Page 1

1: General Information

100: Service Information

2: Chassis

204: Suspension

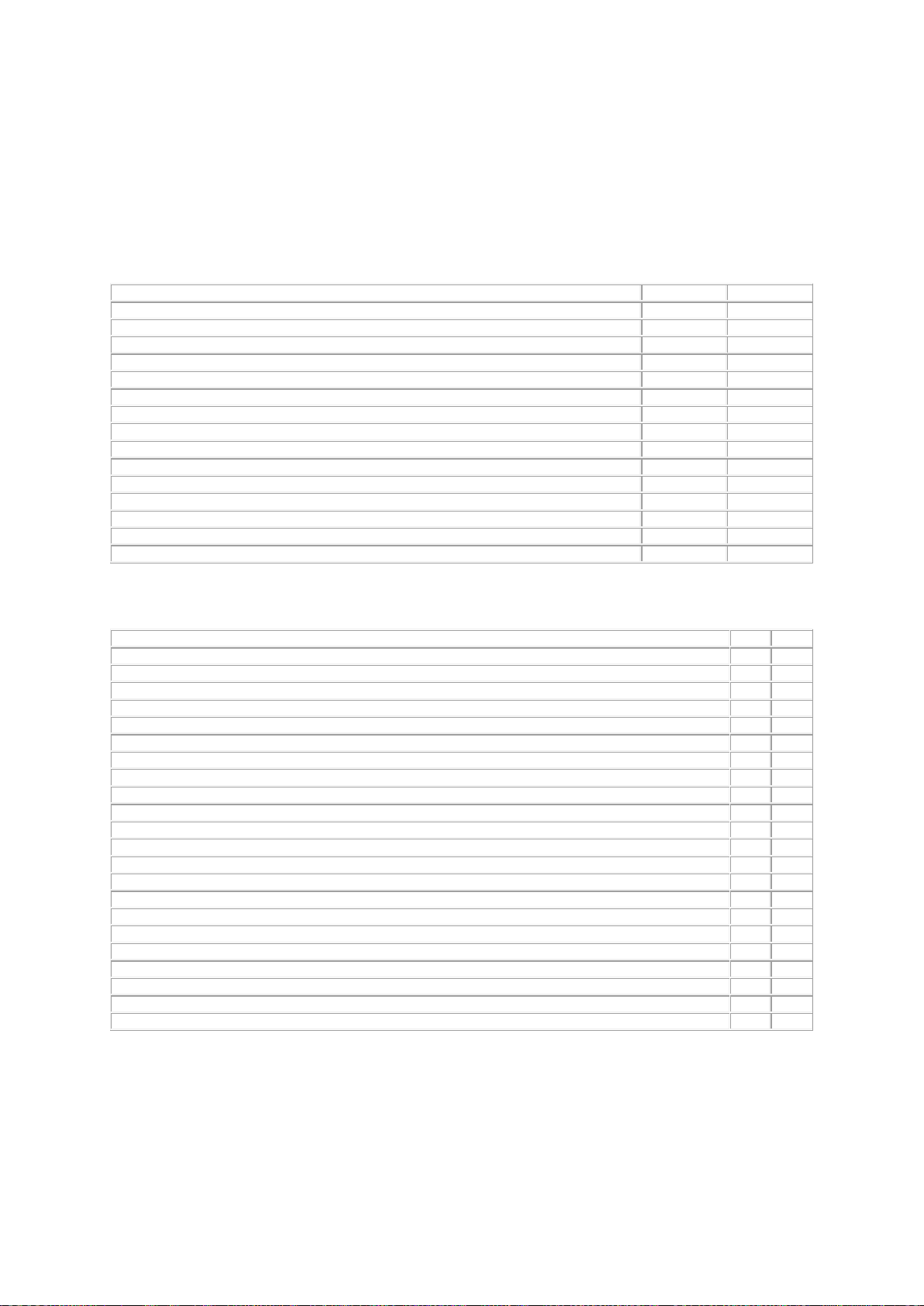

CONTENTS

100-00: General Information

Description and Operation

About This Manual

How To Use This Manual

Important Safety Instructions

Standard Workshop Practices

General Service Information

Health and Safety Precautions

Solvents, Sealants and Adhesives

Special Tool Glossary

Road/Roller Testing

DTC: Module Name: Bluetooth Module

100-01: Identification Codes

Description and Operation

Identification Codes

100-02: Jacking and Lifting

Description and Operation

Jacking

Lifting

Vehicle Recovery

100-03: Maintenance Schedules

Description and Operation

Maintenance Schedules - Gasoline Engines

Maintenance Schedules - Diesel Engines

204-00: Suspension System - General Information

Specification

General Procedures

Front Camber, Caster and Toe Adjustment

Four-Wheel Alignment (57.65.04)

204-01: Front Suspension

Specification

Description and Operation

Front Suspension

Removal and Installation

Front Lower Arm (60.35.02) (60.35.03)

Front Lower Arm Bushing (60.35.26)

Front Shock Absorber (60.30.02)

Front Stabilizer Bar (60.10.01)

Front Stabilizer Bar Link (60.10.02/60.10.04)

Rear Lower Arm (60.40.09)

Rear Lower Arm Ball Joint (60.15.04)

Page 2

Rear Lower Arm Bushing (60.35.26)

Shock Absorber and Spring Assembly (60.30.25/99)

Front Wheel Bearing and Wheel Hub (60.25.14)

Wheel Knuckle (60.25.01)

Disassembly and Assembly

Shock Absorber and Spring Assembly

204-02: Rear Suspension

Specification

Description and Operation

Rear Suspension

Removal and Installation

Lower Arm (64.35.54)

Lower Arm Ball Joint (64.15.08)

Lower Arm Bushing (64.35.15)

Lower Arm Rear Bushing (64.35.15)

Rear Stabilizer Bar (64.35.08)

Rear Stabilizer Bar Link (64.35.24)

Toe Link (64.35.70)

Upper Arm (64.35.60) - TDV8 3.6L Diesel

Upper Arm (64.35.60) - 4.4L NA V8 - AJ41/4.2L SC V8 - AJV8

Upper Arm Ball Joint (64.15.07)

Upper Arm Bushing (64.35.22) - TDV8 3.6L Diesel

Upper Arm Bushing (64.35.22) - 4.4L NA V8 - AJ41/4.2L SC V8 - AJV8

Upper Arm Front Bushing (64.35.20)

Upper Arm Rear Bushing (64.35.21)

Wheel Bearing and Wheel Hub (64.15.14)

Wheel Knuckle (64.35.10)

204-04: Wheels and Tires

Description and Operation

Wheels and Tires

Diagnosis and Testing

Wheels and Tires

Tire Pressure Monitoring System (TPMS)

Removal and Installation

Tire Low Pressure Sensor (74.10.05)

Tire Pressure Monitoring System (TPMS) Front Antenna (86.53.16)

Tire Pressure Monitoring System (TPMS) Module (86.54.05)

Tire Pressure Monitoring System (TPMS) Rear Antenna (86.53.17)

Wheel and Tire (60.25.06)

204-05: Vehicle Dynamic Suspension

Specification

Description and Operation

Vehicle Dynamic Suspension

General Procedures

Air Suspension System Depressurize and Pressurize (60.50.38)

Ride Height Adjustments (60.90.03)

Removal and Installation

Air Spring Solenoid Valve

Air Suspension Air Filter (64.50.12)

Page 3

204-06: Ride and Handling Optimization

205: Driveline

205-00: Driveline System - General Information

205-01: Driveshaft

205-02: Rear Drive Axle/Differential

Air Suspension Compressor (60.50.10)

Air Suspension Compressor Drier (60.50.09)

Air Suspension Control Module (60.50.04)

Air Suspension Front Solenoid Valve Block (60.50.11)

Air Suspension Muffler (64.50.01)

Air Suspension Rear Solenoid Valve Block (64.50.11)

Air Suspension Reservoir (60.50.03)

Air Suspension Reservoir Solenoid Valve Block (60.50.05)

Air Suspension Solenoid Valve Block (60.50.11)

Air Suspension Switch

Fill Solenoid Valve

Front Air Shock Absorber (60.30.02.45)

Front Air Spring (60.21.01)

Front Vertical Accelerometer

Rear Air Shock Absorber (64.30.02.45)

Rear Air Spring (64.21.01)

Suspension Height Sensor (60.36.01)

Specification

Description and Operation

Ride and Handling Optimization

Diagnosis and Testing

Ride and Handling Optimization

Removal and Installation

Ride and Handling Optimization Switch (86.65.11)

Specification

Specification

Description and Operation

Driveshaft

Universal Joints

Removal and Installation

Front Driveshaft (47.15.02) - 4.4L NA V8 - AJ41/4.2L SC V8 - AJV8

Front Driveshaft (47.15.02) - TDV8 3.6L Diesel

Rear Driveshaft (47.15.03) - 4.4L NA V8 - AJ41/4.2L SC V8 - AJV8

Rear Driveshaft (47.15.03) - TDV8 3.6L Diesel

Disassembly and Assembly

Driveshaft Universal Joint (47.15.06)

Driveshaft Center Bearing

Driveshaft Slip Yoke

Driveshaft Alignment Bushing

Specification

Description and Operation

Rear Drive Axle and Differential

General Procedures

Differential Draining and Filling (51.25.02)

