Page 1

.-

-... .

..1.

..~.

.

,.

I.

._

,

..:.::

. . ..

425DDEFENDER

.

90.110

130

1,

WORKSHOP MANUAL SUPPLEMENT

Publication Number SLR 621 EN WS 2

Published by the

Technical Publications Department

@

Copyright Land Rover 1991

of

DEFENDER

LT77S GEARBOX

Land Rover

Lode Lane

Solihull

West Midlands, 892 8NW

England

Page 2

Page 3

.....

......

.....

.....

....

.....

.

....)I

....

37

.

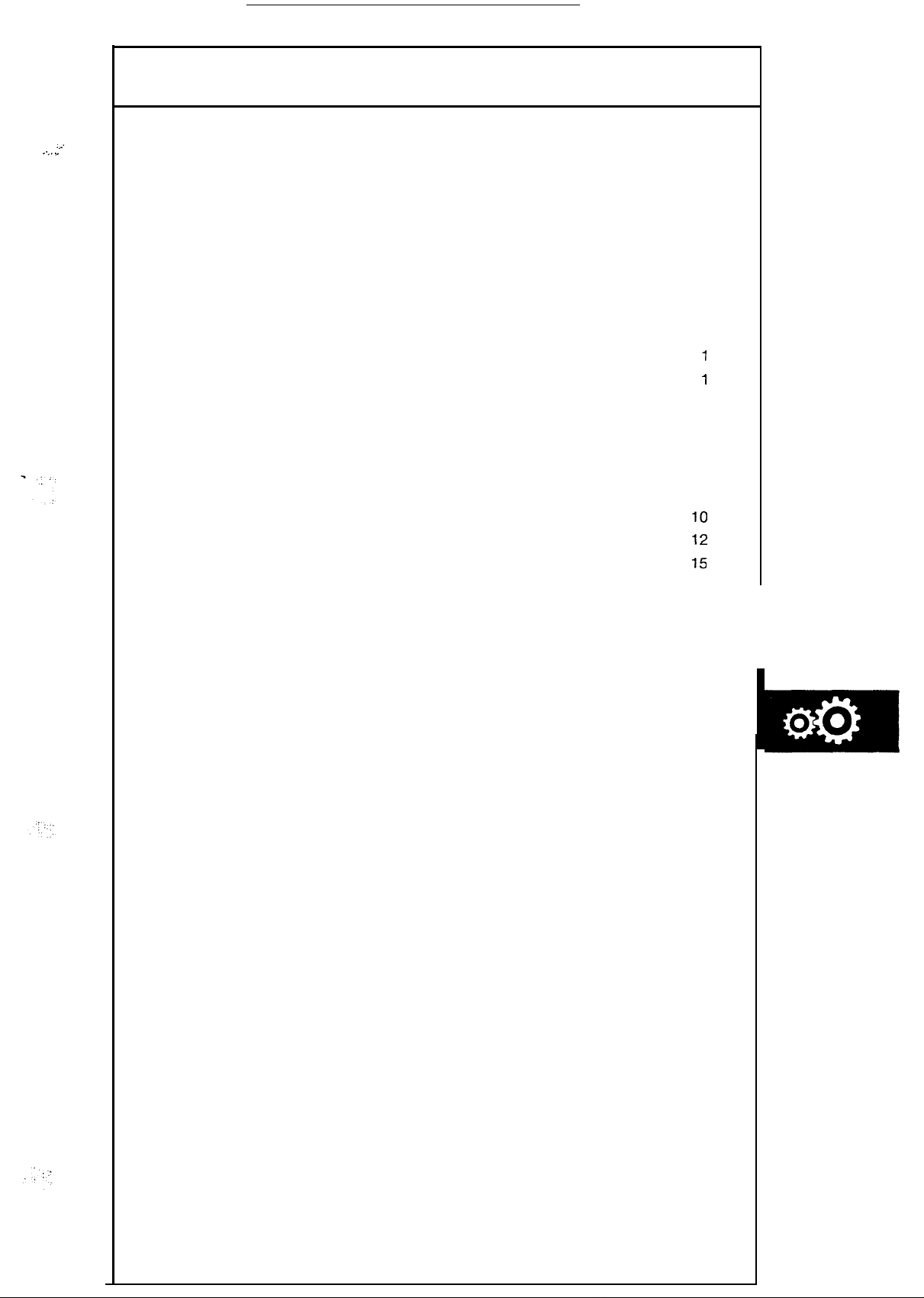

MANUAL

.*.

GEARBOX

CONTENTS

Page

OVERHAUL

DISMANTLE

GEAR SELECTOR HOUSING

EXTENSION HOUSING

MAINSHAFT AND LAYSHAFT FIFTH GEARS

REVERSE SHAFT, LAYSHAFT AND MAINSHAFT

DISMANTLE MAINSHAFT

GEARBOX CASINGS AND OIL PUMP

GEAR CHANGE HOUSING

GEAR SELECTOR HOUSING

SYNCHROMESH ASSEMBLIES

CHECKING BAULK RING CLEARANCES

INPUT SHAFT

MAINSHAFT

MAINSHAFT GEAR END FLOAT CHECKS

ASSEMBLING MAINSHAFT

LAYSHAFT

REVERSE GEAR AND SHAFT

SELECTORS

ASSEMBLING GEARBOX SHAFTS TO CENTRE PLATE

FITTING GEARBOX CASING

FITTING FIFTH GEAR

FIFTH GEAR SELECTOR FORK ASSEMBLY

EXTENSION CASE

INPUT

-

MAINSHAFT BEARING ADJUSTMENT

LAYSHAFT BEARING ADJUSTMENT

GEAR LEVER AND REMOTE HOUSING ASSEMBLY

BELL HOUSING

BELL HOUSING

.....................................................................................................

..........................................................................

....................................................................................

..................................................

...........................................

................................................................................

.............................................................

............................................................................

........................................................................

....................................................................

......................................................

................................................................................................

...................................................................................................

....................................................

...........................................................................

.....................................................................................................

......................................................................

..................................................................................................

.........................................................................

....................................................................................

................................................

........................................................................................

..............................................

............................................................

...................................

-

FOUR CYLINDER ENGINE

-

V8 ENGINE

.......................................................................

...............................................

..............................

1

1

2

3

5

7

8

10

12

15

17

18

18

19

21

23

23

24

25

27

28

30

31

32

32

33

35

35

SPECIFICATIONS. TORQUE

DATA

TORQUE VALUES

SERVICE TOOLS

SERVICE TOOLS

...............................................................................................................

...........................................................................................

.............................................................................................

1

1

1

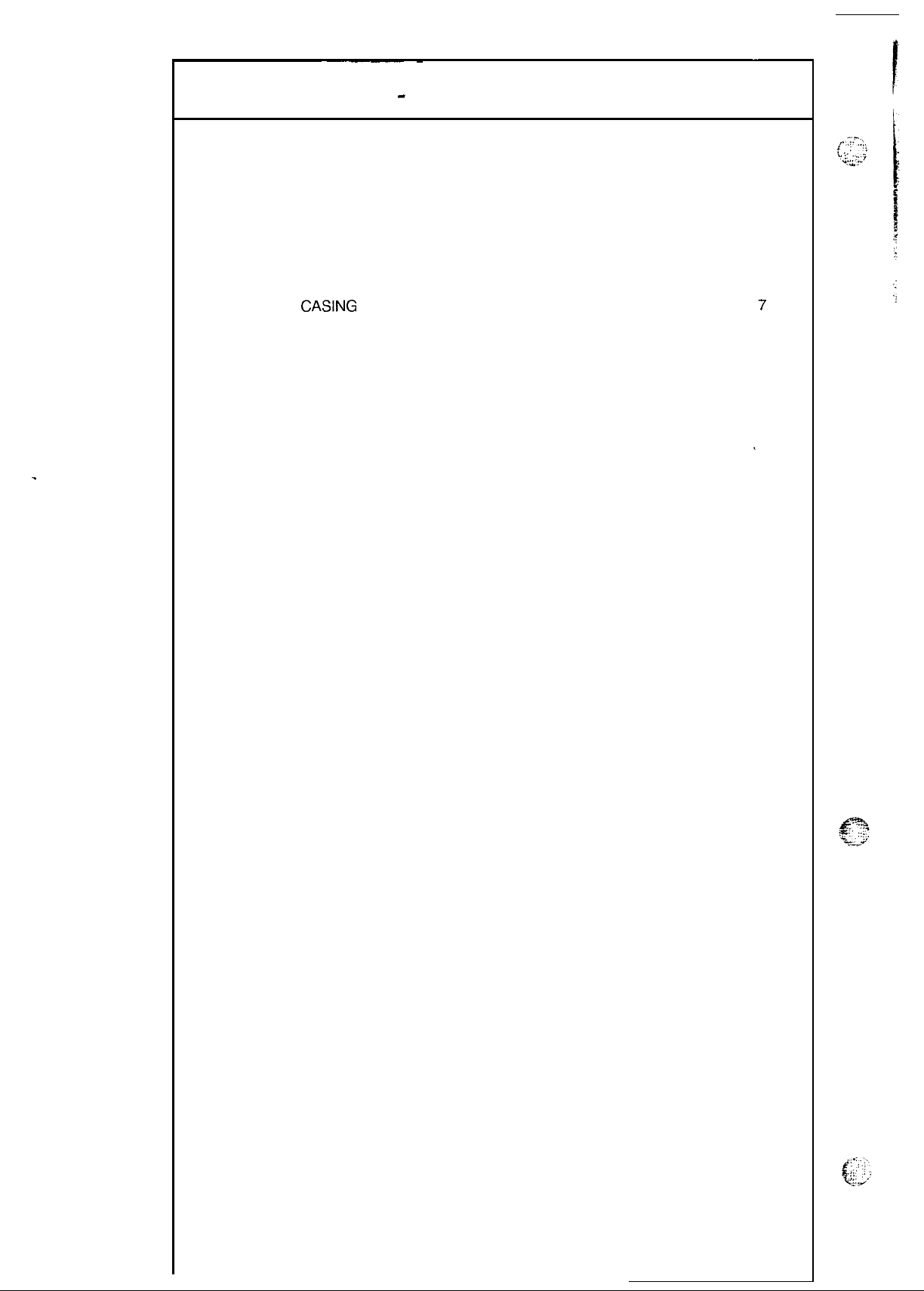

Page 4

37

~

-

MANUAL

CONTENTS

~~

GEARBOX

Page

LOCALLY MANUFACTURED TOOLS

GEARS

GEARBOX

AND SHAFTS

CASING

.........................................................................................

.....................................................................................

..............................................................

3

5

7

Page 5

LT77S

-

I.

2

I.

