Page 1

GAS FULL SIZE

COMPUTERIZED

CONVECTION OVEN

Enviro-STAR (GCSF-ES)

SerSer

Ser

SerSer

vice Manvice Man

vice Man

vice Manvice Man

2M-W1345 Rev. - 08/01/08

ualual

ual

ualual

Page 2

Service Manual for Enviro-Star GCSF-ES

These symbols are intended to alert the user to the presence of important

operating and maintenance instructions in this manual.

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION

THE INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE SMELL OF GAS IS DETECTED.

THIS INFORMATION CAN BE OBTAINED FROM THE LOCAL GAS SUPPLIER.

WARNING!

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO OPERATE THIS DEVICE.

WARNING!

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN UNIT AT THE

MAIN SHUTOFF VALVE AND CONTACT THE LOCAL GAS COMPANY

OR GAS SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

OR LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING!

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE, OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY, OR DEATH.

READ THE INSTALLATION, OPERATING, AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE OPERATING THIS EQUIPMENT.

WARNING

TO REDUCE THE RISK OF ELECTRICAL SHOCK, DO NOT REMOVE THE CONTROL

PANEL. THERE ARE NO USER-SERVICABLE PARTS INSIDE. REPAIRS SHOULD BE

MADE BY AUTHORIZED SERVICE PERSONNEL ONLY.

NOTICE

Using any part other than genuine Lang factory supplied parts relieves the manufacturer of all liability. Lang reserves

the right to change specifications and product design without notice. Such revisions do not entitle the buyer to

corresponding changes, improvements, additions, or replacements for previously purchased equipment.

Due to periodic changes in designs, methods, procedures, policies, and regulations, the specifications

contained in this document are subject to change without notice. While Lang Manufacturing exercises good

faith efforts to provide information that is accurate, we are not responsible for errors or omissions in information

provided or conclusions reached as a result of using the specifications. By using the information provided, the

user assumes all risks in connection with such use.

SM-2

Lang A Division of S tar Mfg. Int'l Inc.

Page 3

Service Manual for Enviro-Star GCSF-ES

TABLE OF CONTENTS

SAFETY PRECAUTIONS ...............................................................................................................2

INTRODUCTION..............................................................................................................................5

GENERAL ...............................................................................................................................5

INSTALLATION........................................................................................................................5

OPERATION ...........................................................................................................................5

CLEANING ..............................................................................................................................5

TOOLS ....................................................................................................................................5

SPECIFICATIONS ...................................................................................................................5

UTILITY REQUIREMENTS.......................................................................................................5

WATER QUALITY REQUIREMENTS ......................................................................................5

DESCRIPTION ................................................................................................................................6

CONVECTION OVEN BASICS .......................................................................................................6

COMPONENT OPERATION ...........................................................................................................6

Electrical Power Circuit...................................................................................................6

Thermostat Operation ..................................................................................................... 6

Gas Flow and Ignition .....................................................................................................7

Ignition System...............................................................................................................7

Specifications...........................................................................................................7

Fan Operation .................................................................................................................9

Door Switch Operation ..................................................................................................10

Oven Lights...................................................................................................................11

Water (Steam) Applications..........................................................................................11

Burnt Gas Exhaust .......................................................................................................11

Draft Inducer Operation ..........................................................................................12

CONTROLS ..................................................................................................................................13

Using Backup Controls .................................................................................................14

Initial Power ON Test ....................................................................................................14

Water/Steam Test ........................................................................................................15

Operating Sequence .....................................................................................................15

MAINTENANCE ............................................................................................................................17

Oven Cleaning .......................................................................................................................17

Stainless Steel Care .............................................................................................................18

Cleaning ................................................................................................................................18

Preserving & Restoration .......................................................................................................18

Heat Tint ...............................................................................................................................18

Lockout/Tagout Procedures...................................................................................................18

Electrical Lockout/Tagout......................................................................................................18

Gas Lockout/Tagout ..............................................................................................................19

Gas Leak Test.......................................................................................................................19

Electronics Access ...............................................................................................................19

Main Power Fuse Replacement.............................................................................................20

Circuit Board Replacement....................................................................................................21

Lang A Division of S tar Mfg. Int'l Inc.

SM-3

Page 4

Service Manual for Enviro-Star GCSF-ES

TABLE OF CONTENTS (continued)

Power Transformer Replacement...........................................................................................22

Beeper Removal ....................................................................................................................23

Relays ...................................................................................................................................23

Relay Operation............................................................................................................24

Relay Replacement.......................................................................................................24

Ignition Controller Replacement.............................................................................................25

Right Side Panel Removal .....................................................................................................25

Temperature Sensor Replacement ........................................................................................26

Fan Motor Starter Capacitor Replacement.............................................................................26

Internal Access .....................................................................................................................27

Fan Blade Removal .............................................................................................................. .27

Fan Motor Replacement ........................................................................................................28

Motor Small Fan Blade Installation........................................................................................29

Burner Area Access ..............................................................................................................29

Igniter Replacement...............................................................................................................30

Flame Sensor Replacement ..................................................................................................30

Burner Replacement..............................................................................................................30

Heat Exchanger Replacement...............................................................................................31

Steamer Assembly Replacement ..........................................................................................32

Over-Temperature Switch Replacement.................................................................................33

Main Gas Solenoid Replacement ..........................................................................................33

Manual Gas Valve Replacement............................................................................................34

Water Solenoid Replacement................................................................................................35

Thermostat Replacement (Backup Controls) .........................................................................36

Steam Switch Replacement (Backup Controls).....................................................................37

Manual/Backup Switch Replacement (Backup Controls).......................................................38

Oven Light Bulb Replacement ...............................................................................................38

Light Fixture Replacement ....................................................................................................39

Top Hinge Cover Removal ......................................................................................................39

Bottom Hinge Cover Removal ................................................................................................40

Left Oven Door Removal ........................................................................................................40

Door Switch Removal ............................................................................................................41

Right Oven Door Removal ......................................................................................................41

TROUBLESHOOTING .........................................................................................................43

OVEN PROBLEMS...............................................................................................................43

IGNITION CONTROL MODULE PROBLEMS .......................................................................49

Flame Sensor Current Test ..........................................................................................4 9

ILLUSTRATED PARTS LISTING .................................................................................................51

ENVIROSTAR EXPLODED VIEW DRAWINGS ....................................................................51

ENVIROSTAR PARTS REFERENCE ...................................................................................56

ENVIROSTAR WIRING DIAGRAMS.....................................................................................62

CALIFORNIA REGULATIONS .......................................................................................................63

SM-4

Lang A Division of S tar Mfg. Int'l Inc.

Page 5

INTRODUCTION

Service Manual for Enviro-Star GCSF-ES

GENERAL

Lang Gas Convection Ovens are manufactured for

use with the type of gas indicated on the data plate

(natural gas or propane). Variations exist between

models. This manual details typical servicing

procedures that would apply to most, but not all, of

the listed models.

INSTALLATION

Refer to the Installation and Operation Manual.

OPERATION

Refer to the Installation and Operation Manual.

CLEANING

Refer to the Installation and Operation Manual.

TOOLS

• Standard set of hand tools

• Gas leak detection equipment

• Gas pressure manometer

WATER QUALITY REQUIREMENTS

-IMPORTANT-

LOCAL WATER CONDITIONS MAY DAMAGE

LANG EQUIPMENT. FAILURE TO PROPERLY

TREAT WATER MAY RESULT IN DAMAGE AND

MAY VOID SOME OR ALL OF THE WARRANTY.

WATER SPECIFICATIONS: After treatment, the water

must continuously be within the following parameters:

Cold Water

Minimum GPH 3

PSI 20 to 80

PH 6.8 to 7.6

Hardness 2 to 4 grains/gallon

Total Dissolved Solids <100 PPM

Conductivity <1/500,000 Ohms/in.

Maximum Salinity Ion Content

Chloramines <0.5 PPM

Chlorine <0.5 PPM

Chlorides <30 PPM

Water line pressure and quality MUST meet the

Lang Manufacturing Specifications listed below.

Contact your local water equipment system provider

to assist you in determining your specific water

quality, or contact Lang Technical Support for

assistance, 1-800-807-9054.

Copper <0.05 PPM

Iron <0.1 PPM

Manganese <0.05 PPM

Sulfates <40 PPM

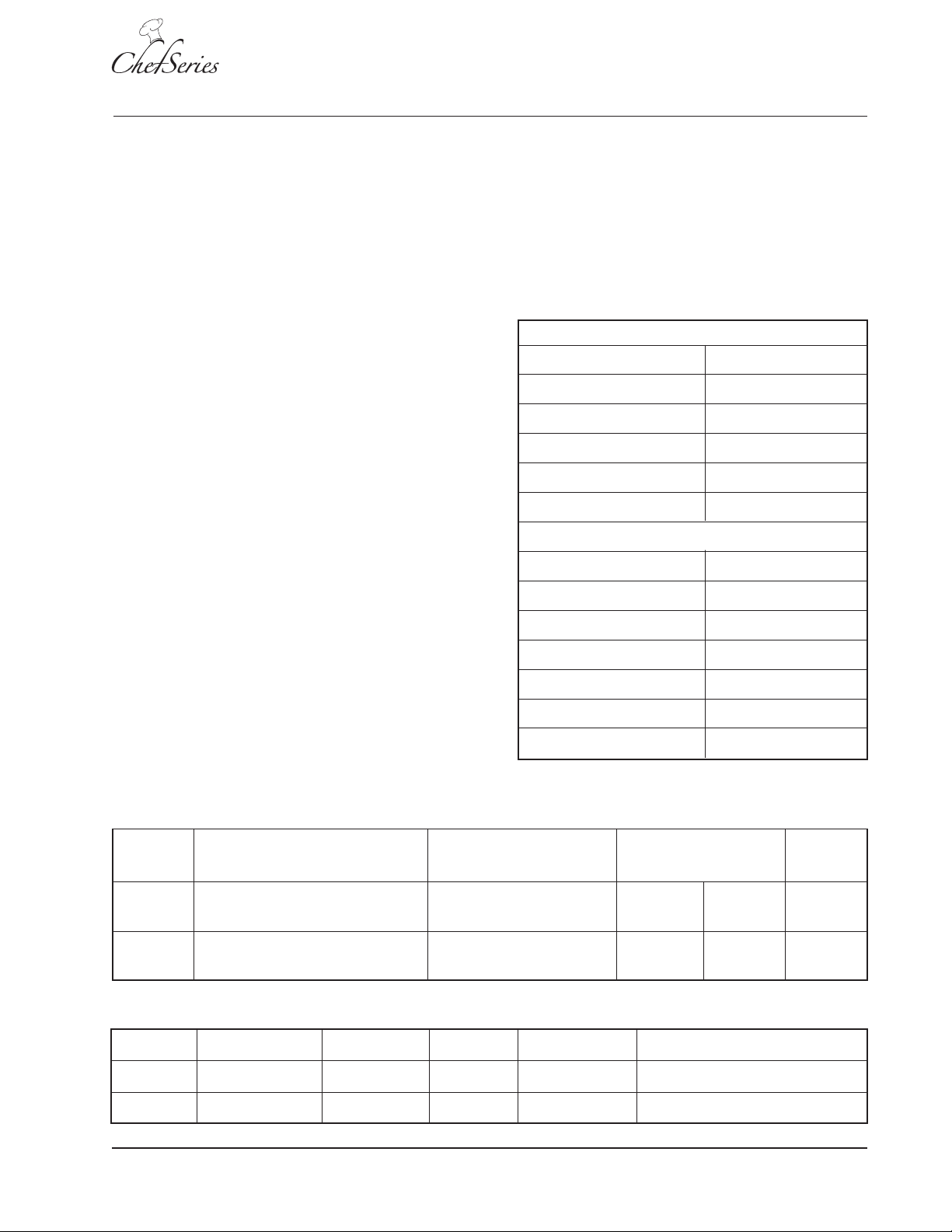

SPECIFICATIONS

Model Height × Width x Depth Clearance From Weight Freight

Combustible Surfaces Installed Shipping Class

GCSF-1 36″ × 40″ × 40″ Side:0″, Back:1″, Floor:4″ 555 lbs. 620 lbs. 70

(91.4cm × 101.6cm × 101.6cm) (252 kg) (281 kg)

GCSF-2 74″ × 40.4″ × 40″ Side:0″, Back:1″, Floor:4″ 1110 lbs. 1240 lbs. 70

(188cm × 102.6cm × 101.6cm) (503 kg) (562 kg)

UTILITY REQUIREMENTS

Model Voltage Total kW Phase Amps/Line Total Gas Req.

GCSF-1 120V/60Hz 0.7 1 5.8 1/2" NPT, 60,000 BTU/hr

GCSF-2 120V/60Hz 1.4 1 11.6 1/2" NPT , 120,000 BTU/hr

Lang A Division of S tar Mfg. Int'l Inc.

SM-5

Page 6

Service Manual for Enviro-Star GCSF-ES

DESCRIPTION

CONVECTION OVEN BASICS

A convection oven is an electro-mechanical, sealedtype of oven in which the combustion products are

separated from the air inside the oven. Heated air is

circulated by a fan into the oven and over the food

product, removing a thin layer of moisture from the

food and allowing heat to penetrate.

This method requires shorter cooking times at

lower temperatures and produces consistent results,

which may vary due to differences in preparation

rather than in oven operation.

Steam in the cooking process prevents the removal

of all the moisture during baking and produces a

better product. And when applied to bread dough

during the first five minutes, it allows yeast to work

longer producing better spring and volume and a

moist, flexible outer surface. Once the outside

layer of dough sets, gases in the loaf no longer

expand to increase loaf size.

Steaming bread dough as it bakes gelatinizes

starch on the outer layer and prevents the crust

from cracking. However, too much steam results in

an undesirable crust. During the last stages of

baking, a dry oven is needed to produce a crisp,

brown crust.

