Page 1

1

Page 2

TABLE OF CONTENTS

CHAPTER PAGE

1. TABLE OF CONTENTS .........................................................................2

2. GENERAL INFORMATION....................................................................3

3. WORKING PRINCIPLE..........................................................................8

4. INSTALLATION...................................................................................... 12

5. OPERATION..........................................................................................33

6. MAINTENANCE & CLEANING............................................................... 48

7. TROUBLESHOOTING ........................................................................... 53

8. TECHNICAL DATA ................................................................................60

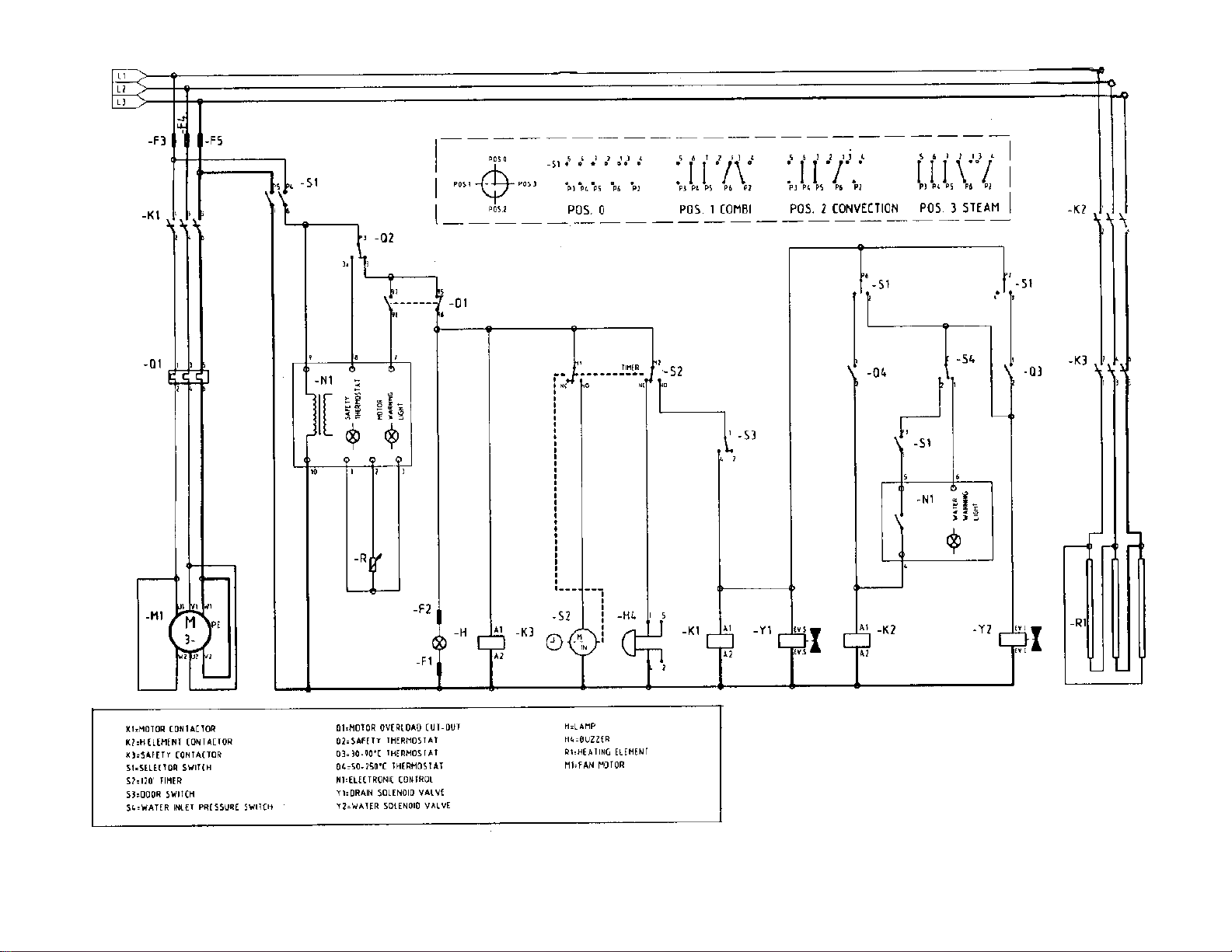

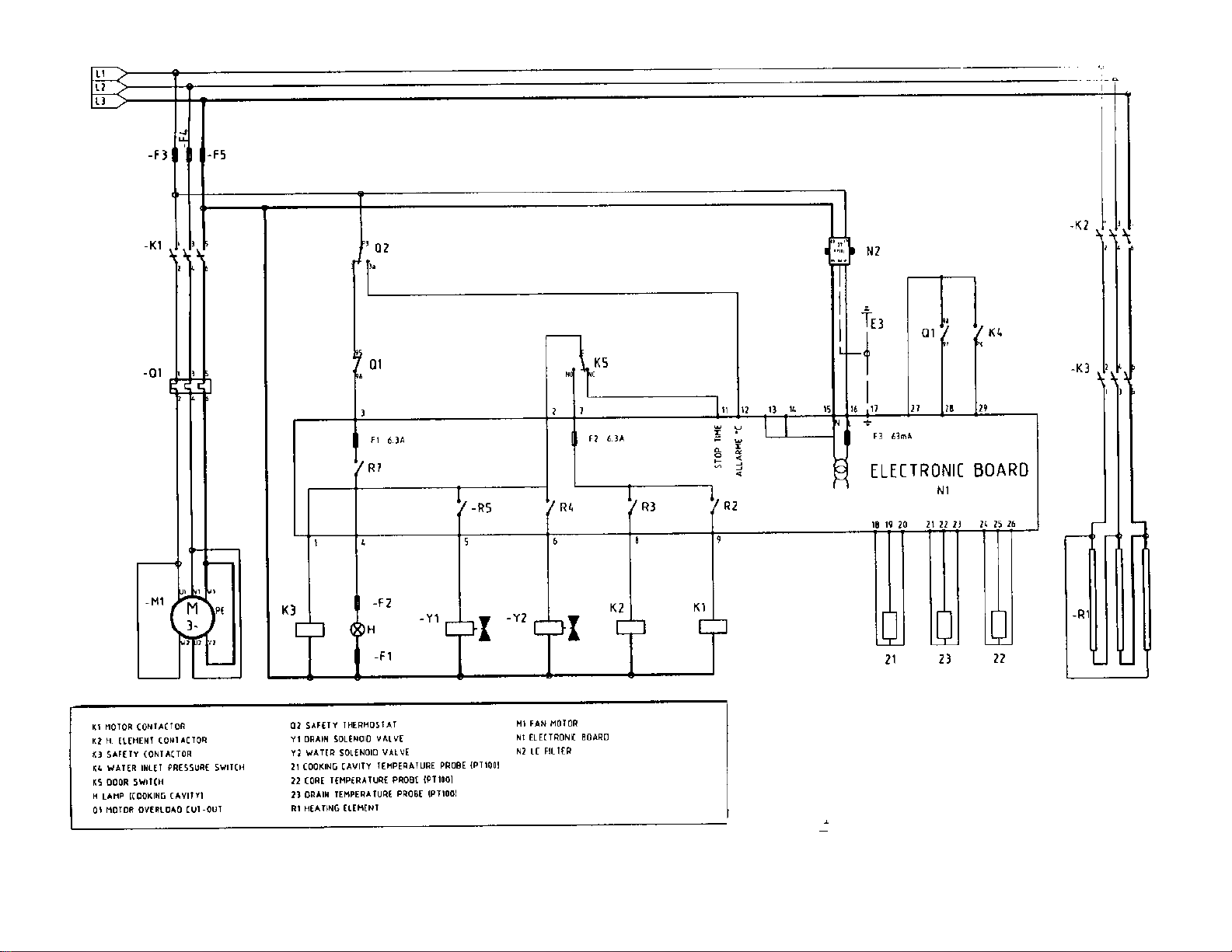

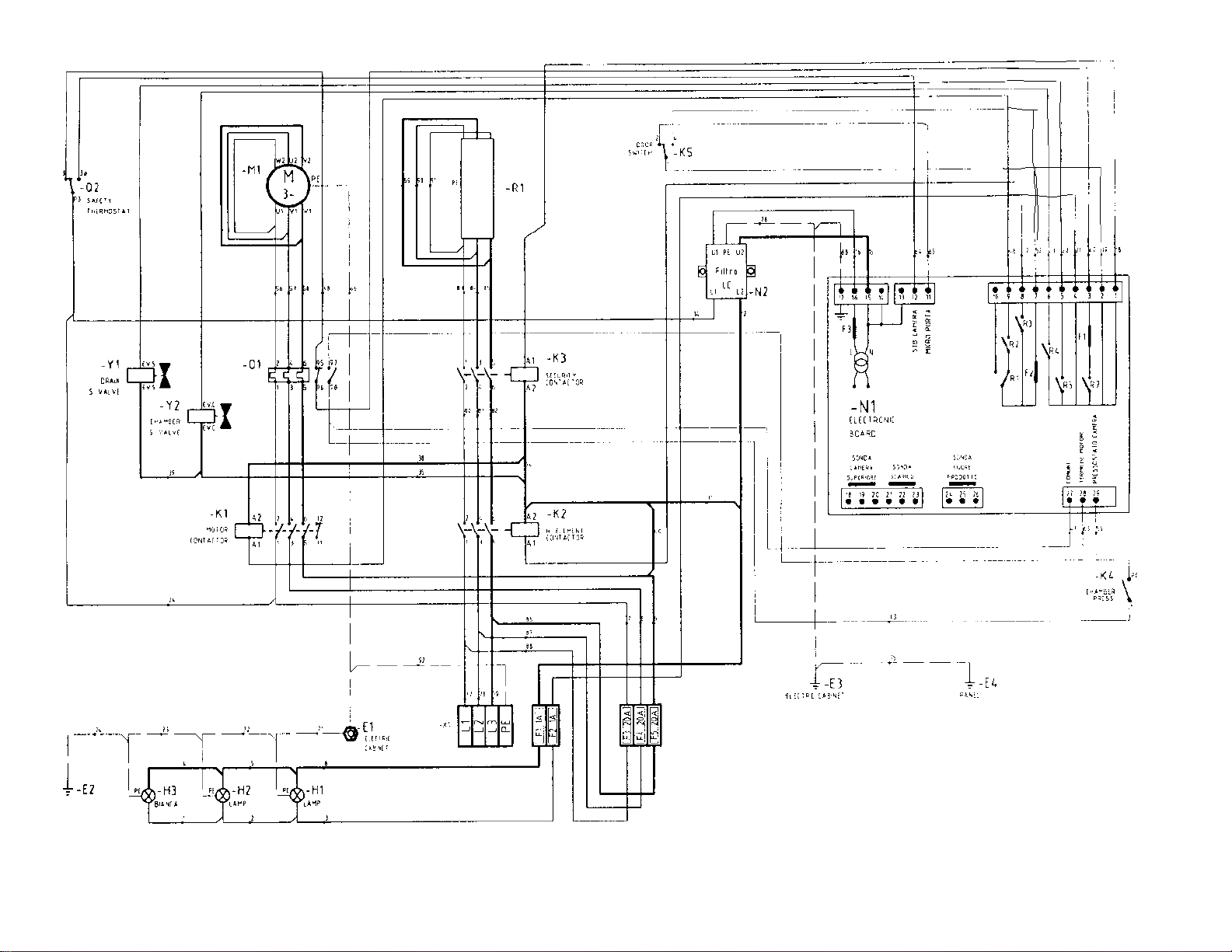

9. ELECTRIC WIRING DIAGRAMS ........................................................... 74

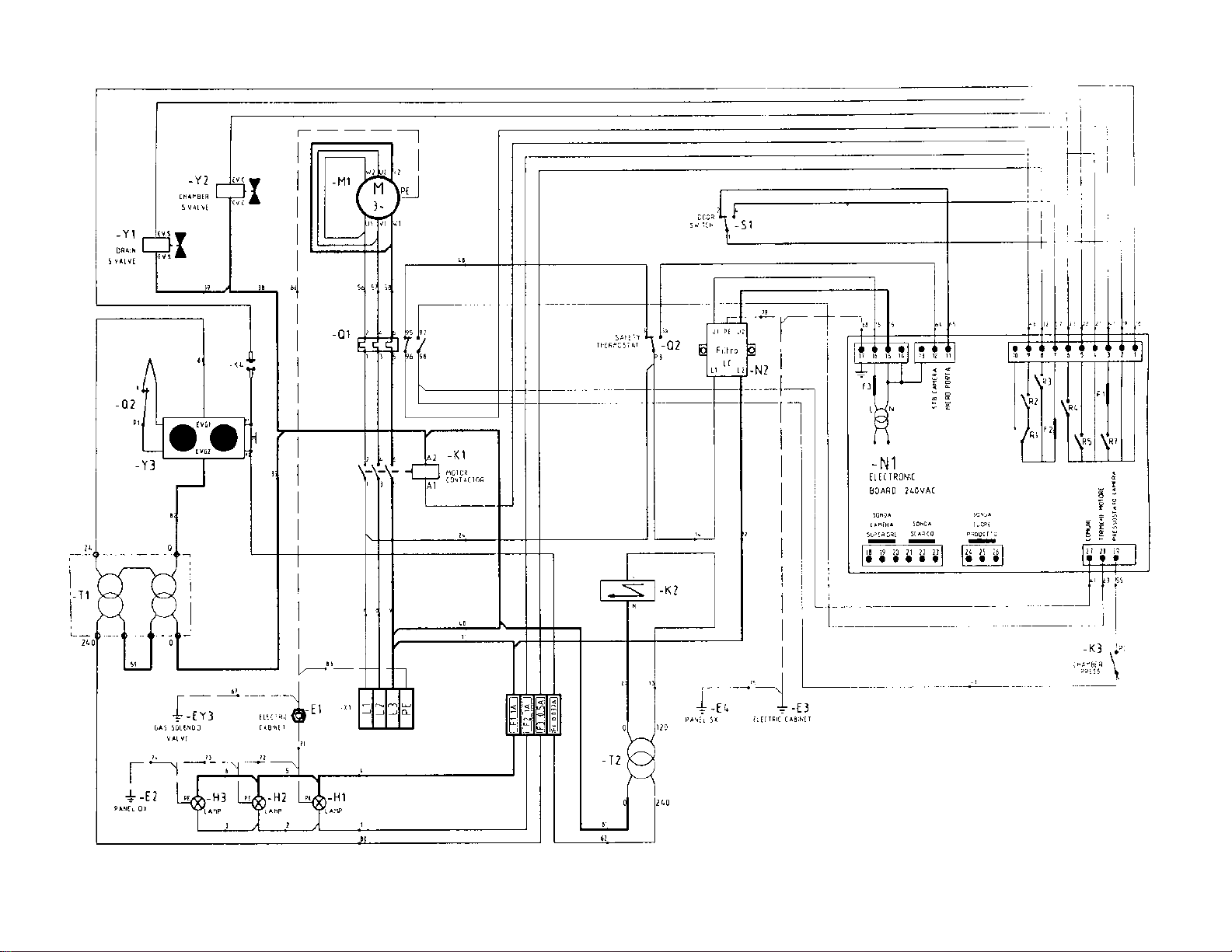

10. GAS WIRING DIAGRAMS .................................................................... 93

2

Page 3

GENERAL INFORMATION

Description and Use

Steam Cooking

Advantages to using the Steam Mode:

! No waiting time, steam is immediately generated

! Steam Temperature of 218°F

! Saturated Steam

! Steam while cooking reduces cooking times and energy consumption

! Hea t transfer is 10 times more efficient than boiling water

! Vitamins, Proteins, Minerals, Flavors, and Juices are retained in the food

! Different product flavors do not mix while cooking (i.e. fish, meat, and

vegetables)

! Food shrinkage is minimal

The Combi-ovens with mechanical controls have a circuit board that sets the

temperature to 218°F.

The Combi-ovens with digital controls have a circuit board that can adjust the

temperature from 86°F to 218°F.

Hot Air Convection Cooking

The Hot Air Convection Mode uniformly blows hot air in the slightly

overpressurized cavity. This mode will provide the best ro asting, baking and

browning.

! Meat and poultry pores are immediately closed and their natural juices are

retained

! Hot air does not escape because the unit is watertight

! The insulation of the oven cavity maintains the latent heat longer

! Th is mode can grill, broil and prepare everything that was previously prepared

in pans and stockpots

! Due to the design of the oven cavity and the placement of the fan, grease

does not build up inside the double glazed door

3

Page 4

Low Temperature Steaming

Digital Models Mechanical Models

Combi Mode

Steam Percentage

Low Temperature Steaming is controlled by the circuit board on the digital

models. On the Mechanical models low temperature steaming is obtained by

selecting combi mode and setting the steam percentage.

This mode is for cooking delicate or temperature sensitive food, stuffing, eggs,

fish, as well as pre-cooked vacuum-packed products.

Advantages to Low Temperature Steaming:

! The taste of several foods can be enhanced by lowering the temperature

slightly

! Protein products (eggs, stuffing, fish, etc.) do not harden

! Meat and fish products get improved consistency and texture

! Shrinkage and weight loss is reduced

Combining Hot Air with Steam

Digital Models Mechanical Models

Combi Mode

Steam Percentage

Cooking Temperatures from 86°F to 482°F.

The Combi Mode combines hot air and steam together.

Advantages to the Combi Mode:

! Juicer Meat and Poultry, no foil on baked potatoes, stuffed vegetables, etc.

! Full control of the steam percentage in the oven cavity

! Reduced shrinkage and weight loss

! Reduced cooking times

4

Page 5

! Reduced energy consumption

! Reduced cooking temperatures

! Self basting of the food when directly placed on the racks

! Healthier quality of cooked products

Re-heating (Digital Models Only)

Re-heating Mode

Half Speed Fan Control

Steam Percentage

Cooking temperatures from 284°F to 338°F

The Re-heating Mode uses a limited range of temperatures to help when reheating pre-cooked and chilled food.

! The reduced range of temperatures allows you to re-heat little to large

quantities of pre-cooked and chilled food

! You can avoid dried food by using the different percentage levels during the

re-heat process

! Maintains the original color, flavor, and taste as when originally cooked

High Temperature Steam Cooking

Cooking temperatures from 230°F to 257°F

The High Temperature Steam Mode is standard on Digital Models only.

Advantages to the high temperature steam mode:

! No waiting time, steam is immediately generated

! Pressureless high temperature saturated steam

! Steam while cooking reduces cooking times and energy consumption

! Hea t transfer is 20 times more efficient than boiling water

! Vitamins, Proteins, Minerals, Flavors, and Juices are retained in the food

5

Page 6

! Different product flavors do not mix while cooking (i.e. fish, meat, and

vegetables)

! Food shrinkage is minimal

Combi-ovens with mechanical controls and get high temperature steam by

selecting the Combi Mode at temperatures between 230°F and 257°F and the

maximum steam percentage.

+

Cooking with Low Speed Fan Control

The Low Speed Fan Control is standard on the Digital Programmable models

only.

It can be set in the Combi Mode, Hot Air Convection Mode, and the Re-heating

Mode.

The Hold mode automatically uses the low speed fan.

This mode is usually used for pastries, brea d and other deli cate products.

6

Page 7

Core Probe Cooking Control

Temperature Control up to 210°F

The Core Probe Control is standard on the digital models only.