r

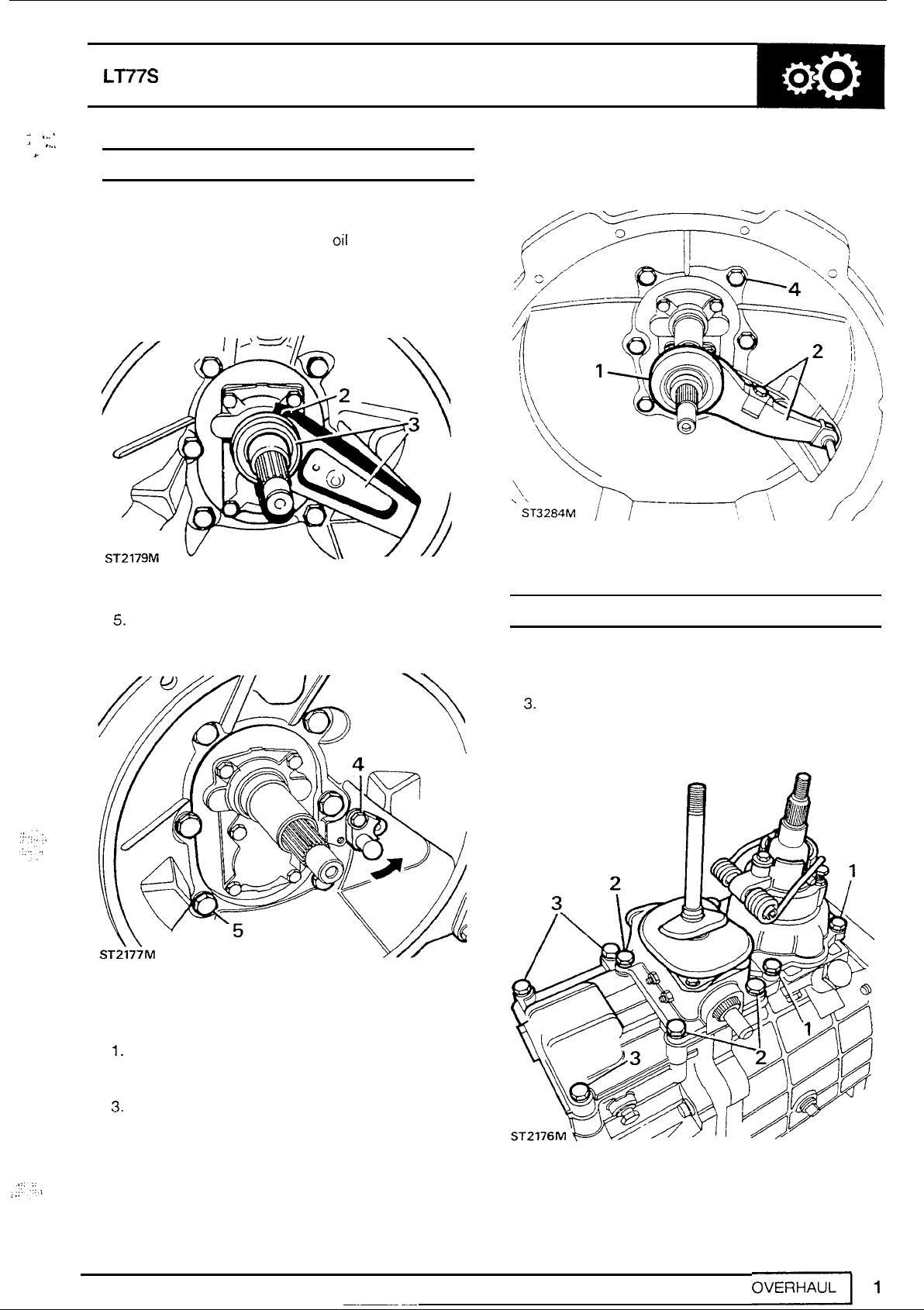

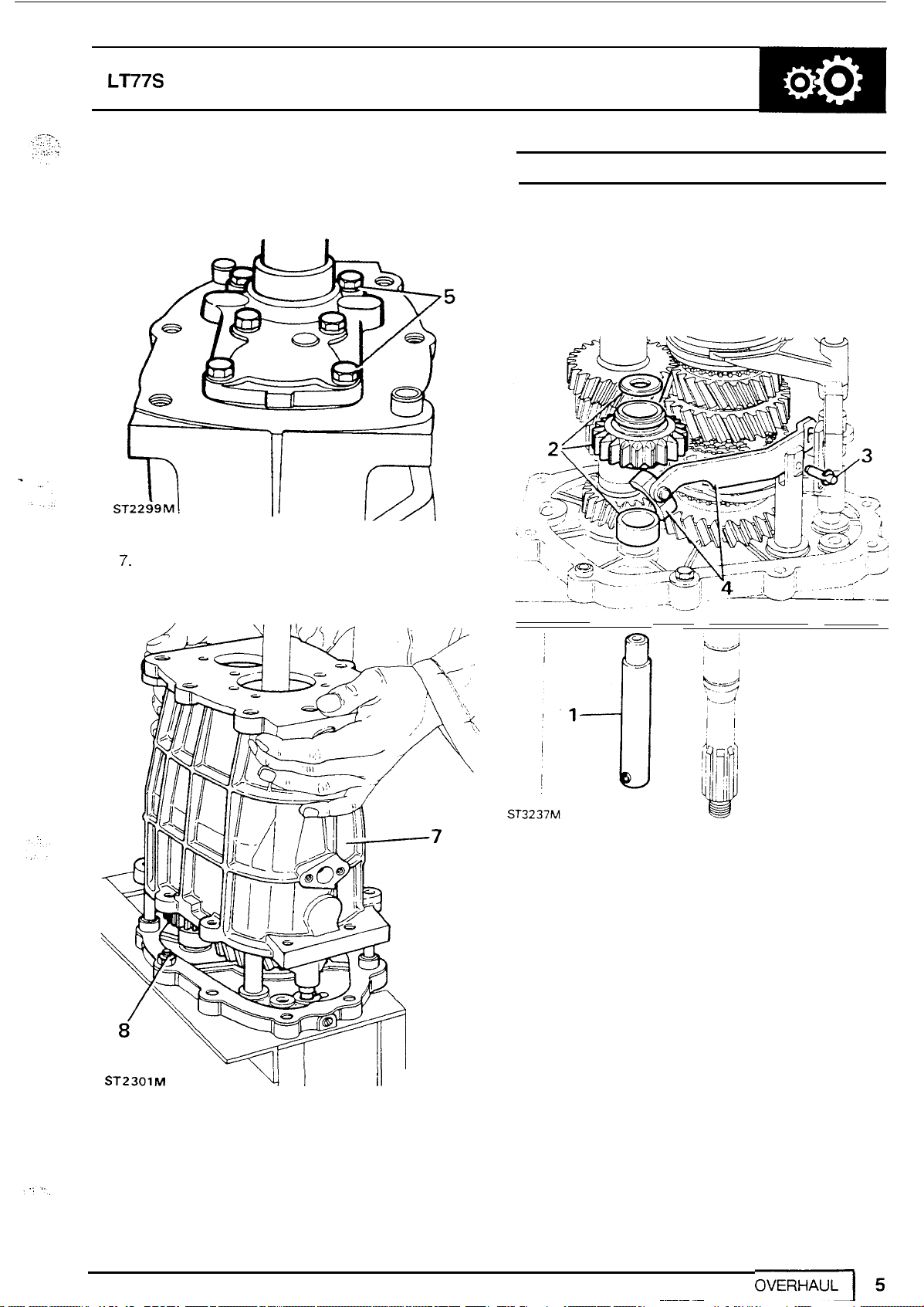

DISMANTLE

MANUAL

GEARBOX

Bell housing

1.

Remove transfer box, drain

-

four cylinder engine

oil

and clean

exterior.

2.

If

fitted, clutch release bearing clip.

3.

Remove clutch release assembly.

4.

Remove one pivot post bolt, slacken the other

and move post aside.

5.

Remove

six

bolts and withdraw bell housing.

GEAR

SELECTOR

1.

Remove four bolts and remove main gearbox

HOUSING

selector housing.

2.

Remove transfer box housing.

3.

Remove remaining bolts and remove remote

housing.

Bell housing

1.

Remove clutch release bearing.

2.

Remove screw and spring clip and remove

-

V8

engine

release lever.

3.

Remove

4.

Remove six bolts and bell housing.

"C"

clip from pivot post.

Page 6

I

37

4.

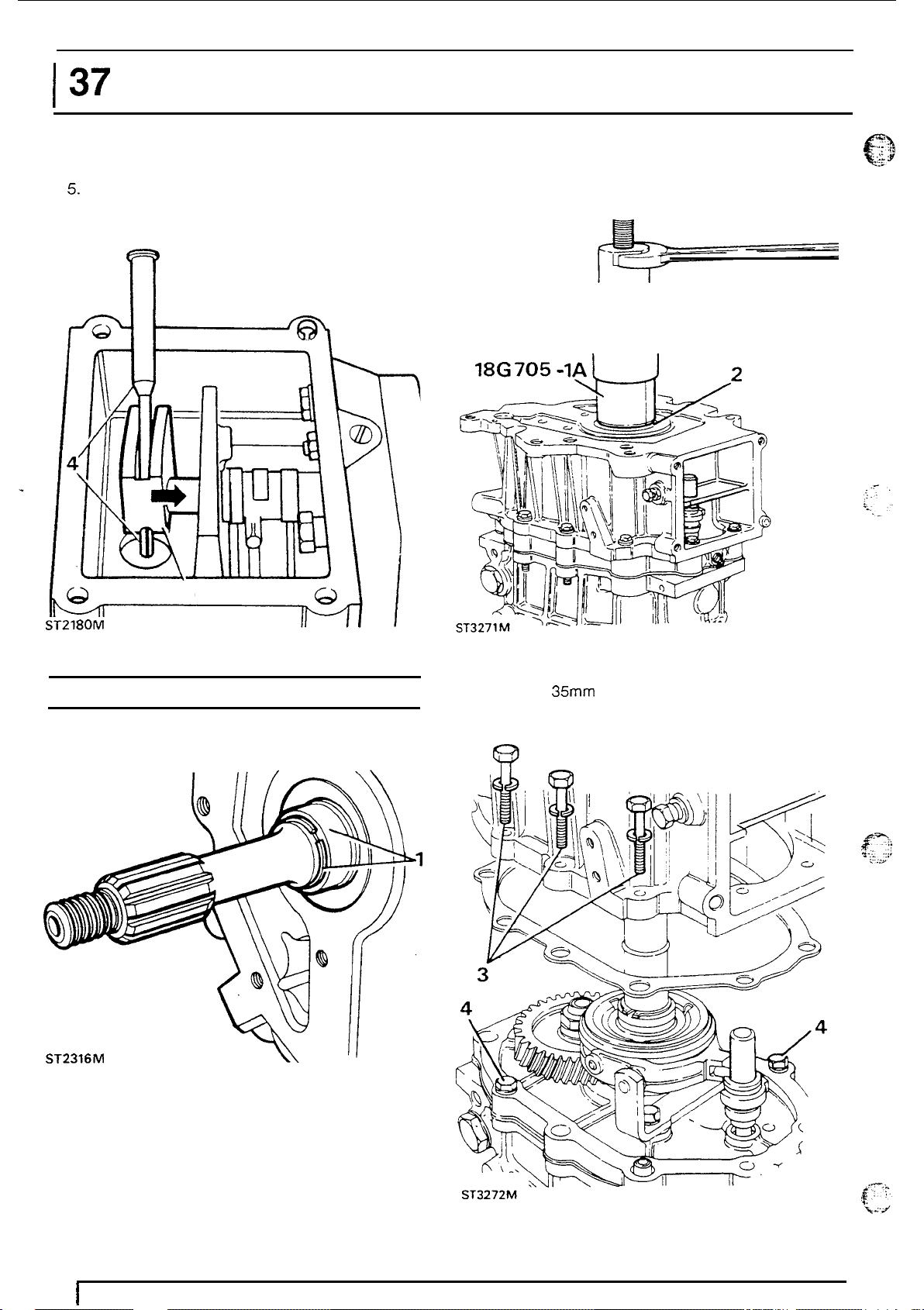

Drive out quadrant

5.

Move selector shaft forward to remove

quadrant.

MANUALGEARBOX

roll

pin.

2.

Using service

withdraw the oil seal collar.

tool

18G

&-

705

DEFENDER

and

18G 705

-

1A

n

5

ST2180M

EXTENSION

1.

Remove snap ring retaining oil seal collar.

HOUSING

.

18G 705

/U

3.

Remove the fifth gear extension housing.

4.

Secure the centre plate

two

8 x 35" bolts.

to

the gearcase with

ST2316M

2

I

OVERHAUL

Page 7

'..

':.

.:

r.

.,

~$

.:

I..

~.

LT77S

MAINSHAFT AND LAYSHAFT FIFTH GEARS

1.

Remove mainshaft

2.

Remove

3.

Remove

4.

Remove fifth gear selector

5.

Remove selector fork bracket.

oil

pump drive shaft.

"E"

"0"

ring.

clips from selector fork.

Spool.

MANUAL

9.

Remove circlip retaining mainshaft fifth gear

GEARBOX

synchromesh.

10.

Fit special tool

18G

1400-1

and

18G

illustrated.

1400

as

..

..

