Lang Manufacturing GGB-48TI Service Manual

Installation

Operation

Maintenance

Model:

GGB-24, GGB-36, GGB-48,

Lang Manufacturing Company 6500 Merrill Creek Parkway Everett, WA 98203

PN 60801-04 Rev. F Ph: 425-349-2400 Fax: 425-349-2733 Copyright 1994, 1995

1

IMPORTANT IMPORTANT IMPORTANT

This manual has been prepared for personnel authorized, qualified, certified or licensed to install gas

quipment, who should perform the initial field startup and adjustments of the equipment covered by this

manual

Post in a prominent location, a set of instructions to be followed in the event the user smell gas. Obtain

these instructions from your local gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other gas

appliance.

In the event a gas odor is detected, shut down units at the

main shut-off valve and contact the local gas company or

supplier for service.

Installation, startup and adjustments of this appliance should be accomplished by personnel qualified to

install gas equipment.

Retain this manual for future reference.

Lang Manufacturing Company

9040 Willows Rd.

P. O. Box 905

Redmond, WA 98052-0905

Phone: 1-800-224-LANG (5264)

Fax: 206-861-1978

Copyright 1994, 1995

Lang Manufacturing Company 6500 Merrill Creek Parkway Everett, WA 98203

PN 60801-04 Rev. F Ph: 425-349-2400 Fax: 425-349-2733 Copyright 1994, 1995

TABLE OF CONTENTS

INSTALLATION................................................................................................................................................. 1

RECEIVING THE GRIDDLE..............................................................................................................................1

DATA PLATE .......................................................................................................................................................1

VENTILATION AND CLEARANCES..............................................................................................................1

GAS CONNECTION............................................................................................................................................ 2

SPECIFICATIONS................................................................................................................................................ 3

MISCELLANEOUS INSTALLATION REQUIREMENTS ............................................................................. 4

LEGS..................................................................................................................................................................4

STAND, LEG AND CASTER.........................................................................................................................4

DROP DOWN DOOR...................................................................................................................................... 4

BURNER NUTS................................................................................................................................................4

OPERATION....................................................................................................................................................... 5

INITIAL STARTUP PROCEDURE....................................................................................................................5

CLEANING THE SHIPPING PRESERVATIVE .......................................................................................... 5

SEASONING THE GRIDDLE PLATE .......................................................................................................... 5

GRIDDLE OPERATION...................................................................................................................................... 5

TEMPERATURE SETTINGS .........................................................................................................................5

LOADING THE GRIDDLE.............................................................................................................................5

BROILER OPERATION...................................................................................................................................... 6

MAINTENANCE................................................................................................................................................. 7

CLEANING ...........................................................................................................................................................7

DAILY CLEANING-GRIDDLE .....................................................................................................................7

WEEKLY CLEANING-GRIDDLE.................................................................................................................7

WEEKLY CLEANING-BROILER .................................................................................................................7

CALIBRATION ....................................................................................................................................................7

SERVICE.............................................................................................................................................................. 9

BURNER AIR SHUTTER ADJUSTMENT.......................................................................................................9

GRIDDLE.......................................................................................................................................................... 9

BROILER........................................................................................................................................................... 9

ACCESS TO BROILER CONTROL COMPONENTS ...................................................................................10

TRANSFORMER AND AIR SWITCH ........................................................................................................10

SPARK CONTROL MODULE .....................................................................................................................10

SAFETY THERMOSTAT..............................................................................................................................11

COMBUSTION BLOWER............................................................................................................................11

ACCESS TO GRIDDLE CONTROL COMPONENTS...................................................................................11

TROUBLE SHOOTING...................................................................................................................................13

GRIDDLE ............................................................................................................................................................12

BROILER.............................................................................................................................................................13

PARTS LIST......................................................................................................................................................14

WIRING DIAGRAM ........................................................................................................................................15

WARRANTY......................................................................................................................................................16

INSTALLATION

RECEIVING THE GRIDDLE

Upon receipt, check for freight damage, both visible and concealed. Visible damage should be noted on the

freight bill at the time of delivery and signed by the driver. Concealed loss or damage means loss or

damage which does not become apparent until the merchandise has been unpacked. If concealed loss or

damage is discovered, make a written request for inspection by the carrier's agent within 15 days of

delivery. All packing material should be kept for inspection. Do not return damaged merchandise to

Lang Manufacturing Company. File your claim with the carrier.

