Page 1

Table of Contents

Parallel Arm Rotary Cutter

RCP2560 & RCPM2560 Series

18671

316-057M

Operator’s Manual

Read the Operator’s manual entirely. When

you see this symbol, the subsequent

!

instructions andwarningsareserious - follow

without exception. Your life and the lives of

others depend on it!

© Copyright 2008 Printed

Cover photo may show optional equipment

not supplied with standard unit.

4/28/08

Page 2

Table of Contents

Table of Contents

Table of Contents

Land Pride

Important Safety Information . . . . . . . . . . .1

Safety at All Times . . . . . . . . . . . . . . . . . . . . . . . . . 1

Look For The Safety Alert Symbol . . . . . . . . . . . . .1

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Section 1: Introduction . . . . . . . . . . . . . . .8

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . .8

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . . 8

Serial Number Plate . . . . . . . . . . . . . . . . . . . . . 8

Further Assistance . . . . . . . . . . . . . . . . . . . . . .8

Section 2: Assembly & Set-up . . . . . . . . . .9

Tractor Requirements . . . . . . . . . . . . . . . . . . . . . .9

Preparation Checklist . . . . . . . . . . . . . . . . . . . . . . 10

Dealer Preparations . . . . . . . . . . . . . . . . . . . . . . . 10

3-Point Hookup . . . . . . . . . . . . . . . . . . . . . . . . . . 10

PTO Hookup . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Hydraulic Hookup . . . . . . . . . . . . . . . . . . . . . . . . 13

Electrical Hookup . . . . . . . . . . . . . . . . . . . . . . . . . 14

Functional Check . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operator Protective Shield . . . . . . . . . . . . . . . . . . 16

Setting Flow Control Valve . . . . . . . . . . . . . . . . . . 17

Section 3: Hydraulics . . . . . . . . . . . . . . . .18

Hydraulic Cylinder Plumbing . . . . . . . . . . . . . . . . 18

Marking Hydraulic Line Lengths . . . . . . . . . . . . . .19

Section 4: Adjustments . . . . . . . . . . . . . .22

Deck Level Adjustments . . . . . . . . . . . . . . . . . . . 22

Section 5: Transporting . . . . . . . . . . . . . .23

Section 7: Maintenance & Lubrication . . 27

Lubrication Points . . . . . . . . . . . . . . . . . . . . . . . .27

Parallel Arm Cutter Zerks . . . . . . . . . . . . . . . .27

PTO Zerks . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Driveline Profiles . . . . . . . . . . . . . . . . . . . . . . .27

Blade Servicing (Replacement) . . . . . . . . . . . . . .28

Tractor Maintenance . . . . . . . . . . . . . . . . . . . . . .29

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Section 8: Specifications & Capacities . .31

Section 9: Troubleshooting . . . . . . . . . . .33

Section 10: Appendix . . . . . . . . . . . . . . . .34

Torque Values Chart . . . . . . . . . . . . . . . . . . . . . .34

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Section 6: Operating Procedures . . . . . .24

Breakaway Operations . . . . . . . . . . . . . . . . . . . . . 24

Tension Bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Breakaway Cylinder . . . . . . . . . . . . . . . . . . . . . . . 25

General Operating Instructions . . . . . . . . . . . . . .26

© Copyright 2008 All rights Reserved

Land Pride provides this publication“as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the preparation of this manual, Land

Pride assumes no responsibilityfor errors or omissions.Neither is any liability assumed fordamages resulting from the use of the information contained herein. Land Pridereserves

the right to reviseand improveits products as it sees fit. This publication describes the state of this product at the time of its publication,and maynot reflectthe product in the future.

Land Prideis a registered trademark.

All other brands and product names are trademarks or registered trademarks of their respectiveholders.

Printed in the United States of America.

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

4/28/08

Page 3

Land Pride

▲

Table of Contents

Important Safety Information

Important Safety Information

These are common practices that may or may not be applicable to the products described in

this manual.

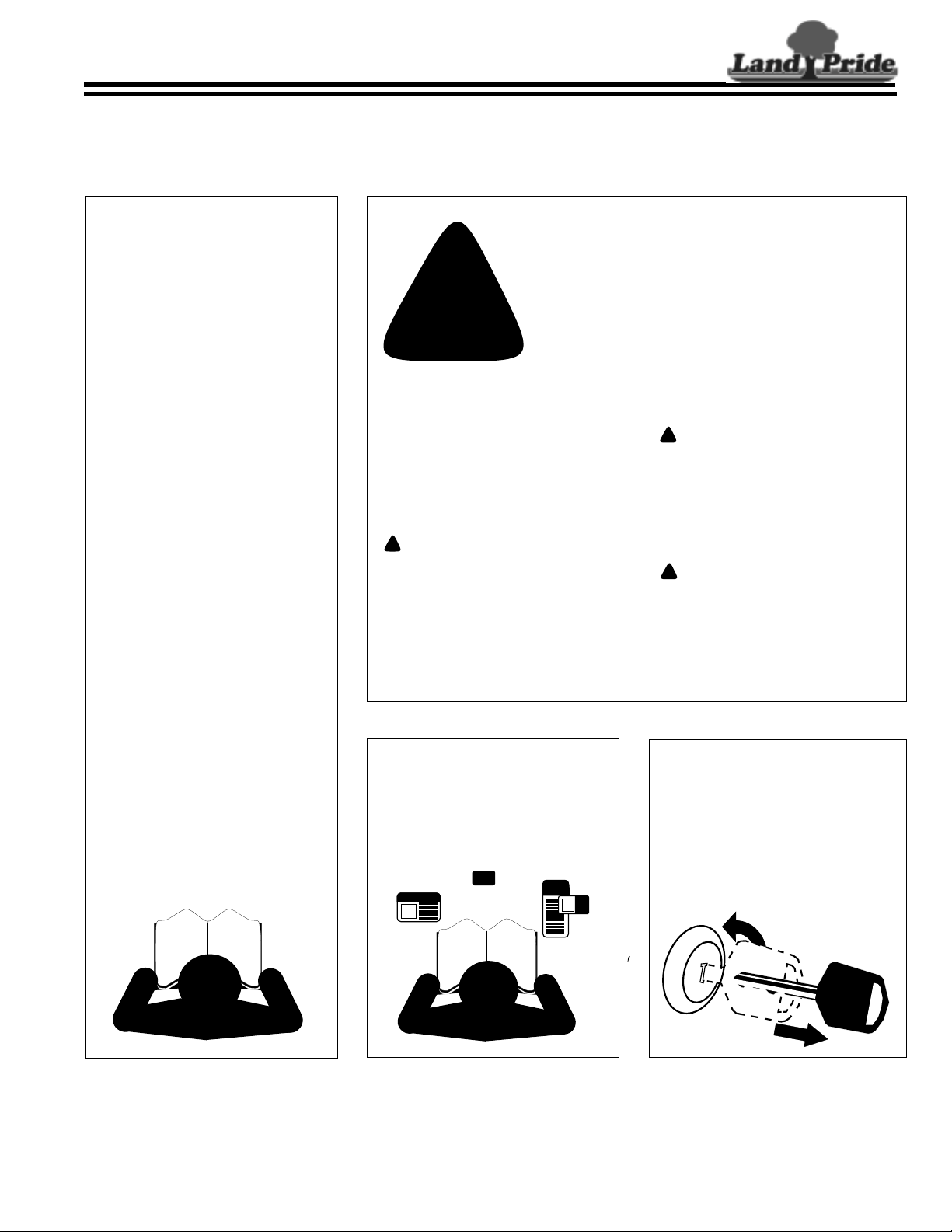

Safety at All Times

Thoroughly read and understand

the instructions given in this

manual before operation. Refer to

the “Safety Label” section, read

all instructions noted on them.

Do not allow anyone to operate

this equipment who has not fully

read and comprehended this

manual and who has not been

properly trained in the safe

operation of the equipment.

▲ Operator should be familiar with

all functions of the unit.

▲ Operate implement from the

driver’s seat only.

▲ Make sure all guards and shields

are in place and secured before

operating the implement.

▲ Do not leave tractor or implement

unattended with engine running.

▲ Dismounting from a moving

tractor could cause serious injury

or death.

▲ Do not stand between the tractor

and implement during hitching.

▲ Keep hands, feet, and clothing

away from power-driven parts.

▲ Wear snug fitting clothing to avoid

entanglement with moving parts.

▲ Watch out for wires, trees, etc.,

when raising implement. Make

sure all persons are clear of

working area.

▲ Turning tractor too tight may

cause implement to ride up on

wheels. This could result in injury

or equipment damage.

Look For The Safety Alert Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

!

Be Aware of

Signal Words

A Signal word designates a degree or

level of hazard seriousness. The

signal words are:

!

DANGER

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury. This

signal word is limited to the most

extreme situations, typically for

machine components that, for

functional purposes, cannot be

guarded.

For Your Protection

▲ Thoroughly read and understand

the “Safety Label” section, read all

instructions noted on them.

equipment, hazard control and accident prevention

are dependent upon the awareness, concern,

prudence and proper training of personnelinvolved in

the operation, transport, maintenance and storage of

equipment.

!

WARNING

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury, and

includes hazards that are exposed

when guards are removed. It mayalso

be used to alert against unsafe

practices.

!

CAUTION

Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

Shutdown and Storage

▲ Lower machine to ground, put

tractor in park, turn off engine, and

remove the key.

▲ Detach and store implements in a

area where children normally do

not play. Secure implement by

using blocks and supports.

4/28/08

OFF

REMO

VE

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

1

Page 4

Important Safety Information

Table of Contents

Land Pride

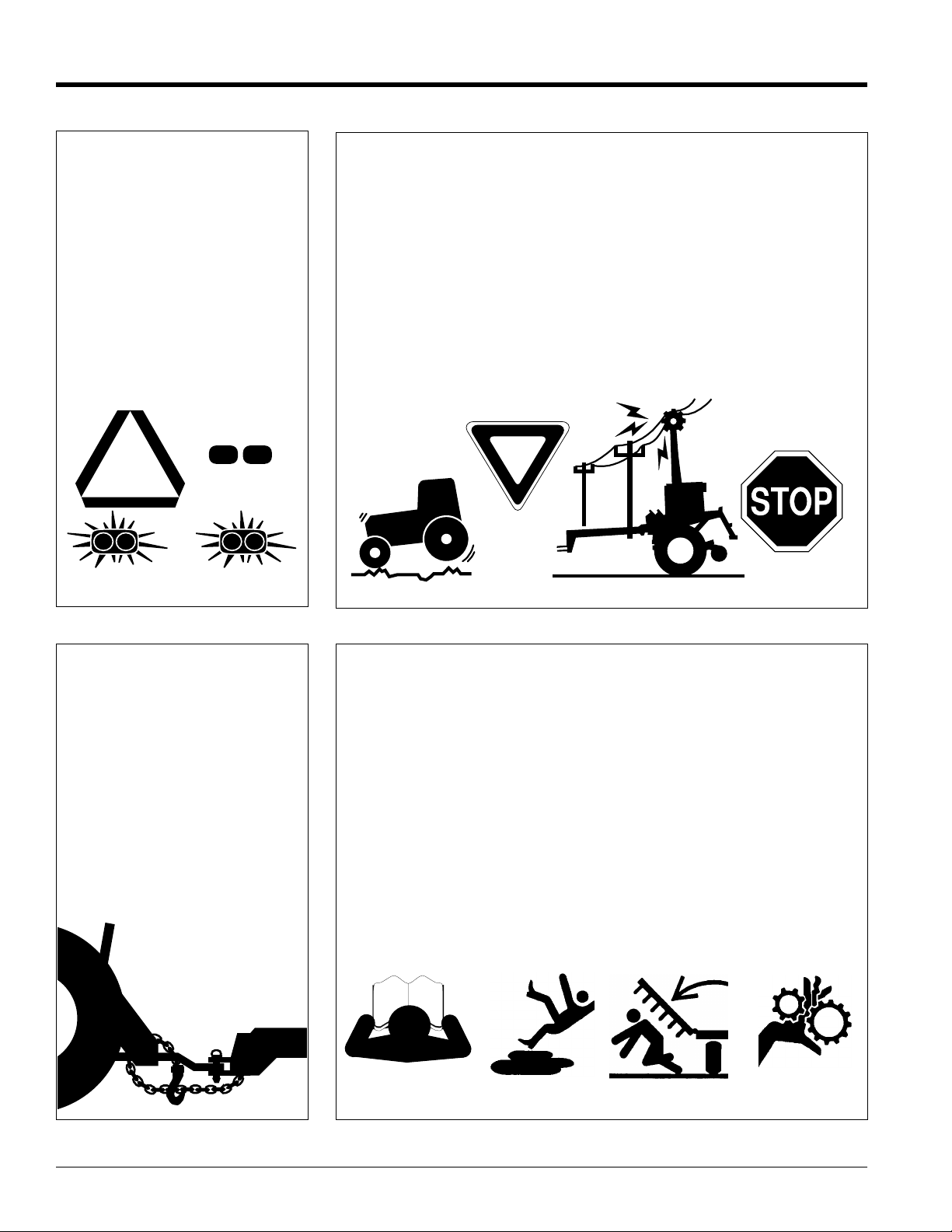

Use Safety

Lights and Devices

▲ Slow moving tractors, self-

propelled equipment, and towed

implements can create a hazard

when driven on public roads. They

are difficult to see, especially at

night.

▲ Flashing warning lights and turn

signals are recommended

whenever driving on public roads.

Use lights and devices provided

with implement.

Transport

Machinery Safely

▲ Comply with state and local laws.

▲ Maximum transport speed for

implement is 20 mph. DO NOT

EXCEED.Never travel at a speed

which does not allow adequate

control of steering and stopping.

Some rough terrain require a

slower speed.

▲ Sudden braking can cause a

towed load to swerve and upset.

Reduce speed if towed load is not

equipped with brakes.

▲ Use the following maximum

speed - tow load weight ratios as

a guideline:

20 mph when weight is less

than or equal to the weight of

tractor.

10 mph when weight is double

the weight of tractor.

IMPORTANT: Do not tow a load that

is more than double the weight of

tractor.

Use A Safety Chain

▲ A safety chain will help control

drawn machinery should it

separate from the tractor

drawbar.

▲ Use a chain with the strength

rating equal to or greater than

the gross weight of the towed

machinery.

▲ Attach the chain to the tractor

drawbar support or other

specified anchor location. Allow

only enough slack in the chain to

permit turning.

▲ Do not use safety chain for

towing.

Practice Safe Maintenance

▲ Understand procedure before

doing work. Use proper tools and

equipment, refer to Operator’s

Manual for additional information.

▲ Work in a clean dry area.

▲ Lower the implement to the

ground, put tractor in park, turnoff

engine, and remove key before

performing maintenance.

▲ Allow implement to cool

completely.

▲ Do not grease or oil implement

while it is in operation.

▲ Inspect all parts. Make sure parts

are in good condition & installed

properly.

▲ Remove buildup of grease, oil or

debris.

