LAVAZZA Cap100US, LB5010 Instructions For Installation And Use Manual

Type Cap100US - LB5010

ENGLISHFRANÇAISESPAÑOLPORTUGUÊS

INSTRUCTIONS FOR INSTALLATION AND USE

Read these instructions carefully before using the machine

MANUEL D’INSTALLATION ET D’UTILISATION

Lire attentivement ces instructions avant d’utiliser la machine

MANUAL DE INSTALACIÓN Y DE USO

Leer atentamente las siguientes instrucciones de uso antes de utilizar la

máquina

MANUAL DE INSTALAÇÃO E USO

Ler atentamente estas instruções de uso antes de usar a máquina

ENGLISH. ..........................................3 - 29

FRANÇAIS. ...................................... 30- 56

ESPAÑOL. ......................................... 57-83

PORTUGUÊS. .................................. 84-110

••3

ENGLISH

CONTENTS

1 - MACHINE COMPOSITION ............................ 4

2 - EXPLANATORY NOTES ....................................5

2.1 Abbreviations ........................................................... 5

2.2 Editing symbols ......................................................... 5

3-

USER ........................................................................... 5

4 - MAINTENANCE TECHNICIAN..................... 5

5 - INTENDED USE OF THE MACHINE ............ 5

6 - WARNINGS AND CAUTIONS ..................... 6

7 - GENERAL PRECAUTIONS ............................... 6

8 - INFORMATION ABOUT THE MACHINE ... 6

8.1 Identification data.................................................................... 6

8.2 Technical features .................................................................... 6

8.3 Overall dimensions .................................................... 6

8.4 Brew group ............................................................... 7

8.5 Cappuccinatore Group .............................................. 7

9 - SAFETY DEVICES ................................................ 7

9.1 Residual risks ............................................................. 7

10

- INSTALLATION.................................................... 8

10.1 Notes on location ...................................................... 8

10.2 Machine positioning ................................................. 8

10.3 Water connection ..................................................... 8

10.4 Electrical connection ................................................. 9

10.5 Serial port connection ............................................... 9

11

- FIRST START-UP OF THE MACHINE ............. 9

12

- USE OF THE MACHINE ................................... 9

12.1 Machine status .......................................................... 9

12.2 Control description ................................................. 10

12.3 Menu programmable functions ................................. 12

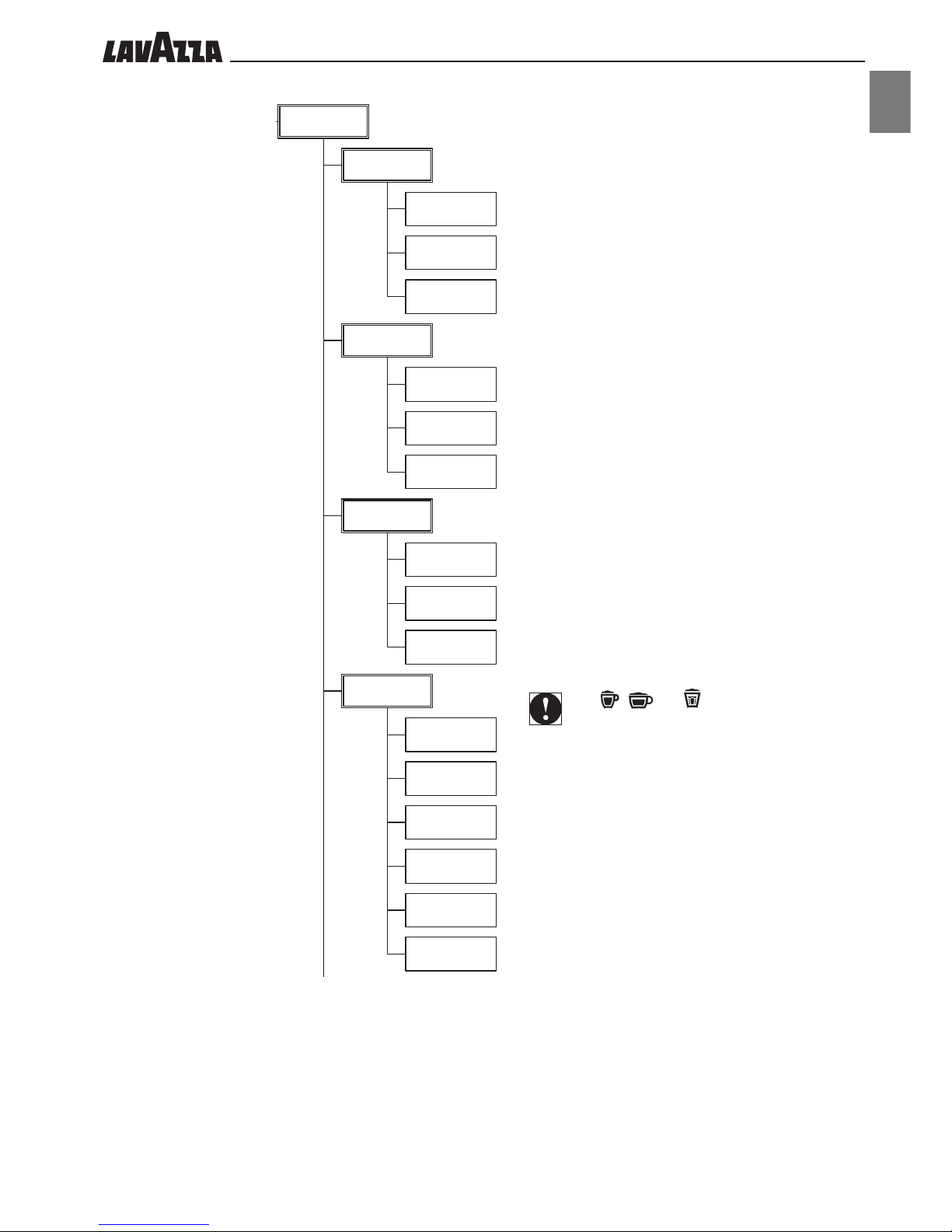

12.4 Structure of the programming menu ......................... 12

12.5 Function description ................................................ 13

12.6 Structure of the maintenance menu ........................... 18

12.7 Display messages ..................................................... 22

12.8 Turning off the machine........................................... 22

13

- SCHEDULED MAINTENANCE .................... 2 3

13.1 Cleaning the machine ............................................. 23

13.1.1 Coffee dispenser (F. 12) ........................................... 23

13.1.2 Drip tray and relative grille ...................................... 23

13.1.3 Capsule drawer ....................................................... 23

13.1.4 Steam and hot water spouts ..................................... 23

13.1.5 Cup warming plate .................................................. 23

13.1.6 Brew Group ............................................................ 23

13.1.7 Capsule discharge hopper ....................................... 23

13.1.8 Cleaning the cappuccinatore ................................... 24

13.1.9 Regeneration of the purifier ..................................... 26

14

- UNSCHEDULED MAINTENANCE.............. 2 7

14.1 Brew group ............................................................. 27

15

- INSTRUCTIONS FOR END-OF-LIFE

DISPOSAL TREATMENT ................................. 2 8

16

- TROUBLES, CAUSES AND CURES ............ 2 9

INTRODUCTION

• This manual is an integral part of the machine and must be kept in good working order, in a well-known and easily accessible place,

throughout its operational life (even in case of changes of ownership). It is intended to convey the information required to use the

machine correctly and safely.

• If this manual is lost or worn out, please ask the Authorized Customer Service Centre for a copy, specifying the model and year of

manufacture.

• Authorized Customer Service Centres are also available to provide any technical explanations, operating information, technical

assistance or spare part supply.

• The issues covered are exclusively aimed at safe use of the machine for people, the machine itself and the environment, through the

interpretation of a simple failure diagnosis and anomalous operating conditions, by performing simple test and maintenance operations, fully compliant with the requirements specified in the following pages, and with Health and Safety Regulations in force.

• Before any operation, please read this manual very carefully and make sure its contents have been fully understood.

• If the machine is used by several people (individually), each person must read the instruction manual carefully.

• The Manufacturer reserves the right to make changes and improvements to the specified models without notice.

• For special requirements please refer to the Distributor or the local Importer (if any), or the Manufacturer

• All rights of this publication are reserved to LAVAZZA. Any reproduction or disclosure in full or in part, not duly authorised in writing, is strictly

