LBC Bakery Equipment LRP15-40 Service Manual

© COPYRIGHT 2017 LBC BAKERY EQUIPMENT, INC. 1 REV C 1/2017

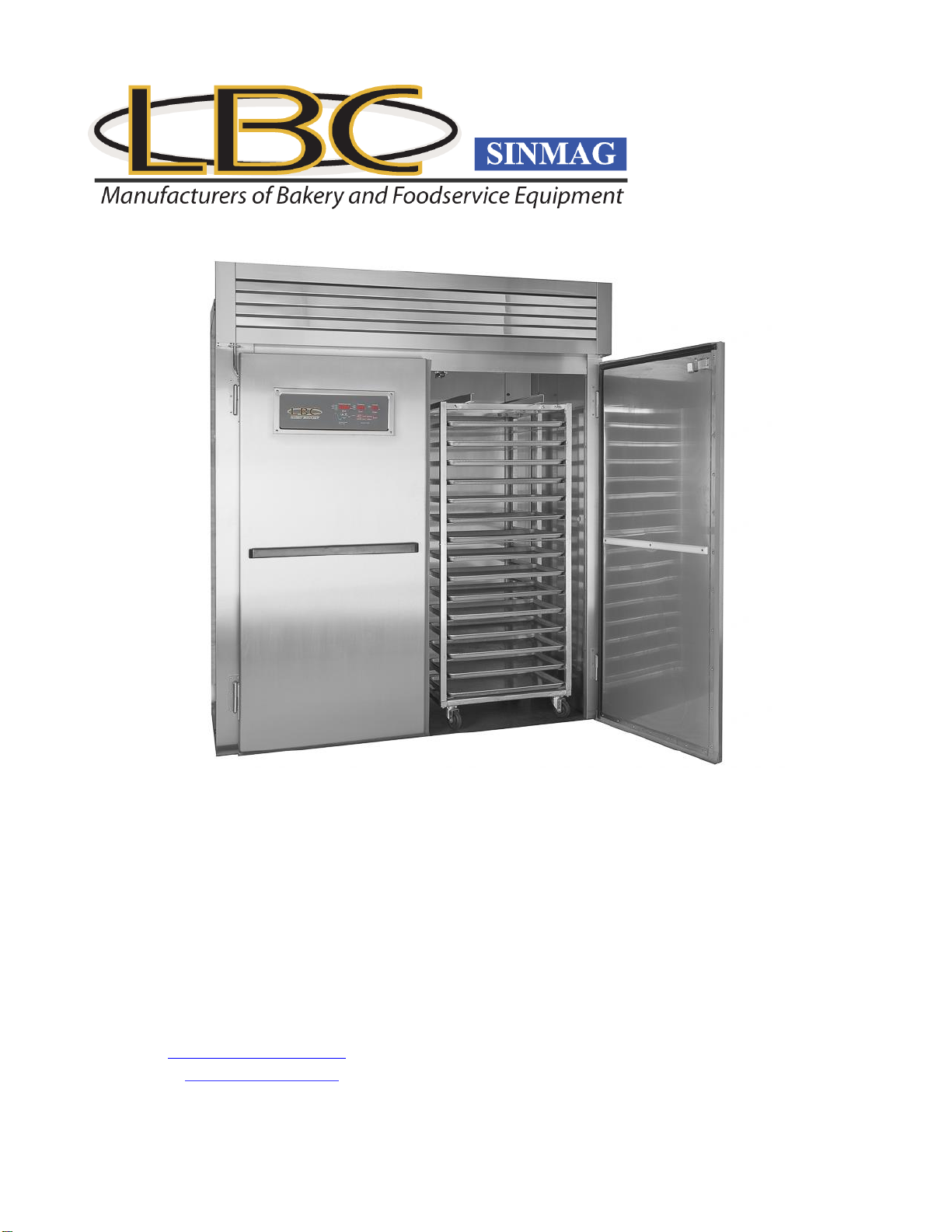

Models LPR and LRPR

Roll-in Rack Proofer and Retarder-Proofer

Installation, Service and Parts Manual

LBC Bakery Equipment, Inc.

6026 31st Ave NE

Tulalip, WA 98271, USA

Phone: 888-RACKOVN (888-722-5686)

Fax: 425-642-8310

Email: service@lbcbakery.com

Website: www.lbcbakery.com

© COPYRIGHT 2017 LBC BAKERY EQUIPMENT, INC. 2 REV C 1/2017

THE INFORMATION IN THIS MANUAL IS CRUCIAL AND MUST BE RETAINED FOR

FUTURE REFERENCE. READ, UNDERSTAND, AND FOLLOW THE INSTRUCTIONS AND

WARNINGS CONTAINED IN THIS MANUAL.

DANGER

POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, COULD RESULT IN DEATH.

WARNING

POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, COULD RESULT IN DEATH OR SERIOUS INJURY.

CAUTION

POTENTIALLY HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, MAY RESULT IN MINOR OR MODERATE INJURY.

NOTICE

Helpful operation and installation instructions and tips are

present.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY

OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

Model #:

Purchased From:

Serial #:

Location:

Date Purchased:

Date Installed:

Purchase Order #:

For Service, Call:

3

TABLE OF CONTENTS

CHAPTER PAGE

TABLE OF CONTENTS ...................................................................................... 3

SPECIFICATION SHEETS .................................................................................. 4

CONDITIONS OF INSTALLATION ................................................................... 12

READ FIRST ........................................................................................................ 14

SAFETY PROCEDURES, LOCK-OUT ............................................................... 16

ASSEMBLY .......................................................................................................... 17

ELECTRICAL SUPPLY CONNECTIONS .......................................................... 37

RETARDER/PROOFER ONLY ........................................................................... 38

REFRIGERATION INFORMATION ................................................................... 47

ELECTRICAL SCHEMATICS ............................................................................. 48

PARTS ................................................................................................................... 52

