Page 1

Embedded &

Industrial Computing

Hardware platforms for next generation networking infrastructure

LEC-7110

V1.2

>>

User's Manual

Publication date:2014-07-17

Page 2

About

About

Overview

Icon Descriptions

The icons are used in the manual to serve as an indication

of interest topics or important messages. Below is a

description of these icons:

NOTE: This check mark indicates that

there is a note of interest and is something

that you should pay special attention to

while using the product.

Online Resources

The listed websites are links to the on-line product

information and technical support.

Resource Website

Lanner http://www.lannerinc.com

Product Resources

RMA http://eRMA.lannerinc.com

WARNING: This exclamation point

indicates that there is a caution or

warning and it is something that could

damage your property or product.

http://www.lannerinc.com/

download-center/

Acknowledgement

Intel, Pentium and Celeron are registered trademarks of

Intel Corp.

Microsoft Windows and MS-DOS are registered trademarks

of Microsoft Corp.

All other product names or trademarks are properties of

their respective owners.

Compliances and Certification

CE Certication

This product has passed the CE test for environmental

specifications. Test conditions for passing included the

equipment being operated within an industrial enclosure.

In order to protect the product from being damaged by

ESD (Electrostatic Discharge) and EMI leakage, we strongly

recommend the use of CE-compliant industrial enclosure

products.

FCC Class A Certication

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when

the equipment is operated in a commercial environment.

This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause

harmful interference to radio communications. Operation

of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required

to correct the interference at his own expense.

Revision History

Copyright and Trademarks

This document is copyrighted, © 2014. All rights are

reserved. The original manufacturer reserves the right to

make improvements to the products described in this

manual at any time without notice.

No part of this manual may be reproduced, copied,

translated or transmitted in any form or by any means

without the prior written permission of the original

manufacturer. Information provided in this manual is

intended to be accurate and reliable. However, the original

manufacturer assumes no responsibility for its use, nor for

any infringements upon the rights of third parties that

may result from such use.

Embedded and Industrial Computing

Version Changes

1.2 Change the Appendices for Lanner GPIO, DIO,

and watchdog utility installation and usage.

2

Page 3

TTaTTable of Contentsbeable of Contents

Chapter 1: Introduction 4

System Specication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 2: System Components 6

System Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Front Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Rear Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 3: Board Layout 11

External Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Internal Connectors and Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Connectors and Jumpers List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Jumper Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Chapter 4: Hardware Setup 17

Preparing the Hardware Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Installing the System Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Installing the Hard Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Installing the 3G SIM Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Installing the Wireless 3G module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Wall Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Appendix A: Lanner GPIO Driver Installation 19

Appendix B: Programming Watchdog Timer 22

Appendix C: Digital Input/Output 24

Appendix D: Terms and Conditions 29

Warranty Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

RMA Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

3

Page 4

Chapter 1

Introduction

Chapter 1:

Introduction

Thank you for choosing the LEC-7110. The LEC-7110 is

Lanner’s flagship IPC. It features the Dual Core Intel®

Atom™ D2550 processor.

The LEC-7110 is an ideal solution for digital signage and

infortainment or self-service kiosk whether it is carried on

the public transportation or situated in a public setting .

This all-in-one system is fanless and has a dust-proof case

with compact design (268x174x44mm).

The system can be conveniently situated in a place

where space is limited and the weather condition

is diverse (operating temperature -10 to +55C with

Industrial components and -5 to +45oC with commercial

components).

The list shows the versatile connectivity that the device

provides:

Intel integrated Graphics Media Accelerator 3150 •

which supports VGA (up to 1920x1200) and HDMI with

integrated audio and video function (1920 x1200)

Dual 10/100/1000 Mbps LAN (provided by Intel 82583 •

Ethernet controller)

One

• Mini-PCIe expansion slots (it comes with a SIM

card reader that can support 3G Internet)

•

Two SATA 2.0 Ports (SATA1 supports SATA DOM

connection). It provides storage for photos, videos and

other multi- media contents.

USB x 6 (2 external ports on the back, 2 external ports on •

the front, and 2 internal pin header)

COM x 2 (1 is in DB-9 port and the other one is a pin •

header; both of them are RS-232 compatible.)

Digital Input/Output (through 2 x 5-pin terminal block) •

Audio input and output connectors (Realtek ALC886 •

codec)

System Specification

LEC 7 Series

Dimension (WxHxD)

Processor

Chipset

System

Memory

Storage

Ethernet Controller

Graphic Controller

Audio Controller

IO

Power Input

AC Adapter

Hardware Monitor

OS Support

Certications

Compliance

Operating Temperature Range

with

Commercial Components

Technology DDR3 SODIMM x1

Max. Capacity Up to 4GB

IDE None

SATA

LAN GbE RJ45 x2

Display

Video Grabber No

Audio RCA x2 for Line-out and Mic-in

Serial I/O

GPS No

Digital I/O

USB 2.0 Type A x4; Internal x2

Power Input DC jack with lock

Expansion

Others

LEC-7110

268x44x174mm

(10.55”x1.73”x6.85”)

Intel Atom D2550 1.86GHz

Intel NM10

2.5” HDD/SSD drive bay x1,

SATA Port for SATA DOMx1

Intel 82583 x2

Intel GMA3150

Realtek ALC886

DB15 x1 for VGA (1920x1200)

HDMI x1 (1920x1200)

DB9 x1 for RS232 x1;

Pin header for RS232x1

2 x 5-pin terminal block for DI x4

and DO x4 (5V TTL)

Mini-PCIe x1 with External SIM

card reader

External: Power-on button, 1x

SMA antenna hole, reset.

Internal: PS/2 keyboard and

mouse

+12Vdc +/- 5%, ATX mode

60W +12V @ 5A

Fintek F81865 integrated watchdog timer 1~255 level

Linux , XPE/WES2009, XP PRO

FES, WS7E, WS7P, WIN 7 PRO-E

CE, FCC Class A

No

-10 to +55C (with Industrial)

-5 to +45C (with commercial)

Embedded and Industrial Computing

4

Page 5

Chapter 1

Package Contents

Your package contains the following items:

The LEC-7110 Embedded System •

DC+12V 60W Power Adapter •

Serial-ATA/Power Cable •

Wall-Mounting Kit •

Drivers and User’s Manual CD •

Introduction

Embedded and Industrial Computing

5

Page 6

Chapter 2

Chapter 2:

