Page 1

Table of Contents

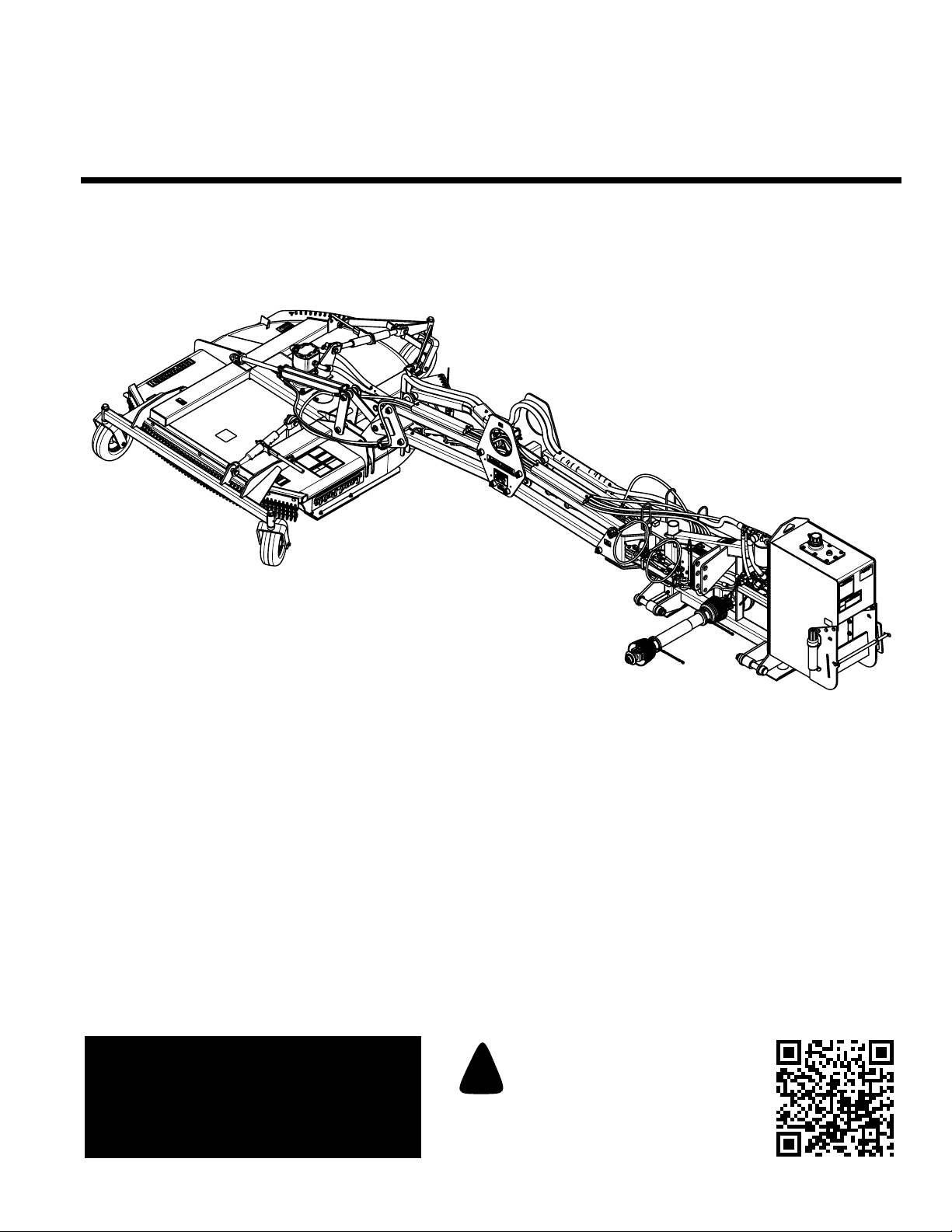

Parallel Arm Rotary Cutter

RCP2660, RCPM2660, RCP3060 and RCPM3060

30028

Operator’s Manual

Read the Operator’sManual entirely.When you

see this symbol, the subsequent instructions and

warnings are serious - follow without exception.

!

Your life and the lives of others depend on it!

Coverphoto may show optional equipment

not supplied with standard unit.

© Copyright 2013 Printed

316-111M

1/11/13

Page 2

Table of Contents

Table of Contents

Important Safety Information . . . . . . . . . . . . . 1

Safety at All Times . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . 10

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . . 10

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Section 1: Assembly & Set-up . . . . . . . . . . . 12

Tractor Requirements . . . . . . . . . . . . . . . . . . . . . . 12

Protective Equipment Requirements . . . . . . . . . . . 13

Dealer Preparations . . . . . . . . . . . . . . . . . . . . . . . 13

Hooking-up the Rotary Cutter . . . . . . . . . . . . . . . . 14

Driveline Installation . . . . . . . . . . . . . . . . . . . . . . . 15

Check Driveline Collapsible Length . . . . . . . . . . 15

Shorten Driveline . . . . . . . . . . . . . . . . . . . . . . . . 16

Check Driveline Maximum Length . . . . . . . . . . . 16

Check Driveline Interference . . . . . . . . . . . . . . . 16

Hydraulic Reservoir Oil Fill . . . . . . . . . . . . . . . . . . 17

Transport Safety Chain . . . . . . . . . . . . . . . . . . . . . 17

Breakaway Cylinder . . . . . . . . . . . . . . . . . . . . . . . 17

Weight Hanger Assembly . . . . . . . . . . . . . . . . . . . 18

Gauge Wheels (Optional) . . . . . . . . . . . . . . . . . . . 18

Section 2: Hydraulic Set-up Options . . . . . . 19

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Tractor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Hydraulic Hose Hook-up . . . . . . . . . . . . . . . . . . 19

Console Control Lever Functional Checks . . . . . 20

Solenoid Control . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Independent Control . . . . . . . . . . . . . . . . . . . . . . . 22

Solenoid Valve Block Functions . . . . . . . . . . . . . . 22

Independent Control . . . . . . . . . . . . . . . . . . . . . . 22

Solenoid Control . . . . . . . . . . . . . . . . . . . . . . . . . 22

Control Sticks . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Control Stick Hook-up . . . . . . . . . . . . . . . . . . . . 24

Control Stick Operation . . . . . . . . . . . . . . . . . . . 25

Control Stick Functional Checks . . . . . . . . . . . . . 25

Section 3: Adjustments . . . . . . . . . . . . . . . . . 28

Hydraulic Flow Control . . . . . . . . . . . . . . . . . . . . . 28

Flow Control Valve on the Rotary Cutter . . . . . . 28

Turtle/Rabbit Flow Control at the Tractor . . . . . . 28

Deck Level Adjustments . . . . . . . . . . . . . . . . . . . . 29

Without Gauge Wheels . . . . . . . . . . . . . . . . . . . 29

With Gauge Wheels . . . . . . . . . . . . . . . . . . . . . . 29

Section 4: Operating Procedures . . . . . . . . . 30

Operating Checklist . . . . . . . . . . . . . . . . . . . . . . . . 30

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Basic Operating Instructions . . . . . . . . . . . . . . . . . 31

Breakaway Instructions . . . . . . . . . . . . . . . . . . . . . 32

Shear Bolt Replacement . . . . . . . . . . . . . . . . . . 32

Un-hooking the Rotary Cutter . . . . . . . . . . . . . . . .32

General Operating Instructions . . . . . . . . . . . . . . .33

Section 5: Optional Equipment . . . . . . . . . . . 34

Parallel Arm Rotary Cutter Options . . . . . . . . . . . .34

Bolt-on Weight Hangers . . . . . . . . . . . . . . . . . . . . .35

Operator Protective Shield . . . . . . . . . . . . . . . . . . .36

Section 6: Hydraulic Plumbing . . . . . . . . . . . 37

Breakaway Cylinder . . . . . . . . . . . . . . . . . . . . . . . . 37

Pressure Shut Down Valve Operation . . . . . . . . 37

Tractor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Solenoid Control . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Solenoid Plumbing . . . . . . . . . . . . . . . . . . . . . . .38

Hydraulic Cylinder Plumbing . . . . . . . . . . . . . . . .38

Deck Motor Plumbing . . . . . . . . . . . . . . . . . . . . . 39

Independent Control . . . . . . . . . . . . . . . . . . . . . . .40

Cylinder Pump Plumbing . . . . . . . . . . . . . . . . . .40

Hydraulic Cylinder Plumbing . . . . . . . . . . . . . . . .40

Deck Motor Plumbing . . . . . . . . . . . . . . . . . . . . . 41

Section 7: Electrical Wiring Schematics . . . . 42

Solenoid Control Option . . . . . . . . . . . . . . . . . . . . .42

Wiring Schematic Without Gauge Wheels . . . . .42

Wiring Schematic With Gauge Wheels . . . . . . . .43

Independent Control Option . . . . . . . . . . . . . . . . . . 44

Wiring Schematic Without Gauge Wheels . . . . .44

Wiring Schematic With Gauge Wheels . . . . . . . .45

Section 8: Maintenance & Lubrication . . . . . 46

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Rotary Cutter Blades . . . . . . . . . . . . . . . . . . . . . . . 46

Skid Shoes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Solenoid Valve Block . . . . . . . . . . . . . . . . . . . . . . . 48

Hydraulic Hose Replacement . . . . . . . . . . . . . . . .48

Tractor Maintenance . . . . . . . . . . . . . . . . . . . . . . . 49

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Lubrication Points . . . . . . . . . . . . . . . . . . . . . . . . . 50

Parallel Arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Deck Pivot . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Parallel Arm Pivot . . . . . . . . . . . . . . . . . . . . . . . .50

Driveline Yokes . . . . . . . . . . . . . . . . . . . . . . . . . 51

Driveline Profile . . . . . . . . . . . . . . . . . . . . . . . . . 51

Gauge Wheel Yoke and Wheel Bearing . . . . . . .51

Ratchet Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Motor Spindle Hub . . . . . . . . . . . . . . . . . . . . . . . . .52

Hydraulic Reservoir . . . . . . . . . . . . . . . . . . . . . . . . 52

Speed Increaser . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Section 9: Specifications & Capacities . . . . . 53

Section 10: Features & Benefits . . . . . . . . . . 55

Section 11: Troubleshooting . . . . . . . . . . . . . 56

Section 12: Torque Values Chart . . . . . . . . . . 58

Section 13: Warranty . . . . . . . . . . . . . . . . . . . 59

© Copyright 2013 All rights Reserved

Land Pride provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the

preparationof this manual,Land Pride assumesno responsibility forerrors oromissions. Neither isany liabilityassumedfor damagesresulting from theuse

oftheinformation contained herein. LandPridereservesthe right to reviseandimprove its productsasit sees fit. This publicationdescribes the state of this

product at the time of its publication, and may not reflect the product in the future.

Land Pride is a registered trademark.

All other brands and product names are trademarks or registered trademarks of their respective holders.

Printed in the United States of America.

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

1/11/13

Page 3

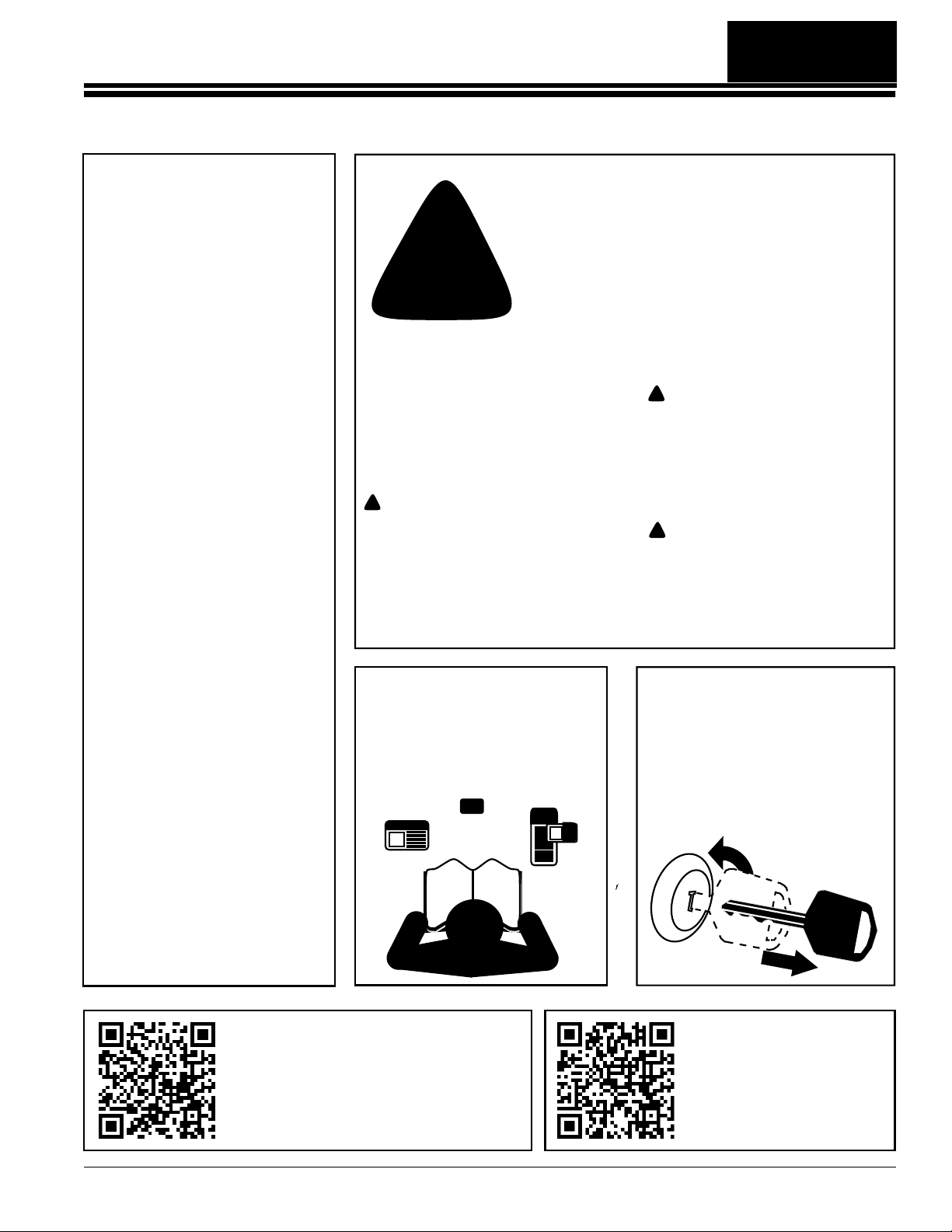

▲

Table of Contents

Important Safety Information

Important Safety Information

These are common practices that may or may not be applicable to the products described in

this manual.

