GAS

COUNTERTOP RANGE

GHP2, GHP4, GHP6, GHP8

Installation and

Operation

Instructions

2M-W1662 Rev. - 3/29/11

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause

property damage, injury or death. Read

the installation, operating and maintenance

instructions thoroughly before installing or

servicing this equipment.

FOR YOUR SAFETY: Do not store or use

gasoline or other ammable vapors or liquids

in the vicinity of this or any other appliance.

Retain This Manual for Future Reference.

WARNING: This appliance shall be installed

in accordance with current regulations and

used only in well-ventilated space. Refer to

instructions before installing and using this

appliance.

In addition, there should be posted, in a

prominent location, detailed instructions to

be followed in the event the operator smells

gas. Obtain the instructions from the local

gas supplier.

1

SAFETY SYMBOL

Model No.:

Serial No.:

Voltage:

1-Phase or 3 Phase:

Purchased From:

Location:

Purchase Date:

Installed Date:

These symbols are intended to alert the user to the presence of important operating

and maintenance instructions in the manual accompanying the appliance.

FOR YOU R SAFT EY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN

THE VICINTIY OF THIS OR ANY OTHER APPLIANCE.

The installation of the Appliance must conform to the NATIONAL FUEL GAS CODE "ANSI Z223.1 - LATEST

EDITION" AND ALL LOCAL GAS COMPANY RULES AND REGULATIONS.

IN CANADA INSTALLATION SHALL BE IN ACCORDANCE WITH THE CURRENT CAN/CGA-B149.1 NATURAL

GAS INSTALLATION CODE OR CAN/CGA-B149.2 PROPANE INSTALLATION CODE AND LOCAL CODES WHERE

APPLICABLE.

POST I N PROM INEN T LOCATION

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT USER SMELLS GAS. THIS INFORMATION

SHALL BE OBTAINED BY CONSULTING YOUR LOCAL GAS SUPPLIER. AS A MINIMUM, TURN

OFF THE GAS AND CALL YOUR GAS COMPANY AND YOUR AUTHORIZED SERVICE AGENT.

EVACUATE ALL PERSONNEL FROM THE AREA.

WARNIN G

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATION

& MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

WARN ING

RISK OF FIRE OR ELECTRIC SHOCK

DO NOT OPEN

WARNIN G, TO REDUCE THE RISK OF ELECTRICAL SHOCK, DO NOT REMOVE

CONTROL PANEL. NO USER-SERVICABLE PARTS INSIDE.

REPAIRS SHOULD BE DONE BY AUTHORIZED SERVICE PERSONNEL ONLY.

NOTICE

Using any part other than genuine Lang factory supplied parts relieves the manufacturer of all liability.

Lang reserves the right to change speci cations and product design without notice. Such

revisions do not entitle the buyer to corresponding changes, improvements, additions or

replacements for previously purchased equipment.

Due to periodic changes in designs, methods, procedures, policies and regulations, the

specifications contained in this sheet are subject to change without notice. While Lang

Manufacturing exercises good faith efforts to provide information that is accurate, we are

not responsible for errors or omissions in information provided or conclusions reached as a

result of using the speci cations. By using the information provided, the user assumes all risks in con-

nection with such use.

MAINTENANCE AND REPAIRS

Contact your local dealer for service or required maintenance. Please record the model number, serial

number, voltage and purchase & Installation Information in the area below and have it ready when you

call to ensure a faster service.

2

PROBLEMS, QUESTIONS or CONCERNS

Before you proceed consult you authorized Lang service agent directory

or

Call the Lang Technical Service & Parts Department at 1-800-438-5264.

TABLE OF CONTENTS

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Equipment Description .

General Installation Data

Exhaust Canopy .

Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Leveling Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Manual Shut-Off Valve . . . . . . . . . . . . . . . . . . . . . . 8

Connecting Gas Supply Line . . . . . . . . . . . . . . . . . . . 8

Propane Gas Conversion . . . . . . . . . . . . . . . . . . . . . 8

Checking for Gas Leaks . . . . . . . . . . . . . . . . . . . . . . 8

Pilot Lighting Instructions . . . . . . . . . . . . . . . . . . . . . 9

Burner Ignition & Adjustment . . . . . . . . . . . . . . . . . . . 9

General Operating Instructions

Drip Pan .

Burner Operation . . . . . . . . . . . . . . . . . . . . . . . . . 10

Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Broiling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Tilting the Grate . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Shutting Down Instructions . . . . . . . . . . . . . . . . . . . . 10

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Wiring Diagram .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . 6

Exploded View & Parts List . .

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

NOTICE Service on this or any other Lang appliance must be performed by

. . . . . . . . . . . . . . . . . . . 12 - 16

qualied personnel only.

Consult your Lang Authorized Service Agent Directory.

You can call our toll free number 1-800-438-5264 or

visit our website www.langworld.com for the service agent nearest you.

3

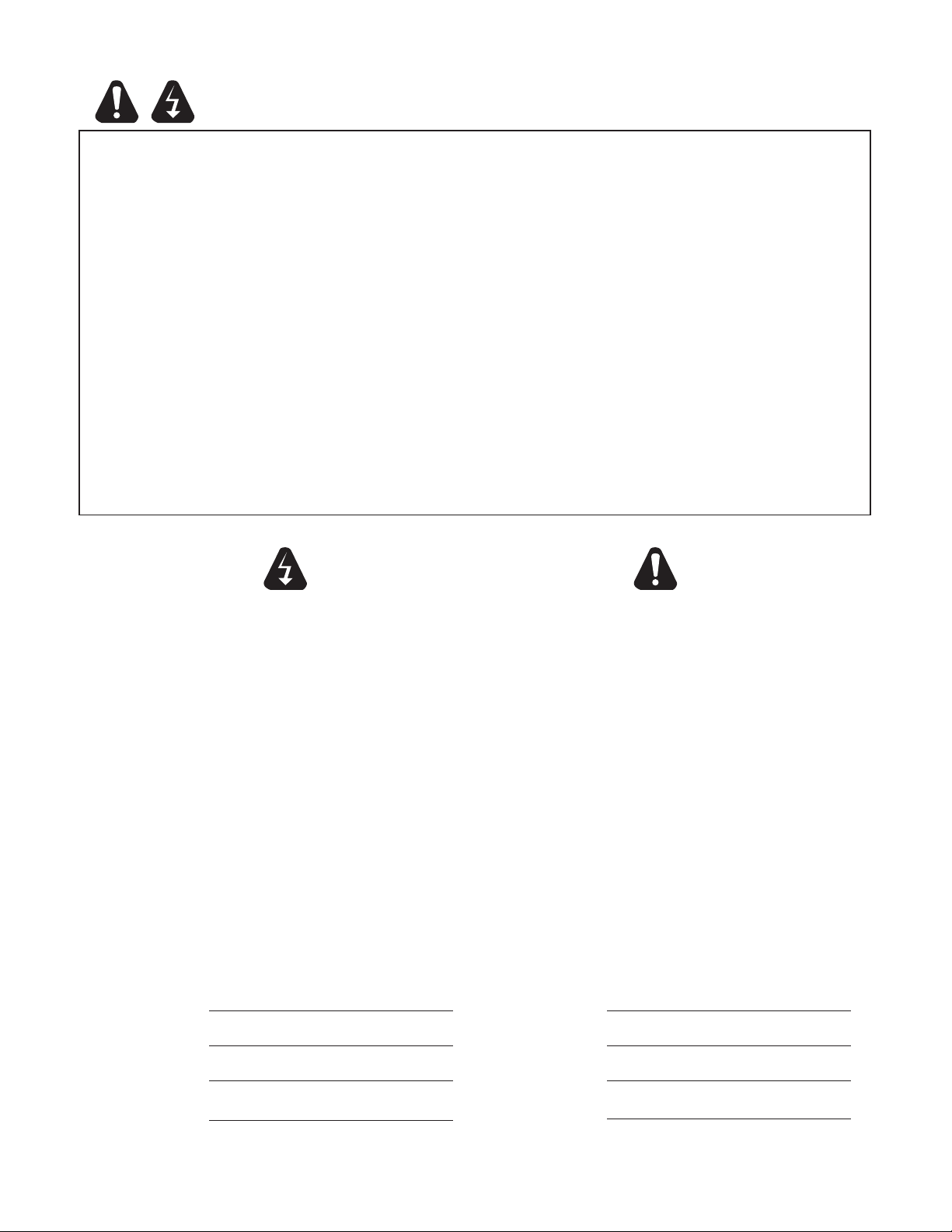

SPECIFICATIONS

6 1/8”