Page 8

137

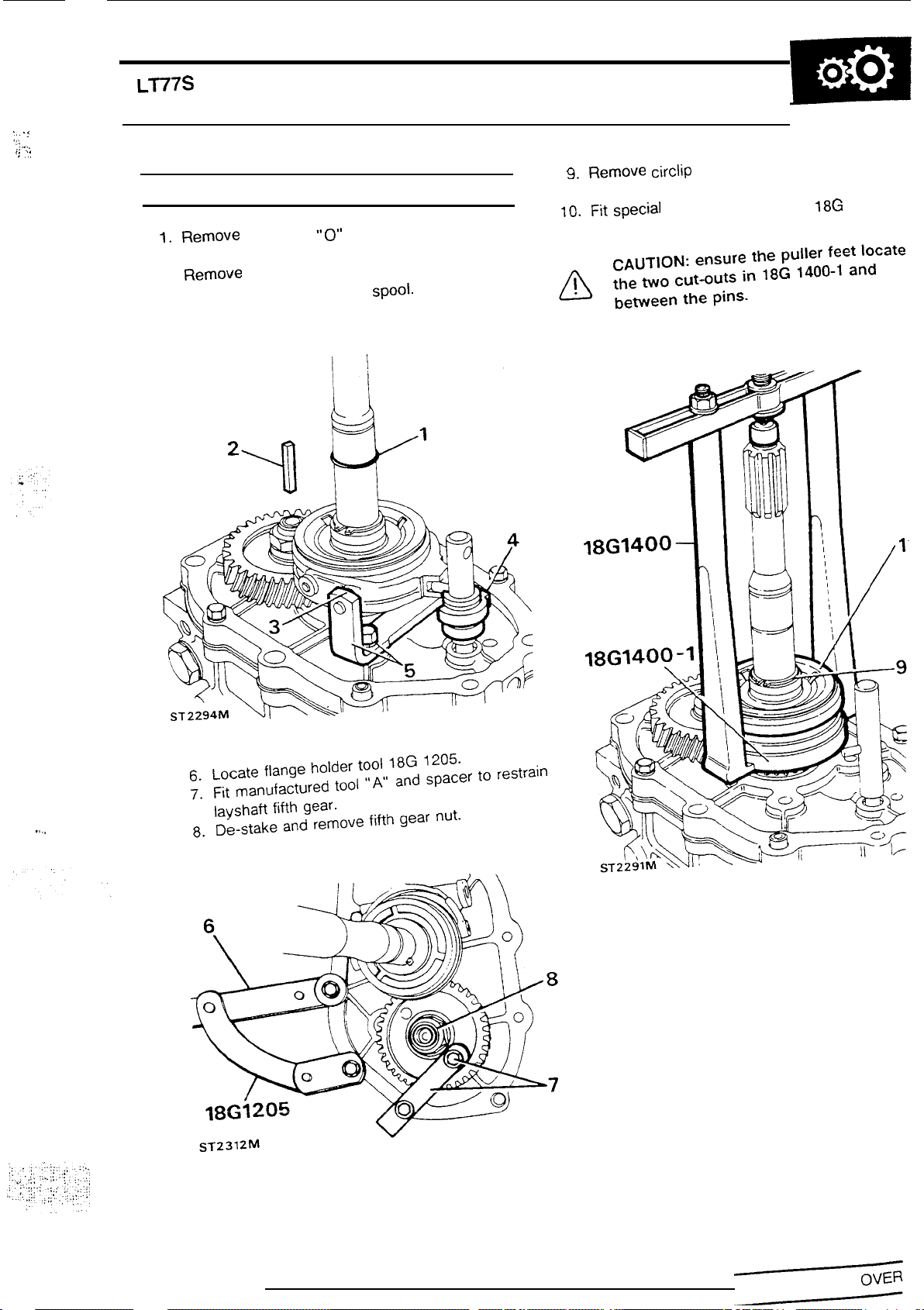

11.

Remove fifth gear synchromesh.

ST2296M

12.

Remove layshaft fifth gear using special tools

18G

MANUALGEARBOX

705

and 18G

705-1A.

DEFENDER

I1

3.

Invert gear case and locate studs in workstand

holes.

4.

Remove selector shaft spool retainer.

i

-.

-

18G705-1A

Main gear case.

1.

Secure reverse shaft retainer, manufactured

tool

"A";

to

centre plate.

2.

Fit

studs, manufactured

tool"B"

to gear case.

4

1

OVERHAUL

Page 9

LT77S

MANUAL

GEARBOX

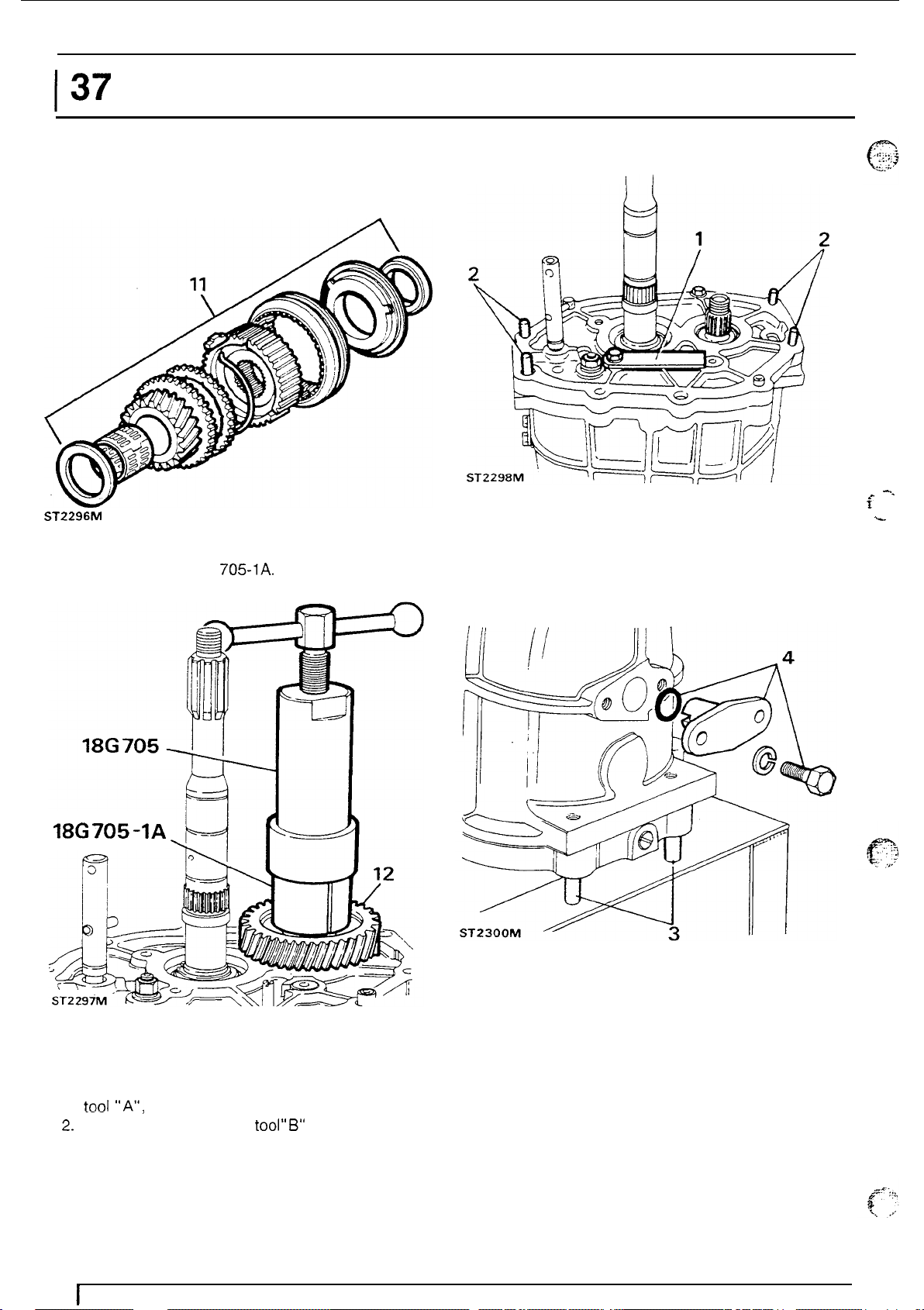

5.

Remove front cover and gasket.

6.

Retrieve selective washers.

7.

Remove

8.

Secure centre plate with nut and

bolts

and lift-off gear case.

bolt.

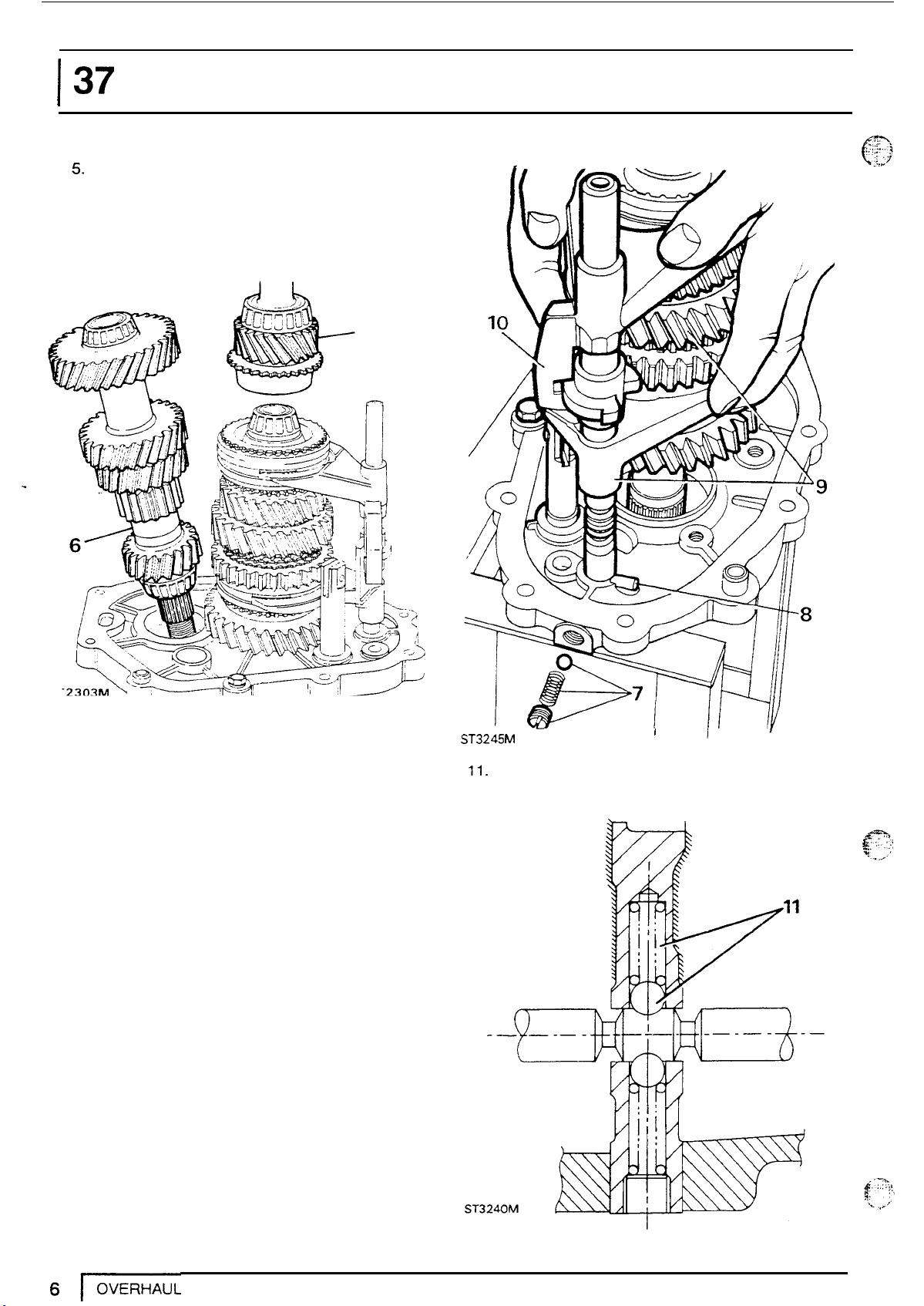

REVERSE

1.

2.

3.

4.

SHAFT,

Remove retainer (tool

Remove

spacer.

Remove reverse lever pin with

attached.

Remove lever and slipper pad.

LAYSHAFT

thrust

washer, reverse gear and

AND MAINSHAFT

"A"

)

and reverse shaft.

"E"

clip

ST23OlM

Yt

II

I

Page 10

I

37

5.

Remove input shaft and fourth gear baulk ring.

6.

Remove layshaft by tilting, as illustrated and

lifting mainshaft.

MANUALGEARBOX

DEFENDER

5

ST

7.

Unscrew plug and remove spring and outboard

detent ball.

8.

Align fifth gear selector pin with centre plate

slot.

9.

Remove mainshaft, gears, selectors and forks.

10.

Remove selector fork assembly from gears.

ST3245

M

11.

Collect inboard detent ball and spring from

centre plate.

I

U

Page 11

Ll77S

c:".

..

.::

,

, . ,

I

I

. .

,

,..

.

..::.:,

,

...

...

1

..