Core Probe Control advantages:

! It automatically shuts off the cooking process as soon as the core probe set

temperature has been reached

! Cooking times are not required, products come out exactly the same every

time

! Products can be cooked to rare, medium or well done to perfection

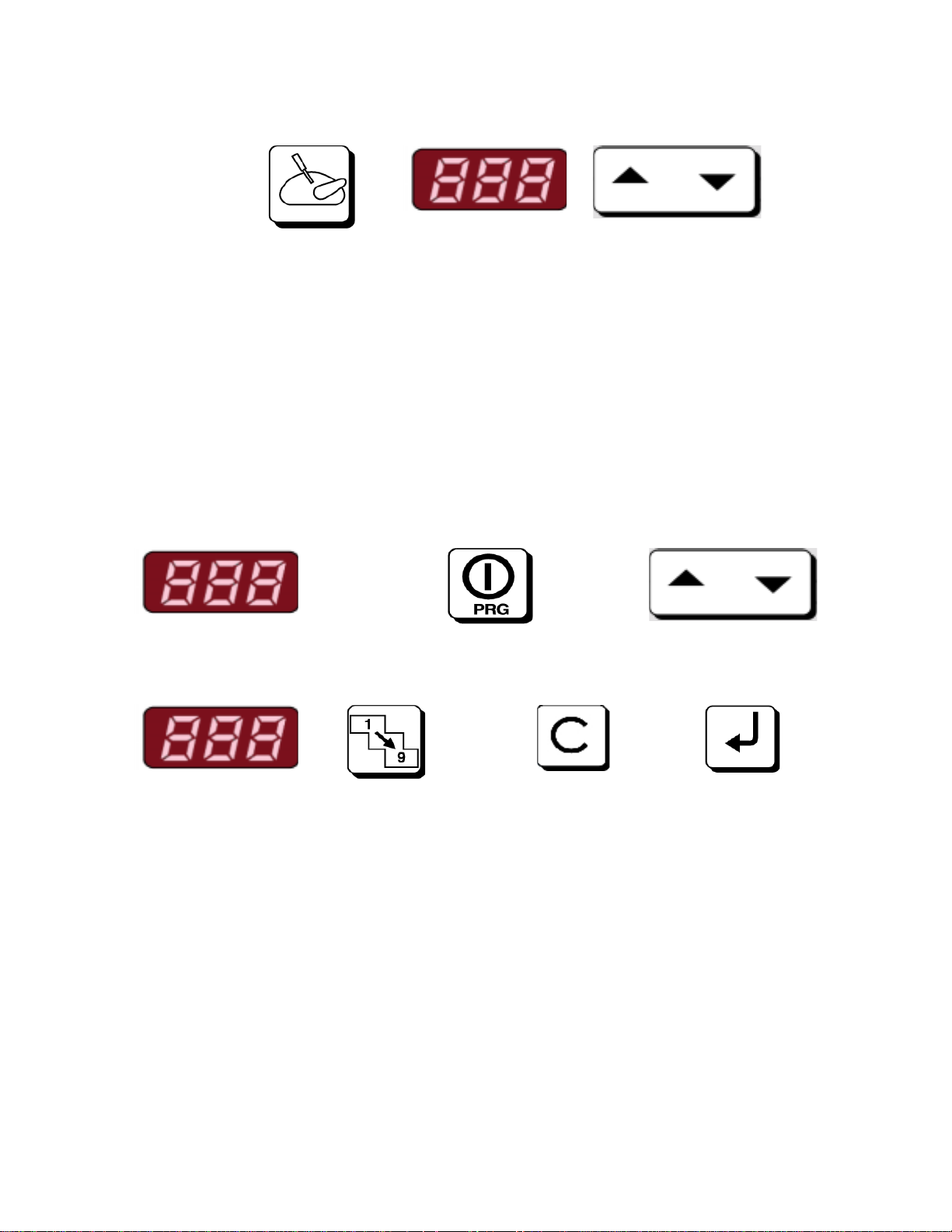

Program Mode

Program Display Program Section On/Off Program Number

Cooking Step Cooking Steps Step / Program Enter / Confirm

Display Cancel (Store)

The Program Mode is standard on the Digital Programmable models only. This

mode allows the user to store up to 99 recipes with up to 9 steps for each

program.

7

Page 8

BOILER SYSTEM LIMITS

! High energy consumption

! Long waiting time to get steam

! Steam generator scale buildup

! High maintenance costs

WORKING PRINCIPLE

8

Page 9

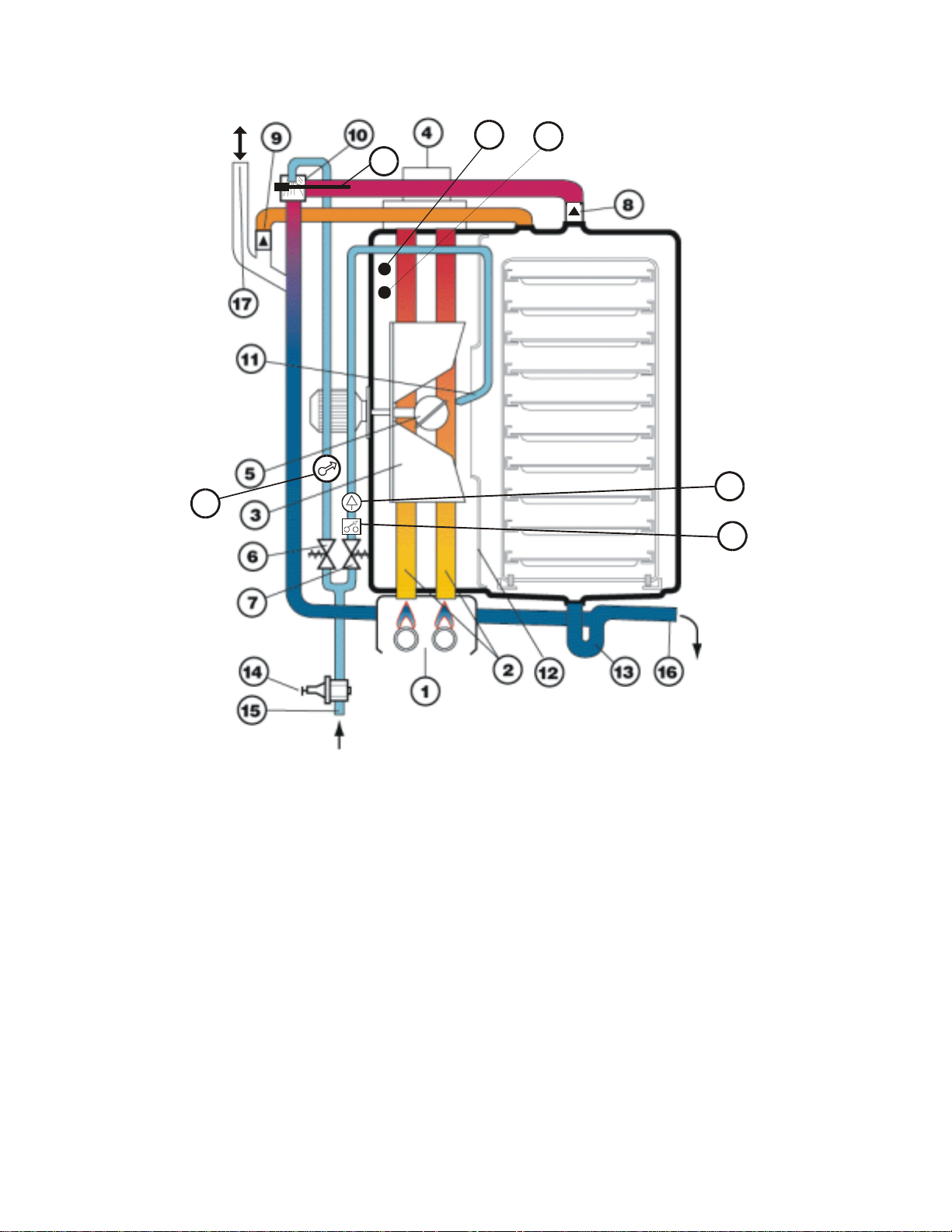

18

21

22

23

19

20

1 Burner 13 Drain Trap

2 Heat Element / Exchanger 14 Pressure reducing valve

3 Fan 15 Water inlet

4 Flue 16 Water Drain

5 Atomizer 17 Steam / Vent Outlet

6 Cooling Water Solenoid Valve 18 Water Pressure Gauge

7 Humidifier Solenoid Valve 19 Water Calibrated Injector

8 Overpressure Valve 20 Pressure Switch

9 Underpressure Valve 21 Drain Temp. Detecting Probe

10 Cooling Nozzle 22 Temp. Controlling Probe

11 Injection Pipe 23 Safety Thermostat Probe

12 Baffle

9

Page 10

HOW THE LANG COMBI WORKS

In the Lang Combi water is introduced directly into the cooking chamber where it

is atomized on the heat exchanger (2)/heating elements, then immediately

transformed into steam.

In gas models the heating of the cooking chamber is done through the heat

exchanger (2) which is heated by the bottom burners (1).

In the electric models the heating of the cooking chamber is done through the

elements.

The fan (3) is located between the heat exchanger tubes (2) or in the center of

the heating elements. Its function is to increase heat exchange with the air in the

cooking chamber for increased cooking uniformity. The air is drawn from the

center and blown to the sides of the baffle (12) passing through either the heat

exchanger or the elements.

The diffuser (5) is located in the center of the fan (3). Its purpose is to atomize

the water falling on it. Then the fan blows the mist into the heat exchanger or

elements for immediate steam.

The cooking is separated from the heat exchanging area by the baffle (12). The

correct rotation direction of the fan is stamped into the baffle. The baffle is easy

to open for easy cleaning and access.

The cooking chamber and all inner components are made of stainless steel (fan

(3), baffle (12), diffuser (5), etc.).

To obtain the best cooking results, our oven used dry overheated steam. This is

possible by maintaining a slight overpressure in the cooking chamber and a

temperature of more than 212°F.

In steam mode the working temperature of the oven is fixed at 217°F for

mechanical models and is vari abl e from 86°F to 217°F for electronic models,

while the cooking chamber pressure is controlled to 0.05 psi.

The slight overpressure is guaranteed by a sealed door and an overpressure

valve (8) located on the ceiling of the cooking chamber. The overpressure valve

is a simple counterweight to let steam escape when the inside pressure exceeds

0.05 psi.

On all models, the temperature in the steam mode is electronically controlled for

a minimum accuracy of +/- ?°F.

When the internal temperature is hot and a cold product is placed inside or cold

water is injected (11) to create steam, a depression takes place inside the

10

Page 11

cooking chamber. To avoid an implosion, there is another safety valve (9), which

works to restore the internal pressure.

The water system is connected to the atmosphere through the water drain trap

(13) and the upper pipe (17), which is fitted with a silencer. The drain connection

must be ventilated to guarantee a constant pressure inside the cooking chamber.

The drain trap system with the ventilation connection is considered a safety

system to prevent accidental explosion.

Only use cold water for the combi ovens for the following reasons:

! To produce steam through a calibrated injector (11)

! To keep the drain trap clear and permanently full to ensure chamber pressure

! To condensate the steam by means of a wide angle cooling injector (10) so

that most of the escaping steam will be transformed into water and the food

smell particles will be captured and transferre d to the drain system

! T o cool down the liquids in the drain system to reduce the possibility of

bacteria proliferation. The maximum temperature limit is 140°F.

The water inlet pressure has been factory set at 14.5 psi. There is a pressure

regulator (14), which can be adjusted if needed. The quantity of water converted

into steam is determined by the pressure and the size of the injector (19).

When working in steam/super steam modes:

If the pressure is set too high, we can achieve an excessive wet condition where

it will be hard to reach the temperature of 217°F inside the cooking chamber. If

the pressure is set too low, we cannot achieve a saturated steam condition.

The pressure regulator (14) precedes two solenoid valves (6) and (7).

A pressure switch (20) just following the solenoid valve (7) is set at 5.8 psi, when

the inlet water pressure jumps under this value:

! The unit will stop working and the led alarm indicator will light when working in

steam/super steam modes

! An led/display alarm indication (E6 – for electronic models) when working in

combi mode

! An led/display alarm indication (E7 – for electronic programmable models)

when working in convection mode

11

Page 12

INSTALLATION

General Installation Instructions

Positioning

Keep the appliance area free and clear of combustible material and do not

obstruct the flow of combustion or ventilation air.

The installation of any components such as a vent hood, grease extractors,

and/or fire extinguisher systems, must conform to their applicable local/nationally

recognized installation standards.

Gas Connection

All gas connections must be in accordance with local codes and comply with the

National Fuel Gas Code ANSI Z223.1 latest edition, Natural Gas Installation

Code CAN/CGA – B149.1 or Propane Installation Code CAN/CGA – B149.2.

Connect each oven separately. A gas shut off valve must be installed to the

oven(s) and located in an accessible area.

This appliance and its individual s huto ff val v e must be discon nected from the gas

supply piping system during any pressure testing of that system at test pressures

in excess of 1/2 PSGI and the appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff valve during any pressure

testing of the gas supply system at test pressures equal to or less than 1/2 PSIG.

Test Gas

Always check the pressure of the gas supply. Test for gas leaks. Use a

commercial leak detector or a soapy and water solution.

OPEN FLAME TO TEST FOR GAS LEAKS.

Electrical Connection

The appliance must be electrically grounded in accordance with local codes, or in

the absence of local codes, with the National Electrical Code, ANSI/NFPS 70.

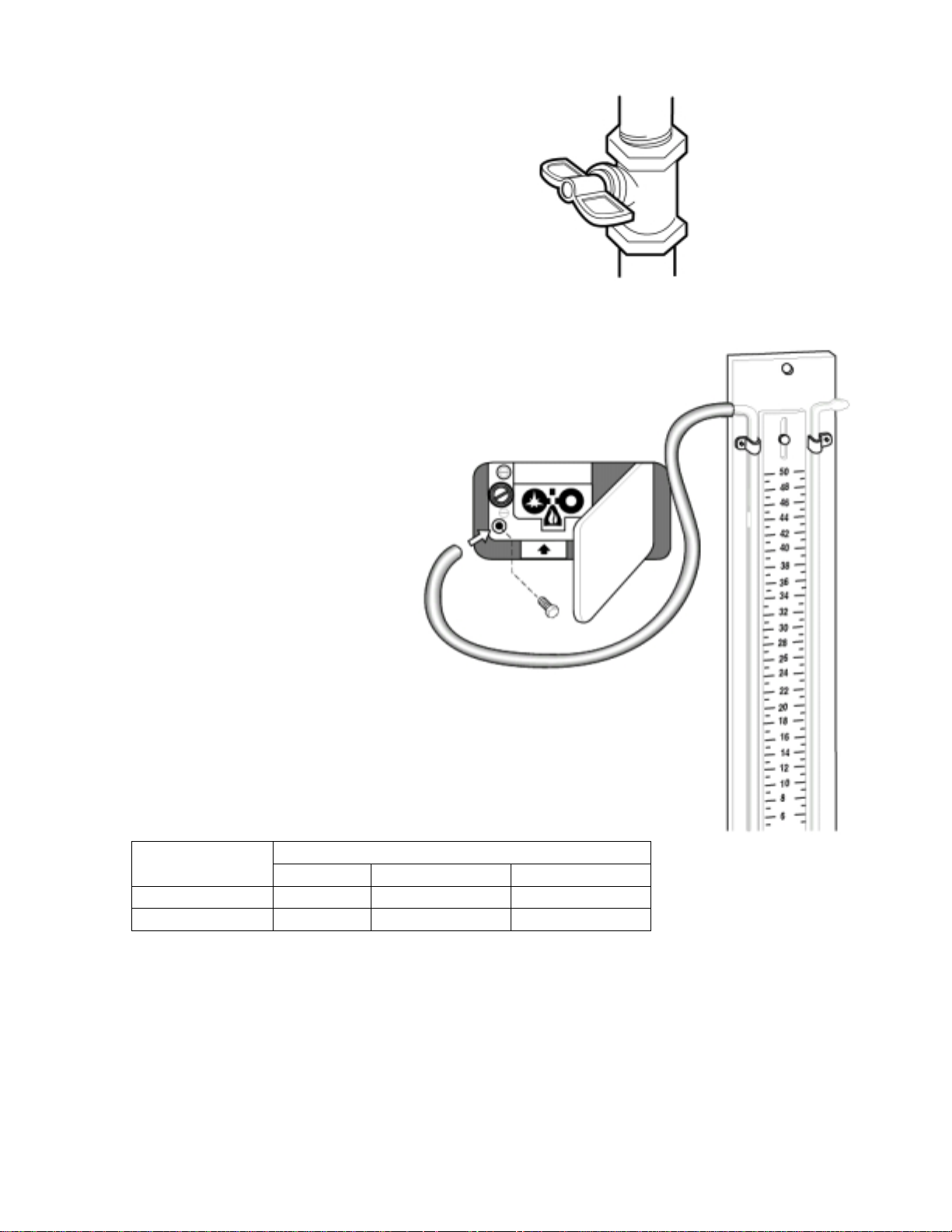

Water Connection

This appliance must be installed to comply with the applicable Federal, state, or

local plumbing codes having jurisdiction.

Always install a manual shut-off valve upstream of the appliance.

Downstream of the manual shut-off valve, install appropriate fittings for easy

disconnection of the appliance and filters which can easily be inspected and

cleaned.

Use Materials, seals and fittings approved according to applicable standards.

Use suitable pipes which been have properly treated in order to prevent the

release of iron oxides into the water (as these can alter the taste of the food and

mark stainless steel).

If necessary, install a suitable water treatment system.

DO NOT USE AN

12

Page 13

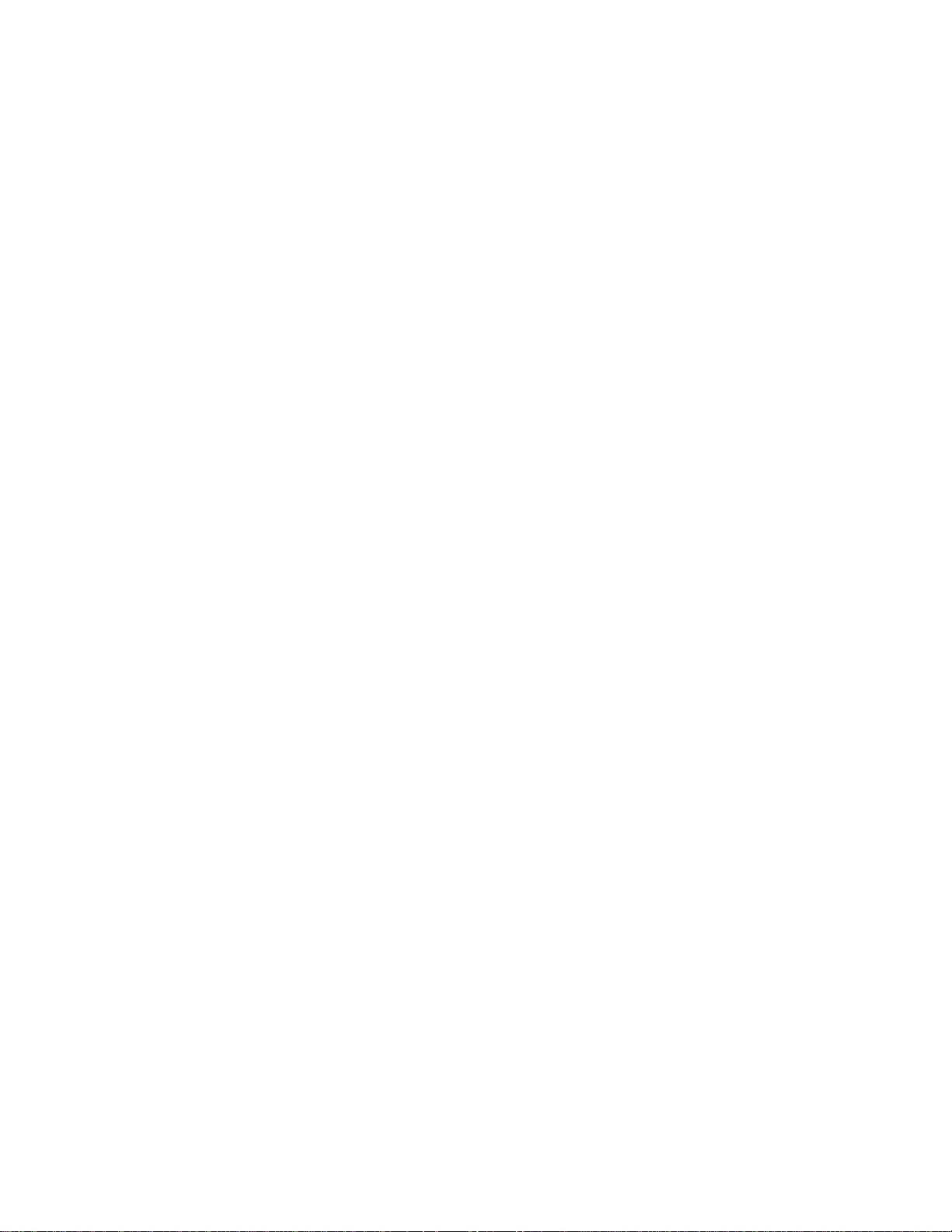

Connections

Gas inlet 3/4” NPT

Flue outlet *

Water inlet 3/4” NPT

Water drain 1 1/2”

”

Terminal Board 3 Ph

Cable gland

Ground Terminal

* The oven must be installed under a

ventilation hood only.

