Page 1

INSTRUCTIONS FOR THE TECHNICAL EXPERT

LCE-401DP

05 2000 II

39D0390

Page 2

IMPORTANT IMPORTANT IMPORTANT

Post in a prominent location, a set of instructions to be followed in the event

the user smell gas. Obtain these instructions from your local gas supplier.

FOR YOUR SAFETY: Do not store or use gasoline or other flammable vapors

and liquids in the vicintiy of this or any other gas appliance.

In the event a gas odor is detected, shut down units at the main shut-off valve

and contact the local gas company or supplier for service.

WARNING: Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death. Read the

installation, operating and maintenance intructions thoroughly before installing

or servicing this equipment.

Installation, startup and adjustments of this appliance should be accomplished

by personnel qualified to install gas equipment.

Retain this manual for future reference.

Page 3

Page 4

Section A

GENERAL INSTRUCTIONS

1. Preliminary operations

Make sure the appliance is supplied complete and has not been

damaged in transit.

2. Positioning

Keep the appliance area free and clear of combustible material and do not obstruct the flow of

combustion or ventilation air.

The installation of any components such as a vent hood, grease extractors, and/or fire

extinguisher systems, must conform to the their applicable nationally recognized installation

standards.

3. Gas connection

☞

For the exact position and size of connections, consult the gas connection chart

enclosed in Section B.

All gas connections must be in accordance with local codes and comply with the National

Fuel Gas Code ANSI Z223.1 latest edition, Natural Gas Installation Code CAN/CGA - B149.1

or Propane Installation Code CAN/CGA - B149.2.

Connect each oven separately. A gas shut off valve must be installed to the oven(s) and

located in an accessible area.

This appliance and its individual shutoff valve must be disconnected from the gas supply

piping system during any pressure testing of that system at test pressures in excess of 1/2

PSGI (3.45 kPA) and the appliance must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure testing of the gas supply

system at test pressures equal to or less than 1/2 PSIG (3.45 kPA).

3.1 Test gas

Model

XXX

NAT. - 7" 4.5"

1 2 3

Btu/h

Serial number

120V1N 60 Hz A

1) Gas type and supply pressure

2) Injector pressure

3) Input rating Btu/h

☞

gas with wich it is to be operated.

Always check the pressure of the the gas supply. For this purpose, use the pressure test

outlet provided on the appliance, following procedure outlined in section B.

Test for gas leaks. Use a commercial leak detector or a soap and water solution.

Check the data plate to make sure that the appliance has been tested for the type of

WARNING

DO NOT USE AN OPEN FLAME TO TEST FOR GAS LEAKS.

- 1 -

Page 5

Section A

GENERAL INSTRUCTIONS

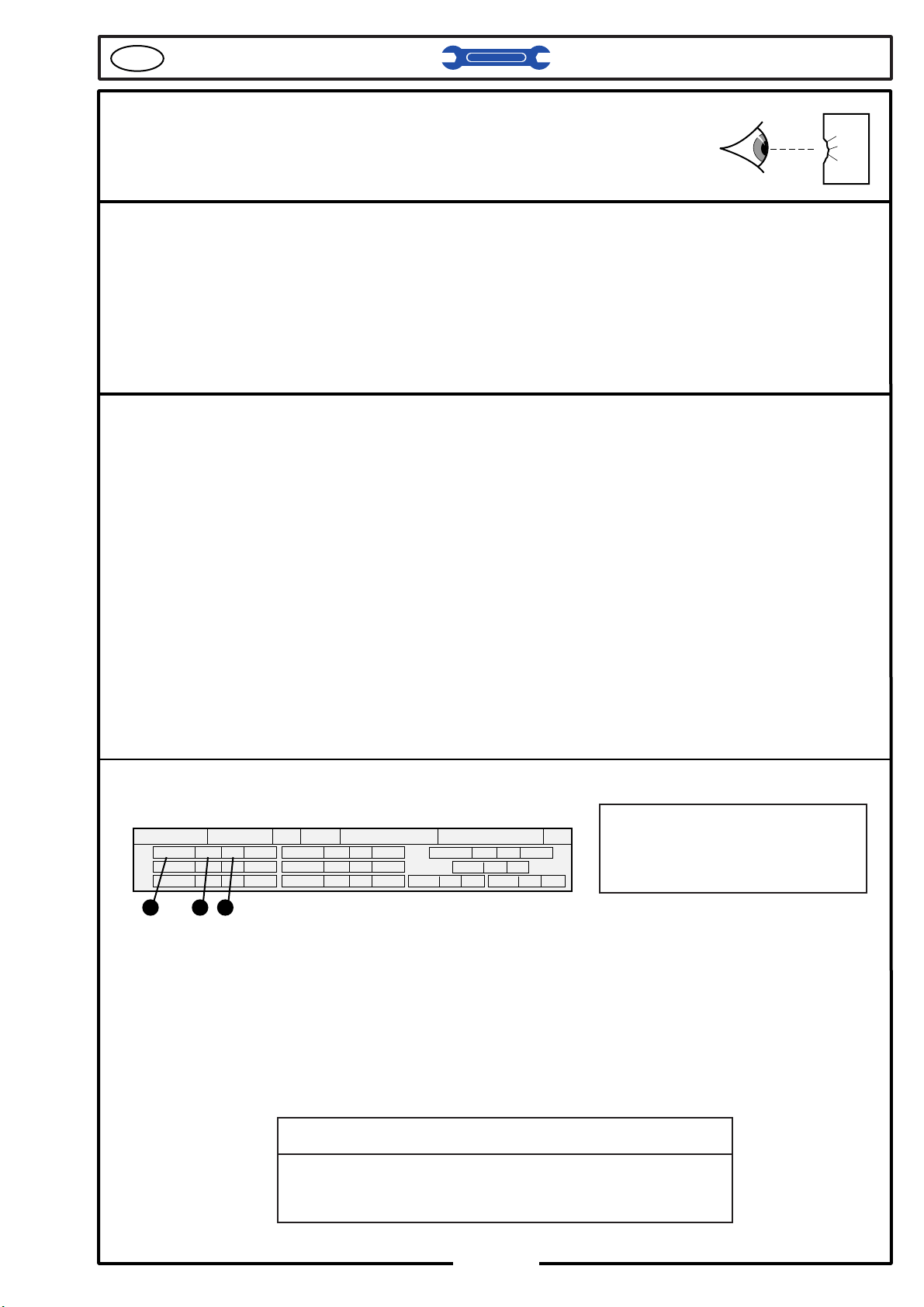

4. Electrical connection

The appliace must be electrically grounded in accordance with local codes, or in the absence

of local codes, with the

Code, CSA C22.1

-.2.

National Electrical Code, ANSI/NFPA 70

, or the

Canadian Electrical

4.1 Operating voltage

Model

XXX Serial number

NAT. - 7" 4.5" Btu/h

120V1N 60 Hz A

☞

☞

☞

Check the data plate to make sure the operating voltage and frequency of the

appliance correspond to those of mains supply.

Adhere scrupulously to the indications in the technical chart and in the wiring diagram,

and the instructions contained in section B.

In the notes for the customer service is indicated the location of the wiring diagram on

the appliance.

Check the current absorption indicated on the data plate to determine the crosssectional area of the supply cable.

XXXXXXXXXX 0000

208V3

~ A Hz kW

0000000000000000000

5. Water connection

This appliance is to be installed to comply with the applicable Federal, state, or local

plumbing codes having jurisdiction.

☞

☞

☞

☞

Always install a stop-valve upstream of the appliance.

Downstream of the stop-cock, install appropriate fittings for easy disconnection of the

appliance and filters which can easily be inspected and cleaned.

Use materials, seals and fittings approved according to applicable standards. Use

suitable pipes which have properly treated in order to prevent the release of iron

oxides into the water (as these can alter the taste of the food and mark stainless

steel).

Make sure the water specifications are within the limits indicated in section B.

If necessary, install a suitable water treatment system.

- 2 -

Page 6

Page 7

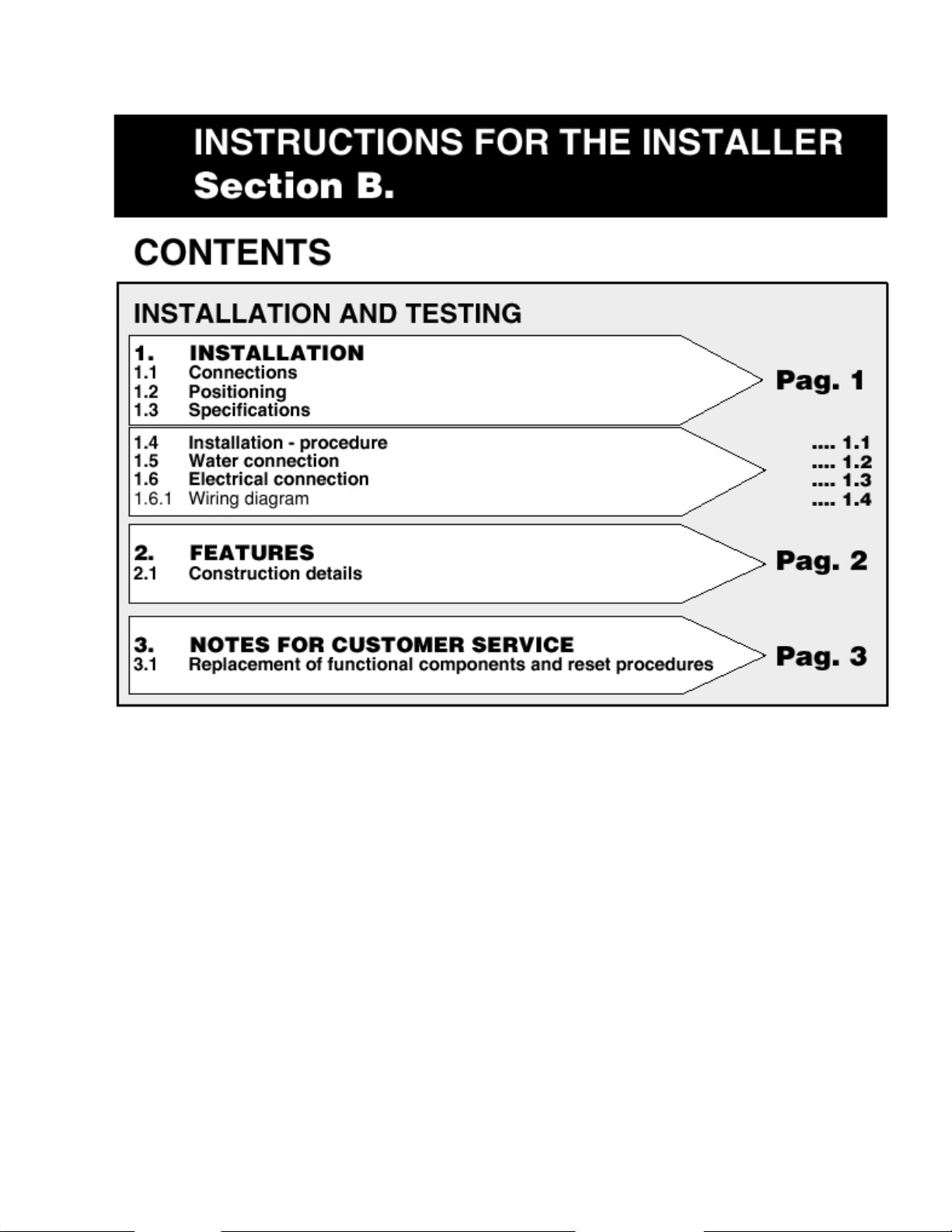

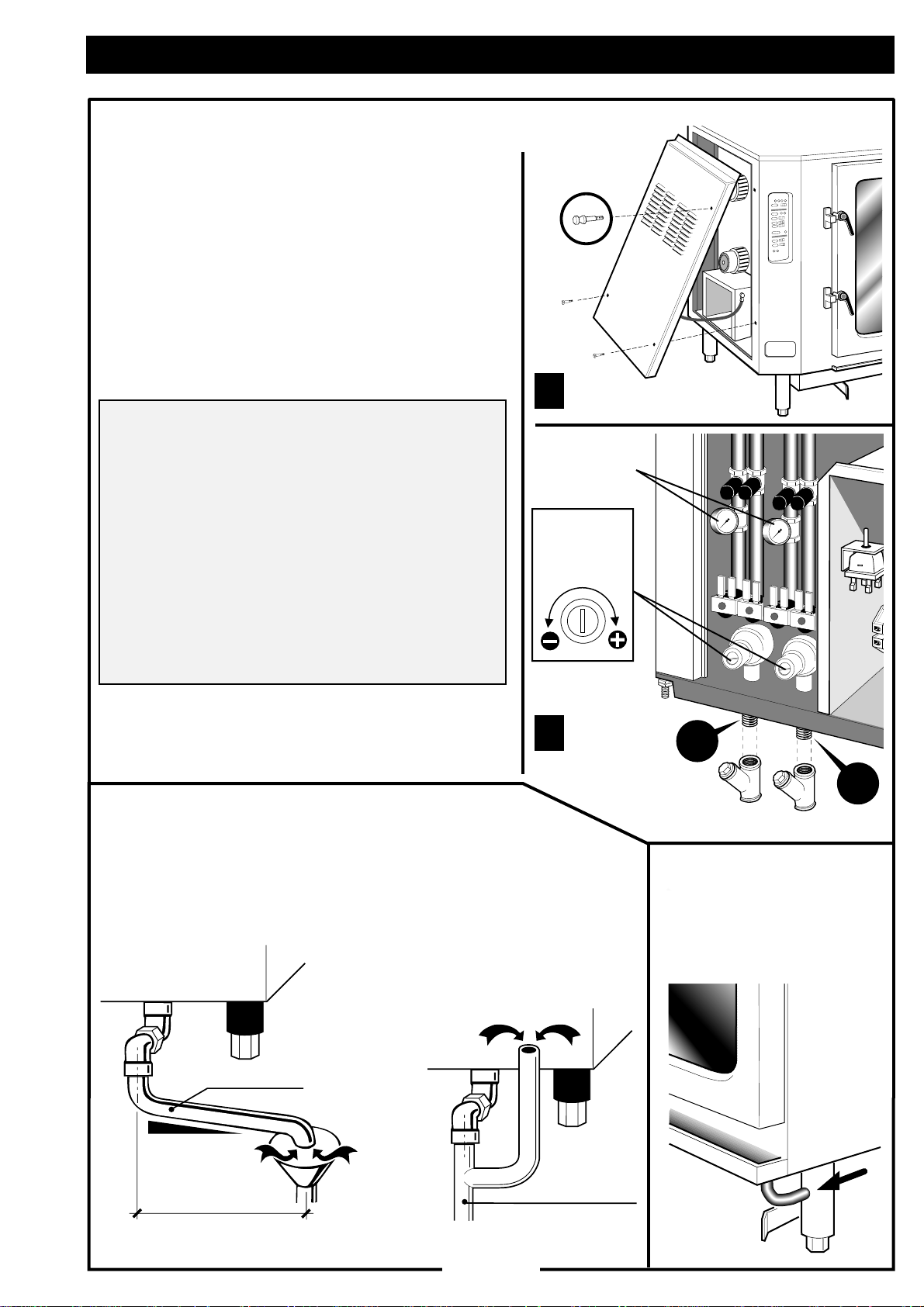

1. INSTALLATION

1.1 Connections

LCE-401DP

46.4"

Water inlet

Demineralised

water inlet

Water drain

Terminal board 3 Ph

Cable gland

Equipotential terminal

1.2 Positioning

• leave at least 4" clearance

between the rear of the appliance and the

wall

• leave at least 20" clearance at the

sides of the appliance

3

Ø

3

Ø

Ø 1"

/4"

/4"

1

63.7"

/

2

11.8"

2.7"

4.2"

3.7"

6.5"

2.1"

13.9"

75.5"

18.8"

35"

2"

46.4"

The cooling outlets of the control

section of the oven (side panel)

must not be near sources of

hot fumes or steam.

1.9"

All clearance requirements are the same for combustible or non combustible constructions.

For use only on non combustible foor.

1.3 Specifications

208V 3 Ph 60Hz 52.8 kW 147 A

240V 3 Ph 60Hz 52.8 kW 127 A

480V 3 Ph 60Hz 52.8 kW 66 A

(total weight of the appliance is marked on the packaging)

ELECTRICAL RATING

VOLTAGE POWER RATING MAX. LOAD (A)

Maximum sound pressure is no higher than 70 dB (A)

- 1 -

Page 8

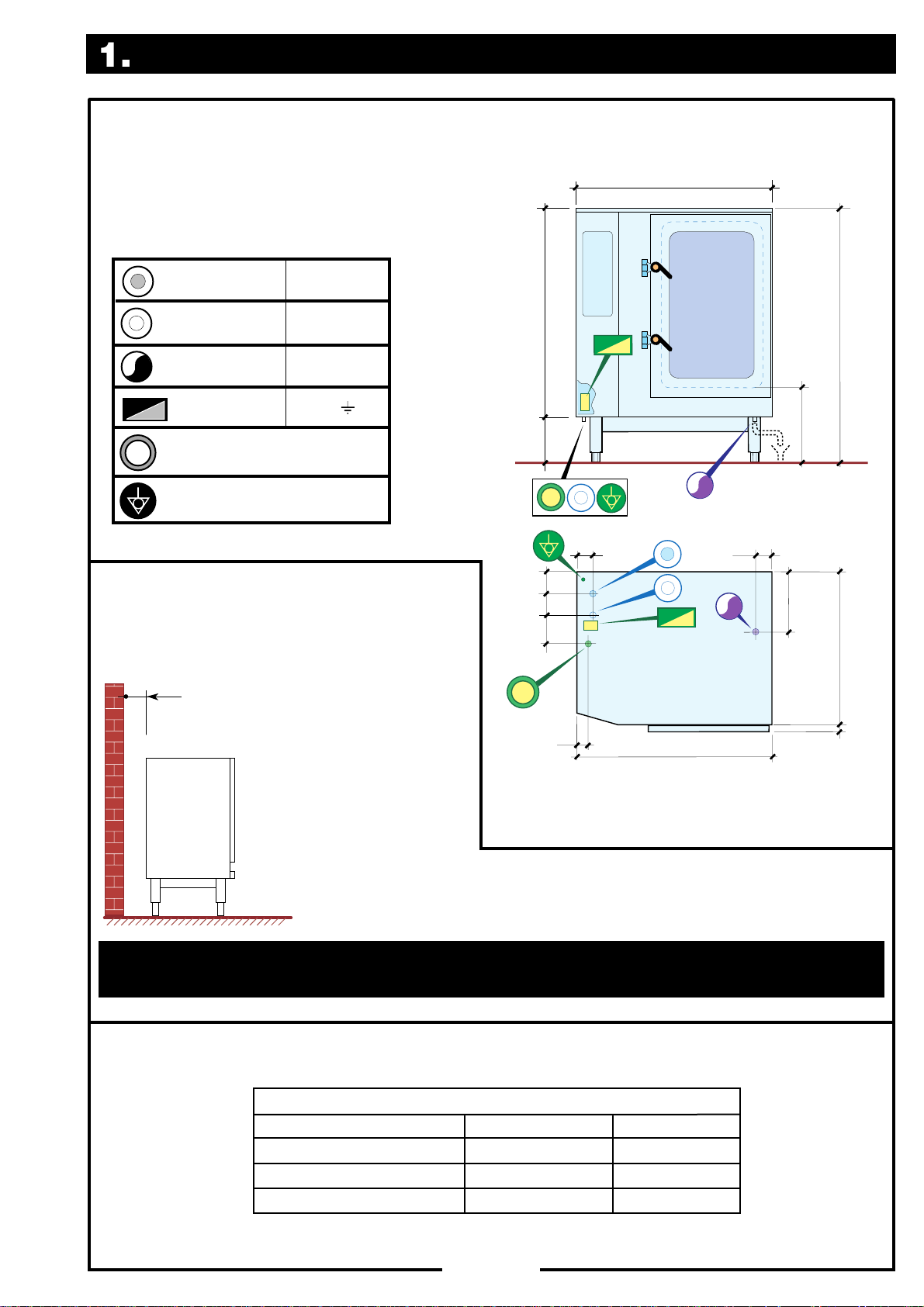

1. INSTALLATION

1.4 Installation - procedure

Fit the following units on the top of the oven:

• Steam vent pipe

Fit the following units beneath the oven:

• Transfer truck guides, to be preassembled as shown in the figure and then screwed to the

oven base through the predrilled holes.

1-1

Page 9

1. INSTALLATION

1.5 Water connections

Connecting the water supply

1) Remove the lh side panel by unscrewing the

two fixing screws at the bottom (if the optional spray gun is fitted - also the relative fixing

screws must be removed).

2) Fit the supplied filters on the water inlet connections in an accessible position.

The appliance must be supplied exclusively with

cold water conforming to the following specifications:

Pressure:

(30

- 80 PSI)

pH: from 7 to 7.5;

Conductivity: less than 200 µS/cm;

t.d.s. < 100 ppm

Hardness: connection W1: from 6.3 to 8.8 °e (5...7

°d, 9 ...13 °f, or 90 ...125 ppm); connection W2:

we recommend demineralised water or very soft

water (0.7...3.5 °e = 1...5 °f = 0.5...2.8 °d = 10...50

ppm)(5 - 10° clark);

Max. salinity and ion content in mg/l:

- chlorides < 30; sulphates < 40; Fe (iron) < 0.1; Cu

(copper) < 0.05; Mn (manganese) < 0.05.

between 200 and 600 kPa

;

Spray gun

support

1

Pressure

gauges

Water

pressure

regulator

screws

Internal pressure gauges must give a reading

of 100 kPa (15 PSI); if the reading is

different, correct by adjusting the pressure

2

regulators.

Water drain

WARNING: to ensure the appliance operates correctly and to

avoid the risk of serious damage, the drain must be vented (i.e.

in communication with the atmosphere).

The material of the drainage pipe must be heat resistant type and

not flexible.

min. Ø 1"

min. 5% (3°)

1/2

w1

w2

3/4"

Condensate drain

Connect a suitable tube to

the fitting on the condensate tray and connect to

the drain pipe.

3/4"

max. 5 ft

1-2

min. Ø 1"

1/2

Page 10

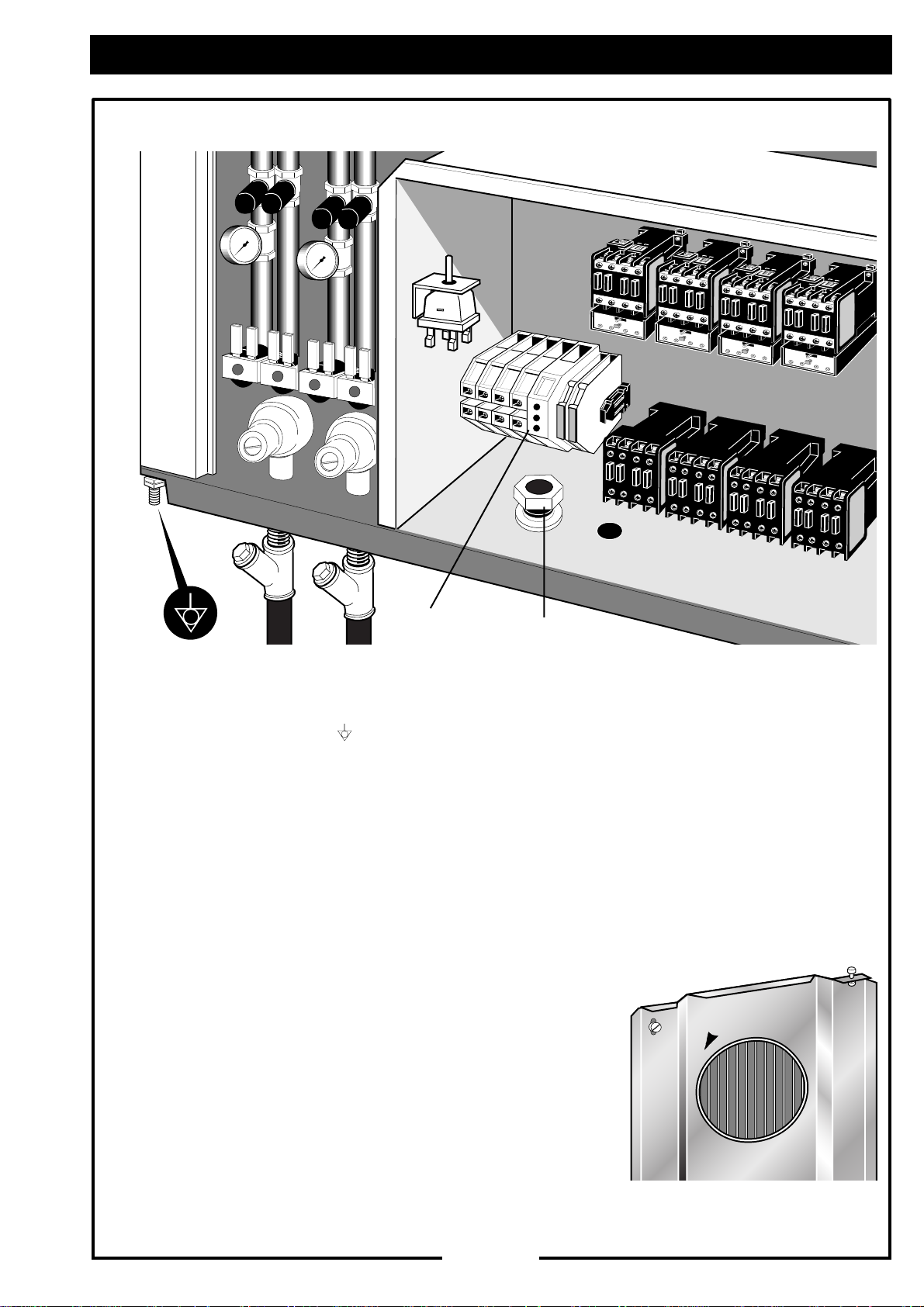

1. INSTALLATION

1.6 Electrical connection

terminal board

Equipotential connection

• The equipotential terminal ( ) is located beneath the appliance at the rear lh corner.

Mains connection

• Remove the lh side panel as indicated in heading 1.5.

• Read the general precautionary notes in Chapter 4, Section A. of this handbook.

• Fit the suitable cable gland in the relative hole.

• Route the cable from the main power switch through the cable gland, and connect the wires

to the terminal board (see electrical diagram on next page).

N.B.: After making the connection ensure that the motor turns

in the direction indicated by the arrow on the fan shroud (in

the oven chamber).

cable gland

1-3

Page 11

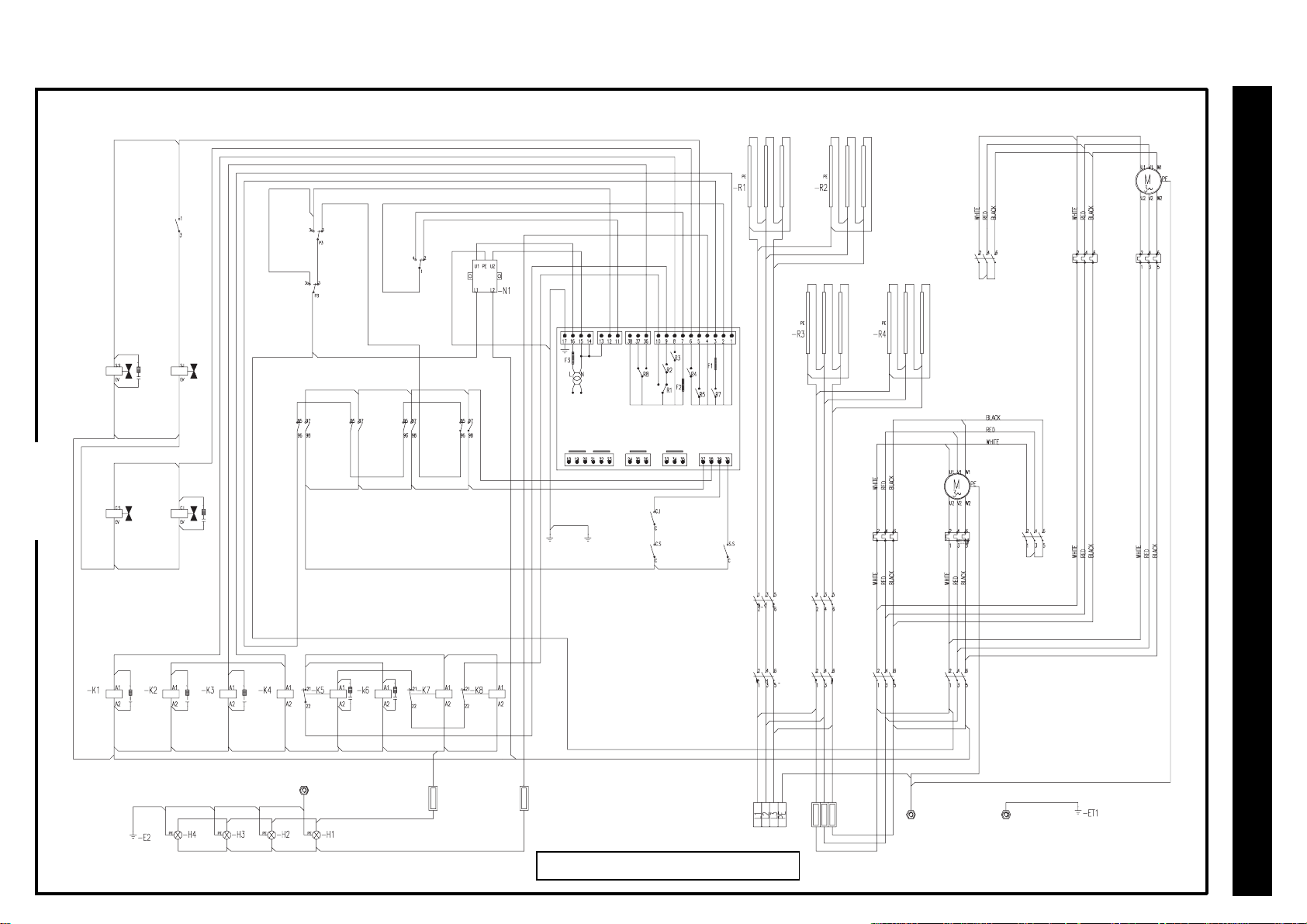

1.6.1 Wiring diagram

DRAIN

THERMOSTAT

30-90°C

SAFETY THERMOSTAT

LOWER CHAMBER

UPPER DRAIN

LOWER DRAIN

HALF SPEED

UPPER MOTOR

UPPER CHAMBER

SAFETY THERMOSTAT

UPPER

MOTOR

LOWER

MOTOR

DOOR

MICROSWITCH

LOWER

MOTOR

FILTER

LC

STB CAMERA

ELECTRONIC BOARD

UPPER

CHAMBER

DRAIN

PROBE

PROBE

MICRO DOOR

CORE

PROBE

LOWER

CHAMBER

PROBE

UPPER SMALL

UPPER LARGE

LOWER SMALL

FULL SPEED LOWER

MOTOR CONTACTOR

LOWER LARGE

HALF SPEED LOWER

MOTOR OVERLOAD RELAY

LOWER

MOTOR

FULL SPEED

LOWER MOTOR

OVERLOAD RELAY

1. INSTALLATION

1-4

UPPER CHAMBER

UPPER

H.ELEMENT

CONTACTOR

UPPER

SECURITY

CONTACTOR

RIGHT PANEL

LOWER CHAMBER

LOWER

H.ELEMENT

CONTACTOR

LOWER

SECURITY

CONTACTOR

LAMP LAMP LAMP LAMP

HALF

SPEED

CONTACTOR

CONTACTOR

ELECTRIC CABINET

FULL

SPEED

UPPER

MOTOR

F1 1A

LOWER

MOTOR

LOWER

CHAMBER PRESS.

UPPER

DRAIN PRESS.

UPPER SECURITY

CONTACTOR

H.ELEMENT

CONTACTOR

UPPER

F2 1A

LEFT PANEL

UPPER

CHAMBER PRESS.

LCE-401DP 208/240V 3Ph

LOWER

SECURITY

CONTACTOR

LOWER

H.ELEMENT

CONTACTOR

TERMINAL BOARD

UPPER MOTOR

OVERLOAD RELAY

CONTACTOR

F3 20A

F4 20A

F5 20A

HALF SPEED

LOWER

SPEED

MOTOR

UPPER

MOTOR

FULL

SPEED

MOTOR

CONTACTOR

ELECTRIC CABINET

FULL SPEED

UPPER MOTOR

CONTACTOR

ELECTRIC CABINET

TRANSFORMER

Page 12

1.6.1 Wiring diagram

1. INSTALLATION

1-4

DRAIN

THERMOSTAT

30-90°C

UPPER DRAIN

UPPER CHAMBER

LOWER DRAIN

LOWER CHAMBER

UPPER CHAMBER

SAFETY THERMOSTAT

SAFETY THERMOSTAT

LOWER CHAMBER

HALF SPEED

UPPER MOTOR

UPPER

MOTOR

LOWER

MOTOR

DOOR

MICROSWITCH

LOWER

MOTOR

FILTER

LC

STB CAMERA

ELECTRONIC BOARD

UPPER

CHAMBER

DRAIN

PROBE

PROBE

LOWER

CHAMBER PRESS.

LEFT PANEL

CHAMBER PRESS.

MICRO DOOR

CORE

PROBE

UPPER

LOWER

CHAMBER

PROBE

UPPER

DRAIN PRESS.

UPPER SECURITY

CONTACTOR

UPPER

LOWER

SECURITY

CONTACTOR

LOWER

UPPER MOTOR

OVERLOAD RELAY

HALF SPEED

FULL SPEED LOWER

MOTOR CONTACTOR

UPPER

MOTOR

HALF SPEED LOWER

MOTOR OVERLOAD RELAY

FULL SPEED

UPPER MOTOR

CONTACTOR

LOWER

MOTOR

FULL SPEED

LOWER MOTOR

OVERLOAD RELAY

UPPER

H.ELEMENT

CONTACTOR

UPPER

SECURITY

CONTACTOR

RIGHT PANEL

LOWER

H.ELEMENT

CONTACTOR

LOWER

SECURITY

CONTACTOR

HALF

SPEED

CONTACTOR

FULL

SPEED

CONTACTOR

ELECTRIC CABINET

LAMP LAMP LAMP LAMP

LCE-401DP 480V 3Ph

UPPER

MOTOR

LOWER

MOTOR

F1 1A

F2 1A

FUSE HOLDER

UPPER

H.ELEMENT

CONTACTOR

LOWER

H.ELEMENT

CONTACTOR

TERMINAL BOARD

F3 20A

CONTACTOR

F4 20A

F5 20A

LOWER

SPEED

MOTOR

FULL

SPEED

MOTOR

CONTACTOR

ELECTRIC CABINET

F6 2A

ELECTRIC CABINET

TRANSFORMER

Page 13

2. FEATURES

2.1 Construction details

1

5

6

7

8

9

10

11

12

13

LCE-401DP

1) Steam vent pipe

2) Adjustable foot

3) Guides for service transfer truck

4) Condensate tray drain outlet

5) Stand-by key

6) Alarms display

7) Cooking mode selection keys

8) Special function keys

9) Thermostat controls

10) Timer controls

2

3

11) Core temperature probe selector

12) Programming - memory storage section

13) Cooking START/ STOP key

only DP

*

4

*

-

-

Page 14

3. NOTES FOR CUSTOMER SERVICE1.6

3.1 Replacement of functional components and reset procedures

The above operations must be carried out by skilled and authorised personnel.

Disassemble only the specified side panels. Do not remove the rear panel.

WARNING

☞

Replacing light bulbs or the diffuser glass

☞

Disconnect the electrical supply

by setting the main power switch

to OFF.

- remove the rh side panel by unscrewing the relative

screws

- unscrew the screw and nut shown in the figure and

withdraw the lampholder support; replace the bulb

with a bulb of identical specifications.

- to remove the diffuser glass for replacement, unscrew

the other three nuts inside the lampholder and

withdraw the glass.

OFF

T

Replacing fuses

☞

Remove the lh side panel;

- the plug-in type fuse holders are located at the side of the

terminal board; replace with rapid-acting fuses (see value on

electrical diagram).

Resetting overload cut-outs

☞

Remove the lh side panel.

- The overload cut-out disconnects the power supply to the motor

in the presence of overheating due to overload; before pressing

the reset button, find and eliminate the cause of the overload.

☞

Resetting the safety thermostat

The safety thermostat shuts down the oven

when internal temperature exceeds 572°F.

To restart the oven:

1

F1

R7

30

R5

6

29

R4

F2

28

R3

- Remove the lh side panel.

- Allow the oven to cool for about 10 minutes,

find and eliminate the cause of overheating

and then press the reset button.

27

26

R2

R1

12

109 8 7 6 54 3 2

25

2223

111213

2324

22

N

21

14

L

20

15

F3

16

19

21

17

18

120V

21 - Oven temperature probe

22 - Food temperature probe

23 - Drain temperature probe

24 - Safety contactor

25 - Backup thermostat

9

18

L

U

25

LC

L

U

19

10 - Fan motor

12 - Electronic card

16 - Motor overload cutout

18 - Safety thermostat

19 - LC filter

1

WARNING: VOLTAGE BETWEEN L1 AND N MUST BE 120V

A1

A2

A1

A2

2

8

24

3N

L

2

L

208V3N

240V3N

1

L

1B

F1

F2

5 - Water inlet solenoid valve

6 - Inlet pressure switch

7 - Lighting = 2 x 25 W

8 - Heating element contactor

9 - Door microswitch

10

3

A1

A2

V2

16

W1

V1

U2

U1

W2

77

5

7

4

1 - Terminal board

1B - Fuse carrier (F 0.5 A)

2 - Heating elements

3 - Motor contactor

4 - Drain solenoid valve

ELECTRICAL DIAGRAM

- 3 -

Page 15

INSTRUCTIONS FOR THE USER

LCE-401DP

05 II2000

39D0390

Page 16

Section A.

GENERAL INSTRUCTIONS

1. Contents

2. Hazards in the work environment

2.1 Fire

2.2 Accidents

2.3 Electricity

2.4 Gas

3. Correct use

3.1 Working in safety

3.2 What to do in the event of a malfunction

3.3 Prolonged period of non-use

3.4 Definitive deactivation of the equipment

4. Malfunctions

4.1 Problems, causes and remedies

1

2

3

4

5. Maintenance

5.1 Maintenance contract

5.1.1 User-serviceable parts

5.2 Advice

6. Cleaning

6.1 Cleaning of appliances

6.2 Cleaning of stainless steel

6.2.1 Ordinary daily maintenance

6.2.2 Precautions during use

6.2.3 Protecting the stainless steel

7. Observance of regulations

7.1 Standards and regulations

7.2 Liability

5

6

7

8

- 1 -

Page 17

2. HAZARDS IN THE WORK ENVIRONMENT

2.1 FIRE

Curtains, cloths, chopping-boards or other wooden objects must be kept a safe

distance from hobs and other heat sources; the same applies to vessels

containing alcohol, solvents or inflammable cleaning agents, etc. The risk of

fire in a kitchen is very high.

Fires usually start in a precise point and can be prevented from spreading if

panic is avoided. Hasty reactions may worsen the situation. Never use water to

extinguish an electrical fire; first disconnect the electrical power supply then

extinguish the fire using suitable materials or fire extinguishers.

2.2 ACCIDENTS

There is also a high risk of personal injury (burns, falls) in a commercial kitchen.

Make sure the handles of pans do not protrude from the hob, and frying pans

and other fryer equipment must not be left unattended at any time. Any oil or

grease spilled on the floor must be cleaned up immediately to prevent

slipping.

2.3 ELECTRICITY

The most serious hazards associated with electricity are those of fire

and electrocution.

Follow the safety instructions below:

• Electrical installations: all installation and maintenance should be

carried out by a qualified electrician in accordance with current safety

standards. The main switch must be easily accessible. Cables, plugs

and sockets must be kept in perfect condition.

• Safety: always turn off the main switch before cleaning or any other

operation on the appliance.

Never pull on a power supply cable to unplug an appliance from a

socket.

Do not attempt to repair a damaged cable with insulating tape or other

means, have the entire cable replaced by qualified personnel.

2.4 GAS

The smell of gas is a sign of a probable leak. In this event, close the main shut-off

valve, open doors and windows, and take care not to cause any sparks or

flames.

If you cannot identify the cause of the leak, call a qualified service engineer.

A high percentage of accidents happen because the gas appliances are not

checked regularly: gas appliances are only safe if they are kept in perfect

working order (see chapter 5).

Essential safety precautions when working with gas appliances

To light a gas burner, first bring the flame near to the burner and then turn on the gas.

It is important that the gas burns properly (blue flame) and that there are no restrictions in

the flueways, as these might give rise to dangerous emissions of carbon monoxide

fumes (which are even more hazardous than mains gas, because they are odourless

and give poisoning symptoms that may be confused with harmless disorders).

We strongly recommend the installation of electronic sensors by qualified personnel.

- 2 -

Page 18

3. CORRECT USE

Adhere scrupulously to the instructions in Section B and do not tamper with the appliance's

☞

safety devices, as this would invalidate any warranty and release the manufacturer from all

liability.

The equipment may be utilised only for the specific uses for which it is intended (as indicated

☞

in Section B).

Any other use is deemed improper and thus hazardous.

THE MANUFACTURER ACCEPTS NO LIABILITY FOR ANY DAMAGE, LOSS OR INJURY

DERIVING FROM INCORRECT INSTALLATION OR USE AND IN THIS CASE DOES NOT

GUARANTEE THE CORRECT OPERATING OF THE APPLIANCE.

3.1 WORKING IN SAFETY

Not to know or to underestimate the risks deriving from the incorrect or improper use of the

appliance can be very dangerous. It is important to adopt working habits in the daily use of the

appliances:

☞

learn the correct use of the various appliances which comprise the

installation;

☞

☞

☞

Inexperience, negligence or haste may cause situations of emergency which otherwise could

have been avoided. Prevention is the first rule for working in safety. Ensure that the electrical

system is perfect order and that gas appliances are inspected regularly. Always think beforehand

of what you are about to do and how to do it, and act in such a way as to ensure your own safety

and that of your colleagues.

after each use, always make sure that all appliances are turned off and

then close the shut-off valve and/or turn off the main switch;

do not use inflammable cleaning agents and do not leave containers with these

substances near the appliance;

the appliance is intended for professional use and must be used by qualified

personnel only!

check the correct operation of the appliance every 6 months. On type B appliances, the

☞

fume exhaust duct must also be checked.

3.2 WHAT TO DO IN THE EVENT OF A MALFUNCTION

Do not attempt any repairs yourself. Turn off the main switch, gas shut-off valves,

water taps, etc. as applicable, and call a qualified service engineer.

We strongly recommend that you contact our Service Centre in your area, which

can provide the necessary expertise and equipment, and which maintains a stock

of original replacement parts.

3.3 PROLONGED PERIODS OF NON-USE

If the appliance is not to be used for a prolonged period, close the gas shut-off valve and/or turn

off the main switch. Clean the appliance thoroughly as indicated in Section B, and protect it

from dust with a cover allowing free air circulation.

3.4 DEFINITIVE DEACTIVATION OF THE EQUIPMENT

Seek assistance from qualified personnel.

- 3 -

Page 19

;

;

4. MALFUNCTIONS

4.1 Problems, causes and remedies

The guide below will help the User to rectify minor faults; in the event of any other problems,

contact the approved Service Centre, the only service centre authorised to repair the

appliance.

• SMELL OF GAS

This may be an occasional leak: Boiling water has extinguished a flame, but in this case the safety device

intervenes and locks the gas outlet before a dangerous gas concentration is reached in the room. Close the

gas cock and aerate the room. If this is not the cause, have the equipment checked by skilled personnel.

• THE PILOT FLAME DOES NOT IGNITE

Check that the ignition device (whether electric, piezoelectric or electronic)

functions correctly; try igniting the pilot flame with a match.

There may be air in the piping, especially after a period of non-use; in this case, repeat the ignition

operation, this time trying for a little longer.

• THE PILOT FLAME DOES NOT REMAIN LIT

The control knob is being released too soon, before the thermocouple has had time to reach operating

temperature. Repeat the ignition operation, but keep the knob pressed in for a little longer.

• THE PILOT FLAME IGNITES BUT THE BURNER REMAINS OFF

Check that thermostat control knob is turned to a temperature setting and activate the

ignition enabling device (if present).

If the gas flow is controlled by an electric or electronic system, make sure the system is

receiving electrical power (any displays or indicator lights must be lit).

• DEFECTIVE COMBUSTION (YELLOW FLAME)

This may be caused by dirt in the burner or by clogged smoke pipes. It may also be caused by

dripping condensate created by an obstruction or dirt in the flue.

Call a competent service engineer.

• MALFUNCTION OF ELECTRIC EQUIPMENT

This may be due to the absence of a supply phase (frequent tripping of the overload

cutout): check any fuses and replace if necessary.

If either the thermal-magnetic circuit breaker or residual current device (RCD) trips continuously, call an

authorised service engineer.

• PROBLEMS WITH WASHING EQUIPMENT

Poor washing results (dishwashing machine, vegetable washer, etc.) may be due

to the lack of a supply phase (see above) or to too little water pressure, in which

case a pressure boosting device must be installed. It may also be necessary to

install a water softener if white deosits are left on dishes after washing.

• INSUFFICIENT COOLING IN REFRIGERATING EQUIPMENT

This may be due to incorrect positioning (near to heat sources), or to excessive ice on

the evaporator (appliances without automatic defroster), in which case it will be

necessary to defrost manually

.

• INSUFFICIENT AIR SUCTION IN EXHAUSTING SYSTEMS

Ensure all grease filters are kept clean.

- 4 -

;;;;

;;;;

Page 20

5. MAINTENANCE

5.1 MAINTENANCE CONTRACT

It is advisable to have the equipment regularly checked by a qualified service

engineer so as to ensure its efficiency and to guarantee maximum working safety.

We therefore recommend that the user enters into a maintenance contract with

specialised companies capable of guaranteeing the following operations:

☞

☞

☞

☞

5.1.1 User-serviceable parts

The user is only authorised to replace any deteriorated service components

(handles, removable basins, grilles, etc.). The user is not authorised to

replace functional components or to tamper with the appliance in any

way.

The parts that may be replaced by the user are explicitly listed in section 2 of

manual B together with instructions for their replacement. If this information is

missing, consult a qualified service engineer.

N.B.: intentional damage, or damage due to lack of care or

negligence or to failure to observe the prescriptions,

instructions and standards, or due to incorrect connections

or non-authorised tampering with the appliance, negate any

guarantee or liability on the part of the manufacturer.

Maintenance of service installations

Regular inspection of appliances

Conversion operations (change of gas type or operating voltage)

Repairs.

5.2 ADVICE

Make a note of the emergency phone-number

of your qualified service engineer.

- 5 -

Page 21

6. CLEANING

6.1 CLEANING OF APPLIANCES

•

Before cleaning, close the main gas valve and/or the main electrical power

switch and allow the appliance to cool.

• To clean any stainless steel, chromium-plated, enamelled, plastic,

duraluminium or painted parts, use lukewarm water and non-abrasive, noncorrosive commercial detergents. Rinse and dry thoroughly after cleaning.

OFF

• Never use water jets

pressure water jets. See also the detailed cleaning instructions indicated in

Section B.

• For the proper care of stainless steel parts, adhere scrupulously to the

recommendations below.

directly on the appliances for cleaning, particularly high-

6.2 CLEANING OF STAINLESS STEEL

Stainless steel is so called because it is not affected by oxidation; this is due to a thin molecular

layer of oxide on the surface which protects against further oxidation.

There are, however, substances which can modify or destroy this layer, giving rise to corrosion;

besides preventing the protective film of oxide from reforming, these substances corrode the

stainless steel itself and can cause irreparable damage.

It is therefore necessary to prevent this by choosing correct cleaning products and by complying

with the following simple recommendations: never forget that when using these appliances, the

first and fundamental rule is to guarantee that the treated products are both non-toxic and

hygienic.

Before using any detergent to clean either the stainless steeI or the immediate and surrounding

floor area, always ask your supplier for the most suitable product which does not cause corrosion

on the steel itself; the onset of rust is most commonly caused by the use of unsuitable cleaning

materials (strongly acid chlorate based detergents) or on inadequate maintenance.

6.2.1 Ordinary daily maintenance

Carefully and frequently cIean the surfaces using a damp cloth; use soap and water

or normal detergents, so Iong as these do not contain abrasives or chlorine

based substances such as sodium hypochlorite (bleach), hydrochloric acid or other

such solutions. These products quickly and irrepairably corrode stainless steel.

When cleaning fIoors underneath or near the appliances, never use the above

mentioned products as vapours or splashes could subject the steel to similar

destructive effects.

Only ever rub in the direction of the satining, then thoroughly rinse with clean water

and carefully dry.

☞

Spots of baked food: wash spots of baked food with hot water before they

have time to harden. If the residue has already hardened, use soap and

water or detergent without chlorate, using a wooden spatula or fine

stainless steel wool if necessary; thoroughly rinse and dry.

- 6 -

Page 22

☞

Scale deposits: scale deposits at the bottom of tanks, pans, etc., must be removed with

commercial descaling products applied according to the relative instructions.

☞

☞

☞

Scoring: scratches on the surfaces must be smoothed with very fine stainless steel wool,

or synthetic fibrous abrasive pads, by rubbing in the direction of the satining; rinse well and

dry. Never use wire wool on stainless steel surfaces since very small iron deposits could

remain there and create the formation ot rust by contamination.

Rust: water supply pipe, inevitably convey particles of rust dissolved in the water especially

in new installation plants or when taps are opened after a period of inactivity. These iron

deposits must not be allowed to remain on the stainless steel since

they produce rust by contamination.

Use suitable products to remove any rust marks, from companies

which produce detergents for industrial use.

After application, thoroughly rinse with clean water, neutralizing the

action of the product with an alkaline detergent normally used to clean

such appliances or with another specific product.

Burns: to eliminate burns or scorch marks from the steel, use soft

stainless steel wool or abrasive latex soap, carefully rub in the

direction of the grain of satin finish and take care to prevent the

surface from becoming scratched; thoroughly rinse and dry.

6.2.2 Precautions during use

☞

6.2.3 Protecting the stainless steel

When not in daily use, stainless steel is best treated with a thin film of oil, vaseline or

similar oil based product.

Sauces and condiments: all stainless steel vessels used to hold acid ingredients (vinegar,

salt, lemon juice, tomato, etc.) must be thoroughly cleaned.

Use only fine grain salt as an additive to cooking procedures.

Do not allow any salt deposits to remain in pans or containers after use.

Store containers uncovered.

- 7 -

Page 23

7. OBSERVANCE OF REGULATIONS

7.1 Standards and regulations

All laws, standards and regulations in force on the installation site must be observed,

including:

☞

☞

☞

☞

☞

☞

☞

☞

☞

7.2 Liability

Safety at work and accident prevention regulations;

Signs indicating obligation or prohibition;

Fire prevention standards;

Ventilation and the reduced emission of atmospheric pollutants;

Safety and maintenance of systems and flues;

Drains and waste treatments;

Production areas and the separation of work areas in compliance with hygiene

regulations;

Correct disposal of waste;

Environment hygiene, personal hygiene, food product hygiene.

The owner or manager of the kitchen is responsible for the following:

• the ensure conformance to the above regulations during the installation stage

and the observance of these regulations by the workforce;

• the training and conduct of kitchen personnel.

- 8 -

Page 24

Section B. -

INSTRUCTIONS FOR THE USER

LEARN TO USE THE APPLIANCE

1. SUMMARY

2. FEATURES

2.1 Construction details

3. OPERATING INSTRUCTIONS

3.1 Quick reference guide

3.2 Using the oven

3.2.1 Cooking without programming

3.3 Alarm signal

3.3.1 Fault finding

3.4 Advanced functions

3.4.1 Cooking with programming

Page 1

Page 2

Page 3

.... 3.1

.... 3.2

.... 3.3

3.4.2 Starting a cooking programme

3.4.3 Remarks on special featurees

4. CORRECT USE AND CLEANING

4.1 Correct use

4.1.1 Action to take if oven is not working

4.2 Cleaning

4.2.1 Daily cleaning

4.2.2 Cleaning functional parts of the oven

4.2.3 Cleaning the appliance prior to prolonged disuse

5. MAINTENANCE

5.1 Maintenance contract

.... 3.4

Page 4

.... 4.1

.... 4.2

Page 5

6. ACCESSOIRES

Page 25

2. FEATURES

2.1 Construction details

1

5

6

7

8

9

10

11

12

13

LCE-401DP

1) Steam vent pipe

2) Adjustable foot

3) Guides for service transfer truck

4) Condensate tray drain outlet

5) Stand-by key

6) Alarms display

7) Cooking mode selection keys

8) Special function keys

9) Thermostat controls

10) Timer controls

2

3

11) Core temperature probe selector

12) Programming - memory storage section

13) Cooking START/ STOP key

only DP

*

4

*

-

-

Page 26

3. OPERATING INSTRUCTIONS

3.1 Quick reference guide

ON-OFF BUTTON

STAND-BY key with green light idicator

(it switches on only when the appliance is

connected); by pushing the key the electronic panel and the light inside the cooking

chamber activate and deactivate..

ALARMS

See paragraph 3.3.1 to

identify the failure code

(from E1 to E7) shown on

this display

Flashing red indicator:: it lights when the

temperature inside the chamber is too high

for the selected cooking programme

Flashing red indicator: it lights either

when there is not enough water for the

cooking and when the pressure is

inadequate; it also lights together with

alarms E6 and E7 (and in this last case the

alarm display does not light)

Red indicator: it lights when the appliance

has been working for five hours and cleaning operation is due as per section 4.2.1.

By pushing the START-STOP key the five

hours count is reset and resumes from

zero.

Note.: for more details on these indicators, see section

3.3and 3.3.1.

COOKING SELECTION BUTTONS

STEAM COOKING with green indicator

(ON when the program has been chosen).

Working temperature range: from 122 to 218°F.

CONTROL BUTTONS

WATER INLET button (it can be activated

only with MIXED COOKING and

REGENERATION); the relevant display shows

the humidity percentage level

FULL or HALF SPEED FAN selection button

(it can be activated only with CONVECTION

COOKING - MIXED COOKING REGENERATION); the green indicator is on

when the low ventilation is activated

CONSERVATION at 158°F key with green

light indicator on when it is activated; sets a

chamber temperature of 158°F with low

ventilation; it switches on automatically at the end

of a cycle and is deactivated by key STOP

CHAMBER TEMPERATURE button: when

the cycle is not on it temporarily switches the

display reading from the set temperature to

the sensed one; when the cycle is on it

switches the display readind from the sensed

temperature to the set onea

COOKING TIME button: when the cycle is on

it switches the displayed value from the left

time to the set time; when the cycle is not on

the display is always showing the set time.

In case of cookings in sequence: when the

cycle is not on it switches the display from the

the set time of that cycle to the total time of

the sequence; when the cycle is on it switches

from the count-down of that cycle to the total

count-down of the sequence

CORE TEMPERATURE button: when the

cycle is on it switches the display from the set

temperature to the temperature sensed by the

probe; when the cycle is not on it activates or

disactivates the core temperature cooking

CONVECTION COOKING with green

indicator (

chosen).

Working temperature range: from 122 to 482°F.

MIXED COOKING (CONVECTION +

STEAM) with green indicator (ON when

the program has been chosen).

Working temperature range: from 122 to 482°F.

REGENERATION with green indicator

(ON when the program has been chosen).

Working temperature range: from 284 to

338°F.

OVERHEATED STEAM COOKING with

green indicator (on when the program

has been chosen).

Working temperature range: from 230 to

257°F.

UP-DOWN BUTTONS

ON when the program has been

they allow to increase and

decrease the numeric value

shown on the relevant display

PROGRAMING BUTTONS

PROGRAM MEMORY selection button: it

activates the program setting and the

relevant display shows the last selected

program (P01-P99)

Selection button for "COOKINGS IN

SEQUENCE": steps from a cooking

program to the next in the series (to see or

to set); by pushing it during the cooking phase

it is possible to modify the displayed cooking

MEMORY ERASE button: it allows to cancel

programs or cookings in sequence (the

displays relevant to the memories are

flashing); pushing it twice (without pushing key

ENTER) the erasure operation is cancelled.

ENTER button: it allows to store the modified

data or to erase either a program or a cooking

program from a series

START-STOP BUTTON

Button to START-STOP a PROGRAM

with green flashing indicator during the

cooking phase

- 3 -

Page 27

3. OPERATING INSTRUCTIONS

3.2 Using the oven

N.B.: At the start of each cooking session we advise preheating the oven by

running a short cooking cycle when empty; at the end of the cycle the oven will

automatically stop and an audible signal will sound for 30 seconds.

Coooking

Cooking can be carried out without programming, in which case cooking mode, time and

temperature (see below) must be set manually, or using pre-stored cooking programs (refer

to cooking with programming in subheading 3.4.1).

3.2.1 COOKING WITHOUT PROGRAMMING

- If displays 24 and 27 are illuminated, press key 25 to deactivate the programming function.

- Select the required cooking mode by pressing one of the

following keys:

6

(STEAM); 7 (CONVECTION); 8 (MIXED mode); 9 (RE-

GENERATION); 10 (SUPASTEAM)

.

- set the required chamber temperature on display 15 by

means of arrow-keys 17;

2

1

3 5

4

Note: when cooking in modes 8 or 9 (COMBI or

REGENERATION), display 11 switches on automatically. By

means of button 12, it is possible to set the humidity inside the

chamber. In modes 7, 8 or 9 it is possible to select "half speed

fan" for cooking delicate products by pressing 13.

Cooking with timer

- select the cooking with timer by means of button 19;

use the arrow-keys 20 to set the cooking time on display 18.

-

- Start the cycle using button 31 (START/STOP); the timer

display will show the count-down to the end of the cycle.

- When the cooking is finished, the heating stops and an

acoustic alarm will activate for some seconds.

Cooking with core temperature probe

- Use button 22 to select probe cooking;

- set the temperature required at the centre of the product

6

11

15

18

21

24

27

7 8 9 10

12

16

19

22

25 26

28

31

13

29 30

14

17

20

23

on display 21 by means of arrow-keys 23.

- Start the cycle using button 31 (START/STOP).

- When the cooking is finished, the heating stops and an acoustic alarm will activate for some

seconds.

Note: when the probe is inserted into the center of the food and activated, the cycle stops when center

of the product reaches the required temperature.

Changing settings during cooking

- The value set can be modified during the cooking phase by keeping the cooking key pressed

while modifying by means of keys 17, 20 or 23.

- To modify the values of a cooking program different from the one being carried out, keep

pressed the key relevant to the wanted cooking and proceed to the modification by means of

keys 12, 13, 17, 20 or 23.

Note: time changes during cooking will affect only the time remaining to the end of the cycle.

3-1

Page 28

3. OPERATING INSTRUCTIONS

3.3 Alarm signals

During general use of the appliance be aware of the following alarm signals:

When this indicator lamp flashes the oven chamber temperature is too high for the selected cooking

mode. This lamp will light whenever you change from a high temperature cooking mode

(CONVECTION or MIXED) to a lower temperature mode 214-218°F STEAM COOKING,

284-338°F REGENERATION CYCLE, 230-257°F for SUPASTEAM). When

this lamp is illuminated heating is inhibited until the temperature falls to within the permissible range,

after which the lamp will switch off and the oven will operate in the selected mode.

This indicator lamp should not illuminate during CONVECTION or MIXED CYCLE cooking modes.

This lamp flashes to indicate water supply problems (either due to a temporary interruption of the

supply or a drop in mains pressure). If this occurs during a STEAM, REGENERATION or

SUPASTEAM cycle, oven heating is immediately inhibited. At this point press START to check

whether the problem is still present. If the lamp continues to flash (and the water supply is OK)

seek the cause among those listed in heading 3.2. If the lamp starts flashing during

CONVECTION or MIXED CYCLE cooking, the oven will continue to operate normally and the

indicator lamp will switch off as soon as normal conditions are restored.

Illuminates after 5 hours of cooking to signal that the cleaning operations described in

subheading 4.2.1 must be carried out; the oven continues to operate when this indicator lamp is

lit; pressing the START-STOP key switches off the indicator lamp and the operating hours count

restarts from zero.

In the presence of malfunctions this display illuminates and shows an alarm code.

Identify the cause of the problem and remedy it by following the instructions in the

chart below (subheading 3.3.1).

3.3.1 Fault finding

If the oven is not operating, check that the main power switch is set to ON and that mains

power is effectively present (check fuses), or check the following chart:

or

flashing

or

flashing

Indicator lamp flashes

kkkkkkkkkkk

Indicator lamp flashes k

E1

Display shows

following codes:

E3

E4

E5

E6

E7

E8

Indicator lamp is lit

E2

Faulty cooking chamber temperature

probe

If core temperature probe is not skewered in

food and the oven chamber is at ambient

temperature: core temperature probe is faulty.

You have switched from CONVECTION or MIXED mode operation to

REGENERATION or STEAM mode

Mains water supply interrupted or low

pressure

vvv

Water flow control valve is incorrectly

set

Faulty oven chamber temperature probe

Faulty core temperature probe

Faulty steam discharge temperature probe

Motor thermal trip

Safety thermostat trip

Faulty oven chamber pressure switch

Faulty drain pressure switch

Faulty oven chamber lower probe

Oven has been in effective use for 5

hours

Call Customer Service

vv

Call Customer Service vv

vvvv

vvv

Wait for the temperature in the oven

chamber to return to within the specified

range for the selected cooking mode

Inform the water company or install a

pressure increase system

Call a qualified technician to calibrate

the valve or call Customer Service

Call Customer Service

Call Customer Service

Call Customer Service

Call Customer Service

Call Customer Service

Call Customer Service

Call Customer Service

Call Customer Service

Clean the oven as described in

subheading 4.2.1.

or

flashing

Faulty steam discharge temperature probe

3-2

Call Customer Service

Page 29

3. OPERATING INSTRUCTIONS

3.4 Advanced functions

3.4.1 COKING WITH PROGRAMMING

Storing a single cooking cycle in the memory

- Press key 25 to activate the programming function.

- Select a programme (from P01 to P99) using the up/down keys 26.

- Select the desired cooking mode by pressing one of the following keys:

6 (STEAM); 7 (CONVECTION); 8 (MIXED mode); 9 (REGENERATION); 10 (SUPASTEAM).

Note: when cooking in modes 8 or 9 (COMBI or REGENERATION), display 11 switches on

automatically. By means of button 12, it is possible to set the humidity inside the chamber. In modes

7, 8 or 9 it is possible to select "half speed fan" for cooking delicate products by pressing 13.

- Set the required chamber temperature on display 15 by

means of arrow-keys 17;

Choose

2

1

3 5

4

Timer control

- select timer control

cooking by means of

button 19;

- use arrow-keys 20 to

set the cooking time

on display 18.

N.B.: after setting of a time value (or core temperature

value), display 27 will show 1-1 (program composed by a

single cooking cycle); first digit = active cooking cycle,

second digit = total number of cycles in the sequence (see

below: storing a sequence).

- Push key 30 to store the cooking cycle. This cycle can

be used as a program involving only one type of

cooking, or it can be included in a program involving

Core temperature probe control

- Use button 22 to select

core temperature probe

controlled cooking;

- by means of arrow-keys 23

set on display 21 the

required core temperature.

6

15

18

21

24

27

11

7 8 9 10

12

16

19

22

25 26

28

13

29 30

14

17

20

23

several different cooking cycles in sequence as

explained in following section.

31

Storing a program composed by a sequence of different cooking cycles

- Push key 28: display 27 will show 2-1 (the first digit indicates the running cooking cycle, the

second digit indicates the total number of cycles included in the sequence; it is possible to

store up to 9 cycles in a sequence).

- Set the new cycle as per the instructions in previous section; after having set a time or a core

temperature, display 27 will indicate 2-2 (i.e second cooking cycle of a sequence composed

by two cycles).

Note: by pushing key 19 display 18 will show the total time of the program (sum of the times of

each cyle included in the sequence).

- Push key 30 to store the program.

Changing settings (when the oven is not cooking)

- Use arrow-buttons 26 to select the program to be modified (P01 to P99)

- Use button 28 to select the cooking cycle to be changed

- Proceed with the changes

- Push button 30 to store the data; if button 30 is not pushed, the modifications will be

temporary, i.e. they will be active only until a new program is selected.

3-3

Page 30

3. OPERATING INSTRUCTIONS

3.4.2 STARTING A COOKING PROGRAM (either single cycle or sequence)

- Should it not be activated, push button 25 to activate program memory.

- Use arrow-buttons 26 to chose one of the previously

stored program from P01 to P99

- Start the cycle using button 31 (START/STOP); the first

cooking cycle of the sequence will start and the timer

display will show the count-down to the end of that cycle.

When the cycle is over, the display will indicate the next

one and so on until the end of the sequence.

2

6

1

3 5

7 8 9 10

4

Note: by pushing button 19 display 18 will show the total time

to the end of the program (sum of the times of the single

cyles included in the sequence))

- When the cooking is finished, the heating stops and an

acoustic alarm will sound for about ten seconds.

15

18

11

12

16

19

13

14

17

20

Changing settings during cooking

- The preset values of time or temperature can only be

21

22

23

changed by keeping pressed the key of the running

cooking mode while changing the settings using keys 17,

20 or 23 (the running cooking mode is identified by the

relative indicator light).

- To change the next-in-the-list cooking program, select

it by pushing key 28, then keep it pressed and proceed

24

27

25 26

28

31

29 30

with the changes by means of keys 12, 13, 17, 20 or 23.

N

ote: any change of time during cooking works only on the count-down

.

- Push button 30 to store the data; if key 30 is not pushed, the modifications will be temporary,

i.e. they will be active only until a new program is selected.

Note:

• If the door is opened while cooking is in progress, not only will the heating and fan stop, but

the timer will also stop; time count-down will start from this point when the door is closed.

• When unplugged, the appliance keeps stored the programs indefinitely.

3.4.3 REMARKS ON SPECIAL FEATURES

• core temperature probe: it can be set in any type of cooking (MIXED, STEAM,

REGENERATION, SUPASTEAM). It excludes the timer and the cooking is stopped as soon

as the temperature in the core of the food has reached the set value.

• half speed fan: allows cooking with the fan at half speed and is added to a program by

means of key 13 before pressing START; the setting is not stored unless ENTER (key 30)

is pressed.

It cannot be added to STEAM or SUPASTEAM cookings

• cook / hold: key 14 activates, at the end of a cooking cycle, a preset program that sets

the chamber temperature at 70°C and the fan at half speed.

It can be either activated and deactivated directly (i.e. pressing 14 only) at any

moment, even during cooking or when a cooking sequence is being carried out; when

the “hold” program starts, it can be stopped only by pressing STOP.

3-4

Page 31

4. CORRECT USE AND CLEANING

4.1 Correct use

• This oven is designed to cook foods and must be used exclusively by

personnel with suitable professional qualifications and in compliance with

the instructions and warnings in this handbook; any other type of use is

considered improper and potentially dangerous.

• Do not use accessories or spare parts other than those specified and

recommended by the manufacturer.

• Exercise caution when opening the oven door to prevent scalding

caused by escaping steam and burns caused by touching hot parts

of the appliance.

Grid rack

The oven chamber is equipped with rack

(code SRG40GE) with 20 guides for a

maximum of 20 Gastronorm 2/1 grids or

containers, or 40 Gastronorm 1/1 grids

or containers (1.5" high).

Maximum load on rack (food and

containers): 485 lb

Removing and transporting cooked food

We supply the optional transfer truck

model C401, with special hydraulic lift

system, to handle the entire fully-loaded

rack (see chapter 6: ACCESSORIES).

For enhanced safety and stability, the

transfer truck is equipped with pedal operated

brakes.

Use the transfer truck in compliance with the specific instructions supplied

with this accessory.

WARNING: the transfer truck must be moved with caution to avoid

collisions with people or objects in the kitchen and to eliminate the risk

of grids or containers falling and the possible spillage of liquids. Use the

utmost care in relation to the weight of the loaded rack and to avoid the

risk of burns or scalds caused by contact with hot food or hot parts.

N.B.: To position the loaded rack in a blast chilling room or storage area you need base

element model BAS401 designed for use with transfer truck C401 (see chapter 6:

ACCESSORIES).

4.1.1 Action to take if oven is not working

If the problem is not among the cases indicated in heading 3.4, shut down the

oven and call Customer Service.

- 4 -

Page 32

4. CORRECT USE AND CLEANING

4.2 Cleaning

• Before cleaning the appliance, switch it off, close the gas and water

shut-off valves and disconnect the electrical power supply, and

allow the oven to cool.

• For daily cleaning of structural and stainless steel parts, see chap-

ter 6, section A. Cleaning procedures can be assisted using the

optional detergent spray unit and water spray gun (see chapter

6, section B in this manual).

4.2.1 Daily cleaning

Condensate tray

• Make sure the condensate drain

hole is free.

Cooking chamber

A.

• Remove the filter strainer from

the bottom of the oven chamber

and clean it;

• Spray detergent on the oven

walls using special detergent

spray unit (

• Rinse thoroughly (*) and dry all

parts;

);

*

LDL

FILTER

GRID

PND

WARNING: do not spray

cold water onto the lamp

diffuser glass when oven

chamber temperature is

above 150°C (318°F).

• Heat the oven with no food for 15

minutes in STEAM mode followed by 15 minutes in CON-

VECTION mode at 482°F;

• At the end of cleaning procedures,

if the oven is to remain unused until the next day, leave the door ajar to allow air to circulate in the oven chamber.

N.B.: we recommend cleaning the oven as described above before a steam cooking

cycle when the previous cycle was CONVECTION or MIXED mode.

Refer to subheading 4.2.2 on the next page for instructions on cleaning the fan, water filter

and drain siphon.

(

) these procedures can be facilitated with accessories LDL and PND (see chapter 6).

*

4-1

Page 33

4. CORRECT USE AND CLEANING

4.2.2 Cleaning functional parts of the oven

Descaling the fan rotor

The fan rotors must be descaled

periodically depending on the hardness of the water supply.

• Remove the rack from the oven

chamber;

• Unscrew the two fixing screws

and open the deflector panel on

its hinges;

• Descale the fan rotor with a

suitable descaling agent,

following the manufacturer's

instructions as reported on the

pack.

N.B: for thorough cleaning,

disassemble the fan as follows:

- unscrew the spherical diffuser while

immobilising the fan rotor and slacken the

two grub screws on the rotor hub;

- screw the supplied M14 extractor bolt into the hub

until the fan rotor is disengaged

from the spindle.

M14

Important: when reassembling

the fan, check that the rotor is

pushed fully home on the spindle

4 mm

22

before tightening the grub screws.

Cleaning the water filters

• Close the main

water supply

valve, unscrew

the plugs, withdraw the filter

elements and

clean them.

Cleaning the drain siphon (located beneath the oven)

• Unscrew the plug and remove any accumulated debris.

4.2.3 Cleaning the appliance prior to prolonged disuse

• Perform all the cleaning procedures illustrated in this chapter.

• Refer to the instructions in sectione A, heading 3.3 of this

handbook.

4-2

A.

Page 34

5. MAINTENANCE

5.1 Maintenance contract

Refer to chapter 5, section A of this handbook.

The appliance should be thoroughly checked at six-monthly

intervals by a qualified technician (heating unit, mechanical

stability, corrosion...) with particular emphasis on all control

and safety devices.

A.

6. ACCESSORIES

LDL

Do not use accessories other than the ones shown here

SRG40GE

PND

FG

SRG40GE

C401

BAS401

LDL

PND

FG

BAS401

G

rid rack (standard supply) with 20 guides for 40 Gastronorm 1/1 containers

or 20 Gastronorm 2/1 containers (h 1.5" max

ransfer truck for grid rack SRG40, with special hydraulic lift system

T

S

upport base for grid rack SRG40

S

pray gun

etergent spray unit

D

rease filter

G

- 5 -

C401

)

Loading...

Loading...