prohibited. INDEX

••4

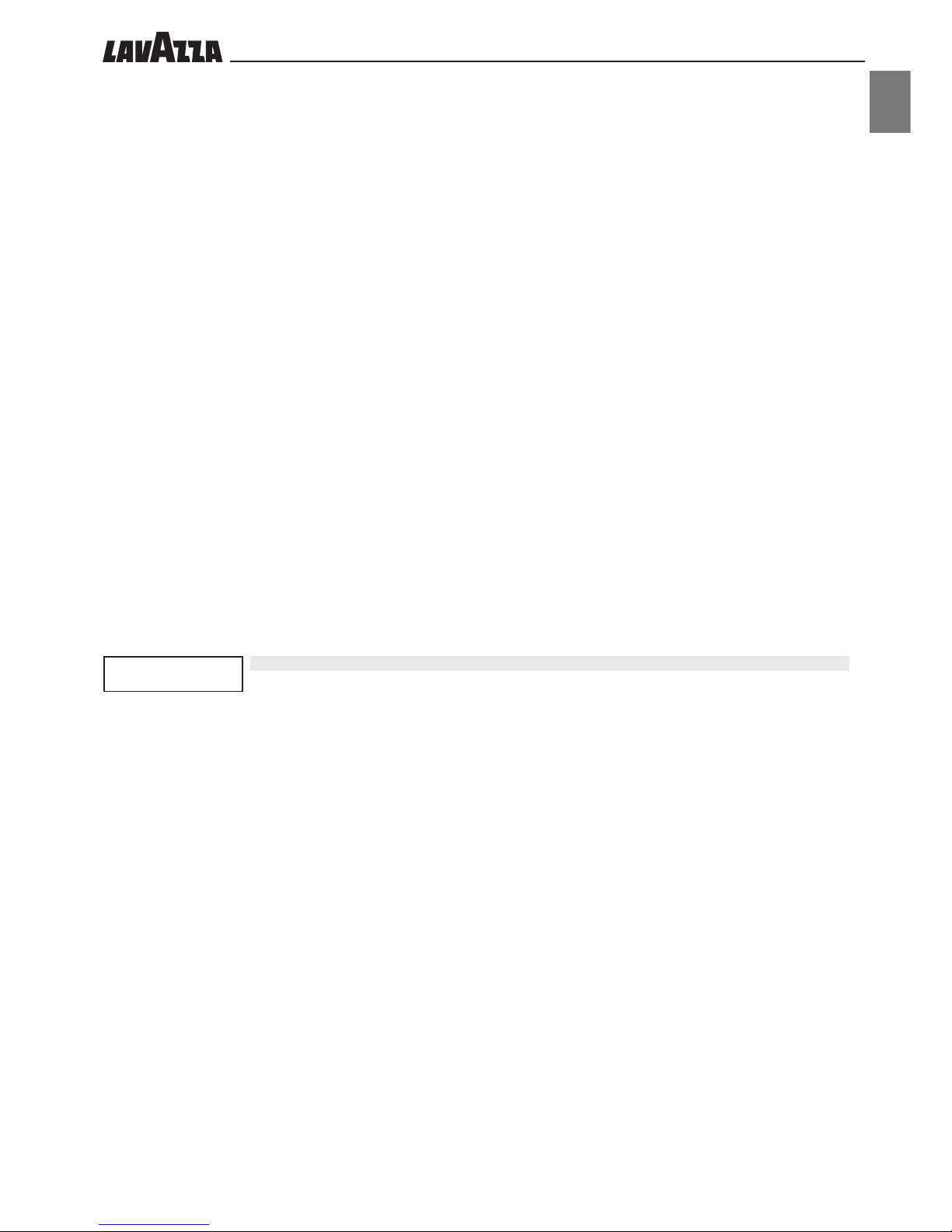

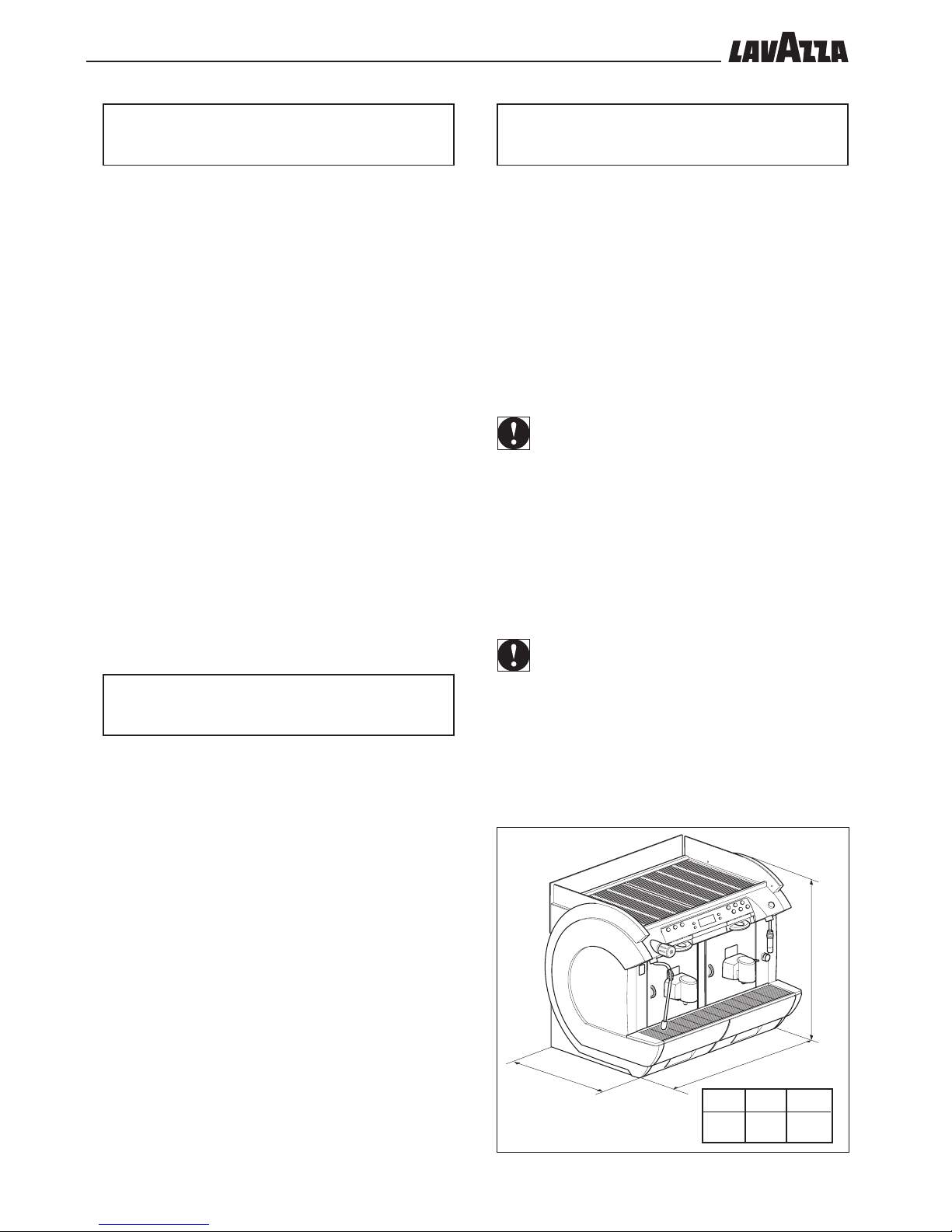

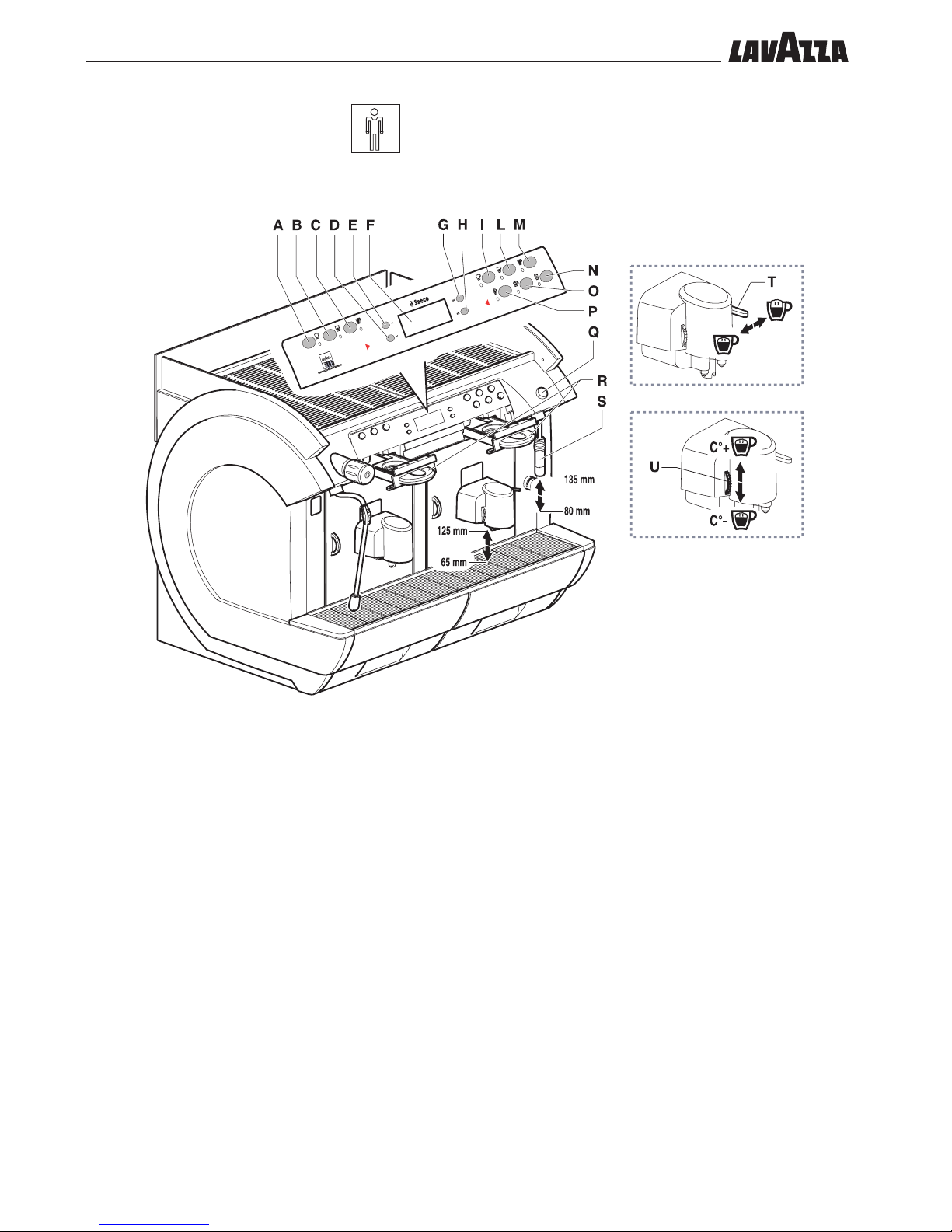

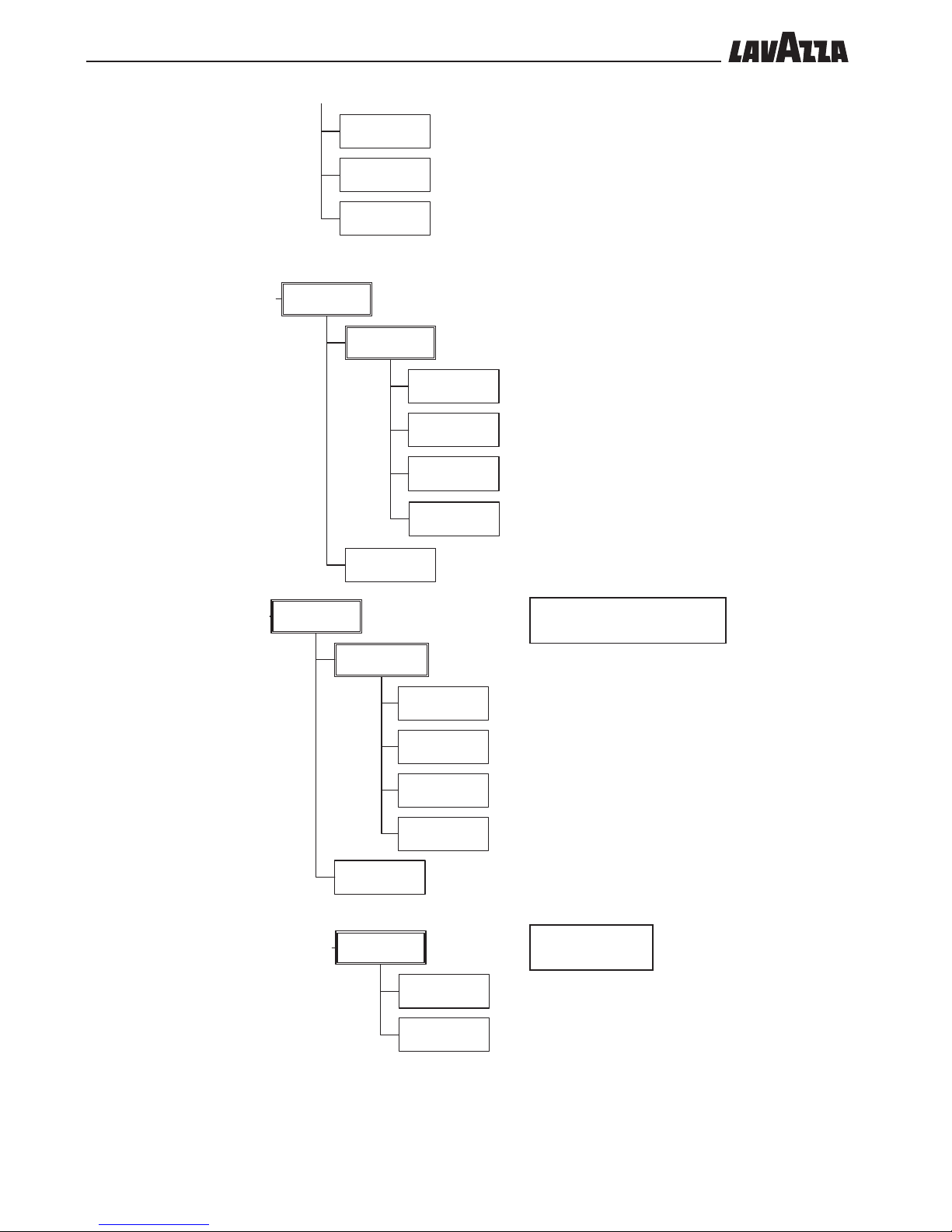

F. 1

1 - MACHINE COMPOSITION

NOTE - If not expressly indicated in the text, the position numbers of machine parts refer to the following figure.

A Data plate

B System information plate

1 Left hand side panel

2 Glass

3 Rear panel

4 Cup warming plate

5 Steam knob

Clockwise: steam jet open

Counterclockwise: steam jet closed

6 Capsule drawer

7 Control panel

8 Capsule insertion drawer

9 Hot water button

10 Right hand side panel

11 Door

12 Rubber protector

13 Hot water spout

14 Spout clamp

15 Drip tray

16 Capsule drawer

17 Rubber protector

18 Capsule drawer

19 Steam spout

20 Door

21 Main switch

“I” - Enabled electric functions – Machine on –

LED illuminated.

“O” - Disabled electric functions – Machine off –

Button “I” LED turned off.

22 Coffee brew group

23 Brew group cover

24 Milk foam control

25 Temperature adjusting knob

26 Milk dispenser

27 Brew group

28 Capsule discharge hopper

••5

ENGLISH

2 - EXPLANATORY NOTES

2.1 Abbreviations

F. = Figure

P. = Page

Sect. = Section

T. = Table

2.2 Editing symbols

WARNING!

Please pay close attention to the symbols: they are not designed

so that technical concepts or safety warnings do not have to be

repeated. They should thus be considered as memory prompts.

Please read the list of symbols whenever in doubt about their

meaning.

WARNING! - Information regarding user safety and machine integrity.

IMPORTANT! - Draws attention to particularly important issues.

Maintenance technician – Operations to

be performed exclusively by personnel in charge of unscheduled maintenance and repairs.

Machine off – Operations to be performed with power supply cut off.

User – Operations to be performed by the

user of the machine.

3 - USER

Adult person who is exclusively in charge of the following operations:

- Use, control and turning off of the machine.

- Brewing parameters setting.

- Emptying the ground and liquid trays.

- External cleaning of the machine.

WARNING

Children, teenagers and people unable to care for

themselves are prohibited from using this machine .

4 - MAINTENANCE

TECHNICIAN

Person in charge of the following operations:

- Installation, start-up, adjustment and setting up of the machine.

- Unscheduled maintenance, repairs and replacement of spare

parts.

5 - INTENDED USE OF THE

MACHINE

The machines in this manual have been designed, manufactured

and protected for automatic dispensing (programmable) of the

following beverages:

- coffee based capsules;

- milk and coffee based capsules.

- hot water and water steam for the preparation and heating of

beverages.

- hot milk.

IMPORTANT

Any other use of the machines is not foreseen by the

Manufacturer who is exempted from any liability for any

damage caused by their improper use. The improper use

also causes any type of warranty to expire.

••6

LPh

745 550 625

F. 2

L

P

h

6 - WARNINGS AND

CAUTIONS

Do not use detergents, thinners, solvents etc. for scheduled maintenance.

Cleaning is limited to non-live parts and must be performed by using

neutral or biodegradable products, or with the power cable unplugged.

Scheduled maintenance must be performed by qualified personnel or at least by suitably informed and trained personnel, with the necessary mental and physical requirements, and in full compliance with the

instructions indicated below and with the Safety and Health Regulations

in force.

It is strictly forbidden to place and/or leave tools or anything else

on the machine which may be detrimental to people’s safety or the

integrity of the machine.

Changes and tampering (even slight), as well as the use of non

original spare parts, exempt the Manufacturer from any liability for damages of any kind and cause the warranty to expire.

Use drinking water only.

N.B.: Do not use hot water.

It is essential to supply the machine with water treated by a descaling

device, which guarantees the compliance with the abovementioned

limitations. Make sure the water network provides drinking water, with

pressure ranging between 1 and 8 Bars.

7 - GENERAL PRECAUTIONS

• Before using the appliance, always make sure that the con-

tents of this manual have been thoroughly understood beforehand. Failure to comply with the instructions in this manual

exempts the Manufacturer from any liability for damages of

any kind caused to persons and/or property.

• Keep this edition for future reference.

• If installing for the first time, check beforehand for complian-

ce with the minimal safety regulations, placing and operability

of the machine, by taking note of environmental conditions

(temperature, humidity, light) and the suitability of the working

space.

• Any damage to the power cable requires Authorized Techni-

cal Assistance or a maintenance technician.

• Do not use the machine outdoors.

• In the event of failure, always ask the maintenance techni-

cian for assistance.

• Do not use water jets to clean the machine.

8 - INFORMATION ABOUT

THE MACHINE

8.1 Identification data

Plate (A) displays the following machine identification data:

• Manufacturer and marking

• model

• Serial no.

• year of manufacture

• supply voltage (V) and frequency (Hz)

• power consumption (W)

• number of phases of the electrical power line

• permitted pressure in the water network (MPa)

IMPORTANT

When contacting the Authorized Customer Service Centres,

please indicate model and serial number of the machine.

8.2 Technical features

Power supply voltage .................... 240V 60Hz

Power cable length ....................... mm 1.700

Installed power .......................... 5500 W

Water pressure .........................MPa0.1÷0.8 (1÷8 bar)

Weight ....................................kg 66

IMPORTANT

The machines are programmable for any type of dispensing

dosage. Most of the electrical components are supplied with

24 VDc.

8.3 Overall dimensions

••7

ENGLISH

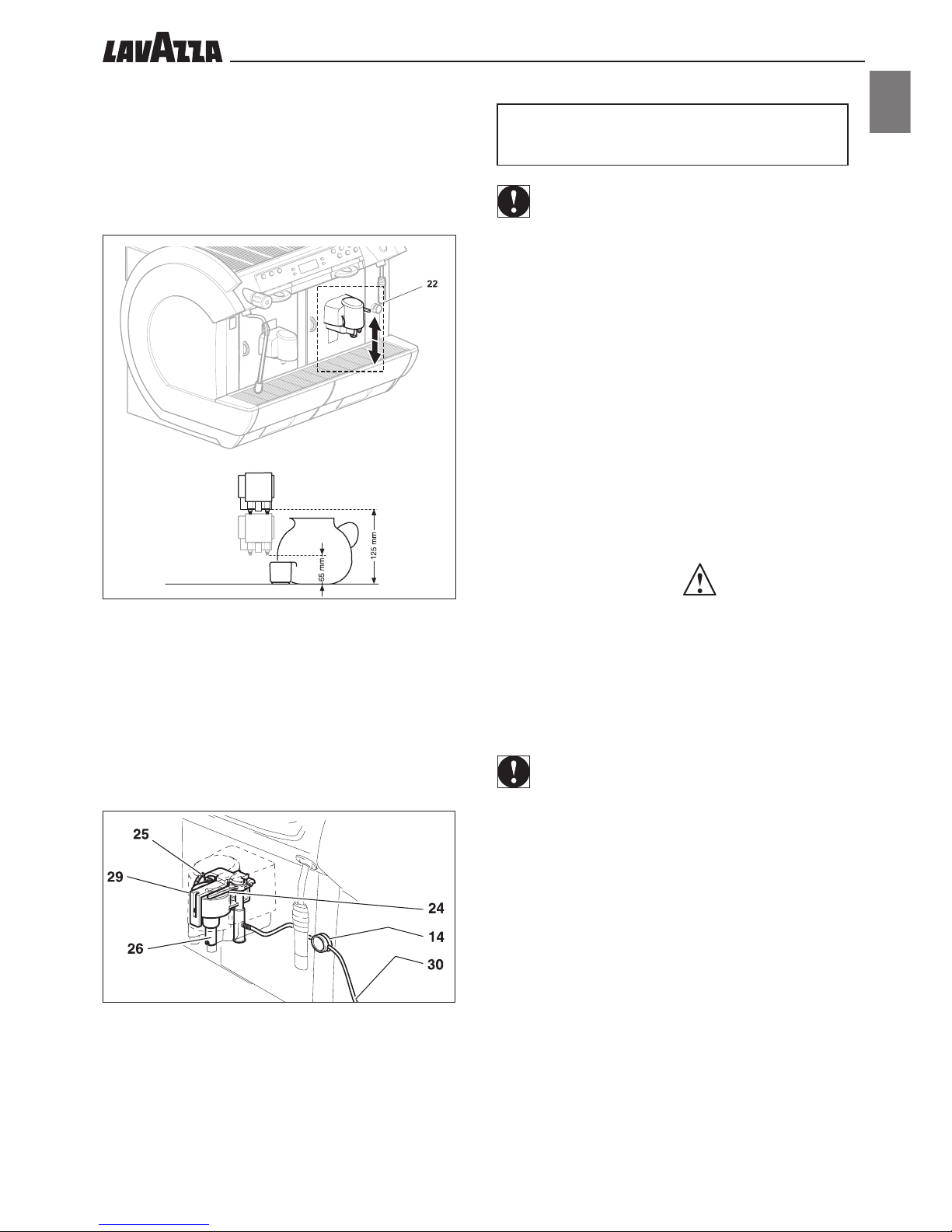

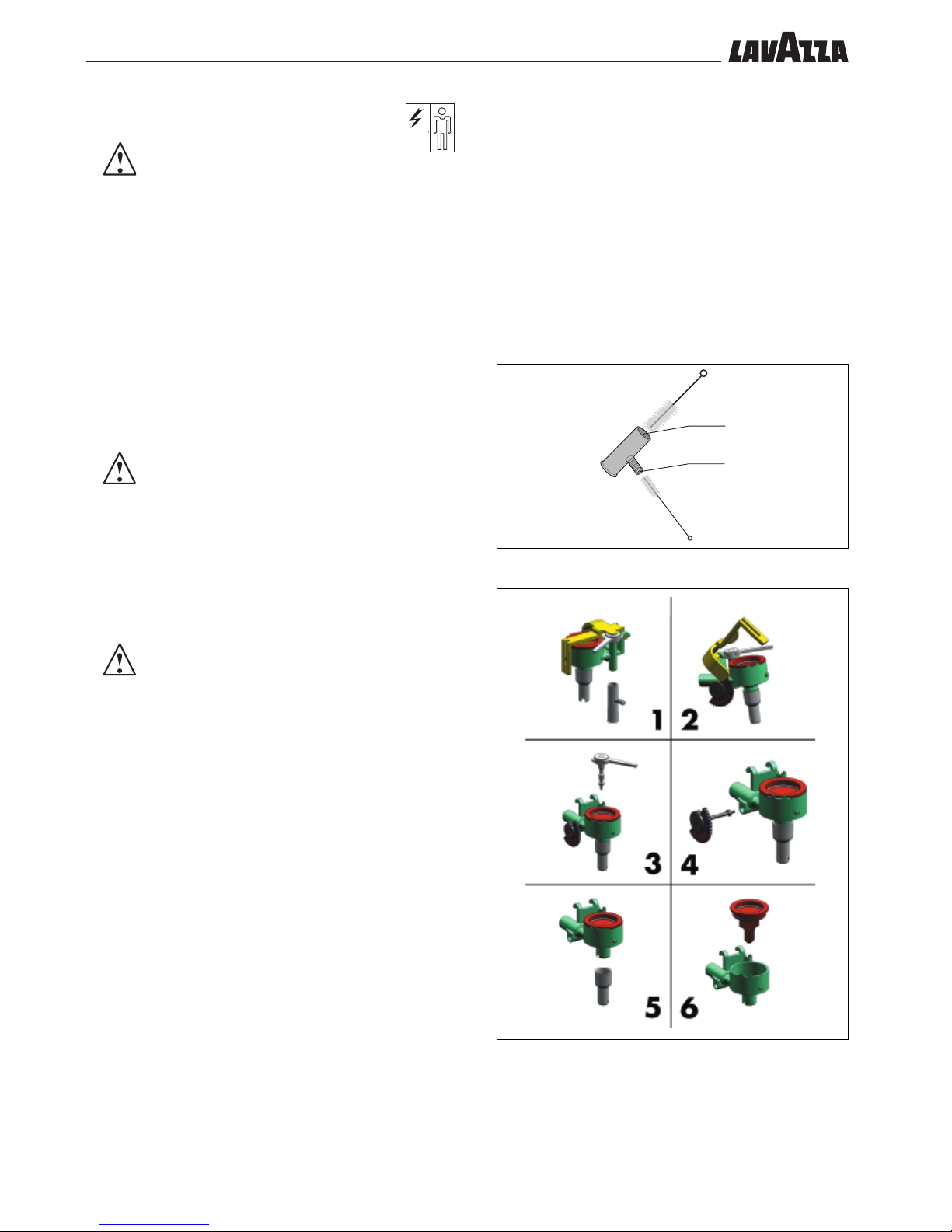

F. 3

F. 4

8.4 Brew group

The position of this group (22) can be changed according to the height

of the container used.

It is possible to position the brew group at the top or at the

bottom.

Different brewing heights can therefore be obtained.

8.5 Cappuccinatore Group

The cappuccinatore group is composed of:

- milk suction pipe (30);

- spout clamp (14);

- cappuccinatore (29);

- cream quality control (24);

- temperature setting lever (25);

- Milk dispenser (26).

The milk used for the CAPPUCCINATORE must be kept in a fridge at a

temperature no higher than 4° C; do not leave it outside the fridge for

more than 30 minutes.

9 - SAFETY DEVICES

IMPORTANT

The machines in this manual are manufactured in

compliance with the relevant Directives in force and are

therefore protected as to all parts which may be potentially

dangerous.

Any overpressure of the water system which controls the

production of steam and hot water is detected by 3 safety valves.

A thermostat prevents the boilers from overheating.

The position of the capsule drawer (16 and 18) and of the

door (11 and 20), is controlled by 2 microswitches which stop

the machine if one of the components is not properly in place;

(the display will show the component out of place).

An electronic pulse counter saves the number of beverages

produced and enables planning of the scheduled maintenance.

The steam (19) and hot water (13) spouts are equipped

with suitable rubber protectors (12 and 17) so they can be held

and directed even if hot.

9.1 Residual risks

The manufacturing characteristics of the machines in this publication do not protect the user from steam or hot water jets.

Danger of burns – When dispensing hot water or steam,

do not direct the jets towards other people or yourselves. Only

hold the pipe on the appropriate anti-burning protections (12

and 17).

IMPORTANT

Do not use containers not made of “food-safe” materials.