Not suitable for connections to type B

gas vent.

Positioning

Leave at least 4” clearance between

the rear of the appliance and the wall.

Leave at least 20” clearance at the

sides of the appliance.

9.5”

5.7”

”

22.8”

”

”

”

”

”

”

”

”

”

”

”

35”

2”

The cooling outlets of the control

section of the oven (side panel) must

not be near sources of hot fumes or

steam.

All clearance requirements are the same for combustible or noncombustible constructions. For use only on a non-combustible floor.

13

Page 14

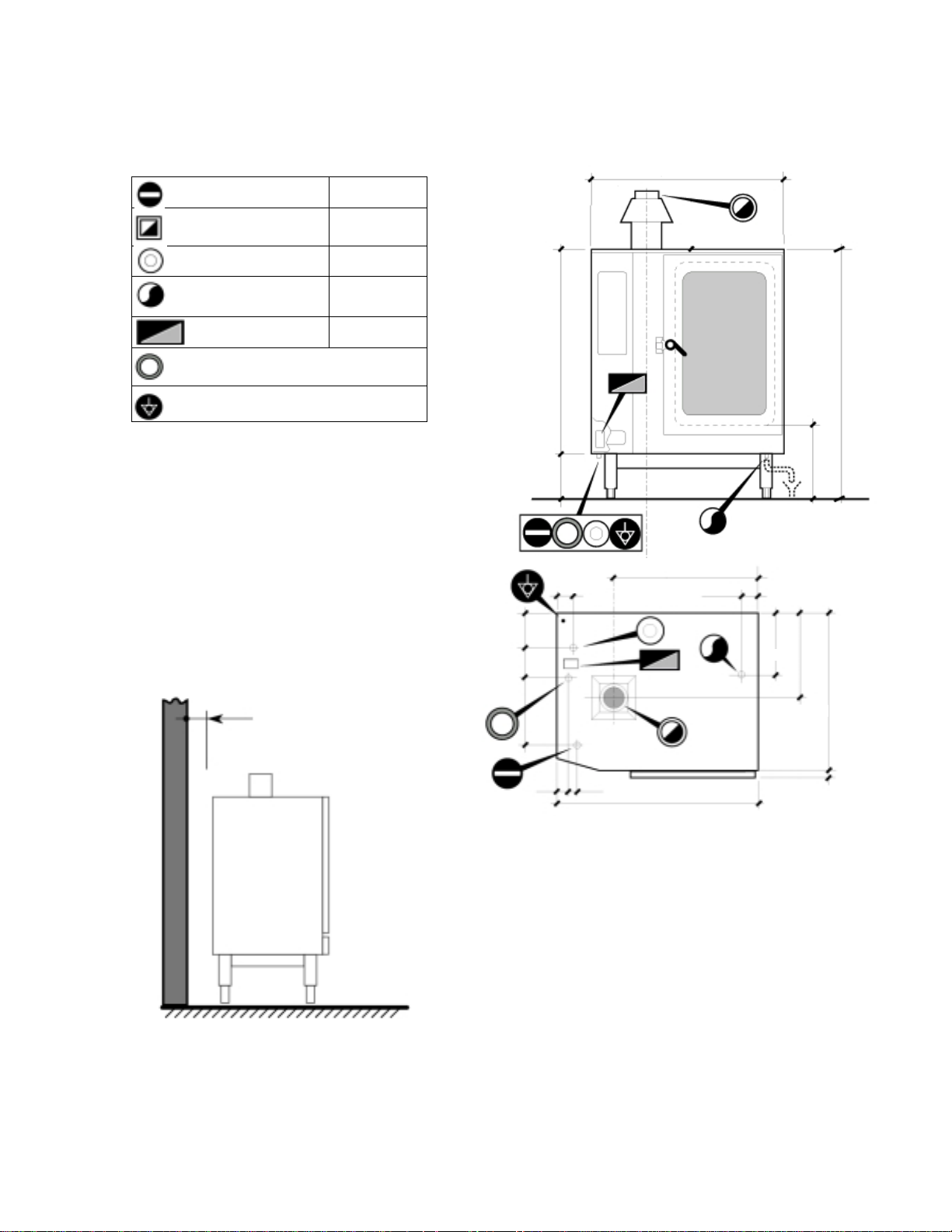

Installation

A

B

Fit the following parts

on the top of the oven:

1) Flue deflector

2) Steam vent

Water connection

3) Remove the left hand side

panel by unscrewing the two

1/4 turn screws at the bottom (if the optional

spray gun is fitted - also remove the support

screw).

4) Install the filter supplied with the unit in an

accessible position on the water inlet, as shown

in the examples below:

a) installation on TB610 frame (optional) or

other support not protruding beyond the

perimeter marked by the feet;

b) installation on other support of larger

dimensions.

The appliance must be supplied with

cold

water

Conforming to the following specifications:

Spray gun

support screw

Water

pressure

regulator

screw

Pressure

PH

: form 7 to 7.5

Conductivity

: between 40 – 80 psi

: less than 200 µS/cm

t.d.s. < 100 ppm

Hardness

Max. salinty and ion content in mg/l

: from 6.3 to 8.8 °e

:

Chlorides < 30, sulphates < 40, Fe (iron) < 0.1,

Cu (copper) < 0.05, Mn (manganese) < 0.05

The internal pressure gauge must show a pressure

of 15 psi, if it shows a different value, adjust to the

correct pressure using the regulator screw.

”

°

Water drain

CAUTION: to avoid the risk of

serious damage, the drain must be

vented

. The material of the drainage

pipe must be heat resistance type

and not flexible.

’

14

”

Page 15

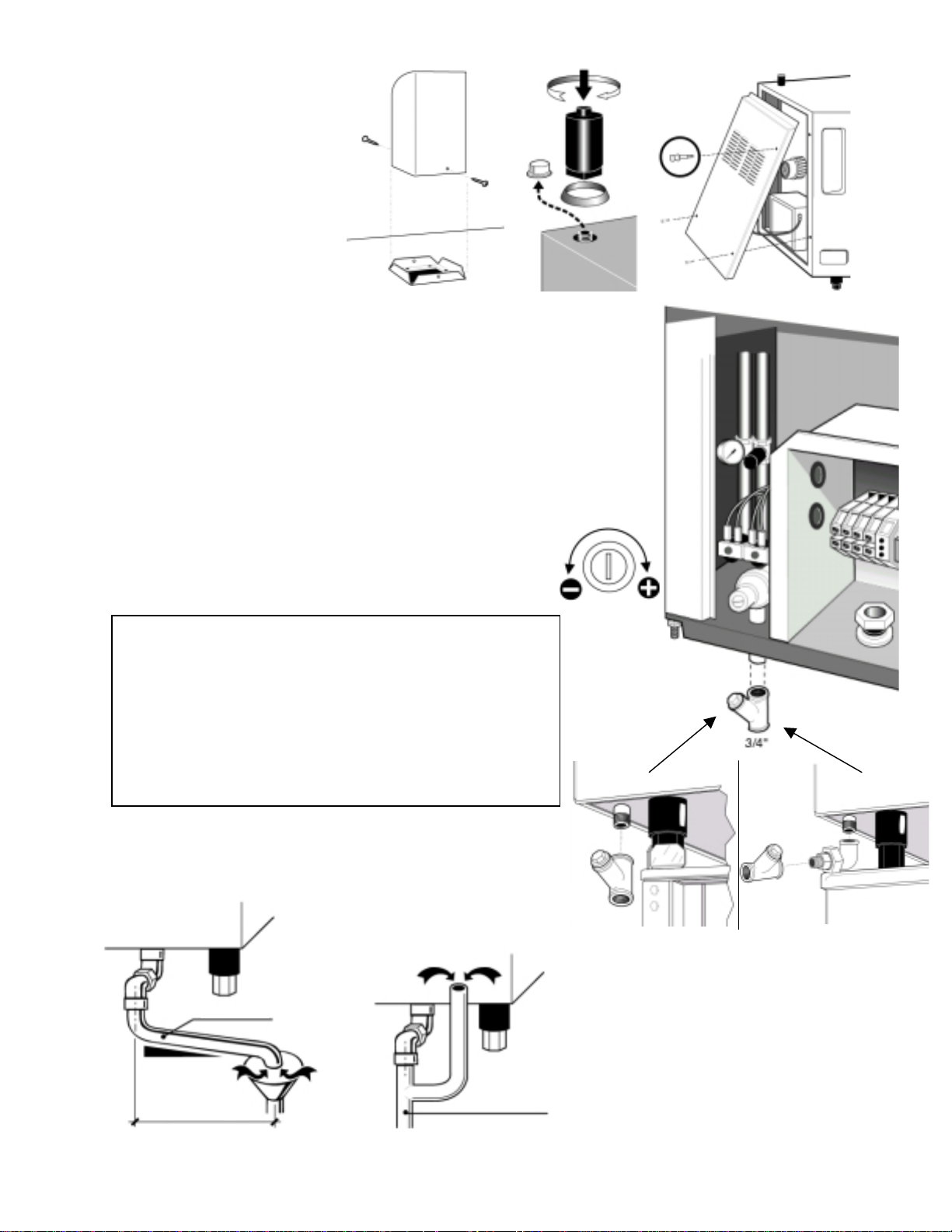

Electrical Connection

Ground Connection

The ground terminal is located

beneath the appliance at the rear

left hand corner.

Main Connection

Remove the left hand side panel.

Read the general precautionary

notes in the beginning of this

chapter.

Fit the suitable cable gland in the

relative hole.

Route the cable from the main

Power switch through the cable

gland, and connect the wires to the

terminal block.

Terminal block

Note: After making the electrical

connection, ensure the motor turns

in the direction indicated by the

arrow stamped in the baffle.

Cable gland

15

Page 16

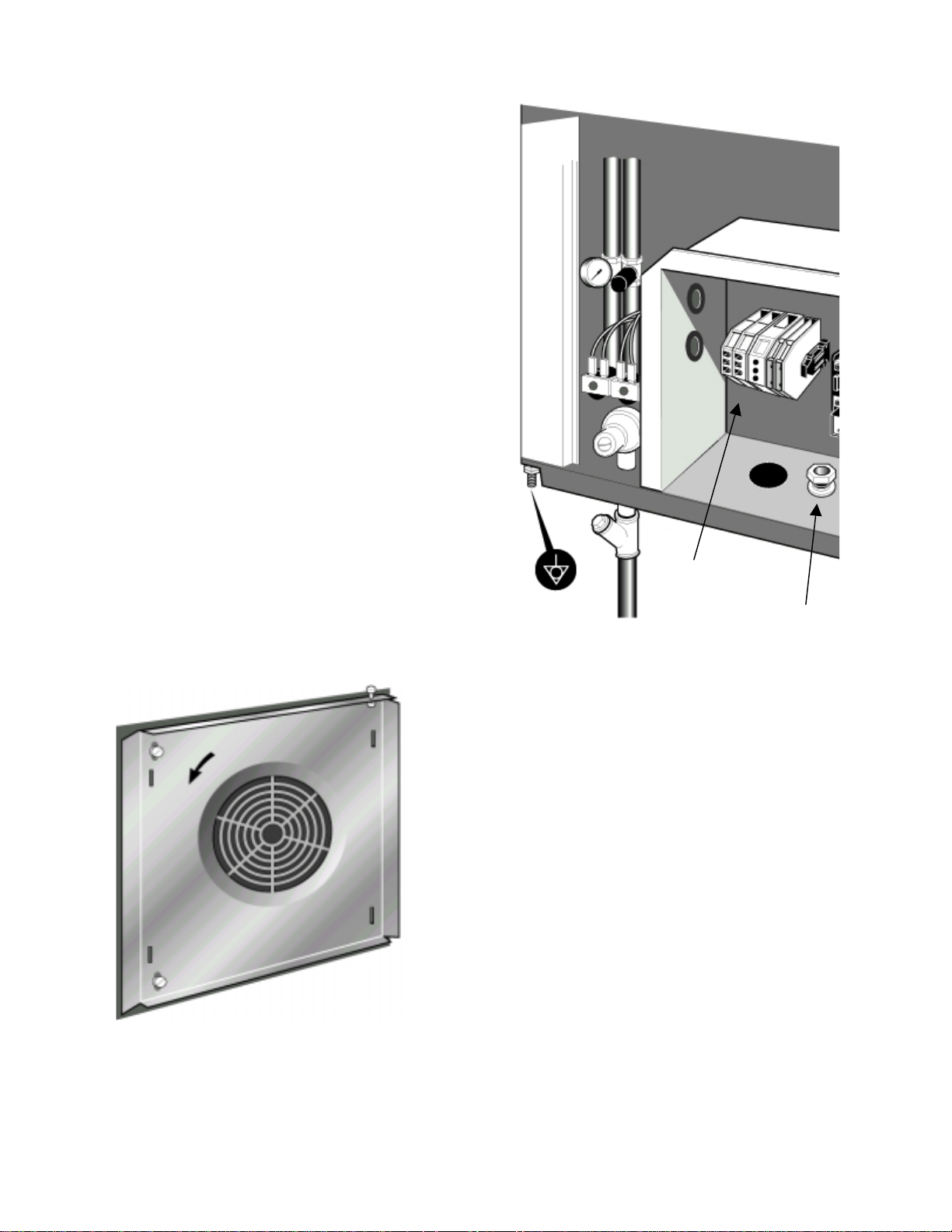

401 units only:

Refer to the water connection section earlier in this chapter. There are two

connections on the 401 models.

Condensation Drain

Connect a suitable tube to the fitting on the condensation tray and connect to the

drainpipe.

16

Page 17

Gas pressure check

Turn the main gas valve off.

Open the door in the bottom left corner

of the unit.

Remove the cap screw of the pressure test

point and connect a pressure gauge to the

outlet.

Open the main gas valve and turn on the appliance

to maximum capacity.

Make sure the pressure lies within the limits indicated

in the table below.

Gas Type

Pressure in inches of Water Column

Rated Minimum Maximum

Natural Gas 7” 4” 10”

Propane 11” 8” 13”

After checking the gas pressure, remove the pressure gauge and close the

pressure test point.

17

Page 18

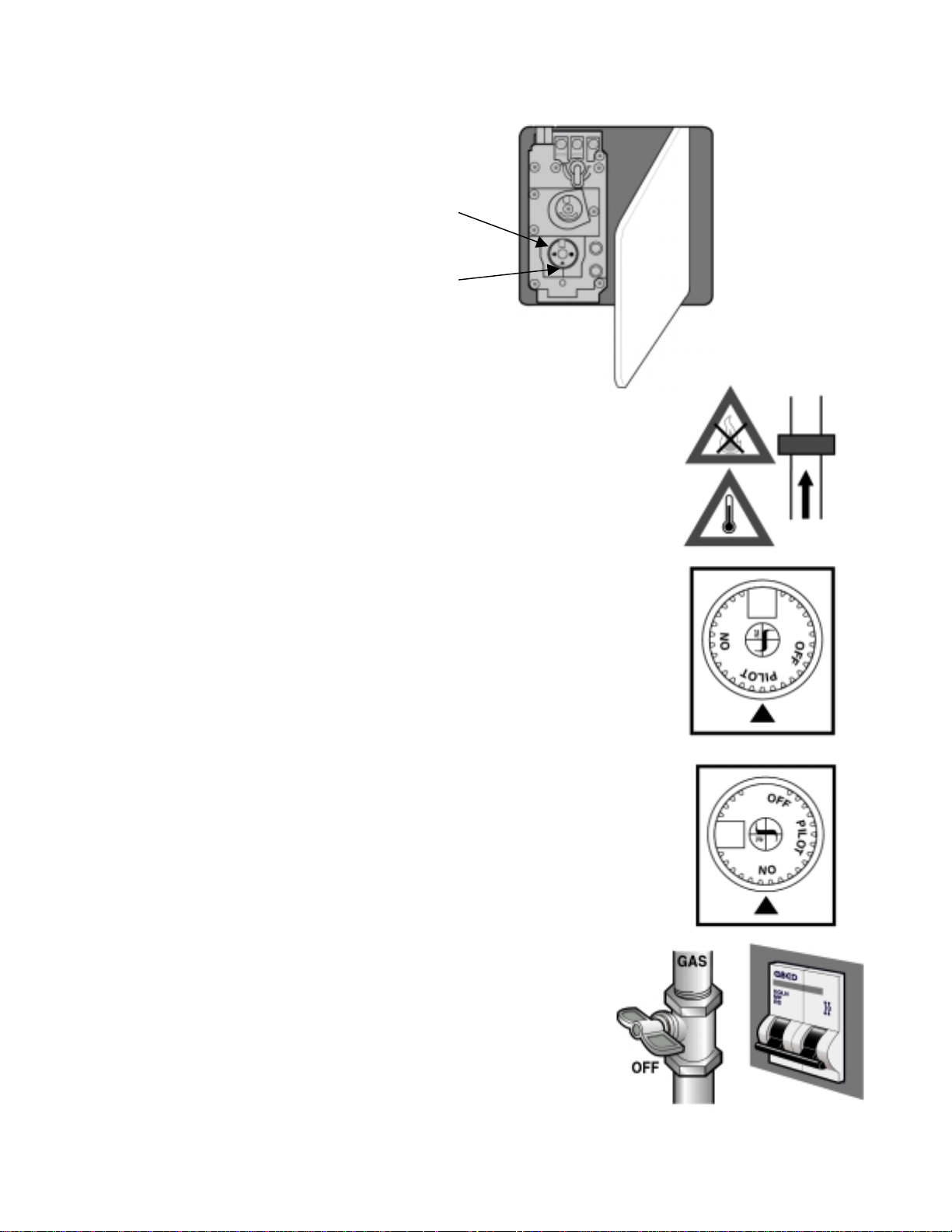

Starting the gas valve

Controls

Burner Control Knob

Reference Mark

Safety Devices

A thermocouple device locks the gas valve in case the flame is

extinguished. There is also a safety thermostat in case the

oven overheats.