System Components

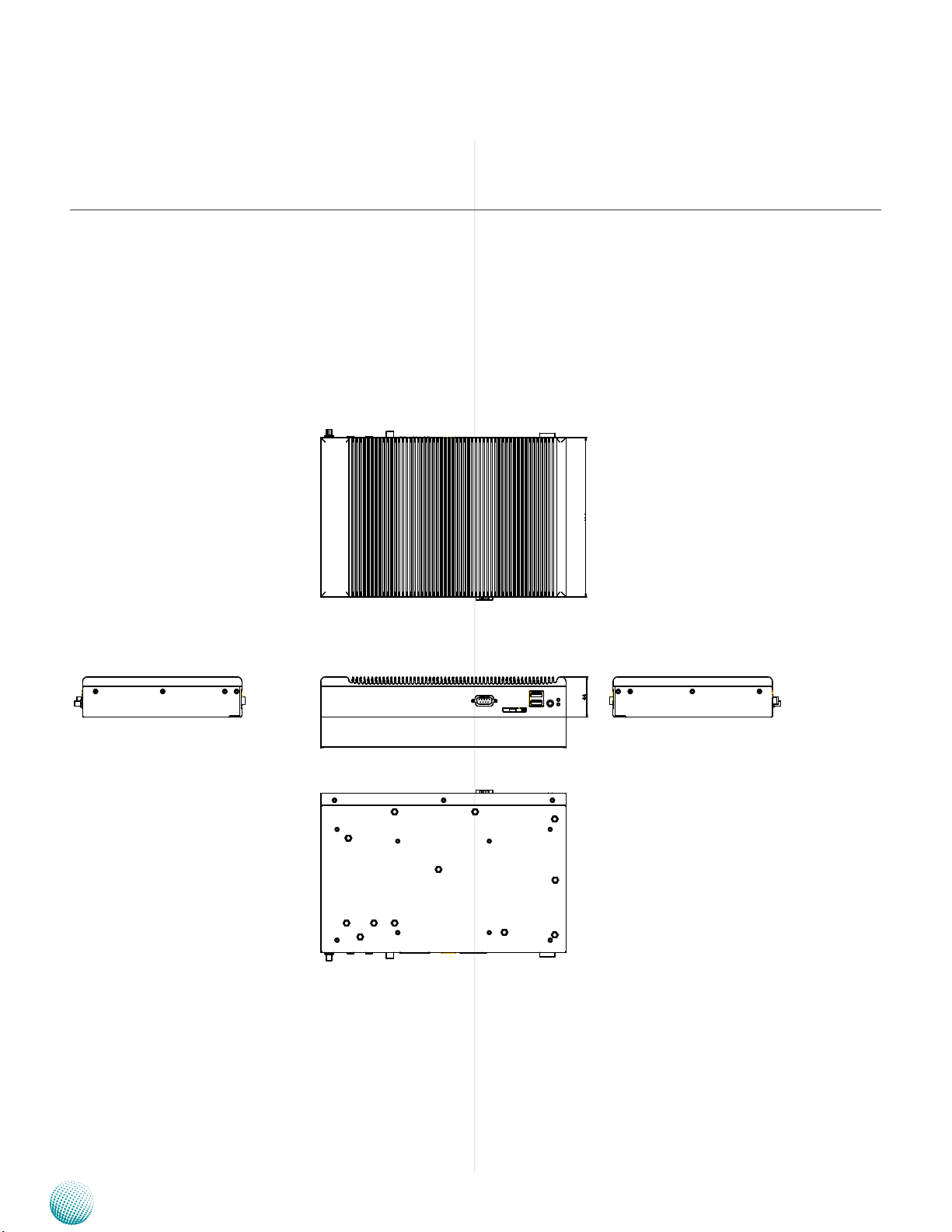

System Drawing

Mechanical dimensions of the LEC-7110

Unit: mm

System Components

268

174

44

Embedded and Industrial Computing

6

Page 7

Chapter 2

LEB-7110

LEB-7110

LEK-HDA1

Realtek ALC886

2x 1/8 Phone Jack

DDR3 800/1067

1x SO-DIMM up to 4GB

GbE Controller

2x Intel 82583

Flash BIOS

MCU

(32-bit ARM

Cortex-M0

microcontroller)

Processor

Intel

D2550

(BGA)

PCH

NM10

Fintek

81865

2x PCIe

SPI

Flash

(Store the status of

the DIO before

system reboot)

1x 2.5" HDD/SSD

1x SATA DOM

VGA

Up to 1920x 1200

HDMI

SATA Connector

2x SATA Connectors

Mini PCIe with

SIM card Reader

1x Socket

USB 2.0

2x Port-A in front

2x Port-A in rear

2x Pin Header

Serial Port

2x pin header for RS-232

H/W Monitor

WDT

SATA

PCIe

USB

USB

LAN 1

RJ-45

LAN 2

RJ-45

(reserved pin

header for PoE

splitter)

Digital I/O

4x in, 4x out, terminal blocks

100mA for each output port

Power Adapter

+12V AC to DC Power

(DC-Jack with lock)

Audio Output

1/8 Phone Jack

Mic Input

1/8 Phone Jack

+12V

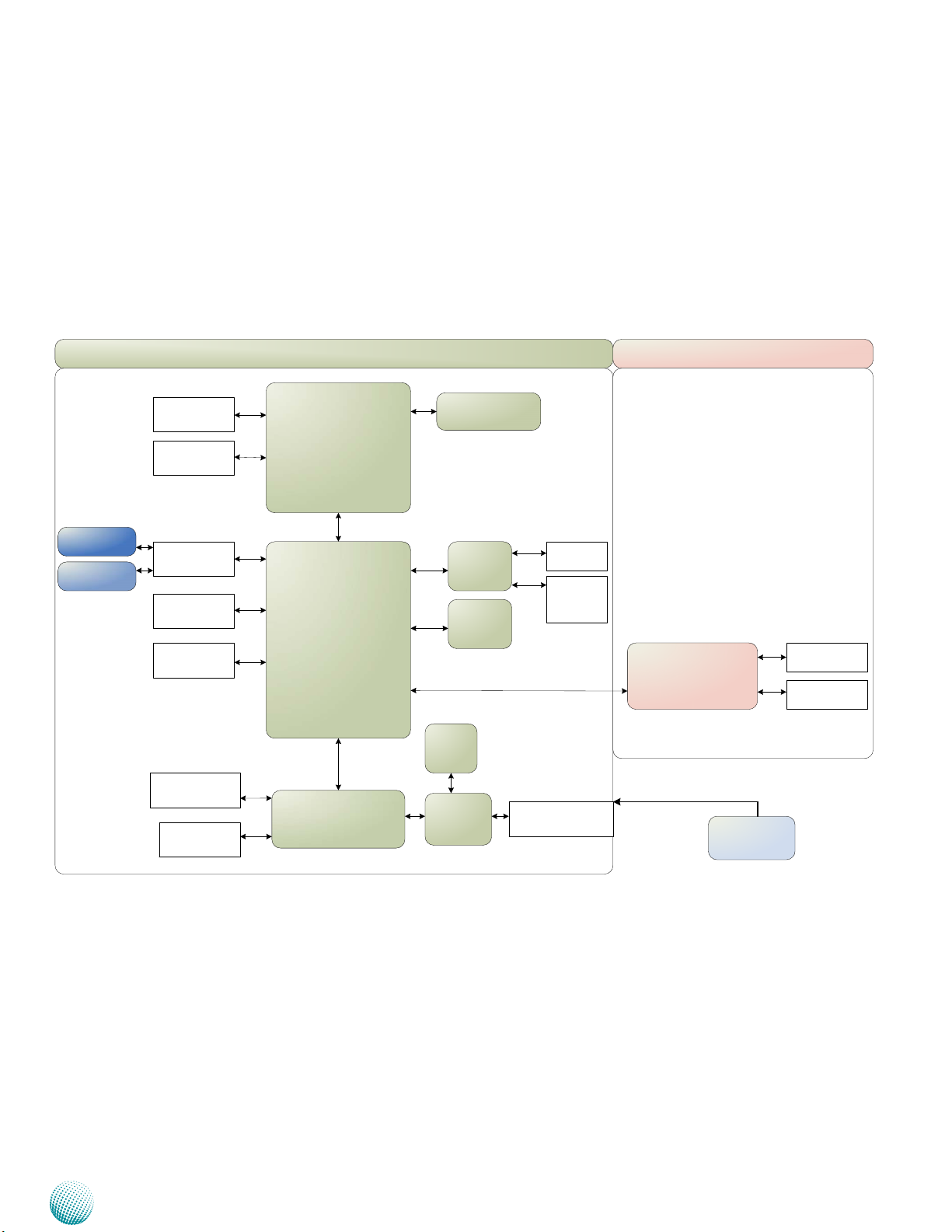

Block Diagram

The block diagram depicts the relationships among the

interfaces and modules on the motherboard..

