LBC Bakery Equipment LMO-E Installation Manual

Installation, Operations and Maintenance Manual

for LBC Models LMO-G and LMO-E gas and electric “Mini”

Rotating Rack Ovens

Rev.009 Aug 2012

LBC Bakery Equipment, Inc.

5901 23rd Drive West

Suite 105

Everett, WA 98203

Toll Free: 888-722-5686

Fax: 425-642-8305

E-mail; sales@lbcbakery.com

www.lbcbakery.com

LBC Bakery Equipment Co 1

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL

QUALIFIED TO INSTALL GAS EQUIPMENT, WHO SHOULD

PERFORM THE INITIAL FIELD START-UP AND ADJUSTMENTS OF

THE EQUIPMENT COVERED BY THIS MANUAL

POST IN A PROMINENT LOCATION, THE INSTRUCTIONS TO BE

FOLLOWED IN THE EVENT THE SMELL OF GAS IS DETECTED.

THIS INFORMATION CAN BE OBTAINED FROM THE LOCAL GAS

SUPPLIER

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN UNIT AT

MAIN SHUTOFF VALVE AND CONTACT THE LOCAL GAS

COMPANY OR GAS SUPPLIER FOR SERVICE

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

OR LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO

OPERATE THIS DEVICE.

KEEP AREA AROUND THE OVEN CLEAR OF COMBUSTIBLES. DO

NOT OBSTRUCT COMBUSTION AND VENTILATION OPENINGS

ON THE OVEN.

LBC Bakery Equipment Co 2

Table of Contents

Page 4 Inspect and Uncrate

Installation Codes

Model Designations

Page 5 Utility Connection Points

Page 6 Installation

Install Caster

Installation location

Page 7 1: Gas Connections

2: Venting

Page 8 Venting Illustration

Safety Considerations

Page 9 3: Plumbing Connections

Water Supply

Drain Connections

4: Electrical Connections

Gas Models

Electric Models

Page 10 Electrical Connection Illustration

Page 11-12 Installation and Start-up Procedures

Page13 Controls Operation

Page14-18 Wiring Diagrams

Page 19-24 Illustrated Parts List

Page 25 Standard Warranty

LBC Bakery Equipment Co 3

Installation of this equipment must be

performed by an authorized service

representative. Prior to installation

verify that all electrical and gas

supplies coincide with the

manufacturers data label located on

the right side below the service panel.

Inspection and Un-crating

Upon receipt of shipments, all

packages should be inspected, and all

visible or concealed damages noted

and signed for on the bill of lading.

Any other damages should be reported

to the carrier within 10 days. Freight

damages are the responsibility of the

consignee.

All orders for replacement products

resulting in freight damages will be

processed under LBC’s standard terms.

Any reimbursement or credit is the

responsibility of the freight carrier

Carefully unpack the oven and place it

in a work area as near to the final

installation position as possible.

The LMO oven ships with the following

items please inspect your shipment to

ensure that these items were included.

LMO Oven Rack

Decorative hood front, sides

and back pieces

Flexible gas hose, connectors

and restraints

If moving the oven trough a 36” door

opening it will be necessary to remove

the oven door, door latch, door hinges

and the decorative hood.

Installation Codes

For US Installation

The LMO oven must be installed in

accordance with all State and local

codes and:

National Fuel Gas Code, ANSI-Z223-1

(latest edition)

National Electrical Code, ANSI/NFPA70 (latest edition)

For Canadian installation

The LMO oven must be installed in

accordance with all local codes and;

CAN/CGA-B149.1 National Gas

Installation Code

CAN/CGA-B149.1 National Fuel Gas

Code

Note: The decorative trim is not intended for use as an exhaust hood.

Model Number Coding

LMO followed by G (gas models) or E (electric model) followed by 6 (6-pan rack) 0r

8 (8-pan rack) followed by S (for stand) or P (for proofer base) followed by N (for

natural gas) or LP for (Propane gas) or 208, 240 or 480 (for electric models)

Sample Model Number: LMO-E8P-480: This is a 480 Volt electric oven with an 8

pan rack and a proofer base.

