Page 1

LEC-7000 Fanless Embedded System User’s Manual

LEC-7000 Series

Intel® Atom N270 (1.6Ghz) CPU onboard

Fanless Embedded System

User’s Manual

1

Page 2

LEC-7000 Fanless Embedded System User’s Manual

LEC-7000 Series

User’s Manual

© Copyright 2007, Lanner Electronics, Inc. All rights reserved. This document contains

proprietary information that is protected by copyright. No part of this document may be

reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any

language in any form by any means without the written express of Lanner Electronics, Inc.

The author and Lanner Electronics, Inc. have used their best efforts in preparing this manual.

However, the author and Lanner Electronics, Inc. make no warranties of any kind, expressed

or implied, with regard to the informational content, documentation, or files contained in this

manual, and shall not be liable for technical or editorial errors or omissions contained herein.

In no event shall the author or publisher be responsible or liable for any incidental or

consequential damages resulting from the furnishing, performance, or use of this material.

TRADEMARKS Internet Explorer, Windows Explorer, and Windows are trademarks or registered

trademarks of Microsoft Corporation. Other products mentioned herein may be trademarks/or

registered trademarks of their respective owners.

2

Page 3

LEC-7000 Fanless Embedded System User’s Manual

Safety Guidelines

Follow these guidelines to ensure general safety:

z Keep the chassis area clear and dust-free during and after installation.

z Do not wear loose clothing or jewelry that could get caught in the chassis. Fasten your

tie or scarf and roll up your sleeves.

z Wear safety glasses if you are working under any conditions that might be hazardous to

your eyes.

z Do not perform any action that creates a potential hazard to people or makes the

equipment unsafe.

z Disconnect all power by turning off the power and unplugging the power cord before

installing or removing a chassis or working near power supplies

z Do not work alone if potentially hazardous conditions exist.

z Never assume that power is disconnected from a circuit; always check the circuit.

z LITHIUM BATTERY CAUTION:

Risk of Explosion if Battery is replaced by an incorrect type.

Dispose of used batteries according to the instructions.

Operating Safety

z Electrical equipment generates heat. Ambient air temperature may not be adequate to

cool equipment to acceptable operating temperatures without adequate circulation. Be

sure that the room in which you choose to operate your system has adequate air

circulation.

z Ensure that the chassis cover is secure. The chassis design allows cooling air to

circulate effectively. An open chassis permits air leaks, which may interrupt and

redirect the flow of cooling air from internal components.

Electrostatic discharge (ESD) can damage equipment and impair electrical circuitry. ESD

damage occurs when electronic components are improperly handled and can result in

complete or intermittent failures. Be sure to follow ESD-prevention procedures when

removing and replacing components to avoid these problems.

z Wear an ESD-preventive wrist strap, ensuring that it makes good skin contact. If no

wrist strap is available, ground yourself by touching the metal part of the chassis.

z Periodically check the resistance value of the antistatic strap, which should be between

1 and 10 megohms (Mohms).

3

Page 4

LEC-7000 Fanless Embedded System User’s Manual

EMC Notice

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and,

if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case users will be required to correct the

interference at their own expense.

Class A Notice for FCC

Modifying the equipment without the authorization of Lanner Electronics, Inc. may result in

the equipment no longer complying with FCC requirements for Class A digital devices. In that

event, your right to use the equipment may be limited by FCC regulations, and you may be

required to correct any interference to radio or television communications at your own

expense.

This equipment is in compliance with the essential requirements and other relevant

provisions of Directive 1999/5/EC.

4

Page 5

LEC-7000 Fanless Embedded System User’s Manual

Contents

Safety Guidelines ....................................................................... 2

EMC Notice ………………………………………………………………………..4

Contents……............................................................................... 5

1. Product Overview.................................................................. 6

1.1 Product Introduction ........................................................ 6

1.2 Features and Benefits....................................................... 6

1.3 Specifications ................................................................... 7

1.4 Block Diagram .................................................................. 8

1.5 Package Contents............................................................. 9

1.6 Technical Assistance......................................................... 9

2. System Components............................................................ 10

2.1 LEC-7000 (VES-402) System Board ................................. 10

2.1.1 Board Layout ................................................................ 11

2.1.1 Board Dimensions......................................................... 12

2.1.2 Jumper Settings and I/O Connectors ........................... 13

2.2.1 Connector Pin Assignments .......................................... 14

2.2 LEC-7000 Embedded System Mechanisms ...................... 19

2.2.1 Front View................................................................... 19

2.2.2 Rear View .................................................................... 20

3. Hardware Installation Guide ............................................... 21

3.1 LEC-7000 Embedded System .......................................... 21

3.1.1 Begin Installation......................................................... 21

3.1.2 System Memory Installation......................................... 22

3.1.3 CompactFlash Card Installation.................................... 22

3.1.4 HDD Installation........................................................... 23

3.1.5 System Complete.......................................................... 25

3.2 Mounting Kits ................................................................. 26

3.2.1 Wall Mount (Optional) .................................................. 26

3.2.2 VESA Mount (Optional)................................................. 27

3.2.3 Rack Mount Kit (Optional) ............................................ 27

A. Appendix A: LAN Port LED Indicators.................................. 28

B. Appendix B: Watchdog Timer .............................................. 29

B.1 Most Introduction.......................................................... 29

B.2 Detail Register Descriptions ........................................... 29

B.2.1 To used the watch-dog timer........................................ 29

Terms and Conditions............................................................... 30

Warranty Policy........................................................................ 30

RMA Service ............................................................................. 30

