Land Rover Treker 4200NT, Treker 4400 NT User Manual

Engine Cold Weather Kit W/Diverter

Assembly Instructions

Treker 4200/4400 NT Series Manual No. 701-094M

Before You Start

When you see this symbol, the subsequent

instructions and warnings are serious - follow

!

without exception. Your life and the lives of

others depend on it!

These optional assembly instructions contain only

information required to assemble the Engine Cold

Weather Kit to the NT Series Treker. A detailed

Operator’s Manual was supplied with the Treker. Refer

to the Operator’s Manual for additional specific

information especially information relating to safety

concerns. Also included in the Operator’s Manual is

important information on operation, adjustment,

troubleshooting, and maintenance for this attachment

(some manual sections do not apply to all options).

A separate Parts Manual for replacement parts can be

purchasedfromyourdealeroravailablefreeofchargeat

www.landpride.com. Have model and serial numbers

handy when placing an order.

Manual Part Numbers:

• Operator’sManual . . . . . . . . . . . . . . . . . 700-108M

• Parts Manual . . . . . . . . . . . . . . . . . . . . . 700-108P

General Information

This Engine Cold Weather Kit w/Diverter applies to:

Treker 4200/4400 NT Series...............Kit No. 701-092A

The Engine Cold Weather kit is designed to prevent or

eliminate effects of carburetor icing on the 20hp Honda

engineforLandPrideTrekers. Carburetor icing mayoccur

at temperatures of 45 degrees Fahrenheit and lower.

Typical symptoms will be loss of power,hard starting,

engine backfiring, plug fouling, gas in the oil, or engine

stalling. Application of this kit will force warm air directly

into the air intake filter reducing or eliminating the icing

condition and its related symptoms. Vehicles started at

freezing temperatures should be allowed to warm-up for

approximately 4-5 minutes prior to full vehicle operation.

When outdoor temperatures are consistently above 45

degreesFahrenheit,theairbypassvalveshouldbeturned

to the summer setting to bypass air awayfrom the engine

exhaust manifold or a noticeable power loss will occur.

The oil and filter must be changed if plugs have become

fouled and if the dipstick indicates an oil overfill condition

with gas in the oil. Do not overfill engine with oil or plug

fouling will likely reoccur.

Tools required:

• 3/8" Nut driver & drill

• 1/2” Wrench or socket and driver

• 9/16" Wrench or socket and driver

• 13 mm Socket

• Straight blade screwdriver

• Cross blade screwdriver

• Knife

Assembly Instructions

A detailed listing of parts for Kit No. 701-092A is

provided on page 3. Use the list as a checklist to

inventory parts received.

Initial Preparations

!

Securely support cargo box in the up position to prevent

injury when working under the cargo box.

1. Parkvehicleon a flatsurface,movegearshiftleverto

2. Raise cargo box fully up and securely support it in

3. Turn off engine and remove ignition key.

Refer to Figure 1:

4. Loosen the two worm drivehoseclampssecuringthe

5. Remove rubber air intake hose and save for

CAUTION!

neutral, set par k brake, and chock front and back of

the right rear wheel to prevent the vehicle from

rolling.

the up position to prevent injury while working

around the engine.

rubber air intake hose and save for reuse.

modification and reinstallation.

NOTE: It is not necessar y to disconnect engine

snorkel and snorkel hose.