Safety at All Times

Thoroughly read and understand

the instructions given in this

manual before operation. Refer to

the “Safety Label” section, read all

instructions noted on them.

Do not allowanyoneto operate this

equipment who has not fully read

and comprehended this manual

and who has not been properly

trained in the safe operation of the

equipment.

▲ Operator should be familiar with all

functions of the unit.

▲ Operate implement from the

driver’s seat only.

▲ The operator must not use drugs

or alcohol as they can change the

alertness or coordination of that

person while operating equipment.

The operator should, if taking overthe-counter drugs, seek medical

advice on whether he or she can

safely operate the equipment.

▲ Make sure all guards and shields

are in place and secured before

operating implement.

▲ Do not leave tractor or implement

unattended with engine running.

▲ Dismounting from a moving tractor

could cause serious injury or

death.

▲ Do not allow anyone to stand

between tractor and implement

while backing up to implement.

▲ Keep hands, feet, and clothing

away from power-driven parts.

▲ Wear snug fitting clothing to avoid

entanglement with moving parts.

▲ Watch out for wires, trees, etc.,

when raising implement. Make

sure all persons are clear of

working area.

▲ Turningtractor too tight may cause

implement to ride up on wheels.

This could result in injury or

equipment damage.

▲ Do not carry passengers on

implement at any time.

Look For The Safety Alert Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

!

Be Aware of

Signal Words

A Signal word designates a degree or

level of hazard seriousness. The

signal words are:

!

DANGER

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury. This

signal word is limited to the most

extreme situations, typically for

machine components that, for

functional purposes, cannot be

guarded.

For Your Protection

▲ Thoroughly read and understand

the “Safety Label” section, read all

instructions noted on them.

equipment, hazard control, and accident prevention

are dependent upon the awareness, concern,

prudence, and proper training of personnel involved

in the operation, transport, maintenance, and storage

of equipment.

!

WARNING

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury, and

includes hazards that are exposed

when guards are removed. It may also

be used to alert against unsafe

practices.

!

CAUTION

Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

Shutdown and Storage

▲ Lower machine to ground, put

tractor in park, turn off engine, and

remove the key.

▲ Detach and store implements in an

area where children normally do

not play. Secure implement by

using blocks and supports.

OFF

REMO

VE

1/11/13

Parts Manual QR Locator

The QR (Quick Reference) code on the front

cover and to the left will take you to the

Parts Manual for this equipment. Download

the appropriate App on your smart phone,

open the App, point your phone on the QR

code and take a picture.

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

Dealer QR Locator

The QR code on the left will

link you to available dealers

for Land Pride products.

Refer to Parts Manual

QR Locator on this page for

detailed instructions.

1

Page 4

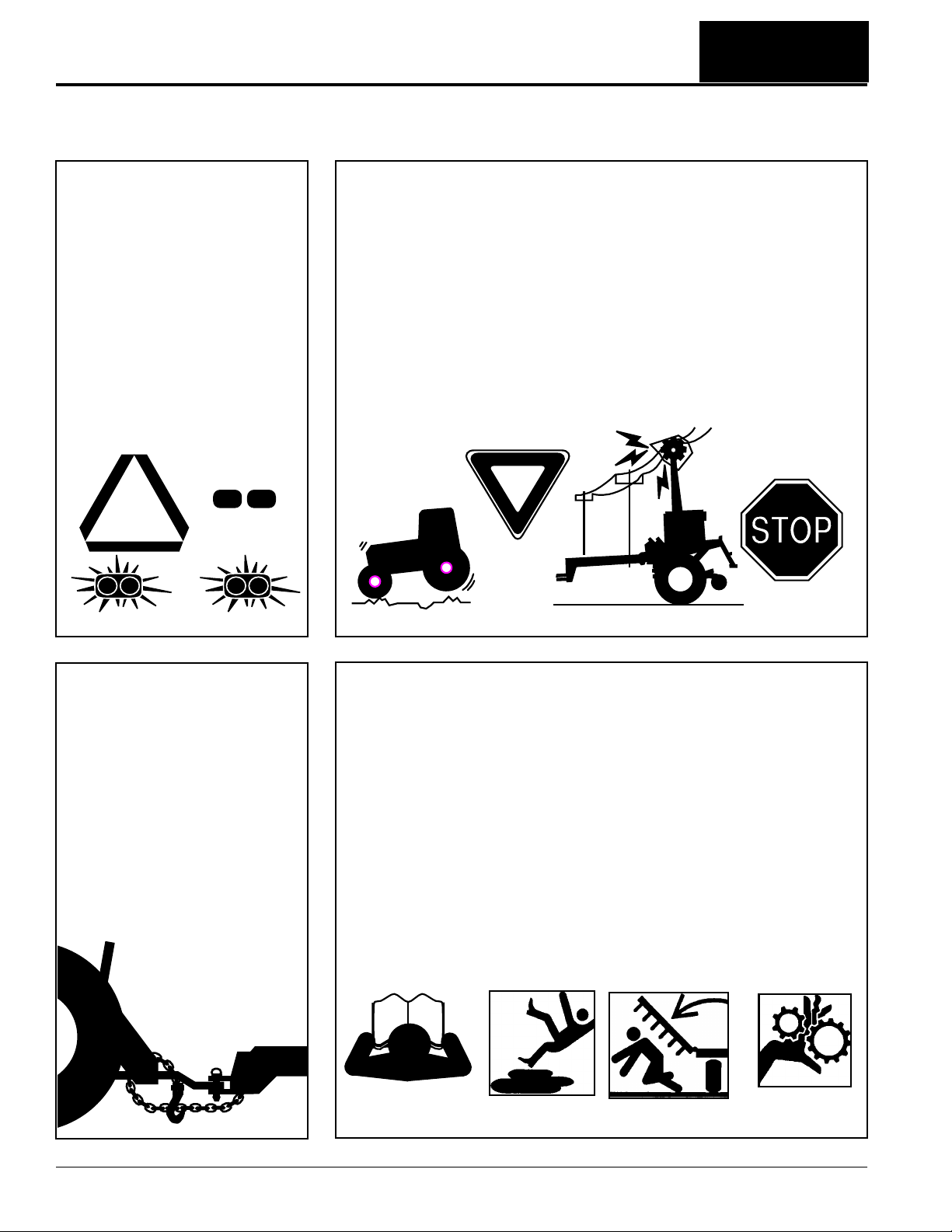

Table of Contents

Important Safety Information

These are common practices that may or may not be applicable to the products described in

this manual.

Use Safety

Lights and Devices

▲ Slow moving tractors, self-

propelled equipment, and towed

implements can create a hazard

whendriven on publicroads.They

are difficult to see, especially at

night.

▲ Flashing warning lights and turn

signals are recommended

whenever driving on public roads.

Transport

Machinery Safely

▲ Comply with state and local laws.

▲ Maximum transport speed for

implement is 20 mph. DO NOT

EXCEED.Never travel at a speed

which does not allow adequate

control of steering and stopping.

Some rough terrain require a

slower speed.

▲ Sudden braking can cause a

towed load to swerve and upset.

Reduce speed if towed load is not

equipped with brakes.

▲ Use the following maximum

speed - tow load weight ratios as

a guideline:

20 mph when weight is less

than or equal to the weight of

tractor.

10 mph when weight is more

than weight of tractor but less

than double the weight of

tractor.

▲ IMPORTANT: Do not tow a load

that is more than double the

weight of tractor.

Use A Safety Chain

▲ A safety chain will help control

drawn machinery should it

separate from the tractor

drawbar.

▲ Use a chain with the strength

rating equal to or greater than

the gross weight of the towed

machinery.

▲ Attach the chain to the tractor

drawbar support or other

specified anchor location. Allow

only enough slack in the chain

to permit turning.

▲ Do not use safety chain for

towing.

Practice Safe

Maintenance

▲ Understand procedure before

doing work. Use proper tools and

equipment, refer to Operator’s

Manual for additional information.

▲ Work in a clean dry area.

▲ Lower the implement to the

ground, put tractor in park, turn off

engine, and remove key before

performing maintenance.

▲ Allow implement to cool

completely.

▲ Do not grease or oil implement

while it is in operation.

▲ Inspect all parts. Make sure parts

are in good condition & installed

properly.

▲ Remove buildup of grease, oil, or

debris.

▲ Remove all tools and unused

parts from implement before

operation.

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

2

1/11/13

Page 5

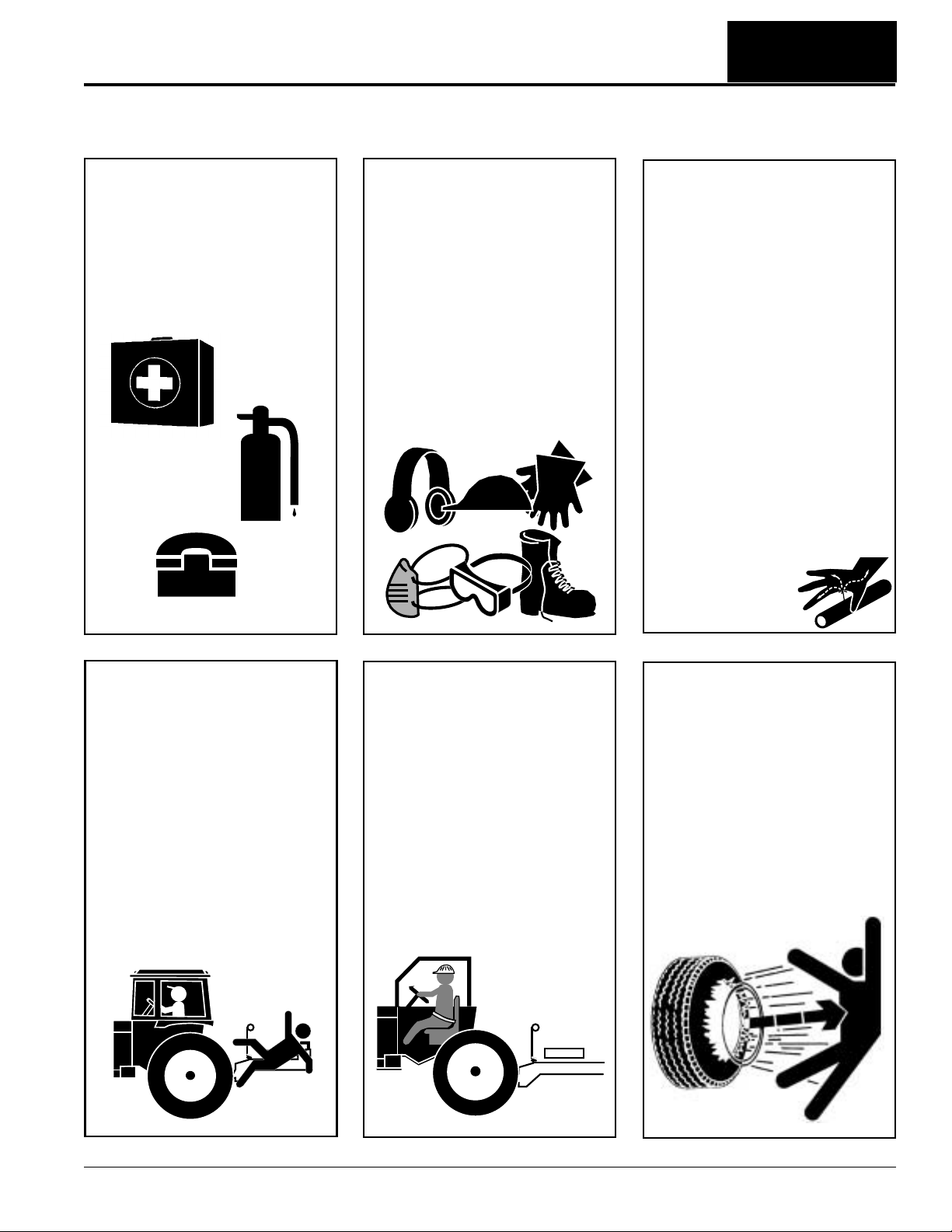

Table of Contents

Important Safety Information

These are common practices that may or may not be applicable to the products described in

this manual.

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire

extinguisher handy.

▲ Keep emergency numbers for

doctor, ambulance, hospital, and

fire department near phone.

911

Wear

Protective Equipment

▲ Wear protective clothing and

equipment appropriate for the job.

Avoid loose fitting clothing.

▲ Prolonged exposure to loud noise

can cause hearing impairment or

hearing loss. Wear suitable

hearing protection such as

earmuffs or earplugs.