Page 4

205-03: Front Drive Axle/Differential

205-04: Front Drive Halfshafts

205-05: Rear Drive Halfshafts

206: Brake System

206-00: Brake System - General Information

In-Vehicle Repair

Axle Housing Bushing (51.15.43) - 4.4L NA V8 - AJ41/4.2L SC V8 -

AJV8

Axle Housing Bushing (51.15.43) - TDV8 3.6L Diesel

Axle Shaft Seal

Differential Locking Module (51.30.01)

Differential Locking Motor (51.15.03)

Drive Pinion Seal (51.20.01)

Rear Axle Oil Temperature Sensor (51.15.06)

Removal and Installation

Axle Assembly (51.15.01)

Differential Support Insulator - 4.4L NA V8 - AJ41/4.2L SC V8 - AJV8

Specification

Description and Operation

Front Drive Axle and Differential

General Procedures

Differential Draining and Filling (54.15.02)

In-Vehicle Repair

Drive Pinion Seal (54.10.20)

Removal and Installation

Differential Breather Tube

Specification

Description and Operation

Front Drive Halfshafts

Halfshaft Joint

Removal and Installation

Front Halfshaft LH (47.10.01)

Front Halfshaft RH (47.10.02)

Halfshaft Bearing (47.10.41)

Halfshaft Seal LH (54.10.18)

Halfshaft Seal RH (54.10.21)

Specification

Description and Operation

Rear Drive Halfshafts

Removal and Installation

Rear Halfshaft (47.11.01)

Outer Constant Velocity (CV) Joint Boot (47.11.03)

Inner Constant Velocity (CV) Joint Boot (47.11.16)

Halfshaft Bearing (51.10.29)

Specification

General Procedures

Front Brake Disc Runout Check (70.12.15.01)

Rear Brake Disc Runout Check (70.12.36.01)

Brake System Bleeding (70.25.02) - Vehicles With: High Performance

Brakes

Page 5

Brake System Bleeding (70.25.02) - Vehicles With: Standard Brakes

Brake System Pressure Bleeding (70.25.02)

Component Bleeding - Vehicles With: High Performance Brakes

Component Bleeding - Vehicles With: Standard Brakes

206-03: Front Disc Brake

Specification

Description and Operation

Front Disc Brake

Removal and Installation

Brake Disc (70.12.10) - Vehicles With: Standard Brakes

Brake Disc (70.12.10) - Vehicles With: High Performance Brakes

Brake Pads (70.40.02) - Vehicles With: Standard Brakes

Brake Pads (70.40.02) - Vehicles With: High Performance Brakes

Brake Caliper (70.55.24) - Vehicles With: Standard Brakes

Brake Caliper (70.55.24) - Vehicles With: High Performance Brakes

206-04: Rear Disc Brake

Specification

Description and Operation

Rear Disc Brake

Removal and Installation

Brake Disc (70.12.33)

Brake Pads (70.40.03)

Brake Caliper (70.55.25)

Disassembly and Assembly

Brake Caliper

206-05: Parking Brake and Actuation

Specification

Description and Operation

Parking Brake

General Procedures

Parking Brake Shoe and Lining Adjustment (70.40.11)

Parking Brake Shoes Bedding-In (70.40.12)

Removal and Installation

Parking Brake Actuator (70.35.48)

Parking Brake Cable LH

Parking Brake Cable RH

Parking Brake Shoes (70.40.09)

Parking Brake Switch (70.35.46)

206-06: Hydraulic Brake Actuation

Description and Operation

Hydraulic Brake Actuation

Removal and Installation

Brake Fluid Reservoir (70.25.31) - Vehicles With: Standard Brakes

Brake Fluid Reservoir (70.25.31) - Vehicles With: High Performance

Brakes

Brake Master Cylinder (70.30.08) - Vehicles With: Standard Brakes

Brake Master Cylinder (70.30.08) - Vehicles With: High Performance

Brakes

Brake Pedal (70.35.01) - Vehicles With: 6-Speed Automatic

Transmission - 6HP26

Page 6

206-07: Power Brake Actuation

Specification

Description and Operation

Removal and Installation

206-09A: Anti-Lock Control - Traction Control

Specification

Description and Operation

Diagnosis and Testing

Removal and Installation

206-09B: Anti-Lock Control - Stability Assist

Specification

Removal and Installation

211: Steering System

211-00: Steering System - General Information

Specification

General Procedures

211-02: Power Steering

Specification

Description and Operation

General Procedures

Removal and Installation

211-03: Steering Linkage

Specification

Removal and Installation

Brake Pedal and Bracket (70.35.03) - Vehicles With: 6-Speed Automatic

Transmission - 6HP26

Brake Pedal Motor

Brake Booster

Brake Booster (70.50.01) - Vehicles With: Standard Brakes

Brake Booster (70.50.01) - Vehicles With: High Performance Brakes

Brake Vacuum Pump (70.50.19) - 4.4L NA V8 - AJ41/4.2L SC V8 - AJV8

Anti-Lock Control - Traction Control

Anti-Lock Control - Traction Control - VIN Range: 263535->ONWARDS

Anti-Lock Brake System (ABS) Module (70.25.12) - Vehicles With:

Standard Brakes

Anti-Lock Brake System (ABS) Module (70.25.12) - Vehicles With: High

Performance Brakes

Front Wheel Speed Sensor (70.65.30)

Rear Wheel Speed Sensor (70.65.31)

Yaw Rate Sensor (70.70.35)

Power Steering System Filling and Bleeding

Power Steering System Flushing

Power Steering

Power Steering Control Valve Actuator (57.10.05)

Power Steering Fluid Cooler (57.15.11) - 4.2L SC V8 - AJV8

Power Steering Pump (57.20.14) - 4.2L SC V8 - AJV8

Steering Angle Sensor (57.40.02)

Steering Gear Boot (57.10.29)

Tie Rod End (57.55.07) - 3-Door

Tie Rod End (57.55.07)

Page 7

3: Powertrain

303: Engine

211-04: Steering Column

Specification

Description and Operation

Steering Column

Removal and Installation

Ignition Switch Lock Cylinder

Steering Column (57.40.01) (57.40.06)

Steering Column Shaft (57.40.22)

Steering Column Tilt Motor

Steering Column Telescopic Motor

Steering Wheel (57.61.01)

Tilt/Telescopic Motors

211-05: Steering Column Switches

Specification

Removal and Installation

Hazard Flasher Switch (86.65.50)

Ignition Switch (86.65.02)

Steering Column Control Switch

Steering Column Multifunction Switch LH (86.65.55)

303-00: Engine System - General Information

Specification

Diagnosis and Testing

Engine (12.90.09.01) - 4.4L NA V8 - AJ41/4.2L SC V8 - AJV8

General Procedures

Bearing Inspection

Camshaft Bearing Journal Clearance

Camshaft Bearing Journal Diameter

Camshaft End Play

Camshaft Lobe Lift

Camshaft Surface Inspection

Connecting Rod Cleaning

Connecting Rod Large End Bore

Crankshaft End Play

Crankshaft Main Bearing Journal Clearance

Cylinder Bore Out-of-Round

Cylinder Head Distortion

Exhaust Manifold Cleaning and Inspection

Piston Inspection

Piston Pin Diameter

Piston Pin to Bore Diameter

Piston Ring End Gap

Piston Ring-to-Groove Clearance

Valve Spring Free Length

Valve Stem Diameter

303-01A: Engine - 4.2L SC V8 - AJV8

Specification

Description and Operation

Page 8

Engine

General Procedures

Valve Clearance Check (12.29.73)

Valve Clearance Adjustment (12.29.76)

Engine Oil Draining and Filling (12.60.05)

In-Vehicle Repair

Camshafts RH (12.13.20)

Camshafts LH (12.13.21)

Crankshaft Pulley (12.21.01)

Crankshaft Front Seal (12.21.14)

Crankshaft Rear Seal (12.21.20)

Cylinder Head LH (12.29.04)

Timing Drive Components (12.65.13)

Valve Cover LH (12.29.43)

Valve Cover RH (12.29.44)

Engine Mount LH (12.45.11)

Engine Mount RH (12.45.12)

Flexplate (12.53.13)

Oil Level Indicator and Tube (12.60.09)

Auxiliary Oil Cooler Thermostat (12.60.17)

Oil Pump (12.60.26)

Oil Filter Housing (12.60.27)

Oil Pan (12.60.44)

Oil Cooler (12.60.68)

Engine Front Cover (12.65.01)

Exhaust Manifold LH (30.15.10)

Exhaust Manifold RH (30.15.11)

Auxiliary Oil Cooler

Removal and Installation

Crankshaft Main Bearing Carrier (12.21.42)

Removal

Engine (12.41.01.99)

Disassembly

Engine

Assembly

Engine

Installation

Engine (12.41.01.99)

303-03A: Engine Cooling - 4.2L SC V8 - AJV8

Specification

Description and Operation

Engine Cooling

General Procedures

Cooling System Draining, Filling and Bleeding (26.10.01)

Cooling System Pressure Test

Removal and Installation

Coolant Expansion Tank (26.15.01)

Cooling Fan (26.25.19)

Radiator (26.40.01)

Page 9

Thermostat (26.45.01)

Coolant Pump (26.50.01)

Coolant Manifold (26.30.64)

303-03D: Supercharger Cooling

Specification

Description and Operation

Supercharger Cooling

General Procedures

Supercharger Cooling System Draining, Filling and Bleeding (19.46.01)

Removal and Installation

Coolant Pump (26.50.26)

Radiator (26.40.10)

