Page 1

Installation

Operation

Maintenance

136SB, 136SMB,

160SB, 160SMB Salamander

Lang Manufacturing 10 Sunnen Drive St. Louis, MO 63143

Part Number 2M-60807-01 Phone: 314-678-6315 Fax: 314-781-2714

Rev E www.langworld.com

October 4, 2012

Page 2

TABLE OF CONTENTS

INSTALLATION ..........................................................................................................................................1

RECEIVING

ELECTRICAL

VENTILATION

PLACEMENT

THE APPLIANCE ....................................................................................................................1

CONNECTION......................................................................................................................1

AND CLEARANCES..........................................................................................................1

ON RANGE............................................................................................................................2

NON - PREDRILLED RANGES..................................................................................................................2

PREDRILLED RANGES .............................................................................................................................2

OPERATION.................................................................................................................................................3

INITIAL

PREHEAT .......................................................................................................................................3

WIRING DIAGRAMS..................................................................................................................................4

208/240

440/480

VOLT ................................................................................................................................................4

VOLT ................................................................................................................................................5

EXPLODED VIEW & PARTS LIST ......................................................................................................6-7

Page 3

INSTALLATION

RECEIVING THE APPLIANCE

Upon receipt of the appliance, check for freight damage both visible and concealed. Visible damage

should be noted on the freight bill at the time of delivery and signed by the carrier's agent. Concealed loss

or damage means loss or damage which does not become apparent until the merchandise has been

unpacked. If concealed loss or damage is discovered, make a written request for inspection by the carrier's

agent within 15 days of delivery. All packing material should be kept for inspection. Do not return

damaged merchandise to Star Manufacturing International. File your claim with the carrier.

Uncrate the appliance as near its intended location as practical. The crating will help protect the unit from

the physical damage normally associated with moving it through hallways and doorways.

ELECTRICAL CONNECTION

The electrical connection must be made in accordance with local codes or in the absence of local codes

with NFPA No. 70 latest edition (in Canada use: CAS STD. C22.1).

Supply wire size must be large enough to carry the amperage load for the number of appliances being

installed. Wire size information can be found on the data plate and on the chart below.