System Components

Embedded and Industrial Computing

7

Page 8

Chapter 2

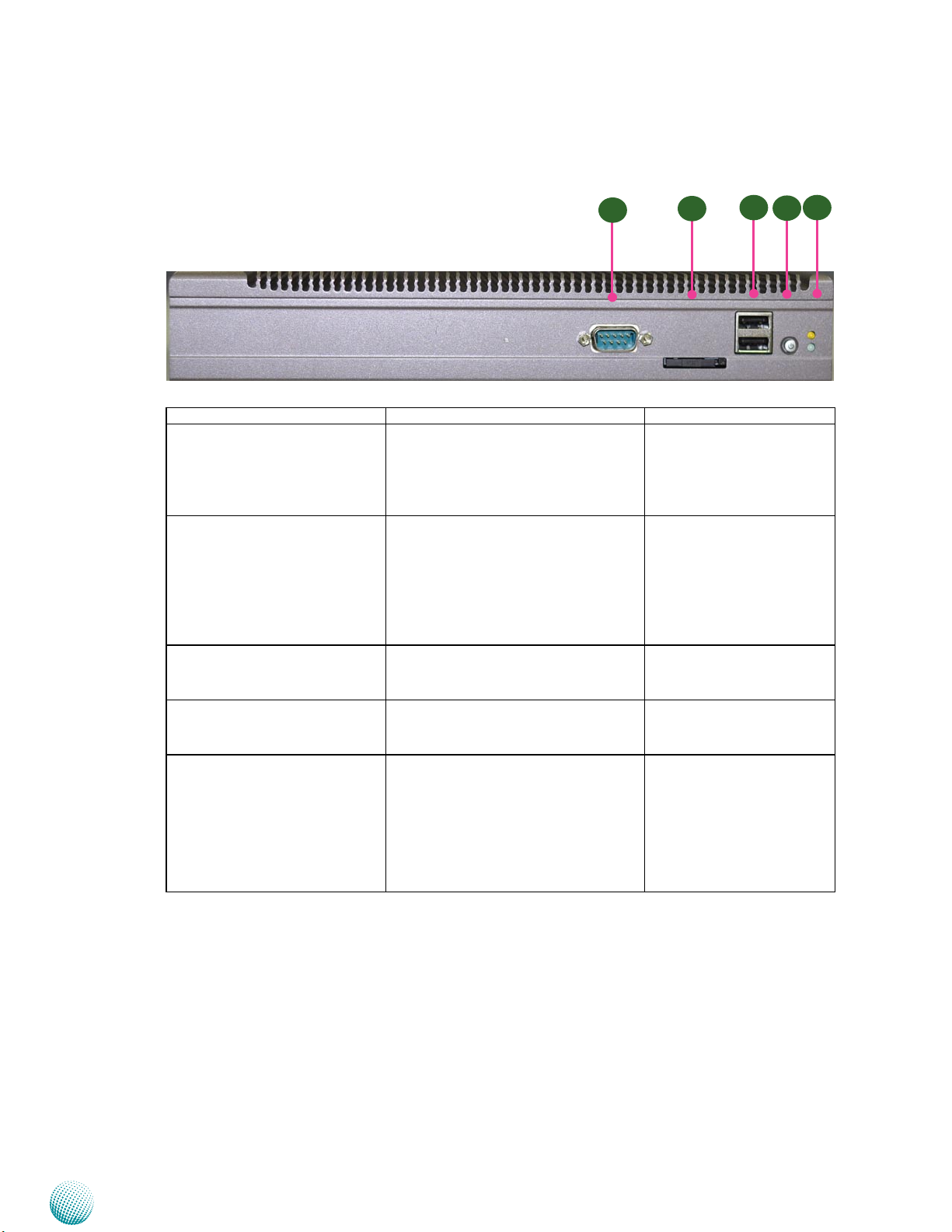

Front Components

System Components

F1

Component Description Pin Definition Reference

F1 COM Port 1 Serial ports through the DB-9

connector; COM1 supports RS-232

communication protocol. In addition to

this port, a pin header is also provided

(COM2 in RS-232)

F2 SIM Card Reader External SIM card reader for wireless 3G

connection. To open the reader, Insert

the tip of a pointy object (or a small

paper clip) into the SIM eject lever on

the SIM card reader. Press firmly and

push it straight in until the tray pops

out.

F3 Dual USB Stack Connector An USB type A connector; in addition to

this connector, an internal pin header is

provided.

F4 Power Button with dual LED ATX Power-on button with LEDs:

Standby mode in Red; Power-on mode

in Green

F5 HDD (Yellow) and

Power LED (Green)