Pilot flame ignition

Press the control knob and turn it to the PILOT position.

Press the knob for a few seconds and the flame will light.

Release the knob and check that the pilot flame stays on.

If it goes out wait 30 seconds and repeat instructions.

Main burner ignition

Press the control knob and turn it to the ON position.

The gas valve is now set for normal operation.

Stand-by position

To keep the burner on, with the main burner off, turn the

control knob to the PILOT position.

Turning off

Press and turn the control knob to the OFF position.

18

Page 19

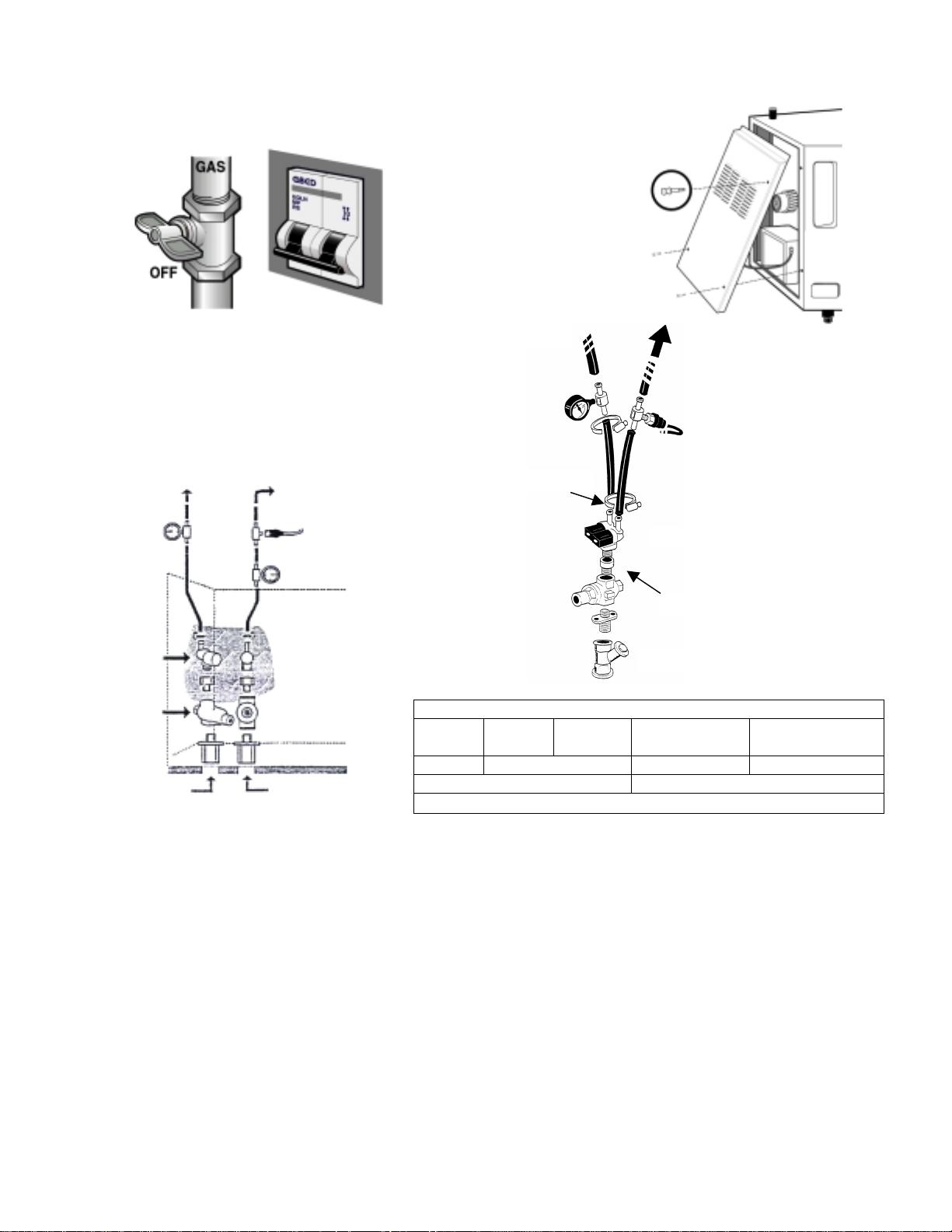

DOUBLE WATER FEED KIT

Close the gas and water supply

and cut out the main wall switch.

Remove the side Panel.

Drain

Oven Chamber

Drain

Non-Softened

Water Inlet

Oven Chamber

Bag

Hardnes

s

pH Cl < 150 mg/l SO4 < 400 mg/l Fe < 0.1 mg/l

Softened Water Inlet

Disconnect

Bag

Disconnect

Water Inlet

Water Specifications

°d

5 - 7

Mn < 0.05 mg/l Cu < 0.05 mg/l

°f

9 - 13

Conductivity < 200 µS/cm

°e

6.3 - 8.8

Softening system water consumption:

Maximum water consumption for steam is 4 gallons per hour.

Maximum water consumption for cleaning Spray Nozzle is 8 to 13 gallons per

hour.