COMPONENT OPERATION

Electrical Power Circuit

The operating voltage (120 VAC) is routed from the

power source to a terminal block.

NOTICE: See the wiring diagrams in the

Troubleshooting section.

The AC line is connected through a 15 Amp fuse

(F7) to a contact on the motor relay (MR2), interior

light relay (LR1), and the primary winding of a stepdown transformer (T1).

The transformer provides 24 VAC through the circuit

board to control the oven electrical components.

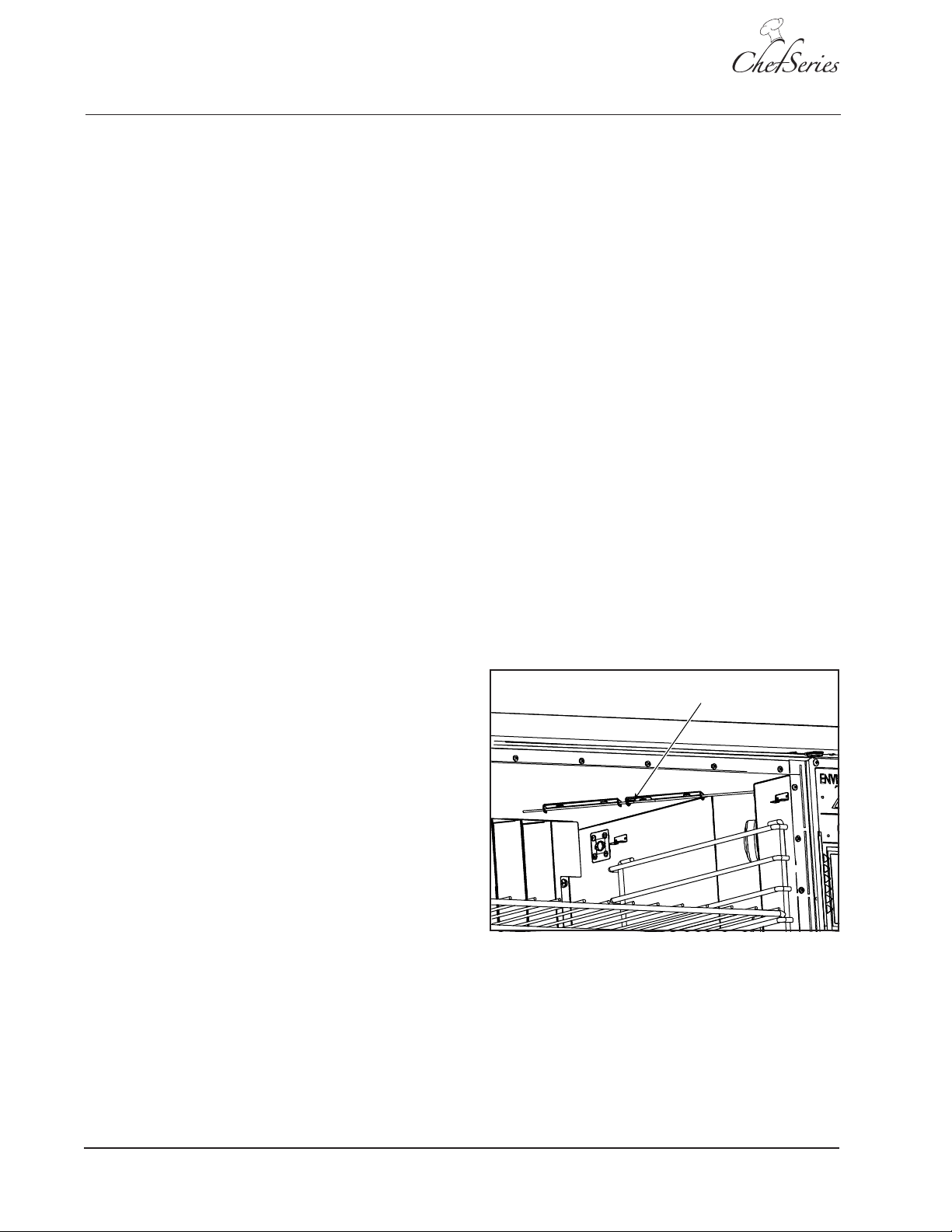

Thermostat Operation

The thermostat maintains oven temperature at the

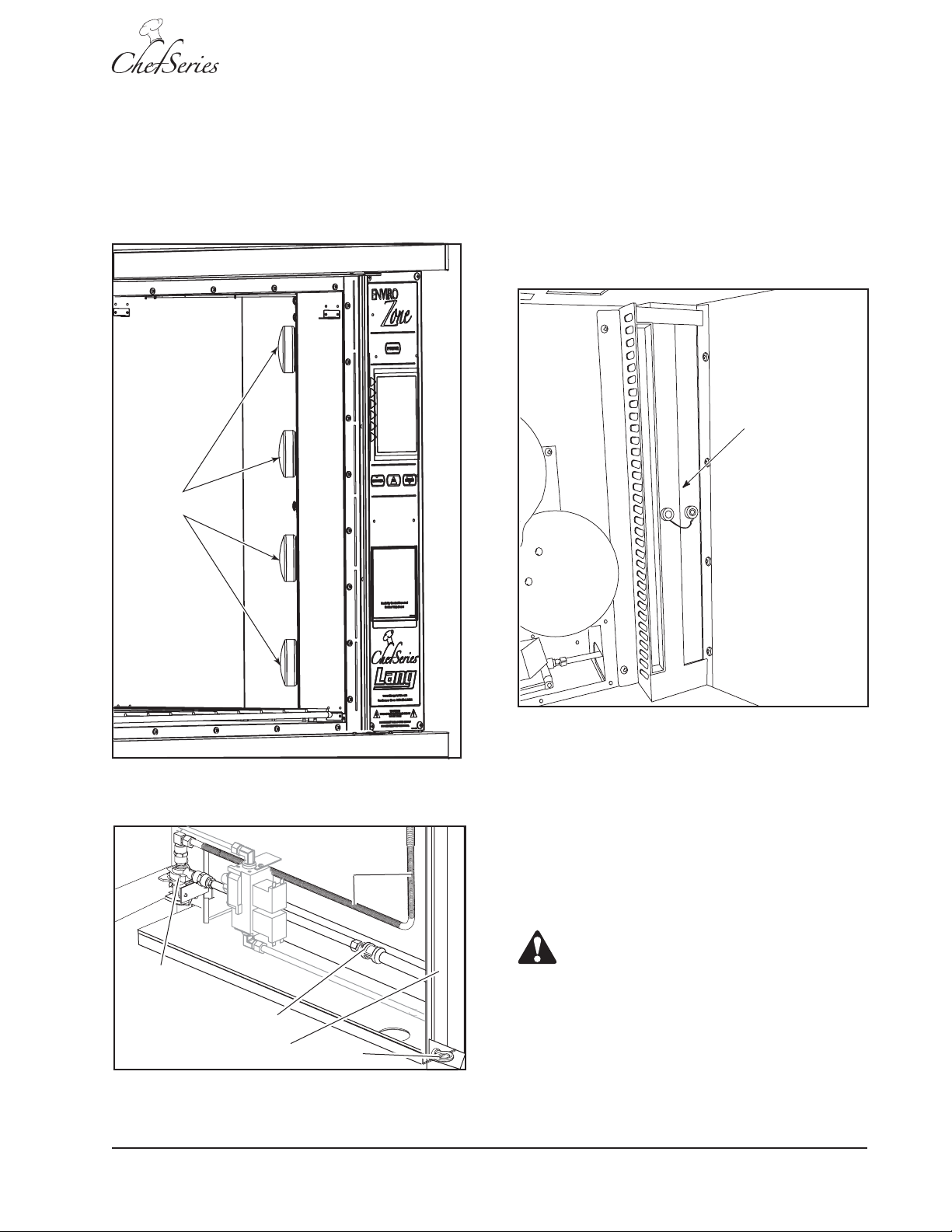

desired setting. A sensor (Figure 1) mounted inside

the oven monitors oven temperature. The unit is

equipped with both:

• a mechanical thermostat

• a programmable temperature controller.

Times and temperatures may vary due to factors

such as food quality and quantity, type of pan and

thermostat calibration. Differences in altitude will

also affect cooking times and temperatures.

Time & Temperature Conversion: To convert

standard oven recipes for use in a convection oven,

reduce cooking temperature by 25° F – 75° F and

the time by 25% – 35%.

Fan Speeds: The convection fan can be set for HI

or LOW speed. Most baking is done on HI, but

delicate products (i.e., Meringue pie) require a

LOW fan setting.

Oven Sensor

Figure 1: Oven Sensor

When the operator selects a temperature setting or

the product to bake, the oven is heated until the

temperature reaches the selected setting. The

controls circuit monitors the temperature sensor

and activates the ignition control module to ignite

the burner when heat is required.

SM-6

Lang A Division of S tar Mfg. Int'l Inc.

Page 7

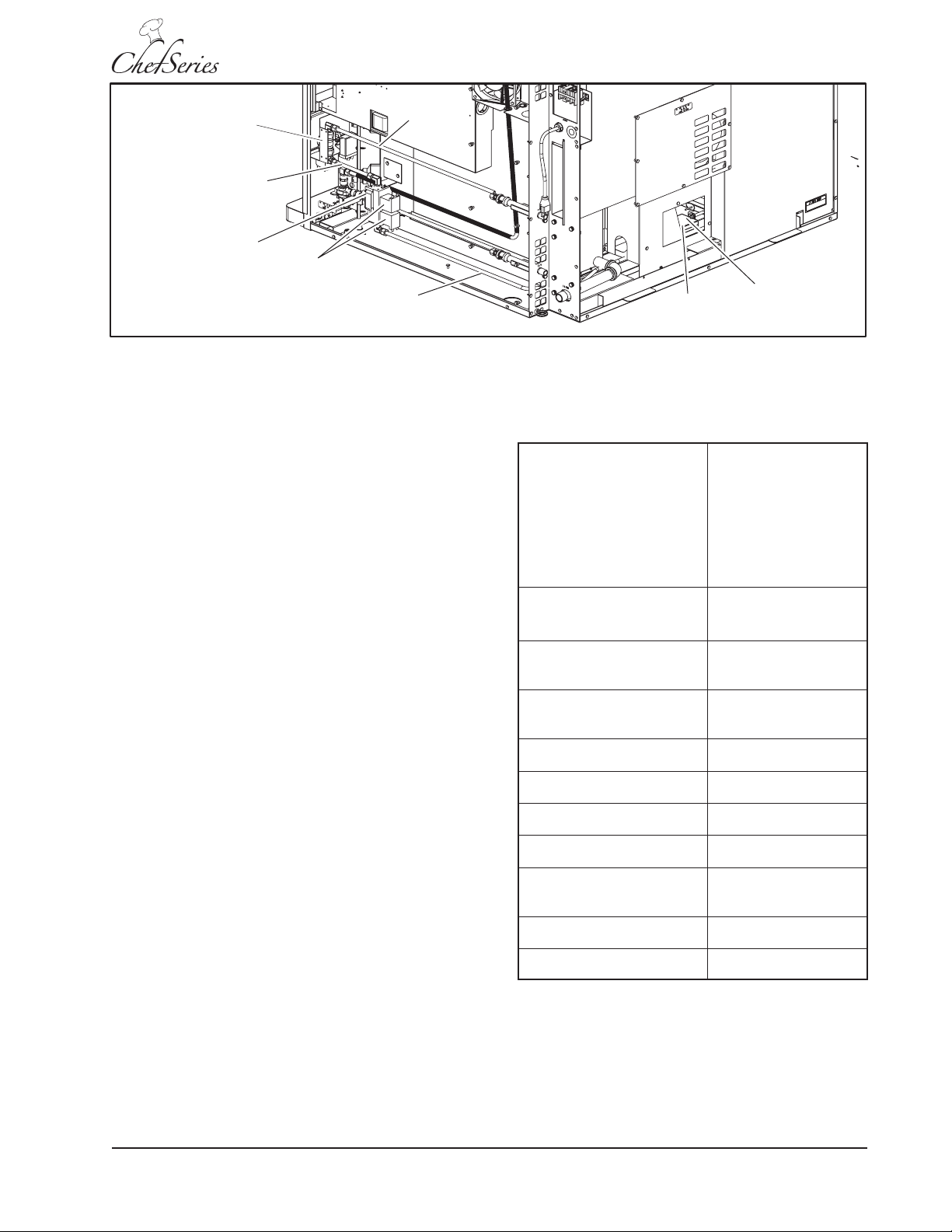

Figure 2: Gas Flow Diagram

Igniter &

Flame

Sensor

Burner

Gas Inlet

Line

Manual Gas

Valve

Burner Gas

Line

Solenoid

Valves

Main Gas

Valve

Intermediate

Gas Line

Service Manual for Enviro-Star GCSF-ES

Gas Flow and Ignition

Natural gas is supplied through the manual gas

valve (Figure 2) to the main gas solenoid. When the

temperature is selected the ignition control module

activates the igniter and opens the gas solenoid.

Gas flows to the burner and the igniter lights the

flame. The ignition control module monitors the

flame sensor to determine if the burner is on. If the

burner does not ignite, the solenoid valve closes

shutting off gas flow to the oven.

Ignition System

The igniter module controls ignition of the burner

gas. The module monitors burner ignition, heat and

shut down.

SPECIFICATIONS:

Fenwal 35-66 Series Igniter Module

INPUT POWER

Voltage

Current

OUTPUT POWER

Gas Valve 2.0A max @ 24 V AC

OPERATING TEMPERA TURE -40°F to +175°F

FLAME SENSITIVITY 0.7 micro amps

IGNITER 24 VAC

Trail for Ignition 7 Seconds

Inter-Purge 15 Seconds

Control: 18 to 30

VAC 50/60 HzLine:

24 VAC

300 MA @ 24 V A C

with fan and gas

valve relay energized

(-40°C to +80°C)

(minimum)

Lang A Division of S tar Mfg. Int'l Inc.