WARRANTY ........................................................................................................ 56

4

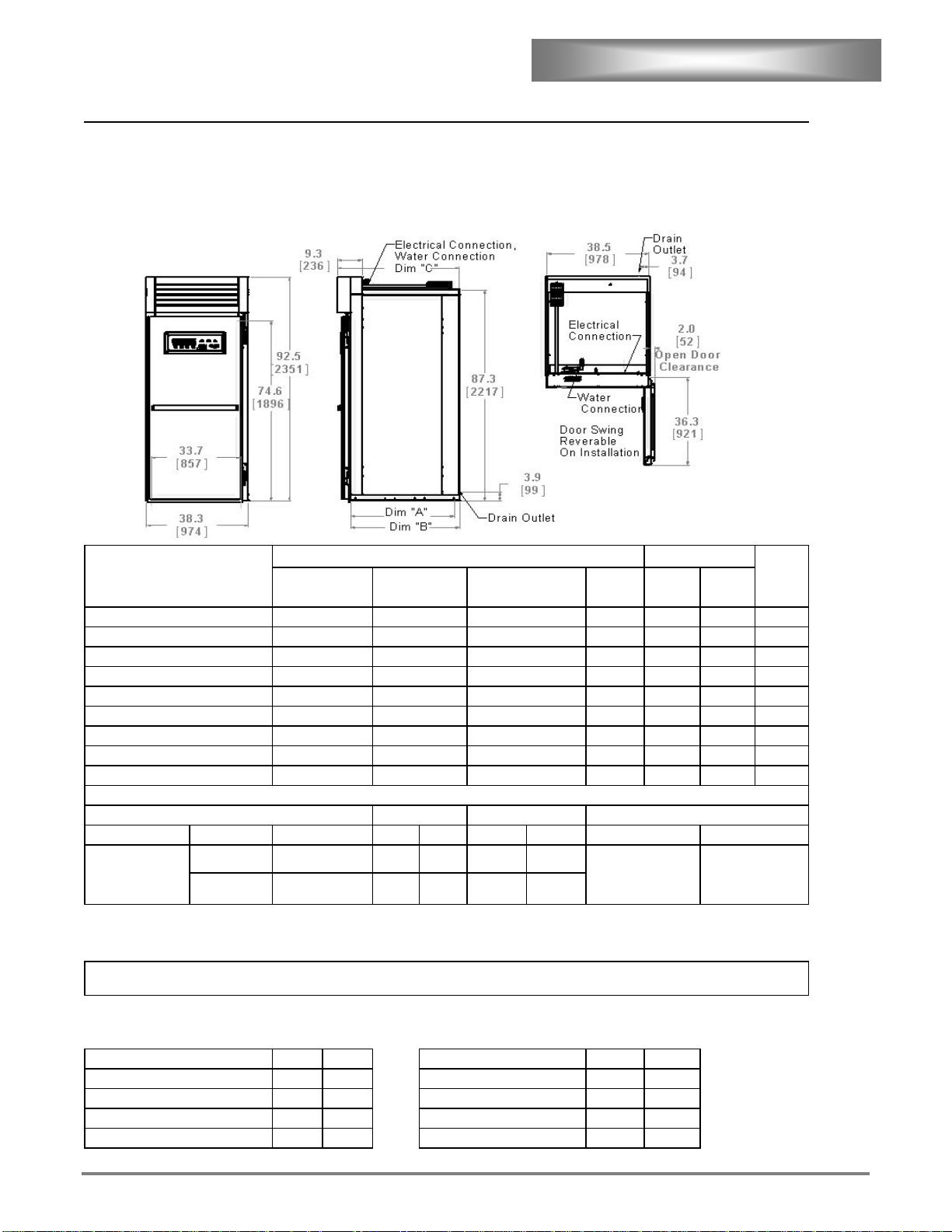

EQUIPMENT DESCRIPTION

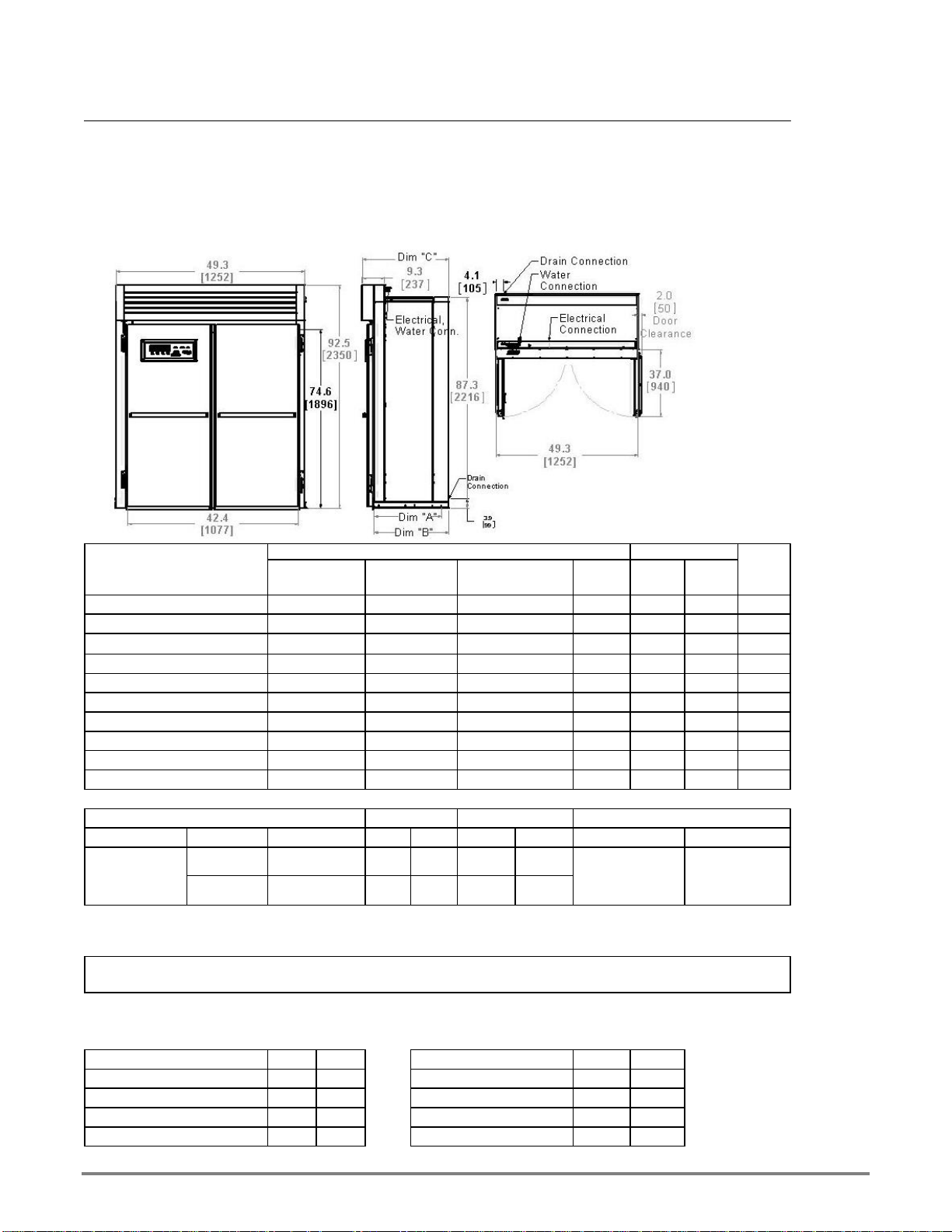

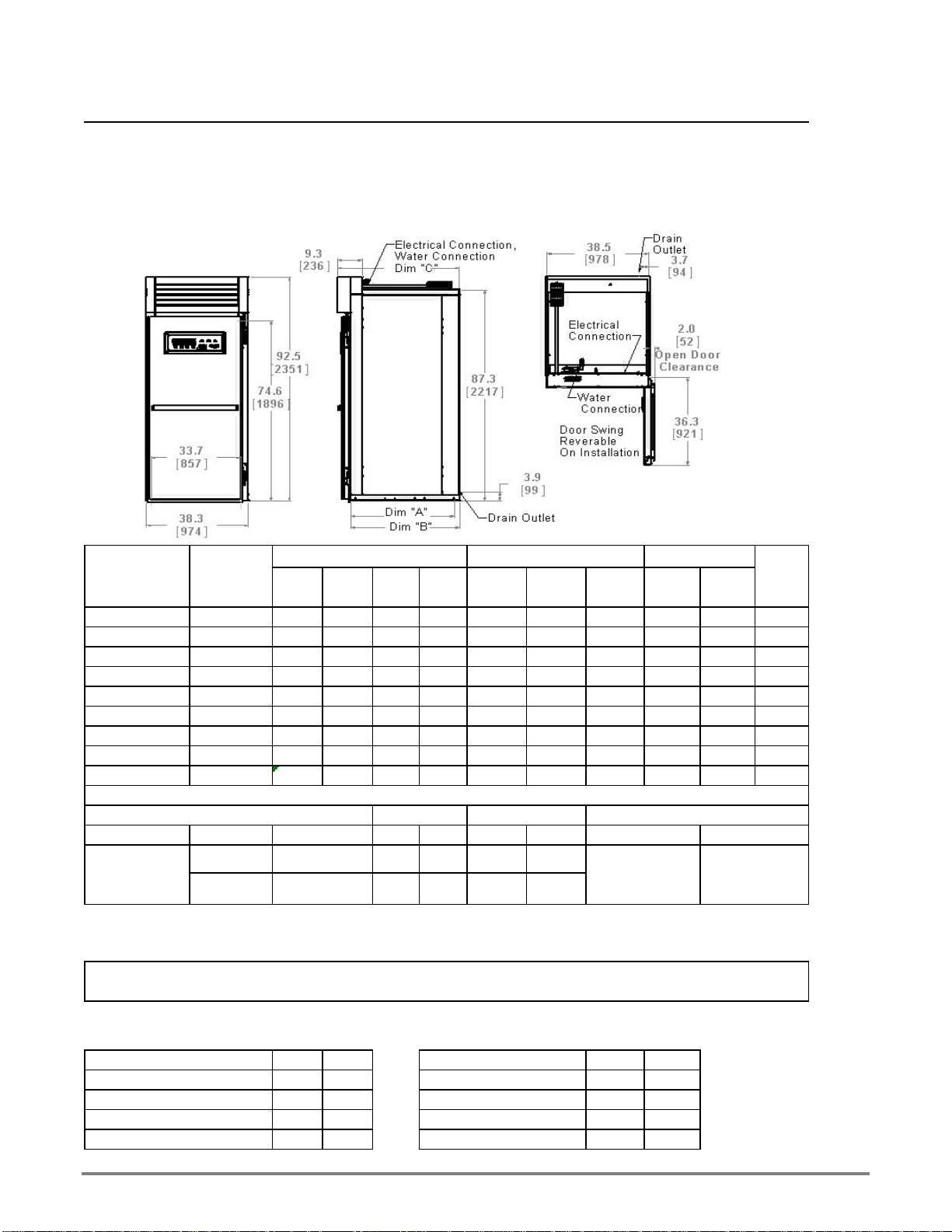

Roll-In Proofer MODEL: LRP1 Series

INSTALLATION REQUIREMENT

1/2" NPT Cold water connection

208/120 or 240/120 1-phase or 3-phase 3/4" Copper vented drain connection

OPTIONS & ACCESSORIES

Width

Actual Ship

LRP1-40 38.3 892 992 70

LRP1-50 38.3 991 1116 70

LRP1-60 38.3 1094 1219 70

LRP1-70 38.3 1197 1322 70

LRP1-80 38.3 1321 1446 70

LRP1-90 38.3 1424 1549 70

LRP1-100 38.3 1527 1652 70

LRP1-110 38.3 1651 1776 70

LRP1-120 38.3 1754 1879 70

Model Voltage 1-Ph 3-PH 1-Ph 3-Ph

208/120 VAC

30 20 50 50

240/120 VAC

35 20 50 50

Unit Value Unit Value

ppm 22 ppm 0.65

ppb 17 s.u. 8.5

ppm 3.3 ppm 8.5

ppm 0.6 ppm 11.9

*MCA: Minimum Circuit Ampacity. *Max Fuse: Maximum allowable circuit protector.