LBC Bakery Equipment Co 4

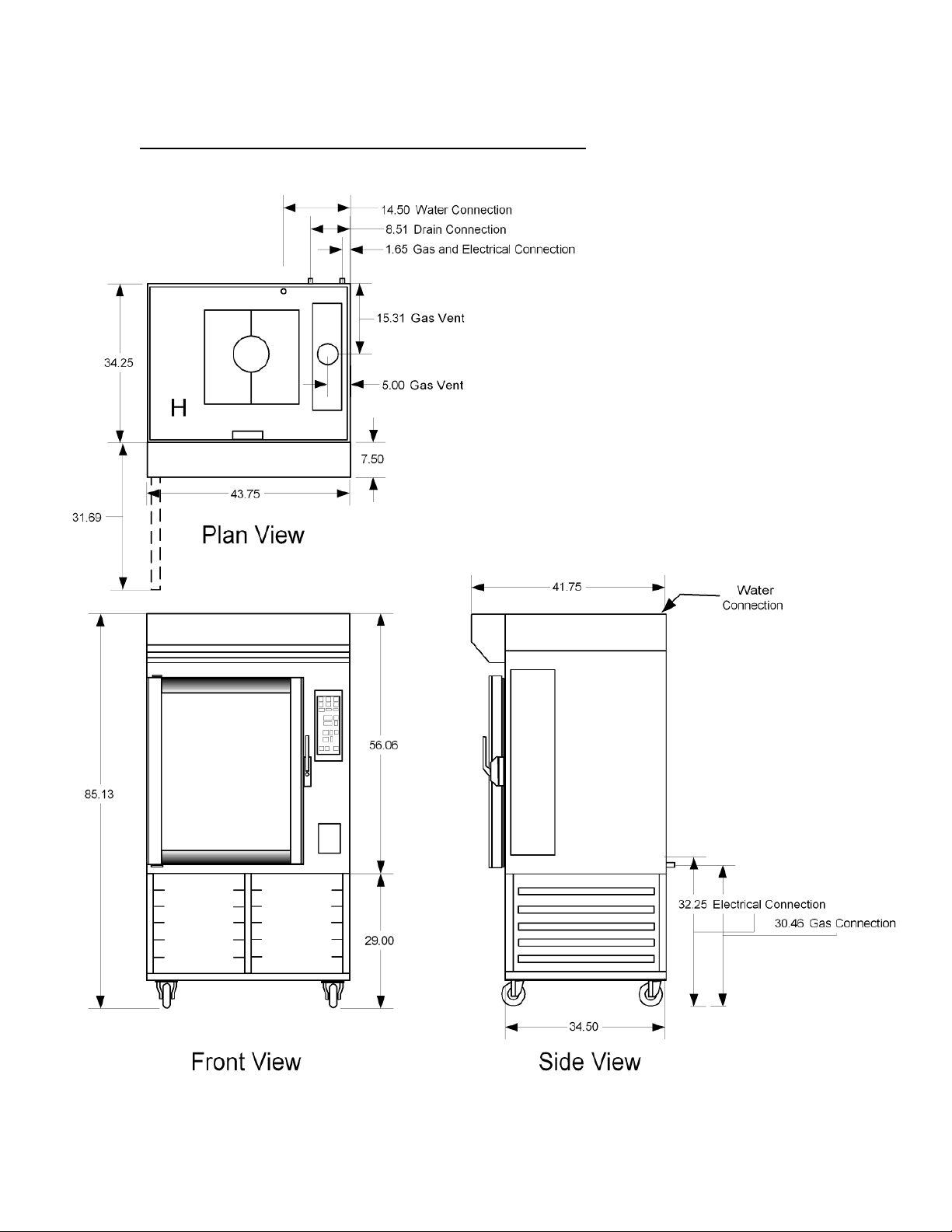

Utility Connection Points and Dimensional Drawing

LBC Bakery Equipment Co 5

Installation

The LMO oven must be installed on the ovens stand using the supplied fasteners or installed

on any non-combustible surface adequate to support the weight of the appliance.

Ovens shipped with a stand must have the casters installed.

With the oven still on the shipping pallet slide the oven and stand forward and install the two

front locking casters.

Move the oven and stand forward onto a pallet truck, lift the oven and stand off of the pallet

and install the two rear casters.

IMPORTANT:

Gas ovens can not be mounted directly to a solid surface as the combustion air intake is from

the bottom side of the oven.

ALL GAS MODELS MUST BE MOUNTED ON 6” LEGS OR OVEN STAND

The LMO oven must be sealed to the stand using an NSF approved sealant.

Gas ovens mounted on the oven stand with casters must utilize the following…

A connector that complies with the Standard for Connectors for Movable Gas Appliances, ANZI

Z21.69

Or Connectors for Movable Gas Appliances, CAN/CGA-6.16

A quick disconnect device that complies with the Standard for Quick-Disconnect Devices for

Use With Gas Fuel, ANZI Z21.41

Or Quick Disconnect Devices for Use with Gas Fuel, CAN1-6.9

Adequate means must be provided to limit the movement of the appliance.