Pre-Purge 15 Seconds

Tries for Ignition 3 Tries with 1 Hour

Automatic Reset

Post Purge None

Options None

NOTE: Follow the wiring diagram and gas flow chart

to better understand the ignition description.

SM-7

Page 8

Service Manual for Enviro-Star GCSF-ES

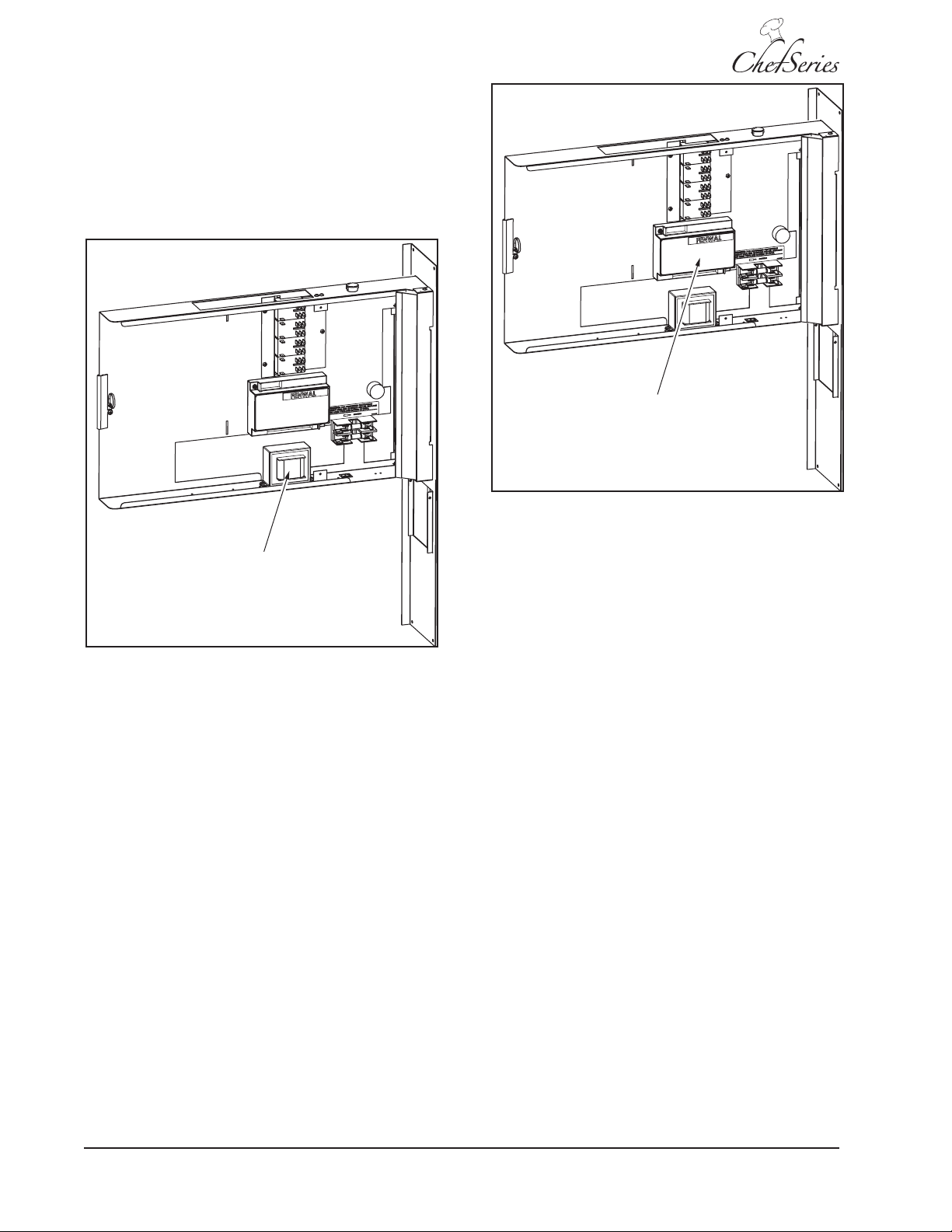

The oven ignition and control system operates on

120 and 24 VAC. When the power switch is placed

in the ON position, 120 VAC is routed through fuse

F7 (15A). The voltage from the fuse is routed to one

side (incoming) of a 24 VAC transformer (Figure 3).

The other side of the transformer (incoming) is

connected to a neutral input.

Ignition

Controller

Transformer

Figure 3: Transformer

The transformer converts the 120 VAC to 24 VAC

and routes the 24 VAC through the outgoing side

through a back-up switch, a back-up thermostat

switch and an over-temperature switch to the ignition

controller pin W.

The ignition control module (Figure 4) operates

on 24 VAC at pin W provided by the transformer.

The module controls the main gas solenoid and

the igniter.

Figure 4: Ignition Control Module

When the power switch is placed in the ON position

and a temperature is selected using the temperature

knob a call for heat is generated in the controller.

• The controller performs a self check routine.

• The diagnostic LED flashes for one second.

• A safety timing sequence begins.

• The controller performs a 15-second pre-purge of

the system.

• The controller must detect that the air switch is

working properly, before it energizes the igniter

and the surface of the igniter tip heats up.

• The main gas valve solenoids open allowing gas

to flow to the burner.

• The gas in the burner is ignited by the igniter tip.

A TFI (trail for ignition) period checks the flame sensor

for evidence of a flame at the burner. If flame does

not ignite within 7-seconds the control module closes

the main gas valve solenoids and gas stops flowing to

the burner.

SM-8

When a flame is detected, voltage to the igniter

stops and the igniter cools. The thermostat, pressure

switch and burner flame are monitored for proper

operation. When the selected temperature is reached

voltage stops flowing to the main gas valve solenoids

(Figure 5) and gas stops flowing to the burner.

Lang A Division of S tar Mfg. Int'l Inc.

Page 9

Service Manual for Enviro-Star GCSF-ES

Figure 5: Igniter Controller Diagram

If flame is not detected during the TFI, the main gas

valve solenoids close and a 15-second inter-purge

delay starts. The control will attempt two additional

TFI periods before locking out. In lockout the main

gas valve solenoids will be locked out immediately.

The controller will reset after one hour if the

thermostat is still calling for heat. A new TFI

sequence will begin.

NOTE: If locking out occurs, a manual reset must

be performed by resetting the thermostat or

removing 24 VAC (turn off the power switch) for a

period of 5-seconds.

The following table lists the igniter terminals and

functions.

NOTE: See the Troubleshooting section for

instructions on performing a flame sensor current

check.

./4%

3EE THE

TROUBLESHOOTING

SECTION FOR

INSTRUCTIONS ON

PERFORMING A

FLAME SENSOR

CURRENT CHECK

Igniter Module Terminal Uses (Figure 5)

S1 Igniter Output – 24 V AC

L1 24 VAC Input

L2 Not Used

S2 Flame Sensor Input

PS Air Proving Switch

W Thermostat Input

MV1 Main Gas Valve Solenoids Output

GND Ground Input

F1 120 VAC Input

F2 120 VAC Fan Drive Output

FC Not Used

R 24V Hot to Transformer

Lang A Division of S tar Mfg. Int'l Inc.

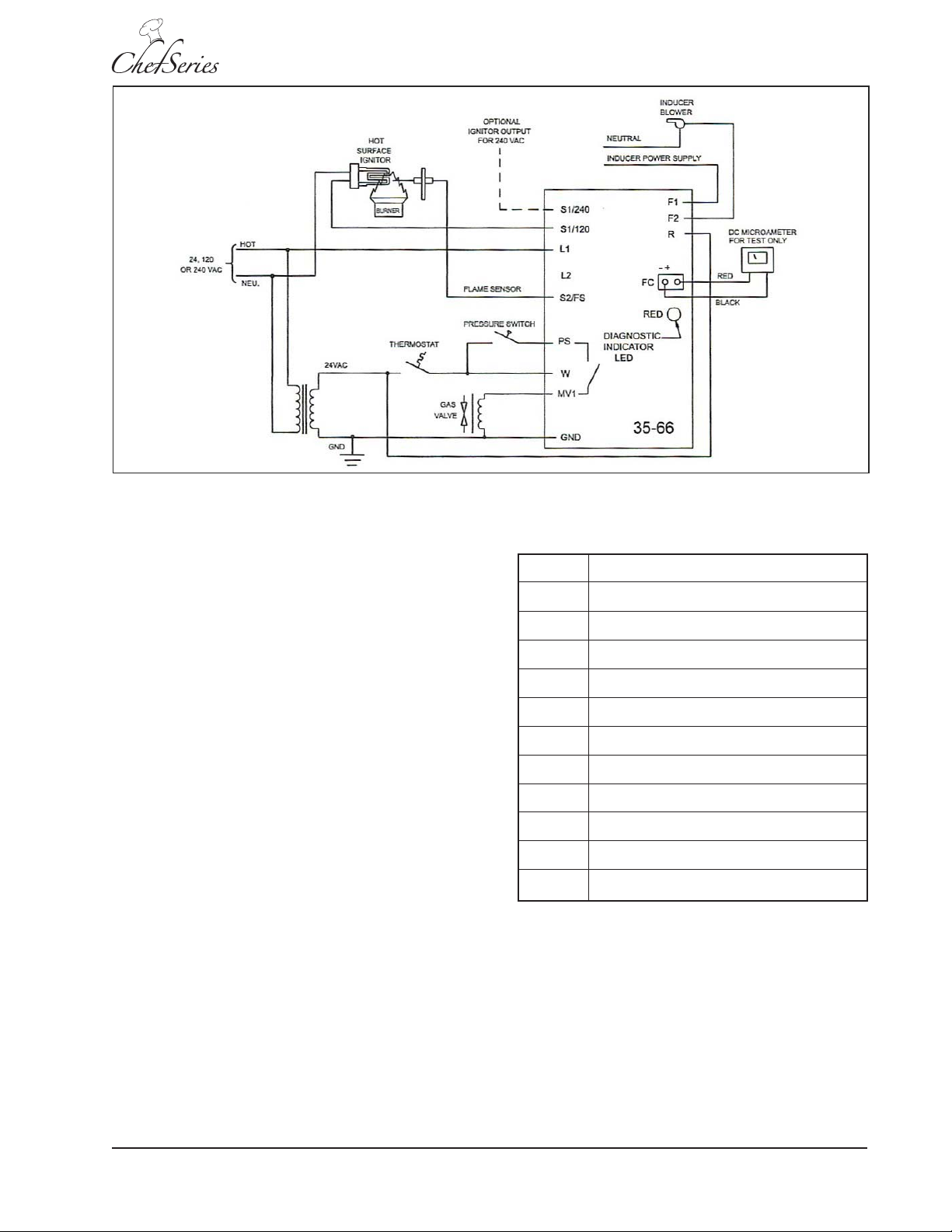

Fan Operation

The fan switch has two settings: HI and LOW. The

fan is mounted inside the oven and must be ON

when the oven is in operation. The main burner

heats the oven through the burner box. The main

burner flames do not come into contact with the air

inside the oven. The fan circulates the air inside the

oven over the lower surface and maintains a constant,

even temperature. The motor control reverses the

direction of the fan periodically to provide consistent

baking operation.

SM-9

Page 10

Service Manual for Enviro-Star GCSF-ES

Door Switch Operation

When the oven door is closed, the door switch

(Figure 7) grounds four motor relays: MR2, the

ignition control module, the gas solenoid, and the

igniter. When the door is open, the ground is

removed and the fan motor and gas to the burner

shuts off. When the door is open, the ignition

control module and igniter cannot operate.

Door Switch

Figure 6: Fan Motor Connections

The fan motor (Figure 6) operates on 120 VAC.

Three relays operate on 24 VAC control motor.

The relays function as follows:

• Motor relay 1 (MR1) ON/OFF controls fan rotation

by reversing the phase of the motor windings.

• Motor relay 2 (MR2) ON/OFF controls motor

operation by routing 120 VAC to the fan motor.

• Motor relay 3 (MR3) ON/OFF controls fan speed

by routing 120 VAC to the motor windings.

DOOR OPEN

Door Switch

DOOR CLOSED

Figure 7: Door Open/Closed

SM-10

Lang A Division of S tar Mfg. Int'l Inc.

Page 11

Oven Lights

Service Manual for Enviro-Star GCSF-ES

Water (Steam) Applications

Light relay (LR1) routes voltage to one side of the

four oven lights (Figure 8). The other side of the

lights is connected to a neutral. When the

controller applies 24 VAC to the light relay, 120

VAC is routed to the oven lights, illuminating the

oven cooking area.

2YHQ/LJKWV

When steam is required for the baking process, the

controller activates the water solenoid (SV1)

(Figure 9). Water is passed through the water stall

(Figure 10) and heated to produce steam. The steam

fills the cooking area. The water system has a 3/8″

inlet line and a 3/8″ supply line to the water stall. The

water stall drain is 3/4″ allowing excess water to drain

quickly from the water stall.

6WHDPHU

$VVHPEO\

Figure 8: Oven Lights

Water

Outlet

Water

Solenoid

Water Inlet

Line

Water Stall

Figure 9: Water Flow Diagram

Lang A Division of S tar Mfg. Int'l Inc.

Line

Drain

Figure 10: Steamer Assembly (Water Stall)

Burnt Gas Exhaust

When natural gas is burned in the appliance, the

burnt gases must be vented away from the appliance.

The gases are exhausted out a vent and through a

flue (chimney or exhaust vent). There are numerous

exhaust/vent systems available to carry the exhaust

gases away from the appliance and work area.

WARNING

BURNING NATURAL GAS PRODUCES EXHAUST

GASES THAT CONTAIN CARBON MONOXIDE.