5

*MCA

Weight

Freight

Class

LRP1-(40 -120)

Drain

Total Electrical Requirements By Model

Ships KD requires on-site installation

Stainless Steel Floor

Model

Parameter

Parameter

Total kW

*Max Fuse

1/2" NPT .07

GPM @ 60 PSI

1/2"PVC; 210 F;

<1 GPM Max.

Total Hardness

Alkalinity

Aluminium

Calsium

Free Chlorine Residual

Magnesium

pH

32.1

42.1

52.1

62.1

72.1

82.1

79.3

89.3

99.3

Sodium

6.6

This Appliance is designed to operate at normal room temperatures. Clearance from combustibles

is 0.0" sides and back, For Install on non-porous surfaces only

IMPORTANT: Your local water conditions may damage your LBC appliance. Failure to properly treat water may

result in damage and may void your warranty. Ensure that your water supply meets these minimum specification.

Water

92.1

102.1

112.1

109.3

119.3

Depth

Over All "C"

49.3

59.3

69.3

Ext. "B"

41

51

61

129.3

Internal "A"

91

101

111

1217181

5

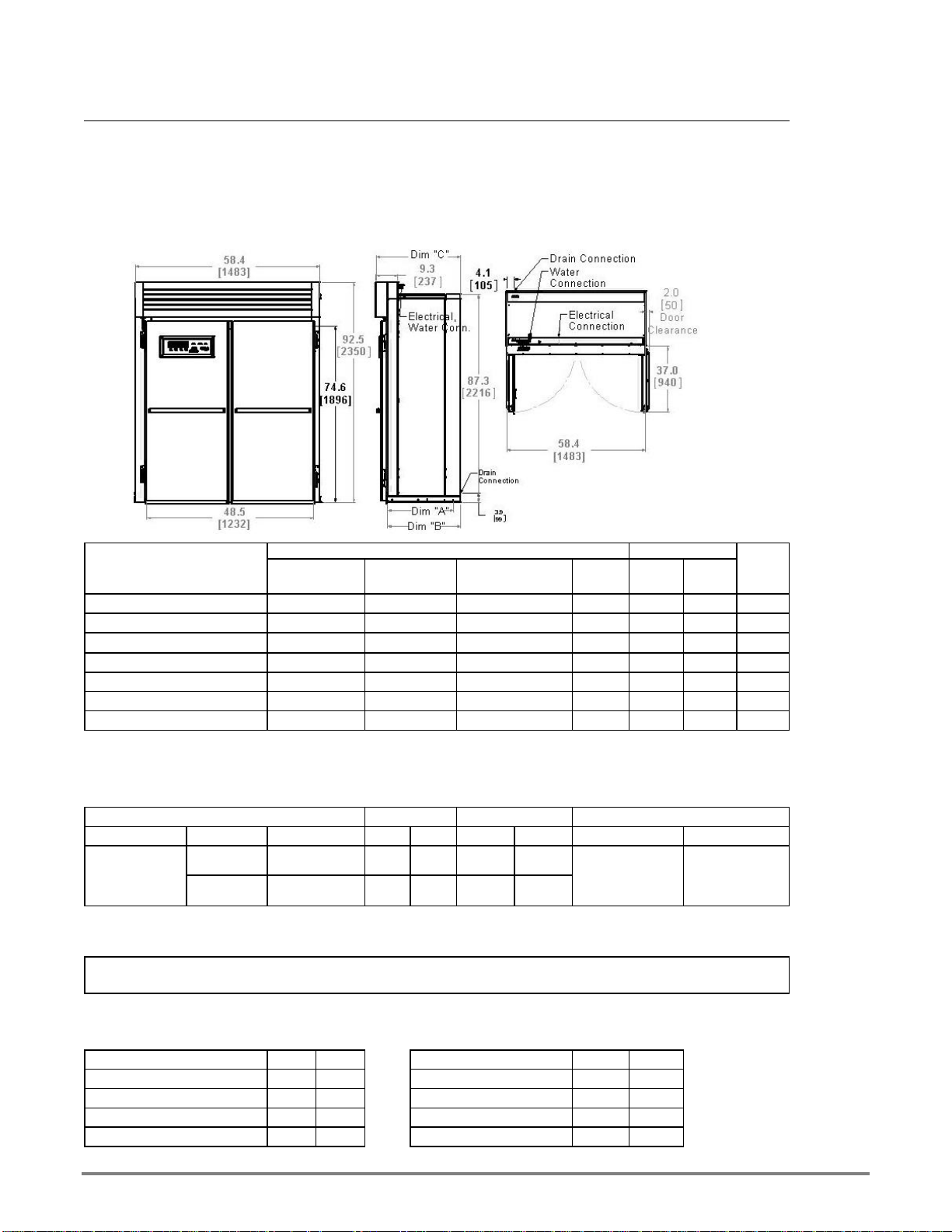

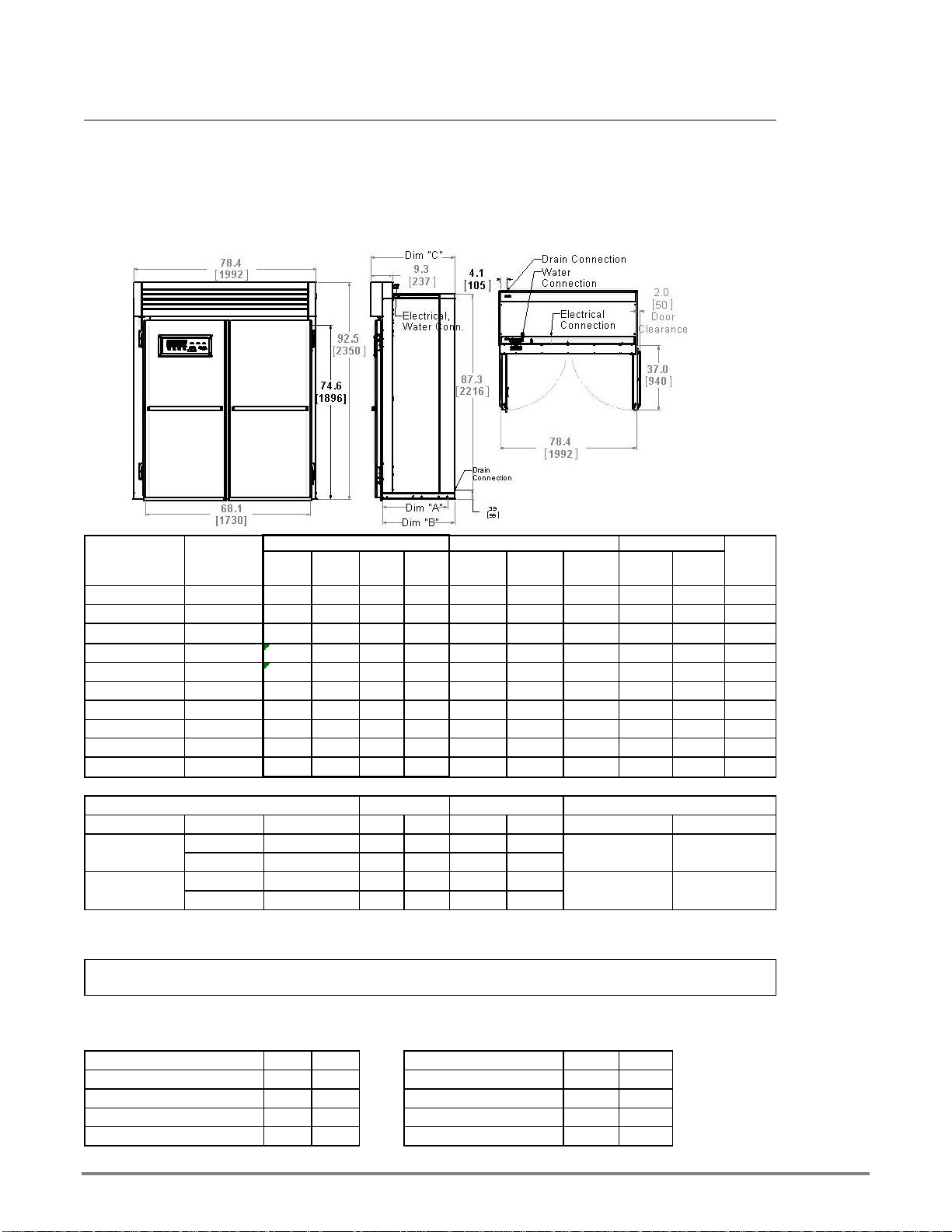

Roll-In Proofer MODEL: LRP15 Series

INSTALLATION REQUIREMENT

1/2" NPT Cold water conection

208/120 or 240/120 VAC 1 or 3-phase 3/4" Copper vented drain connection

OPTIONS & ACCESSORIES

Width

Actual Ship

49.3 1107 1232 70

49.3 1279 1404 70

49.3 1336 1461 70

49.3 1418 1543 70

49.3 1565 1690 70

49.3 1824 1949 70

49.3 1881 2006 70

49.3 2053 2178 70

49.3 2110 2235 70

Model Voltage 1-Ph 3-Ph 1-Ph 3-Ph

208/120 VAC

30 18 50 50

240/120 VAC

34 20 50 50

Unit Value Unit Value

ppm 22 ppm 0.65

ppb 17 s.u. 8.5

ppm 3.3 ppm 8.5

ppm 0.6 ppm 11.9

*MCA

*Max Fuse

Ships KD requires on-site installation

Stainless Steel Floors

Total Electrical Requirements By Model

Freight

Class

Weight

LRP15-60

LRP15-70

Depth

LRP15-(all)

5

6.6

Water

Total Hardness

IMPORTANT: Your local water conditions may damage your LBC appliance. Failure to properly treat water may

result in damage and may void your warranty. Ensure that your water supply meets these minimum water quality

specification.

