LBC Bakery Equipment EDO-281 Installation Manual

EDO Model Electric Modular Stone Hearth Deck Oven

Two Pan Deck Ovens Models: EDO-281, 282, 283 and 284

Three Pan Deck Ovens Models: EDO-381, 382, 383 and 384

Installation and Operations Manual

Rev 002 07/08

Model EDO-384 Shown

LBC Bakery Equipment, Inc.

1410 80 Street SW, Suite C, Everett WA 98203 Ph: 888-722-5686 www.lbcbakery.com

Page 1 of 18

Table of Contents

Page Item

3

Warnings and Freight Claims

Section I: Installation

4 Selecting Installation location

5

6

Electrical connections

Water Supply

Testing Oven

7

8

Start-up

Trouble Shooting

Section II: Operations

9 Operations

Controls Operation

10 Loading Oven

11 Starting a Bake

Cleaning and Maintenance

12-14 Parts Illustrations and Listings

15 Wiring Diagrams

16-17 Limited Warranty

LBC Bakery Equipment, Inc.

1410 80 Street SW, Suite C, Everett WA 98203 Ph: 888-722-5686 www.lbcbakery.com

Page 2 of 18

DO NOT OPERATE, CLEAN OR SERVICE THIS MACHINE BEFORE

READING THIS MANUAL AND UNDERSTANDING COMPLETELY THE

SAFETY INSTRUCTIONS FOUND IN THIS MANUAL AND ON THE

CAUTION!

MACHINES LABELS

IMORTANT!

ALL OPERATORS OF THIS OVEN MUST BE OF LEGAL AGE TO

OPERATE SUCH EQUIPMENT AND MUST BE FAMILIAR WITH AND

UNDERSTAND ALL CAUTION LABELS.

DISCONNECT FROM POWER SOURCE WHEN CLEANING AND/OR SERVICING

THIS MACHINE

NEVER ATTEMPT TO CLEAN THIS MACHINE WHILE IT IS HOT OR HEATING AS

RISK OF SERIOUS INJURY COULD RESULT

NEVER OPERATE THIS MACHINE WITH SAFETY COVERS OR INSPECTION

PLATES REMOVED OR WITH SAFETY SWITCHES INOPERATIVE

The EDO Deck oven has been packaged to withstand rough handling; however,

it is important that you inspect the shipment for damages, concealed or

otherwise and that you sign the bill of lading to note any such damages. These

damages are the responsibility of the consignee and must be reported to the

carrier within 10 days in order to file for a claim.

LBC Bakery Equipment, Inc. will not warrant any equipment that is not installed

by a trained installation contractor or that has not been connected to utilities by

a licensed electrician and plumber. Please consult our warranty at the end of

this document.

LBC Bakery Equipment, Inc.

1410 80 Street SW, Suite C, Everett WA 98203 Ph: 888-722-5686 www.lbcbakery.com

Page 3 of 18

I:

Installation Section

A: Selecting an Installation Location

Installation of the EDO Electric deck oven should be made in accordance with all

local codes. Check with your local building department to determine if the oven

will need to be placed under a hood.

The installation location should be free and clear of all obstruction.

The floor should be smooth and level and must be capable of supporting the

weight of the appliance.

Allow adequate clearance at the sides of the oven for serviceability.

The EDO deck oven is equipped

with four (4) leveling feet located

under the equipment stand, two

at the front and two at the rear.

Once the oven is installed in its

operating position, lower the feet

by turning them clockwise to

level and secure the appliance

from movement.

Illustration 1: Levelers and stand.

LBC Bakery Equipment, Inc.