Select a location that has a smooth level surface and has adequate room to operate the

appliance (see Illustration – 1 for oven dimensions and utility connection points)

Ensure that the oven is installed on a level surface. If the unit is mounted on the movable

oven stand, loosen the caster bolt and place shims under the base until level, re-tighten the

caster bolts.

LBC Bakery Equipment Co 6

1: Gas Connections

CAUTION: Gas supply connections and any

pipe joint compound must be resistant to the

action of propane gases.

The LMO-G is an indirect gas fired oven

consisting of a heat exchanger that consists of

15 (fifteen) in-shot burners and tubes totaling

90,000 BTU/HR.

Verify that the gas supply matched the type

listed on the data label. If the incoming

pressure exceeds ½ psig (3.45kPa) 14” W.C.

install a pressure regulator before the oven’s

gas valve.

Codes require installation of a gas shutoff

valve in the gas line ahead of the oven. The

gas supply line must be at least the equivalent

of ¾” iron pipe. Corrugated lines should not

be used.

Connect the gas supply line to the ¾” NPT

incoming gas connection located at the rear of

the oven. Ensure that the pipes are free and

2: Ventilation

Ventilation requirements vary with each

installation and must comply with applicable

portions of the National Fire Protection

Association Standard 96 as well as any and

all State and local codes.

Exhaust Fan Interlock

A connection point (5 AMPS Max.) is provided

for indirect vent (Exhaust Hood) or optional

direct vent (Draft Hood). It is located in the

electrical connection box at the right rear

side of the oven. Consult local codes for vent

interlock requirements.

Indirect Vent (Installed under an

exhaust hood) – Standard installation

configuration.

Locate the oven under an exhaust hood with

adequate overhangs and exhaust rates to

completely capture the byproducts of

combustion discharged from the flue. From

clear of any dirt or obstruction. If the oven is

supplied with a flexible gas line, secure it to

the oven and wall per the manufacturers

instructions.

Verify that the line pressure before the gas

valves stays between 5” and 14” W.C. for

natural gas or 11” and 14” for W.C. for

propane gas – both with and without the

burner firing.

WARNING: PRIOR TO LIGHTING, LEAK

TEST ALL JOINTS AND FITTINGS USING

SOAPY WATER. DO NOT LEAK TEST USING AN

OPEN FLAME.

Testing the gas supply;

When the supply pressure exceeds ½ psig the

oven and its individual shut-off valve must be

disconnected from the supply piping

When the supply pressure is ½ psig or less,

the ovens should be isolated from the gas

supply system by closing its individual manual

shutoff valve.

the termination of the flue to the filters of the

hood venting system a clearance of 18” must

be maintained. The exhaust hood fan can be

directly interlocked to the oven (consult the

wiring diagram for terminal location*).

Direct Vent (Draft Hood) – Optional

configuration

Move the oven into position and attached the

customer supplied exhaust ducting and draft

diverter.

Verify that the air is being drawn into the

bottom of the draft diverter while the burner

is firing, using a draft gauge or smoke test.

Using a draft gauge, verify that a draft of

between 0.03” – 0.11” W.C. is maintained at

a point 6” above the draft diverter’s upper

collar. Any exhaust fan or draft inducer used

to maintain system suction must be operating

when the oven is turned on. (See exhaust fan

interlock.)

LBC Bakery Equipment Co 7

Sample Installation

SAFETY CONSIDERATIONS:

Your LBC BAKERY oven was manufactured to rigid standards. The oven is ETL listed as a unit, and

meets applicable safety standards.

A) The responsibility of the manufacturer is to supply suitable, comprehensive instructions and

recommendations for the operation and maintenance of the subject units.

B) All operations, maintenance and repair of the subject units must be performed by properly trained

and qualified personnel, and all such operations, maintenance and repair must be performed in a

diligent manner. It is the responsibility of the owner/operator to insure proper training and

diligence of any person coming into contact with either the subject units or the output (product,

exhaust or otherwise) of the subject units. It is the responsibility of the owner/operator to

ensure that the subject units are installed and operated in accordance with OSHA Standard

1910.263.

C) A regular periodic program of cleaning, inspection and maintenance must be established and

comprehensive maintenance records maintained. It is the sole responsibility of the user to

establish, schedule and enforce the frequency and scope of these programs in keeping with

recommended practice and with due consideration given to actual operating conditions. For

suggested cleaning schedule visit our Website @ www.lbcbakery.com First click on Manuals,

then click on Equipment Cleaning under Operation and Programming Manuals, or call LBC @ 1888-722-5686 to have one faxed.

D) The units must be operated within limits, which will not exceed the working limits of any

component.

LBC Bakery Equipment Co 8

Loading...

Loading...