CARBON MONOXIDE IS A DEADLY GAS THAT

KILLS. ENSURE THAT APPLIANCE EXHAUST

VENTS, FLUES AND CHIMNEYS ARE

INSTALLED AND SERVICED BY PROFESSIONAL

INSTALLATION PERSONNEL AND ARE

ADEQUATE FOR THE APPLIANCE BEING

INSTALLED.

SM-11

Page 12

Service Manual for Enviro-Star GCSF-ES

T

A negative pressure in the appliance allows the

exhaust gases to flow up the flue. The flue helps

generate air flow around the burner, allowing the

burner to burn the gas more efficiently. A draft

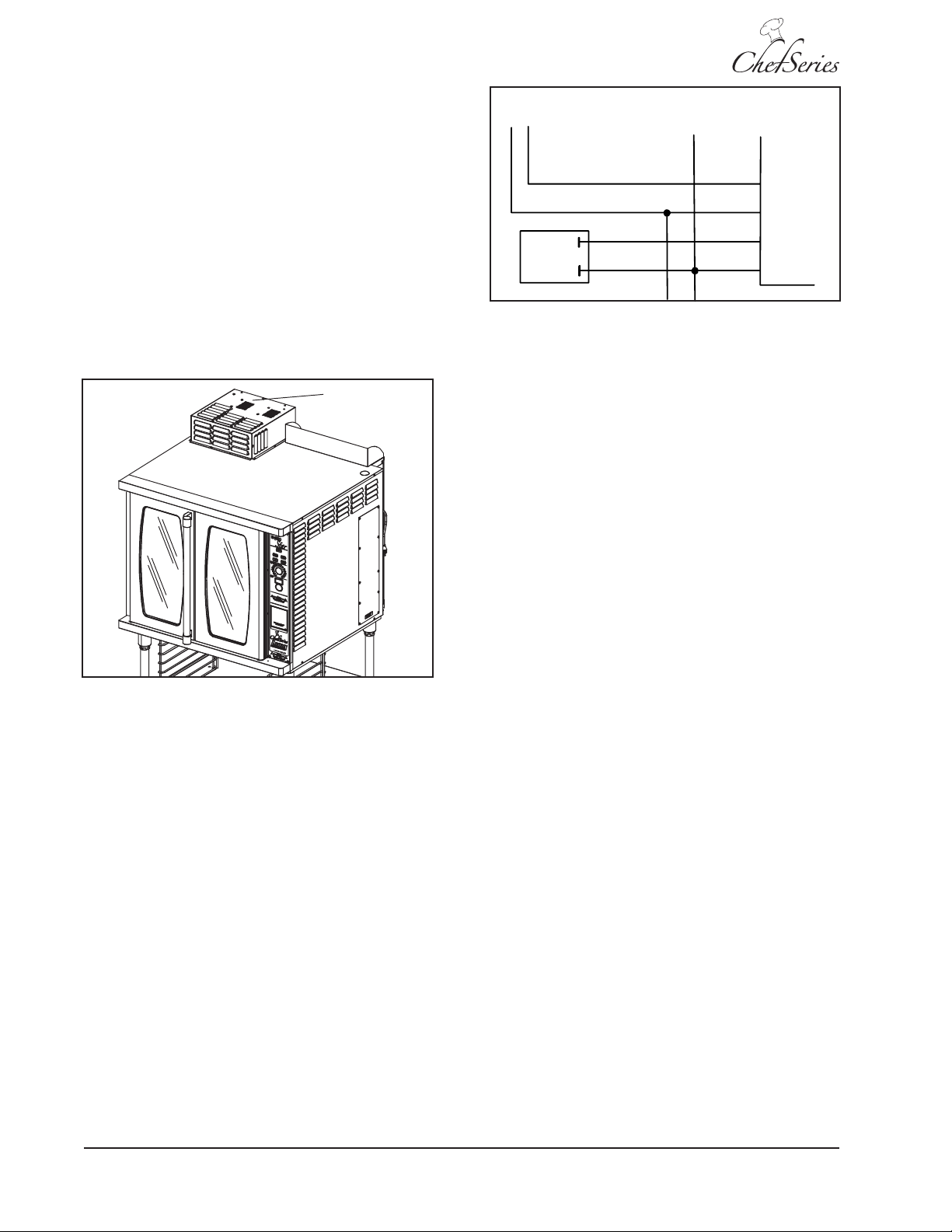

inducer (Figure 11) provides air to the burner and

helps exhaust the burnt gasses.

Draft Inducer Operation

The Draft Inducer is a device mounted on the top

of the oven over the exhaust vent. It provides

secondary air to the burners by creating a draft. The

operation of the Draft Inducer is controlled by the

Ignition Control.

Draft Inducer

O AIR PROVIN G

SWITCH

PS

54

W

37

55

34

MV1

GND

GAS

VALVE

37

55

34

Figure 12: Igniter Controller Internal Switch

During oven operation, combustion air flow is

monitored by the proving switch (pressure switch).

If the switch contacts remain closed for 30-seconds

during ignition sequence without an output signal to

the draft fan an airflow fault will be generated. If the

pressure switch (proving switch) contacts open

during a call for heat operation, the controller

(Figure 12) will begin a pre-purge period and a trail

for ignition sequence.

Figure 11: Draft Inducer

NOTE: See the wiring diagram for wire routing for

the draft inducer.

The draft inducer uses a proving switch to ensure

proper air flow when the burner is in operation. The

switch is mounted between the controller W terminal

and the PS terminal. An internal controller switch

(Figure 12) between the PS and MV1 terminals,

routes voltage to the main gas valve. If the internal

switch is open, the main gas valve solenoid will not

open to allow gas flow to the burner.

NOTE: In a description of the draft inducer, the

pressure switch is often referred to as a proving

switch. The terms mean the same thing and both

refer to the switch monitoring the draft inducer

air flow.

If the pressure switch (proving switch) contacts

remain open for 30-seconds after draft inducer fan

output (F1 and F2) begins, an airflow fault will be

signaled and the fan will remain ON. If the pressure

contacts open later during a call for heat, the

controller will begin a pre-purge period and the trail

for ignition sequence.

If the airflow signal (PS) is lost while the burner is

firing, the controller will immediately de-energize

the main gas valve solenoid and an airflow fault will

be displayed. The controller will continue to monitor

the proving switch (pressure switch) input waiting

for airflow to return. When airflow is detected, a trail

for ignition sequence will begin, followed by a prepurge period. If airflow does not return, the controller

will enter a lockout condition and the draft inducer

fan will shut OFF.

During normal sequence, if a flame signal occurs

due to the main gas valve solenoid not closing all

the way, the controller will energize the draft inducer

fan. If the gas valve solenoid closes, the controller

will shut off the draft inducer fan.

SM-12

Lang A Division of S tar Mfg. Int'l Inc.

Page 13

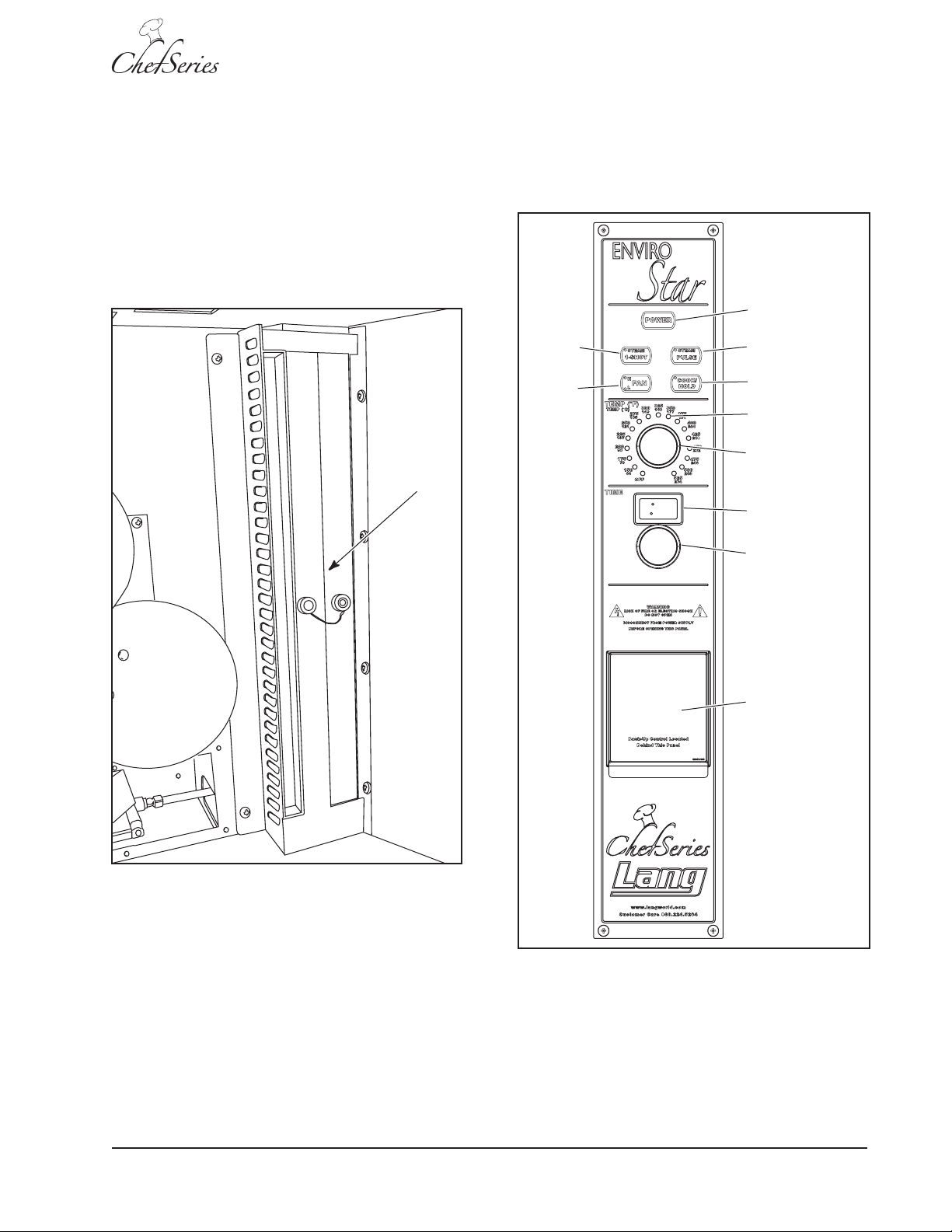

CONTROLS

Service Manual for Enviro-Star GCSF-ES

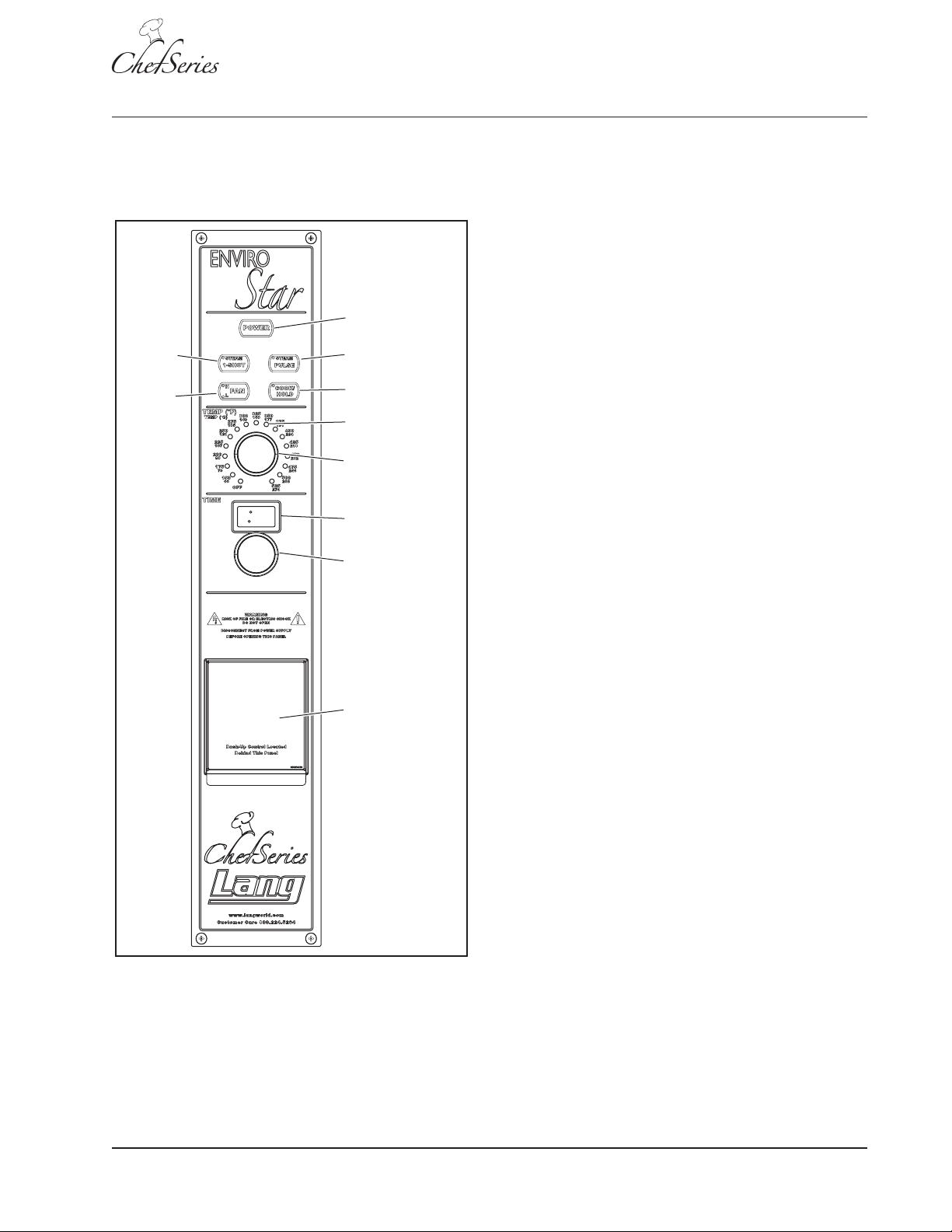

The electronic control panel (Figure 13) is used to

control oven operation. The unit also has manual

backup controls.