Parameter

Parameter

This Appliance is designed to operate at normal room temperatures; Clearance from combustibles

is 0.0" sides and back, For Install on non-porous surfaces only

*MCA: Minimum Circuit Ampacity. *Max Fuse: Maximum allowable circuit protector.

Aluminium

Calsium

Free Chlorine Residual

Magnesium

Sodium

pH

Alkalinity

Drain

1/2" NPT .07

GPM @ 60 PSI

1/2"PVC; 210 F;

<1 GPM Max.

Total kW

Internal "A"

31.4

41.4

Model

LRP15-40

LRP15-50

111.4

LRP15-80

LRP15-90

LRP15-100

LRP15-110

LRP15-120

101.4

91

101

51.4

61.4

71.4

81.4

91.4

79.3

89.3

99.3

Ext. "B"

415161

71

81

109.3

119.3

129.3

111

112

Over All "C"

49.3

59.3

69.3

6

Roll-In Proofer MODEL: LRP2N Series

INSTALLATION REQUIREMENT

1/2" NPT Cold water conection

208/120 or 240/120 VAC 1 or 3-phase 3/4" Copper vented drain connection

OPTIONS & ACCESSORIES

Width

Actual Ship

58.4 1070 1170 70

58.4 1102 1227 70

58.4 1306 1431 70

58.4 1363 1488 70

58.4 1510 1635 70

58.4 1801 1926 70

58.4 1948 2073 70

Model Voltage 1-Ph 3-Ph 1-Ph 3-Ph

208/120 VAC

30 18 50 50

240/120 VAC

34 20 50 50

Unit Value Unit Value

ppm 22 ppm 0.65

ppb 17 s.u. 8.5

ppm 3.3 ppm 8.5

ppm 0.6 ppm 11.9

LRP2N-60

LRP2N-100

LRP2N-110

56.1

*MCA

*Max Fuse

Ships KD requires on-site installation

Stainless Steel Floors

Total Electrical Requirements By Model

Freight

Class

Weight

LRP2N-70

LRP2N-80

Depth

LRP2- (all)

5

6.6

Water

Total Hardness

IMPORTANT: Your local water conditions may damage your LBC appliance. Failure to properly treat water may

result in damage and may void your warranty. Ensure that your water supply meets these minimum water quality

specification.

Parameter

Parameter

This Appliance is designed to operate at normal room temperatures; Clearance from combustibles

is 0.0" sides and back, For Install on non-porous surfaces only

*MCA: Minimum Circuit Ampacity. *Max Fuse: Maximum allowable circuit protector.

Aluminium

Calsium

Free Chlorine Residual

Magnesium

Sodium

pH

Alkalinity

Drain

1/2" NPT .07

GPM @ 60 PSI

1/2"PVC; 210 F;

<1 GPM Max.

Total kW

Internal "A"

26.1

36.1

Model

LRP2N-30

LRP2N-40

111.1

66.1

76.1

96.1

106.1

89.3

109.3

119.3

Ext. "B"

31.1

41.1

61.1

71.1

81.1

101.1

Over All "C"

39.3

49.3

69.3

79.3

7

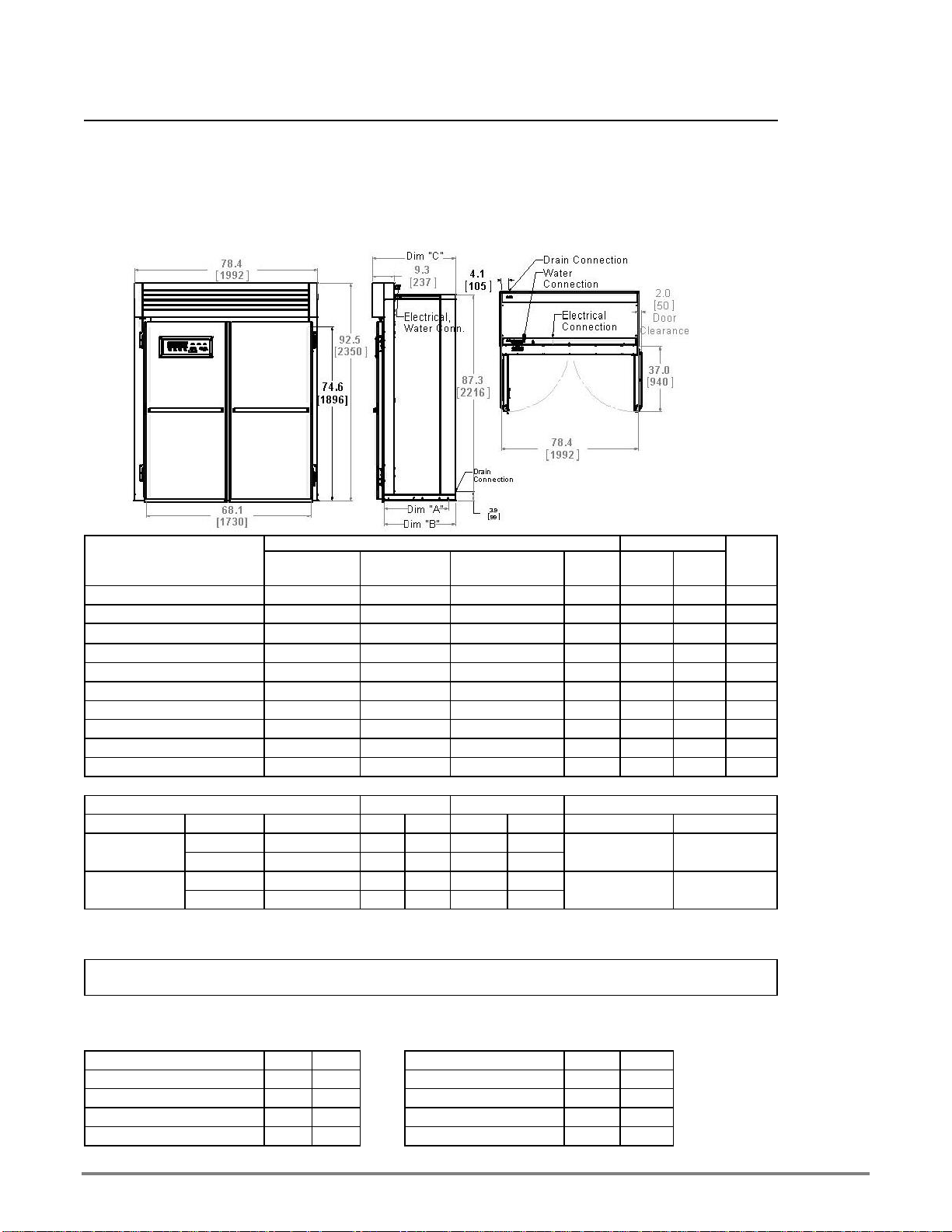

Roll-In Proofer MODEL: LRP2 Series

INSTALLATION REQUIREMENT

1/2" NPT Cold water conection

208/120 or 240/120 VAC 1 or 3-phase 3/4" Copper vented drain connection

OPTIONS & ACCESSORIES

Width

Actual Ship

78.4 1100 1200 70

78.4 1157 1282 70

78.4 1329 1454 70

78.4 1411 1536 70

78.4 1493 1618 70

78.4 1665 1790 70

78.4 1924 2049 70

78.4 2006 2131 70

78.4 2178 2303 70

78.4 2260 2385 70

Model Voltage 1-Ph 3-Ph 1-Ph 3-Ph

208/120 VAC

30 18 50 50

240/120 VAC

34 20 50 50

208/120 VAC

NA 35 NA 60

240/120 VAC

NA 39 NA 60

Unit Value Unit Value

ppm 22 ppm 0.65

ppb 17 s.u. 8.5

ppm 3.3 ppm 8.5

ppm 0.6 ppm 11.9

109.3

119.3

129.3

111.1

121.1

Over All "C"

39.3

49.3

59.3

69.3

79.3

89.3

99.3

Ext. "B"

31.1

41.1

51.1

61.1

71.1

81.1

91.1

101.1

56.1

66.1

76.1

86.1

96.1

116.1

LRP2-80

LRP2-90

LRP2-100

LRP2-110

LRP2-120

106.1

Internal "A"

26.1

36.1

46.1

Model

LRP2-30

LRP2-40

LRP2-50

1/2"PVC; 210 F;

<1 GPM Max.