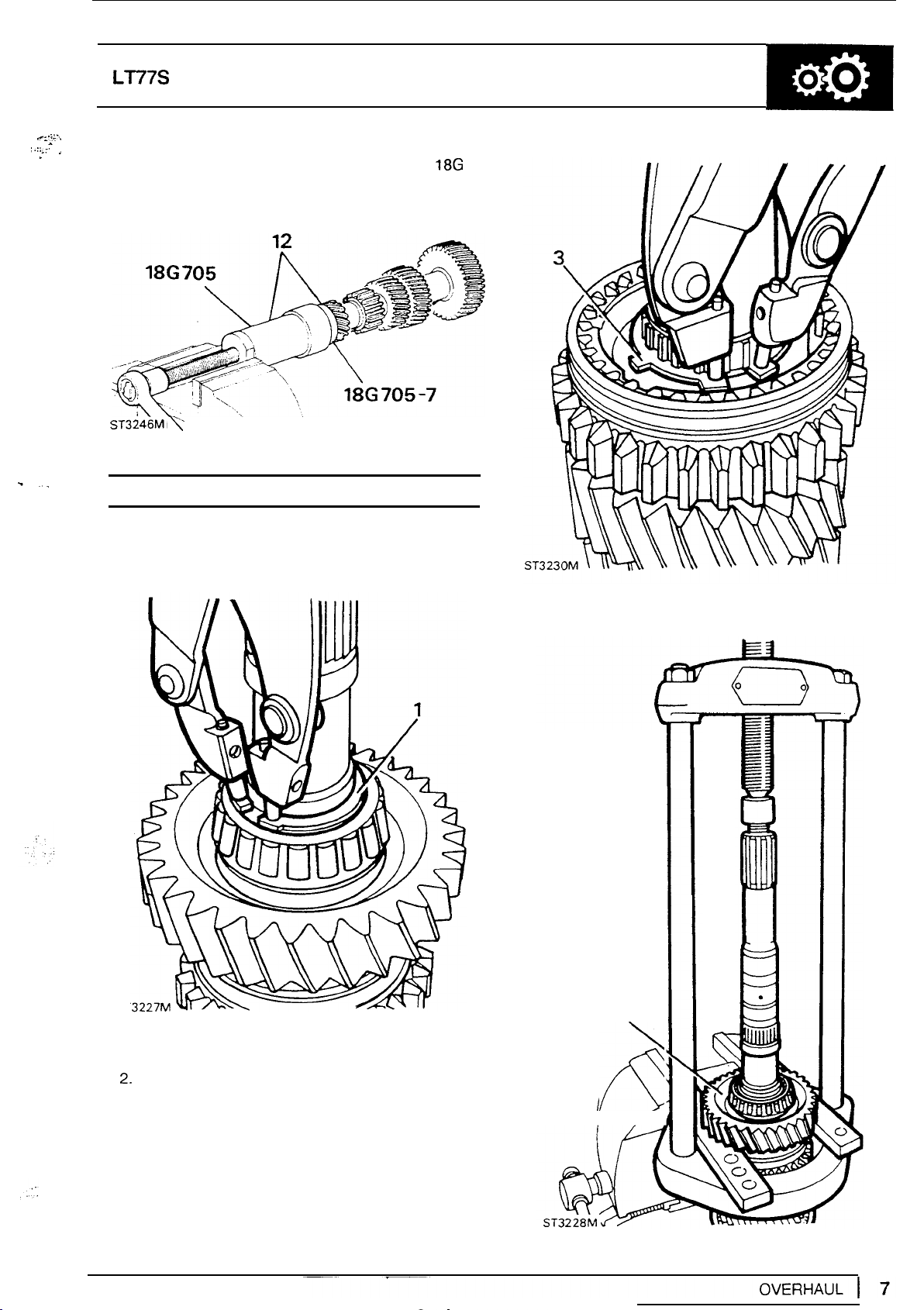

12.

Using extractor tool

705-7,

withdraw layshaft bearings.

18G

705

and collets

18G

MANUAL

GEARBOX

-.

ST3246M,

DISMANTLE

\

1.

Remove circlip retaining first gear assembly.

\

.

MAINSHAFT

4.

With

mainshaft.

MS

47

press

first

gear assembly from

r

-i

ST

2.

Remove taper bearing, bush, needle bearing,

first gear spacer, cone, inner and outer baulk

rings.

3.

Remove circlip

synchromesh assembly.

to

release

first

and second gear

4

R

I/

A

Page 12

137

5.

Remove first and second synchromesh baulk

rings.

6.

Using

gear, press

synchromesh second and third gear assembly.

MANUALGEARBOX

MS

47 and support bars under second

off

pilot bearing, third, fourth

DEFENDER

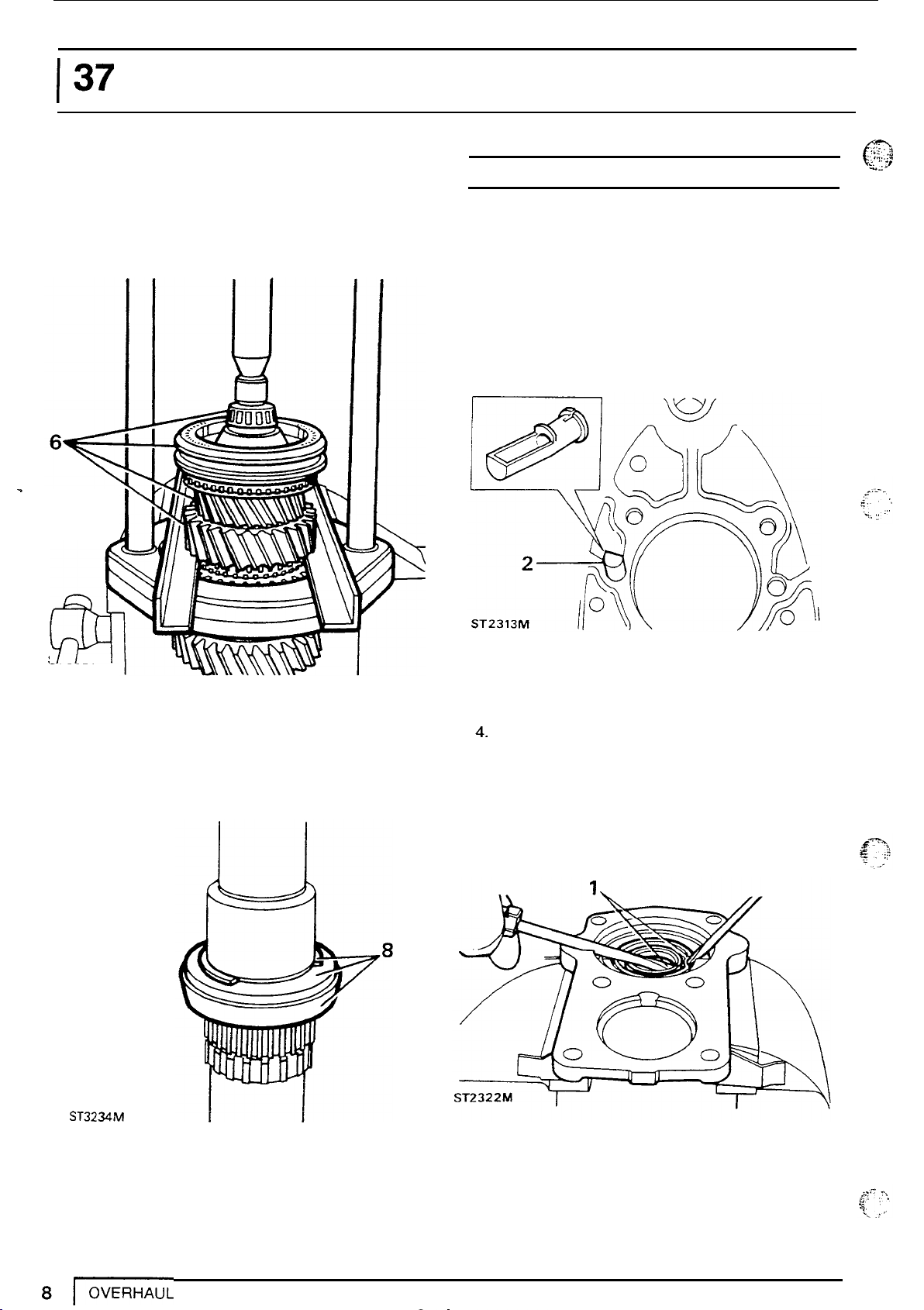

GEARBOX CASINGS AND

Degrease and clean all components and discard

gaskets and seals.

Gearbox casing

1.

Remove mainshaft and layshaft bearing tracks.

2.

Remove plastic scoop from inside the casing.

OIL

PUMP

(3

L..

7

ST3326M

64

7. Remove washer, third, fourth synchromesh,

8.

i

third gear baulk ring, split needle rollers, bush,

needle bearing and second gear.

Remove snap ring, spacer, second gear cone

and circlip.

3.

Inspect case for damage, cracks and stripped

threads.

4. Fit a new scoop with scoop side towards top of

casing.

Front cover

1.

Remove oil seal from cover.

seal at this stage

Do

not fit a new

ST3234M

Page 13

LT77S MANUAL

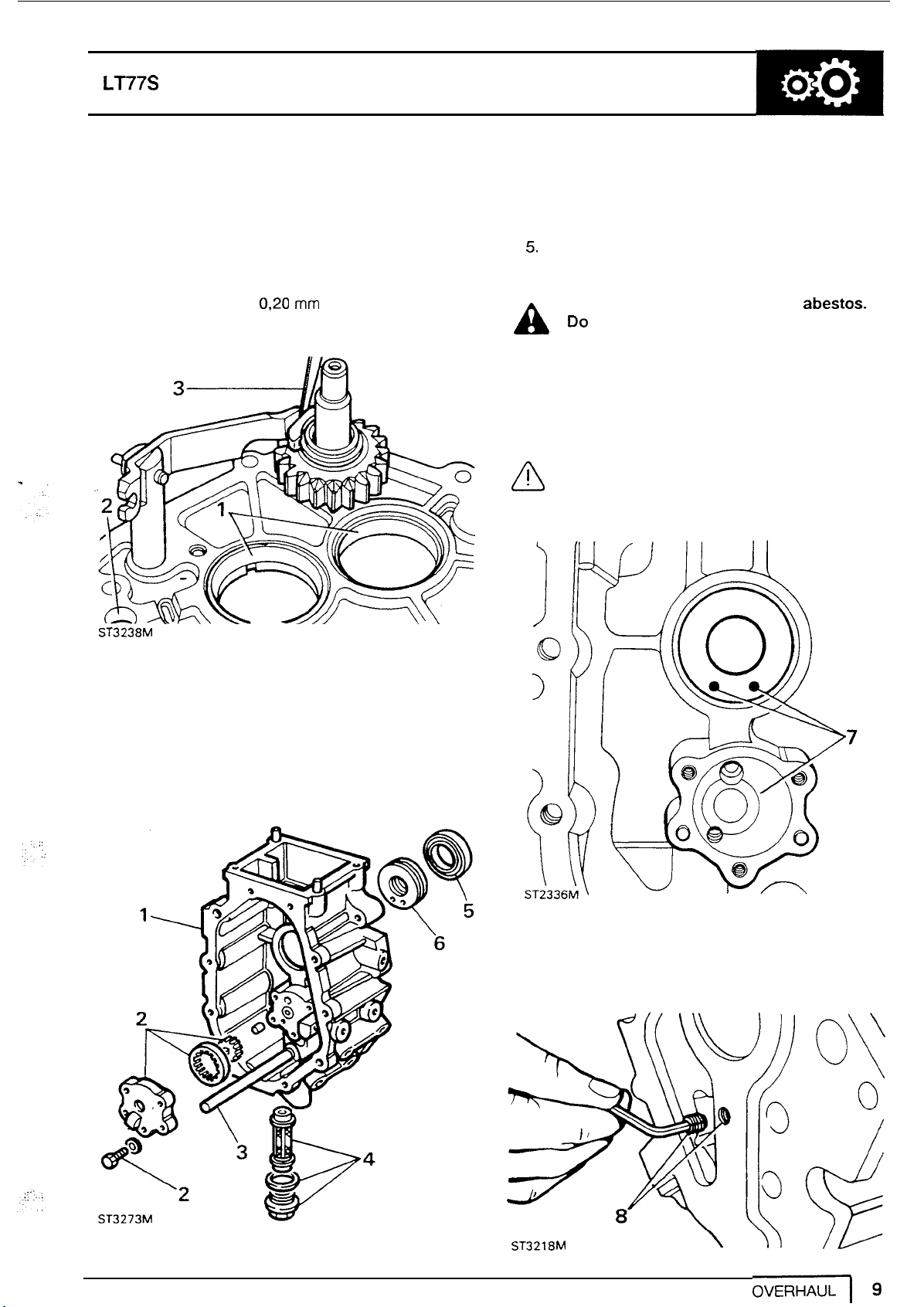

3.

Centre plate

1.

Remove bearing tracks.

2.

Inspect for damage and selector rail bore for

wear.

3.

Temporally fit reverse shaft gear and lever and

check clearance between slipper and lever

does not exceed

0,20

mm

(0.008

in).

Check oil pick up pipe for obstruction but do

not remove.

4.

Remove drain plug assembly. Clean and renew

filter and washers if necessary.

5.

Renew oil seal.