▲ Remove all tools and unused

parts from implement before

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

2

4/28/08

Page 5

Land Pride

Important Safety Information

Table of Contents

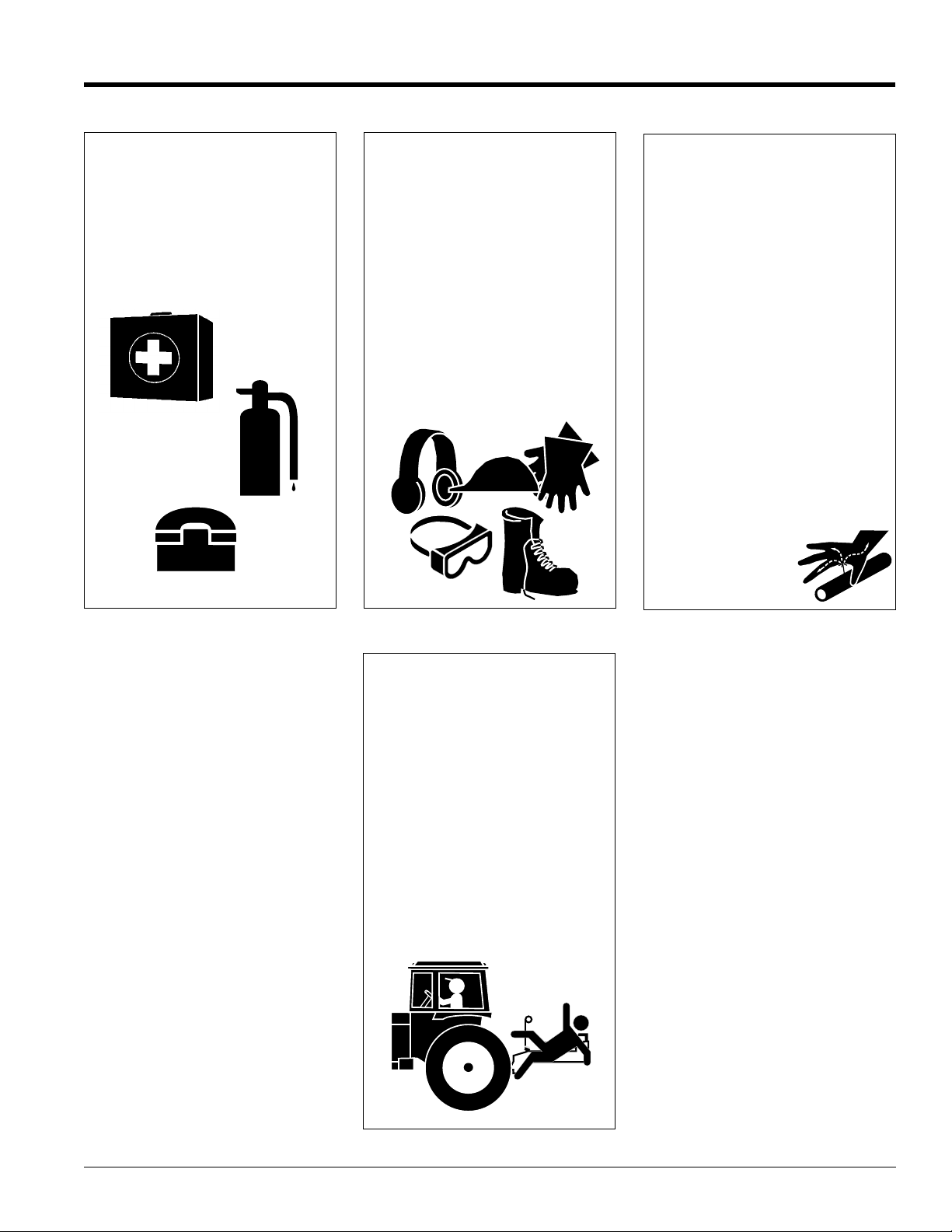

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire

extinguisher handy.

▲ Keep emergency numbers for

doctor, ambulance, hospital and

fire department near phone.

911

Wear

Protective Equipment

▲ Protectiveclothing and equipment

should be worn.

▲ Wear clothing and equipment

appropriate for the job. Avoid

loose fitting clothing.

▲ Prolonged exposure to loud noise

can cause hearing impairment or

hearing loss. Wear suitable

hearing protection such as

earmuffs or earplugs.

▲ Operating equipment safely

requires the full attention of the

operator. Avoid wearing radio

headphones while operating

machinery.

Avoid High

Pressure Fluids Hazard

▲ Escaping fluid underpressurecan

penetratetheskincausingserious

injury.

▲ Avoid the hazard by relieving

pressure before disconnecting

hydraulic lines or performing work

on the system.

▲ Make sure all hydraulic fluid

connections are tight and all

hydraulic hoses and lines are in

good condition before applying

pressure to the system.

▲ Use a piece of paper or

cardboard, NOT BODYPARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety

glasses or goggles when working

with hydraulic systems.

▲ If an accident occurs, see a

doctor immediately. Any fluid

injected into the skin must be

treated within a few hours or

gangrene may result.

Keep Riders

Off Machinery

▲ Riders obstruct the operator’s

view, they could be struck by

foreign objects or thrown from the

machine.

▲ Never allow children to operate

equipment.

4/28/08

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

3

Page 6

Important Safety Information

Table of Contents

Land Pride

Safety Labels

Your cutter comes equipped with all safety labels in place. They

were designed to help you safely operate your implement. Read

and follow their directions.

1. Keep all safety labels clean and legible.

2. Replace all damaged or missing labels. To order new

labels go to your nearest Land Pride dealer.

3. Some new equipment installed during repair requires

safety labels to be affixed to the replaced component as

specified by Land Pride. When ordering new components

12326

make sure the correct safety labels are included in the

request.

4. Refer to this section for proper label placement.

To install new labels:

a. Clean the area the label is to be placed.

b. Spray soapy water on the surface where the label is to

be placed.

c. Peel backing from label.Press firmly onto the surface.

d. Squeeze out air bubbles with the edge of a credit card.

818-045C

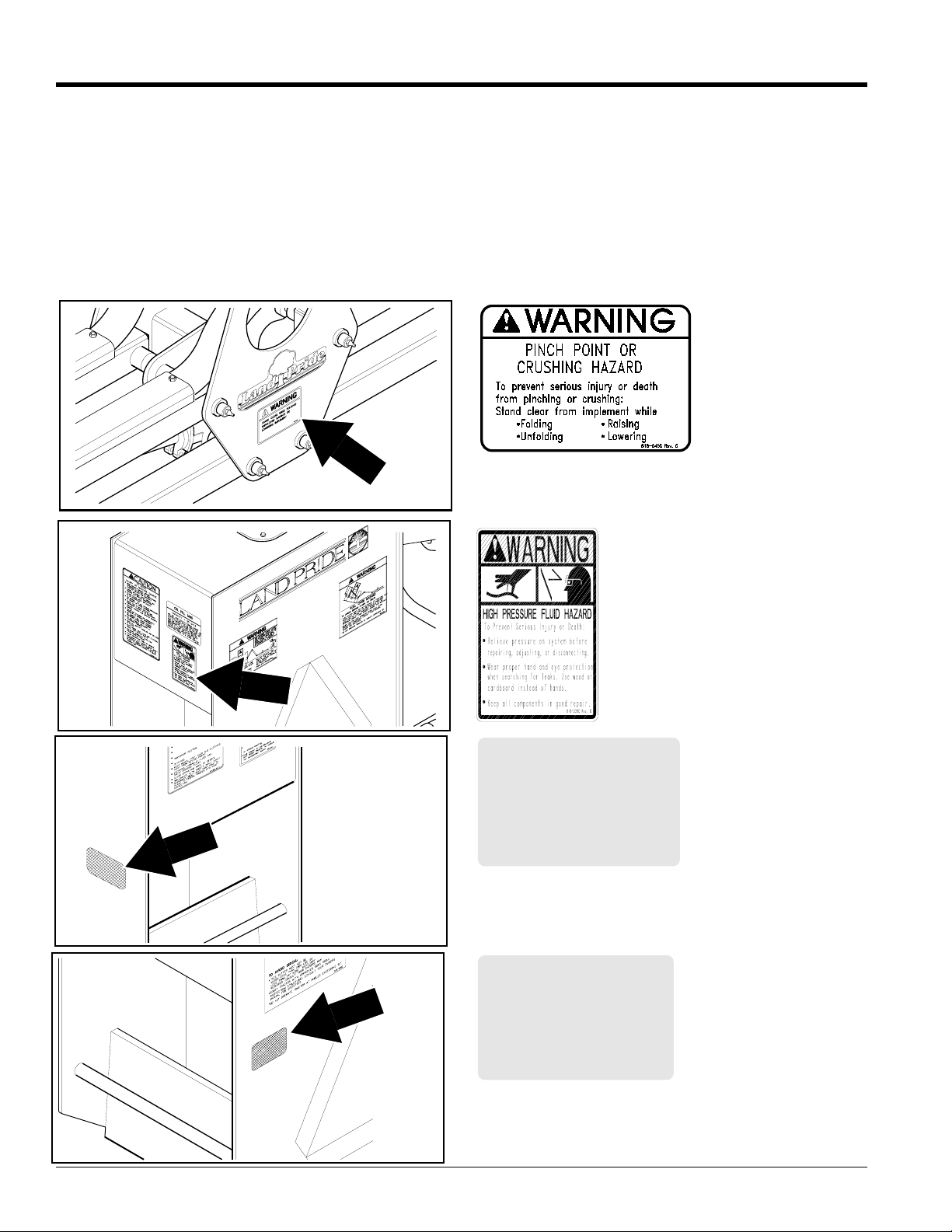

Warning - Pinch Point Hazard

12121

818-339C

Warning - High

Pressure Fluid

Hazard

818-229C

Amber Reflectors

12319

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

4

818-230C

Red Reflector

12320

4/28/08

Page 7

Land Pride

Important Safety Information

Table of Contents

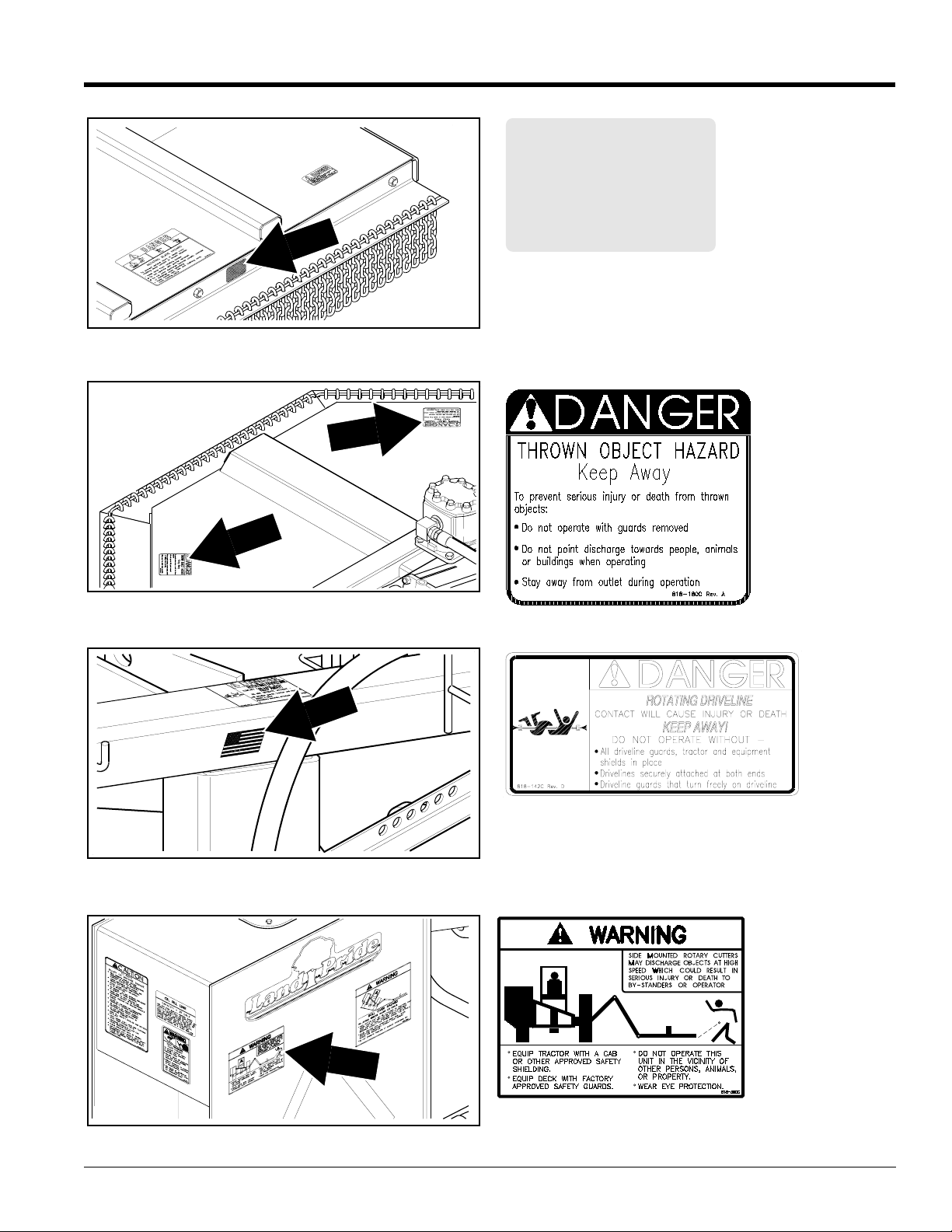

818-230C

Red Reflector

12429

818-180C

Danger Thrown Object

Hazard Keep

Away!

12322

12323

818-142C

Danger - Rotating Driveline Hazard

818-390C

Warning Thrown Object

Hazard

12321

4/28/08

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

5

Page 8

Important Safety Information

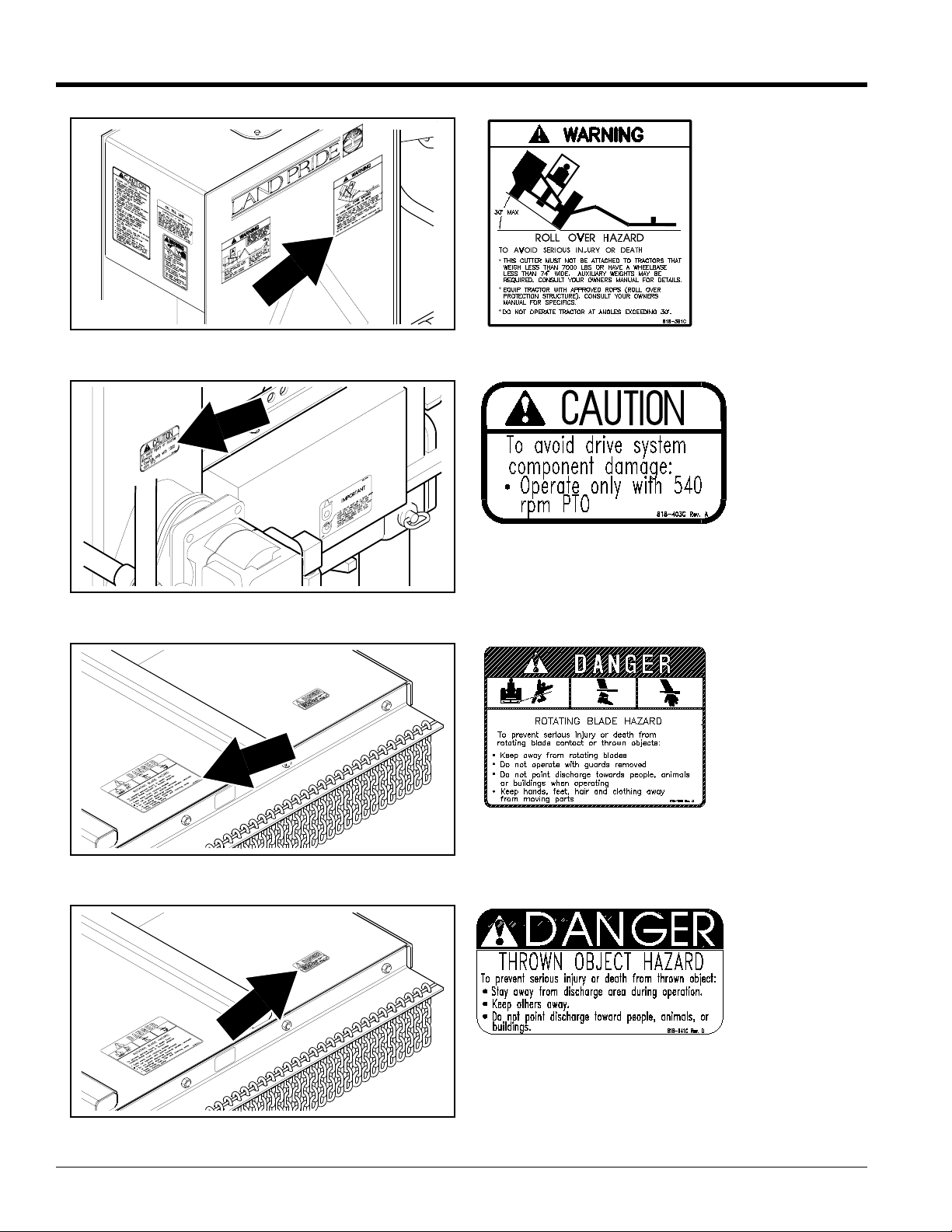

12222

Table of Contents

Land Pride

818-391C

Warning - Tractor

Roll Over Hazard

12324

12325

818-403C

(Used on 540 rpm PTO only)