▲ Operating equipment safely

requires the full attention of the

operator. Avoid wearing radio

headphones while operating

machinery.

Avoid High

Pressure Fluids Hazard

▲ Escaping fluidunder pressure can

penetrate the skin causing

serious injury.

▲ Avoid the hazard by relieving

pressure before disconnecting

hydrauliclines or performing work

on the system.

▲ Make sure all hydraulic fluid

connections are tight and all

hydraulic hoses and lines are in

good condition before applying

pressure to the system.

▲ Use a piece of paper or

cardboard, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety

glasses or goggles when working

with hydraulic systems.

▲ If an accident occurs, see a

doctor immediately. Any fluid

injected into the skin must be

treated within a few hours or

gangrene may result.

Keep Riders

Off Machinery

▲ Riders obstruct the operator’s

view, they could be struck by

foreign objects or thrown from the

machine.

▲ Never allow children to operate

equipment.

Use Seat Belt and ROPS

▲ Operate only tractors equipped

with Roll-Over Protective

Structure (ROPS) and seat belt.

▲ Fasten seat belt snugly and

securely to help protect operator

from being thrown, crushed, or

severely injured if a rollover

occurs; and from falling off the

tractor and being ran over by the

tractorand/or cutter. Not using the

seat belt can result in serious

injury or death.

▲ Wearing protective equipment

such as safety shoes, safety

glasses, hard hat, and ear plugs

is highly recommended.

Tire Safety

▲ Tire changing can be dangerous

and should be preformed by

trained personnel using the

correct tools and equipment.

▲ When inflating tires, use a clip-on

chuck and extension hose long

enough to allow you to stand to

one side and NOT in front of or

over the tire assembly. Use a

safety cage if available.

▲ When removing and installing

wheels, use wheel handling

equipment adequate for the

weight involved.

1/11/13

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

3

Page 6

Important Safety Information

Table of Contents

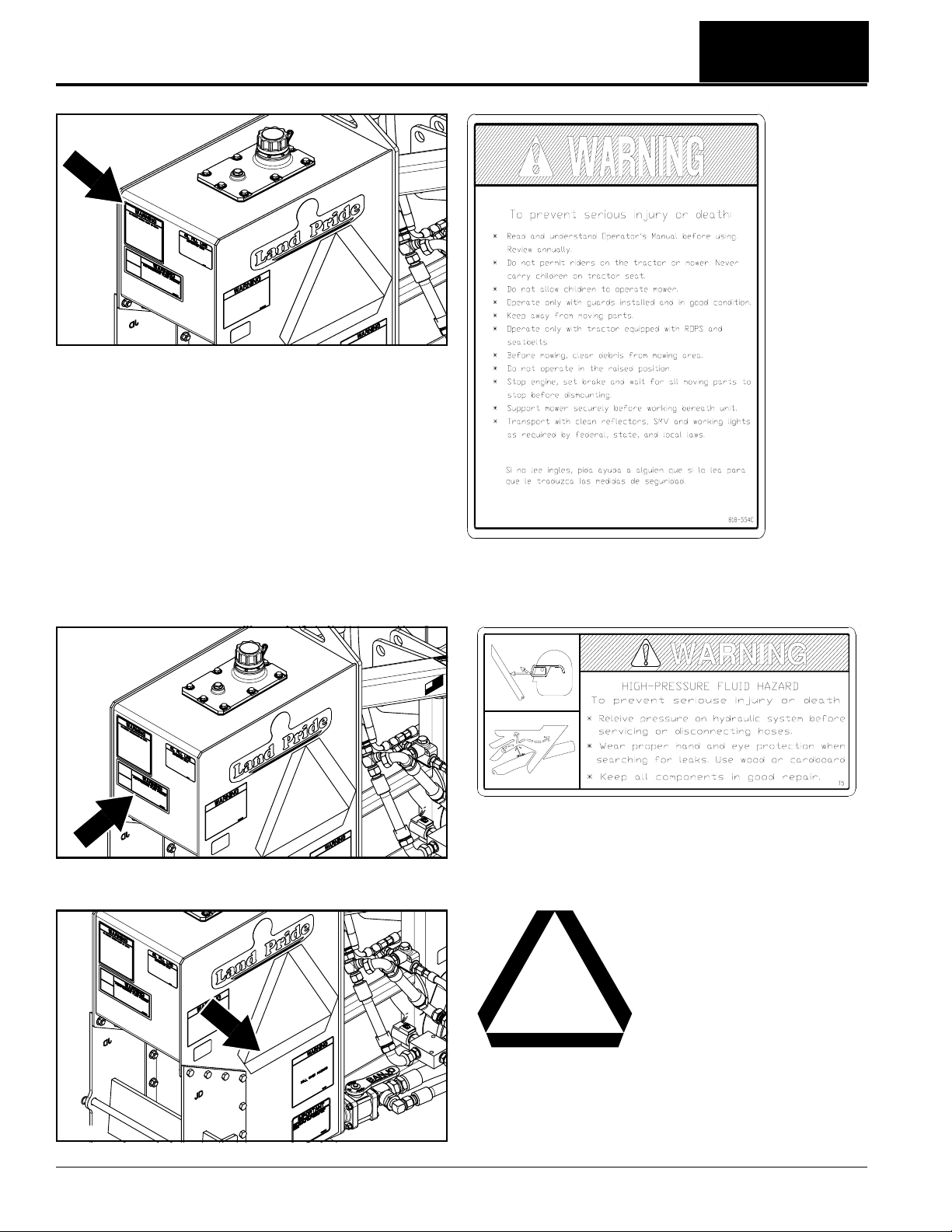

Safety Labels

YourParallelArm Rotary Cutter comes equippedwithall safety

labels in place. They were designed to help you safely operate

your implement. Read and follow their directions.

1. Keep all safety labels clean and legible.

2. Refer to this section for proper label placement. Replace

all damaged or missing labels. Order new labels from your

nearest Land Pride dealer. To find your nearest dealer,

visit our dealer locator at www.landpride.com.

3. Some new equipment installed during repair requires

safety labels to be affixed to the replaced component as

specified by Land Pride. When ordering new components

make sure the correct safety labels are included in the

request.

4. Refer to this section for proper label placement.

To install new labels:

a. Clean the area the label is to be placed.

b. Spray soapy water on the surface where the label is to

be placed.

c. Peel backing from label. Press firmly onto the surface.

d. Squeeze out air bubbles with the edge of a credit card

or with a similar type straight edge.

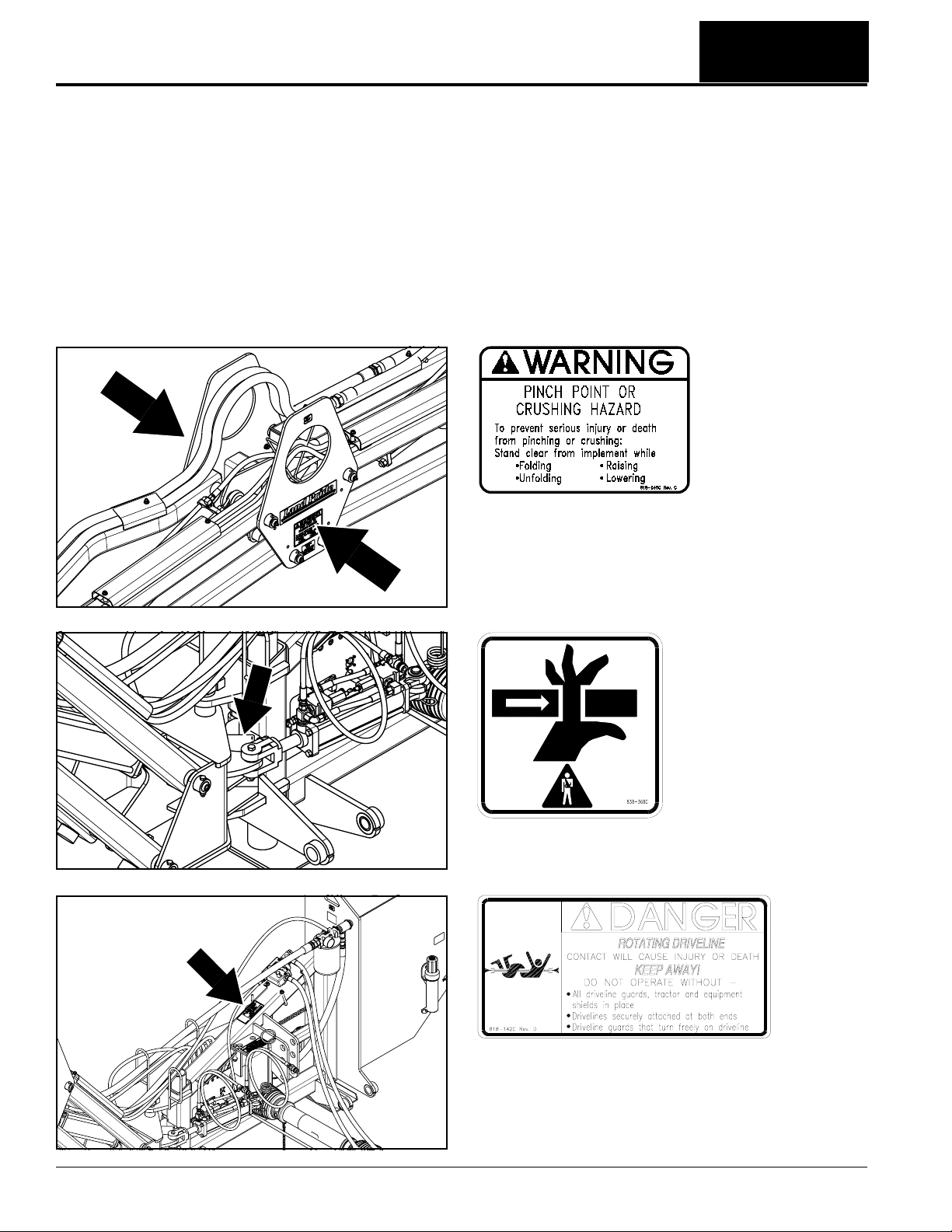

818-045C

Warning - Pinch Point Hazard

2-Places

22058

22057

838-368C

Warning - Pinch Point Hazard

818-142C

Danger - Rotating Driveline Hazard

26694

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

4

1/11/13

Page 7

Important Safety Information

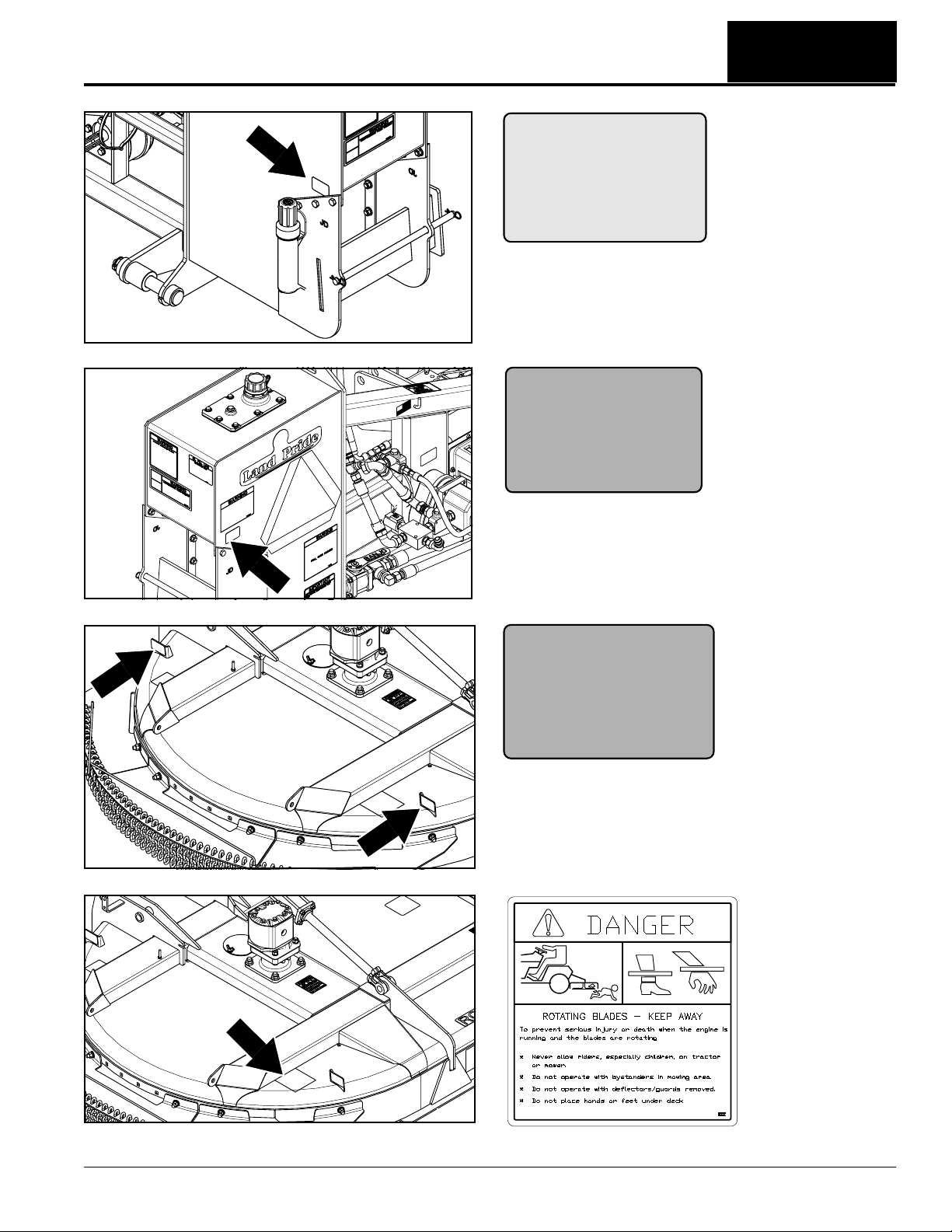

30031

Table of Contents

818-229C

Amber Reflector

30032

22007

818-230C

Red Reflector

818-230C

Red Reflector (2 places)