Ppm

90 - 125

19

Page 20

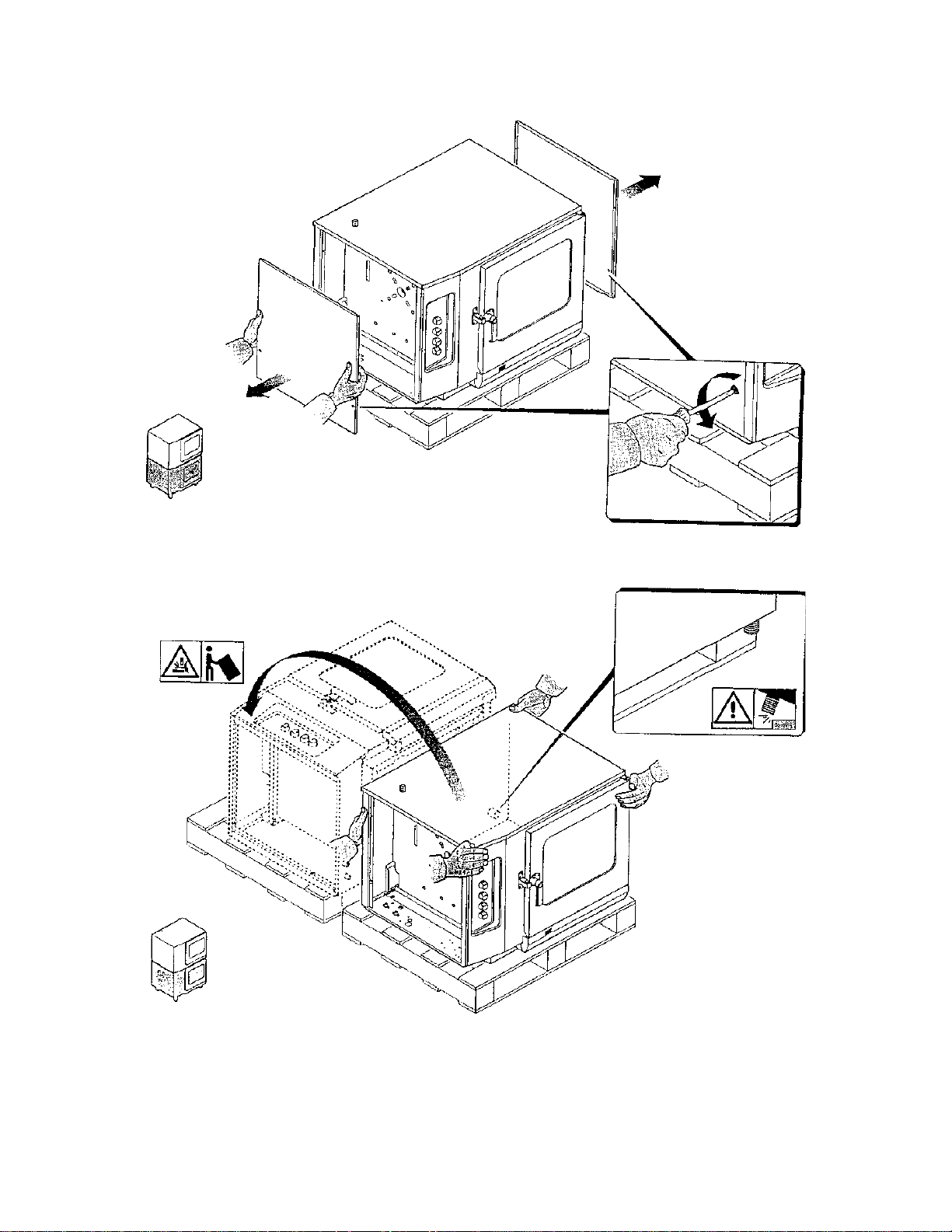

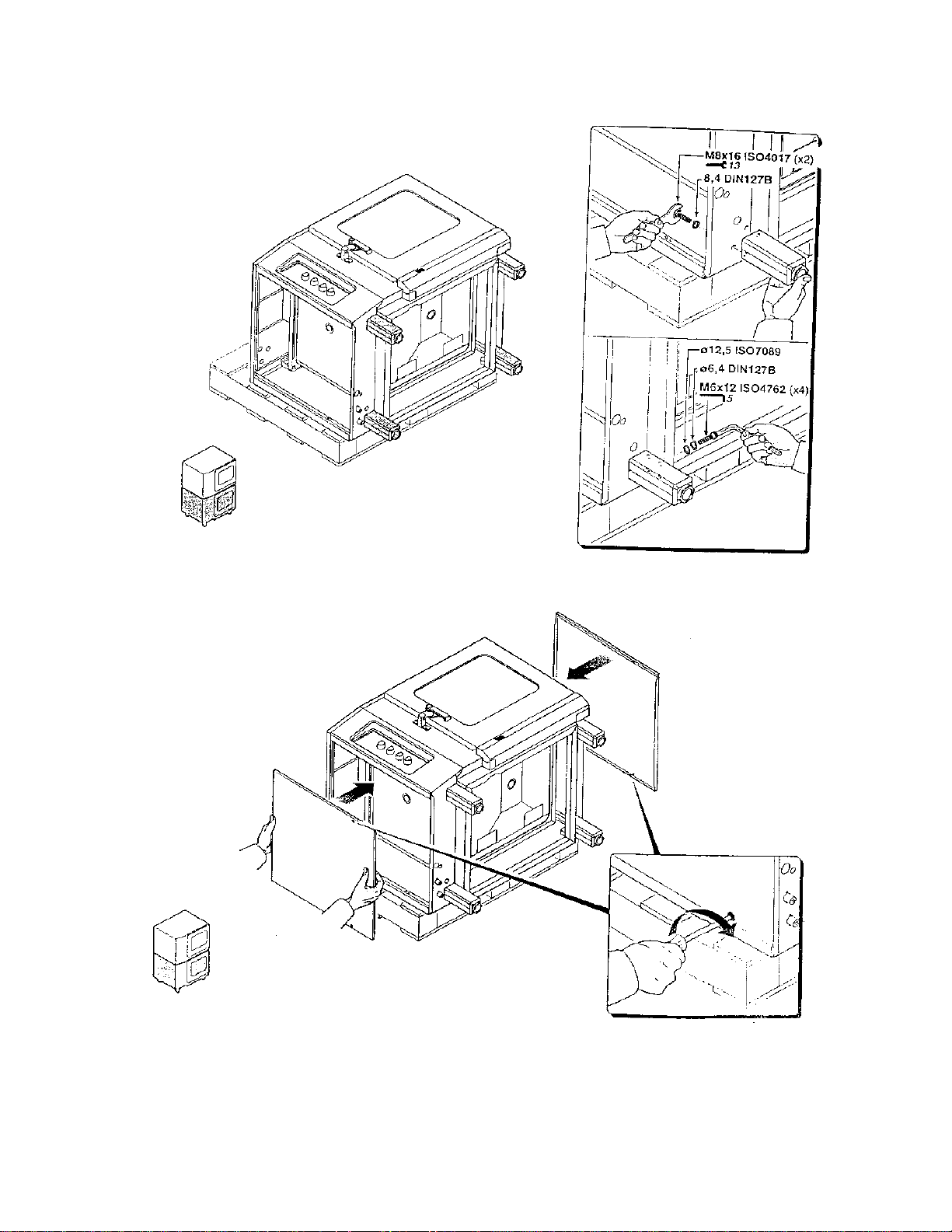

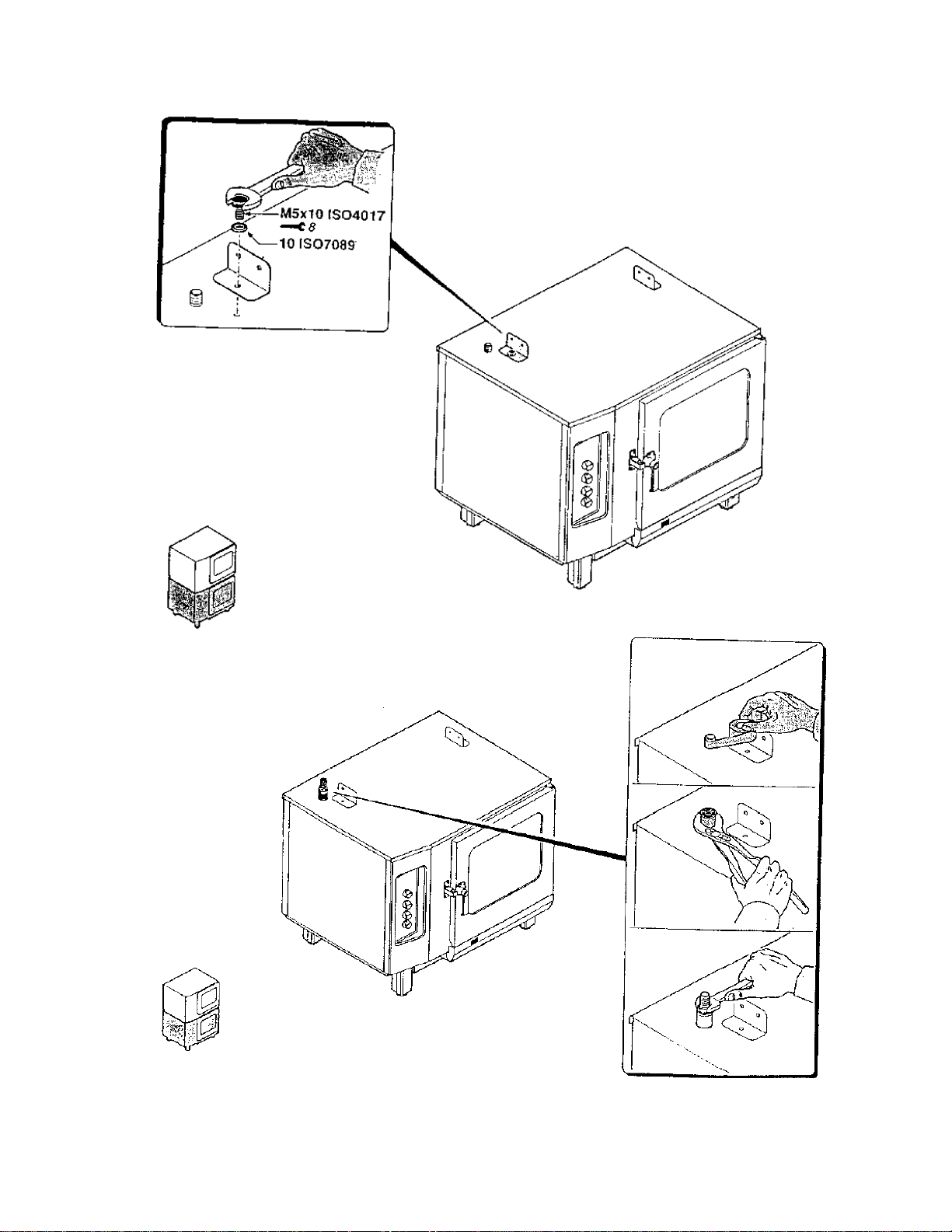

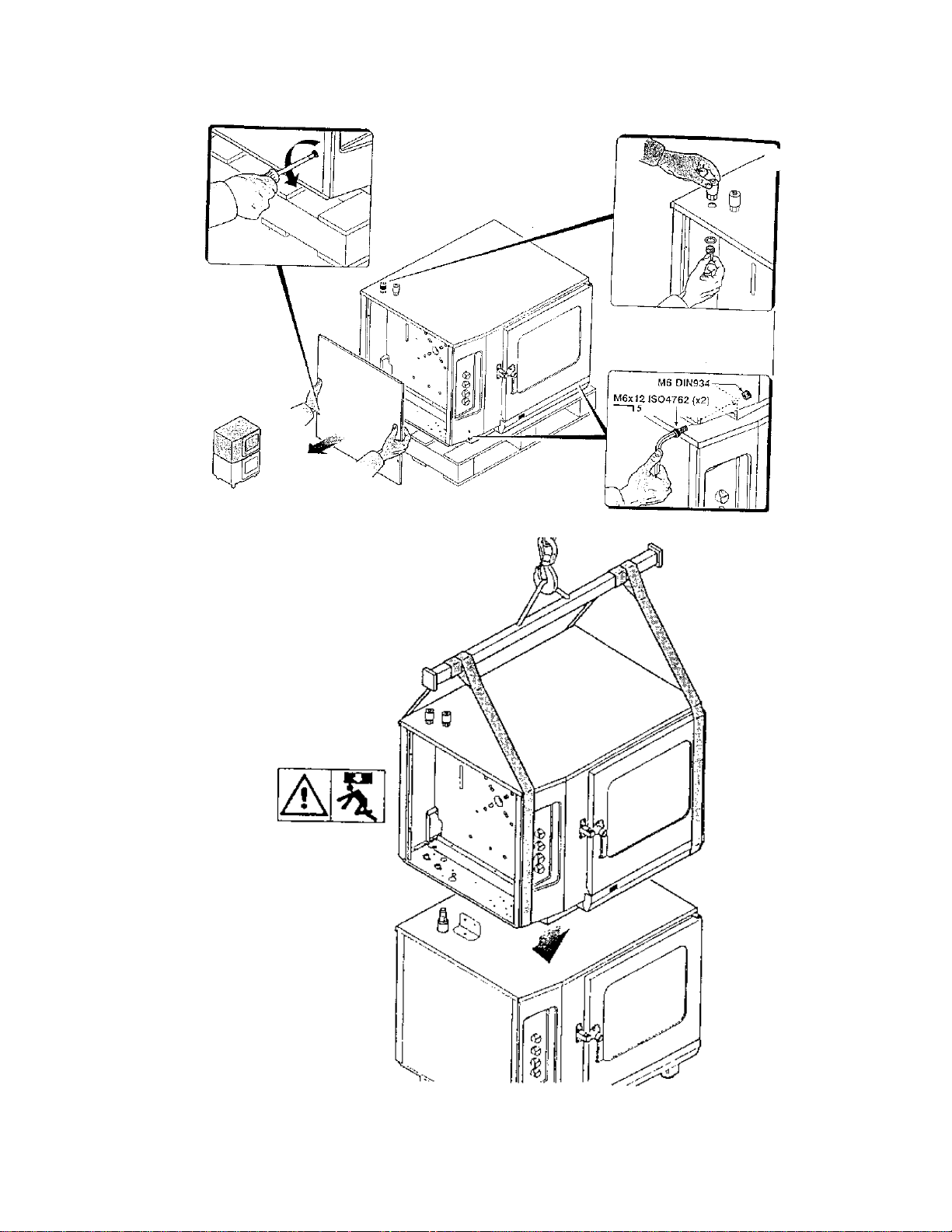

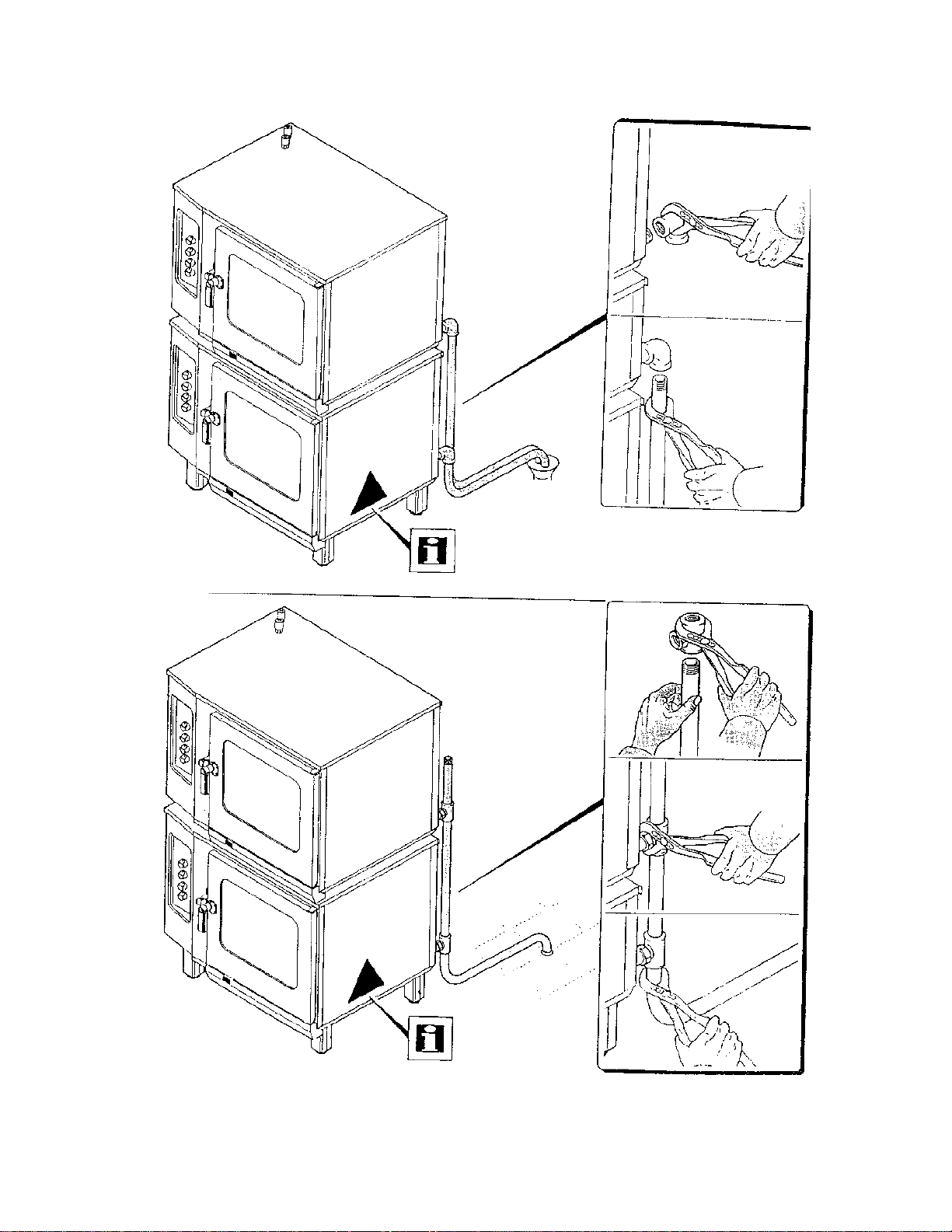

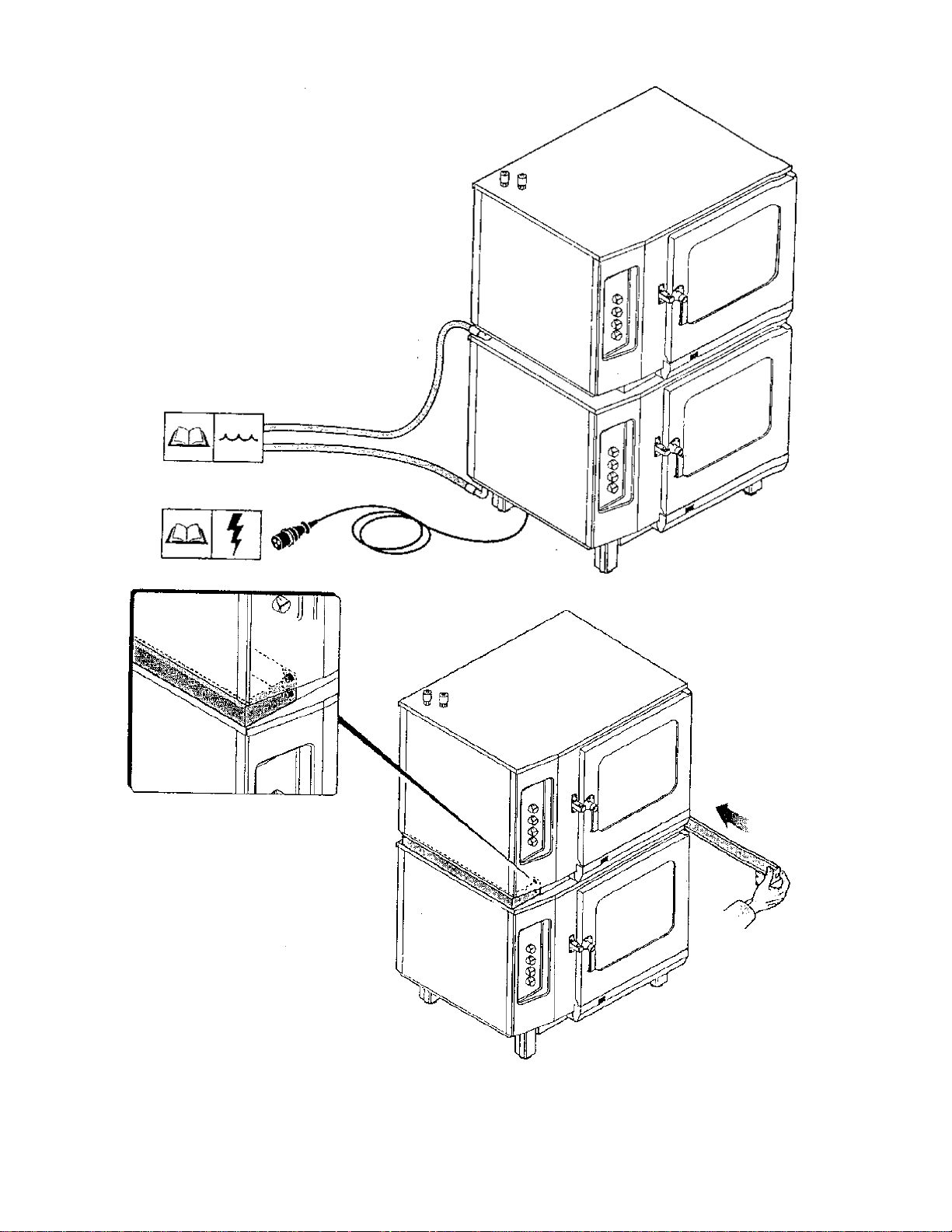

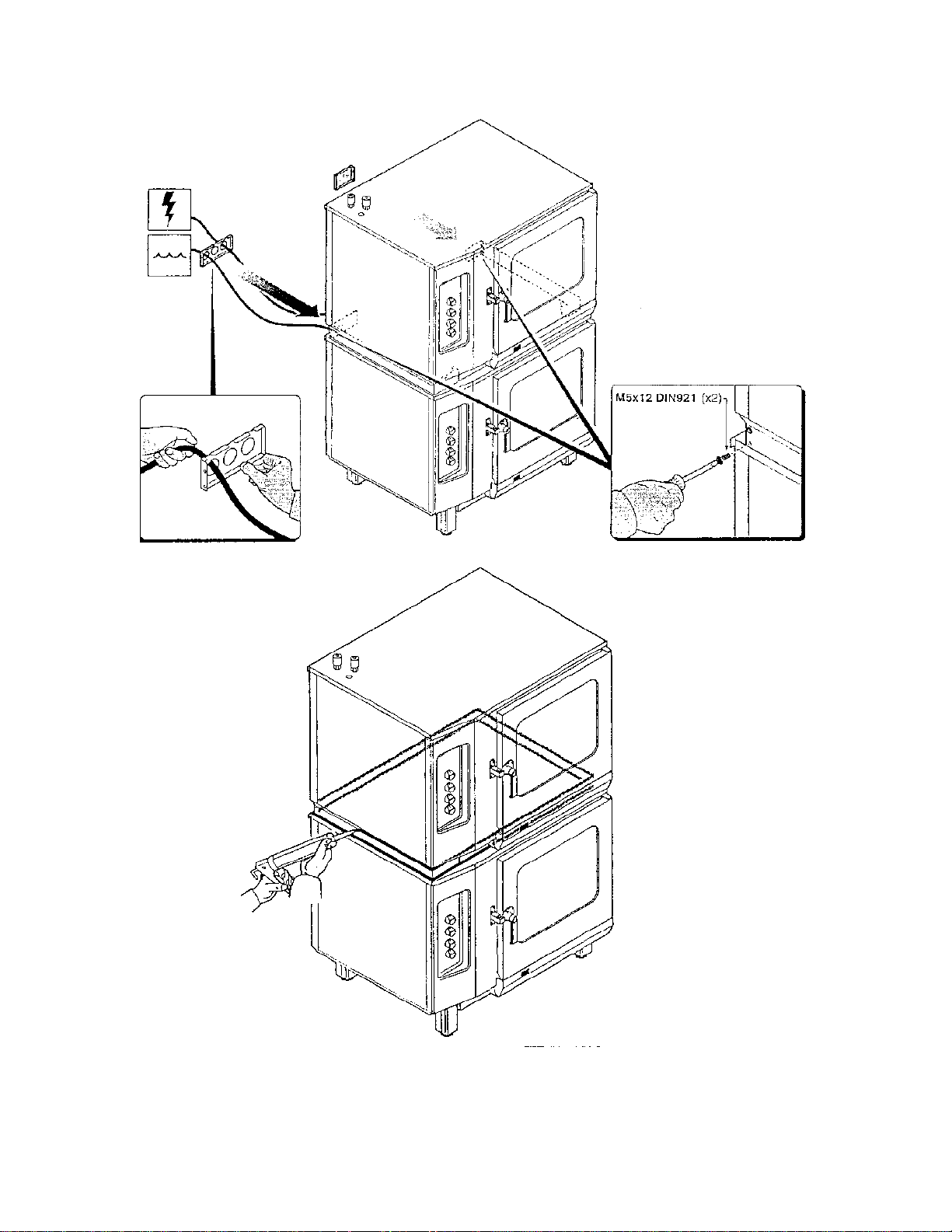

Stacking Kit Instructions

This section illustrates assembly procedures fo r the LCE 72 Only. In order to

draw particular attention to warnings and suggestions, some symbols have been

used.

Danger or Caution.

Note: Read and observe the instructions given on the appliance.

Consult the manual before carrying out connection.

Plumbing system.

Electrical system.

20

Page 21

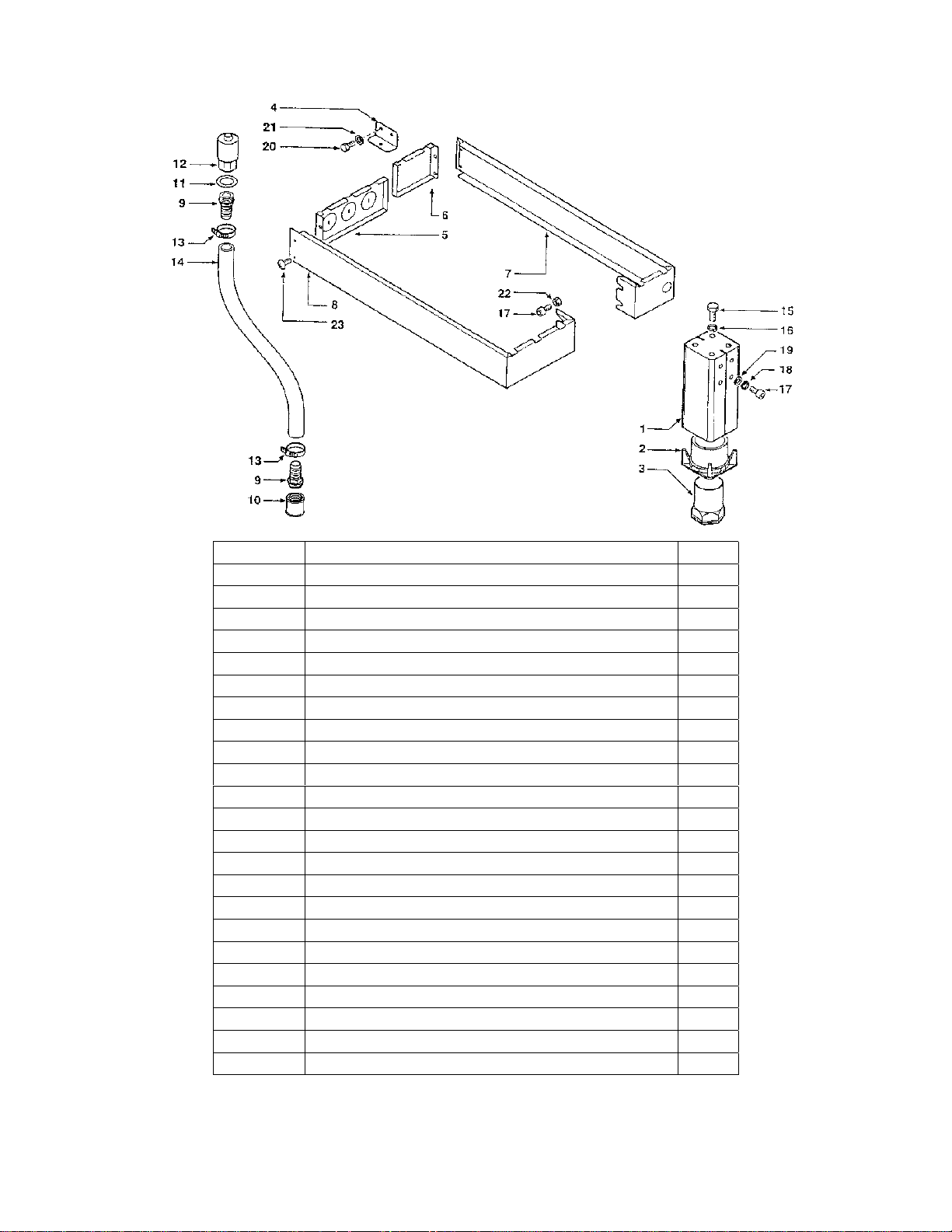

Number Description Qty.

1 Upright 4

2 Support 4

3 Foot 4

4 Bracket 2

5 Runner 1

6 Support 1

7 Right Enclosure 1

8 Left Enclosure 1

9 Connector 2

10 Pipe Coupling 1

11 Washer 1

12 Silencer 1

13 Hose Clamp 2

14 Rubber Hose 1

15 Screw 8

16 Washer 8

17 Screw 20

18 Washer 16

19 Washer 16

20 Screw 7

21 Washer 7

22 Nut 4

23 Screw 4

21

Page 22

222324252627282930

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

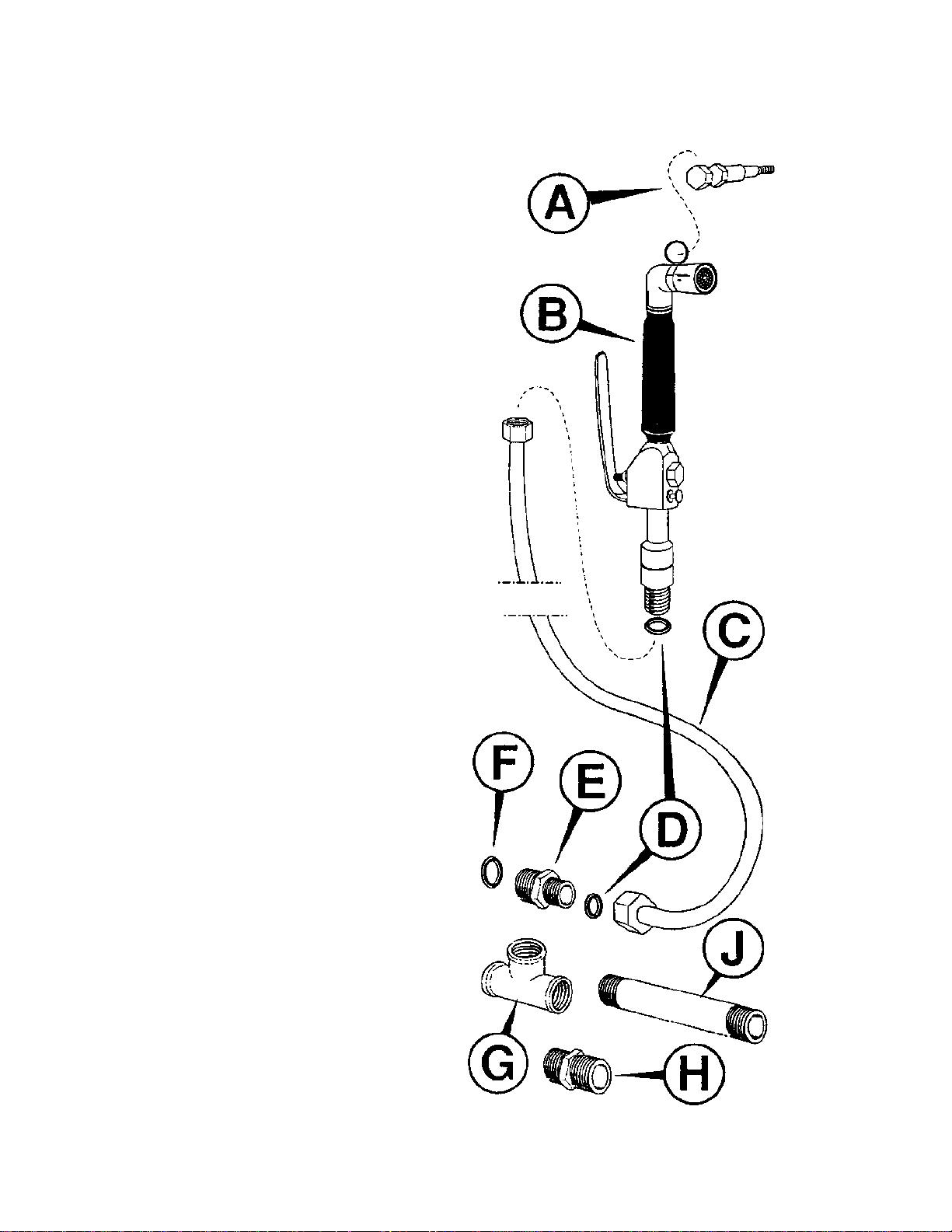

A = Supporting Screw

B = Spray Gun

C = Flexible pipe – 1/2” NPT

D = Gasket – 1/2”

E = Adapter 3/4” – 1/2”

F = Gasket – 3/4”

G = Tee 3/4”

H = Barrel Nipple 3/4”

J = Short 3/4”

Spray Hose Cleaning Kit

Page 31

31

Page 32

Spray the detergent/scale remover on all

parts of the oven/oven cavity and leave

on (if necessary, for the whole night).

Do not use descaling products

containing chlorine based

substances.

Rinse thoroughly with plenty of water.

Put the oven in steam mode for 15 minutes to

sterilize the oven. Then put the oven in

convection mode for 10 minutes to dry the unit

out.

Reassemble all parts removed and

leave the door open.

32

Page 33

OPERATION

450

400

350

485

300

0

100

150

250

33

Page 34

343536

Page 35

Page 36

Control Panel Manual Controls

LED’s:

Excessive temperature for the

cooking method selected

Insufficient water supply pressure

Fan motor blocked (*)

Safety thermostat tripped (*)

When thes e LED’s light they always signal

an abnormal situation. Consult the trouble

shooting section.

(*) require electrical re-setting.

Power LED (Oven ON)

Oven Temperature Display

Function Select Knob

Selects the following modes of operation

400

450

350

485

300

0

100

150

250

OFF

Steam

Convection

Combi

Thermostat Knob

Regulates Oven temperature for

convection and combi mode

Timer

Sets cooking time in all three modes

Steam Control knob

Regulates steam supply during combi mode

Page 37

STEAM MODE

Preheating

Turn Knob 1 to STEAM

Turn Knob 3 to Infinity (∞)

When the temperature display shows 214 - 217°F,

place the food in the oven and set the timer for the

recommended cooking time. When this time has

elapsed, the oven will switch off and a beeper will

sound for about 30 seconds.

Malfunction indicator lights

LED

When this L ED comes on it means that the ove n

temperature is too hot for the cooking mode

selected. Once the temperature drops below

the 217°F the LED will go out.

LED

This LED will flash when the water is being supplied.

If it stays on, the oven will shut down because there

is not enough water pressure. When the pressure

returns to normal operating pressure the LED will

go out.

400

450

350

485

300

0

100

150

250

LED

When this LED lights it means th at the motor has

overheated.

LED

When this LED lights it means th at the oven has

overheated.

37

Page 38

CONVECTION MODE

Preheating

Set knob 1 to CONVECTION

Turn knob 3 to Infinity (∞)

Set the required cooking temperature on the

thermostat

When the temperature display shows the set

temperature, place the food in the oven and set the

cooking time on the timer. At the end of the cycle

the oven will shut down and a beeper will sound for

about 30 seconds.

Malfunction indicator lights

LED

This LED cannot light in this mode.

LED

This LED cannot light in this mode.

LED

When this LED lights it means th at the motor has

overheated.

400

450

350

485

300

0

100

150

250

LED

When this LED lights it means th at the oven has

overheated.

38

Page 39

COMBI MODE

Preheating

Turn knob 1 to Combi

Turn knob 3 to Infinity (∞)

Set temperature on thermostat knob 2

Set the steam level on knob 4

When the temperature display shows the set

temperature, place the food in the oven and set the

cooking time on the timer. At the end of the cycle

the oven will shut down and a beeper will sound for

about 30 seconds.

Malfunction indicator lights

LED

This LED cannot light in this mode.

LED

This LED will flash when the water is being supplied.

If it stays on, the oven will shut down because there

is not enough water pressure. When the pressure

returns to normal operating pressure the LED will

go out.

450

400

350

485

300

0

100

150

250

LED

When this LED lights it means th at the motor has

overheated.

LED

When this LED lights it means th at the oven has

overheated.

39

Page 40

Control Panel Digital Controls

STAND BY

If the oven is connected to electricity, the electronic panel switches on or off by

pushing the “Stand By” key.

Once the electronic panel has power, the cooking parameters can be set.

COOKING

Select the required cooking mode by pressing one of the following keys:

1- STEAM COOKING - temperature range: from 86°F to 217°F.

2- CONVECTION COOKING - temperature rang e: fr om 86°F to 482°F.

3- COMBINATION COOKING - temperature range: from 86°F to 482°F.

4- RETHERMALIZATION COOKING - temperature range: from 284°F to 338°F.

5- SUPERSTEAM COOKING - temper a tur e range: from 230°F to 257°F.

40

Page 41

Set the required temperature by using the up and down arrow keys. The

temperature selected will appear on the display. During the cooking cycle, the

temperature display shows the actual temperature of the oven.

The Temperature Key changes the readout from the temperature set to the

actual temperature when the cooking mode is activated, and the timer activates.

When you s elect either the combinat io n or Rethermalization Cooking Mode, the

humidity display switches on automatically.

By setting the Humidity Key,

it is possible to set the humidity inside the cooking chamber in ten degree

increments.

FOR THE PROGRAMMABLE MODELS ONLY:

With convection, combination and rethermalization cooking modes, it is

possible to select half speed fan

for delicate products by using the Half Speed Key.

The Cook ‘N’ Hold key

will automatically activate a holding temperature of 158° for 30 minutes at the

end of a cooking cycle.

41

Page 42

COOKING WITH THE TIMER

Use the Time Key to select the desired time for cooking/baking.

Use the up and down arrow keys to set the cooking time. You can read the time

set on timer display. During the cooking the timer display shows the count down

to the end of the cycle. The timer key changes the readout from count down to

set when cooking is activated.

When the cooking is finished, the heating elements automatically turn off, and an

alarm will activate for a short period of time.

Note

If the door is opened during the cooking process, not only will the heating and fan

stop, but the timer will also stop; time count-down will start from this point when

the door is closed.

When unplugged, or in the even of a power interruption, the oven will maintain

and store programs- indefinitely.

COOKING WITH THE CORE PROBE

Select the cooking with probe function by pushing the Core Probe Key.

Cooking with the probe can be utilized in any mode of cooking: steam,

convection, or combi. Set the temperature required at the center of the product

by means of up and down arrow keys. The temperature range is from 86°F to

210°F. Cooking with probe by-passes the timer, and the generation of heat is

automatically stopped as soon as the temperature of the food where the probe is

located has reached the temperature set point.

When the set point is reached, th e heating stops and the alarm will activate for

several seconds.

Note

The temperature set point can be modified during the cooking cycle by

depressing the cooking key pressed while changing the temperature using the up

and down arrow keys.

42

Page 43

FOR PROGRAMMABLE MODELS ONLY

COOKING WITH PROGRAMMING

1- STORING A SINGLE COOKING CYCLE PROGRAM IN THE COMPUTER

MEMORY:

Press the Program Key to activate the programming function.

Select a program – from P01 TO P99 using the up down arrow keys.

Select the desired cooking mode.

After setting the time or a core temperature setting, the program display will show 1-1. It

means the program is comprised of a single cooking cycle or tier: first digit = active

cooking cycle, second digit = total number of cycles or tiers in the sequence.

Push the Enter Key to store the cooking cycle program.

1- STORING A PROGRAM CONSISTING OF A SEQUENCE OF MORE THAN ONE

COOKING CYCLES OR TIERS

Push the Sequence (Tiered) Cooking Key

The display will show 2-1: the first digit indicates the running cooking cycle, the second

digit indicates the total number of cycles (tiers) included in the sequence. It is possible to

store up to 9 cycles (tiers) in a program.

Set the new program.

After having set a time or a core temperature, the display will show 2-2. This indicates

that it is the second cooking cycle of a program composed of two tiers.

Push the enter key to store the program.

Note: By pushing the time key, the time display will show the total time of the program.

3- CHANGING SETTINGS

Use the up and down arrow keys to select the program to be modified (P01 TO P99).

Use the sequence (tiered) cooking key to select the cooking program to be changed

Proceed to make the desired changes.

Push the enter key to store the data

43

Page 44

START / STOP

If you have set the cooking parameters, you can start/activate the cooking phase

by pushing the Start Key.

NOTE:

TO SET THE OVEN FOR FAHRENHEIT DEGREES, DEPRESS THE

TEMPERATURE KEY WHILE PLUGGING THE OVEN TO THE ELECTRICAL

POWER.

44

Page 45

On/Off Button

STAND-BY Button with green indicator (the applaince is connected to

power) switches the panel on or off by pushing the button.

Alarm Lights

Failure code (E1 to E7), see troubleshooting section.

Flashing Red

Chamber is too hot for steam mode.

Flashing Red

Failure in water pressure, it will light with the display saying E6 or E7.

Red Light

Oven has been used for five hours, routine cleaning is recommended.

Cooking Mode Buttons

Steam Mode.

Green light shows when selected (Temp. 86 - 217°F).

Convection Mode.

Green light shows when selected (Temp. 86 - 482°F).

Combination Mo de.

Green light shows when selected (Temp. 86 - 482°F).

Regeneration Mode.

Green light shows when selected (Temp. 284 - 338°F).

Supersteam Mode.

Green light shows when selected (Temp. 230 - 257°F).

Up / Down Buttons

Increase or decrease set value.

Operating Controls

Steam Percentage Control.

Sets humidity level.

Temperature Control.

Changes readout from set to active.

Cooking Time Control.

When cooking is activated, changes re adout from cou nt-down to set .

45

Page 46

Core Temperature Control.

Changes readout from set to active.

Start / Stop Button

During the cooking phase this green light flashes.

Using the Oven

At the start of each cooking session we advise preheating the oven by running a

short cooking cycle when the oven is empty. At the end of the cycle the oven will

automatically stop and an buzzer will sound for 30 seconds.

Cooking

Select the required cooking mode by pressing one

of the following keys: 6 (STEAM), 7 (Convection),

8 (Combi), 9 (Regeneration), 10 (Supersteam)

Set the required chamber temperature using

arrow-keys 15.

Note: When cooking in modes 8 or 9 (Combi or

Regeneration) it is possible to set the steam.

2

1

9876

543

10

Cooking with the timer

Select the cooking timer by pressing 17

Use the arrow keys 18 to set the cooking time on

the display 16. Start the cycle using button 22

(START/STOP), the timer display will show the

count-down time. When the cooking is finished,

the buzzer will sound for 30 seconds.

Cooking with the core temperature probe

Use button 20 to select the core probe.

Set the temperature required at the center of

the product by using the arrow keys 21.

Start the cycle using button 22 (START/STOP).

When the cooking is finished, the buzzer will

sound for 30 seconds.

Note: when the probe is activated and reaches

the set temperature the oven will stop cooking.

11

19

1413

20

22

12

15

181716

21

46

Page 47

Changing setting during cooking

The value set can be modified during the cooking phase by keeping the cooking

key pressed while modifying the display using keys 15, 18, or 21.

To modify the values of a cooking program different from the one being used,

keep the relevant key pressed and proceed to modify as necessary using keys

15, 18, or 21.

Note: time changes during cooking will affect only the time remaining.

Note: If the door is opened while cooking is in process, not only will the heat and

the fan stop, but the timer will stop also. The timer will resume once the door is

closed.

When unplugged, the unit will store the programs indefinitely.

The core temperature probe can be set in any mode (Combi, Convection, Steam,

Regeneration, Super steam). It does not use the timer when in this mode.

47

Page 48

CLEANING

Turn the unit off.

Allow the unit to cool to at least 140°F.

Remove the racks from the oven.

Daily Cleaning

Drip Tray

The drip tray must be emptied and cleaned

frequently. If it is connected to a drainage

outlet, check that the outlet hole is not

clogged.

Cooking Chamber

Remove the rack slide from the cooking

chamber.

Remove the filter strainer from the bottom

of the oven chamber and clean it.

Spray detergent (detergent without chloride

or chlorine, specific for stainless steel) on

the walls of the unit using the special

detergent spray unit.

Wait 30 minutes.

Rinse thoroughly with water.

Heat the oven in steam mode for 15

minutes.

Heat the oven in convection mode for 15

minutes.

If the unit is not going to be used again until

tomorrow, leave the door partially open all

night.

MAINTENANCE & CLEANING

Yearly

The under-pressure valve #9 will need to be cleaned and checked for proper

operation.

48

Page 49

Cleaning functional parts of the oven

De-scaling the blower wheel

The blower wheel must be de-scaled every 15

days.

Remove the racks and rack slides.

Unscrew the two screws securing the baffle to

the oven, and open the baffle.

De-scale the blower wheel with a suitable descaling agent.

For thorough cleaning of the blower wheel

Unscrew the atomizer while keeping the blower

wheel from turning and loosen the two set

screws on the motor shaft.

Screw the supplied extractor bolt into the shaft

until the blower wheel is disengaged from the

shaft.

Note: When reassembling the fan, ensure the

blower wheel is seated fully on the shaft before

tightening the set screws.

Cleaning the water filter

Close the main water supply valve, unscrew

the plug, and remove the filter and clean it.

Cleaning the drain siphon (located beneath the

oven)

Unscrew the plug and remove any

accumulated debris.

Note: Limescale deposits must be removed regularly, especially from the heat

exchanger. When the scale film becomes thick, it is either very difficult or

impossible to remove. Limesca le is a thermal insulating material. W hen the

scale film on the heat exchanger becomes too thick, heat exchanging is impeded

causing the pipes and the combustion chamber to overheat and possibly break.

Limescale is porous and absorbs grease and odors that might be released later.

49

Page 50

MAINTENANCE

WARNING: DISCONNECT THE UNIT’S

POWER FROM THE WALL BEFORE

PROCEEDING WITH ANY OF THESE

PROCEDURES.

Replacing light bulbs or the light glass

Remove the left hand side panel by unscrewing

the 1/4 turn screws.

Unscrew the screw and nut shown in the figure

and remove the lamp-holder.

Replace the bulb.

To remove the light glass for replacement,

unscrew the other three nuts inside the lampholder and remove the glass.

Replacing fuses

Remove the left hand side panel.

The plug-in type fuses holders are located at

the side of the terminal board. Replace with

rapid-acting fuses.

Resetting overload cut-outs

The overload cut-out, disconnects the power

supply to the motor when it overheats due to

overload.

Before pressing the reset button, find and

eliminate the cause of the overload.

Resetting the safety thermostat

The safety thermostat shuts down the oven

when internal temperatur e ex ceeds 572°F.

To restart the oven:

Remove the left hand panel.

Allow the oven to cool for about 10 minutes,

find and correct the cause of overheating

and then press the reset button.

Electrical

Diagram

50

Page 51

GAS CONVERSIONS

WARNING: ENSURE THE MAIN GAS

VALVE IS TURN OFF BEFORE

PROCEEDING.

Replacement of Injectors

The injectors are reachable through

the bottom of the oven. Remove the

drip tray.

Unscrew each injector and replace it

with the one suitable for the type of

gas at your location.

Replacement of Pilot Flame Injector

Unscrew cap A, unscrew injector B

and replace it as necessary for the

type of gas at your locat ion.

After replacing the injector, turn on

the pilot flame and adjust the primary

air nut as necessary.

Air

Regulation

Ring

51

Page 52

Adjustments to the gas valve

NATURAL GAS

Remove screw A from the pressure connection

and connect a pressure gauge.

PROPANE

Remove the plug B and check if

it matches with detail E. If

positive screw it completely, if

not remove screw C, spring

D

and replace them with plug E.

Remove the plug B and ensure the adjustment

screw C is there, otherwise insert the spring

D

with the screw C.

Start the burner and adjust the screw C until

the pressure gauge shows the correct reading.

After having checked that the flame is stable,

stop the burner, disconnect the pressure

gauge, screw the plug B in completely, seal

the adjustment screw C with a drop of paint

and replace plug

B.

52

Page 53

PROBLEMS POSSIBLE CAUSES SOLUTIONS

Power is on, display or

LED is not on.

Power is on, lights in the

cooking chamber do not

work.

Start-button pressed, no

water flow for cooling

system.

Start-button pressed, no

fan, no burner or

elements.

Start-button pressed, fan

works, no burner or

elements.

GAS UNIT ONLY:

Spark ignition of pilot

flame is out of wo rk.

Fuses F3-F4 are blown.

Light Bulbs are burnt out.

Fuses F1-F2 are blown.

Solenoid valve (6) is not

energized.

Solenoid valve coil is

burnt.

Door does not activate

microswitch.

Fuse F1 is blown.

Door does not activate

microswitch.

Microswitch is not

working.

Fuse F1 or F2 is blown.

Gas valve or heating

elements are burnt.

GAS UNITS ONLY:

Low voltage transformer

(or its fuse) is blown.

Gas valve switch is

button is not working.

Spark igniter is broken.

High voltage spark cable

is damaged.

TROUBLESHOOTING

Check power.

Check fuses near the

terminal block.

Check light bulbs.

Check fuses.

Clean or de-scale

solenoid valve.

Replace coil.

Replace solenoid valve.

Check door hinges.

Replace microswitch.

Check fuse F1.

Check that the door

closes properly.

Replace microswitch.

Check fuses F1 & F2.

Check gas flow.

Check gas valve.

Check low voltage

transformer and its fuse.

Replace switch button.

Replace spark igniter.

Replace High voltage

cable.

53

Page 54

GAS UNITS ONLY:

Air in the pilot flame pipe. Repeat ignition

Pilot flame can not be

ignited.

GAS UNITS ONLY:

Pilot flame estinguishes.

Start-button pressed, No

steam.

Thermocouple bulb is

dirty or damaged.

Solenoid valve (7) is

energized but is

defective.

Solenoid coil is burnt.

Scale has obstructed

water.

Water pressure regulator

is wrong.

Water nozzle (19) is

obstructed.

Fuse F1 is blown.

Start-button pressed, unit

steams when no steam is

selected.

Scale built up in the

solenoid valve (7).

Solenoid valve is

defective.

Start-button pressed,

steam is not at the set

level (too much or too

little).

Thermostat controlling

temperature of the

condensation tube is

defective.

Cooling water nozzle (10)

is obstructed.

Solenoid valve (6) is

obstructed or defective.

Inconsistent Cooking. Motor is spinning in the

wrong direction.

Noises from the trap. Drain (16) is obstructed

or not ventilated.

Silencer (17) is

obstructed by a rag or

pan.

Cooling water nozzle (10)

is obstructed.

procedure several times

to bleed the air out.

Clean or replace the

thermocouple.

Disassemble solenoid

valve (7) and clean or descale.

Replace coil.

De-scale water pipe.

Set water pressure

regulator properly.

Clean water nozzle.

Check fuse F1.

Disassemble solenoid

valve (7) and de-scale.

Replace solenoid valve

or its coil.

Replace thermostat

controlling tempe r ature of

the condensation tube.

Disassemble and clean

or de-scale water nozzle

(10).

Disassemble solenoid

valve and clean or descale.

Replace coil or solenoid

valve.

Change the motor phase.

Verify and clean drain

(16), or proved adequate

venting.

Keep silencer free.

Disassemble cooling

water nozzle (10) and

clean or de-scale.

54

Page 55

WORKING MODES

Device Steam / Super-steam Convection Combi

Solenoid valve

(7)

Permanently

energized.

Permanently

energized.

Alternately

energized / de-

energized.

Calibrated quantity of

water through pipe

(11) by means of

pressure regulator

(14) and nozzle (19).

Variable quantity

of water according

to set percentage.

Duty cycle is 5

sec. on 9 sec. off.

Nozzle (19)

61 = .5

101 = .6

141 = .7

241 = .7

401 = .7

22

21

23

Contr o l formula for

humidity %.

10% = 122°F

20% = 131°F

30% = 140°F

40% = 149°F

50% = 158°F

60% = 167°F

18

19

20

70% = 176°F

80% = 185°F

90% = 194°F

Solenoid valve

(6)

Permanently

energized.

Calibrated quantity of

water to cool down

drain system by

means of the pressure

regulator (14) and

nozzle (10).

Permanently

energized.