Caution - 540 RPM PTO

818-186C

Danger - Keep Away Rotating Blade Hazard

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

6

12325

818-141C

Danger - Thrown Object Hazard

4/28/08

Page 9

Land Pride

Important Safety Information

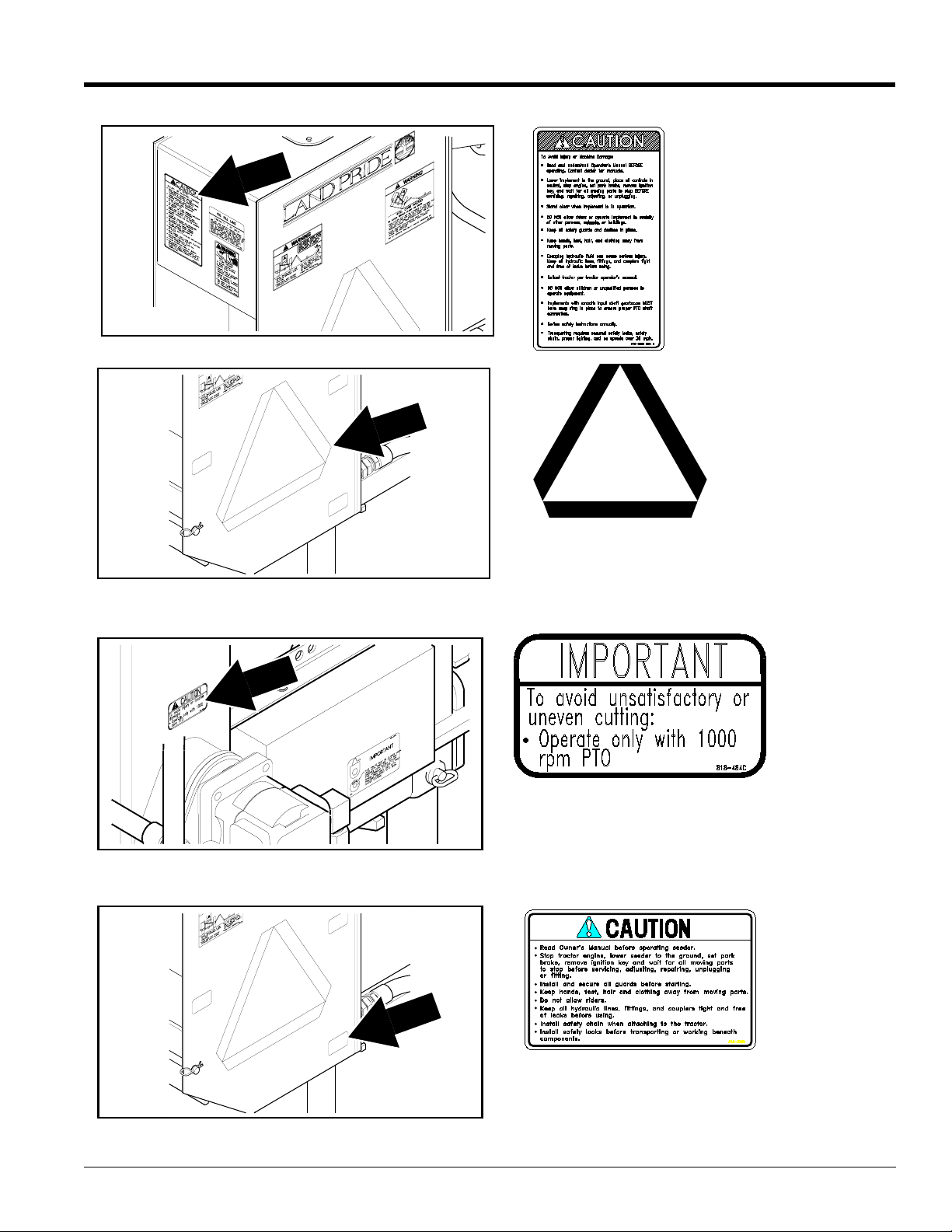

12222

Table of Contents

818-350C

Caution - General

Safety Information

13568

12324

818-003C

Slow Moving Vehicle Emblem

818-484C

(Used on 1000 rpm PTO only)

Important - 1000 rpm PTO

4/28/08

13568

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

818-338C

Caution! General Safety Information

7

Page 10

Table of Contents

Section 1: Introduction

Section 1: Introduction

Land Pride welcomes you to the growing family of new

product owners.

This Cutter has been designed with care and built by

skilledworkersusingqualitymaterials.Properassembly,

maintenance, and safe operating practices will help you

get years of satisfactory use from the machine.

Application

The RCP2560 Series Hydraulic Parallel Arm Rotary

Cutters are designed and built by Land Pride to provide

excellentcuttingperformanceonditchbanksandsloping

areas adjacent to right-of-ways, lakes, ponds and

streams. They are designed to work equally as well in

and around areas of restricted access such as over or

under fences, guardrails, low overhanging branches,

tree limbs, and hedges. These units perform extremely

well in tall grass cutting applications and will easily cut

through standing brush up to two inches in diameter.

The RCP2560 series is adapted for Category 2 or 3

three-point hitch mounting on 75 to 150 hp. tractors

weighing 7000 lbs. or more. Pump and reservoir system

require either 540 or 1000 input rpm. Cutter drive and

tractor will need to be equipped with, depending upon

operator configuration, one to four hydraulic outlets to

operate the cutters lift/extension/rotation arm.

SeeSection8:Specifications&Capacities on page 31for

additional information and performance enhancing

options.

Using This Manual

•

This Operator’s Manual is designed to help familiarize

you with safety, assembly, operation, adjustments,

troubleshooting, and maintenance. Read this manual

and follow the recommendations to help ensure safe

and efficient operation.

• The information contained within this manual was

current at the time of printing. Some parts may change

slightly to assure you of the best performance.

• To order a new Operator’s or Parts Manual contact

your authorized dealer. Manuals can also be

downloaded, free-of-charge from our website at

www.landpride.com or printed from the Land Pride

Service & Support Center by your dealer.

Terminology

“Right” or “Left” as used in this manual is determined by

facing the direction the machine will operate while in use

unless otherwise stated.

Definitions

Land Pride

Owner Assistance

The Warranty Registration card should be filled out by

the dealer at the time of purchase. This information is

necessary to provide you with quality customer service.

If customer service or repair parts are required contact a

LandPridedealer. A dealer has trained personnel, repair

parts and equipment needed to service the cutter.

The parts on your cutter have been specially designed

and should only be replaced with genuine Land Pride

parts. Therefore, should your cutter require replacement

parts go to your Land Pride Dealer.

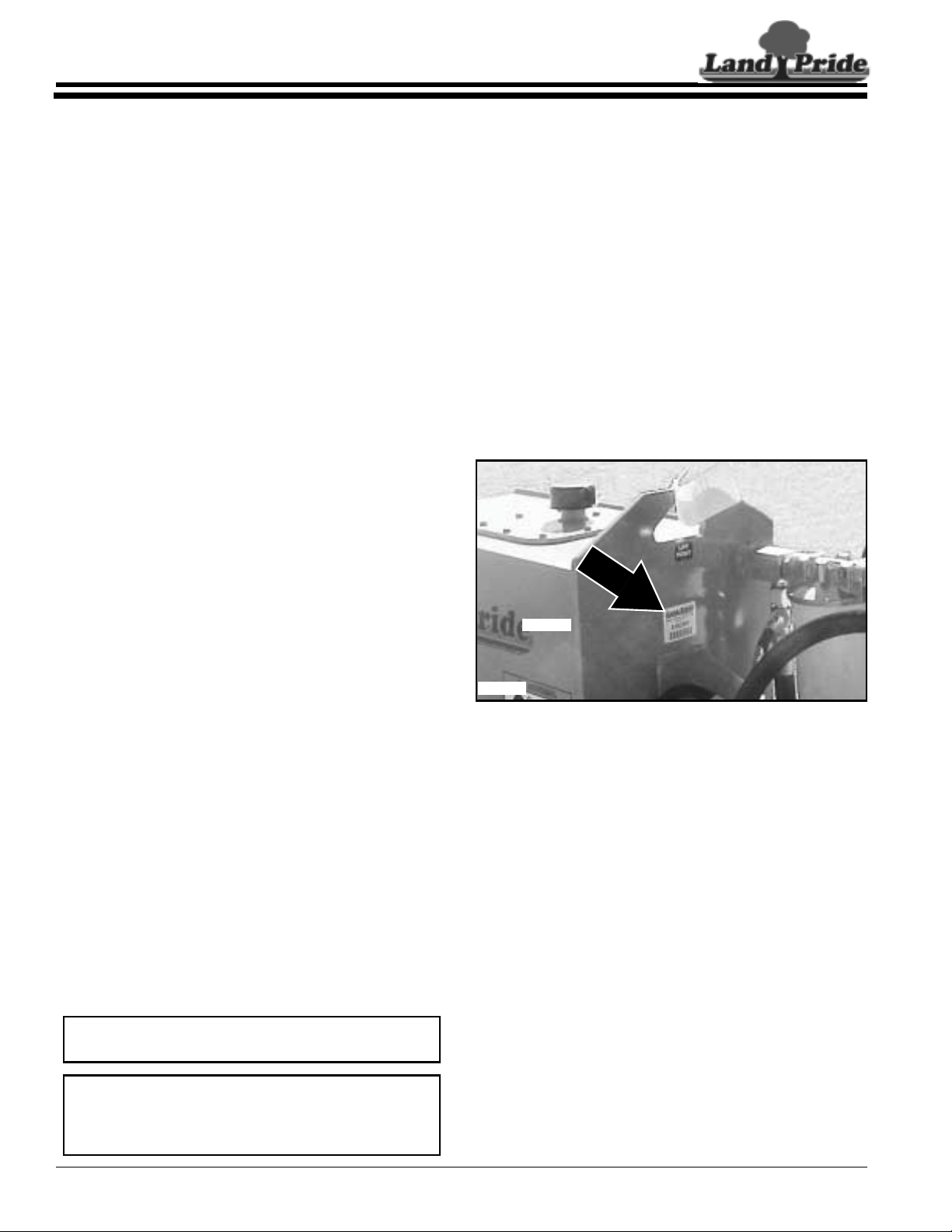

Serial Number Plate

For prompt service always use the serial number and

modelnumber when ordering partsfrom your Land Pride

dealer.Besuretoincludeyourserialandmodel numbers

incorrespondencealso. Refer to Figure 1forthe location

of your serial number plate.

22008

22008

Serial Number Plate Location

Figure 1

Further Assistance

Your dealer wants you to be satisfied with your new

cutter.Ifforanyreasonyoudonotunderstand any part of

thismanual or are not satisfied with theservice received,

the following actions are suggested:

1. Discuss the matter with your dealership ser vice

manager making sure he is aware of any problems

youmay haveand that he has had the opportunity to

assist you.

2. If you are still not satisfied, seek out the owner or

general manager of the dealership, explain the

problem and request assistance.

3. For further assistance write to:

NOTE: A special point of information that the

operator must be aware of before continuing.

IMPORTANT: A special point of information related

to its preceding topic. Land Pride’s intention is that

this information should be read and noted before

continuing.

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

8

Land Pride Service Department

1525 East North Street

P.O. Box 5060

Salina, Ks. 67402-5060

E-mail address

lpservicedept@landpride.com

4/28/08

Page 11

Land Pride

Section 2: Assembly & Set-up

Section 2: Assembly & Set-up

Table of Contents

Tractor Requirements

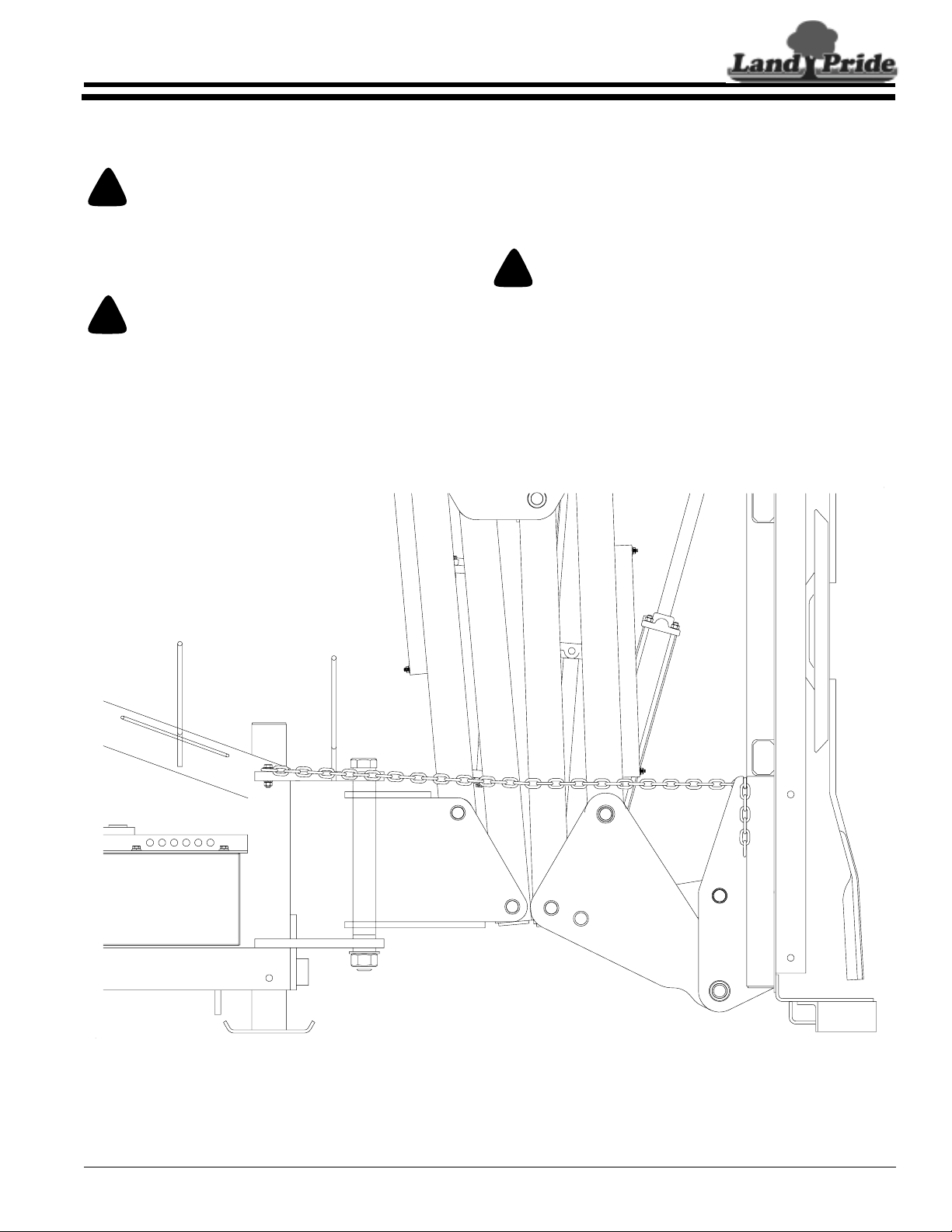

The Parallel Arm Cutter, by design, must be used only

on tractors that are capable of controlling the cutter

under all operatingconditions. When the arms are fully

extended, a right-hand torque load on the tractor is

present which will try to tip the tractor over! The tractor

MUST have a minimum weight of 7000 lbs. A 3-Point

Category II or Category III hitch with hydraulic lift

control is required.

