LBC Bakery Equipment LMO-Max-G Service Manual

1 © Copyright 2017

MODELS LMO Max-E & LMO Max-G

ROTATING RACK OVEN

INSTALLATION and SERVICE MANUAL

GAS OVENS: POST IN A PROMINENT LOCATION, THE INSTRUCTIONS TO BE

FOLLOWED IN THE EVENT THE SMELL OF GAS IS DETECTED. THIS INFORMATION

SHALL BE OBTAINED FROM THE LOCAL GAS SUPPLIER.

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

LBC BAKERY EQUIPMENT, INC.

6026 31st Ave NE

Tulalip, WA 98203, USA

Toll Free: 888-722-5686

E-mail: sales@lbcbakery.com

www.lbcbakery.com Rev E 1/2017

2 © Copyright 2017

R READ FIRST (Part 1 of 2) .

ALL OPERATORS OF THIS EQUIPMENT MUST BE OF LEGAL AGE TO OPERATE

SUCH EQUIPMENT AND MUST BE FAMILIAR WITH AND UNDERSTAND ALL

CAUTION LABELS.

READ, UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND WARNINGS

CONTAINED IN THIS MANUAL. IT IS THE RESPONSIBILITY OF THE

OWNER/OPERATOR OF THIS APPLIANCE TO TRAIN, SUPERVISE AND AUTHORIZE

ANY PERSON DESIGNATED AS AN OPERATOR. ALL OPERATORS MUST READ

AND UNDERSTAND THIS MANUAL.

IMPORTANT

GAS OVENS: IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN UNIT

AT MAIN SHUTOFF VALVE AND CONTACT YOUR LOCAL GAS COMPANY OR

GAS SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO OPERATE THIS

DEVICE.

KEEP AREA AROUND THE OVEN CLEAR OF COMBUSTIBLES.

GAS OVENS: DO NOT OBSTRUCT COMBUSTION AND VENTILATION OPENINGS

ON THE OVEN.

WIRING SCHEMATICS ARE LOCATED BEHIND THE APPLIANCE CONTROL PANEL

IN CONTROL COMPARTMENT.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

DO NOT OPERATE, CLEAN OR SERVICE THIS MACHINE BEFORE READING

THIS MANUAL AND UNDERSTANDING COMPLETELY THE SAFETY

INSTRUCTIONS FOUND HEREIN AND ON THE MACHINE’S LABELS.

3 © Copyright 2017

R READ FIRST (Part 2 of 2) .

WARNING

THIS APPLIANCE IS EQUIPPED WITH A THREE-PRONG (GROUNDED) PLUG

FOR YOUR PROTECTION AGAINST SHOCK HAZARD. PLUG DIRECTLY INTO A

THREE-PRONG RECEPTACLE. DO NOT CUT OR REMOVE THE GROUNDING

PRONG FROM THIS PLUG.

WARNING

DISCONNECT FROM POWER SOURCE WHEN CLEANING AND/OR SERVICING

THIS MACHINE.

WARNING

NEVER ATTEMPT TO CLEAN THIS MACHINE WHILE IT IS HOT OR HEATING AS

RISK OF SERIOUS INJURY COULD RESULT.

WARNING

NEVER OPERATE THIS MACHINE WITH SAFETY COVERS OR INSPECTION

PLATES REMOVED OR WITH SAFETY SWITCHES INOPERATIVE.

4 © Copyright 2017

TABLE of CONTENTS .

Read First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Gas Ovens: Lighting & Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Specifications

Electric Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Gas Ovens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Gas Ovens: Natural/Propane Gas Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Startup and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pressure Panel Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Control Operation and Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Temperature Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Illustrated Parts Breakdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Electrical Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

LBC Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5 © Copyright 2017

GAS OVENS: LIGHTING & SHUTDOWN .

Lighting Instructions

After Long-Term Shutdown

1. Turn on the gas supply to the oven.

2. Open the gas valve access door located behind the control panel. Switch the gas valve to

“ON.”

3. Keep the gas valve door open until the burner lights the first time.

WARNING

IF THE BURNER DOES NOT LIGHT, TURN OFF ALL GAS TO THE

OVEN FOR 5 MINUTES AND THEN BEGIN AT STEP 1.