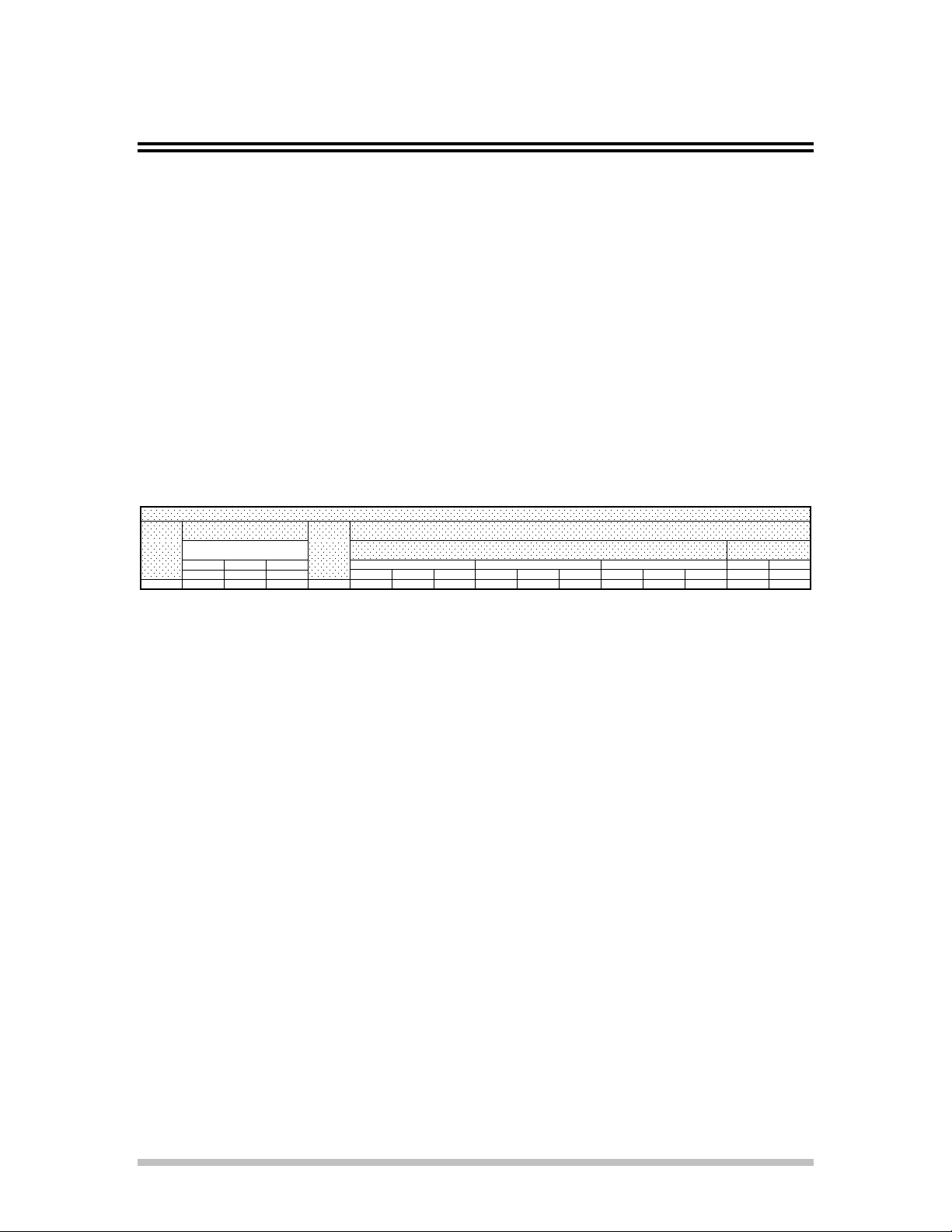

MODEL

NUMBER

36S-SH 6.0 6.0 0.0 6.0 28.8 28.8 0.0 25.0 25.0 0.0 12.5 12.5 0.0 28.8 25.0

TH REE PH A SE LOA DIN G NONINAL AM PS PER LINE

K. W. PER PHA SE

L1 - L2 L2 -L3 L3 - L1 208 VOLT 240 VOLT 480 VOLT 208 V. 240 V.

TOTAL

K.W.

L1 L2 L3 L1 L2 L3 L1 L2 L3 L1 L2

ELECT RI C A L D AT A

TH REE PHA SE SIN GLE PHA SE

VENTILATION AND CLEARANCES

Standard minimum clearance from combustible construction is as follows:

3 inches from sides

3 inches from back

Keep the appliance area free and clear of combustible material and do not obstruct the flow of combustion

or ventilation air.

The installation of any components such as a vent hood, grease extractors, and/or fire extinguisher systems,

must conform to the their applicable nationally recognized installation standards.

1

Page 4

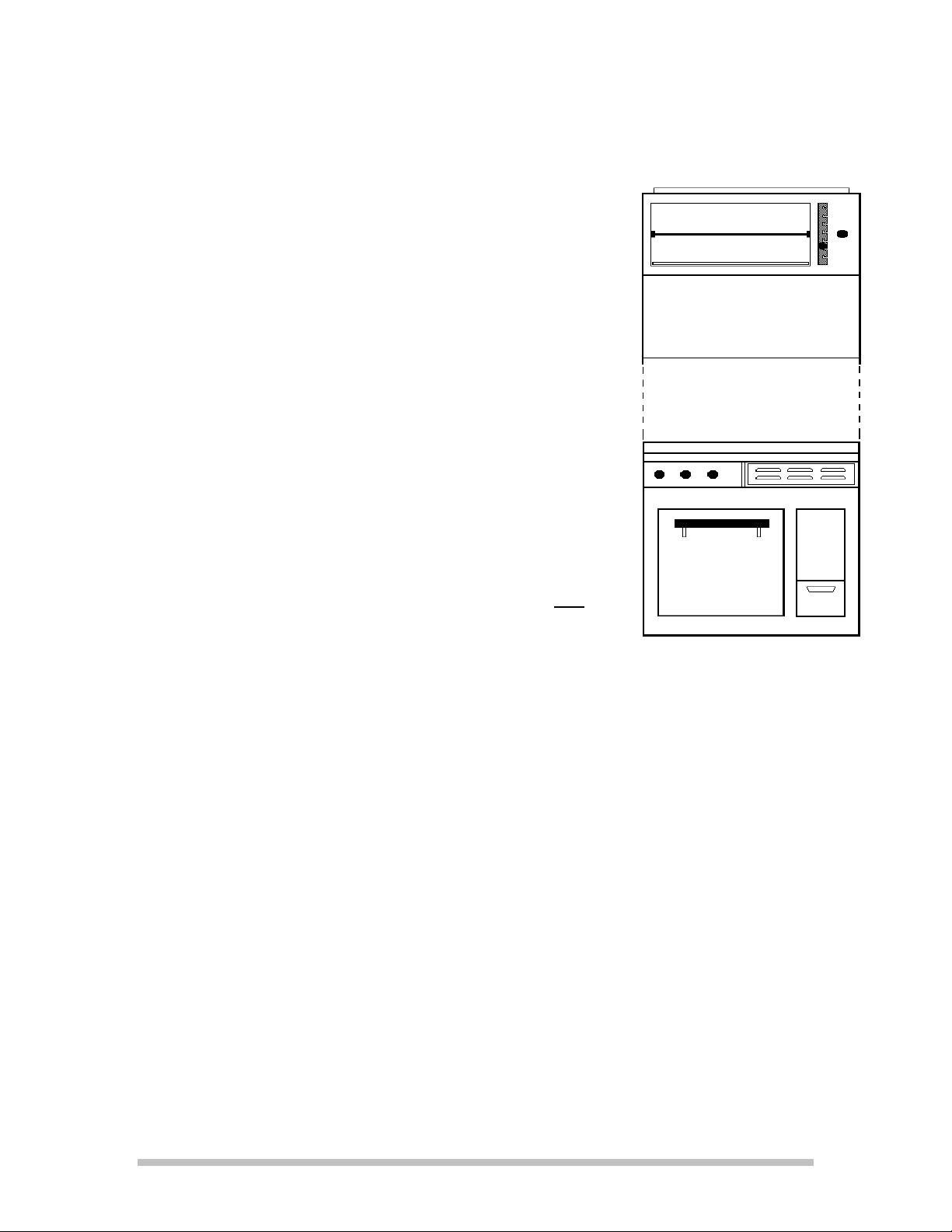

PLACEMENT ON RANGE

NON - PREDRILLED RANGES

If the range that the Salamander is to be installed on has been

predrilled by the factory, proceed to the next section - Predrilled

Ranges. If the range has not been predrilled, continue with this

section.