Uncrate the appliance as near its intended location as practical. The crating will help protect the unit from

the physical damage normally associated with moving it through hallways and doorways.

DATA PLATE

A data plate is located on the left end of the griddle, just behind and over the top of the control panel.

The appliance’s voltage, wattage, gas type, gas pressure and clearances are located on this plate.

This information should be carefully read and understood before proceeding with the installation.

VENTILATION AND CLEARANCES

This appliance must be installed under a ventilation hood. The installation of any components such as vent

hoods, grease extractors, or fire extinguisher systems, must conform to their applicable nationally

recognized installation standards.

Minimum clearances from combustible materials shall be:

6 inches from side walls

14 inches from back wall

Minimum clearance from any surface shall be:

4 inches from bottom

Keep the appliance area free and clear of combustible material and do not obstruct the flow of combustion

or ventilation air.

1

GAS CONNECTION

DANGER

FIRE AND EXPLOSION HAZARD

AS WITH ANY GAS APPLIANCE ON CASTERS, ANY LANG GAS GRIDDLE, GAS

CLAMSHELL®, OR GAS CONVECTION OVEN ON CASTERS MUST BE INSTALLED WITH:

A CONNECTOR THAT COMPLIES WITH THE STANDARD FOR CONNECTORS FOR

MOVABLE GAS APPLIANCES, ANSI Z21.69A LATEST EDITION

AND

A QUICK DISCONNECT THAT COMPLIES WITH THE STANDARD FOR QUICK DISCONNECT

DEVICES FOR USE WITH GAS FUEL, ANSI Z21.41 LATEST EDITION.

AND

A TETHER OR OTHER MEANS TO LIMIT APPLIANCE MOVEMENT WITHOUT RELIANCE ON

THE GAS SUPPLY PIPING. INSTALL THE EYEBOLT INTO THE HOLE PROVIDED IN THE

REAR OF THE APPLIANCE, AND SECURELY ATTACH THE TETHER TO THE EYEBOLT.

FAILURE TO INSTALL THESE PARTS CAN LEAD TO LEAKAGE OF GAS AND RESULTING

FIRE, EXPLOSION, PERSONAL INJURY AND DEATH.

All gas connectors must be in accordance with local codes and comply with the National Federal Gas code

ANSI Z223.1 latest edition.

This griddle is manufactured for use with the type of gas indicated on the nameplate. Contact the factory if

your type of gas does not match the nameplate data.

This appliance should be installed with a separate gas valve in the gas line ahead of the unit. Use a 3/4 inch

or larger gas supply line.

A pressure regulator and gas valve are supplied with each appliance.

This regulator and valve must be installed in the gas supply line. (Note the direction of the gas flow arrow.)