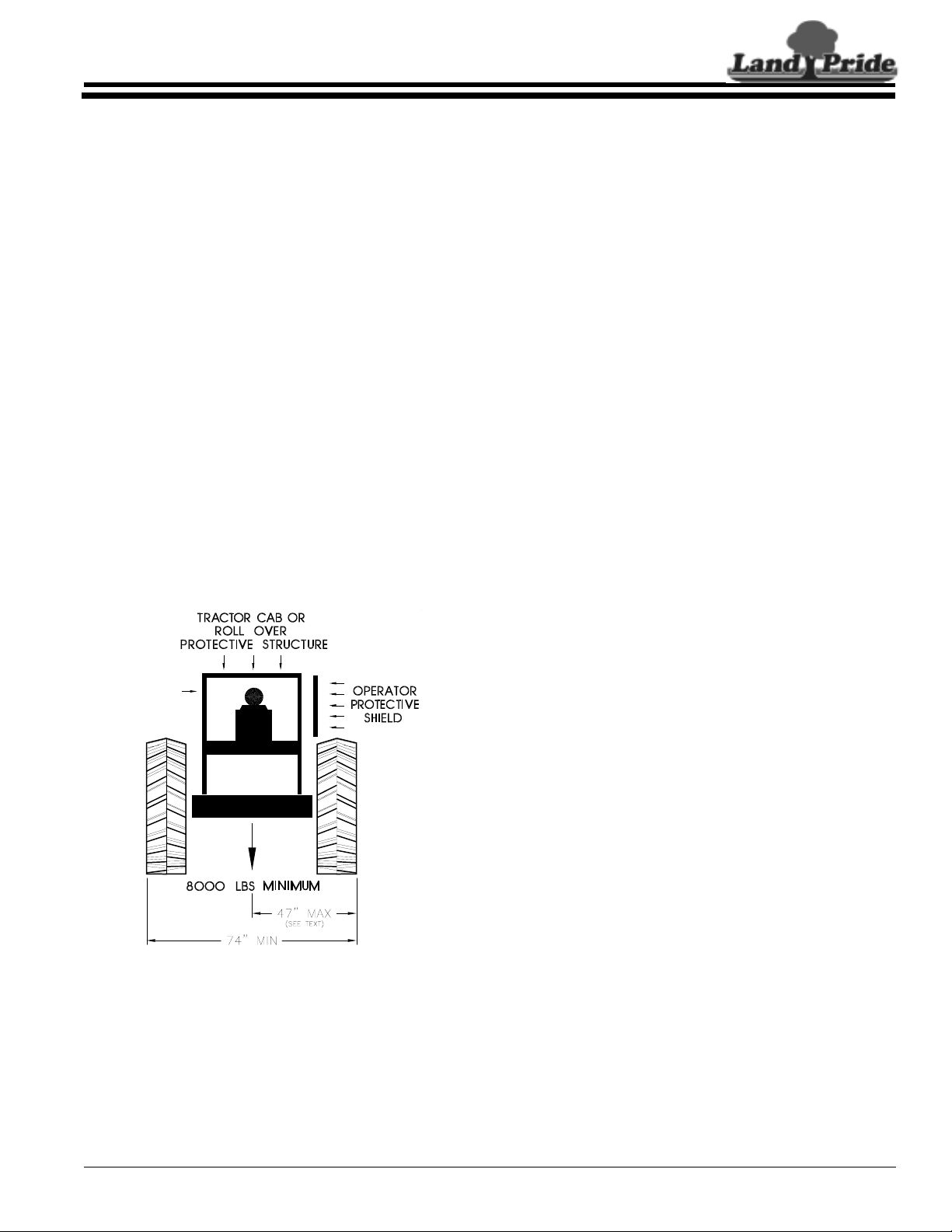

As shown in Figure 2-1, the rear wheel base must be

not less than 74" wide asmeasured from the outside of

each tire. If the right-hand tractor tire is more than 47"

from the center of the tractor, it may interfere with the

hydraulic motor on the deck when it is in the transport

position. If the tractor is equipped with dual wheels, the

right-hand dual may have to be removed.

A single, tractor duplex hydraulic outlet is required if

the cutter is equipped with the optional Electric

Cylinder Control. Three duplex hydraulic outlets will be

needed for parallel arm and deck control if the cutter is

NOT equipped with the optional Electric Cylinder

Control.

Anadditionaltractor,duplexhydraulicoutletisrequired

if the cutter is equipped with the optional hydraulic

breakaway cylinder.

A tractor Power Take-Off (PTO) is required for pump/

motoroperation. This cutteris available witheither 540

rpmor 1000 rpm rated PTO speed increasers.For best

fuel economy, it is recommended that the 540 rpm unit

be used on 1000 rpm tractors. However, PTO output

RPM must be carefully controlled (by engine RPM)

such that the PTO speed does not exceed 540 RPM.

The actual horsepower required for pump/motor

operation is approximately 30 HP.

If the tractor weight is less than 8500 lbs, auxiliary

counterbalance weights will be required. These

weights can be added to the weight bracket of the

hydraulic reservoir or (preferably) to the left-hand

tractor wheel.

The reservoir weight bracket is designed to be used

with conventional John Deere type suitcase weights each weight being 100 lbs. A total of 8 weights can be

added to the bracket.

ThetractorMUSTbeequippedwithoperatorprotective

equipment in the form of shielding from thrown objects

andRollOverProtectiveStructure(ROPS)asshownin

Figure 2-1.

A universal operator protective shield is available from

Great Plains Mfg. Refer to page 16 for more

information and installation.

It is also recommended that protective shielding or

screen be added to the right hand side of the tractor

engine cowling and radiator. This will help protect the

tractor finish and radiator against thrown objects.

The lower 3-Point links of the 3-Point hitch must be

stabilized to prevent side-to-side movement. Most

tractors have sway blocks or adjustable chains for this

purpose.

4/28/08

Minimum Tractor Requirements

Figure 2-1

12250

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

9

Page 12

Section 2: Assembly & Set-up

Table of Contents

Land Pride

Dealer Preparations

This cutter has been assembled at the factory. Some

preparation will be necessary to attach the cutter to the

customer’s tractor. Ensure that the intended tractor

conforms to the requirements stated under the heading

“Tractor Requirements” on page 9.

IMPORTANT: Hydraulic fluid must be added to the

hydraulic reservoir before this unit is placed into

operation. Do not attempt to run the pump without

fluid or damage to the pump will occur.

3-Point Hookup

Prepare the cutter as follows:

1. Locate the cutter on a flat and level concrete

surface.

2. For proper hitch configuration determine the hitch

category for the tractor being used.

(Refer to Figure 2-2 on page 11)

Preparation Checklist

3. Back the tractor into position and connect the

3-Point hitch ar ms and top link. Start the tractor,

thenslowly raise the 3-Point hitch about 1-2". Stow

the jack stands in the raised position.

Check to be sure that the deck safety chain is in

place.

Slowlyoperate thetractor's3-Pointhydraulic control

up and down and check for clearance between the

tires, reservoir, frame, drawbar etc.

Ensure that the lower arms are blocked to prevent

excessive side movement. Adjust the tractor's

Lower lift arms to level the cutter from left to right.

Adjustthe top-link so thatthecutterisapproximately

level from front to rear. A final adjustment will be

made later.

Before operating this unit, 80-90 EP Gear Lube must be added to the gearbox & motor as indicated in the

maintenance lubrication section (page 27) of this manual.

35 Gallons of Hydraulic Fluid for the hydraulic reservoir. Use any high quality mineral based hydraulic fluid such as

Mobil Fluid 424 with a viscosity rating of 10W-30.

Additional hydraulic fluid (approx 2 gallons) for the tractor reservoir.

Miscellaneous assembly tools: hammer, tape measure, hacksaw, assortment of wrenches and sockets,1/4" drill/drill

bits,

spirit level.

Quick disconnect adaptors to match your tractors duplex outlets. Quantities required depend on options selected:

(2) If equipped with Electric Cylinder Control Option

(6) If not equipped with Electric Switching Option

(2) If equipped with hydraulic Breakaway Cylinder Option

Possible need for forklift or hoist capable of lifting 2500 lbs.

Auxiliary tractor weights (depending on tractor size).

A minimum of two people available during assembly.

If a pin, bolt or other part has been removed, and you are unsure where it is used, use the parts section of this

manual to identify it. Be sure the part gets used in the correct location. By double checking while you assemble, you

will lessen the chance of using a bolt incorrectly that may be needed later.

Safety decals are legible and undamaged from shipment.

PTO shaft and loose parts bag/box shipped with the cutter.

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

10

4/28/08

Page 13

Land Pride

Section 2: Assembly & Set-up

Table of Contents

Category III

Standard & Quick Hitch

Category II

Quick Hitch

Category II

Standard Hitch

4/28/08

12251

Hitch Category

Figure 2-2

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

11

Page 14

Section 2: Assembly & Set-up

Table of Contents

Land Pride

PTO Hookup

IMPORTANT: Do not engage tractor PTO until

driveline is fully connected and hydraulic fluid has

been added to the cutter reservoir.

IMPORTANT: A quick hitch may be used, but is not

recommended because it moves the cutter deck

back about 5" and impedes operator visibility.

IMPORTANT: See Figure 1-4 below. Avoid

premature PTO dr iveline breakdown. PTO driveline

mustnot exceedanangle of 25 degrees upordown

while operating cutter.

Maximum PTO driveline Movement

Figure 1-4

b. Set tractor in park, shut tractor engine off, set park

brake and remove switch key.

c. Pull driveline apart into two sections as shown in

Figure1-5.Attach outer driveline universal joint to

the tractor PTO shaft. Attach inner driveline

universaljoint to the Rotary Cutter gearbox shaft.

Pull on each drivelinesection to be sure universal

joints are secured to the shafts.

d. Hold driveline sections parallel to each other to

determine if theyaretoolong. The inner and outer

shieldsoneach section should end approximately

1" short of reaching the universal joint shield on

the adjacent section (see “B” dimension). If they

are too long, measure 1" (“B” dimension) back

from the universal joint shieldand make a mark at

this location on the inner and outer driveline

shields.

e. Cut off inner shield at mark (“X” dimension). Cut

same amount off inner shaft (“X1” dimension).

Repeat cut off procedure (“Y”&“Y1” dimensions)

to outer driveline half.

f. Remove all burrs and cuttings.

13800

IMPORTANT: Always check driveline minimum

length during initial setup, when connecting to a

differenttractorand when alternatingbetweenusing

aquickhitch and a standard3-point hitch. More than

one driveline may be required to fit all applications.

IMPORTANT: Itisnecessary to aligningthe tractor’s

PTO shaft level with the Rotary Cutter’s gearbox

shaft when checking driveline minimum length. Too

long a driveline can damage tractor, gearbox and

driveline.

Check Driveline Minimum Length

Refer to Figure 1-5

1. Start tractor and slowly engage 3-point controls to

move lower arms until the Rotary Cutter’s gearbox

shaft is approximately level with tractor's PTO shaft.

2. Slide inner yoke of the driveline over the cutter’s

gearbox shaft and secure with locking collar.

3. Slide outer yoke end of driveline over tractor PTO

shaft and secure with locking collar. Skip to step 5 on

page 12 if driveline fits between tractor and Rotary

Cutter.

4. Thedrivelinewillrequireshorteningifitis too long to fit

between tractor and Rotary Cutter. Shorten driveline

as follows:

a. Raise/lower 3-point lower arms until Rotary Cutter

and tractor PTO shafts are approximately level

with each other. Securely support cutter frame in

this position with blocking.

Shortening PTO Driveline Shields and Shafts

Figure 1-5

5. Apply multi-purpose grease to the inside of the outer

driveline shaft and reassemble the two shafts.

6. Attach inner driveline yoke to the cutter gearbox input

shaft.

7. Attach outer driveline yoke to the tractor's PTO shaft.

8. The driveline should now be moved back and forth to

insure that both ends are secured to the tractor and

Rotary Cutter PTO shafts. Reattach any end that is

loose.

IMPORTANT: Two small chains supplied with the

driveline must be attached to restrict dr iveline shield

rotation.

9. Hookoneofthedrivelinesafetychains in a hole on the

outeryokeshieldand the opposite end to the tractor to

restrict outer shield rotation.

10. Hook second driveline safety chain in a hole on the

inner yoke shield and opposite end to the Rotary

Cutter frame to restrict inner shield rotation.

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

12

4/28/08

Page 15

Land Pride

Table of Contents

Section 2: Assembly & Set-up

11. Start tractor and raise cutter just enough to remove

support blocks used in step 4a on page 12.

12. Slowly engage tractor’s hydraulic 3-point controls to

raise and lower the cutter. Check drawbar clearance.

Move or remove drawbar as needed.

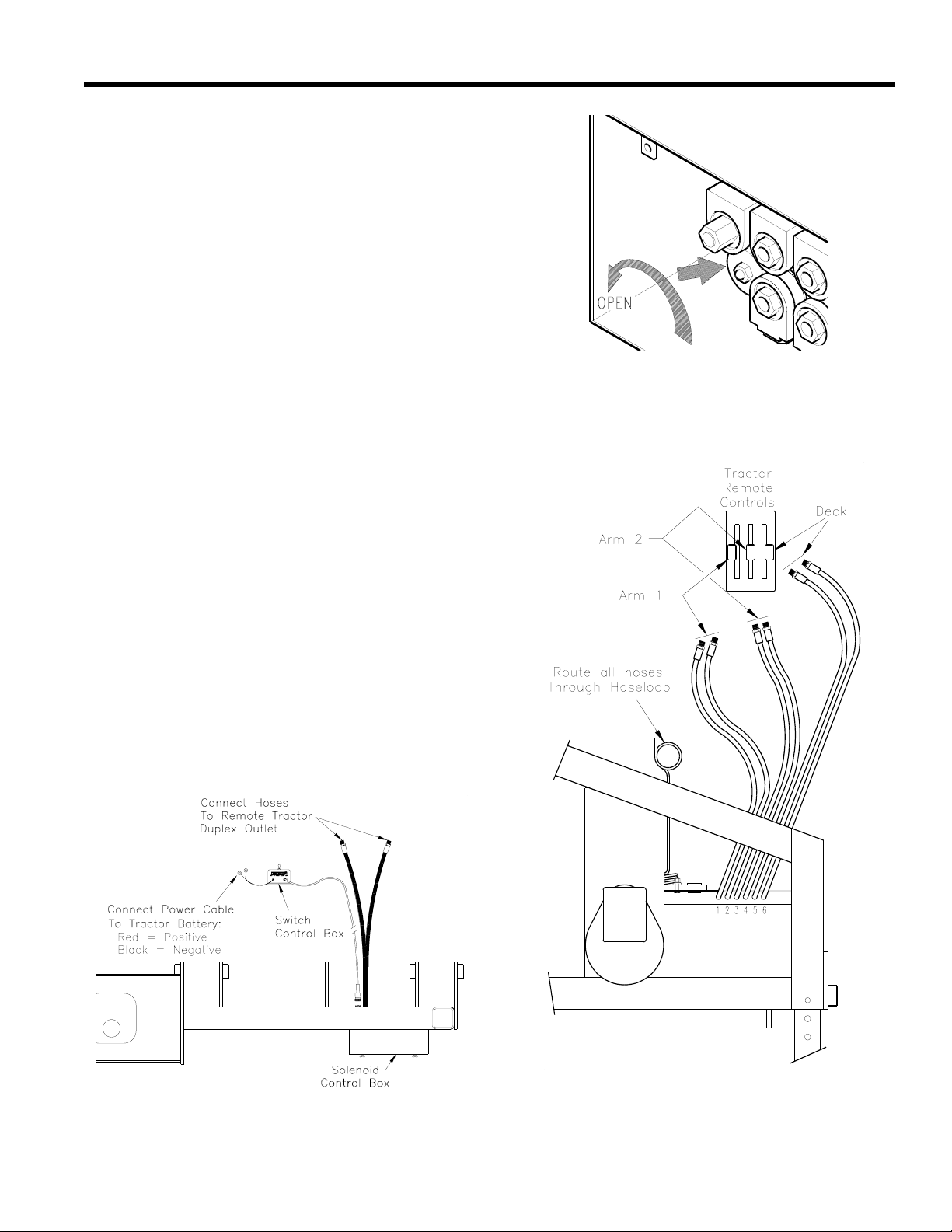

Hydraulic Hookup

1. Connect the hydraulic hoses to the tractor duplex

outlet(s). “Pioneer” quick disconnect hose couplings

are supplied with each hose. Some tractors use

other types of quick couplers.

a. See Figure 2-4: If the cutter is equipped with the

optional electric cylinder control, two hoses from

the solenoid valve control box will be attached to

a single duplex outlet on the tractor.