Intercooler Hose

303-04A: Fuel Charging and Controls - 4.2L SC V8 - AJV8

Specification

Description and Operation

Fuel Charging and Controls

Removal and Installation

Fuel Rail (19.60.04)

Fuel Injector (19.60.10)

Throttle Body Gasket

303-04D: Fuel Charging and Controls - Turbocharger

Description and Operation

Turbocharger

Diagnosis and Testing

Turbocharger

Removal and Installation

Turbocharger LH

Turbocharger RH

Turbocharger Actuator Rod

303-05A: Accessory Drive - 4.2L SC V8 - AJV8

Specification

Description and Operation

Accessory Drive

Removal and Installation

Cooling Fan Belt (26.25.01)

Cooling Fan Belt Tensioner (26.25.02)

Accessory Drive Belt (86.10.03)

Accessory Drive Belt Tensioner (86.10.06)

Accessory Drive Belt Idler Pulley (86.10.23)

303-06A: Starting System - 4.2L SC V8 - AJV8

Specification

Description and Operation

Starting System

Removal and Installation

Starter Motor (86.60.01)

303-07A: Engine Ignition - 4.2L SC V8 - AJV8

Specification

Description and Operation

Page 10

Engine Ignition

Removal and Installation

Spark Plugs (18.20.02)

Ignition Coil-On-Plug (18.20.44)

303-07C: Glow Plug System

Specification

Description and Operation

Glow Plug System

Diagnosis and Testing

Glow Plug System

Removal and Installation

Glow Plugs (19.60.31)

303-08B: Engine Emission Control - 4.2L SC V8 - AJV8

Description and Operation

Engine Emission Control

303-12A: Intake Air Distribution and Filtering - 4.2L SC V8 - AJV8

Specification

Description and Operation

Intake Air Distribution and Filtering

Removal and Installation

Air Cleaner (19.10.01)

Air Cleaner Element (19.10.10)

Supercharger (19.46.15)

Supercharger Outlet Pipe (19.46.16)

Intake Air Resonator (19.70.03)

Charge Air Cooler LH (19.46.19)

Charge Air Cooler RH (19.46.18)

Throttle Body Elbow (19.22.43)

303-13A: Evaporative Emissions - 4.2L SC V8 - AJV8

Specification

Description and Operation

Evaporative Emissions

General Procedures

Evaporative Emission System Leak Test (17.90.02.01)

Removal and Installation

Evaporative Emission Canister Purge Valve (17.15.39)

Evaporative Emission Canister Vent Solenoid

Evaporative Emission Canister (17.15.13)

303-14A: Electronic Engine Controls - 4.2L SC V8 - AJV8

Specification

Description and Operation

Electronic Engine Controls

Diagnosis and Testing

Electronic Engine Controls

General Procedures

Powertrain Control Module (PCM) Long Drive Cycle Self-Test

Powertrain Control Module (PCM) Short Drive Cycle Self-Test

Removal and Installation

Engine Oil Pressure (EOP) Sensor (12.60.50)

Page 11

Oil Temperature Sensor (12.60.65)

Engine Coolant Temperature (ECT) Sensor (18.30.10)

Crankshaft Position (CKP) Sensor (18.30.12)

Throttle Position (TP) Sensor (18.30.17)

Camshaft Position (CMP) Sensor LH (18.30.25)

Camshaft Position (CMP) Sensor RH (18.30.26)

Knock Sensor (KS) (18.30.30)

Manifold Absolute Pressure (MAP) Sensor (18.30.56)

Fuel Temperature Sensor (19.22.08)

Heated Oxygen Sensor (HO2S) LH (19.22.16)

Mass Air Flow (MAF) Sensor (19.22.25)

Catalyst Monitor Sensor LH (19.22.71)

Intake Air Temperature (IAT) Sensor (18.30.09)

Fuel Rail Pressure (FRP) Sensor (19.22.29)

307: Automatic Transmission/Transaxle

307-01A: Automatic Transmission/Transaxle - 4.2L SC V8 - AJV8

Specification

Description and Operation

Automatic Transmission

General Procedures

Transmission Fluid Drain and Refill (44.24.02)

Transmission Fluid Level Check (44.24.06)

In-Vehicle Repair

Selector Shaft Seal (44.15.34)

Transmission Control Module (TCM) (44.15.46)

Output Shaft Seal (44.20.21)

Fluid Pan, Gasket and Filter (44.24.04)

Main Control Valve Body (44.40.01)

Transmission Support Insulator (12.45.08)

Removal and Installation

Transmission (44.20.01)

307-01D: Automatic Transmission/Transaxle - 3.6L V8 - TdV8/4.4L NA V8 - AJ41/4.2L SC

V8 - AJV8

Removal and Installation

Input Shaft Seal

307-02A: Transmission/Transaxle Cooling - 4.2L SC V8 - AJV8

Description and Operation

Transmission Cooling

Removal and Installation

Transmission Fluid Cooler (44.24.10)

307-05A: Automatic Transmission/Transaxle External Controls - 4.2L SC V8 - AJV8

Specification

Description and Operation

External Controls

General Procedures

Selector Lever Cable Adjustment (44.30.04)

308: Manual Transmission/Transaxle, Clutch and Transfer Case

308-07A: Four-Wheel Drive Systems

Specification

Description and Operation

Page 12

Removal and Installation

308-07B: Transfer Case

Specification

Description and Operation

General Procedures

In-Vehicle Repair

Removal

Installation

309: Exhaust System

309-00A: Exhaust System - 4.2L SC V8 - AJV8

Specification

Description and Operation

Removal and Installation

310: Fuel System

310-00: Fuel System - General Information

Specification

General Procedures

310-01A: Fuel Tank and Lines - 4.2L SC V8 - AJV8

Specification

Description and Operation

Removal and Installation

310-02A: Acceleration Control - 4.2L SC V8 - AJV8

Four-Wheel Drive Systems - 3.6L (TdV8) Diesel

Four-Wheel Drive Systems - 4.2L/4.4L

Transfer Case Shift Motor (41.30.03)

High/Low Range Sensor (41.30.07)

Transfer Case Clutch Solenoid (41.30.08)

Transfer Case

Transfer Case Draining and Filling (41.20.04)

Transfer Case Input Shaft Seal (41.20.50) - 4.2L SC V8 - AJV8

Transfer Case Front Output Shaft Seal (41.20.51) - 4.2L SC V8 - AJV8

Transfer Case Rear Output Shaft Seal (41.20.54) - 4.2L SC V8 - AJV8

Transfer Case (41.20.25.99) - 4.2L SC V8 - AJV8

Transfer Case (41.20.25) - 4.2L SC V8 - AJV8

Exhaust System

Catalytic Converter LH (17.50.03)

Catalytic Converter RH (17.50.04)

Exhaust System (30.10.08)

Tailpipe (30.10.22)

Diesel Filter Water Drain-Off

Fuel System Pressure Release (19.50.02) - 4.2L SC V8 - AJV8

Fuel System Pressure Check (19.50.13) - 4.4L NA V8 - AJ41/4.2L SC

V8 - AJV8

Fuel Tank Draining (19.55.02)

Fuel Tank and Lines

Fuel Pump Module (19.45.03)

Fuel Tank Filler Pipe (19.55.07)

Vapor Vent Box

Fuel Tank (19.55.01)

Fuel Filter (19.25.03)

Page 13

Description and Operation

Acceleration Control

303-01C: Engine - TDV8 3.6L Diesel

Specification

Description and Operation

Engine

Diagnosis and Testing

Engine

General Procedures

Engine Oil Draining and Filling (12.60.05)

In-Vehicle Repair

Camshaft LH (12.13.02)

Camshaft RH (12.13.03)

Crankshaft Front Seal (12.21.14)

Crankshaft Pulley (12.21.01)

Crankshaft Rear Seal (12.21.20)

Cylinder Head LH (12.29.04)

Cylinder Head RH (12.29.05)

Engine Mount LH (12.45.11)

Engine Mount RH (12.45.12)

Exhaust Manifold LH (30.15.10)

Exhaust Manifold RH (30.15.11)

Flexplate (12.53.13)

Intake Manifold Plenum Chamber

Oil Pan (12.60.44)

Oil Pump (12.60.26)

Timing Drive Components (12.65.13)

Valve Cover LH (12.29.43)

Valve Cover RH (12.29.44)

Removal

Engine (12.41.01.99)

Disassembly

Engine

Assembly

Engine

Installation

Engine (12.41.01.99)

303-03C: Engine Cooling - TDV8 3.6L Diesel

Specification

Description and Operation

Engine Cooling

Diagnosis and Testing

Engine Cooling

General Procedures

Cooling System Partial Draining, Filling and Bleeding

Cooling System Partial Draining and Vacuum Filling

Cooling System Pressure Test

Removal and Installation

Auxiliary Radiator

Coolant Expansion Tank (26.15.01)

Cooling Fan (26.25.19)

Cooling Fan Shroud (26.25.11)

Cooling Module

Coolant Pump (26.50.01)

Radiator (26.40.01)

Page 14

Thermostat (26.45.01)

303-03D: Supercharger Cooling

Specification

Description and Operation

Supercharger Cooling

General Procedures

Supercharger Cooling System Draining, Filling and Bleeding (19.46.01)

Removal and Installation

Coolant Pump (26.50.26)

Radiator (26.40.10)

Intercooler Hose

303-04C: Fuel Charging and Controls - TDV8 3.6L Diesel

Specification

Description and Operation

Fuel Charging and Controls

Diagnosis and Testing

Fuel Charging and Controls

General Procedures

Fuel Injection Component Cleaning

Fuel Injector Balance and Spill Check (19.90.08)