1410 80 Street SW, Suite C, Everett WA 98203 Ph: 888-722-5686 www.lbcbakery.com

Page 4 of 18

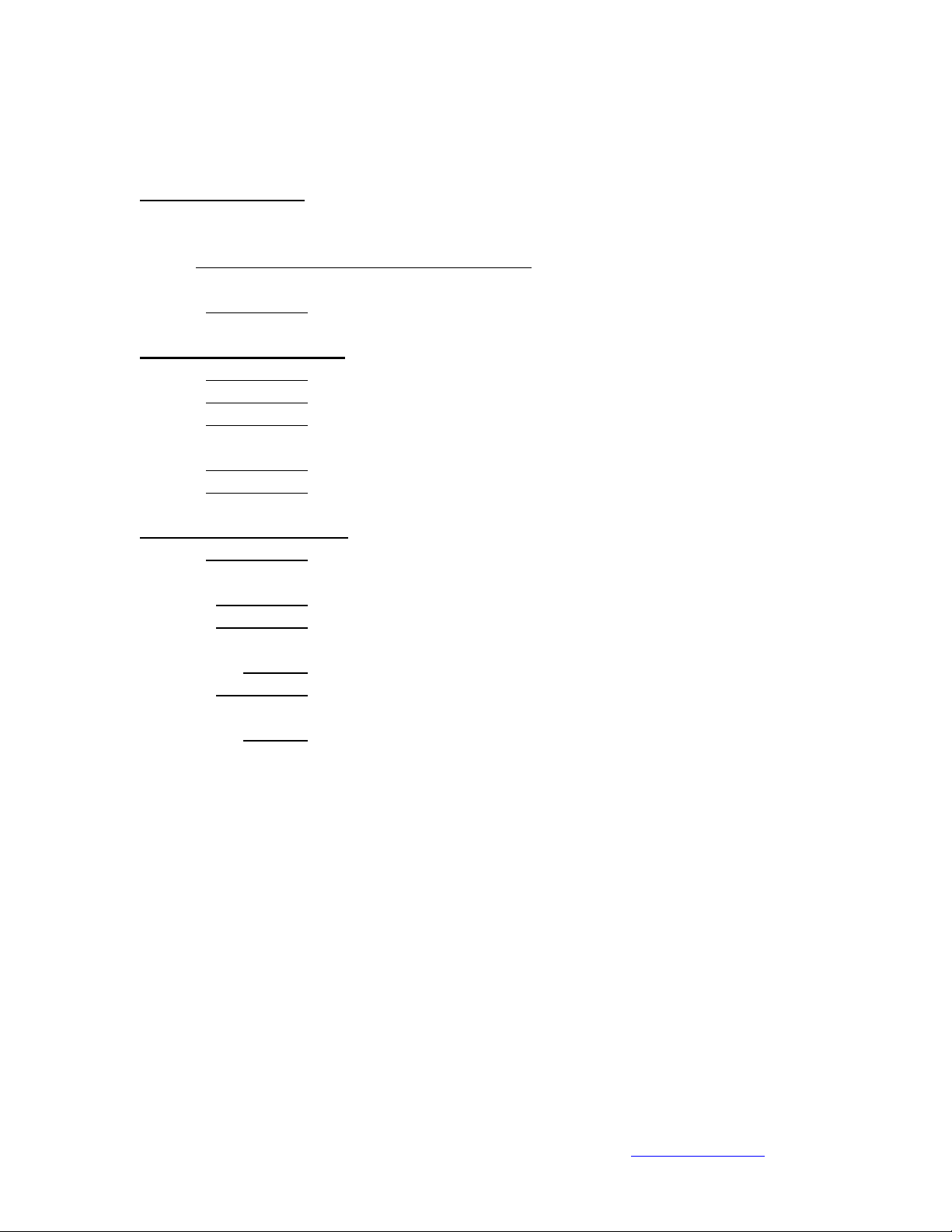

B: Electrical Connections

Electrical connection must comply with all applicable State and local codes and in

accordance with the NEC and NFPA.

Electrical connections MUST be made by a licensed electrician.

A separate service circuit breaker should be installed so that main power can be

disconnected during service

208 VAC 240 VAC 480 VAC

Model Ph.

EDO-281 3 5.4 15.6 20 7.2 20.8 30 7.2 10.4 15

EDO-282 3 10.8 31.2 40 14.4 41.6 55 14.4 20.8 30

EDO-283 3 16.2 46.8 60 21.6 62.4 80 21.6 31.2 40

EDO-284 3 21.6 62.4 80 28.8 83.2 105 28.8 41.6 55

EDO-381 3 7.4 23.7 30 9.8 27.1 35 9.8 13.5 20

EDO-382 3 14.8 47.4 60 19.6 54.2 70 19.6 27 35

EDO-383 3 22.2 71.1 90 29.4 81.3 105 29.4 40.5 55

EDO-384 3 29.6 94.8 120 39.2 108.4 140 39.2 54 70

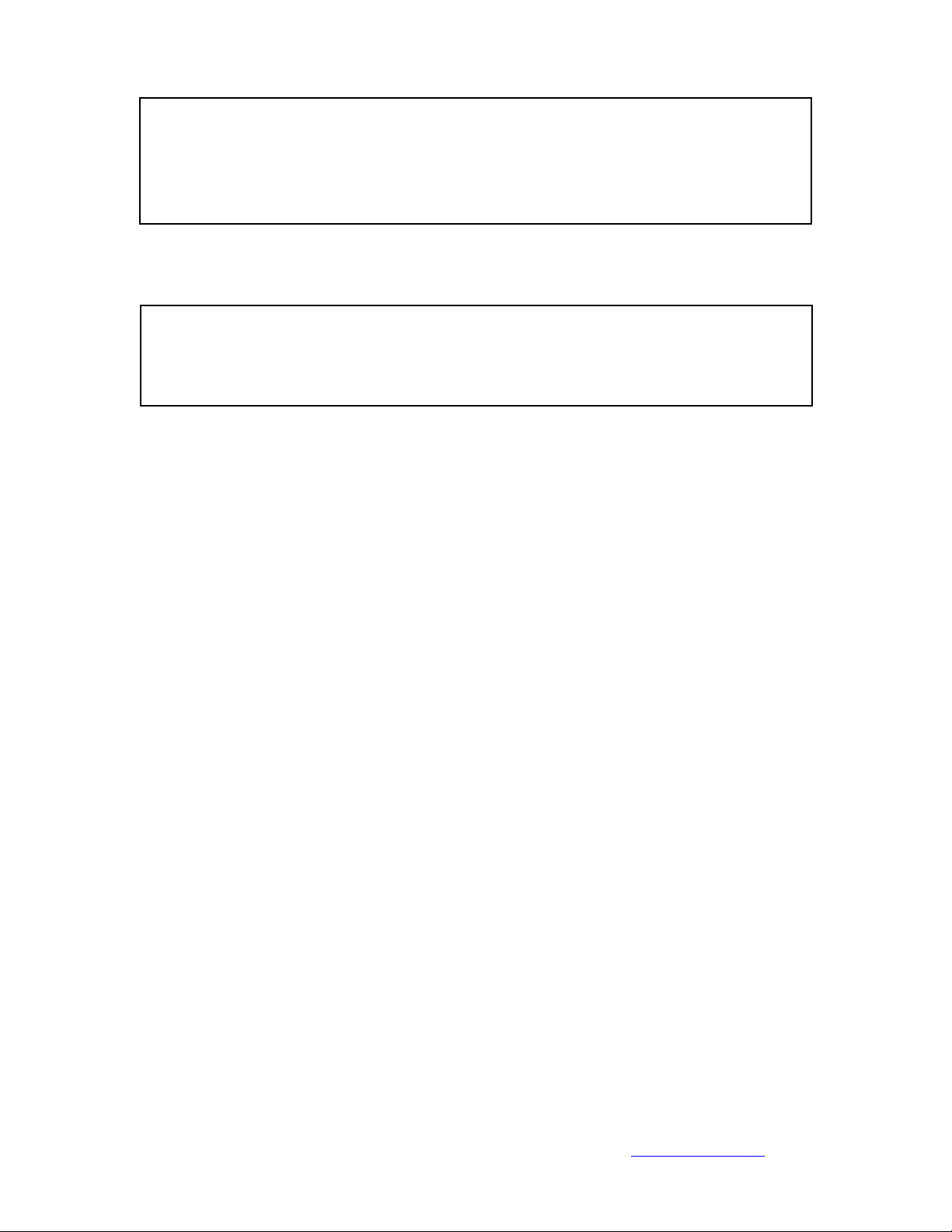

Illustration 2: Power Supply

Remove the power supply box cover.

Route the supply conduit through the knock out

located at the bottom of the box and secure it into

position.

Connect the three phase power supply to the three

pole terminal block located within the power supply

box.

Ensure that the supply ground is firmly attached to

the ground terminal.

Illustration 3: Power Connection Terminal

Ensure all connections are tight, test the circuit, then replace the cover.

1410 80 Street SW, Suite C, Everett WA 98203 Ph: 888-722-5686 www.lbcbakery.com

Page 5 of 18

Total

kW

Amps

Circuit

Size

Total

kW

Amps

Circuit

Size

Total

kW

Use only Copper Wire Rated at 85 Degrees Centigrade

The EDO deck ovens are pre-wired

internally at the factory.

To make the external connections locate

the power supply box located at the left

rear of the bottom oven deck.

Ensure there is enough slack in the

power supply to allow the oven to be

moved in and out of position for service

access.

LBC Bakery Equipment, Inc.

Amps

Circuit

Size

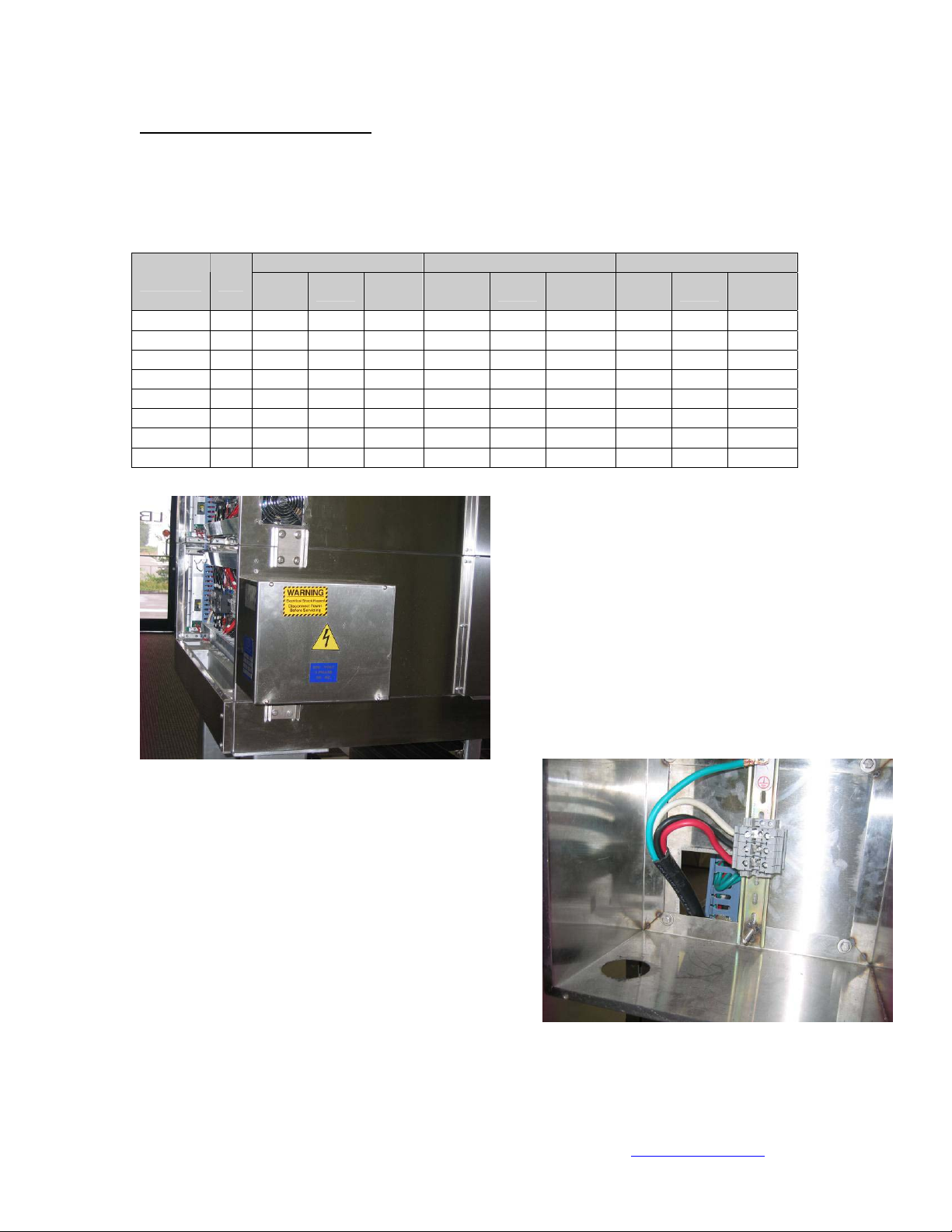

C: Water Supply

Each EDO oven deck is equipped with a “Steam Pod” located behind the access

panel at the left side of the oven. There are NO DRAINS

required for these

pods.

The water supply should be Filtered and Softened Cold Water at 15 PSI.

Exceeding 15 PSI will cause the water to overflow into the oven interior.

The EDO deck ovens are supplied from

the factory with a ½” NPT ball valve

and “Y” Trap located at the top left

side of the upper oven deck.

The water supply connection is made

at the ½” ball valve. The supply line

should be made from a suitable

flexible line to allow the oven to be

moved in and out of position.

Inspect final connections for leaks.