See Figure 2-5: You must determine if the tractor

being used is configured for “OPEN” or

“CLOSED” center hydraulic flow. Consult the

tractor operator's manual if unsure. Remove the

access cover located at the rear of the solenoid

valve control box to adjust the flow control valve.

If the tractor is OPEN center, the valve must be

open(turnknob counterclockwise). If the tractor is

CLOSED center, the valve must be closed (turn

knob clockwise).

b. See Figure 2-6: If the cutter is NOTequippedwith

the optional Electric Cylinder Control, six hoses

(2 per cylinder) will be connected to 3 duplex

outlets on your tractor. Each tractor duplex outlet

must be capable of infinite, variable flow control

by the operator and should have center detent

(off) levers. A typical tractor setup is shown in

Figure 2-6. The hoses on each outlet should be

connected such that when the control lever is

pushed“forward”,thearm (or deck)extends.If the

levers operate in reverse, simply reverse the

hoses at the duplex receptacle.

12374

12255

Flow Control Valve Knob

Figure 2-5

Optional Electrical Control Hook-Up (S/N 163695-)

Figure 2-4

4/28/08

12253

Hose Hookup Without Electric Cylinder Control Option

Figure 2-6

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

13

Page 16

Table of Contents

Section 2: Assembly & Set-up

c. See Figure 2-7: If the cutter is equipped with the

optionalbreakawaycylinder,twoadditionalhoses

will be connected toa single duplexoutleton your

tractor.

12256

Breakaway Cylinder Hose Connections

Figure 2-7

2. Add 35 gallons of hydraulic fluid to the hydraulic

reservoir. Use any high quality mineral based

hydraulicfluid such asMobilfluid424 with a viscosity

rating of 10W-30. Use care to ensure that dust or

otherforeignparticles do notcontaminatethe fluid or

reservoir. Check the fluid level by inserting the

dipstick and cap all the way into the filler tube.

Electrical Hookup

NOTE: If the tractor has dual 6 volt batteries, see

the tractors owners manual for proper 12 volt

hook-up.

Land Pride

12257

Electric Switch Control Box

Figure 2-8

Mount the Switch Control Box using either sheet metal

screws (for plastic type consoles) or machine screws,

nutsand washer. Routethe control cableto the Solenoid

Control Box and connect the circular plastic connector to

the mating connector on the box.

See Figure 2-4 on page 13.Route the power cable to the

tractor battery or circuit breaker panel. A 10 Amp or

larger fuse/circuit breaker source should be used.

Connect the red lead to the positive power source.

Connect the black lead to the negative source.

IMPORTANT: Connect leads to 12VDC power

source only. Connection to 24VDC or larger will

damage electrohydraulic components.

Ensure that the 10 Amp circuit breaker located on the

switch control box is pushed in prior to functional check.

IMPORTANT: This section only applies to Unitswith

Solenoid Control Valve Option.

Determine if tractor is “OPEN” or “CLOSED” Center

HydraulicSystem. If unsure consultyour tractors owners

manual and/or contact your tractor dealer.

IMPORTANT: All dual 6 volt batteries are not

hooked up correctly cylinders may not function

properly due to solenoid valves not being fully

charged. Arm and deck functions will be slow.

See Figure 2-8: Find a suitable location for the Switch

Control Box. Based on our experience, the location

should be close to the right hand side of the operator most generally on the tractor fender or fender console.

Exact location should be convenient to the specific

operator. Orient the Control Box such that the switches

are relative to the movement of the deck and parallel

arms. I.e., when the switch is toggled, the arms or deck

should move in the same relative direction as the handle

of the switch.

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

14

12443

Deck Safety Chain

Figure 2-9

4/28/08

Page 17

Land Pride

Section 2: Assembly & Set-up

Table of Contents

Functional Check

1. Removethe decksafety chain from thelatch position

and place the loose end on the stowage hook

provided.SeeFigure 2-9. Startthetractorandadjust

the 3-point hitch until the PTO shaft is approximately

level.

2. Cycle the parallel arm and deck cylinders for proper

operation.

!

Hydraulic fluid under pressure can penetrate skin. Wear

protective gloves and safety glasses or goggles when working

with hydraulic systems. Use a piece of cardboard or wood

rather than hands when searching for hydraulic leaks. If

hydraulic fluid is injected into the skin, it must be treated by a

doctor within a few hours or gangrene may result.

DANGER

NOTE: The following procedure assumes that the

cutter is equipped with the optional Electric Cylinder

Control. Go to step “c” if your cutter is not equipped

with this option.

a. In Step 1.a. (Hydraulic Hookup), two hoses from

the Solenoid Control Valve were connected to a

single duplex outlet on the tractor. If the tractor is

equipped with more than one remote duplex

outlet, you must first determine which console

lever is used to control this outlet. The control

lever must then be locked into the “Automatic

Extend Position” or the “Automatic Retract

Position”.

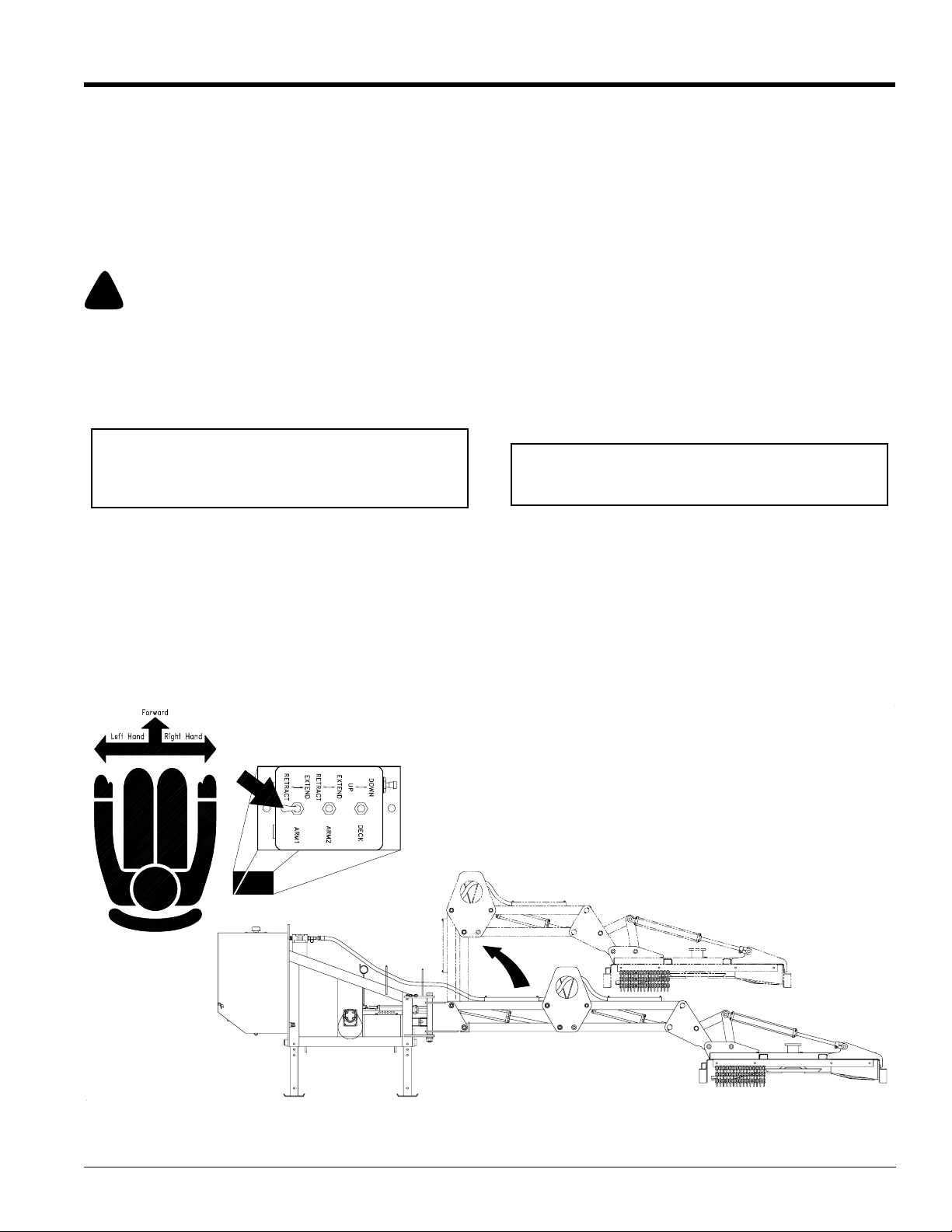

b. Toggle the switch on the control box labeled

“ARM1” by pushing it forward (away from you).

The inboard parallel arm should extend outward.

If it does not move, or moves in the opposite

direction (retracts), you should either change the

position of the console lever (from retract to

extend or vice-versa) or reverse the hoses at the

duplex outlet. Toggle the ARM1 switch by pulling

back on it. The inboard parallel arm should

retract. See Figure 2-10.

Repeat this procedure for the remaining arm and

deck cylinders. Cycle all of the cylinders to full

extension and retraction to remove any air that

might be trapped in the system.

Check the hydraulic fluid level in your tractor's

reservoir. If low, add fluid to the system before

proceeding. The cylinders and hoses will require

approximately 1 3/4 gallons from the tractor.

NOTE: Thefollowing procedure is for those cutters

that are not equipped with the Electric Cylinder

Control.

c. Operate the tractor console control lever

designated for “ARM1” by pushing it forward. The

inboard arm should extend outward. If the arm

tries to retract, reverse the hoses at the duplex

outlet. See Figure 2-10.

Repeat this procedure for the remaining arm and

deck cylinders. Cycle all of the cylinders to full

extension and retraction to purge any air that

might be trapped in the system.

12254

4/28/08

Parallel Arm Movement

Figure 2-10

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

15

Page 18

Section 2: Assembly & Set-up

Table of Contents

Land Pride

Check the hydraulic fluid level in your tractor's

reservoir. If low, add fluid to the system before

proceeding. The cylinders and hoses will require

approximately 1 3/4 gallons from the tractor.

d. Move the tractor and cutter to a remote location

(awayfrom all other persons) to check pump/

motor operation. Check to be sure the Hydraulic

Reservoir shut-off valve is full OPEN. If this

service valve is turned off, damage will occur to

the pump.

Position the cutter deck flat on the ground or

concrete surface. SLOWLY engage the PTO to

start blade rotation. On initial start-up, blade

position may cause the deck to “vibrate”. After 23 revolutions, these vibrations should stop. If the

deck continues to vibrate, shut off the PTO, raise

the deck and check for locked blades.

Gradually increase engine RPM until PTO output

RPM is 540. The deck should not exhibit

excessive vibration.

IMPORTANT: If the tractor being used is equipped

with a 1000 RPM PTO output, be sure that throttle

RPM is reduced to limit PTO output to 540 RPM.

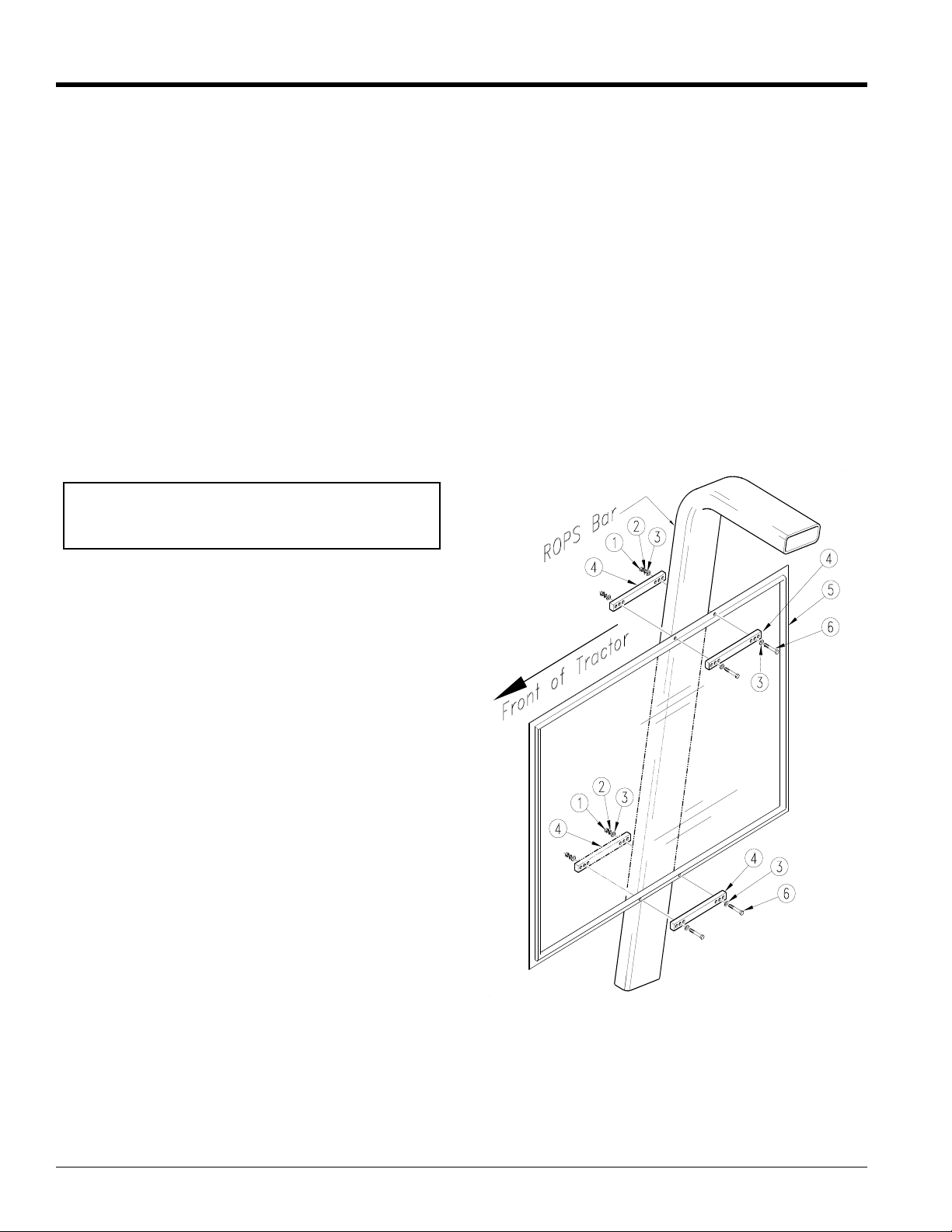

Carefullyremove the shieldfrom the shipping carton and

temporarily position it on the inside surface of the ROPS

bar. Locate the shield forward/back, up/down to provide

the best overall coverage for the tractor operator. Use a

spirit level to level the shield before marking. Mark the

top frame location with a pencil on each side of the

ROPS bar, and mark the vertical ROPS location on the

frame of the shield.

Position the shield (#5) on a flat work surface. Locate

one of the 316-116D (#4) flatbars next to the pencil

marks to determine which set of holes will clear the

vertical marks for the ROPS location. Mark the hole

location and drill two 1/4" diameter holes through the

frameofthe shield. Similarly mark and drilltwoadditional

holes for the lower clamp location.

Attach the shield to the inside surface of the ROPS bar

using the mounting hardware provided (#1), (#2), (#3),

and (#6).

Operator Protective Shield

Anoptional operator protective shieldis available for use

on tractors not equipped with cabs or other protective

shielding. This shield isa "universal" type andis suitable

for attachment to a conventional Roll Over Protective

Structure (ROPS) bar that is already attached to the

tractor. The shield is constructed of an extruded

aluminum frame and is glazed with 1/4" clear, lexan

polycarbonate.

Mounting hardware will permit attachment to ROPS

having cross-section dimensions of 2" x 4", 2" x 5", and

2" x 6" or 2 1/2" x 4", 2 1/2" x5 and 2 1/2" x6. Other sizes

may require longer mounting bolts and/or custom

flatbars. Installation requires that 4 mounting holes be

drilled in the frame of theshield. No modification is made

to the ROPS.

Installation

Refer to Figure 2-11:

Measurethe width andthickness of the ROPS bar on the

tractorto determine that theclamping hardware supplied

will be adequate.