HDD

Blinking: data access activities•

Off: no data access activities•

Power

On: The computer is on.•

Off: The computer is off .•

F2

JCOMA1 on page 14

USB3 on page 15

F3

F4

F5

Embedded and Industrial Computing

8

Page 9

Chapter 2

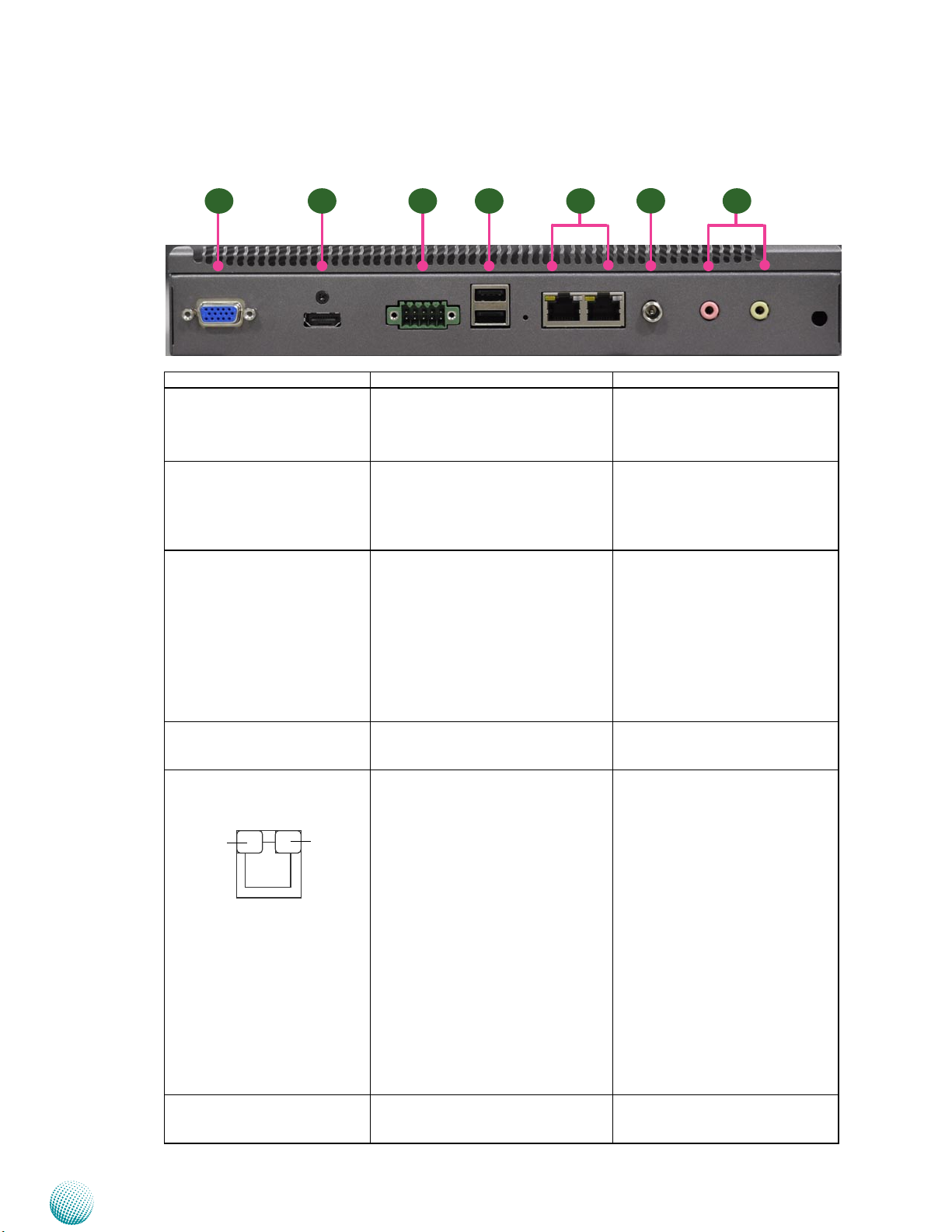

Rear Components

System Components

R1 R2 R3 R4 R5

Component Description Pin Definition Reference

R1 VGA Port DB-15 Female Connector for VGA

connection (up to 1920x1200).The

graphic engine is provided by Intel

onboard graphic GMA3150.

R2 HDMI An HDMI port which also

integrates with an audio output

offers maximum resolution up to

1920x1200. The graphic engine is

provided by Intel GMA 3150.

R3 DIO Port 4 digital input and 4 output ports

to support input and output

operations. The MCU and its flash

will help to retain the DIO last state

even when the system reboots

or shuts down. Refer to Chapter

3 Board Layout and Appendix

B Digital Input/Output for DIO

control.

R4 Dual USB Stack Connector An USB type A connector; in

addition to this connector, an

internal pin header is provided.

R5 Dual 10/100/1000 LAN

Ports

LINK/ACT

R6 DC Jack DC-in 12V power socket with

SPEED

Two RJ-45 (network) jacks with LED

indicators as described below. The

LAN ports are provided by Realtek

RTL8111. They both support WOL

(Wake-on-LAN) and Remote-wakeup.

LINK/ACT (Yellow)

On/Flashing: The port is linking •

and active in data transmission.

Off: The port is not linking.•

SPEED (Green/Amber)

Amber: The connection speed is •

1000Mbps.

Green: The connection speed is •

100Mbps

Off: .The connection speed is •

10Mbps.

Lock. Only use the power adapter

supplied with the LEC-7110 System.

R6

VGA1 on page 16

HDMI1 Connector on page 16

DI1 on page 15

USB1 on Page 15

LAN1_1/1_2 on page 13

DC_IN1 on page 16

R7

Embedded and Industrial Computing

9

Page 10

Chapter 2

R1 VGA Port DB-15 Female Connector for VGA

F7 Microphone Port

Line-Out Port

System Components

Component Description Pin Definition Reference

VGA1 on page 16

connection (up to 1920x1200).The

graphic engine is provided by Intel

onboard graphic GMA3150.

The microphone port connects to a

microphone.

The line-out port connects a

headphone or speaker.

The audio ports are provided by

Realtek ALC886

JAUDIO1 on page 16

Embedded and Industrial Computing

10

Page 11

Chapter 3

Chapter 3:

Board Layout

External Connectors

The following picture highlights the location of system

input/output connectors. Refer to the table 3.1 Connector

List for more details.

Board Layout

DC_IN1

LAN1_2 LAN1_1

RST1

USB1

DI1

HDMI1

VGA1

Embedded and Industrial Computing

JCOMA1

USB3

PSBTN1

LED2

11

Page 12

Chapter 3

Internal Connectors and Jumpers

The following picture highlights the location of internal

connectors and jumpers. Refer to the table 3.1 Connector

List for more details.

Board Layout

DC_IN2 J25

SATA1JSATA1

USB2

JCOMB1

JTAG1

KB1

SC3T1 FAN1

JAUDIO1

Embedded and Industrial Computing

JLED1

SPIROM1

LPC1

JCCMOS1

PW1

SATA2

SC1T1

CN1

LEB-7110

12

Page 13

Chapter 3

Board Layout

Connectors and Jumpers List

The tables below list the function of each of the board

jumpers and connectors by labels shown in the above

section. The next section in this chapter gives pin

definitions and instructions on setting jumpers.

Table 3.1 Connector List for LEB-7110

Labels Function Pin Denition Reference

Page

DC_IN1 DC Power Jack P16

DC_IN2 Internal DC_IN Connector P16

DI1 Digital I/O Connector P15

HDMI1 High Denition Multimedia Interface P16

JAUDIO1 Audio Daughter Board Connector P16

JCCMOS1 CMOS Jumper P15

JCOMA1 External Serial Port with D-SUB9 Connector(COM1) P14

JCOMB1 Internal Serial Port with Pin Header (COM2) P14

JLED1 System Status LED P16

JSATA1 SATA1 Connector Power Setting P14

JTAG1 MCU Debug Port P15

KB1 PS/2 Keyboard & Mouse Connector P15

LAN1_1/LAN1_2 Dual RJ-45 with LED P14

LPC1 LPC Interface Reserved for Factory

MPCIE1 Mini PCI-E Connector P16

PW1 SATA HDD Power Connector P14

SATA1 SATA Connector P14

SATA2 SATA Connector P14

SC1T1 COMA1 Pin9 Function Selection Jumper P14

SC3T1 MCU Communication Setting P15

USB1 Dual Type A USB Connector P15

USB2 Internal USB Connector with Pin Header P15

USB3 Dual Type A USB Connector P15

VGA1 VGA Port with DE-15 Connector P16

Embedded and Industrial Computing

13

Page 14

Chapter 3

Board Layout

Jumper Settings

LEB-7110

Serial-ATA Connector (SATA1, SATA2): It is for connecting

a 2.5’’ harddisk to be served as your system’s storage. It

can support SATA II which features Data transfer rates up to

3.0 Gb/s (300 MB/s). Note that SATA I supports SATA DOM

connection and it has a jumper to switch the powermode

of this port.

Pin No. Function

7

1 GND

6

5

2 TX+

4

3 TX-

3

4 GND

2

5 RX-

1

SATA1

6 RX+

7 SATA Power

SATA2

4-pin Serial-ATA Power Connector (PW1): It is for

connecting the SATA power cord (for SATA2 connector).

4

3

2

1

Pin No. Function

1 +12V

2 GND

3 GND

4 +5V

SATA1Power Mode Selection (JSATA1): The SATA1

interface’s pin can be switched by this jumper to supply

power to a SATA DOM.

Pin No. Function

1

1 GND

2

2 TX+

3

4

3 TX-

5

4 GND

6

5 RX-

7

6 RX+

7 SATA Power

RS-232 Serial Port COM2 (JCOMB1): It is a RS-232 port

with a internal pin header.

Pin No. Pin Name Pin No. Pin Name

1 Data Carrier Detect

(DCDB #)

2 Data Set Ready

(DSRB #)

3 Receive Data

(RXDB)

4 Request To Send

(RTSB #)

5 Transmit Data

(TXDB)

6 Clear To Send

(CTSB #)

7 Data Terminal Ready

(DTRB #)

8 Ring Indicator

(RIB #)

9 Ground

10 KEY

COMA1 Pin 9 Function Selection (SC1T1): The Pin No. 9

of RS-232 can be altered to supply power. J

1

3

5

2

4

6

SC1T1

RS-232 Pin 9 Function JP1, JP2

+5V 1-2

+12V 3-4

RI#(Default) 5-6

LAN1_1/LAN1_2: Dual RJ-45 with LED: The LAN ports

are provided by Intel 82583 Ethernet Controllers. The

following lists its main features:

Pin No. Function

3

2

1

1-2 GND (Default)

2-3 +5V

RS-232 Serial Port COM1 (JCOMA1): It is a RS-232 port

through the D-SUB9 connector.

12345

6789

Pin No. Pin Name Pin No. Pin Name

1 Data Carrier Detect

(DCDA# )

2 Receive Data

( RXDA )

3 Transmit Data

(TXDA)

4 Data Terminal Ready

(DTRA #)

5 Ground

(GND )

Embedded and Industrial Computing

6 Data Set Ready

(DSRA # )

7 Request To Send

(RTSA # )

8 Clear To Send

(CTSA # )

9 Ring Indicator

(RIA # )

The Preboot eXecution Environment (PXE) remote •

boot support

TCP segmentation offload•

TCP, UDP, IPv4 checksum offload•

Supports IEEE 802.1Q VLAN tagging•

Pin No. Description

Fast Ethernet Gigabit Ethernet

1 TX+ MD0+

2 TX- MD03 RX+ MD1+

4 T45 MD2+

5 T45 MD26 RX- MD17 T78 MD3+

8 T78 MD39 10-/100-/1000+

10 10+/100+/100011 Link+/ACT12 Link-/ACT+

14

Page 15

Chapter 3

Board Layout

Clear CMOS jumper (JCCMOS1): It is for clearing the

CMOS memory.

1

2

3

Pin No. Pin Name

1-2 Normal (Default)

2-3 Clear CMOS

Digital I/O (DI1)

Digital IN/OUT(DIO1) Connector: The 8 pins of digital

Input/Output (GPIO) support input and output operations

through the 2x5-pin terminal block.

1 3 5 7 9

2 4 6 8 10

Pin No. Pin Name

1 Input0

3 Input1

5 Input2

7 Input3

9 GND

Pin No. Pin Name

2 Output0

4 Output1

6 Output2

8 Output3

10 GND

TTL Level is +5V; Maximum input/output current for

each port is 100mA

Input/Output Voltage Logic Register

Digital_IN:

Low 0

0~0.7V

Digital_Out:

0V

Digital_IN:

High 1

2~5V

Digital_Out:

5V

The default BIOS value is 0 for digital_IN and 1for Digital_Out

Dual USB Type A Connector (USB1/USB3):

Pin No. Pin Name

5 6 7 8

1 2 3 4

1 USB_VCC1

2 -USB

3 +USB

4 GND

5 USB_VCC2

6 -USB

7 +USB

8 GND

USB 2.0 Pin Header (USB2):

9

8

7

6

5

4

3

2

1

1 USB_VCC

3 KEY

5 -USB

7 +USB

9 GND

Pin No. Pin Name

10

Pin No. Pin Name

2 GND

4 +USB

6 -USB

8 KEY

10 USB_VCC

MCU Communication Setting (SC3T1): MCU

communication setting jumper

PIN NO. DESCRIPTION

2 4 6

1 3 5

1-3 2-4 Internal

RS232(COM3)

(default)

3-5 4-6 From JTAG1 RS232

(debug only)

PS/2 Keyboard and Mouse (KB1)

2 4 6 8

1 3 5 7

Pin No. Description Pin No. Description

1 VCC 2 MSCLK

3 MSDATA 4 KEY

5 KBDATA 6 KEY

7 GND 8 KBCLK

Embedded and Industrial Computing

MCU Debug Port (JTAG1): The MCU is provided by NXP’s

LPC1110 which is a ARM-Cortex-M0 based, low-cost 32-bit

microcontroller for 8/16-bit applications. It has a 4 KB onchip flash programming memory. The MCU and its flash

will help to retain the DIO last state even when the system

reboots or shuts down.

1

2

3

4

5

6

7

8

Pin No. Pin Name Debug Tools

1 ICE_DATA FOR ICE Debug

2 ICE_CLK

3 ICE_RST#

4 GND

5 MCU_PRO

6 MCU_VCC

7 ICE_RX For Ext RS232

8 ICE_TX

15

Page 16

Chapter 3

Board Layout

Mini PCI-Express Connector 1(MPCIE1): It comes with a

SIM card reader (externally accessible on the front panel)

to support wireless 3G service.

PIN Pin Name PIN Pin Name

1 WAKE# 2 +3.3V

3 RSVD 4 GND

5 RSVD 6 +1.5V

7 CLKREQ# 8 UIM_PWR

9 GND 10 UIM_DATA

11 REFCLK- 12 UIM_CLK

13 REFCLK+ 14 UIM_RESET

15 GND 16 UIM_VPP

Key

17 RSVD 18 GND

19 RSVD 20 W_DISABLE#

21 GND 22 PERST#

23 PERn0 24 +3.3V

25 PERp0 26 GND

27 GND 28 +1.5V

29 GND 30 SMB_CLK

31 PETn0 32 SMB_DATA

33 PETp0 34 GND

35 GND 36 USB_D+

37 GND 38 USB_D39 +3.3V 40 GND

41 +3.3V 42 LED_WWAN#

43 GND 44 LED_WLAN#

45 RSVD 46 LED_WPAN#

47 RSVD 48 +1.5V

49 RSVD 50 GND

51 RSVD 52 +3.3V

System Status LED (JLED1)

High-Definition Multimedia Interface (HDMI1): High-

Definition Multimedia Interface

Pin No. Description Pin No. Description

1 DATA2+ 2 GND

3 DATA2- 4 DATA1+

5 GND 6 DATA17 DATA0+ 8 GND

9 DATA0- 10 CLK+

11 GND 12 CLK13 N.C 14 N.C

15 DDC CLK 16 DDC DAT

17 GND 18 HDMI_VCC

19 HPD

DC Power JackK ( DC_IN1)

Pin No. Description

1 DC_IN (+)

2 DC_IN (-) / GND

Internal DC In Connector ( DC_IN2)

Pin No. Pin Name

1 HDD_LED2 HDD_LED+

3 3G_LED4 3G_LED+

5 PWR_LED6

PWR_LED+

DE-15 VGA Connector (VGA1):The graphic function is

powered by the integrated Intel GMA 3150.

5

10

15

Pin No. Description Pin No. Description

1 CRT-R 6 GND

2 CRT-G 7 GND

3 CRT-B 8 GND

4 N.C 9 VCC

5 GND 10 GND

Pin No. Description

11 N.C

12 V_SDAT

13 HSYNC

14 VSYNC

15 V_SCLK

1

6

11

2 1

Pin No. Description

1 DC_IN (+)

2 DC_IN (-) / GND

Audio Daughter Board Connector (JAUDIO1): It

is for connecting the daughter board to support the

Microphone and Line-in port.