1/11/13

818-564C

Danger - Keep Away

22007

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

Rotating Blade Hazard

5

Page 8

Important Safety Information

Table of Contents

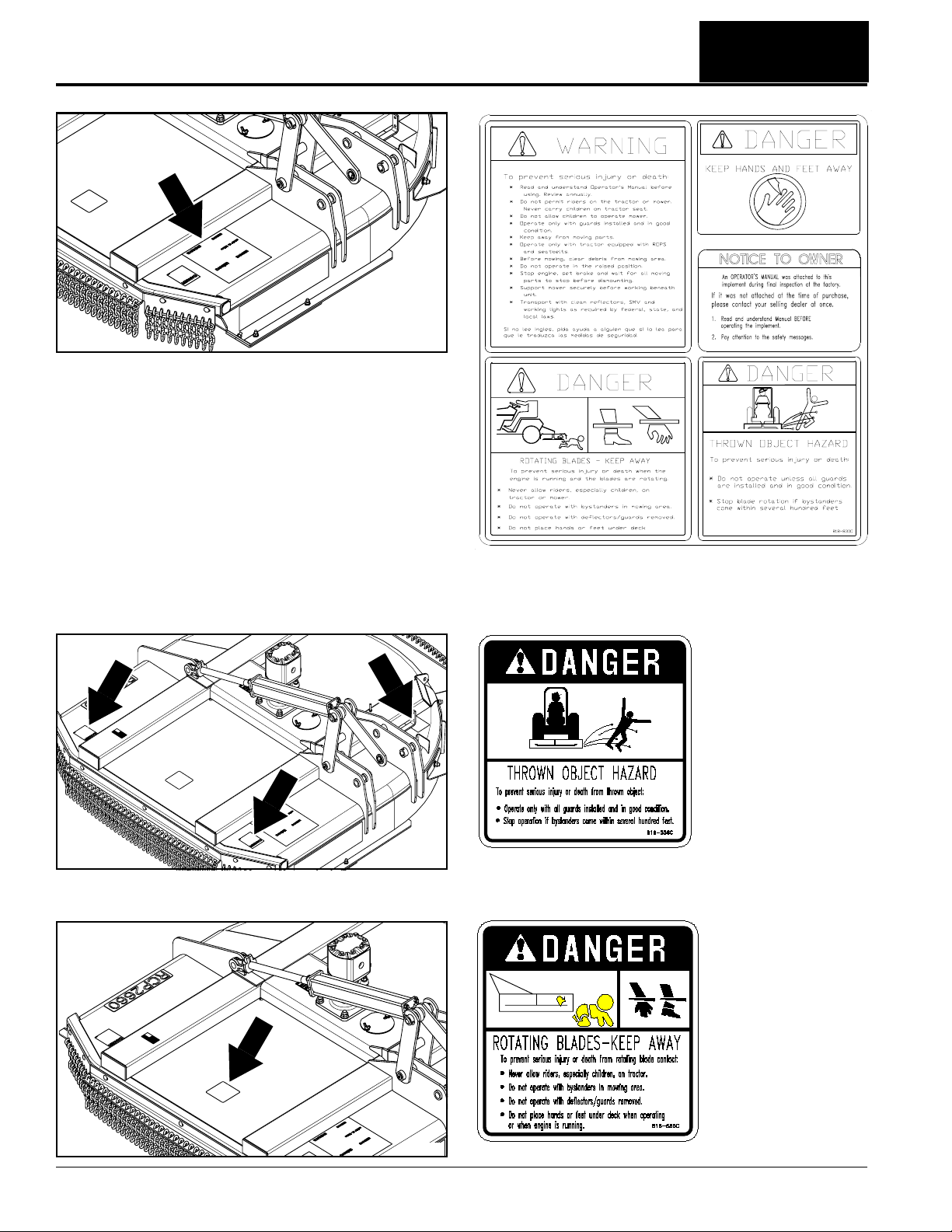

22006

22006

818-830C

Warning/Danger/Notice - Combination Safety Decal

818-556C

Danger - Thrown Object

Hazard (3-Places)

22006

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

6

818-555C

Danger - Rotating

Blades Keep Away

1/11/13

Page 9

Important Safety Information

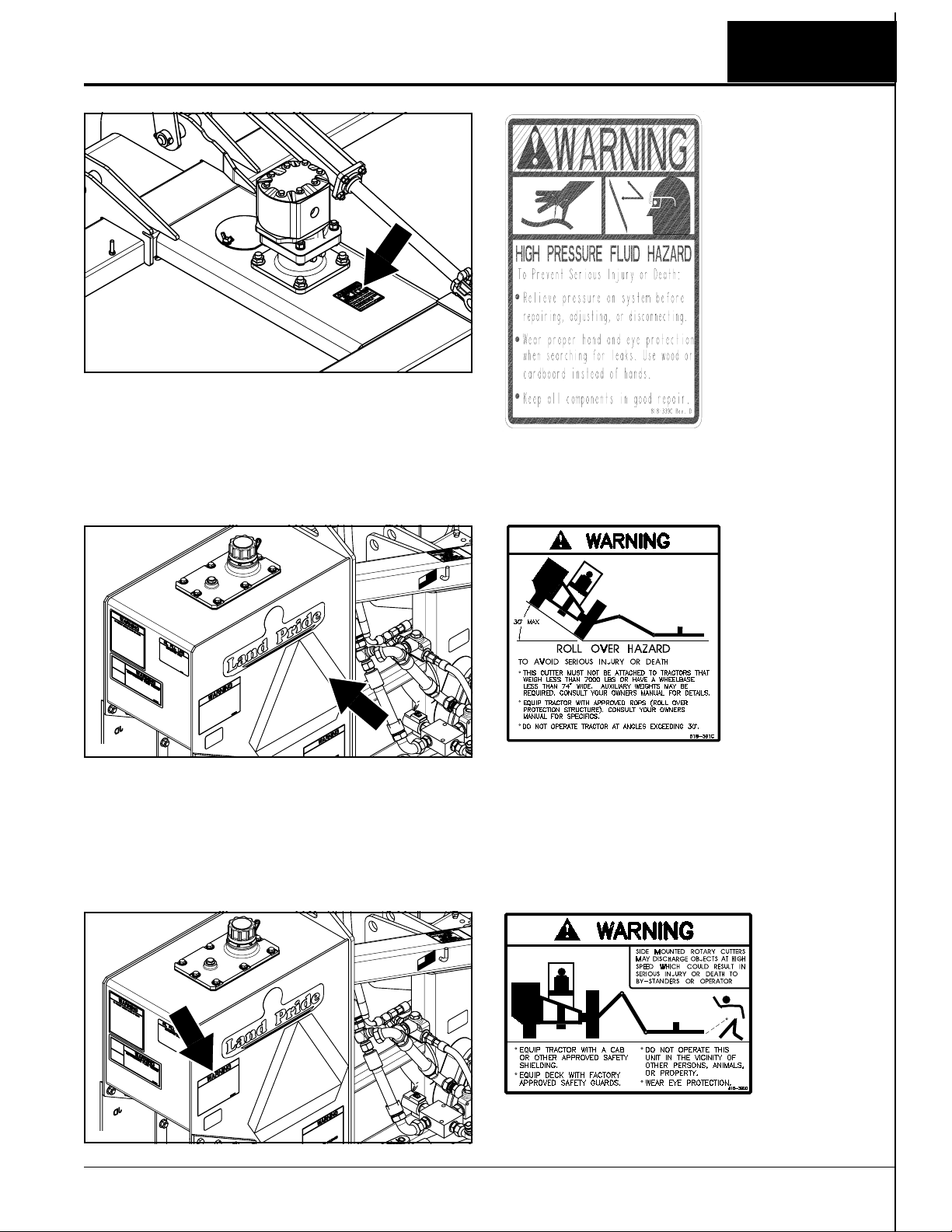

22007

Table of Contents

818-339C

Warning - High Pressure

Fluid Hazard

30032

30032

818-391C

Warning - Tractor Roll

Over Hazard

818-390C

Warning - Thrown

Object Hazard

1/11/13

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

7

Page 10

Important Safety Information

30032

Table of Contents

30032

818-554C

Caution - General Safety Information

818-831C

Warning - High Pressure Fluid Hazard

30032

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

8

818-003C

Slow Moving Vehicle Emblem

1/11/13

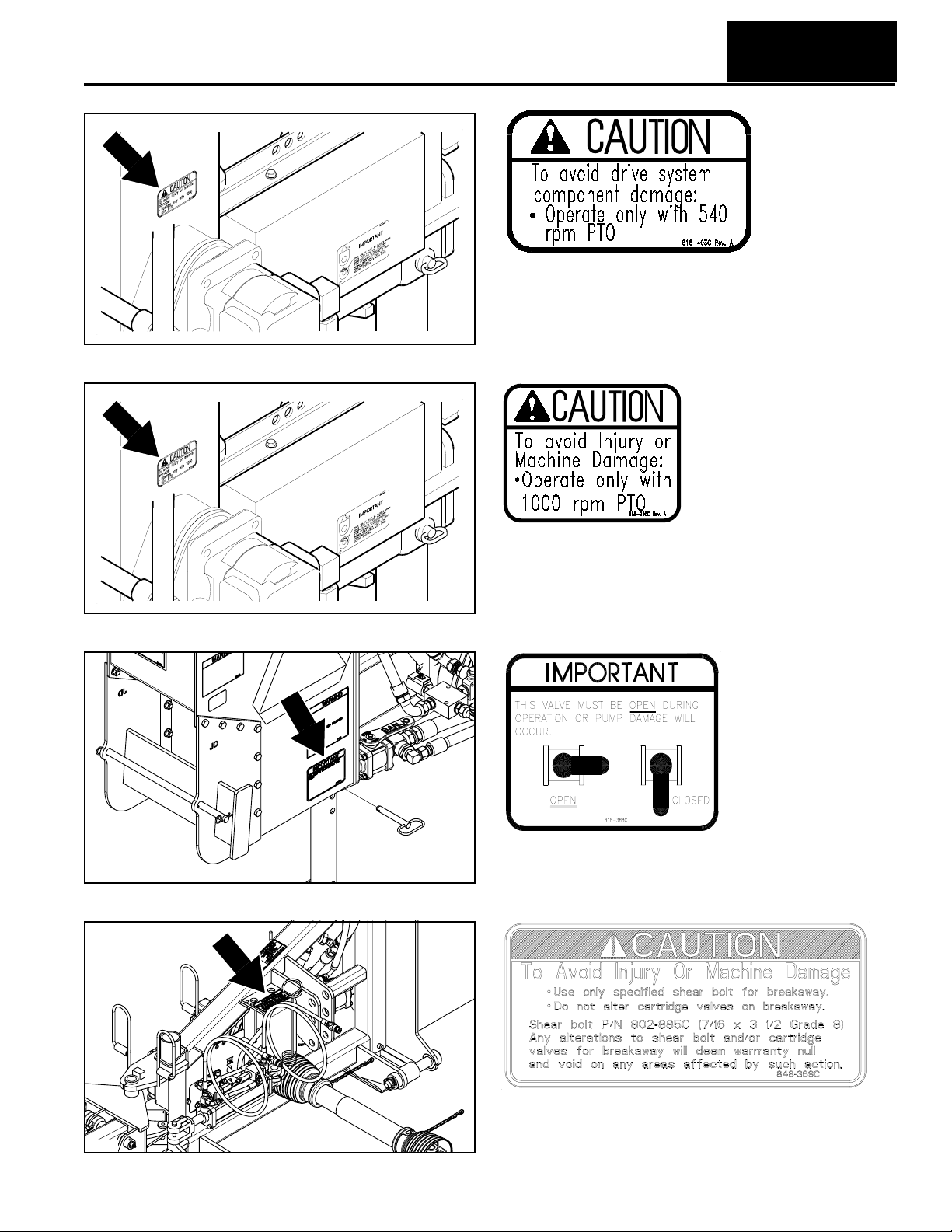

Page 11

Important Safety Information

Table of Contents

818-403C

(Used only on RCP2660 & RCP3060 Series)

Caution - Operate only with 540 rpm PTO

12324

30032

818-240C

(Used only on RCPM2660 & RCPM3060 Series)

Important - Operate only with 1000 rpm PTO

12324

818-388C

Important - Valve must be open

30033

1/11/13

848-369C

Caution: Avoid Injury or Machine Damage

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

9

Page 12

Table of Contents

Introduction

Introduction

Land Pride welcomes you to the growing family of new

product owners.

ThisRotaryCutter has been designed withcare and built

by skilled workers using quality materials. Proper

assembly,maintenance,andsafeoperatingpractices will

help youget years of satisfactory use from this machine.

Application

The Hydraulic Parallel Arm Rotary Cutters are designed

and built by Land Pride to provide excellent cutting

performance on ditch banks and other sloping areas

adjacent to right-of-ways, lakes, ponds, and streams.