Removal and Installation

Fuel Injectors LH

Fuel Injectors RH

Fuel Pump (19.45.08)

Fuel Rail LH

Fuel Rail RH

Throttle Body (19.22.44)

303-04D: Fuel Charging and Controls - Turbocharger

Description and Operation

Turbocharger

Diagnosis and Testing

Turbocharger

Removal and Installation

Turbocharger LH

Turbocharger RH

Turbocharger Actuator Rod

303-05C: Accessory Drive - TDV8 3.6L Diesel

Specification

Description and Operation

Accessory Drive

Diagnosis and Testing

Accessory Drive

Removal and Installation

Accessory Drive Belt (86.10.03)

Accessory Drive Belt Tensioner (86.10.06)

Accessory Drive Belt Idler Pulley (86.10.23)

303-06C: Starting System - TDV8 3.6L Diesel

Specification

Description and Operation

Starting System

Diagnosis and Testing

Starting System

Removal and Installation

Starter Motor (86.60.01)

303-07C: Glow Plug System

Page 15

Specification

Description and Operation

Glow Plug System

Diagnosis and Testing

Glow Plug System

Removal and Installation

Glow Plugs (19.60.31)

303-08A: Engine Emission Control - TDV8 3.6L Diesel

Specification

Description and Operation

Engine Emission Control

Diagnosis and Testing

Engine Emission Control

Removal and Installation

Crankcase Vent Oil Separator (17.10.04)

Exhaust Gas Recirculation (EGR) Cooler (17.45.38)

Exhaust Gas Recirculation (EGR) Valve LH (17.45.16)

Exhaust Gas Recirculation (EGR) Valve RH (17.45.17)

Exhaust Gas Recirculation (EGR) Valve Outlet Tube (17.45.18)

303-12C: Intake Air Distribution and Filtering - TDV8 3.6L Diesel

Description and Operation

Intake Air Distribution and Filtering

Diagnosis and Testing

Intake Air Distribution and Filtering

Removal and Installation

Air Cleaner (19.10.01)

Air Cleaner Element (19.10.10)

Charge Air Cooler (19.46.19)

303-14C: Electronic Engine Controls - TDV8 3.6L Diesel

Specification

Description and Operation

Electronic Engine Controls

Diagnosis and Testing

Electronic Engine Controls - 3.6L (TdV8) Diesel

Removal and Installation

Camshaft Position (CMP) Sensor (18.30.24)

Crankshaft Position (CKP) Sensor (18.30.12)

Crankshaft Position (CKP) Sensor Ring (18.30.14)

Engine Control Module (ECM) (18.30.03)

Engine Coolant Temperature (ECT) Sensor (18.30.10)

Engine Oil Pressure (EOP) Sensor (12.60.50)

Exhaust Gas Temperature Sensor

Fuel Rail Pressure (FRP) Sensor (19.22.29)

Fuel Temperature Sensor (19.22.08)

Knock Sensor (KS) LH (18.30.28)

Knock Sensor (KS) RH (18.30.30)

Manifold Absolute Pressure and Temperature (MAPT) Sensor

Mass Air Flow (MAF) Sensor (19.22.25)

307: Automatic Transmission/Transaxle

307-01C: Automatic Transmission/Transaxle - TDV8 3.6L Diesel

Specification

Description and Operation

Automatic Transmission

General Procedures

Transmission Fluid Drain and Refill (44.24.02)

Page 16

Transmission Fluid Level Check (44.24.06)

In-Vehicle Repair

Fluid Pan, Gasket and Filter (44.24.04)

Main Control Valve Body (44.40.01)

Output Shaft Seal (44.20.21)

Selector Shaft Seal (44.15.34)

Transmission Control Module (TCM) (44.15.46)

Transmission Support Insulator (12.45.08)

Removal and Installation

Transmission (44.20.01)

307-01D: Automatic Transmission/Transaxle - TDV8 3.6L Diesel/V8 4.4L Petrol/V8 S/C

4.2L Petrol

Removal and Installation

Input Shaft Seal

307-02C: Transmission/Transaxle Cooling - TDV8 3.6L Diesel

Specification

Description and Operation

Transmission Cooling

Removal and Installation

Transmission Fluid Cooler (44.24.10)

307-05C: Automatic Transmission/Transaxle External Controls - TDV8 3.6L Diesel

Specification

Description and Operation

External Controls

General Procedures

Selector Lever Cable Adjustment (44.30.04)

Removal and Installation

Selector Lever Assembly (44.15.04)

Selector Lever Cable (44.15.08)

Selector Lever Gate Finish Panel

Selector Lever Knob (44.15.07)

Selector Lever Position Sensor

308: Manual Transmission/Transaxle, Clutch and Transfer Case

308-07A: Four-Wheel Drive Systems

Specification

Description and Operation

Four-Wheel Drive Systems - TDV8 3.6L Diesel

Diagnosis and Testing

Four-Wheel Drive Systems

Removal and Installation

Transfer Case Shift Motor (41.30.03)

High/Low Range Sensor (41.30.07)

Transfer Case Clutch Solenoid (41.30.08)

308-07B: Transfer Case

Specification

Description and Operation

Transfer Case

General Procedures

Transfer Case Draining and Filling (41.20.04)

In-Vehicle Repair

Transfer Case Input Shaft Seal (41.20.50) - TDV8 3.6L Diesel

Transfer Case Front Output Shaft Seal (41.20.51) - TDV8 3.6L Diesel

Transfer Case Rear Output Shaft Seal (41.20.54) - TDV8 3.6L Diesel

Removal

Transfer Case (41.20.25.99) - TDV8 3.6L Diesel

Page 17

Installation

309: Exhaust System

309-00C: Exhaust System - TDV8 3.6L Diesel

Specification

Description and Operation

Removal and Installation

310: Fuel System

310-00: Fuel System - General Information

Specification

General Procedures

310-01C: Fuel Tank and Lines - TDV8 3.6L Diesel

Specification

Description and Operation

Diagnosis and Testing

Removal and Installation

310-02C: Acceleration Control - TDV8 3.6L Diesel

Specification

Description and Operation

Removal and Installation

310-03B: Speed Control - TDV8 3.6L Diesel

Description and Operation

Removal and Installation

Transfer Case (41.20.25) - TDV8 3.6L Diesel

Exhaust System

Catalytic Converter (17.50.01)

Catalytic Converter LH (17.50.03) - Vehicles Without: Diesel Particulate

Filter (DPF)

Catalytic Converter RH (17.50.04) - Vehicles Without: Diesel Particulate

Filter (DPF)

Catalytic Converter LH (17.50.03) - Vehicles With: Diesel Particulate

Filter (DPF)

Catalytic Converter RH (17.50.04) - Vehicles With: Diesel Particulate

Filter (DPF)

Diesel Particulate Filter (DPF)

Diesel Particulate Filter (DPF) Differential Pressure Sensor

Exhaust System (30.10.08) - Vehicles Without: Diesel Particulate Filter

(DPF)

Exhaust System (30.10.08) - Vehicles With: Diesel Particulate Filter

(DPF)

Tailpipe (30.10.22)

Diesel Filter Water Drain-Off

Fuel System Pressure Check (19.50.13) - TDV8 3.6L Diesel

Fuel Tank Draining (19.55.02)

High-Pressure Fuel System Bleeding - TDV8 3.6L Diesel

Low-Pressure Fuel System Bleeding (19.50.07) - TDV8 3.6L Diesel

Fuel Tank and Lines

Fuel Tank and Lines

Auxiliary Fuel Cooler

Fuel Cooler

Fuel Filter Element (192502)

Fuel Tank (19.55.01)

Fuel Tank Filler Pipe (19.55.07)

Acceleration Control

Accelerator Pedal (19.20.01)

Speed Control

Speed Control Switch

Page 18

4: Electrical

412: Climate Control System

412-00: Climate Control System - General Information

Specification

General Procedures

Air Conditioning (A/C) System Recovery, Evacuation and Charging

(82.30.02)

412-01: Air Distribution and Filtering

Specification

Description and Operation

Air Distribution and Filtering

Removal and Installation

Center Registers

Driver Side Register

Driver Side Register Trim Panel (76.46.12)

Passenger Side Register

Passenger Side Register Trim Panel (76.46.13)

Plenum Chamber (80.15.62)

Upper Center Registers

412-02A: Heating and Ventilation

Specification

Description and Operation

Heating and Ventilation

Removal and Installation

Blower Motor (80.20.15)

Heater Control Valve

Heater Core (80.20.29)

Heater Core and Evaporator Core Housing

412-02B: Auxiliary Heating

Specification

Description and Operation

Auxiliary Heater

Removal and Installation

Auxiliary Heater

Fuel Fired Booster Heater - 4.2L SC V8 - AJV8

412-03A: Air Conditioning

Specification

Description and Operation

Air Conditioning

Removal and Installation

Air Conditioning (A/C) Compressor (82.10.20) - 4.2L SC V8 - AJV8

Condenser Core (82.15.07) - 4.2L SC V8 - AJV8

Condenser Fan - 4.2L SC V8 - AJV8

Evaporator Core (82.25.20) (82.25.22)

Thermostatic Expansion Valve (82.25.01)

Air Conditioning (A/C) Compressor (82.10.20) - TDV8 3.6L Diesel

Condenser Core (82.15.07) - TDV8 3.6L Diesel

Condenser Fan - TDV8 3.6L Diesel

Evaporator Core (82.25.20) (82.25.22)

