LBC Bakery Equipment LMO-P Installation Manual

Installation, Operations and Maintenance Manual

for LBC Models LMO-P Proofer Base

Rev.002 May 2011

LBC Bakery Equipment, Inc.

1410-80

th

Street SW

Suite C

Everett, WA 98203

Toll Free: 888-722-5686

Fax: 425-642-8305

E-mail; sales@lbcbakery.com

www.lbcbakery.com

1

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL

QUALIFIED TO INSTALL ELECTRIC EQUIPMENT, WHO SHOULD

PERFORM THE INITIAL FIELD START-UP AND ADJUSTMENTS OF

THE EQUIPMENT COVERED BY THIS MANUAL

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

OR LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO

OPERATE THIS DEVICE.

KEEP AREA AROUND THE OVEN CLEAR OF COMBUSTIBLES. DO

NOT OBSTRUCT COMBUSTION AND VENTILATION OPENINGS

ON THE OVEN OR PROOFER.

2

Installation of this equipment must be

performed by an authorized service

representative. Prior to installation

verify that all electrical supplies

coincide with the manufacturer’s data

label located on the right side below

the service panel.

Inspection and Un-crating

Upon receipt of shipments, all

packages should be inspected, and all

visible or concealed damages noted

and signed for on the bill of lading.

Any other damages should be reported

to the carrier within 10 days. Freight

damages are the responsibility of the

consignee.

All orders for replacement products

resulting in freight damages will be

processed under LBC’s standard terms.

Any reimbursement or credit is the

responsibility of the freight carrier

Carefully unpack the oven and place it

in a work area as near to the final

installation position as possible.

If moving the oven trough a 36” door

opening it will be necessary to remove

the proofer doors, door latches and

door hinges.

Installation Codes

For US Installation

The LMO-P proofer must be installed in

accordance with all State and local

codes and:

National Electrical Code, ANSI/NFPA70 (latest edition)

For Canadian installation

The LMO-P proofer must be installed in

accordance with all local codes and;

CAN/CGA-B149.1 National Fuel Gas

Code

Model Number Coding

LMO followed by G (gas models) or E (electric model) followed by 6 (6-pan rack) 0r

8 (8-pan rack) followed by S (for stand) or P (for proofer base) followed by N (for

natural gas) or LP for (Propane gas) or 208, 240 or 480 (for electric models)

Sample Model Number: LMO-E8P-480: This is a 480 Volt electric oven with an 8

pan rack and a proofer base.

3

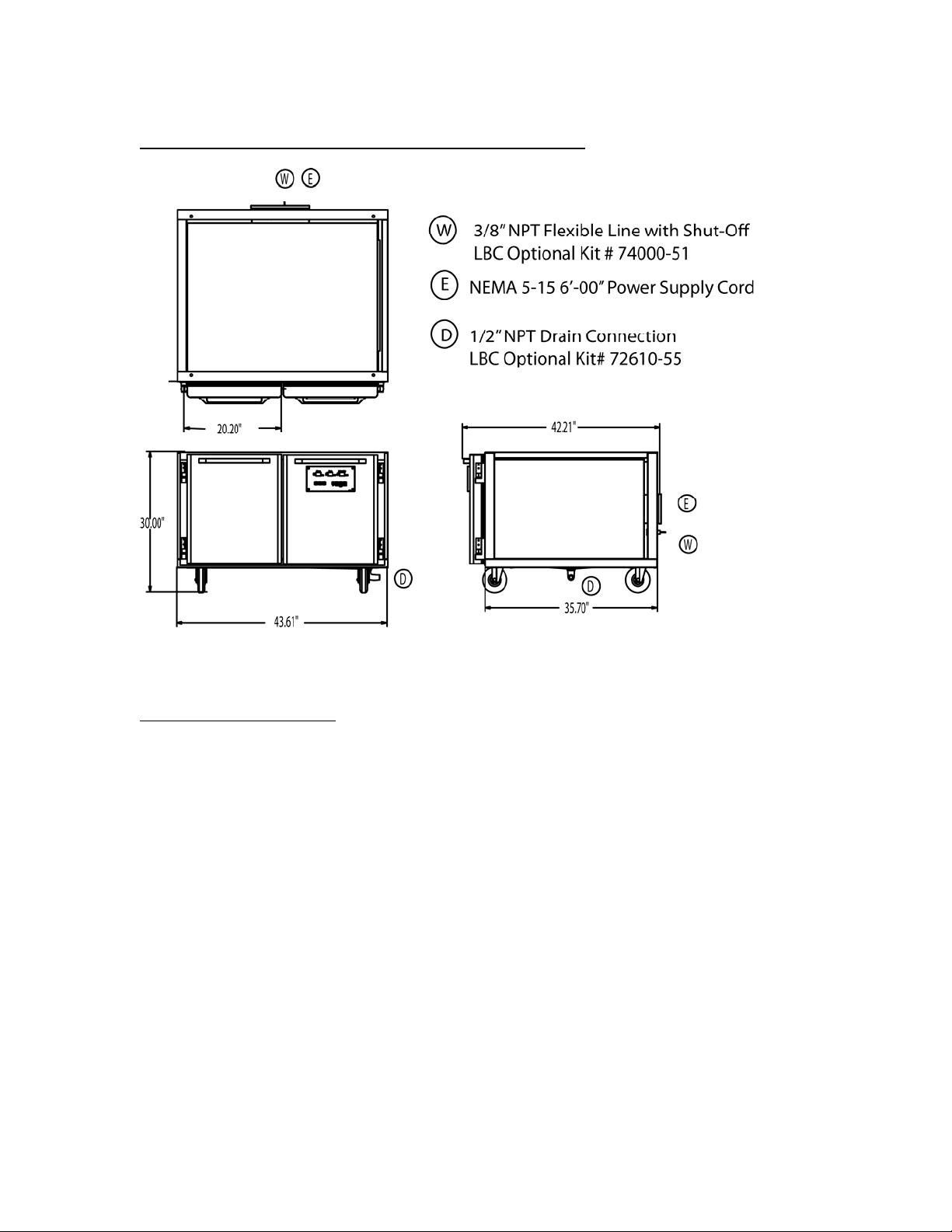

Utility Connection Points and Dimensional Drawing

3: Plumbing Connections

WARNING: PLUMBING CONNECTIONS

MUST COMPLY WITH APPLICABLE

SANITARY, SAFETY AND PLUMBING

CODES.

Water Supply

Proofer water supply should have a

hardness of 4-6 grains per gallon, pH of

6.5 to 8.0 and chlorides of less than 30

PPM. Water conditions outside of these

parameters may void the warranty. Please

consult your local water company and or

water condition dealer before installing the

oven or proofers water supply.

Connect the cold water supply to the 3/8”

NPT fitting located at the rear of the

proofer with a 6’-00” flexible clear water

line. Water supply should have a pressure

of 30 to 75 psi when the supply valve is

opened.

Drain Connections

Connect a ½” drain line to the ½” NPT

drain connector located at the bottom right

side of the proofer. Route the drain line to

a floor drain allowing a minimum 1” air gap

between the drain line outlet and the floor

drain.

If the proofer is being used with an oven it

is recommended that separate drain and

water lines are provided.

4

Loading...

Loading...