Lang GCOF-T User Manual

GAS FULL SIZE

COMPUTERIZED

CONVECTION OVEN

GCOF-T

Installation and

Operation

Instructions

2M-W1349 Rev. A 10/27/15

GCOF-T

SAFETY SYMBOL

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT USER SMELLS GAS. THIS

INFORMATION SHALL BE OBTAINED BY CONSULTING YOUR LOCAL GAS SUPPLIER.

AS A MINIMUM, TURN OFF THE GAS AND CALL YOUR GAS COMPANY AND YOUR

AUTHORIZED SERVICE AGENT. EVACUATE ALL PERSONNEL FROM THE AREA.

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION,

OPERATION & MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

WARNING, TO REDUCE THE RISK OF ELECTRICAL SHOCK, DO NOT REMOVE

CONTROL PANEL. NO USER-SERVICABLE PARTS INSIDE.

REPAIRS SHOULD BE DONE BY AUTHORIZED SERVICE PERSONNEL ONLY.

FOR YOUR SAFTEY

THE VICINTIY OF THIS OR ANY OTHER APPLIANCE.

POST IN PROMINENT LOCATION

WARNING

SERVICING THIS EQUIPMENT.

WARNING

RISK OF FIRE OR ELECTRIC SHOCK

DO NOT OPEN

NOTICE

Using any part other than genuine Lang factory supplied parts relieves the manufacturer of all

liability.

Lang reserves the right to change specications and product design without notice. Such

revisions do not entitle the buyer to corresponding changes, improvements, additions or

replacements for previously purchased equipment.

Due to periodic changes in designs, methods, procedures, policies and regulations,

the specications contained in this sheet are subject to change without notice. While

Lang exercises good faith efforts to provide information that is accurate, we are not

responsible for errors or omissions in information provided or conclusions reached as a

result of using the specications. By using the information provided, the user assumes all risks

in connection with such use.

MAINTENANCE AND REPAIRS

Contact your local dealer for service or required maintenance. Please record the model number, serial

number, voltage and purchase & Installation Information in the area below and have it ready when you

call to ensure a faster service.

Model No.:

Serial No.:

Voltage:

Purchased From:

Location:

Purchase

Date:

2M-W1349, GCOF-T Gas Full Size Convection Oven

1-Phase

or 3 Phase:

Installed Date:

2

PROBLEMS, QUESTIONS or CONCERNS

Before you proceed consult you authorized Lang service agent directory

or

Call the Lang Technical Service Department at 314-678-6315.

TABLE OF CONTENTS

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Equipment Description . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation

Leg Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Leg Pad Adapter Installation . . . . . . . . . . . . . . . . . . . 8

Stacking the Oven . . . . . . . . . . . . . . . . . . . . . . . . . 9

Flu Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ventilation & Clearence . . . . . . . . . . . . . . . . . . . . . . 10

Electrical Connection . . . . . . . . . . . . . . . . . . . . . . .10

Gas Connection . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Gas Conversions . . . . . . . . . . . . . . . . . . . . . . . . .12

Initial Start-Up

Pre-Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Power On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

General Operation & Programming

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Typical Operation Sequence . . . . . . . . . . . . . . . . . . .14

Hints & Suggestions . . . . . . . . . . . . . . . . . . . . . . . . 15

Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Maintenance

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Troubleshooting

Symptoms / Possible Causes / Test . . . . . . . . . . . . . . . . 17

Wiring Diagram

2M-W1349, GCOF-T Gas Full Size Convection Oven

120VAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Exploded View & Parts List . . . . . . . . . . . . . . . . . . . . . 20-25

NOTICE ServiceonthisoranyotherLangappliancemustbeperformedbyqualiedper-

sonnel only. Consult your Lang Authorized Service Agent Directory.

You can call our tech service number 314-678-6315

or visit our website www.langworld.com for the service agent nearest you.