They are designed to work equally as well in and around

areas of restricted access such as overor under fences,

guardrails, low overhanging branches, tree limbs, and

hedges. These units perform extremely well in tall grass

cutting applications and will easily cut through standing

brush up to two inches in diameter. An optional cutter

head equipped with two forward and one rear gauge

wheel is also available for customers who want to

maintain a constant cutting height with minimal control

lever manipulation.

The RCP2660 and RCPM2660 cutters are adapted for

Category 2 or 3 three-point hitch mounting on 75 hp. to

150 hp. tractors weighing 8,000 lbs. or more.

The RCP3060 and RCPM3060 cutters are adapted for

Category 2 or 3 three-point hitch mounting on 95 hp. to

175 hp. tractors weighing 12,000 lbs. or more.

The Hydraulic drive requires 540 rpm input PTO speed

for RCP2660 & RCP3060 models and 1000 rpm for

RCPM2660 & RCPM3060 models. Depending upon

hydraulicconfiguration,one,two,or four duplexhydraulic

outlets are required on the tractor to operate the cutter’s

parallel arms and deck angle.

See “Specifications & Capacities” on page 53

and “Features & Benefits” on page 55 for additional

information and performance enhancing options.

Terminology

“Right” or “Left” as used in this manual is determined by

facingthe direction the machine will operate while in use

unless otherwise stated.

Definitions

IMPORTANT: A special point of information related

to the following topic. Land Pride’s intention is this

information must be read & noted beforecontinuing.

NOTE: A special point of information that the

operator should be aware of before continuing.

Owner Assistance

The Online Warranty Registration or Warranty

Registration card should be completed by the dealer at

the time of purchase. This information is necessary to

provide you with quality customer service.

The parts on your ParallelAr m Rotary Cutter have been

specially designed by Land Pride and should only be

replaced with genuine Land Pride parts. Contact a Land

Pride dealer if customer service or repair parts are

required. Your Land Pr ide dealer has trained personnel,

repair parts, and equipment needed to service the

implement.

Serial Number

Model No. _____________Serial No. _______________

For quick reference and prompt service, record model

number and ser ial number in the spaces provided above

and again on warranty page 59. Always provide model

and serial number when ordering parts and in all

correspondences with your Land Pr ide dealer. Refer to

Figure 1 for location of your serial number plate.

Using This Manual

•

This Operator’s Manual is designed to help familiarize

you with safety, assembly, operation, adjustments,

troubleshooting, and maintenance. Read this manual

and follow the recommendations to help ensure safe

and efficient operation.

• The information contained within this manual was

current at the time of printing. Some parts may change

slightly to assure you of the best performance.

• To order a new Operator’s or Parts Manual contact

your authorized dealer. Manuals can also be

downloaded, free-of-charge from our website at

www.landpride.com.

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

10

30033

Serial Number Plate Location

Figure 1

1/11/13

Page 13

Table of Contents

Introduction

Further Assistance

Your dealer wants you to be satisfied with your new

cutter.If for anyreasonyou do notunderstand anypart of

thismanual or are not satisfied with the service received,

the following actions are suggested:

1. Discuss the matter with your dealership ser vice

manager making sure that person is aware of any

problemsyou mayhave and has had the opportunity

to assist you.

2. If you are still not satisfied, seek out the owner or

general manager of the dealership, explain the

problem, and request assistance.

3. For further assistance write to:

Land Pride Service Department

1525 East North Street

P.O. Box 5060

Salina, Ks. 67402-5060

E-mail address

lpservicedept@landpride.com

1/11/13

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

11

Page 14

Section 1: Assembly & Set-up

Table of Contents

Section 1: Assembly & Set-up

Tractor Requirements

Horsepower

Tractor horsepower must be capable of controlling the

Parallel Arm Rotary Cutter under all operating

conditions. Smaller tractors must not be used.

RCP2660 & RCPM2660

Horsepower Range . . . . . . . . . . . . . . . . . .75-150 HP

RCP3060 & RCPM3060

Horsepower Range . . . . . . . . . . . . . . . . . .95-175 HP

Weight

Absolute Minimum: Tractor weightmust be sufficient to

controlthe ParallelArmRotaryCutter underall operating

conditions. Tractors not meeting the absolute minimum

weight listed below must not be used.

Basic Minimum: A right-hand overturning torque load is

present on the tractor when parallel ar ms are fully

extended. Tractors will need auxiliary counterbalance

weights added if the tractor’s total weight is less than the

basic minimum weight listed below.

It is best to add auxiliary weights to the left rear tractor

wheel. In addition, up to eight 100 lb. suitcase type

weights can be added to the optional weight hanger on

the hydraulic reser voir. However, adding weights to the

reservoir can lighten the tractor’s front end.

RCP2660 & RCPM2660

Tractor absolute minimum weight. . . . . . . . 8,000 lbs.

Tractor basic minimum weight. . . . . . . . . . 8,500 lbs.

RCP3060 & RCPM3060

Tractor absolute minimum weight. . . . . . . 12,000 lbs.

Tractor basic minimum weight. . . . . . . . . 13,500 lbs.

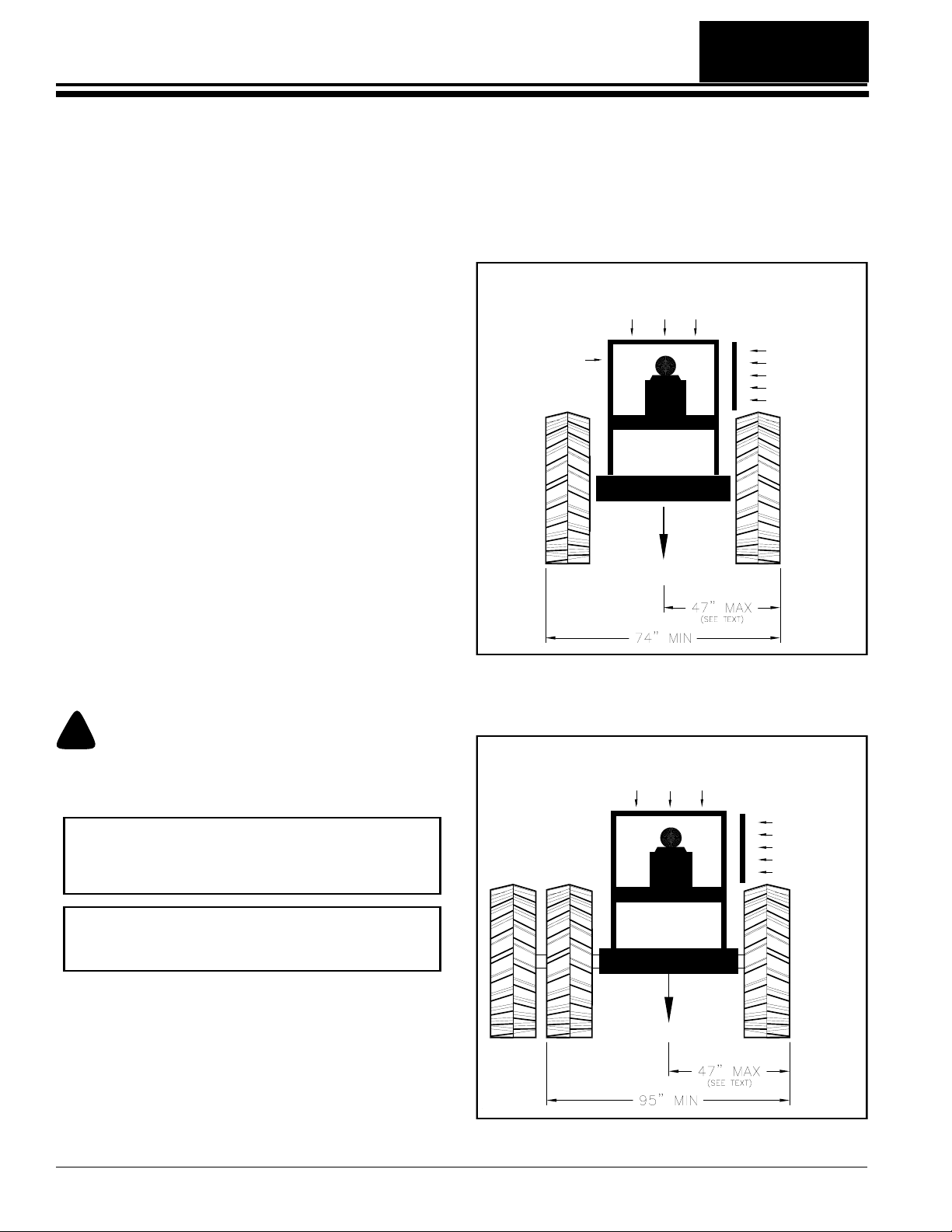

The front gauge wheel and mount may interfere with the

right rear tractor tire when deck is folded for transporting.

This is especially true if the outside face of the tire is

more than 47" away from the tractor center. Tractors

equipped with dual wheels may need the outside right

rear wheel removed. The RCP(M)3060 cutter requires a

dual wheel on the left-hand side or wheel weights equal

to the weight of a dual wheel.

TRACTOR CAB OR

ROLL OVER

PROTECTIVE STRUCTURE

OPERATOR

PROTECTIVE

SHIELD

8,000 LBS. MIM.

12250

RCP2660 & RCPM2660 Minimum Tractor Requirements

Figure 1-1

!

Front tractor weights and/or ballast to tires may be required

to offset weight of cutter and auxiliary weights. Consult your

tractor manual to determine if additional ballast is needed.

WARNING

IMPORTANT: Extended parallel arms will pull the

tractor’s front to the right. When necessary, add

weight to the tractor front to stabilize it. Consult your

tractor’s manual for allowable added weights.

IMPORTANT: The tractor’s right rear wheel should

be pressurized to the manufactures highest

recommended air pressure.

LEFT-HAND DUAL

OR LEFT-HAND

WHEEL WEIGHTS

Wheel Base

Refer to Figure 1-1 & Figure 1-2:

Rear wheel base must meet minimum requirements

when measured from outside face to outside faceof rear

tractor tires. Smaller wheel bases must not be used.

RCP2660 & RCPM2660

Rear Wheel Base. . . . . . . . . . . . . . . . . .74" minimum

RCP3060 & RCPM3060

Rear Wheel Base . . . . . . . . . . . . . . . . . 95" minimum

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

12

RCP3060 & RCPM3060 Minimum Tractor Requirements

TRACTOR CAB OR

ROLL OVER

PROTECTIVE STRUCTURE

REQUIRED

OPERATOR

PROTECTIVE

SHIELD

12,000 LBS. MIM.

24583

Figure 1-2

1/11/13

Page 15

Section 1: Assembly & Set-up

Table of Contents

Hitch

A 3-Point Category II or Category III hitch is required.

The lower 3-Point arms of the 3-Point hitch must be

stabilized to prevent side-to-side movement. Most

tractors have sway blocks or adjustable chains for this

purpose.

Hydraulic Outlets

Thenumber of tractorhydraulicduplexoutlets required is

dependent upon how the Rotary Cutter is set-up.

Independent Control:

One duplex outlet is required to operate the breakaway

cylinder.APTO drivenpump onthe unit pumpshydraulic

fluid from the reservoir to the parallel arm cylinders and

deck pivot cylinder. The cylinders are solenoid activated

withmomentary push button switches at the control stick.

Solenoid Control:

Two duplex outlets are required. One duplex outlet is

required to operate the breakaway cylinder. The second

duplex outlet operates the parallel arm cylinders and

deck pivot cylinder.The cylinders aresolenoid activated

withmomentary pushbuttonswitchesat thecontrolstick.

The second duplex outlet must be capable of continuous

hydraulic fluid flow.

Tractor Control:

Four duplex outlets are required to operate the parallel

arm cylinders, deck pivot cylinder, and breakaway

cylinder. Each cylinder is connected to a duplex outlet

and activated with tractor control levers. Each duplex

outlet must be capable of infinite variable flow control

(turtle/rabbit control) with center detent “OFF” levers.If

gauge wheels are included, “ARM 2” and “Deck Pivot”

levers must be capable of being placed in float position .

PTO Speed

TheRCP cutters requires540 rpmPowerTake-Off (PTO)

speed and the RCPM cutter requires 1000 rpm PTO

speed to operate the hydraulic pump(s) & motor.

Required tractor horsepower to operate thepump(s) and

motor is approximately 30 HP.

Protective Equipment Requirements

Refer to Figure 1-1:

The tractor MUST be equipped with protective

equipment designed to shield the operator from thrown

objects and tractor rollover. An enclosed tractor cab with

a Roll Over Protective Structure (ROPS) may qualify.

See the tractor’smanual to see if it qualifies.

Tractors with only a ROPS must havea protective shield

added to the right-hand fender. A universal operator

protective shield is available from Land Pr ide. Refer to

page 36 for additional information and installation.

It is also recommended that a protective shield or screen

be added to the right-hand side of the tractor engine

cowling and radiator. This will help protect the tractor’s

finish and radiator against thrown objects.

Dealer Preparations

This cutter has been assembled at the factory. However,

some preparations will be necessary to attach the cutter

to customer’s tractor.

• Make certain the intended tractor conforms to the

“Tractor Requirements” on page 12.

• Review and check off Preparation Checklist below

before proceeding.

Preparation Checklist

Upper hitch pin is not Included with unit. Determine

customer’s tractor hitch type. (Cat II or Cat III). Buy

required upper hitch pin locally or order a Land Pride

hitch pin if customer’s tractor does not included the pin.

See Land Pride’s upper hitch pin part numbers below.