6.

Renew Ferrobestos bush.

WARNING: This bush contains abestos.

A

substances.

A

Do

not attempt

INTRODUCTION,

7.

Fit

new bush with drain holes towards

casing.

CAUTION: If drain holes are not

positioned correctly oil may build up

behind oil seal and cause a leak.

GEARBOX

to

clean it. see

Information, Poisonous

bottom

of

ST3238M

Extension case

1.

Examine for damage

faces.

2.

Remove oil pump cover, inspect gears and

housing and renew if required.

to

threads and machined

8.

If extension housing is being renewed transfer

grub screw

threads.

to

new housing. Apply Loctite to

ST3218M

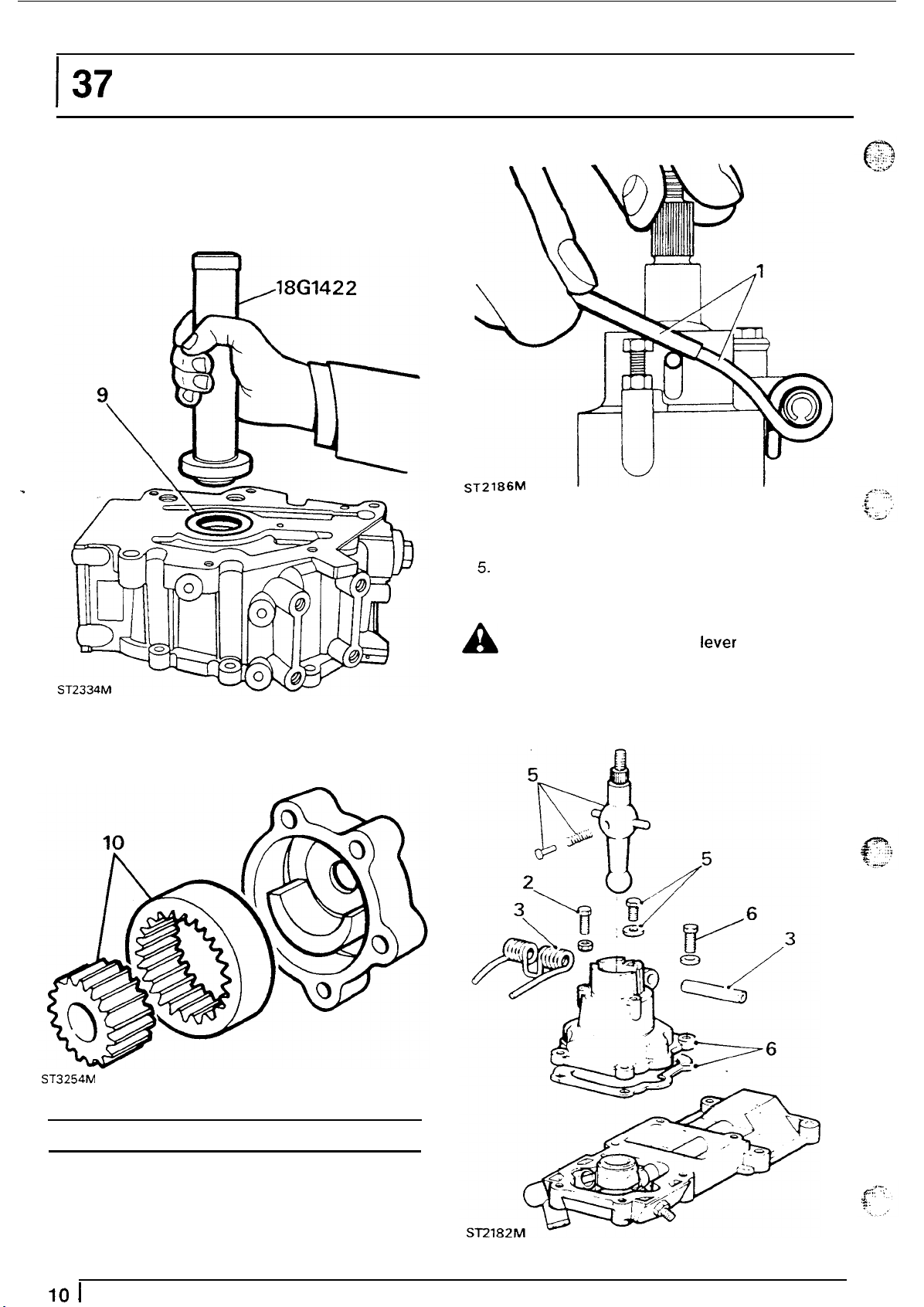

Page 14

I

37

9.

Fit oil seal to housing, lip side leading, using

18G

MANUALGEARBOX

1422.

Apply

SAE

40

oil

to

lip.

DEFENDER

ST2186M

3.

Drive-out

4.

Remove gear lever extension from lower gear

lever.

5.

Remove bolt and special washer to remove

lower gear lever.

roll

pin

to

remove bias spring.

10.

Assemble gears to oil pump and fit cover.

WARNING: Hold

A

pad while removing the lever to prevent

causing personal injury.

6.

Remove gear selector housing from remote

housing.

the nylon spring loaded

it

ST3254M

GEAR CHANGE

1.

With a length of tube, release the bias spring

from adjusting screws.

2.

Remove bias spring adjusting screws.

10

I

OVERHAUL

HOUSING

Page 15

LT77S

,

"'

7.

Clean and examine all components and renew

where necessary.

8.

Assemble above parts

multi

-

purpose grease

In

reverse order using

on

gear lever.

MANUAL

10.

Remove circlip to release rollers and pin from

quadrant.

GEARBOX

NOTE:

properly located and that the lever

fitted

Ensure spring loaded pad

to

the housing with the pad on the

is

is

opposite side to the bias spring. Leave bias

spring adjusting screws slack until assembly

of

gearbox.

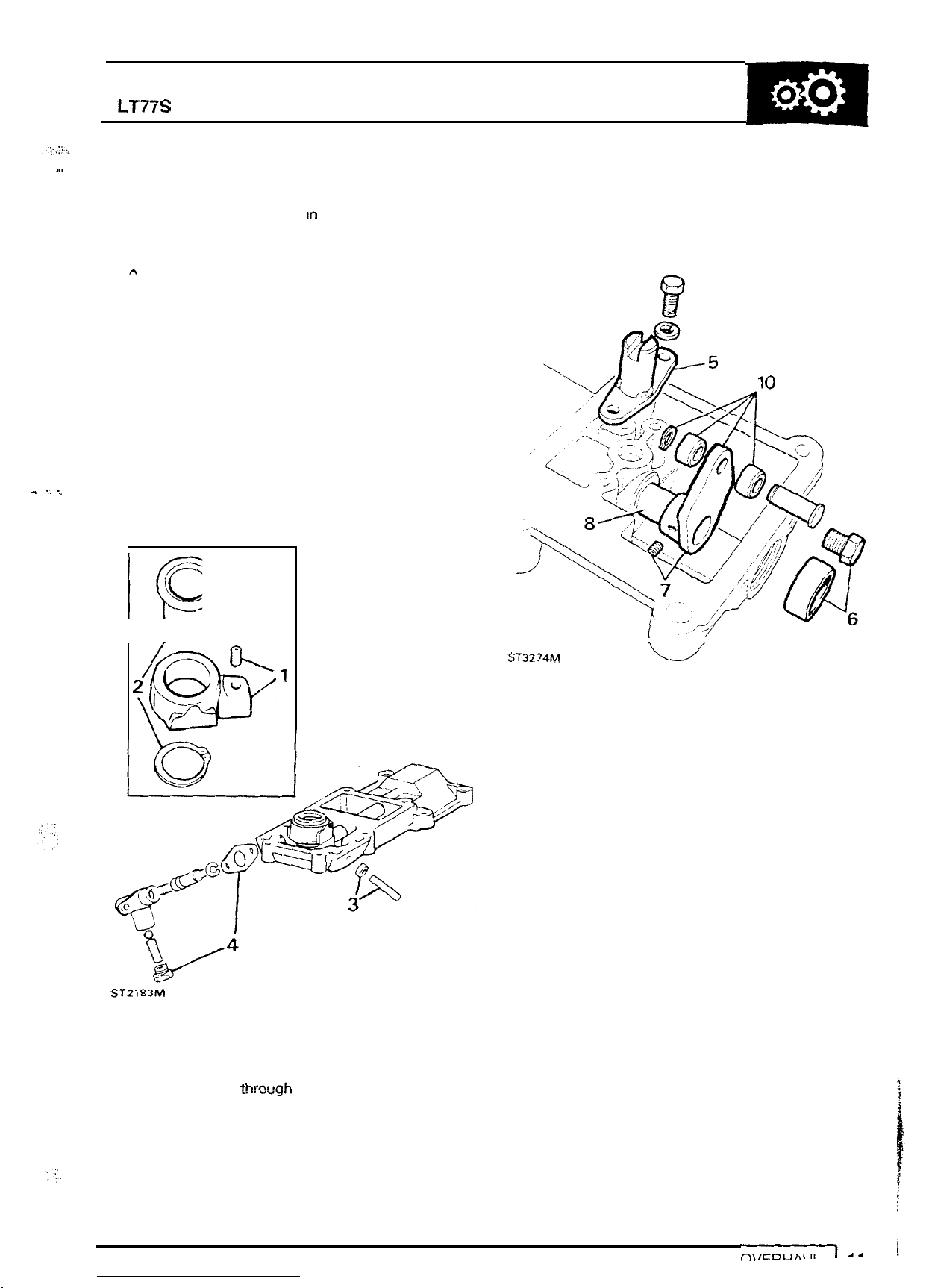

Remote gear

1.

Release socket headed screw

trunnion.

2.

Remove circlip to release seating from trunnion.

3.

1

.:

',

Remove fifth gear locknut and stud.

4.

Remove reverse gear plunger and shim.

I

/

lever

4,

housing.

to

remove

ST3274M

U

fg$y

ST2183M

5.

Remove fifth gear spool guide.

6.

Remove blanking plug.

7.

Drift-out roll pin securing quadrant

8.

With selector

9. Remove selector shaft

thr~ugh

hole.

"0"

ring.

to

shaft.

11.

Clean and examine all components and renew

where necessary.

12.

Assemble housing by first fitting

shaft.

13.

Fit quadrant and secure with roll pin.

14.

Fit rollers and secure with circlip.

15.

Fit fifth gear spool retainer and apply Loctite

290

to

bolt threads.

16. Apply Loctite

17.

Fit seating

18.

Fit trunnion

retaining screw threads.

19. Fit reverse gear plunger and original shims.

20.

Fit fifth gear stud stop and locknut.

21.

Fit new bucket plug with Hylomar

22.

Fit gear selector housing to remote housing.

290

to

reverse switch threads.

to

trunnion

to

shaft and apply Loctite to

and

"0"

ring

secure with circlip.

PL

32.

to

Page 16

37

MANUAL GEARBOX

DEFENDER

-

(,

.

-_

1

I

GEAR

SELECTOR HOUSING

1.:

t

I

0,:

i/'

1. Gear selector housing

2.

Gasket

3.

Roll

pin

14. Reverse gear plunger

15.

Gear

lever

Seating

16.

Trunnion

19.

'0'

ring

20.

Selector

21. Quadrant

22.

Roll

23.

Rollers

shaft

pin

i

Page 17

LT77S

MANUAL

GEARBOX

Reverse gear plunger assembly.

1.

Remove plug spring and ball.

2.

Remove circlip to release plunger and spring.

3.

Clean and examine components.

4.

Assemble plunger and spring with multi-purpose

grease and secure with circlip.

5.

Lubricate and fit detent ball and spring with light

oil. Apply Loctite 290 to plug threads and fit.

6.

Check that plunger returns when depressed.

NOTE:

A

10.

11. Fit

12. Insert shaft into fork and secure end cover with

13.

14.

15. Fit bushes

mutti-purpose grease on all moving

9.

Fit internal and external

assembly.

Fit detent spring.

"0"

of cross shaft.

screws.

Fit Nylon seat, groove downwards, to gear

lever.

Fit gear lever and seat to cross shaft and

secure with circlip.

pin and split pin.

Assemble the housing using

"0"

rings to

rings

to

end cover and fit to short end

to

gear lever and secure with clevis

parts.

fork

ST2201

Transfer gear housing.

M

1.

Remove the

assembly.

2.

Disconnect the gear lever from selector fork.

3.

Retrieve the non metallic bushes.

4.

Remove circlip to release ball and seat and

withdraw gear lever.

5.

Remove screws from end cover

cover and cross shaft.

6.

Remove selector fork.

7.

Remove detent spring and plate.

8.