5

Page 6

LEC-7000 Fanless Embedded System User’s Manual

1. Product Overview

1.1 Product Introduction

Figure 1 – LEC-7000 Outlook

The LEC-7000 Fanless Embedded System built-in Intel Atom N270 (1.6Ghz CPU) onboard

and the board integrates chipsets Intel® 945GSE+ICH7M deliver lower Power consumption,

multiple I/O functions for interactive applications and various embedded computing

solutions. LEC-7000 built-in in DDR2 SO-DIMM socket for DDR2 533/667 memory, Maximum

memory capacity up to 2GB. The board also features CRT VGA Output and DVI-D VGA output

for Dual Display, Dual PCIex1 Ethernet Port one Serial ATA channels for total one Serial ATA

hard drives at maximum transfer rate up to 150MB/sec, Four USB 2.0 high speed compliant,

built-in high definition audio codec that can achieve the best stability and reliability for Digital

Signage Platform, Industrial controller applications.

1.2 Features and Benefits

z Intel® Atom™ 1.6 GHz onboard CPU

z Robust fanless enclosure

z Slim 36mm case with heat dispersing fins

z -20°C to 50°C operating temperature

z Supports up to 2GB DDR2 memory (512MB IC onboard)

z Dual Display (CRT+DVI-D)

z Dual 10/100/1000 Mbps LAN

z USB x 4, COM x 2

z Compact Flash Type I/II or SATA HDD support

z Wall or VESA mounting brackets (optional)

6

Page 7

LEC-7000 Fanless Embedded System User’s Manual

1.3 Specifications

FEATURE DESCRIPTION

Form Factor Fanless Embedded System

Platform

System Memory

Networking

Video Controller Intel 945GSE built-in Intel Extreme

Audio Codec ALC888 HD Codec

Front I/O

Rear I/O

Expansion

Hardware

Monitoring

OS Supported Linux kernel 2.4.16 or above,

Environmental

Parameters

Processor Onboard Intel® Atom™ 1.6 GHz

Chipset Intel 945GSE+ICH7M

BIOS AMIBIOS with 8Mbit BIOS Flash

FSB 533MHz

Technology DDR2 533/667

Memory On Board 512MB DDR2 onboard

Memory Socket SODIMM x 1 (up to 2GB)

Max Memory 2GB

Standard Color Grey Appearance

Construction Aluminum extrusion

Solid State CF Socket Storage

HDD 2.5” SATA HDD support

GbE (LAN) 2 (RTL8111C-VC-VR)

Wake On LAN Yes

PXE Version 2.1

COM COM1 supports RS232/422/485 with 5V

Status LEDs

USB 2.0 4

Audio Mic In / Line Out

GbE LAN 2 x RJ45

Power ATX Power Switch

Controller Winbond W83627UHGintegrated

Watchdog timer 255 level software programmable

Temperature, ambient

operating

Graphics

or 12V Power

COM2 supports RS232 Only)

DVI-D Video

VGA

Power

HDD

1 x 2 Phoenix Connector Power Input

DC Jack (optional)

Mini-PCI socket for Mini-PC Wireless

Module (Optional)

hardware monitor

watchdog timer

XPE/Win XP-32 bit, Win CE

6.0

-20°~50°C

Humidity (RH), ambient

operating

7

10~95% relative humidity,

non-condensing

Page 8

LEC-7000 Fanless Embedded System User’s Manual

Dimensions 140D x 190W x 36H mm

Input VAC 100~240V adapter Power Supply

Output 12V DC with 60W ATX mode

power adapter

Compliance CE, FCC, RoHS

Note: All specifications and images are subject to change without notice.