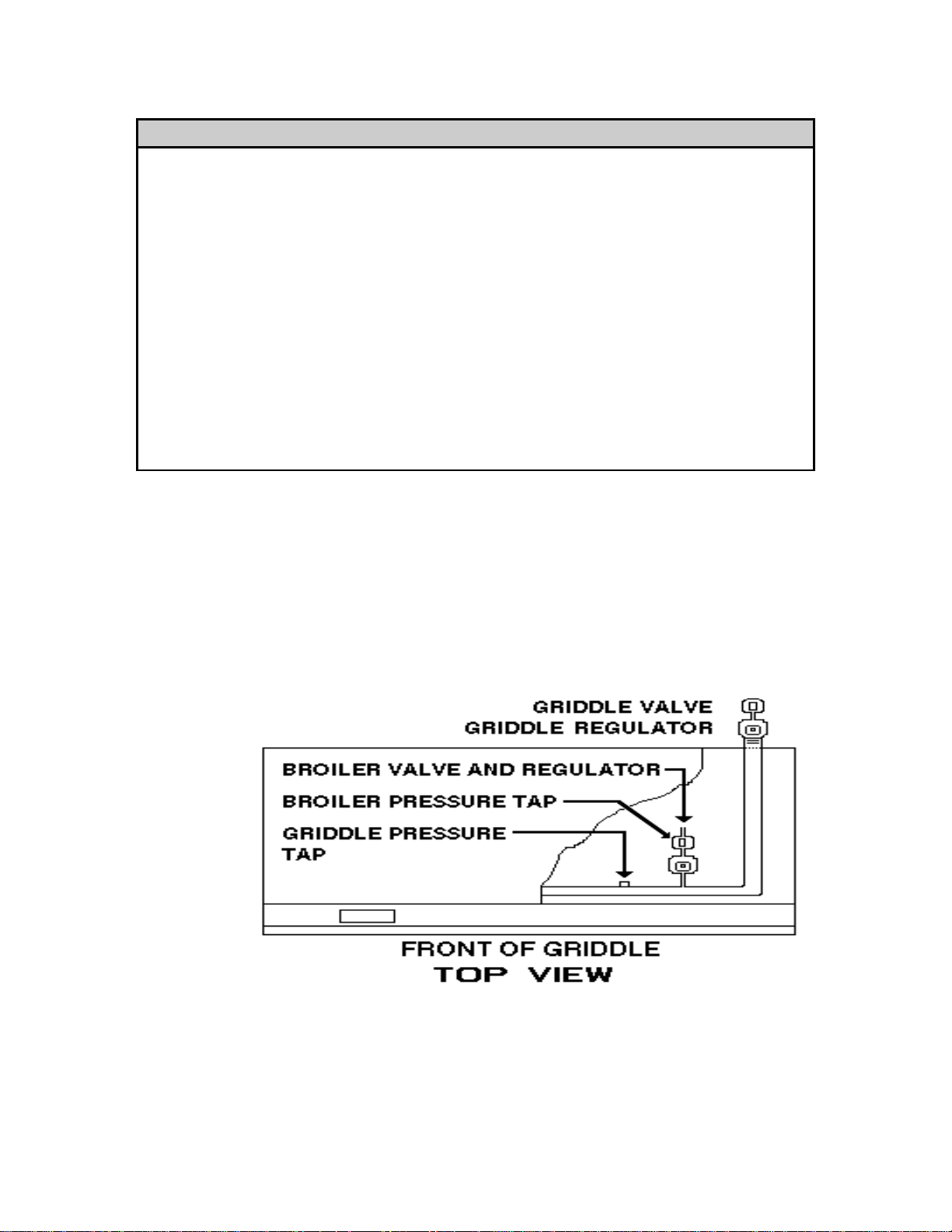

The pressure in the manifold of the appliance should be tested with a manometer and the regulator adjusted

for proper pressure with the appliance operating at full fire. A 1/8 inch NPT tap is provided in the manifold

for connecting a manometer.

Figure 1

2

Number

Surface

Of Griddle

Controls

Number of

Burners

Of Grease

Drawers

(Required)

Number

Total BTU

Output

Connection(s)

Maximum

Pressure

Cord/Plug &

Regulator

GGB48-TI

143,000

One 3/4" NPT

5101/2 LB

115

3.5

Supplied

Correct manifold pressures are:

Griddle:

5 inches water column for natural gas.

10 inches water column for propane.

Broiler:

3 1/2 inches water column for natural gas.

6 inches water column for propane.

When replacing the plug in the manifold, a use a pipe joint compound or sealant that is resistant to the

action of liquid petroleum gas.

Initial adjustments are the responsibility of the installer and are not chargeable to Lang Manufacturing

Company.

WARNING

BEFORE LIGHTING, USE A SOAP AND WATER SOLUTION TO TEST ALL JOINTS FOR GAS

LEAKS

After the griddle is in its final position, adjust the legs so the griddle body is level back to front. This will

allow the grease to run into the grease gutter and provide the proper combustion air for the burners.

This appliance and its individual shutoff valve must be disconnected from the gas supply piping system

during any testing of that system at test pressures in excess of 1/2 PSIG (3.45 kPA) and the appliance must

be isolated from the gas supply piping system by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 PSIG (3.45 kPA).

WARNING

ELECTRICAL GROUNDING INSTRUCTIONS

THIS APPLIANCE IS EQUIPPED WITH A 3-PRONG (GROUNDING) PLUG FOR YOUR

PROTECTION AGAINST SHOCK HAZARD AND MUST BE PLUGGED DIRECTLY INTO A

PROPERLY GROUNDED 3-PRONG RECEPTACLE.

DO NOT CUT OR REMOVE THIS GROUNDING PRONG FROM THE PLUG.