Daily Use

1. Press the “Power” button to turn the oven on. Close the oven door.

2. Set the oven temperature to the desired operating temperature by pressing the up or down

arrow buttons next to the “Set Temperature” display.

Shutdown Instructions

Daily Use

Press the “Power” button to turn the oven off.

Long-Term Shutdown

Open the gas valve access door located behind the control panel. Switch the gas valve to

“OFF” and turn off the gas supply to the oven.

6 © Copyright 2017

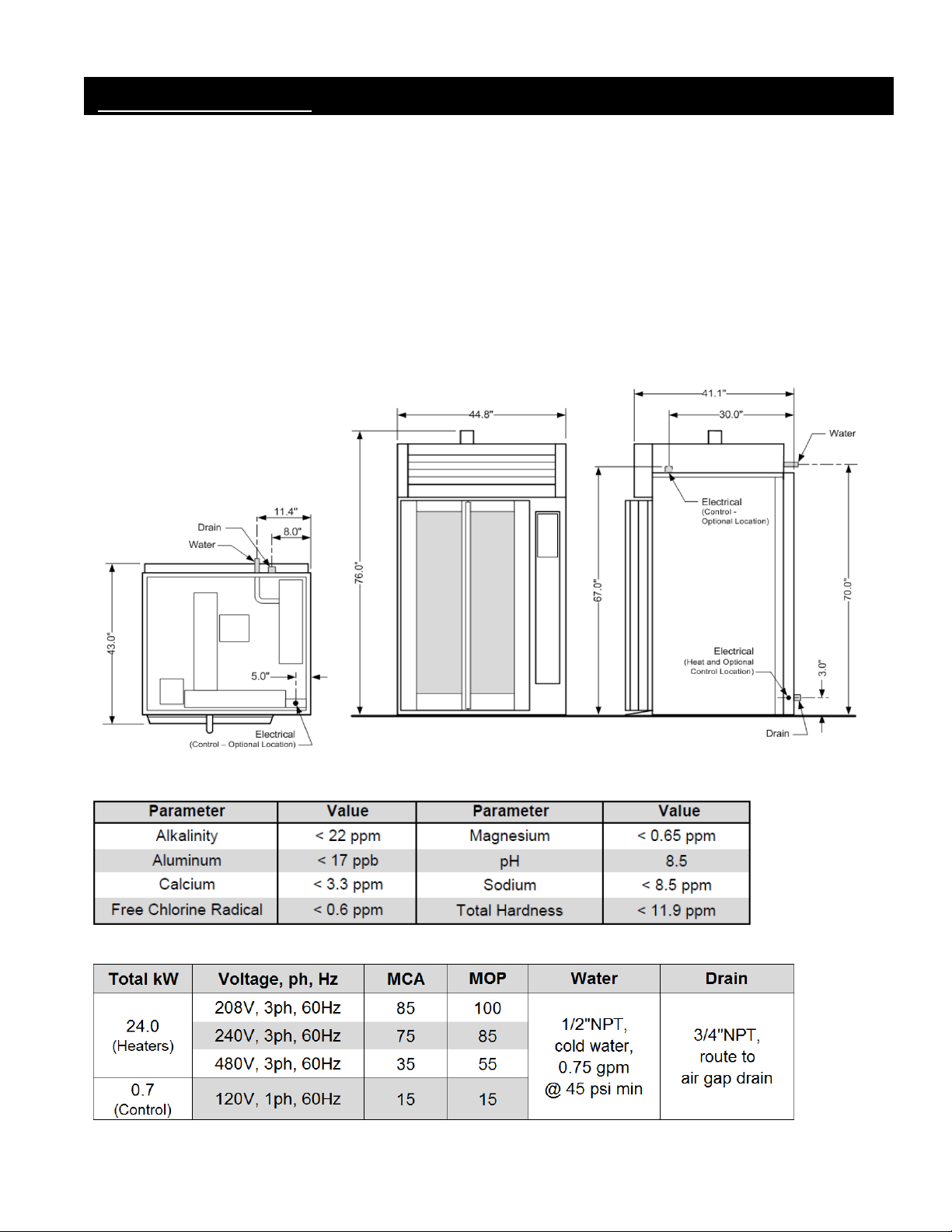

ELECTRIC OVENS: SPECIFICATIONS .

Installation Requirements

Oven ships fully assembled and will fit through a 36” door opening with removal of the oven

door assembly, valence and back panel. Check local codes to determine if the oven needs to be

installed under a hood.

Clearance to Combustibles: 1” from back and sides, 18” from top

Flooring: Appliance must be installed on a floor of noncombustible construction with

noncombustible flooring and surface finish and with no combustible material against the

underside thereof, or on noncombustible slabs or arches having no combustible material

against the underside. Such construction shall in all cases extend not less than 12” beyond the

equipment on all sides.

Water Quality Requirements

Utility Requirements

7 © Copyright 2017

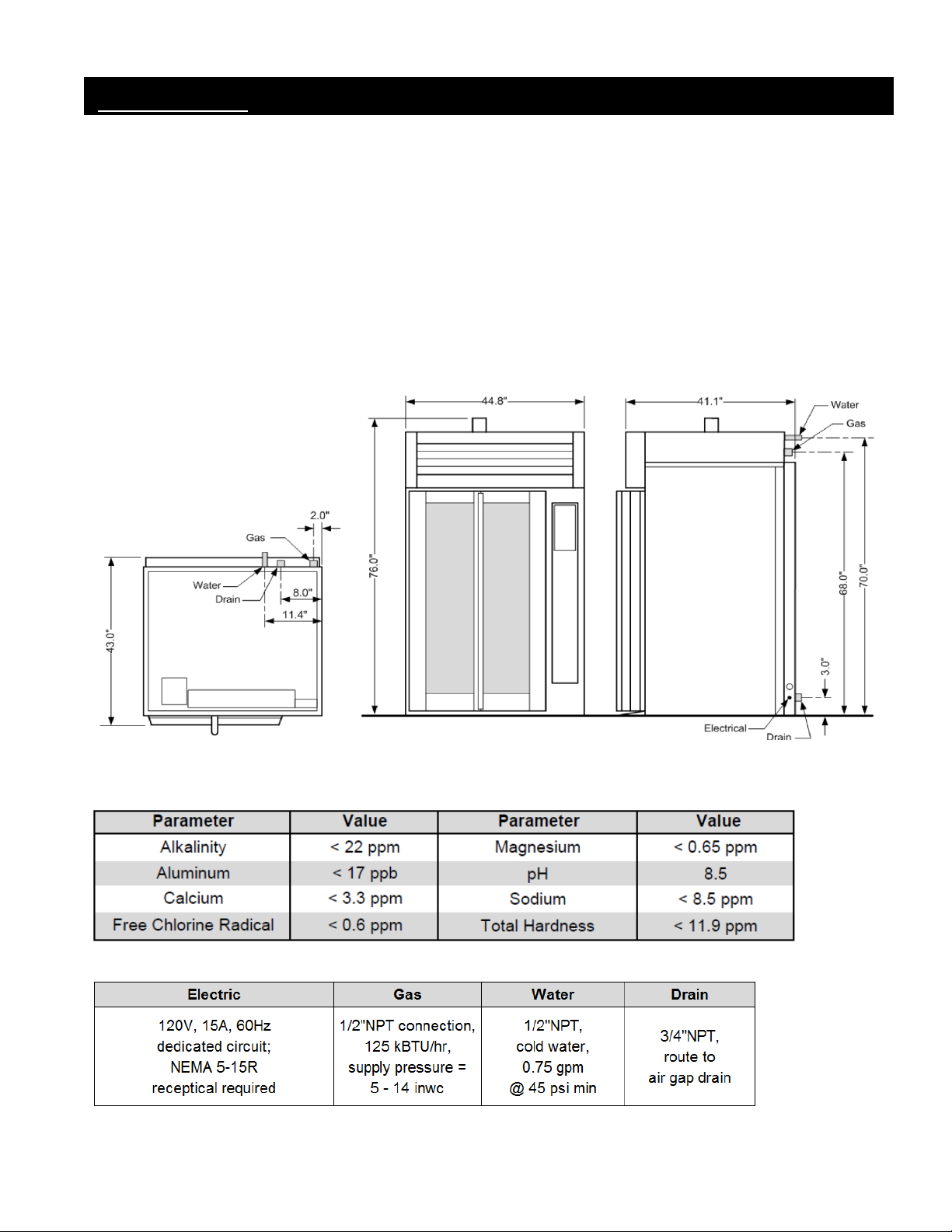

GAS OVENS: SPECIFICATIONS .