Clean and examine ail parts and renew where

necessary.

four

screws and remove gaiter

to

withdraw

Page 18

137

15

MANUALGEARBOX

I

DEFENDER

-

12

ST

2185

M

1. Gaiter retaining screw

2.

Gaiter.

3. Gaiter support plate.

4.

Gate plate.

5.

Gasket.

6. Split pin.

7.

Clivis pin.

8. Circlip retaining Nylon seat.

9.

Gear lever ball.

Nylon

10.

seat.

-

4

off,

17

11. Cross shaft.

12. Gear lever.

13. Gear change housing.

14. Non

15. Counter sunk screws.

16. End cover.

17. Detent spring and plate.

18. Selector fork.

19.

-

mettalic bushes.

"0"

rings.

Page 19

LT77S MANUAL

SYNCHROMESH ASSEMBLIES

-

fourth and fifth gear synchromesh.

Third

NOTE: the above assemblies are the

same except that fifth gear synchromesh

has a retainer plate.

1.

Mark relationship of inner and outer members.

2.

Remove wire clip from both sides

of

assembly.

GEARBOX

3.

Remove slippers and separate the two

members.

4.

Examine all parts for damage and wear

including wire clips for tension.

5.

Check

members and mainshaft splines. (except fifth

gear synchromesh).

6.

Examine inner and outer splines for wear.

no

radial movement exists between inner

ST2803M

7.

Examine the dog teeth on

damage.

NOTE: example"A shows a tooth

a

good condition. Example"6" shows the

rounded corners of a worn tooth.

SR449M

all

U

gears

for

wear and

in

OVERHAUL

I

15

Page 20

137

MANUALGEARBOX

DEFENDER

First-second synchromesh

8.

Repeat instructions

synchromesh.

9.

Examine step in each

10.

Check that the step on both sides of the

internal splines are sharp not rounded.

NOTE: this applies only to splines on

selector groove side

1

to

6

for third-fourth

of

outer splines.

of

member.

12.

Fit the slippers and secure with a spring each

side

of

the synchromesh.

NOTE: The hooked end of each spring

must locate in the same slipper with the

free ends running

and

resting against the remaining slippers.

ST2467M

in

opposite directions

r;

ST3244M

\

11.

Fit

inner member to outer

splines of inner member are under the spur

gear teeth.

ST3247M

lb

so

that the wide

11

13.

Assemble third-fourth and fifth gear

synchromesh components as in instruction

NOTE: The back plate for fifth gear is

fitted to the rear of the assembly with the

single tag locating

member.

ST3276M

in

a

slot in the inner

12.

16

1

OVERHAUL

Page 21

LT77S MANUAL

GEARBOX

CHECKING BAULK RING CLEARANCES

Check clearance

of

all baulk rings and gears by

pressing the baulk ring against the gear and

measuring the

be

0,38mm (0.015in).

gap.

The minimum clearance should

First gear

Third gear

ST

Fourth gear

second gear

ST3259M

ST32

26M

Fifth gear

ST3261M

OVERHAUL

17

Page 22

I

37

MANUALGEARBOX

DEFENDER

INPUT SHAFT

1.

Examine the gear and dog teeth for wear and

damage.

2.

Polish oil seal track if necessary.

3.

Using

18G

284

AAH

and

18G

284

bearing track.

18G284AAH

\

18G284

ST3278M

4.

Using

18G 47BA

bearing.

and

MS

47

remove taper

remove pilot

6.

Using Press

adaptor

18G

MS

47

BAX

47,

Collets

fit a new taper bearing.

18G

478

and

..

.?.

:c

t

..-.

.

-

-\~

,

.

:.,

_r

NOTE: ensure that the bearing

0

ST3279M

supported by the

5.

Support the shaft under

new track.

lip

inside

MS

18G

47

and press

is

47

BA.

in

a

MAINSHAFT

1.

Examine bearing journals for wear and scores.

2.

Check condition

3.

Examine splines for wear and damage.

4.

Use an air line

from the pump is clear and feed

bearing.

5.

Check oil feed holes to roller bearings are clear.

of

circlip grooves.

to

check that the main oil feed

to

spigot

3

ST3241

M

Page 23

LT77S

MANUAL

GEARBOX

MAINSHAFT GEAR END FLOAT CHECKS

1.

Hold mainshaft in vice front end downwards.

2.

Fit front circlip

3. Fit second gear cone.

4.

Fit spacer.

5.

Fit snap ring.

ST3235M

for

first-second synchromesh.

-

Third gear end

1.

Fit needle roller

2.

fit third gear bush

3.

Place gear

downwards, and with

gear check clearance between straight edge

and gear.

ST3251

M

float.

to

third gear.

to

third gear.

on

flat surface, bush flange

a

straight edge across

Not

to exceed

0,20

(0.008in).

Second gear end-float.

1.

Fit needle roller and second gear

2.

Fit third gear bush.

3.

Check clearance between second gear and

bush flange.

4.

Remove above components.

Not

to

exceed 0,20

(0.008in).

First

gear bush end-float.

1.

Invert mainshaft rear end uppermost.

2.

Fit inner and outer second gear baulk rings.

ST3252M

'

'I\\

OVERHAUL

1

19

Page 24

1

37

MANUALGEARBOX DEFENDER

3. Fit first-second synchromesh hub, fork groove

uppermost.

4.

Fit circlip.

ST3231

-

First-second synchromesh assembly

M

8.

Fit first gear bush.

9.

Fit dummy bearing.

Fit

10.

11.

12.

circlip.

Check clearance between dummy bearing and

Not

to

bush.

Remove circlip, dummy bearing and bush.

exceed 0,75mm (0.003in).

9

8

7

S

T3

2

57M

5.

Fit first gear inner and outer baulk ring.

6.

Fit cone.

7. Fit spacer.

ST3

253M

Selective first gear bush

Part number Thickness

FTC2005

FTC2006

FTC2007

FTC2008

FTC2009

Check first gear to bush end-float.

1.

Fit roller bearing and bush

2. Place bush flange side downwards on a raised

block on a flat surface.

rest

on

1---7

I

NOTE:

the same diameter as the bush flange

that the gear is suspended and does not

the flat surface.

the block should be approximately

I

30,905/30,955

30,955131,005

31,005131,055

31,055/31,105

31

,

1

to

05/31

,155

first gear.

so

Page 25

LT77S MANUAL GEARBOX

3.

Place straight edge across gear and check

clearance between gear and straight

to exceed 0,20mm (0.008in).

'/

ST3255M

edge.Not

\

37

1

3

ASSEMBLING

1.

With the first-second synchromesh hub and

spacer in position, assemble the rear end

shaft.

2. Fit the roller bearing and bush to first gear.

3.

Fit first gear to mainshaft.

MAINSHAFT

of

the

4.

Fit the taper bearing to mainshaft using

collets

18G

47

BA

and adaptor

18G

MS47-

47

MS

BAX.

47,

ST3229M

First gear assembly

ST3262M

(.

OVERHAUL

121

Page 26

37

A

5.

Invert mainshaft and press assembly back

against circlip.

MS

MANUAL GEARBOX DEFENDER

CAUTION: Ensure that the slots in the

baulk ring align with the synchromesh

slippers while pressing on the bearing.

47’

5

\

7.

Posltlon mainshaft in vice, rear end downwards

and fit second gear needle roller, and second

gear.

8.

Fit third gear bush.

9.

Fit third gear needle

10.

Fit third gear.

11.

Fit third gear baulk ring.

rollers.

w

5

’2

ST3264M

NOTE: Instruction

is probable that when pressing on the

bearing it will have clamped the first gear

bush preventing

6.

Reposition mainshaft

driver blade check that the first gear bush is

free to turn.

LJ

5

it

from turning.

in

is

necessary since it

vice and using a screw

ST3256M

22

I

6’

OVERHAUL

ST3233M

Third-fourth synchomesh assembly

Page 27

LT77S MANUAL

12.

Fit third-fourth gear synchromesh hub.

13.

Using

MS

47

with

supports

press the spigot bearing

under first gear,

on

to

shaft.

-

1

2

LAYSHAFT

1.

Examine the layshaft for wear and damage.

2.

Press bearings

supporting bars.

GEARBOX

on

to

layshaft using

MS

47

and

ST3266M

"U/

MS.47

/

\

REVERSE GEAR AND SHAFT

1.

Remove one circlip from the idler gear and

remove bearings.

i

ST2466M

OVERHAUL

I23

Page 28

1

37

A

engagement. Renew bearings if worn or if the

gear jumps out of engagement.

MANUALGEARBOX DEFENDER

NOTE: One bearing cage is twisted in

manufacture. The twist causes the gear

to tilt on the shaft forcing the gear into

SELECTORS

1.

Examine selector rail and pins for wear and

damage.

Examine first-second selector fork for wear

2.

cracks and damage.

p

v

.

;

2.

Fit the bearings either way round and secure

with the circlip.

3.

Check condition of idler gear and mating teeth

on layshaft and synchromesh outer member.

NOTE:

only supplied as a complete assembly.

Examine third-fourth selector fork for wear,

3.

cracks and damage.

Examine fifth gear selector fork, pads and pivot

4.

pins.

Examine interlock spools for wear and damage.

5.

The the selector rail and fork

1

is

I

'!

..

.

...

....

.:

.

*i

.

..

ST2447M

4.

Examine idler shaft for wear. scores and oittina.

ST2482M

Renew retaining circlips if distorted.

6.

4

Page 29

LT77S

..

A

MANUAL

GEARBOX

Assembling selectors.

7.

Rest first-second fork and shaft assembly

bench and locate pin in jaw of fork.

8.

Fit interlock spool and third-fourth fork and

engage

ST2-M

9.

Slide spool and fork towards first- second

selector until

keeping the

jaw.

spool

8

in

jaw of fork.

7

slot

in

spool

locates over pin

spool

engaged in third-fourth fork

on

ASSEMBLING GEARBOX

SHAFTS

PLATE

Fitting gears to centre plate

1.

Secure centre plate

tracks and inboard detent ball and spring.

to

workstand,

TO

fit

CENTRE

bearing

ST2487M

ST3282M

I

2.

Check both synchromesh units are in neutral

and

fit

selector shaft assembly.

3.

Fit

J

mainshaft and selectors

slot

align pin with

in plate.

to

centre plate and

Page 30

137

4.

Fit layshaft While lifting mainshaft to clear

layshaft rear bearing.

5.

Turn selector shaft and interlock spool

reverse lever to engage spool flange.

6.

Fit reverse lever

pin and circlip.

7.

Fit slipper pad to lever.

8.

Fit reverse gear shaft, spacer and gear.

9.

Fit slipper

shaft engages

MANUALGEARBOX

to

pivot post and secure with

to

reverse gear and ensure

in

slot in centre plate.

to

roll

allow

pin in

DEFENDER

10.

Secure reverse shaft with manufactured tool

"A"

.

11.

Fit reverse gear thrust washer to shaft.

12.

Fit fourth gear baulk ring.

13.

Lubricate spigot bearing and fit input shaft.

14.

Remove centre plate workstand bolt and fit

gasket.

I

I

'9

I

.rU'

I

ST3239M

ST3267M

-1

ST2492M

26

I

OVERHAUL

10

R8

II

Page 31

LT77S MANUAL

2

>

-

I

:

GEARBOX

FITTING GEARBOX CASING

1.

Turn selector shaft and spool

to

neutral

position.

2.

Fit out-board detent ball and sprlng and secure

with plug.

ST2494M

3.

Fit guide studs to casing and check

correctly fitted.

4.

Without using force, fit gearcase.

NOTE: Ensure that the centre plate

dowels and selector shaft are properly

located.

5.

Secure centre plate and gearcase to workstand

8

x

with two

6.

Apply PL

fit

spool retainer.

35" bolts.

32

to joint face and bolt threads and

oil

2

scoop

ST2515M

CAUTION:,Do not use force to fit retainer.

A

position.

reposition spool

I

S

Provided the spool has not been

disturbed the retainer will slide into

If

not, remove the gear case and

or

shaft.

7.

Remove detent plug, apply Loctite 290 or

Hylomar PL

8.

Fit

layshaft and input shaft bearing tracks.

32

to thread, refit and stake.

OVERHAUL

27

Page 32

137

FITTING FIFTH

A

to the layshaft front bearing. Tool"D"and

packing disc should be made to the dimensions

given

to

the input shaft bearing outer track.

1.

Secure the plate with two 8x25" bolts. Insert

disc between plate and layshaft.

MANUALGEARBOX

GEAR

CAUTION:

fit on

pressing the gear, must not be transfered

absorb

Since the fifth gear is a tight

the

layshaft, the force, when

the

force. The plate also retains

-

4.

Fit a new stake nut but do not tighten.

5.

Fit fifth gear assembly to mainshaft.

DEFENDER

6%

';'

2. Release and invert gearbox and remove reverse

shaft retainer plate.

3.

With the extraction

gear

I,

ST2519M

on

to

layshaft using

I

groove

I

uppermost, drive fifth

18G

1422.

28

I

OVERHAUL

Page 33

;:::-:

...

!::.

. .

~.I,

..

,::.q

.

...

...

..

LT77S

I

..,

'

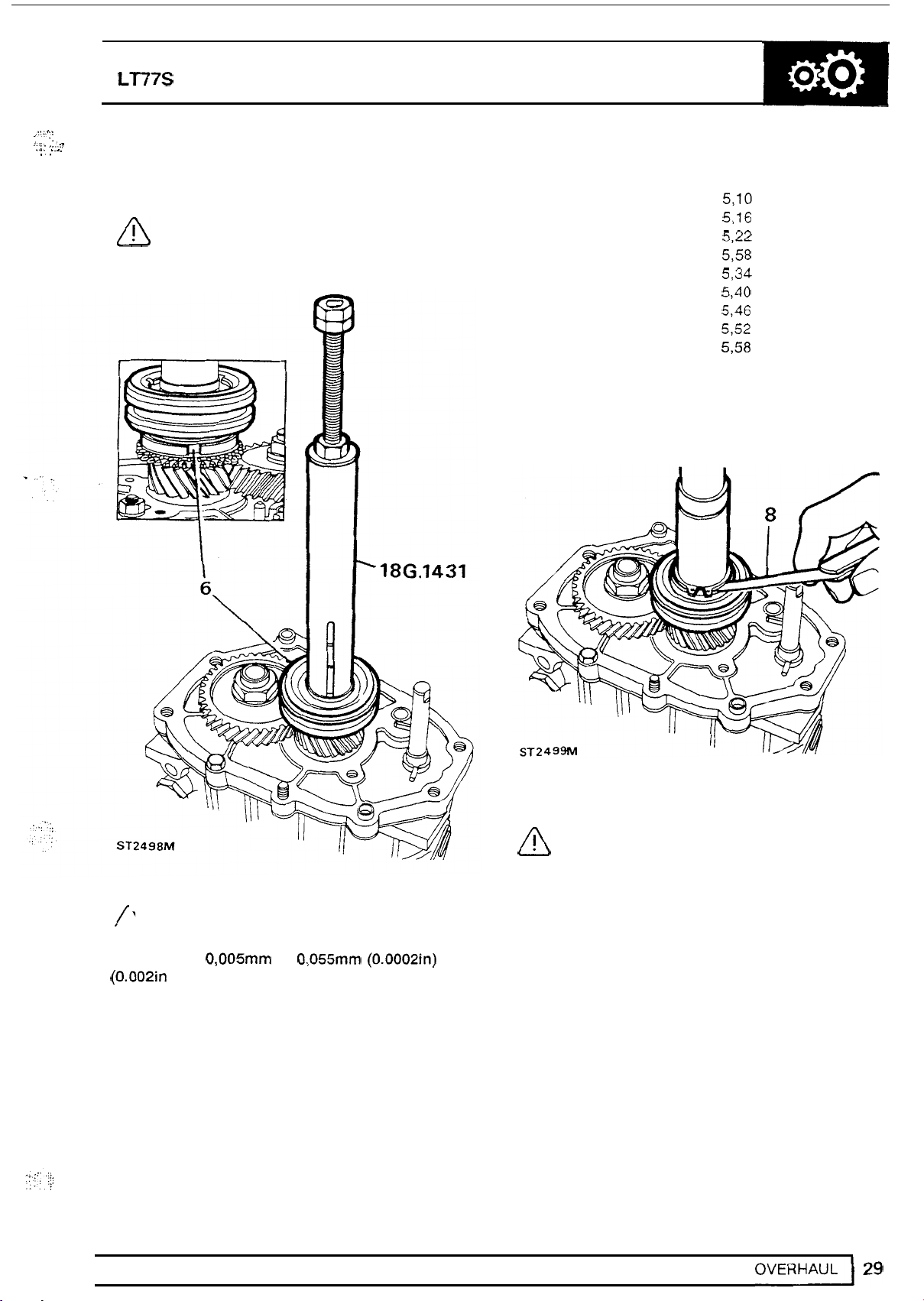

6.

Press fifth gear synchromesh assembly

mainshaft using

CAUTION: Before pressing the assembly

A

fully home, ensure that the slipper pads

locate

18G 1431.

in

the baulk ring slots.

to

MANUAL

Part number Thickness

5284

FRC

FRC

5286

FRC

5288

FRC

5290

FRC

5292

FRC

5294

FRC

5296

FRC

5298

FRC

5300

FRC

5302

7.

Fit the thinnest washer and secure with circlip.

8.

Measure clearance between circlip and washer,

GEARBOX

5,lO

5,16

5,22

5,58

5,34

5,40

5,46

5,52

558

5.64

NOTE:

synchromesh inner member on the

main

clearance is

(0.002in and to achieve this the following

selective washers are available.

Only

limited movement

-

shaft is permissable. The maximum

0,005" to 0,055mm (0.0002in) to

of

the

9.

Tighten layshaft stake nut using

CAUTION: The practice of locking gears

A

required.

to

provide a restraint

not acceptable due to

18G

to

tighten the

high

torque figure

1205.

nut

is

Page 34

1-37

MANUAL GEARBOX DEFENDER

10.

Secure

using a suitable torque wrench tighten the nut

to

11.

Using a round nose punch, form the collar into

the layshaft

tool

"A"

to gear and gear case and

the correct torque.

slots.

FIFTH

GEAR

1.

Fit fifth gear selector fork bracket.

2.

Fit the fifth gear spool long end towards centre

plate.

3.

Fit slippers to selector fork.

4.

Fit fork to synchromesh and secure with pins

and

SELECTOR

"E"

clips.

FORK

ASSEMBLY

NOTE: Before fitting pins and clips cover

A

holes in centre plate to prevent them

falling into casing.

5.

Engage tongue of spool in selector fork.

6.

Fit oil pump drive

to

layshaft.

Page 35

.

-.

.

,~.

:,'

.

....

,

..

.

.

LT77S

..

.f.

..

..

,..

EXTENSION CASE

MANUAL

GEARBOX

1. Release centre plate from workstand and

gasket on joint face.

2.

Fit

extension case

pipe.

Remove

while

guide

aligning oil pick-up

studs

and secure to main

case.

A

3.

Fit

NOTE:

remove case and re

if

CAUTION: To protect

fitting, cover mainshaft splines with

smooth tape.

"0"

Do

not use force, if necessary

-

align oil pump drive

case does not fit first time.

"0"

ring while

ring

to mainshaft groove.

fit

4.

ST2512M

4.

Fit

"0"

d'

ring

collar to mainshaft using 18G

1431

ST

'3221

M

U

7

OVERHAUL

~

I31

Page 36

137

INPUT-MAINSHAFT BEARING ADJUSTMENT

1.

Turn gearbox over with input shaft uppermost.

Remove layshaft support plate.

0

intended end float, and the bearings are not

-

loaded.

pre

2.

Measure the thickness of a new front cover

gasket.

3.

Place the original shim

and finger tighten the bolts.

4.

Measure the clearance between front cover and

gearcase with two feeler gauges.

MANUALGEARBOX DEFENDER

NOTE: Correct shimming of the

shaft bearing is vital to ensure that the

mainshaft assembly has the design

on

mainshaft bearing

input

Mainshaft selective washers

Part number

FRC

4327

FRC

4329

FRC

4331

FRC

4333

FRC

4335

FRC

4337

FRC

4339

FRC

4341

FRC

4343

FRC

4345

FRC

4347

FRC

4349

FRC

4351

FRC

4353

FRC

4355

FRC

4357

FRC

4359

FRC

4361

FRC

4363

FRC

4365

FRC

4367

FRC

4369

Thickness(")

!,63

1,81

1,87

1,93

1,99

2,05

2,ll

2,17

2,23

2,29

2.35

2,41

2,47

2,53

2,59

2,65

2,67

2,77

131

137

1,69

1,75

rj

I,

..

ST3269M'

5.

will have no pre

(0.0025in) end float.

6.

'

If required, change the selective washer

provide a clearance of 0,35mm to 0,085"

(0.001

thickness.

Remove front cover and keep gasket and

selective washer together.

to

O.OO3ins)

NOTE: This will ensure

gasket and cover is fitted to the correct

torque, the input and mainshaft bearings

-

load and.not more than 0,06mm

less than the gasket

that

to

when the

LAYSHAFT BEARING ADJUSTMENT

Place original selective washer

1.

bearing, fit front cover without gasket, and

finger tighten bolts.

Measure clearance, with two feeler gauges,

2.

between cover and gearcase. Select

that will provide a clearance equal to the

thickness of the gasket that was selected and

measured when calculating the adjustment of

the input and mainshaft bearing.

on

layshaft

a

shim

32

I

OVERHAUL

ST2503M

11

Page 37

LT77S MANUAL

A'.

..

NOTE: This will ensure zero layshaft

a

cover

torqued.

bearing end float

0,025"

and

gasket are fitted and bolts correctly

3. Remove cover and selected washer and fit new

oil seal, lip towards gearcase.

4. Fit mainshaft and layshaft selected washers and

gasket.

(0.001

and

not more than ASSEMBLY

in) pre-load once the

GEAR LEVER AND REMOTE HOUSING

1.

Fit

quadrant

NOTE: Push shaft forward, fit quadrant

a

so

rear. Return shaft to neutral position.

ledge

GEARBOX

to

selector shaft with new roll pin.

is

to the left viewing

box

from

4

ST2521M

5.

Wrap protective tape round input shaft splines.

6. Apply Hylomar PL 32 to

cover.

Layshaft selective washers.

Part number

FTC 0262

FTC 0264

FTC 0266

FTC 0268

FTC 0270

FTC 0272

FTC 0274

FTC 0276

FTC 0278

FTC 0280

FTC 0282

FTC 0284

FTC 0286

FTC 0288

FTC 0290

FTC 0292

FTC 0294

FTC 0296

U

bolt

threads and secure

Thickness(")

1,36

1,42

1,48

134

1,60

1,66

1,72

1,78

1,84

1,90

1,96

2,02

2,08

2,14

2,20

2,26

2,32

2,38

2. With a new gasket, fit remote housing locating

over dowels.

in

NOTE: Ensure rollers locate

a

Reverse gear plunger adjustment.

fork.

3.

Fit transfer gear change housing.

1.

Fit plunger with original shims and tighten

2. Slacken locknut, turn adjuster screw

dimension

in). Tighten locknut.

"A"

is

approximately 12 mm

A

/'

ST3223M

quadrant

so

-----

-

(

that

(0.50

-

bolts.