4”

3”

14 7/8”

15 5/8”

18 1/2”

GAS INLET

120V Electrical Connection

5 1/2’ Ft Cord

IL2180

GAS CHEFSERIES COUNTERTOP RANGES

Model Height x Width x Depth

15 3/8” x 11 7/8” x 28 3/16”

GHP2

(39.1cm x 30.2cm x 71.6cm)

15 3/8” x 23 7/8” x 28 3/16”

GHP4

(39.1cm x 60.6cm x 71.6cm)

15 3/8” x 35 7/8” x 28 3/16”

GHP6

(39.1cm x 91.1cm x 71.6cm)

15 3/8” x 47 7/8” x 28 3/16”

GHP8

(39.1cm x 121.6 x 71.6cm)

* Noncombustible oor only

Model Gas Requirment (3/4” NPT)

GHP2 64,000 BTU/hr

GHP4 128,000 BTU/hr

GHP6 192,000 BTU/hr

GHP8 256,000 BTU/hr

EQUIPMENT SPECIFICATIONS

Clearance from

combustible surface*

Sides & Back: 7”

Actual Shipping

Weight

Freight

Class

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

4

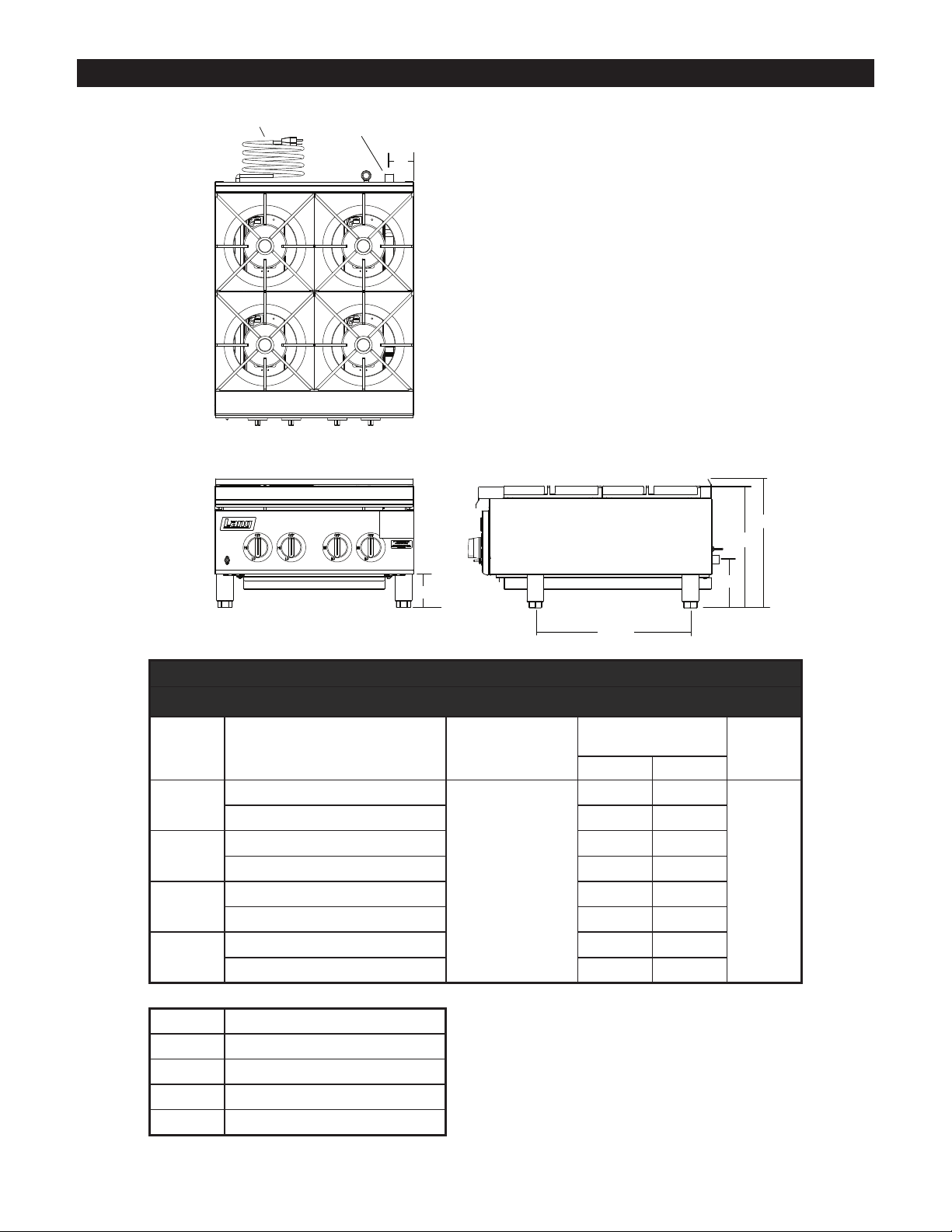

EQUIPMENT DESCRIPTION

On/Off

Switch

Hinged

Front Panel

Drip

Pan

Burner

Knob

Gas

Inlet

Wall

Mounting

Power

Cord

Burner Grate

Optional

“Instant-ON”

4” Adj. Legs Standard

(Tall Legs & Casters Optional)

Lighting

Instructions

IL2181

On/Off Switch

When the switch is in the "ON" position, it allows gas to ow through the solenoid

to the burners. When turned "OFF" the ow of gas ends and the unit shuts

down.

Hinged Front Panel

Held in place by (2) two screws, once they & the knobs are removed, the front

panel can ip down allowing the unit to be easily serviced.

Drip Pan Catches drippings & removes for easy cleaning

Burner Knob Provide individual control to the front and rear burners

Lighting Instructions List the proper way to use the hotplate

4" Adj Legs

Allow for ventilation under the hotplate. Provides a meand of leveling the

appliance, and of cleaning underneath.

Gas Inlet Gas supply should be connected by a qualied gas installer

Wall Restraint

Power Cord

Burner Grate

The installation shall be made with a gas connecctor that complies with local

codes connectors.

This unit comes provided with a power cord specic to it needs, replacing or

changing the cord in any way voids its warranty.

Holds food product at proper distance from burner ame. Remove for easy

cleaning.

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

5

CAUTION

GENERAL INSTALLATION DATA

This equipment is designed and sold for commercial use only by personnel trained and

experienced in its operation and is not sold for consumer use in and around the home nor

for use directly by the general public in food service locations.

The Lang Chefseries® gas countertop range is equipped for the type of gas indicated on

the nameplate mounted on the side panel.

-IMPORTANTBe sure to remove all paper protection and packing material from unit prior to

lighting.

Clearance from non-combustible construction must be 7" minimum from back

and sides, there must be a 4" space from the bottom of the unit to the counter

surface.

The installation of the Appliance must conform to the NATIONAL FUEL GAS

CODE "ANSI Z223.1 - LATEST EDITION" AND ALL LOCAL GAS COMPANY

RULES AND REGULATIONS.

IN CANADA INSTALLATION SHALL BE IN ACCORDANCE WITH THE

CURRENT CAN/CGA-B149.1 NATURAL GAS INSTALLATION CODE OR

CAN/CGA-B149.2 PROPANE INSTALLATION CODE AND LOCAL CODES

WHERE APPLICABLE.