Place the Salamander on top of the range so that the back of the range

is flush with the back of the Salamander.

Mark the five holes in through the flange in the Salamander onto the

top of the range.

Mark the three holes through the side of the Salamander onto the side

of the range.

Remove the Salamander from the range.

Drill all eleven holes using a # 27 drill bit.

Tap the five holes in the top of the range with a 10-32 tap.

PREDRILLED RANGES

Place the Salamander on top of the range so that the holes in the

salamander line up with the holes in the range and the backs are flush.

Install five 10-32 x 3/8” Truss Head Machine Screws through the

holes in the back flange of the Salamander into the top of the range.

Install three 10-32 x 3/8” Truss Head MS SS Screws through each

side of the Salamander into the side of the range.

2

Page 5

OPERATION

INITIAL PREHEAT

Rotate the temperature dial until Hi is at the top.

Raise the broiler rack to the top most position and allow the rack to heat.

Lower the rack and place the product on it.

Raise the rack to the desired cooking position.

Set the temperature dial to the desired position.

3

Page 6

208/240 VOLT

WIRING DIAGRAMS

4

Page 7

440/480 VOLT

5

Page 8

21

1

15

14

17

16

20

19

18

12

2

4

5

6

7

3

9

8

13

SOME ITEMS ARE INCLUDED FOR

ILLUSTRATIVE PURPOSES AND IN

CERTAIN INSTANCES MAY NOT BE AVAILABLE

This drawing contains information confidential

to Lang Manufacturing

No reproduction or disclosure of it's

contents is permitted.

Model:

136SB - 160SB Salamander

11

10

SK2308 Rev. A 11/15/13

Page 9

PARTS LIST November 15, 2013, Rev E

Model No: 136SB, 136SBM, 160SB, 160SBM

SALAMANDER ELECTRIC BROILER

Key

Number

1 J9-SAL-130 1 BODY TOP C.T.M. ALL

2 J9-SAL-1424-1 1 BODY BACK C.T.M. ALL

3 2E-30500-09 1 TRM BLOCK 3 POLE SMALL 95 ALL

4 2C-20109-21 2 SCRW S/S 8-32X1 R/H M/S ALL

5 2E-31400-04 1 XFRMR 480/240VAC 100VA 136SB-480V, M-440V, M-480V

6 2E-30700-03 1 CONTC 3POLE 40A208-240VAC ALL

7 J9-SAL-141 1 BREAKER MOUNT ALL

8 J9-SAL-125-2 1 BODY SIDE RH C.T.M ALL

9 J9-SAL-179-3 1 HIGH SHELF ASSY SHORT 136SB

J9-SAL-179-4 1 HIGH SHELF ASSY SHORT 32S-HS

J9-SAL-179-5 1 HIGH SHELF ASSY SHORT 160SB

12 2E-30305-01 1 SWT INF 240V 15AMP ALL

13 J9-70701-04 1 KNOB ASSY INF CONTROL - BLACK

J9-70701-04-2 1 KNOB ASSY INF CONTROL - RED

14 2M-60301-43 1 DIE CAST PLT LANG SATIN ALL

15 J9-SAL-126-1 1 BODY FRONT C.T.M. ALL

16 J9-SAL-148-1 1 ELEMENT FRAME ASSY ALL

17 2N-11100-01 2 ELMNT BRL/SAL 208V 3KW 208V

2N-11100-02 2 ELMNT BRL/SAL 240V 3KW 240V

2N-11100-05 2 ELMNT BRLL/SAL 480V 2700W 440V / 480V

18 K9-SKSAL135-W1 1 GREASE PAN COMMERCIAL APPLICATIONS

K9-SKSAL135 1 GREASE PAN 36S-SH MARINE APPLICATIONS

19 J9-SAL-125-3 1 BODY SIDE RH C.T.M. ALL

20 J9-SAL-119 1 RACK DRIP PAN ALL

21 2B-50200-17 1 RACK SALAMANDER W/HANDLE ALL

Part

Number

Qty

Per

Description

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE 1

INCLUDE MODEL AND SERIAL NUMBER OF 1

Some items are included for illustrative purposes only and in certain instances may not be available.

Page 10

Page 11

Page 12

STAR INTERNATIONAL HOLDINGS INC. COMPANY

Star - Holman - Lang - Wells - Bloomeld - Toastmaster

10 Sunnen Drive, St. Louis, MO 63143 U.S.A.

(314) 678-6303

www.star-mfg.com

Loading...

Loading...