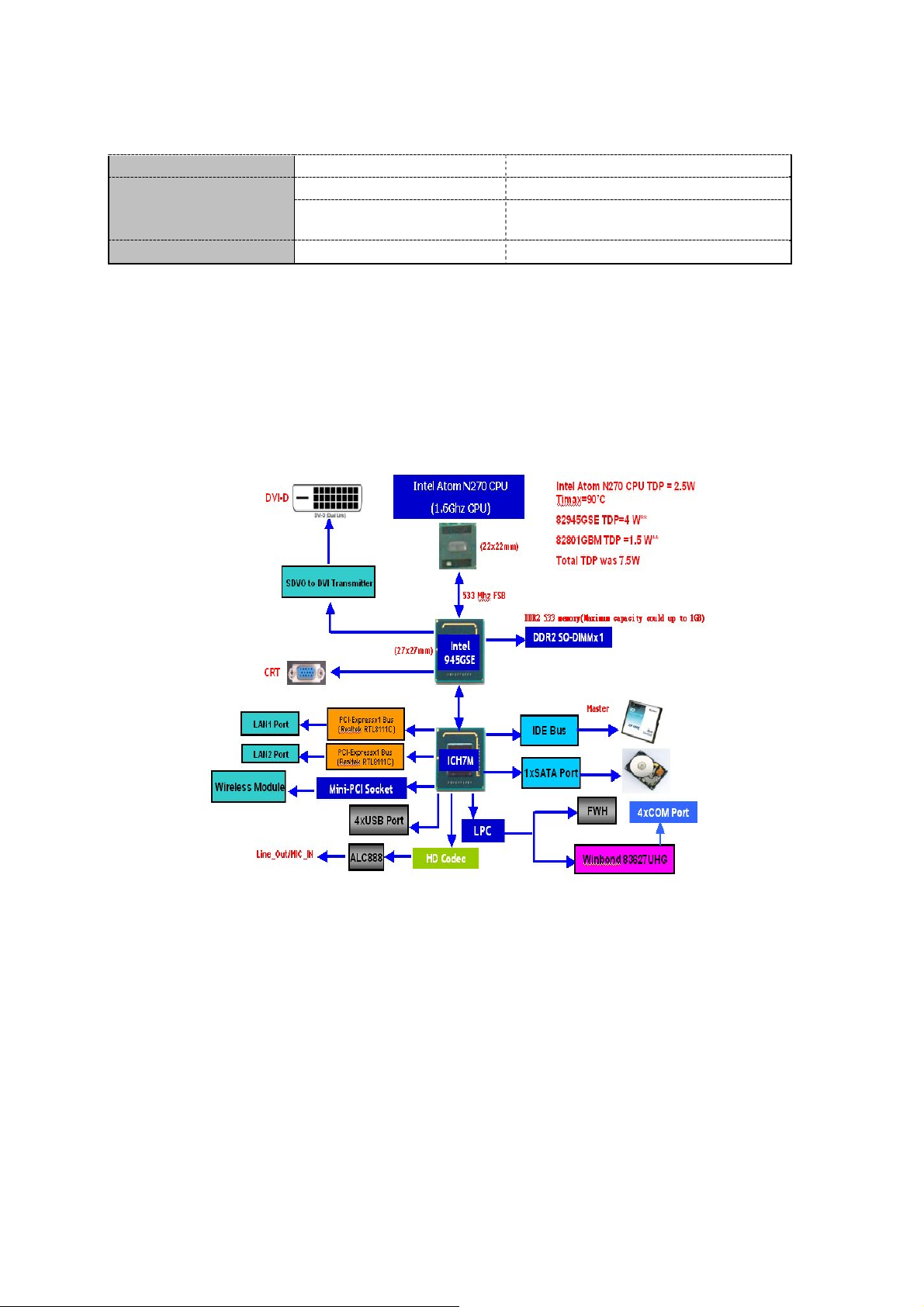

1.4 Block Diagram

Figure 2 – Block Diagram

8

Page 9

LEC-7000 Fanless Embedded System User’s Manual

1.5 Package Contents

Carefully unpack your package and make sure that you have the following items.

LEC-7000 Embedded System x 1

z DC+12V 60W Power Adapter x 1

z Power Cord x 1

z Rubber foot / Screw x 4

z E Drivers and User’s manual CDx1

Note: If you should find any components missing or damaged, please contact your dealer

immediately for assistance.

1.6 Technical Assistance

Should you have any questions or problems with your product, please contact the Lanner

sales team.

Phone: 886-2-8692-6060

Fax: 886-2-8692-6101

E-mail: sales@lannerinc.com

Prior to contacting us, we ask that you first check the electronic product documentation for

assistance. Should you still have questions, we recommend you have the following

information on hand in order to expedite the process:

1. LEC-7000 model name

2. Part number

3. Local network configuration details

4. Abnormal behavior and/or error messages reported by your network system

5. Your questions, or a description of the problem you are experiencing

9

Page 10

LEC-7000 Fanless Embedded System User’s Manual

2. System Components

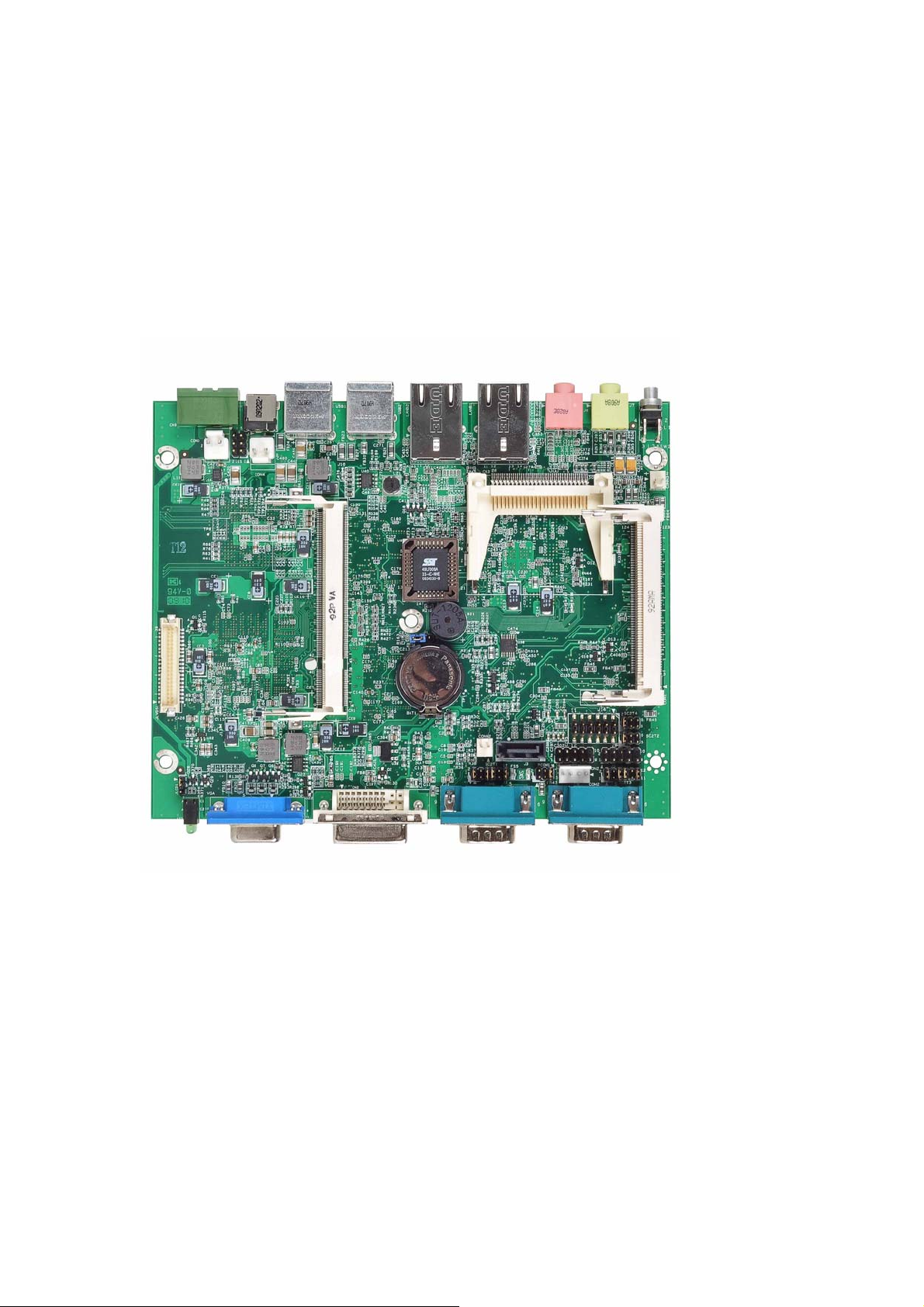

2.1 LEC-7000(VES-402) System Board

VES-402 is the system board bundled with the LEC-7000 Fanless Embedded System

platform. The succeeding sections list VES-402 related jumper settings and connector pin

assignments.