NOTICE

When this appliance is installed with casters, it must be installed with the casters supplied, a

connector complying with either ANSI Z21.69 or CAN/CGA-6.16 and a quick-disconnect device

complying with either ANSI Z21.41 or CAN1-6.9. It must also be installed with restraining

means to guard against transmission of strain to the connector, as specied in the appliance

manufacturer's instructions.

For your protection, we recommend a qualied installing agency install this appliance.

They should be familiar with gas installations and your local gas requirements. In any

case, your gas company should be called to approve the nal installation.

This appliance, its pressure regulator and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing of that system at test

pressures in excess of 1/2 PSIG. This appliance and its pressure regulator must be isolated

from the gas supply piping system by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test pressures equal to or less than 1/2

PSIG.

EXHAUST CANOPY

Open hot plates inherently create a good deal of heat, moisture and fumes and should be

installed under an efcient exhaust hood with ame proof lters. A vertical distance of not

less than 48" shall be provided between the top of the appliance and lters or any other

combustible material. Exhaust installation must conform to local codes.

AIR SUPPLY

Provisions for adequate air supply must be provided.

CAUTION

Air for combustion enters from the bottom & front of the unit.

Do not obstruct this area.

6

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

IL2182

GENERAL INSTALLATION DATA (continued)

LEVELING UNIT

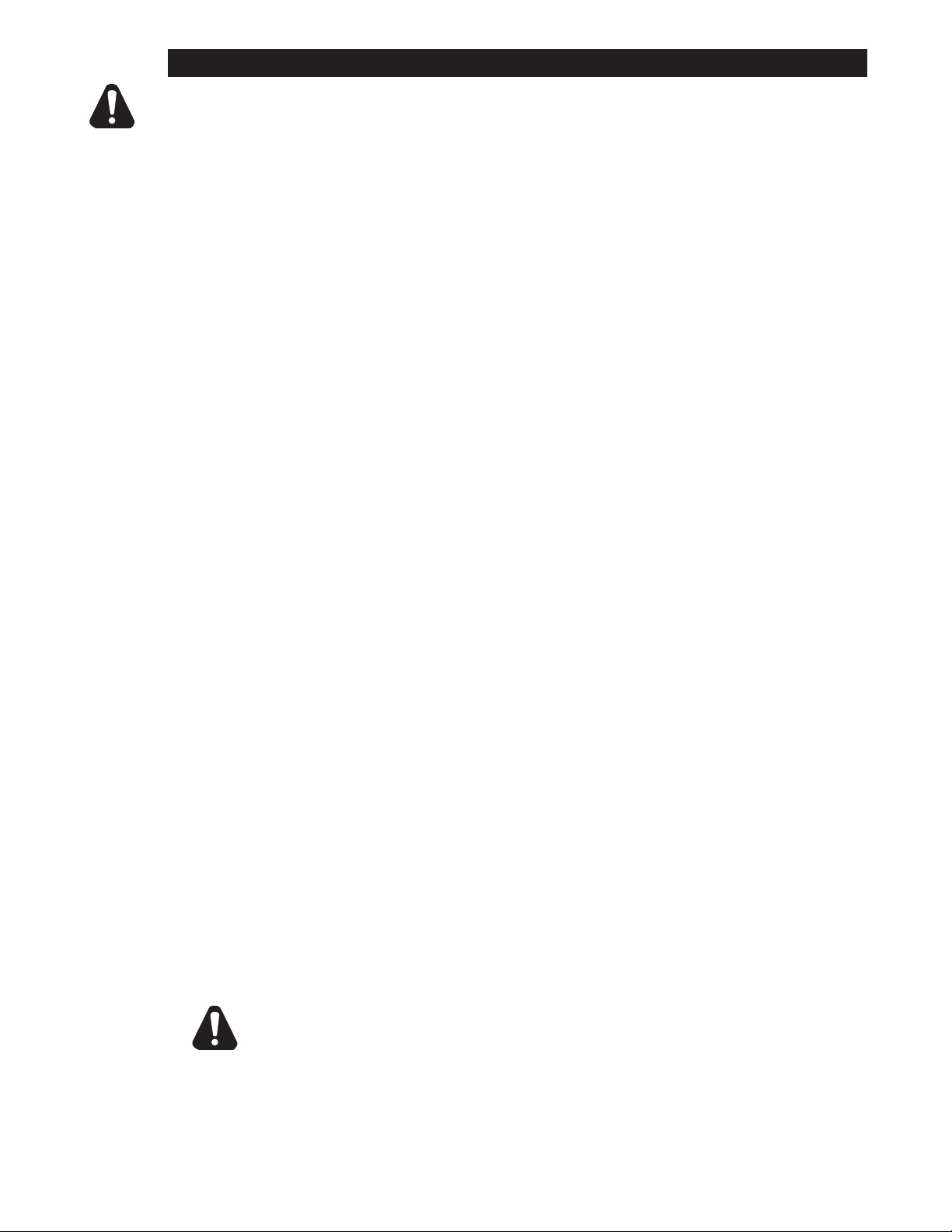

This range is supplied with 4 feet or oor stand legs which must be screwed into the body.

Unit must be level. Level unit by adjusting the (4) feet which have an adjustment of

1-3/4" for accurate and perfect line-up with other units.

DO NOT INSTALL WITHOUT ATTACHING FEET OR SUPPLIED

STAND LEGS AND SHELF - DO NOT REMOVE FEET.

CAUTION

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

Model GHP4 with Standard 4" legs.

Tall legs and casters are also available as an option.