Sodium

13.2

pH

Alkalinity

Drain

Total Hardness

IMPORTANT: Your local water conditions may damage your LBC appliance. Failure to properly treat water may

result in damage and may void your warranty. Ensure that your water supply meets these minimum water quality

specification.

Parameter

Parameter

This Appliance is designed to operate at normal room temperatures; Clearance from combustibles

is 0.0" sides and back, For Install on non-porous surfaces only

*MCA: Minimum Circuit Ampacity. *Max Fuse: Maximum allowable circuit protector.

Aluminium

Calsium

Free Chlorine Residual

Magnesium

1/2" NPT .07

GPM @ 60 PSI

1/2"PVC; 210 F;

<1 GPM Max.

Total kW

LRP2- (90-120)

10.2

LRP2- (40-80)

5

6.6

Water

1/2" NPT .14

GPM @ 60 PSI

*MCA

*Max Fuse

Ships KD requires on-site installation

Stainless Steel Floors

Total Electrical Requirements By Model

Freight

Class

Weight

LRP2-60

LRP2-70

Depth

8

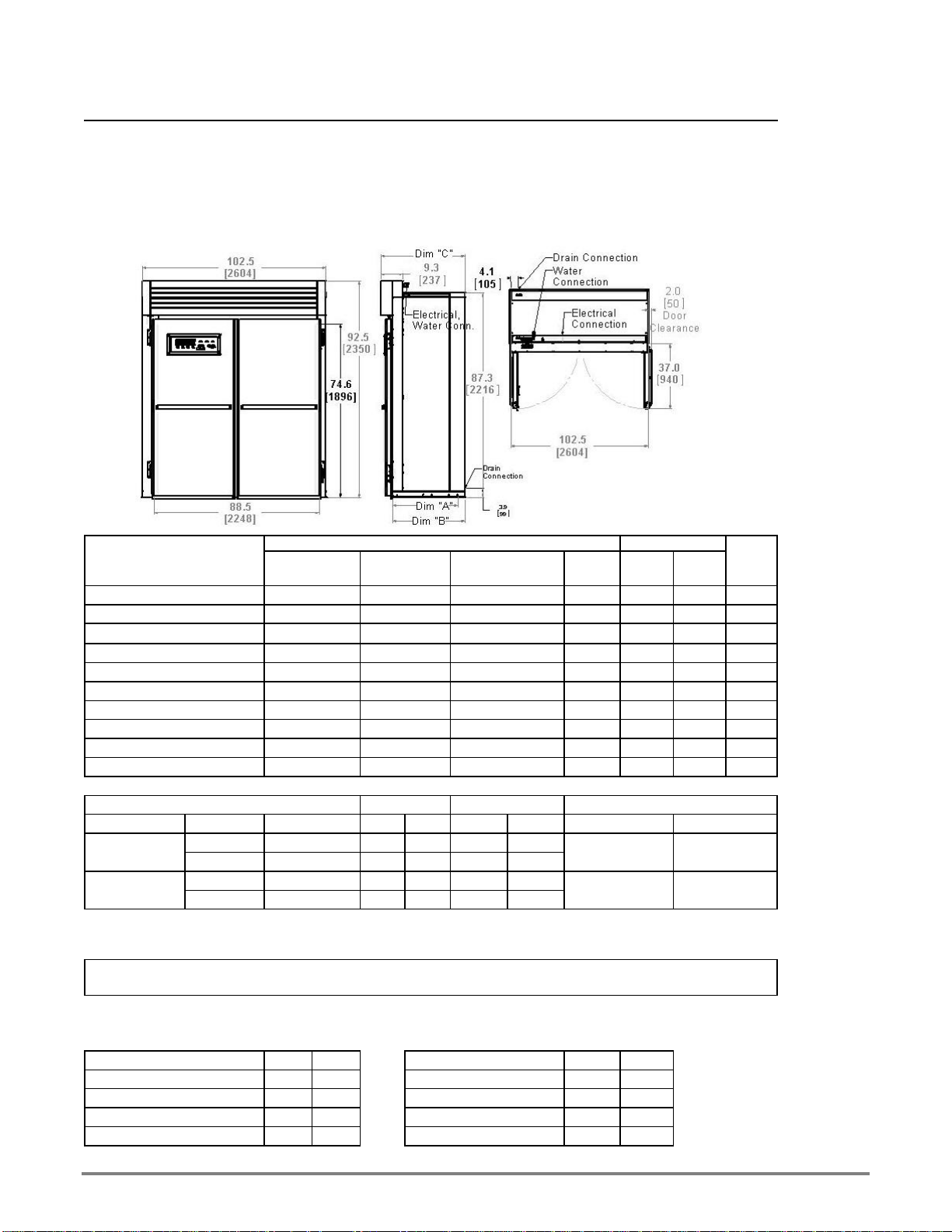

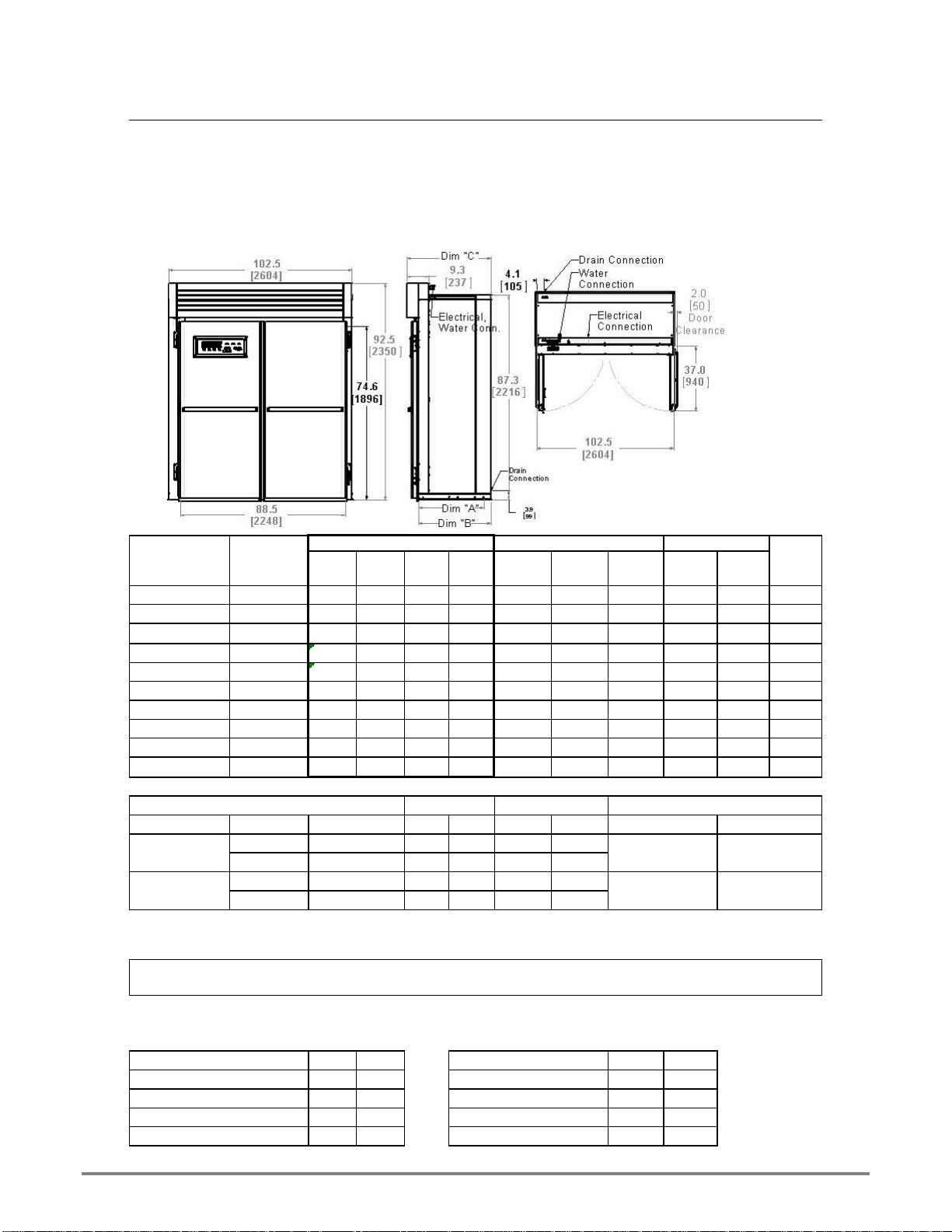

Roll-In Proofer MODEL: LRP3 Series

INSTALLATION REQUIREMENT

1/2" NPT Cold water connection

208/120 or 240/120 VAC 1 or 3-phase 3/4" Copper vented drain connection

OPTIONS & ACCESSORIES

Width

Actual Ship

102.5 1172 1472 70

102.5 1282 1582 70

102.5 1422 1722 70

102.5 1532 1832 70

102.5 1642 1942 70

102.5 1782 2082 70

102.5 2069 2369 70

102.5 2179 2479 70

102.5 2319 2619 70

102.5 2429 2729 70

Model Voltage 1-Ph 3-Ph 1-Ph 3-Ph

208/120 VAC

30 18 50 50

240/120 VAC

34 20 50 50

208/120 VAC

NA 35 NA 60

240/120 VAC

NA 39 NA 60

Unit Value Unit Value

ppm 22 ppm 0.65

ppb 17 s.u. 8.5

ppm 3.3 ppm 8.5

ppm 0.6 ppm 11.9

109.3

119.3

129.3

111.1

121.1

Over All "C"

39.3

49.3

59.3

69.3

79.3

89.3

99.3

Ext. "B"

31.1

41.1

51.1

61.1

71.1

81.1

91.1

101.1

56.1

66.1

76.1

86.1

96.1

116.1

LRP3-80

LRP3-90

LRP3-100

LRP3-110

LRP3-120

106.1

Internal "A"

26.1

36.1

46.1

Model

LRP3-30

LRP3-40

LRP3-50

1/2"PVC; 210 F;

<1 GPM Max.