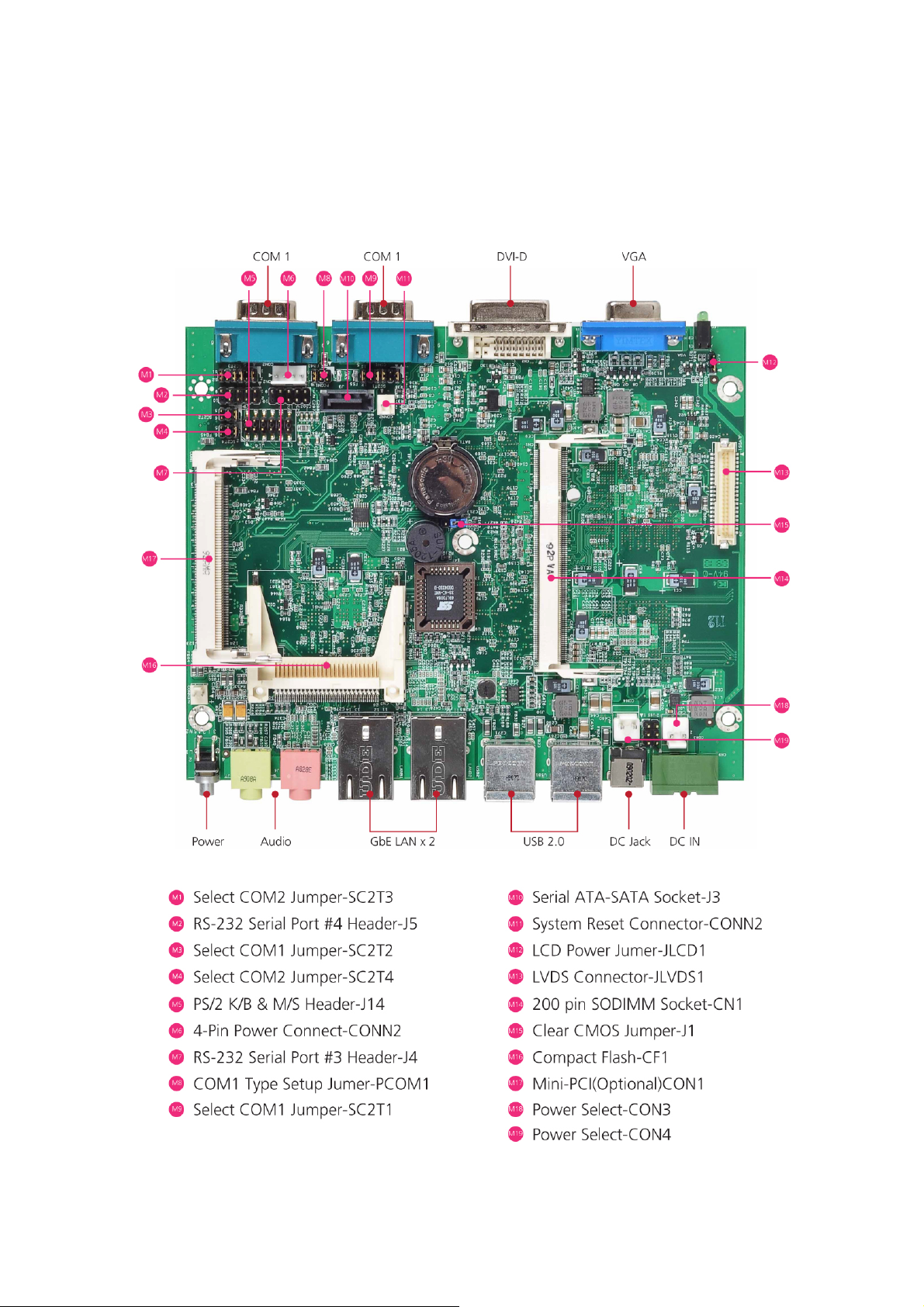

Figure 3 –VES-402 System Board

10

Page 11

LEC-7000 Fanless Embedded System User’s Manual

2.1.1 Board Layout

Figure 4 –VES-402 Jumpers and Connectors

11

Page 12

LEC-7000 Fanless Embedded System User’s Manual

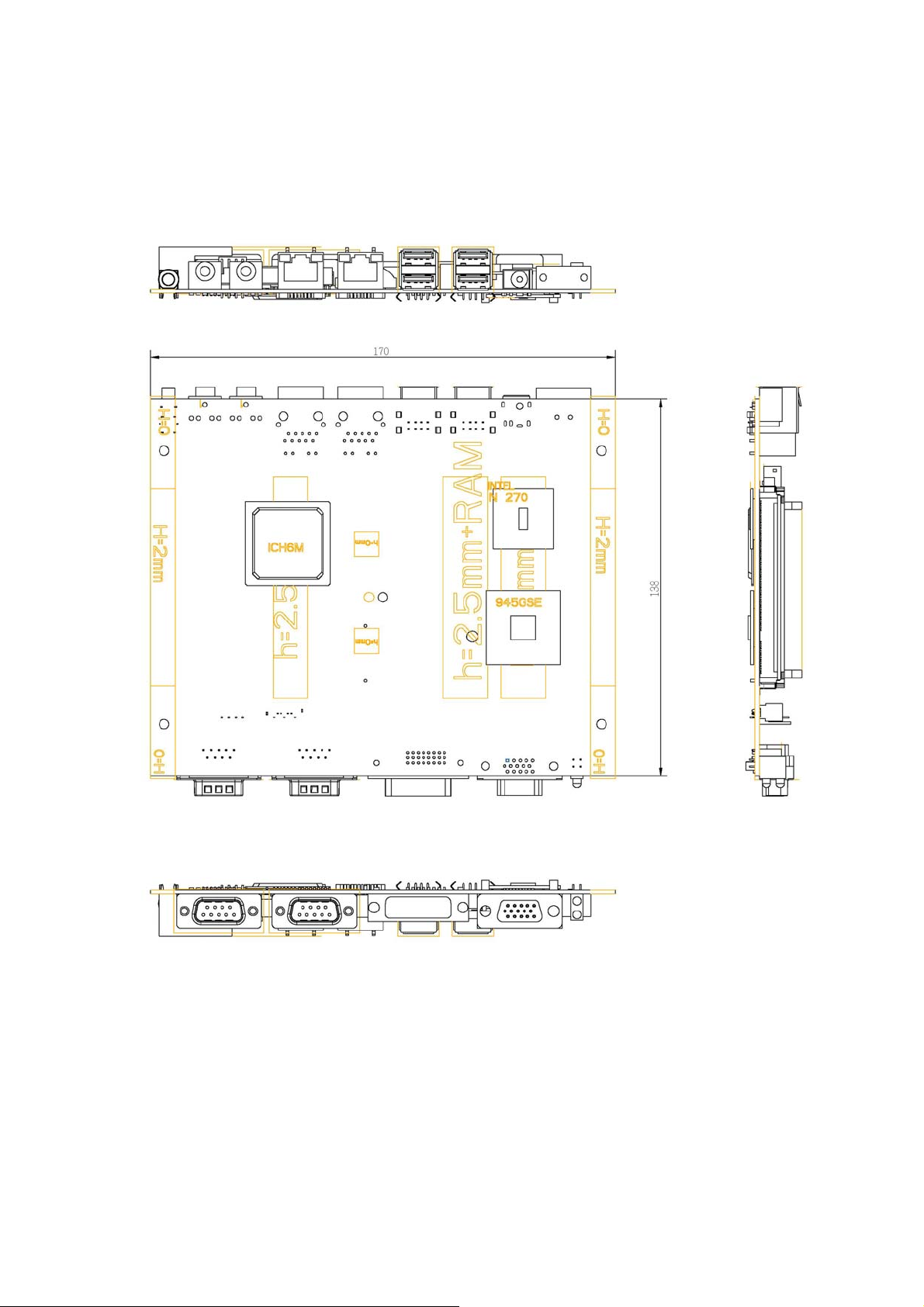

2.1.1 Board Dimensions

Figure 5 – Board Dimension

12

Page 13

LEC-7000 Fanless Embedded System User’s Manual

2.1.2 Jumper Settings and I/O Connectors

The jumper settings and I/O connectors of the VES-402 board are specific to the LEC-2050.

Changing these settings may result in malfunctions or damages to your system.

Jumper Settings and I/O Connector Summary for VES-402:

JUMPER FUNCTION

CF1

CN1

CON1

CON2

CONN2

J1

J15

J14

Compact Flash

200 pin SODIMM Socket

Mini-PCI (Optional)

4-Pin Power Connector

System Reset Connector

Clear CMOS Jumper

POWER SELECT

PS/2 K/B & M/S Header

J3 Serial ATA-SATA Socket

J4

J5

JLCD1

JLVDS1

COM1

PCOM1

RS-232 Serial Port #3 Header

RS-232 Serial Port #4 Header

LCD Power Jumper

LVDS Connector

COM1 Pin Definition

COM1

Pin 9

Function Jumper

SC2T1 Select COM1 Jumper

SC2T2 Select COM1 Jumper

COM2 COM2 Pin Definition

SC2T3 Select COM2 Jumper

SC2T4 Select COM2 Jumper

14

Page 14

LEC-7000 Fanless Embedded System User’s Manual

2.2.1 Connector Pin Assignments

J14:2X4-Pin PS/2 Keyboard&Mouse Header(2.54mm)

PIN DESCRIPTION PIN DESCRIPTION

1 5V 2 MSCLK

3 MSDATA 4 -

5 KBDATA 6 -

7 Ground 8 KBCLK

15

Page 15

LEC-7000 Fanless Embedded System User’s Manual

COM1 Pin Definition:

PIN NO.