••8

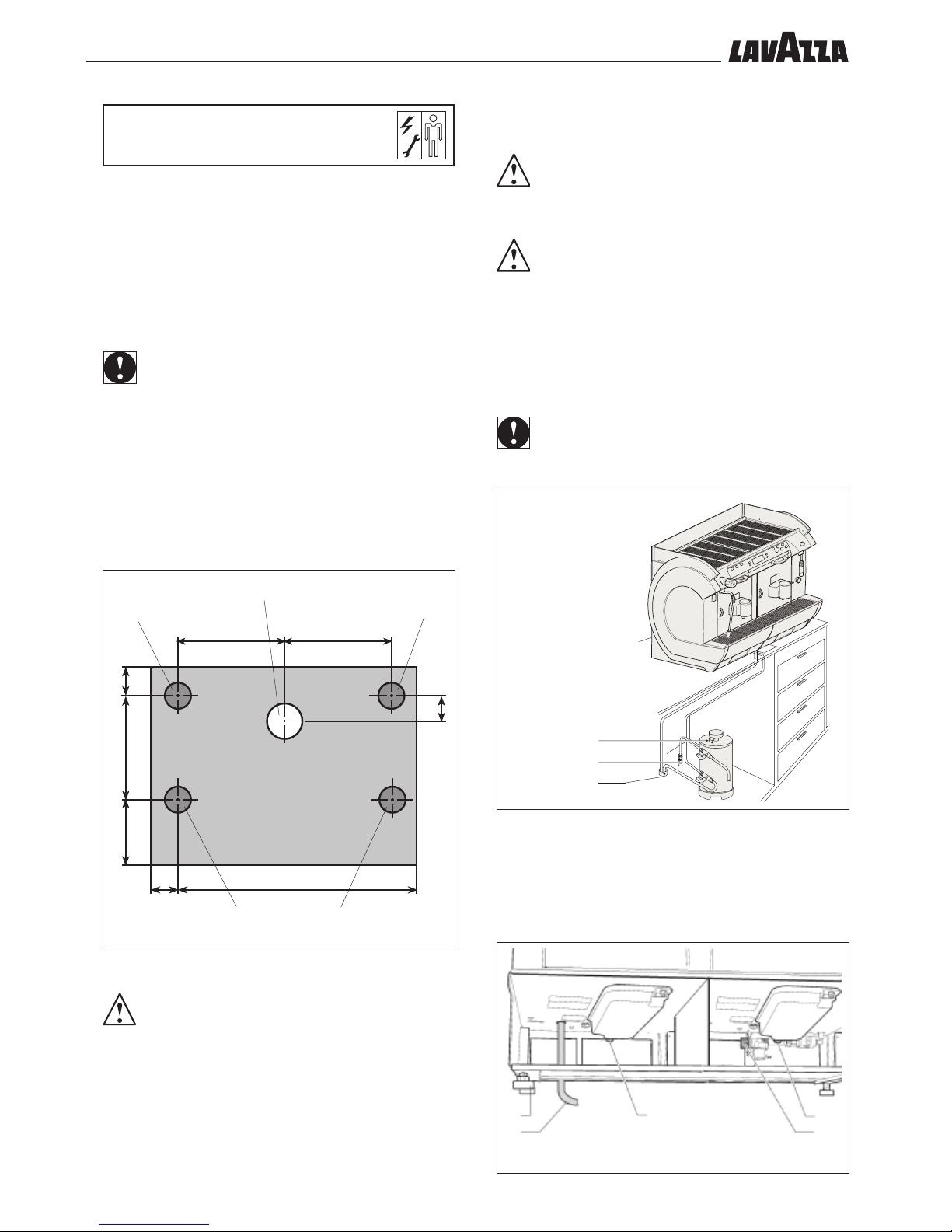

75 667

296 296

80288183

70

F. 5

A

B

B

B

B

F. 7

G

F

H

I

F. 6

C

D

E

H

10 - INSTALLATION

10.1 Notes on location

The machine must be installed in a dry and sheltered area, with:

- ambient temperature: +10° C + 25° C

- maximum humidity: 65%.

10.2 Machine positioning

IMPORTANT

Check that the installation surface is large and solid enough to

support the machine safely.

Make a Ø 100 mm hole (A - F. 5) on the supporting surface.

Place the machine in a steady position on the supporting surface (the

circles B – F. 5 indicate the optimal position of the adjustable feet).

Level the machine using the adjustable feet (F – F. 7).

10.3 Water connection

WARNING

Water and waste connections shall complhy with applicable

federal states, or local codes.

WARNING

Water hardness should never be above 8°F.

It is essential to supply the machine with water treated by a descaling

device, which guarantees compliance with the abovementioned limitations. Make sure the water network provides drinking water, with pressure ranging between 1 and 8 Bars.

- Connect the purifier (C) to the water network (D).

IMPORTANT

Before connecting the purifier to the machine, perform a washing

cycle until the water is clear; then proceed with the connection

of the purifier to the machine.

C – PURIFIER

D – WATER NETWORK

E - DRAIN CHANNEL

Connect a drain hose to the coupling (H – F. 7) and fasten it using the

hose clamp.

Using only using a hose and couplings made of “food-safe” materials,

connect the machine to the drinking water network, by means of the

coupling (I – F. 7).

Insert the outlet and filling pipes into the hole A.

WARNING /IMPORTANT

For a correct and ergonomic use of the machine, it is

recommended to install it onto a surface which is at least 1 m

high.

••9

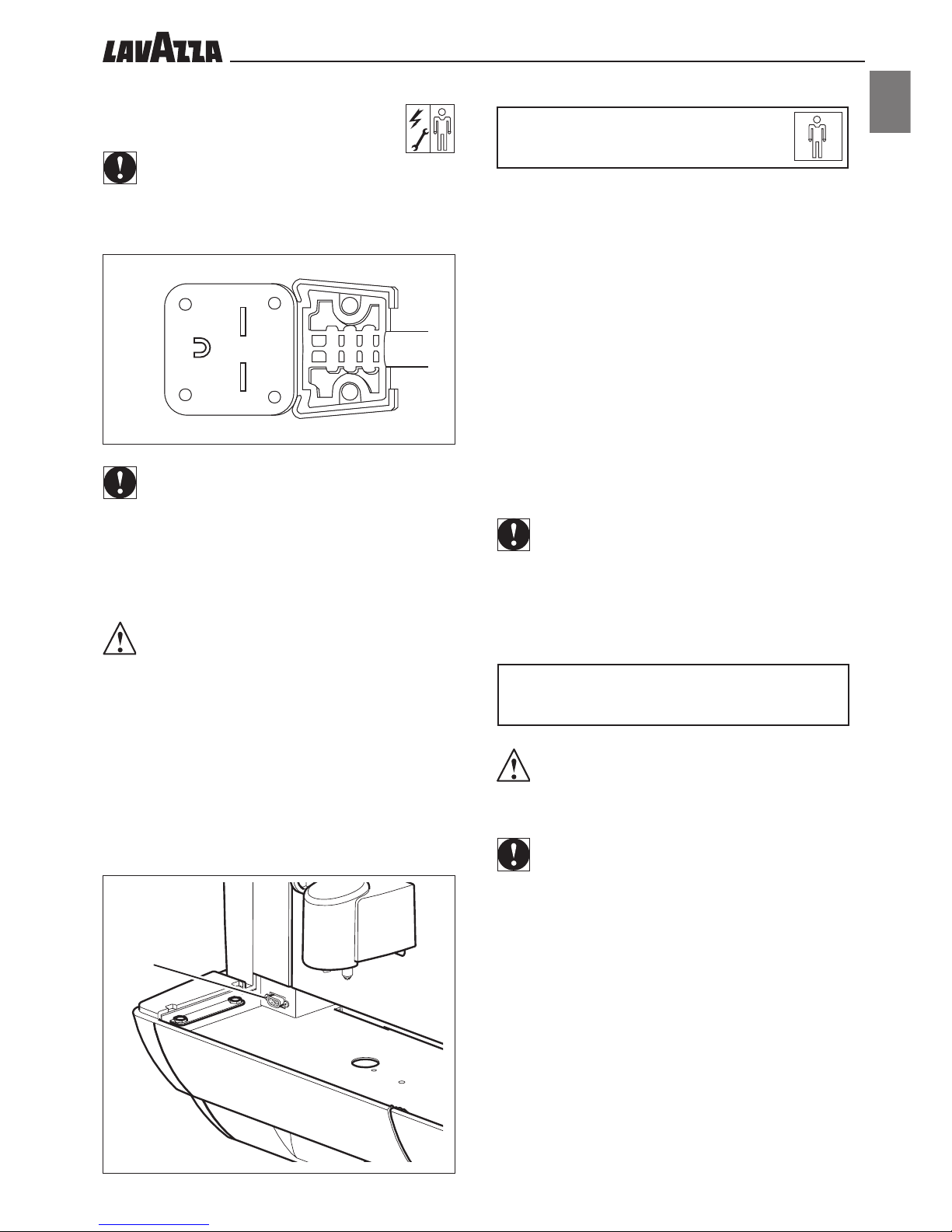

ENGLISH

F. 9

L

10.4 Electrical connection

IMPORTANT

The machine must be connected to a system-mono phase 240V

60Hz.

Insert the power cable (G – F.7) into hole A (F. 5).

According to the laws in force in the country of use of the machine,

the power cable must be equipped with an all-polar switch (with

minimum distance of 3 mm between contacts).

• The all-polar switch must be suitable to the machine supply

voltage and able to monitor all voltage polarities.

• Check that the size of the cables is suitable for the machine’s

absorption.

The connection point (socket or all-polar switch) must be located

in an easily accessible place for the user to be able to disconnect

the machine from the power supply line, if necessary.

Connect the cable (G - F. 7) to the power supply line.

10.5 Serial port connection

By means of the serial port RS 232 the machine may be connected to a

Personal Computer or devices supplied to the AUTHORIZED CUSTOMER SERVICE CENTRES for programming operations (L - F. 9).

11 - FIRST START-UP

OF THE MACHINE

Check that the removable parts (15,16 and 18) are present and that

the doors (11 and 20) are closed.

Otherwise, the message indicating the part out of place will appear on the display when the machine is turned on.

- Turn on the machine by means of the relevant switch (21);

- Open the capsule insertion box (6 and 8).

- Insert the capsule in the relevant seat as shown in figure F. 11

- Place the dispenser (22) so that a suitable height can be obtai-

ned for the containers used (Pr. 8.4).

- Place a container below the dispenser.

- Press the button corresponding to the type of beverage chosen.

IMPORTANT

Even though all the buttons have been already programmed to

standard values, it is necessary to check that the quantity of the

beverage dispensed corresponds to the one chosen. Otherwise

the dispensing buttons must be programmed (Pr. 12.6)

12 - USE OF THE MACHINE

WARNING

It is important to have read this manual carefully before use, to

ensure sufficient knowledge of the machine.

IMPORTANT

After a long period of disuse, the previous section “First

start-up of the machine” must be read before

the machine is used.

12.1 Machine status

Depending on the power supply, the machine may be in the following

conditions:

Off and electrically insulated

- Main switch (21) set in “0” position (or machine unplugged).

- Only the settings memory is active.

On

- Main switch (21) (or machine plugged).

- All functions are active and the display is on.

F. 8

••10

F. 10

12.2 Control description

A “Strong coffee” key

B “Medium coffee” key

C “Long coffee” key

D “Down” key

E “Up” key

F Display

G “Esc” key

H “Ent” key

I “Strong coffee” key

L “Medium coffee” key

M “Long coffee” key

N “Hot milk” key

O “Cappuccino” key

P “Espresso macchiato” key

Q “Hot water” key

R Capsule insertion drawer

S Hot water spout

T Milk foam control

U Milk temperature adjusting knob

••11

ENGLISH

A , I

B , L

C, M

P

O

N

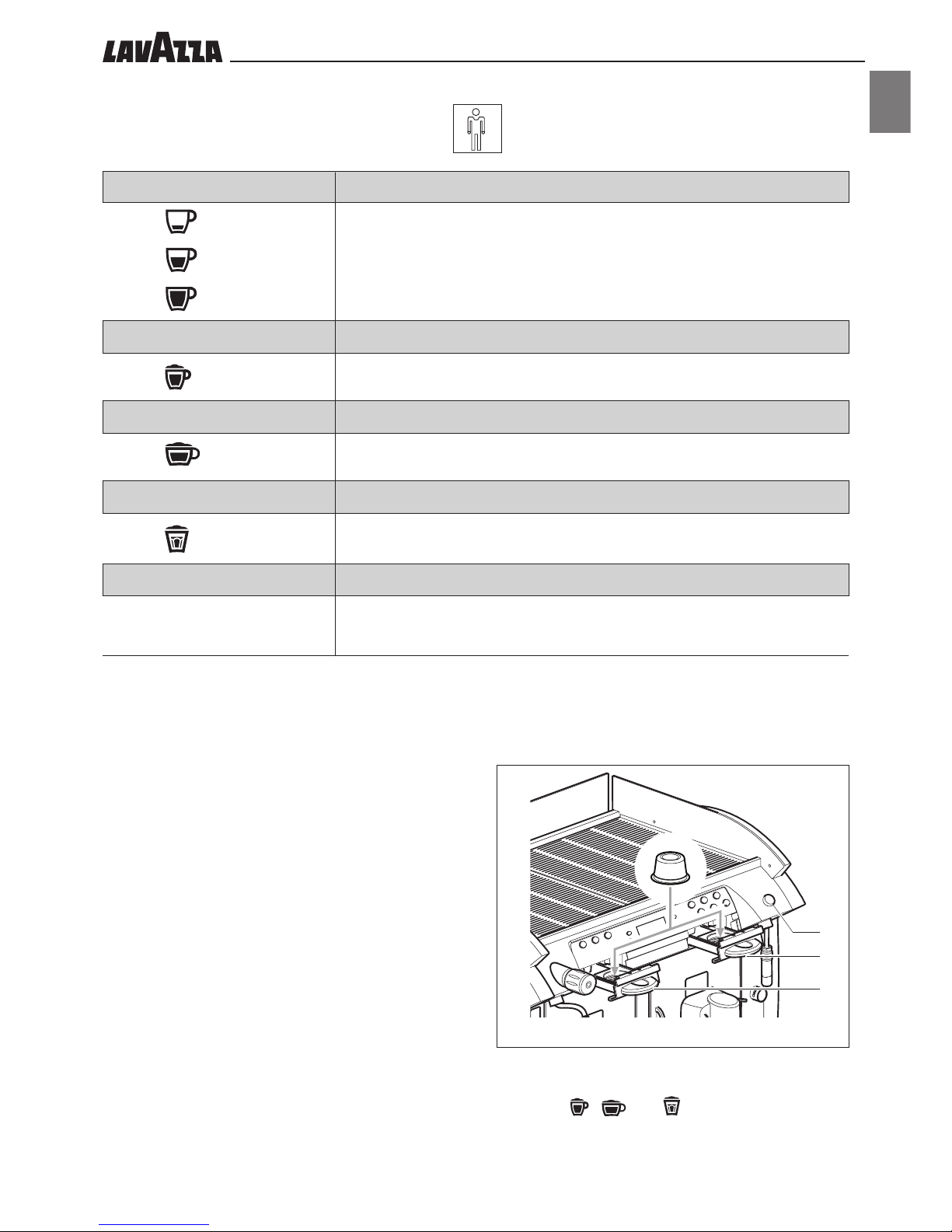

F. 11

6

8

L

Q

COFFEE

• Definitions: “Strong coffee” – “Medium coffee” – “Long coffee”, indicate three

different dispensing levels.

• On delivery the machines are set to default values.

(**)

ESPRESSO MACCHIATO

• Beverage composed of coffee with a dash of milk.

(*) , (**) , (***)

CAPPUCCINO

• Beverage composed of coffee and hot milk.

(*) , (***) , (***)

HOT MILK

• Beverage composed of milk only

(*) , (***)

HOT WATER

• Dispensing obtained using water

(*)

Milk foam adjustment

The quality of cream in the beverages depends on the use of the

adjustment lever (T).

• By turning the lever to the right, a greater quantity of cream can

be obtained.

• By turning the lever to the left, there will be a smaller quantity of

cream.

Milk temperature setting

The milk temperature is adjusted through the lever (U).

• By turning the lever upward, the temperature will increase.

• By turning the lever downward, the temperature will decrease.

(**)

Inserting the capsules

• Open the capsule box (6 and 8).

• Insert the capsule in the relevant seat as shown in figure F. 11

(***)

NB:.: Keys , and can be preset for brewing

beverages with any possible combination of milk and coffee.