8

7

6

5

4

3

2

1

Pin No. Description

1 LINE_OUT_R

2 GND

3 GND

4 LINE_OUT_L

5 MIC_R

6 GND

7 GND

8 MIC_L

Embedded and Industrial Computing

16

Page 17

Chapter 4

Chapter 4:

Hardware Setup

Preparing the Hardware Installation

To access some components and perform certain service

procedures, you must perform the following procedures

first.

Hardware Setup

WARNING: To reduce the risk of personal injury,

electric shock, or damage to the equipment,

remove the power cord to remove power from the

server. The front panel Power On/Standby button

does not completely shut off system power.

Portions of the power supply and some internal

circuitry remain active until AC power is removed.

Unpower the LEC-7110 and remove the power cord.1.

Unscrew the 3 threaded screws on both sides of the 2.

top cover of the LEC-7110 System.

Slide the cover backwards and open it.3.

Note:

The motherboards can support up to 4 GB 1.

memory capacity in maximum.

Installing the Hard Disk

The system can accommodate two Serial-ATA disks. Follow

these steps to install a hard disk into the LEC-7110:

Unscrew the 4 screws on the hard disk tray to take out 1.

the hard disk tray from the system.

Place hard disk on the hard disk tray and align the holes 2.

of the hard disk with the mounting holes on the tray.

Secure the hard disk with 4 mounting screws on the 3.

hard disk tray.

Connect the Serial-ATA cable to the hard disk.4.

Plug the Serial-ATA power and data cables to the Serial-5.

ATA power and data connectors on the main board.

Put the hard disk tray with the installed hard disk back 6.

to the system and secure it with mounting screws.

1

Installing the System Memory

The motherboard supports DDR3 memory. It comes with

one Double Data Rate (DDR3) Small Outline Dual Inline

Memory Modules (SO-DIMM) sockets.

Align the SO-DIMM connector key with the SO-DIMM 1.

socket key.

Install the SO-DIMM.2.

Embedded and Industrial Computing

2

17

Page 18

Chapter 4

Hardware Setup

Installing the 3G SIM Card

Open the SIM tray by inserting the tip of a pointy object 1.

(or a small paper clip) into the SIM eject lever.

Press firmly and push it straight in until the tray pops 2.

out.

Pull out the SIM tray and place the SIM card in the tray.3.

The angled corner of the SIM ensures that the card ts

only the correct way in the tray.

With the tray aligned as shown, carefully replace the 4.

SIM tray containing the SIM card in the system.

Installing the Wireless 3G module

Align the wireless module’s key with the Mini-PCIe slot 1.

notch.

Wall Mounting

The product ships with wall mounting kit. To mount your

product on the wall, follow the instructions below:

First make a hole for the anchor in the surface on the 1.

wall.

Then press the anchor into the hole until it is flush with 2.

the surface. You may need a hammer to tap the wall

anchor.

Use a screwdriver to screw the threaded screw into the 3.

plastic anchor.

Attach the wall mounting bracket to the back of the 4.

device, securing it in place with four of the flat-head

screws provided.

Hang the device on the wall.5.

Unit: mm

Insert the wireless module into the connector 2.

diagonally.

Fasten the wireless module to the board with the 3.

screws (Use the Mini-PCIe module screws contained

within the package).

Fasten with

screws

Insert

diagonally

Embedded and Industrial Computing

18

Page 19

Appendix A

Driver Installation

Appendix A:

Lanner GPIO Driver

Installation

This section provides the instructions on how to install

the L_IO driver which is the library and driver needed

for Lanner General Purpose Input/Output interface or

functions.

To install the Lanner GPIO driver to be used in Digital I/O

function, follow these steps:

Restart the computer, and then log on with 1.

Administrator privileges.

Insert the Drivers and2. User’s Manual CD to the USBoptical drive.

Browse the contents of the support CD to locate the 3.

file LIO.rar and unzip the file.

From the control panel, click the ADD Hardware 4.

program .

Select Next to proceed7.

Select Add a new hardware device8.

Select Next to proceed5.

Select the “I accept the terms in the license agreement” 6.

and then click Next.

Network Application Platforms

Choose to select the hardware Manually9.

19

Page 20

Appendix A

Driver Installation

Choose Show all device and click Next.10.

Click HaveDisk to locate the L_IO.inf file11.

Select OK to confirm with the installation13.

Select the Lanner IO driver and click Next.14.

Click Next15.

Select the L_IO.inf12.

Network Application Platforms

20

Page 21

Appendix A

Click 16. Complete to close the installation program.

To verify the GPIO driver installation, do the following

steps:

Driver Installation

Right-click on the My Computer icon, and then select 1.

Properties form the menu.

Click the Hardware tab, then click the Device Manager 2.

button.

Click the + sign next to the Lanner_Device, then the 3.

Lanner IO Driver should be listed.

Network Application Platforms

21

Page 22

Appendix B

Programming Watchdog Timer

Appendix B:

Programming Watchdog

Timer

A watchdog timer is a piece of hardware that can be used

to automatically detect system anomalies and reset the

system (or one pair of network ports in bypassed state;

However, only one function can be activated at a time.)

in case there are any problems. Generally speaking, a

watchdog timer is based on a counter that counts down

from an initial value to zero. The software selects the

counter’s initial value and periodically restarts it. Should

the counter reach zero before the software restarts it,

the software is presumed to be malfunctioning and the

processor’s reset signal is asserted. Thus, the processor

will be restarted as if a human operator had cycled the

power.

For sample watchdog code, see wd_bp folder under Driver

and Utility on the Driver and Manual CD

Set the access mode with these two parameters 2.

by editing the Makefile.linux directly: DIRECT_IO_

ACCESS= [0|1] (enter either 1 or 0) and LANNER_

DRIVER= [0|1] (enter either 1 or 0). 1 is for direct access

and no driver is needed. You will only need to execute

the program directly. However, when it equaled to 0,

driver installation is needed. Refer to the following

Install section for more details.

Type make to build source code:3.

make Makefile (Note: omit the file extensions)

After compiled, the executable program (bpwd_tst) and

the driver (bpwd_drv.ko) will be in the bin subdirectory.

Install on the Linux and FreeBSD

The installation procedures depend on the access mode

that you have set by using the above mentioned method.

If you have set DIRECT_IO_ACCESS=1, driver installation is

not necessary. Proceed to the next section on executing

If you have set DIRECT_IO_ACCESS=0, Lanner bypass

driver needs to be installed. Install the driver and create

a node in the /dev directory as shown in the following

example:

Executing the commands through the Command Line:

1. wd_tst --swtsr (Set Watchdog Timeout State to Reset)

2. wd_tst --swt xxx (Set Watchdog Timer 1-255 seconds)

3. wd_tst[*] --start (Start Watchdog Timer)

4. wd_tst --stop (Stop Watchdog Timer)

The following procedures are required for running the

watchdog program on DOS, Linux and FreeBSD.

Note:

For DOS environment, use DJGPP as compiler 1.

and the makefile: Makefile.dos.

For Linux, support kernel versions are 2.4.x and 2.

2.6.x. Use the makefile:Makefile.linux.

For FreeBSD, support version is FreeBSD 8.0. 3.

Use the makefile: Makefile.