Power

1-Shot

Steam

Fan

HI/LOW

Pulse Steam

COOK-N-HOLD

LED Temp

Indicator

Temp Knob

LED Timer

Screen

Timer Knob

Electronic Control Panel (Figure 13)

POWER:

• ON/OFF button

• When pressed ON, interior lights and panel

indicators turn on

• When pressed OFF, interior lights and panel

indicators turn off and the fan remains ON until

the oven cools down to 250° F

FAN:

• ON/OFF Switch

• Has two operating speeds: L=LOW & H=HI

• Must be turned on during operation

• During operation, the fan will reverse directions

periodically to maintain consistent condition

LED TEMPERATURE INDICATOR:

• Displays oven temperature

• ON indicates oven at set point

• Blinks with a call for heat or cooling to temperature

BACKUP

CONTROL

ACCESS DOOR

Figure 13: Electronic Control Panel

TEMPERATURE KNOB:

• Used to set oven temperature

• Dial to desired temperature

TIMER SCREEN:

• LED digital display

• Displays time remaining in cooking cycle

• Displays time selection for Steam Pulse

• Displays time selection for Steam 1- Shot time

TIMER KNOB:

• Sets cooking time

• Sets Steam Pulse time

• Sets Steam 1-Shot time

COOK/HOLD:

• Activated when cooking cycle stops and a

beeper will sound 5 times

• Beeper will sound 5 times

• COOK/HOLD light will turn OFF

• Oven temperature will drop to 150° F

• Temperature will remain at 150° F until operator

chooses a new cooking cycle or turns the oven

OFF

Lang A Division of S tar Mfg. Int'l Inc.

SM-13

Page 14

Service Manual for Enviro-Star GCSF-ES

1-SHOT STEAM:

Initial Power ON Test

• Provides a 1 – 20 second single–shot of steam

to the cooking chamber

• Adjust by holding down the button while turning the

TIMER KNOB until the desired time is displayed on

the LED TIMER SCREEN (Figure 13)

PULSE STEAM:

• Sends a 1-second shot of steam to the cooking

chamber

• Adjust time from 1 – 120 seconds by holding

down the button and turning the TIMER KNOB

until the desired time is displayed on the LED

TIMER SCREEN

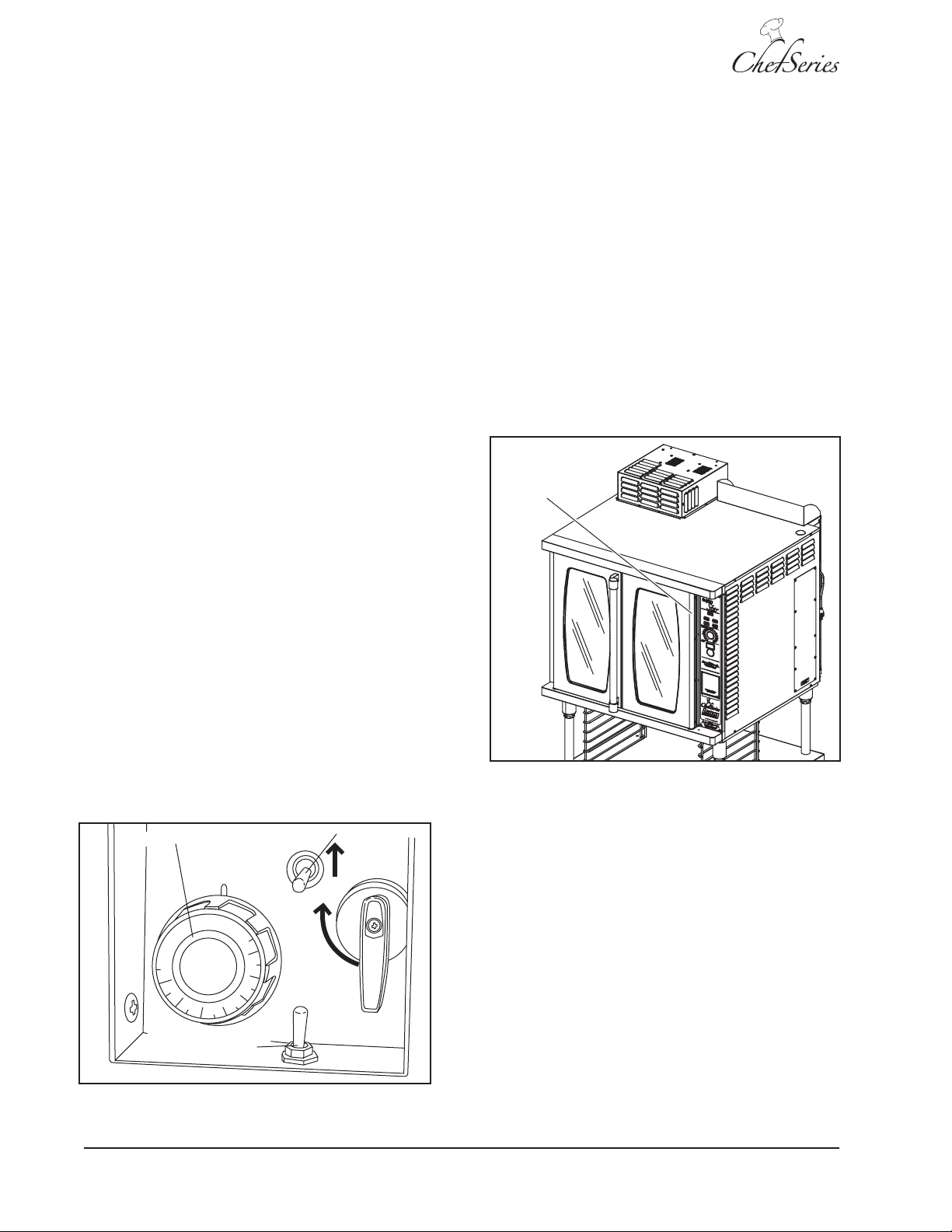

Using Backup Controls

The EnviroSTAR oven is designed with a set of

backup controls that can be used manually instead

of using the electronic oven controls. These controls

(Figure 14) are mounted behind a door below the

oven control panel (Figure 13). Controls include the

BACKUP/MANUAL switch, a TEMPERATURE knob

and a STEAM switch.

Follow these steps to verify the operation and

temperature control of the oven:

• Press the POWER button ON and verify that

the interior and panel lights turn on.

• Set the temperature to 300°F and verify that the

TEMP INDICATOR light is blinking.

• Verify that the oven reaches the set point and

signals Ready with an audible tone within 12

minutes (starting with a cold oven).

• Set the timer to 10 minutes and verify that the

fan stops and reverses direction after

approximately 108 seconds. (A full reversing

cycle takes 120 seconds.)

Door Switch

The BACKUP/MANUAL switch overrides the electronic

controls and activates the backup controls. The

TEMPERATURE knob controls the temperature. The

STEAM toggle switch controls the steam. In this

mode, the fan will operate at HI speed only.

The Backup mode does not use the energy-saving

option and does not allow the fan to operate at Low

speed or reverse direction.

To use the backup controls, place the BACKUP/

MANUAL switch in the BACKUP position.

Temperature Knob

TEMP

OFF

100

150

200

250

Backup / Electronic

Controls Switch

STEAM

450

400

350

300

Steam Switch

G

A

S

S

H

U

T

O

F

F

Figure 15: Door Switch Location

• Open the oven door (Figure 15) and verify that

the fan and TIMER stop then restart when the

door is closed.

• Turn both the TIMER KNOB and TEMP KNOB

to zero.

• Confirm that the fan stays on until the

temperature drops below 250°F.

SM-14

Figure 14: Backup Controls

Lang A Division of S tar Mfg. Int'l Inc.

Page 15

Water/Steam Test

Power

Pulse Steam

COOK-N-HOLD

1-Shot

Steam

Fan

HI/LOW

LED Temp

Indicator

Temp Knob

LED Timer

Screen

Timer Knob

BACKUP

CONTROL

ACCESS DOOR

Service Manual for Enviro-Star GCSF-ES

Operating Sequence

Follow these steps to verify the water and steam

operation of the oven:

1. Identify the water purification system used.

2. Flush the water system to remove tainted

water from the system.

3. Put the oven into Backup mode and set the

temperature to 400°F.

6WHDPHU

$VVHPEO\

NOTE: Refer to the Lang™ GCSF-ES/GCSF-EZ

Installation and Operation Instructions for full

operational description, including optional features.

Figure 16: Water/Steam System (Water Stall)

4. Once up to temperature, use the STEAM

SWITCH on the control panel (Figure 17) to

flush water through the steam system (water

stall) (Figure 16) for one minute.

5. Check the water drain for proper operation.

Figure 17: Electronic Control Panel

Lang A Division of S tar Mfg. Int'l Inc.

SM-15

Page 16

Service Manual for Enviro-Star GCSF-ES

The following table lists typical operating sequences

in order and results.

Operating Sequence

ACTION RESUL T

Power button pressed ON Panel lights and interior

lights illuminate.

HI or LOW fan speed selected HI or LOW fan speed light

illuminates.

TEMP KNOB used to select Oven begins heating and

125° F – 525° F fan begins air circulation.

NOTE: The minimum NOTE: The fan will

temperature for steam reverse direction every

operation is 125° F. two minutes during the

cooking process.

STEAM PULSE button pressed STEAM PULSE light

while selecting a steam pulse illuminates, TIMER LED

time from 1 – 120 seconds momentarily displays

pulse time and steam

pulse is applied.

Set temperature reached Buzzer sounds eight

within 12 minutes times.

Product loaded into oven Product begins to bake.

TIMER used to set cooking Cook time displays on

time LED and countdown

begins.

NOTE: If the steam pulse

is used, a one-second

shot of steam is applied

to the baking area.

Optional COOK/HOLD button COOK/HOLD light

pressed illuminates.

Set cooking time expires Five-beep tone

sounds.

NOTE: If COOK/HOLD is

used, the oven

temperature will drop to

150° F , the COOK/HOLD

light will turn OFF and the

oven will maintain at

150° F until the oven is

turned OFF or a new

cooking cycle is started.

Product removed from oven Oven is ready for

cooking.

SM-16

Lang A Division of S tar Mfg. Int'l Inc.

Page 17

MAINTENANCE

Service Manual for Enviro-Star GCSF-ES

CAUTION

Always keep clear of combustible materials.

CAUTION

Keep the floor in front of equipment clean and

dry. If spills occur, clean immediately to avoid

the danger of slips or falls.

• Water filters and conditioners should be

inspected and replaced per manufacturer’s

recommendations.

OVEN CLEANING

Exterior

See STAINLESS STEEL CARE AND CLEANING.

Interior

WARNING

KEEP WATER AND SOLUTIONS OUT OF THE

CONTROLS AREA. NEVER SPRAY OR HOSE

THE CONTROL PANEL.

CAUTION

Most cleaners are harmful to the skin, eyes,

mucous membranes and clothing. Precautions

should be taken to wear rubber gloves, goggles

or a face shield and protective clothing.

CAUTION

Do not use caustic cleaners.

• Always start with a cold oven.

• Always follow the oven cleaner instructions.

• Do not use caustic cleaners. Using any harsh

chemicals will result in removal of the ETC

coating and etching of the porcelain.

• The oven interior should be cleaned using mild

soap and a non-metal scouring pad.

• Care should be taken to prevent caustic cleaning

compounds from coming in contact with the fan

wheel.

• Oven interior should be wiped down daily and

thoroughly cleaned weekly using warm water

and mild detergent. Do not use caustic cleaners.

• This appliance should be checked at six-month

intervals by a qualified technician (heating unit,

mechanical stability, corrosion, etc.), especially

control and safety devices.

• The oven racks and rack slides may be removed

and cleaned outside the oven using oven cleaner.

• The stainless exterior can easily be cleaned

using stainless steel cleaner.

• Always apply stainless steel cleaners when

the oven is cold and rub in the direction of the

metal’s grain.

CAUTION

Carefully read all warnings and follow the

directions on the label of the cleaner to be used.

CAUTION

Never leave a chlorine sanitizer in contact with

stainless steel surfaces longer than ten minutes.

Prolonged contact can cause corrosion.

Lang A Division of S tar Mfg. Int'l Inc.

SM-17

Page 18

Service Manual for Enviro-Star GCSF-ES

STAINLESS STEEL CARE

Cleaning

Stainless steel contains 70-80% iron, which will

rust if not properly maintained. It also contains 1230% chromium, which forms an invisible passive,

protective film that shields against corrosion. If the

film remains intact, the stainless steel will remain

intact. However, if the film is damaged, the stainless

steel can break down and rust. To prevent stainless

steel breakdown, follow these steps:

CAUTION

Never use any metal tools. Scrapers, files, wire

brushes or scouring pads (except for stainless

steel scouring pads) will mar the surface!

CAUTION

Never use steel wool, which will leave behind

particles that rust!

CAUTION

Never use acid-based or chloride-containing

cleaning solutions, which will break down the

protective film!

Preserve the life of stainless steel with a regular

application of a high quality stainless steel polishing

cleaner as a final step to daily cleaning.

If signs of breakdown appear, restore the stainless

steel surface. First, thoroughly clean, rinse and dry

the surface. Then, on a daily basis, apply a highquality stainless steel polish according to

manufacturer’s instructions.

Heat Tint

Darkened areas, called heat tint, may appear on

stainless steel exposed to excessive heat, which

causes the protective film to thicken. It is unsightly

but is not a sign of permanent damage.

To remove heat tint, follow the routine cleaning

procedure. Stubborn heat tint will require heavyduty cleaning.