Calibrated

quantity of water

to cool down

drain system by

means of t he

pressure

regulator (14) and

nozzle (10).

55

Permanently

energized.

Calibrated

quantity of water

to cool down drain

system by means

of the pressure

regulator (14) and

nozzle (10).

Page 56

ALARMS FOR THE MANUAL CONTROL COMBI’S

The power LED lights but

the temperature display

does not show any

change in temperature.

LED Lights

LED Lights

LED Lights

LED Lights

Knob 1 (page 36) has not

been set to a cooking

Turn in to a cooking

mode.

mode.

Timer Knob 3 (page 36)

has not been set to a

Set any time higher than

zero.

cooking time.

Thermostat knob 2 (page

36) has not been set.

In convection or Combi

cooking, the temperature

must be set.

You switched from

CONVECTION or COMBI

cooking to steam.

Wait until the oven

temperature drops to 214

- 218°F.

No water supply. Call your local plumber.

Insufficient water

pressure.

Contact your water dept.

to increase your water

pressure.

Faulty solenoid valve. Call your local servicer.

Water control valve out of

calibration.

Your local servicer

should calibrate the

valve.

One of the phases is

missing.

Check electrical

connection and reset as

described on page 50.

Motor blocked. Call your local servicer.

Oven has momentarily

overheated.

Wail unit it cools down

and rest as described on

page 50.

Faulty Thermostat. Call your local servicer.

56

Page 57

ALARMS FOR THE DIGITAL CONTROL COMBI’S

When this indicator lamp fla shes the oven c hamber temper ature is too high for the

selected cooking mode. This lamp will light whenever you change from a high

temperature cooking mode (Convection or Combi) to a lower temperature mode

(214 - 218°F Steam, 284 - 338°F Rethermalization mode, 230 - 257°F for SuperSteam). When this lamp is illumin ated heating is stopped until the temperature falls

to within the permissible range. The lamp will then turn off and the oven will

operate normally.

Note: This lamp should not illuminate during convection or combi modes.

This lamp flashes to indicate water supply problems (either due to a temporary

interruption of the supply or a drop in water pressure). If this occurs during a

Steam, Re-thermalization, or Super-Steam, oven heating is immediately stopped.

At this point press START to check whether the problem is still present. If the lam p

continues to flash (and the water supply is OK) check for the possible causes. If

the lamp starts flashing during the Convection or Combi cooking, the oven will

continue to operate normally and the indicator lamp will switch off as soon a s

normal conditions are restored.

Illuminates after 5 hours of cooking to signal that the cleaning procedures should

be completed. The oven continues to operate. Pressing the START-STOP key

switches off the indicator lamp and the hours of cooking count restarts from zero.

This display will show an alarm code to help identify the cause of the

problem. You can remedy it by following the instructions in the chart

below.

Alarm Codes

000

flashing

00

flashing

LED flashes

LED flashes

or - - -

or - -

Faulty cooking chamber temperature probe.

If core temperature probe is not skewered in

food and the oven chamber is at ambient

temperature: core temperature probe is

faulty.

You have switched from convection or

combi mode operation to steam mo de.

Then unit must cool down.

Main water supply was interrupted or the

pressure is too low.

Water flow control valve is incorrectly set.

57

Page 58

Display shows the following

Codes:

LED flashes

E1

E2

E3

E4

E5

E6

E7

E8

Faulty oven chamber temperature probe.

Faulty core temperature probe.

Faulty steam discharge temperature probe.

Motor thermal trip.

Safety thermostat trip.

Faulty oven chamber pressure switch.

Faulty drain pressure switch.

Faulty oven chamber lower probe.

Oven has been in effective use for 5 hours.

00

or - -

flashing

TO CHECK CIRCUIT BOARD INPUT/OUTPUT ON DIGITAL MODELS

Make sure the unit is plugged in.

If any pre-set value is shown on the displays, press push-button

as to get “STAND-BY condition.

Keep both push-buttons “TIME” and “START” simultaneously

pressed for about 5 seconds, until a “beep” sounds. This operation does not

change or clear any pre-set value. It allows the operator to check all input/output

relays and the relevant connected remote switches. By pressing all the pushbuttons from the top (left to right), the relevant LED light switches on, while a

relay is energized. According to the circuit board type, an opportunity is given to

energize one of the relays.

A progressive number, corresponding to the pressed pu sh-button, will be shown

on the display. This allows us to verify all circuit board input, both from the digital

pad, from outside switches (i.e. pressure switches etc.) and from inputs at

120/208V (i.e. door micro-switches and safety thermostats).

To get out from this program, keep again the above mentioned push-buttons

pressed until a beep sounds.

Faulty steam discharge temperature probe.

58

Page 59

TO CHECK THE PT100 PROBE IN THE CONDENSATION TUBE ON DIGITAL

MODELS

This can be done while the unit is cooking.

Keep both push-buttons “TIME” and “TIME DOWN”

Simultaneously pressed.

This operation does not change or clear any pre-set value of the circuit board. It

allows the operator to verify the humidity level in the oven by display the

temperature in the condensation tube.

10% = 122°F

20% = 131°F

30% = 140°F

40% = 149°F

50% = 158°F

60% = 167°F

70% = 176°F

80% = 185°F

90% = 194°F

59

Page 60

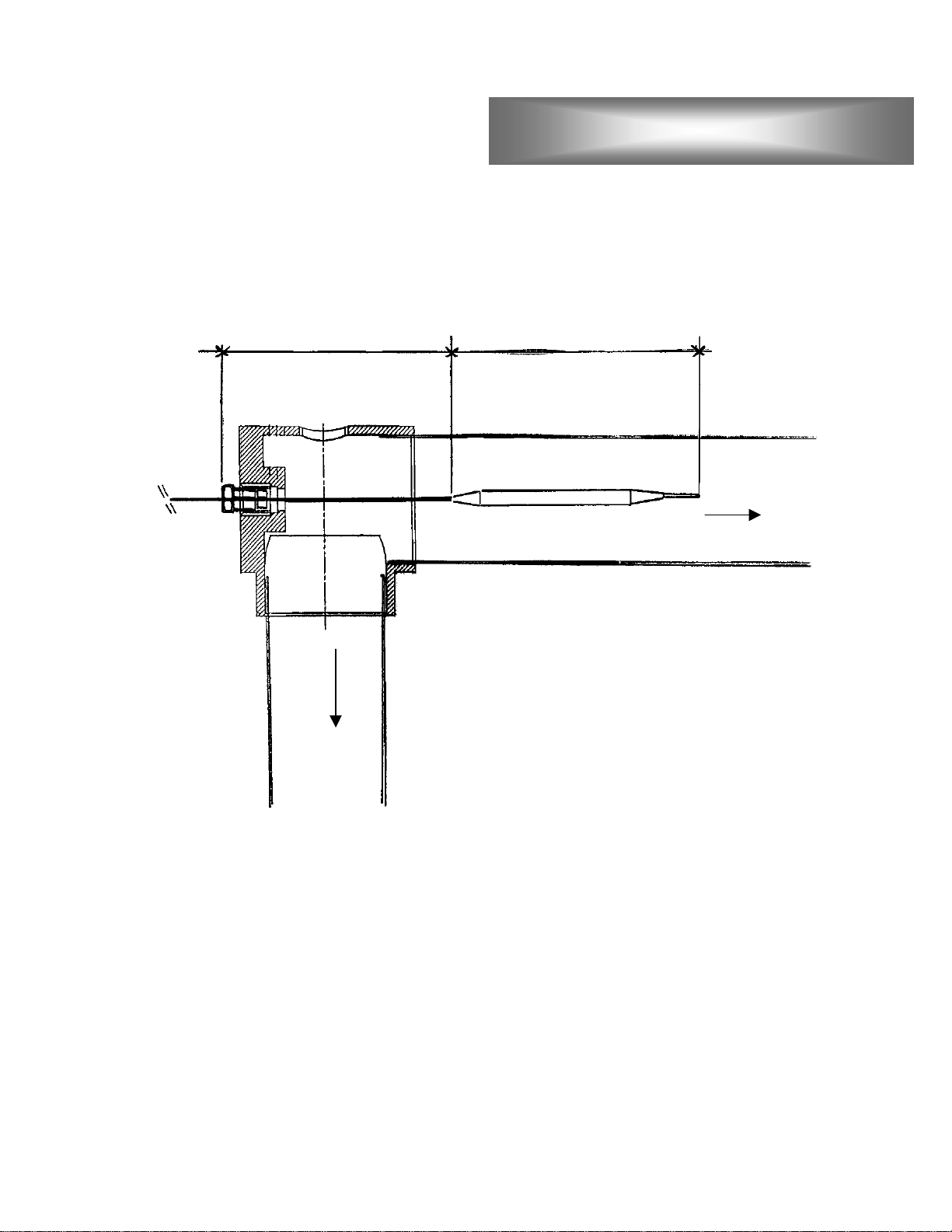

TECHNICAL DATA

Total distance from A to B for all digital models is 5 5/16”.

Total distance from A to B for mechanical models is:

8 11/16” for models LC-61, 72, & 101

10 7/16” for models LC-141, 241, & 401

Drain Temp. Detecting Probe

To the cooking

chamber

To the

drain

60

Page 61

PT-100 Temperature Probe

White

Red

Red

White

Red

Red

61

Page 62

PT-100 resistance chart

Temp. Resistance Temp. Resistance Temp. Resistance

0°F 93.04 Ω 185°F 132.79 Ω 370°F 171.33 Ω

5°F 94.13 Ω 190°F 133.85 Ω 375°F 172.36 Ω

10°F 95.22 Ω 195°F 134.90 Ω 380°F 173.38 Ω

15°F 96.31 Ω 200°F 135.96 Ω 385°F 174.41 Ω

20°F 97.39 Ω 205°F 137.01 Ω 390°F 175.43 Ω

25°F 98.48 Ω 210°F 138.07 Ω 395°F 176.45 Ω

30°F 99.57 Ω 215°F 139.12 Ω 400°F 177.47 Ω

35°F 100.65 Ω 220°F 140.17 Ω 405°F 178.49 Ω

40°F 101.73 Ω 225°F 141.23 Ω 410°F 179.51 Ω

45°F 102.82 Ω 230°F 142.28 Ω 415°F 180.53 Ω

50°F 103.90 Ω 235°F 143.33 Ω 420°F 181.55 Ω

55°F 104.98 Ω 240°F 144.37 Ω 425°F 182.56 Ω

60°F 106.06 Ω 245°F 145.42 Ω 430°F 183.58 Ω

65°F 107.14 Ω 250°F 146.47 Ω 435°F 184.59 Ω

70°F 108.22 Ω 255°F 147.52 Ω 440°F 185.61 Ω

75°F 109.30 Ω 260°F 148.56 Ω 445°F 186.62 Ω

80°F 110.38 Ω 265°F 149.61 Ω 450°F 187.63 Ω

85°F 111.45 Ω 270°F 150.65 Ω 455°F 188.64 Ω

90°F 112.53 Ω 275°F 151.69 Ω 460°F 189.65 Ω

95°F 11.60 Ω 280°F 152.73 Ω 465°F 190.66 Ω

100°F 114.67 Ω 285°F 153.77 Ω 470°F 191.67 Ω

105°F 115.75 Ω 290°F 154.81 Ω 475°F 192.68 Ω

110°F 116.82 Ω 295°F 155.85 Ω 480°F 193.68 Ω

115°F 117.89 Ω 300°F 156.89 Ω 485°F 194.69 Ω

120°F 118.96 Ω 305°F 157.93 Ω 490°F 195.69 Ω

125°F 120.03 Ω 310°F 158.97 Ω 495°F 196.70 Ω

130°F 121.10 Ω 315°F 160.00 Ω 500°F 197.70 Ω

135°F 122.16 Ω 320°F 161.04 Ω 505°F 198.70 Ω

140°F 123.23 Ω 325°F 162.07 Ω 510°F 199.70 Ω

145°F 124.30 Ω 330°F 163.10 Ω 515°F 200.70 Ω

150°F 125.36 Ω 335°F 164.13 Ω 520°F 201.70 Ω

155°F 126.42 Ω 340°F 165.17 Ω 525°F 202.70 Ω

160°F 127.49 Ω 345°F 166.20 Ω 530°F 203.70 Ω

165°F 128.55 Ω 350°F 167.23 Ω 535°F 204.70 Ω

170°F 129.61 Ω 355°F 168.25 Ω 540°F 205.69 Ω

175°F 130.67 Ω 360°F 169.28 Ω 545°F 206.69 Ω

180°F 131.73 Ω 365°F 170.31 Ω 550°F 207.68 Ω

62

Page 63

Water consumption table

Oven

Model

LC-61 .5 mm 14.5 psi 2 gal 28 gal 10 gal

LC-101 .6 mm 14.5 psi 3 gal 28 gal 30 gal

LC-72 .7 mm 14.5 psi 5 gal 28 gal 33 gal

LC-141 .7 mm 14.5 psi 5 gal 28 gal 33 gal

LC-241 .7 mm 14.5 psi 5 gal 28 gal 33 gal

LC-401 2 x .7 mm 14.5 psi 2 x 5 gal 2 x 28 gal 66 gal

Injector

Size

Water

Pressure

Water to

steam

Water to

drain

Total

Water Qty.

63

Page 64

MODEL LANG COMBI ELECTRIC: LCE-61

64

PAN CAPACITY Maximum 6 Full Size Sheet Pans

6 Full Size Steam Table Pans

Optimum 6 Full Size Sheet Pans

4 Full Size Steam Table Pans

INTERIOR 20 Gauge Stainless Steel Critical Components, 316 Stainless

Interior, 304 Stainless

Inside Oven Dimensions

(W x D x H): 24" x 24 5/8" x 17 29/32"

(610mm x 620mm x 450mm)

2 Oven Lights

1 Oven Drain Screen

1 Removable Drip Tray

Stainless Steel Rack Frame With 6 Support Rails

6 Stainless Steel Oven Racks

EXTERIOR 20 Gauge Stainless Steel

Outside Dimensions (Height Includes Legs)

(W x D x H): 371/2" x 29" x 311/2"

(950mm x 740mm x 800mm)

ELECTRICAL 208 and 240 Volt AC, 50/60 Hz, 3 Phase

Total kW: 9.5 kW

Amperage Per Line

• 208 / 3 Phase: 26.4 Amp/Phase

• 240 / 3 Phase: 22.8 Amp/Phase

Terminal Block Connection

WATER Cold Water Intake Size:

Water Pressure: 40 psi Min, 80 psi Max

Water Consumption: 30 Gal/Hr (113 Liters/Hr)

3

/4" NPT

S P E C I F I C AT I O N S

DRAIN Vented Drain Required

Drain Size: 11/2" NPT

WEIGHT Shipping Weight (Crated): 353 lb (160 kg)

Net Weight (Uncrated): 309 lb (140 kg)

INSTALLATION Legs 4" (100mm) Included

Vent Hood Check Local Codes

Water Shut Off Valve Check Local Codes

Water Back Flow Preventer Required

Minimum Clearances Required

• Sides (Includes Service Access): 20" (500mm)

• Back: 4" (100mm)

• Counter Top: 4" (100mm)

ACCESSORIES Water Wash Down Hose Included (Part Number LDL)

Plastic Detergent Spray Bottle Included (Part Number PND)

Stainless Steel Oven Rack 6 Included (Part Number G610X)

OPTIONS Control Options: Manual Dial (M)

Digital (D)

Digital Programmable (DP)

Stainless Stand: TB610P

Stainless Stand With Bottom Shelf: TB610

Stainless Roll In Rack Frame, 6 Position: SRG6 (Standard Spacing)

Stainless Roll In Rack Frame, 4 Position: SRG685

Guides For Roll In Rack: GSR610

Rack Frame Transport Trolley: C610

U

L

N S F

U SC

®

Page 65

MODEL LANG COMBI ELECTRIC: LCE-101

65

PAN CAPACITY Maximum 10 Full Size Sheet Pans

10 Full Size Steam Table Pans

Optimum 10 Full Size Sheet Pans

8 Full Size Steam Table Pans

INTERIOR 20 Gauge Stainless Steel Critical Components, 316 Stainless

Interior, 304 Stainless

Inside Oven Dimensions (W x D x H): 24" x 24 5/8" x 27 3/8"

(610mm x 620mm x 690mm)

2 Oven Lights

1 Oven Drain Screen

1 Removable Drip Tray

Stainless Steel Rack Frame With 10 Support Rails

EXTERIOR 20 Gauge Stainless Steel

Outside Dimensions (Height Includes Legs)

(W x D x H): 371/2" x 29" x 41"

(950mm x 740mm x 1030mm)

ELECTRICAL 208 and 240 Volt AC, 50/60 Hz, 3 Phase

Total kW: 17.9 kW

Amperage Per Phase

• 208 / 3 Phase: 49.7 Amp/Phase

• 240 / 3 Phase: 43.1 Amp/Phase

Terminal Block Connection

WATER Cold Water Intake Size:

Water Pressure: 40 psi Min, 80 psi Max

Water Consumption: 31 Gal/Hr (117 Liters/Hr)

3

/4" NPT

S P E C I F I C AT I O N S

DRAIN Vented Drain Required

Drain Size: 11/2" NPT

WEIGHT Shipping Weight (Crated): 386 lb (175 kg)

Net Weight (Uncrated): 364 lb (165 kg)

INSTALLATION Legs 4" (100mm) Included

Vent Hood Check Local Codes

Water Shut Off Valve Check Local Codes

Water Back Flow Preventer Required

Minimum Clearances Required

• Sides (Includes Service Access): 20" (500mm)

• Back: 4" (100mm)

• Counter Top: 4" (100mm)

ACCESSORIES Water Wash Down Hose Included (Part Number LDL)

Plastic Detergent Spray Bottle Included (Part Number PND)

OPTIONS Control Options: Manual Dial (M)

Digital (D)

Digital Programmable (DP)

Stainless Steel Oven Rack: G610X

Stainless Roll In Rack Frame, 10 Position: SRG10 (Standard Spacing)

Stainless Roll In Rack Frame, 7 Position: SRG1085

Stainless Stand: TB610P

Stainless Stand With Bottom Shelf: TB610

Rack Frame Transport Trolley: C610

Guides For Roll In Rack: GSR610

U

L

N S F

U SC

®

Page 66

MODEL LANG COMBI ELECTRIC: LCE-72

66

PAN CAPACITY Maximum 7 Full Size Sheet Pans

14 Full Size Steam Table Pans

Optimum 7 Full Size Sheet Pans

10 Full Size Steam Table Pans

INTERIOR 20 Gauge Stainless Steel Critical Components, 316 Stainless

Interior, 304 Stainless

Inside Oven Dimensions (W x D x H): 33" x 32 1/2" x 22 1/32"

(840mm x 830mm x 560mm)

2 Oven Lights

1 Oven Drain Screen

1 Removable Drip Tray

7 Stainless Steel Racks

Stainless Steel Rack Frame With 7 Support Rails

EXTERIOR 20 Gauge Stainless Steel

Outside Dimensions (Height Includes Stand)

(W x D x H): 461/2" x 371/2" x 63"

(1180mm x 940mm x 1500mm)

ELECTRICAL 208 and 240 Volt AC, 50/60 Hz, 3 Phase

Total kW: 17.9 kW

Amperage Per Phase

• 208 / 3 Phase: 49.7 Amp/Phase

• 240 / 3 Phase: 43.1 Amp/Phase

Terminal Block Connection

WATER Cold Water Intake Size:

Water Pressure: 40 psi Min, 80 psi Max

Water Consumption: 33 Gal/Hr (124 Liters/Hr)