Sodium

13.2

pH

Alkalinity

Drain

1/2" NPT .07

GPM @ 60 PSI

1/2"PVC; 210 F;

<1 GPM Max.

Total kW

LRP3- (90-120)

Total Hardness

IMPORTANT: Your local water conditions may damage your LBC appliance. Failure to properly treat water may

result in damage and may void your warranty. Ensure that your water supply meets these minimum water quality

specification.

Parameter

Parameter

This Appliance is designed to operate at normal room temperatures; Clearance from combustibles

is 0.0" sides and back, For Install on non-porous surfaces only

*MCA: Minimum Circuit Ampacity. *Max Fuse: Maximum allowable circuit protector.

Aluminium

Calsium

Free Chlorine Residual

Magnesium

10.2

LRP3- (30-80)

5

6.6

Water

1/2" NPT .14

GPM @ 60 PSI

*MCA

*Max Fuse

Ships KD requires on-site installation

Stainless Steel Floors

Total Electrical Requirements By Model

Freight

Class

Weight

LRP3-60

LRP3-70

Depth

9

High Output Roll-In Retarder Proofer MODEL: LRPR1 -HO Series

INSTALLATION REQUIREMENT

1/2" NPT Cold water connection

208/120 or 240/120 1-phase or 3-phase 3/4" Copper vented drain connection

Refrigeration system may require installation by a licensed refrigeration technician

OPTIONS & ACCESSORIES

Part

No.

HP

*MCA

*Max

Fuse

Internal

"A"

Ext. "B"

Over All

"C"

Actual Ship

LRPR1-40HO 3500

-13 1/3 5.8 15

32.1 41 49.3 900 1000 70

LRPR1-50HO 3500

-13 1/3 5.8 15

42.1 51 59.3 991 1116 70

LRPR1-60HO 4500

-14 1/2 6.7 15

52.1 61 69.3 1094 1219 70

LRPR1-70HO 4500

-14 1/2 6.7 15

62.1 71 79.3 1197 1322 70

LRPR1-80HO 5500

-15 1/2+ 8.1 15

72.1 81 89.3 1321 1446 70

LRPR1-90HO 5500

-15 1/2+ 8.1 15

82.1 91 99.3 1424 1549 70

LRPR1-100HO 7000

-18 3/4 8.8 15

92.1 101 109.3 1527 1652 70

LRPR1-110HO 7000

-18 3/4 8.8 15

102.1 111 119.3 1651 1776 70

LRPR1-120HO 9000

-01 1 12.5 20

112.1 121 129.3 1754 1879 70

Model Voltage 1-Ph 3-PH 1-Ph 3-Ph

208/120 VAC

30 20 50 50

240/120 VAC

35 20 50 50

Unit Value Unit Value

ppm 22 ppm 0.65

ppb 17 s.u. 8.5

ppm 3.3 ppm 8.5

ppm 0.6 ppm 11.9

Sodium

Total Hardness

Alkalinity

Aluminium

Calsium

Free Chlorine Residual

Magnesium

pH

6.6

This Appliance is designed to operate at normal room temperatures; if installed next to an oven or

other heat source allow a minimum clearance of 4" to prevent heat transfer. Clearance from

combustibles is 0.0" sides and back, For Install on non-porous surfaces only

IMPORTANT: Your local water conditions may damage your LBC appliance. Failure to properly treat water may

result in damage and may void your warranty. Ensure that your water supply meets these minimum specification.

Water

Drain

Total Electrical Requirements By Model

1/2"PVC; 210 F;

<1 GPM Max.

Ships KD requires on-site installation

Retarder

BTU Rating

@ 35 Deg F

Refrigeration Condenser Stainless Steel Floor

Model

Parameter

Parameter

Depth

Total kW

*Max Fuse

1/2" NPT .07

GPM @ 60 PSI

*MCA: Minimum Circuit Ampacity. *Max Fuse: Maximum allowable circuit protector. *Note: Optional

Condenser requires separate electrical supply

5

*MCA

Optional Condenser Specs

Weight

Freight

Class

LRPR1-

(40 -120HO)

10

High-Output Roll-In Retarder Proofer MODEL: LRPR2 -HO Series

INSTALLATION REQUIREMENT

1/2" NPT Cold water connection

208/120 or 240/120 VAC 1 or 3-phase 3/4" Copper vented drain connection

Refrigeration system may require installation by a licensed refrigeration technician

OPTIONS & ACCESSORIES

Part

No.

HP *MCA

*Max

Fuse

Internal

"A"

Ext. "B"

Over All

"C"

Actual Ship

LRPR2-30HO 5500

-15 1/2+ 8.1 15

26 31 39.3 1100 1200 70

LRPR2-40HO 5500

-15 1/2+ 8.1 15

36.1 41.1 49.4 1157 1282 70

LRPR2-50HO 7000

-18 3/4 8.8 15

46.1 51.1 59.4 1329 1454 70

LRPR2-60HO 9000

-01 1 12.5 20

56.1 61.1 69.4 1411 1536 70

LRPR2-70HO 9000

-01 1 12.5 20

66.2 71.2 79.5 1493 1618 70

LRPR2-80HO 11,000

-34 2 15.9 20

76.2 81.2 89.5 1665 1790 70

LRPR2-90HO 11,000

-34 2 15.9 20

87.1 91 99.3 1924 2049 70

LRPR2-100HO 15,000

-24 2.25 17.8 25

97.1 101 109.3 2006 2131 70

LRPR2-110HO 15,000

-24 2.25 17.8 25

107.1 111 119.3 2178 2303 70

LRPR2-120HO 18,000 -24 2.25 17.8 25 117.1 121 129.3 2260 2385 70

Model Voltage 1-Ph 3-Ph 1-Ph 3-Ph

208/120 VAC

30 18 50 50

240/120 VAC

34 20 50 50

208/120 VAC

NA 35 NA 60

240/120 VAC

NA 39 NA 60

Unit Value Unit Value

ppm 22 ppm 0.65

ppb 17 s.u. 8.5

ppm 3.3 ppm 8.5

ppm 0.6 ppm 11.9

Water

1/2" NPT .14

GPM @ 60 PSI

1/2"PVC; 210 F;

<1 GPM Max.

Sodium

Total Hardness

IMPORTANT: Your local water conditions may damage your LBC appliance. Failure to properly treat water may

result in damage and may void your warranty. Ensure that your water supply meets these minimum water quality

specification.

Parameter

Parameter

This Appliance is designed to operate at normal room temperatures; if installed next to an oven or

other heat source allow a minimum clearance of 4" to prevent heat transfer. Clearance from

combustibles is 0.0" sides and back, For Install on non-porous surfaces only

*MCA: Minimum Circuit Ampacity. *Max Fuse: Maximum allowable circuit protector. *Note: Optional

Condenser requires separate electrical supply

13.2

Aluminium

Calsium

Free Chlorine Residual

Magnesium

pH

Alkalinity

Depth

Drain

1/2" NPT .07

GPM @ 60 PSI

1/2"PVC; 210 F;

<1 GPM Max.

Total kW

LRPR2-

(90HO-120HO)

10.2

LRPR2-

(40HO-80HO)

5

6.6

*MCA

*Max Fuse

Ships KD requires on-site installation

Refrigeration Condenser; Stainless Steel Floors

Retarder

BTU Rating

@ 35 Deg F

Model

Optional Consdenser Specs

Total Electrical Requirements By Model

Freight

Class

Weight

11

High-Output Roll-In Retarder Proofer MODEL: LRPR3 -HO Series

INSTALLATION REQUIREMENT

1/2" NPT Cold water connection

208/120 or 240/120 VAC 1 or 3-phase 3/4" Copper vented drain connection

Refrigeration system may require installation by a licensed refrigeration technician

OPTIONS & ACCESSORIES

Part

No.