Page 38

137

MANUALGEARBOX

DEFENDER

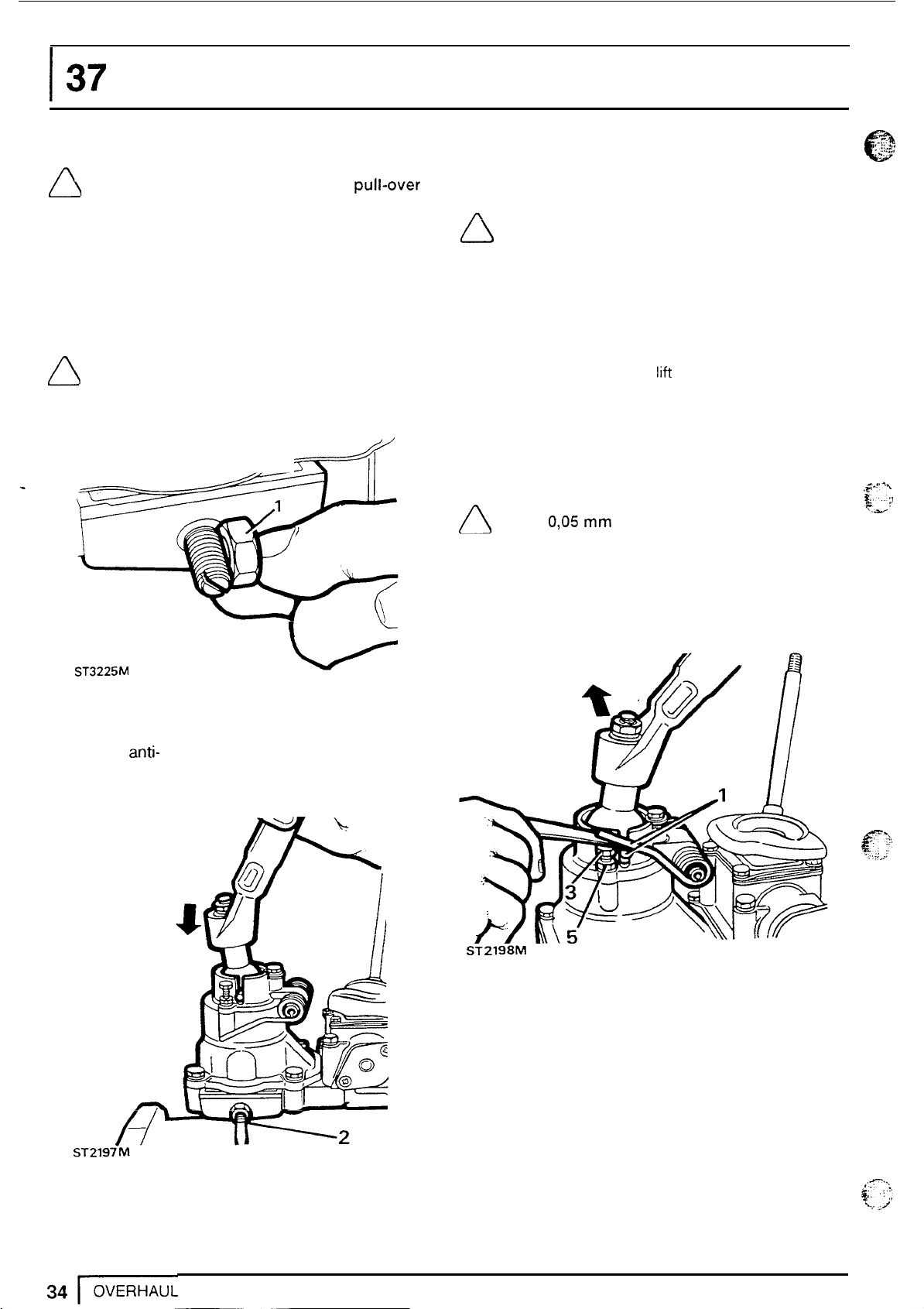

NOTE: If necessary, final adjustment can

be made

load turn screw clockwise

anti-clockwise to reduce load.

Fifth gear stop screw adjustment.

1.

Adjust screw to protrude from housing the

distance across corners

NOTE: This is only an approximate

setting which will limit travel of selector

yoke but will allow fifth gear to be

selected.

in

vehicle. To increase pull-over

of

locknut.

/

------

LA

I

or

Bias spring adjustment

NOTE: The purpose of this adjustment is

A

of the gear lever cross pin when third or fourth

gear is engaged. This will ensure that when

lever is

is automatically aligned for

selection.

//

L

to set both bolts

legs apply equal pressure on both ends

in

neutral, the gear change mechanism

1.

Select fourth gear and

the cross pins.

2.

Turn adjustment

legs.

3.

Apply light pressure

and adjust left hand bolt.

NOTE: Clearance between spring leg and

bolt

0,05

mm

gauge.

4.

Move lever to left and adjust right hand bolt

clearance.

5.

Tighten locknuts.

so

that the bias spring

third

or fourth gear

lift

both spring legs over

bolts

until heads touch spring

to

gear lever to the right

(0.002

in.) using feeler

the

to

,jy

$-:'

4%

ST3225M

2.

Select fifth gear. While applying light pressure

to

gear lever towards right, turn screw

clockwise until it contacts yoke. Turn screw half

a

turn anti- clockwise and tighten nut.

ST2198M

Page 39

LT77S

I

'8:

i

..

,I

BELL HOUSING - FOUR CYLINDER ENGINE

1.

Fit bellhousing locating over hollow dowels and

MANUAL

BELL HOUSING

1.

Fit bell housing locating

GEARBOX

-

V8

ENGINE

on

hollow dowels.

secure with bolts.

NOTE: Fit the

dowels and

12

x

45

12

x

30 mm bolts

mm bolts through

in

NOTE: Fit the

dowels and

positions.

12

x

45" bolts through

12

x

30" bolts in remaining

remaining positions.

2.

Apply molybdenum disulphide grease to pivot

2.

Secure pivot post.

3.

Apply molybdenum disulphide grease to pivot

post, lever pads and pins.

4.

Assemble pads to lever and lever to bearing

post, release lever, socket and push

the bearing guide.

Fit

'C'

3.

4.

washer to pivot post.

Fit spring clip to lever and fit lever to pivot post.

rod.

Not

and fit assembly to pivot post.

5.

Fit staple to release assembly, short leg to

lever.

NOTE: Position spring clip behind 'C'

washer and tighten screw.

NOTE: The staple is an aid to assembly

only which may become dislodged

or

lost in service without detriment.

5.

Fit bearing and retain with plastic staple.

ST2202M

4

ST3286M

4

4

L

Page 40

Page 41

..

..

LT77S

DATA

MANUAL

GEARBOX

Reverse lever and slipper pad clearance

Reverse gear plunger operating load

Synchromesh assemblies push through load

Clearance between baulk rings and gears

Fifth gear end float

Third gear end float

Second gear end float

First gear bush end float

First gear end float

Fifth gear synchromesh end float

TORQUE

A

correct torque.

VALUES

NOTE:

regularly checked for accuracy to ensure

all

that

............................................................

..........................................................

......................................................

...................................................

............................................................

......................................

Torque wrenches should be

fixings are tightened to the

Oil

pump

to

extension case

Clip

clutch release lever

Spool retainer

Spool guide

Extension case to gearcase

Pivot plate, clutch release

Remote housing

Gear lever housing

Guide, clutch release sleeve

Slave cylinder

Front cover to gearcase

Fifth gear support bracket

Plunger housing to remote housing

Gear lever retainer

Lower gear lever

Reverse lever pivot post nut

Clutch housing

Plug, detent spring and ball

Oil

drain plug

Oil filter plug

Oil filler

Breather

Fifth gear layshaft stake nut

Bottom cover

to

to

to

-

level plug

to

gearcase

remote housing

to

bell housing

to

to

gearbox bolts

clutch housing

..........................

................................

........................

gearcase

to

remote housing

bolts

extension nut

................_...

0,725 mm

45

to

55

8,2

to

10

0,38

mm

0,020 mm

0,020 mm

0,020 mm

0,075

mm

0,20

mm

0,005

to

0,055

kg

kgf

mm

Nm

7- 10

7

-

10

7 - 10

7

-

10

7- 10

22 - 28

22

-

28

22

-

28

-

28

22

22

-

28

22

-

28

22

-

28

22

-

28

7

-

10

40 - 47

-

28

22

65

-

80

-

28

22

47 - 54

65

-

80

-

35

25

14

-

16

204 - 231

7

-

10

SPECIFICATIONS,

TORQUE

Page 42

Page 43

LT77S

MANUAL

GEARBOX

SERVICE

injury and or damage to components.

18G 705 Puller, bearing remover

TOOLS

NOTE:

specified, only these tools should be

used to avoid the possibility of personal

Where the use of special tools

is

18G 1400

18G.7400-1

Remover synchromesh hub and

gear cluster

-.

__

8G 705

8G 705-7

-

ia~.705-

1A

oil

Adaptor for mainshaft

track and layshaft fifth gear

seal

0

Adaptor for layshaft bearings

8G

1400-1

MS47

1s

47 Hand press

186.47BA

Adaptor mainshaft fifth gear

8G

47BA

Adaptor input shaft bearing

SERVICE

TOOLS

1

Page 44

37

18G.47BAX

MANUAL

GEARBOX

DEFENDER

18G.1431

18G 47BAX Conversion kit

18G 284 Impulse extractor

18G

18G1205

18G

1431

1205

Mainshaft rear

Flange holder

oil

seal replacer

8G 284AAH

8G

1422

2

I

SERVICETOOLS

18G284AAH

Adaptor for input shaft pilot

bearing track

Mainshaft rear oil seal replacer

Page 45

"\

-

.

-

LT77S MANUAL GEARBOX

..

LOCALLY MANUFACTURED

In addition to the special service

tools can be locally made

and assembly of the gearbox. The following overhaul

procedure is based upon the assumption that these

tools

are available.

Tool

'A'.

Dual purpose tool. Reverse shaft retainer

prevent the shaft falling out when the gearbox in

inverted. Also, a layshaft fifth gear retainer to hold

the fifth gear whilst releasing stake nut. Use 5mm

mild steel to manufacture the tool. When using the

tool

for the layshaft nut, a suitable spacer is required

20" diameter 23" long, with an 8mm diameter

clearance hole.

TOOLS

tools,

the following

to

assist the dismantling

to

Tool

'C'.

Mild steel dummy centre bearing for the

selection of first gear bush.

C

A

ST2

15

4M

53.0"

-+

+

-

0.10

0.005

0-000

Tool

'B'.

Four pilot studs with an 8mm thread for

locating in the four counter sunk blind holes

workstand.

B

in

the

Tool

'D'.

Layshaft support plate

25" bolts and washers to the front of the gearbox

It

case.

track.

also supports the input shaft bearing outer

is

fitted with two 8

D

ST1118M

x

ST

21

55M

.

SERVICE

TOOLS

Page 46

137

Tool

'E'.

during overhaul. Manufacture from

angle iron. The single hole marked

drilled through the material with a

MANUALGEARBOX

Workstand for securely locating the gearbox

30"

10" drill.

1

'A'

should be

52mm

x

30"

DEFENDER

The four counter sunk blind holes marked

also be made with a

drilled through

I

64mm

lOmm drill, but must not be

the

material.

I

I

1

Omm

I

I

I

+

'B'

should

228"

80mm

+

I

I

I

4

SERVICE

ST2153M

TOOLS

Page 47

..

.

I.

... . .

.I

.,

,:

...

..

I:.

,.

.

.

.

...

,

!

::

*,;A.

.

...

..

,

..

,

.,

LT77S MANUAL GEARBOX

GEARS

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

AND

SHAFTS

1.

Third - fourth selector fork. 53.

2.

Interlock spool. 54.

3.

First

-

second fork and selector rail assembly.

4.

First - second synchromesh. 56.

5.

First gear synchromesh outer baulk ring. 57.

First gear synchromesh inner baulk ring. 58.

6.

7.

Cone.

Thrust washer.

8.

First gear.

9.

Needle roller bearings.

First gear selective bush.

Centre taper roller bearing.

Circlip.

Thrust washer.

Fifth gear.

Fifth gear baulk ring.

Fifth gear synchromesh.

Fifth gear synchromesh back plate.

Fifth gear synchromesh selective washer.

Circlip.

"0"

ring.

Oil

seal collar.

Snap ring.

Fourth gear baulk ring.

Pilot

taper bearing.

Spacer.

-

Third

fourth synchromesh.

Third gear baulk ring.

Third gear.

Third gear bush.

Second gear.

Thrust washer.

Cone.

Second gear synchromesh inner baulk ring.

Second gear synchromesh outer baulk ring.

Mainshaft.

Input shaft bearing track and selective washer.

Input shaft.

Input shaft taper bearing.

Fourth gear.

Selective shim.

Taper bearing.

Layshaft fourth gear.

Layshaft third gear.

Layshaft second gear.

Layshaft reverse gear.

Layshaft first gear.

Taper bearing.

Layshaft fifth gear.

Layshaft iifih gear retaining stake nut.

-

Circlips retaining first gear and first

second gear

synchromesh.

Snap ring retaining second gear cone and

52.

spacer.

Spacer.

Snap ring.

Reverse idler gear.

55.

Thrust washer.

Snap ring.

Fifth gear

spool.

SERVICE

TOOLS

5

Page 48

I

I

37

MANUALGEARBOX DEFENDER

Si3281

M

SERVICE TOOLS

Page 49

rc

..

,

,U,

LT77S

GEARBOX

1.

Front

2.

Front cover

3.

Front

4. Oil drain plug and washer.

5.

Oil

6. Gearbox main casing.

7.

Spool retainer.

8.

Gasket.

9.

Inboard detent ball and spring.

10.

Reverse lever and slipper.

11. Locating dowels

12. Reverse lever pivot

13. Centre plate.

CASING

cover.

oil

cover gasket.

level plug.

seal.

-

centre plate

post.

to

maincase.

MANUAL

GEARBOX

14. Selector plug, detent ball and spring.

15.

Gasket.

16. Fifth gear selector bracket.

17. Fifth gear selector

fork.

18. Reverse gear shaft.

19. Oil pick

-

up pipe.

20. Oil pump drive shaft.

Oil

21.

pump gears and cover.

22. Fifth gear extension housing.

23. Fifth gear extension housing drain plug and

filter.

24. Ferrobestos bush.

25.

Oil

seal.

'.

~ ~~

SERVICE TOOLS

Page 50

Loading...

Loading...