1

2

3

4

5 Ground (GND)

6

7

8

9

10 KEY

RS-232 RS-485 RS-422

Data Carrier

Detect (DCDA #)

Receive Data

(RXDA)

Transmit Data

(TXDA)

Data Terminal

Ready (DTRA #)

Data Set Ready

(DSRA #)

Request To Send

(RTSA #)

Clear To Send

(CTSA #)

Ring

Indicator(RIA#)

Serial Port Type

TXRX- TX-

TXRX+ TX+

RX-

RX+

SC2T1/SC2T2: Select COM1 Type Jumper

9

5

6

1

COM1

COM1 TYPE SC2T2 SC2T1

RS-232 (Default) 1-2 1-2,5-6,7-8,11-12

RS-422 3-4 2-4,3-5,6-8,9-11

RS-485 5-6 2-4,3-5,6-8,9-11

PCOM1: COM1 Pin 9 Function Jumper

The Ring Indicator (pin 9) of RS-232 port of COM1 can be altered to provide

different functions as the following:

16

Page 16

LEC-7000 Fanless Embedded System User’s Manual

PIN NO. DESCRIPTION

1-2 +5V

3-4 +12V

5-6 RI

COM2 Pin Definition:

PIN NO.

1

2

3

4

5 Ground (GND)

6

7

8

9

10 KEY

RS-232 RS-485 RS-422

Data Carrier

Detect (DCDA #)

Receive Data

(RXDA)

Transmit Data

(TXDA)

Data Terminal

Ready (DTRA #)

Data Set Ready

(DSRA #)

Request To Send

(RTSA #)

Clear To Send

(CTSA #)

Ring

Indicator(RIA#)

Serial Port Type

TXRX- TX-

TXRX+ TX+

RX-

RX+

SC2T3/SC2T4: Select COM2 Type Jumper

9 6

5

1

COM2

COM2 TYPE SC2T4 SC2T3

RS-232 (Default) 1-2 1-2,5-6,7-8,11-12

RS-422 3-4 2-4,3-5,6-8,9-11

RS-485 5-6 2-4,3-5,6-8,9-11

17

Page 17

LEC-7000 Fanless Embedded System User’s Manual

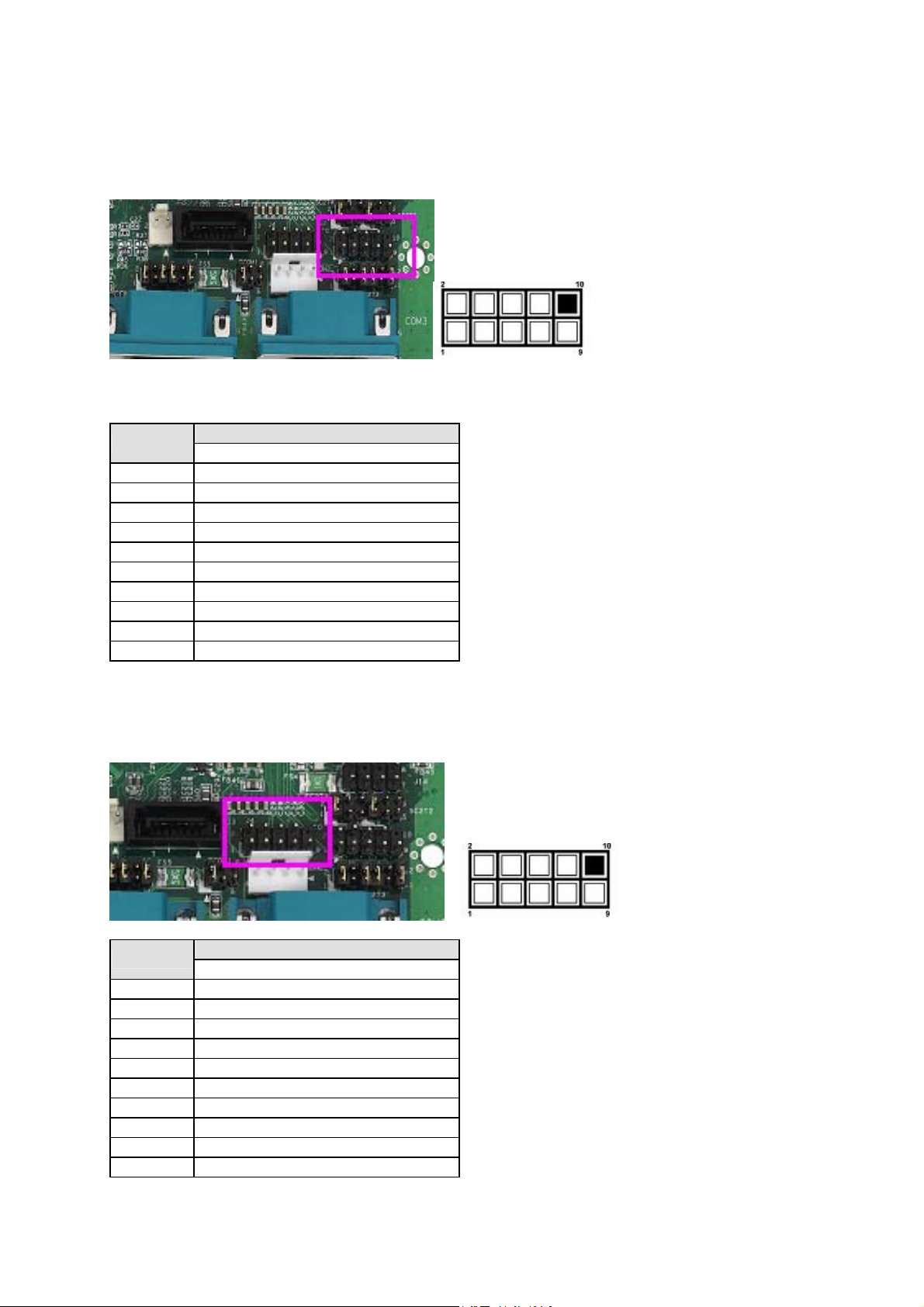

J5: RS-232 Serial Port #4 Header (2X5 Pin 2.54mm Header)

PIN NO.