HP *MCA

*Max

Fuse

Internal

"A"

Ext. "B"

Over All

"C"

Actual Ship

LRPR3-30HO 7000

-15 1/2+ 8.1 15

26 31 39.3 1172 1472 70

LRPR3-40HO 9000

-18 3/4 8.8 15

36.1 41.1 49.4 1282 1582 70

LRPR3-50HO 9000

-18 3/4 8.8 15

46.1 51.1 59.4 1422 1722 70

LRPR3-60HO 11,000

-01 1 12.5 20

56.1 61.1 69.4 1532 1832 70

LRPR3-70HO 11,000

-01 1 12.5 20

66.2 71.2 79.5 1642 1942 70

LRPR3-80HO 15,000

-34 2 15.9 20

76.2 81.2 89.5 1982 2282 70

LRPR3-90HO 15,000

-34 2 15.9 20

87.1 91 99.3 2269 2569 70

LRPR3-100HO 15,000

-34 2 15.9 20

97.1 101 109.3 2379 2679 70

LRPR3-110HO 19,000

-24 2.25 17.8 25

107.1 111 119.3 2619 2919 70

LRPR3-120HO 19,000 -24 2.25 17.8 25 117.1 121 129.3 2729 3029 70

Model Voltage 1-Ph 3-Ph 1-Ph 3-Ph

208/120 VAC

30 18 50 50

240/120 VAC

34 20 50 50

208/120 VAC

NA 35 NA 60

240/120 VAC

NA 39 NA 60

Unit Value Unit Value

ppm 22 ppm 0.65

ppb 17 s.u. 8.5

ppm 3.3 ppm 8.5

ppm 0.6 ppm 11.9

*MCA

*Max Fuse

Ships KD requires on-site installation

Refrigeration Condenser; Stainless Steel Floors

Retarder

BTU Rating

@ 35 Deg F

Model

Optional Consdenser Specs

Total Electrical Requirements By Model

Freight

Class

Weight

Depth

Drain

1/2" NPT .07

GPM @ 60 PSI

1/2"PVC; 210 F;

<1 GPM Max.

Total kW

LRPR3-

(90HO-120HO)

10.2

LRPR3-

(30HO-80HO)

5

6.6

13.2

Aluminium

Calsium

Free Chlorine Residual

Magnesium

pH

Alkalinity

Water

1/2" NPT .14

GPM @ 60 PSI

1/2"PVC; 210 F;

<1 GPM Max.

Sodium

Total Hardness

IMPORTANT: Your local water conditions may damage your LBC appliance. Failure to properly treat water may

result in damage and may void your warranty. Ensure that your water supply meets these minimum water quality

specification.

Parameter

Parameter

This Appliance is designed to operate at normal room temperatures; if installed next to an oven or

other heat source allow a minimum clearance of 4" to prevent heat transfer. Clearance from

combustibles is 0.0" sides and back, For Install on non-porous surfaces only

*MCA: Minimum Circuit Ampacity. *Max Fuse: Maximum allowable circuit protector. *Note: Optional

Condenser requires separate electrical supply

12

Conditions of Installation

LBC Bakery Equipment, Inc. shall, for a fee contingent on site location and provided that the conditions of

installation are met, provide a factory authorized service agency to installation the LBC Model LRP Roll-in Proofers

and LRPR Retarder Proofers.

Before LBC Bakery Equipment, Co. or its authorized agent arrives; the job site must be ready for the installation.

If the installation site is not properly prepared or if there are construction delays the customer shall be

responsible for all expenses incurred during this delay. All expenses resulting from job delay or extension, for

reasons beyond the control of LBC Bakery Equipment Inc., will be the responsibility of the customer

.

Installation shall be conducted during normal business hours.

This installation is for a single trip. Start-up and training are not included.

CODES and ORDINANCES

IN ALL CASES, THE ELCTRICAL, MECHANICAL, UTILITY AND VENTILATION CONNECTIONS MUST MEET ALL

FEDERAL, STATE AND LOCAL CODES OR ORDINANCES.

It is the customer’s responsibility to:

1. Secure all required permits and meet local code requirements.

2. Ensure that the installation site is cleared and ready for installation before the

authorized installer arrives on site. The site shall be smooth and level.

3. Provide all utilities and hook-ups: gas, electrical, water and drains within five (5) feet of

the installation location per the specifications provided by LBC Bakery Equipment, Inc.

4. Provided licensed trades person to make the final utility connections.

5. Provide licensed refrigeration technicians to install and charge the refrigeration

components.

6. Remove all trash, crates etc. resulting from the installation

7. Provide any peripheral sheet metal work required by local codes or otherwise to bridge

the gaps between the ovens and the walls that are caused by wall protrusions.

13

RECIEVING:

LBC Roll-in Rack proofers and retarder proofers are shipped in a “Knock-down” conditions.

The proofer crates vary is size and weight depending on the model purchased.

The crate weights range between 950 LBS and 2500 LBS. Adequate materials handling

equipment is required to unload these crates and to move them into the installation area.

DRAINS:

A three quarter (3/4) inch vented drain is required for these proofers. The facility drain should

be located within five (5) feet of the proofer drain (consult specification sheet for proofer drain

location).

WATER CONNECTIONS:

A one half inch (1/2”) copper cold water supply rated at 9 GPM, 40 psi minimum is required

for these proofers. The water line should be brought to within five feet (5’) preliminarily of the

oven site. (consult specification sheet for the location of the water connection). Water

treatment may be required, it is strongly suggested that the supply water be tested and

treated for impurities.

ELECTRICAL:

Electrical supply for the LBC Bakery Equipment Proofers and Retarder Proofers is a single

208/120 or 240/120 VAC, single or three phase supply.

Consult specification sheet for complete electrical requirements.

CODES and ORDINANCES

In all cases, the electrical, mechanical, utility and ventilation connections MUST

meet all Federal, State and local codes and or ordinances. LBC is not responsible

for these utility connections.

Additional fees may be levied for return trips to start-up the equipment.

This installation does not include operator training; consult your local sales representative for

equipment training

I have read and understand all of these conditions of installation.

By: Date:

14

IMPORTANT READ FIRST IMPORTANT

WARNING

MOVING PARTS HAZARD. FOLLOW LOCKOUT PROCEDURES BEFORE

REMOVING AIR DUCT OR EVAPORATOR FAN GUARDS

WARNING

ELECTRICAL HAZARD BEHIND UPPER FRONT TRIM. FOLLOW LOCKOUT

PROCEDURES BEFORE SERVICING.

WARNING

THE LBC BAKERY LRP SERIES PROOFER PRODUCES HUMIDITY WHICH

WILL NATURALLY CONDENSE AND ACCUMULATE WATER ON THE

INTERIOR FLOOR CAUSING IT TO BECOME SLIPPERY. ADJACENT

EXTERIOR FLOOR MAY ALSO BECOME SLIPPERY. USE EXTREME

CAUTION WHEN WALKING IN OR AROUND THIS APPLIANCE.

NOTICE

This picture shows an LRP1, LRP2, and LRP3. The LRP1 and some LRP2

models have only one climitizer. Larger models have two climitizers.

DANGER

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

NOTICE

For best results, always allow your proofer to reach set temperature and

humidity before putting product in.

NOTICE

For best results, proof at lower temperatures rather than higher.

NOTICE

To dry proof: Set humidity to the lowest setting (either 45 or less). At

this setting the humidity generator is turned off and will not produce

humidity.

NOTICE

When the actual humidity is less than 46% display will show 45. When the

actual humidity is higher than 45%, display will show the actual humidity.

NOTICE

Service on this or any other LBC BAKERY equipment must be performed

by qualified personnel only. Consult your authorized service agency

directory or call the factory at 1-888-722-5686 or go to

WWW.LBCBAKERY.COM for the service agent nearest you.

NOTICE

The LRP1 has hinges mounted on the right jamb only.

CAUTION

THIS APPLIANCE, WHEN INSTALLED, MUST BE ELECTRICALLY

GROUNDED IN ACCORDANCE WITH LOCAL CODES, OR IN THE

ABSENCE OF LOCAL CODES, WITH THE NATIONAL ELECTRICAL CODE,

ANSI/NFPA 70-1996.

15

IMPORTANT READ FIRST IMPORTANT

CAUTION

FOR INSTALLATION IN CANADA THE INSTALLATION MUST BE IN

ACCORDANCE WITH CAN/CGA-B149.1&2 OF THE INSTALLATION CODE,

AND LOCAL CODES WHERE APPLICABLE. ALL ELECTRIC WIRING MUST

BE IN ACCORDANCE WITH THE CURRENT CANADIAN ELECTRICAL

CODE, C22.1 PART 1. GROUNDING THIS APPLIANCE MUST CONFORM

TO CANADIAN ELECTRICAL CODE, CSA C22.2.

WARNING

INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL QUALIFIED

TO WORK WITH ELECTRICITY AND PLUMBING. IMPROPER

INSTALLATION CAN CAUSE INJURY TO PERSONNEL AND /OR DAMAGE

TO EQUIMENT. UNIT MUST BE INSTALLED IN ACCORDANCE WITH ALL

APPLICAL CODES

WARNING

MOVING PARTS HAZARD. FOLLOW LOCKOUT PROCEDURES BEFORE

REMOVING AIR DUCT OR EVAPORATOR FAN GUARDS

WARNING

ELECTRICAL HAZARD BEHIND UPPER FRONT TRIM. FOLLOW LOCKOUT

PROCEDURES BEFORE SERVICING.

