Page 1

Embedded &

Industrial Computing

Hardware Platforms for Embedded and Industrial Computing

LEC-3100

>>

User's Manual

Publication date:2011-05-10

Page 2

TTaTTable of Contentsbeable of Contents

Chapter 1: Introduction 1

System Specication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Front Panel Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Rear Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2: Hardware Setup 6

Preparing the Hardware Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installing the System Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installing the Hard Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installing a CompactFlash Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 3: Motherboard Information 8

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Motherboard Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Jumper Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Appendix: Terms and Conditions 14

Warranty Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

RMA Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

i

Page 3

Chapter 1

Introduction

Chapter 1: Introduction

Thank you for choosing the LEC-3100. The LEC-3100

is an embedded automation computer that features

fanless rackmount design targeted for high demand

serial port connectivity in an industrial environment or

transportation control system.

The LEC-3100’s CPU core consists of an Intel 945GSE with

ICH7M chipset mounted on its bottom side, an approach

that improves thermal management and increases the

space for I/O functions and connectors. This innovative

design has enabled the LEC-3100 to integrate additional

COM ports (a total of 10 RS232/RS485/RS422 configurable

ports and all are capable of automatic flow control by

hardware and isolation) and 5 Ethernet controllers, 4

digital inputs and 4 digital outputs, 4 USB2.0 ports, one

DVI display, and a PCI-104 expansion stack location.

Please refer to the chart below for a detailed description

of the system’s specifications.

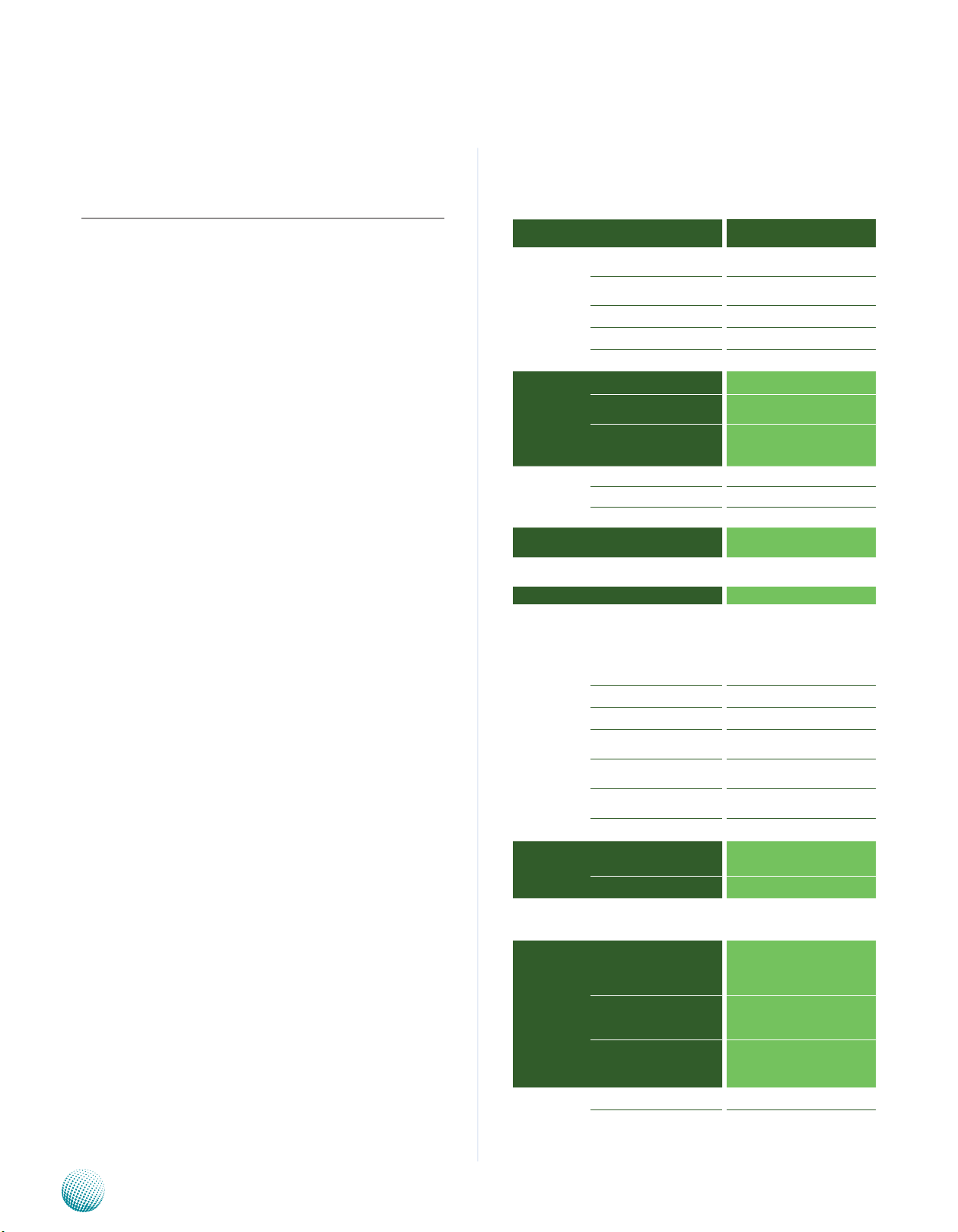

System Specification

FEATURE

Platform

Memory

Storage

Networking

Video

Audio

I/O

Hardware

Monitor

OS Supported

Environmental Parameters

DESCRIPTION LEC-3100

Form Factor 1U Rackmount

Processor Intel Atom N270

Chipset Intel 945GSE + ICH7M

BIOS AMIBIOS with 8Mbit FWH

Max. FSB 533MHz

Memory IC On Board No

Memory Socket

Max Memory 2GB (1 x 2GB Module)

Compact Flash 1 x CF Socket Type I/II

SATA 1 x 2.5” SATA HDD

IDE 2 x 22pin IDE header

Controller (Interface)

Controller Onboard 945GSE

Codec ALC888 HD Codec

COM Ports

USB 2.0 4 (3 x External, 1 x Internal)

DVI 1 (1600 x 1200)

LAN

Audio

DIO

Expansion PCI/104

Controller

Watchdog timer Yes (1~255 level)

Operating Temperature

(With Industrial Components:

CF, Memory, SSD, HDD)

Operating Temperature

(With Commercial Components)

1 x SODIMM (up to 2GB per

slot)

Intel 82574L x 4,

Intel 82562GZ x1

2 x DB9

8 x Phoenix Contact

All ports are isolated and can

use RS-232/422/485 control

signals Corresponding LEDs

on front panel

1x RJ45 FE and 4 x RJ45 GbE,

LEDs on front panel

Line in, Line out, Mic In

(optional)

4 in, 4 out, LEDs on front

panel

Winbond W83627 UHG integrated hardware monitor

Embedded Windows XP/Linux

kernel 2.4.16 or above/WindowsXP 32 bit

-20°~50°C / 14°~131°F

-5°C~45°C / 23°~113°F

Embedded and Industrial Computing

Dimensions

Extended Operating

Temperature Tested

W x H x D 271 x 44.5 x 440 mm

Weight 3Kg

N/A

1

Page 4

Chapter 1

Introduction

Power

Compliance

DC Power Input 9V ~ 36V DC in

AC Power Input

110/240V AC in, 10% Tolerence

CE, FCC, RoHS

Package Contents

Your package contains the following items:

LEC-3100 Embedded System •

Rack Mounting Kit •

Drivers and User’s Manual CD •

Embedded and Industrial Computing

2

Page 5

Chapter 1

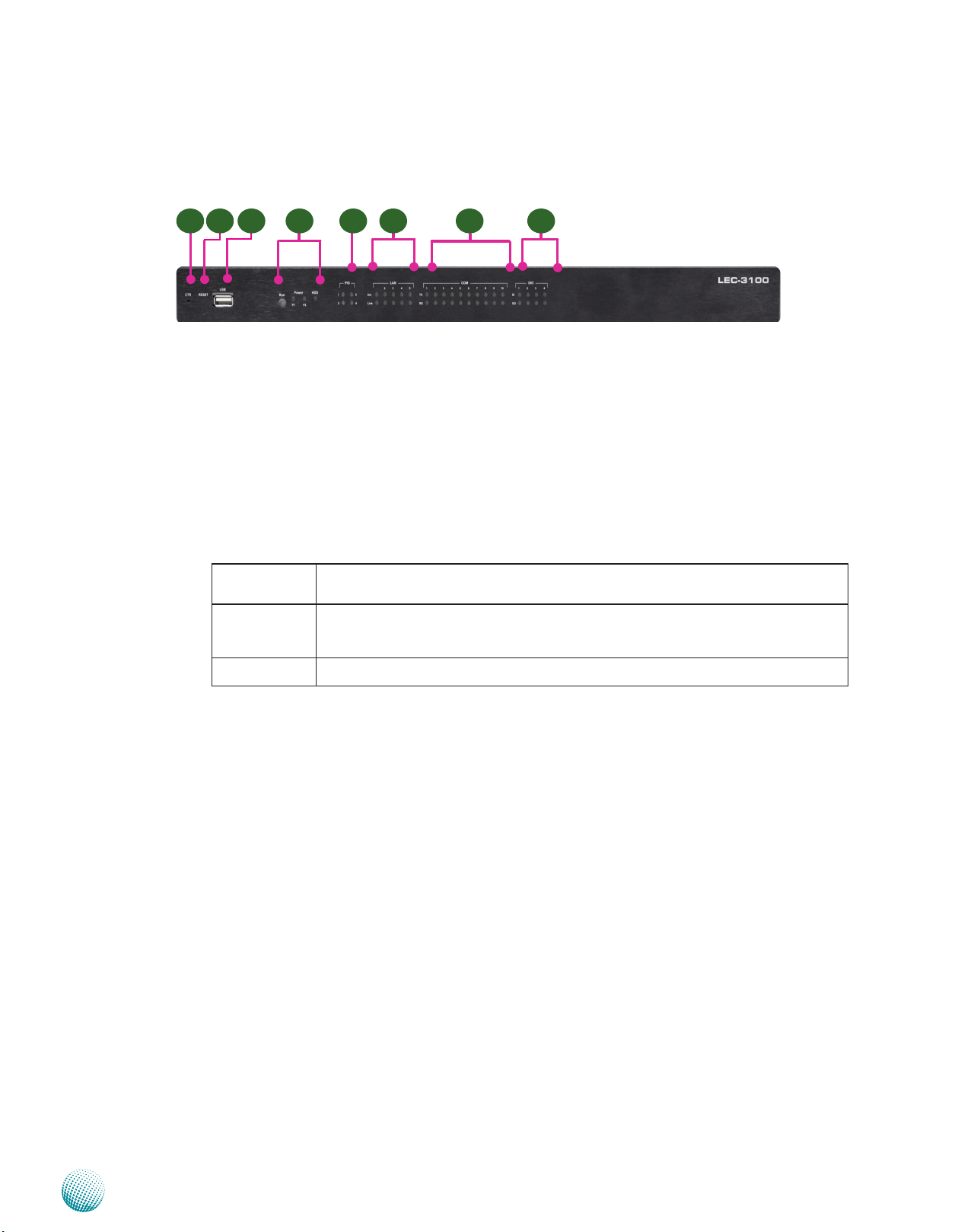

Front Panel Features

F1 F5F2 F3 F4 F6 F7 F8

F1 CTR

This is a software reset switch which could be programmed to reset your application to its default settings.

F2 Reset Switch

It is a hardware reset switch. Use a pointed object to press it 5 seconds then release it to reset the system without

turning off the power.

F3 USB 2.0 type A ports

Introduction

It connects to any USB devices, for example, a flash drive.

F5 Run/Power/HDD LED

Run A programmable dual green/amber LED which can be used for indicating system

status.

Power Green indicates Power-on, where as Off indicates Power-off status.

P1: Status for the built-in power supply unit.

P2: Status for the redundant 1x2-pin Phoenix Contact

Hard Disk Yellow indicates that HDD is present, whereas Off indicates HDD is not present.

F5 PIO Status LED

The set of 4 LEDs can be programmed to display the status of any hardware components or system operating

status. Refer to the Driver and Manual CD for a sample code to implement this feature.

F6 LAN Status LED

ACT LED: If the LED is on, it indicates that the port is linked.

Link LED: If it blinks, it indicates there is traffic.

F7 Serial Port Status LED for COM1 through COM10

The LEDs on the upper row show the status of transmission activities, whereas those on the bottom row show

the status of receiving activities.

F8 These LEDs indicate the Digital I/O operating status.

The LEDs on the upper row show the connection status of input pins, whereas those on the bottom row show

the connection status of output pins.

Embedded and Industrial Computing

3

Page 6

Chapter 1

Rear Panel Features

R1

R2

R4

5 4 3 2 1

Pin 1

COM8

Pin 1

COM7

R5

Pin 1

COM4

Pin 1

COM3

COM2

COM1

Introduction

LAN 2

LAN 4

R3

10 9 8 7 6

Pin 1

COM9COM10

Pin 1

COM6

Pin 1

COM5

Pin 1

R6

R7 R8

LAN 1

LAN 3LAN 5

R9

R1 Power Switch

The power switch comes with the switch which can be used to turn on/off the power from the power

supply.

R2 Power Socket

The AC inlet comes from the unit’s built-in 150W open frame power.

R3 Redundant Power Supply Socket

A redundant power supply through 1x2-pin Phoenix Contact with 9~36V is provided on the system. The

socket also features reversed wiring protection. Hence, it will not cause any damage to the system by reversed

wiring of ground line and power line.

Pin No. 1 2

12

Function DC + DC-

R4 Digital Input/Output port:

The general-purpose input/output (GPIO) peripheral is provided through 10-pin terminal block connector.

Pin 1to 4- Digital Inputs. Pin 6-9-Digital Output.

Pin NO. Pin 1 Pin 2 Pin 3 Pin 4 Pin 5

Assignment

Assignment

R5 20-pin Phoenix Contact Terminal Block

This terminal block can be connected as 8 Com ports with serial port type of RS-232, RS-422 or RS-485; it

supports dip switch selection among RS-232, RS-422 and 485. The following table lists the pin assignments.

Refer to Chapter 3 Motherboard Information for dip switch adjustment information. Note that Pin 1 starts

from right. These connectors are isolated COM ports which will protect system from being damaged due to

power surge or failure of the connected devices.

Port Type

RS-232 SOUT RTS SIN CTS Ground

RS-422 TX+ TX- RX- RX+ Ground

RS-485 TX+ TX- RX- RX+ Ground

RS-485 (2 wires) D+ D- Ground

Embedded and Industrial Computing

Input 0 Input 1 Input 2 Input 3 Ground

Pin NO. Pin 6 Pin 7 Pin 8 Pin 9 Pin 10

Output 0 Output 1 Output 2 Output 3 Ground

Pin NO.

Pin 1 Pin 2 Pin 3 Pin 4 Pin 5

(GND)

(GND)

(GND)

4

Page 7

Chapter 1

R6 Two RS-232 Serial Port (Right: COM1, Left: COM2)

These two serial ports have default operation mode of RS-232 communication channel, but can be configured

as either RS-422 or RS-485 serial communication channel through jumper selection. Refer to Chapter 3

Motherboard Information for jumper selection information. They are also isolated ports.

Pin No. Pin name for RS-232 Pin name for RS-485/RS-422 Pin name for RS-485(2 wires)

1 Data Carrier Detect (DCDA#) TX- D2 Received Data (RXDA) TX+ D+

3 Transmitted Data (TXDA) RX+

4 Data Terminal Ready (DTRA#) RX5 Signal Ground (GND) Ground (GND) Ground (GND)

Introduction

1 2 3 4 5

6 7 8 9

Pin No. Pin name for RS-232 Pin name for RS-485

6 Data Set Ready (DSRA#)

7 Request to Send (RTSA#)

8 Clear to Send (CTSA#)

9 Ring Indicator (RIA#)

R7 DVI-I Connector

It is a Dual Link DVI-I Connector which supports both digital and analog signals, allowing either type of monitor

(analog or digital) to be operated from the same connector (or with a special purpose DVI-A or DVI-I to VGA

cable). By using suitable DVI-I cable, you can connect an appropriate device; for example, an LCD panel.

R8 Two USB 2.0 type A ports

It connects to any USB devices, for example, a flash drive. There is another external port on the front panel and

one internal USB pitch connector on the mainboard.

R9 One FastEthernet LAN port (LAN 5) and 4 Gigabit Ethernet LAN ports (LAN1-4)

LAN 5 is provided by Intel 82562GZ Ethernet controller which supports10/100Mbps connection speeds.

LAN 1-4 are provided by Intel 82574L Ethernet controller which supports10/100/1000Mbps connection

speeds.

Using suitable RJ-45 cable, you can connect LEC-3100 System to a computer, or to any other piece of equipment

that has an Ethernet connection such as a hub or a switch.

Embedded and Industrial Computing

5

Page 8

Chapter 2

Introduction

Chapter 2: Hardware Setup

Preparing the Hardware Installation

To access some components and perform certain service

procedures, you must perform the following procedures

first.

WARNING: To reduce the risk of personal injury,

electric shock, or damage to the equipment,

remove the power cord to remove power from the

server. The front panel Power On/Standby button

does not completely shut off system power.

Portions of the power supply and some internal

circuitry remain active until AC power is removed.

Unpower the LEC-3100 and remove the power cord.1.

Unscrew the 4 threaded screws from the side and 2.

3 from the back of the top cover on the LEC-3100

System.

Slide the cover backwards and open the cover 3.

upwards.

1

Note:

The SO-DIMM installed must meet the speed 1.

requirement (DDR2 533). Do not install DIMMs

supporting different speeds.

The motherboards can support up to 2 GB 2.

memory capacity in maximum.

Installing the Hard Disk

The system can accommodate one Serial-ATA disks. Follow

these steps to install a hard disk into the LEC-3100:

Unsrew the 4 screws on the hard disk tray to take out 1.

the hard disk tray from the system.

Place hard disk on the hard disk tray and align the holes 2.

of the hard disk with the mounting holes on the tray.

Secure the hard disk with 4 mounting screws on the 3.

hard disk tray.

Connect the Serial-ATA power and drive cables to the 4.

hard disk’s power and drive connectors respectively.

Plug the Serial-ATA cables to the Serial-ATA Connectors 5.

on the main board.

Put the hard disk tray with the installed hard disk 6.

back to the system and secure it with the mounting

screws..