Installation Requirements

Oven ships fully assembled and will fit through a 36” door opening with removal of the oven door

assembly, valence and back panel.

Clearance to Combustibles: 1” from back and sides, 18” from top

Flooring: Appliance must be installed on a floor of noncombustible construction with

noncombustible flooring and surface finish and with no combustible material against the

underside thereof, or on noncombustible slabs or arches having no combustible material against

the underside. Such construction shall in all cases extend not less than 12” beyond the

equipment on all sides.

Water Quality Requirements

Utility Requirements

8 © Copyright 2017

SAFETY CONSIDERATIONS .

Your LBC Bakery Equipment oven was manufactured to rigid standards. The oven is ETL listed

as a unit, and meets applicable safety standards.

A) The responsibility of the manufacturer is to supply suitable, comprehensive

instructions and recommendations for operation and maintenance of appliance.

B) All operations, maintenance and repair of oven must be performed by properly trained

and qualified personnel, and all operations, maintenance and repair must be

performed in a diligent manner. It is responsibility of owner/operator to ensure

proper training and diligence of any person coming into contact with either oven or

output (product, exhaust or otherwise) of oven. It is responsibility of owner/operator

to ensure oven is installed and operated in accordance with OSHA Standard 1910.263.

C) A regular periodic program of cleaning, inspection and maintenance must be

established and comprehensive maintenance records maintained. It is sole

responsibility of user to establish, schedule and enforce frequency and scope of these

programs in keeping with recommended practice and with due consideration given to

actual operating conditions.

D) The units must be operated within limits which will not exceed working limits of any

component.

9 © Copyright 2017

RECEIVING ..

CAUTION

THIS APPLIANCE WEIGHS MORE THAN 1000 LBS. FOR SAFE HANDLING, INSTALLER

SHOULD OBTAIN HELP AS NEEDED OR EMPLOY APPROPRIATE MATERIAL-HANDLING

EQUIPMENT (SUCH AS A FORKLIFT, DOLLY OR PALLET JACK) TO REMOVE THE UNIT

FROM ITS PACKING MATERIALS AND MOVE IT TO THE PLACE OF INSTALLATION.

NOTE: IF REQUIRED, YOU CAN REMOVE THE INNER RIGHT WALL COVER AND

REMOVE THE STEAMER MASS IN FOUR SECTIONS.

Upon receiving the appliance, immediately check for damage (both visible and concealed) and loss.

Visible damage must be noted on the freight bill at the time of delivery and signed by the

carrier’s agent. Concealed damage or loss means damage or loss which does not become apparent

until the merchandise has been uncrated. If concealed damage or loss is discovered upon

unpacking, make a written request for inspection by the carrier’s agent within 15 days of

delivery. All packing material should be kept for inspection. DO NOT return damaged

merchandise to LBC Bakery Equipment, Inc.; you must file your own claim with the carrier.

10 © Copyright 2017

INSTALLATION (Part 1 of 4) .

General Information

This appliance, when installed, must be electrically grounded in accordance with state and local

codes, or in the absence of local codes, with the National Electrical Code (ANSI/NFPA 70) or the

Canadian Electrical Code (CSA C22.2 No. 3, latest edition) as applicable.

The appliance requires some assembly by an authorized LBC trained service technician.

Do not enclose the top of the appliance to other construction. The top of the oven must be

accessible for service and must not be enclosed or covered. This clearance may be gained by

removing baffles, filters and other components, provided that removing the components does not

create a hazard. Gas Ovens: The top of the oven must also be open and have adequate air supply for

combustion.