Page 19

Receiver Drier (82.17.03) - TDV8 3.6L Diesel

Thermostatic Expansion Valve (82.25.01)

412-03B: Auxiliary Climate Control

Specification

Description and Operation

Auxiliary Climate Control

Removal and Installation

Auxiliary Climate Control Assembly (82.26.22)

Auxiliary Evaporator Outlet and Inlet Line

Auxiliary Footwell Vent/Duct Blend Door Actuator

Auxiliary Heater Core and Evaporator Core Housing

Auxiliary Temperature Blend Door Actuator (82.26.34)

Auxiliary Blower Motor (82.26.33)

Auxiliary Blower Motor Resistor

Evaporator Core (82.26.20)

Heater Core (82.26.19)

Register

412-04: Control Components

Description and Operation

Control Components

Removal and Installation

Ambient Air Temperature Sensor (80.40.31)

Climate Control Assembly (80.10.02)

Defrost Vent/Register Blend Door Actuator (80.10.36)

Driver Side Recirculation Blend Door Actuator

Driver Side Temperature Blend Door Actuator (80.10.37)

Footwell Vent/Duct Blend Door Actuator

Instrument Panel Blend Door Actuator (80.20.09)

In-Vehicle Temperature Sensor (82.20.93)

Passenger Side Recirculation Blend Door Actuator

Passenger Side Temperature Blend Door Actuator (80.10.38)

Sunload Sensor (82.20.92)

413: Instrumentation and Warning Systems

413-00: Instrument Cluster and Panel Illumination

Specification

Description and Operation

Instrument Cluster and Panel Illumination

413-01: Instrument Cluster

Specification

Description and Operation

Instrument Cluster

Removal and Installation

Instrument Cluster (80.20.01.99) (88.20.01)

413-06: Horn

Specification

Removal and Installation

Horn (86.30.09)

Horn Switch (86.30.01)

413-07: Clock

Page 20

Removal and Installation

Clock (88.15.07)

413-08: Information and Message Center

Description and Operation

Information and Message Center

413-09A: Warning Devices

Specification

Removal and Installation

Low Washer Fluid Warning Indicator Switch

413-09B: Engine Protection System

Specification

Removal and Installation

Engine Protection System Module

413-13: Parking Aid

Specification

Description and Operation

Parking Aid

Diagnosis and Testing

Parking Aid

Removal and Installation

Front Inner Parking Aid Sensor (86.54.21)

Front Parking Aid Speaker

Front Outer Parking Aid Sensor (86.54.22)

Parking Aid Camera

Parking Aid Module (86.54.10)

Rear Parking Aid Sensor

Rear Parking Aid Speaker (86.54.19)

414: Battery and Charging System

414-00: Charging System - General Information

Specification

Description and Operation

Charging System

General Procedures

Battery Charging

414-01: Battery, Mounting and Cables

Specification

Description and Operation

Battery and Cables

Removal and Installation

Battery (86.15.01)

Battery Tray (76.10.30)

Auxiliary Battery Tray (76.10.31)

414-02A: Generator and Regulator - 4.2L SC V8 - AJV8

Specification

Description and Operation

Generator

Removal and Installation

Generator (86.10.02)

414-02C: Generator and Regulator - TDV8 3.6L Diesel

Page 21

Specification

Description and Operation

Generator

Removal and Installation

Generator (86.10.02)

415: Information and Entertainment Systems

415-00: Information and Entertainment System - General Information

Diagnosis and Testing

Information and Entertainment System

Cellular Phone

415-01A: Audio Unit

Specification

Description and Operation

Audio System

Removal and Installation

Audio Unit (86.50.81)

Audio Unit Amplifier

Compact Disc (CD) Changer

Integrated Control Panel (ICP)

Rear Auxiliary Audio Controls

Satellite Radio Tuner

Steering Wheel Audio Controls

Subwoofer Amplifier

Television (TV) Amplifier

Television (TV) Amplifier and Fuel Fired Booster Heater Transceiver

Unit

Television (TV) Receiver

415-01B: Information and Entertainment System

Description and Operation

Intercom System

415-02: Antenna

Specification

Description and Operation

Antenna

Removal and Installation

Antenna

Antenna Module

Power Antenna

415-03: Speakers

Specification

Description and Operation

Speakers

Removal and Installation

Front Door Speaker (86.50.10)

Rear Door Speaker (86.50.12)

Instrument Panel Speaker (86.50.11)

Quarter Panel Speaker (86.50.48)

Tailgate Speaker (86.50.47)

415-07: Video System

Page 22

Description and Operation

Diagnosis and Testing

Removal and Installation

417: Lighting

417-01: Exterior Lighting

Specification

Description and Operation

Diagnosis and Testing

General Procedures

Removal and Installation

417-02: Interior Lighting

Description and Operation

Removal and Installation

417-04: Daytime Running Lamps (DRL)

Description and Operation

418: Electrical Distribution

418-00: Module Communications Network

Specification

Description and Operation

Removal and Installation

418-01: Module Configuration

Video System

Video System

Digital Versatile Disc (DVD) Player

Portable Camera

Portable Camera Docking Station

Rear Passenger Entertainment Control Panel

Video System Module

Exterior Lighting

Headlamps

Headlamp Adjustment (86.40.17)

Adaptive Front Lighting Module (86.54.06)

Front Fog Lamp (86.40.96)

Headlamp Assembly (86.40.49)

Headlamp Bulb (86.40.09)

Headlamp Switch (86.65.09)

High Mounted Stoplamp (86.41.32)

Lamp Outage Module

License Plate Lamp (86.40.86)

Rear Lamp Assembly (86.40.70)

Side Turn Signal Lamp (86.40.53)

Stoplamp Switch (70.35.42)

Trailer Module

Interior Lighting

Center Interior Lamp

Daytime Running Lamps (DRL)

Communications Network

Central Junction Box (CJB) (86.70.56)

Engine Junction Box (EJB)

Page 23

419: Electronic Feature Group

5: Body and Paint

General Procedures

Module Configuration

418-02: Wiring Harnesses

Specification

Description and Operation

Wiring Harness

General Procedures

Wiring Harness Repair

Removal and Installation

Engine Wiring Harness (86.70.17) - 4.2L SC V8 - AJV8

Tailgate Wiring Harness

419-01A: Anti-Theft - Active

Specification

Description and Operation

Anti-Theft - Active

Removal and Installation

Anti-Theft Transceiver Module

Hood Switch (86.77.20)

Inclination Sensor

Intrusion Sensor

419-01B: Anti-Theft - Passive

Description and Operation

Anti-Theft - Passive

Removal and Installation

Passive Anti-Theft System (PATS) Module (86.77.07)

419-07: Navigation System

Description and Operation

Navigation System

Diagnosis and Testing

Navigation System

Removal and Installation

Navigation System Digital Versatile Disc (DVD) Unit

Navigation System Traffic Module

419-08: Cellular Phone

Description and Operation

Cellular Phone

Removal and Installation

Cellular Phone Antenna (86.53.11)

Microphone

Portable Support Electronics (PSE) Module

419-10: Multifunction Electronic Modules

Description and Operation

Module Controlled Functions

Removal and Installation

Generic Electronic Module (GEM)

Information and Entertainment Module

Multifunction Voice Activated Module

Page 24

501: Body and Paint

501-00: Body System - General Information

Specification

Description and Operation

501-02: Front End Body Panels

Removal and Installation

501-03: Body Closures

Description and Operation

Removal and Installation

501-05: Interior Trim and Ornamentation

Specification

Removal and Installation

501-08: Exterior Trim and Ornamentation

Description and Operation

Body

Body

Body

Cowl Panel Grille

Engine Undershield (76.10.50)

Fender (76.10.24)

Fender Splash Shield (76.10.48)

Headlamp Mounting Bracket

Radiator Grille Support (76.10.12)

Radiator Splash Shield (76.11.81)

Body Closures

Door

Liftgate Strut

Tailgate Strut

A-Pillar Trim Panel (76.13.26)

B-Pillar Trim Panel

C-Pillar Lower Trim Panel (76.13.34) (76.13.37)

C-Pillar Upper Trim Panel (76.13.35)

Cowl Side Trim Panel (76.13.27)

Engine Cover (12.30.50) - 4.2L SC V8 - AJV8

Front Door Speaker Grille

Front Door Trim Panel (76.34.01)

Front Scuff Plate Trim Panel (76.49.17)

Headliner (76.64.15)

Liftgate Lower Trim Panel

Liftgate Upper Trim Panel

Loadspace Trim Panel

Rear Door Trim Panel (76.34.04)

Rear Scuff Plate Trim Panel

Rear Quarter Trim Panel (76.13.12)

Sun Visor

Tailgate Trim Panel (76.49.23)

Exterior Trim

Exterior Trim

Exterior Trim

Page 25

Diagnosis and Testing

Power Side Step

Removal and Installation

Front Fender Moulding (76.43.54)

Front Fender Trim Panel

Front Door Lower Moulding

Power Side Step

Power Side Step Hinge

Power Side Step Motor

Radiator Grille (76.55.03)

Rear Door Lower Moulding

Rear Fender Splash Shield (76.10.49)

Roof Moulding (76.43.68)

Rear Quarter Panel Moulding (76.43.55)

Rear Spoiler

Rocker Panel Moulding

Tailgate Moulding (76.43.99)

Towbar

501-09: Rear View Mirrors

Specification

Description and Operation

Rear View Mirrors

Removal and Installation

Exterior Mirror (76.11.10)