805-079C - Upper Hitch Pin Cat II (1" dia. x 3 3/8" usable)

805-196C - Upper Hitch Pin Cat III (1 1/4" dia. x 3 3/8" usable)

Before operating this unit, 80-90 EP Gear Lube must

be added to the gearbox & motor as indicated in the

“Maintenance & Lubrication” section for “Speed

Increaser” on page 52 of this manual.

35 Gallons of Hydraulic Fluid is needed for the

hydraulic reser voir. Use any high quality mineral based

hydraulic fluid such as Mobilfluid 424 with a viscosity

rating of 10W-30.

Additional hydraulic fluid (approx 2 gallons) for the

tractor reservoir.

Miscellaneous assembly tools: hammer, tape measure,

assortment of wrenches and sockets, and spirit level.

Quick disconnect adaptors that match tractor’s duplex

outlets. Quantity required depends on option selected:

(4) If equipped with solenoid control box.

(8) If not equipped with hose hook-up.

Possibleneed for forklift or hoist capable of lifting 2500

lbs.

Auxiliary tractor weights (depending on tractor size).

See “Tractor Requirements” on page 12

A minimum of two people available during assembly.

If a pin, bolt or other part has been removed, and you

are unsure where it is used, use the Parts Manual to

identify it. Be sure the part gets used in the correct

location. By double checking while you assemble, you

will lessen the chance of using a bolt incorrectly that

may be needed later.

Safety decals are legible and undamaged from

shipment.

PTO driveline and loose parts bag/box shipped with

the cutter are present.

.

1/11/13

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

13

Page 16

Table of Contents

Section 1: Assembly & Set-up

The following set-up instructions are standard for all

options. They should be completed before continuing

with optional set-up instructions.

Hooking-up the Rotary Cutter

!

A Crushing Hazard exists when hooking-up equipment to a

tractor. Do not allow anyone to stand between tractor and

implement while backing-up to implement. Do not operate

hydraulic 3-Point lift controls while someone is directly

behind tractor or near implement.

DANGER

IMPORTANT: Hydraulic fluid must be added to the

cutterhydraulicreservoir before operating thepump.

Otherwise, the hydraulic pump will be damaged.

NOTE: Driveline installation instructions will follow

after hooking-up cutter to a tractor. This is because

the distance between tractor PTO shaft and speed

increaser input shaft can vary from tractor to tractor.

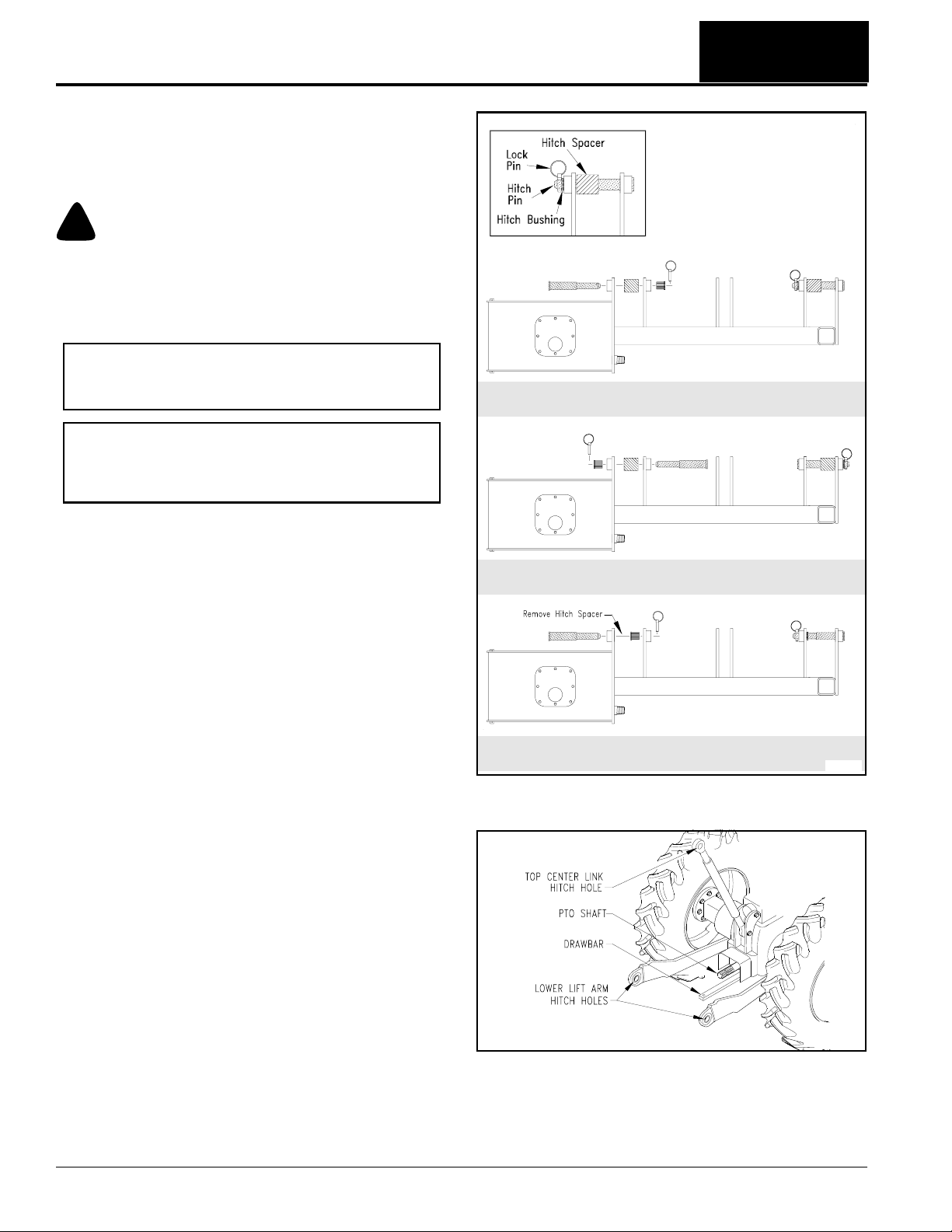

Category III 3-Point Hitch

Prepare cutter as follows:

1. Be sure transport safety chain is hooked to the deck.

See Figure 1-9 on page 17.

2. Position cutter on a flat level concrete surface.

Refer to Figure 1-3:

3. There are three hitch categories represented in

Figure 1-3. Determine which category fits the tractor

being used and arrange cutter hitch pins as shown

for that category.

Refer to Figure 1-4:

4. Slowly back tractor up to the Rotary Cutter while

using tractor’s 3-Point hydraulic controls to align

lower hitch link holes with clevis holes on the cutter.

5. Place tractor gear selector in par k and/or set brakes,

shut engine off, and remove ignition key.

6. Aligned and positioned tractor’s lower hitch holes in

the clevises. Attach the lower arms to the clevises

with hitch pins and secure with linch pins.

7. Adjusttop centerlink in orout toalign centerlink hole

with the cutter’s center hitch pin hole. Connect top

center link to cutter hitch pin hole using customer

supplied clevis pin and linch pin.

8. Makecer tain the lower3-Point arms are stabilized to

prevent excessive side movement.

9. Returnto tractorandslowlyraise tractor 3-Pointhitch

about 1 to 2 inches. Stow jack stands in the raised

position.

10. Slowly operatetractor's 3-Pointarms upand downto

check clearance between cutter components and

tractorcomponents. Moveorremovetractor drawbar

if it interferes with cutter.

11. Adjust tractor's lower arms to level cutter frame from

left to right.

Category II Quick HItch

Category II 3-Point Hitch

24642

Hitch Pin Configuration (Based on Hitch Category)

Figure 1-3

23998

Tractor 3-Point Hitch

Figure 1-4

12. Adjust center top-link to level cutter frame from front

to rear.

13. Final deck leveling adjustments will be made later.

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

14

1/11/13

Page 17

Section 1: Assembly & Set-up

Table of Contents

Driveline Installation

!

Do not engage tractor PTO while hooking-up and unhooking

driveline or while someone is standing near the driveline. A

person’s body and/or clothing can become entangled in the

driveline resulting in serious injury or death.

All guards and shields must be installed and in good working

condition at all times during cutter operation.

Always disengage PTO, engage parking brake, shut tractor

engine off, remove switch key, and wait for blades to come to

a complete stop before dismounting tractor.

Do not over-speed PTO or machine breakage may result.

Some tractors are equipped with multispeed PTO ranges. Be

certain your tractor’s PTO is set for the cutter’s rated PTO

speed. See Specifications & Capacities for rated PTO speed.

DANGER

!

DANGER

!

WARNING

!

WARNING

IMPORTANT: Do not engage tractor PTO until

driveline is fully connected and hydraulic fluid has

been added to the cutter reservoir.

IMPORTANT: A quick hitch may be used, but is not

recommended because it moves the cutter deck

back about 5" and impedes operator visibility.

IMPORTANT: An additional driveline may be

required if cutter is to be used on more than one

tractor, especially if a Quick Hitch is used.

The dr iveline must belubricated before puttingit into

service. Refer to “Lubrication Points” on page 50.

The tractor’s PTO shaft and cutter gearbox shaft

must be aligned and level with each other when

hooking-up the driveline to the tractor.

6. If driveline yokewill not lock in place, skip to “Check

Driveline Collapsible Length” below.

IMPORTANT: Two small chains are supplied with

the driveline.To keepdriveline shields from rotating,

thesechains mustbe attachedto theouter andinner

driveline shields and to the cutter and tractor.

7. Attach safety chain on the inner driveline shield to

the parallel arm frame. Re-latch safety chain to the

inner driveline shield.

8. Attach safety chain on the outer driveline shield to

the tractor frame. Re-latch safety chain to the outer

driveline shield.

9. Continue with “Check Driveline Collapsible

Length” below.

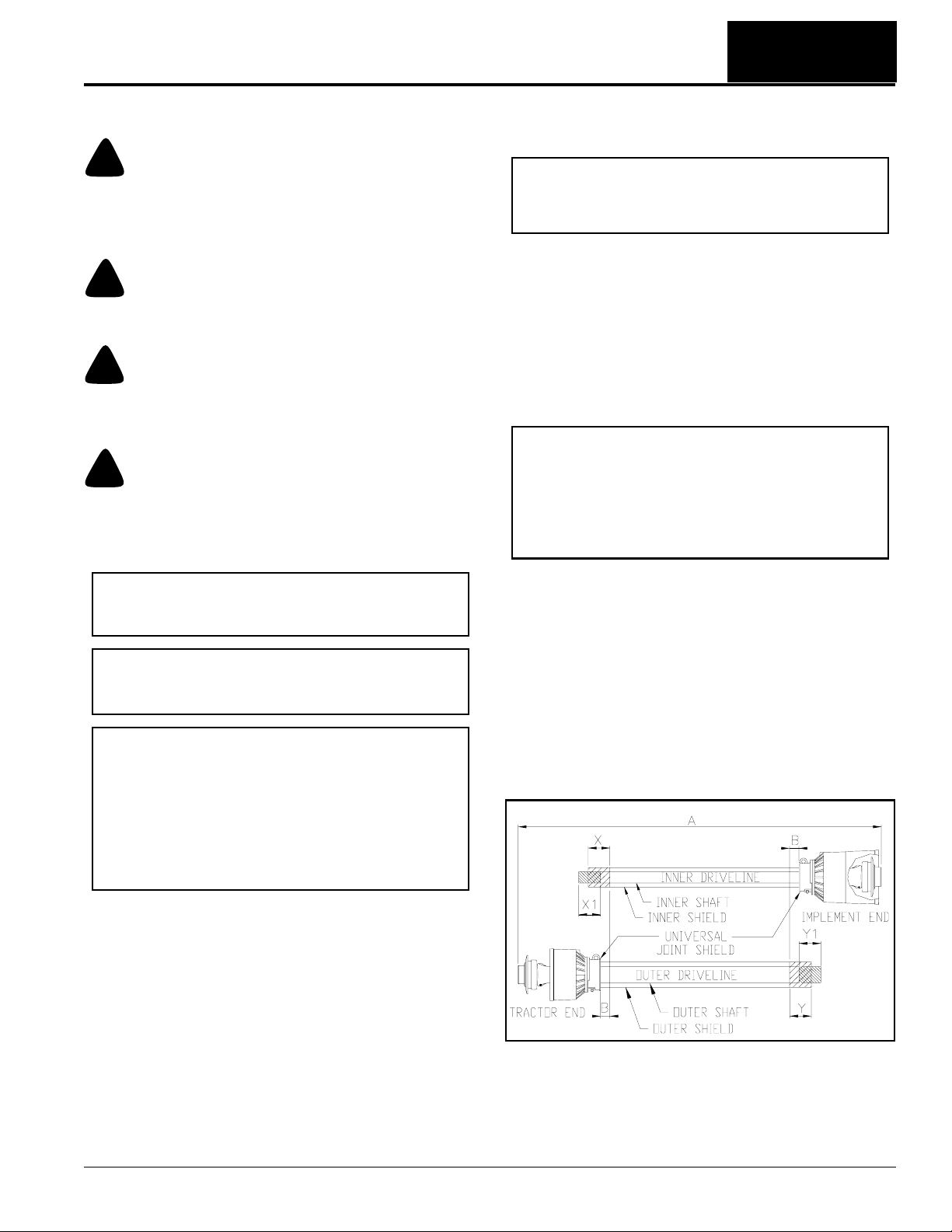

Check Driveline Collapsible Length

IMPORTANT: A driveline that is too long can bottom

out causing structural damage to tractor and cutter.

Alwayscheckdrivelinecollapsedlength duringinitial

setup, when connecting to a different tractor, and

when alternating between using a quick hitch and a

standard 3-Pointhitch. More than one driveline may

be required to fit all applications.