3

/4" NPT

S P E C I F I C AT I O N S

DRAIN Vented Drain Required

Drain Size: 11/2" NPT

WEIGHT Shipping Weight (Crated): 460 lb (210 kg)

Net Weight (Uncrated): 400 lb (180 kg)

INSTALLATION Legs None

Vent Hood Check Local Codes

Water Shut Off Valve Check Local Codes

Water Back Flow Preventer Required

Minimum Clearances Required

• Sides (Includes Service Access): 20" (500mm)

• Back: 4" (100mm)

• Floor: 6" (150mm)

ACCESSORIES Water Wash Down Hose Included (Part Number LDL)

Plastic Detergent Spray Bottle Included (Part Number PND)

Stainless Steel Oven Rack 7 Included (Part Number G241X)

OPTIONS Control Options: Manual Dial (M)

Digital (D)

Digital Programmable (DP)

Stainless Stand With Bottom Shelf: KSTD72

Oven Stacking Kit: KSTDC72

Stainless Roll In Rack Frame, 7 Position: TRG14 (Standard Spacing)

Stainless Roll In Rack Frame, 5 Position: TRG1485

Rack Frame Transport Trolley: C1424

U

L

N S F

U SC

®

Page 67

MODEL LANG COMBI ELECTRIC: LCE-241

67

PAN CAPACITY Maximum 12 Full Size Sheet Pans

24 Full Size Steam Table Pans

Optimum 12 Full Size Sheet Pans

18 Full Size Steam Table Pans

INTERIOR 20 Gauge Stainless Steel Critical Components, 316 Stainless

Interior, 304 Stainless

Inside Oven Dimensions (W x D x H): 33" x 321/2" x 33 25/32"

(840mm x 820mm x 860mm)

3 Oven Lights

1 Oven Drain Screen

1 Removable Drip Tray

12 Stainless Steel Racks

Stainless Steel Rack Frame With 12 Support Rails

EXTERIOR 20 Gauge Stainless Steel

Outside Dimensions (Height Includes Legs)

(W x D x H): 461/2" x 371/2" x 63"

(1180mm x 940mm x 1500mm)

ELECTRICAL 208 and 240 Volt AC, 50/60 Hz, 3 Phase

Total kW: 26.0 kW

Amperage Per Phase

• 208 / 3 Phase: 72.2 Amp/Phase

• 240 / 3 Phase: 62.6 Amp/Phase

Terminal Block Connection

WATER Cold Water Intake Size:

Water Pressure: 40 psi Min, 80 psi Max

Water Consumption: 33 GalHr (124 Liters/Hr)

3

/4" NPT

S P E C I F I C AT I O N S

DRAIN Vented Drain Required

Drain Size: 11/2" NPT

WEIGHT Shipping Weight (Crated): 628 lb (285 kg)

Net Weight (Uncrated): 551 lb (250 kg)

INSTALLATION Legs 12" (305mm) Included

Vent Hood Check Local Codes

Water Shut Off Valve Check Local Codes

Water Back Flow Preventer Required

Minimum Clearances Required

• Sides (Includes Service Access): 20" (500mm)

• Back: 4" (100mm)

• Floor: 6" (150mm)

ACCESSORIES Water Wash Down Hose Included (Part Number LDL)

Plastic Detergent Spray Bottle Included (Part Number PND)

Stainless Steel Oven Rack 12 Included (Part Number G241X)

OPTIONS Control Options: Manual Dial (M)

Digital (D)

Digital Programmable (DP)

Stainless Roll In Rack Frame, 12 Position: TRG24 (Standard Spacing)

Stainless Roll In Rack Frame, 9 Position: TRG2485

Rack Frame Transport Trolley: C1424

U

L

N S F

U SC

®

Page 68

MODEL LANG COMBI ELECTRIC: LCE-401

68

PAN CAPACITY Maximum 20 Full Size Sheet Pans

40 Full Size Steam Table Pans

Optimum 20 Full Size Sheet Pans

28 Full Size Steam Table Pans

INTERIOR 20 Gauge Stainless Steel Critical Components, 316 Stainless

Interior, 304 Stainless

Inside Oven Dimensions (W x D x H): 33" x 32 1/2" x 54 11/32"

(840mm x 820mm x 1390mm)

4 Oven Lights

1 Oven Drain Screen

1 Removable Drip Tray

Stainless Steel Rack Frame With 20 Support Rails

10 Stainless Steel Oven Racks

EXTERIOR 20 Gauge Stainless Steel

Outside Dimensions (Height Includes Legs)

(W x D x H): 461/2" x 371/2" x 761/2"

(1180mm x 940mm x 1920mm)

ELECTRICAL 208, 240 and 480 Volt AC, 50/60 Hz, 3 Phase

Total kW: 52.0 kW

Amperage Per Phase

• 208 / 3 Phase: 144.5 Amp/Phase

• 240 / 3 Phase: 125.2 Amp/Phase

• 480 / 3 Phase: 63.6 Amp/Phase

Terminal Block Connection

WATER Cold Water Intake Size:

Water Pressure: 40 psi Min, 80 psi Max

Water Consumption: 66 Gal/Hr (248 Liters/Hr)

3

/4" NPT (2 each)

S P E C I F I C AT I O N S

DRAIN Vented Drain Required

Drain Size: 11/2" NPT (2 each)

WEIGHT Shipping Weight (Crated): 947 lb (430 kg)

Net Weight (Uncrated): 860 lb (390 kg)

INSTALLATION Legs 12" (305mm) Included

Vent Hood Check Local Codes

Water Shut Off Valve Check Local Codes

Water Back Flow Preventer Required

Minimum Clearances Required

• Sides (Includes Service Access): 20" (500mm)

• Back: 4" (100mm)

• Floor: 6" (150mm)

ACCESSORIES Water Wash Down Hose Included (Part Number LDL)

Plastic Detergent Spray Bottle Included (Part Number PND)

Stainless Steel Oven Rack 10 Included (Part Number G241X)

Stainless Roll In Rack Frame, 20 Position: Included (Part Number SRG40GE)

Rack Frame Transport Trolley: 1 Per Oven (Part Number C401)

OPTIONS Control Options: Digital Programmable (DP)

Stainless Roll In Rack Frame, 14 Position: SRG4085GE

Stainless Rack Frame Stand: BAS401

Stainless Steel Oven Rack: G241X

U

L

N S F

U SC

®

Page 69

MODEL LANG COMBI GAS: LCG-61

69

PAN CAPACITY Maximum 6 Full Size Sheet Pans

6 Full Size Steam Table Pans

Optimum 6 Full Size Sheet Pans

4 Full Size Steam Table Pans

INTERIOR 20 Gauge Stainless Steel Critical Components, 316 Stainless

Interior, 304 Stainless

Inside Oven Dimensions (W x D x H): 24" x 24 5/8" x 17 29/32"

(610mm x 620mm x 450mm)

2 Oven Lights

1 Oven Drain Screen

1 Removable Drip Tray

Stainless Steel Rack Frame With 6 Support Rails

6 Stainless Steel Oven Racks

EXTERIOR 20 Gauge Stainless Steel

Outside Dimensions (Height Includes Legs)

(W x D x H): 371/2" x 29" x 311/2"

(950mm x 740mm x 800mm)

S P E C I F I C AT I O N S

GAS Total BTU: 45,000 BTU

Gas Connection:

Gas Pressure Required: 7 to 14 Inches W/C

ELECTRICAL 208/240 Volt AC, 50/60 Hz, 3 Phase

Total kW: 1.0 kW

Amperage Per Phase

• 208/240 3 Phase: 3.1 Amp/Phase

Terminal Block Connection

WATER Cold Water Intake Size:

Water Pressure: 40 psi Min, 80 psi Max

Water Consumption: 30 Gal/Hr (113 Liters/Hr)

DRAIN Vented Drain Required

Drain Size: 11/2" NPT

WEIGHT Shipping Weight (Crated): 342 lb (155 kg)

Net Weight (Uncrated): 309 lb (140 kg)

INSTALLATION Legs 4" (100mm) Included

Vent Hood Required

Water Shut Off Valve Check Local Codes

Water Back Flow Preventer Required

Minimum Clearances Required

• Top (Clearance for Vent Stack to Hood): 111/4" (290mm)

• Sides (Includes Service Access): 20" (500mm)

• Back: 4" (100mm)

• Counter Top: 4" (100mm)

3

/4" NPT

3

/4" NPT

ACCESSORIES Water Wash Down Hose Included (Part Number LDL)

Plastic Detergent Spray Bottle Included (Part Number PND)

Stainless Steel Oven Rack 6 Included (Part Number G610X)

OPTIONS Control Options: Manual Dial (M)

Digital (D)

Digital Programmable (DP)

Stainless Roll In Rack Frame, 6 Position: SRG6 (Standard Spacing)

Stainless Roll In Rack Frame, 4 Position: SRG685

Stainless Stand With Bottom Shelf: TB610

Rack Frame Transport Trolley: C610

Guides For Roll In Rack: GSR610

N S F

®

Page 70

MODEL LANG COMBI GAS: LCG-101

70

PAN CAPACITY Maximum 10 Full Size Sheet Pans

10 Full Size Steam Table Pans

Optimum 10 Full Size Sheet Pans

8 Full Size Steam Table Pans

INTERIOR 20 Gauge Stainless Steel Critical Components, 316 Stainless

Interior, 304 Stainless

Inside Oven Dimensions (W x D x H): 24" x 245/8" x 273/8"

(610mm x 620mm x 690mm)

2 Oven Lights

1 Oven Drain Screen

1 Removable Drip Tray

Stainless Steel Rack Frame With 10 Support Rails

EXTERIOR 20 Gauge Stainless Steel

Outside Dimensions (Height Includes Legs)

(W x D x H): 371/2" x 29" x 41"

(950mm x 740mm x 1030mm)

S P E C I F I C AT I O N S

GAS Total BTU: 70,000 BTU

Gas Connection:

Gas Pressure Required: 7 to 14 Inches W/C

ELECTRICAL 208/240 Volt AC, 50/60 Hz, 3 Phase

Total kW: 1.0 kW

Amperage Per Phase

• 208/240 3 Phase: 3.1 Amp/Phase

Terminal Block Connection

WATER Cold Water Intake Size:

Water Pressure: 40 psi Min, 80 psi Max

Water Consumption: 31 Gal/Hr (117 Liters/Hr)

DRAIN Vented Drain Required

Drain Size: 11/2" NPT

WEIGHT Shipping Weight (Crated): 430 lb (195 kg)

Net Weight (Uncrated): 408 lb (185 kg)

INSTALLATION Legs 4" (100mm) Included

Vent Hood Required

Water Shut Off Valve Check Local Codes

Water Back Flow Preventer Required

Minimum Clearances Required

• Top (Clearance for Vent Stack to Hood): 173/4" (450mm)

• Sides (Includes Service Access): 20" (500mm)

• Back: 4" (100mm)

• Counter Top: 4" (100mm)

3

/4" NPT

3

/4" NPT

ACCESSORIES Water Wash Down Hose Included (Part Number LDL)

Plastic Detergent Spray Bottle Included (Part Number PND)

OPTIONS Control Options: Manual Dial (M)

Digital (D)

Digital Programmable (DP)

Stainless Steel Oven Rack: G610X

Stainless Roll In Rack Frame, 10 Position: SRG10 (Standard Spacing)

Stainless Roll In Rack Frame, 7 Position: SRG1085

Stainless Stand With Bottom Shelf: TB610

Rack Frame Transport Trolley: C610

Guides For Roll In Rack: GSR610

N S F

®

Page 71

MODEL LANG COMBI GAS: LCG-141

71

PAN CAPACITY Maximum 7 Full Size Sheet Pans

14 Full Size Steam Table Pans

Optimum 7 Full Size Sheet Pans

10 Full Size Steam Table Pans

INTERIOR 20 Gauge Stainless Steel Critical Components, 316 Stainless

Interior, 304 Stainless

Inside Oven Dimensions (W x D x H): 33" x 321/2" x 22 1/32"

(840mm x 830mm x 560mm)

2 Oven Lights

1 Oven Drain Screen

1 Removable Drip Tray

7 Stainless Steel Racks

Stainless Steel Rack Frame With 7 Support Rails

EXTERIOR 20 Gauge Stainless Steel

Outside Dimensions (Height Includes Stand)

(W x D x H): 461/2" x 371/2" x 63"

(1180mm x 940mm x 1500mm)

S P E C I F I C AT I O N S

GAS Total BTU: 85,000 BTU

Gas Connection:

Gas Pressure Required: 7 to 14 Inches W/C

ELECTRICAL 208/240 Volt AC, 50/60 Hz, 3 Phase

Total kW: 1.0 kW

Amperage Per Phase

• 208/240 3 Phase: 3.1 Amp/Phase

Terminal Block Connection

WATER Cold Water Intake Size:

Water Pressure: 40 psi Min, 80 psi Max

Water Consumption: 33 Gal/Hr (124 Liters/Hr)

DRAIN Vented Drain Required

Drain Size: 11/2" NPT

WEIGHT Shipping Weight (Crated): 550 lb (250 kg)

Net Weight (Uncrated): 485 lb (220 kg)

INSTALLATION Legs 28" (71mm) Stand Included

Vent Hood Required

Water Shut Off Valve Check Local Codes

Water Back Flow Preventer Required

Minimum Clearances Required

•Top (Clearance for Vent Stack to Hood): 173/4" (450mm)

• Sides (Includes Service Access): 20" (500mm)

• Back: 4" (100mm)

• Floor: 6" (150mm)

3

/4" NPT

3

/4" NPT

ACCESSORIES Water Wash Down Hose Included (Part Number LDL)

Plastic Detergent Spray Bottle Included (Part Number PND)

Stainless Steel Oven Rack 7 Included (Part Number G241X)

Stainless Stand With Bottom Shelf Included (Part Number KSTD72)

OPTIONS Control Options: Manual Dial (M)

Digital (D)

Digital Programmable (DP)

Stainless Roll In Rack Frame, 7 Position: TRG14 (Standard Spacing)

Stainless Roll In Rack Frame, 5 Position: TRG1485

Rack Frame Transport Trolley: C1424

N S F

®

Page 72

MODEL LANG COMBI GAS: LCG-241

72

PAN CAPACITY Maximum 12 Full Size Sheet Pans

24 Full Size Steam Table Pans

Optimum 12 Full Size Sheet Pans

18 Full Size Steam Table Pans

INTERIOR 20 Gauge Stainless Steel Critical Components, 316 Stainless

Interior, 304 Stainless

Inside Oven Dimensions (W x D x H): 33" x 321/2" x 333/4"

(840mm x 820mm x 860mm)

3 Oven Lights

1 Oven Drain Screen

1 Removable Drip Tray

12 Stainless Steel Racks

Stainless Steel Rack Frame With 12 Support Rails

EXTERIOR 20 Gauge Stainless Steel

Outside Dimensions (Height Includes Legs)

(W x D x H): 461/2" x 371/2" x 63"

(1180mm x 940mm x 1500mm)

S P E C I F I C AT I O N S

GAS Total BTU: 115,000 BTU

Gas Connection:

Gas Pressure Required: 7 to 14 Inches W/C

ELECTRICAL 208/240 Volt AC, 50/60 Hz, 3 Phase

Total kW: 1.0 kW

Amperage Per Phase

• 208/240 3 Phase: 3.1 Amp/Phase

Terminal Block Connection

WATER Cold Water Intake Size:

Water Pressure: 40 psi Min, 80 psi Max

Water Consumption: 33 Gal/Hr (124 Liters/Hr)

DRAIN Vented Drain Required

Drain Size: 11/2" NPT

WEIGHT Shipping Weight (Crated): 639 lb (290 kg)

Net Weight (Uncrated): 595 lb (270 kg)

INSTALLATION Legs 12" (305mm) Included

Vent Hood Required

Water Shut Off Valve Check Local Codes

Water Back Flow Preventer Required

Minimum Clearances Required

• Top (Clearance for Vent Stack to Hood): 173/4" (450mm)

• Sides (Includes Service Access): 20" (500mm)

• Back: 4" (100mm)

• Floor: 6" (150mm)

3

/4" NPT

3

/4" NPT

ACCESSORIES Water Wash Down Hose Included (Part Number LDL)

Plastic Detergent Spray Bottle Included (Part Number PND)

Stainless Steel Oven Rack 12 Included (Part Number G241X)

OPTIONS Control Options: Manual Dial (M)

Digital (D)

Digital Programmable (DP)

Stainless Roll In Rack Frame, 12 Position: TRG24 (Standard Spacing)

Stainless Roll In Rack Frame, 9 Position: TRG2485

Rack Frame Transport Trolley: C1424

N S F

®

Page 73

MODEL LANG COMBI GAS: LCG-401

73

PAN CAPACITY Maximum 20 Full Size Sheet Pans

40 Full Size Steam Table Pans

Optimum 20 Full Size Sheet Pans

28 Full Size Steam Table Pans

INTERIOR 20 Gauge Stainless Steel Critical Components, 316 Stainless

Interior, 304 Stainless

Inside Oven Dimensions (W x D x H): 33" x 321/2" x 5411/32"

(840mm x 820mm x 1390mm)

4 Oven Lights

1 Oven Drain Screen

1 Removable Drip Tray

Stainless Steel Rack Frame With 20 Support Rails

10 Stainless Steel Oven Racks

EXTERIOR 20 Gauge Stainless Steel

Outside Dimensions (Height Includes Legs)

(W x D x H): 521/2" x 371/2" x 761/2"

(1330mm x 940mm x 1920mm)

S P E C I F I C AT I O N S

GAS Total BTU: 170,000 BTU

Gas Connection:

Gas Pressure Required: 7 to 14 Inches W/C

ELECTRICAL 208/240 Volt AC, 50/60 Hz, 3 Phase

Total kW: 1.0 kW

Amperage Per Phase

• 208/240 3 Phase: 6.0 Amp/Phase

Terminal Block Connection

WATER Cold Water Intake Size:

Water Pressure: 40 psi Min, 80 psi Max

Water Consumption: 66 Gal/Hr (248 Liters/Hr)

DRAIN Vented Drain Required

Drain Size: 11/2" NPT

WEIGHT Shipping Weight (Crated): 1145 lb (520 kg)

Net Weight (Uncrated): 1035 lb (470 kg)

INSTALLATION Legs 12" (305mm) Included

Vent Hood Required

Water Shut Off Valve Check Local Codes

Water Back Flow Preventer Required

Minimum Clearances Required

•Top (Clearance for Vent Stack to Hood): 203/4" (450mm)

• Sides (Includes Service Access): 20" (500mm)

• Back: 4" (100mm)

• Floor: 6" (150mm)

3

/4" NPT

3

/4" NPT (2 each)

ACCESSORIES Water Wash Down Hose Included (Part Number LDL)

Plastic Detergent Spray Bottle Included (Part Number PND)

Stainless Steel Oven Rack 10 Included (Part Number G241X)

Stainless Roll In Rack Frame, 20 Position: Included (Part Number SRG40GE)

Rack Frame Transport Trolley 1 Per Oven (Part Number C401)

OPTIONS Control Options: Digital Programmable (DP)

Stainless Roll In Rack Frame, 14 Position SRG4085GE

Stainless Rack Frame Stand BAS401

N S F

®

Page 74

74

LCE-61 M

Page 75

75

LCE-61 M

Page 76

76

LCE-61 D

Page 77

77

LCE-61 D

Page 78

78

LCE-61 DP

Page 79

79

LCE-61 DP

Page 80

80

LCE-101 M

LCE-141 M

Page 81

81

LCE-101 M

LCE-141 M

Page 82

82