Illustration 4: Water Supply Connection

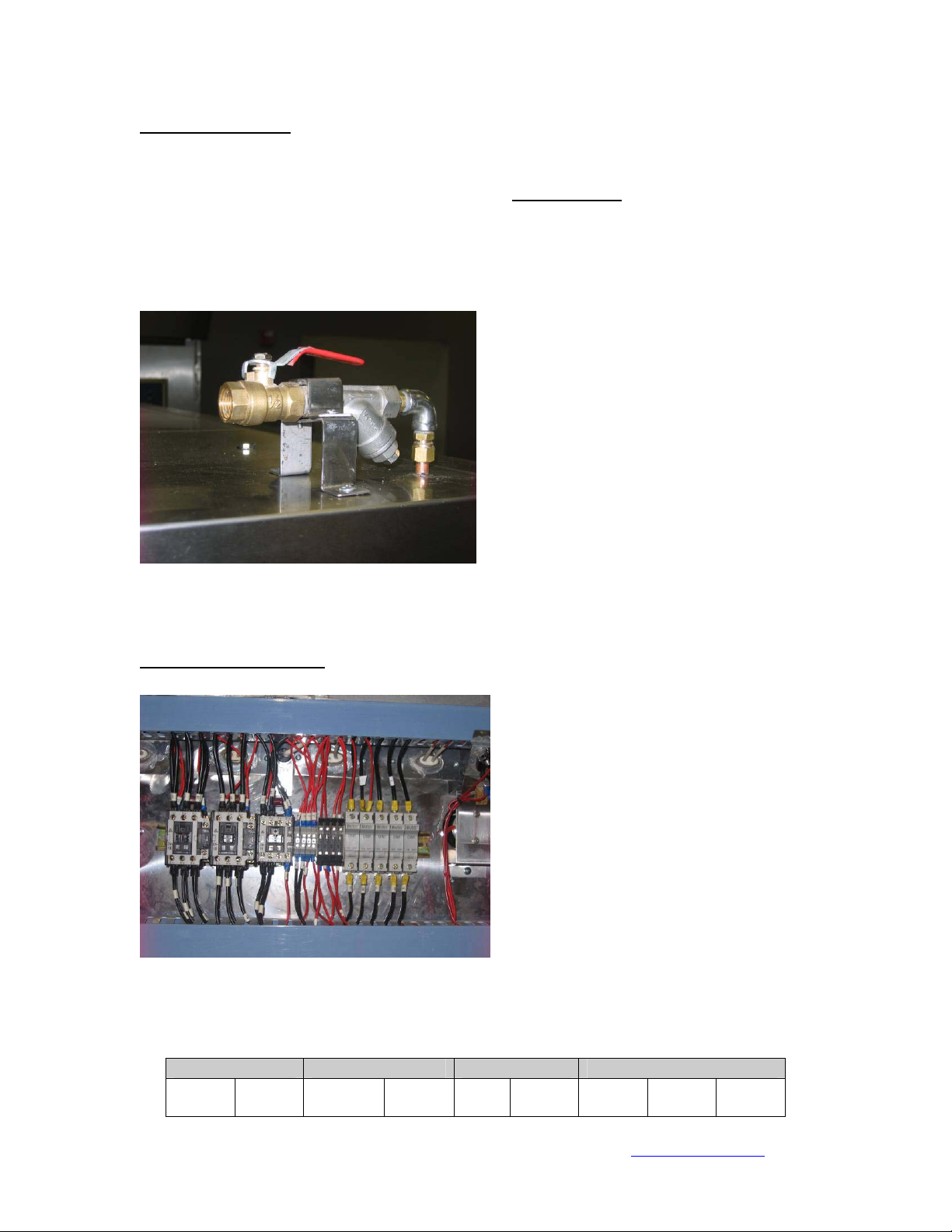

D: Testing the Oven

Remove the right side access

panel(s).

Check that the fuses are installed

within their holders.

Check for continuity at each of the

fuses (see rating chart below).

Check that the heater contactors

have not tripped.

Illustration 5: Internal Fuses and Contactors

Fuse Ratings

Controls Lamp Steam Pods Heater Elements

1 A

230V

1410 80 Street SW, Suite C, Everett WA 98203 Ph: 888-722-5686 www.lbcbakery.com

Page 6 of 18

1 A

230V

500 mA

230V

500 mA

230V

LBC Bakery Equipment, Inc.

15 A

230V

15 A

230V

30 V

230V

30 A

230V

30 A

230V

Loading...

Loading...