LAVAZZA LB2317 Operation And Maintenance

Automatic Machine for Espresso Coffee and Hot Beverages

UKUK

WARNING: Read these instructions carefully before using the machine.

OPERATION AND MAINTENANCE

English

2

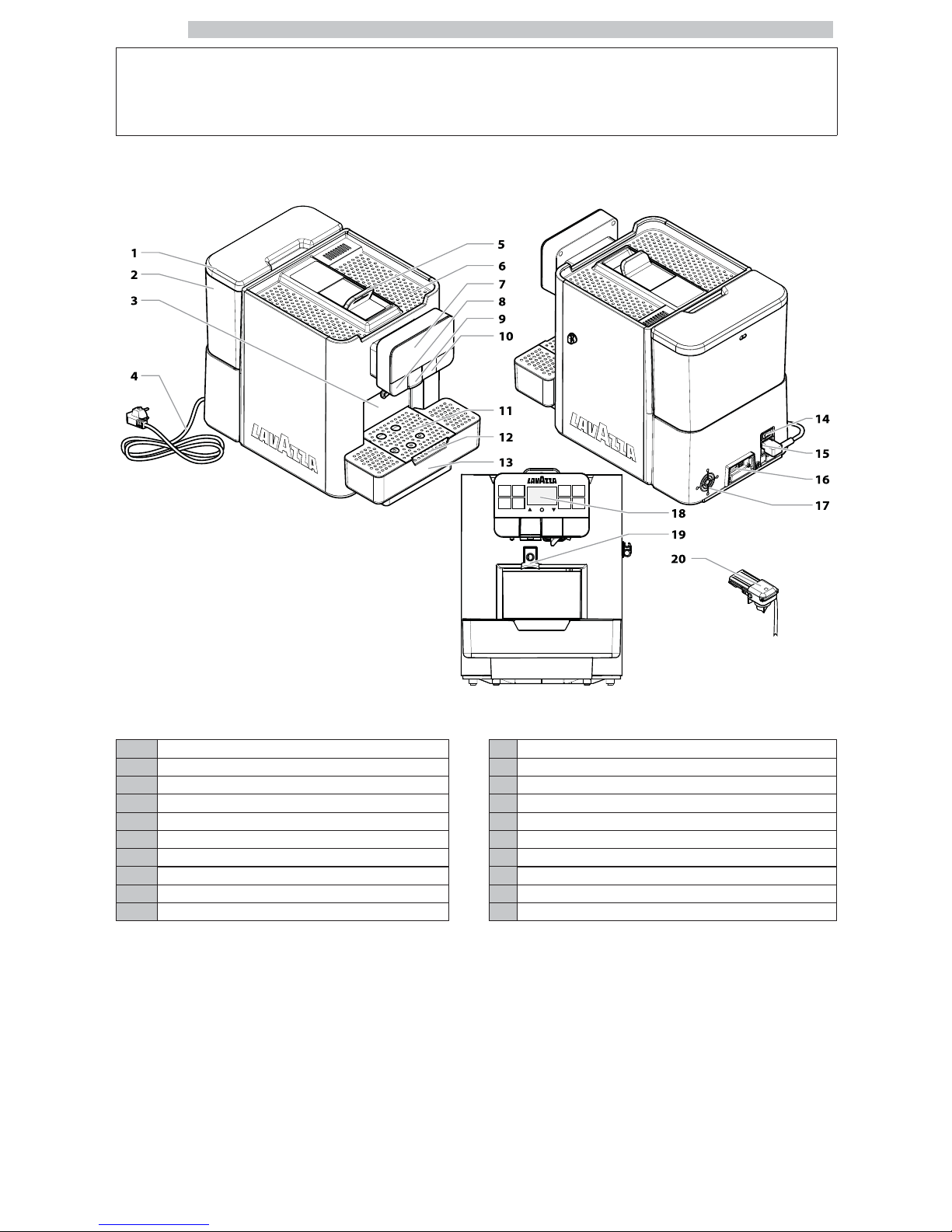

MAIN PARTS

1 Water tank lid

11

Cup holder (small cups)

2 Water tank

12

Cup holder (mugs)

3 Used capsule drawer

13

Drip tray

4 Power cord

14

Power button

5 Capsule loading tray

15

Chassis plug

6 Cup holder surface

16

USB port

7 Touch control panel

17

Ventilation fan

8 Hot water dispensing spout

18

Display

9 Moving coffee dispensing spout

19

Double espresso dispensing spout

10 Cappuccinatore cover

20

Cappuccinatore

English

3

SAFETY INSTRUCTIONS

Never allow water to

come into contact

with any of the

electrical parts of the

machine: danger of

short circuit! Hot

water and steam may

cause scalding!

Intended Use

The machine is intended to

be used in small

offices/organisations only.

Do not make any technical

changes or use the

machine for unauthorised

purposes since this would

create serious hazards!

The machine may be used

by children older than 8 and

upwards or by persons with

reduced physical, mental or

sensory abilities or lacking

sufficient experience and/or

skills, provided that they are

supervised or instructed on

how to use the appliance

correctly and that they

understand the hazards

involved.

Children must not play

with the appliance.

Children must not carry

out any cleaning and

maintenance operations

without being monitored.

English

4

Power Supply

The machine must be

connected to the power

supply by the service

provider, in accordance

with its specifications.

Power cord

Never use the machine if

the power cord is

defective.

Report any defects in the

cord and/or plug to the

service provider immediately.

Do not pass the power

cord around corners, over

sharp edges or over hot

objects and keep it away

from oil.

If the power cord is

damaged, it must be

replaced by the

manufacturer, its service

centre or by adequately

qualified personnel in

order to avoid any risks.

Do not use the power

cord to carry or pull the

machine. Do not pull out

the plug by the power

cord or touch it with wet

hands or feet. Do not let

the power cord hang freely

from tables or shelves.

For the Safety of

Others

Ensure that children cannot

play with the machine

and/or the packaging

materials.

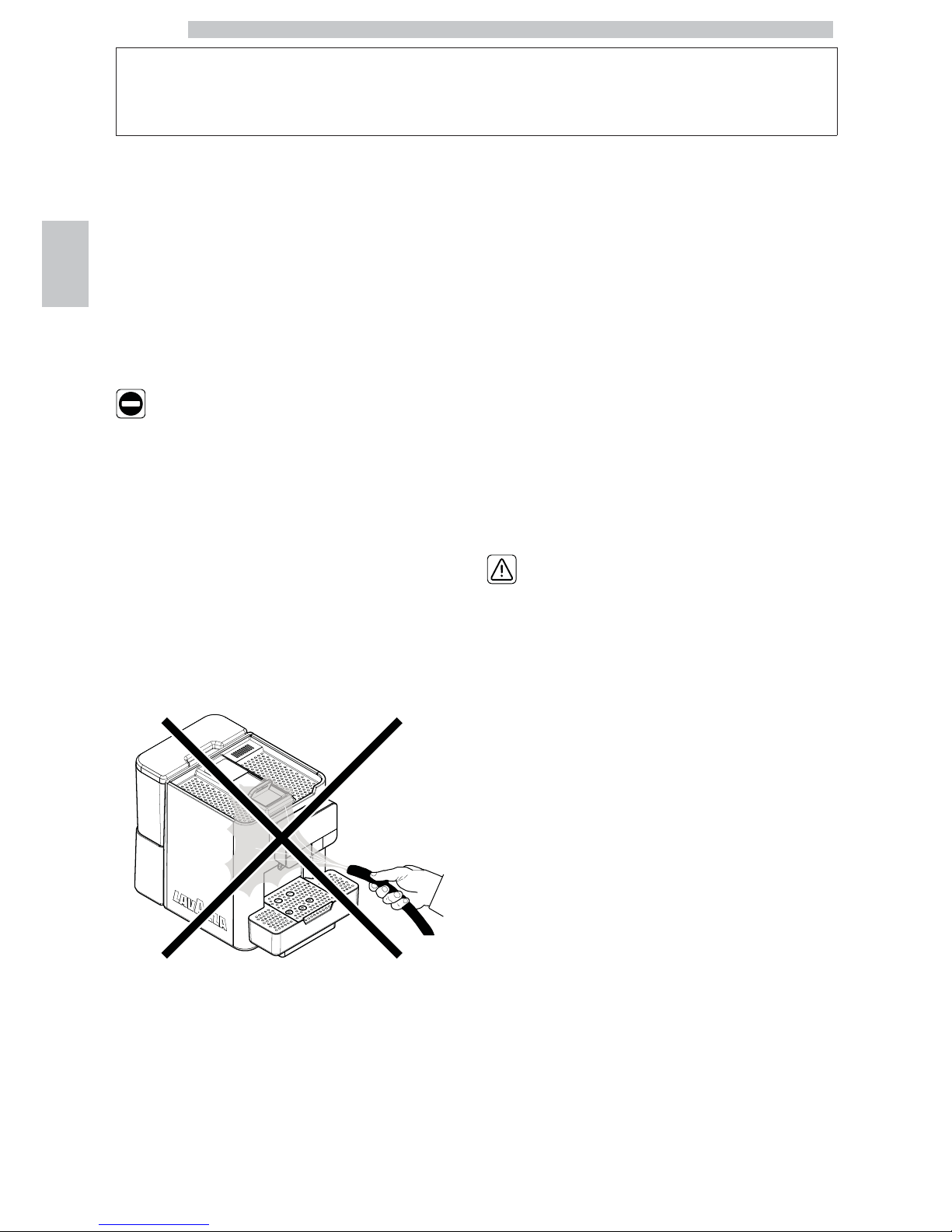

Danger of Burning

Do not touch the hot

water dispensing spout or

the coffee/beverage

dispensing spout.