Installing the System Memory

The motherboard supports DDR2 memory that features

data transfer rates of 533 MHz to meet the higher

bandwidth requirements of the latest operating system

and Internet applications. It comes with one Double Data

Rate(DDR2) Small Outline Dual Inline Memory Modules

(SO-DIMM) socket.

Align the cutout of the SO-DIMM with the notch of the 1.

memory slot.

Install the SO-DIMM.2.

Notch

Cutout

1

2

Embedded and Industrial Computing

6

Page 9

Chapter 2

Installing a CompactFlash Card

LEC-3100 provides one CompactFlash slot. Follow the

procedures bellow for installing a CompactFlash card.

Align CompactFlash card and the card slot with the 1.

arrow pointing toward the connector.

Push the card to insert into the connector.2.

Introduction

1

2

Embedded and Industrial Computing

7

Page 10

Chapter 3

Chapter 3: Motherboard Information

Block Diagram

The block diagram depicts the relationships among the

interfaces or modules on the motherboard. Please refer

to the following figure for your motherboard’s layout

design.

Motherboard Information

Embedded and Industrial Computing

8

Page 11

Chapter 3

Motherboard Layout

The motherboard layout shows the connectors and

jumpers on the board. Refer to the following picture

as a reference of the pin assignments and the internal

connectors.

Motherboard Information

J2

PS1

LCM1

J5

CN4

PSW1

J11

J1

J8

J13

J6

CON1

J7

SW1/SW2

CN1

J3

CN9

CN8

C10_SW1

C10_SW2

Embedded and Industrial Computing

C7_SW1

C7_SW2

C8_SW1

C8_SW2

C4_SW1

C4_SW2

C6_SW1

C6_SW2

C5_SW1

C5_SW2

SC3T2/SC2T2/SC4T2/

SC3T1/SC2T1/SC4T1/

SC1T2

COM2/COM1

SC1T1

USB2

LAN1

RJ2/RJ1

9

Page 12

Chapter 3

Motherboard Information

Jumper Settings

SATA Connector (J2): The system supports one SATA 2.5”

drive.

The Intel ICH7 provides hardware support for Advanced

Host Controller Interface (AHCI) which is a programming

interface for SATA host controllers. AHCI provides advanced

performance and usability enhancements with SATA such

as Hot-Plug and NCQ (Native Command Queing)

Pin No. Function

7

6

5

4

3

2

1

Note: To configure your Hard disk using the

AHCI feature, you need to enable the AHCI

option in the hard disk configuration of the BIOS

menu.

SATA Power Connector (CON1): Connect the 4-pin SATA

power connector to this port.

1 GND

2 TX+

3 TX4 GND

5 RX6 RX+

7 GND

Pin No. Function

4

3

2

1

1 NC

2 GND

3 GND

4 +5V

Keyboard and mouse interface Connectors(J3): It is

for connecting the PS/2 keyboard and mouse interface

cable.

Function Pin No.

5V 1

MSDATA 3

KBDATA 5

GND 7

2468

1357

Pin No. Function

2 MSCLK

6 KEY

6 KEY

8 KBCLK

Clear CMOS jumper (J1): It is for clearing the CMOS

memory and system setup parameters by erasing the data

stored in the CMOS RAM such as the system passwords.

1

2

3

Pin No. Function

1-2 Normal (Default)

2-3 Clear CMOS

CompactFlash Connector (CN4): It is for connecting a

Compact Flash card to be served as your system’s storage.

The connector is a CF Type II slot which could fit both CF

Type I or CF Type II cards.

CompactFlash Primary/Slave Selection Jumper (J5):

The system’s CompactFlash connects to LEC-3100’s

Primary IDE port in parallel with IDE connector J13. This

jumper configures the CF socket to be the Master (default)

or Slave IDE device.

3

2

1

Pin No. Function

2-3 Master (Default)

1-2 Slave

Digital I/O Connector (CN8): This connector provides 4

digital inputs and 4 digital outputs. The connector type

of LEC-3100 is a plug-in screw terminal block that enables

you to connect to field I/O devices directly.

5 4 3 2 1

10 9 8 7 6

Pin No. 1 2 3 4 5

Function Input 0 Input 1 Input 2 Input 3 Ground

Pn No. 6 7 8 9 10

Function Output 0 Output 1 Output 2 Output 3 Ground

Digital Inputs/Output Requirements

Logic 0: 0 ~ 2V DC

Logic 1: 2 ~ 5V DC

Current limit: Maximum 100mA for each pin

Embedded and Industrial Computing

SO-DIMM Socket (CN1): The 200-pin DDR2 SO-DIMM is

for connecting the DDR2 533 MHz memory. The system

can support up to 2GB in maximum.

Mainboard DC Power Input Connector (PS1): Attach the

4-wires DC power cable to the power input terminal block

on the mainboard. The system has an ATX-style power

input (VDC 24V) and system control.

Pin No. Function

1 DC+ (+24V)

2 DC+ (+24V)

1 2 3 4

3 DC-(GND)

4 DC-(GND)

Phoenix Power Contact (CN9): It is a power socket for

power supply (9~36 VDC) through Phoenix Contact. The

connector provides protection for reversed wiring of

ground line and power line.

Pin No. 1 2

12

Function DC +/- DC -/+

10

Page 13

Chapter 3

Motherboard Information

COM port type adjustment switches (C3_SW1 /C3_SW2,

C4_SW1/C4_SW2, C5_SW1/C5_SW2, C6_SW1/C6_SW2,

C7_SW1/C7_SW2, C8_SW1/C8_SW2, C9_SW1/C9_SW2,

and C10_SW1/C10_SW2): These pairs of switches —

C3_SW1 /C3_SW2, C4_SW1/C4_SW2, C5_SW1/C5_SW2,

C6_SW1/C6_SW2, C7_SW1/C7_SW2, C8_SW1/C8_SW2,

C9_SW1/C9_SW2, and C10_SW1/C10_SW2— are used to

adjust the serial port type for COM3, COM4, COM5, and

COM6, COM7, COM8, COM9, and COM10 respectively. Use

the table below as the switch adjustment information for

COM3 through COM10.

OFF

ON

4

3

2

1

Switch No.

Port Type

RS-232 1 OFF

RS-422

RS-485 (4 Wires)

RS-485 (2 Wires *)

Switch No.

Function

RS-232 1 OFF

RS-422

RS-485 4 Wire

RS-485 2 Wire with /

without Termination

†,‡

(

)

4 ON OFF

Switch 1

2 ON

3 OFF

4 OFF

1 ON

2 OFF

3 OFF

4 OFF

1 ON

2 OFF

3 OFF

4 ON

Switch II

2 OFF

3 OFF

4 OFF

1 ON

2 ON

3 ON

4 OFF

1 ON

2 ON

3 ON

COM1 Serial Type Selection Jumper (SC1T1, SC2T1,

SC3T1, SC4T1): This set of 4 jumpers are used to select

the serial type for COM1 port. Use the table below as the

jumper selection information for COM1.

Jumper

Serial Type

RS-232

(Default)

SCITI SC2T1 SC3T1 SC4T1

1-5

1-2 None None

2-6

3-7

4-8

RS-422 5-9

3-4 2-3 None

6-10

7-11

8-12

RS-485 5-9

5-6 2-3 None

6-10

7-11

8-12

Note: The RS-485 has automatic flow control by

hardware.

COM1 Interface Type and LCM Selection Jumper (J4,

J6): Since the LCM and COM1 interface type shares the

same jumper reference, you also need to adjust Jumpers

J4 and J6 accordingly to select COM1 serial type. Refer to

LCD Module (LCM1) on Page 13 for LCM pinout information.

J4

Jumper

Interface Type

Serial Port (Rs-232

1

2

3

3 2 1

J6

J4 J6

1-2 2-3

/422/485)

LCD Module 2-3 1-2

Note:

COM2 Serial Type Selection Jumper (SC1T2, SC2T2,

* The RS-485 has automatic flow control by

hardware and the default is set by RTS.

† The selector 4 of Switch 2 can only determine

SC3T2, SC4T2): This set of 4 jumpers are used to select

the serial type for COM2 port. Use the table below as the

jumper selection information for COM2.

the termination of RS-485 signal.

‡ The RS-485 2-wire communication has a default

Jumper

SCIT2 SC2T2 SC3T2 SC4T2

setting of termination disabled. The termination

resistor has 120 OHM.

Serial Type

RS-232

(Default)

1-5

2-6

1-2 None None

3-7

4-8

Embedded and Industrial Computing

11

Page 14

Chapter 3

Motherboard Information

Jumper

Serial Type

RS-422 5-9

SCIT2 SC2T2 SC3T2 SC4T2

3-4 2-3 None

6-10

7-11

8-12

RS-485 5-9

5-6 2-3 None

6-10

7-11

8-12

Note: The RS-485 has automatic flow control by

hardware.

COM3~COM 10(CN6 and CN7): The Winbond W83627UHG

Super I/O chipset is connected to the LEC-3100 system

through the LPC bus interfaced to the ICH7M. The Super I/O

chipset provides 6 COM ports- two DB-9 male connectors

and 4 by terminal blocks. The Fintek F81216AD chipset is

also connected to the system through the LPC bus and

provides the addition of 4 COM ports. Together they make

a total of 10 COM ports.

IDE Drive Connector (J13): This 2x22 Pin IDE connector

carries the Primary IDE port signals from the ICH7M chipset.

This port can be used for connection of two drives (Ultra

ATA 33/66/100 IDE Hard Disks with transferring rate of 33

MB/s, 66 MB/s and 88.9 MB/s respectively are supported ).

If two hard disks are connected, one has to be configured

as Master and the other would be Slave, daisy-chained on

a single 44-pin ribbon cable. Since the motherboard’s CF

socket (CN4) also connects in parallel to this set of signals,

the CompactFlash can be configured (via jumper J5) to be

either the Master or Slave IDE device.

Function Pin No.

NC 44

VCC 42

GND 40

HDC CS 1# 38

SA2 36

NC 34

N/C 32

GND 30

GND 28

GND 26

GND 24

GND 22

KEY 20

DATA15 18

DATA14 16

DATA13 14

DATA12 12

DATA11 10

DATA10 8

DATA9 6

DATA8 4

GND 2

44

42

40

38

36

34

32

30

28

26

6

4

2

43

42

41

39

37

35

33

31

29

27

¦

¦

¦

¦

¦

¦

5

3

1

Function Pin No.

GND 43

VCC 41

HDD Active 39

HDC CS0# 37

SA0 35

SA1 33

IRQ 31

DMA ACK# 29

IRDY 27

IOR# 25

IOW# 23

DMA REQ# 21

¦

¦

¦

¦

¦

¦

GND 19

DATA0 17

DATA1 15

DATA2 13

DATA3 11

DATA4 9

DATA5 7

DATA6 5

DATA7 3

RESET# 1

PCI-104 PCI Connector (J11): The mainboard’s PCI-104 PCI

(J11) expansion bus signals are generated by the ICH-7M,

and are essentially identical in function and signaling to a

normal PC motherboard’s PCI bus except for the physical

connector, which is arranged as four 30-pin rows.

Note:

We recommend that you use only Lanner

I/O module with this connector to avoid

incompatibility as some pins have been altered.

A30

D30

Row NO.

Row A Row B Row C Row D

A1

D1

Pin NO.

1 KEY2 NC VCC5 AD0

2 GPIO6 AD2 AD1 VCC5

3 AD5 GND AD4 AD3

4 C/BE-0 AD7 GND AD6

5 GND AD9 AD8 GND

6 AD11 GPIO8 AD10 M66EN_

Pull Low

7 AD14 AD13 GND AD12

8 VCC3 C/BE-1 AD15 VCC3

9 SERR- GND SMB_DAT PAR

10 GND PERR- VCC3 SMB_CLK

11 STOP- VCC3 LOCK- GND

12 VCC3 TRDY- GND DEVSEL13 FRAME- GND IRDY- VCC3

14 GND AD16 VCC3 C/BE-2

15 AD18 VCC3 AD17 GND

16 AD21 AD20 GND AD19

17 VCC3 AD23 AD22 VCC3

18 IDSL0_

AD18

GND IDSL1_

AD19

IDSL2_

AD20

19 AD24 C/BE-3 GPIO9 NC

20 GND AD26 AD25 GND

21 AD29 VCC5 AD28 AD27

22 VCC5 AD30 GND AD31

23 REQ-0 GND REQ-1 GPIO12

24 GND REQ-2 VCC5 GNT-0

25 GNT-1 GPIO7 GNT-2 GND

26 VCC5 PCICLK0 GND PCICLK1

27 PCICLK2 VCC5 PCICLK3 GND

28 GND PIRQ-D VCC5 PCIRST29 NC PIRQ-A PIRQ-B PIRQ-C

30 PCI_PME# REQ-3 GNT-3 KEY1

Embedded and Industrial Computing

12

Page 15

Chapter 3

Motherboard Information

USB 2.0 Ports (J8): The board provides 4 USB 2.0 type A

ports. Dual ports on the front panel (Reference NO.: J7),

one port on the back panel (Reference No.: USB2), and

one USB pitch (Reference No.: J8) on the board.

USB3

4

3

2

1

Pin No. Function

1 USB_VCC

2 USB-

3 USB+

4 GND

LCD Module (LCM1): The LCD module connector is a

serial type port which can be connected to display the

real-time operating status and conguration parameters

of the system.

Ground Data

Terminal

Ready

(DTR1 #)

9 7 5 3 1 Pin No.

Transmit Data

(TXD1)

9 7 5 3 1

Receive

Data (RXD1)

Data

Carrier

Detect

(DCD1#)

Function

Software Reset Switch by GPIO (SW2): In addition to

the hardware reset switch (SW1), the software reset by

GPIO can be programmed to suit your specic application need. For example, it could reset a software to its

default settings. Refer to the description of CTR on Front

Panel Features in Chapter 1, Introduction. Look in your

Driver and Manual CD for sample code to implement this

feature.

Pin No. Function

1 GPIO 12 signal

2 Ground

3 Ground

4 Ground

Hardware Reset Switch(SW1): Compared to SW2, this

is a hardware reset switch which can be used to reset the

system without turning o the power.

Pin No. Function

1 Reset Signal

2 Ground

3 Ground

4 Ground

DVI-I Connector (DVII1):

10 8 6 4 2

10. 8 6 4 2 Pin No.

KEY Ring Indicator

(RI1#)

Clear to Send

(CTS1#)

Request

to Send

(RTS1#)

Data Set

Ready

(DSR1#)

Function

Note: In order to connect the LCM, you will need

to adjust BOTH Jumper J4 and J6 accordingly.

Note that COM1 will be disabled when the jumper

setting is set to LCD Module use. Refer to the COM1

Interface Type and LCM Selection Jumper (J4, J6) on

the previous page for more information.

Jumper

Interface Type

Serial Port (Rs-232

J4 J6

1-2 2-3

/422/485)

LCD Module 2-3 1-2

Pin No. Function Pin No. Function

1 TMDS Data 2¬ 13 TMDS Data 3+

2 TMDS Data 2+ 14 5V

3 TMDS Data 2/4 shield 15 GND

4 TMDS Data 4¬ 16 HOT PLUG DET

5 TMDS Data 4+ 17

6 DDC CLOCK 18

7 DDC DATA 19 TMDS Data 0/5 shield

8 Analog vertical sync 20 TMDS Data 5¬

9 TMDS Data 1¬ 21 TMDS Data 5+

10 TMDS Data 1+ 22

11 TMDS Data 1/3 shield 23

12 TMDS Data 3¬ 24

C1 Analog Red

C2 Analog Green

C5 Analog GND

C3 Analog Blue

C4 Analog Horizontal sync

TMDS Data 0

TMDS Data 0+

TMDS CLK shield

TMDS CLK+

TMDS CLK¬

ATX Power Button Connector (PSW1)

Embedded and Industrial Computing

1 2

Pin No. Function

1 PANSW2 GND

13

Page 16

Appendix

Terms and Conditions

Appendix: Terms and Conditions

Warranty Policy

All products are under warranty against defects in 1.

materials and workmanship for a period of one year

from the date of purchase.

The buyer will bear the return freight charges for 2.

goods returned for repair within the warranty period;

whereas the manufacturer will bear the after service

freight charges for goods returned to the user.

The buyer will pay for repair (for replaced components 3.

plus service time) and transportation charges (both

ways) for items after the expiration of the warranty

period.

If the RMA Service Request Form does not meet the 4.

stated requirement as listed on “RMA Service,” RMA

goods will be returned at customer’s expense.

The following conditions are excluded from this 5.

warranty:

RMA Service

Requesting a RMA#

To obtain a RMA number, simply fill out and fax the 6.

“RMA Request Form” to your supplier.

The customer is required to fill out the problem code 7.

as listed. If your problem is not among the codes listed,

please write the symptom description in the remarks

box.

Ship the defective unit(s) on freight prepaid terms. 8.

Use the original packing materials when possible.

Mark the RMA# clearly on the box. 9.

Note: Customer is responsible for shipping

damage(s) resulting from inadequate/loose

packing of the defective unit(s). All RMA# are valid

for 30 days only; RMA goods received after the

effective RMA# period will be rejected.

Improper or inadequate maintenance by the customer

Unauthorized modification, misuse, or reversed

engineering of the product Operation outside of the

environmental specifications for the product.

Embedded and Industrial Computing

14

Page 17

Appendix

RMA Service Request Form

When requesting RMA service, please fill out the following form. Without

this form enclosed, your RMA cannot be processed.

RMA No:

Reasons to Return: Ŀ Repair(Please include failure details)

Ŀ Testing Purpose

Company: Contact Person:

Phone No. Purchased Date:

Fax No.: Applied Date:

Return Shipping Address:

Shipping by: Ŀ Air Freight Ŀ Sea Ŀ Express ___

Ŀ Others:________________

Item Model Name Serial Number Configuration

Item Problem Code Failure Status

*Problem Code:

01:D.O.A.

02: Second Time

R.M.A.

03: CMOS Data Lost

04: FDC Fail

05: HDC Fail

06: Bad Slot

07: BIOS Problem

08: Keyboard Controller Fail

09: Cache RMA Problem

10: Memory Socket Bad

11: Hang Up Software

12: Out Look Damage

13: SCSI

14: LPT Port

15: PS2

16: LAN

17: COM Port

18: Watchdog Timer

19: DIO

20: Buzzer

21: Shut Down

22: Panel Fail

23: CRT Fail

24: Others (Pls specify)

Request Party

Confirmed By Supplier

Authorized Signature / Date Authorized Signature / Date

Terms and Conditions

Embedded and Industrial Computing

15

Loading...

Loading...