Page 1

LANG BAKERY EQUIPMENT COMPANY • 6500 Merrill Creek Parkway, Everett, WA 98203

TOLL FREE: 888-RACKOVN (888-722-5686) • FAX: 866-947-0122 • www.langbakery.com

Item No.

Project

Quantity

BakerSeries

®

Gas, Roll-In Rotating [Double] Rack Oven Model: LRO-2G

CONSTRUCTION FEATURES

• Heavy duty 300 Series stainless steel interior and exterior

• VertiFlow® vertical stainless steel tube heat exchanger

• Cooking compartment insulated with 5” thick high-temp insulation

• Fully integrated ventilation hood assembly, with single point

exhaust connection

• Automatic heavy duty rack lift and rotation system

• Cooking chamber illuminated by externally mounted florescent

lamp

• Heavy duty door with single pane 9.75” X 57.5” viewing window

• Interior safety door release mechanism

• Accommodates two standard side-load, two end-load or one

double side-load rack

PERFORMANCE FEATURES

• Heat Exchanger provides high heat transfer efficiency and quick

temperature recovery

• VertiFlow System uses natural draft effect for air intake & exhaust,

eliminating need for blowers, motors and airflow switches

• 200-550˚F cooking temperature range

• Steam system uses large 520-lb. thermal mass gravity feed

waterfall. No nozzles or orifices to clog.

• Rotating rack and even heat distribution ensure uniform baking

and browning

• Self-adjusting slip clutch on rotating system protects operator and

oven from damage and automatically stops rack in unloading

position

INTEGRATED HOOD FEATURES AND PERFORMANCE

• Integrated hood meets NFPA 96 & Uniform Mechanical Code

requirements for Type I & Type II Construction

• 20 gauge stainless steel body

• Hood provides 5.9 square feet of effective filter area, with filter

velocity of 120 FPM, .03” wc at 800 CFM

• Single point 8” round vent duct, velocity: 2,300 FPM at 800 CFM

CONTROL PACKAGE

• Rack lift & rotation system activates automatically, when door

is closed

• Simple digital TIME & TEMP displays

• Programmable for temperature, time, steam, blower delay, vent,

cycling steam and cycling blower

• Easy direct manual operation

• STOP, START, Vent & Fan touch pads

SHORT/BID SPECIFICATION

Rack Oven shall be Lang Bakery Equipment Co. Model LRO-2G

290,000 BTU/hr. gas heated rotating double rack unit with:

Vertiflow® stainless steel tube heat exchanger; gravity feed,

waterfall type steam generation system, 5” thick compartment

insulation and 0” combustible wall clearance; heavy duty rack lift

and rotation

system; simple solid-state controls, with digital time-temperature

readout, 10 hour cook cycle and five stage programming capability;

an integrated ventilation hood meeting NFPA 96 and Type I & II

UMC construction standards, plus all the features listed:

STANDARD PRODUCT WARRANTY

One year, parts & labor

Sheet No. LSP-RR2 (rev. 10/05)

Model LRO-2G

Maximum Capacity LRO-2G

18” x 26” Full-Sheet Pans* 40

12” x 20” x 4” Hotel Pans** 40

1 lb. Loaves of Bread 200

1-1/2 lb. Loves of Bread 150

PAN/PRODUCTION CAPACITY GUIDE

* 3” spacing

** 6” spacing

®

USC

Page 2

LANG BAKERY EQUIPMENT COMPANY • 6500 Merrill Creek Parkway, Everett, WA 98203

TOLL FREE: 888-RACKOVN (888-722-5686) • FAX: 866-947-0122 • www.langbakery.com

© 2005 Lang Bakery Equipment Company Printed in U.S.A. 10/05-M-12092

Due to continuous improvements, specifications subject to change without notice.

