Page 1

Item No.

Project

Quantity

BakerSeries Roll-in High Output Retarder Proofer

Construction Features

. Two Door, triple wide rack capacity

.

.

.

.

.

.

.

. Refrigeration components compliant with R404a refrigeration

Performance Features

.

.

.

.

.

Model LRPR3-40HO Shown

MODEL / RACK CAPACITY

Model / Depth Side Load End Load Double

LRPR3-30HO 3 Racks 4 Racks None

LRPR3-40HO 6 Racks 4 Racks 3 racks

LRPR3-50HO 8 Racks 7 Racks 3 Racks

LRPR3-60HO 10 racks 8 Racks 4 Racks

LRPR3-70HO

LRPR3-80HO

LRPR3-90HO

LRPR3-100HO

LRPR3-110HO

LRPR3-120HO

10 Racks 10 Racks 5 Racks

13 Racks 11 Racks 6 Racks

15 Racks 12 Racks 6 Racks

15 Racks 14 Racks 7 Racks

18 Racks 16 Racks 8 Racks

20 Racks 17 Racks 9 Racks

Short Bid Specification:

Proofer Retarder shall be an LBC Bakery Equipment Model

LRPR3-

100HO, 110HO, 120HO] 5 to 13.2kW electrically heated, double door,

triple-wide roll-in rack unit with: quick responding air-wash heat /

humidity system; refrigeration system including solenoid valve(s),

expansion valve(s), line dryer(s) and epoxy coated evaporator coils;

modular foam insulated cam lock panel construction; all 300 series

stainless steel interior, with protective cart bumpers; heavy-duty door

with magnetic seal/mechanical closure system and full width protective

bar handle; simple computerized controls, door mounted at eye-level,

with accurate digital temperature, humidity and time readouts; plus all

the features listed and options checked.

[insert 30HO,40HO,50HO,60HO,70HO,80HO, 90 HO,

. Evaporators sized for high humidity levels, prevents drying

. Refrigeration sized for rapid pull down required by scratch baking

. Interior bumpers protect interior walls from damage

. Lighted interior

Controls Features

.

.

.

. Digital set Temperature, Humidity, Time

.

.

.

MODEL: LRPR3 HO - Series

Heavy duty stainless steel exterior with 300 Series

stainless steel interior and aluminized steel top

Walls Ceilings and doors are foam insulated

Modular wall and ceiling panels with cam lock construction

Rapid responding air-wash heat and humidity system

High capacity refrigeration system with epoxy coated evaporator coils

208/240 VAC single or 3-phase power, field convertible

Optional remote condensers

Dual purpose, provides both proofing and retarding

70 - 120 Degree F proofing range

34 - 45 Degree F retarding Range

50 - 99% humidity range

Non-submerged calrod type heaters

All digital controls mounted in the door at eye-level

PID Type controls for rapid accurate response without overshoot

Operate in individual modes or automatic mode

Real-Time clock

Installed in the left hand door at eye-level

Large LED displays

Condenser Sold Separately

STANDARD PRODUCT WARRANTY

One-Year Parts and Labor (contiguous US Including Alaska and Hawaii, Canada)

LBC Bakery Equipment,Inc. 1410 80th Street SW Everett WA 98203

TOLL FREE 888-RACKOVN (888-722-5686) FAX: 425-642-8305 www.lbcbakery.com

Sheet Number LRPR3HO v 2(rev 10/07)

Page 2

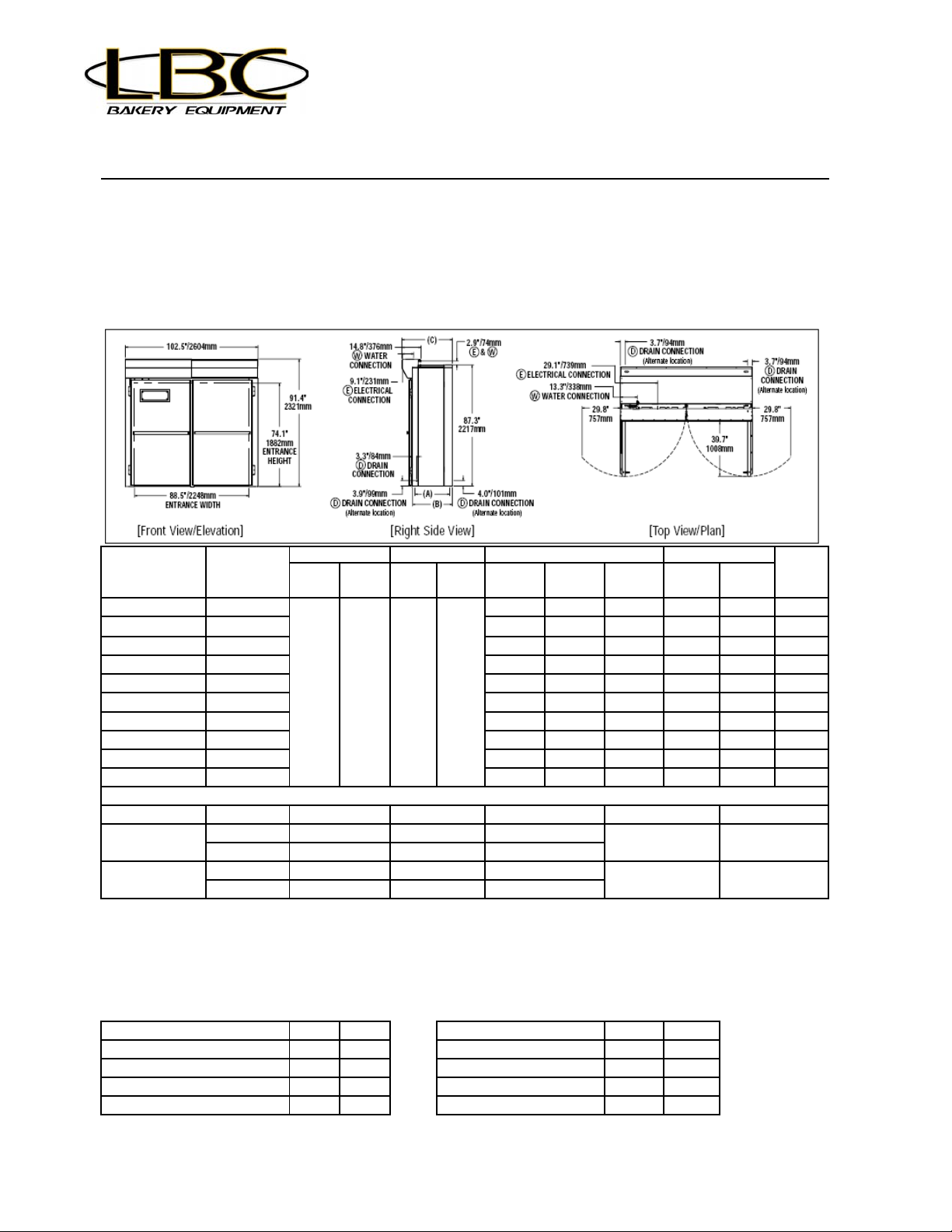

High Output Roll-In Retarder Proofer MODEL: LRPR3 -HO Serie

s

T

S

V

INSTALLATION REQUIREMEN

Ships KD requires on-site installation

Either 208 or 240 VAC 1 or 3-phase 1/2" PVC vented drain connection

Refrigeration system must be installed by a licensed refrigeration technician

OPTIONS & ACCESSORIE

Refrigeration Condenser; Requires separate connection

Stainless Steel Floor

1/2" NPT Cold water connection

WidthHeight

Retarder

Model

LRPR3-30HO 7000 26.0" 31.0" 39.3" 1372 1472 70

LRPR3-40HO 9000 36.1" 41.1" 49.4" 1457 1582 70

LRPR3-50HO 9000 46.1" 51.1" 59.4" 1597 1722 70

LRPR3-60HO 11000 56.1" 61.1" 69.4" 1707 1832 70

LRPR3-70HO 11000 66.2" 71.2" 79.5" 1817 1942 70

LRPR3-80HO 15000 76.2" 81.2" 89.5" 1957 2082 70

LRPR3-90HO 15000 86.2" 91.2" 99.5" 2220 2345 70

LRPR3-100HO 15000 96.2" 101.2" 109.5" 2354 2479 70

LRPR3-110HO 18000 106.3" 111.3" 119.6" 2494 2619 70

LRPR3-120HO 18000 116.3" 121.3" 129.6" 2604 2729 70

Model Voltage

LRPR3-

(40HO - 80HO)

LRPR3-

(90HO-120HO)

This Appliance is designed to operate at normal room temperatures; if installed next to an oven or other

heat source allow a minimum clearance of 4" to prevent heat transfer. Clearance from combustibles is

IMPORTANT: Your local water conditions may damage your LBC appliance. Failure to properly treat water may

result in damage and may void your warranty. Ensure that your water supply meets these minimum water quality

BTU Rating

208 VAC

240 VAC

208 VAC

240 VAC

0.0" sides and back, For Install on non-porous surfaces only

Parameter

Alkalinity

Aluminum

Calcium

Free Chlorine Residual

Int Ext Int Ext

74.1" 91.4" 96.6" 102.5"

Electrical Requirements by Model

Total kW 1-Phase 3-Phase

5

6.6

10.2

13.2

UnitValue Unit

ppm 22 ppm 0.65

ppb 17 s.u. 8.5

ppm 3.3 ppm 8.5

ppm 0.6 ppm 11.9

24.0 AMPS

48.0 AMPS

55.0 AMPS

specification.

Parameter

Magnesium

pH

Sodium

Total Hardness

Internal

"A" Ext. "B"

Depth Weight

Over All

"C"

13.8 AMPS

15.8 AMPS27.5 AMPS

26.6 AMPS

31.6 AMPS

1/2" NPT .07 GPM

@ 60 PSI

1/2" NPT .14 GPM

@ 60 PSI

Freight

Actual Ship

Water Drain

1/2"PVC; 210 F;

<1 GPM Max.

1/2"PVC; 210 F;

<1 GPM Max.

alue

Class

LBC Bakery Equipment Co. 1410 80th Street SW Suite C, Everett, WA 98203

TOLL FREE: 888-RACKOVN (888-722-5686) FAX: 425-642-8305 www.lbcbakery.com

Loading...

Loading...