Build

To build program source code on Linux platform, use the

following steps as a guideline:

For Linux:

Insert module and create node in /dev as below

example:

#insmod wd_drv.[k]o

#mknod /dev/wd_drv c 241 0

For FreeBSD:

Insert module as below example:

#kldload -v ./wd_drv.ko

Execute

# wd_tst --swtsb (Set Watchdog Timeout State to Bypass

function)

# wd_tst --swtsr (Set Watchdog Timeout State to Reset

function)

# wd_tst --swt xxx (Set Watchdog Timer 1-255 seconds)

# wd_tst[*] --start (Start Watchdog Timer)

# wd_tst --stop (Stop Watchdog Timer)

Copy the proper makefile from the Driver and Manual 1.

CD to your system

Embedded and Industrial Computing

Note:

wd_tst --start will not be available if 1.

22

Page 23

Appendix B

DIRECT_IO_ACCESS=1, use the command: “./

wd_tst --swt xxx” to start the watchdog timer

instead .

Watchdog timer can support two functions, 2.

- system rest or LAN bypass. However, only

one function can be activated at a time. You

should modify the code or switch it to the

desired state/function accordingly.

For more details, refer to the README file 3.

Install on Windows

Refer to Appendix A: Lanner GPIO driver installation to

install Lanner GPIO driver first and then Install GPIO_Demo.

msi

Execute via the Demo Program

This Demo program provides graphic interface for you to

assign/read value on the specific GPIO pins.

Programming Watchdog Timer

To access the program, click start->programs->Lanner

GPIO Demo->Demo

Watchdog Timer Demo:

Enter the number of seconds to start count down before

the system can be reset. Press start to start the counter

and stop to stop the counter.

Embedded and Industrial Computing

23

Page 24

Appendix C

Digital Input/Output Control

Appendix C:

Digital Input/Output

The Digitanl I/O on the rear panel is designed to provide

the input and output operation for the system. For sample

DIO code, see DIO folder under LEC-7110 Utility in the

Driver and Manual CD.

Install IOA3_Demo Program on Windows

Refer to Appendix A: Lanner GPIO driver installation to

install Lanner GPIO driver first and then Install IOA3_

DemoSetup.msi

Argument:

The decimal value of port is calculated as shown in the

following table:

Pin No. Pin Name binary

representation

2 Output0 1000 8

4 Output1 0100 4

6 Output2 0010 2

8 Output3 0001 1

10 GND

1 3 5 7 9

2 4 6 8 10

Pin No. Pin Name binary

representation

1 Input0 1000 8

3 Input1 0100 4

5 Input2 0010 2

7 Input3 0001 1

9 GND

decimal

representation

decimal

representation

Via the Command Line

Specific to the PCH chipset used or Super IO chipset, the

commands and functionality vary by product models.

For more information, refer to the README or User Guide

contained within the utility folder.

For example: Here we have IOA3 utility, to execute, follow

the command description below:

The IOA3 utility for Digital Input/

Output-------------------------------------

The IOA3 device utility (ioa3.exe) Usage:

IOA3 COM3 GET VariableName

IOA3 COM3 SET VariableName value

IOA3 COM3 “get output_state” (get the high/low state for

the digital_OUT ports)

“set output_state decimal value of the port” (set

the high/low state for digital_OUT ports)

For instance, to set the output state to DO3, DO2, DO1,

DO0=1 1 1 1, type:

IOA3 COM3 set output_state 15

Likewise, to get the output state of DO3, DO2, DO1, DO0:

IOA3 COM3 get output_state

“get input_state” (get the high/low state for the

digital_IN ports)

Embedded and Industrial Computing

24

Page 25

Appendix C

Digital Input/Output Control

Read Digial_In state

IOA3 COM3 GET INPUT_STATE command

INPUT_STATE= 15 response massage

Via the IOA3_Demo Program

This IOA3_Demo program provides graphic interface for

you to assign/read value on the specific GPIO pins.

To access the program, click start->programs->IOA3_

Tools->IOA3_Demo

DIO Sample Code

// IGpin_stDlg.cpp : implementation file

//

#include “stdafx.h”

#include “IGpin_st.h”

#include “IGpin_stDlg.h”

#include “Ignition.h”

#ifdef _DEBUG

#define new DEBUG_NEW

#endif

// CAboutDlg dialog used for App About

class CAboutDlg : public CDialog

{

public:

CAboutDlg();

// Dialog Data

enum { IDD = IDD_ABOUTBOX };

protected:

virtual void DoDataExchange(CDataExchange* pDX); //

DDX/DDV support

// Implementation

protected:

DECLARE_MESSAGE_MAP()

};

CAboutDlg::CAboutDlg() : CDialog(CAboutDlg::IDD)

{

}

void CAboutDlg::DoDataExchange(CDataExchange* pDX)

{

CDialog::DoDataExchange(pDX);

}

BEGIN_MESSAGE_MAP(CAboutDlg, CDialog)

END_MESSAGE_MAP()

// CIGpin_stDlg dialog

Embedded and Industrial Computing

25

Page 26

Appendix C

Digital Input/Output Control

CIGpin_stDlg::CIGpin_stDlg(CWnd* pParent /*=NULL*/)

: CDialog(CIGpin_stDlg::IDD, pParent)

{

m_hIcon = AfxGetApp()->LoadIcon(IDR_MAINFRAME);

}

void CIGpin_stDlg::DoDataExchange(CDataExchange* pDX)

{

CDialog::DoDataExchange(pDX);

DDX_Control(pDX, IDC_COMPORT, m_ComPort);

DDX_Control(pDX, IDC_FirmwareVersion, m_FirmwareVersion);

DDX_Control(pDX, IDC_DigitalOut1 , m_DigitalOut1);

DDX_Control(pDX, IDC_DigitalOut2 , m_DigitalOut2);

DDX_Control(pDX, IDC_DigitalOut3 , m_DigitalOut3);

DDX_Control(pDX, IDC_DigitalOut4 , m_DigitalOut4);

DDX_Control(pDX, IDC_DigitalIn1 , m_DigitalIn1);

DDX_Control(pDX, IDC_DigitalIn2 , m_DigitalIn2);

DDX_Control(pDX, IDC_DigitalIn3 , m_DigitalIn3);

DDX_Control(pDX, IDC_DigitalIn4 , m_DigitalIn4);

}

BEGIN_MESSAGE_MAP(CIGpin_stDlg, CDialog)

ON_WM_SYSCOMMAND()

ON_WM_PAINT()

ON_WM_QUERYDRAGICON()

//}}AFX_MSG_MAP

ON_CBN_SELCHANGE(IDC_COMPORT, &CIGpin_stDlg::OnCb

nSelchangeComport)

ON_WM_TIMER()

END_MESSAGE_MAP()

{

static char szValue[32] ;

sprintf (szValue, “%d”, nValue) ;

return szValue ;

}

// CIGpin_stDlg message handlers

BOOL CIGpin_stDlg::OnInitDialog()

{

CDialog::OnInitDialog();

// Add “About...” menu item to system menu.

// IDM_ABOUTBOX must be in the system command range.