7

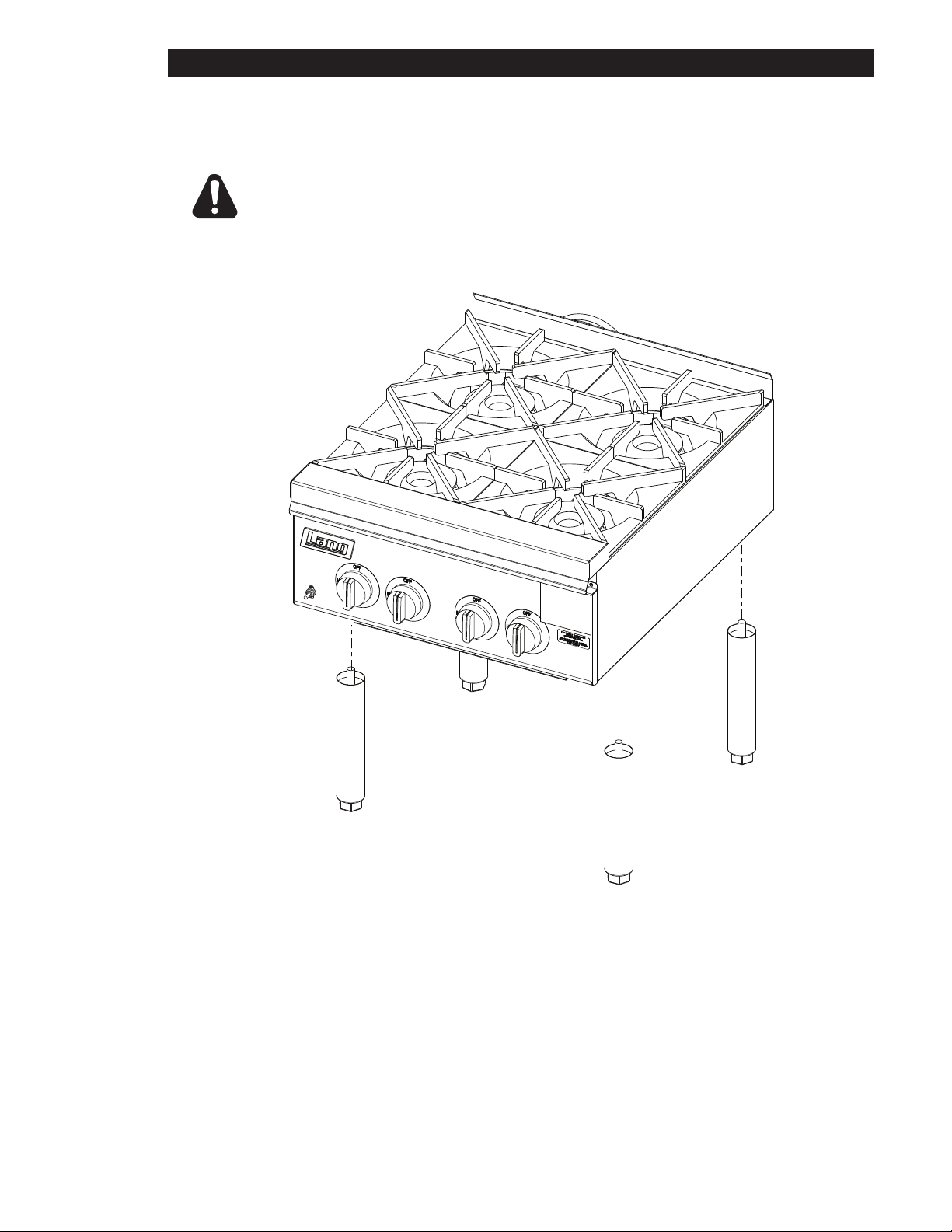

FLOW

BACK OF UNIT

IL1828a

DRIP LEG*

GAS

SHUT-OFF

VALVE*

SUPPLIED

REGULATOR

* by others

GAS

SUPPLY*

VENT

GENERAL INSTALLATION DATA (continued)

GAS PIPING

Gas piping shall be of such size and so installed as to provide a supply of gas sufcient

to meet the full gas input of the appliance. If the appliance is to be connected to existing

piping, it shall be checked to determine if it has adequate capacity. Joint compound shall be

used sparingly and only on the male threads of the pipe joints. Such compounds shall be

resistant to the action of L.P. gases.

WARNING: Any loose dirt or metal particles which are allowed to enter the gas lines on this

appliance will damage the valve and affect its operation. When installing this appliance, all

pipe and ttings must be free from all internal loose dirt.

GAS PRESSURE REGULATOR

A convertible pressure regulator is

provided with each range. It should

be connected to the inlet pipe at the

rear of the unit. The gas supply is then

connected to it. The supply pressure

to the regulator is not to exceed 1/2

PSIG. The water column manifold

pressure for 5" with natural gas & 10"

for LP gas.

Correct manifold pressures are:

5 inches water column for natural gas

10 inches water column for propane

MANUAL SHUT OFF VALVE

A manual shut off valve should be installed upstream from the manifold and within six feet of

the range.

CONNECTING GAS SUPPLY LINE

The gas inlet of the range is sealed at the factory to prevent entry of dirt. Do not remove this

seal until the actual connection is made to the gas supply line.

CHECKING FOR GAS LEAKS

Check entire piping system for leaks. Soap and water solution or other material acceptable

for the purpose, shall be used in locating gas leakage.

Matches, candle ame or other sources of ignition shall not be used

for locating gas leaks.

CAUTION

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

8

GENERAL INSTALLATION DATA (continued)

PILOT LIGHTING INSTRUCTIONS

The range is equipped with an automatic pilot/ignter with an electronic spark.

1.

Be sure all gas control knobs on the units front panel are turned OFF.

2.

Turn on main gas supply valve to unit.

3.

Turn "ON" the switch on front control panel to activate electonic pilot lighter.

4.

The pilots on this broiler have been pre-set at the factory. Turn the adjustable screw

counterclockwise to open and clockwise to close.

5.

Adjust pilot light ames, if necessary as small as possible, but high enough to light burner

immediately when burner valve is turned on high.

6.

Turn burner knobs to desired setting.

7.

To turn burners off, turn knobs to "OFF" and turn "OFF" switch on front control panel.

BURNER IGNITION AND ADJUSTMENT

1.

To ignite burners turn burner valve knob counter clockwise to "ON"position.

2.

Slowly decrease openings of air shutters to give a soft blue ame having luminous tips, then

slowly increase openings to a point where the yellow tips disappear and a hard blue ame is

obtained.

INITIAL LIGHTING

When range is rst lit, it will smoke for approximately 20-30 minutes until the preservation oils

and impurities from the manufacturing process are burned off.

DO NOT ATTEMPT TO OPERATE UNIT DURING A POWER FAILURE.

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

9

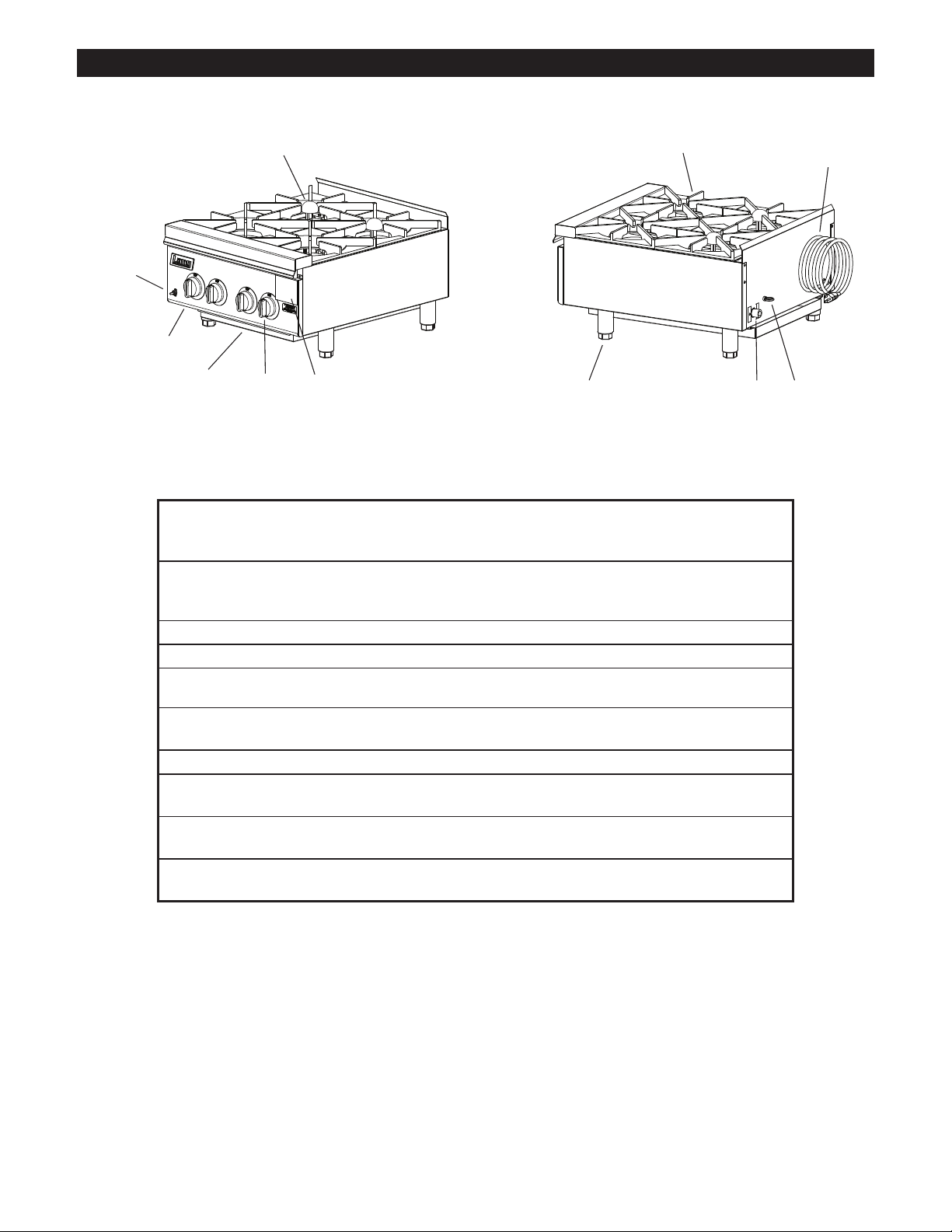

GENERAL OPERATING INSTRUCTIONS

IL2185

Grate

Burner

Drip Pan

Burner Bottom

& Venturi Assy

DRIP PAN

The drip pan is located at the bottom of the unit, and is easily removed from the front of the

unit. The pan helps collect spills, drips and catches grease. This should be checked daily

and cleaned using mild detergent and warm water.