1. Make sure dr iveline is properly installed and level

beforecheckingdrivelinecollapsiblelength.(Referto

“Driveline Installation” instructions on page 15.)

Refer to Figure 1-5:

2. With driveline level, measure (“B” dimension) back

from universal joint shield to end of outer driveline

shield as shown in Figure 1-5.

3. If measurement is 1" or more, skip to “Check

Driveline Maximum Length” on page 16. If

measurement is less than 1",shorten drivelineusing

instructions provided under “Shorten Driveline” on

page 16.

Refer to Figure 1-5:

1. Start tractor and slowly engage 3-Point controls to

move lower arms until the PTO shaft for the speed

increaser is aligned and levelwith tractor PTO shaft.

Securely block cutter in this position.

2. Place tractor gear selector in park, shut tractor

engine off, set park brake, and remove switch key.

3. Slide inner yoke of driveline over speed increaser

shaft and secure with locking collar.

4. Slide outer yoke of driveline over tractor PTO shaft

and secure with locking collar.

5. Push and pull on driveline yokes to be certain they

are securely fastened to the speed increaser and

PTO shafts.

1/11/13

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

22009

Shortening PTO Driveline Shields & Shafts

Figure 1-5

15

Page 18

Section 1: Assembly & Set-up

Table of Contents

Shorten Driveline

Refer to Figure 1-5:

Be sure to check driveline collapsed length first. If

required, shorten driveline as follows:

1. Un-hook driveline and safety chain from tractor PTO

shaft. Pull outer and inner drivelines apart.

2. Reattach outer dr iveline to tractor PTOshaft. Pull on

inner and outer driveline yokes to be sure universal

joints are properly secured.

3. Holdinner and outerdrivelines parallel to each other:

a. Measure 1" (“B” dimension) back from outer

drivelineuniversal jointshield and makea markat

this location on the inner driveline shield.

b. Measure 1" (“B” dimension) back from the inner

drivelineuniversaljoint shieldand makea mar k at

this location on the outer driveline shield.

4. Remove driveline from tractor PTO shaft and speed

increaser shaft.

5. Measure from end of inner shield to scribed mark

(“X” dimension). Cutoff innershield atthe mark. Cut

same amount off the inner shaft (“X1” dimension).

6. Measure from end of outer shield to scribed mark

(“Y” dimension). Cutoff outershield at themark. Cut

same amount off the outer shaft (“Y1” dimension).

7. Remove all burrs and cuttings.

8. Continuewith“Check Driveline Maximum Length”.

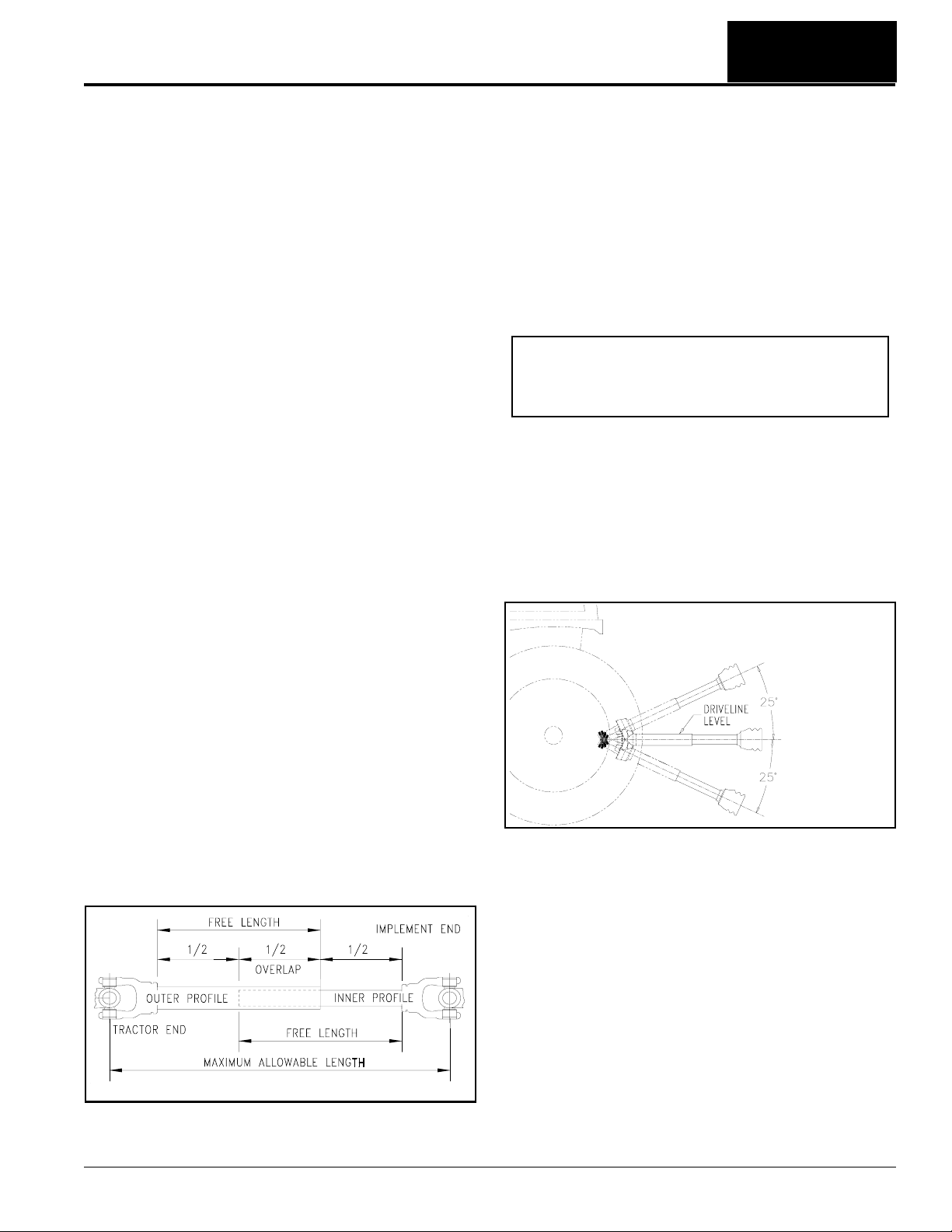

Check Driveline Maximum Length

Refer to Figure 1-6:

Thedrivelinemaximum allowablelength must,when fully

extended,haveaminimum overlap ofprofile tubesbynot

less than 1/2 the free length with both inner and outer

profile tubes being of equal length.

1. Apply multi-purpose greaseto the inside of the outer

shaft and reassemble the driveline.

2. Assemblethe twodriveline profiles together with just

1/2 overlapping of the profile tubes as shown. Once

assembled,measureandrecordmaximum allowable

length here. ________

3. Continue with “Check Driveline Interference”.

Check Driveline Interference

1. Make certain driveline yokes and safety chains are

properly attached. See steps 7 -9 on page 15.

2. Start tractorandraise ParallelArmRotar y Cutterjust

enough to remove support blocks from under the

cutter.

3. Slowly engage tractor hydraulic3-Point control lever

to lower cutter while checking for sufficient drawbar

clearance. Movedrawbar ahead, aside, or remove if

required.

Refer to Figure 1-7:

IMPORTANT: Avoid premature driveline

breakdown. A driveline that is operating must not

exceed an angle of 25 degrees up or down while

operating 3-Point lift.

4. With PTO off, raise implement fully up to make the

following checks below. If driveline exceeds any of

the limits listed, set tractor 3-Point lift limiter at a

height that will keep the driveline within its lift limits

and to avoid premature driveline breakdown.

• Driveline does not exceed 25

o

up.

• Driveline does not exceed maximum allowable

length recorded in step 2 under “Check Driveline

Maximum Length”.

24872

Maximum PTO Driveline Movement During Operation

Figure 1-7

24804

Outer Shielding has been removed for clarity.

Driveline Maximum Extended Length

Figure 1-6

1/11/13

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

16

Page 19

Section 1: Assembly & Set-up

Table of Contents

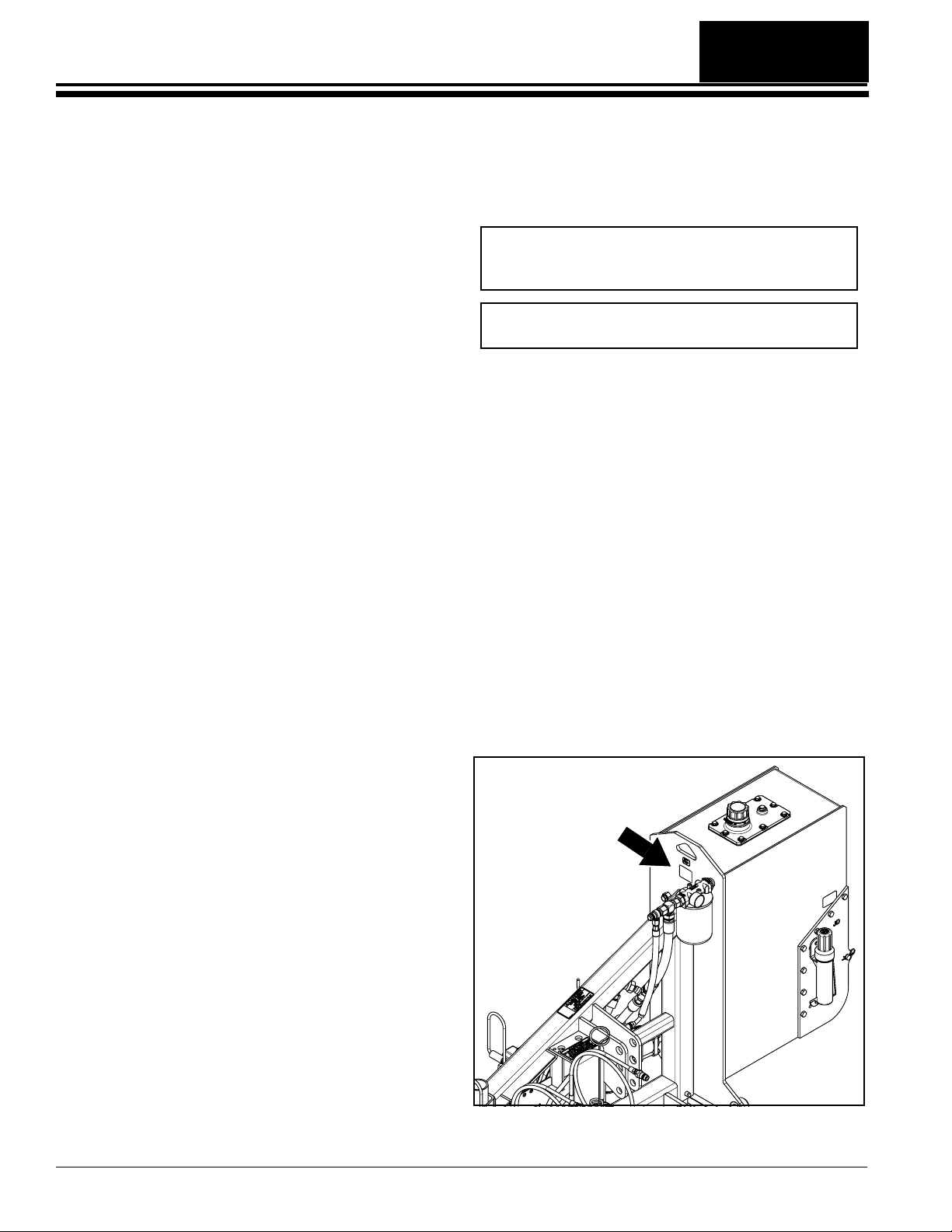

Hydraulic Reservoir Oil Fill

Refer to Figure 1-8:

The Rotar y Cutter is shipped without hydraulic fluid.

1. Parkcutter on a levelsurface,set park brake,turn off

ignition switch, and remove switch key.

2. Remove fill cap and dipstick from reservoir and add

35gallonsof Mobilfluic424to thehydraulicreservoir.

Use care to ensure that dust or other foreign

particles do not contaminate the fluid.

IMPORTANT: Any high quality mineral based

hydraulicfluidsuch as Mobilfluid 424 with a viscosity

rating of 10W-30 is acceptable. For alter nate fluids,

search on the web for "Mobilfluid 424" or go to

www.mobil.com.

3. Wipe dipstick clean. Fully insert it and remove.

Checkoil levelon dipstick.Fill with recommended oil

to the full mark. Replace fill cap and dipstick.

Transport Safety Chain

Refer to Figure 1-8 & Figure 1-9:

!

WARNING

Transport safety chain must remain hooked to the deck until

ready to extend parallel arms and deck cylinder. Float Switch

must be “OFF” until gauge wheels are resting on the ground.

The transpor t safety chain should always be hooked to

the deck hook when cutter is folded up. Otherwise, the

operating levers and/or push button switches could be

bumped or hoses could burst allowing deck to fall and

cause damage to cutter, tractor, and anyone nearby.

When unhooking the transport safety chain, make sure

the arm anddeck cylinders areretracted and if available,

theFloat Switch is set to “OFF”. Donot forcesafetychain

off the deck hook. If safetychain does not remove easily,

investigate the problem and correct before continuing.

Once unhooked, store safety chain on the storage hook.

