LBC Bakery Equipment BRD-36-3 Installation Manual

BRD 36 Part Bun and Roll Divider Rounder

Model BRD-36-3, 36 part ¾ - 3 oz

Model BRD-36-4, 36 part 1 ½ - 4 oz

Installation and Operations Manual

Rev 001 07/08

Model BRD-36-3 Shown

Table of Contents

Page 3 Warnings

Page 4 Initial Inspection and Overview

Page 5 Installation

Electrical Connections

Install Press Handle

Page 6 Adjust Knives

Page 7 Lubrication

Installers Certificate

Page 8 Blank

Page 9 - 10 Operations

Page 11 – 13 Cleaning

LBC Bakery Equipment, Inc.

1410 80 Street SW, Suite C, Everett WA 98203 Ph: 888-722-5686 www.lbcbakery.com

Page 2 of 14

DO NOT OPERATE, CLEAN OR SERVICE THIS MACHINE BEFORE

READING THIS MANUAL AND UNDERSTANDING COMPLETELY THE

SAFETY INSTRUCTIONS FOUND IN THIS MANUAL AND ON THE

CAUTION!

MACHINES LABELS

ALL OPERATORS OF THIS OVEN MUST BE OF LEGAL AGE TO

OPERATE SUCH EQUIPMENT AND MUST BE FAMILIAR WITH AND

UNDERSTAND ALL CAUTION LABELS.

IMORTANT!

DISCONNECT FROM POWER SOURCE WHEN CLEANING AND/OR

SERVICING THIS MACHINE

NEVER ATTEMPT TO CLEAN THIS MACHINE WHILE IT IS IN MOTION,

SERIOUS INJURY COULD RESULT

NEVER OPERATE THIS MACHINE WITH SAFETY COVERS OR

INSPECTION PLATES REMOVED OR WITH SAFETY SWITCHES

INOPERATIVE

The BRD Divider Rounder has been packaged to withstand rough handling; however, it

is important that you inspect the shipment for damages, concealed or otherwise and

that you sign the bill of lading to note any such damages. These damages are the

responsibility of the consignee and must be reported to the carrier within 10 days in

order to file for a claim.

Please consult our warranty at the end of this document.

LBC Bakery Equipment, Inc.

1410 80 Street SW, Suite C, Everett WA 98203 Ph: 888-722-5686 www.lbcbakery.com

Page 3 of 14

Installers Section

I:

Initial Inspection

Open the shipping crate, and locate the following items:

1. Three (3) Molding Plates

2. One (1) Pressing Handle

3. One (1) plastic bottle of hydraulic fluid (located inside the base).

NEVER operate the machine without oil in the transmission.

NEVER spray down the machine as it will result in removal of important grease

and oil.

Note the electrical ratings on the data plate; ensure the supply voltage matched

these rating.