Exterior Mirror Glass (76.11.08)

Exterior Mirror Motor (76.11.09)

Interior Rear View Mirror

501-10: Seating

Description and Operation

Seats

Diagnosis and Testing

Seats

Removal and Installation

Climate Controlled Seat Switch

Front Seat (78.10.44/99)

Front Seat Backrest Cover (78.90.08)

Front Seat Backrest Lower Rear Cover

Front Seat Backrest Heater and Blower Assembly

Front Seat Cushion Heater and Blower Assembly

Front Seat Cushion Cover (78.30.01)

Front Seat Head Restraint - Vehicles With: Head Restraint Video

Display

Front Seat Head Restraint - Vehicles Without: Head Restraint Video

Display

Front Seat Head Restraint Motor

Front Seat Recliner Motor (78.70.34)

Lumbar Assembly

Lumbar Control Switch

Seat Armrest (78.10.01)

Seat Control Switch

Page 26

Rear Seat (78.10.70/78.10.71)

Rear Seat Armrest

Rear Seat Backrest Cover (78.90.72)

Rear Seat Cushion Cover (78.40.70)

501-11: Glass, Frames and Mechanisms

Description and Operation

Glass, Frames and Mechanisms

Diagnosis and Testing

Glass, Frames and Mechanisms

General Procedures

Heated Window Grid Wire Repair

Lead Terminal Repair

Door Window Glass Adjustment

Door Window Glass Adjustment

Rear Quarter Window Glass Adjustment

Rear Quarter Window Glass Adjustment

Liftgate Window Glass Adjustment

Power Door Window Initialization

Power Door Window Initialization

Power Rear Window Initialization

Heated Window Grid Wire Repair

Lead Terminal Repair

Windshield Reseal

Door Window Glass and Rear Quarter Window Glass Adjustment

Removal and Installation

Driver Door Window Control Switch

Front Door Window Regulator Motor

Front Door Window Glass (76.31.01)

Liftgate Window Glass (76.31.22)

Rear Door Window Glass (76.31.02)

Rear Door Window Regulator Motor

Rear Quarter Window Glass (76.81.20)

Windshield Glass (76.81.01)

Windshield Moulding

Rear Door Fixed Window Glass (76.31.31)

501-12: Instrument Panel and Console

Description and Operation

Instrument Panel

Floor Console

Overhead Console

Removal and Installation

Floor Console (76.25.01)

Floor Console Cup Holder

Floor Console Extension

Floor Console Stowage Compartment

Floor Console Stowage Compartment Lid

Floor Console Upper Panel (76.25.11)

In-Vehicle Crossbeam

Instrument Panel Center Reinforcement (76.46.34)

Page 27

Instrument Panel Lower Section (76.46.05)

Instrument Panel Reinforcement

Instrument Panel Upper Section (76.46.04)

Lower Center Registers Panel Assembly

Lower Glove Compartment

Lower Glove Compartment Lid

Overhead Console (76.25.02)

Upper Glove Compartment

Upper Glove Compartment Lid

501-14: Handles, Locks, Latches and Entry Systems

Description and Operation

Handles, Locks, Latches and Entry Systems

Diagnosis and Testing

Locks, Latches and Entry Systems

General Procedures

Tailgate Striker Adjustment (76.28.03)

Liftgate Striker Adjustment (76.37.28)

Removal and Installation

Exterior Front Door Handle (76.58.07)

Exterior Door Handle Mechanism

Front Door Latch (76.37.12)

Ignition Lock Cylinder (57.40.28)

Liftgate Latch (76.37.19)

Tailgate Latch (76.37.83)

Tailgate Latch Actuator

Tailgate Release Switch

501-16: Wipers and Washers

Specification

Description and Operation

Wipers and Washers

Removal and Installation

Rain Sensor (84.12.11)

Rear Window Wiper Motor (84.35.12)

Rear Window Wiper Pivot Arm

Windshield Washer Pump (84.10.21)

Windshield Washer Reservoir (84.10.03)

Windshield Wiper Intermittent Wipe Relay

Windshield Wiper Motor (84.15.12)

Windshield Wiper Pivot Arm

Wiper Linkage Assembly

501-17: Roof Opening Panel

Description and Operation

Roof Opening Panel

General Procedures

Roof Opening Panel Alignment (76.84.82)

Removal and Installation

Air Deflector

Roof Opening Panel Glass (76.84.03)

Lifter Arms

Page 28

Roof Opening Panel (76.84.01)

Roof Opening Panel Motor (76.84.07)

Roof Opening Panel Shield

501-19: Bumpers

Specification

Removal and Installation

Front Bumper (76.22.49)

Front Bumper Cover (76.22.72)

Front Bumper Lower Cover (76.22.78)

Rear Bumper (76.22.52)

Rear Bumper Cover (76.22.74)

501-20A: Safety Belt System

Specification

Description and Operation

Safety Belt System

Removal and Installation

Front Safety Belt Buckle (76.73.30)

Front Safety Belt Retractor (76.73.13)

Rear Center Safety Belt Buckle (76.73.64)

Rear Center Safety Belt Retractor

Rear Safety Belt Buckle (76.73.30)

Rear Safety Belt Retractor

501-20B: Supplemental Restraint System

Specification

Description and Operation

Air Bag and Safety Belt Pretensioner Supplemental Restraint System

(SRS)

Diagnosis and Testing

Air Bag Supplemental Restraint System (SRS)

General Procedures

Air Bag Disposal

Removal and Installation

B-Pillar Side Impact Sensor (76.74.23)

Clockspring (76.74.20)

Driver Air Bag Module (76.74.01)

Driver Lower Air Bag Module

Front Seat Side Air Bag Module

Front Side Air Curtain Module

Occupant Classification Sensor (76.74.76)

Passenger Air Bag Deactivation (PAD) Switch (76.74.19)

Passenger Air Bag Module (76.74.02)

Side Air Bag Module (76.74.30)

Side Air Curtain Module (76.74.40)

501-25A: Body Repairs - General Information

Description and Operation

Sealer, Underbody Protection Material and Adhesives

501-25B: Body Repairs - Water Leaks

Description and Operation

Water Leaks

501-25C: Body Repairs - Corrosion Protection

Page 29

Description and Operation

501-26: Body Repairs - Vehicle Specific Information and Tolerance Checks

Description and Operation

501-27: Front End Sheet Metal Repairs

Removal and Installation

501-28: Roof Sheet Metal Repairs

Removal and Installation

501-29: Side Panel Sheet Metal Repairs

Removal and Installation

501-30: Rear End Sheet Metal Repairs

Removal and Installation

501-36: Paint - General Information

Description and Operation

502: Frame and Mounting

502-00: Uni-Body, Subframe and Mounting System

Corrosion Protection

Body and Frame

Auxiliary Front Crossmember

Fender Apron Panel

Fender Apron Panel Closing Panel

Fender Apron Panel Front Extension

Fender Apron Panel Inner Reinforcement

Fender Apron Panel Reinforcement Front Section

Fender Apron Panel Reinforcement Rear Section

Front Side Member and Suspension Top Mount Assembly

Front Side Member Closing Panel

Front Side Member Extension

Hood Latch Panel (76.16.22)

Side Member Deformation Element

Roof Panel

A-Pillar Assembly

A-Pillar Reinforcement

B and C-Pillar Assembly

Rocker Panel (77.40.60)

Rocker Panel Inner Reinforcement

Rocker Panel Section

Inner Quarter Panel (77.40.37)

Quarter Panel (77.40.09)

Quarter Panel Lower Extension

Rear Crossmember

Rear Crossmember Section

Rear Floor Panel

Rear Floor Panel Section (77.70.02)

Rear Lamp Mounting Panel (77.80.25)

Rear Quarter Upper Panel

Rear Side Member

Rear Side Member Section (77.70.07)

Spare Wheel Well

Tools and Equipment for Paint Repairs

Page 30

Removal and Installation

Rear Subframe Bushing - 4.4L NA V8 - AJ41/4.2L SC V8 - AJV8

502-02: Full Frame and Body Mounting

Specification

Removal and Installation

Transmission Support Crossmember (76.10.09 or 76.10.92) - 4.4L NA

V8 - AJ41/4.2L SC V8 - AJV8

Service Bulletins

Fuel Fired Burning Heater Diagnostic's

Range Rover (LM) - Drone Noise on Supercharged Vehicles with 20

inch Wheels

E-Box Cooling Fan Noise

All Land Rover - Special Equipment Release Notification

All Land Rover - Electronic Product Quality Report (EPQR)

Enhancements

All Land Rover - Special Service Tools on EPQR

Range Rover (LM) - Sensor Cluster Fault Diagnosis

Range Rover (LM) - Internal Control Module Faults Relating to the

ABS Module Diagnosis

Range Rover (LM) - CAN Faults Relating to the ABS Module

Diagnosis

Range Rover (LM) - Wheel Speed Sensor Concerns Diagnosis

Range Rover (LM) - Storage Location of Front Towing Eye

Range Rover (LM) - Spare Key Location

Range Rover (LM) - Special Tool Notification

Height Sensor Procedure Change

Page 31

General Information - About This Manual

Description and Operation

Introduction

This manual has been written in a format that is designed to meet the needs of technicians worldwide. The

objective is to use common formats and include similar content in each manual.

This manual provides general descriptions for accomplishing diagnosis and testing, service and repair work with

tested and effective techniques. Following them will help to ensure reliability.