ASSERT((IDM_ABOUTBOX & 0xFFF0) == IDM_ABOUTBOX);

ASSERT(IDM_ABOUTBOX < 0xF000);

CMenu* pSysMenu = GetSystemMenu(FALSE);

if (pSysMenu != NULL)

{

CString strAboutMenu;

strAboutMenu.LoadString(IDS_ABOUTBOX);

if (!strAboutMenu.IsEmpty())

{

pSysMenu->AppendMenu(MF_

SEPARATOR);

pSysMenu->AppendMenu(MF_STRING, IDM_ABOUTBOX,

strAboutMenu);

}

}

// CISM3Dlg message handlers

int GetIGValue (char *str)

{

static char szBuf[128] ;

strcpy (szBuf, “Communication Error”) ;

if (Ignition_Get (str, szBuf) )

throw szBuf ;

return atol (szBuf) ;

}

char *ltoa (long nValue)

Embedded and Industrial Computing

// Set the icon for this dialog. The framework does this

automatically

// when the application’s main window is not a dialog

SetIcon(m_hIcon, TRUE); // Set

big icon

SetIcon(m_hIcon, FALSE); // Set small

icon

// TODO: Add extra initialization here

char *szCOM = “COM3” ;

if (__argc == 2)

szCOM = __argv[1] ;

for (int i = 1 ; i <= 8 ; i++)

{

26

Page 27

Appendix C

Digital Input/Output Control

CString str ;

str.Format (“COM%d”, i) ;

int nIndex = m_ComPort.InsertString (-1, (LPCSTR)

str) ;

}

m_ComPort.SelectString (0, szCOM) ;

b_ComOK = Ignition_Init ( (char*) (LPCSTR)szCOM, 9600) ;

if (b_ComOK == FALSE)

MessageBox (“Com port init fail”) ;

SetTimer (0, 100, NULL) ;

return TRUE; // return TRUE unless you set the focus to a

control

}

void CIGpin_stDlg::OnSysCommand(UINT nID, LPARAM lParam)

{

if ((nID & 0xFFF0) == IDM_ABOUTBOX)

{

CAboutDlg dlgAbout;

dlgAbout.DoModal();

}

else

{

CDialog::OnSysCommand(nID, lParam);

}

}

// If you add a minimize button to your dialog, you will need the code

below

// to draw the icon. For MFC applications using the document/view

model,

// this is automatically done for you by the framework.

void CIGpin_stDlg::OnPaint()

{

if (IsIconic())

{

CPaintDC dc(this); // device context for painting

S e n d M es sa ge ( WM _I CO NE RA SE B K GN D,

reinterpret_cast<WPARAM>(dc.GetSafeHdc()), 0);

GetClientRect(&rect);

int x = (rect.Width() - cxIcon + 1) / 2;

int y = (rect.Height() - cyIcon + 1) / 2;

// Draw the icon

dc.DrawIcon(x, y, m_hIcon);

}

else

{

CDialog::OnPaint();

}

}

// The system calls this function to obtain the cursor to display while the

user drags

// the minimized window.

HCURSOR CIGpin_stDlg::OnQueryDragIcon()

{

return static_cast<HCURSOR>(m_hIcon);

}

void CIGpin_stDlg::OnCbnSelchangeComport()

{

// TODO: Add your control notification handler code here

char szCom[16] ;

m_ComPort.GetWindowText (szCom, sizeof (szCom) ) ;

b_ComOK = Ignition_Init ( (char*) (LPCSTR)szCom, 9600) ;

//57600

if (b_ComOK == FALSE) //false = 0

MessageBox (“Com port init fail”) ;

}

void CIGpin_stDlg::OnTimer(UINT_PTR nIDEvent)

{

// TODO: Add your message handler code here and/or call

default

//CDialog::OnTimer(nIDEvent);

if (nIDEvent != 0)

return ;

// Center icon in client rectangle

int cxIcon = GetSystemMetrics(SM_CXICON);

int cyIcon = GetSystemMetrics(SM_CYICON);

CRect rect;

Embedded and Industrial Computing

char szBuf[128] ;

int nDout;

//int nDout = GetIGValue (“OUTPUT_STATE”);

int nDin = GetIGValue (“INPUT_STATE”);

27

Page 28

Appendix C

// Digital Input

m_DigitalIn1.SetCheck (nDin & 1);

m_DigitalIn2.SetCheck (nDin & 2);

m_DigitalIn3.SetCheck (nDin & 4);

m_DigitalIn4.SetCheck (nDin & 8);

nDout = m_DigitalOut1.GetCheck () * 1

+ m_DigitalOut2.GetCheck () * 2

+ m_DigitalOut3.GetCheck () * 4

+ m_DigitalOut4.GetCheck () * 8 ;

if (Ignition_Set (“OUTPUT_STATE” , ltoa (nDout ) ) ) MessageBox

(“Update OUTPUT_STATE fail”) ;

Ignition_Get (“VERSION”, szBuf ) ;

m_FirmwareVersion.SetWindowText (szBuf) ;

}

Digital Input/Output Control

Embedded and Industrial Computing

28

Page 29

Appendix D

Terms and Conditions

Appendix D:

Terms and Conditions

Warranty Policy

All products are under warranty against defects in 1.

materials and workmanship for a period of one year

from the date of purchase.

The buyer will bear the return freight charges for 2.

goods returned for repair within the warranty period;

whereas the manufacturer will bear the after service

freight charges for goods returned to the user.

The buyer will pay for repair (for replaced components 3.

plus service time) and transportation charges (both

ways) for items after the expiration of the warranty

period.

If the RMA Service Request Form does not meet the 4.

stated requirement as listed on “RMA Service,” RMA

goods will be returned at customer’s expense.

The following conditions are excluded from this 5.

warranty:

RMA Service

Requesting a RMA#

To obtain a RMA number, simply fill out and fax the 1.

“RMA Request Form” to your supplier.

The customer is required to fill out the problem code 2.

as listed. If your problem is not among the codes listed,

please write the symptom description in the remarks

box.

Ship the defective unit(s) on freight prepaid terms. 3.

Use the original packing materials when possible.

Mark the RMA# clearly on the box. 4.

Note: Customer is responsible for shipping

damage(s) resulting from inadequate/loose

packing of the defective unit(s). All RMA# are valid

for 30 days only; RMA goods received after the

effective RMA# period will be rejected.

Improper or inadequate maintenance by the customer

Unauthorized modification, misuse, or reversed

engineering of the product Operation outside of the

environmental specifications for the product.

Embedded and Industrial Computing

29

Page 30

Appendix D

RMA Service Request Form

When requesting RMA service, please fill out the following form. Without

this form enclosed, your RMA cannot be processed.

RMA No:

Reasons to Return: Ŀ Repair(Please include failure details)

Ŀ Testing Purpose

Company: Contact Person:

Phone No. Purchased Date:

Fax No.: Applied Date:

Return Shipping Address:

Shipping by: Ŀ Air Freight Ŀ Sea Ŀ Express ___

Ŀ Others:________________

Item Model Name Serial Number Configuration

Item Problem Code Failure Status

*Problem Code:

01:D.O.A.

02: Second Time

R.M.A.

03: CMOS Data Lost

04: FDC Fail

05: HDC Fail

06: Bad Slot

07: BIOS Problem

08: Keyboard Controller Fail

09: Cache RMA Problem

10: Memory Socket Bad

11: Hang Up Software

12: Out Look Damage

13: SCSI

14: LPT Port

15: PS2

16: LAN

17: COM Port

18: Watchdog Timer

19: DIO

20: Buzzer

21: Shut Down

22: Panel Fail

23: CRT Fail

24: Others (Pls specify)

Request Party

Confirmed By Supplier

Authorized Signature / Date Authorized Signature / Date

Terms and Conditions

Embedded and Industrial Computing

30

Loading...

Loading...