WARNING

THIS APPLIANCE MUST BE INSTALLED WITH A MINIMUM OF 1 INCH CLEARANCE FROM

SIDES AND BACK AND 18 INCHES CLEARANCE FROM THE TOP TO COMBUSTIBLE

SURFACES.

WARNING

THIS APPLIANCE MUST BE INSTALLED ON A NON-COMBUSTIBLE FLOOR EXTENDING

12 INCHES BEYOND THE APPLIANCE, WITH NON-COMBUSTIBLE CONSTRUCTION

UNDER THE FLOOR.

General Information – Gas Ovens

This appliance must be installed under a ventilation hood.

This appliance must be connected to a gas shutoff valve in accordance with CSA 9.1-M97 – ANSI

Z21.15-1997 and Addenda CGA 9.1 a-2001 – Z21.15a-2001, Manually Operated Gas Valves for

Appliance, Appliance Connector Valves and End Valves.

The installation of this appliance must conform with local codes, or in the absence of local codes,

with the National Fuel Gas Code (ANSI Z223.1/NFPA 54) or the Natural Gas and Propane Installation

Code (CSA B149.1) as applicable, including:

The appliance and its individual shutoff valve must be disconnected from the gas supply piping

system during any pressure testing of that system at test pressures in excess of 1/2 psi.

The appliance must be isolated from the gas supply piping system by closing its individual shutoff

valve during any pressure testing of the gas supply piping system at test pressures equal to or less

than 1/2 psi.

This appliance is configured to operate on natural gas or propane gas. A gas conversion kit is

available for this appliance. See the name plate on the appliance to determine if the appliance is

configured for natural gas or propane gas. For conversion instructions, see the “Natural/Propane Gas

Conversion” section of this manual.

11 © Copyright 2017

INSTALLATION (Part 2 of 4) .

Uncrating and Moving

1. Move oven to area where it is to be installed. NOTE: If the oven is to be moved through a 36”

door, see section directly below.

2. Disassemble crate. Use caution to avoid damage to oven with pry bars or nail removers.

3. Remove plastic wrap and padding from outside of oven. Remove components from inside of

the oven.

4. Use a fork lift to lift oven off of shipping skid. Slide forks under outer wall of oven. Do not lift

at middle of oven floor. As an alternate method, oven is equipped with lifting eyes on top.

Connect a chain or lifting strap capable of lifting 2000 pounds to the two lifting eyes to raise

oven off of skid. Place oven on floor close to its final location.

Moving Oven through a 36” Doorway

1. Disassemble crate. Use caution to avoid damage to oven with pry bars or nail removers.

Remove plastic wrap and padding from outside of oven. Remove components from inside of

the oven.

2. Remove top access cover of oven. Remove two screws on top of forward valance, then tilt

access cover forward and lift it out.

3. Open loading doors. Remove door latch cam follower.

4. Remove valance assembly by removing the four screws attaching it to side trim. Slide the

valance forward.

5. Remove top trim.

6. Remove screw attaching magnetic reed door switch to front of oven above control. Allow

switch to hang in position.

7. Remove door assembly.

WARNING

DOOR ASSEMBLY IS HEAVY. USE EVERY PRECAUTION TO AVOID

PINCHING FINGERS. USE ASSISTANCE TO MOVE DOOR ASSEMBLY.

a. Remove the two screws attaching the lower door hinge to the front of the oven on both

doors.

b. Remove the screws connecting the oven floor to the threshold.

c. Remove the four screws connecting the door mechanism to the front of the oven at the

top of the door assembly. Use caution to keep fingers out of pinch points.

d. Carefully move door assembly away from front of oven without tilting it. Wrap door

assembly with stretch wrap, rope or tape to keep doors from opening or moving.

e. Prop door in a safe location. Make sure it will not fall.

8. Gas Ovens: Remove two screws from gas inlet pipe bracket at back of oven. Push gas pipe

forward so it clears door opening.

9. Remove power cord and rear panel from oven.

10. Move the oven through doorway sideways. NOTE 1: Oven weighs more than 1000 lb. If

required, you can remove inner right wall cover and remove steamer mass in four sections.

NOTE 2: Oven floor can be removed if necessary to lift oven from the inside.

11. Replace all components removed in steps 1 through 10.

Loading...

Loading...