Lang Manufacturing LCG-101D Service Manual

LANG MANUFACTURING COMPANY • 6500 Merrill Creek Parkway, Everett, WA 98203

TOLL FREE: 800.882.6368 • FAX: 425.349.2733 • www.langworld.com

Item No.

Project

Quantity

Gas, 10-Pan, Half Size Combi Oven Model: LCG-101-[M/D/DP]

CONSTRUCTION FEATURES

• Heavy duty 304 Series stainless steel construction, with attractive No. 4 finish

• Cooking compartment is 316 Series stainless

• Heavy duty compartment door hinged right, with large double pane,

tempered glass window

• Oversize, heavy duty cam-lock door handle

• Powerful blower mounted on left side of compartment, with baffles and

safety screen

•Two shielded cooking compartment lights

• Stainless steel pan rack frame with ten stainless steel wire racks provided

• Removable stainless steel condensate collection tray mounted below door

• 4” stainless steel legs with adjustable bullet feet provided for table top

mounting

PERFORMANCE FEATURES

• Choice of: convection oven, convection steam or combi-cooking modes

[Base –M Controls]

• 86 to 482˚F operating temperature range [in OVEN & COMBI modes]

• 217˚F SteamPLUS™ STEAM mode temperature, for faster cooking

• 10-90% humidity control [Proofing Capability]

• Boilerless steam generation system for easier cleaning, less maintenance,

less downtime & lower utility costs

• Air-tight cooking compartment with slight 1/2 psi overpressure

• In-compartment meat probe [D & DP Controls]

• Spray gun and hose provided as standard for quick and easy

compartment cleaning

• Recessed, wash down resistant left side control panel [IPX-5 Water Tested]

• Choice of three control packages [See below]

CONTROL PACKAGE [Specify One]

❏ Manual Controls [-M]

• Simple dial-set time, temperature and % humidity controls

• OVEN, STEAM or COMBI modes

• Digital oven temperature display

• System status/warning lights

• Panel color coded for simplicity

❏ Digital Controls [-D]

• All touch-pad controls

• OVEN, STEAM, COMBI, RETHERM & [230-257˚F] SuperSteam™ modes

• Cook-to-[Meat] Probe standard

• Both set & actual time & temp readouts

• Humidity key for setting 10-90% steam

• Reheat settings, within safe range

• System self-test and “Cleaning Due” alert systems

❏ Digital Programmable Controls [-DP]

• ALL Digital Control Functions, plus:

• Up to 99 Cook Program memory, with up to 9 steps or stages

• Auto-Cook & Hold programming

• 2-speed fan motor control

SHORT/BID SPECIFICATION

Combi Oven shall be a LANG Manufacturing Model LCG-101-___

with [M=Manual, D=Digital, or DP=Digital Programmable] Control

Package, 70,000 BTU/hr. gas heated 10-pan half-size unit, with:

boilerless, in-cavity steam generation system; SteamPLUS 217˚F

standard steam; compartment humidity control; large double

pane glass viewing door, with easy-open heavy duty cam-lock

handle; 316 Series stainless steel compartment with powerful leftside mounted blower, two shielded compartment lights and pan

racks standard; plus a standard 2-year parts & labor warranty, all

the features listed and the options/accessories checked:

STANDARD PRODUCT WARRANTY

Two years, parts & labor

Model LCG-101-DP shown

Pan Type Max. Capacity Optimum

13” X 18” Half-Sheet 10 10

12” X 20” Hotel* 10 8

PAN CAPACITY GUIDE

* 2-1/2” deep pans

Sheet No. LSP-CO2 (rev. 7/03)

®

®

LANG MANUFACTURING COMPANY • 6500 Merrill Creek Parkway, Everett, WA 98203

TOLL FREE: 800.882.6368 • FAX: 425.349.2733 • www.langworld.com

© 2003 Lang Manufacturing Company Printed in U.S.A. 7/03-M-11789

Due to continuous improvements, specifications subject to change without notice.

Model

E Electrical Requirements

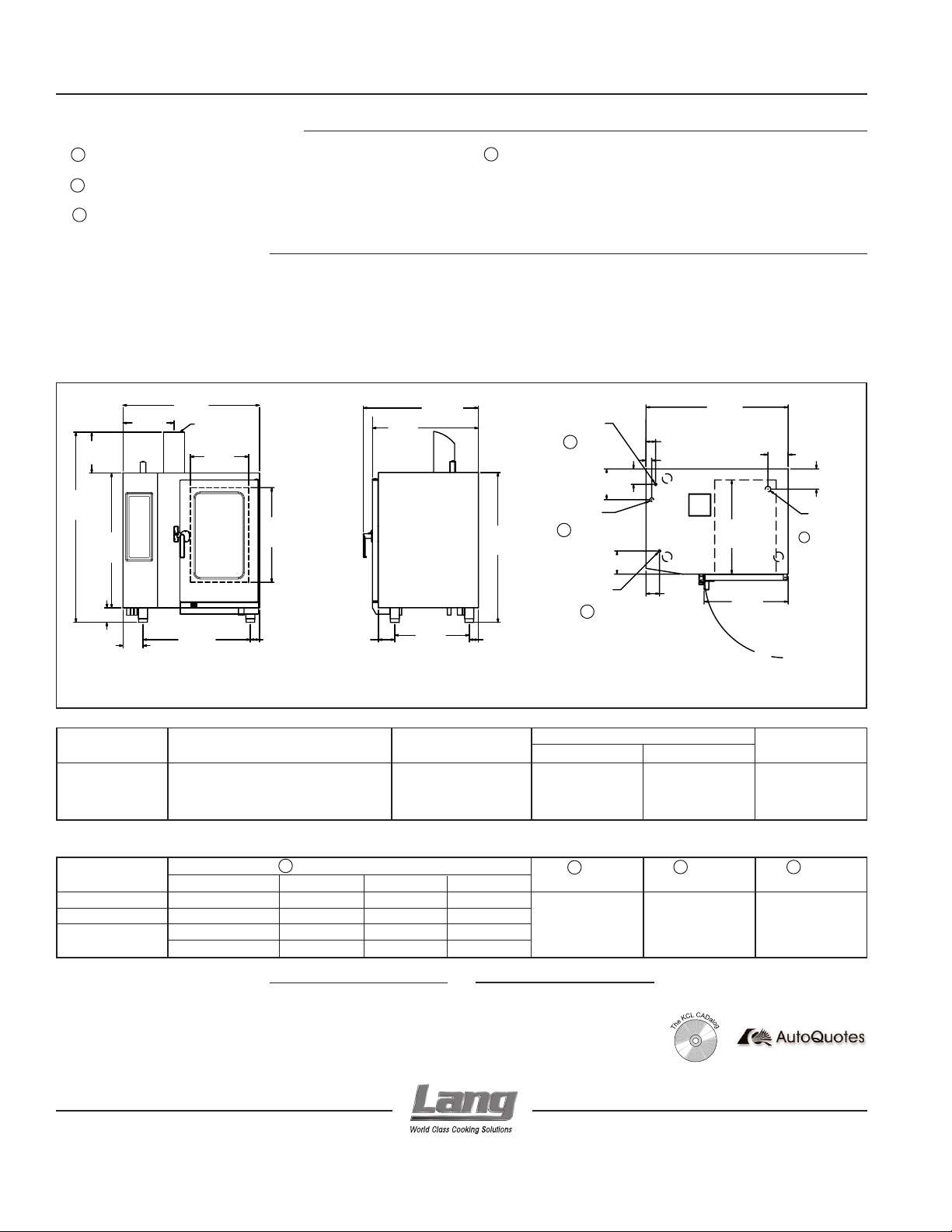

G Gas W Water D Drain

Voltage Total kW Phase Amps/Line

Requirements Requirements Requirements

LCG-101-M 120V/60Hz 0.5 1 4.3

LCG-101-D 120V/60Hz 0.5 1 4.3 3/4” NPT 3/4” NPT 1-1/2” NPT

LCG-101-DP

208V/60Hz 1.0 3 3.1

(70,000 BTU/hr) (.5 GPM @ 30 PSI)

240V/60Hz 1.0 3 3.1

Model Height x Width x Depth

Clearance from

Weight

Freight

combustible surface

Actual Shipping

Class

52.3” x 37.5” x 31.5”

Top*: 11-1/4” (290mm)

408 lbs. 430 lbs.

LCG-101

1327mm x 953mm x 800mm

Sides**: 2” (51mm)

185 kg 195 kg

70

Back: 4” (100mm)

OPTIONS & ACCESSORIES

❏ Stainless steel roll-in rack frame, 10-pan guides [std. spacing]

❏ Stainless steel roll-in rack frame, 7-pan guides [3.34” spacing]

❏ Roll-in plate rack for 12” plates

❏ Thermal cover for roll-in plate rack

❏ Rack frame transport trolley

❏ Roll-in rack guide

❏ Stainless steel support stand, w/bottom shelf

❏ Stainless steel cabinet style stand

❏ Extra wire pan racks [6 provided as std.]

❏ Two step safety release door latch

❏ HACCP time/temp data port [-DP only]

INSTALLATION REQUIREMENTS

•G Specify: ❏ natural gas or ❏ propane gas:

via 3/4” NPT connection

•E120V [

–M &-D Controls] 208/240V [-DP Controls], 3-Phase, 50/60 Hz

electrical connection

•W 3/4” NPT cold water connection

•D 1-1/2” NPT vended drain connection

• Installation under approved vent hood required. Flue gas vent stack provided

as standard

[All connections from unit bottom. See below for location and delivery

requirements]

Sheet No. LSP-CO2 (rev. 7/03)

[Front View/Elevation] [Right Side View] [Top View/Plan]

Gas, 10-Pan, Half Size Combi Oven Model: LCG-101-[M/D/DP]

MINIMUM WATER QUALITY

Water: cold water feed

Line Pressure: 30-80 PSI

pH: 7-7.5

Chlorides < 30 PPM

Sulfates < 40 PPM

* Top clearance for flue vent; ** 20” for service access.

CAD SYMBOLS & PRICING

37.5"

953mm

14.0"

11.3"

286mm

52.3"

1327mm

4.0"

102mm

37.0"

940mm

5.5"

140mm

356mm

GAS FLUE

16.0"

406mm

29.5"

749mm

26.0"

660mm

2.5"

64mm

4.5"

114mm

31.5"

800mm

29.0"

737mm

41.0"

1041mm

20.4"

518mm

2.5"

64mm

.8"

19mm

W WATER

CONNECTION

8.0"

203mm

1.0"

25mm

E ELECTRIC

CONNECTION

4.0"

102mm

2.5"/64mm

1.5"/38mm

6.0"/152mm

.8"

19mm

G GAS

CONNECTION

3.5"

89mm

37.5"

953mm

24.5"

622mm

21.9"

556mm

5.0"

127mm

5.0"/127mm

1.5"

38mm

D

DRAIN

CONNECTION

Loading...

Loading...