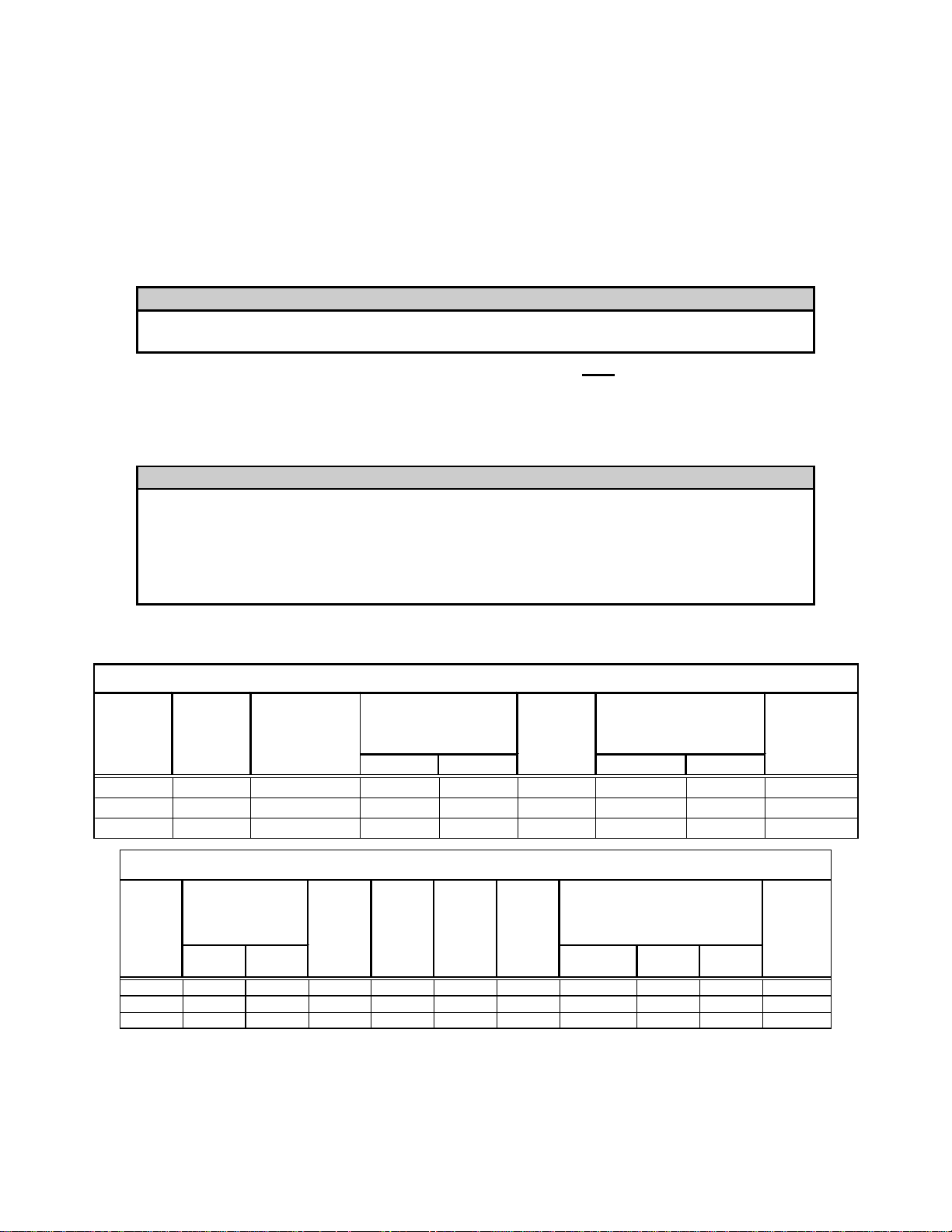

SPECIFICATIONS

Gas And Electrical Requirements

Model

Gas

Gas Pressures In

Inches Of Water

Natural Propane Voltage Amps

GGB24-TI 89,000 One 3/4" NPT 5 10 1/2 LB 115 3.5 Supplied

GGB36-TI 116,000 One 3/4" NPT 5 10 1/2 LB 115 3.5 Supplied

Delivery

Electrical Connection

Pressure

Construction Specifications

Square

Overall Griddle

Model

GGB24-TI 24 Inches 23 Inches 552 2 2 1 5 Inches 14 Inches 4 Inches 250

GGB36-TI 36 Inches 24 Inches 828 3 3 1 5 Inches 14 Inches 4 Inches 460

GGB48-TI 48 Inches 25 Inches 1104 3 4 1 5 Inches 14 Inches 4 Inches 600

Surface

Width Depth Sides Back

Inches Of

Griddle

Number

Number

Griddle

Clearance From Combustible

Surfaces

Bottom

Shipping

Weight

3

Loading...

Loading...