BURNER OPERATION

Each burner is controlled by an individual high-low, on-off valve. A variety of temperatures

may be obtained by turning the burner valve knob to any position between HI and LO. It is

possible through this arrangement to have a high heat or a variety of settings, while having a

low heat simmering selection. For heating each section, turn the valve counter clockwise for

the section to a position of "HI". For holding or simmering, turn the valves closer to the "LO"

position on the dial. You select the heat pattern you like, and set the valves accordingly. Be

sure burners are staying fully lit when set in low positions.

SHUTTING DOWN INSTRUCTIONS

Turn "OFF" the pilot lighting switch on the front panel and put the burner valve knobs to the

off position to turn burners off and close manual valve gas shutoff.

CLEANING

It takes very little time and effort to keep your unit attractive and performing at top efciency.

If grease is permitted to accumulate, it will form a gummy cake and then carbonize into

a hard substance which is extremely difcult to remove. To prevent this condition, the

following suggestions for cleanliness shoud be followed:

1.

Clean regularly, allow the unit to cool.

2.

Remove grate section & burner head and

brush out any carbon particles, wash in sink

using mild detergent and warm water.

3.

The burner bottom and venturi assemlby

must be free of grease and foreign

material.

4.

Daily-use a clean cloth and good nonabrasive cleaner to clean the stainless

steel body of the range. Wipe in the

direction of the grain with a soft cloth.

5.

At least once a day remove the waste

drawer and wash in the same way as an

ordinary cooking utensil. The drawer is

removed by pulling forward.

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

10

5

1

*

+

/

111

1111

+++++++

***

****

///

////

%/.

:+7

*51

%/.

:+7

:+7

%/.

%/.%/.%/.%/.

%/.

%/.%/.%/.

:+7

:+7

:+7

:+7

:+7

:+7

:+7

:+7

25*

25*

25*

25*

25*

25*

25*

25*

*51*51*51*51*51*51*51*51

32:(5&25'

6:,7&+

62/(12,'9$/9(

63$5.02'8/(

3,/27%851(5

*+3*+3*+3*+3

7(50,1$/%/2&.237,21$/

5(9

'$7((&2

'(6&5,37,212)&+$1*(

'5

7+,6'5$:,1*&217$,16,1)250$7,21&21),'(17,$/7267$50)*,17/

,1&125(352'8&7,2125',6&/2685(2),76&217(176,63(50,77('

72/(5$1&(81/(66127('[[[

$1*/(6

5(9,6,216

3$5712

02'(/12

7,7/(

0$7(5,$/

),1,6+

67$50$18)$&785,1*,17(51$7,21$/,1&

6811(1'5,9(

67/28,60286$

'5

&.

'$7(

0:

:'*+3*DV+RW3ODWH

'-6

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

11

SK2493 Rev. - 3/04/11

Model:

GHP Gas Hotplate

See Detail

A

1

2

9

10

11

17

16

18

19

20

21

14

13

12

15

7

8

3

4

5

6

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

12

To

Burner

To Pilot

Detail A

SK2494 Rev. - 3/04/11

Model:

GHP Gas Hotplate Detail A

22

25

26

27

29

30

31

32

33

28

24

23

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

13

PARTS LIST March 29, 2011, Rev -

GAS HOTPLATES, MODEL GHP2, GHP4, GHP6 & GHP8

Fig No Part Number.. Description Quantity. Application

2 GHP4ODB

1 2R-W1664 TOP CAP - DOMED, "INSTANT ON"

2 2F-Z0637 CASTING

2F-Z5473-W1 BURNER SET - CAST IRON

3

2I-Z5476 GASKET U-MAX HOTPLATES

4 T9-143-013 ASSY-INSTANT ON MECHANISM

2J-80201-24 PLT LT BURNR FR GEI12LEAD, FRONT

5

2J-80201-W31 PILOT BURNER R/H 36" LEAD, BACK

6 2F-W1666 VENTURI ASSY

7 T9-143-001 SIDE ASSY-LH 1 ALL

8 2A-72500-20 LEG 10.25 WITH ADJ HEX 4 ALL

9 2J-80300-03 SPRK IGNITR MODULE SM2

10 2E-30501-02 TRM STRP 3 POLE W/PUSH ON 1 ALL

T9-143-109 GREASE TRAY ASSY-GHP2

11

12 T9-143-000 SIDE ASSY-RH 1 ALL

T9-143-209 GREASE TRAY ASSY-GHP4 GHP4

T9-143-209 GREASE TRAY ASSY-GHP6 GHP6

T9-143-409 GREASE TRAY ASSY-GHP8 GHP8

4 GHP8ODB

6 GHP6ODB

8 GHP8ODA

2 GHP2

4 GHP4

6 GHP6

8 GHP8

2 GHP2

4 GHP4

6 GHP6

8 GHP8

2 GHP2

4 GHP4

6 GHP6

8 GHP8

1 GHP2ODB

2 GHP4ODB

4 GHP8ODB

6 GHP6ODB

8 GHP8ODA

1 GHP2

2 GHP4

6 GHP6

4 GHP8

1 GHP2

2 GHP4

3 GHP6

4 GHP8

2 GPP2

4 GHP4

6 GPP6

8 GHP8

2 GHP2

4 GHP4

6 GHP6

8 GHP8

GHP2

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE 1

INCLUDE MODEL AND SERIAL NUMBER OF 3

Some items are included for illustrative purposes only and in certain instances may not be available.

14

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

PARTS LIST March 29, 2011, Rev -

GAS HOTPLATES, MODEL GHP2, GHP4, GHP6 & GHP8

Fig No Part Number.. Description Quantity. Application

14 2C-20602-04 TINNERMAN SPD NUT 1/8 DIA 2 ALL

15 K9-60301-43-1 DIE CAST PLT LANG SATIN, w/CLIPS 1 ALL

2 GHP2

16 2M-W728-W2 LABEL - CONTROL OFF-HI-LO

17 2R-W498 KNOB-RED

18 2I-05-07-0013 BOOT SWITCH 1 ALL

19 2M-12-07-0038 LABEL ON & OFF 1 ALL

20 Z1-70-07-0343 SWITCH GUARD 1 ALL

21 2E-Z12020 SWITCH-TOGGLE 2P ST 1 ALL

22 T9-143-024 WELDMENT - FLEX TUBE 17" 1 ALL

23 2J-Z4686 REGULATOR-3/4 X 3/4 1 ALL

24 T9-143-020 REGULATOR BRACKET 2 ALL

25

26 2K-70304-05 ELBOW, PIPE 90o ST 3/4 1 ALL

27 2V-80502-06 SLENOID VLVE 120VAC 3/4 1 ALL

28 2K-70308-01 PIPE PLUG REG 1/8 NPT BLK 1 ALL

29 2V-Z6939 VALVE HI-LO

30 2K-70101-W123 ADAPTER BRASS 1/8NPTF X

31 2A-W1185 ORIFICE FITTING - 90 DEG

32

2J-70101-104 FLEX GAS HOSE 17 X 3/4

2J-70101-105 FLEX GAS HOSE 31 X 3/4 1 GHP4, GHP6, GHP8

2A-Z4931 ORIFIE #52 BLK

2A-Z5542 ORIFICE HOOD #37

4 GHP4

6 GHP6

8 GHP8

2 GHP2

4 GHP4

6 GHP6

8 GHP8

1 GHP4, GHP6, GHP8

2 GHP2

2 GHP2

4 GHP4

6 GHP6

8 GHP8

2 GHP2

4 GHP4

6 GHP6

8 GHP8

2 GHP2

4 GHP4

6 GHP6

8 GHP8

2 GHP2-LP

4 GHP4-LP

6 GHP6-LP

8 GHP8-LP

2 GHP2-NAT

4 GHP4-NAT

6 GHP6-NAT

8 GHP8-NAT

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE 2

INCLUDE MODEL AND SERIAL NUMBER OF 3

Some items are included for illustrative purposes only and in certain instances may not be available.