Please refer to an authorized customer service centre to change

the default settings.

strong

medium

long

••12

p1. Products

p1.1. Global................................................ 40

p1.1.1. AutoProgram ........................... 40

p1.1.2. Prebrewing.............................. 40

p1.1.3. Milk Drainage ......................... 40

p1.1.4. Milk Cleaning .......................... 40

p1.2. Details ................................................ 41

p1.2.1. Left products ........................... 41

p1.2.2. Right products ..................... 42-43

p1.2.3. HotWater ............................... 43

p2. System

p2.1. Temperature ........................................ 43

p2.1.1. Delta Temperature .................... 43

p2.1.2. Coffee Heater*

p2.2. Security .............................................. 44

p2.2.1. Operator Password .................. 44

p2.2.2. Technical Password*

p2.3. Options .............................................. 44

p2.3.1. Cup Heater............................. 44

p2.3.2. Antifreezing*

p2.3.3. Unit Visible*

p2.3.4. Buzzer*

p2.4. Date/Time .......................................... 44

p2.4.1. Date ...................................... 44

p2.4.2. Date Format ............................ 44

p2.4.3. Time ....................................... 44

p2.4.4. Time format ............................. 44

p3 Factory Default . ........................................ 44

s1. Maintenance

s1.1. Water filter.......................................... 45

s1.1.1. New filter date ......................... 45

s1.1.2. Liters to Renew ......................... 45

s1.1.3. Filter limit ................................. 45

s1.1.4. Reset filter ................................ 45

s1.1.5. Filter enable ............................. 45

s1.2. Drillers ................................................ 45

s1.2.1. Warning enabled ..................... 45

s1.2.2. Left drillers states ...................... 45

s1.2.3. Right drillers states .................... 45

s1.3. Test mode*

s1.3.1. Master test*

s1.3.2. Left Coffee test*

s1.3.3. Right Coffee test*

s1.3.4. Water/Steam test*

s2. System Info

s2.1. Identification ....................................... 47

s2.1.1. Software Version ...................... 47

s2.1.2. Machine Code ........................ 47

s2.2. Error Log ............................................. 47

s2.2.1. Errors ...................................... 47

s2.2.2. Reset log*

s2.3. Audit.................................................. 48

s2.3.1. Counters from init ..................... 48

s2.3.2. Counters from reset ................... 48

s2.3.3. Reset Audit

.............................. 48

s3. Install/Uninstall

s3.1. Install*

s3.1.1. Language*

s3.1.2. Machine Code*

s3.1.3. Display Contrast*

s3.2. Uninstall*

s3.2.1. Empty Boiler*

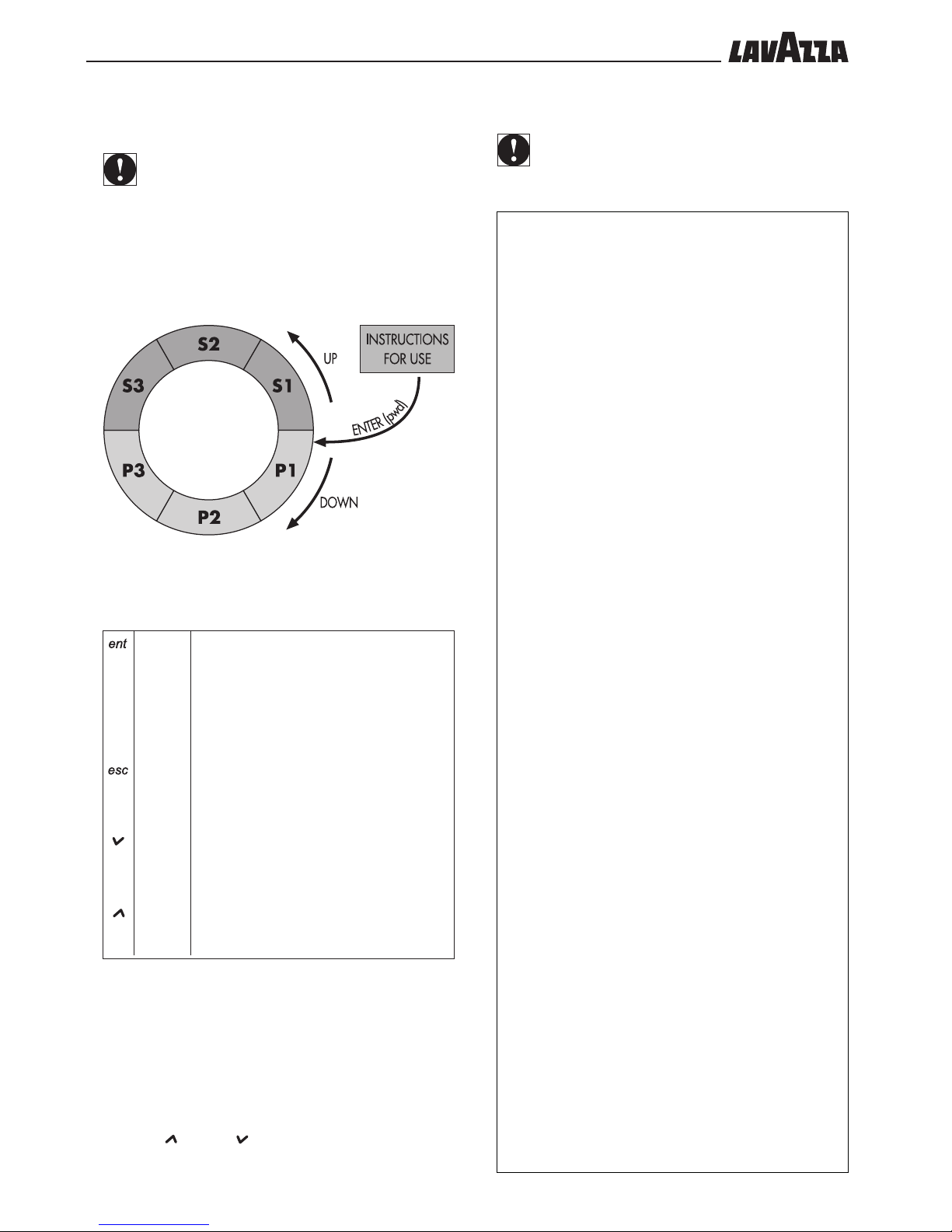

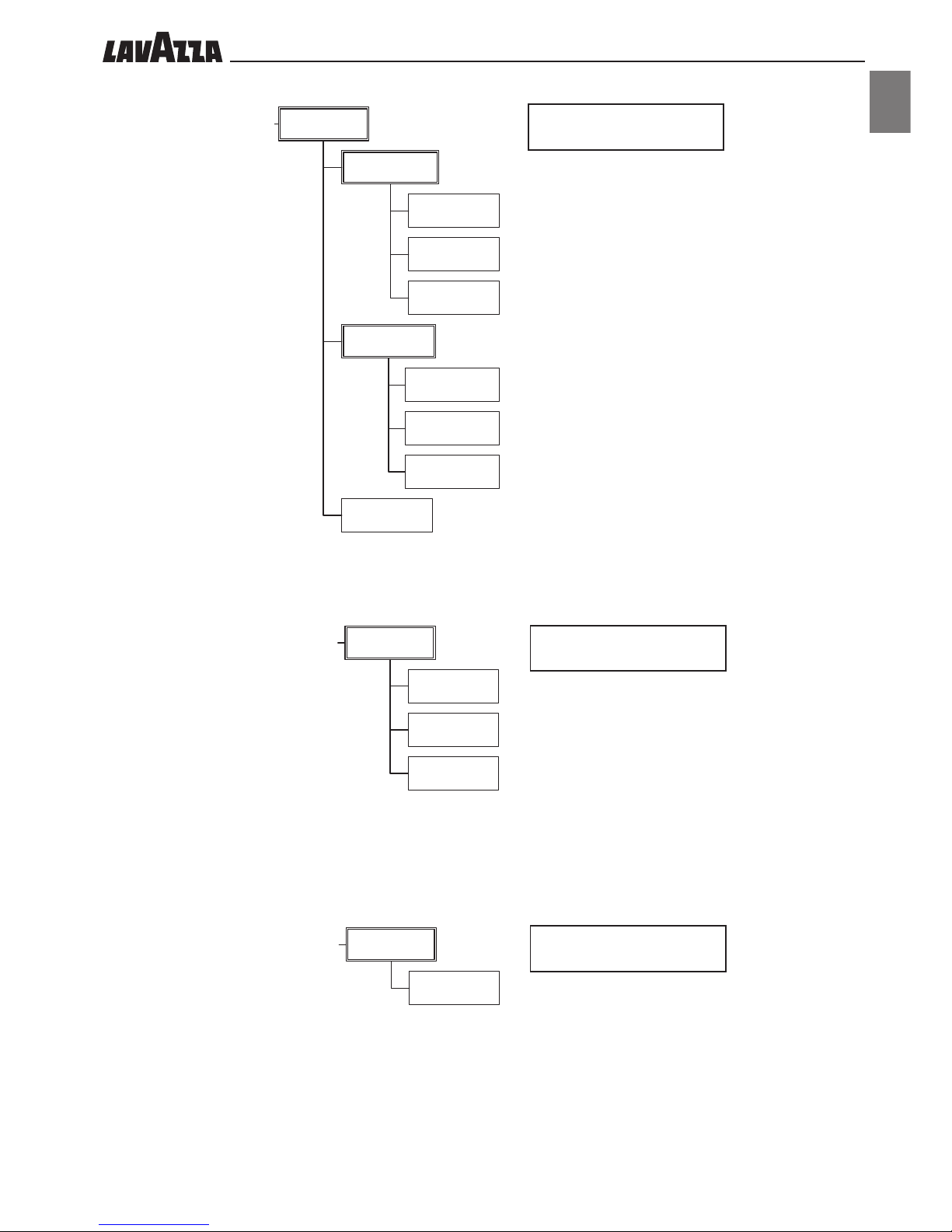

12.3 Menu programmable functions

IMPORTANT

The machine allows some adjustments and settings through

the menu settings, which adapt the dispensed product to

the User requirements

To easily access the programming menu, please see the figure

below:

(Enter) to access the programming menu (the following will

appear on the display: “PASSWORD”);

to move from one menu level to the next; prepare data to be changed; confirm data or a

function;

(Escape) to cancel the changes not confirmed;

to go back up to the previous menu level until

the menu is exited.

(Down) to move to the next item within the same pro-

gramming level;

to increase the value of data to be changed.

(Up) to move to the previous item within the same

programming level;

to reduce the value of data to be changed.

Some functions require the setting of one or more parameters

(already set to standard values).

To operate on data values to be re-set, the following is necessary:

- Select function.

- Confirm function using the “ENT” (Enter) key.

- The flashing cursor appears under the value to be changed.

- Use the “ ” (Up) or “ ”(Down) keys to change its value.

- Confirm changed data using the “ENT” (Enter) key.

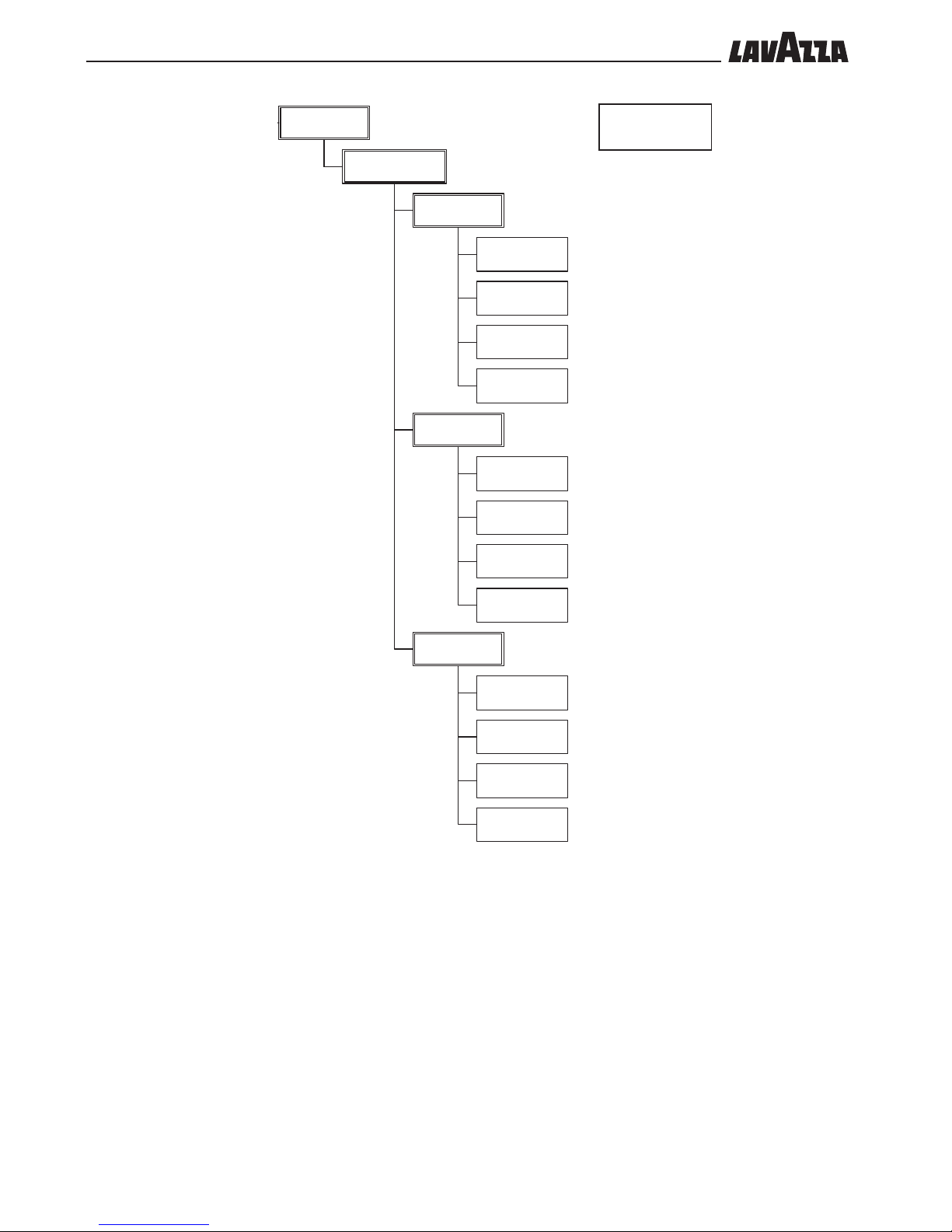

12.4

Structure of the programming menu

IMPORTANT

During programming, the menu items marked with an *

can be viewed (and therefore programmable) only with

the “Technician Password”.

••13

ENGLISH

p1. Products

p1.1. Global

p1.1.1. AutoProgram

p1.1.2. Prebrewing

p1.1.3. Milk Drainage

p1.1.4. Milk Cleaning

p1.2. Details

p1.2.1. Left products

p1.2.2. Right products

p1.2.3. HotWater

p2. System

p2.1. Temperature

p2.1.1. Delta Temperature

p2.1.2. Coffee Heater

p2.2. Security

p2.2.1. Operator Password

p2.2.2. Technical Password

p2.3. Options

p2.3.1. Cup Heater

p2.3.2. Antifreezing

p2.3.3. Unit Visible

p2.3.4. Buzzer

p2.4. Date/Time

p2.4.1. Date

p2.4.2. Date Format

p2.4.3. Time

p2.4.4. Time format

p3. Factory Default

s1. Maintenance

s1.1. Water filter

s1.1.1. New filter date

s1.1.2. Liters to Renew

s1.1.3. Filter limit

s1.1.4. Reset filter

s1.1.5. Filter enable

s1.2. Drillers

s1.2.1. Warning enabled

s1.2.2. Left driller state

s1.2.3. Right driller state

s1.3. Test mode

s1.3.1. Master test

s1.3.2. Left Coffee test

s1.3.3. Right Coffee test

s1.3.4. Water/Steam test

s2. System Info

s2.1. Identification

s2.1.1. Software Version

s2.1.2. Machine Code

s2.2. Error Log

s2.2.1. Errors

s2.2.2. Reset log

s2.3. Audit

s2.3.1. Counters from init

s2.3.2. Counters from reset

s2.3.3. Reset Audit

s3. Install/Uninstall

s3.1. Install

s3.1.1. Language

s3.1.2. Machine Code

s3.1.3. Display Contrast

s3.2. Uninstall

s3.2.1. Empty Boiler

12.5 Function description

P1.1

GLOBAL

P1.1.1 Auto-programming

This functions enables to set the beverage dose.

To set the dose, press the “ENT” key and access the menu item

“P.1.1.1.1 AUTOPROG. RUNNING”:

- to program the keys , and , press the selected key to

start the programming, press the key again to save the desired

dose.

- to program the keys , and , press the selected key to

start the programming of the product, press the key again to save

the desired dose of coffee and press the key again to save the

desired dose of milk.

The saved values will be shown on the display at the end of the

programming.

P1.1.2 Prebrewing

This function enables to stop the first brewing phase for a while. This

may improve the quality of coffee which can “brew” with the first

part of water, during the stop.

The length of the stop can be set with increasing values: 0, +, ++,+++.

P1.1.3 Milk drainage

This function indicates the opening time of the solenoid valve draining the condensate in the pipe which supplies the steam to the

cappuccinatore. It can be adjusted from 0 to 8 seconds.

P1.1.4 Milk cleaning

This function indicates the length of steam washing which is performed at the end of any milk dispensing. It can be adjusted from 0 to

8 seconds.

P1.1.

Global

P1.1.1.

AutoProgram

P1.1.2.

Prebrewing

P1.1.3.

Milk Drainage

P1.1.4.

Milk Cleaning

••14

P1.2.

Details

P1.2.1.

Left products

P1.2.1.1.

Espresso

P1.2.1.1.1.

Test

P1.2.1.1.2.

Multiple

P1.2.1.1.3.

Dose

P1.2.1.1.4.

Copy to all

P1.2.1.2.

Coffee

P1.2.1.2.1.

Test

P1.2.1.2.2.

Multiple

P1.2.1.2.3.

Dose

P1.2.1.2.4.

Copy to all

P1.2.1.3.

Large Coffee

P1.2.1.3.1.

Test

P1.2.1.3.2.

Multiple

P1.2.1.3.3.

Dose

P1.2.1.3.4.