English

5

Fire Safety Precautions

In case of fire, use carbon

dioxide (CO2)

extinguishers. Do not use

water or dry powder

extinguishers.

Suitable Location for

Operation and Maintenance

The machine should be

installed by the service

provider in accordance

with the safety regulations

in force at the time of

installation.

The machine may only be

moved by the service

provider.

Do not use the machine

outdoors.

Do not install the machine

in a location where water

jets may be used.

Avoid placing open flames

and/or incandescent

objects near the machine

so as not to damage or

melt the machine housing.

Do not use in places

where the temperature

may drop to a level equal

to and/or lower than 2°C

or higher than 32°C. If the

machine has been exposed

to such conditions, alert

the service provider, who

will carry out a safety

check.

The appliance must be

installed on a horizontal

surface.

The machine must only be

installed in places where it

can be checked by

qualified staff.

English

6

Cleaning

Before cleaning the

machine, the power button

must be switched to OFF

(0) and the plug must be

removed from the power

socket. Wait for the

machine to cool down.

Never immerse the

machine in water!

It is strictly forbidden to

tamper with the internal

parts of the machine.

Do not clean the machine

using a jet of water.

The appliance and its

components must be

cleaned and washed

following a period of

inactivity.

Using Milk

Milk must be used and

stored in accordance with

the instructions given on

the manufacturer's original

packaging.

We accept no liability for

use of milk unsuitable for

human consumption.

Milk must be kept cold, as

high temperatures will

make it turn sour - this is a

natural characteristic of

milk. For this reason, the

Cappuccinatore must be

cleaned after each use, as

described in the manual.

Clean the Cappuccinatore

following the instructions

described in this manual.

English

7

Milk Dosage

The machine has a default

dose set-up for all milk

beverages. However, the

dose of beverage in the

cup may vary according to

the type of milk used.

Therefore it is

recommended to check

the doses - using a milk

type which is normally

used - and, if necessary, to

set them again according

to the user needs.

Storing the Machine

If the machine is to remain

inactive for a long time,

turn it off and unplug it.

Store the machine in a dry

place, out of the reach of

children. Keep it protected

from dust and dirt.

Repairs / Maintenance

In case of breakdown, defect

or a suspected fault resulting

from a fall, immediately

remove the plug from the

power socket and alert the

service provider or

specialised technician.

Never attempt to operate

the machine if it is faulty.

Only the service provider

and/or technician may

service or repair the

machine.

Only skilled and

experienced people - with

particular reference to

safety and hygiene - are

allowed to access the

service area.

English

8

CONTENTS

MAIN PARTS

2

1 INTRODUCTION TO THE MANUAL

9

1.1 PREAMBLE

9

1.2 ICONS USED

10

2 INFORMATION ABOUT THE MACHINE

11

2.1 INFORMATION FOR THE MAINTENANCE

TECHNICIAN

11

2.2 DESCRIPTION AND INTENDED USE

11

2.3 APPLIANCE IDENTIFICATION

12

2.4 TECHNICAL SERVICE LAVAZZA

12

2.5 TECHNICAL SPECIFICATIONS

13

3 SAFETY

14

3.1 PREAMBLE

14

3.2 GENERAL SAFETY INSTRUCTIONS

14

3.3 OPERATOR REQUIREMENTS

15

4 HANDLING AND STORAGE

16

4.1 UNLOADING AND HANDLING

16

4.2 STORAGE

16

5 INSTALLATION

17

5.1 CAUTIONS

17

5.2 UNPACKING AND POSITIONING

18

5.3 CONNECTION TO THE ELECTRIC NETWORK

20

6 DESCRIPTION OF CONTROLS

21

6.1 POWER BUTTON

21

6.2 DISPLAY

21

6.3 KEYPAD

21

6.4 BUTTON DESCRIPTION DURING NORMAL

OPERATION

21

7 SUPPLY AND START UP

23

7.1 FILLING THE WATER TANK

23

7.2 MEASURING AND ADJUSTING WATER

HARDNESS

24

7.3 AQUACLEAN FILTER

24

7.4 "INTENZA+" WATER FILTER

30

7.5 ADJUSTING THE COFFEE DISPENSING SPOUT

32

7.6 TURNING ON/OFF THE MACHINE

33

7.7 FIRST USE - USE AFTER A LONG PERIOD OF

INACTIVITY

33

7.8 WASHING THE PARTS COMING INTO

CONTACT WITH FOOD

35

7.9 USING THE APPLIANCE

35

8 PROGRAMMING MENU

36

8.1 BUTTON DESCRIPTION IN PROGRAMMING

MODE

36

8.2 USER PROGRAMMING

36

8.3 MAINTENANCE PROGRAMMING

39

8.4 TECHNICAL PROGRAMMING

46

9 OPERATION AND USE

57

9.1 WARM-UP AND RINSING

57

9.2 RINSING AND SELF-CLEANING

57

9.3 LOADING CAPSULES

58

9.4 USING THE SUCTION TUBE

59

9.5 BREWING A SINGLE COFFEE/PRODUCT

60

9.6 BREWING A DOUBLE ESPRESSO

65

9.7 DISPENSING HOT WATER

66

9.8 EMPTYING THE CAPSULE DRAWER AND THE

DRIP TRAY

66

10 CLEANING AND MAINTENANCE

69

10.1 GENERAL NOTES FOR CORRECT

OPERATION

69

10.2 CLEANING AND SCHEDULED

MAINTENANCE

70

11 TROUBLESHOOTING

82

11.1 WARNING SIGNALS

82

11.2 PROBLEMS - CAUSES - SOLUTIONS

85

12 STORAGE - DISPOSAL

86

12.1 LOCATION CHANGE

86

12.2 INACTIVITY AND STORAGE

86

13 INSTRUCTIONS FOR END OF

OPERATIONAL LIFE DISPOSAL

87

English

1

9

1 INTRODUCTION TO THE MANUAL

1.1 Preamble

This publication is an

essential part of the

machine and must be read

carefully for a proper use

compliant with basic safety

requirements.

This manual contains the

technical information

necessary to properly

perform the operating,

installation, cleaning and

maintenance procedures.

Always refer to this manual

before carrying out any

operation.

Manufacturer: SaGa Coffee S.p.A.

Località Casona, 1066 - 40041 Gaggio Montano

Bologna, Italy

www.saecoprofessional.com

This product has been manufactured by SaGa Coffee S.p.A.

and sold under its own responsibility. SaGa Coffee S.p.A. is

the guarantor of the product. Saeco is a registered

trademark of Koninklijke Philips N.V. and its use is licensed

by Koninklijke Philips N.V.

This publication should be

carefully kept and must be

provided with the machine

throughout its service life,

including any transfer of

ownership.

If this manual is damaged

or lost, a copy may be

requested from the

manufacturer or the

technical service by

indicating the data

contained on the data

plate on the rear side of

the machine.

The manufacturer reserves

the right to make changes

without prior notice.

English

1

10

1.2 Icons Used

Various kinds of warnings are contained in this manual to

highlight the different hazard or competence levels.

Each icon is followed by a message suggesting operating

and behaviour procedures and providing useful information

for the correct operation of the machine.

Warning

It is used to highlight danger situations for the persons in

charge of using, refilling and servicing the machine.

Prohibition

It is used to highlight actions/operations not to be

performed.

Important

It is used to indicate operations that, if correctly

performed, preserve the correct operation of the

machine.

Suggested solutions

It is used to indicate alternative procedures which make

programming and/or maintenance operations quicker.

User

It is used to indicate the user of the machine. Users are

not allowed to perform any cleaning or maintenance

operations.

Supply operator

It is used to indicate those operations that must be

performed only by the person in charge of refilling and

cleaning the machine.

Supply operators can not perform any operations

requiring a Maintenance Technician.

Maintenance technician

It is used to signal those operations that must be

performed only by the specialised maintenance technicians.

English

2

11

2 INFORMATION ABOUT THE MACHINE

2.1 Information for the

Maintenance Technician

The appliance must be

installed in a well-lit,

sheltered and dry place

and on a counter able to

bear its weight.

To ensure its correct operation and reliability over time,

comply with the following recommendations:

• ambient temperature: from +2°C to +32°C;

• maximum humidity allowed: 80% (non-condensed).

For special installations, not covered by this manual, please

contact the dealer or the local importer. If this is not

possible, please contact the Manufacturer.

The technical service is available for any explanation or

information regarding the correct operation of the

machine and to satisfy any request for spare parts supply

or technical assistance.

The Maintenance Technician must carefully read and

observe the safety warnings contained in this manual to

ensure that installation, start-up, use and maintenance

operations are performed in complete safety.

This manual is an essential part supplied with the machine

and must always be available for consultation before

carrying out any operation on the machine.

2.2 Description and Intended Use

This machine automatically brews:

• coffee and espresso brewed with compatible LAVAZZA

BLUE capsules only.

• hot water to prepare beverages;

• milk-based beverages using the Cappuccinatore supplied.

The elegant machine housing has been designed for use in

small offices, businesses and institutions.

Using the machine for any other purpose is considered

dangerous and as a misuse.

Misuse voids all forms of

warranty, releasing the

Manufacturer from any

responsibility for damage

to property and/or

personal injury.

The following are also

considered misuse:

• any use other than the intended use and/or employing

methods other than those described in this manual;

• any operation on the machine in breach of the instructions

provided in this manual;

• any tampering with parts and/or safety devices not

previously authorised by the Manufacturer and performed

by unauthorised personnel;

• using capsules other than compatible LAVAZZA BLUE capsules.

• use of the machine outdoors.

In such cases, the user shall bear the costs of repair.

English

2

12

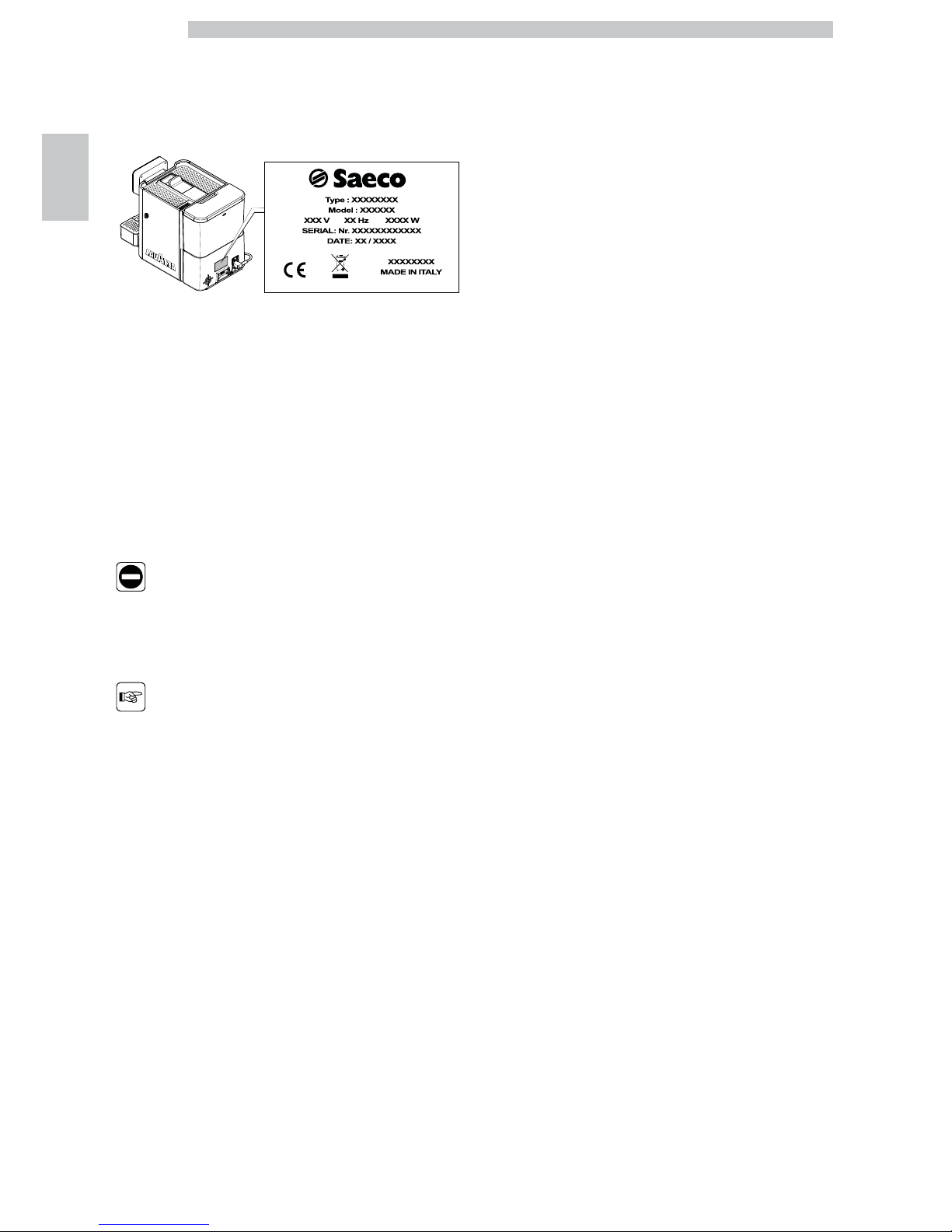

2.3 Appliance Identification

The appliance is identified by the model name and serial

number shown on the special plate.

The plate contains the following data:

• name of the Manufacturer;

• marks of conformity;

• model;

• serial number;

• year and month of manufacture;

• supply voltage (V);

• supply frequency (Hz);

• electrical power consumption (W);

• appliance code.

It is strictly forbidden to

tamper with or modify the

data plate.

When contacting the

technical service, always

refer to this plate by

indicating the technical

data shown on it.

2.4 Technical Service Lavazza

In the event of a failure or malfunction that can not be

solved, please contact:

Technical Service Lavazza

Corso Piemonte 61/A

10099 San Mauro Torinese (TO) - ltaly Tel. +39 0112398429

Fax. +39 01123980466

technicalservice@lavazza.it

English

2

13

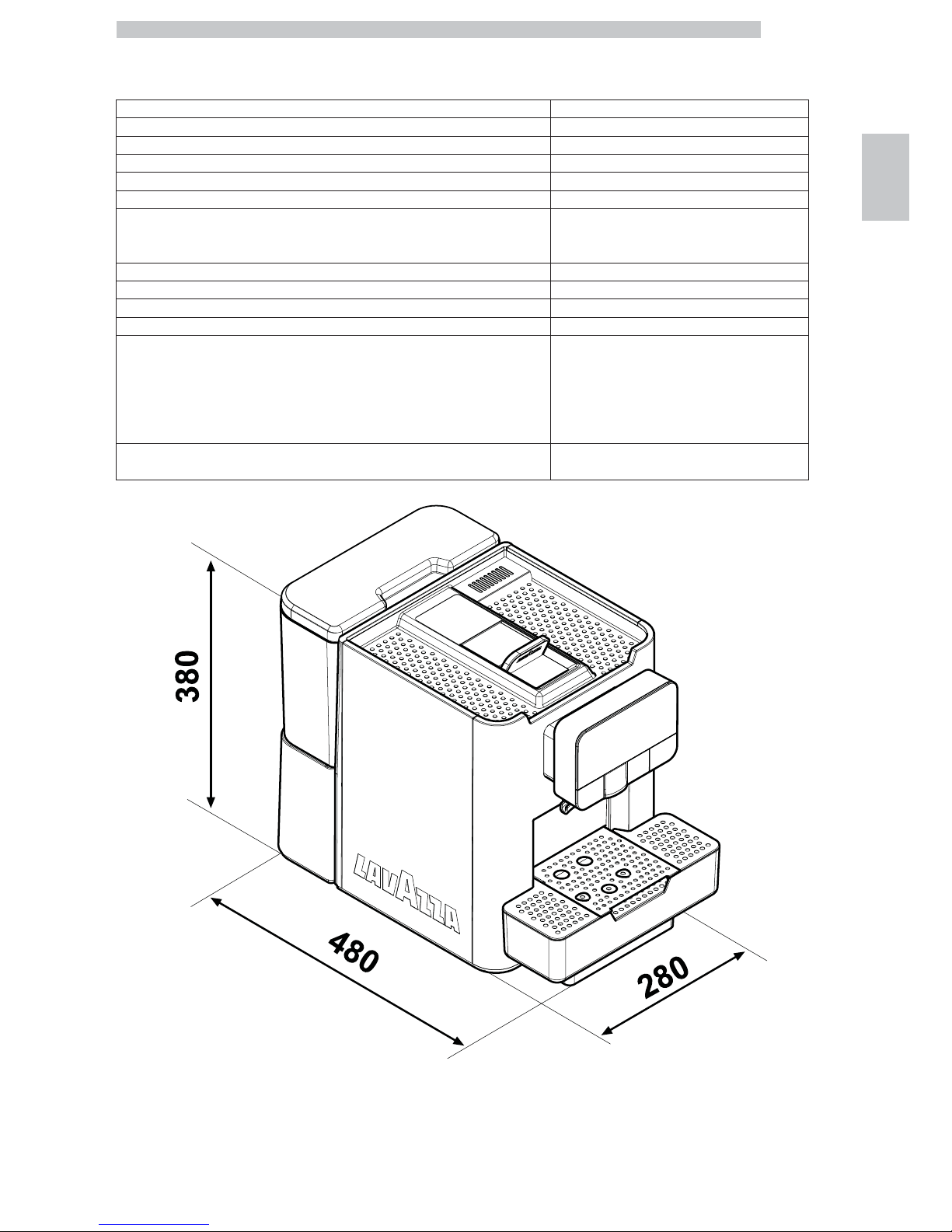

2.5 Technical Specifications

Size (w x h x d) 280 x 380 x 480 mm

Weight approx. 9 kg

Machine housing material Thermoplastic material

Power Rating See the data plate

Supply Voltage See the data plate

Power cord length approx. 1,200 mm

Capacity Water tank 4 litres

Used capsule drawer

25 capsules

Capsule Type Lavazza BLUE

Control panel Front panel

A-weighted sound pressure level less than 70 dB

Pump pressure Max. 1.9 MPA (19.0 bar)

Operating conditions

Minimum temperature:

above 2°C

Maximum temperature:

less than 32°C

Maximum humidity:

less than 80%

Safety devices Boiler pressure safety valve

Safety thermostat

Subject to engineering and manufacturing changes due to technological improvements.

Machine compliant with EU Directive 2014/30/EU.

English

3

14

3 SAFETY

3.1 Preamble

The manufacturer acknowledged the following standards in

the design and certification stages:

• CAN/CSA-C22.2 No. 109-17 - Commercial Cooking

Appliances

• UL 197 - Commercial Electric Cooking Appliances

3.2 General Safety Instructions

It is forbidden to:

• tamper with or disable the safety systems installed on the

machine;

• perform maintenance operations on the appliance, before

unplugging the power cord;

• install the appliance outdoors. It is advisable to place it in a

dry place where the temperature does not drop below

2°C, in order to prevent any possible freezing.

• use the appliance for purposes other than those indicated

in the sale contract and in this manual;

• electrically connect the appliance using multi-sockets or

adapters;

• use jets of water for cleaning operations.

It is mandatory to:

• check conformity of the power supply;

• use original spare parts;

• carefully read the instructions contained in this manual and

in the attached documents;

• use personal protective equipment when performing

installation, testing and maintenance operations.

Precautionary measures to prevent human errors:

• make the operator aware of safety issues;

• handle the appliance, either packaged or unpackaged, in

complete safety;

• deeply know the installation procedures, its correct

operation and its limits;

• dismantle the appliance in complete safety, in accordance

with the workers' health and environmental protection

regulations in force.

To prevent machining

residues from coming into

contact with the beverages,

dispense about 0.5 l of

water for each dispensing

path before definitely

starting the appliance. The

dispensed beverages can

be drunk only after

performing this operation.

English

3

15

In case of failure or

malfunctioning, please refer

only to the qualified

personnel of the technical

service.

The manufacturer is not

liable for damage to

persons or property

resulting from failure to

follow the safety

instructions provided in

this section.

3.3 Operator Requirements

Three operators with different skills are required in order

to guarantee the appliance’s safety:

User

The user is not allowed to access the internal parts of the

machine.

Supply operator

Only the Maintenance Technician is in charge of refilling

the machine with products, cleaning the outside of the

appliance, turning it on and off.

The Supply operator is not

allowed to carry out

operations indicated in this

manual as competence of

the Maintenance

Technician.

Maintenance technician

The maintenance technician is the only person authorised to

service the machine, start the programming procedures and

perform the adjustment, set up and maintenance operations.

Access to the internal area

is restricted to persons

having knowledge and

practical experience of the

appliance, in particular as

far as safety and hygiene

are concerned.

English

4

16

4 HANDLING AND STORAGE

All the operations

described in this chapter

must be performed

exclusively by the service

provider or a specialised

technician, who shall

organise all the operating

steps and use only suitable

means to ensure strict

compliance with the safety

regulations in force.

4.1 Unloading and Handling

Unloading from the transport vehicle and handling

operations of the appliance must be carried out by

qualified personnel only and using suitable equipment.

The appliance must always

be kept in upright position.

Do not:

• drag the appliance;

• overturn or lay down the appliance during transport and

handling;

• shake the appliance;

• lift the appliance by using ropes or cranes;

• leave the appliance exposed to bad weather, in humid

areas or close to heat sources.

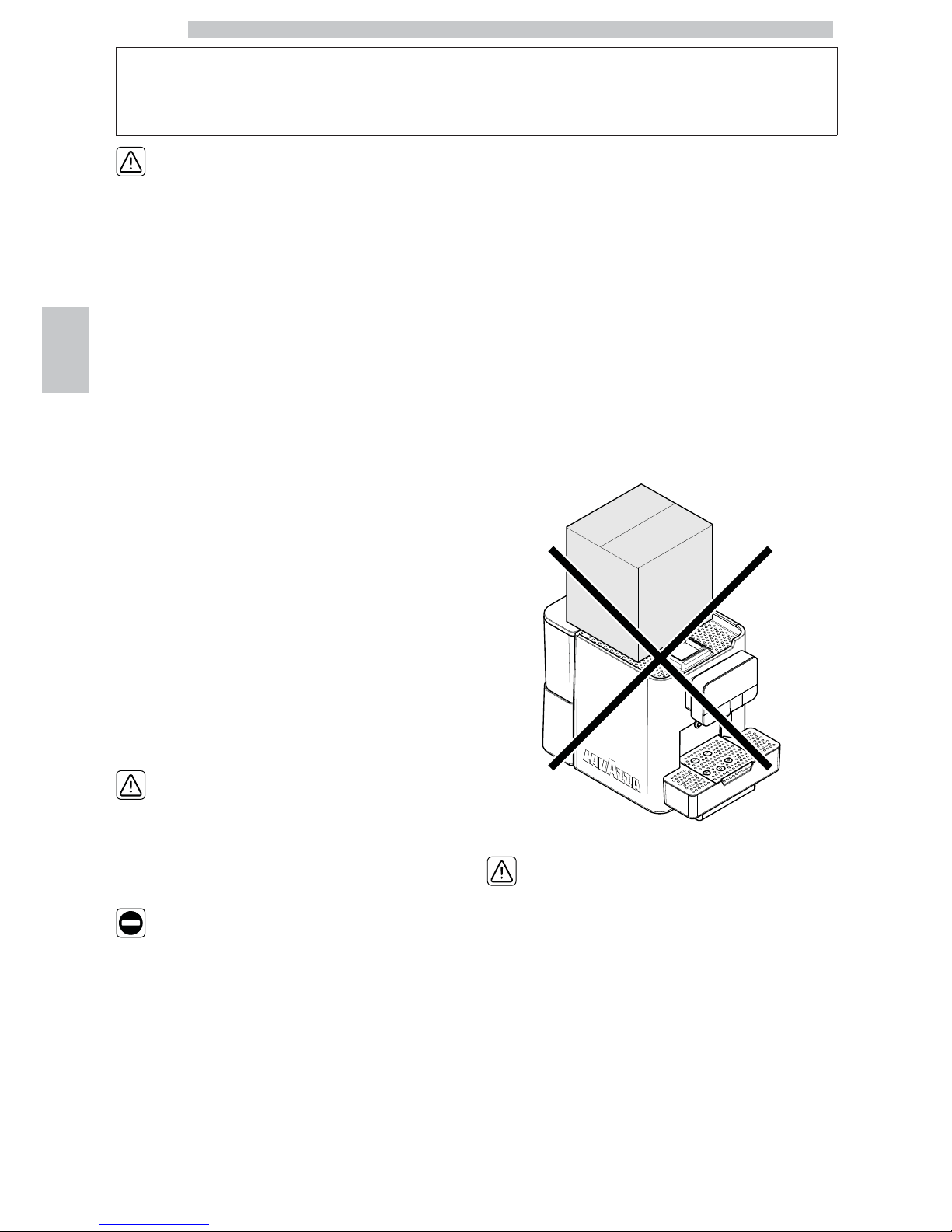

4.2 Storage

The machine is packed in cardboard and expanded

polystyrene packaging.

If the appliance is not immediately installed, it shall be kept

in a sheltered place according to the following instructions:

• the packaged appliance shall be stored in a closed, dry

area at a temperature between 1°C and 40°C;

• maximum humidity below 90% (non-condensed);

• do not put other appliances or boxes on the appliance;

• in any case, it is good practice to protect the appliance

from possible deposits of dust or other substances.

Due to the total weight,

do not stack more than

three machines on top of

each other. The machine

should be stored in its

original packaging, in a dry

and/or dust-FREE place.

English

5

17

5 INSTALLATION

All the operations

described in this chapter

must be performed

exclusively by the service

provider or a specialised

technician, who shall

organise all the operating

steps and use only suitable

means to ensure strict

compliance with the safety

regulations in force.

5.1 Cautions

The appliance cannot be

installed in external areas.

Avoid placing it in areas

where the temperature is

lower than 2°C or higher

than 32°C and in

particularly humid or dusty

places. It should neither be

installed in places where

water jets are used for

cleaning operations nor

where there is a risk of fire

or explosion.

Make sure that the installation place is compatible with the

following specifications, before unpacking the appliance:

• the power socket which the appliance is connected to

should be easily accessible and at a distance not higher

that 1.2 metres;

• the gradient of the supporting surface should NOT

exceed 2°;

• the socket voltage must correspond to that indicated on

the appliance data plate.

The appliance must be

installed on a horizontal

surface.

English

5

18

The supporting surface

must be adequate to bear

the machine weight and

clean.

Access to the machine and

the plug should be kept

clear at all times in order

to allow users to easily

reach them and to leave

the area immediately if

required.

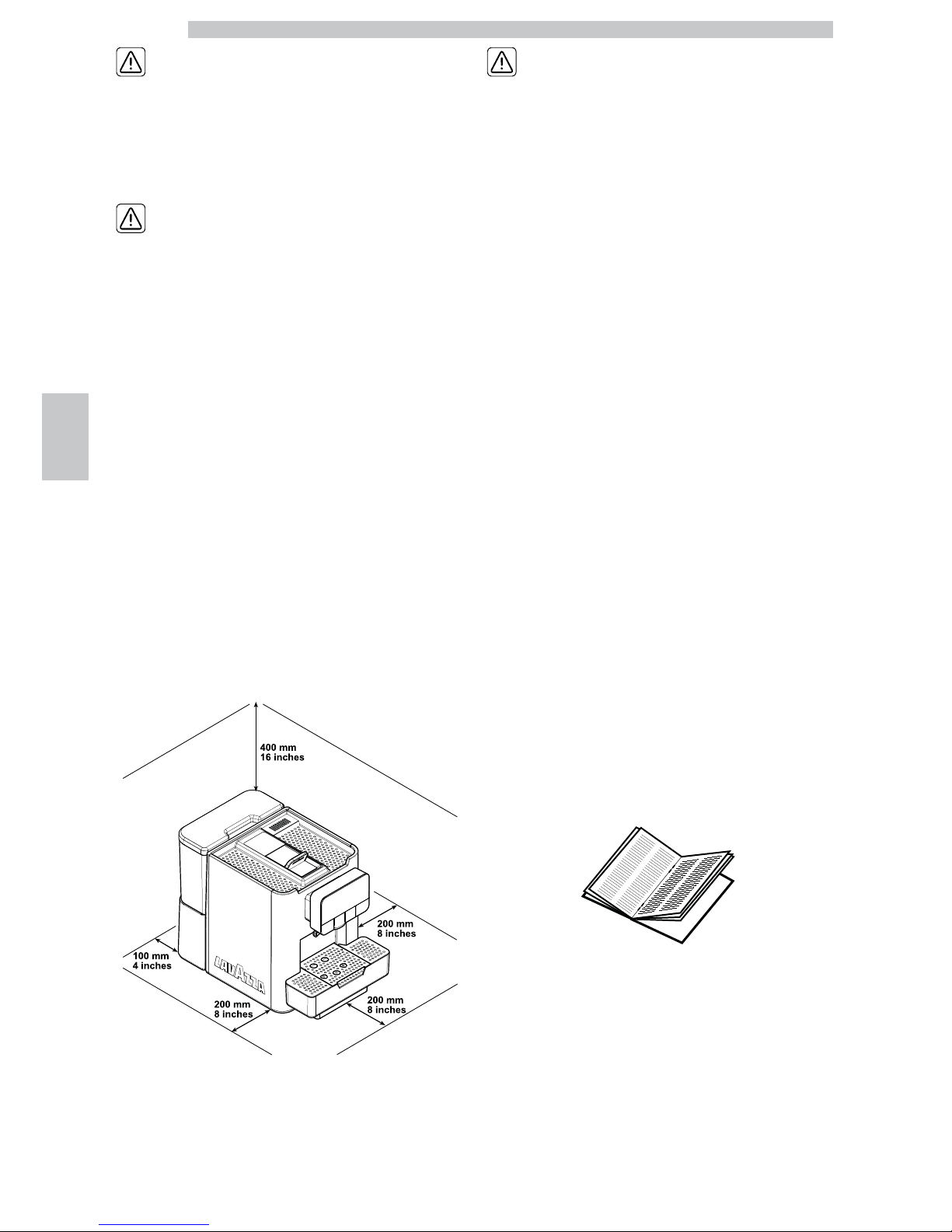

The following illustration shows the required access distances:

• to the keypad on the front of the appliance;

• to the service units in the event of malfunction.

The presence of magnetic

fields or proximity to

electrical machines which

generate interference

could cause the electronic

controls of the machine to

malfunction. At

temperatures close to 0°C,

internal parts containing

water are at risk of

freezing. Do not use the

machine under these

conditions.

5.2 Unpacking and Positioning

On receipt of the appliance, make sure that it has not

suffered any damage during transport or that the packaging

has not been unduly opened with consequent stealing of

the components contained in it. If damage of any kind is

found, the courier must be informed and notice must be

immediately given to the importer or to the seller. If these

are not in the purchaser’s country, please contact the

manufacturing company directly.

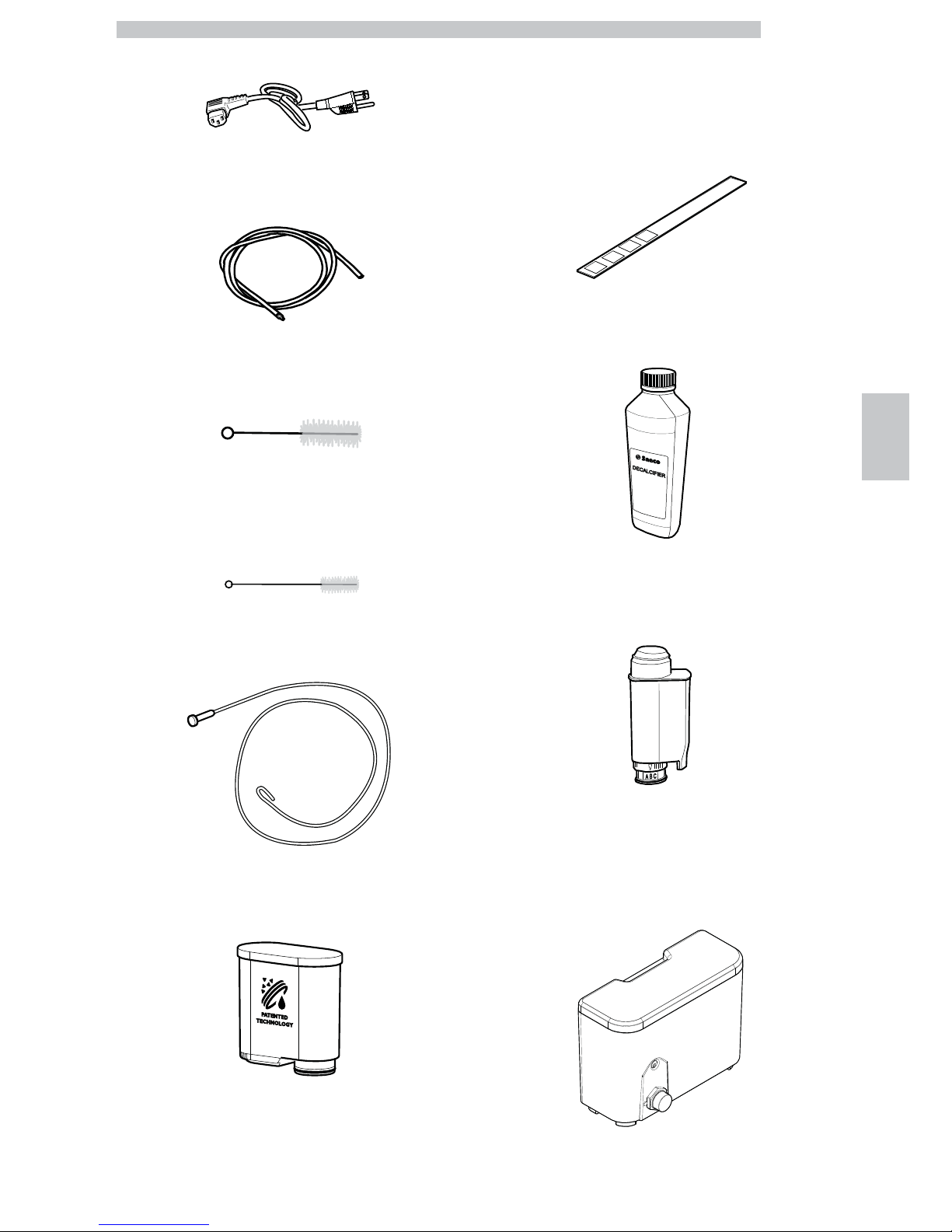

List of Standard Accessories

Manual: instructions on how to use the machine.

English

5

19

Power cord: to connect the machine to the mains.

Silicone hose: once connected to the Cappuccinatore it

allows to suck the milk from the container.

6 mm diameter brush.

4 mm diameter brush.

Cappuccinatore silicone hose scraper.

"AquaClean" filter: to remove any unpleasant flavours in

the water and reduce water hardness. This will improve

machine use.

List of Optional Accessories (not included)

Water hardness test: quick test to determine the actual

hardness of the water used to prepare beverages; this test

is of fundamental importance to set the water hardness in

the machine.

Descaling solution: to remove limescale build-up in the

water circuit caused by normal use.

"Intenza +" water filter: to remove any unpleasant flavours

in the water and reduce water hardness. This will improve

machine use.

Water net connection tank kit (code 18400053): it allows to

connect the machine to the water network via the replacement

of the standard water tank, supplied with the machine, with

this water net connection tank kit. Follow all the instructions

provided with the kit for a correct assembly and use.

English

5

20

5.3 Connection to the Electric

Network

This operation must only be

performed by specialised

technical personnel or by

the service provider.

The Maintenance

Technician, who is in

charge of the appliance's

installation, shall make sure

that:

• the power supply system complies with the safety

instructions in force;

• the voltage corresponds to that indicated on the appliance

data plate.

In case of doubt, do not

proceed with the

installation and ask qualified

and authorised personnel

to accurately check the

system.

Do not use adapters or

multi-sockets.

Make sure that the power

cord plug is easily

reachable after installation.

English

6

21

6 DESCRIPTION OF CONTROLS

6.1 Power button

It is located in the lower left part in the rear of the

machine.

If set to the "I" position the machine turns on (electrical

functions enabled).

If set to the "O" position the machine turns off (electrical

functions disabled).

6.2 Display

The display shows the messages during normal operation

and during the programming and maintenance phase.

6.3 Keypad

The function of each button

changes according to the

change of the appliance

phase (ordinary dispensing

or programming phase).

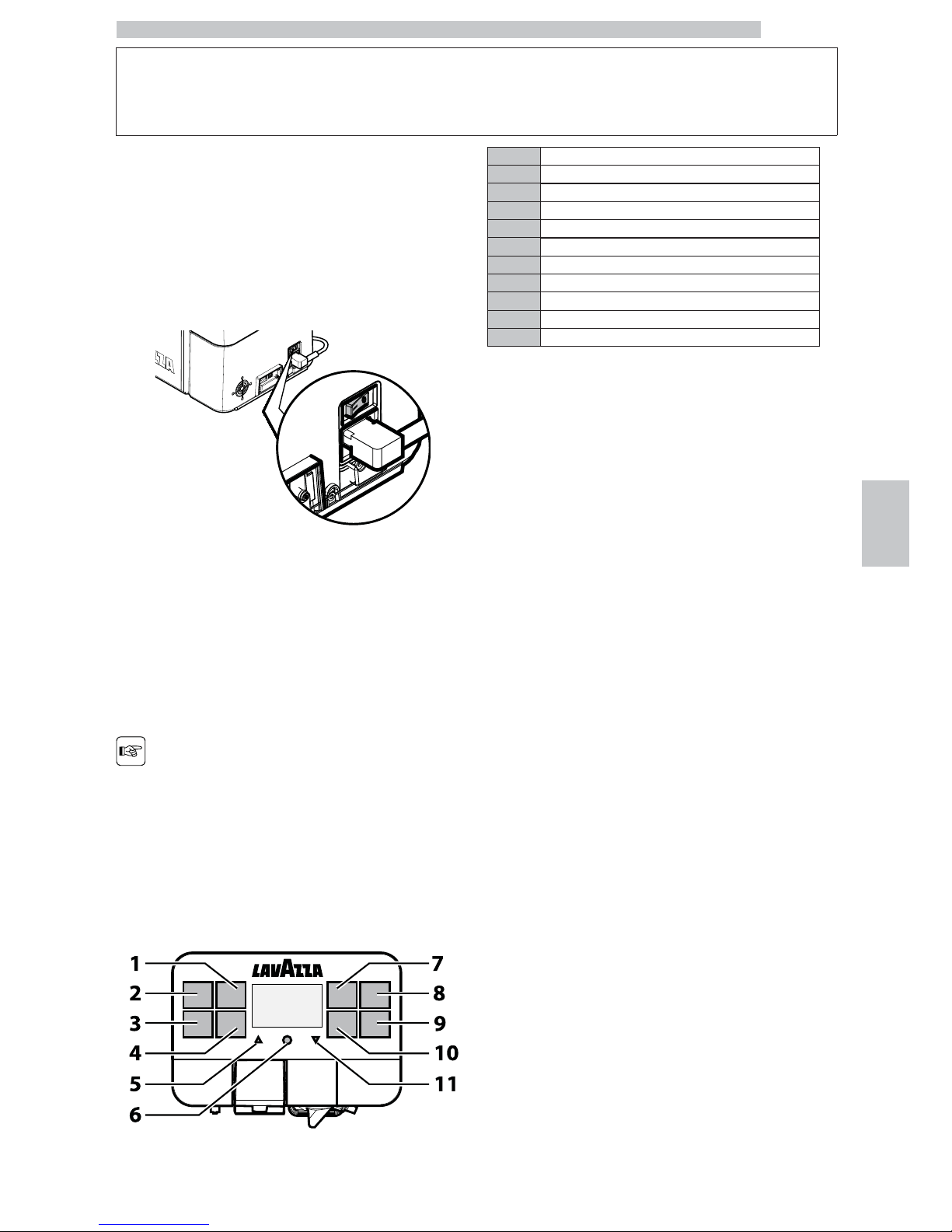

1 "Double Espresso" button

2 "Espresso" button

3 "Caffè Crema" button

4 "Hot Water" button

5 "Up" button

6 "MENU/OK" button

7 "Coffee with milk" button

8 "Cappuccino" button

9 "Latte Macchiato" button

10 "Soluble" button

11 "Down" button

6.4 Button Description during

Normal Operation

"Double Espresso" button

Press this button to brew a double espresso. Press it twice

consecutively - within three seconds after the first time

you pressed it - to brew a long double espresso.

"Espresso" button

When this button is pressed, an espresso coffee is brewed.

Press it twice consecutively - within three seconds after

the first time you pressed it - to brew a long espresso.

"Caffè Crema" button

Press this button to brew a caffè crema.

"Hot Water" button

Press this button to dispense hot water.

"Up" button

Press this button to scroll down the user menu options.

"MENU/OK" button

Press this button to access the user menu, which allows

you to perform a few machine washing cycles

(Cappuccinatore and brew group) and to access the

maintenance menu. Once entered the menu, this button

allows you to confirm the selected menu option.

"Coffee with milk" button

Press this button to brew a coffee with a dash of milk.

English

6

22

"Cappuccino" button

When this button is pressed, a cappuccino is brewed.

Press it twice consecutively - within three seconds after

the first time you pressed it - to brew a large cappuccino.

"Latte Macchiato" button

When this button is pressed, a Latte Macchiato is brewed.

Press it twice consecutively - within three seconds after

the first time you pressed it - to dispense a frothed milk.

"Soluble" button

Press this button to brew an instant product.

"Down" button

Press this button to scroll down the user menu options.

English

7

23

7 SUPPLY AND START UP

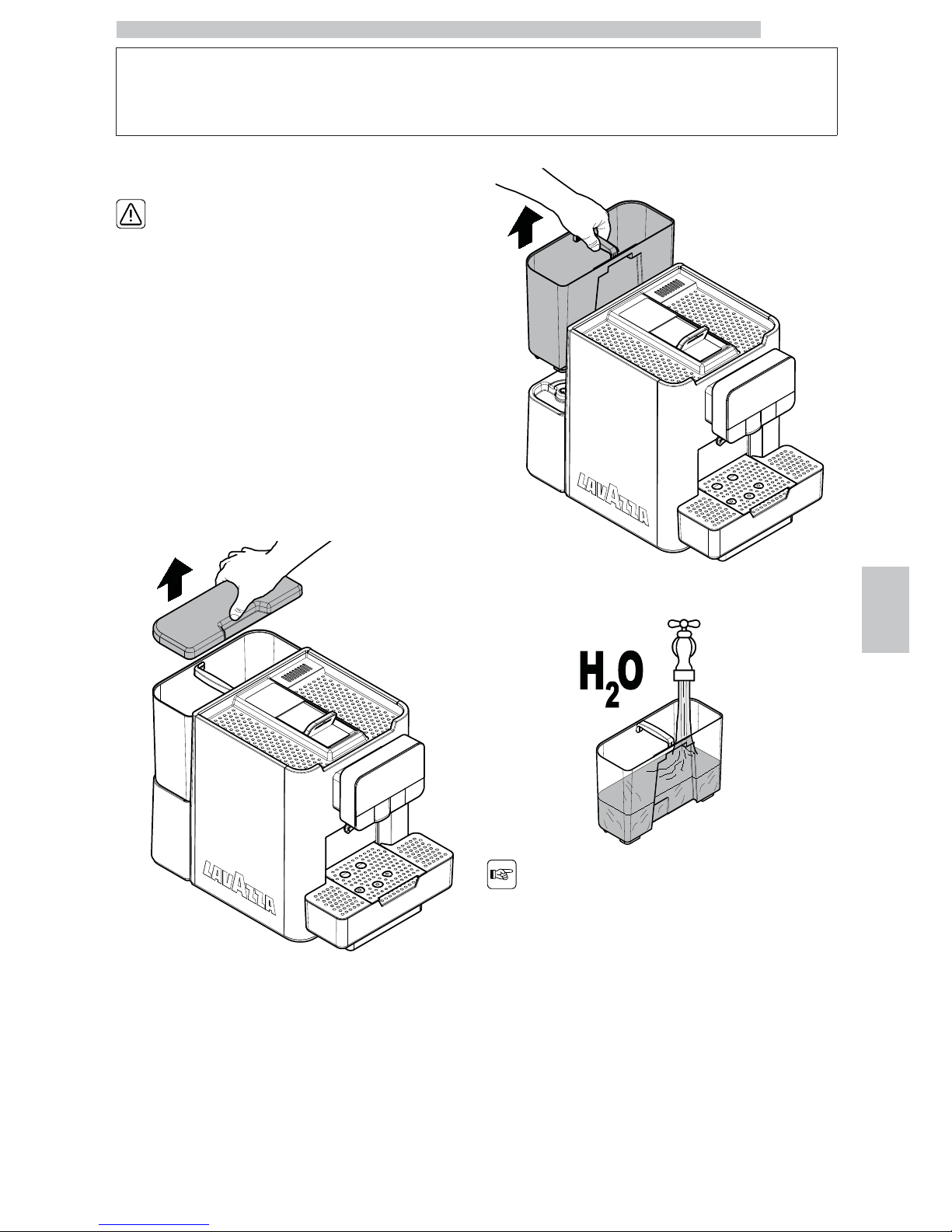

7.1 Filling the Water Tank

Before using the machine

for the first time, wash the

water tank carefully. Fill the

water tank with fresh

drinking water only. Hot or

carbonated water, as well

as other liquids, will

damage the machine.

Remove the lid from the water tank.

Remove the tank; lift it using the inside handle.

Rinse and fill it with fresh water; do not exceed the level

(MAX) indicated on the tank.

When filling the water

tank, use sterile disposable

gloves to prevent

bacteriological

contamination.

Insert the water tank back into its seat and refit the lid.

English

7

24

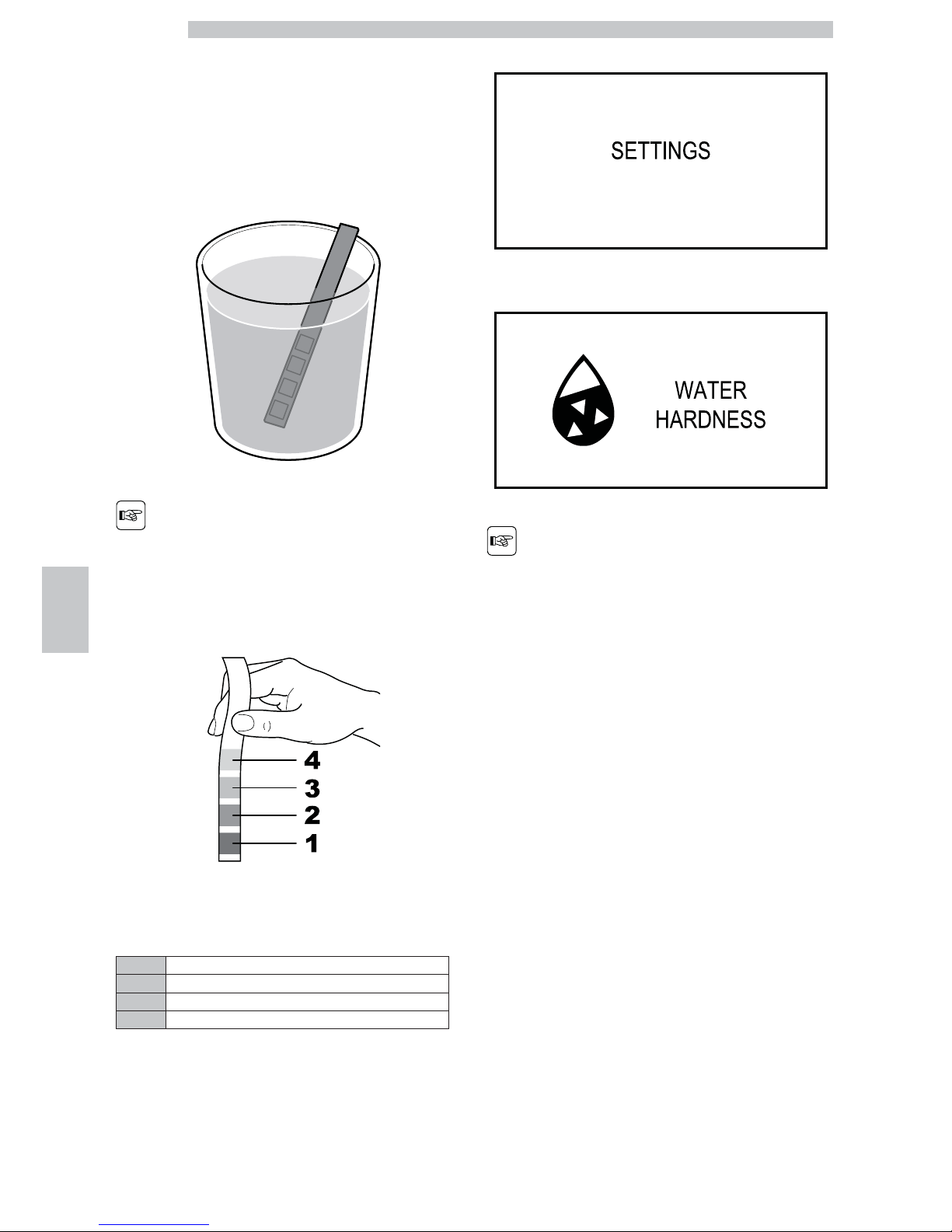

7.2 Measuring and Adjusting

Water Hardness

Measuring water hardness is very important in order to

correctly manage the anti-scale filter and the frequency

with which the machine must be descaled. Immerse the

water hardness test strip (not included) in water for 1

second.

the test strip is only valid

for one measurement.

Check how many squares change colour and then consult

the table.

The numbers correspond to the settings indicated in the

following machine adjustments.

1 HARDNESS 1 (very soft)

2 HARDNESS 2 (soft)

3 HARDNESS 3 (medium)

4 HARDNESS 4 (hard)

Switch to machine programming mode as described in

section "Access to the Technical Menu".

Scroll the menu until you reach the "Settings" option.

Press the "OK" button to confirm.

Scroll the menu until you reach the "Water hardness" option.

Press the "OK" button to confirm.

The machine is supplied

with standard adjustments,

suitable for most uses.

Press the "Up" button to increase the value or the "Down"

button to decrease the value. Press the "OK" button to

confirm the selected change.

After adjusting the water hardness, install the anti-scale

filter as described in the following section.

7.3 AquaClean Filter

Water is a key element for a good espresso coffee.

Therefore, it should always be filtered in a professional

manner. The AquaClean filter is designed to reduce

limescale build-up inside the coffee machine and to provide

filtered water in order to preserve the coffee aroma and

flavour in each cup. By using the series of 8 AquaClean

filters as indicated in this user manual, you will not need to

descale the machine for the next 5000 cups (with 100-ml

capacity). This filter is easy to use and its sophisticated

technology is effective in preventing limescale build-up.

This way, water will always be perfect and will give a much

more intense aroma to your espresso coffee.

English

7

25

Measuring water hardness

is very important in order

to correctly manage the

anti-scale filter and the

frequency with which the

machine must be descaled.

Descale the machine

before using the

AquaClean filter.

In case you did not activate

the filter upon first use and

you already prepared more

than 50 cups (with 100-ml

capacity), descale the

machine before activating

the filter.

Replace the AquaClean

filter as soon as its capacity

drops to 0% and the filter

icon blinks quickly. Replace

the AquaClean filter at

least each 3 months, even

if the machine is yet to

inform you that it needs to

be replaced.

We recommend to buy a

new filter when its capacity

drops to 10% and the filter

icon starts blinking slowly.

In this way you can replace

the filter when its capacity

drops at 0%.

The anti-scale filter should

be replaced whenever

indicated by the machine.

Before descaling, remove

the anti-scale filter from

the water tank.

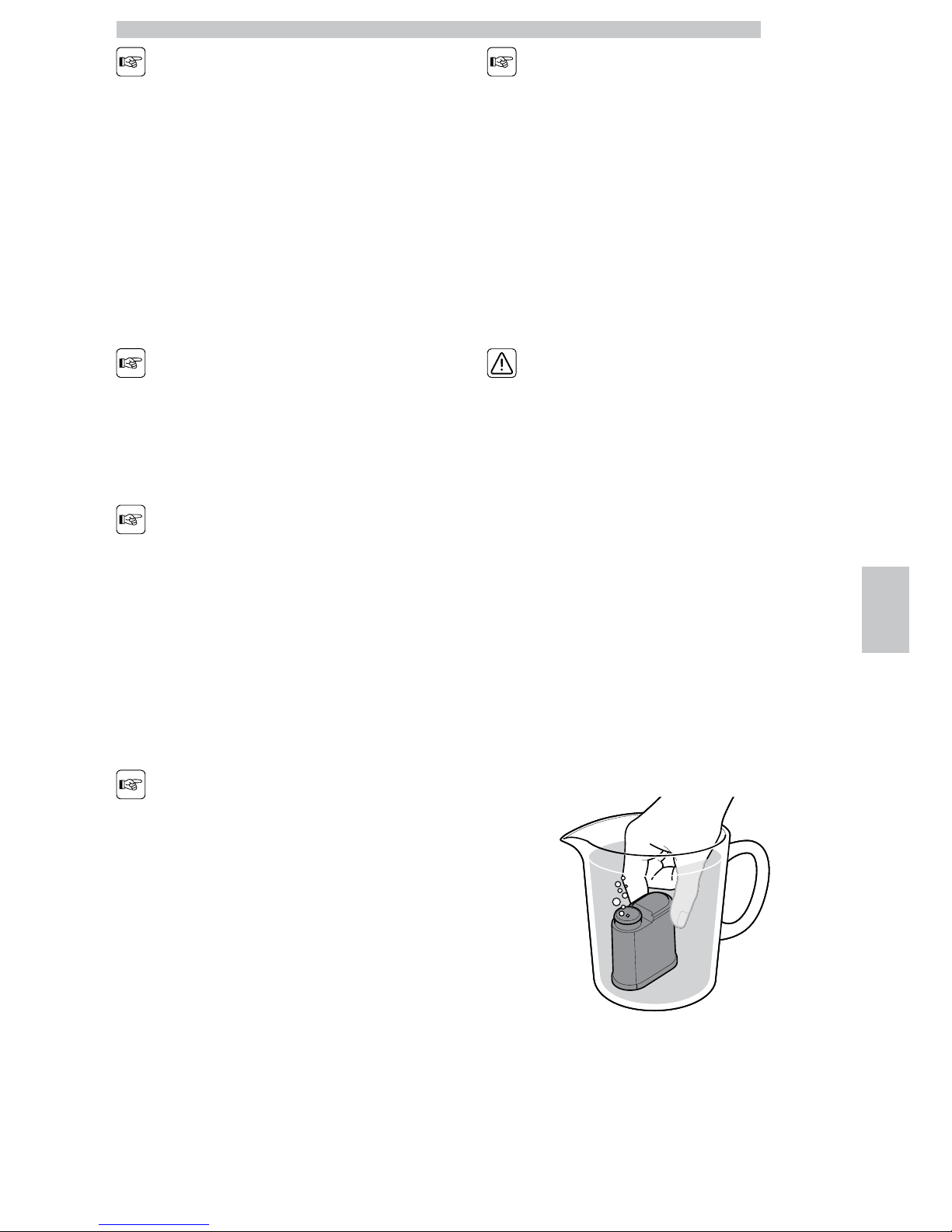

7.3.1 Preparing and Installing the

AquaClean Filter

You can install the AquaClean filter when first installing the

machine as part of the overall installation procedure. If you

did not install the AquaClean filter upon first use, you can

install it later by accessing the menu as described here

below. Remove the AquaClean filter from its packaging.