To reduce heat tint, limit the exposure of equipment

to excessive heat.

LOCKOUT/TAGOUT PROCEDURES

This section of the manual describes removal and

replacement of the various parts available from an

authorized service provider. For part numbers, refer

to the exploded view parts list in the Operations

Manual provided with the unit.

CAUTION

Never rub in a circular motion!

CAUTION

Never leave any food products or salt on the

surface. Many foods are acidic. Salt contains

chloride!

For routine cleaning, use warm water, mild soap or

detergent and a sponge or soft cloth.

For heavy-duty cleaning, use warm water, a

degreaser and a plastic, stainless steel or ScotchBrite pad.

Always rinse thoroughly. Always rub gently in the

direction of the steel grain.

Preserving & Restoring

Special stainless steel polishing cleaners can

preserve and restore the protective film.

Electrical Lockout/Tagout

The Lockout/Tagout procedure is used to protect

personnel working on an electrical appliance.

Perform the following steps when performing any

type of maintenance or service on an electrically

operated appliance.

1. In electrical box, place unit’s circuit breaker

into OFF position.

2. Place a lock or other device on electrical box

cover to prevent someone from placing circuit

breaker ON.

3. Place a tag on electrical box cover to indicate

that unit has been disconnected for service and

power should not be restored until tag is removed

by maintenance personnel.

4. Disconnect unit power cord from electrical

outlet.

5. Place a tag on cord to indicate that oven has

been disconnected for service and power should

not be restored until tag is removed by

maintenance personnel.

SM-18

Lang A Division of S tar Mfg. Int'l Inc.

Page 19

Gas Lockout/Tagout

Service Manual for Enviro-Star GCSF-ES

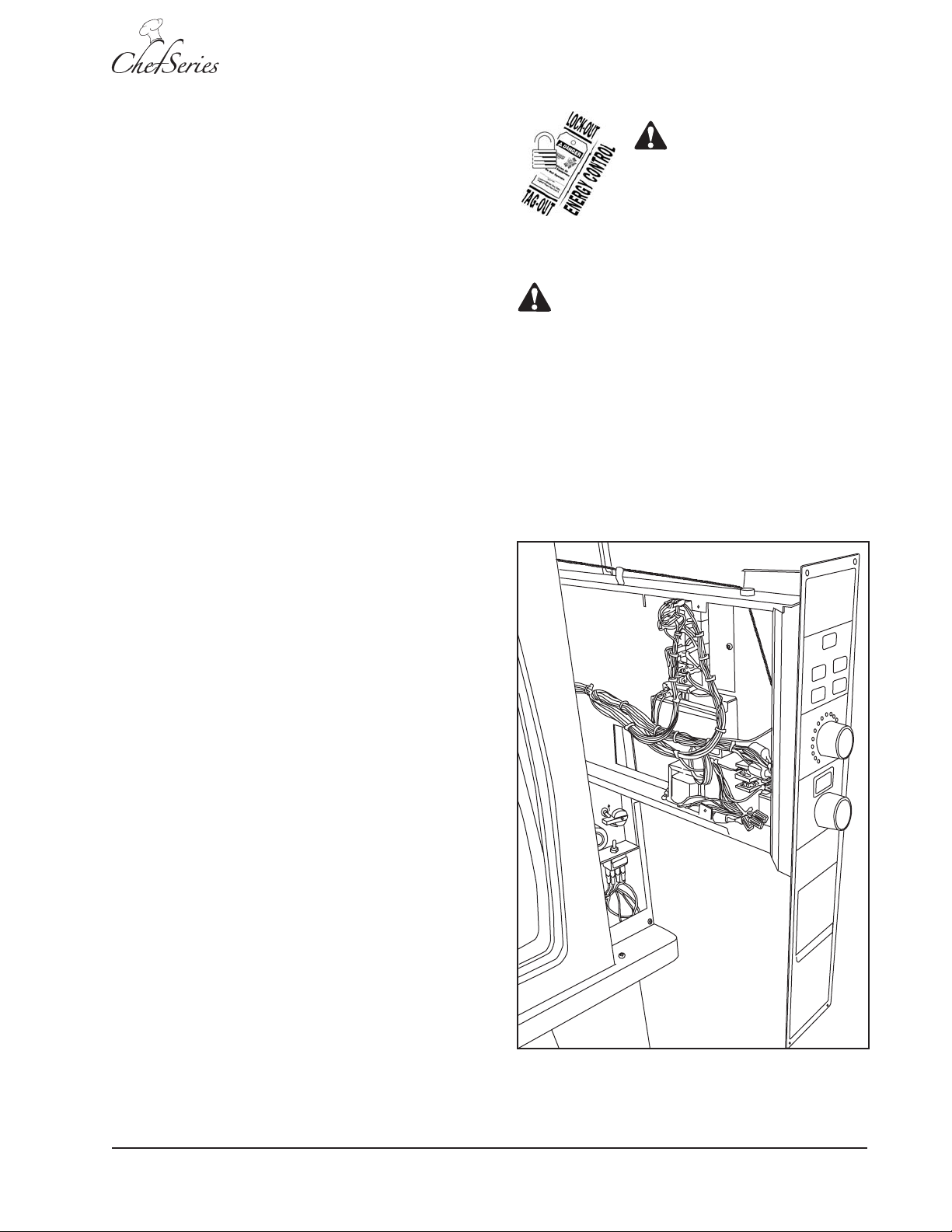

Electronics Access

The Gas Lockout/Tagout procedure is used to

protect personnel working on a gas appliance.

Before performing any type of maintenance or

service on a gas appliance, follow these steps:

1. Locate the natural gas or inlet valve and place

the valve in the OFF position.

2. Place a tag on the valve indicating that service

is being performed on equipment and the natural

gas must remain off until service is complete by

the maintenance personnel.

3. Place a locking device on the natural gas inlet

valve preventing actuation until the lock is

removed by the maintenance personnel.

4. On the appliance, make sure all flame sources

are extinguished and/or removed by

maintenance personnel.

5. Bleed residual gas from the appliance inlet line

and allow time for the gas to dissipate before

beginning service on the appliance.

Gas Leak Test

WARNING

PERFORM THE ELECTRICAL

LOCKOUT/TAGOUT

PROCEDURE.

1. Perform the Electrical Lockout/Tagout

procedure, found on page 18 of this manual..

CAUTION

In the following steps, the upper and lower edges

of the electronics drawer slide in and out of the

mounting brackets. DO NOT pull the drawer

completely out from the oven, as it could slip out

and damage wiring and/or other components. If

further access to the drawer area is needed,

perform the External Right Side Panel Removal

procedure.

2. Open the oven doors approximately eight to ten

inches.

After completing service on any natural gas

appliance, all gas joints disturbed during service

must be check for leaks. DO NOT USE AN OPEN

FLAME. Use a hazardous gas tester or a soap and

water solution.

1. Apply a soap and water solution to gas joint and

check for bubbles.

2. If bubbles are present, the joint is leaking and

must be repaired before using the appliance.

Lang A Division of S tar Mfg. Int'l Inc.

Figure 18: Electronics Drawer

SM-19

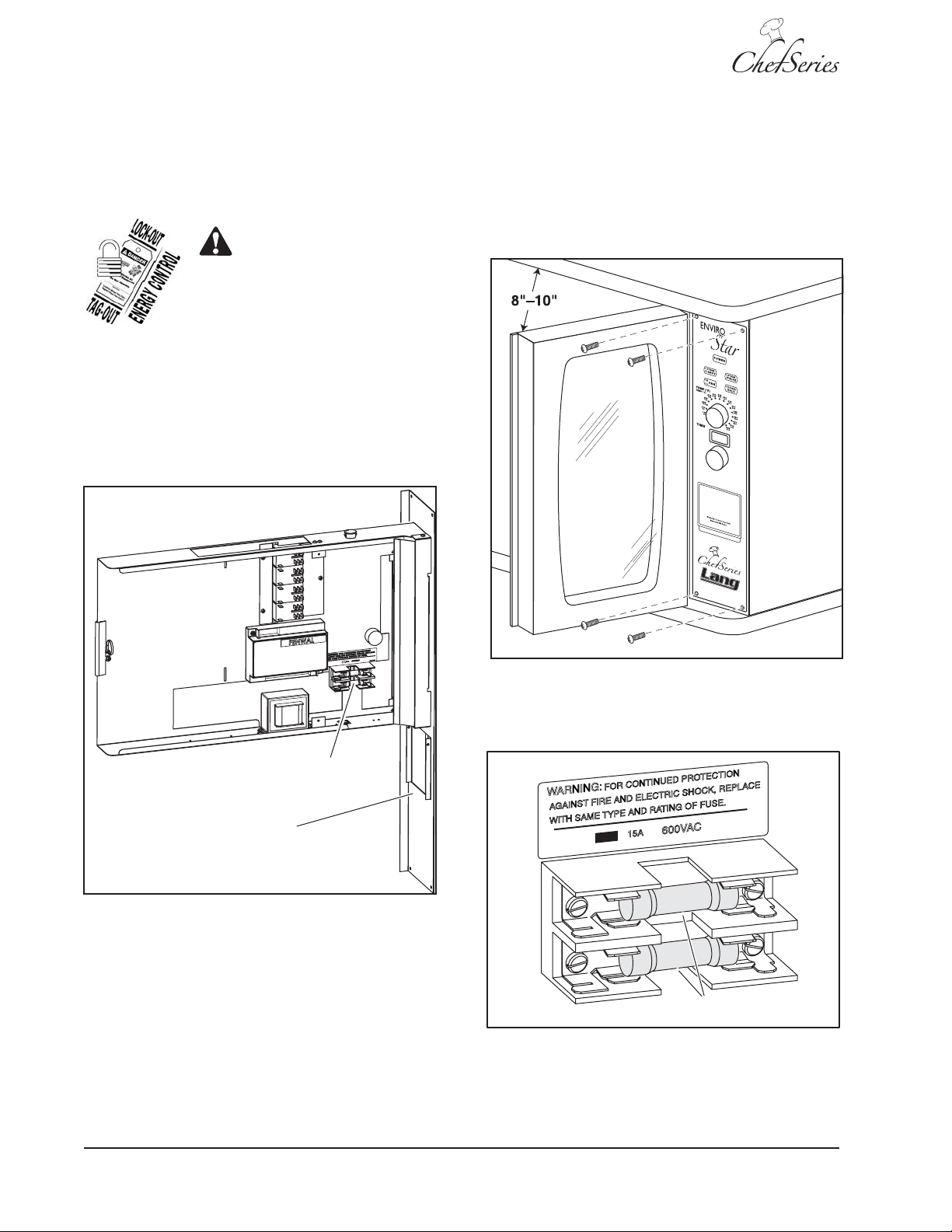

Page 20

Service Manual for Enviro-Star GCSF-ES

WARNING:

FO

R CONTINUED PROTECTION

AGAINST FIRE AND ELECTRIC SHOCK, REPLACE

WITH SAME TYPE AND RAT IN G OF FUSE.

600VAC

15A

60302-77

Fuse

3. Remove four screws located at the top and

bottom of the front panel.

7. Slide the electronics drawer closed, but do not

install mounting screws.

4. Carefully slide the electronics drawer

(Figure 18) out from the oven.

Main Power Fuse Replacement

WARNING

PERFORM THE ELECTRICAL

LOCKOUT/TAGOUT

PROCEDURE.

1. Perform the Electrical Lockout/Tagout

procedure, found on page 18 of this manual.

2. Perform the Electronics Access procedure.

3. Locate the fuse block (Figure 19) in the

electronics drawer (Figure 20).

8. Connect the oven to external power, and press

the front panel POWER button to ensure the

oven is operational.

9. When proper operation is determined, install

and tighten four mounting screws.

Fuses

Electronics

Drawer

Figure 19: Fuse Locator

4. Use an Ohmmeter to ensure the fuse is open

before replacing it. An ohm reading indicates

5. Using a fuse puller or similar tool remove the

the fuse has continuity and is good.

fuse.

6. Install an exact replacement fuse (Figure 21) in

the fuse holder. (Class G, Type SC-15, Time

Delay, rated for 600 VAC)

Figure 20: Electronics Drawer Access

Figure 21: Fuse Replacement

SM-20

Lang A Division of S tar Mfg. Int'l Inc.

Page 21

Circuit Board Replacement

Beeper

Keypad

Ribbon

Cable

Door

Open

Sensor

Temperature

Sensor

Output

Connector

WARNING

PERFORM THE ELECTRICAL

LOCKOUT/TAGOUT

PROCEDURE.

Service Manual for Enviro-Star GCSF-ES

NOTE: A spacer and two washers remain on each

mounting stud. Do not lose the washers and

spacers.

9. To install a replacement circuit board, carefully

insert the temperature selector and timer shafts

through the front panel and position the circuit

board on the four corner studs.

1. Perform the Electrical Lockout/Tagout

procedure, found on page 18 of this manual.

2. Perform the Electronics Access procedure.

3. Remove the heat shield on the right side front

(Figure 22) of the electronics drawer by removing

mounting screws at the top and bottom.

10. Secure the circuit board with nylon washers

and nuts but do not tighten nuts.

11. Secure the temperature selector and timer with

a washer and nut and tighten nut securely.

12. Install knobs on the temperature selector and

timer.

13. Tighten the circuit board nuts securely.

14. Using tags created during removal, connect five

cables to the circuit board.

15. Slide the electronics drawer closed but do not

install mounting screws.

16. Connect the oven to external power, and press

the panel POWER button ON to ensure the

oven is operational.

17. Secure the electronics drawer with four screws

and tighten screws securely.

18. Place the heat shield in position, secure with

two screws and tighten screws securely.

Heat Shield

Figure 22: Heat Shield

4. Tag and disconnect five cables (Figures 23 and

24) from the circuit board. DO NOT pull on the

wires!

5. Carefully pull off the knobs from the temperature

selector and timer.

6. Remove the mounting nut and washer from

temperature selector and timer shafts.

7. Remove the nuts and nylon washers from in the

four corners of the circuit board.

8. Carefully remove the circuit board from the

threaded studs.

Figure 23: Circuit Board Connectors

Lang A Division of S tar Mfg. Int'l Inc.

SM-21

Page 22

Service Manual for Enviro-Star GCSF-ES

Transformer

Beeper

Temperature

Output

Connector

Keypad

Ribbon

Cable

Door

Open

Sensor

Sensor

11. Connect the oven to external power, and press

the POWER button ON to ensure the oven is

operational.

12. Secure electronics drawer with four screws and

tighten screws securely.

Figure 24: Circuit Board Cables

Power Transformer Replacement

WARNING

PERFORM THE ELECTRICAL

LOCKOUT/TAGOUT

PROCEDURE.

1. Perform the Electrical Lockout/Tagout

procedure, found on page 18 of this manual.

2. Perform the Electronics Access procedure.

3. Remove two mounting screws from the wire

cover (Figure 25), pivot cover to the left and

remove.

4. Cut the ties securing transformer wires.

5. Remove two screws securing transformer

(Figure 26) to the drawer base.

6. Tag and disconnect transformer wires.

7. Position replacement transformer and secure

with two mounting screws.

&RPSRQHQW 7UDQVIRUPHU

:LUH&RYHU

Figure 25: Component Wire Cover Location

8. Using tags created during removal, connect

wires to the replacement transformer.

9. Secure the wiring with plastic ties.

10. Slide the electronics drawer closed but do not

install mounting screws.

SM-22

Figure 26: Transformer

Lang A Division of S tar Mfg. Int'l Inc.

Page 23

Beeper Removal

Relays

Service Manual for Enviro-Star GCSF-ES

Relays

WARNING

PERFORM THE ELECTRICAL

LOCKOUT/TAGOUT

PROCEDURE.

1. Perform the Electrical Lockout/Tagout

procedure, found on page 18 of this manual.

2. Perform the Electronics Access procedure.

3. Remove the beeper connector from the circuit

board (Figure 27).

Four 24 VAC relays are used to operate the relay

coil, which acts like a switch. The relays control the

circuits as follows:

Beeper

Figure 27: Beeper Location

4. While holding the beeper, remove the mounting

ring from the side of the drawer housing.

5. Install the new beeper and connect the cable

connector into the circuit board.

6. Slide the electronics drawer closed but do not

install mounting screws.

7. Connect the oven to external power and press

the POWER button ON to ensure the oven is

operational.

8. Secure electronics drawer with four screws and

tighten securely.

Figure 28: Relay Mounting

• Relay 1 – MR1 – Fan Motor Forward/Reverse

• Relay 2 – MR2 – Fan Motor Run

• Relay 3 – MR3 – Fan Motor HI/LOW Speed

• Relay 4 – LR1 – Light

Figure 29: Basic Relay Operation

Lang A Division of S tar Mfg. Int'l Inc.

SM-23

Page 24

Service Manual for Enviro-Star GCSF-ES

12 13 11

13 10

MOTOR

REL AY 1

(FWD/REV)

MOTOR

REL AY 2

(RUN)

MOTOR

REL AY 3

(HI/LO SPEED)

LIGHT

REL AY

LR1

20 19 21

21 24 20

15 10

32

41

35

34

32

48

32

42

Relay Operation

Relays use low voltage (Figure 29) to activate a

switch that routes a higher voltage to a component.

All four oven relays operate in the same manner.

One side of the coil (Figure 29) is grounded. When

activated by the control system (circuit board), 24

VAC is routed to the other side of the coil. With

ground and 24 VAC applied to the coil, a magnetic

field is generated. The magnetic field pulls the

switch down. The 120 VAC is then routed through

the switch to one side of the light bulb. Because the

other side of the light bulb is grounded, the bulb

illuminates.

3. Remove two mounting screws from the wire

cover (Figure 30), pivot the cover to the left and

remove.

4. Locate the relay (Figure 31) and remove the

screw and relay clamp on the right side.

5. Tag and disconnect wires from the relay.

6. Using tags created during removal, connect

wires to the relay.

7. Position the relay for installation.

8. Secure the relay with the clamp and screw.

9. Slide the electronics drawer closed but do not

install the mounting screws.

Relay Replacement

WARNING

PERFORM THE ELECTRICAL

LOCKOUT/TAGOUT

PROCEDURE.

1. Perform the Electrical Lockout/Tagout

procedure, found on page 18 of this manual.

2. Perform the Electronics Access procedure.

&RPSRQHQW 7UDQVIRUPHU

:LUH&RYHU

Figure 30: Wire Cover

10. Connect the oven to external power, and press

the POWER button ON to ensure the oven is

operational.

11. Secure the electronics drawer with four screws.

Figure 31: Relay Connections

SM-24

Lang A Division of S tar Mfg. Int'l Inc.

Page 25

Ignition Controller Replacement

Service Manual for Enviro-Star GCSF-ES

Right Side Panel Removal

WARNING

PERFORM THE ELECTRICAL

LOCKOUT/TAGOUT

PROCEDURE.

1. Perform the Electrical Lockout/Tagout

procedure, found on page 18 of this manual.

2. Perform the Electronics Access procedure.

3. Remove two mounting screws from the wire

cover (Figure 30), pivot the cover to the left and

remove.

4. Locate the ignition controller (Figure 32) in the

electronics drawer.

5. Remove mounting screws from the upper left

and lower right corners.

6. Tag and disconnect wires from the ignition

controller.

7. Position the new ignition controller and secure

with two screws.

The gas valves, water valves and connections are

mounted behind the right side panel.

CAUTION

Sheet metal edges can cut! Avoid bare hand

contact with metal edges. Wear protective gloves

during installation, operation, cleaning, and

maintenance.

WARNING

PERFORM THE ELECTRICAL

LOCKOUT/TAGOUT

PROCEDURE.

1. Perform the Electrical Lockout/Tagout

procedure, found on page 18 of this manual.

2. Remove four screws from the right side panel

(Figure 33) at rear of the oven.

Ignition

Controller

Figure 32: Ignition Controller

8. Using tags created during removal, connect

wires to the replacement controller.

9. Slide the electronics drawer closed, but do not

install mounting screws.

10. Connect the oven to external power, and press

the POWER button ON to ensure the oven is

operational.

Right Side

Panel

Figure 33: Right Side Panel

3. Remove the two screws from lower edge of the

right side panel.

4. Remove two screws from the upper edge of the

right side panel.

NOTE: The right side panel has a flange along the

top, bottom and rear.

5. Carefully slide the side panel back about ¾ inch

and straight down for removal.

6. To install right side panel, reverse above steps.

11. Secure the electronics drawer with four screws.

Lang A Division of S tar Mfg. Int'l Inc.

SM-25

Page 26

Service Manual for Enviro-Star GCSF-ES

Temperature Sensor Replacement

WARNING

PERFORM THE ELECTRICAL

LOCKOUT/TAGOUT

PROCEDURE.

1. Perform the Electrical Lockout/Tagout

procedure, found on page 18 of this manual.

2. Perform the Electronics Access procedure.

7HPSHUDWXUH

6HQVRU

3. Perform the External Right Side Panel Removal

procedure.

4. Disconnect the temperature sensor plug from

the circuit board connector (Figure 23) and pull

the tube through the grommet in the drawer.

2YHQ6HQVRU

Figure 34: Temperature Sensor Location

5. Grasp the sensor (Figure 34) near the entry into

the oven, push it out of the oven and into the

electronics drawer.

Figure 35: Temperature Sensor

12. Slide the electronics drawer closed but do not

install the mounting screws.

13. Connect the oven to external power, and press

the POWER button ON to ensure the oven is

operational.

14. Secure the electronics drawer with four screws.

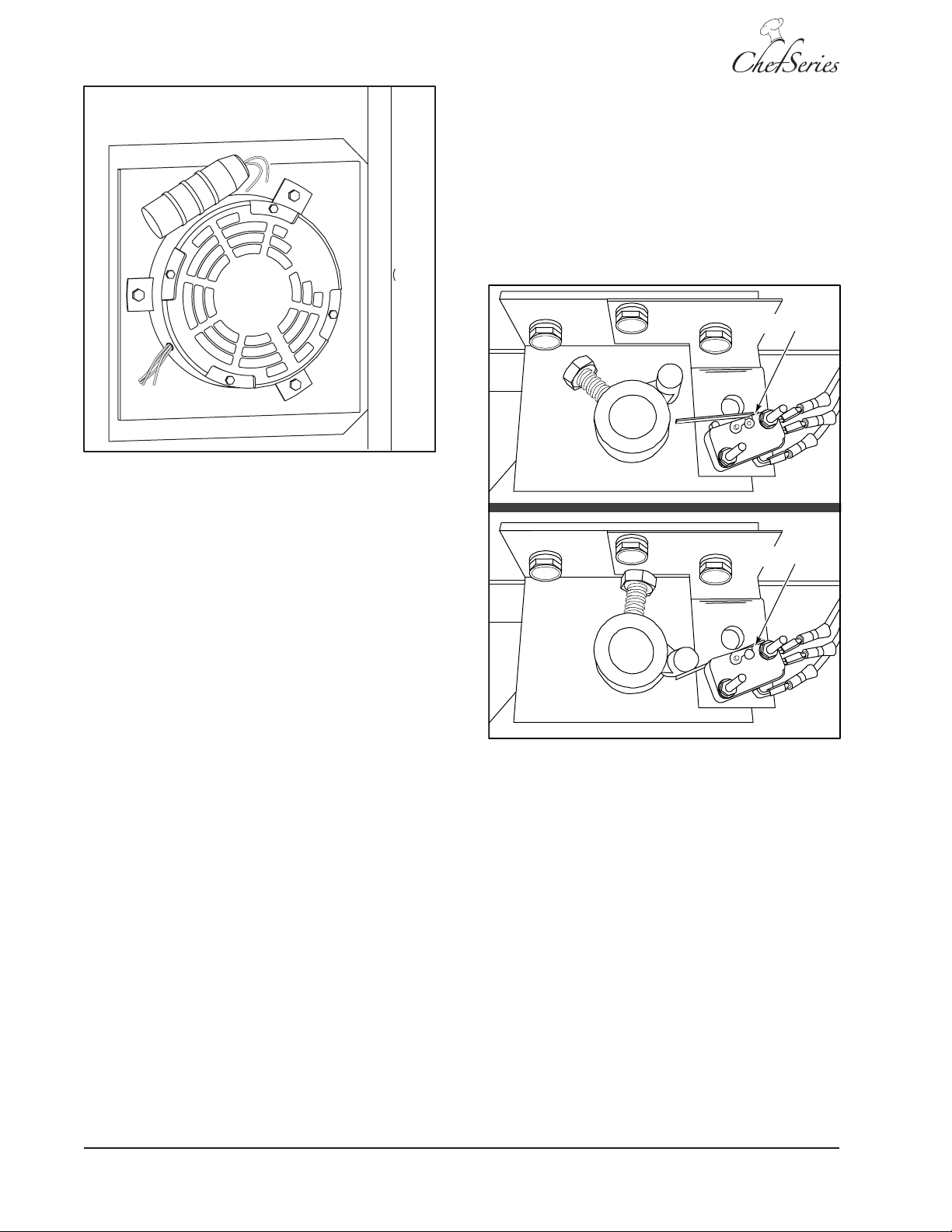

Fan Motor Starter Capacitor Replacement

WARNING

PERFORM THE ELECTRICAL

LOCKOUT/TAGOUT

PROCEDURE.

1. Perform the Electrical Lockout/Tagout

procedure, found on page 18 of this manual.

2. Remove the motor access panel at the rear of

the oven.

WARNING

ELECTRICAL HAZARD THE CAPACITOR MAY

BE CHARGED.

6. Pull the sensor out of the oven wall and into the

electronics drawer.

7. Slide the tip of the new sensor through the oven

wall hole into the oven.

8. Slide the tip of the sensor through the holes and

into the mounting bracket until it protrudes ¾

inch from the end of the bracket.

9. Pass the temperature sensor tube (Figure 35)

through the grommet into the electronics drawer.

10. Attach the connector to the circuit board

(Figure 23).

11. To install all previously removed parts, reverse

the above steps.

SM-26

3. Remove the rubber boot covering the connectors

on the motor starting capacitor (Figure 36).

4. Discharge the capacitor.

5. Tag and disconnect wires from the capacitor.

6. Remove three screws securing the capacitor

mounting straps to the rear housing.

7. Remove mounting straps from the capacitor

and install onto the new capacitor.

8. Position the new capacitor for installation.

9. Secure the capacitor with three screws in the

mounting straps.

Lang A Division of S tar Mfg. Int'l Inc.

Page 27

10. Using tags created during removal, connect

Set

Screws

wires to the new capacitor.

11. Position the motor access panel at the rear of

the oven.

12. Connect the oven to external power and press

the POWER button ON to ensure the oven is

operational.

Service Manual for Enviro-Star GCSF-ES

6. Remove four thumb screws (Figure 38) from the

corners of the fan shroud.

7. Pivot the bottom of the fan shroud forward and

the upper edge back to carefully remove it from

the oven.

Fan Motor

Starter

Capacitor

Figure 36: Fan Motor Starter Capacitor

Internal Access

1. Remove the cooking racks from the oven.

2. Remove the rack guides from the left and right

oven walls.

3. Grasp the left edge of the intake cover (Figure 37)

and pull the cover forward while pressing back the

spring clip on the left side of the fan shroud.

4. Slide the intake cover slightly forward and to the

left for removal.

5. Pivot the lower edge of the intake cover forward

and the upper edge back to carefully remove it

from the oven.