Copy to all

p1. Products

p1.1. Global

p1.1.1. AutoProgram

p1.1.2. Prebrewing

p1.1.3. Milk Drainage

p1.1.4. Milk Cleaning

p1.2. Details

p1.2.1. Left products

p1.2.2. Right products

p1.2.3. HotWater

p2. System

p2.1. Temperature

p2.1.1. Delta Temperature

p2.1.2. Coffee Heater

p2.2. Security

p2.2.1. Operator Password

p2.2.2. Technical Password

p2.3. Options

p2.3.1. Cup Heater

p2.3.2. Antifreezing

p2.3.3. Unit Visible

p2.3.4. Buzzer

p2.4. Date/Time

p2.4.1. Date

p2.4.2. Date Format

p2.4.3. Time

p2.4.4. Time format

p3. Factory Default

s1. Maintenance

s1.1. Water filter

s1.1.1. New filter date

s1.1.2. Liters to Renew

s1.1.3. Filter limit

s1.1.4. Reset filter

s1.1.5. Filter enable

s1.2. Drillers

s1.2.1. Warning enabled

s1.2.2. Left driller state

s1.2.3. Right driller state

s1.3. Test mode

s1.3.1. Master test

s1.3.2. Left Coffee test

s1.3.3. Right Coffee test

s1.3.4. Water/Steam test

s2. System Info

s2.1. Identification

s2.1.1. Software Version

s2.1.2. Machine Code

s2.2. Error Log

s2.2.1. Errors

s2.2.2. Reset log

s2.3. Audit

s2.3.1. Counters from init

s2.3.2. Counters from reset

s2.3.3. Reset Audit

s3. Install/Uninstall

s3.1. Install

s3.1.1. Language

s3.1.2. Machine Code

s3.1.3. Display Contrast

s3.2. Uninstall

s3.2.1. Empty Boiler

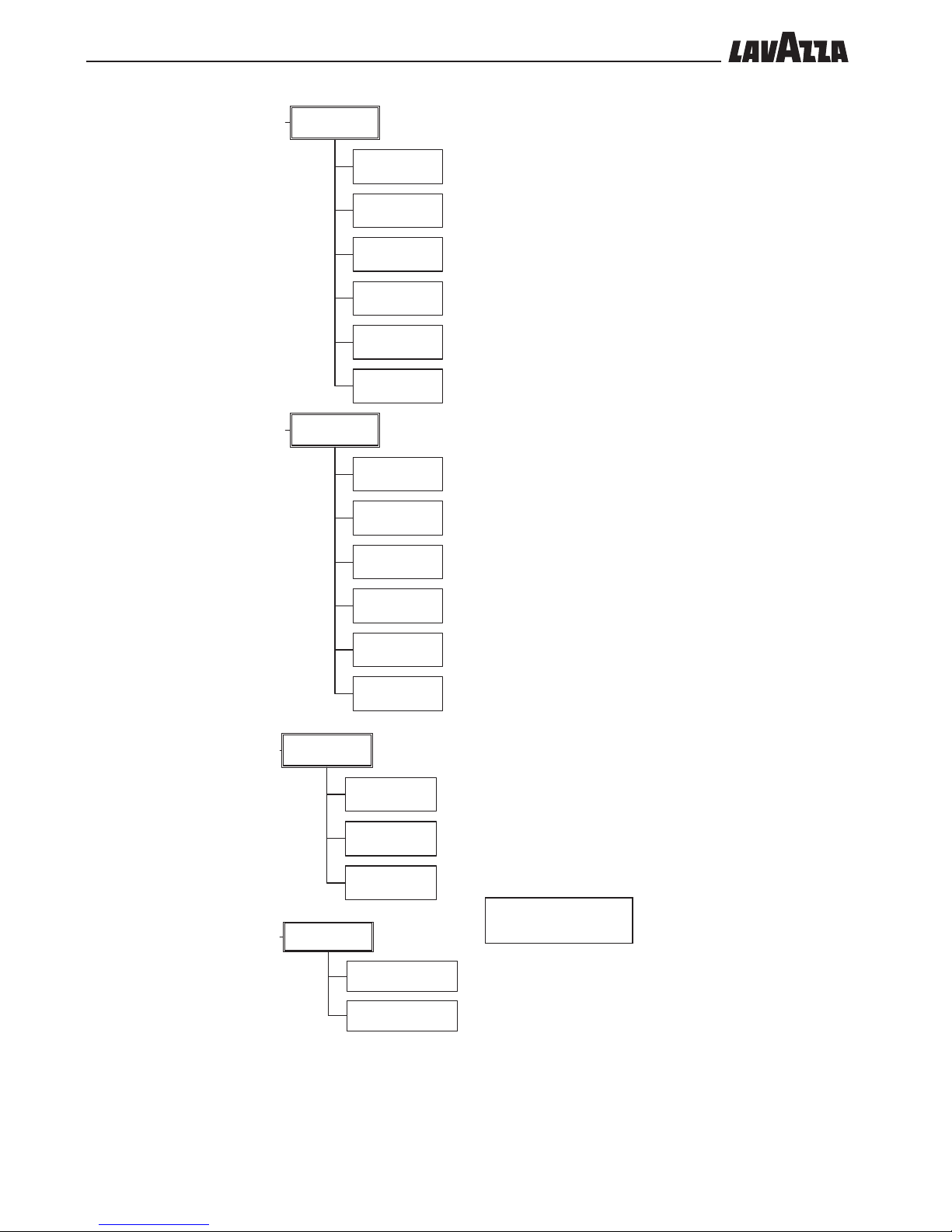

P1.2

DETAILS

P1.2.1 Left products

Enables setting of the parameters of the beverages on the left part of the machine:

P1.2.1.1. Espresso

The full product is displayed and by pressing Enter the following parameters may be

selected/set:

Test: enables dispensing of the product.

Multiple: allows enabling or disabling of

the double dose.

Dose: enables setting of the quantity of water

for the beverage.

Copy to all: enables automatic setting of

the ESPRESSO of the right part of the machine as well as the one on the left part.

P1.2.1.2. Coffee

The full product is displayed and by pressing Enter the following parameters may be

selected/set:

Test: enables dispensing of the product.

Multiple: allows enabling or disabling of

the double dose.

Dose: enables setting of the quantity of water

for the beverage.

Copy to all: enables automatic setting of

COFFEE on the right part of the machine as

well as on the left part.

P1.2.1.3. LargeCoffee

The full product is displayed and by pressing Enter the following parameters may be

selected/set:

Test: enables dispensing of the product.

Multiple: allows enabling or disabling of

the double dose.

Dose: enables setting of the quantity of water

for the beverage.

Copy to all: enables automatic setting of

the LARGECOFFEE on the right part of the

machine as well as on the left part.

••15

ENGLISH

P1.2.2.

Right products

P1.2.2.1.

Espresso

P1.2.2.1.1.

Test

P1.2.2.1.2.

Multiple

P1.2.2.1.3.

Dose

P1.2.2.2.

Coffee

P1.2.2.2.1.

Test

P1.2.2.2.2.

Multiple

P1.2.2.2.3.

Dose

P1.2.2.3.

Large Coffee

P1.2.2.3.1.

Test

P1.2.2.3.2.

Multiple

P1.2.2.3.3.

Dose

P1.2.2.4.

Macchiato

P1.2.2.4.1.

Test

P1.2.2.4.2.

Multiple

P1.2.2.4.3.

Type1

P1.2.2.4.4.

Dose1

P1.2.2.4.5.

Type2

P1.2.2.4.6.

Dose2

P1.2.2 Right products

Enables setting of the parameters of the beverage on the right part

of the machine:

P1.2.2.1. Espresso

The full product is displayed and by pressing Enter the

following parameters may be selected/set:

Test: enables dispensing of the product.

Multiple: allows enabling or disabling of the double

dose.

Dose: enables setting of the quantity of water for the

beverage.

P1.2.2.2. Coffee

The full product is displayed and by pressing Enter the

following parameters may be selected/set:

Test: enables dispensing of the product.

Multiple: allows enabling or disabling of the double

dose.

Dose: enables setting of the quantity of water for the

beverage.

P1.2.2.3. LargeCoffee

The full product is displayed and by pressing Enter the

following parameters may be selected/set:

Test: enables dispensing of the product.

Multiple: allows enabling or disabling of the double

dose.

Dose: enables setting of the quantity of water for the

beverage.

Keys , and can be preset for brewing

beverages of any possible combination of milk and

coffee.

P1.2.2.4. Macchiato

The full product is displayed and by pressing Enter the

following parameters may be selected/set:

Test: enables dispensing of the product.

Multiple: allows enabling or disabling of the double

dose.

Type1: enables setting of product 1 (COFFEE).

Dose1: enables setting of the quantity of water for beve-

rage 1.

Type2: enables setting of product 2 (MILK).

Dose2: enables setting of the brewing time of product 2.

p1. Products

p1.1. Global

p1.1.1. AutoProgram

p1.1.2. Prebrewing

p1.1.3. Milk Drainage

p1.1.4. Milk Cleaning

p1.2. Details

p1.2.1. Left products

p1.2.2. Right products

p1.2.3. HotWater

p2. System

p2.1. Temperature

p2.1.1. Delta Temperature

p2.1.2. Coffee Heater

p2.2. Security

p2.2.1. Operator Password

p2.2.2. Technical Password

p2.3. Options

p2.3.1. Cup Heater

p2.3.2. Antifreezing

p2.3.3. Unit Visible

p2.3.4. Buzzer

p2.4. Date/Time

p2.4.1. Date

p2.4.2. Date Format

p2.4.3. Time

p2.4.4. Time format

p3. Factory Default

s1. Maintenance

s1.1. Water filter

s1.1.1. New filter date

s1.1.2. Liters to Renew

s1.1.3. Filter limit

s1.1.4. Reset filter

s1.1.5. Filter enable

s1.2. Drillers

s1.2.1. Warning enabled

s1.2.2. Left driller state

s1.2.3. Right driller state

s1.3. Test mode

s1.3.1. Master test

s1.3.2. Left Coffee test

s1.3.3. Right Coffee test

s1.3.4. Water/Steam test

s2. System Info

s2.1. Identification

s2.1.1. Software Version

s2.1.2. Machine Code

s2.2. Error Log

s2.2.1. Errors

s2.2.2. Reset log

s2.3. Audit

s2.3.1. Counters from init

s2.3.2. Counters from reset

s2.3.3. Reset Audit

s3. Install/Uninstall

s3.1. Install

s3.1.1. Language

s3.1.2. Machine Code

s3.1.3. Display Contrast

s3.2. Uninstall

s3.2.1. Empty Boiler

••16

P1.2.2.5.

Cappuccino

P1.2.2.5.1.

Test

P1.2.2.5.2.

Multiple

P1.2.2.5.3.

Type1

P1.2.2.5.4.

Dose1

P1.2.2.5.5.

Type2

P1.2.2.5.6.

Dose2

P1.2.2.6.

Milk

P1.2.2.6.1.

Test

P1.2.2.6.2.

Multiple

P1.2.2.6.3.

Type1

P1.2.2.6.4.

Dose1

P1.2.2.6.5.

Type2

P1.2.2.6.6.

Dose2

P2.1.

Temperature

P2.1.1.

Delta Temperature

P2.1.2.

Coffee Heater

P1.2.3.

Hot Water

P1.2.3.1.

Test

P1.2.3.2.

Multiple

P1.2.3.3.

Manual Dose

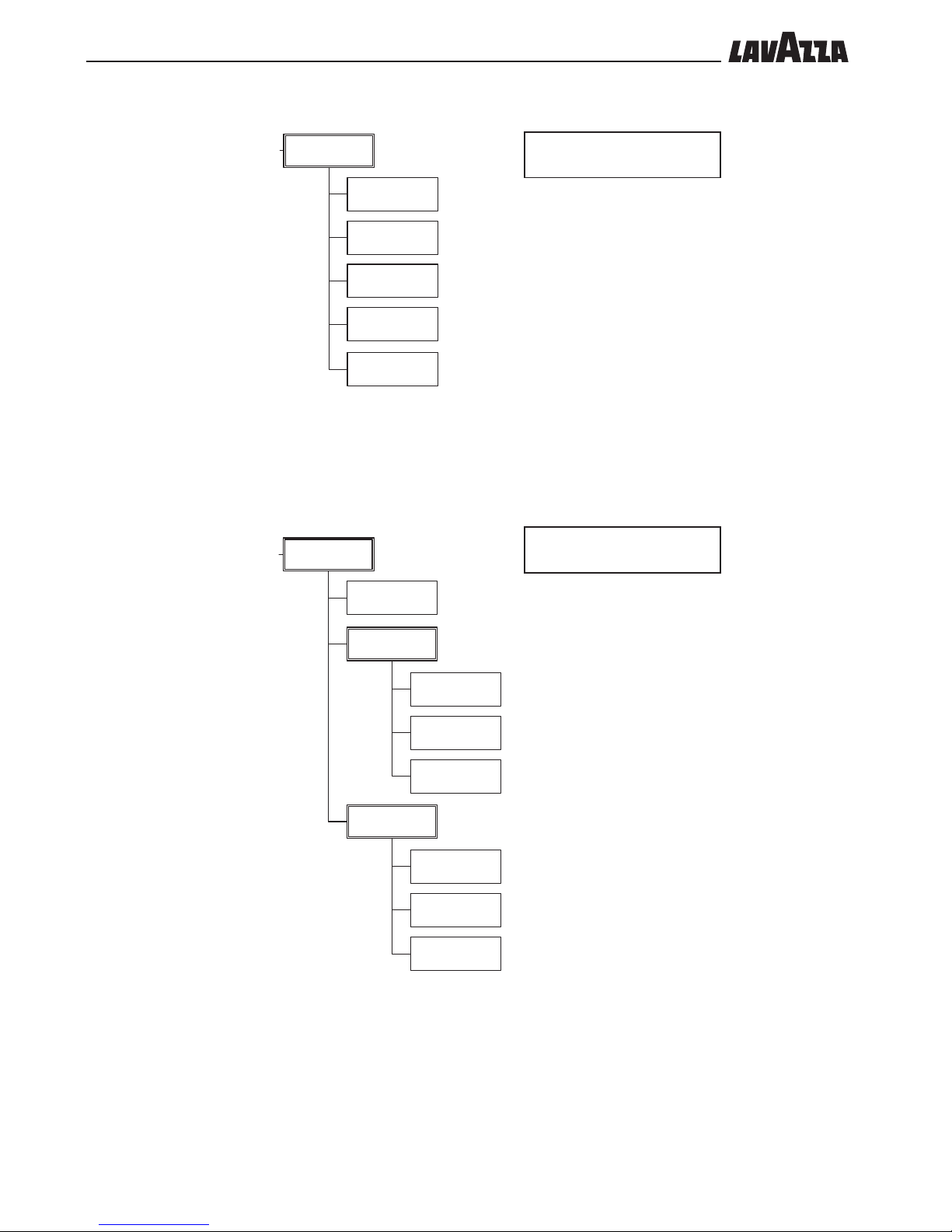

P1.2.2.5. Cappuccino

The full product is displayed and by pressing Enter the following

parameters may be selected/set:

Test: enables dispensing of the product.

Multiple: allows enabling or disabling of the double dose.

Type1: enables setting of product 1 (MILK).

Dose1: enables setting of the brewing time of product 1.

Type2: enables setting of product 2 (COFFEE).

Dose2: enables setting of the quantity of water for beverage 2.

P1.2.2.6. Milk

The full product is displayed and by pressing Enter the following

parameters may be selected/set:

Test: enables dispensing of the product.

Multiple: allows enabling or disabling of the double dose.

Type1: enables setting of product 1 (MILK).

Dose1: enables setting of the brewing time of product 1.

Type2: Dose2: -

P1.2.3 Hot water

Enables setting of the parameters for hot water. The following parameters can be selected/set:

Test: enables hot water dispensing.

Multiple: allows enabling or disabling of the function to dispense

up to eight beverages. Function not implemented.

ManualDose: enables setting of the quantity of water to be di-

spensed for each selection.

P2.1

TEMPERATURE

For each coffee dispensed, it is possible to change the temperature

of the water used during dispensing and programmed during the

installation phase.

P2.1.1. Delta Temperature

sets the temperature change for both groups; the setup is the temperature set and the change can be made by means of “+” and “-”

keys:

- by pressing “+” this temperature is increased.

- by pressing “-” this temperature is decreased.

P2.1.2. Coffee Heater (technician only)

p1. Products

p1.1. Global

p1.1.1. AutoProgram

p1.1.2. Prebrewing

p1.1.3. Milk Drainage

p1.1.4. Milk Cleaning

p1.2. Details

p1.2.1. Left products

p1.2.2. Right products

p1.2.3. HotWater

p2. System

p2.1. Temperature

p2.1.1. Delta Temperature

p2.1.2. Coffee Heater

p2.2. Security

p2.2.1. Operator Password

p2.2.2. Technical Password

p2.3. Options

p2.3.1. Cup Heater

p2.3.2. Antifreezing

p2.3.3. Unit Visible

p2.3.4. Buzzer

p2.4. Date/Time

p2.4.1. Date

p2.4.2. Date Format

p2.4.3. Time

p2.4.4. Time format

p3. Factory Default

s1. Maintenance

s1.1. Water filter

s1.1.1. New filter date

s1.1.2. Liters to Renew

s1.1.3. Filter limit

s1.1.4. Reset filter

s1.1.5. Filter enable

s1.2. Drillers

s1.2.1. Warning enabled

s1.2.2. Left driller state

s1.2.3. Right driller state

s1.3. Test mode

s1.3.1. Master test

s1.3.2. Left Coffee test

s1.3.3. Right Coffee test

s1.3.4. Water/Steam test

s2. System Info

s2.1. Identification

s2.1.1. Software Version

s2.1.2. Machine Code

s2.2. Error Log

s2.2.1. Errors

s2.2.2. Reset log

s2.3. Audit

s2.3.1. Counters from init

s2.3.2. Counters from reset

s2.3.3. Reset Audit

s3. Install/Uninstall

s3.1. Install

s3.1.1. Language

s3.1.2. Machine Code

s3.1.3. Display Contrast

s3.2. Uninstall

s3.2.1. Empty Boiler

••17

ENGLISH

P2.2.

Security

P2.2.1.

Operator Password

P2.2.2.

Technical Password

P2.3.

Options

P2.3.1.

Cup Heater

P2.3.2.

Antifreezing

P2.3.3.

Unit Visible

P2.3.4.

Buzzer

P2.4.

Date/Time

P2.4.1.

Date

P2.4.1.1.

Day

P2.4.1.2.

Month

P2.4.1.3.

Year

P2.4.2.

Date Format

P2.4.3.

Time

P2.4.4.

Time format

P2.2

SECURITY

This function enables a password to be assigned to access the

programming. If no password has been assigned, the programming menu is entered directly.

P2.2.1. Operator password

By setting this password, the machine user is not authorized to operate on certain items. (see sect. “12.4

Structure of the programming menu”)

P2.2.2.

Technician password (technician only)

P2.3

OPTIONS

Allows enabling of certain standard functions.

P2.3.1. Cup Heater

By confirming “ON” the cup warming plate turns on together with

the machine.

By confirming “OFF” the cup warming plate is always off.

P2.3.2. Anti-freezing (technician only)

P2.3.3. Unit Visible (technician only)

P2.3.4. Buzzer (technician only)

P2.4

DATE/TIME

This function enables setting of the calendar and the clock of the

machine.

P2.4.1. Date

P2.4.1.1. Day

Allows the date to be changed

P2.4.1.2. Month

Allows the month to be changed

P2.4.1.3. Year

Allows the year to be changed

P2.4.2. Data format

Allows the data format to be changed.

P2.4.3. Time

Enables the time to be changed.

P2.4.4. Time format

Allows the time format to be changed.

p1. Products

p1.1. Global

p1.1.1. AutoProgram

p1.1.2. Prebrewing

p1.1.3. Milk Drainage

p1.1.4. Milk Cleaning

p1.2. Details

p1.2.1. Left products

p1.2.2. Right products

p1.2.3. HotWater

p2. System

p2.1. Temperature

p2.1.1. Delta Temperature

p2.1.2. Coffee Heater

p2.2. Security

p2.2.1. Operator Password

p2.2.2. Technical Password

p2.3. Options

p2.3.1. Cup Heater

p2.3.2. Antifreezing

p2.3.3. Unit Visible

p2.3.4. Buzzer

p2.4. Date/Time

p2.4.1. Date

p2.4.2. Date Format

p2.4.3. Time

p2.4.4. Time format

p3. Factory Default

s1. Maintenance

s1.1. Water filter

s1.1.1. New filter date

s1.1.2. Liters to Renew

s1.1.3. Filter limit

s1.1.4. Reset filter

s1.1.5. Filter enable

s1.2. Drillers

s1.2.1. Warning enabled

s1.2.2. Left driller state

s1.2.3. Right driller state

s1.3. Test mode

s1.3.1. Master test

s1.3.2. Left Coffee test

s1.3.3. Right Coffee test

s1.3.4. Water/Steam test

s2. System Info

s2.1. Identification

s2.1.1. Software Version

s2.1.2. Machine Code

s2.2. Error Log

s2.2.1. Errors

s2.2.2. Reset log

s2.3. Audit

s2.3.1. Counters from init

s2.3.2. Counters from reset

s2.3.3. Reset Audit

s3. Install/Uninstall

s3.1. Install

s3.1.1. Language

s3.1.2. Machine Code

s3.1.3. Display Contrast

s3.2. Uninstall

s3.2.1. Empty Boiler

P3.