15

STAR I NT ERN ATION AL HOLDIN GS I NC. COM PANY

Star - Holman - Lang - Wells - Bloomeld - Toastmaster

10 Sunnen Drive, St. Louis, MO 63143 U.S.A.

(314) 781-2777

www.star-mfg.com

GAS HOTPLATES, MODEL GHP2, GHP4, GHP6 & GHP8

Fig No Part Number.. Description Quantity. Application

1 GHP1

33 2V-70402-06 VALVE PILOT 1/8NPTX1/4CC

AR 2M-61133-W1 W/D GHP AR ALL

NI 2A-80401-02 PILOT BURNER ORIFICE .010

NI 2C-20119-01 EYEBLTFORGD/SHLDR1/4-20X1 1 ALL

NI 2E-31107-02-W2 CORDSET 14/3 15A 120V 10' 1 ALL

NI 2K-Y1139 BUSHING HEYCO SB500-6

NI 2M-60304-W1 LABEL-LIGHTING INST. 1 GHP8

NI 2M-61133-W1WL LABEL - W/D GHP 1 GHP8

2 GHP4

3 GHP6

4 GHP8

2 GHP2-LP

4 GHP4-LP

8 GHP8-LP

1 GHP2

2 GHP4

3 GHP6

4 GHP8

16

IL2185-FR

Grille

Brûleur

Cuvette de propreté

Fond du brûleur

et tube de venturi

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

10

tirant vers l'avant.

ustensile de cuisine. Retirer le tiroir en

fois par jour et nettoyer comme tout autre

Vider la cuvette de propreté au moins une

5.

chiffon doux.

Nettoyer dans le sens du grain avec un

la surface en acier inoxydable de l'appareil.

non abrasif quotidiennement pour nettoyer

Utiliser un chiffon propre et un bon nettoyant

4.

graisse ou des matériaux inconnus.

doivent pas être en contact avec de la

Le fond du brûleur et le tuyau venturi ne

3.

et de l'eau chaude.

nettoyer dans l'évier avec un savon doux

enlever la grille et les têtes des brûleurs et

Pour éliminer les particules de carbone,

2.

l'appareil.

Nettoyer régulièrement, laisser refroidir

1.

étapes de nettoyage suivantes :

cette situation, nous vous suggérons les

est très difcile à éliminer. Pour éviter

transformer en une substance dure qui

qui va ensuite carboniser et se

votre appareil. Si des dépôts de graisses s'accumulent, ils vont former un galet gommant

Il faut très peu de temps et d'effort pour conserver l'apparence et l'efcacité maximale de

NETTOYAGE

gaz.

boutons de réglage pour éteindre les brûleurs et fermer le robinet de fermeture manuel du

Mettre l'interrupteur de la amme pilote à « Arrêt » sur le panneau de contrôle, fermer les

INSTRUCTIONS DE FERMETURE

conséquence. S'assurer que les brûleurs restent allumés quand ils sont à feu doux.

plus près de « feu doux ». Le choix de la chaleur est libre, il suft de placer les boutons en

d'une montre jusqu'à la position « feu vif ». Pour réserver ou faire mijoter, placer le bouton

Pour chauffer chaque section, tourner le bouton de la section désirée à l'envers des aiguilles

un « feu vif » ou d'autres sélections de températures, en même temps qu'un « feu doux ».

grand éventail de températures. Gâce à cette façon de procéder, il est possible d'avoir

plaçant le bouton dans toutes les positions entre « feu vif » et « feu doux », on obtient un

Il y a un bouton « marche », « feu vif », « feu doux » et « arrêt » pour chaque brûleur. En

UTILISATION DU BRÛLEUR

quotidiennement et nettoyée avec un savon doux et de l'eau chaude.

ci. La cuvette recueille les déversements, les excédents et la graisse. Elle doit être vériée

La cuvette de propreté se trouve sous l'appareil et elle est facile à retirer par l'avant de celui-

CUVETTE DE PROPRETÉ

Mode d'emploi

9

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

NE PAS UTILISER LORS D'UNE PANNE DE COURANT.

soient éliminées.

jusqu'à ce que les huiles de protection et les impuretés dues au processus de fabrication

Lors du premier allumage, l'appareil produira de la fumée pendant environ 20 à 30 minutes,

PREMIER ALLUMAGE

ne reste qu'une amme bleue.

lumineux. Ensuite, augmenter doucement l'ouverture jusqu'à ce que le jaune disparaisse et qu'il

Réduire doucement l'ouverture des obturateurs d'air pour obtenir une amme bleue au bout

2.

montre jusqu'à ce qu'il soit en position « Marche ».

Pour allumer un brûleur, tourner le bouton de réglage dans le sens contraire des aiguilles d'une

1.

ALLUMAGE DU BRÛLEUR ET RÉGLAGES

de contrôle avant.

fermer les brûleurs, mettre les poignées à « OFF » et fermer l'interrupteur sur le panneau

7.

Pour

Tourner les boutons à l'intensité souhaitée.

6.

brûleurs s'allument immédiatement lorsque la valve est au plus fort.

Si nécessaire, ajuster les ammes pilotes le plus bas possible, mais assez fort pour que les

5.

fermer.

dans le sens contraire des aiguilles d'une montre pour ouvrir et dans le sens des aiguilles pour

Les ammes pilotes ont été ajustées au moment de leur fabrication. Tourner les vis ajustables

4.

électronique.

Allumer l'interrupteur sur le panneau de contrôle avant pour activer la amme pilote

3.

Ouvrir la conduite de gaz principale.

2.

« Arrêt ».

S'assurer que tous les boutons de réglage du panneau de contrôle avant sont en position

1.

électronique.

La gamme complète est équipée d'un allumeur automatique muni d'une étincelle

INSTRUCTIONS POUR LA FLAMME PILOTE

INSTALLATION GÉNÉRALE (suite)

FLUX

FOND DE L'APPAREIL

IL1828-FR

POINT DE PURGE*

SUPPLIED

REGULATOR

*par d'autres

ALIMENTATION

EN GAZ*

TUYAU DE V

ENTILATION

ROBINET DE

FERMETURE

DU GAZ*

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

8

sources inammables pour situer la fuite.

ATTENTION

Ne pas utiliser d'allumettes, de chandelles allumées ou d'autres

savonneuse, ou un substitut acceptable, pour situer la fuite.

Vérier qu'il n'y a aucune fuite sur tous les conduits du système. Utiliser une solution d'eau

VÉRIFICATION DE FUITES DE GAZ

d'alimentation du gaz.

Garder le seau intact jusqu'au moment de la connexion de la pièce aux conduits

L'orice d'admission de gaz est scellé en usine pour éviter l'accumulation de poussière.

CONNEXION DE L'ALIMENTATION DE GAZ

de 1,83 m de l'appareil.

Un robinet de fermeture manuelle doit être installé en amont de la rampe à gaz et à moins

ROBINET DE FERMETURE MANUELLE

12,7 cm de colonne d'eau pour le gaz naturel.

12,7 cm de colonne d'eau pour le gaz naturel.