SS Hose

Clamp

AirCleaner

Canister

Existing Air Intake Assembly

Figure 1

Rubber Air

Intake Hose

21127

© Copyright 2005

11/23/05

Manual No. 701-094M

1

Assembly Instructions

Air Intake Installation

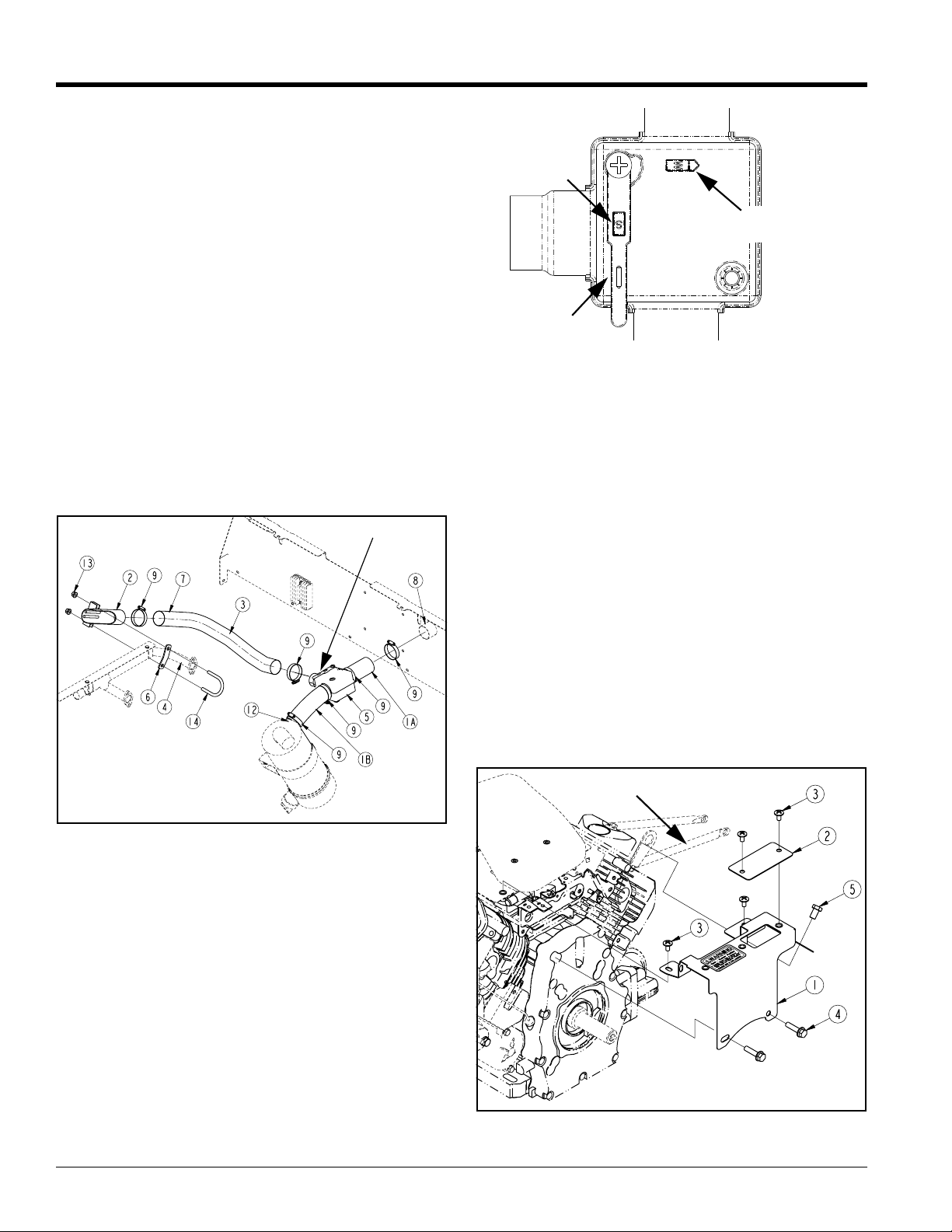

Refer to Figure 3:

1. Refer to air hose (#1A). Cut one end of existing air

intake hose to 4 1/4" long.

1. Orient air diverter assembly (#5) as shown.

2. Slip two wor m dr ive hose clamps (#9) over the

air intake hose (#1A). Insert air hose (#1A) over the

air intake nozzle (#8) and over the air diverter (#5)

nozzle. Do not tighten hose clamps.

3. Refer to air hose (#1B). Measure the distance

between the diverter assembly (#5) nozzle to the air

filter inlet nozzle (#10). Add 2" to this distance and

cut the other end of the air intake hose to this length.

4. Slip two worm drive hose clamps (#9) over the cut to

length air intake hose (#1B). Inser t air intake hose

(#1B) over air diverter (#5) nozzle and air intake

nozzle of air filter canister (#12). Do not tighten hose

clamps.

5. Expand the flexible heat riser tube (#3) to

approximately30". Be careful not to deform the tube

while expanding it.

Air Bypass Handle

Land Pride

Summer

Position

Winter

Position

Air Bypass

Handle

Air Bypass handle Position (Summer Position Shown)

Figure 4

Throttle Heat Shield Installation

Refer to Figure 5:

1. Remove M8 hex flange cap screw (#5) from engine

stabilizer bracket.

1. Positionheat shield coverassembly(#1) onto engine

housing as shown. Make certain the heat shield is

positioned under the engine stabilizer bracket.

2. Secure heat shield with two 1/4" x 1/2" phillips head

machine screws (#3), two 5/16" x 1 1/4" hex flange

head screws (#4) and replace the M8 hex flange cap

screw (#5).

3. Torque 1/4" phillips heads machine screws to 5.6 ft.

lbs, 5/16" hex head screws to 17 ft. lbs. and M8 hex

cap screws to 19 ft. lbs.

4. Warmair cover(#2)shouldbe secured overthe heat

shield opening when temperatures are below 45

degrees Fahrenheit and over the warning decal

when temperatures are above 45 degrees

Fahrenheit.

Stabilizer

22441

Air Intake Installation

Figure 3

Bracket

6. Slip two wor m dr ive hose clamps (#9) over the

flexible heat riser tube (#3). Insert flexible heat riser

tube (#3) over air diverter (#5) nozzle and heat tube

weldment (#2). Do not tighten hose clamps.

7. Clamp heat tube weldment (#2) to engine exhaust

manifold (#4) with 2" U-bolt (#14), clamp plate (#6)

and 3/8" hex nuts (#13). Torque nuts to 20 ft. lbs.

8. Tighten all six wor m dr ive hose clamps (#9).

Refer to Figure 4:

9. Rotate the air bypass handle counter clockwise to

the winter position marked with a “W” when

temperatures are below 45 degrees Fahrenheit.

Rotate the air bypass handle clockwise to summer

position marked with a “S” when temperatures are

above 45 degrees Fahrenheit.

Manual No. 701-094M 11/23/05

2

Heat Shield Installation

Figure 5

22451

■

Loading...

Loading...