Thumb

Spring

Clip

Screws

Retaining Slot

Thumb

Screws

Retaining Slot

Figure 38: Fan Shroud

Fan Blade Removal

1. Perform the Internal Access procedure.

2. Measure and note the distance from the end of

the motor shaft (Figure 39) to the outer edge of

the fan blade mounting clamp (typically 1 inch).

Figure 37: Intake Cover Removal

Lang A Division of S tar Mfg. Int'l Inc.

Figure 39: Fan Blade Removal

SM-27

Page 28

Service Manual for Enviro-Star GCSF-ES

3. Loosen the two set screws securing the fan

blade to the motor shaft.

4. Slide the fan blade (Figure 40) assembly off the

motor shaft. A puller may be necessary to

remove fan blade.

10. If the new motor does not have a small fan blade

mounted on the shaft, perform the Motor Small

Fan Blade Installation procedure.

Remove

Third Bolt

Figure 40: Fan Assembly

Fan Motor Replacement

WARNING

PERFORM THE ELECTRICAL

LOCKOUT/TAGOUT

PROCEDURE.

1. Perform the Electrical Lockout/Tagout

procedure, found on page 18 of this manual.

2. Perform the Fan Blade Removal procedure.

3. At the rear of the oven, remove the motor

access panel.

4. Discharge the capacitor.

5. Remove the rubber boot (Figure 38) covering

the connectors on the motor starter capacitor.

6. Tag and disconnect wires from the capacitor.

7. Loosen the three motor-mounting bolts and

remove the upper and lower right bolts and splitring lock washers.

Figure 41: Fan Motor

11. Tag and disconnect wires from the motor.

12. Using tags created during removal, connect

wires to the replacement motor.

13. Insert the motor shaft and the small fan blade

through the rear housing.

14. Position the motor with the wires on the lower

left and secure the motor with three mounting

bolts and tighten bolts evenly and securely.

15. Inside the oven, position the motor shaft with

the flat surface facing up.

16. Position the fan blade with the clamp facing

away from the motor.

17. Position the fan blade assembly with one set

screw pointing up and the second pointing to

the left.

18. Slide the fan blade onto the motor shaft.

19. Using the measurement taken during removal,

position the fan blade on the motor shaft and

tighten set screws securely.

8. While supporting the motor (Figure 41), remove

the third bolt and washer.

9. Carefully remove the motor from the oven.

SM-28

20. To install all previously removed parts, reverse

the above steps.

21. Connect the oven to external power and press

the POWER button ON to ensure the oven is

operational.

Lang A Division of S tar Mfg. Int'l Inc.

Page 29

Motor Small Fan Blade Installation

Service Manual for Enviro-Star GCSF-ES

Burner Area Access

WARNING

PERFORM THE ELECTRICAL

LOCKOUT/TAGOUT

PROCEDURE.

1. Perform the Electrical Lockout/Tagout

procedure, found on page 18 of this manual.

2. Perform the Fan Motor Replacement procedure

up to removing the small fan blade.

3. On the old motor, measure and note the distance

from the end of the motor shaft to the outer edge

of the small fan blade mounting clamp (typically

7-3/8 inches).

4. Loosen the mounting clamp set screw and slide

the small fan off the motor shaft.

5. With the clamp facing away from the motor,

slide the fan blade onto the motor shaft.

6. Position the small fan blade the distance

measured during removal and tighten set screw

securely.

WARNING

PERFORM THE ELECTRICAL

LOCKOUT/TAGOUT

PROCEDURE.

WARNING

PERFORM THE GAS LOCKOUT/

TAGOUT PROCEDURE.

WARNING

ALL GAS JOINTS DISTURBED DURING

SERVICING MUST BE CHECKED FOR LEAKS.

DO NOT USE AN OPEN FLAME. USE A SOAP

AND WATER SOLUTION AND CHECK FOR

BUBBLES, WHICH INDICATE A GAS LEAK.

1. Perform the Electrical Lockout/Tagout

procedure, found on page 18 of this manual.

2. Perform the Gas Lockout/Tagout procedure,

found on page 19 of this manual.

Figure 42: Small Fan Blade

Small

Fan

Blade

3. Perform the Internal Access procedure.

4. Perform the Fan Blade Removal procedure.

5. Remove 14 screws securing the burner

access cover.

Burner Access Cover

Lang A Division of S tar Mfg. Int'l Inc.

Figure 43: Burner Access Cover

SM-29

Page 30

Service Manual for Enviro-Star GCSF-ES

Igniter Replacement

Flame Sensor Replacement

1. Perform the Burner Area Access procedure.

2. Remove the igniter (Figure 44) by removing the

screw securing it to the burner.

3. Remove tie-straps securing the wires in the

wiring harness.

4. Tag and disconnect igniter wiring.

5. Using tags created during removal, connect

wires to the new igniter.

6. Position the igniter in the burner and secure

with a screw.

7. To install all previously removed parts, reverse

the above steps.

8. Turn the external gas supply ON, and press the

POWER button ON to ensure the oven is

operational.

)ODPH

6HQVRU

WARNING

PERFORM THE ELECTRICAL

LOCKOUT/TAGOUT

PROCEDURE.

1. Perform the Electrical Lockout/Tagout

procedure, found on page 18 of this manual.

2. Perform the Internal Access procedure.

3. Perform the Burner Area Access procedure.

4. Remove the flame sensor (Figure 44) by removing

the screw securing it to the burner.

5. Tag and disconnect the wire from the igniter.

6. Position the new igniter for installation and

secure with a screw.

7. Using tag created during removal, connect the

wire to the igniter.

8. To install all previously removed parts, reverse

the above steps.

9. Turn the external gas supply ON and press the

POWER button ON to ensure the oven is

operational.

,JQLWHU

Figure 44: Igniter and Flame Sensor

Burner Replacement

1. Perform the Burner Area Access procedure.

2. Perform the Flame Sensor Replacement

procedure.

3. Perform the Igniter Replacement procedure.

4. Remove mounting screws from the igniter and

flame sensor bracket and remove the bracket.

WARNING

DO NOT PLACE FINGERS UNDER THE BURNER.

WHEN SCREWS ARE REMOVED THE BURNER

WILL DROP FROM THE MOUNTING BRACKETS.

SERIOUS PERSONAL INJURY MAY OCCUR TO

FINGERS.

5. To avoid injury to fingers during removal, place

a screwdriver under the left side of the burner

(Figure 45).

6. Remove two screws securing the burner to the

heat exchanger assembly.

7. Carefully slide the burner (Figure 46) out from

under the heat exchanger.

SM-30

Lang A Division of S tar Mfg. Int'l Inc.

Page 31

8. Position the new burner for installation and

secure the burner with two screws into the heat

exchanger.

Service Manual for Enviro-Star GCSF-ES

Heat Exchanger Replacement

WARNING

9. Ensure the burner is level before continuing.

NOTE: If the burner is installed at an angle it will

NOT heat up the Flame Sensor Probe.

10. To install all previously removed parts, reverse

the above steps.

11. Turn the external gas supply ON and press the

POWER button ON to ensure the oven is

operational.

THE HEAT EXCHANGER IS VERY HEAVY. USE

A BRACE UNDERNEATH THE HEAT

EXCHANGER (FIGURE 48) FOR SUPPORT

BEFORE REMOVING THE MOUNTING SCREWS.

1. Perform the Burner Replacement procedure.

2. Remove the top and middle left panel screws

(Figure 47) near the heat exchanger.

Remove These

Two Screws

Burner

Figure 45: Burner Replacement

Figure 46: Burner

Figure 47: Left Panel Mounting Screws

3. Remove eight mounting screws from the sides

of the heat exchanger.

4. Place the handle of a screwdriver under the

brace (Figure 48) and apply upward pressure on

the heat exchanger while removing four screws

at the top.

5. Use the brace to support the heat exchanger

while working it out of the mounting position.

6. Tilt the top of the heat exchanger assembly

forward toward the oven doors and lay it down

on the brace.

7. Carefully slide the heat exchanger assembly

out of the oven.

8. Place the new heat exchanger assembly on the

brace and slide it into the oven.

9. Tip the heat exchanger up and use the brace to

carefully work it into position.

Lang A Division of S tar Mfg. Int'l Inc.

SM-31

Page 32

Service Manual for Enviro-Star GCSF-ES

7. Position the new steamer assembly against

the right side wall and push to the rear so the

water outlet tube slides into position.

Press Down

On Brace

Screwdriver

Figure 48: Heat Exchanger Removal and

Installation

10. Place the handle of a screwdriver under the

brace (Figure 48) and apply upward pressure on

the heat exchanger while installing four screws

at the top and eight screws on the sides.

11. To install all previously removed parts, reverse

the above steps.

12. Turn the external gas supply ON and press the

POWER button ON to ensure the oven is

operational.

Steamer Assembly (Water Stall)

Replacement

8. To install all previously removed parts, reverse

the above steps.

9. Press the front panel POWER button ON to

ensure the oven is operational.

6WHDPHU

$VVHPEO\

WARNING

PERFORM THE ELECTRICAL

LOCKOUT/TAGOUT

PROCEDURE.

1. Perform the Electrical Lockout/Tagout

procedure, found on page 18 of this manual.

2. Perform the Internal Access procedure.

3. Perform the Fan Blade Removal procedure.

4. Remove two screws and washers from the left

side and four screws and washers from the right

side of the steamer assembly (Figure 49).

5. Use a flat blade screwdriver to carefully pry the

assembly away from the rear oven wall.

NOTE: The steamer assembly water outlet tube at

the bottom will slide out of the drain tube as the

assembly is removed.

6. Slide the steamer assembly towards the oven

doors and remove it.

Figure 49: Steamer Assembly

SM-32

Lang A Division of S tar Mfg. Int'l Inc.

Page 33

Over-Temperature Switch Replacement

Service Manual for Enviro-Star GCSF-ES

Main Gas Solenoid Replacement

WARNING

PERFORM THE ELECTRICAL

LOCKOUT/TAGOUT

PROCEDURE.

1. Perform the Electrical Lockout/Tagout

procedure, found on page 18 of this manual.

2. Perform the Internal Access procedure.

3. Remove four mounting screws (Figure 50).

4. Carefully pull the switch and wires into the

oven.

5. Tag and disconnect wires from the switch.

6. Using tags created during removal, connect the

wires to the new switch.

7. Push excess wire back into the access hole.

8. Position the switch for installation and secure

with four mounting screws.

9. To install all previously removed parts, reverse

the above steps.

10. Turn the electric supply ON and press the

POWER button ON to ensure the oven is

operational.

WARNING

PERFORM THE ELECTRICAL

LOCKOUT/TAGOUT

PROCEDURE.

WARNING

PERFORM THE GAS

LOCKOUT/TAGOUT

PROCEDURE.

WARNING

ALL GAS JOINTS DISTURBED DURING

SERVICING MUST BE CHECKED FOR LEAKS.

DO NOT USE AN OPEN FLAME. USE A SOAP

AND WATER SOLUTION AND CHECK FOR

BUBBLES, WHICH INDICATE A GAS LEAK.

1. Perform the Electrical Lockout/Tagout

procedure, found on page 18 of this manual.

2. Perform the Gas Lockout/Tagout procedure,

found on page 19 of this manual.

3. Perform the External Right Side Panel Removal

procedure.

4. Tag and disconnect wires from the main gas

valve (Figure 51).

Oven Temperature

at 550° F

Figure 50: Over-Temperature Switch

Lang A Division of S tar Mfg. Int'l Inc.

Figure 51: Main Gas Solenoid

SM-33

Page 34

Service Manual for Enviro-Star GCSF-ES

5. Loosen two gas line fittings.

6. Remove two screws securing the gas valve

bracket to the oven housing.

Manual Gas Valve Replacement

WARNING

7. While supporting the gas valve, disconnect the

two gas lines and remove the valve from the

oven.

8. Remove the gas valve bracket from the old valve

and secure it to the new one.

9. Insert two gas lines into the new gas valve.

10. Position the gas valve bracket on the oven

housing and secure with two screws.

11. Tighten two gas line fittings.

12. Using tags created during removal, connect

wires to the gas valve solenoids.

WARNING

ALL GAS JOINTS DISTURBED DURING

SERVICING MUST BE CHECKED FOR LEAKS.

DO NOT USE AN OPEN FLAME. USE A SOAP

AND WATER SOLUTION AND CHECK FOR

BUBBLES, WHICH INDICATE A GAS LEAK.

13. Turn the external gas line valve ON and perform

the Gas Leak Test at the input side of the new

gas valve.

14. Turn the electric supply ON and press the

POWER button ON to ensure the oven is

operational.

15. Increase the oven temperature until the gas

valve opens and the burner ignites.

16. Perform the Gas Leak Test at all visible gas

connections.

17. Press the front panel POWER button OFF.

18. To install all previously removed parts, reverse

the above steps.

PERFORM THE ELECTRICAL

LOCKOUT/TAGOUT

PROCEDURE.

WARNING

PERFORM THE GAS

LOCKOUT/TAGOUT

PROCEDURE.

WARNING

ALL GAS JOINTS DISTURBED DURING

SERVICING MUST BE CHECKED FOR LEAKS.

DO NOT USE AN OPEN FLAME. USE A SOAP

AND WATER SOLUTION AND CHECK FOR

BUBBLES, WHICH INDICATE A GAS LEAK.

1. Perform the Electrical Lockout/Tagout

procedure, found on page 18 of this manual.

2. Perform the Gas Lockout/Tagout procedure,

found on page 19 of this manual.

3. Turn OFF the electric supply to the oven.

4. Perform the Right Side Panel Removal

procedure.

5. Remove the handle from the gas valve

(Figure 52).

6. Loosen two gas line fittings on the manual

gas valve.

7. Cut tie-straps (Figure 52) securing the manual

gas valve to the backup control bracket.

8. Disconnect two gas lines and remove the valve

from the oven.

9. Remove the handle from the new manual gas

valve.

SM-34

10. Position the new gas valve through the backup

control bracket and attach the handle.

11. Install two gas lines into the valve and tighten