Factory default

P3.

FACTORY DEFAULT

(technician only)

••18

S1.1.

Water filter

S1.1.1.

New filter date

S1.1.2.

Liters to Renew

S1.1.3.

Filter limit

S1.1.4.

Reset filter

S1.1.5.

Filter enable

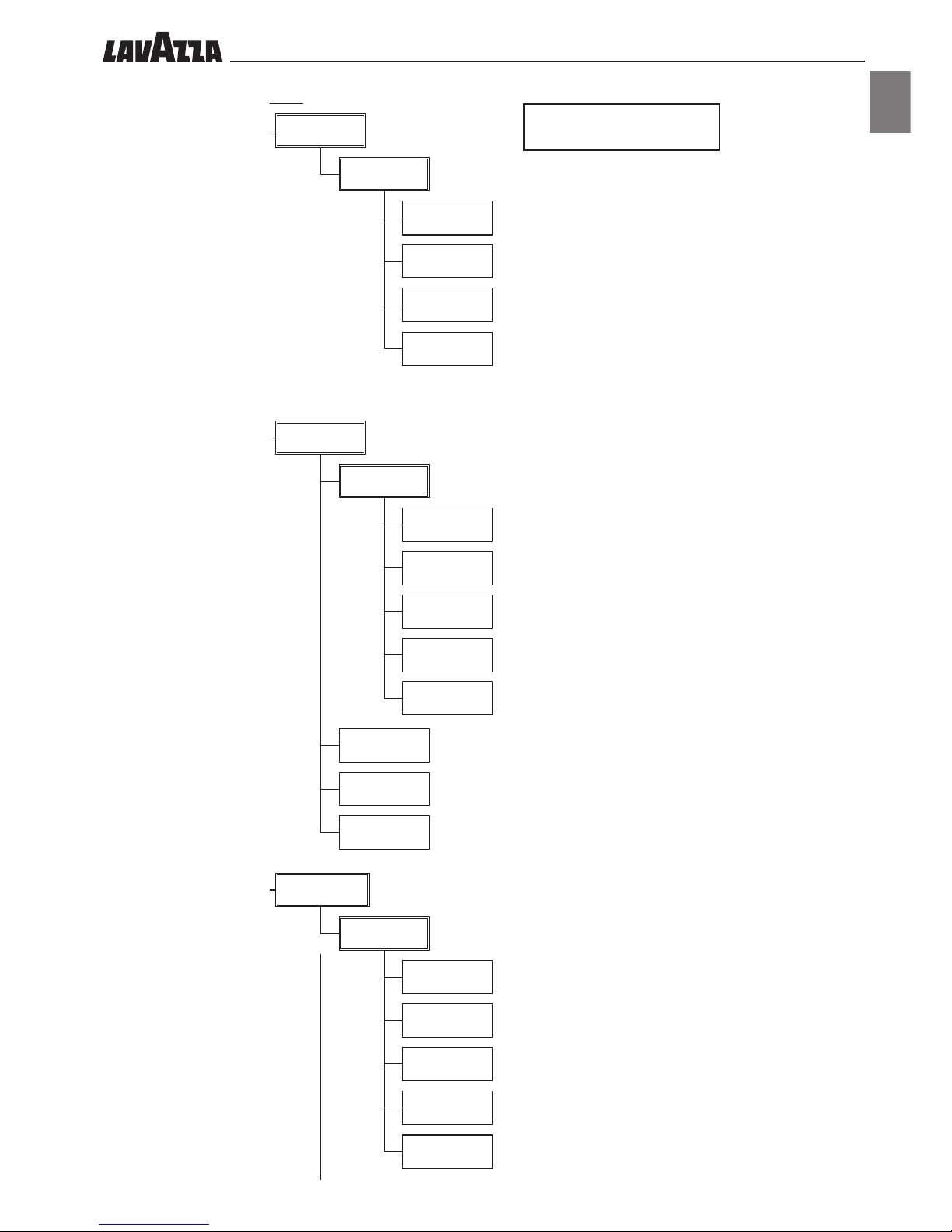

12.6 Structure of the maintenance menu

S1.1.

WATER FILTER

S1.1.1. New filter date

Displays the date of the last descaling.

S1.1.2. Liters to Renew

Displays the litres left before descaling needs to be performed.

S1.1.3. Filter limit

Enables setting the filter duration litres. Press Enter to set the number

of litres.

S1.1.4. Reset filter

Enables performance of the descaling procedure.

S1.1.5. Filter enable

Function which allows enabling/disabling display of the service

warning.

p1. Products

p1.1. Global

p1.1.1. AutoProgram

p1.1.2. Prebrewing

p1.1.3. Milk Drainage

p1.1.4. Milk Cleaning

p1.2. Details

p1.2.1. Left products

p1.2.2. Right products

p1.2.3. HotWater

p2. System

p2.1. Temperature

p2.1.1. Delta Temperature

p2.1.2. Coffee Heater

p2.2. Security

p2.2.1. Operator Password

p2.2.2. Technical Password

p2.3. Options

p2.3.1. Cup Heater

p2.3.2. Antifreezing

p2.3.3. Unit Visible

p2.3.4. Buzzer

p2.4. Date/Time

p2.4.1. Date

p2.4.2. Date Format

p2.4.3. Time

p2.4.4. Time format

p3. Factory Default

s1. Maintenance

s1.1. Water filter

s1.1.1. New filter date

s1.1.2. Liters to Renew

s1.1.3. Filter limit

s1.1.4. Reset filter

s1.1.5. Filter enable

s1.2. Drillers

s1.2.1. Warning enabled

s1.2.2. Left driller state

s1.2.3. Right driller state

s1.3. Test mode

s1.3.1. Master test

s1.3.2. Left Coffee test

s1.3.3. Right Coffee test

s1.3.4. Water/Steam test

s2. System Info

s2.1. Identification

s2.1.1. Software Version

s2.1.2. Machine Code

s2.2. Error Log

s2.2.1. Errors

s2.2.2. Reset log

s2.3. Audit

s2.3.1. Counters from init

s2.3.2. Counters from reset

s2.3.3. Reset Audit

s3. Install/Uninstall

s3.1. Install

s3.1.1. Language

s3.1.2. Machine Code

s3.1.3. Display Contrast

s3.2. Uninstall

s3.2.1. Empty Boiler

S1.2.

DRILLERS

S1.2.1. Warning enabled

Function which allows enabling/disabling the warning to replace

the piercers.

S1.2.2. Left driller state

S1.2.2.1. Last changed

Displays the last replacement of the piercers.

S1.2.2.2. Remaining autonomy

Displays the remaining duration of the piercers.

S1.2.2.3. Change now (technician only)

S1.2.3. Right driller state

S1.2.3.1. Last changed

Displays the last replacement of the piercers.

S1.2.3.2. Remaining autonomy

Displays the remaining duration of the piercers.

S1.2.3.3. Change now (technician only)

S1.2.2.

Left driller state

S1.2.2.1.

Last changed

S1.2.2.2.

Remaining autonomy

S1.2.2.3.

Change now

S1.2.

Drillers

S1.2.1.

Warning enabled

S1.2.3.

Right driller state

S1.2.3.1.

Last changed

S1.2.3.2.

Remaining autonomy

S1.2.3.3.

Change now

••19

ENGLISH

p1. Products

p1.1. Global

p1.1.1. AutoProgram

p1.1.2. Prebrewing

p1.1.3. Milk Drainage

p1.1.4. Milk Cleaning

p1.2. Details

p1.2.1. Left products

p1.2.2. Right products

p1.2.3. HotWater

p2. System

p2.1. Temperature

p2.1.1. Delta Temperature

p2.1.2. Coffee Heater

p2.2. Security

p2.2.1. Operator Password

p2.2.2. Technical Password

p2.3. Options

p2.3.1. Cup Heater

p2.3.2. Antifreezing

p2.3.3. Unit Visible

p2.3.4. Buzzer

p2.4. Date/Time

p2.4.1. Date

p2.4.2. Date Format

p2.4.3. Time

p2.4.4. Time format

p3. Factory Default

s1. Maintenance

s1.1. Water filter

s1.1.1. New filter date

s1.1.2. Liters to Renew

s1.1.3. Filter limit

s1.1.4. Reset filter

s1.1.5. Filter enable

s1.2. Drillers

s1.2.1. Warning enabled

s1.2.2. Left driller state

s1.2.3. Right driller state

s1.3. Test mode

s1.3.1. Master test

s1.3.2. Left Coffee test

s1.3.3. Right Coffee test

s1.3.4. Water/Steam test

s2. System Info

s2.1. Identification

s2.1.1. Software Version

s2.1.2. Machine Code

s2.2. Error Log

s2.2.1. Errors

s2.2.2. Reset log

s2.3. Audit

s2.3.1. Counters from init

s2.3.2. Counters from reset

s2.3.3. Reset Audit

s3. Install/Uninstall

s3.1. Install

s3.1.1. Language

s3.1.2. Machine Code

s3.1.3. Display Contrast

s3.2. Uninstall

s3.2.1. Empty Boiler

S1.3.

TEST MODE

S1.3.1. Master test (technician only)

S1.3.1.1. Low level test (technician only)

S1.3.1.1.1. Keyboards test (technician only)

S1.3.1.1.2. Safety test (technician only)

S1.3.1.1.3. Outputs test (technician only)

S1.3.1.1.4.

Board temperature (technician only)

S1.3.1.

Master test

S1.3.1.1.

Low level test

S1.3.1.1.1.

Keyboard test

S1.3.1.1.2.

Safety test

S1.3.1.1.3.

Outputs test

S1.3.1.1.4.

Board Temperature

S1.3.2.

Left coffee test

S1.3.2.1.

Low level test

S1.3.2.1.1.

Pod drawer test

S1.3.2.1.2.

Heater test

S1.3.2.1.3.

Brewing test

S1.3.2.1.4.

Hydraulic test

S1.3.2.2.

Check motor

S1.3.2.3.

Check flow

S1.3.2.4.

Check temp

S1.3.2.1.5.

Board Temperature

S1.3.3.

Right coffee test

S1.3.3.1.

Low level test

S1.3.3.1.1.

Pod drawer test

S1.3.3.1.2.

Heater test

S1.3.3.1.3.

Brewing test

S1.3.3.1.4.

Hydraulic test

S1.3.3.1.5.

Board Temperature

S1.3.2. Left coffee test (technician only)

S1.3.2.1. Low level test (technician only)

S1.3.2.1.1.

Pod drawer test (technician only)

S1.3.2.1.2. Heater test (technician only)

S1.3.2.1.3. Brewing test (technician only)

S1.3.2.1.4. Hydraulic test (technician only)

S1.3.2.1.5.

Board temperature (technician only)

S1.3.2.2. Check motor (technician only)

S1.3.2.3. Check flow (technician only)

S1.3.2.4. Check temp (technician only)

S1.3.3. Right coffee test (technician only)

S1.3.3.1. Low level test (technician only)

S1.3.3.1.1. Pod drawer test (technician only)

S1.3.3.1.2. Heater test (technician only)

S1.3.3.1.3. Brewing test (technician only)

S1.3.3.1.4. Hydraulic test (technician only)

S1.3.3.1.5. Board temperature (technician only)

••20

S1.3.3.2. Check motor (technician only)

.

S1.3.3.3. Check flow (technician only)

S1.3.3.4. Check temp (technician only)

S1.3.4. Water/Steam test (technician only)

S1.3.4.1. Low level test (technician only)

S1.3.4.1.1. Boiler test (technician only)

S1.3.4.1.2.

Water sys. test (technician only)

S1.3.4.1.3.

Steam sys. test (technician only)

S1.3.4.1.4.

Board temperature (technician only)

S1.3.4.3. Check water flow (technician only)

p1. Products

p1.1. Global

p1.1.1. AutoProgram

p1.1.2. Prebrewing

p1.1.3. Milk Drainage

p1.1.4. Milk Cleaning

p1.2. Details

p1.2.1. Left products

p1.2.2. Right products

p1.2.3. HotWater

p2. System

p2.1. Temperature

p2.1.1. Delta Temperature

p2.1.2. Coffee Heater

p2.2. Security

p2.2.1. Operator Password

p2.2.2. Technical Password

p2.3. Options

p2.3.1. Cup Heater

p2.3.2. Antifreezing

p2.3.3. Unit Visible

p2.3.4. Buzzer

p2.4. Date/Time

p2.4.1. Date

p2.4.2. Date Format

p2.4.3. Time

p2.4.4. Time format

p3. Factory Default

s1. Maintenance

s1.1. Water filter

s1.1.1. New filter date

s1.1.2. Liters to Renew

s1.1.3. Filter limit

s1.1.4. Reset filter

s1.1.5. Filter enable

s1.2. Drillers

s1.2.1. Warning enabled

s1.2.2. Left driller state

s1.2.3. Right driller state

s1.3. Test mode

s1.3.1. Master test

s1.3.2. Left Coffee test

s1.3.3. Right Coffee test

s1.3.4. Water/Steam test

s2. System Info

s2.1. Identification

s2.1.1. Software Version

s2.1.2. Machine Code

s2.2. Error Log

s2.2.1. Errors

s2.2.2. Reset log

s2.3. Audit

s2.3.1. Counters from init

s2.3.2. Counters from reset

s2.3.3. Reset Audit

s3. Install/Uninstall

s3.1. Install

s3.1.1. Language

s3.1.2. Machine Code

s3.1.3. Display Contrast

s3.2. Uninstall

s3.2.1. Empty Boiler

S1.3.3.2.

Check motor

S1.3.3.3.

Check flow

S1.3.3.4.

Check temp

S2.1.

Identification

S2.1.1.

Software Version

S2.1.1.1.

Master unit

S2.1.1.2.

Right coffee

S2.1.1.3.

Left coffee

S2.1.1.4.

Water / Steam

S2.1.2.

Machine Code

S2.1

IDENTIFICATION

S2.1.1.Software version

Enables display of the software versions of the following cards:

- Master unit;

- Right coffee;

- Left coffee;

- Water&Steam

S2.1.2.Machine code

Enables to display the machine code

S1.3.4.

Water/Steam test

S1.3.4.1.

Low level test

S1.3.4.1.1.

Boiler test

S1.3.4.1.2.

Water sys. test

S1.3.4.1.3.

Steam sys. test

S1.3.4.2.

Check water flow

S1.3.4.1.4.

Board Temperature

S2.2.

Error Log

S2.2.1.

Errors

S2.2.2.

Reset log

S2.2

ERROR LOG

This function allows the last 50 errors occurred to the machine to

be displayed:

S2.2.1. Errors

Displays each individual error and provides certain information

about it (since last reset):

- part of the machine affected by the error;

- error number;

- error date and time.

S2.2.2. Reset log (technician only)

••21

ENGLISH

S2.3.

Audit

S2.3.1.

Counters from init

S2.3.1.1.

Right products

S2.3.1.2.

Left products

S2.3.1.3.

Hot water

S2.3.2.

Counters from reset

S2.3.2.1.

Right products

S2.3.2.2.

Left products

S2.3.2.3.

Hot water

S2.3.3.

Reset Audit

S2.3

AUDIT

S2.3.1. Counters from init

Displays the number of beverages dispensed. The beverage

count is divided into brew groups (right and left), and then for

each single beverage (espresso, milk, cappuccino, macchiato,

long and coffee).

S2.3.2. Counters from reset

Displays the number of beverages dispensed since the last reset

of the counters. The beverage count is divided into brew groups

(right and left), and then for each single beverage (espresso,

milk, cappuccino, macchiato, long and coffee).

S2.3.3. Reset audit

Enables resetting of counters of both brew groups.

p1. Products

p1.1. Global

p1.1.1. AutoProgram

p1.1.2. Prebrewing

p1.1.3. Milk Drainage

p1.1.4. Milk Cleaning

p1.2. Details

p1.2.1. Left products

p1.2.2. Right products

p1.2.3. HotWater

p2. System

p2.1. Temperature

p2.1.1. Delta Temperature

p2.1.2. Coffee Heater

p2.2. Security

p2.2.1. Operator Password

p2.2.2. Technical Password

p2.3. Options

p2.3.1. Cup Heater

p2.3.2. Antifreezing

p2.3.3. Unit Visible

p2.3.4. Buzzer

p2.4. Date/Time

p2.4.1. Date

p2.4.2. Date Format

p2.4.3. Time

p2.4.4. Time format

p3. Factory Default

s1. Maintenance

s1.1. Water filter

s1.1.1. New filter date

s1.1.2. Liters to Renew

s1.1.3. Filter limit

s1.1.4. Reset filter

s1.1.5. Filter enable

s1.2. Drillers

s1.2.1. Warning enabled

s1.2.2. Left driller state

s1.2.3. Right driller state

s1.3. Test mode

s1.3.1. Master test

s1.3.2. Left Coffee test

s1.3.3. Right Coffee test

s1.3.4. Water/Steam test

s2. System Info

s2.1. Identification

s2.1.1. Software Version

s2.1.2. Machine Code

s2.2. Error Log

s2.2.1. Errors

s2.2.2. Reset log

s2.3. Audit

s2.3.1. Counters from init

s2.3.2. Counters from reset

s2.3.3. Reset Audit

s3. Install/Uninstall

s3.1. Install

s3.1.1. Language

s3.1.2. Machine Code

s3.1.3. Display Contrast

s3.2. Uninstall

s3.2.1. Empty Boiler

S3.1.

Install

S3.1.1.

Language

S3.1.2.

Machine Code

S3.1.3.

Display Contrast

S3.2.

Uninstall

S3.2.1.

Empty Boiler

S3.1

INSTALL

S3.1.1. Language (technician only)

S3.1.2. Machine Code (technician only)

S3.1.3. Display Contrast (technician only)

S3.2

UNISTALL

S3.2.1. Empty Boiler (technician only)

••22

Message

BREW GROUP ERROR

EMPTY DREGDRWAWER

(WARNING)

EMPTY DREGDRWAWER

(ALARM)

CLOSE DOOR

CLOSE DREGDRAWER

PUT HOPPER

12.7 Display messages

Cause

Appears when an error occurs which can be identified by a number displayed on the service menu

at item S.2.2.1.1

Appears when the capsule drawer is almost full

(the machine has dispensed the programmed

number of beverages). Further dispensing can be

performed.

Appears when the capsule drawer is completely

full (the machine has dispensed the programmed

number of beverages). The machine is blocked

and no more dispensing can be performed until

the capsule drawer is emptied.

The door is not closed correctly.

The capsule drawer is not properly in place.

The hopper is not properly in place.

Solution

Obtain the error identification number

from the service menu, turn off the machine and call the AUTHORIZED CUSTOMER SERVICE CENTRE.

For the errors indicated below, before

calling the AUTHORIZED CUSTOMER

SERVICE CENTRE it is necessary to carry out the following checks:

52 check that water is present in the

water network;

55 check that the group is correctly in

place.

Empty the capsule drawer

Empty the capsule drawer

Close the door

Insert the capsule drawer correctly

Insert the hopper correctly

12.8 Turning off the machine

This is achieved by setting the main switch (21) in the “0” position or by

unplugging the machine.

••23

ENGLISH

F. 12

C

A

B

13 - SCHEDULED

MAINTENANCE

Warning

• For operating problems, normally reported on the display,

switch off the machine immediately, turn off the power supply using

the all-pole switch or by unplugging the machine and contact the

nearest customer service centre.

• Before carrying out any maintenance and/or cleaning

operation, disconnect the power supply using the main switch (21)

and the all-pole switch (or unplug the machine).

• All operations must be performed when the machine is cold.

• Do not perform any cleaning operation when the machine is in

“standby”.

• The cleaning products are available from all suppliers of coffee

machine spare parts. If they cannot be found locally, please ask the

principal company or the installer for assistance.

• Never wash any of the machine components in the dishwasher.

• Do not use direct jets of water.

13.1 Cleaning the machine

• Cleaning must be performed daily and if the machine will

remain inactive for a prolonged period of time, in order to avoid the

solidification of deposits in the containers, trays and dispensers.

• The removable components of the machine must be cleaned

and rinsed in tap water.

• Clean the casing, panels and machine controls using soft cloths dam-

pened with lukewarm water.

• The non-removable components and the machine must be

cleaned only with cold or lukewarm water, using non abrasive sponges and wet cloths.

• All the parts requiring cleaning are easily accessible and do not

require the use of tools.

IMPORTANT

Regular maintenance and cleaning will keep the machine in

good working order for longer as well as ensuring compliance

with basic hygiene standards.

The machine automatically warns when maintenance or

descaling operations must be carried out; the number of

beverages dispensed can be seen on the machine display; lack

of maintenance by the Maintenance Technician may cause the

machine to block.

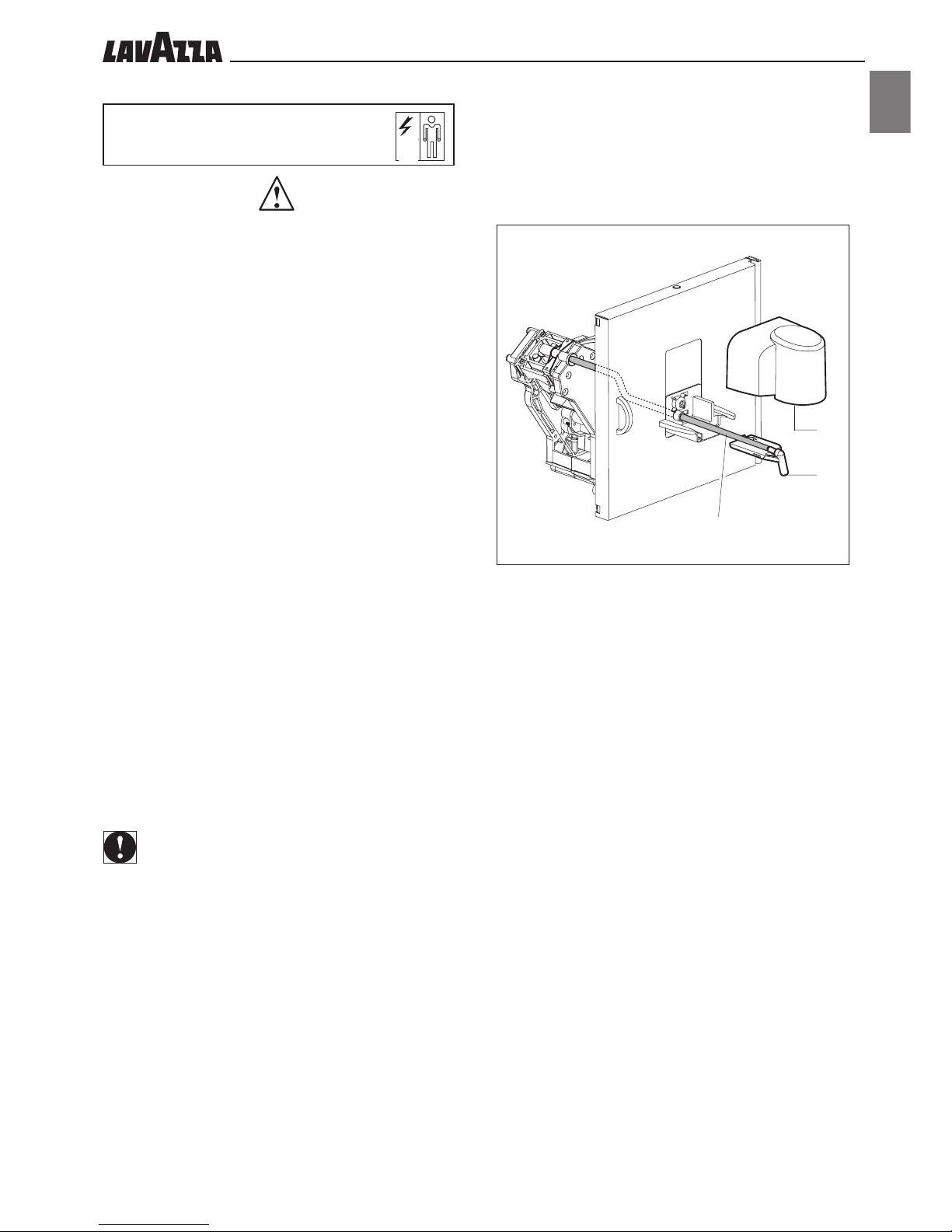

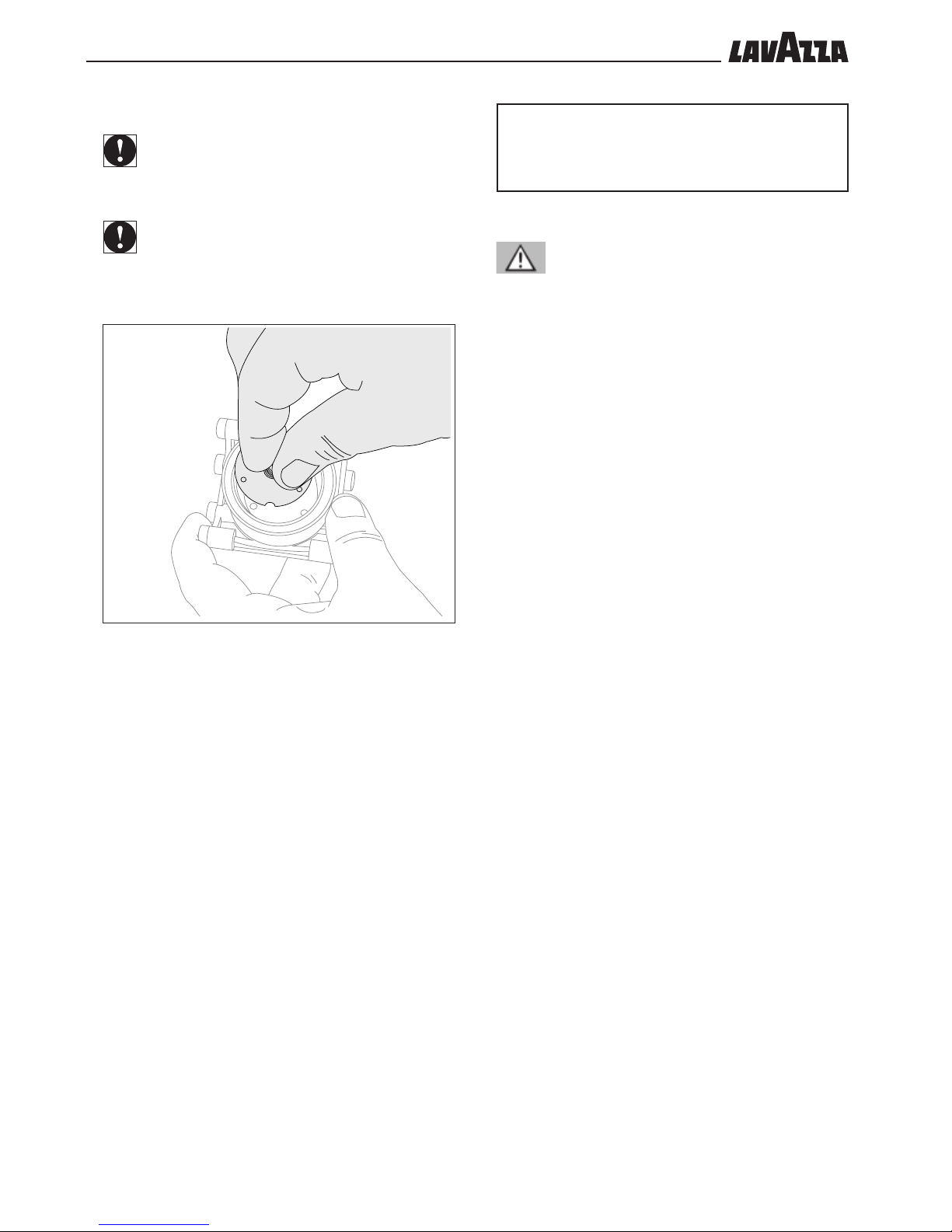

13.1.1 Coffee dispenser (F. 12)

The following can be removed:

- the upper protection (A), of the dispenser by pulling it outwards;

- the coffee dispenser (B) by pulling it outwards;

- the coffee coupling (C) from the brew group.

13.1.2 Drip tray and relative grille

Remove the drip tray (15) and wash it in tap water, paying particular

attention to the grille.

13.1.3 Capsule drawer

Wash the capsule drawer in tap water (16 and 18) after removing it

from its seat.

13.1.4 Steam and hot water spouts

Clean the spouts (13 and 19) with a wet non abrasive cloth.

If the nozzles are clogged the end of the spouts can be unscrewed and

the nozzles re-opened using a pin.

13.1.5 Cup warming plate

Clean the cup warming plate (4) with a wet non abrasive cloth.

13.1.6 Brew Group

Remove the brew group (27) and clean it in tap water.

13.1.7 Capsule discharge hopper

Remove the capsule discharge hopper (28) and clean it in tap water.

••24

F. 14

13.1.8 Cleaning the cappuccinatore

WARNING

Do not perform any cleaning operation of the cappuccinatore

when the machine is in “standby”.

The CAPPUCCINATORE must be cleaned each time it is used,

in order to avoid the solidification of deposits.

All removable components must be washed and rinsed in tap

water.

Warning! Danger of scalding. Hot water, steam sprays

and milk residue may spill out of the cappuccinatore during the

washing cycles. Do not place hands or other parts of the body

close to these parts until the cleaning cycle is complete.

The aim of this operation is to remove all the grease and scale deposits

that have formed during the flow and emulsion of the milk.

If the washing cycle is not performed, this would cause the deposits to

solidify, resulting in a loss of performance for the cappuccinatore.

WARNING

The operations described below should be performed with the

machine switched on and under pressure.

Periodic cleaning

This operation must be performed approximately every 30 minutes if the

cappuccinatore is used continuously.

- Remove the hose from the milk container and immerse it in cold water.

- Press the milk dispensing button to clean the cappuccinatore.

WARNING

It is recommended that the abovementioned cycle is performed

at least twice at intervals of one minute.

Cleaning of the cappuccinatore each evening

To be performed at the end of the working day.

- Fill a container with ½ litre of cold water and one dose of liquid

detergent (see product instructions).

- Remove the suction tube from the milk container and immerse it in the

detergent solution.

- By pressing the MILK button the water will flow out of the cappuccino

dispensing head. The message MILK will appear on the display.

Keep dispensing the milk beverage until the liquid has run out.

- The detergent will be drawn up automatically and flow out of the

cappuccinatore head.

- Once the washing cycle is complete, remove the chromed cover.

- Remove the cappuccinatore (see figure 14):

- Gently pull downwards and remove the connector of the milk tube

placed at the side of the cappuccinatore.

- Remove the cappuccinatore by pulling it from the front towards you.

- Dismantle the cappuccinatore completely and disassemble the five

parts.

- Prepare a new dose of detergent solution (as above) and immerse

the parts of the cappuccinatore.

- Wash each part with a sponge and remove all organic residue,

then re-immerse the cappuccinatore in the solution for at least two

hours.

- Replace the components.

- Put the cappuccinatore back in the machine, insert the milk pipe

connector placed at the side of the cappuccinatore and replace the

chromed cover in its seat.

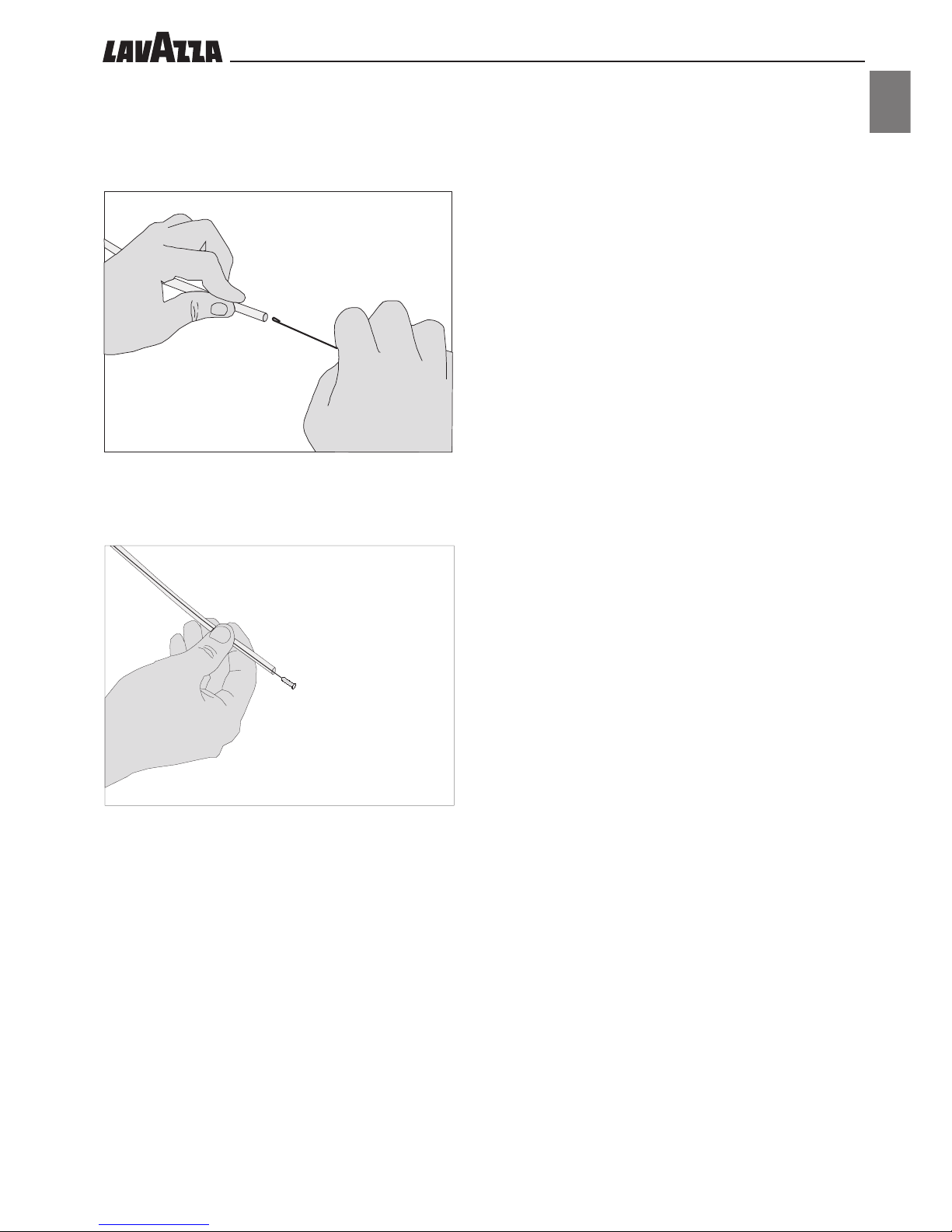

- Clean the holes A and B using the appropriate bottle brushes (see

figure)

F. 13

A

B

- Rinse allowing at least ½ litre of cold water to be pumped

through the cappuccinatore.

••25

ENGLISH

Cleaning of the cappuccinatore tube

- Remove the tube from the cappuccinatore fitting and from the milk

container

- Insert the bottle brush into the tube (see figure)

- Pull it outwards; repeat this operation at least twice

F. 15

F. 16

••26

F. 17

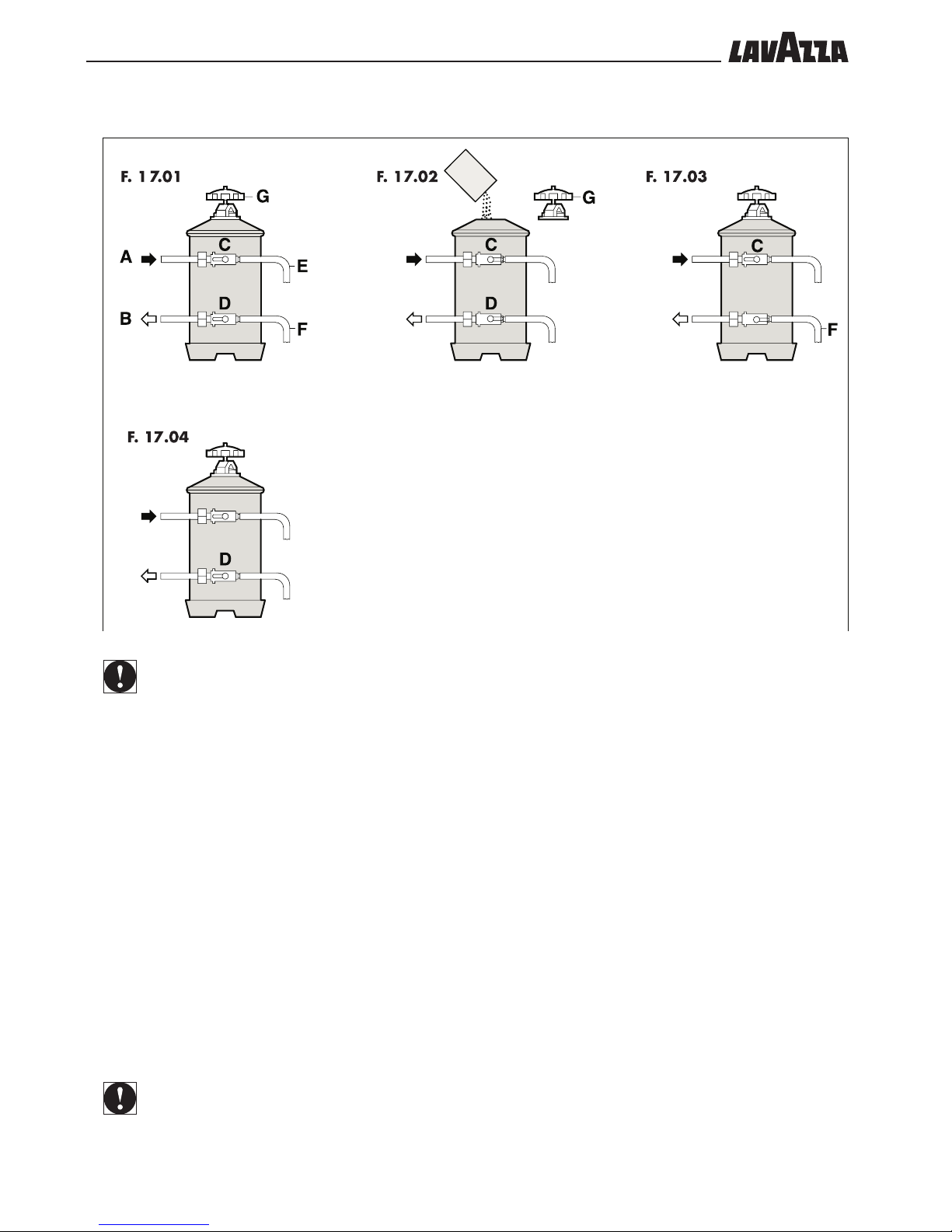

13.1.9 Regeneration of the purifier

A WATER INLET

B WATER OUTLET

C INLET TAP LEVER

D OUTLET TAP LEVER

E GROUP VACUUM UNIT

F REGENERATION PIPE

G COVER KNOB

IMPORTANT

Regenerate the purifier at the scheduled deadlines

indicated below:

HARDNESS ° F

From 00 to 20

From 21 to 30

From 31 to 40

From 41 to 50

PURIFIER TYPE 8 LITRES

regeneration after 1100 l.

regeneration after 850 l.

regeneration after 650 l.

regeneration after 450 l.

PURIFIER TYPE 12 LITRES

regeneration after 1600 l.

regeneration after 1250 l.

regeneration after 950 l.

regeneration after 650 l.

- Place an empty container with a capacity of 2 litres under the

pipe E

- Move the levers C and D from left to right as in fig. 17.02, remove

the cover by releasing the knob G, add 1.5 Kg of sodium chloride

(cooking salt), in the purifier (type 8 litres) and 2 kg in the purifier

(type 12 litres).

- Replace the cover and reposition the lever C from right to left

as in fig. 17.03 and let the salty water drain from the tap F until there

is fresh water.

- Reposition the lever D from right to left as in fig. 17.04.

IMPORTANT

The regeneration operations are correct only if the purifier

is the one shown in the figures. If it does not correspond,

proceed as indicated in the instructions attached to the

purifier.

••27

ENGLISH

PUSH

P

U

S

H

P

U

S

H

F. 18

F. 19

F. 20

F. 21

F. 22

14 - UNSCHEDULED

MAINTENANCE

IMPORTANT

Any repair and part replacements form part of the

unscheduled maintenance. They are therefore only to be

carried out by the Maintenance Technician.

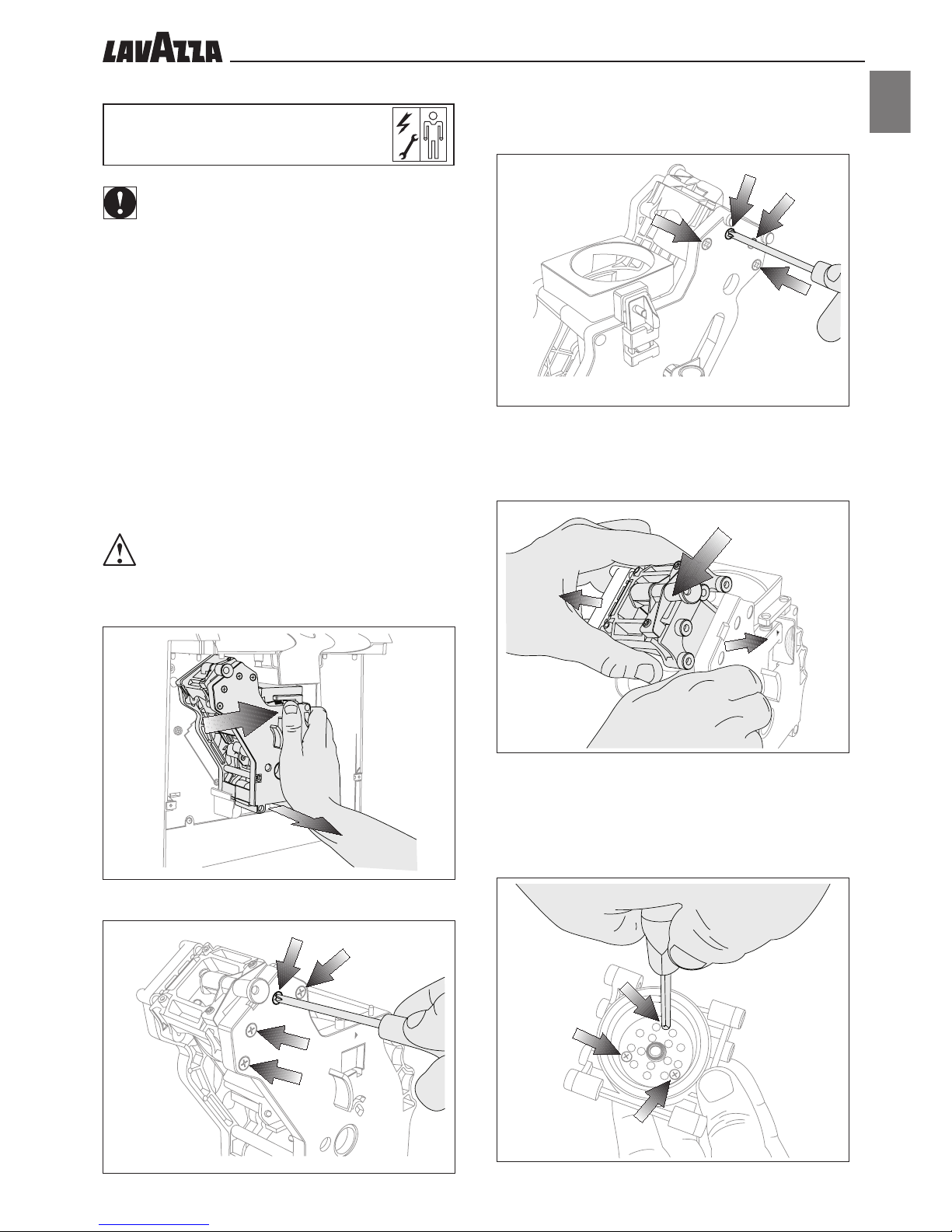

14.1 Brew group

It is recommended that the piercing filter is replaced every 40005000 cycles in order to guarantee higher quality of the coffee.

Deassembling the Piercing Filter

This section explains how to deassemble a piercing filter and

carry out maintenance on it.

Press the “PUSH” lever and remove the brew group by pulling it

outwards.

WARNING

This unit includes very sharp parts which may cause injuries

to the operator. Please be very careful when performing

maintenance operations.

Unscrew the 4 screws on the front of the brew group.

Unscrew the 4 screws located at the rear of the brew group.

Widen the walls of the brew group slightly, and take out the nonremovable container for coffee capsules.

Unscrew the 3 screws holding the perforator in place.

••28

F. 23

Remove the used perforator and put the new perforator back in place.

IMPORTANT

The perforator can be installed only in a pre-set position. To

install the perforator correctly, use the notch placed inside the

piston stop as a reference.

IMPORTANT

The perforator must be replaced if a pin is damaged.

15 - INSTRUCTIONS FOR

END-OF-LIFE DISPOSAL

TREATMENT

Warning

The diposal of the vending machine or of a part of it must be carried out

with full respect of the environment and according to local laws in force.

••29

ENGLISH

16 - TROUBLES, CAUSES

AND CURES

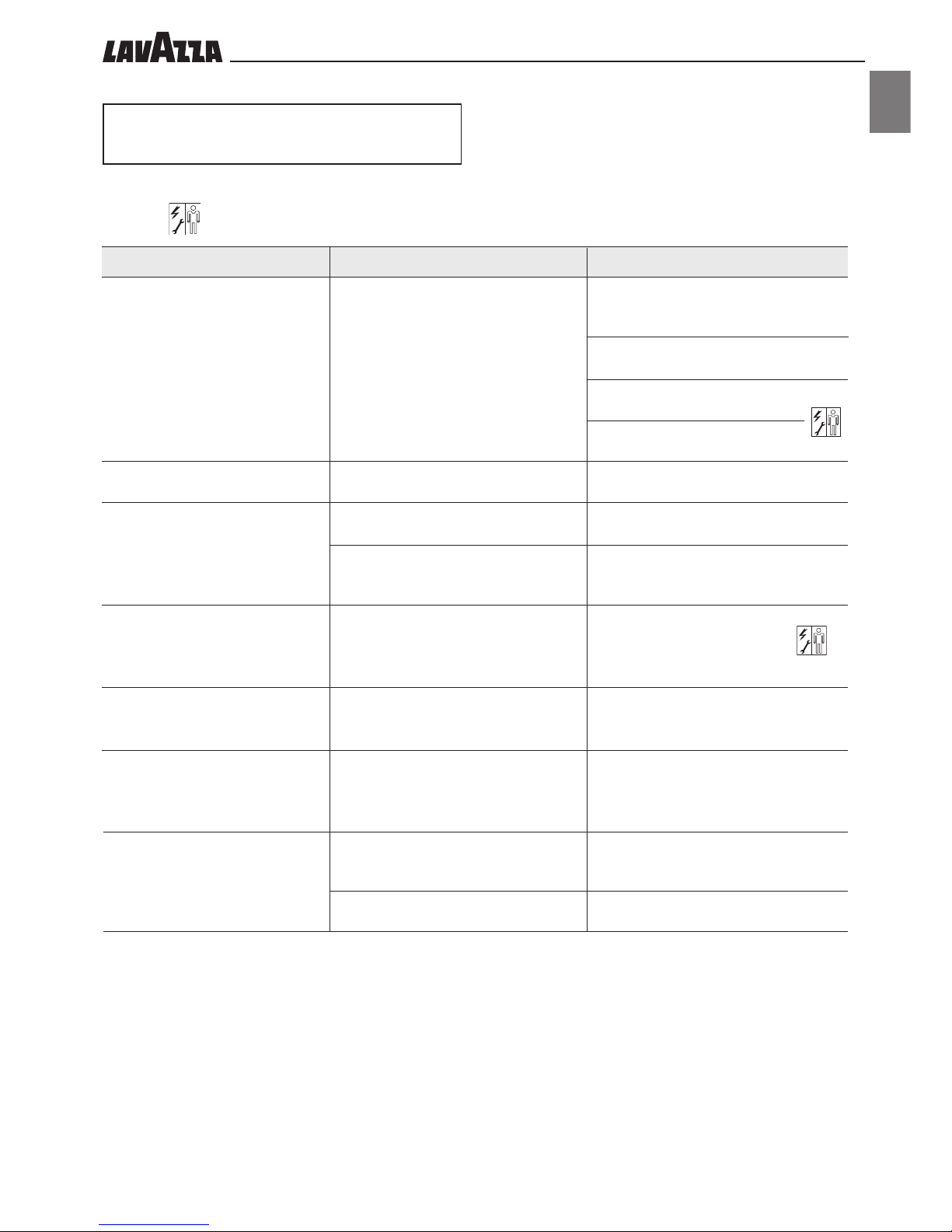

TROUBLE CAUSE

CURE

The machine does not start

No water or steam supply

Coffee is not hot enough

The machine requires too much

time to warm up, the water

quantity is reduced

The brew group cannot be

removed

The brew group cannot be refit

The cappuccinatore does not

dispense milk

No voltage

The steam/hot water spout’s hole is clogged

The cup has not been preheated

The machine has not yet reached the

suitable temperature

The machine circuit is clogged by scale

The brew group is not in the right position

The brew group is not in the right position

The milk used is not cold enough (see warnings)

No more milk in the container

Check:

- if the plug is connected

- if the all-pole switch (if any) is on

- the system fuses

- the electric connections

Clean it with a thin needle

Preheat the cup on the cup warming plate

Wait for the machine to reach the suitable

temperature

Descale the machine

Switch the machine on and off through the

main switch

Manually turn the group onto the standard

position, matching the reference mark placed

on the structure with the arrow

Move the temperature adjusting lever

downward

Fill milk container

Here is a list of the possible machine troubles.

The symbol in the “cure” box means that the operation must be carried out by the Maintenance Technician only.

••30

1 - COMPOSITION DE LA MACHINE ............ 3 1

2 - REMARQUES À CONSULTER....................... 3 2

2.1 Abréviations ........................................................... 32

2.2 Symboles utilisés ...................................................... 32

3 - UTILISATEUR....................................................... 3 2

4 - TECHNICIEN D’ENTRETIEN......................... 3 2

5 - UTILISATION PRÉVUE DE LA MACHINE .3 2

6 - AVERTISSEMENTS ET PRÉCAUTIONS...... 3 3

7 - PRÉCAUTIONS GÉNÉRALES ....................... 3 3

8 - INFORMATIONS SUR LA MACHINE ....... 3 3

8.1 Données d’identification .......................................... 33

8.2 Caractéristiques techniques ...................................... 33

8.3 Dimensions d’encombrement ................................... 33

8.4 Groupe de distribution de café ................................. 34

8.5 Groupe Cappuccinatore .......................................... 34

9 - DISPOSITIFS DE SÉCURITÉ ........................... 3 4

9.1 Risques résiduels ...................................................... 34

10

- INSTALLATION................................................. 3 5

10.1 Remarques sur l’emplacement ................................... 35

10.2 Mise en place de l’appareil ...................................... 35

10.3 Branchement de l’eau .............................................. 35

10.4 Raccordement électrique .......................................... 36

10.5 Connexion du port série .......................................... 36

1 1 - PREMIÈRE MISE EN CIRCUIT DE LA MACHINE. 3 6

12

- EMPLOI DE LA MACHINE ............................ 3 6

12.1 États de la machine ................................................. 36

12.2 Description des commandes ..................................... 37

12.3 Fonctions programmables du menu .......................... 39

12.4 Structure du menu de programmation ....................... 39

12.5 Description des fonctions......................................... 40

12.6 Structure du menu de service .................................... 45

12.7 Messages affichés .................................................... 49

12.8 Mise hors circuit de la machine ................................ 49

13

- ENTRETIEN DE ROUTINE .............................. 5 0

13.1 Nettoyage de la machine ......................................... 50

13.1.1 Distributeur de café (Fig. 12) .................................... 50

13.1.2 Bac et grille égouttoir .............................................. 50

13.1.3 Bac à capsules......................................................... 50

13.1.4 Tuyaux de distribution de vapeur et d’eau chaude ..... 50

13.1.5 Plaque chauffe-tasses ............................................... 50

13.1.6 Groupe de distribution ............................................. 50

13.1.7 Trémie d’éjection capsule ......................................... 50

13.1.8 Nettoyage du cappuccinatore .................................. 51

13.1.9 Régénération adoucisseur ........................................ 53

14

- ENTRETIEN CURATIF ...................................... 5 4

14.1 Groupe de distribution............................................. 54

15

- INSTRUCTIONS POUR LE TRAITEMENT

DE FIN DE VIE UTILE....................................... 5 5

16

- INCONVÉNIENTS - PROBLÈMES ET SOLUTIONS .............. 5 6

AVANT-PROPOS

• Ce manuel fait partie intégrante de la machine et il est donc à garder dans de bonnes conditions, dans un endroit facilement accessible

pendant toute la vie opérationnelle de la machine (compte tenu des passages de propriété aussi). L’objectif de ce manuel est le passage

d’informations nécessaires pour l’utilisation correcte et en toute sécurité de la machine.

• En cas de perte ou bien de détérioration de ce manuel, s’adresser à un Centre d’Assistance Agréé, afin d’en demander une copie,

et préciser le modèle et l’année de fabrication de la machine.

• Les Centres d’Assistance Agréés sont également disponibles pour tout renseignement concernant les aspects techniques, le fonction-

nement, l’assistance technique et les pièces de rechange.

• Les sujets présentés dans ce manuel sont valables pour l’utilisation de la machine dans des conditions de sécurité pour les

personnes, la machine et l’environnement, dans l’interprétation d’un simple diagnostic des endommagements et des conditions de

fonctionnement anomal, en effectuant de simples opérations de contrôle et d’entretien, dans le respect absolu des prescriptions reportées

dans les pages suivantes et des Normes de Sécurité et de Santé en vigueur.

• Avant d’effectuer toute intervention, lire attentivement le manuel et s’assurer d’en avoir bien compris le contenu.

• Si la machine est employée (individuellement) par plusieurs utilisateurs, il faut absolument que chaque utilisateur connaisse en détail

le mode d’emploi.

• Le Constructeur se réserve le droit de modifier ou bien d’effectuer des améliorations de la machine sans préavis.

• En cas d’exigences spéciales, s’adresser au Distributeur ou à l’Importateur (si présent) de son pays ou bien au Constructeur de la

machine.

• Tous les droits de ce manuel sont strictement réservés à la Maison LAVAZZA. La reproduction ou la diffusion, même en partie, sans

autorisation écrite, sont interdites.

TABLE DES MATIÈRES

Loading...

Loading...