro

greenhouse heater must include provision for adequate air

exchange as follows:

I

-- An exhaust fan capable of providing at least 550

cfm of discharge air.

-- An inlet shuttered louver of at least 220 sq. in. area.

-- The inlet shutters must be electromachanically

operated and electrically interlocked with the heater

such that the heater can not operate if the inlet

shutters do not open when heating is required.

-- Refer to Indoor Ventilation Requirements in this

manual.

-- An exhaust shuttered louver of at least 100 sq. in.

area.

-- The exhaust shutter must be electromechanically

operated and electrically interlocked with the heater

such that the heater can not operate if the exhaust

shutters do not open when heating is required.

1. Read all safety precautions and follow L.B. White

recommendations when installing this heater. If

during the installation or relocating of heater, you

suspect that a part is damaged or defective, call a

qualified service agency for repair or replacement.

2.

Make sure the heater is properly positioned before use

and is hung level. Observe and obey all minimum safe

distances of the heater to the nearest combustible

materials. Minimum safe distances are given on the

heater nameplate and on page 4 of this manual.

3. The heater may be used either indoors or outdoors.

For heaters intended for outdoor installation, the

heater is to be installed at least 18 inches above the

ground or to a height that would prevent snow

blockage of heater’s air inlet. Refer to instructions

provided in the optional L.B. White outdoor mounting

and ducting kit, part number 23579.

The heater must have the proper gas regulator installed

4.

for the application. A regulator must be connected to

the gas supply so that gas pressure at the inlet to the

gas valve is regulated within the range specified on the

dataplate at all times. Contact your gas supplier, or the

L.B. White Co., Inc. if you have any questions.

5. The heater’s gas regulator (with pressure relief valve)

should be installed outside of building. Any

regulators inside the buildings must be properly

vented to the outside. Local, state and national

codes always apply to regulator installation. Natural

gas regulators with vent limiting device may be

mounted indoors without venting to outdoors.

6.

All gas pressure regulators must be installed in strict

accordance with the manufacturer’s safety instructions.

These instructions accompany each regulator.

7. Insure that all accessories that ship within the heater

have been removed from inside of heater and

installed. This pertains to air diverters, hose,

regulators, etc.

8. Make certain that a sediment trap is installed at the

gas valve inlet to prevent foreign materials (pipe

compound, pipe chips and scale) from entering the

gas valve. Debris blown into the gas valve may cause

that valve to malfunction resulting in a serious gas

leak that could result in a possible fire or explosion

causing loss of products, building or even life. A

properly installed sediment trap will keep foreign

materials from entering the gas valve and protect the

safe functioning of that important safety component.

9. Any heater connected to a piping system must have

an accessible, approved manual shut off valve

installed within six feet (6 ft.) of the heater it serves.

10. Check all connections for gas leaks using approved

gas leak detectors. Gas leak testing is performed as

follows:

■ Do not use open flame (matches, torches, candles, etc.)

in checking for gas leaks.

■ Use only approved leak detectors.

■ Failure to follow this warning can lead to fires or

explosions.

■ Fires or explosions can lead to property damage,

personal injury or loss of life.

-- Check all pipe connections, hose connections,

fittings and adapters upstream of the gas control

with approved gas leak detectors.

-- In the event a gas leak is detected, check the

components involved for cleanliness and proper

application of pipe compound before further

tightening.

-- Furthermore tighten the gas connections as

necessary to stop the leak.

Page 9

-- After all connections are checked and any leaks

only

8

are stopped, turn on the main burner.

-- Stand clear while the main burner ignites to

prevent injury caused from hidden leaks that could

cause flashback.

-- With the main burner in operation, check all

connections, hose connections, fittings and joints

as well as the gas control valve inlet and outlet

connections with approved gas leak detectors.

-- If a leak is detected, check the components

involved for cleanliness in the thread areas and

proper application of pipe compound before further

tightening.

-- Tighten the gas connection as necessary to stop

the leak.

-- If necessary, replace the parts or components

involved if the leak cannot be stopped.

-- Ensure all gas leaks have been identified and

repaired before proceeding.

dataplate for the gas configuration of the specific

heater. Do not use the heater in an L.P. gas liquid

withdrawal system or application. If you are in doubt,

contact the L.B. White Co., Inc.

15. Eventually, like all electrical/mechanical devices, the

thermostat can fail. Thermostat failure may result in

either an underheating or overheating condition which

may damage or kill plants. Plants should be

protected by a separate back-up control system that

limits high and low temperatures and also activates

appropriate alarms.

16. Take time to understand how to operate and maintain

the heater by using this Owner’s Manual. Make sure

you know how to shut off the gas supply to the

building and also to the individual heater. Contact

your fuel gas supplier if you have any questions.

11. A qualified service agency must check for proper

operating gas pressure upon installation of the

heater.

12. Light according to instructions on heater or within

owner's manual.

13. It is extremely important to use the proper size and

type of gas supply line to assure proper functioning of

the heater. Contact your fuel gas supplier for proper

line sizing and installation.

14. This heater can be configured for use with either L.P.

gas vapor withdrawal or natural gas. Consult the

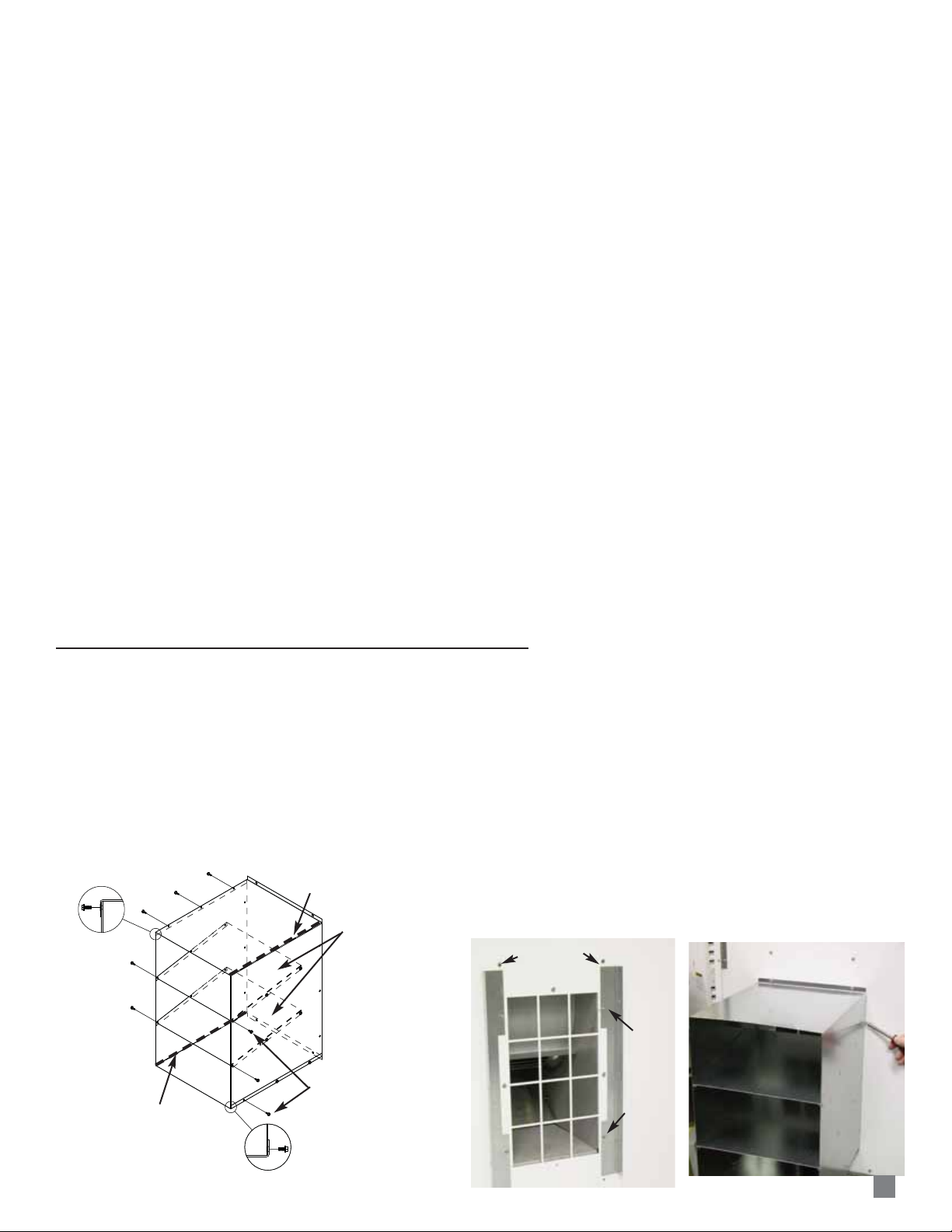

1. The air discharge diverter duct provides improved

directional air flow and greater heat throw, beneficial

o

in heating long houses. Use the duct

on indoor

mounted heaters. Do not use the diverter when the

heater is mounted outside the green house. The

diverter duct requires hand forming prior to assembly.

Make 90 degree bends utilizing the performations

provided. Assemble as shown in Fig. 1.

FIG. 1

PERFORATIONS

17. Any defects found in performing any of the service or

maintenance procedures must be eliminated and

defective parts replaced immediately. The heater

must be retested by properly qualified service

personnel before placing the heater back into use.

18. Do not exceed input rating stamped on the dataplate

of the heater. Do not exceed the burner manifold

pressure stated on the dataplate. Do not use an

orifice size different than specified for the specific

input rating of this heater, fuel type configuration and

altitude.

AIR DISCHARGE DIVERTER DUCT

Part Number 25977

(Accessory)

2. Remove the upper and lower screws at both sides of

the blower outlet, and the two screws at outlet top.

3. Install flanges as shown in Fig. 2, using the same

screws. Tighten the screws securely.

4. Position the diverter over the flanges. Align holes in

diverter to flange holes and to vacant holes at top

and bottom of blower outlet.

5. Fasten the diverter to the flanges with the screws

provided. See Fig. 3.

PERFORATIONS

VANES

MUST BE

DIRECTED

DOWNWARD

SCREWS

FROM KIT

FIG. 2 FIG. 3

SCREWS REMOVED AT OUTLET TOP

UPPER

SCREW

LOWER

SCREW

Page 10

INDOOR VENTILATION REQUIREMENTS

Air Inlet

9

This heater requires a properly sized, motorized air inlet

shutter and exhaust fan for indoor installation. These

components, along with specific instructions, are provided

in indoor ventilation kit # 25985.

Locate the air inlet directly beneath the heater and align it

to the heaters air inlet for combustion air supply. Ensure

the motorized air inlet and the heater’s air inlet are kept

free of any blockages.

■ The air inlet must be located directly beneath the

heater’s air inlet, and have access to outside fresh air.

See Fig. 4a.

■ The heater draws its combustion air through holes in its

base. The motorized air inlet must be centered to the

heater’s air inlet. See Fig. 4b.

■ The motorized air inlet must be no more than 1 ½ ft.

from the back of the heater and properly aligned to the

heater. See Fig. 4c.

■ The heater should have a minimum clearance of 1 ½ ft.

above the ground. See Fig. 4c.

FIG. 4b

Underside View

FIG. 4c

Side View

HEATER AIR INLET

1 1/2 FT MAX.

AIR INLET

TRANSITION

CENTERED

INTERIOR EXTERIOR

OUTSIDE

FRESH AIR

OUTSIDE

AIR SOURCE

Refer to Figs. 4a, 4b, and 4c for air inlet placement. If the

air inlet must be installed away from the heater in a location

other than as follows, duct kit part number 25987 must

also be installed to allow supply of combustion air to the

heater.

FIG. 4a

Blower Outlet View

1 1/2 FT MAX.

AIR

DISCHARGE

1 1/2 FT

MIN.

1 1/2 FT

MAX.

TOP OF AIR INLET

TRANSITION ALIGNED

WITH BASE OF HEATER

OUTSIDE

OUTSIDE

AIR SOURCE

FRESH AIR

MOTORIZED AIR INLET

ALIGNED TO AIR INLET

IN BASE OF HEATER

Page 11

E

Exhaust Fan

must

FIG. 5

The exhaust fan

be located at an upper area of the

end wall opposite from the heater, preferably in an area

higher than the heater’s discharge. See Fig. 5. The fan

does not need to be directly in line to the heater. Ensure the

exhaust fan is kept free of blockage.

EXHAUST FAN IN UPPER AREA OF

GREENHOUSE

CHAIN OR CABLE

AIR FLOW

ENTRY / EXIT

AIR INLET LOCATED

DIRECTLY BENEATH HEATER

AIR INLET.

HANGING THE HEATER

As shipped, the heater is configured for mounting to an

optional mounting bracket kit, part number 23652, which is

installed on freestanding supports or mounted directly to

the structure’s wall. Separate installation instructions

accompany the kit.

The heater may also be suspended by chain to the

greenhouse’s overhead structure by using an optional chain

hanging kit, part number 07802. Refer to the following

instructions.and illustrations.

1. Remove case top hole plugs. See Fig. 6.

FIG. 6

2. Assemble eyebolts and chain according to the

illustration and tighten all eyebolts securely.

FIG. 7

EYE BOLT

CHAIN

NUT 1/4-20

FLAT WASHER

FLAT WASHER

HEATER TOP

NUT 1/4-20

3. Ensure the heater is securely fastened to overhead

supports and is hanging level. (Check crosswise and

lengthwise.)

4. See Fig. 5 for typical indoor installation. In any

installation, consideration must be given to making

sure the heater is located away from the people

entering or exiting the greenhouse so they cannot

accidentally knock the heater or tamper with the

heater and its gas supply line in any way. Additionally,

the heater must be located so that it does not block

the normal entryway or exit of the building. Observe

and obey minimum clearance distances to

combustible materials as stated in the specification

section of this owner’s manual and on the heater’s

dataplate.

10

Page 12

To Connect the Series Tap Plug Thermostat Kit:

To Connect the Direct Wired Thermostat Kit to the

Control Box on the Heater:

WARNING

Electrical Shock Hazard

11

Check all

conne c t i ons f or gas leaks using appro v e d g a s leak

detectors.

SEDIMENT TRAP ASSEMBLY

Assemble the tee, nipples and cap together and tighten

securely. See Fig. 8. The sediment trap assembly must

always be mounted in a vertical

position. Make sure pipe

thread compound that is resistant to both L.P. gas and

natural gas is used in making all connections.

THERMOSTAT INSTALLATION

■ Disconnect the electrical supply before connecting the

thermostat to the heater.

■ Failure to follow this warning can result in electrical

shock, leading to personal injury or death.

T

1.

a. Connect the power cord of the heater to the

female side of the plug on the end of the

thermostat cord.

b. Plug the male side of the series tap plug on the

thermostat cord into a three-wire (grounded)

electrical outlet within the building.

FIG. 8

NIPPLE

HOSE ADAPTER

TO GAS CONTROL

VALVE INLET

2.

a. The installation and wiring of a thermostat must

be done by an electrician or someone properly

qualified.

b. The thermostat may use 18 gauge, 2 wire cord to

handle the low voltage being supplied to the

thermostat from the transformer.

c. Follow all instructions provided with the

thermostat kit.

d. The heater must be tested for proper operation

after the thermostat has been connected.

TEE

NIPPLE

CAP

MANUAL SHUT-OFF VALVE, HOSE

AND REGULATOR ASSEMBLY

1. Always use approved pipe thread compound suitable

for use with L.P. gas or natural gas on the threaded

connections.

2. Assemble the components together according to the

figure. This view is to show general assembly of the

components only. The regulator must always be

mounted so its vent, regardless of location on the

regulator, is always pointed downward.

3. Tighten all connections securely and check for gas

leaks.

FIG. 9

REGULATOR VENT

TO CONTROL

VALVE INLET

REGULATOR

NIPPLE

VALVE, MANUAL

SHUT-OFF

GAS FLOW

GAS HOSE

ADAPTER

SEDIMENT TRAP

Page 13

12

Start-Up Instructions

Follow steps 1 - 6 on initial start-up after heater installation

by a qualified gas heater service person. For normal startup, simply turn thermostat above room temperature. The

heater will start.

1. Open all manual fuel supply valves and check for gas

leaks using approved leak detectors. The gas control

valve on the heater has a manual shut-off feature

incorporated into the valve assembly. Make sure the

indicator on the valve is turned to the on position.

See Fig. 10.

FIG. 10

ON

OFF

2. Connect the electrical cord to an approved electrical

outlet.

3. Set the thermostat (if supplied) to desired room

temperature.

LED is visible through the plastic window of the

control box. A constant light from the LED is an

indicator that the heater is functioning correctly.

5. On a call for heat, the motor will start and run for five

(5) seconds and then stop. This pre-purge is a safety

feature and a normal operational characteristic prior

to ignition taking place. After the motor has stopped,

the igniter will heat up (approximately 17 seconds).

After igniter warm up time has been achieved, the

motor will start again and shortly thereafter ignition

will occur.

NOTE: It is normal for air to be trapped in the gas

hose on new installations. The heater may

attempt more than one trial for ignition before

the air is finally purged from the line and

ignition takes place.

6. The HSI control will make up to three trials for

ignition. Each trial for ignition will take approximately

20 seconds. The first two trials for ignition will occur

within 40 seconds if ignition is not achieved. A 15

minute wait period will then begin after the second

trial for ignition has taken place. After the 15 minute

time has passed, the third and final trial for ignition

will take place. If ignition is not achieved at this final

trial, the system will lock out, and a three flash

pattern will be indicated by the LED.

4. This heater includes a hot surface ignition (HSI)

control module for purposes of controlling the timing

of the ignition process of the heater as well as

monitoring of the safety functions. The HSI module is

contained within the control enclosure.

When the heater receives a call for heat, the red light

emitting diode (LED) on the ignition control will come

on. This LED indicates the status of the heater. The

If the heater is to be shut down for cleaning, maintenance or

repair, follow steps 1 - 5. Otherwise, simply turn thermostat

to off or no heat for standard shut down.

1. Close all manual fuel supply valves.

2. With the heater lit, allow heater to burn off excess

fuel in gas supply hose.

7. Do not exceed input rating stamped on nameplate or

manufacturer’s recommended burner orifice pressure

for size orifice(s) used. Make certain that the primary

air supply to main burner is open and free of dust, dirt

and debris for complete, proper combustion.

Shut-Down Instructions

3. Turn the indicator on the gas control to off.

4. Turn thermostat to off or no heat position.

5. Disconnect the heater from the electrical supply.

1

Page 14

13

WARNING

Cleaning Instructions

WARNING

Fire, Burn, and Explosion Hazard

■ This heater contains electrical and mechanical components in the gas management, and safety systems.

■ Such components may become inoperative or fail due to dust, dirt, wear and aging.

■ Periodic cleaning and inspection as well as proper maintenance are essential to avoid serious injury or property

damage.

1. Before cleaning, shut off all gas supply valves and

disconnect electrical supply.

2. At least once a year give the heater a thorough

cleaning, preferably before the beginning of the fall

heating season. At that time, remove the fan and

motor assembly and brush or blow off the fan wheel.

Additionally, ensure the burner casting and orifice are

free of dust accumulation, insect nests, webs, etc.

Maintenance Instructions

1. The area surrounding the heater shall be kept clear

and free from combustible materials, gasoline, and

other flammable vapors and liquids.

2. Have your gas supplier check all gas piping annually

for leaks or restrictions in gas lines.

3. Regulators must be periodically inspected to make

sure the regulator vents are not blocked. Debris,

insects, insect nests, snow, or ice on a regulator can

block vents and cause excess pressure at the heater.

4. Regulators can wear out and function improperly.

Have your gas supplier check the date codes on all

regulators installed and check delivery pressures to

the heater to make sure that the regulator is reliable.

Do not use a pressure washer, water, or liquid cleaning

solution on any heater components. Use of a pressure

washer, water, or liquid cleaning solution on the control

components can cause severe personal injury or

property damage due to water and/or liquids:

■ In electrical components, and wires causing electrical

shock or equipment failure.

■ On gas control valves causing corrosion which can

result in gas leaks and fire or explosion from the leak.

Clean all internal components of the heater with

pressurized air, a dry brush, or a dry cloth.

5. Check all wiring associated terminals and electrical

components within the heater for corrosion, frayed or

cut insulation, tight connections, etc. Repair or

replace as necessary.

6. Review all heater markings (i.e. wiring diagram,

warnings, start-up, shut-down, troubleshooting, etc.)

at the time of maintenance for legibility. Make sure

none are cut, torn, or otherwise damaged. Any

damaged markings must be replaced immediately by

contacting the L.B. White Co., Inc. Dataplates, startup and shut-down instructions and warnings are

available at no cost. A nominal charge will be applied

for wiring diagrams.

1

Page 15

14

MOTOR MOUNT PLATE

WARNING

Burn Hazard

■ Heater surfaces are hot for a period of time after the

heater has been shut down.

■ Allow the heater to cool before performing service,

maintenance, or cleaning.

■ Failure to follow this warning will result in burns

causing injury.

WARNING

Fire and Explosion Hazard

■ Do not disassemble or attempt to repair any

component part of the heater, including regulators

and gas hoses.

■ All components must be replaced if defects are

found.

■ Failure to follow this warning will result in gas leaks.

■ Gas leaks cause fire or explosions, leading to

property damage, injury, or death.

Service Instructions

GENERAL

4. The thermostat, and high limt switch can be tested by

jumpering the suspect part out of the electrical

circuit.:

-- Reconnect the electrical supply and open fuel

supply valves.

-- If the heater lights, the component is defective

and must be replaced.

-- Do not operate the heater with the component

jumpered. Replace the part immediately.

-- An alternate method for checking the

components is to perform a continuity check.

5. Do not jumper the air proving switch. If jumpered, the

ignition control will not allow heater operation. Test

the air proving switch for continuity. If defective,

replace the switch

6. For reassembly, reverse the respective service

procedure. Ensure gas connections are tightened

securely.

1. Close the fuel supply valve to the heater and

disconnect the electrical supply before servicing

unless necessary for your service procedure.

2. Open end panels for access to heater components.

3 Disconnect the appropriate electrical leads for the

component being replaced.

1. Remove the motor mounting plate screws and pull

the fan and motor assembly from the housing.

2. Loosen the square head set screw(s) on the fan

wheel.

3. Pull the fan wheel from the motor shaft. Use a wheel

puller if necessary.

4. Remove the four (4) nuts securing the motor to the

mounting plate.

7. After servicing, start the heater to ensure proper

operation. Check for gas leaks with approved leak

detectors.

8. Clean the heater’s orifice with compressed air or a

soft, dry rag. Do not use files, drills, broaches, etc. to

clean the orifice. Doing so may enlarge the hole,

causing combustion or ignition problems. Replace

the orifice if it cannot be cleaned properly.

MOTOR AND FAN WHEEL ASSEMBLY

NOTES:a. Fan wheel to motor mount plate spacing must be

adjusted to the clearance specified in the table

below before tightening the fan wheel to the

motor shaft.

b. Make sure that set screw(s) of the fan are on the

flats of motor shaft when tightening.

FIG. 11

FAN WHEEL

MOTOR

CLEARANCE

1/8 IN.

1

Page 16

15

AIR PROVING SWITCH

Be

careful not to melt the plastic housing of the switch

when conducting this test.

WARNING

Fire Hazard

1. Remove two sheet metal screws holding air proving

FIG. 12

switch assembly to blower housing. Remove

assembly by turning switch assembly 90 degrees so

the switch paddle can be pulled through oblong hole

on side of fan housing. See Fig. 12.

3. Disconnect the leads from the air proving switch.

SWITCH W/ PADDLE

4. When installing replacement switch, use care in not

bending the switch arm, otherwise ignition problems

may occur. Replacement includes mounting bracket.

LEADS

TESTING THE MANUAL RESET HIGH LIMIT SWITCH

■ Do not operate the heater with the high limit switch

bypassed.

■ Operating the heater with a bypassed high limit switch

may lead to overheating, possibly resulting in a fire,

with subsequent damage to the heater, building

damage, or loss of livestock.

3. Within a minute, you should hear a pop coming

from the switch, which indicates the contacts of the

switch have opened.

4. Allow the switch cool down for about a minute

before firmly pressing the red reset button on the

switch.

5. Check for electrical continuity across the switch

terminals to make sure the contacts have closed.

HOUSING SIDE

PANEL

NUTS

PADDLE

OBLONG HOLE

The high limit switch should be tested a minimum of once

6. Reinstall the switch back into the heater.

per year when the heater is given a thorough cleaning.

FIG. 13

1. Remove the high limit switch from the heat

chamber.

2. Holding the switch by one of its mounting legs or

electrical terminals, apply a small flame only to the

sensing surface on the back of the switch.

BURNER ORIFICE and GAS CONTROL VALVE

1. Remove the following

-- Hose and sediment trap from inlet of gas valve

-- Screws securing valve bracket to heater base.

-- Burner bolt from underside of base.

-- Screws and spacers securing burner casting to

heat chamber.

2. Remove control valve with burner from heater. Rotate

the valve/manifold assembly as necessary so orifice

and orifice block can exit the burner casting venturi

port..

3. Replace components as needed.

FIG. 14

RESET BUTTON

TERMINAL

MOUNTING

LEG

GAS CONTROL

VALV E

SENSING

SURFACE

FLAME

ORIFICE

BLOCK

1

BURNER

ORIFICE

Page 17

T

A. Preparation

B. Gauge Installation

C. Reading Pressures

D. Completion

Gas Pressure Checks

WARNING

16

■ Do not disassemble the gas control valve.

■ Do not attempt to replace any components of the gas

control valve.

■ The gas control valve must be replaced if any physical

damage occurs to the control valve assembly.

■ Failure to follow this warning will result in fire or

explosions, leading to injury or death to humans, and

property damage.

ATTENTION

■ The following explains a typical procedure to be followed

in checking gas pressures.

■ The gas pressures will vary depending upon fuel type.

■ Consult the dataplate on the heater or page 4 in this

manual for specific pressures to be used in conjunction

with this procedure.

■ Gas pressure measured at the inlet to the gas valve is

Inlet Pressure and gas pressure measured at the outlet

of the gas valve is Burner Manifold Pressure.

A

1. Obtain two pressure gauges capable of reading up to

35 in. W.C.

2. Disconnect the heater from the electrical supply and

close the fuel supply valve to the heater inlet.

3. Open the burner access panel.

2. Securely connect a pressure gauge to each pressure

tap.

3. Open the fuel supply valves to the heater and

reconnect the heater electrical supply.

4. Start the heater

1. With the heater operating, the pressure gauges

should read the pressures specified on the dataplate

.

2. Do the readings at the inlet and outlet pressure

gauges agree with that specified on the dataplate?

If so, then no further checking or adjustment is

required. Proceed to section D.

3. If the inlet pressures do not agree with that specified

on the dataplate, then the regulator controlling gas

pressure to the heater requires adjustment.

4. If the inlet pressures are correct and the burner

manifold pressure does not agree with that specifed

on the dataplate, then the gas control valve’s internal

pressure regulator requires adjustment. See Fig. 16

for regulator location.

FIG. 16

OUTLET PRESSURE TAP

INTERNAL PRESSURE REGULATOR

LOW PRESSURE GUAGE

ON

OFF

INLET PRESSURE TAP

LOW PRESSURE GUAGE

4. Brush or blow off any dust and dirt on or in the vicinity

of the gas control valve.

1. Locate the inlet and outlet pressure taps, see Fig. 15.

Remove the pressure tap plug using a 3/16 in. allen

key.

FIG. 15

ON

OFF

INLET PRESSURE TAP

OUTLET PRESSURE

OUTLET PRESSURE

TAP

TYPICAL PRESSURE GAUGE INSTALLATION. ALWAYS

EXAMPLE SHOWS PRESSURE FOR PROPANE GAS

REFER TO DATA PLATE FOR FUEL TYPE AND

ALWAYS REFER TO PRESSURE ON DATAPLATE

PRESSURE REQUIREMENTS.

1. Once the proper inlet and burner manifold pressures

have been confirmed and/or properly set, close the

fuel supply valve to the heater and allow the heater to

burn off any gas remaining in the gas supply line.

2. Disconnect the heater from its electrical supply.

3. Remove the gauges and connecting hoses.

4. Install pressure tap plugs and tighten securely.

Check for gas leaks.

Page 18

17

IGNITER

1. Disconnect the plastic male and female plugs

located at the end of the igniter leads. See Fig. 17.

2. Loosen the screw securing the igniter shield and the

igniter to the mounting bracket. Remove the igniter

and shield.

3. Ensure the igniter is located so the its lip on back

side of igniter is resting on the edge of the mounting

bracket and the mounting hole in the igniter aligns

with the mounting hole in the bracket.

4. Slide the igniter shield over the igniter so hole in

shield aligns with hole in igniter and bracket.

FLAME SENSOR

1. Remove the sensor from its mounting bracket. Clean

the sensor’s rod with emery cloth or steel wool to

buildup of dirt to help maintain proper flame sense.

See Fig. 17.

2. Check the flame sensor’s insulative base for any

cracks. If cracks are found, replace the sensor.

■ Handle the igniter by its ceramic base, or by its leads.

■ Center the igniter shield over the igniter element,

making sure the shield does not touch the igniter

element, otherwise igniter damage will occur when the

igniter is energized.

■ Do not overtighten the igniter mounting screw.

Overtightening may crack the base of the igniter,

leading to premature failure.

For proper flame sense operation, the flame sensor tip

■

must be properly positioned within the burner flame.

See Fig. 18.

FIG. 18

FIG. 17

SCREW

IGNITER

SHIELD

WASHER

MALE CONNECTOR

SENSOR

SCREW

FEMALE CONNECTOR

BURNER

BRACKET

BURNER

FLAME

BURNER

CASTING

1/2 in. to 3/4 in.

3/8 TO 1/2 IN.

FLAME SENSOR

1

Page 19

Troubleshooting Instructions

OPPERATION SEQUENCE:

IGNITIOON TTRIAL SEQUENCE:

18

READ THIS ENTIRE SECTION BEFORE BEGINNING TO

TROUBLESHOOT PROBLEMS.

WARNING

■ This heater can start at any time.

■ Troubleshooting this system may require operating the

unit with line voltage present and gas on. Use extreme

caution when working on the heater.

■ Failure to follow this warning may result in personal

injury or death.

following troubleshooting guide provides systematic

procedures for isolating equipment problems. This guide is

intended for use by a QUALIFIED GAS HEATER SERVICE

PERSON. DO NOT ATTEMPT TO SERVICE THESE HEATERS

UNLESS YOU HAVE BEEN PROPERLY TRAINED.

TEST EQUIPMENT REQUIRED

The following pieces of test equipment will be required to

troubleshoot this system with minimal time and effort.

• Digital Multimeter - for measuring voltage and resistance.

• Low Pressure Gauge - for checking inlet and outlet

pressures at the gas control valve against dataplate rating.

INITIAL PREPARATION

The

■ Visually inspect equipment for apparent damage.

■ Check all wiring for loose connections and worn

insulation.

The ignition control module is self-diagnostic. The red light

located on the control will flash a specific pattern depending

upon the problem which is diagnosed. To use the flow charts, t

identify the problem by the light pattern of the L.E.D. (light

emitting code) diagnostic light. If the light is flashing, the flash

pattern will be followed by a pause and then a repeat of the

flash pattern until the problem is corrected. The light will only

be on when the selector switch is positioned to HEAT and the

thermostat or controller is calling for heat. The light will not be

on when the selector switch is positioned to VENT.

Heating Mode Problems

L.E.D. light is not on during a call for heat. . . . . . . . . . . . . . . 19

L.E.D. diagnostic light is flashing:

A. Rapid flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

B. Long flash ( 2 seconds on-2 seconds off) . . . 20

C. One time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

D. Two times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

E. Three times. . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

F. Four times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

G.Five times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

H.Six times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Page

-- Line voltage is sent to motor relay and transformer

-- Terminal at transformer branches off line voltage to terminal

L1 on ignition control.

-- Transformer reduces line voltage to 24 VAC.

-- 24 VAC is sent to thermostat.

-- Thermostat contacts close on call for heat and return 24

volts to terminal W on ignition control.

-- Red light on ignition control is illuminated.

-- Ignition control sends flame sense current to flame sensor.

-- Ignition control module performs self safety check.

-- Internal components are tested.

-- Air proving circuit is tested

-- Control sends 24 VAC from terminal PSI to air . . .

proving switch.

-- Ignition control module begins ignition trial sequence.

-- Ignition control sends 115 volts from terminal IND to motor

relay.

-- Motor relay closes.

-- Line voltage is sent to motor

-- Motor starts.

-- Air proving switch closes and 24 volts are returned to

terminal PSO of ignition control.

-- Motor stops.

-- Ignition control module sends 115 volts to hot surface igniter.

-- Igniter reaches ignition temperature in 17 seconds.

-- Ignition control restarts the fan motor while sending 24 VAC

to air proving switch.

-- Switch closes and 24 volts is returned back to control.

-- Ignition control send 24 volts from terminal GV to high limit

switch.

-- If limit switch contacts are closed, limit sends 24 volts

to gas control valve

-- Gas control valve opens

-- Ignition occurs.

-- Flame sense current is passed through burner flame back to

ignition control.

-- Igniter stays powered until ignition control proves flame sense

-- Igniter then shuts down.

-- Gas control valve stays open

-- Room warms to desired temperature.

-- Thermostat is satisfied.

-- Heater shuts down.

-- Process starts again on a call for heat.

-- First trial for ignition takes approximately 30 seconds

-- Two more ignition trials occur

-- Second trial immediatley follows if first trial failed.

-- If second trial fails

-- Ignition control starts a 15 minute waiting period

-- Allows the ignition interruption to pass

-- At end of 15 minutes

-- Ignition control attempts third and final ignition trial

-- If igntion control does not prove burner flame after third

trial, the control goes into safety lockout ( 3 flash)

-- Gas valve closes.

-- Hot surface igniter shuts down

-- Fan motor stops.

-- To retry for ignition, turn the heater off and then on.

Page 20

LED Light

Not On

Does

transformer

Yes

Is 24 volts

delivered to

Yes

reduce

incoming

Yes

No

thermostat?

No

volts?

voltage to 24

No

Check wiring between

transformer and

thermostat. Check

continuity. Repair as

needed.

Defective transformer.

Relace transformer.

Replace thermostat

Defective

ignition control.

Is transformer

receiving proper

Yes

Is proper voltage

supplied to heater?

Yes

Normal Operation

Is heater

connected to

power supply?

voltage?

No

No

Check wiring for

continuity between

transformer and power

supply. Repair or replace

requirments.

Provide proper

electrical supply

voltage, contact

Check data plate for

breakers

supply. Check

Ensure heater is

connected to power

electrician.

Yes

Is

continuity.

thermostat

defective? Check for

Yes

Is

above room

thermostat set

No

No

temperature?

Yes

Are 24 volts

from thermostat?

control terminal W

supplied to ignition

above room

temperature.

Set thermostat

No

Defective wire or

Reapir or replace.

electrical connection.

19

LED Constant On

Problem

Page 21

LED Flashing

One Time

Flash Pattern

Begins

Immediately

After Condition

Occurs.

Free the switch .

Rapid Flash

Long Flash

Determine casue of

flapper binding.

Check for damage to

fan housing,.

Yes

Replace air proving switch

Yes

Remove jumper from switch.

Yes

Problem

Reverse polarity. Have electrician check neutral and hot wire

Is

No

housing?

binding in fan

ignition control module will present the three time flash pattern. Either recycle the heater or wait for

Heater has attempted two ignition trials. Heater is in a 15 minute wait period before attempting its third

connections that outlet heater is connected to.

heater to attempt third ignition trial.

(final) trial for ignition. If ignition is not achieved after the third trial, the heater will lock out and the

airflow switch arm

Is

continuity.

air proving switch stuck

closed or shorted ? Check

No

been jumpered?

Has air proving switch

No

Defective wire or poor

Repair wire or connections.

connections to air proving switch.

Two seconds

on, two seconds

off repetitively

for 15 minutes.

20

Page 22

21

Two Times

Defective ignition

control. Replace

ignition control.

Check for binding of

air-proving switch arm

on housing, Repair or

replace as necessary.

Yes

Check for proper clearance of

fan wheel to motor mount. If

good, replace fan wheel, or

check for housing alignment.

Tighten set screw(s) on fan. Make

sure set screw(s) are tightened

against flat(s) of motor shaft.

Clean the fan wheel with

compressed air or soft brush.

Remove obstruction.

Clean as necessary.

Yes

Yes

from air proving

switch to terminal

PSO on controller?

Are 24 volts returned

Yes

from terminal PS1

air proving switch?

on controller to the

Are 24 volts supplied

Yes

No

Are air-proving switch

No

component. Repair or replace as

Check wiring between module and

necessary. If wiring is good, replace

No

check.)

(Perform continuity

contacts stuck open?

Replace motor.

Defective motor.

Yes

Is

ignition control module.

voltage sent from

relay to motor?

Yes

binding?

Is fan wheel

No

Check wiring between

No

replace relay

needed. If good,

relay and motor. If

defective, repair as

Yes

shaft?

Is fan wheel

loose on motor

No

Yes

dirt?

Is fan wheel

plugged with

No

Defective air proving switch. Replace switch.

No

Is there an obstruction

air-proving switch closure?

in blower outlet preventing

Does

2

for heat?

for prepurge

during initial call

fan motor start up

Flash pattern

begins 12

seconds after

condition

Yes

No

No

- OR -

from ignition

control terminal

IND to motor relay

Are 115 volts sent

occurs.

(Pattern

indicates

lack of air

proving in fan

section

of unit.)

contact electrician.

If improper voltage is supplied,

relay , check wiring bewtween

If no voltage is supplied to motor

motor relay and ignition control. If

good, replace control.

Page 23

22

Three Times

No

--

Replace

sensor.

Are 24 volts

the high limit

supplied from

control valve?

switch to the gas

Yes

of controller to

high limit switch

Are 24 volts sent

from terminal GV

after igniter warm

up and fan motor

Yes

closed?

Are high limit

switch contacts

Yes

to heater?

Is proper gas

pressure supplied

Yes

restarts?

No

No

valve. Check wiring

Check for voltage to

and repair if defective.

replace limit switch.

If wiring is good and

voltage is not present,

No

control.

replace ignition

Check for voltage to

Perform continuity check.

If switch is open reset the switch.

If wiring is good and

switch. Check wiring

and repair if defective

voltage is not present,

Obstructions in air inlets or

Check the following:

-- Confirm correct fuel for heater.

-- Proper voltage to motor

-- Dust and dirt build-up

-- Plugged fan assembly

-- Fan not tightened to motor

discharge outlet of heater.

gauge.

Provide proper

and check with a

pressure to heater

Yes

Is

insulator

cracked?

flame sensor

Yes

Is flame

sensor clean?

Yes

sensor?

checked

control and

Has wiring been

between ignition

Yes

glow?

Does igniter

No

Is

flame sensor

No

steel wool.

with emery cloth or

Clean flame sensor

No

module and

Check wiring between

Yes

No

Is igniter

properly

positioned?

or replace .

component. Repair

properly

connected?

No

Position flame

sensor so 1/2 -

Defective igniter.

Perform continuity

check and replace

Yes

Are

115 volts

supplied from

ignition control

terminal HSI on

No

Connect igniter

burner flame.

3/4 in. of tip is in

igniter If necessary.

No

igniter?

module to

Check wiring between module and

supply wiring.

to igniter power

component. Repair or replace as

necessary or replace ignition control .

properly

Is heater

grounded?

Yes

Is

LP tank

heater open?

supply valves to

full and properly

sized and are all gas

Ignition

failure Heater

does not light

or stay lit.

No

grounded for

System must be

Contact electrician.

proper operation.

No

gas supply valves

Fill tank or resize if

necessary. Open all

Yes

No

Have

the burner

blockage?

orifice, burner

been checked for

casting and manifold

Remove orifice and

out with compressed

burner casting. Blow

soft brush.

air or clean with a

Yes

Yes

Is proper

outlet of gas

burner manifold

pressure read at

No

valve?

is read, adjust outlet

pressure.

(A) If low or high pressure

read, replace the gas

control valve.

(B) If gas pressure is not

2

Page 24

23

Five Times

Six Times

Four Times

If HSI board does not reset, then replace the board. (Internal board fault.)

If HSI board resets, then have qualified electrician check power source for

power quality problems. (Frequency, line noise, line spikes, loose connections,

too small wire gauge.)

See flame sensor related problems in

three time flash pattern.

Low microamp output from flame sensor. The heater will

continue to operate as normal. Flame sense is low and that

flame failure or improper operation can occur at any time. See

flame sensor related problems in three time flash pattern.

2

Rapid On/Off

cycling of the

burner.

Page 25

24

Electrical Connection and Ladder Diagram

115 Volt Supply

120 VOLT

2

Page 26

25

230 Volt Supply

2

120 VOLT

Page 27

26

Heater Component Function

Air Proving Switch

Safety device used to insure that the proper air flow is being

achieved before the gas valve is opened.

Burner

Cast iron component used to channel gas and provide an

area at which the fuel may ignite.

Burner Orifice

Brass metering device used to feed gas to burner at a

specific rate.

Fan Housing

Chamber used for delivering air for efficient air movement.

Fan Wheel

Component used in conjunction with the motor and fan

housing to pull the hot air from heater and blow it into room

for heating (also known as a squirrel cage).

Gas Control Valve

A device which consists of a low pressure regulator and

electrical solenoids which are used for the control of gas

flow to the burner assembly. A feature of the control is a

built in gas shut off which is used to isolate the heater from

its gas supply when servicing.

Gas Hose

Flexible connector used to convey gas from supply line in

building to heater.

Heat Chamber

Metal “fire box” within the appliance that provides an area

where burner flame mixes with combustion air, thereby

providing heat.

High Limit Switch

Safety device wired into the control system which is used to

break an electrical circuit to the gas control valve in event of

overheat situation.

Hot Surface Igniter

Ignition device used on automatic ignition control systems.

Ignites gas by surface temperature rather than spark or

flame.

Ignition Control Module

Electronic printed circuit board which sends and receives

voltages to various controls in an automatic ignition system.

An important safety feature of the control board is that it will

shut down the entire heater, thereby stopping the flow of

fuel gas if burner flame goes out.

Motor

Electric device used to force preheated air through the

heater and to circulate heat within a certain area. Converts

electrical energy into mechanical energy.

Motor Relay

Electrical component wired between ignition control and

motor. Used to feed voltage to motor upon receipt of voltage

from ignition control.

Regulator

Mechanical device used in L.P. and natural gas distribution

systems to reduce a higher inlet pressure to a preset lower

pressure. The regulator is responsible to supply a steady

outlet pressure to the heater(s) despite changes in inlet

pressure, heater demand and weather conditions.

Thermostat

Electrical device used as an automatic “on/off” switch

which will respond to changes in temperature in a certain

area. Can be wired so contacts in the thermostat open or

close on temperature increase or decrease.

Transformer

Electrical control used to accept line power supply primary

voltage and reduce it to lower secondary voltage to operate

certain control systems.

(Accessory)

2

Page 28

27

Parts Identification

PARTS SCHEMATIC

30

28

22

29

25

35

38

37

39

27

13

26

34

33

32

31

14

1

12

11

2

36

23

24

21

20

19

16

17

5

6

7

8

18

15

9

2

10

3

4

Page 29

28

Parts Identification

Item Description Part Number

PARTS LIST

1 Regulator LP Gas 06553

Natural Gas 24414

2 Valve, Manual Shut Off with Nipple 03399

3 Hose, 1/2 x 10 ft., Rigid x Swivel 20714

4 Adapter, Hose, 1/2 NPT x 1/2 NPS 25873

5 Kit, Sediment Trap 00815

6 Screws (2) 572502

7 Bracket with Screws 570141

8 Valve, Gas Control LP Gas 570666

Natural Gas 570667

9 Manifold U Shape with Orifice LP Gas 572492

Natural Gas 572495

10 Washer and Bolt 25866

11 Base LP Gas 572493

12 Orifice LP Gas 570318

Natural Gas 570319

13 Burner w/ Mounting Hardware 25842

14 Spacers and Screws 570211

15 Igniter, Hot Surface 509201

16 Shield, Igniter 572494

17 Screw and Washer, Igniter Shield 572512

18 Bracket w/ Screws 570089

19 Flame Sensor 520139

20 High Limit Switch LP Gas 572501

Natural Gas 505566

21 Heat Chamber LP Gas 572499

Natural Gas 572500

22 Control Box w/Cover 572485

23 Window w/ O-Ring 570002

24 Cover, Control Box 572484

25 Relay, Motor 570221

26 Ignition Control 509298

27 Transformer 509615

28 Case Assembly, w/ Labels LP Gas, 115 Volt 572475

LP Gas, 230 Volt 572477

Natural Gas, 115 Volt 572480

Natural Gas, 230 Volt 572481

29 Door, Motor End 572488

30 Door, Burner End 572498

31 Fan Housing w/ Motor Mount and Air Proving Switch 572491

32 Fan Wheel 570440

33 Air Proving Switch 09925

34 Motor Mount 570251

35 Motor 115 Volt 25757

230 Volt 08635

36 Latch Kit 570228

37 Wire Harness, Igniter, Red 572503

38 Wire Harness, Neutral 230 Volt 572497

39 Power Cord 115 Volt 572486

2

Page 30

Warranty Policy

HEATER

L.B. White Co., Inc. warrants that the component parts of its

heater are free from defects in material and workmanship,

when properly installed, operated, and maintained in

accordance with the Installation and Maintenance

Instructions, safety guides and labels contained with each

unit. If, within 12 months from the date of purchase by

the end user, any component is found to be defective,

L.B. White Co., Inc. will at its option, repair or replace the

defective part or heater, with a new part or heater, F.O.B.,

Onalaska, Wisconsin.

PARTS

L.B. White Co., Inc. warrants that replacement parts

purchased from the company and used on the appropriate

L. B. White equipment are free from defects both in material

and workmanship for 12 months from the date of

purchase by the end user. Warranty is automatic if a

component is found defective within 12 months of the date

code marked on the part. If the defect occurs more than 12

months later than the date code but within 12 months from

the date of purchase by the end user, a copy of a bill of sale

will be required to establish warranty qualification.

The warranty set forth above is the exclusive warranty

provided by L.B. White, and all other warranties, including

any implied warranties or merchantability or fitness for a

particular purpose, are expressly disclaimed. In the event

any implied warranty is not hereby effectively disclaimed

due to operation of law, such implied warranty is limited in

A warranty card on file at L.B. White will automatically

qualify a unit and its component parts for warranty

consideration. If a warranty card is not on file, a copy of the

bill of sale will be required to establish warranty

qualification. If neither is available, the warranty period will

be 12 months from date of shipment from L.B. White.

duration to the duration of the applicable warranty stated

above. The remedies set forth above are the sole and

exclusive remedies available hereunder. L.B. White will not

be liable for any incidental or consequential damages