Important Safety Instructions

Appropriate service methods and correct repair procedures are essential for the safe, reliable operation of all

motor vehicles as well as the personal safety of the individual carrying out the work.

Anyone who departs from the instructions provided in this manual must first establish that personal safety or

vehicle integrity is not compromised by the choice of method, tools or components.

Warnings, Cautions and Notes in This Manual

WARNING: Warnings are used to indicate that failure to follow a procedure correctly may result in

personal injury.

CAUTION: Cautions are used to indicate that failure to follow a procedure correctly may result in damage

to the vehicle or equipment being used.

• NOTE: Notes are used to provide additional essential information required to carry out a complete and

satisfactory repair.

Generic warnings or cautions are in their relevant description and operation procedure within section 100-00. If

the generic warnings or cautions are required for a procedure, there will be a referral to the appropriate

description and operation procedure.

If a warning, caution or note only applies to one step, it is placed at the beginning of the specific step.

Trustmark Authoring Standards (TAS) Removal and Installation Procedures

• NOTE: TAS style procedures can be identified by steps that have no accompanying step text and the

magenta color of the electrical connectors and fasteners such as nuts, bolts, clamps or clips.

A TAS removal and installation procedure uses a sequence of color illustrations to indicate the order to be

followed when removing/disassembling or installing/assembling a component.

Many of the TAS procedures will have the installation information within the removal steps. These procedures

will have the following note at the beginning of the procedure:

• NOTE: Removal steps in this procedure may contain installation details.

Items such as O-ring seals, gaskets, seals, self-locking nuts and bolts are to be discarded and new components

installed unless otherwise stated within the procedure. Coated nuts or bolts are to be reused, unless damaged

or otherwise stated within the procedure.

Specification procedures will contain all technical data that are not part of a repair procedure.

TAS Graphics

Colors used in the graphic are as follows:

Page 32

Blue - Indicates the target item, item to be removed/installed or disassembled/assembled

Green and Brown - Indicates a secondary item that needs to be detached, removed/installed or

disassembled/assembled prior to the target item

Magenta - Indicates electrical connectors and fasteners such as nuts, bolts, clamps or clips

Pale Blue - is for the special tool(s) and general equipment.

There may be multiple steps assigned to one illustration.

Numbered pointers are used to indicate the number of electrical connectors and fasteners such as nuts, bolts,

clamps or clips.

Items in the illustration can be transparent or use cutouts to show hidden detail(s).

TAS Symbols

Symbols are used inside the graphics and in the text area to enhance the information display. The following

paragraphs describe the various types and categories of symbols.

Prohibition symbols advise on prohibited actions to either avoid damage or health and safety related risks.

Page 33

Health and Safety symbols recommend the use of particular protection equipment to avoid or at least reduce

the risk or severity of possible injuries.

Warning symbols are used to indicate potential risks resulting from a certain component or area.

Page 34

Instruction symbols are used to apply sealer, lubricant, weight, tape or cleaning detergent to a component.

Location symbols are used to show the location of a component or system within the vehicle.

Page 35

Gearshift lever or selector lever position symbols are used to show which gearshift lever or selector lever

position is to be set.

Page 36

Pointer symbols are used to draw the attention to components and give special instructions such as a required

sequence or number of components. The number of components is reflected by the value inside the luty arrow.

A sequence number is located inside the circle. Numbers inside circles are also used to allocate special

information such as tightening torques or chemicals to a particular component.

Movement arrows are used to show three dimensional or rotational movements. These movements can include

specific values inside the symbol if required.

Page 37

Standard tool symbols recommend the use of certain standard tools. These tools can include dimension values

if required.

The following graphic illustrates a set of symbols that are used to provide detailed information on where to

apply a material.

Page 38

Measurement symbols provide detailed information on where to carry out a specific measurement. These

symbols can include specific values if required.

Special Tools and Torque Figure(s)

Special tools will be shown with the tool number in the illustration. The special tool number(s), general

equipment, material(s) and torque figure(s) used for the procedure step will be shown in the text column.

Page 39

General Information - How To Use This Manual

Description and Operation

Copyright Statement

Copyright.© Land Rover Ltd., 2005

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted

in any form, electronic, mechanical, photocopying, recording or other means, without prior written permission

of Land Rover Ltd., Banbury Road, Lighthorne, Warwick, CV35 0RG

How to use This Manual

This manual covers all aspects of 2006 model year updates in order to service the vehicle effectively, and is to

be used in conjunction with the existing workshop manual Part number: LRL0477.

The manual is structured into five main sections, General Information, Chassis, Powertrain, Electrical and Body

and Paint with each section dealing with a specific part of a vehicle system.

Each of the five main sections contain sub-sections dealing with items which form a part of that specific

system.

Pages at the start of the manual list all sections available. Each section has a contents list detailing, where

applicable, Specifications, Description and Operation, Diagnosis and Testing, General Procedures and Repair

Procedures.

Where components need to be removed or disassembled in sequence, each operation in the sequence will be

identified numerically and also graphically in an accompanying illustration.

• NOTE: Dimensions quoted are to design engineering specifications with service limits quoted, where

applicable.

Workshop Manual Organization

The five main sections, together with the areas which they cover are given below:

Section 1 - General Information.

Section 2 - Chassis.

Section 3 - Powertrain.

Section 4 - Electrical.

Section 5 - Body and Paint.

Sub-section numbers appear after the initial section number, for example, Section 412-03 covers air

conditioning, which is part of the electrical section.

In the number given above, the first digit of the number '4' indicates the section i.e. Electrical.

The second and third digits '12' of the number indicate the vehicle system i.e. Air Conditioning.

The last two digits of the number '03' indicate the part of the system covered by the sub-section i.e. Air

Conditioning Compressor.

Page 40

General Information - Important Safety Instructions

Description and Operation

Safety Notice

Appropriate service methods and correct repair procedures are essential for the safe, reliable operation of all

motor vehicles, as well as the safety of the person doing the work. This manual provides general directions for

accomplishing service and repair work with tested effective techniques. Following them will help assure

reliability.

There are numerous variations in procedures, techniques, tools, and parts for servicing vehicles, as well as in

the skill of the person doing the work. This manual cannot possibly anticipate all such variations and provide

advice or cautions as to each. Accordingly, anyone who departs from the instructions provided in the manual

must first establish that neither personal safety or vehicle integrity is compromised from choices of methods,

tools or parts.

General Information - Standard Workshop Practices

Description and Operation

Vehicle in Workshop

When working on a vehicle in the workshop always make sure that:

Where practicable, the parking brake is applied and the wheels are securely chocked to prevent the

vehicle moving forwards or backwards.

Whenever possible, the ignition key is removed before any work is carried out on the vehicle.

If the engine is to be run, there is adequate ventilation, or an extraction hose is used to remove

exhaust fumes.

There is adequate room to raise the vehicle and remove the wheels, if necessary.

Fender covers are always installed if any work is to be carried out in the engine compartment.

Where practicable, the battery is disconnected if working on the engine, underneath the vehicle, or if

the vehicle is raised.

• CAUTIONS:

Prior to disconnecting the battery, refer to the Electrical Section of this manual - Battery

disconnection/connection and the following paragraphs.

For additional information, refer to: Specifications (414-00 Charging System - General Information,

Specifications).

When electric arc welding on a vehicle, always disconnect the generator wiring to prevent the possibility

of a surge of current causing damage to the internal components of the generator.

If using welding equipment on the vehicle, a suitable fire extinguisher is readily available.

Battery - General

WARNING: It is essential that a period of 10 minutes elapses after the battery is disconnected

before any work is undertaken on any part of the SRS.

• CAUTIONS:

After re-connecting the battery, the steering wheel must be turned to full left-hand and right-hand lock

(with engine running). This allows the DSC system to relearn the steering wheel position. Failure to do so will

result in a variety of instrument warning lights being illuminated.

Page 41

Prior to carrying out any procedures which involve disconnecting/connecting the battery, refer to the

Electrical Section of this manual - Battery disconnection/connection.

For additional information, refer to: Specifications (414-01 Battery, Mounting and Cables, Specifications).

A discharged battery condition may have been caused by an electrical short circuit. If this condition

exists there will be an apparently live circuit on the vehicle even when all normal circuits are switched off. This

can cause arcing when the jumper cables are connected.

Jump Starting a Vehicle

• CAUTIONS:

While it is not recommended that a vehicle is jump started, it is recognized that this may occasionally be

the only practical way to mobilize a vehicle. Reference should be made to the following and also to the

Electrical Section of this manual - Jump Starting.

It is advisable not to use starter/charger sets for jump starting but if this is unavoidable, make sure that

the sets are not used in the 'START' mode.

Always make sure that the jumper cables are adequate for the task.

Always make sure that the slave battery is of the same voltage (12 volts) as the vehicle battery. The

batteries must be connected in parallel.

Make sure that the battery terminals of both batteries are fully tightened.

Where another vehicle is used to jump start a disabled vehicle, make sure that the two vehicles are

not touching.

It is advisable that the engine of the donor vehicle is switched off during jump starting; take care to

make sure that the battery of the donor vehicle does not also become discharged.

Always make sure that switchable electric circuits are OFF before connecting jump cables. This

reduces the risk of arcing occurring when the final connection is made.

Following jump starting of a disabled vehicle, the discharged battery must be checked for serviceability and

recharged as soon as possible to avoid permanent damage.

Do not rely on the generator to restore a discharged battery. For a generator to recharge a battery, it would

take in excess of eight hours continuous driving with no additional loads placed on the battery.