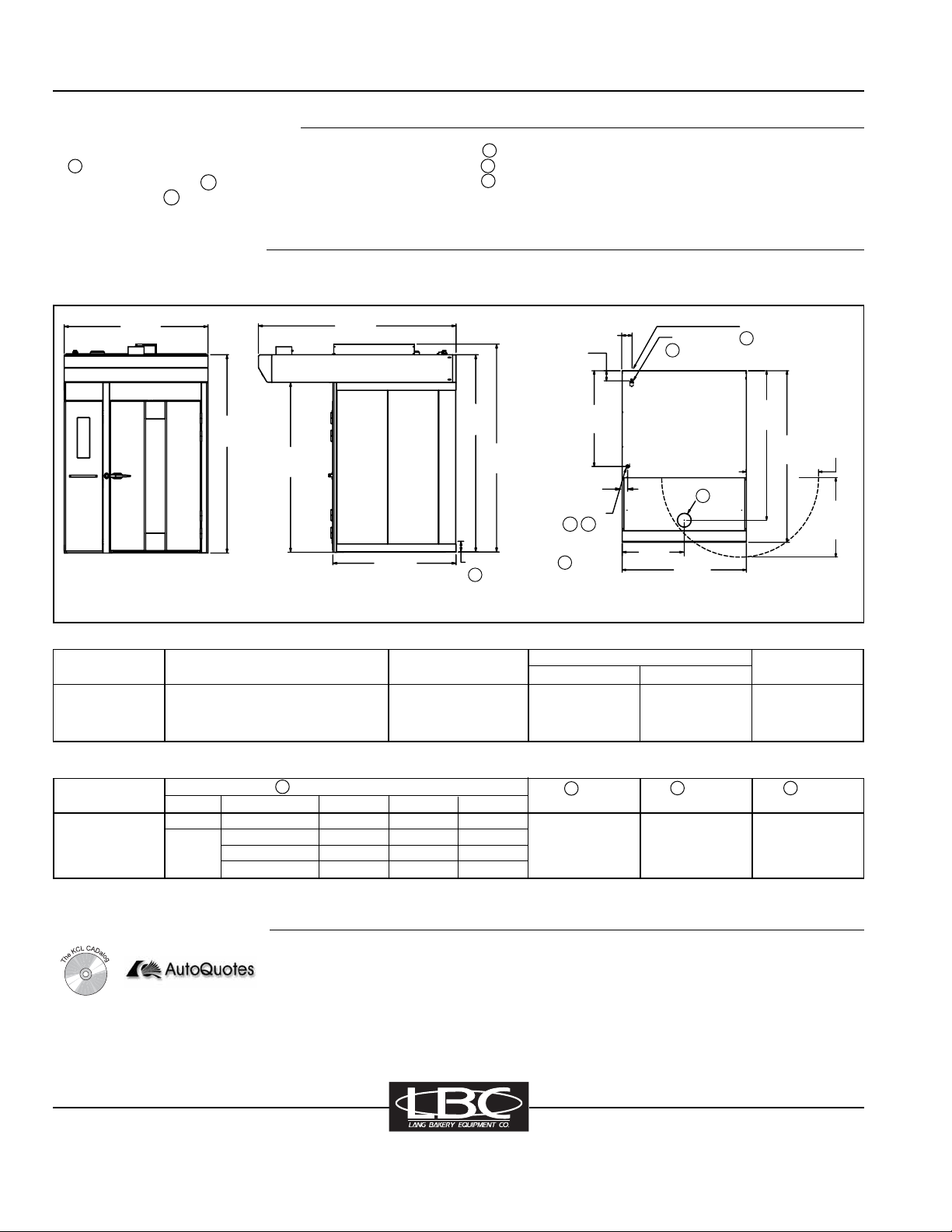

Model Height x Width x Depth*

Clearance from

Weight

Freight

combustible surface**

Actual Shipping

Class

104.5” x 72.0” x 99.5” Sides: 0” 4060 lbs. 4360 lbs.

LRO-2G

2654mm x 1829mm x 2527mm Back: 0” 1842 kg 1978 kg

70

OPTIONS & ACCESSORIES

❏ Side load oven racks ❏ Front load oven racks

INSTALLATION REQUIREMENTS

• Oven is shipped in two sections for movement through 36” door

• G Specify: ❏ natural gas or ❏ propane gas: via 3/4” NPT connection

• Two electric connections: E1 120V, 1-Phase, 50/60 Hz electrical connection

[for controls] and E2 208V-240V, 3-Phase [for rotary motor & heat

circulation blower]

• W 1/2” NPT cold water connection

• D 3/4” NPT vented drain connection

• V 8” connection to Vent Hood Duct

• Ventilator fan & motor required [Provided by others]

[Connections from rear and top. See below]

Sheet No. LSP-RR2 (rev. 10/05)

[Front View/Elevation] [Right Side View] [Top View/Plan]

BakerSeries

®

Gas, Roll-In Rotating [Double] Rack Oven Model: LRO-2G

* 34” maximum rack rotation diameter. ** Noncombustible floor only.

*** 5.5” above finished floor.

Model

E Electrical Requirements

G Gas W Water D Drain

Connect. Voltage Total kW Phase Amps/Line

Requirements Requirements Requirements

E1 120V/60Hz 1.4 1 12

LRO-2G

208V/60Hz 1.0 3 5 3/4” NPT 1/2” NPT 3/4” NPT***

E2 240V/60Hz 1.2 3 5

(290,000 BTU/hr) (9GPM @ 40PSI) (210˚F, 1GPM max.)

480V/60Hz 2.4 3 5

CAD SYMBOLS & PRICING

72.0"

1829mm

99.5"

2527mm

85.4"

2170mm

99.5"

2527mm

99.5"

2527mm

104.5"

2654mm

5.9"

149mm

5.5"

140mm

55.5"

1409mm

2.2"/56mm

1.3"/32mm

E1 E2

ELECTRICAL &

19mm

62.0"

1575mm

5.1"/130mm

D DRAIN

CONNECTION

.8"/

G GAS

CONNECTION

36.0"

914mm

.5"/13mm

W WATER

CONNECTION

V VENT

72.0"

1829mm

.8"/19mm

D DRAIN

CONNECTION

86.6"

2200mm

99.5"

2527mm

41.9"

1065mm

46.1"

1770mm

DOOR SWING

Loading...

Loading...