Page 1

Item No.

Y

Project

Quantity

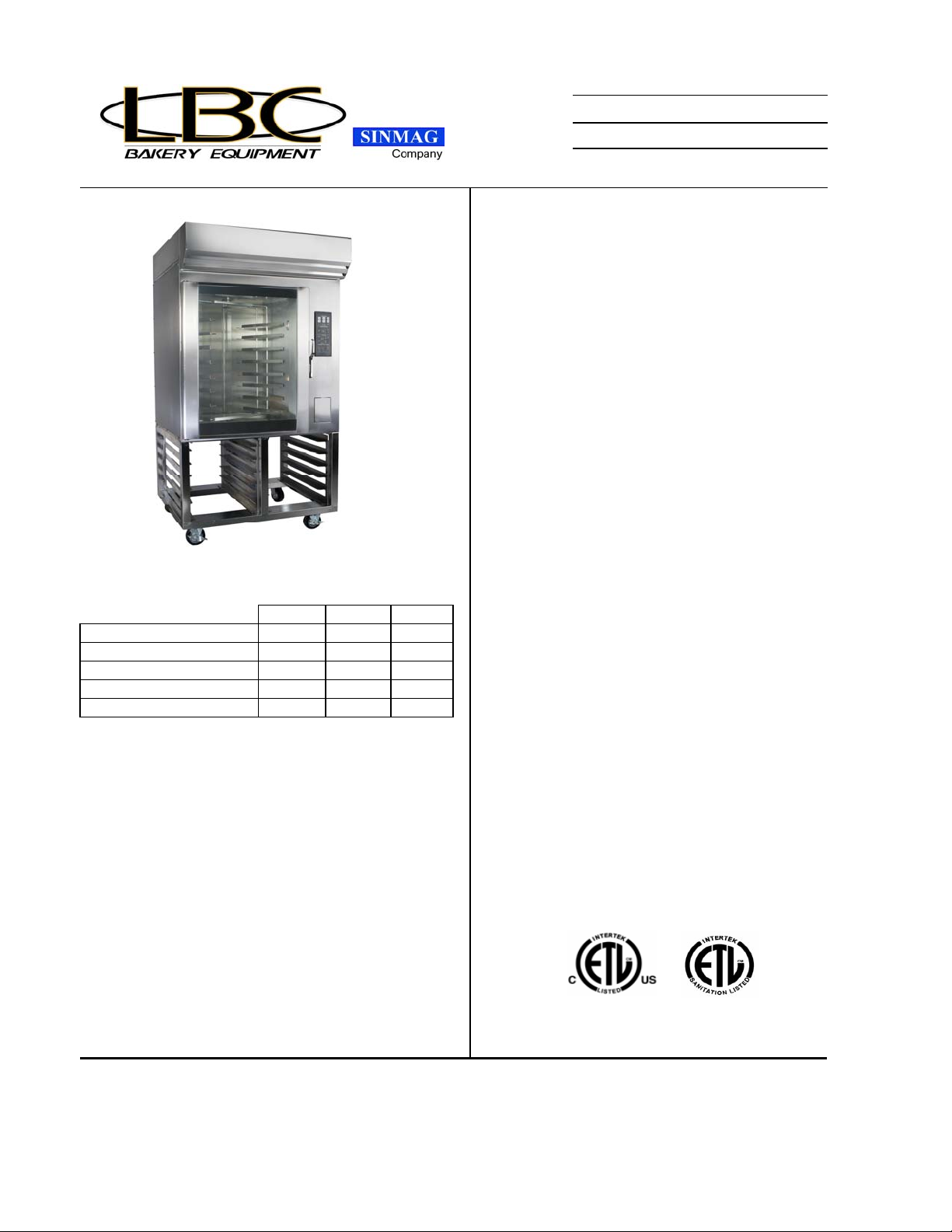

BakerSeries Gas "Mini" Rotating Rack Oven MODEL: LMO-G - Series

Construction Features

Heavy duty stainless steel interior and exterior

.

Vertical Tube Heat-exchanger

.

150 Lbs. Thermal Mass

.

Low pressure water injection steam system

.

6" Exhaust collar for "B" type vent, or direct vent under hood

.

Field connection point for hood proving switch*

.

Full-view double pane door window

.

Hinged inner glass window for easy cleaning

.

.

Full perimeter silicone door seal

. Mechanical door latch with magnetic closer

Performance Features

90,000 Btu/Hr burner system

.

0.75 GPH water delivery system

.

10/20 second normal steam time

.

Safety limited torque drive rotation system

.

Low noise circulation system

.

. Brightly lit interior

Model LMO-G8-N-S Shown

/ RACK CAPACIT

LMO-G6 LMO-G8 LMO-G10 Controls Features

18 x 26 Sheet Pans

12" x 20" Hotel Pans

Pan Bread 16oz Loaves

8 Oz. Baguettes

Cookies 2 oz.

6810.Large LED display for time, temperature and steam

680

30 N/A N/A

30 40 N/A

12 Doz. 16 Doz. 20 Doz.

Short Bid Specification:

Oven shall be LBC Mini Rotating Rack Oven, model no. LMO-G [insert

6-N, 6-LP, 8-N, 8-LP, 6S-N, 6S-LP, 8S-N, 8S-LP, 10S-N, 10S-LP] with

capacity for 6, 8 or 10 - 18" x 26" sheet pans. The oven shall operate

on natural gas or propane gas [specify at time of order]. The oven shall

have an internal steam system consisting of 150 pounds of steel bars

and a water drop system that dispenses water to the steel mass

through multiple large holes in a stainless steel tube located over the

steel mass. The oven shall be indirectly fired at a rate of 90,000

BTU/Hr. using an in-shot burner system and shall have heat exchanger

tubes that are mounted vertically so as to utilize natural draft for

combustion air intake and exhaust. The oven shall be mounted on a

stainless steel stand having front mounted heavy duty locking swivel

casters and rear mounted stationary locking casters or shall be

mounted on 8" stainless steel legs. The oven shall have an optional

proofer base having front mounted heavy duty locking swivel casters

and rear mounted stationary locking casters.

STANDARD PRODUCT WARRANTY

One-Year Parts and Labor (contiguous US Including Alaska and Hawaii, Canada)

. Fast acting programmable vent

Simple manual setting for temperature, time, steam

.

Manual one-touch venting control

.

. Manual blower one-touch delay or pulse blower

. Storage for up-to 99 programmed recipes

. 6-button quick access recipe menu

* The Commonwealth of Massachusetts requires that the gas

flow must be prohibited when the exhaust hood is not

Meets ANSI Z83.11 and NSF-4

Sheet Number LMO-G v8 (rev07/10)

operational.

LBC Bakery Equipment Co., Inc. 1410 80th Street SW Everett WA 98203

TOLL FREE 888-RACKOVN (888-722-5686) FAX: 425-642-8305 www.lbcbakery.com

Page 2

BakerSeries "Mini" Rotating Rack Oven MODEL: LMO-G - Series

S

A

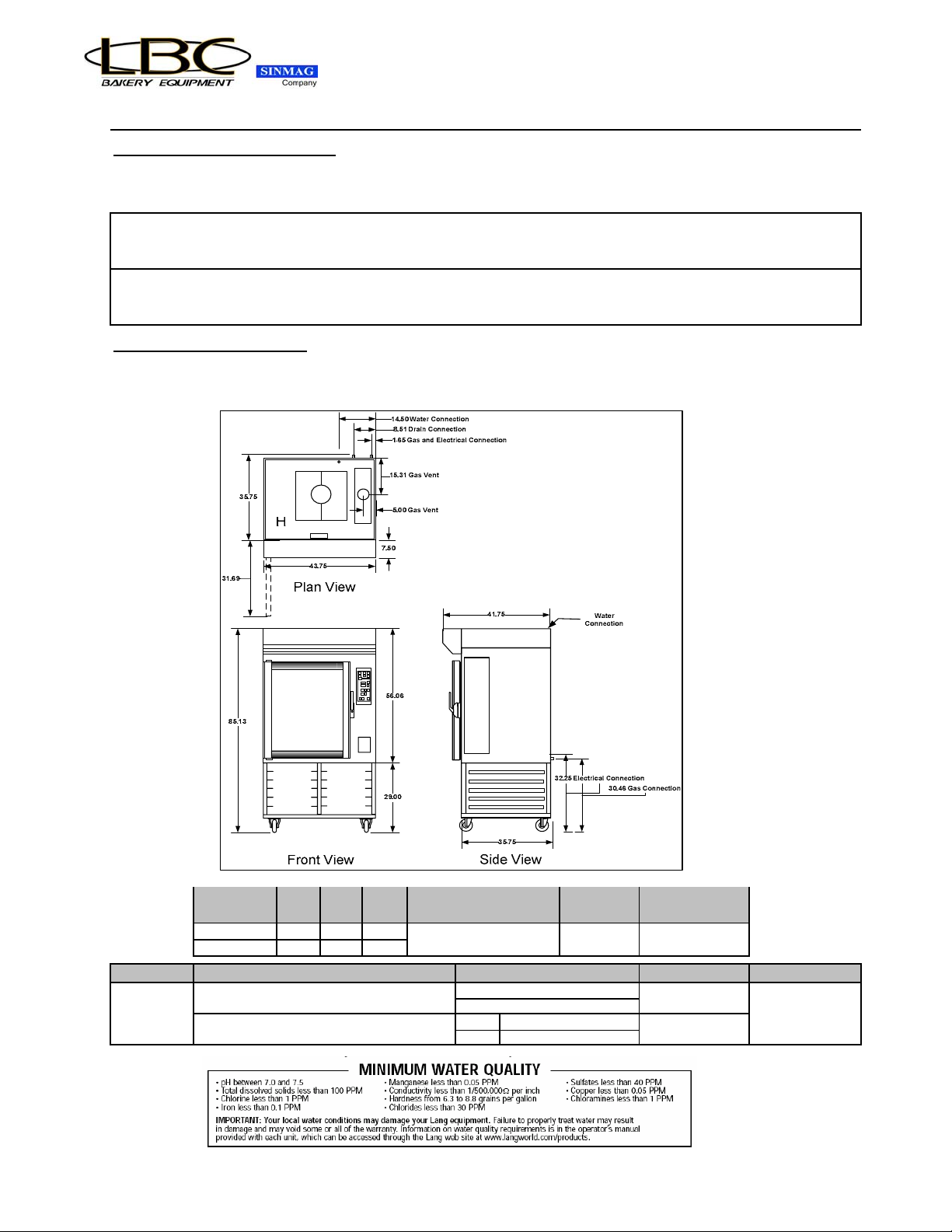

INSTALLATION REQUIREMENT

Ships Full Assembled, will fit through 40" Opening with out removal of door

Remove door, hinges and latch for movement through 36" clear opening

Product of combustion must be vented to the outside

Venting: Type "B" vent, 6" Dia. When used with approved draft inducer LBC Part No.70314-01. Alternate; May

be mounted under an approved Type I or II hood, provided there are 18" of clearance between the exhaust collar

and the hood filters. Consult all State, and local codes.

Note: When a hood or powered ventilation system is used for products of combustion, an interlock, such as

contact points or air-flow proving switch, is required. Consult installation instructions for connection information.

OPTIONS & ACCESSORIE

Stand with Rack Slides 6-Pan Rack @ 5.5" 10-Pan Rack @ 3.3" Gas Connection Kit

Proofer Base 60-Recipe Controller Water Connection Kit

8-Pan Rack @ 4"

S-19 19" Stand 70315-01 Draft Inducer Kit

Model H W D Weight

LMO-G

With Stand

Model Drain

LMO-G

120 VAC 15 Amp Dedicated Circuit

56.06" 43.75" 41.75"

85.13" 43.75" 41.75"

Electrical Requirements Gas

NEMA 5-15R

LBC Bakery Equipment Co. 1410 80th Street SW Suite C, Everett, WA 98203

TOLL FREE: 888-RACKOVN (888-722-5686) FAX: 425-642-8305

Clearance to Combustible

surfaces

0" Back and Sides 18" Top 900 85

1/2" NPT Supply Line

90,000 BTU/HR

Nat

LP

www.lbcbakery.com

5"-14" WC at all times

11"-14" WC at all times

Freight Class

Water

3/8" Cold Water

Supply

0.75 GPM @ 20

PSI

ir Gap routed from

rear of appliance

Loading...

Loading...