1 Data Carrier Detect (DCDB #)

2 Data Set Ready (DSRB #)

3 Receive Data (RXDB)

4 Request To Send (RTSB #)

5 Transmit Data (TXDB)

6 Clear To Send (CTSB #)

7 Data Terminal Ready (DTRB #)

8 Ring Indicator (RIB #)

9 Ground

10 KEY

DESCRIPTION

RS-232

J4: RS-232 Serial Port #3 Header (2X5 Pin 2.54mm Header)

PIN NO.

1 Data Carrier Detect (DCDB #)

2 Data Set Ready (DSRB #)

3 Receive Data (RXDB)

4 Request To Send (RTSB #)

5 Transmit Data (TXDB)

6 Clear To Send (CTSB #)

7 Data Terminal Ready (DTRB #)

8 Ring Indicator (RIB #)

9 Ground

10 KEY

DESCRIPTION

RS-232

16

Page 18

LEC-7000 Fanless Embedded System User’s Manual

CON2: 4-Pin Power Connector (4P Male )

Pin No. Description

1 +12V

2 GND

3 GND

4 +5V

CONN2: System Reset Connector

J1: Clear CMOS Jumper

Description CMOS1

Normal (Default) 1-2

Clear CMOS 2-3

17

Page 19

LEC-7000 Fanless Embedded System User’s Manual

JLCD1: LCD Power Jumper

Description CMOS1

3.3V(Default) 1-2

5V 2-3

JLVDS1: LVDS Connector (2x20 1.25mm Connector)

Pin

No. Description

1 PVDD 2 12V 3 LCD1D0# 4 LCD1D4#

5 LCD1D0 6 LCD1D4 7 PVDD 8 12V

9 LCD1D1# 10 LCD1D5# 11 LCD1D1 12 LCD1D5

13 GND 14 GND 15 LCD1D2# 16 LCD1D6#

17 LCD1D2 18 LCD1D6 19 GND 20 GND

21 LCD1D3# 22 LCD1D7# 23 LCD1D3 24 LCD1D7

25 LCLK1# 26 LCLK2# 27 LCLK1 28 LCLK2

29 ENBLD1 30 BLCON 31 GND 32 GND

33 ENBLD2 34 BLCON2 35 PVDD2 36 GND

37 PVDD2 38 SPD1 39 GND 40 SPCLK1

Pin

No. Description

Pin

No. Description

Pin

No. Description

18

Page 20

LEC-7000 Fanless Embedded System User’s Manual

2.2 LEC-7000 Embedded System Mechanisms

This section of the manual describes the mechanical and device nomenclature of the

LEC-7000.

2.2.1 Front View

Figure 6 – LEC-7000 Front View

19

Page 21

LEC-7000 Fanless Embedded System User’s Manual

2.2.2 Rear View

Figure 7 – LEC-7000 Rear View

20

Page 22

LEC-7000 Fanless Embedded System User’s Manual

3. Hardware Installation Guide

3.1 LEC-7000 Embedded System

Figure 8 – LEC-7000 Embedded System Outlook

3.1.1 Begin Installation

Unscrew 10 thumbscrews of the chassis bottom cover and than remove the chassis bottom cover.

Note: For Safety reasons, please ensure that the power cord is disconnected

before opening the case.

21

Page 23

LEC-7000 Fanless Embedded System User’s Manual

3.1.2 System Memory Installation

Install the memory module into the socket and push it firmly down until it is fully seated.

3.1.3 CompactFlash Card Installation

Carefully insert the CompactFlash card into the slot as shown in the illustration above.

22

Page 24

LEC-7000 Fanless Embedded System User’s Manual

3.1.4 HDD Installation

1. Place the HDD (upside down) in the rack of bottom.

Note: Please install 2.5” HDD

2. Secure with 4 screws from the side

23

Page 25

LEC-7000 Fanless Embedded System User’s Manual

3. Connect the Serial ATA/Power Cable to the HDD

4. Plug the Serial ATA cable to the SATA Connector (J3)

24

Page 26

LEC-7000 Fanless Embedded System User’s Manual

5. Plug the Power cable to the 4-Pin Power Connector (CON2)

3.1.5 System Complete

1. Replace the cover

25

Page 27

LEC-7000 Fanless Embedded System User’s Manual

2. Refasten the thumbscrews and than LEC-7000 Embedded System Installation Complete

Note: Please load the optimized BIOS values.

3.2 Mounting Kits

3.2.1 Wall Mount (Optional)

Figure 9 – Wall Mount View

26

Page 28

LEC-7000 Fanless Embedded System User’s Manual

3.2.2 VESA Mount (Optional)

Figure 10 – Wall Mount View

3.2.3 Rack Mount Kit (Optional)

Figure 11 – Rack Mount View

27

Page 29

LEC-7000 Fanless Embedded System User’s Manual

A. Appendix A: LAN Port LED Indicators

LED/ Color Status Description

Green Off LAN is link to a 10 Mbps device.

Yellow Blinks LAN port is receiving and transmitting packets.

Green On LAN is link to a 10 or 100Mbps device.

Yellow Blinks LAN port is receiving and transmitting packets.

Orange On LAN is link to a 1G bps device.

Yellow Blinks LAN port is receiving and transmitting packets.

28

Page 30

LEC-7000 Fanless Embedded System User’s Manual

B. Appendix B: Watchdog Timer

B.1 Most Introduction

systems need to be self-reliant. If an error should occur it is typically not possible to wait for

the system to be rebooted manually. In some cases, such as space probes, the system is

simply not accessible to human operators. If such systems should ever hang, they would be

permanently disabled. In other cases, the speed at which a human operator would reset the

system would be too slow to meet the uptime requirements of the product.

A watchdog timer is a piece of hardware that can be used to automatically detect system

anomalies and reset the processor in the case any problems are found. Generally speaking,

a watchdog timer is based on a counter that counts down from an initial value to zero. The

software selects the counter's initial value and periodically restarts it. Should the counter

reach zero before the software restarts it, the software is presumed to be malfunctioning,

and the processor's reset signal is asserted. Thus, the processor will be restarted as if a

human operator had cycled the power.

B.2 Detail Register Descriptions

A watchdog action consists of a series of watchdog instructions. A watchdog instruction is

the operation on a register region. This section describes the detail register in LPD I/O

(W83697HG)

B.2.1 To used the watch-dog timer

For DOS system:

Execute the EM9765WD1.EXE file under DOS, then key-in 0~255. The system will reboot

automatically according to the time-out you set.

29

Page 31

C. Appendix C: Simple Testing

Procedures of RS-232/RS-485

Connections

This section illustrates a simple method to test your Serial port’s connection and

data communication.

Let’s use COM2 port with a configuration of RS-485 as an example. To configure

the serial type of COM2, refer to SC2T3/SC2T4: Select COM2 Type Jumper,

Section 2.2.1 Connector Pin Assignments.

1. Enter to BIOS setup utility of the LEC-2050 and make sure that the serial port 2’s base

address is: 2F8.

2. You can connect to the LEC-2050 serial device server’s COM2 serial port with a

RS-232 (DB-9 female) communication cable, with the other end connecting to

the host’s serial port.

3. Install PComm Lift software on the host PC and LEC-2050 to be your testing

terminal.

4. Start the PComm Terminal Emulator from your desktop.

Page 32

5. Select Port Manager on the main menu.

6. Configure the COM port as the following: select port to be COM2, Baud Rate to

be 9600, Data Bit to be 8, Parity to be None, and Stop Bits to be1.

Page 33

7. Click RTS to start sending messages from the host to LEC-2050.

8. Click DTR to start receiving messages from LEC-2050 on the host. Remember

to send messages from the LEC-2050’s terminal before receiving messages on

the host.

Page 34

9. To configure the message encoding method, select Port Manager from the

menu bar of the PComm. Select Send Pattern and then select ASCII or HEX

from the Data Pattern option menu. Enter letters from A to Z if you select ASCII

or enter 0-9 and A-F if you select HEX.

10. If you select ASCII to be the encoding method as shown in the example, you

should see the text messages showing on the receiving end.

Page 35

Page 36

LEC-7000 Fanless Embedded System User’s Manual

Terms and Conditions

Date:2007.03.19

Warranty Policy

1. All products are under warranty against defects in materials and workmanship for a

period of one year from the date of purchase.

The buyer will bear the return freight charges for goods returned for repair within the

2.

warranty period; whereas the manufacturer will bear the after service freight charges for

goods returned to the user.

3. The buyer will pay for repair (for replaced components plus service time) and

transportation charges (both ways) for items after the expiration of the warranty period.

4. If the RMA Service Request Form does not meet the stated requirement as listed on “RMA

Service,” RMA goods will be returned at customer’s expense.

The following conditions are excluded from this warranty:

5.

Improper or inadequate maintenance by the customer

Unauthorized modification, misuse, or reversed engineering of the product

Operation outside of the environmental specifications for the product.

RMA Service

Requesting a RMA#

1. To obtain a RMA number, simply fill out and fax the “RMA Request Form” to your

supplier.

2. The customer is required to fill out the problem code as listed. If your problem is

not among the codes listed, please write the symptom description in the remarks box.

3. Ship the defective unit(s) on freight prepaid terms. Use the original packing

materials when possible.

4. Mark the RMA# clearly on the box.

Note: Customer is responsible for shipping damage(s) resulting from inadequate/loose packing of the

defective unit(s). All RMA# are valid for 30 days only; RMA goods received after the effective RMA#

period will be rejected.

30

Page 37

LEC-7000 Fanless Embedded System User’s Manual

RMA Service Request Form

When requesting RMA service, please fill out the following form. Without this form enclosed,

your RMA cannot be processed.

RMA No:

Company: Contact Person:

Phone No. Purchased Date:

Fax No.: Applied Date:

Return Shipping Address:

Shipping by: □ Air Freight □ Sea □ Express ___

□ Others:________________

Item Model Name Serial Number Configuration

Item Problem Code Failure Status

Reasons to Return: □ Repair(Please include failure details)

□ Testing Purpose

*Problem Code:

01:D.O.A.

02: Second Time

R.M.A.

03: CMOS Data Lost

04: FDC Fail

05: HDC Fail

06: Bad Slot

Request Party

Authorized Signature / Date Authorized Signature / Date

07: BIOS Problem

08: Keyboard Controller Fail

09: Cache RMA Problem

10: Memory Socket Bad

11: Hang Up Software

12: Out Look Damage

13: SCSI

14: LPT Port

15: PS2

16: LAN

17: COM Port

18: Watchdog Timer

Confirmed By Supplier

19: DIO

20: Buzzer

21: Shut Down

22: Panel Fail

23: CRT Fail

24: Others (Pls specify)

31

Loading...

Loading...