WARNING

THE LBC BAKERY LRP SERIES PROOFER PRODUCES HUMIDITY WHICH

WILL NATURALLY CONDENSE AND ACCUMULATE WATER ON THE

INTERIOR FLOOR CAUSING IT TO BECOME SLIPPERY. ADJACENT

EXTERIOR FLOOR MAY ALSO BECOME SLIPPERY. USE EXTREME

CAUTION WHEN WALKING IN OR AROUND THIS APPLIANCE.

16

SAFETY PROCEDURES

Lockout Procedure

1. Announce lockout to other personnel.

2. Turn both heat and control power off at main panel.

3. Clear unit of all personnel.

4. Test lockout by turning power switch on and observing if control panel displays or fan(s)

come on. Check heater circuit with voltmeter.

5. Perform necessary repairs or tests.

6. Clear unit of personnel before restarting.

7. Turn power on at main panel.

8. Announce unit is “on” to other personnel.

Safety Precautions

LBC Bakery Equipment hereby disclaims any and all responsibility for injury, damage, loss or

other claim that may occur to person or property from improper alteration, modification, addition,

operation, maintenance or service, whether it be mechanical, electrical, fuel, operator, motor or

otherwise, which may occur from such improper alteration, modification, addition, operation,

maintenance or service to this piece of equipment.

Safety Considerations

Your LBC Bakery LRP Proofer is manufactured to rigid standards. This equipment is E.T.L.

listed and meets safety and sanitation standards.

The presence of safety equipment control and interlocks on an appliance and attendant

components of installation cannot, in and of themselves, assure absolute safety of operation.

Diligent, capable, well trained operators and maintenance personnel, as well as proper programs

of operation and maintenance, are essential to the safe and reliable operation of this appliance.

A. The responsibility of the manufacturer is to supply suitable, comprehensive

instructions and recommendations for the operation and maintenance of the appliance.

B. All operations, maintenance and repair of the subject units must be performed by properly trained and

qualified personnel, and all such operations, maintenance and repair must be performed in a diligent

manner. It is the responsibility of the owner/operator to insure proper training and diligence of any

person coming into contact with either the subject units or the output (product, exhaust or otherwise) of

the subject units. It is the responsibility of the owner/operator to ensure that the subject units are

installed and operated in accordance with OSHA Standard 1910.263.

C. A regular periodic program of cleaning, inspection and maintenance must be established

and comprehensive maintenance records maintained. It is the sole responsibility of the

user to establish, schedule and enforce the frequency and scope of these programs in

keeping with recommended practice and with due consideration given to actual operating

conditions.

D. The appliance must be operated within limits which will not exceed the working limits of

any component within the appliance as a whole.

WARNING

THE LBC BAKERY LRP SERIES PROOFER PRODUCES HUMIDITY WHICH

WILL NATURALLY CONDENSE AND ACCUMULATE WATER ON THE

INTERIOR FLOOR CAUSING IT TO BECOME SLIPPERY. ADJACENT

EXTERIOR FLOOR MAY ALSO BECOME SLIPPERY. USE EXTREME

CAUTION WHEN WALKING IN OR AROUND THIS APPLIANCE.

NOTICE

Service on this or any other LBC BAKERY equipment must be performed by

qualified personnel only. Consult your authorized service agency directory

or call the factory at 1-888-722-5686 or go to WWW.LBCBAKERY.COM for

the service agency nearest you.

17

ASSEMBLY

NOTE: ON UNITS WITH FLOOR ONLY!

One good blow is better then many small taps when installing anchors.

Drill holes with rotary drill and install anchors in front row

(and middle row if applicable). Drill 10MM diameter hole

1 ½” deep and remove all dust from hole. Do not drill too

deep. Install anchor with provided insert tool.

Note: If concrete subfloor has additional

layer of softer leveling slag and anchors

do not hold, a longer anchor bolt may be

necessary.

Do not install anchors at edges or corners at this time.

Place floor adhesive onto floor and spread with provided

trowel. Seal bottom with a good continuous bead along

edge before setting into final resting position. Apply

weight to floor while adhesive sets.

Note: Row of 3/8” holes is front of

floor. Countersunk sides of holes go up.

Place floor onto prepared surface and mark

position. Take into consideration drain location.

Note: Tile that may come loose

over time should be removed.

Countersunk sides of

holes go up.

18

ASSEMBLY CONT’D

Note: Units without Stainless Floor start here.

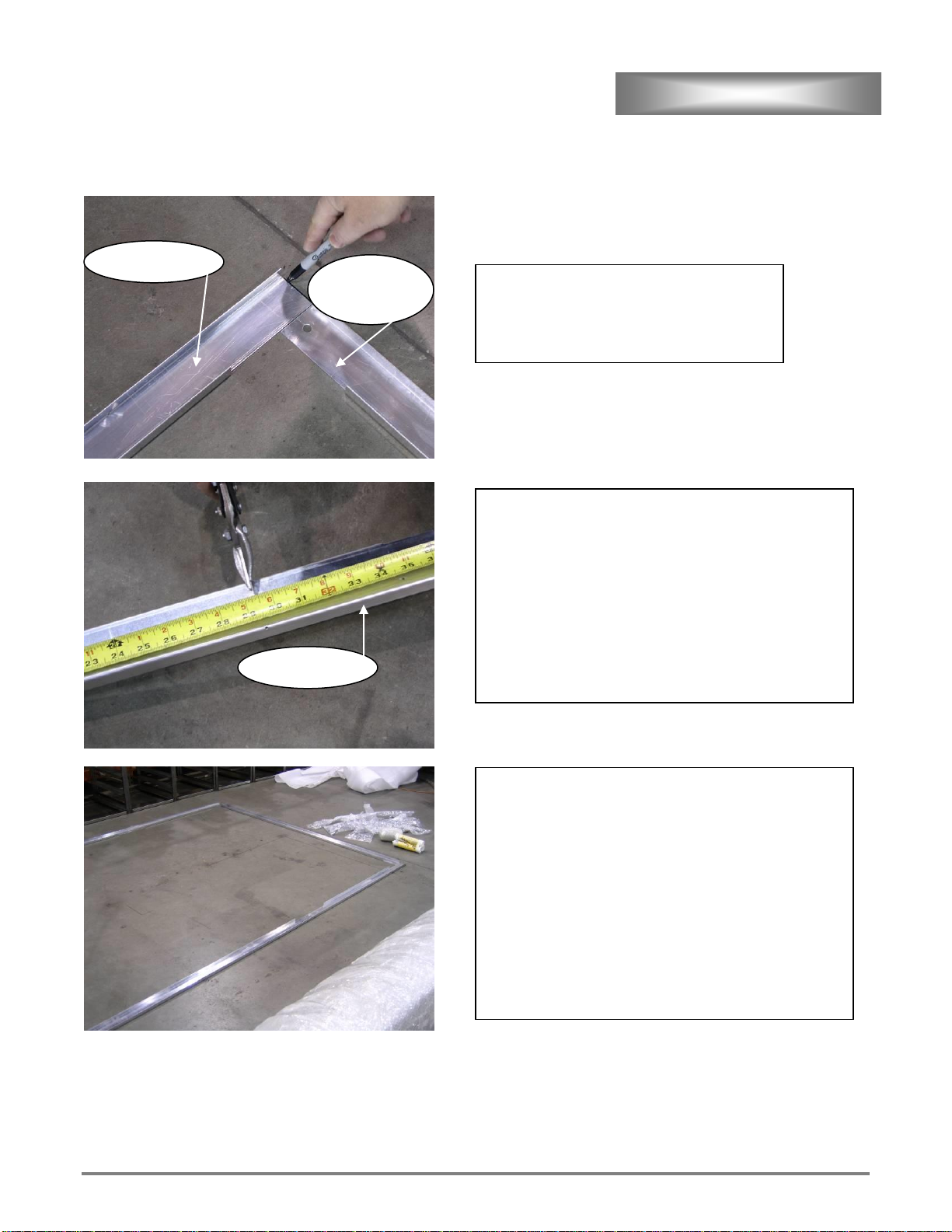

Place wall base channels as pictured. Outside

dimensions should match Specification

Sheet. Mark outside edge with non

permanent marker.

Optional: Seal base channels with small amount of

silicone to stop leaks from developing at bottom of unit.

Press base channel to floor.

Note: Recheck dimensions to insure

wall panels fit into track. Once

silicone dries, base channels are hard

to move. See Spec. Sheet.

See wall panel location Chart 1 for panel placement.

Each proofer is supplied with enough track to install a

120” deep proofer.

Holes in side channel indicate cutting points for base

channels. Cut side channels short enough to leave front

corners exposed.

You may need both channel pieces depending on the

size of the proofer.

No base channel on door side of proofer.

Rear Base

Channel

Side Chanel

Side Chanel

Loading...

Loading...