Trickle charging (defined as voltages <16 volts) may be carried out with the battery connected. Make sure that

the battery terminals are fully tightened prior to trickle charging.

CAUTION: Boost charging may only be carried out with the battery disconnected from the vehicle.

Towing the Vehicle

WARNING: When towing is necessary, reference must be made to the Jacking, Lifting and Towing Section

of this Manual.

When the vehicle is being towed the ignition switch must be in position II (steering lock released and warning

lights illuminated). Only then will the steering, turn signal lamps, horn and stop lamps be operational. Failure

to follow these instructions may result in personal injury. It must be noted that with the engine not running,

the power steering and brake booster will be inoperative therefore, greater effort will be needed to steer the

vehicle and apply the brakes.

Page 42

General Installation Instructions

Component removal

Whenever possible, clean components and the surrounding area before removal.

Blank off openings exposed by component removal.

Following disconnection, seal fuel, oil or hydraulic lines immediately using suitable blanking plugs or

caps.

Seal open ends of exposed oil ways using suitable tapered hardwood plugs or conspicuous plastic

plugs.

Immediately a component is removed, place it in a suitable container; use a separate container for

each component and its associated parts.

Clean bench and provide marking materials, labels and containers before disassembling components.

Disassembling

Observe scrupulous cleanliness when disassembling components, particularly when brake, fuel, air suspension

or hydraulic system parts are disassembled. A particle of dirt or cloth fragment could cause a serious

malfunction if trapped in these systems.

Blow out all tapped holes, crevices, oil ways and fluid passages with dry, compressed air.

WARNING: Suitable eye protection must be worn.

Discard all seals and O-rings and replace with new when reassembling.

Use suitable marker ink to identify mating parts, do not use a scriber or centre punch as they could

initiate cracks or distortion.

Wire or tape mating parts together where necessary to prevent accidental interchange.

Suitably identify parts which are to be renewed and parts requiring further inspection. Keep these

parts separate.

To make sure that the correct replacement part has been obtained, do not discard a part due for

renewal until after comparing it with the new part.

Cleaning components

Always use cleaning agents which are suitable for the work being undertaken and the components being

cleaned. NEVER use gasoline (petrol) as a cleaning agent (degreaser). Always make sure that the component

being cleaned is compatible with the cleaning agent.

Always follow the manufacturer's instructions regarding the use of cleaning agents and make sure that the

environment in which the work is being undertaken is suitable. See Health and Safety Precautions for further

information regarding cleaning.

General inspection of components

All components should be inspected for wear or damage before reassembling.

Always make sure that component to be inspected is clean and free from oil or grease.

When a component is to be checked dimensionally against design specified values, use the

appropriate measuring equipment i.e. micrometers, verniers, surface plates, dial test indicators (DTI).

Always make sure that all measuring equipment is correctly calibrated before use.

Reject a component which is not within specified values/limits or if it appears to be damaged.

A component may be reinstalled if dimensions obtained during checking are at the maximum

tolerance limit and it is in an undamaged condition.

Bearing journal clearances should be checked where necessary using Plastigage.

Gaskets, seals and O-ring seals are to be re-used unless damaged.

Page 43

Joints and Joint Faces

All gaskets should be installed dry unless stated otherwise. Always apply the specified lubricant to O-rings and

install O-rings using the fingers only.

Use gasket removal spray and/or plastic scrapers to remove traces of old gasket.

CAUTION: DO NOT use metal scrapers or emery cloth as these may damage the sealing surfaces.

Many joints use sealants instead of gaskets as the sealing medium. Where this is the case, the sealant together

with its part number will be found listed in the relevant repair operation and also in the sealants table.

CAUTION: Always remove all traces of the old sealant prior to reassembly. Use plastic scrapers, specified

solvents where available or dry, lint free cloth. DO NOT use metal scrapers or emery cloth as these may

damage the sealing surfaces. Make sure that sealing surfaces are free from oil or grease as sealants will not

adhere properly to contaminated surfaces.

Do not allow sealant to enter tapped holes or oil ways.

Locking Devices

Always replace locking devices with one of the same design and of the correct size.

Tab washers

Always release locking tabs before loosening fixings, do not re-use tab washers.

Locknuts

Always use a backing spanner when loosening and tightening locknuts, brake and fuel pipe unions.

Roll pins

Always install new roll pins of the correct size.

Circlips

Always install new circlips ensuring that they are of the correct size for the groove.

Woodruff keys

Woodruff keys may be re-used provided there is no indication of wear or distortion.

Remove any burrs from edges of keyways using a fine file.

Split pins

Never attempt to straighten and re-use a split pin, always make sure that replacement pins are of the correct

size for the hole in which they are to be installed.

Screw Threads

Damaged nuts, bolts and screws must always be discarded. Attempting to recut or repair damaged

threads with a tap or die impairs the strength and fit of the threads and is not recommended.

Page 44

• NOTE: During certain repair operations, it may be necessary to remove traces of thread locking agents using

a tap. Where this is necessary, the instruction to do so will appear in the relevant operation and it is essential

that a tap of the correct size and thread is used.

Some bolts are coated with a thread locking agent and unless stated otherwise, they must not be re-

used. New bolts having the same part number as the original must always be installed. When nuts or

bolts are to be discarded, the repair operation and relevant torque chart will include an instruction to

that effect. Do not use proprietary thread locking agents as they may not meet the specification

required. See also Encapsulated ('Patched') Bolts and Screws.

Always make sure that replacement nuts and bolts are at least equal in strength to those that they

are replacing. Castellated nuts must not be loosened to accept a split pin except in recommended

cases when this forms part of an adjustment.

Do not allow oil or grease to enter blind holes, the hydraulic action resulting from tightening the bolt

or stud can split the housing and also give a false torque reading.

Always tighten a nut, bolt or screw to the specified torque figure, damaged or corroded threads can

give a false torque reading.

Nut and bolt loosening and tightening sequences, where given, must ALWAYS be followed. Distortion

of components or faulty sealing of joints will result if the sequences are not followed. Where an

instruction is given to tighten in stages, these stages must be adhered to; do not attempt to combine

stages particularly where certain stages involve tightening by degrees.

To check or re-tighten a fixing to a specified torque, first loosen a quarter of a turn, then retighten to

the specified torque figure.

Unless instructed otherwise, do not lubricate bolt or nut threads prior to installation.

Where it is stated that bolts and screws may be re-used, the following procedures must be carried out:

Check that threads are undamaged.

Remove all traces of locking agent from the threads.

CAUTION: DO NOT use a wire brush; take care that threads are not damaged.

make sure that threads are clean and free from oil or grease.

Apply the specified locking agent to the bolt threads.

Bolt and Nut Identification

An ISO metric bolt or screw made of steel and larger than 6 mm in diameter can be identified by either of the

symbols ISO M or M embossed or indented on top of the bolt head.

In addition to marks identifying the manufacturer, the top of the bolt head is also marked with symbols

indicating the strength grade e.g. 8.8, 10.9, 12.9, 14.9. Alternatively, some bolts and screws have the M and

strength grade symbol stamped on the flats of the hexagon.

Page 45

Encapsulated ('Patched') bolts and screws

Encapsulated ('patched') bolts and screws have a thread locking agent applied to the threads during

manufacture. Most thread locking agents are colored, the band of color extending for 360° around the thread.

Some locking agents however, are neutral in color and may not be so easily identified apart from a slightly

darker area of thread where the locking agent has been applied. The locking agent is released and activated by

the tightening process and is then chemically cured to provide the locking action.

Self-locking bolts and screws

Unless stated in a specific repair procedure, self-locking bolts and screws i.e. nylon patched or trilobular thread

can be re-used provided that resistance is felt when the locking portion enters the female thread.

Nylon patched bolts and screws have a locking agent either applied to, or inserted in the threaded portion.

They are identified by the presence of a colored section of thread extending approximately 180° around the

thread or by a colored plug inserted into the bolt.

Trilobular bolts have a special thread form which creates a slight interference with the thread of the hole or nut

into which it is screwed.

CAUTION: Do Not re-use self-locking fasteners in critical locations e.g. drive plates/flywheel or engine

bearings. Do not install non self-locking fasteners where a self-locking fastener is specified.

Trilobular bolts should not be used as a substitute for patched bolts.

Page 46

Nut identification

A nut with an ISO metric thread is marked on one face or one of the hexagonal flats with the strength grade

symbol 8, 12, 14. Some nuts with the strength grade 4, 5 or 6 are also marked and some have the metric

symbol M on the hexagonal flat opposite the strength grade marking.

A clock face system is sometimes used as an alternative method of indicating the strength grade. The external

chamfers or a face of the nut is marked in a position relative to the appropriate hour mark on a clock face to

indicate the strength grade.

A dot is used to locate the 12 o'clock position and a dash to indicate the strength grade. If the grade is above

12, two dots identify the 12 o'clock position.

When tightening a slotted or castellated nut, never loosen it to insert a split pin except where specified as part

of an adjustment procedure. If difficulty is experienced in correctly positioning the slot, alternative washers or

nuts should be selected.

Where a nut is tightened to adjust or maintain bearing pre-load, the tightening procedure must be adhered to.

Self-locking nuts

Unless stated otherwise, self-locking nuts once removed must be discarded and new nuts of the same type and

strength grade installed.

Air Suspension

Always make sure that suitable eye protection is worn when working on the air suspension system.

Ball and Roller Bearings

When removing and installing bearings, make sure that the following practices are observed to make sure

component serviceability: