Page 1

RANGE ROVER

CLASSIC

Workshop Manual

Page 2

Workshop manual

RANGE ROVER

This manual covers vehicles from

1995 model year

01

04

05

06

07

09

10

12

01 INTRODUCTION

04 GENERAL SPECIFICATION DATA

05 ENGINE TUNING DATA

07 GENERAL FITTING REMINDERS

09 LUBRICANTS, FLUIDS AND CAPACITIES

10 MAINTENANCE

12 ENGINE Tdi

12 ENGINE 3.9 V8

17 EMISSION CONTROL

19 FUEL SYSTEM Tdi

19 FUEL SYSTEM MFI

19 CRUISE CONTROL

26 COOLING SYSTEM Tdi

26 COOLING SYSTEM V8

30 MANIFOLD AND EXHAUST SYSTEM

33 CLUTCH

37 MANUAL GEARBOX

41 TRANSFER GEARBOX

44 AUTOMATIC GEARBOX

47 PROPELLER SHAFTS

51 REAR AXLE AND FINAL DRIVE

54 FRONT AXLE AND FINAL DRIVE

57 STEERING

60 FRONT SUSPENSION

64 REAR SUSPENSION

68 AIR SUSPENSION

70 BRAKES NON ABS

70 BRAKES ABS

70 BRAKES ELECTRONIC TRACTION

CONTROL

74 WHEELS AND TYRES

76 SUPPLEMENTARY RESTRAINT SYSTEM

76 CHASSIS AND BODY

80 HEATING AND VENTILATION

82 AIR CONDITIONING

84 WIPERS AND WASHERS

86 ELECTRICAL

17

19

26

30

33

37

41

44

47

51

54

57

60

64

68

74

70

Published by Rover Technical Communication

Rover Group Limited 1995

Publication Part No. LRL0030ENG

76

80

82

84

86

Page 3

INTRODUCTION

INTRODUCTION

This workshop manual covers vehicles from 1995

model year onwards. Amendments and additional

pages will be issued to ensure that the manual

covers latest models. Amendments and additions

will be identified by the addition of a dated footer

at the bottom of the page.

This Workshop Manual is designed to assist skilled

technicians in the efficient repair and maintenance of

Land Rover vehicles.

Individuals who undertake their own repairs

should have some skill and training, and limit

repairs to components which could not affect the

safety of the vehicle or its passengers. Any

repairs required to safety critical items such as

steering, brakes, suspension or supplementary

restraint system should be carried out by a Land

Rover Dealer. Repairs to such items should

NEVER be attempted by untrained individuals.

WARNINGS, CAUTIONS and NOTES are given

throughout this Manual in the following form:

WARNING: Procedures which must be

followed precisely to avoid the possibility

of personal injury.

CAUTION: This calls attention to

procedures which must be followed to

avoid damage to components.

NOTE: This calls attention to methods

which make a job easier or gives helpful

information.

REFERENCES

References to the left or right hand side in the manual

are made when viewing the vehicle from the rear.

With the engine and gearbox assembly removed, the

water pump end of the engine is referred to as the

front.

To reduce repetition, some operations covered in this

Manual do not include reference to testing the vehicle

after repair.

It is essential that work is inspected and tested after

completion and if necessary a road test of the vehicle

is carried out particularly where safety related items

are concerned.

REPAIRS AND REPLACEMENTS

When replacement parts are required it is essential

that Land Rover parts are used.

Attention is particularly drawn to the following points

concerning repairs and the fitting of replacement parts

and accessories: Safety features embodied in the

vehicle may be impaired if other than Land Rover

parts are fitted. In certain territories, legislation

prohibits the fitting of parts not to the vehicle

manufacturer’s specification. Torque spanner values

given in the Workshop Manual must be strictly

adhered to. Locking devices, where specified, must be

fitted. If the efficiency of a locking device is impaired

during removal it must be replaced with a new one.

Certain fasteners must not be re-used. These

fasteners are specified in the Workshop Manual.

DIMENSIONS

The dimensions quoted are to design engineering

specification. Alternative unit equivalents, shown in

brackets following the dimensions, have been

converted from the original specification.

POISONOUS SUBSTANCES

Many liquids and other substances used are

poisonous and therefore must not be consumed. It is

also advisable to keep all substances away from open

wounds. These substances among others include

anti-freeze, brake fluid, fuel, windscreen washer

additives, air conditioning refrigerant, lubricants and

various adhesives.

INFORMATION

1

Page 4

01

INTRODUCTION

FUEL HANDLING PRECAUTIONS

The following information provides basic precautions

which must be observed if fuel is to be handled safely.

It also outlines the other areas of risk which must not

be ignored.

This information is issued for basic guidance only, and

in any case of doubt, appropriate enquiries should be

made of your local Fire Officer or Fire Department.

Fuel vapour is highly flammable and in confined

spaces is also very explosive and toxic.

When fuel evaporates it produces 150 times its own

volume in vapour, which when diluted with air

becomes a readily ignitable mixture. The vapour is

heavier than air and will always fall to the lowest level.

It can readily be distributed throughout a workshop by

air current, consequently, even a small spillage of fuel

is very dangerous.

Always have a fire extinguisher containing FOAM CO

GAS, or POWDER close at hand when handling fuel,

or when dismantling fuel systems and in areas where

fuel containers are stored.

Hot fuel handling precautions

WARNING: Before commencing any

operation requiring fuel to be drained from

the fuel tank, the following procedure must

be adhered to:

1. Allow sufficient time for the fuel to cool, thus

avoiding contact with hot fuels.

2. Vent the system by removing the fuel filler cap in

a well ventilated area. Refit the filler cap until the

commencement of fuel drainage.

Fuel transfer

WARNING: Fuel must not be extracted or

drained from any vehicle while it is

standing over a pit.

The transfer of fuel from the vehicle fuel tank must be

carried out in a well ventilated area. An approved

transfer tank must be used according to the transfer

2

tank manufacturer’s instructions and local regulations,

including attention to grounding of tanks.

Fuel tank removal

WARNING: lt is imperative that the battery

is not disconnected during fuel system

repairs as arcing at the battery terminal

could ignite fuel vapour in the atmosphere.

Always disconnect the vehicle battery BEFORE

carrying out work on the fuel system.

Whenever fuel is being handled, transferred or

stored, or when fuel systems are being dismantled

all forms of ignition must be extinguished or

removed, any leadlamps used must be flame proof

and kept clear of spillage.

No one should be permitted to repair components

associated with fuel without first having had fuel

system training.

A FUEL VAPOUR warning label must be attached to

the fuel tank upon removal from the vehicle.

Fuel tank repair

Under no circumstances should a repair to any tank

be attempted.

INFORMATION

2

Page 5

INTRODUCTION

SYNTHETIC RUBBER

Many ’0’ ring seals, flexible pipes and other similar

items which appear to be natural rubber are made of

synthetic materials called Fluoroelastomers. Under

normal operating conditions this material is safe, and

does not present a health hazard. However, if the

material is damaged by fire or excessive heat, it can

break down and produce highly corrosive Hydrofluoric

acid which can cause serious burns on contact with

skin. Should the material be in a burnt or overheated

condition handle only with seamless industrial gloves.

Decontaminate and dispose of the gloves immediately

after use.

If skin contact does occur, remove any contaminated

clothing immediately and obtain medical assistance

without delay. In the meantime, wash the affected

area with copious amounts of cold water or limewater

for fifteen to sixty minutes.

RECOMMENDED SEALANTS

A number of branded products are recommended in

this manual for use during maintenance and repair

work.

These items include:

HYLOMAR GASKET AND JOINTING COMPOUND

and

HYLOSIL RTV SILICON COMPOUND.

They should be available locally from garage

equipment suppliers. If there is any problem obtaining

supplies, contact the following company for advice

and the address of the nearest supplier.

MARSTON LUBRICANTS LTD.

Hylo House,

Cale Lane,

New Springs,

Wigan WN2 1JR

USED ENGINE OIL

WARNING: Prolonged and repeated

contact with engine or motor oil will result

in the removal of natural fats from the

skin, leading to dryness, irritation and dermatitis.

Used engine oil contains potentially harmful

contaminants which may cause skin cancer.

Adequate means of skin protection and washing

facilities should be provided.

Handling precautions

1. Avoid prolonged and repeated contact with oils,

particularly used engine oils.

2. Wear protective clothing, including impervious

gloves where applicable.

3. Do not put oily rags in pockets.

4. Avoid contaminatingclothes,particularly

underwear, with oil.

5. Overalls must be cleaned regularly. Discard

unwashable clothing and oil impregnated

footwear.

6. First aid treatment must be obtained immediately

for open cuts and wounds.

7. Use barrier creams, before each work period, to

help the removal of oil from the skin.

8. Wash with soap and water to ensure all oil is

removed (skin cleansers and nail brushes will

help). Preparations containing lanolin replace the

natural skin oils which have been removed.

9. Do not use gasoline, kerosene, diesel fuel,

petrol, thinners or solvents for washing the skin.

10. If skin disorders develop, obtain medical advice.

11. Where practicable, degrease components prior

to handling.

12. Where there is a risk of eye contact, eye

protection should be worn, for example, goggles

or face shields; in addition an eye wash facility

should be provided.

Disposing of used oils

Tel 01942 824242

Environmental protection precaution

It is illegal to pour used oil onto the ground, down

sewers or drains, or into waterways.

Dispose of used oil through authorised waste disposal

contractors. If in doubt contact your Local Authority for

advice on disposal facilities.

INFORMATION

3

Page 6

01

INTRODUCTION

ACCESSORIES AND CONVERSIONS

DO NOT FIT unapproved accessories or conversions,

as they could affect the safety of the vehicle.

Land Rover will not accept liability for death, personal

injury, or damage to property which may occur as a

direct result of the fitting of non-approved conversions

to the vehicle.

WHEELS AND TYRES

WARNING: DO NOT replace the road

wheels with any type other than genuine

Land Rover wheels which are designed for

multi-purpose on and off road use and have very

important relationships with the proper operation

of the suspension system and vehicle handling.

Replacement tyres must be of the make and sizes

recommended for the vehicle, and all tyres must

be the same make, ply rating and tread pattern.

STEAM CLEANING

To prevent consequential rusting, any steam cleaning

within the engine bay MUST be followed by careful

re-waxing of the metallic components affected.

Particular attention must be given to the steering

column, engine water pipes, hose clips and ignition

coil clamp.

SPECIFICATION

The specification details and instructions set out in

this Manual apply only to a range of vehicles and not

to any one. For the specification of a particularvehicle

purchasers should consult their Dealer

The Manufacturer reserve the right to vary their

specifications with or without notice, and at such times

and in such manner as they think fit. Major as well as

minor changes may be involved in accordance with

the Manufacturer’s policy of constant product

improvement.

Whilst every effort is made to ensure the accuracy of

the particulars contained in this Manual, neither the

Manufacturer or Dealer, by whom this Manual is

supplied, shall in any circumstances be held liable for

any inaccuracy or the consequences thereof.

SPECIAL SERVICE TOOLS

The use of approved special service tools is

important. They are essential if service operations are

to be carried out efficiently, and safely. Where special

tools are specified, only these tools should be used

to avoid the possibility of personal injury or

damage to the components. Also the amount of time

which they save can be considerable.

Every special tool is designed with the close

co-operation of Land Rover, and no tool is put into

production which has not been tested and approved

by us. New tools are only introduced where an

operation cannot be satisfactorily carried out using

existing tools or standard equipment. The user is

therefore assured that the tool is necessary and that it

will perform accurately, efficiently and safely.

Special tools bulletins will be issued periodically giving

details of new tools as they are introduced.

All orders and enquiries from the United Kingdom

should be sent direct to V. L. Churchill. Overseas

orders should be placed with the local V. L. Churchill

distributor, where one exists. Countries where there is

no distributor may order direct from:

V. L. Churchill Limited,

PO Box 3,

Daventry, Northants,

England, NN11 4NF.

The tools recommended in this Workshop Manual are

listed in a multi-language illustrated catalogue,

obtainable from:

Messers. V. L. Churchill at the above address,

or from:

Land Rover Merchandising Service,

PO Box 534,

Erdington,

Birmingham, B24 0Q5,

COPYRIGHT

Land Rover 1995

All rights reserved. No part of this publication may be

produced, stored in a retrieval system or transmitted

in any form, electronic, mechanical, recording or other

means without prior written permission of Land Rover.

INFORMATION

4

Page 7

INTRODUCTION

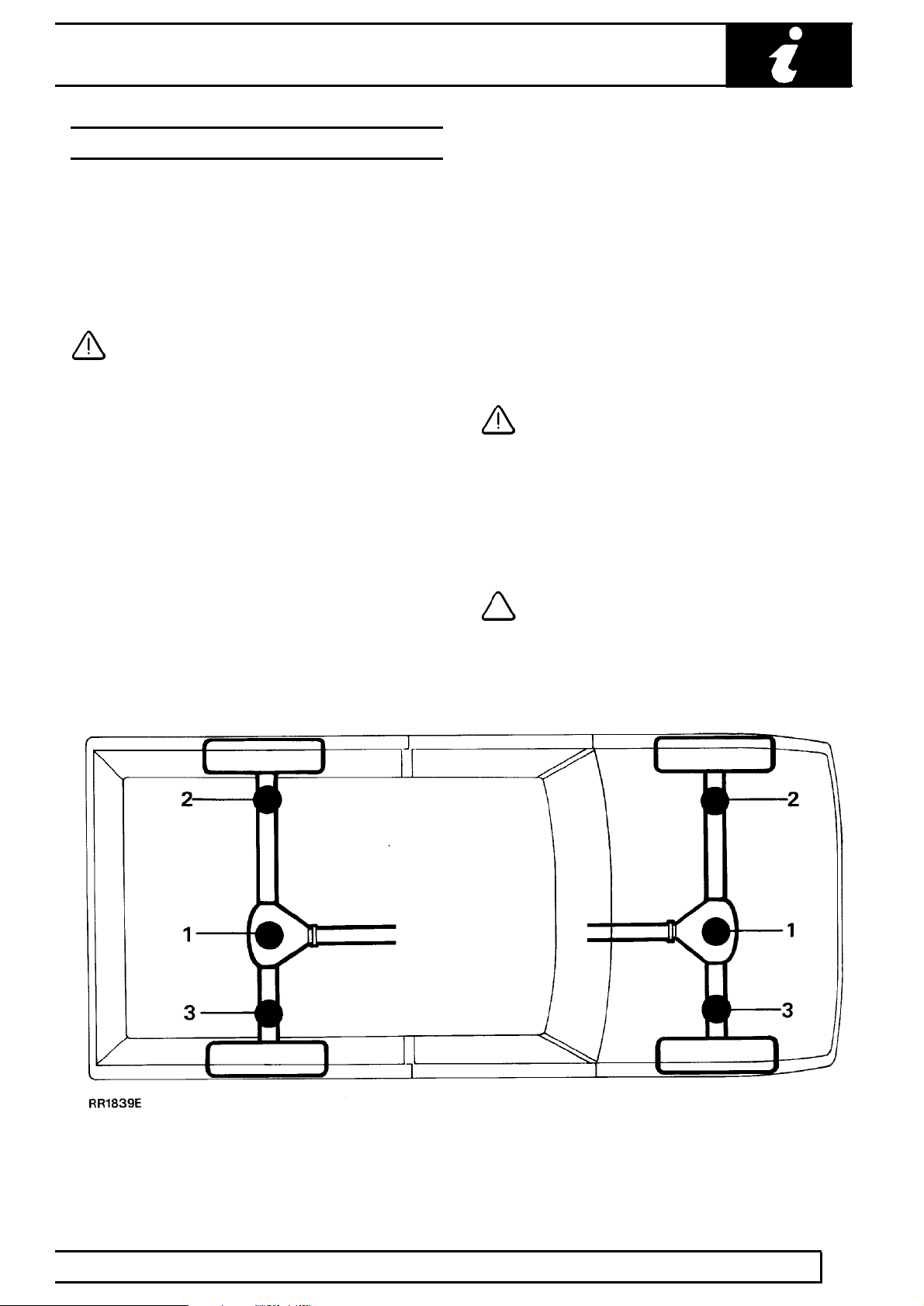

JACKING

The following instructions must be carried out before

raising the vehicle off the ground.

1. Use a solid level ground surface.

2. Apply parking brake.

3. Select ’P’ or 1st gear in main gearbox.

4. Select Low range in transfer gearbox.

CAUTION: To avoid damage occurring to

the under body components of the vehicle

the following jacking procedures must be

adhered to.

DO NOT POSITION JACKS OR AXLE STANDS

UNDER THE FOLLOWING COMPONENTS.

Body structure

Bumpers

Fuel lines

Brake lines

Front radius arms

Panhard rod

Steering linkage

Rear Trailing links

Fuel tank

Engine sump

Gearbox bell housing

Vehicle jack

The jack provided with the vehicle is only intended to

be used in an emergency, for changing a tyre. Do

NOT use the jack for any other purpose. Refer to

Owner’s Manual for vehicle jack location points and

procedure. Never work under a vehicle supported by

the vehicle jack.

Hydraulic jack

A hydraulic jack with a minimum 1500 kg, 3,300 lbs

load capacity must be used.

CAUTION: Do not commence work on the

underside of the vehicle until suitable axle

stands have been positioned under the

axle.

Raise the front of the vehicle

1. Position cup of hydraulic arm under differential

casing.

NOTE: The differential casing is not

central to the axle. Care should be taken

when raising the front road wheels off the

ground as the rear axle has less sway stiffness.

Jack or support vehicle by axles only.

INFORMATION

5

Page 8

01

INTRODUCTION

2. Raise front road wheels to enable an axle stand

to be installed under left hand axle tube.

3. Position an axle stand under right hand axle

tube, carefully lower jack until axle sits securely

on both axle stands, remove trolley jack.

4. Before commencing work on underside of

vehicle re-check security of vehicle on stands.

5. Reverse procedure when removing vehicle from

stands.

Raise rear of vehicle

1. Position cup of hydraulic arm under differential

casing.

2. Raise vehicle to enable axle stands to be

installed under left and right hand axle tubes.

3. Lower jack until axle sits securely on axle

stands, remove trolley jack.

4. Before commencing work on underside of

vehicle re-check security of vehicle on stands.

5. Reverse procedure when removing vehicle from

stands.

DYNAMOMETER TESTING - NON ANTI-LOCK BRAKE VEHICLES

Viscous coupling

The front and rear axles cannot be driven

independently due to the viscous coupling. This

eliminates the need for differential lock by

progressively locking the centre differential

automatically if slip occurs at any wheel.

WARNING: DO NOT attempt to drive

individual wheels with vehicle supported

on floor jacks or stands.

Four wheel dynamometers

Provided that front and rear dynamometer rollers are

rotating at identical speeds and that normal workshop

safety standards are applied, there is no speed

restriction during testing except any that may apply to

the tyres.

Two wheel dynamometers

HYDRAULIC VEHICLE RAMP (FOUR POST)

Use only a ’drive on’ type ramp which supports vehicle

by its own road wheels. If a ’wheel-free’ condition is

required, use a ’drive on’ ramp incorporating a

’wheel-free’ system that supports under axle casings.

Alternatively, place vehicle on a firm, flat floor and

support on axle stands.

TWO POST VEHICLE RAMPS

The manufacturer of LAND ROVER VEHICLES

DOES NOT recommend using ’Two Post’ ramps

that employ four adjustable support arms. These

are NOT considered safe for Land Rover vehicles.

If vehicle is installed on a Two Post ramp

responsibility for safety of vehicle and personnel

performing service operations is in the hands of

the Service Provider.

IMPORTANT: Use a four wheel dynamometer for

brake testing if possible.

If brake testing on a single axle rig is necessary it

must be carried out with propeller shaft to rear axle

removed, AND neutral selected in BOTH main

gearbox and transfer gearbox. When checking brakes,

run engine at idle speed to maintain servo vacuum.

If checking engine performance, the transfer box must

be in high range and propeller shaft to stationary axle

must be removed.

INFORMATION

6

Page 9

DYNAMOMETER TESTING - VEHICLES WITH ANTI-LOCK BRAKES (ABS)

WARNING: Do not attempt to test ABS

function on a dynamometer

Four wheel dynamometers

NOTE: Before testing a vehicle on a four

wheel dynamometer disconnect the valve

relay.

See Electrical Trouble Shooting

Manual.

The ABS function will not work, the ABS warning

light will illuminate. Normal braking will be

available.

Provided that front and rear rollers are rotating at

identical speeds and that normal workshop safety

standards are applied, there is no speed restriction

during testing except any that may apply to the tyres.

INTRODUCTION

3. Secure tow rope, chain or cable to towing eye.

4. Release the parking brake.

Two wheel dynamometers

IMPORTANT: Use a four wheel dynamometer for

brake testing if possible.

NOTE: ABS will not function on a two

wheel dynamometer. The ABS light will

illuminate during testing. Normal braking

will be available.

If brake testing on a single rig is necessary it must be

carried out with propeller shaft to the rear axle

removed, AND neutral selected in BOTH main and

transfer boxes.

If checking engine performance, the transfer box must

be in high range and drive shaft to stationary axle

removed.

TOWING

CAUTION: The vehicle has permanent

four-wheel drive. The following towing

instructions must be adhered to:

Towing the vehicle on all four wheels with driver

operating steering and brakes.

1. Turn ignition key turn to position ’1’ to release

steering lock.

2. Select neutral in main gearbox and transfer

gearbox.

CAUTION: The brake servo and power

assisted steering system will not be

functional without the engine running.

Greater pedal pressure will be required to apply

the brakes, the steering system will require

greater effort to turn the front road wheels.

The vehicle tow connection should be used only

in normal road conditions, ’snatch’ recovery

should be avoided.

Suspended tow by breakdown vehicle

CAUTION: To prevent vehicle damage,

front or rear propeller shaft MUST BE

removed, dependent upon which axle is

being trailed.

1. Mark propellershaft drive flanges at transfer

gearbox and axles with identification lines to

enable the propeller shaft to be refitted in its

original position.

2. Remove the propeller shaft fixings, remove the

shaft from the vehicle.

3. If the front axle is to be trailed turn ignition key to

position ’1’ to release steering lock.

CAUTION: The steering wheel and/or

linkage must be secured in a straight

ahead position. DO NOT use the steering

lock mechanism for this purpose.

INFORMATION

7

Page 10

01

INTRODUCTION

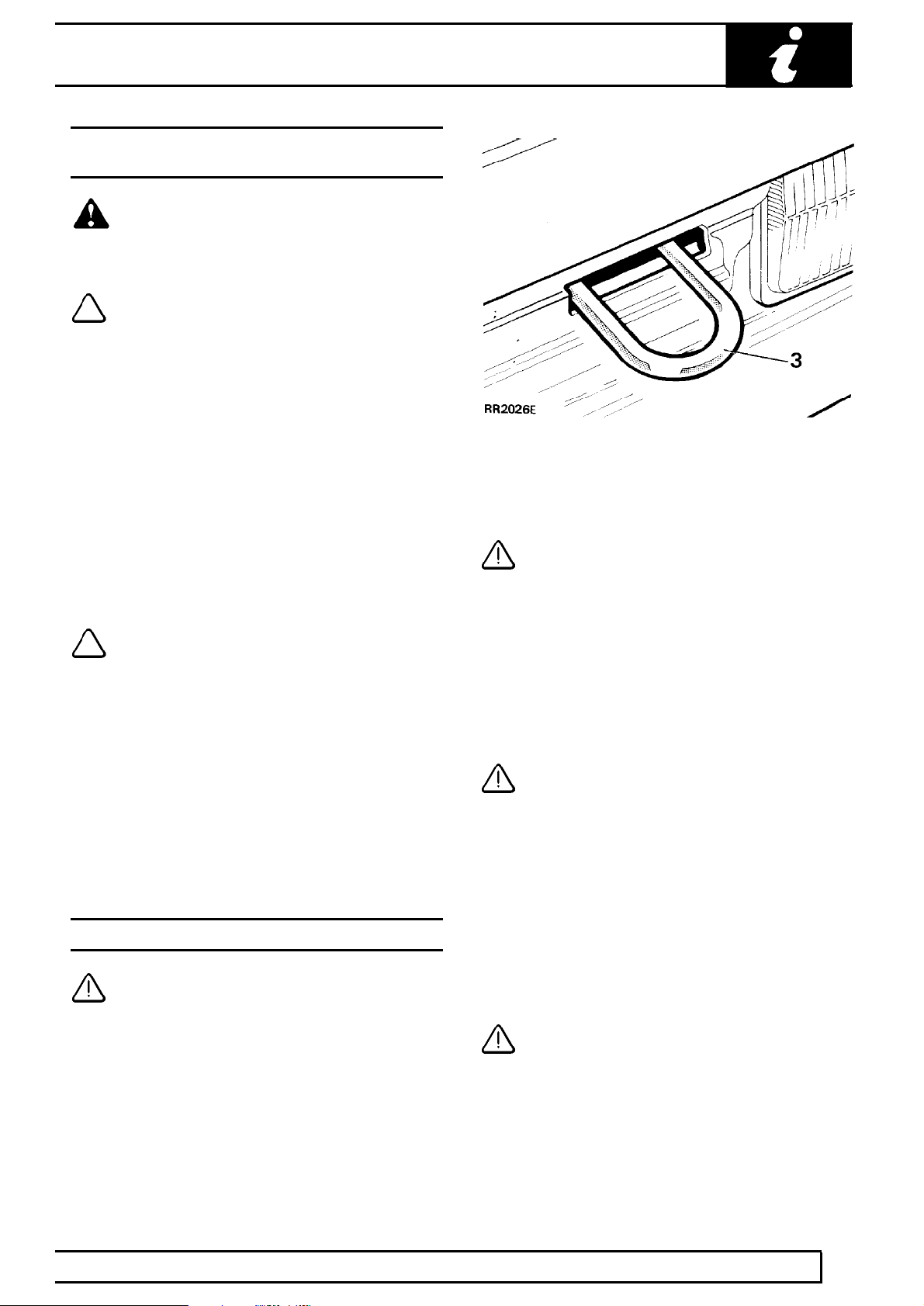

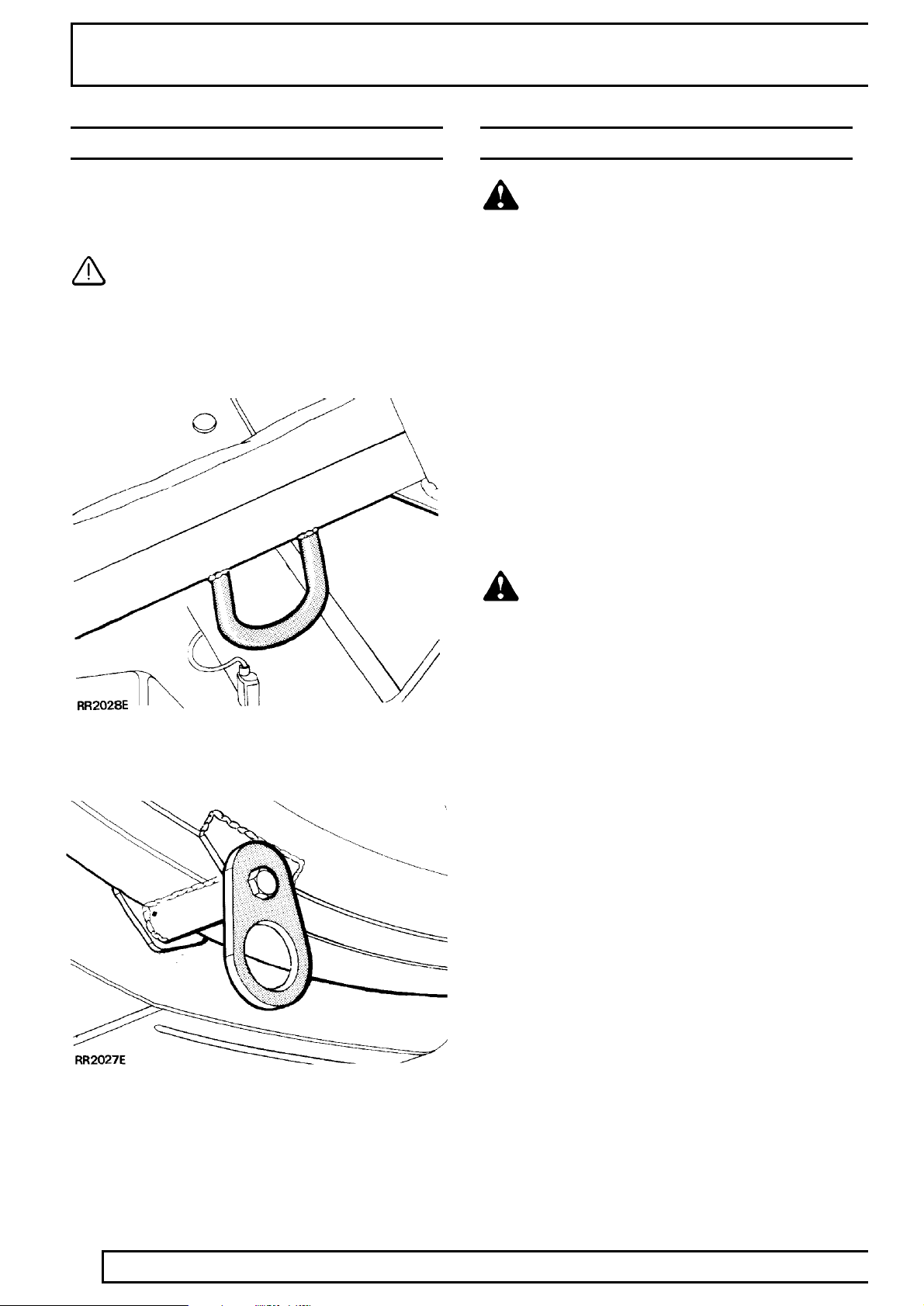

TRANSPORTING THE VEHICLE BY TRAILER

Lashing eyes are provided on front and rear of the

chassis side members, to facilitate the securing of the

vehicle to a trailer or other means of transportation.

CAUTION: Underbody components must

not be used as lashing points.

Install vehicle on trailer and apply park brake. Select

neutral in main gearbox. Selecting ’N’ will prevent

damage to parking pawl of the automatic gearbox.

FRONT OF CHASSIS

JUMP STARTING

WARNING: Hydrogen and oxygen gases

are produced during normal battery

operation. This gas mixture can explode if

flames, sparks or lighted tobacco are brought

near battery. When charging or using a battery in

an enclosed space, always provide ventilation and

shield your eyes.

Keep out of reach of children. Batteries contain

sulphuric acid. Avoid contact with skin, eyes, or

clothing. Also, shield eyes when working near

battery to protect against possible splashing of

acid solution. In case of acid contact with skin,

eyes, or clothing, flush immediately with water for

a minimum of fifteen minutes. If acid is swallowed,

drink large quantities of milk or water, followed by

milk of magnesia, a beaten egg, or vegetable oil.

SEEK MEDICAL AID IMMEDIATELY.

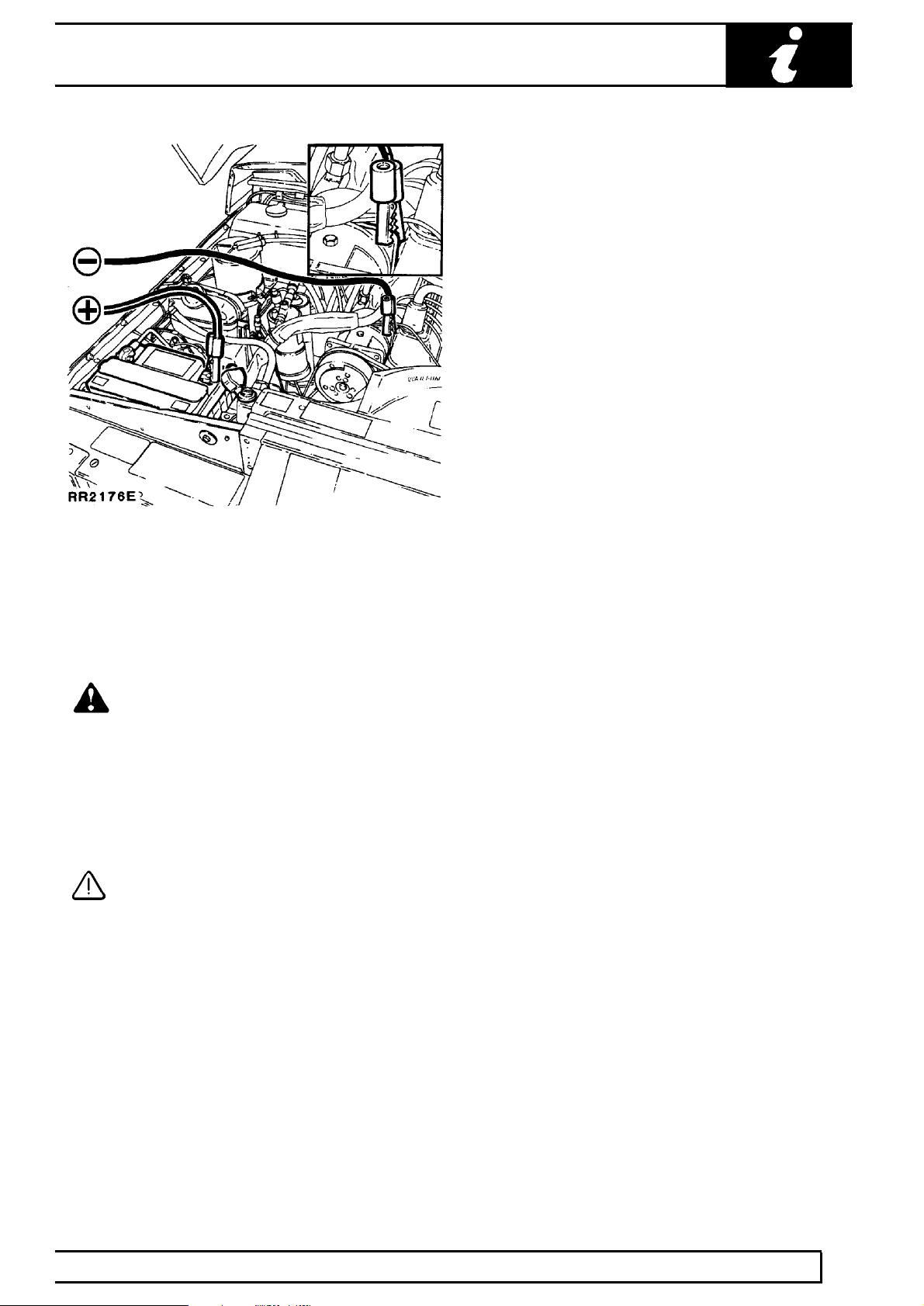

To Jump Start - Negative Ground Battery

WARNING: To avoid any possibility of

injury use particular care when connecting

a booster battery to a discharged battery.

REAR OF CHASSIS

1. Position vehicles so that jump leads will reach,

ensuring that vehicles DO NOT TOUCH,

alternatively a fully charged slave battery may be

positioned on floor adjacent to vehicle.

2. Ensuring that ignition and all electrical

accessories are switched off, that parking brake

is applied and neutral is selected on a manual

gearbox, with an automatic gearbox select

neutral (N) or park (P) and then connect the

jump leads as follows;

A. Connect one end of first jumper cable to positive

(+) terminal of booster battery.

B. Connect other end of first jumper cable to

positive (+) terminal of discharged battery.

C. Connect one end of second jumper cable to

negative terminal of booster battery.

INFORMATION

8

Page 11

INTRODUCTION

D. Connect other end of second jumper cable to a

good earth point on the engine, NOT TO

NEGATIVE TERMINAL OF DISCHARGED

BATTERY. Keep jumper lead away from moving

parts, pulleys, drive belts and fan blade

assembly.

WARNING: Making final cable connection

could cause an electrical arc which if

made near battery could cause an

explosion.

3. If booster battery is installed in another vehicle,

start engine and allow to idle.

4. Start engine of vehicle with discharged battery,

following starting procedure in Owners’ Manual.

CAUTION: If vehicle fails to start within a

maximum time of 12 seconds, switch

ignition off and investigate cause. Failing

to follow this instruction could result in

irrepairable damage to catalysts.

5. Remove negative (-) jumper cable from the

engine and then terminal of booster battery.

6. Remove positive (+) jumper cable from positive

terminals of booster battery and discharged

battery.

INFORMATION

9

Page 12

01

INTRODUCTION

ABBREVIATIONS AND SYMBOLS USED IN THIS MANUAL

Across flats (bolt size) AF............................................

After bottom dead centre ABDC...................................

After top dead centre ATDC.........................................

Alternating current a.c..................................................

Ampere amp................................................................

Ampere hour amp hr....................................................

Before bottom dead centre BBDC................................

Before top dead centre BTDC......................................

Bottom dead centre BDC.............................................

Brake horse power bhp................................................

British Standards BS....................................................

Carbon monoxide CO..................................................

Centimetre cm.............................................................

Centigrade (Celsius) C................................................

Cubic centimetre cm

Cubic inch in

...................................................

...............................................................

Degree (angle) deg or °...............................................

Degree (temperature) deg or °.....................................

Diameter dia................................................................

Direct current d.c..........................................................

Electronic Control Unit ECU........................................

Electronic Fuel Injection EFI........................................

Fahrenheit F.................................................................

Feet ft...........................................................................

Feet per minute ft/min..................................................

Fifth 5th........................................................................

First 1st........................................................................

Fluid ounce fl oz..........................................................

Foot pounds (torque) lbf ft............................................

Fourth 4th.....................................................................

Gramme (force) gf........................................................

Gramme (mass) g........................................................

Gallons gal...................................................................

Gallons (US) US gal.....................................................

High tension (electrical) H.T.........................................

Internal diameter I.D....................................................

Inches of mercury in. Hg..............................................

Inches in......................................................................

Kilogramme (force) kgf.................................................

Kilogramme (mass.) kg................................................

Kilogramme centimetre (torque) kgf.cm.......................

Kilogramme per square millimetre kgf/mm

Kilogramme per square centimetre kgf/cm

.................

.................

Kilogramme metres (torque) kgf.m..............................

Kilometres km..............................................................

Kilometres per hour km/h.............................................

Kilovolts kV...................................................................

Left-hand LH................................................................

Left-hand steering LHStg.............................................

Left-hand thread LHThd...............................................

Litres litre.....................................................................

Low tension l.t..............................................................

Maximum max.............................................................

Metre m........................................................................

Millilitre ml....................................................................

Millimetre mm...............................................................

Miles per gallon mpg....................................................

Miles per hour mph......................................................

Minute (angle) ’............................................................

Minus (of tolerance) -...................................................

Negative (electrical) -...................................................

Newton metres (torque) Nm........................................

Number No..................................................................

Ohms ohm...................................................................

Ounces (force) ozf.......................................................

3

Ounces (mass) oz........................................................

3

Ounce inch (torque) ozf.in...........................................

Outside diameter O.D..................................................

Part number Part No....................................................

Percentage %...............................................................

Pints pt.........................................................................

Pints (US) US pt...........................................................

Plus (tolerance) +.........................................................

Positive (electrical) +....................................................

Pound (force) lbf..........................................................

Pounds inch (torque) in.lbf...........................................

Pound (mass) lb...........................................................

Pounds per square inch P.S.I......................................

Ratio :...........................................................................

Reference ref...............................................................

Revolution per minute rev/min.....................................

Right-hand RH.............................................................

Second (angle) "...........................................................

Second (numerical order) 2nd......................................

Specific gravity sp.gr....................................................

Square centimetres cm

Square inches in

...............................................

.........................................................

Standard wire gauge s.w.g..........................................

Synchroniser/Synchromesh synchro...........................

Third 3rd.......................................................................

Top dead centre TDC..................................................

United Kingdom UK......................................................

2

Vehicle Identification Number VIN...............................

2

Volts V.........................................................................

Watts W.......................................................................

SCREW THREADS

American Standard Taper Pipe NPTF.........................

British Standard Pipe BSP...........................................

Unified Coarse UNC....................................................

Unified Fine UNF.........................................................

2

2

10

INFORMATION

Page 13

CROSS REFERENCE OF EMISSION SYSTEM TERMINOLOGY

INTRODUCTION

NEW TERM (ACRONYM)

Accelerator pedal (AP).................................................

Air cleaner (ACL)..........................................................

Air conditioning (AC)....................................................

Battery positive voltage (B+)........................................

Closed loop (CL)..........................................................

Closed throttle position (CTP)......................................

Canister purge valve (CANPV)....................................

Data link connector (DLC)...........................................

Diagnostic trouble code (DTC).....................................

Distributor ignition (DI).................................................

Engine control module (ECM)......................................

Engine coolant level (ECL)...........................................

Engine coolant temperature (ECT)..............................

Engine coolant temperature sensor (ECTS)................

Engine speed (RPM)....................................................

Evaporative emission system (EVAP)..........................

Engine fuel temperature sensor (EFTS)......................

4th gear, 3rd gear etc. (4GR, 3GR)..............................

Fuel pump (FP)............................................................

Fan control module (FCM)...........................................

Generator (GEN)..........................................................

Ground (GND)..............................................................

Heated oxygen sensor (H02S)....................................

Idle air control (IAC)......................................................

Idle air control valve (IACV).........................................

Ignition control module (ICM).......................................

Inertia fuel shutoff (IFS)................................................

Inertia fuel shutoff switch (IFSS)..................................

Intake air temperature (IAT).........................................

Malfunction indicator lamp (MIL)..................................

Manifold vacuum zone (MVZ)......................................

Mass air flow sensor (MAFS).......................................

Multiport fuel injection (MFI)........................................

On board diagnostic (OBD)..........................................

Open loop (OL)............................................................

Park/neutral position (PNP).........................................

Park/neutral position switch (PNPS)............................

Programmable read only memory (PROM)..................

Relay module (RM)......................................................

Service reminder indicator (SRI)..................................

Solid state relay module (SSRM).................................

Three way catalytic converter (TWC)..........................

Throttle body (TB)........................................................

Throttle position sensor (TPS)......................................

Torque converter clutch (TCC)....................................

Transmission range (TR)..............................................

Transmission range selector (TRS).............................

Vehicle speed sensor (VSS)........................................

Wide open throttle (WOT)............................................

OLD TERM (ACRONYM)

Throttle pedal (-)..........................................................

Air cleaner (-)...............................................................

Air conditioning (AC)....................................................

Battery plus, bat +, bat feed (B+).................................

Closed loop (-).............................................................

Closed throttle, idle position (-)....................................

Charcoal canister purge valve (-).................................

Serial link (-)................................................................

Fault code (-)...............................................................

Electronic ignition (-)....................................................

Electronic control unit (ECU)........................................

Coolant level (-)...........................................................

Coolant temperature (temp).........................................

Coolant temperature thermistor (-)..............................

Engine speed (rev/min)................................................

Evaporative loss system (ELC)...................................

Fuel temperature thermistor (-)....................................

Fourth gear, 3rd gear (-)..............................................

Fuel pump (-)...............................................................

Condenser fan timer (-)................................................

Alternator (-)................................................................

Ground, earth (B-)........................................................

Lambda (02) sensor (-)................................................

Idle speed control (ISC)................................................

Stepper motor (-).........................................................

Ignition module (-)........................................................

Inertia switch (-)...........................................................

Inertia switch (-)...........................................................

Intake temperature/ambient temperature (-)................

EFI warning lamp (-)....................................................

Manifold depression, vacuum (-).................................

Air flow meter (-)..........................................................

Electronic fuel injection (EFI).......................................

Fault code display unit (-)............................................

Open loop (-)...............................................................

Park or neutral (-).........................................................

Start inhibit switch (-)...................................................

Chip, PROM (PROM)...................................................

Relay (-).......................................................................

Check engine light (-)...................................................

Control unit (-)..............................................................

Catalyst, catalytic converter (CAT)..............................

Throttle housing (-)......................................................

Throttle potentiometer (-).............................................

Direct drive clutch (DDC)..............................................

Transmission gear (-)...................................................

Shift lever, shifter (-)....................................................

Road speed transducer (-)...........................................

Full throttle, wide open throttle (WOT).........................

INFORMATION

11

Page 14

01

INTRODUCTION

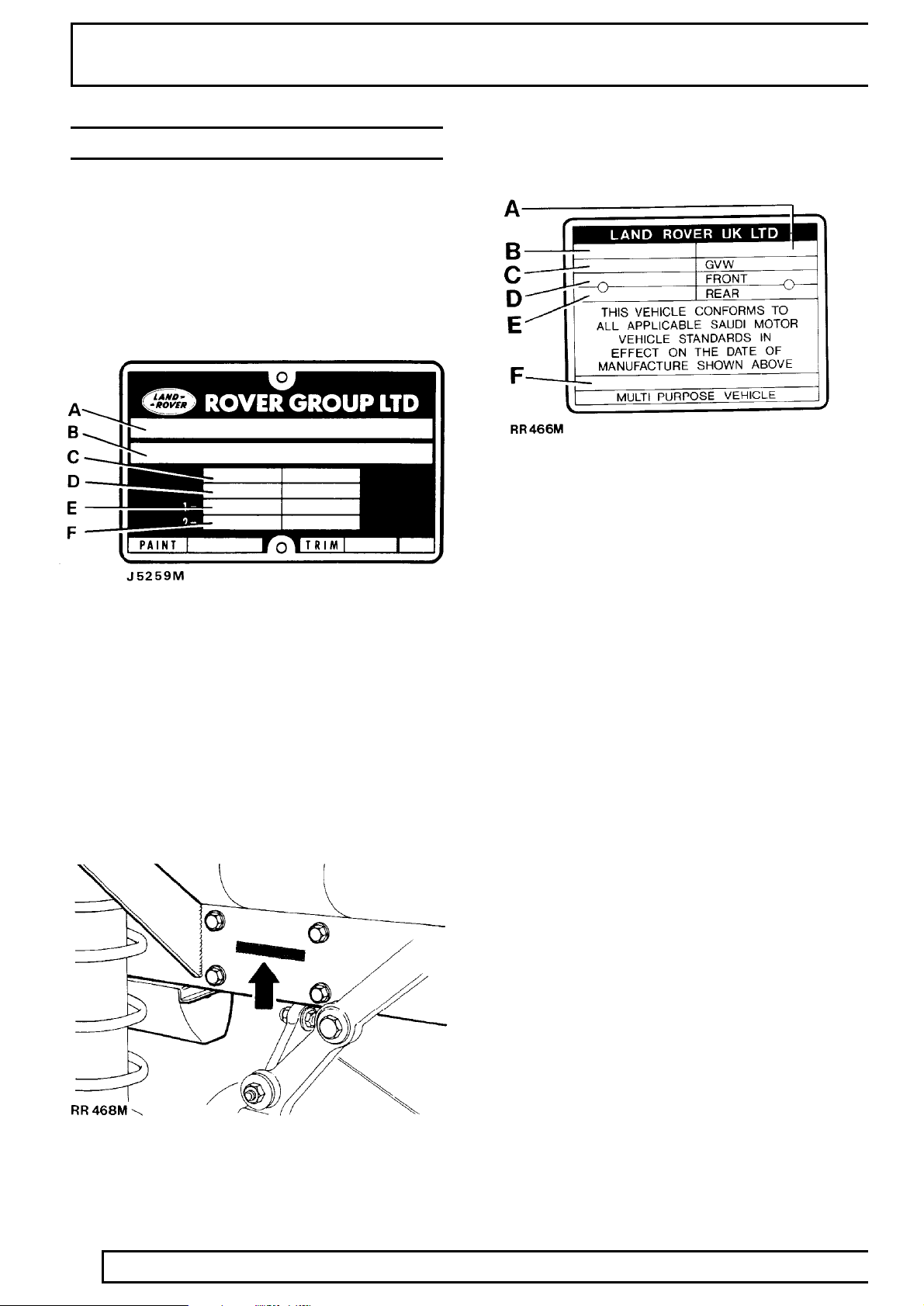

VEHICLE IDENTIFICATION NUMBER (VIN)

The Vehicle Identification Number and the

recommended maximum vehicle weights are stamped

on a plate located under the bonnet [hood] riveted to

the front of the engine compartment.

Vehicle Identification Number Plate (UK, Australia,

R.O.W., Europe)

Vehicle Identification Number Plate (Saudi Arabia)

A. Year of manufacture

B. Month of manufacture

C. Maximum vehicle weight

D. Maximum road weight-front axle

E. Maximum road weight-rear axle

F. VIN (17 digits)

A. Build date (Australia). Type approval

B. VIN (17 digits)

C. Maximum permitted laden weight for vehicle

D. Maximum vehicle and trailer weight

E. Maximum road weight-front axle

F. Maximum road weight-rear axle

The number is also stamped on the right side of the

chassis forward of the spring mounting turret.

The vehicle identification number identifies the

manufacturer, model range, wheel base, body type,

engine, steering, transmission, model year and place

of manufacture. The following example shows the

coding process.

SAL World manufacturer identifier

LH Range Rover or

LJ Discovery

G Class 100 inch

B 2 door

F 300 Tdi or

V V8i Petrol

8 5 speed LHD or

7 5 speed RHD

M 1995 MY

A Solihull site

12

INFORMATION

Page 15

INTRODUCTION

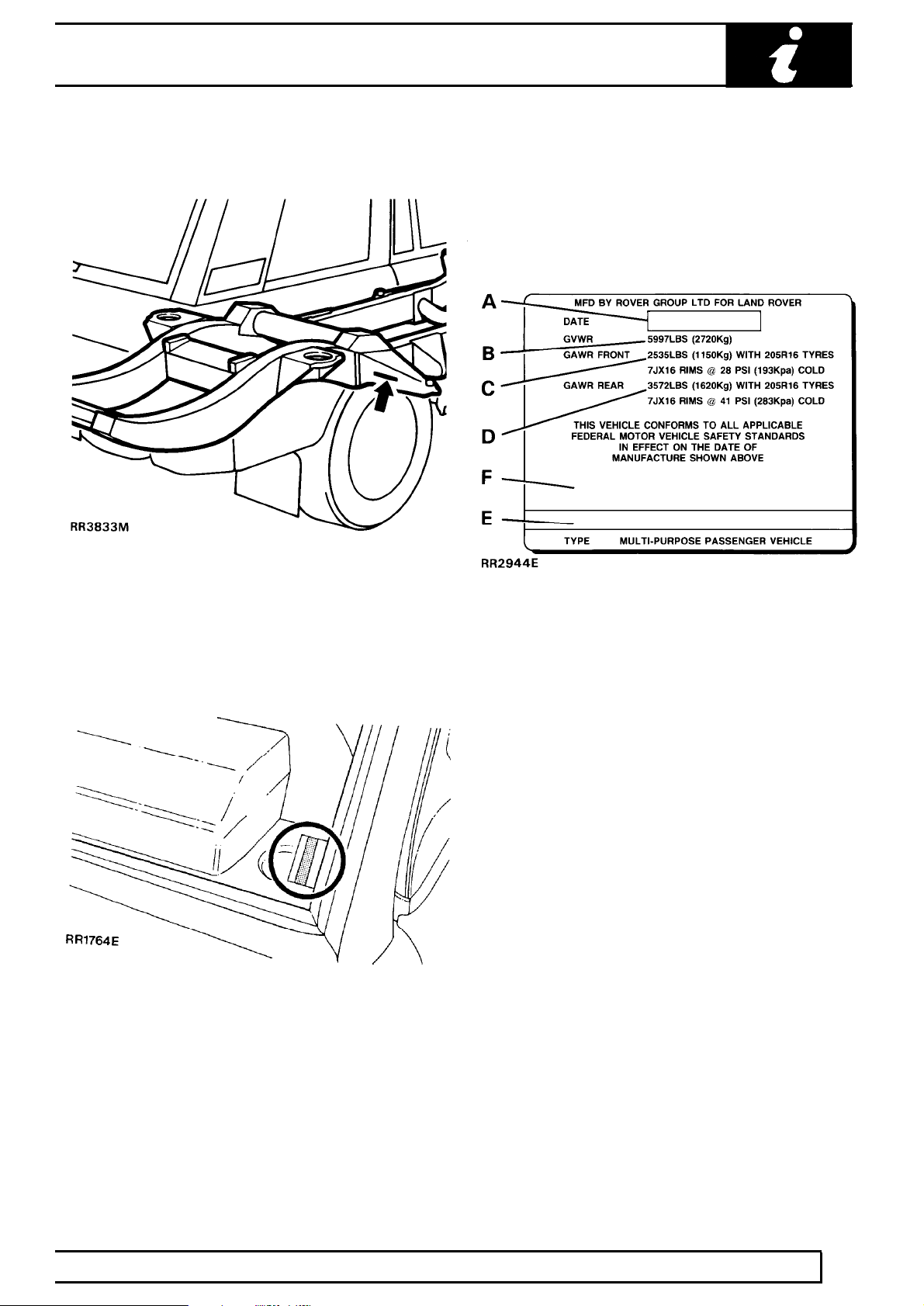

European vehicle identification number (VIN)

Vehicle identification number (VIN)

An adhesive label containing the Vehicle Identification

Number, date of manufacture and gross axle weight

ratings is fixed to the lock face of the front left hand

door. The information includes wheel and tyre sizes

and tyre pressures at gross axle weight ratings.

Stamped on the right hand side chassis forward of

rear wheel.

Federal (USA) vehicle identification number

Stamped on a plate rivetted to the upper left hand ’A’ post, visible through the front screen of the vehicle.

Key to vehicle identification label

A. Month and year of manufacture

B. Gross vehicle weight rating

C. Gross axle weight rating for front axle

D. Gross axle weight rating for rear axle

E. Vehicle identification number (17 digits)

F. Vehicle identification number - bar code

INFORMATION

13

Page 16

01

INTRODUCTION

LOCATION OF IDENTIFICATION NUMBERS

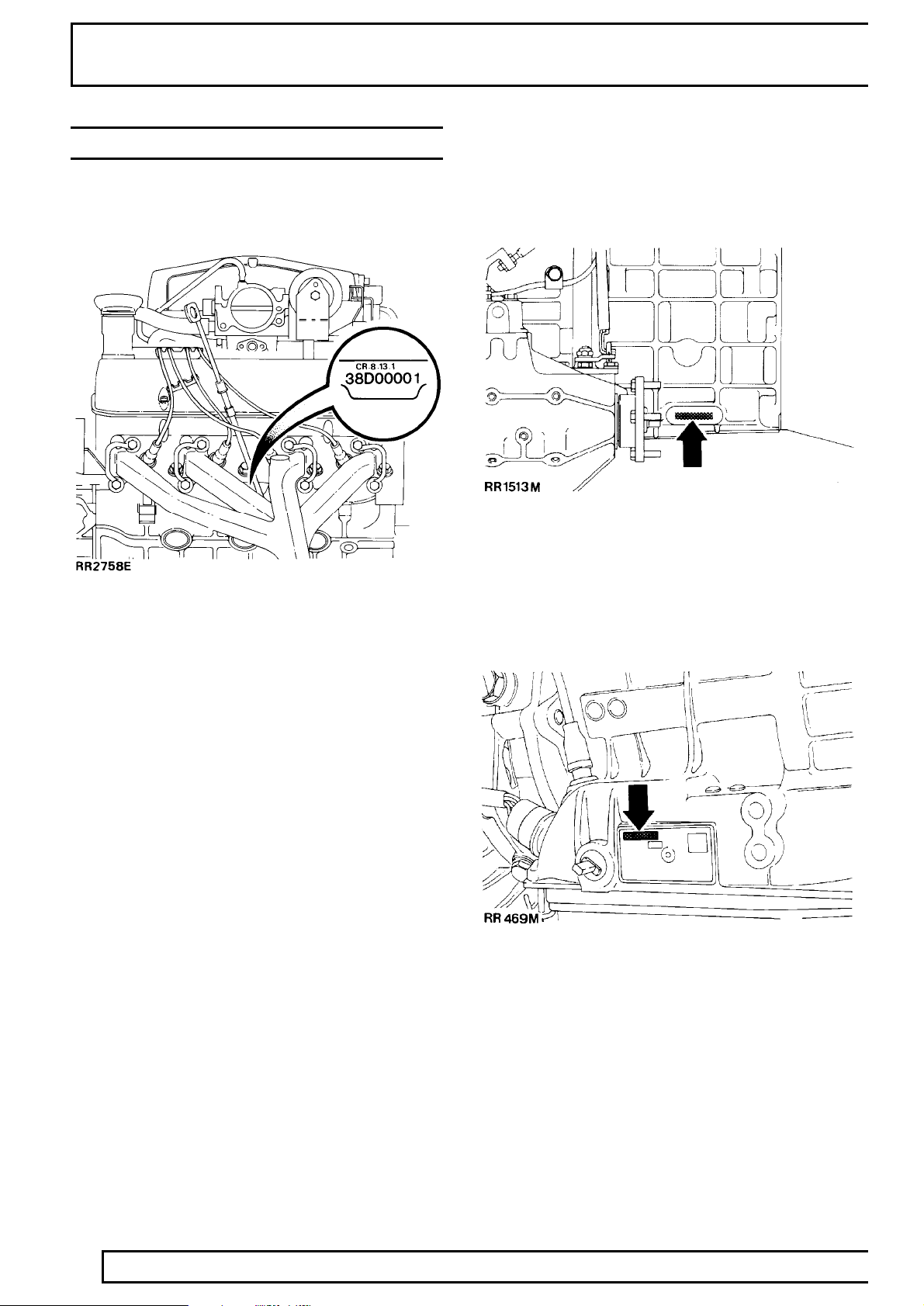

Engine serial number - V8i engine

Stamped on a cast pad on the cylinder block, between

numbers 3 and 5 cylinders.

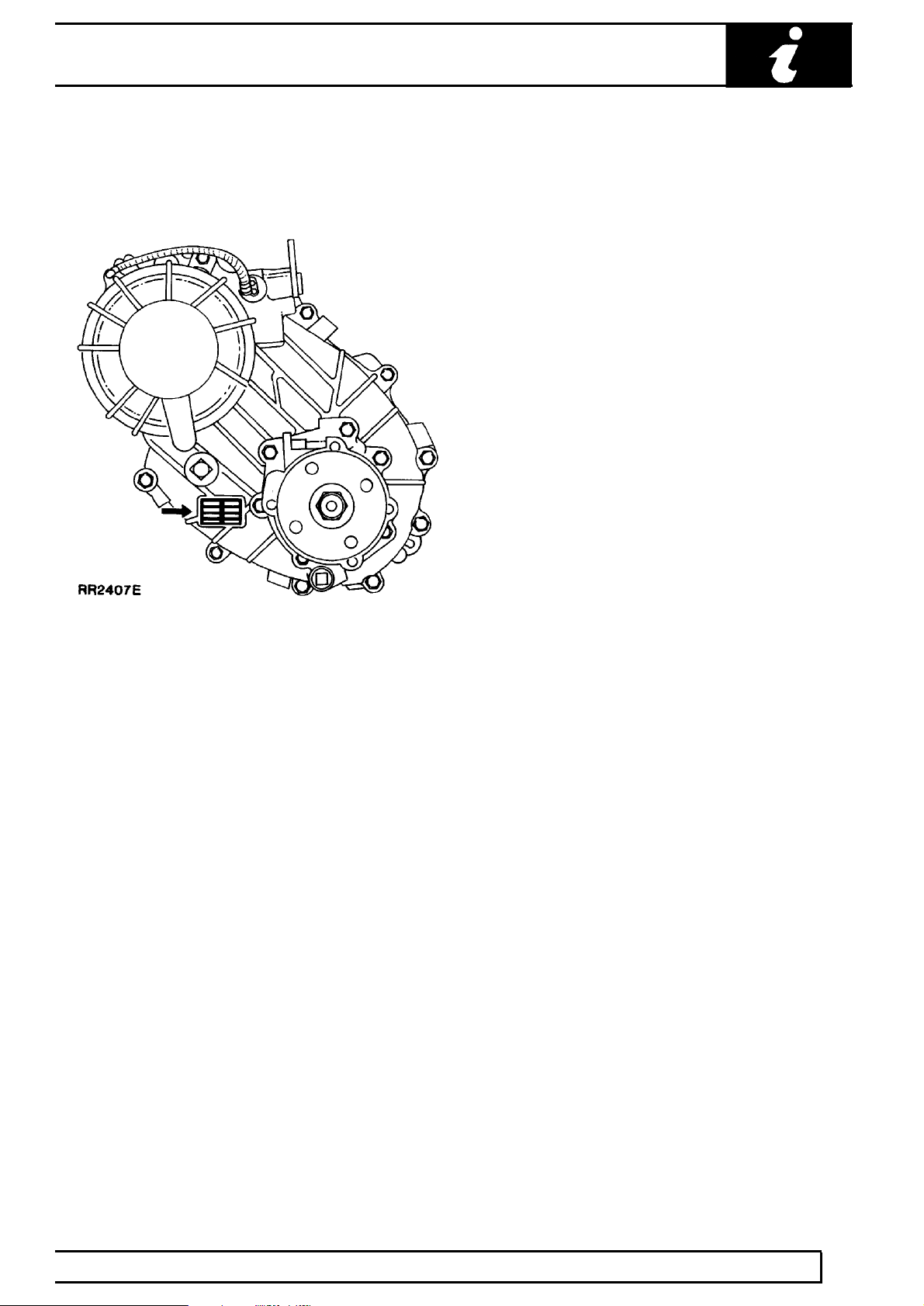

Main gearbox R380

Stamped on a cast pad on the bottom right hand side

of the gearbox.

Automatic gearbox

Engines are identified by the prefix:

3.9 Litre:

35D. - 9.35:1 compression, manual transmission

36D. - 9.35:1 compression, automatic transmission

37D. - 8.13:1 compression, manual transmission

38D. - 8.13:1 compression, automatic transmission

4.2 Litre:

40D. - 8.94:1 compression, automatic transmission

Engine serial number - Diesel engine

Stamped on the RH side of cylinder block above the

camshaft front cover plate.

Stamped on a plate riveted to the bottom left hand

side of the gearbox casing.

14

INFORMATION

Page 17

INTRODUCTION

Transfer gearbox-Borg Warner

Stamped on a plate attached to the gearbox casing,

between filler/level and drain plug.

Front and rear axle

Stamped on the top of the left hand axle tubes.

INFORMATION

15

Page 18

01

INTRODUCTION

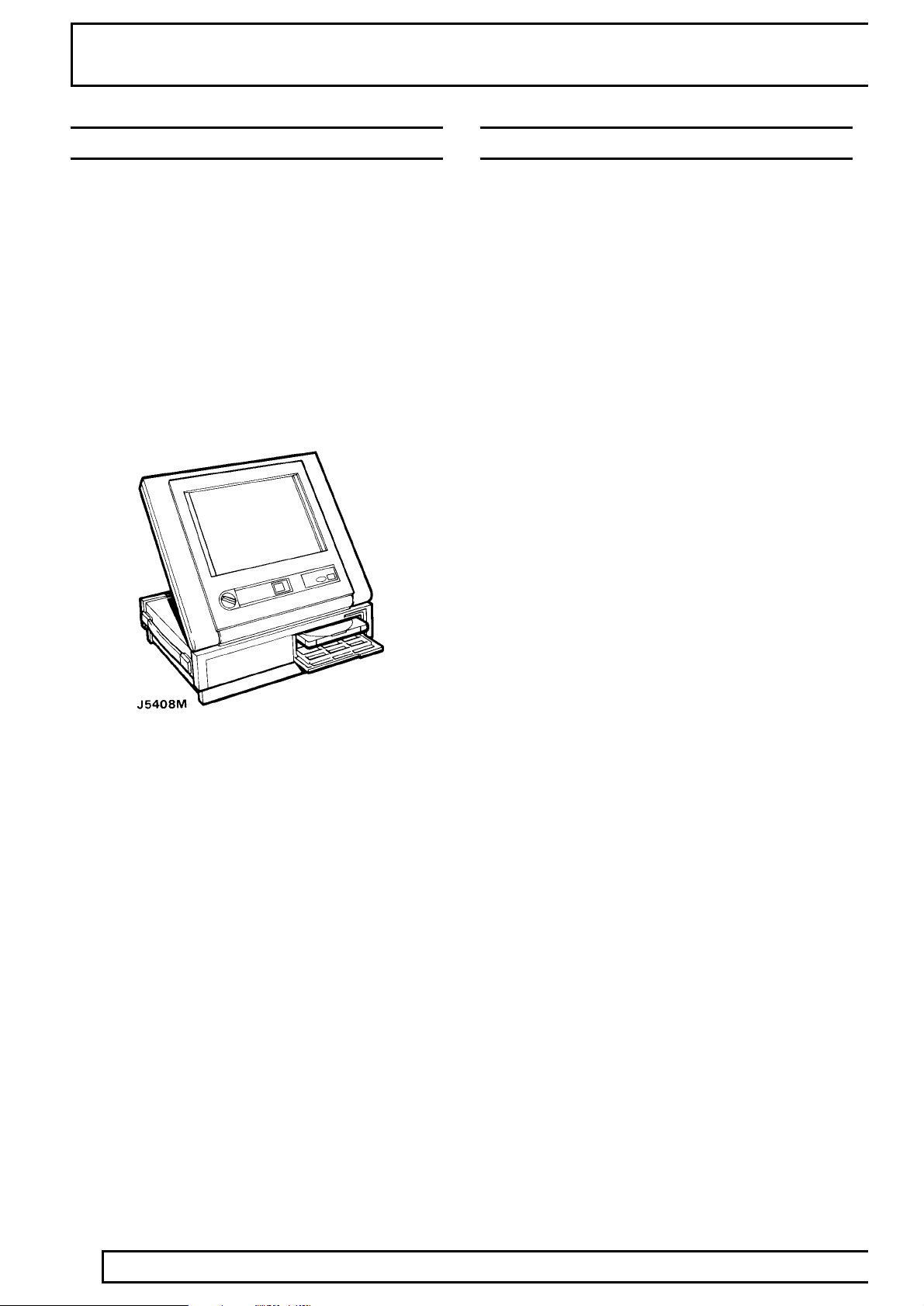

FAULT DIAGNOSTIC EQUIPMENT

TESTBOOK

Todays Land Rover Vehicles are equipped with a

large amount of electronics to provide the best

performance of the vehicles systems.

Diagnostic equipment named TESTBOOK is available

to expand the diagnostic abilities of the dealer

workshop. This repair manual is produced with

Testbook in mind.

Features of Testbook include: - Fully upgradable

support for the technician. Structured diagnostics to

accommodate all skill levels. Touch screen operation.

Direct print out of screen information and test results.

READING THIS MANUAL

This manual is divided into sections shown on the

contents page, alongside a rang of icons, familiar to

service technicians.

Relevant information is contained within each of these

sections. These are further divided into the following

sub-sections which appear at the foot of each page:

Description and operation.

Fault diagnosis.

Adjustment.

Repair.

Overhaul.

Specifications, Torque.

Service tools.

To avoid repeating information through the sections,

where part of the repair operation impacts on another

section, a cross reference is given to direct the reader

to where the information is sited.

For example:

The maintenance section states the need to renew

V8i drive belt. A cross reference sites this information

in: Section: V8i Engine

- Sub-section: Repairs

- Heading: Drive belt renew

ELECTRICAL TROUBLESHOOTING MANUAL

The Electrical Troubleshooting Manual is a separate

publication that is intended for use by trained Land

Rover technicians as an aid to diagnosing electrical

concerns.

It provides circuit diagrams, system diagnosis flow

charts, electrical component location tables, electrical

component location views, and circuit operation

details.

Sections that contain derivatives such as engines are

further separated into within that section.

American terminology

A few words used in this manual differ to words used

in America. Where this occurs the American word is

placed inside brackets. For example: bonnet [hood],

wing [fender], ramp [hoist].

16

INFORMATION

Page 19

GENERAL SPECIFICATION DATA

ENGINE - V8

Type 3.9 litre V8.................................................................................

Number of cylinders Eight, two banks of four.........................................................

Bore 94.00 mm.................................................................................

Stroke 71.12 mm...............................................................................

Capacity 3950 cm

Valve operation Overhead by push-rod................................................................

Compression ratio 8.13:1 or 9.35:1............................................................

Valve operation Overhead by push-rod................................................................

Maximum power: - 8.13:1 127kW at 4550 rev/min............................

Type 4.2 litre V8.................................................................................

Number of cylinders Eight, two banks of four.........................................................

Bore 94.00 mm.................................................................................

Stroke 77.00 mm...............................................................................

Capacity 4275 cm

Valve operation Overhead by push-rod................................................................

Compression ratio 8.94:1............................................................

Valve operation Overhead by push-rod................................................................

Maximum power 149kWat 4850 rev/min...............................................................

...........................................................................

- 9.35:1 134kW at 4750 rev/min............................

...........................................................................

3

3

Crankshaft

Main journal diameter 58.409-58.422 mm.......................................................

Minimum regrind diameter 57.393-57.406mm...............................................

Crankpin journal diameter 50.800-50.812 mm................................................

Minimum regrind diameter 49.784-49.797mm...............................................

Crankshaft end thrust Taken on thrust washers of centre main bearing.......................................................

Crankshaft end float 0.10-0.20 mm.........................................................

Main bearings

Number and type 5, Vandervell shells..............................................................

Material Lead-indium............................................................................

Diametrical clearance 0.010-0.048 mm.......................................................

Undersize bearing shells 0.254 mm, 0.508 mm..................................................

Connecting rods

Type Horizontally split big-end, plain small-end.................................................................................

Length between centres 143.81-143.71 mm...................................................

Big-end bearings

Type and material Vandervell VP lead-indium............................................................

Diametrical clearance 0.015-0.055 mm.......................................................

End-float crankpin 0.15-0.36mm............................................................

Undersize bearing shells 0.254 mm, 0.508 mm..................................................

Piston pins

Length 72.67-72.79 mm..............................................................................

Diameter 22.215-22.220 mm..........................................................................

Fit-in connecting rod Press fit.........................................................

Clearance in piston 0.002-0.007 mm..........................................................

INFORMATION

1

Page 20

04

Pistons

Clearance in bore, measured at bottom

of skirt at right angles to piston pin 0.018-0.041 mm...................................

Piston rings

Number of compression rings 2..........................................

Number of control rings 1....................................................

No 1 compression ring Molybdenum barrel faced.....................................................

No 2 compression ring Tapered and marked ’T’ or ’TOP’.....................................................

Width of compression rings 1.478-1.49 mm..............................................

Compression ring gap 0.40-0.65 mm......................................................

Oil control ring type Hepworth and Grandage..........................................................

Oil control ring width 3.0 mm.........................................................

Oil control ring rail gap 0.38-1.40 mm.....................................................

Camshaft

Location Central...........................................................................

Bearings Tin-aluminium...........................................................................

Number of bearings 5..........................................................

Drive Chain 9.52 mm pitch x 54 pitches..................................................................................

GENERAL SPECIFICATION DATA

Tappets Hydraulic self-adjusting...........................................................................

Valves

Length: Inlet 116.59-117.35 mm..................................

Exhaust 116.59-117.35 mm...........................

Seat angle: Inlet 45°- 45 1/2°..................................

Exhaust 45°- 45 1/2°...........................

Head diameter: Inlet 39.75-40.00 mm..................................

Exhaust 34.226-34.480 mm...........................

Stem diameter: Inlet 8.664-8.679 mm..................................

Exhaust 8.651-8.666 mm...........................

Stem to guide clearance: Inlet 0.025-0.066 mm..................................

Exhaust 0.038-0.078 mm...........................

Valve lift (Inlet and Exhaust) 9.49 mm............................................

Valve spring length fitted 40.4 mm at pressure of 29.5 kg..................................................

Lubrication

System type Wet sump, pressure fed.....................................................................

Oil pump type Eccentric rotor...................................................................

Oil pressure 2.75 bar (40 lbf/in2) at 2500 rev/min with engine at......................................................................

Oil filter-internal Wire screen, pump intake filter in sump................................................................

Oil filter-external Full flow, self-contained cartridge...............................................................

running temperature

INFORMATION

2

Page 21

GENERAL SPECIFICATION DATA

ENGINE - 300Tdi

Type Direct injection, turbocharged, intercooled.................................................................................

Number of cylinders 4.........................................................

Bore 90,47 mm.................................................................................

Stroke 97,00 mm...............................................................................

Capacity 2495 cm

Compression ratio 19.5:1 ± 0.5:1............................................................

Valve operation O.H.V. pushrod operated................................................................

Turbo charger Garrett T25..................................................................

Crankshaft

Main bearing journal diameter 63,475 - 63,487 mm..........................................

Regrind dimensions 63,2333 - 63,246 mm.........................................................

Crankpin journal diameter 58,725 - 58,744 mm................................................

Regrind dimensions 58,4708 - 58,48985 mm.........................................................

Crankshaft end thrust Taken on thrust washers at centre main bearing.......................................................

Crankshaft end float 0,05 - 0,15 mm.........................................................

...........................................................................

Use 0.010 in U/S bearings

Use 0.010 in U/S bearings

3

Main bearings

Number and type 5 halved shells with oil grooves..............................................................

Diametrical clearance 0,0792 - 0,0307 mm.......................................................

Connecting rods

Length between centres 175,38 - 175,43 mm...................................................

Diametrical clearance (big-end bearings) 0,025 - 0,075 mm........................

End float on crankpin 0,15 - 0,356 mm.......................................................

Pistons

Type Aluminium alloy, combustion chamber in crown.................................................................................

Skirt diametrical clearance

(at right angle to gudgeon pin) 0,025 - 0,05 mm.........................................

Maximum height above combustion face 0,8 mm.........................

Gudgeon pins

Type Floating.................................................................................

Fit in piston Hand push fit.......................................................................

Diameter 30,1564 - 30,1625 mm..........................................................................

Clearance in connecting rod 0,0025 - 0,0163 mm............................................

INFORMATION

3

Page 22

04

Piston rings

Type:

- Top Barrel edge, chrome plated........................................................................

- Second Taper faced..................................................................

- Oil control Expander and rails..............................................................

Gap in bore:

- Top 0,40 - 0,60 mm........................................................................

- Second 0,30 - 0,50 mm..................................................................

- Oil control 0,3 - 0,6 mm..............................................................

Clearance in piston grooves:

- Top 0,167 - 0,232 mm........................................................................

- Second 0,05 - 0,08 mm..................................................................

- Oil control 0,05 - 0,08 mm..............................................................

Camshaft

Drive 30 mm (1.2 in) wide dry toothed belt.................................................................................

Location Right hand side (thrust side)...........................................................................

End float 0,1 - 0,2 mm...........................................................................

Number of bearings 4..........................................................

Material Steel shell, white metal lined............................................................................

GENERAL SPECIFICATION DATA

Valves

Tappet clearance:

- Inlet and exhaust 0,20 mm...................................................

Seat angle:

- Inlet 30°.......................................................................

- Exhaust 45°.................................................................

Head diameter:

- Inlet 39,75 - 39,05 mm.......................................................................

- Exhaust 36,35 - 36,65 mm.................................................................

Stem diameter:

- Inlet 7,960 - 7,975 mm.......................................................................

- Exhaust 7,940 - 7,960 mm.................................................................

Valve lift:

- Inlet 9,67 mm.......................................................................

- Exhaust 9.97 mm.................................................................

Cam lift:

- Inlet 6,81 mm.......................................................................

- Exhaust 7,06 mm.................................................................

Valve head stand down:

- Inlet 0,81 - 1,09 mm.......................................................................

- Exhaust 0,86 - 1,14 mm.................................................................

Valve springs

Type Single coil.................................................................................

Length, free 46,28 mm......................................................................

Length, under 21 kg (46 lb) load 40,30mm......................................

INFORMATION

4

Page 23

GENERAL SPECIFICATION DATA

Lubrication

System Wet sump, pressure fed.............................................................................

Pressure, engine warm at normal operating speeds 1.7-3.8 bar (25 - 55 lbf/in2)........

Oil pump:

- Type Double gear 10 teeth, sintered iron gears......................................................................

- Drive Splinedshaft from camshaft skew gear.....................................................................

- End float of both gears 0,026 - 0,135 mm..........................................

- Radial clearance of gears 0,025 - 0,075 mm.....................................

- Backlash of gears 0,1 - 0,2 mm.................................................

Oil pressure relief valve Non-adjustable....................................................

Relief valve spring:

- Full length 51.6 mm.............................................................

- Compressed length at 7.71 kg load 31.0 mm......................

Oil filter Screw-on disposable canister.............................................................................

Engine oil cooler Combined with coolant radiator and intercooler...............................................................

INFORMATION

5

Page 24

04

FUEL SYSTEM - V8 Engine

Fuel system type Lucas 14CUX hot wire system electronicallycontrolled..............................................................

Fuel pump-make/type High pressure electrical, immersed in the fuel tank......................................................

Fuel pump delivery pressure 2.4-2.6bar(34-37 lbf/in2)............................................

Fuel filter Bosch in-line filter ’canister’ type..........................................................................

Airflow Sensor

Make and type Lucas ’Hot Wire’ 5AM.................................................................

Injectors

Make and type Lucas 8NJ.................................................................

Electronic Control Unit

Make and type Lucas 14CUX.................................................................

Fuel pressure regulator

Make and type Lucas 8RV.................................................................

GENERAL SPECIFICATION DATA

Fuel temperature sensor

Make and type Lucas 6TT.................................................................

Coolant temperature sensor

Make and type Lucas 3TT.................................................................

Bypass Air valve (Stepper motor)

Make and type Lucas 2ACM.................................................................

Throttle potentiometer

Make and type Lucas 215SA.................................................................

Lambda sensor - catalyst vehicles

Make and type Lucas 3LS.................................................................

FUEL SYSTEM - 300Tdi Engine

Injection pump type Bosch rotary VE4/11F.

Injectors

Heater plugs

Fuel lift pump type Mechanical with hand primer............................................................

Fuel lift pump pressure 0.4 - 0.55 bar (6 - lbf/in2) at 1800 rpm.....................................................

Fuel filter Paper element in disposable canister..........................................................................

Air cleaner Paper element type........................................................................

Turbocharger Garrett T25.

...........................................................................

.....................................................................

..........................................................

...................................................................

Information, Engine - 300Tdi

See ENGINE TUNING DATA, Information, Engine

- 300Tdi

See ENGINE TUNING DATA, Information, Engine

- 300Tdi

See ENGINE TUNING DATA,

Information, Engine - 300Tdi

See ENGINE TUNING DATA,

INFORMATION

6

Page 25

GENERAL SPECIFICATION DATA

COOLING SYSTEM - V8 ENGINE

Type Pressurized system with cross- flow radiator and.................................................................................

Type of pump Centrifugal...................................................................

Thermostat 88°C.......................................................................

Expansion tank cap pressure (system pressure) 1.0 bar (15 lbf/in2).............

COOLING SYSTEM - 300Tdi ENGINE

System type Pressurised, spill return, thermostatically controlled.....................................................................

Cooling fan 11 blade axial flow 433 mm diameter. 1.29:1 drive.......................................................................

Pump type Centrifugal, impeller, belt driven.........................................................................

Thermostat opening 88°C.........................................................

Expansion tank cap pressure (system pressure) 1.0 bar (15 lbf/in2).............

remote header tank, thermostat control, pump and fan

assisted

water and anti freeze mixture. Pump assisted thermo

syphon. Coolant radiator combined with oil cooler and

turbo intercooler.

ratio. Viscous coupling.

TRANSMISSION

Clutch

Make and type - V8 engine Borg and Beck, diaphragm spring..............................................

Clutch plate diameter 266.5mm.......................................................

Make and type - Diesel engine Valeo, diaphragm spring.........................................

Clutch plate diameter 235mm.......................................................

Transfer gearbox

Borg Warner Two speed reduction on main gearbox output, front.....................................................................

Transfer gearbox ratios

High 1.206:1..................................................................................

Low 3.244:1..................................................................................

Manual gearbox

Type R380 5 speed, single helical constant mesh with.......................................................................

and rear drive permanently engaged via a centre

differential controlled by a Viscous unit giving a 50/50

nominal front and rear torque split.

synchromesh on all forward gears

INFORMATION

7

Page 26

04

Manual gearbox ratios:

5th 0.731:1...........................................................................

4th 1.000:1...........................................................................

3rd 1.397:1...........................................................................

2nd 2.132:1..........................................................................

1st 3.321:1...........................................................................

Reverse 3.429:1...................................................................

Diesel models low first gear 3.692:1....................................

Overall ratio (final drive): High transfer Low transfer

5th 3.119:1........................................................................... 8.39:1

4th 4.267:1........................................................................... 11.476:1

3rd 5.959:1........................................................................... 16.027:1

2nd 9.095:1.......................................................................... 24.462:1

1st 14.172:1........................................................................... 38.115

Reverse 14.629:1................................................................... 39.346:1

Diesel models low 1st gear 15.750:1..................................... 42.362

Automatic gearbox

Model ZF4HP22...............................................................................

Type Four speed and reverse epicyclic gears with fluid.................................................................................

GENERAL SPECIFICATION DATA

torque converter and lock up.

Automatic gearbox ratios

4th 0.728:1...........................................................................

3rd 1.000:1...........................................................................

2nd 1.480:1..........................................................................

1st 2.480:1...........................................................................

Reverse 2.086:1...................................................................

Overall ratio (final drive): High transfer Low transfer

4th 3.11:1........................................................................... 8.36:1

3rd 4.27:1........................................................................... 11.48:1

2nd 6.32:1.......................................................................... 17.00:1

1st 10.59:1........................................................................... 28.50:1

Reverse 8.91:1................................................................... 23.96:1

INFORMATION

8

Page 27

GENERAL SPECIFICATION DATA

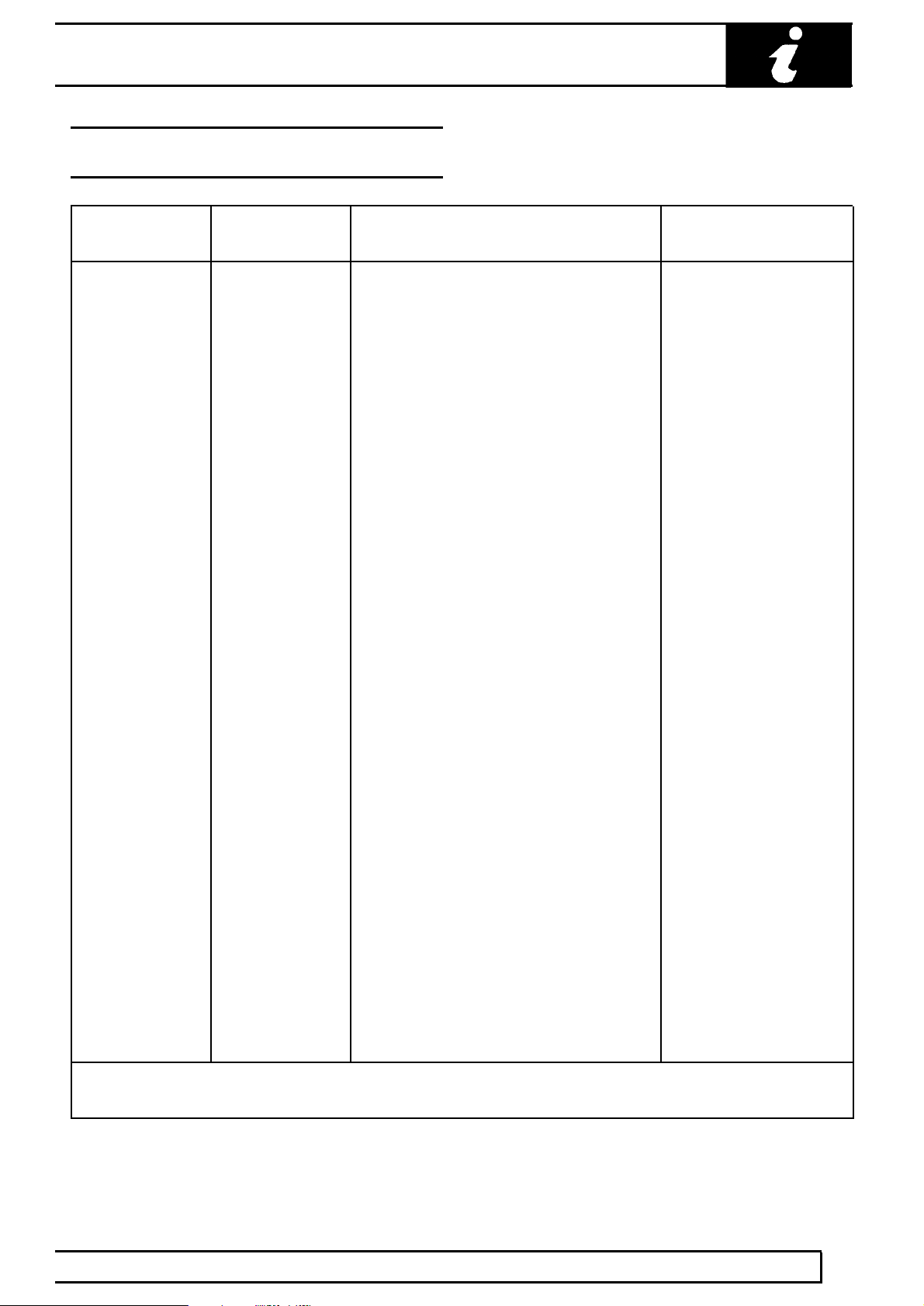

SHIFT SPEED SPECIFICATION - AUTOMATIC ZF4HP22 GEARBOX

OPERATION SELECTOR VEHICLE SPEED ENGINE SPEED

POSITION APPROX APPROX (RPM)

KICKDOWN

MPH KPH

KD4 - 3 D 84 - 92 136 - 150

KD3 - 2 3(D) 57 - 62 91 - 99

KD2 - 1 2(D,3) 27 - 34 44 - 56

KD3 - 4 D N/A N/A

KD2 - 3 D(3) 60 - 63 96 - 104 4750 - 5200

KD1 - 2 D(3,2) 34 - 40 56 - 64 4600 - 5250

FULL THROTTLE

FT4 - 3 D 61 - 67 98 - 108

FT3 - 2 3(D) 40 - 46 64 - 73

FT3 - 4 D 74 - 80 119 - 129 3980 - 4330

FT2 - 3 D(3) 55 - 60 88 - 96 4350 - 4800

T1 - 2 D(3,2) 29 - 34 48 - 56 3950- 465

PART THROTTLE

PT4 - 3 D 47 - 54 75 - 86

PT3 - 2 D(3) 29 - 37 48 - 59

PT2 - 1 D(3,2) 10 - 12 16 - 19

LIGHT THROTTLE

LT3 - 4 D 26 - 30 43 - 49 1430 - 1650

LT2 - 3 D(3) 18 - 22 29 - 35 1420 - 1820

LT1 - 2 D(3,2) 9 - 10 14 - 16 1180 - 1220

ZERO THROTTLE

ZT4 - 3 D 19 - 25 31 - 41

ZT3 - 2 D(3) 12 - 15 19 - 24

ZT2 - 1 D(3,2) 6 - 7 10 - 11

TORQUE CONVERTER

Lock up (IN) D 51 - 54 81 - 86 1875 - 2000

Unlock (OUT) D 49 - 52 78 - 83 1825 - 1930

Note: The speeds given in the above chart are approximate and only intended as a guide. Maximum shift

changes should take place within these tolerance parameters.

INFORMATION

9

Page 28

04

Propeller shafts

Type

Front Tubular 51mm diameter.................................................................................

Front - Catalyst vehicles Solid bar 28.6mm diameter...................................................

Rear Tubular 51mm diameter.................................................................................

Universal joints Open type Hooks O3EHD.................................................................

Rear axle

Type Spiral bevel, fully floating shafts.................................................................................

Ratio 3.54:1.................................................................................

Front axle

Type Spiral bevel, enclosed constant velocity joints,.................................................................................

Ratio 3.54:1.................................................................................

STEERING

GENERAL SPECIFICATION DATA

fully floating shafts

Power steering box

Make/type AdwestVaramatic- worm and roller box........................................................................

Ratio Variable: straight ahead 19.3:1 on lock 17.2:1.................................................................................

Steering wheel turns, lock-to-lock 3.375....................................

Steering pump

Make/type:

V8 engine ZF ’UNICORN’.........................................................................

Diesel engine Hobourn-Eaton series 500...................................................................

Operating pressure - straight ahead position - at idle 7 bar (100 p.s.i.) maximum......

Full lock (left or right) at idle 28 bar (400 p.s.i.) minimum.............................................

Full lock (left or right) 1000 rev/min 70-77 bar (1000-1100 p.s.i.)..................................

Steering geometry

Steering wheel diameter 406.4mm..................................................

Toe-out measurement 0 to 2mm toe out......................................................

Toe-out included angle 0°to 0°16’.....................................................

Camber angle 0°C.................................................................. Check with vehicle in static

unladen condition, that is,

vehicle with water,

Castor angle 3°..................................................................... oil and five gallons of fuel.

Rock the vehicle up and

down at the front to allow

Swivel pin inclination static 7°............................................... it to take up a position

10

INFORMATION

Page 29

GENERAL SPECIFICATION DATA

SUSPENSION

Type:

- Coil spring suspension Coil springs controlled by telescopic dampers front..........................................

- Air suspension Air springs controlled by an ECU providing variable......................................................

Front Lateral location of axle by Panhard rod, and.................................................................................

Rear Lateral location of axle by a centrally positioned ’A’.................................................................................

SHOCK ABSORBERS

and rear.

rate springs and 5 height settings.

longitudinal location by two radius arms.

frame bolted at the apex to a ball joint mounting.

Coil spring suspension: A levelling unit is positioned

between the ball joint and upper cross member.

Longitudinal location of axle by two tubular trailing

links.

Type Telescopic, double-acting non-adjustable.................................................................................

Bore diameter 35.47mm...................................................................

INFORMATION

11

Page 30

04

ROAD SPRING DATA

V8i

LEFT HAND DRIVE Part No. Colour Code

Left hand front NRC4306 Blue/White

Right hand front 572315 Blue

Left hand rear ANR 3519 Brown/Red

Right hand rear ANR 3520 Brown/Yellow

Heavy duty rear NRC 4304 Red/White

RIGHT HAND DRIVE

Left hand front 572315 Blue

Right hand front 572315 Blue

Left hand rear ANR 3520 Brown/Yellow

Right hand rear ANR 3520 Brown/Yellow

Heavy duty rear NRC 4304 Red/White

GENERAL SPECIFICATION DATA

Tdi Diesel

LEFT HAND DRIVE Part No. Colour Code

Left hand front NTC 8476 White/Blue/Pink

Right hand front NRC 8477 Green/Blue/Yellow

Left hand rear ANR 3519 Brown/Red

Right hand rear ANR 3520 Brown/Yellow

Heavy duty rear NRC 4304 Red/White

RIGHT HAND DRIVE

Left hand front NRC 8477 Green/Blue/Yellow

Right hand front NRC 8477

Left hand rear ANR 3520 Brown/Yellow

Right hand rear ANR 3520

Heavy duty rear NRC 4304 Red/White

12

INFORMATION

Page 31

GENERAL SPECIFICATION DATA

BRAKES

Front service brake

Type Outboard discs with four piston calipers.................................................................................

Operation Hydraulic, servo assisted self-adjusting.........................................................................

Pad material Ferodo 3440 non asbestos.....................................................................

Rear service brake

Type Outboard discs with two piston calipers.................................................................................

Operation Hydraulic, servo assisted, self-adjusting.........................................................................