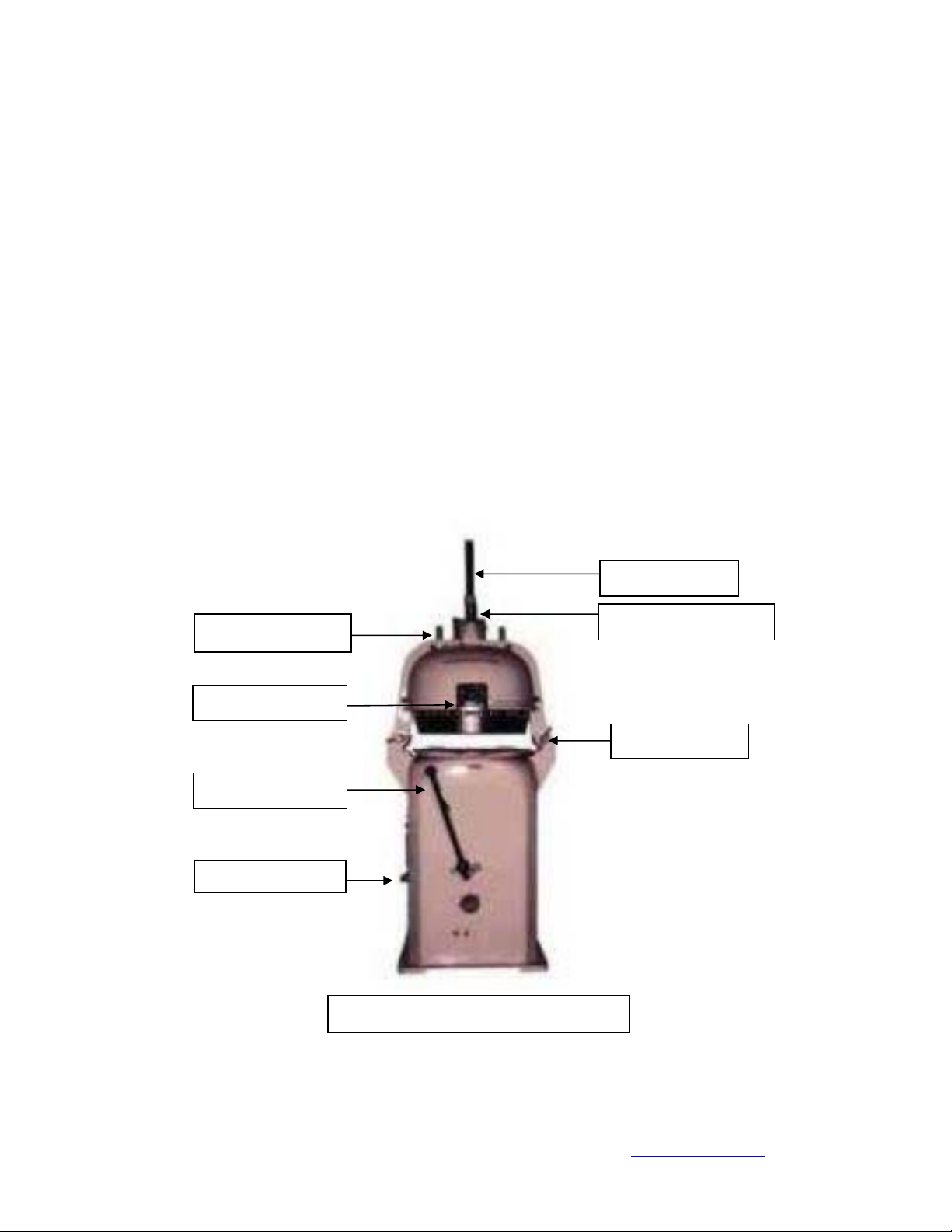

Pressing Handle

Weight Gauge

Dividing Handle

Rounding Handle

On /Off Switch

Handle Stop Bolt

Head Pin

Model BRD Over-View

LBC Bakery Equipment, Inc.

1410 80 Street SW, Suite C, Everett WA 98203 Ph: 888-722-5686 www.lbcbakery.com

Page 4 of 14

II:

Installation Section

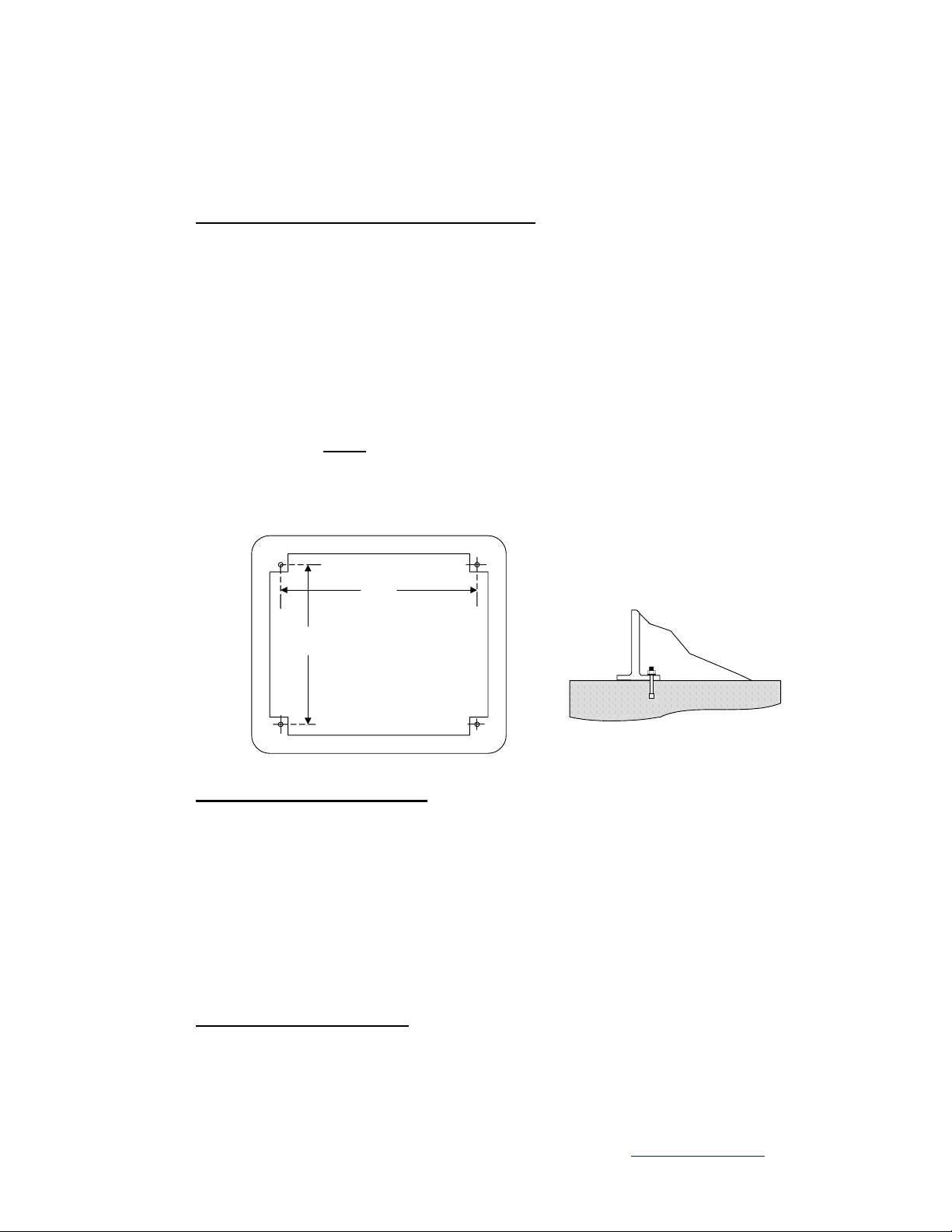

A: Selecting an Installation Location

Installation of the BRD should be made in accordance with all applicable

local codes.

The installation location should be free and clear of all obstruction.

The floor should be smooth and level and must be capable of supporting

the weight of the appliance.

Allow adequate clearance at the sides of the appliance for serviceability.

Allow adequate clearance on the right and left side for tilting of the head.

The BRD must

moving during operation.

Located on the base of the appliance are four (4) mounting holes use

appropriately sized bolts and anchors to secure the BRD to the floor.

14.5"

B: Electrical Connections

Electrical connection must comply with all applicable State and local

codes and in accordance with the NEC and NFPA.

The BRD comes from the factory with a six foot (6’) power supply cord

and plug, the plug configuration is a NEMA P15-20.

If the appliance is to be hard wired, electrical connections MUST be made

by a licensed electrician.

The BRD is rated at 208 Volts Three Phase at 15 Amps. A suitable circuit

is required.

C: Install Press Handle

Install the press handle into its slot at the top of the dividing head.

Secure it into place using the two set screws.

be anchored to the floor to prevent the appliance from

14.5"

Mounting Pattern

Cross Section View

Typical Mounting

LBC Bakery Equipment, Inc.

1410 80 Street SW, Suite C, Everett WA 98203 Ph: 888-722-5686 www.lbcbakery.com

Page 5 of 14

Loading...

Loading...