3

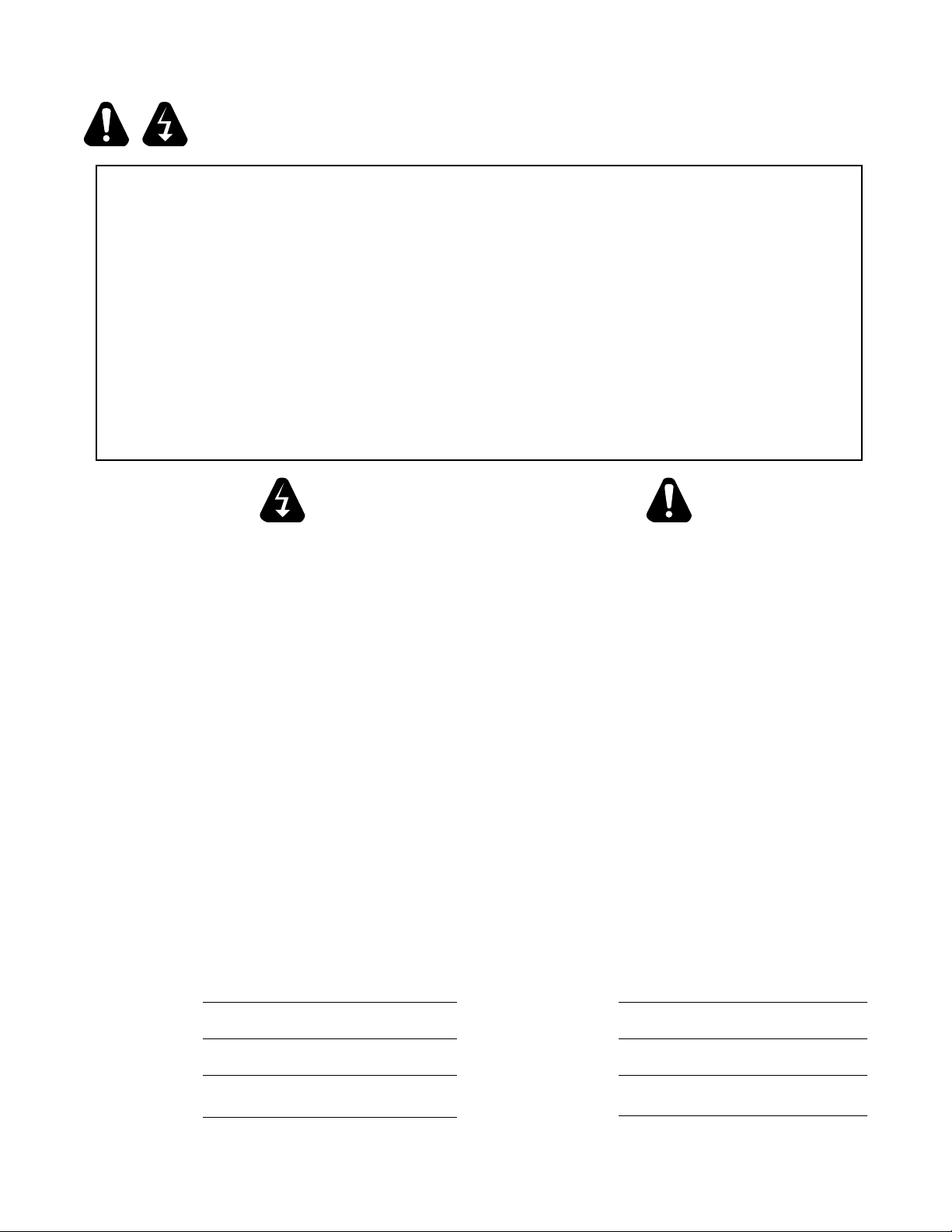

W D

H

15.1”

384mm

2.5”

54mm

GAS

CONNECTION

2.5”

54mm

GAS

CONNECTION

IL2354

Front View Side View Top View

Model Height x Width x Depth

GCOF-T

32” x 40.2” x 40.5”

812mm x 1021mm x 1029mm

SPECIFICATIONS

Clearance from combustible surface

(without optional stand)

Weight

Installed Shipping

Freight

Class

Side:6” (154mm), Back:6” (154mm), Floor:6” (154mm) 70

ELECTRICAL & GAS SPECIFICATIONS

CURRENT MODEL VOLTS AC Hz. AMPS NAT. PROPANE BURNER INPUT

GCOF-T-NAT

X

115 60 7.1

GCOF-T-LP X

FEATURES & BENIFITS

Interior Light

Accu-Temp Controls

Dual Speed Fan

One hand door opening

5 Racks

55000

2M-W1349, GCOF-T Gas Full Size Convection Oven

IL2355

4

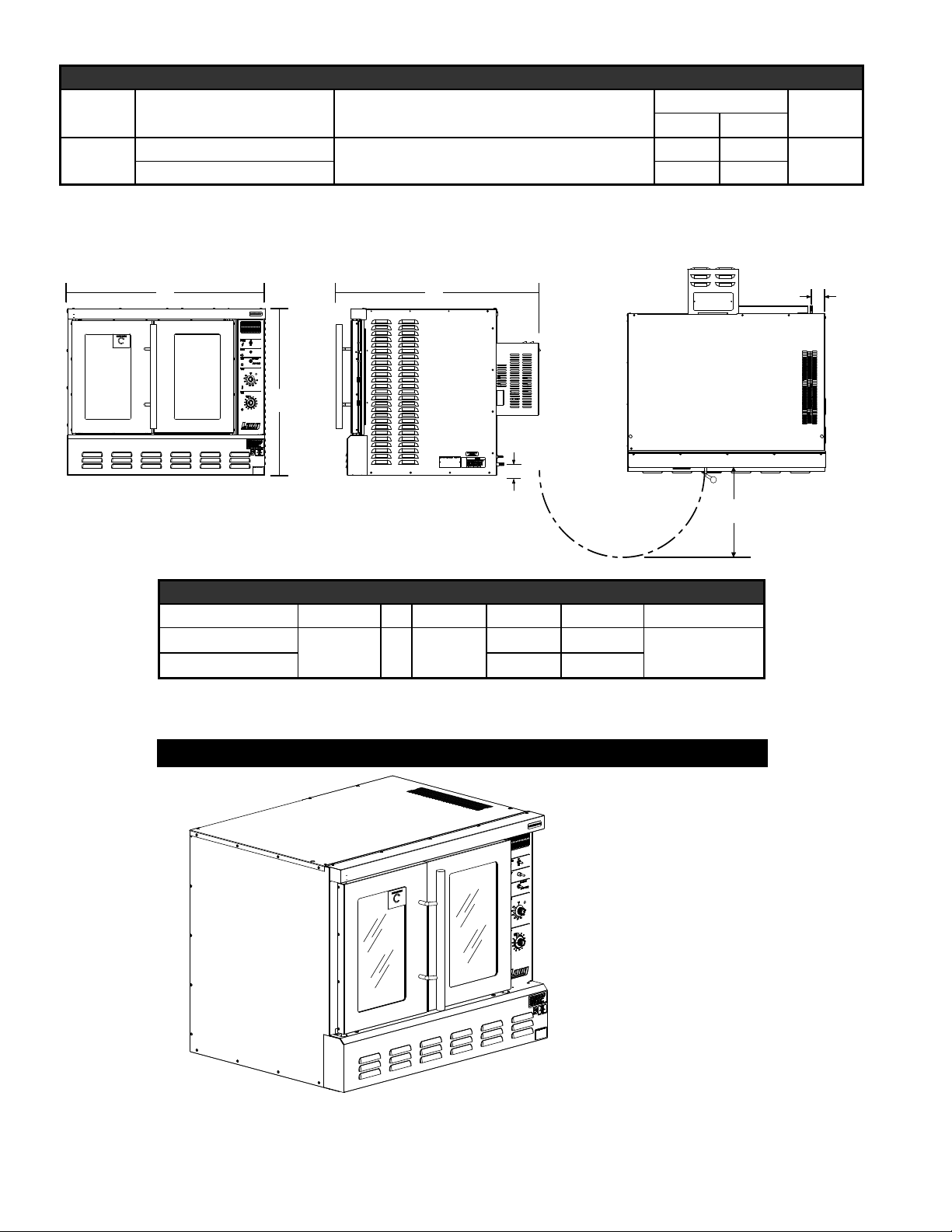

EQUIPMENT DESCRIPTION

Vent

Front

Motor

Wall Anchor

Power Cord

IL2353

Handle

Side Vent

Nameplate

Controls

Gas Inlet

Exterior Construction

The oven exterior dimensions are listed in the Specication Section. The Top, Front, Back, and Sides

are constructed of heavy duty 430 stainless steel, with an attractive No. 4 nish.

The ovens simultaneous-opening heavy duty doors come standard with double pane windows.

The door handle is constructed of Stainless Steel and Phonolic Tubing.

The oven cavity is insulated with high temperature insulation for efciency and reduced heat loss.

Interior Construction

The GCOF oven cavity dimensions are 29” (72.5 cm) Wide, 20” (50.84 cm) High, 21” (53.38 cm) Deep.

The interior of the oven is constructed of porcelainized stainless steel.

Operation

The GCOF-T ovens are forced air convection ovens with a vented oven cavity.

The air is driven by a 1/3 HP fan motor.

Controls

Easy to use manual control knobs.

Solid state temperature sensing and controls.

Pulse and two-speed fan.

Technical

The GCOF-T has electronic ignition and requires a 120V single-phase connection.

2M-W1349, GCOF-T Gas Full Size Convection Oven

Floor space required is 46” (116.84 cm) wide, 46.5” (118.11 cm) deep.

The oven weighs 500 lbs.

Contact the factory for correct orice sizes when installing oven above 4000 ft.

NOTICE The nameplate is on side of the oven right of the control panel.

The oven voltage, wattage, serial number, wire size, and clearance

specicationsareonthedataplate.Thisinformationshould

be carefully read and understood before proceeding with the

installation.

5

CAUTION

UNPACKING

Receiving the Oven

Upon receipt, check for freight damage, both visible and concealed.

Visible damage should be noted on the freight bill at the time of delivery and

signed by the carrier’s agent. Concealed loss or damage means it does not

become apparent until the merchandise has been unpacked. If concealed

loss or damage is discovered upon unpacking, make a written request for

inspection by the carrier’s agent within 15 days of delivery. All packing

material should be kept for inspection. Do not return damaged merchandise

to Star Manufacturing Company. File your claim with the carrier.

Location

Prior to un-crating, move the oven as near to its intended location as practical. The crating will help

protect the unit from the physical damage normally associated with moving it through hallways and

doorways.

Un-crating

The oven will arrive completely assembled inside a wood frame and strapped to a skid. Cut the

straps and remove the wood frame.

The oven can now be removed from the skid.

EACH UNIT WEIGHS 500 LBS. FOR SAFE HANDLING, INSTALLER SHOULD

OBTAIN HELP AS NEEDED, OR EMPLOY APPROPRIATE MATERIALS HANDLING EQUIPMENT (SUCH AS A FORKLIFT, DOLLY, OR PALLET JACK)

TO REMOVE THE UNIT FROM THE SKID AND MOVE IT TO THE PLACE OF

INSTALLATION.

ANY STAND, COUNTER OR OTHER DEVICE ON WHICH OVEN WILL BE

LOCATED MUST BE DESIGNED TO SUPPORT THE WEIGHT OF THE OVEN.

SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN CUT.

2M-W1349, GCOF-T Gas Full Size Convection Oven

6

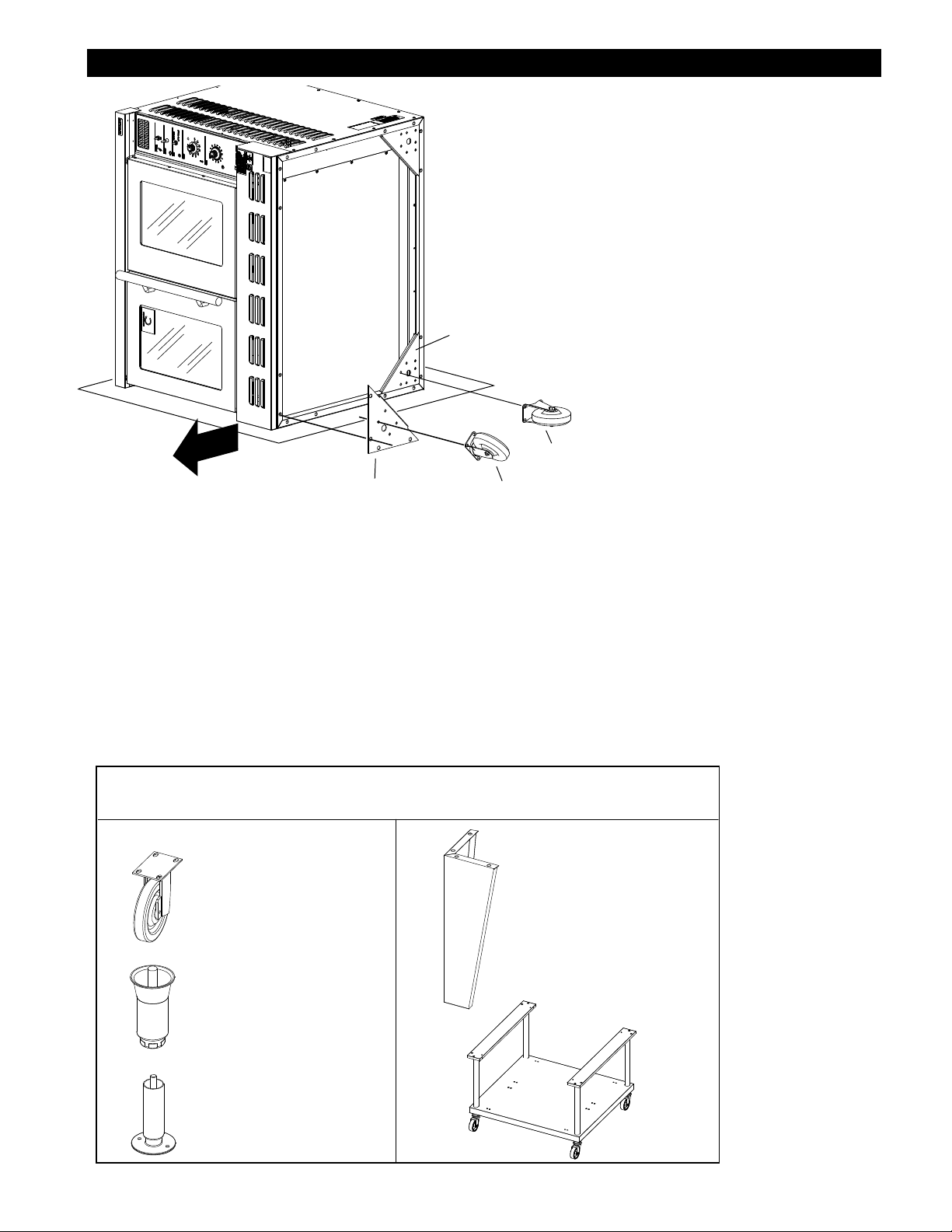

INSTALLATION

Rear

Support Assy

Front

Front

Support Assy

Above: typical leg and caster installation.

Below: accessory options, legs, casters & equipment carts sold

separately. Follow installation instructions with the each specic kit.

Swivel

Caster

Leg Installation

Legs are available separately for both the

single and double deck installations. Single

deck installations require a 27-inch leg or

equipment cart. Double deck installations

require 6-inch legs or casters. All these are

available separately.

Place some cardboard on the ground and

with assistance carefully lay the unit on its

side, as shown here.

The adjustable feet may be screwed in

or out as necessary to level the oven. A

torpedo level placed on an oven rack will

assist in leveling the oven.

Double-Stack Ovens

To install the 6-inch legs, adj. feet or casters

on the lower unit, follow the Leg Pad

instructions in the following section or in the

instructions included with the leg pads.

Caster

IL2356

Single Oven

To install 27” legs or cart to your unit, place

the unit laying on its side (as shown here)

onto a piece of cardborad. Be sure to read

all instructions & follow the instructions

provided with the kit.

27” Leg Installation

With unit in position, fasten the two legs to the front left & rear left corner pads then to the oven using the four

5/16 inch bolts provided in the leg kit. See leg pad adapter illustration to dermine differences between front & rear

support assemblies.

Lift the oven onto its two legs and block the right side up using one of the 27-inch legs set upside down in the

center right side of the oven body. Install the third 27-inch leg onto the oven body on the control side rear. Gently

lift the oven to remove the temporary support leg & install it on the last rear corner.

Accessory Options

Stacked Units

Caster Sets

2M-W1349, GCOF-T Gas Full Size Convection Oven

6” Adj. Leg Sets

Single Units

27” Leg Set

(marine also)

27” Equipment Cart

6” Adj. Bolt Down Leg Sets

(marine only)

IL1525

7

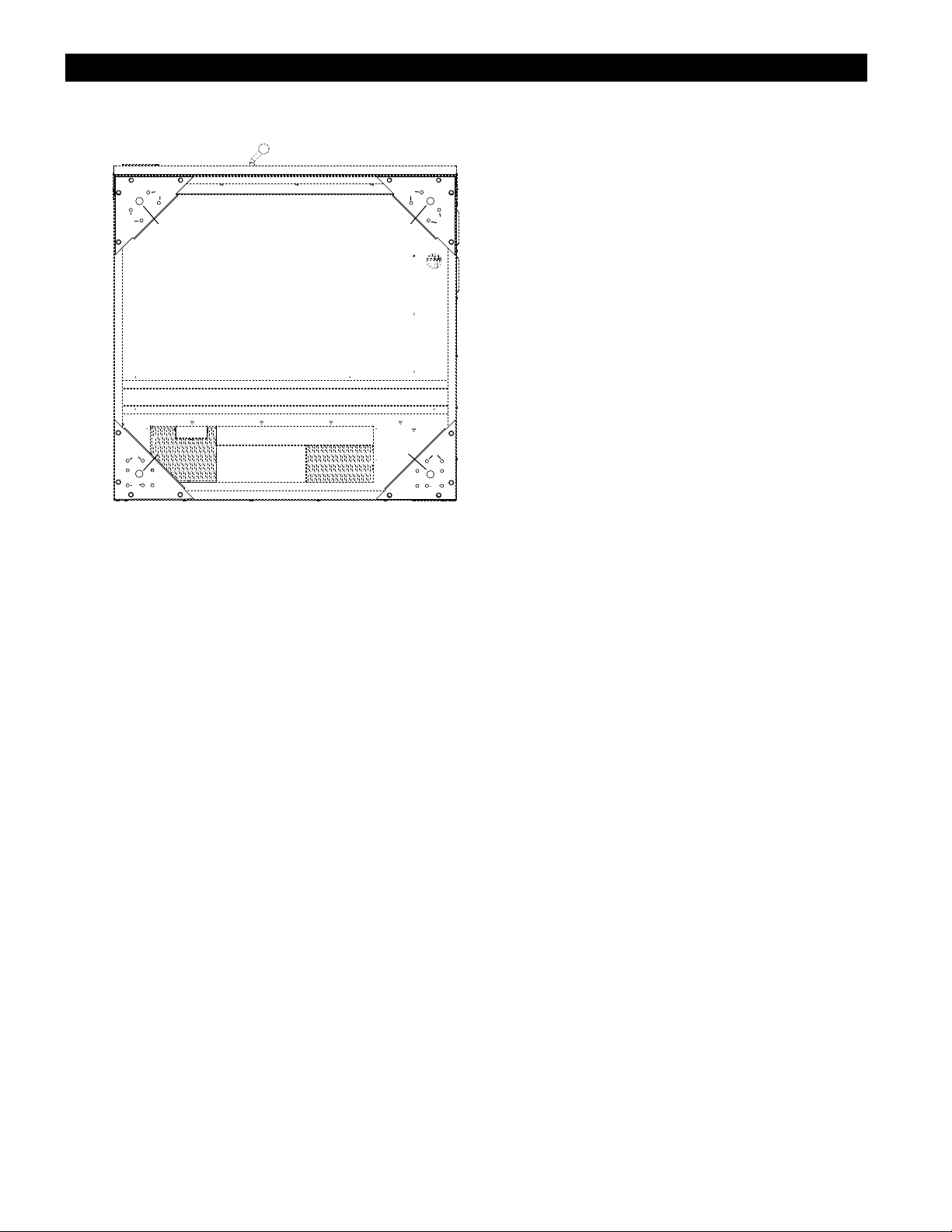

INSTALLATION cont.

Leg Pad Adapter

OVEN FRONT

D

A

E

E

B

E

E E E E

Above: Bottom on unit showing the placement of the leg adapters

and their hole assignment.

D D D

A A

C

OVEN BOTTOM

C

B

IL1523

C

C

B

B

and the other set will create a right rear adapter.

Install four 5/16-inch bolts through the caster base and the adapter holes labeled “B” then install 5/16-inch nuts with

lock washers and at washers.

Adapter to Oven Installation:

Gently tip the oven onto its back. Place the front leg adapter into the front corers of the oven. The holes without

the threaded inserts face the front of the oven and the ange on the adapter points toward the bottom of the oven.

The edge of the leg adapter with the threaded insert slips under the ange on the oven side, while the edge without

the inserts sits on top of the threaded angle on the oven front.

Install two 3/8-inch bolts with lock washers and at washers through the front holes “D” in the leg adapter and into

the threaded inserts on the oven.

Thread one 3/8-inch bolt with lock washer and at washer into the rear threaded hole labeled “E” on each of the leg

adapters.

The forward threaded hole on the front leg adapter does not get a bolt installed.

Place the rear leg adapters into the rear corners of the oven so that the adapter is under the ange of the oven side

and back.

NOTE: If installing a caster place the adapter on the oven so that the casters roll forward.

Install for 3/8-inch bolts with lock washers and at washers through the holes labeled “E” in the ange of the oven

and into the threaded inserts of the leg adapter.

Identify the front and rear leg adapters (the front

adapters have two threaded inserts, the rear has

four). The leg adapters are included with each specic

accessory kit.

A

Leg to Adapter Installation:

E

Install the leg’s threaded stud through the hole in the

adapter labeled “C” with the bent ange of the adapter

facing away from the leg.

Screw the 3/4-inch nut supplied in the adapter kit

onto the leg stud and tighten. Secure to oven using

hardware provided.

Caster to Adapter Installation:

Place the swivel caster against the front leg pad

adapter with the ange of the adapter

E

facing away from the caster.

Install the four 5/16 inch bolts through the caster base

and the adapter holes labeled “A” then install the 5/16

E

inch nuts with washer and lock washers.

Place the rigid casters against the rear leg adapter with

the ange of the adapter facing away from the caster.

Align the caster to the holes in the adapter labeled “B”.

NOTE: There are two sets of “B” holes set at 90° from

the each other. One set will create a left rear adapter

2M-W1349, GCOF-T Gas Full Size Convection Oven

8

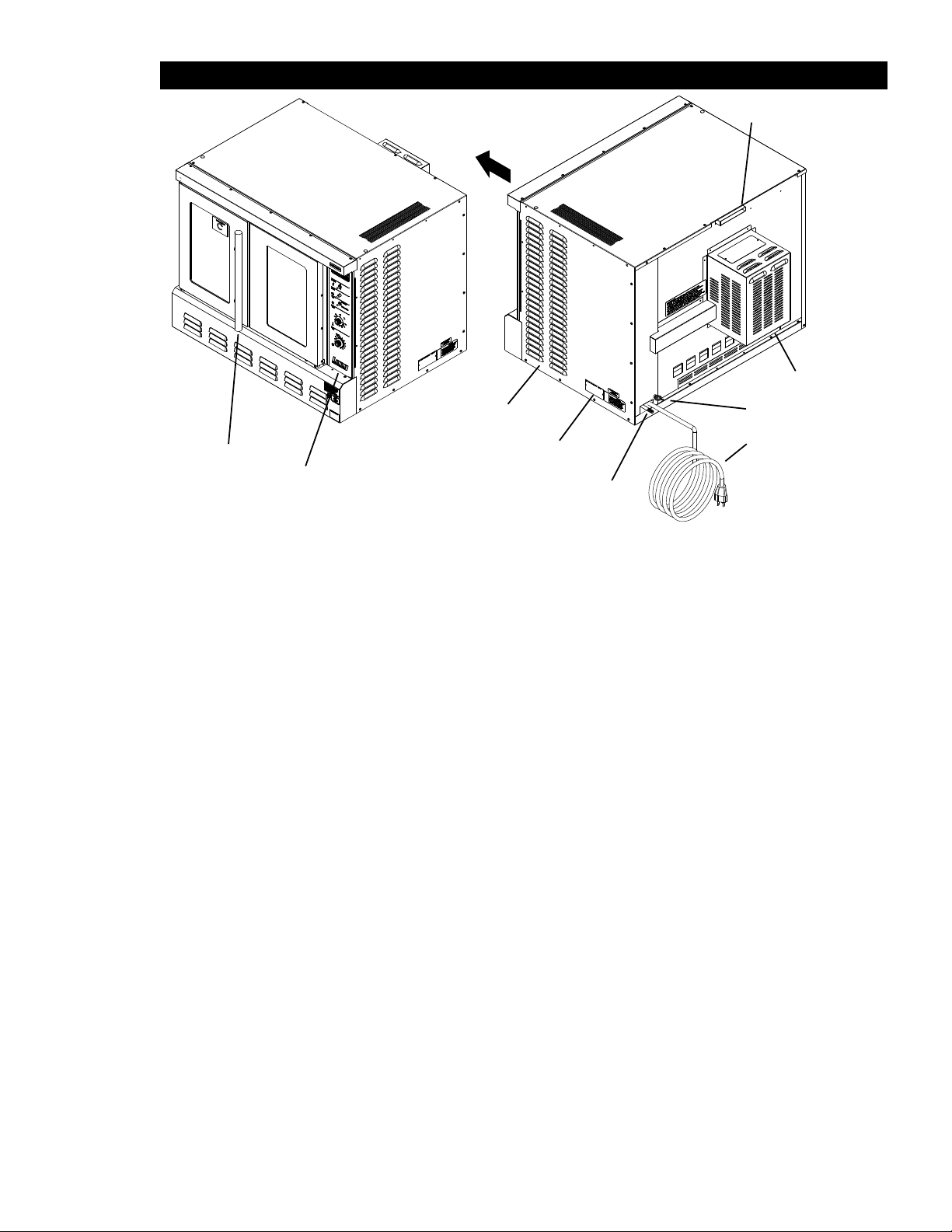

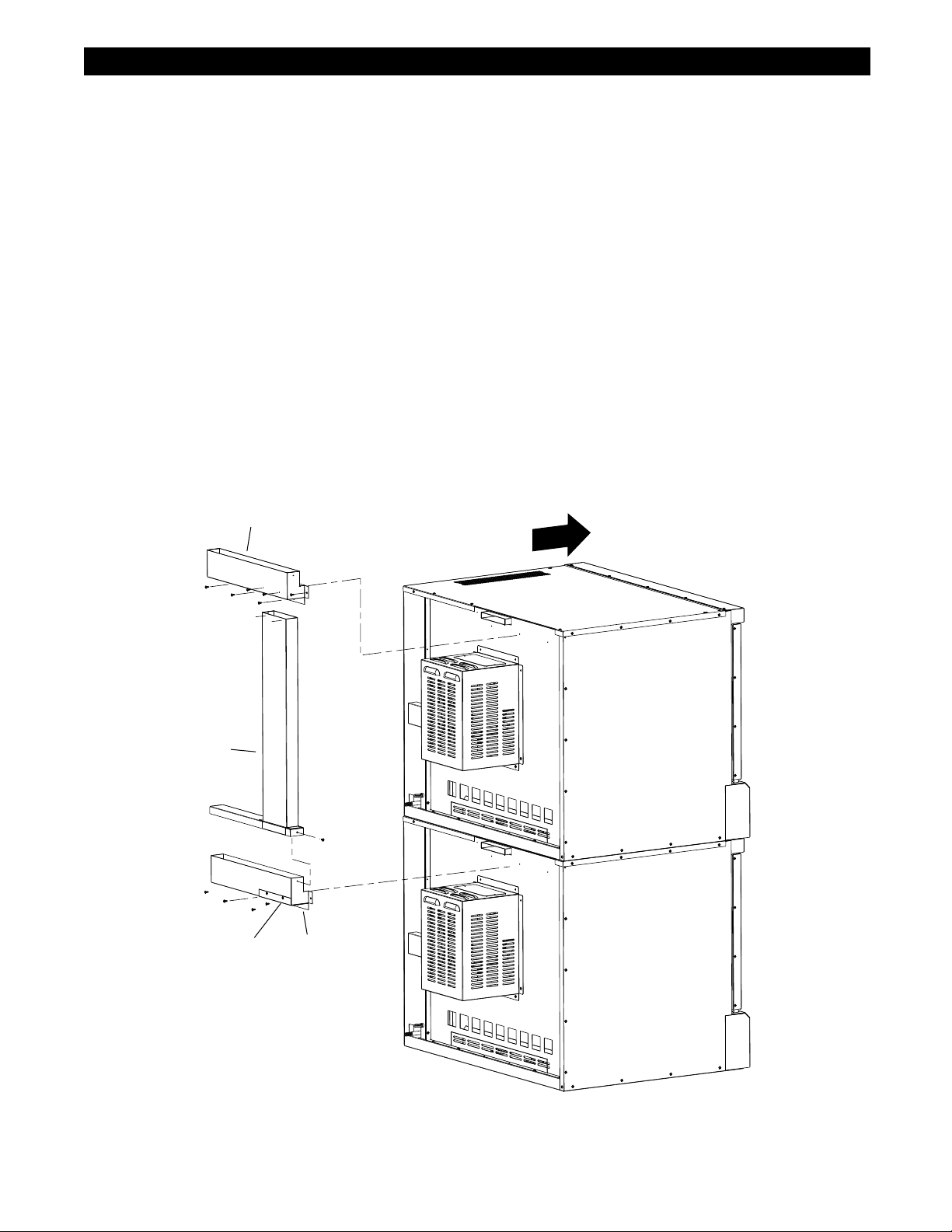

INSTALLATION cont.

Flue Adapter

Stacking the Ovens

Remove all the plug buttons from the top of the lower oven.

Remove the stacking kit from the oven compartment of one oven and install the 1 1/4-inch plastic bushing into

the top of the lower oven.

Tip the top oven backwards and install two 3/8-inch socket head bolts, found in the stacking kit, into the two front

leg holes that match the holes in the top of the lower oven. Install the socket head bolts with the heads of the bolt

pointing away from the oven.

Lift the top oven and gently set on top of the lower oven so that the heads of the socket head bolts nest into the

holes in the top of the lower oven.

NOTE: Each unit must have separate electrical connections

Flue Installation (9Q-GCOFT-FLUEXT Optional Kit)

A ue extension must be installed on the stacked set as shown below.

The extension directs the heat of the lower unit away from the motor of the upper unit. Without this installed, the

upper unit can experience problems including premature motor failure.

The ovens may now be set into position. Be careful if sliding the ovens, they are not designed to slide over

cracks or obstructions in the oor.

Flue

Extension

2M-W1349, GCOF-T Gas Full Size Convection Oven

Cover

Front

Flue

Adapter

IL2509

9

Loading...

Loading...