Compare the parts list on and quantities with the parts

received. Report any missing or damaged items to your

dealer.

To determine the best location for the shield, the cutter

should be connected to the tractor. The parallel arms

should be fully extended and the deck should be

horizontal (or approximately level).

13239

Operator Protective Shield

Figure 2-11

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

16

4/28/08

Page 19

Land Pride

Section 2: Assembly & Set-up

Table of Contents

Setting Flow Control Valve

This procedure is for those units with the solenoid valve

option, on RCP 2560 and RCPM2560.

NOTE: Parallel Arm Cutters with (S/N 163695-) will

require flow control valve kit #316-068K if your

tractor does not have flow control (turtle/rabbit

control) or if your tractor uses an open center

hydraulic system. Check your tractor’s operator’s

manual to determine your tractor’s set-up.

The flow control valve diverts excess oil back to the

tractor, which in turn keeps the back pressure down and

keeps the oil cooler.

IMPORTANT: Overheatingof the oil may occur if the flow

control kit is not installed. Damage to the o-ring in the

solenoid valve and/or the cylinders may occur if the oil

becomes overheated

1. Time the 2nd arm cylinder (arm furthest from the

tractor) from the fully extended position, to the fully

retracted position.

2. Set the tur tle/rabbit control on the tractor,or the flow

control valve (optional), so that the cylinder cycles at

5 seconds.

3. These cylinders require 5 GPM (gallons per minute)

for proper ar m function. Timing of the cylinder is the

easiest way to set the GPM.

.

Timing Procedures

Refer to Figure 2-12:

1. Set the RCP2560 in the transport position with the

arms and deck in the folded position.

2. Retract the 2nd cylinder which will raise the 2nd

arms up. Time this sequence. Time should be 5

seconds.

3. Adjust the turtle/rabbit control or the flow control

valve until the cycle time is 5 seconds.

4. The unit is now set for proper operation.

If the unit is having overheating problems through the

hydraulics, check the tractor’s operator’s manual for

power beyond hook-up.

4/28/08

Timing Procedures

Figure 2-12

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

14739

17

Page 20

Section 3: Hydraulics

Section 3: Hydraulics

Table of Contents

Land Pride

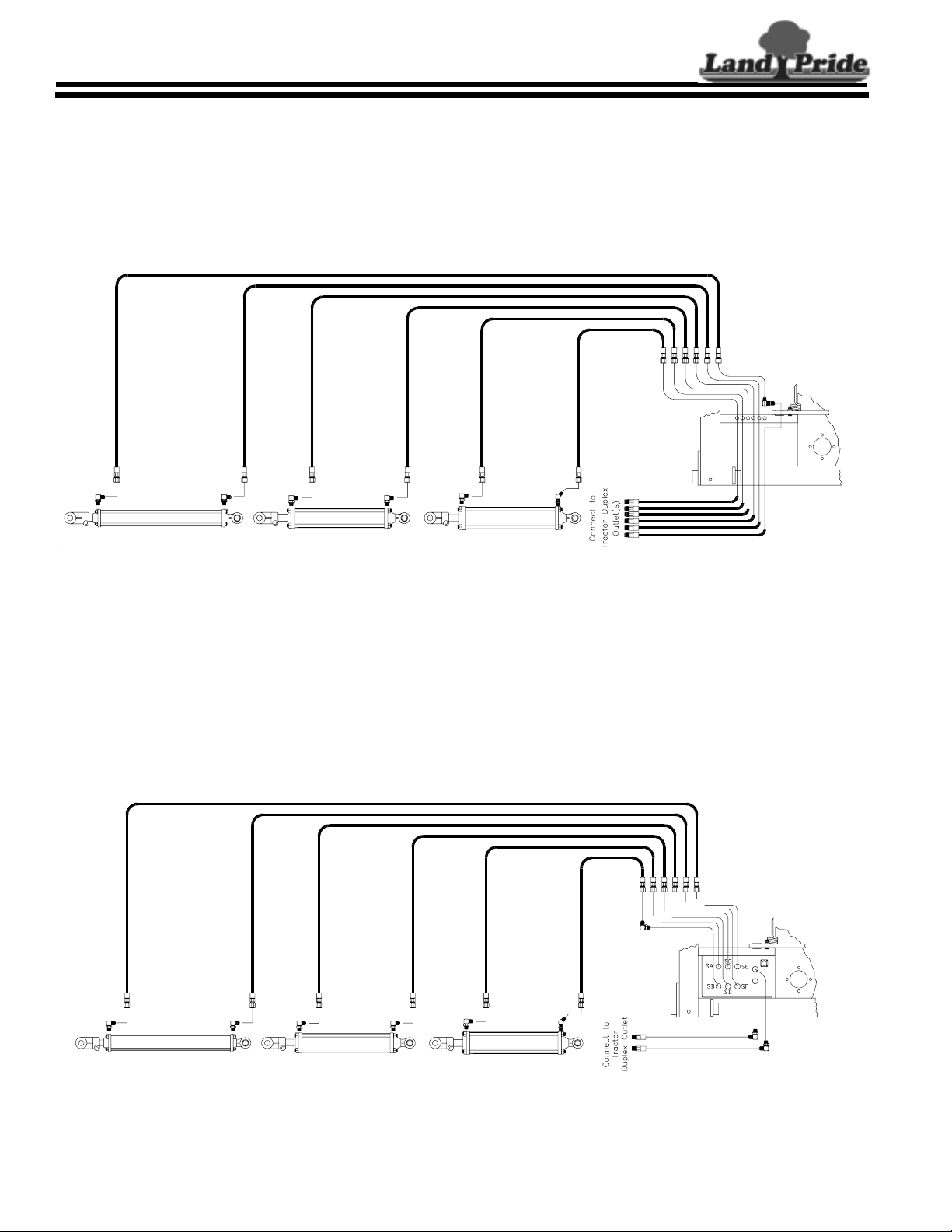

Hydraulic Cylinder Plumbing

The standard Parallel Arm Cutter is equipped with

three (3) remote cylinders to operate the parallel arms

and the cutter deck. These cylinders are connected

12260

Remote Cylinder Plumbing

Figure 3-1

directly to the tractor's remote duplex outlets and

controlled by the tractor operator. Each cylinder

requires a single duplex outlet on the tractor. See

Figure 3-1.

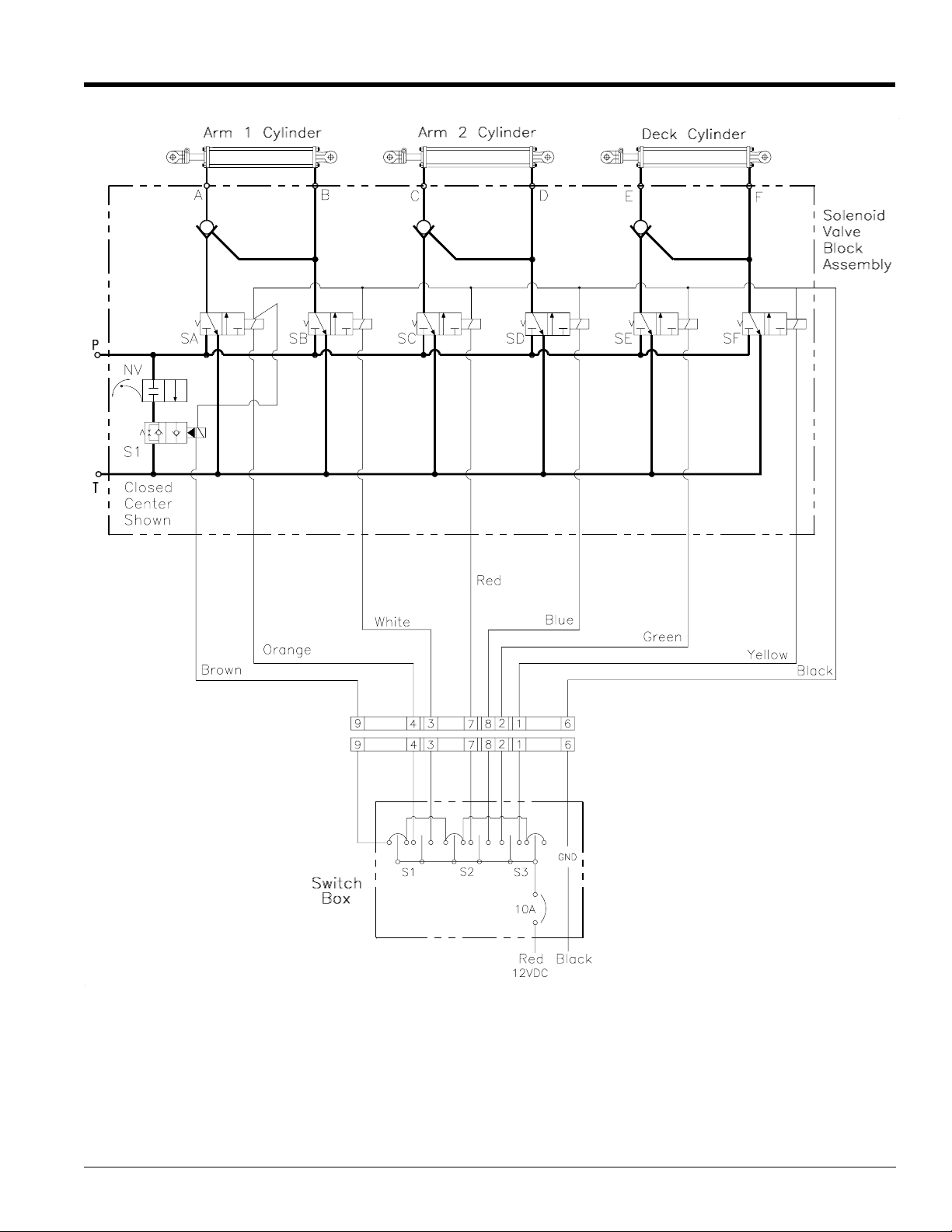

An optional electric cylinder control provides for

toggle switch operation of each cylinder. Response

time is much faster than with tractor controls and this

option is recommended where frequent changes are

12261

Remote Cylinder Plumbing

(Optional Electric Cylinder Control)

Figure 3-2

necessary because of terrain or cutting conditions.

Ditches and embankments are typical examples. The

electriccylindercontroloptioncan be easily added as a

field installation kit. See Figure 3-2.

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

18

4/28/08

Page 21

Land Pride

Section 3: Hydraulics

Table of Contents

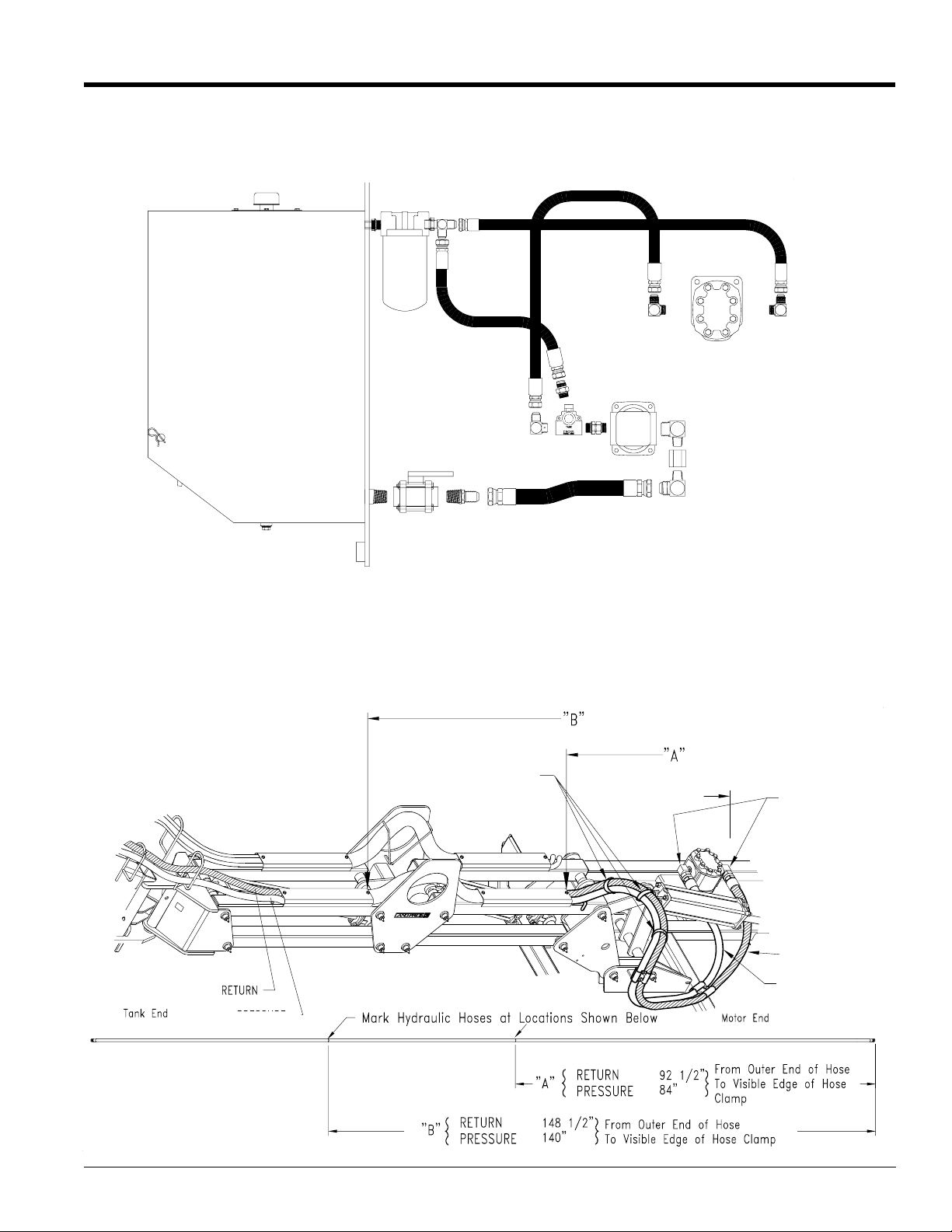

The hydraulic pump/motor circuit is shown in

Figure 3-3. It operates via a tractor driven PTO and is

notconnectedtotractorhydraulics. The pump receives

fluid from a 35 gallon reservoir. If the cutter blades are

stalled, an overpressure relief valve opens to provide a

return path to the reservoir.

12262

Marking Hydraulic Line Lengths

Hydraulic lines are marked to length from motor to

pump and pump to motor as outlined in Figure 3-4

below.

Hose Locations for Hydraulic

Pump and Motor

Figure 3-4

Hydraulic Pump Motor Circuit

Figure 3-3

Tie Strap

Outer End

*Orient 811-411C

Hyd. Fittings so they

are 45˚ down

towards deck

Return Line

Pressure Line

Pressure Line

**Twist return hose (811-404C) counterclockwise until it follows the same

contour as pressure hose

(811-403C).

13776

4/28/08

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

19

Page 22

Section 3: Hydraulics

Table of Contents

Land Pride

The breakaway cylinder or tension bolt is used to

prevent structural damage to the cutter head and

parallelarms. If the cutter head strikes anobject during

forward movement, the breakaway cylinder extends allowing the cutter head and parallel arms to pivot 90

degrees to the rear. This movement is identical to that

of the tension bolt, but the big advantage of the

breakaway cylinder is that it can be easily reset using

the tractor's remote cylinder control levers.

The breakaway cylinder should be installed on the

cutter as shown in Figure 3-5. Be sure that the rod end

of the cylinder is located on the pivot lug as shown.

Connect both hoses from the cylinder to a remote

outlet on the tractor. The tension bolt should never be

used in conjunction with the breakaway cylinder.

The breakaway cylinder is designed to bypass

hydraulic fluid under high pressure when the cutter

head or parallel arms strike an object during forward

movement. Do not use any standard hydraulic cylinder

for a breakaway cylinder or damage could occur to the

unit.

NOTE: All units equipped with the breakaway

cylinderalso have a 1/2"tension bolt installed onthe

breakaway plates for shipping purposes. This bolt

must be removed after the cutter is hooked up to the

tractor.

12231

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

20

Breakaway Cylinder Installation

Figure 3-5

4/28/08

Page 23

Land Pride

Section 3: Hydraulics

Table of Contents

4/28/08

12263

Electric Cylinder Control Schematic (Optional)

Figure 3-6

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

21

Page 24

Section 4: Adjustments

Section 4: Adjustments

Table of Contents

Land Pride

Deck Level Adjustments

The cutter deck should be adjusted for level attitude.

Adjust the cutter head deck cylinder (using the tractor

or optional electric cylinder control) so that the deck is

approximately level from left to right.

5. Raise the 3-Point hitch until the PTOshaft is

approximatelylevel.Extend the parallel ar ms tofull

length.

6. Place a level on the cutter deck to read forward/aft

attitude.

7. Adjust the 3-Point top link so that the front of the

cutter deck is slightly lower than the rear

(approximately 1/2"). See Figure 4-1

Deck level Adjustments

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

22

12264

Figure 4-1

4/28/08

Page 25

Land Pride

Table of Contents

Section 5: Transporting

Section 5: Transporting

!

When traveling on public roads, whether at night or during

the day, use accessory lights and devices for adequate

warning to operator’s of other vehicles. Comply with all

federal, state and local laws.

Always disengage tractor PTO before transporting cutter to

avoid injury from thrown objects or blade contact.

8. Retract both parallel armsand position the deck to

CAUTION

!

CAUTION

vertical with thebladesfacingoutboard (awayfrom

the tractor).

9. Engagethe transpor t safetychainto the deck hook

(Figure 5-1).

10. Raise the 3-Point hitch up to provide 8-12" of

clearance for the deck.

!

The cutter is 10’-6" wide and care should be taken when

encountering oncoming traffic and roadside obstructions. If

in doubt about safe clearance, reduce speed and/or stop until

it is safe to proceed.

CAUTION

4/28/08

Transport Safety Chain

Figure 5-1

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

12265

23

Page 26

Section 6: Operating Procedures

Section 6: Operating Procedures

Table of Contents

Land Pride

!

WARNING

The following operating procedures must be carefully read

and fully understood. You are the tractor operator and are

therefore responsible for the safe operation of this unit. All

other persons must be cleared of the area. Cutter operation

must be stopped when in the vicinity of other persons.

11. After attachment to the tractor, carefully raise and

lower the cutter to ensure that the drawbar, tires,

and other equipment on the tractor do not contact

the cutter frame or PTO shaft.

12. Check all hoses and wires to be sure that they will

not contact the PTO shaft. PTO guards must be in

good condition and in place.

13. When the deck is in the transport position, and the

PTO disengaged, check to be sure the blades are

not locked (overlapped) together. The deck safety

chain must be engaged in the deck hook provided.

14. Check blades for sharpness and ensure that both

blade bolts as well as the center blade carrier hub

nut are tight. Check tractor safety equipment particularly the ROPS (Roll Over Protective

Structure) and the operator safety screen to be

sureboth are in goodworking condition. Wear your

safety glasses.

15. Removeand stow the deck safetychainjustpriorto

cutting. Adjust lower 3-point links such that the

PTO shaft is approximately level. Extend the

cutters parallel arms out and position the deck flat

on the ground.

16. Increase tractor throttle to approximately 500 RPM

and slowly engage the PTO. Initial start-up

vibration is normal, but should stop after a few

revolutions of the blade carrier. If vibration

continues, stop PTO rotation. Wait for the blade

carrier to come to a complete stop before

dismountingfromthetractor,thencheckthe blades

to be sure they are not locked together.

17. Once the cutter is running smooth increase tractor

throttle to provide for 540 PTO RPM.

IMPORTANT: If a 1000 RPM tractor PTO is being

used, engine RPM MUST be reduced to limit PTO

RPM to 540. Excessive engine speed will cause

damage to the speed increaser and other power

train components.

18. Position the cutter deck for best operator visibility.

This is normally with the arms extended to

approximately 3/4 of full extension. Adjust deck

attitude and height. Optimum ground speed will

depend on the density of the material being cut,

operatorawareness,and (in some cases) terrain.If

in doubt, reduce tractor ground speed to a

comfortable level.

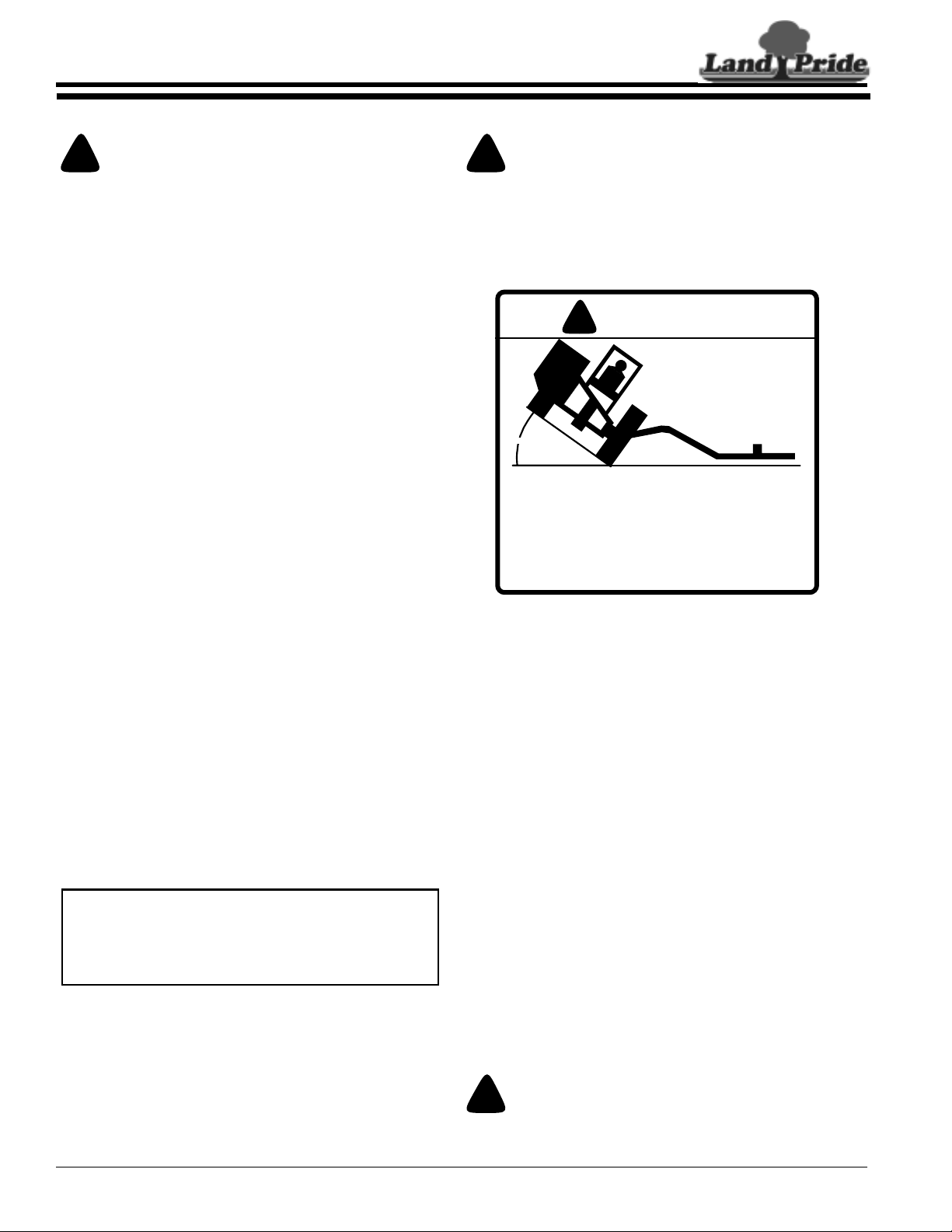

!

Do not operate this cutter under any terrain conditions that

would place the tractor at an angle exceeding 30 degrees

either front-to-rear or left-to-right. Ensure that adequate

ballast weights are provided on both the front of the tractor

and left of the tractor and left hand side of cutter to assure

tractor stability. See Figure 6-1.

WARNING

WARNING

!

30° MAX

TO AVOID SERIOUS INJURY OR DEATH

•THIS CUTTER MUST NOT BE ATTACHED TO TRACTORS THAT

REQUIRED. CONSULT YOUR OWNERS MANUAL FOR DETAILS.

ROLL OVER HAZARD

WEIGH LESS THAN 7000 LBS OR HAVE A WHEELBASE

LESS THAN 74" WIDE. AUXILIARY WEIGHTS MAY BE

•EQUIP TRACTOR WITH APPROVED ROPS (ROLL OVER

PROTECTION STRUCTURE). CONSULT YOUR OWNERS

MANUAL FOR SPECIFICS.

Maximum Tractor Angle

Figure 6-1

818-391C

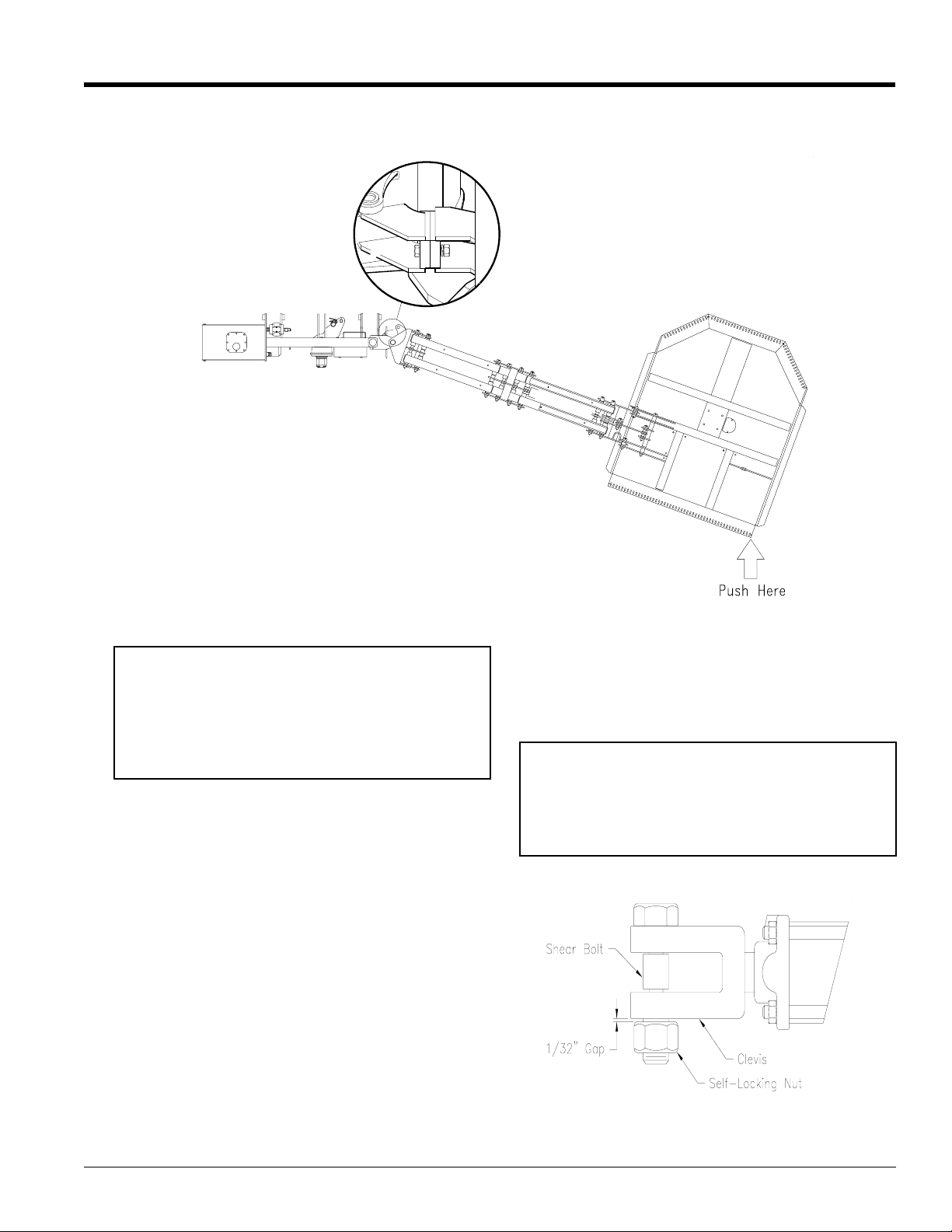

Breakaway Operations

This cutter is designed for breakaway of the cutter

head and parallel arms in the event the cutter head

contacts an immovable object or irregular terrain

duringforward tractor movement. The“breakaway” will

prevent structural damage to the cutter head, parallel

arms, and mainframe in the event of such contact. See

Figure 6-2.

Upon breakaway, the cutter head must be reset to the

original "home" position before normal cutting

operations can be resumed. Reset to the home

position is accomplished somewhat differently

depending on whether the cutter is equipped with the

standard tension bolt or the optional breakaway

(hydraulic) cylinder.

Tension Bolt

1. Raise the arms and deck upward to clear any

obstacles located behind the cutter deck.

2. Slowly back the tractor and cutter awayfrom those

obstacles that would interfere with rotating the

deck and arms back to the “home” position.

!

Shut off PTO power, put the tractor in park and wait for the

blades to stop rotating before dismounting from the tractor.

WARNING

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

24

4/28/08

Page 27

Land Pride

Section 6: Operating Procedures

Table of Contents

3. Push the deck forward until the breakaway plate

reaches the stop plate. See Figure 6-2. Replace

the tension bolt.

Breakaway Cylinder

1. Raise the arms and deck upward to clear any

obstacles located behind the cutter deck.

2. Slowly back the tractor and cutter awayfrom those

obstacles that would interfere with rotating the

deck and arms to the “home” position.

3. Use the tractor’sremote (cylinder) control to rotate

the deck/arms back to the “home” position.

IMPORTANT: Do not attempt to operate the

cutter in reverse. The breakaway mechanism will

function ONLY when the tractor is moving in a

forwarddirection. Cutter operation with the tractor in

reverse gear may cause structural damage to the

parallel arms if the cutter head strikes a solid or

immovable object.

A shear bolt is located at the rod end of the (optional)

breakaway cylinder. This bolt may shear under the

following conditions:

1. After breakaway, the operator backs the tractor

awayfrom the obstruction, but encounters an

additional obstruction or immovable object while

operating the tractor in reverse. Specifically, the

operator failed to raise the deck high enough to

clear the object before operating the tractor in

reverse.

2. The operator tried to reset the deck/arms by

backing the tractor into an obstruction rather than

using the tractor’s remote cylinder control.

3. The shear bolt has become fatigued after repeated

breakaway cycles and resets.

4. The self-locking nut used to hold the shear bolt in

place has been torqued to the point of contacting

the rod end of the cylinder and, because of

preloading causes the shear bolt to shear with

reduced effort.

IMPORTANT: Do not back the tractor to reset the deck

to “home” position. Doing so may cause severe

structural damage to the mainframe.

Breakaway Manual Reset

Figure 6-2

12267

In the event of shear bolt failure, the shear bolt MUST

be replaced with the correct replacement part (316118D). The use of a substitute part may result in

damage to the parallel arms or main frame. A single

replacement part is included with each cutter and is

located on a bracket adjacent to the upper 3-point

hitch.

IMPORTANT: Torque the self-locking nut onto the

shear bolt, but do not turn it so far as to make

contact with the clevis of the hydraulic cylinder. In

other words, the nut should be threaded onto the

shear bolt to within approximately 1/32" of contact

with the clevis. See Figure 6-3.

13403

Shear Bolt Space

Figure 6-3

4/28/08

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

25

Page 28

Section 6: Operating Procedures

Table of Contents

Land Pride

General Operating Instructions

The RCP2560 Series Parallel Arm Hydraulic Rotary

Cutter is uniquely versatile and a powerfully productive

cutting implement in the hands of a skilled,

knowledgeable, and responsible operator. This unit is

frequently operated on inclines in populated areas and

near high traffic. Therefore, it is absolutely essential that

no one operates this cutter without first becoming totally

familiar with the Operator’s Manual. Make sure you pay

particular attention to Section 1 on Safety Rules, Section

2 on Assembly Instructions and Set-up, Section 5 on

Transporting, Section 6 on Operating Procedures, and

Section 7 on Maintenance and Lubrication.

You may put the Rotary Cutter to work once you have

carefully read and fully understood this Operator’s

manual. Transport to the work site at a safe speed and in

a manner that allows faster moving vehicles to pass

safely. A slow moving vehicle sign should always be

properly displayed when using public roads or right-of

ways. Upon arriving at the work site, shut-off the tractor,

set the brakes, remove ignition key, and dismount to

preform the following checks:

• Remove and safely store away deck safety chain.

• Verify thatthe PTO shaft is approximately level. Adjust

3-point link if PTO shaft is not level.

• Visually inspect cutter blades. Make certain they are

not overlapped and locked together.

Return to the tractor, after preforming the above checks,

to start the engine. Extend the cutter’s parallel arm out

and position the deck flat on the ground. Adjust height of

the parallel arm and cutting deck for good visibility and

unobstructed performance. Set engine RPM at idle or

slightly above and engage PTO. Initial start-up vibration

is normal and should smooth out after a few revolutions

of the cutter blades unless the blades are locked

together. Increase tractor throttle PTO speed to 540

RPM. Proceed forward at a mowing speed that is

comfortable and will produce a quality cut for ground

conditions and material density.

The RCP2560 Rotary Cutter is designed with an

automatic breakaway cutter head and parallel arm that

releases when the unit contacts immovable objects or

irregular terrain. The cutter head must be reset to “home

position”after each breakawaybefore cutting operations

can resume. See Section 6, page 24, “Breakaway

Operations” for additional information on resetting the

cutter head to “home position”.

See“Section8: Specifications & Capacities” onpage 31.

for additional information on performance enhancing

options.

It requires patience, practice, and attention to detail to

becomeanexpertoperator on your Land Pride RCP2560

Series Cutter, but the end result is well worth the effort.

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

26

4/28/08

Page 29

Land Pride

Section 7: Maintenance & Lubrication

Section 7: Maintenance & Lubrication

Lubrication Points

Table of Contents

Lubrication

Legend

Multi-purpose

spray lube

12266

Multi-purpose

grease lube

Multi-purpose

oil lube

Parallel Arm Cutter Zerks

14Zerks

Type of Lubrication: Grease

50

50

Hours

8

Hours

Intervals in hours

at which lubrication

is required

12269

14294

PTO Zerks

2 Zerks

Type of Lubrication: Grease

20

Hours

Driveline Profiles

Type of Lubrication: Multi-purpose Grease

Quantity = Disconnect driveline from the tractor and slide

apart. Clean and coat the inner tube of the driveline with a

light film of grease, then reassemble.

4/28/08

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

27

Page 30

Table of Contents

Section 7: Maintenance & Lubrication

Land Pride

The motor spindle hub housing (1), Figure 7-1 has two

cavityplugslocatedononesideof the housing just below

themotormounting flange. Position the cutter deckinthe

transport position and remove either plug to check fluid

level. Fluid level should be within 1/2" of the top of the

port. Add 80-90 weight gearlube as required. The

capacity of the cavity is approximately 1/3 pint.

13994

Motor/Spindle Hub

Figure 7-1

The hydraulic reservoir has an effective capacity of 35

gallons. A dipstick located on the filler cap indicates the

correct reservoir fluid level.

A filter mounted on the hydraulic reservoir is used to

clean the pump and motor system fluid. It should be

replaced after 2 years of service. A conventional 10

micron filter element should be used See Figure 7-2.

The speed increaser gearbox is mounted between the

PTO shaft and the hydraulic pump. It increases the

standard 540 RPM PTO speed to 2000 RPM at the

pump. The oil should be changed after the first 100

working hours. Successive changes should be made

after every 1500 hours or once a year. Use 80-90 weight

gearlube. Check the oil level by removing the level plug

located on the side of the case. Oil may be added by

removing the breather located at the top of the case. A

drain plug is located at the bottom of the case. See

Figure 7-3.

12270

Speed Increaser

Figure 7-3

Blade Servicing (Replacement)

The cutter blades should be inspected on a daily basis.

They must be kept sharp and should be replaced if they

are worn excessively.

Both blades should be sharpened at the same angle as

the original cutting edge and must be replaced or

reground at the same time to maintain proper balance

during rotation. Do not remove any more material than

necessary when sharpening blades.

12469

Filter Removal

Figure 7-2

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

28

IMPORTANT: Replace blades with genuine Land

Pride blades only.If one blade is to be replaced, the

mating blade must also be replaced. Failureto do so

will result in an out-of-balance condition that will

contribute to premature bearing failure on the

spindle hub. Factory blades are 4" wide and 25"

When replacing or sharpening the cutter blades,

examine the blade bolts, shims and blade bolt nut.

Replace if necessary. Be sure that the blades are

installed properly. The airfoil (lift) must be oriented

towards the top of the deck. The blade bolt nuts must be

torqued to 450 ft-lbs.

4/28/08

Page 31

Land Pride

Section 7: Maintenance & Lubrication

Table of Contents

Blade Rotation

Figure 7-4

12271

Blade Rotation is clockwise. See Figure 7-4.

The Skid Shoes should be inspected at the beginning of

each cutting season. Original material thickness is 1/4".

They should be replaced when the material thickness is

less than 1/8" at any point. The skid shoes are

interchangeable from left to right.

Tractor Maintenance

IMPORTANT: One of the most important things you

can do to prevent hydraulic system problems is to

ensure that your tractor's reservoir remain free of

dirt and contamination. Use a clean cloth to wipethe

hose ends before attachment to your tractor.

Replace the filter element for your tractors hydraulic

systemattheprescribedintervals.Doingsowill go a long

way to prevent the occurrence of cartridge valve and

hydraulic cylinder problems on the Parallel Arm Cutter.

NOTE: Removal of the solenoid valves from the

valve block requires the removal of a 1/2" hex nut on

the end of the solenoid armature. Use care when

removing/replacing this nut. Use Locktite or other

thread locking compound when replacing and DO

NOTexert more than 3 ft lbs oftorque on this hexnut.

Remember that 3 ft lbs is slightly higher than finger

tight! See Figure 7-5. Overtightening this nut will

distort the hollow armature shaft and may result in

valve failure. See Solenoid Valve Block

12272

Solenoid Valve Block

Figure 7-5

Storage

At the end of the working season or when the cutter will

not be used for a long period, it is good practice to clean

off any dirt or grease that may have accumulated on the

cutter and any of the moving parts. It may be necessary

to scrape off compacted dirt from the bottom of the deck,

then use a garden hose to thoroughly clean the surface.

A coating of oil may also be applied to the lower deck

area to minimize oxidation.

Check the blades and blade bolts for wear and replace if

necessary. See “Section 7: Maintenance & Lubrication”

on page 27.

Inspect the cutter for loose, damaged or worn parts and

adjust or replace if needed.

Lubricate as noted in “Section 7: Maintenance &

Lubrication” on page 27.

Repaintpartswherepaint is worn or scratched to prevent

rust. Aerosol Buckskin touch-up paint is available from

your Land Pride Dealer. Order Land Pride part #821011C.

Store the cutter ina clean, dryplace. The deckshould be

positioned on a flat surface with the arms retracted and

the jack stands lowered to suitable 3-Point height.

Ensure that the main frame is stable. Use auxiliary

supportsorpostsifnecessary to prevent the possibility of

the unit tipping over.

4/28/08

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

29

Page 32

Table of Contents

Section 7: Maintenance & Lubrication

Maintenance & Lubrication Record

Item to be Serviced When to Perform Reference Date

Land Pride

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

30

4/28/08

Page 33

Land Pride

Table of Contents

Section 8: Specifications & Capacities

Section 8: Specifications & Capacities

RCP 2560 Parallel Arm Series

RCP2560

Cutting Width 58"

Overall Width (Fully Extended) 19’-8"

Transport Width 10’

Minimum Cutting Height (deck level) 2"

Maximum Horizontal Reach from Center of Tractor 186"

Maximum Vertical Reach (above horizontal) 137"

Maximum Vertical Reach (below horizontal) 109"

Deck Rotating Arc 180 degrees

PTO Input Speed 540 RPM

Rotor (motor) RPM (@ 540 PTO) 1000 RPM

Blade Tip Speed 15,000 FPM

Blade Size 1/2" x 4"

Blade Rotation Clockwise

Blade Bolt 1 1/2" with keyway; nut

Dishpan 3/16” X 21" Round, Dish Shaped

Cutting Capacity 2"

Deck Thickness 10 GA

Hydraulic Fluid Mobil 424

Hydraulic Reservoir Capacity 35 Gallons

Hydraulic Fluid Flow Rate 15 GPM (approx.)

Overload Protection Hydraulic Relief Valve

Driveline ASAE Category 2

Hitch 3-Point Cat. 2 & 3 with clevis style lower hitch, Quick hitch,

Minimum Tractor Weight 7000 Lbs.

Minimum Tractor Horsepower 75 HP

Skid Shoes 1/4" Reversible

Shipping Weight 1,930 Lbs (no fluid)

Options: Elect Cylinder Control

Breakaway Cylinder

Operator Safety Shield

1000 rpm Increaser / PTO

4/28/08

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

31

Page 34

Table of Contents

Section 8: Specifications & Capacities

Land Pride

10703

Overall Dimensions

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

32

Figure 9-1

4/28/08

Page 35

Land Pride

Table of Contents

Section 9: Troubleshooting

Section 9: Troubleshooting

Problem Cause Solution

Motor Oil Seal Leaking Returnline from motor has been pinched or

Spindle Hub Seal Leaking Return line from motor has been pinched or

PTO Shaft is bent. (NOTE: PTO

tractor hitch shaft should be

repaired or replaced if bent)

Blades wearing excessively Cutting on sandy ground Raise cutting height.

Blades coming loose Insufficient shimming Add shimming. See text.

Blades breaking Hitting solid objects Thoroughly check the cutting area

Loose Blade Carrier Worn Spindle Hub bearings. Replace Spindle Hub bearings and/or

Blade Carrier bent Hitting solid objects Avoid solid objects/Be alert.

Excessive skid shoe wear Cutting height not level or blade missing Adjust deck height or replace

Excessive vibration Locked blades Inspect and unlock blades.

Deck Cylinder will

not extend and/or retract

Deck Cylinder will not retract Cylinder rod is bent Replace cylinder.

Arm/Deck Cylinder(s) will not

extend and/or retract

Optional Electrical control

switch does not work

is collapsed

is collapsed

Contacting drawbar or Bottoming out Reposition drawbar/Replace PTO tubes

Contacting ground frequently Raise cutting height.

Blade bolts not tightened properly Torque blade bolt nuts to 450 ft lbs.

Shaft nut loose Tighten Spindle Hub shaft nut to

Soil abrasive Raisecuttingheight.

Cutting too low Raise cutting height.

Blades have unequal weight Replace blades as a PAIR.

PTO shaft bent Straighten or replace PTO shaft.

Blade carrier bent Replace/straightenbladecarrier.

PTO cross not centered with yoke Disassemble and inspect for incorrectly

Orifice elbow on rod end is plugged Clean orifice fitting.

Broken/disconnected wire on solenoid Check wiring on cartridge valve solenoids.

Electric solenoid valve is sticking/dirty. Remove solenoid valve and clean or

Circuit Breaker tripped Reset Breaker

Circular Plastic connector is not connected

to receptacle.

No power to switchbox connections. Check battery or power

Tractor spool valve not engaged (open). Lock tractor control valve open.

Flow Control Valve not adjusted properly

for open/closed center tractor

Hoses not connected to proper duplex

outlet on tractor

Defective solenoid on cartridge valve assy. Replace solenoid.

Solenoid Valves sticking. Remove/clean/replace solenoid valve.

Tractor hydraulic fluid level is too low. Add fluid to tractor reservoir.

Replace lower seal of motor. Check motor

return hose for kinks.

Replace lower seal of motor and Spindle

Hub output shaft seal. Check motor return

hose for kinks.

and cut to correct length.

BEFORE beginning to cut. Be alert during

cutting.

shaft.

450 ft lbs. minimum.

located needles or damaged bearing cap.

replace.

Connect remote cable to Solenoid Control

valve.

Adjust flow control valve

Connect hoses to proper tractor outlet.

4/28/08

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

33

Page 36

Section 10: Appendix

Section 10: Appendix

Bolt Head Identification

Table of Contents

Torque Values Chart

Land Pride

Bolt Head Identification

Bolt Size

(Inches)

1

in-tpi

1/4" - 20 7.4 5.6 11 8 16 12 M 5 X 0.8 4 3 6 5 9 7

1/4" - 28 8.5 6 13 10 18 14 M 6 X 1 7 5 11 8 15 11

5/16" - 18 15 11 24 17 33 25 M 8 X 1.25 17 12 26 19 36 27

5/16" - 24 17 13 26 19 37 27 M 8 X 1 18 13 28 21 39 29

3/8" - 16 27 20 42 31 59 44 M10 X 1.5 33 24 52 39 72 53

3/8" - 24 31 22 47 35 67 49 M10 X 0.75 39 29 61 45 85 62

7/16" - 14 43 32 67 49 95 70 M12 X 1.75 58 42 91 67 125 93

7/16" - 20 49 36 75 55 105 78 M12 X 1.5 60 44 95 70 130 97

1/2" - 13 66 49 105 76 145 105 M12 X 1 90 66 105 77 145 105

1/2" - 20 75 55 115 85 165 120 M14 X 2 92 68 145 105 200 150

9/16" - 12 95 70 150 110 210 155 M14 X 1.5 99 73 155 115 l215 160

9/16" - 18 105 79 165 120 235 170 M16 X 2 145 105 225 165 315 230

5/8" - 11 130 97 205 150 285 210 M16 X 1.5 155 115 240 180 335 245

5/8" - 18 150 110 230 170 325 240 M18 X 2.5 195 145 310 230 405 300

3/4" - 10 235 170 360 265 510 375 M18 X 1.5 220 165 350 260 485 355

3/4" - 16 260 190 405 295 570 420 M20 X 2.5 280 205 440 325 610 450

7/8" - 9 225 165 585 430 820 605 M20 X 1.5 310 230 650 480 900 665

7/8" - 14 250 185 640 475 905 670 M24 X 3 480 355 760 560 1050 780

1" - 8 340 250 875 645 1230 910 M24 X 2 525 390 830 610 1150 845

1" - 12 370 275 955 705 1350 995 M30 X 3.5 960 705 1510 1120 2100 1550

1-1/8" - 7 480 355 1080 795 1750 1290 M30 X 2 1060 785 1680 1240 2320 1710

1 1/8" - 12 540 395 1210 890 1960 1440 M36 X 3.5 1730 1270 2650 1950 3660 2700

1 1/4" - 7 680 500 1520 1120 2460 1820 M36 X 2 1880 1380 2960 2190 4100 3220

1 1/4" - 12 750 555 1680 1240 2730 2010

1 3/8" - 6 890 655 1990 1470 3230 2380

1 3/8" - 12 1010 745 2270 1670 3680 2710

1 1/2" - 6 1180 870 2640 1950 4290 3160

1 1/2" - 12 1330 980 2970 2190 4820 3560

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above.

Grade 2 Grade 5

Grade 8

N·m ft-lb3N · m ft-lb N · m ft-lb mm x pitch N · m ft-lb N · m ft-lb N · m ft-lb

Bolt Size

(Metric)

1

in-tpi = nominal thread diameter in inches-threads per in

2

N· m = newton-meters

3

ft-lb= foot pounds

4

mm x pitch = nominal thread diameter in millimeters x

thread pitch

5.8 8.8 10.9

Class 5.8 Class 8.8 Class 10.9

Additional Torque Values

Blade Bolt Lock Nut 450 ft-lbs.

Blade Carrier Hub Nut 450 ft-lbs. minimum

RCP2560 & RCPM2560 Series Parallel Arm Rotary Cutter 316-057M

34

4/28/08

Page 37

Land Pride

Section 10: Appendix

be free from defects in material and workmanship beginning on the date of

purchase by the end user according to the following schedule when used as

intended and under normal service and conditions for personal use.

and the installation by thedealer of any such replacementpart, and does not cover

common wear items such as blades, belts, tines, etc. Land Pride reservesthe right