Les bonnes pressions d'admission sont :

naturel.

de colonne d'eau pour l'utilisation du gaz

à une pression d'admission de 12,7 cm

régulateur. L'appareil est réglé par défaut

excéder 1/2 PSI manométrique dans le

connecté. La pression du gaz ne doit pas

L'approvisionnement en gaz y est ensuite

en gaz y est ensuite connecté.

derrière l'appareil. L'approvisionnement

être connecté au tuyau d'entrée

est fourni avec chaque unité. Il devrait

Un régulateur de pression convertibles

GAZ

RÉGULATEUR DE PRESSION DE

raccords.

l'installation de cet appareil, aucune saleté ne doit rester à l'intérieur des tuyaux et des

de gaz de cet appareil vont endommager les valves et nuire à son efcacité. Lors de

AVERTISSEMENT: Toutes saletés ou particules de métal qui entrerait dans les conduits

de conduits. La pâte utilisée doit résister aux GPL.

adéquates. Utiliser la pâte à joint modérément et uniquement sur les lets mâles des joints

conduits préexistants, ceux-ci devront être vériés pour s'assurer qu'ils ont les capacités

de gaz pour répondre aux demandes de l'appareil. Si l'appareil doit être connecté à des

Les conduits de gaz doivent avoir la bonne taille et être installés de manière à fournir assez

CONDUITS DE GAZ

INSTALLATION GÉNÉRALE (suite)

IL2182

7

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

Grands pieds et roulettes également disponibles en option.

Modèle GHP4 avec pieds standards de 4".

PIEDS.

ATTENTION

PRÉSENTOIR ET LA TABLETTE FOURNIE; NE PAS ENLEVER LES

NE PAS INSTALLER SANS FIXER LES PIEDS OU LES JAMBES DE

ont un jeu de 4,45 cm an de créer un alignement juste et précis avec les autres appareils.

vissées sous l'appareil. L'appareil doit être nivelé. Niveler l'appareil à l'aide des pieds qui

Cette gamme vient avec quatre pieds, ou jambes de présentoir de sol, qui doivent être

NIVELER L'APPAREIL

INSTALLATION GÉNÉRALE (suite)

6

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

de l'appareil. Garder ces endroits libres.

ATTENTION

L'air nécessaire à la combustion entre par le fond et l'avant

Il faut prendre des mesures pour avoir un assez bon approvisionnement en air.

APPROVISIONNEMENT EN AIR

conformément aux normes locales.

dessus de l'appareil et tout ltre ou autre matière combustible. La hotte doit être installée

de ltres ignifugés. Une distance d'au moins 121,92 cm doit être maintenue entre le

d'humidité et de fumée, elles doivent donc être installées sous une hotte efcace équipée

Les plaques chauffantes à aire ouverte produisent évidemment beaucoup de chaleur,

HOTTE

robinets de fermeture manuels.

l'appareil et les régulateurs de pression doivent être isolés du système en fermant les

d'approvisionnement du gaz à une pression égale ou moindre à 1/2 PSI manométrique,

déconnectés de l'approvisionnement en gaz. Lors d'un test de pression du système

les régulateurs de pression et les robinets de fermeture individuels doivent être

Lors d'un test de pression des systèmes dépassant 1/2 PSI manométrique, l'appareil,

entreprise gazière pour qu'elle vienne approuver l'installation nale.

et avec les normes locales en matière de gaz. Dans toute situation, contacter votre

d'installation qualiée. Ils devraient être familiers avec l'installation d'appareil au gaz

Pour votre protection, nous recommandons que cet appareil soit installé par une entreprise

AVIS

la tension au raccord.

du fabricant, l'appareil doit aussi être installé avec des xations pour éviter de transmettre toute

rapide conforme à la norme ANSI Z21.41 ou CAN 1-6.9. Comme spécié dans les instructions

raccord conforme à la norme ANSI Z21.69 ou la CAN/CGA-6.16, et un raccord à démontage

Lorsque cet appareil est installé avec des roulettes, on doit utiliser les roulettes fournies, un

LOCAUX SI NECESSAIRE.

D'INSTALLATION DU PROPANE CAN/CGA-B149.2, ET AUX RÈGLEMENTS

D'INSTALLATION DU GAZ NATUREL CAN/CGA-B149.1, SOIT AU CODE

AU CANADA, L'INSTALLATION DOIT ÊTRE CONFORME SOIT AU CODE

LES RÈGLEMENTS DES ENTREPRISES GAZIÈRES LOCALES.

COMBUSTIBLE « ANSI Z223.1 — EDITION RECENTE » AINSI QU'À TOUS

L'installation de l'appareil doit être conforme au CODE NATIONAL DE GAZ

10,16 cm entre le comptoir et le bas de l'appareil.

17,78 cm de toute construction non combustible, et il doit y avoir un espace de

Le fond et les côtés de l'appareil doivent se trouver à une distance d'au moins

avant de l'allumer.

S'assurer de retirer toutes les protections en papier et tout l'emballage de l'appareil

-IMPORTANT-

sur l'étiquette placée sur le panneau de côté.

La gamme de tables de cuisson Lang chefseries® est conçue pour le type de gaz inscrit

ou près d'une maison, ni pour être utilisé par le public dans un restaurant.

personnel formé et expérimenté et n'est ni en vente pour un usage domestique à l'intérieur

Cet équipement est conçu et vendu uniquement pour un usage commercial par un

ATTENTION

INSTALLATION GÉNÉRALE

5

Interrupteur

Panneau

avant articulé

Cuvette

de propreté

Boutons

du brûleur

Admission

du gaz

Fixation

murale

Fil électrique

Grille du brûleur

"Allumage instantané"

en option

4” ajustables. Pattes normales

(Grandes pattes et roulettes en option)

Instructions

d'allumage

IL2181-FR

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

Grille du brûleur Garde la nourriture à la bonne distance de la amme du brûleur.

besoins; tout remplacement ou modication du l annule sa garantie.

Le l électrique fourni avec cet appareil est conçu spécialement pour ses

locales.

L'installation doit être faite à l'aide de raccords à gaz conformes aux normes

Fil électrique

Fixations au mur

Admission du gaz L'approvisionnement en gaz doit être connecté par un installateur qualié.

l'appareil au niveau et facilitent le nettoyage sous l'appareil.

Permettent à l'air de circuler sous la plaque de cuisson. Permettent de garder

Expliquent la bonne façon d'utiliser la plaque de cuisson.

Pieds ajustables de 4"

d'allumage

Instructions

Boutons du brûleur Permettent un contrôle individuel des brûleurs avants et arrières.

Cuvette de propreté Recueille les miettes et se démonte facilement pour un nettoyage rapide.

vis qui le maintiennent en place et les poignées.

Le panneau avant s'enlève facilement pour l'entretien; il suft d'enlever les deux

articulé

Panneau avant

et l'appareil s'éteint.

solénoïdes jusqu'aux brûleurs. Quand il est à « Arrêt », le gaz cesse de circuler

Interrupteur

Lorsque l'interrupteur est en position « Marche », le gaz circule dans les

DESCRIPTION DE L'ÉQUIPEMENT

6 1/8”

4”

3”

14 7/8”

15 5/8”

18 1/2”

ADMISSION DU GAZ

Connexion électrique de 120V

Fil de 1,68 mètre

IL2180-FR

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

fret

Classication

Poids

4

GHP8 256,000 BTU/hr

GHP6 192,000 BTU/hr

GHP4 128,000 BTU/hr

GHP2 64,000 BTU/hr

Modèle Condition de gaz (3/4 po NPT)

*Plancher non combustible seulement

(39.1cm x 121.6 x 71.6cm)

15 3/8” x 47 7/8” x 28 3/16”

(39.1cm x 91.1cm x 71.6cm)

15 3/8” x 35 7/8” x 28 3/16”

: 7”

Côtés et dos

(39.1cm x 60.6cm x 71.6cm)

15 3/8” x 23 7/8” x 28 3/16”

(39.1cm x 30.2cm x 71.6cm)

15 3/8” x 11 7/8” x 28 3/16”

Réel Transport

surface combustible*

Espace libre de toute

GHP8

GHP6

GHP4

GHP2

Modèle Longueur x largeur x hauteur

GAMME DE TABLES DE CUISSON À GAZ CHEF SERIES

CARACTÉRISTIQUES DE L'ÉQUIPEMENT

CARACTÉRISTIQUES

3

au www.langworld.com pour trouver le détaillant le plus près.