Shake it for about 5 seconds. Immerse the AquaClean

filter upside down in a carafe full of cold water and wait

for the air bubbles to come out.

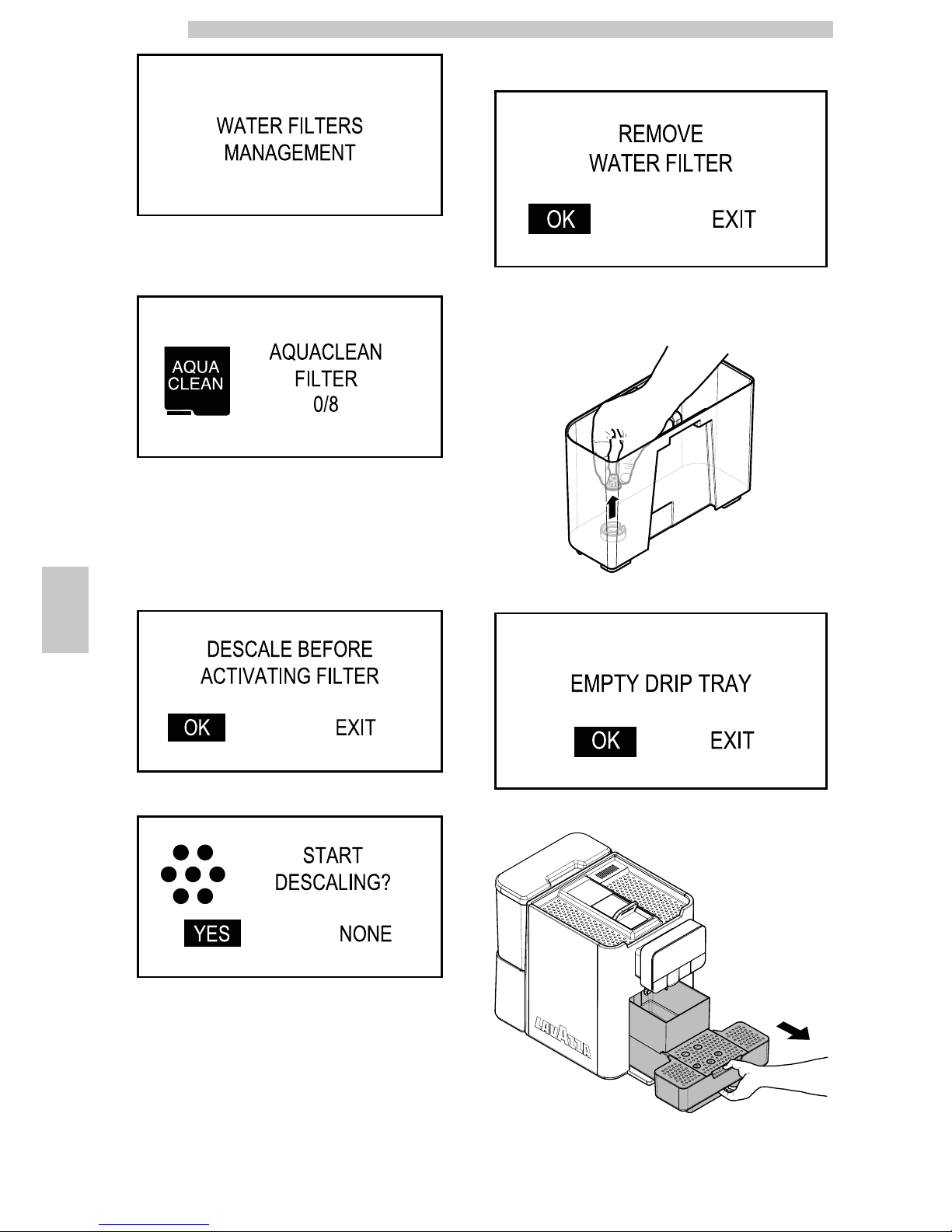

Switch to machine programming mode as described in

section "Access to the Maintenance Menu". Scroll the

menu until you reach the "Water filters management"

option.

English

7

26

Press the "OK" button and scroll until you reach the

"AquaClean" filter. The display shows the number of

AquaClean filters previously installed, from 0 to 8.

Press the "OK" button to confirm. In case 5 litres of water

have been dispensed since the last descaling cycle with no

filters installed in the machine, or an AquaClean filter has

been used up or the AquaClean filter is the eighth of its

sequence, it is necessary to descale the machine and the

following screen is displayed. Otherwise activate the filter

as described below, skipping the descaling operations.

The following screen is displayed:

Select "YES" and press the "OK" button. The following

screen is displayed:

Remove the tank from the machine and empty it. Remove

the small white filter from the tank and store it in a dry

place sheltered from dust.

The following screen is displayed:

Remove and empty the drip tray.

English

7

27

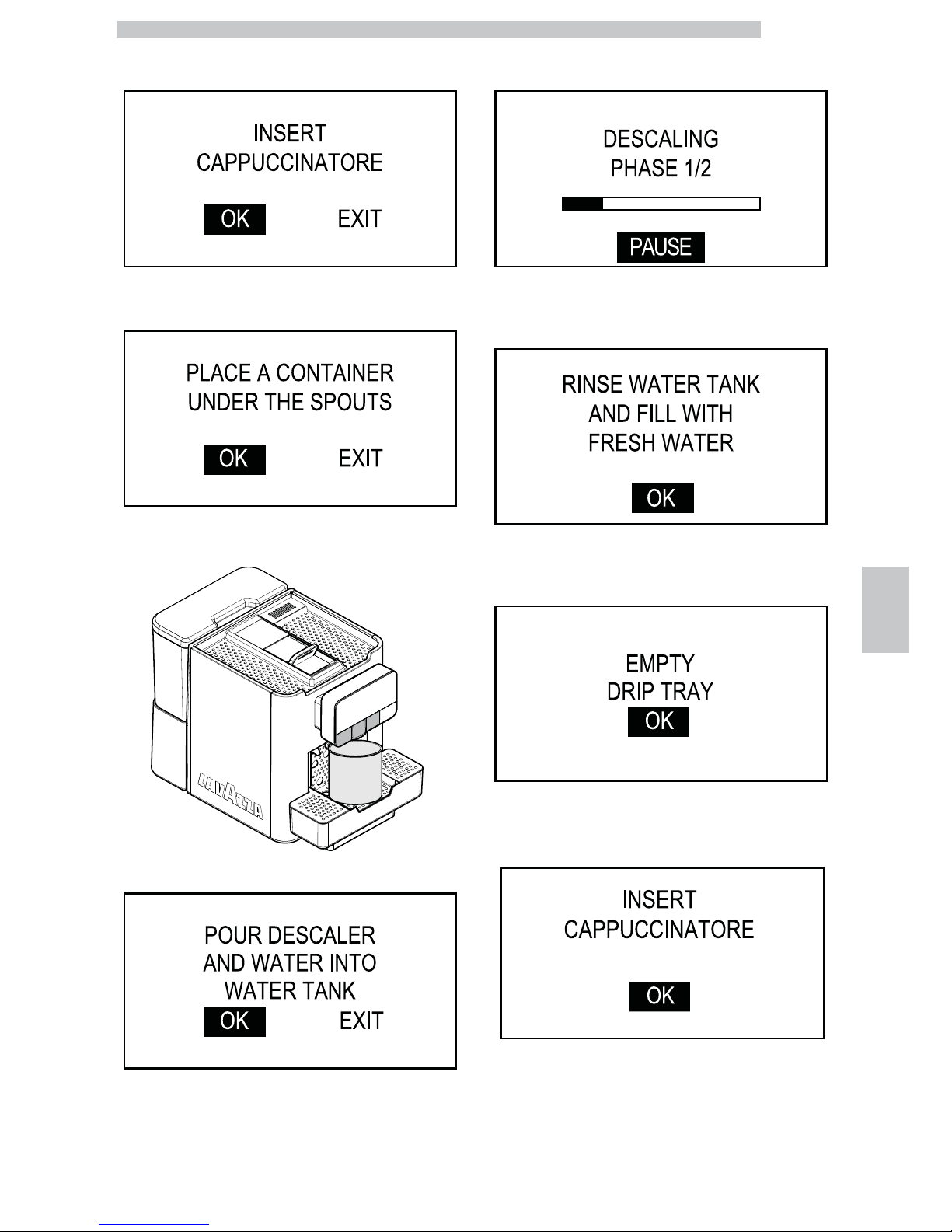

After emptying it put the drip tray back into place. The

following screen is displayed:

Check that the Cappuccinatore is correctly positioned.

Press the "OK" button The following screen is displayed:

Place a large container under the dispensing spouts (hot

water, coffee and cappuccino).

The following screen is displayed:

Pour 250 ml of descaling solution and 750 ml of water into

the water tank. The following screen is displayed:

The first descaling phase starts. When the solution in the

tank is finished, the machine requests to empty and rinse

the tank with fresh drinking water.

Rinse the water tank thoroughly and fill it with fresh

drinking water up to the MAX level. Press the "OK"

button The following screen is displayed:

Remove the drip tray. After emptying it put the drip tray

back into place. Press the "OK" button The following

screen is displayed:

Loading...

Loading...