: 1-800-438-5264, ou visitez notre site web

Contactez-nous sans frais au

Consulter votre répertoire des détaillants Lang agréés.

uniquement par le personnel qualié.

AVIS L'entretien de cet appareil ou de tout autre appareil Lang doit être fait

2M-W1662 Operation Manual - Lang Gas Countertop Range, GHP Series

. . . . . . . . . . . . . . . . . . 12 - 16

. . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Vue éclatée et liste des pièces .

Schéma de câblage . .

Nettoyage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Instructions de fermeture . . . . . . . . . . . . . . . . . . . . . 10

Incliner la grille . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cuisson au grilloir . . . . . . . . . . . . . . . . . . . . . . . . . 10

Allumage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Utilisation du brûleur. . . . . . . . . . . . . . . . . . . . . . . . 10

Cuvette de propreté . .

Mode d'emploi

Allumage du brûleur et réglages . . . . . . . . . . . . . . . . . 9

Instructions pour la amme pilote . . . . . . . . . . . . . . . . . 9

Vérication des fuites de gaz . . . . . . . . . . . . . . . . . . . 8

Conversion du gaz propane . . . . . . . . . . . . . . . . . . . . 8

Connexion de l'alimentation de gaz . . . . . . . . . . . . . . . . 8

Robinet de fermeture manuel . . . . . . . . . . . . . . . . . . . 8

Conduits de gaz . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Niveler l'appareil . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Approvisionnement en air . . . . . . . . . . . . . . . . . . . . . 6

Hottes . .

Installation générale

ou

. . . . . . . . . . . . . . . . . . . . . 5

TABLE DES MATIÈRES

des pièces au 1-800-438-5264.

appeler le service d'assistance technique et le département

Avant de nous contacter, communiquer avec votre distributeur agréé Lang

PROBLÈMES, QUESTIONS ou INQUIÉTUDES

Description de l'équipement .

Caractéristiques . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2

Ces symboles sont conçus pour avertir l'utilisateur de l'existence d'importantes instructions

sur l'utilisation et l'entretien de l'appareil dans le mode d'emploi fourni avec celui-ci.

POUR VOTRE SÉCURI TÉ

ÉVITER D’ENTREPOSER OU D’UTILISER DES GAZ OU AUTRES VAPEURS ET LIQUIDES

INFLAMMABLES PRÈS DE CET APPAREIL OU D'UN AUTRE APPAREIL DU MÊME TYPE.

L'installation de l'appareil doit être conforme au CODE NATIONAL DE GAZ COMBUSTIBLE « ANSI Z223.1

— EDITION RECENTE » AINSI QU'À TOUS LES RÈGLEMENTS DES ENTREPRISES GAZIÈRES LOCALES.

AU CANADA, L'INSTALLATION DOIT ÊTRE CONFORME SOIT AU CODE D'INSTALLATION DU GAZ NATUREL

CAN/CGA-B149.1, SOIT AU CODE D'INSTALLATION DU PROPANE CAN/CGA-B149.2, ET AUX RÈGLEMENTS

LOCAUX S'IL Y A LIEU.

AFFICH ER À LA VUE DE TOU S

INSTRUCTIONS À SUIVRE SI UN UTILISATEUR SENT UNE ODEUR DE GAZ CETTE

INFORMATION SE TROUVE CHEZ VOTRE FOURNISSEUR DE GAZ. AU MINIMUM, FERMER

LE GAZ ET APPELER VOTRE DÉTAILLANT AUTORISÉ. ÉVACUER TOUT LE PERSONNEL DU

SECTEUR

AVERTISSEM ENT

L'INSTALLATION, LES RÉGLAGES, LES MODIFICATIONS, L'UTILISATION OU L'ENTRETIEN

INCORRECT RISQUE DE CAUSER DES DOMMAGES MATÉRIELS OU PHYSIQUES, OU MÊME

LA MORT. BIEN LIRE LES INSTRUCTIONS D'INSTALLATION, D'UTILISATION ET D'ENTRETIEN

AVANT D'INSTALLER OU D'UTILISER L'APPAREIL.

AVERT ISSEM ENT

RISQUES D'INCENDIE OU D'ÉLECTROCUTION

NE PAS OUVRIR

NE PAS OUVRIR LE PANNEAU DE CONTRÔLE AFIN D'ÉVITER LES RISQUES

D'ÉLECTROCUTION. NE COMPORTE AUCUNE PIÈCE QUE L'UTILISATEUR PEUT

RÉPARER. TOUTE RÉPARATION DEVRAIT ÊTRE EFFECTUÉE SEULEMENT PAR LE

PERSONNEL DE SERVICE AUTORISÉ.

AVIS

L'utilisation de pièces autres que les pièces authentiques fournies par les usines Lang exempt les manufacturiers de

toute responsabilité.

Lang se réserve de droit de modier les caractéristiques et le modèle du produit sans préavis. Ces modications ne

donnent pas droit au client sur les changements, améliorations, ajouts ou remplacements pour de la marchandise

achetée au préalable.

À cause des changements périodiques apportés aux concepts, aux méthodes, aux procédures, aux politiques et aux

règlements, les caractéristiques contenues dans ce manuel sont sujettes au changement sans préavis. Bien que Lang

Manufacturing travaille de bonne foi pour fournir l'information juste, nous ne sommes pas responsables des erreurs ou

des omissions présentes, ou des conclusions auxquelles on pourrait arriver en utilisant les mauvaises spécications.

En utilisant les informations fournies, l'utilisateur assume tous les risques en lien avec cette utilisation.

ENTRETIEN ET RÉPARATIONS

Communiquer avec votre fournisseur local pour tout service ou réparation nécessaire. Veuillez enregistrer le numéro de

modèle, le numéro de série, la tension et les dates d'achat et d'installation dans l'espace ci-dessous. Aussi, ayez-le sous

la main lorsque vous appelez pour obtenir un service rapide.call to ensure a faster service.

SYMBOLE DE SÉCURITÉ

No de modèle :

No de série :

Tension :

1 Phase ou 3 Phases :

Acheté chez :

Endroit

Date d'achat :

Date d'installation :

1

Retain This Manual for Future Reference.

local.

se trouve chez votre fournisseur de gaz

dans un espace bien aéré. Cette instruction

aux lois en vigueur et ne doit être utilisé que

Cet appareil doit être installé conformément

d'installer et d'utiliser cet appareil.

bien aéré. Consulter les instructions avant

et ne doit être utilisé que dans un espace

installé conformément aux lois en vigueur

AVERTISSEMENT: Cet appareil doit être

d'un autre appareil du même type.

liquides inammables près de cet appareil ou

ou d'utiliser des gaz ou autres vapeurs et

POUR VOTRE SÉCURITÉ: Éviter d'entreposer

l'appareil.

et d'entretien avant d'installer ou d'utiliser

lire les instructions d'installation, d'utilisation

matériels ou physiques, ou même la mort. Bien

incorrect risque de causer des dommages

les modications, l'utilisation ou l'entretien

AVERTISSEMENT: L'installation, les réglages,

2M-W1662 Rev. - 3/29/11

d'utilisation

d'installation et

Instructions

GHP2, GHP4, GHP6, GHP8

Chef Series

DE CUISSON À GAZ

GAMME DE TABLES

Loading...

Loading...