Fill Cap With Dip Stick

Storage Hook

Transport Safety Chain

Drain Plug

Transport Safety Chain Shown in Storage Position

Figure 1-8

Deck Hook

Transport Safety Chain

Transport Safety Chain Shown Hooked for Transport

Figure 1-9

12443

22031

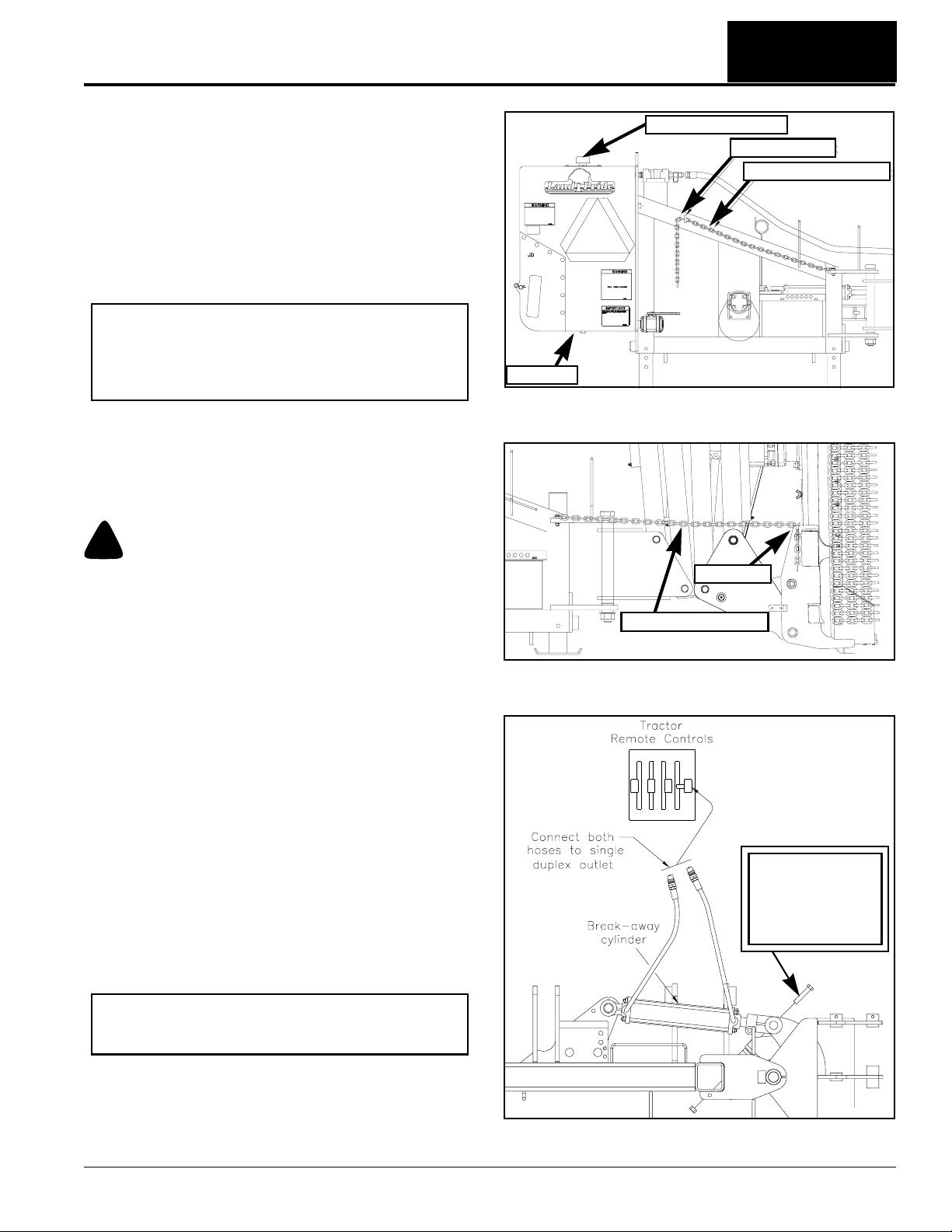

Breakaway Cylinder

Refer to Figure 1-10 on page 17:

The breakaway cylinder protects the Rotary Cutter from

damagewhen cutterdeckor parallelarm contactsa solid

objectwhile moving forward.Itdoes not protectthe cutter

while backing up. Always make certain the area behind

the cutter is clear before backing up. See Breakaway

Cylinder on page 37 for additional information.

IMPORTANT: A 1/2" bolt is installed for shipping

purposes only. This bolt must be remove before

connecting hydraulic hoses to the tractor.

1. Remove 1/2" shipping bolt from cutter before

connecting hydraulic hoses. DO NOT reinstall

shipping bolt.

2. Attach breakawayhoses to a single duplexoutlet on

the tractor as shown in Figure 1-10.

1/11/13

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

Important:

LocateandRemove

1/2" Shipping Bolt

Before Connecting

Hydraulic Hoses.

12256

Breakaway Cylinder Hose Connections

Figure 1-10

17

Page 20

Section 1: Assembly & Set-up

Table of Contents

Weight Hanger Assembly

Refer to Figure 1-11:

There are five different weight hangers that can be

attached to the reservoir. One of the five must be

installed for operation. See “Bolt-on Weight Hangers”

on page 35 for detailed description of availableweight

hangers.

NOTE: Case/International Harvest weight hanger

includes an L-shaped spacer. Be sure to locate this

spacer between the weight hanger side plate and

hydraulic reservoir tank in assembly.

1. Attach weight hanger (#1) to reservoir with four teen

1/2"-13 x 1 1/4" GR5 cap screws (#3) and hex flange

locknuts (#3).Tighten locknuts to the correct torque.

2. Attach manual storage container (#9) to the front

side of the reservoir with two 1/4"-20 x 1 1/4" GR5

cap screws (#4), flat washers (#7), and hex nylock

nuts (#6). Tighten nylock nuts to the correct torque.

3. Insert weight retainer pin (#2) through holes in

weight hanger and secure with hairpin cotters (#8).

Case/International Harvest Weight Hanger Only:

Locate L-shaped spacer between weight hanger

side plate and hydraulic reservoir.

NOTE: Installation of gauge wheel and ratchet jack

iseasier after the deck hasbeen lowered. Therefore,

it is best to install them just before making “Float

Positioning Control Check” on page 20 for Tractor

Controlor just before making “Float Switch ON/OFF

Push Button Check” on page 27 for Solenoid and

Independent Control.

Ratchet Jack Installation

1. Check 5/8" hex flange lock nuts securing bolts (#3).

They should be drawn up snug, not tight.

A-frame (#2) should pivot freely on the two bolts.

2. Cutties securing A-frame(#2) and rotate frame back

to position it behind the deck as shown.

3. Attach ratchet jack (#8) to the cutter deckwith 1" dia.

clevis pins (#6). Secure clevis pins with hair pin

cotters (#3).

4. Insert long handle in the rear ratchet jack and short

handle in the front ratchet jack. Secure handles with

cotter pins. Bend cotter pin legs to keep pins from

falling out.

NOTE: After deck cutting height is set, it is

recommended that the ratchet jack handles be

removed and stored with the tractor and cutter to

protect the deck finish.

30029

Weight Hanger Installation

Figure 1-11

Gauge Wheels (Optional)

Refer to Figure 1-12:

The deck with gauge wheels is shipped from the factory

completely assembled to the parallel arm with the

exception of installing the rear ratchet jack and one

gauge wheel.

Gauge Wheel Installation

1. Install 1 1/4" I.D. machine washer (#4) over yoke

spindle (#1) as shown.

2. Insert yoke spindle (#1) into the front support frame.

3. Install second 1 1/4" I.D. machine washer (#4) over

yoke spindle (#1).

4. Secure yoke spindle to frame with 5/16" dia. roll

pin (#7).

24617

Gauge Wheel Installation

Figure 1-12

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

18

1/11/13

Page 21

Table of Contents

Section 2: Hydraulic Set-up Options

Section 2: Hydraulic Set-up Options

Options

There are three basic Hydraulic Options for the Parallel

Arm RotaryCutter (TractorControl, SolenoidControl and

Independent Control). Each of the three basic options

can be purchased with or without gauge wheels. A brief

description of each follows:

Tractor Control

Refer to Figure 2-2:

Four duplex outlets are required to operate “ARM 1”,

“ARM 2”, “Deck Pivot”, and Breakaway cylinders. The

duplex outlets must be capable of infinite variable flow

control (turtle/rabbit control) and should have center

detent “OFF” control levers for controlling the position of

theparallelar m anddeckpivotcylinders. If gaugewheels

are included, “ARM 2” and “Deck Pivot” control levers

must be capable of being placed in float position.

The hydraulic motor on the deck is powered by a

hydraulicpump connected to the tractor’sPTO shaft and

is turned “ON” and “OFF” at the tractor’s PTO shaft.

Solenoid Control

Refer to Figure 2-14 on page 26:

With this arrangement, the breakaway cylinder is

coupled directly to a duplex outlet at the tractor and

operated with the tractor’s hydraulic control lever.

The remaining three cylinders (“ARM 1”, “ARM 2” &

“Deck Pivot”) are powered by one duplex outlet at the

tractor with the control lever set for continuos hydraulic

flow. A flow control valve mounted on the cutter frame

regulates oil flow through the solenoid valve block. The

three cylinders aresolenoid activated from the tractor

seat with momentary push buttons on the control stick.

If gauge wheels are mounted on the deck, the solenoid

valve block must also include two float valves(poppet

valves) so that “ARM 2” and “Deck Pivot” cylinders can

float with the deck as it is carried by the gauge wheels.

The hydraulic motor on the deck is powered by a

hydraulic motor pump connected to the tractor’s PTO

shaft and is turned “ON” and “OFF” at the tractor’s PTO

shaft.

If gauge wheels are mounted on the deck, the solenoid

valve block must also include two float valves(poppet

valves) so that “ARM 2” and “Deck Pivot” cylinders can

float with the deck as it is carried by the gauge wheels.

Tractor Control

NOTE: The response time with solenoid and

independent controlled cylinders is faster than

tractor controlled cylinders. Therefore, the operator

might want to consider going with solenoid

controlled cylinders or independent controlled

cylinders when frequent changes to deck

positioning are required.

Hydraulic Hose Hook-up

Refer to Figure 2-1:

Three cylinders are connect to three duplex outlets on

the tractor. Make sure these duplex outlets have infinite

variable flow control. Do Not run tractor to make

adjustments to hose hook-up. Adjustments will be made

laterduring Console Control LeverFunctional Checks on

page 20.

1. Connect “ARM 1” hoses to a single duplex outlet on

the tractor. This is best if connected to the control

closest to the operator.

2. Connect “ARM 2” hoses to the control lever next to

“ARM 1” lever.This control levermust be capable of

beingplaced infloat position whengauge wheelsare

included.

3. Connect “Deck Pivot” hoses to the control lever next

to “ARM 2” lever. This control lever must be capable

of being placed in float position when gauge wheels

are included.

Independent Control

Refer to Figure 2-14 on page 26:

With this arrangement, the breakaway cylinder is

coupled directly to a duplex outlet at the tractor and

operated with the tractor’s hydraulic control lever.

The remaining three cylinders (“ARM 1”, “ARM 2”, and

“Deck Pivot”) are powered by a cylinder pump mounted

on the back of the motor pump. The cylinders are

solenoid activated with momentary push buttons on the

control stick.

The hydraulic motor on the deck is powered by a

hydraulic motor pump connected to the tractor’s PTO

shaft. Because the PTO shaft must run continuously to

operate the cylinders, the motor is run with an “ON/OFF”

push button switch on the control stick.

1/11/13

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

24638

Hose Hook-up With Tractor Control Cylinders

Figure 2-1

19

Page 22

Table of Contents

Section 2: Hydraulic Set-up Options

Console Control Lever Functional Checks

!

Hydraulic fluid under high pressure can penetrate skin. Wear

protective gloves and safety glasses or goggles when working

with hydraulic systems. Use a piece of cardboard or wood

rather than hands when searching for hydraulic leaks. If

hydraulic fluid is injected into the skin or eyes, it must be

treated by a doctor familiar with this type of injury within a

few hours or gangrene may result. DO NOT DELAY.

The hoses on each outlet should be connected such that

when the control lever is pushed forward, the arm

(or deck) extends. Cycle hydraulic cylinders with tractor

console controls to ensure they operate properly as

follows:

Pre-Operational Instructions

1. Read and understand “TransportSafety Chain” on

2. Remove transport safety chain from its latched

3. Start tractor and adjust 3-Point hitch until PTO

Control Lever Center Detent Position Check

Refer to Figure 2-2:

1. Operate tractor console control lever designated for

2. Repeat this procedure for“ARM 2” and “Deck Pivot”

DANGER

page 17 before continuing.

position and place loose end on the storage hook.

driveline is approximately level.

“ARM 1” by pushing it forward briefly to see which

way the inboard arm moves. It should extend

outward.If “ARM1” retracts,reversehydraulichoses

at the duplex outlet (See Figure 2-1 on page 19).

cylinders.

3. After hose hook-up has been verified to be correct,

purge hydraulic cylinders of air in the order below:

a. Pushon deckcontrollever tolower the deckdown

into a horizontal position.

b. Push on “ARM 2” control lever until the outboard

parallel arm is fully extend.

c. Push on “ARM 1” control lever until the inboard

parallel arm is fully extend.

d. Repeat steps a to c in reverse order to retract all

three cylinders.

e. Cycle cylinders to full extension and retraction

severaltimes to make sure all air is purged.

4. Check hydraulic fluid level in your tractor's reservoir.

If low, add fluid to the tractor’s hydraulic system

before proceeding. The cylinders and hoses will

require approximately 1 3/4 gallons from tractor

reservoir.

Float Positioning Control Check

Gauge wheels must be installed before setting tractor

operatorlevers to float position. Install gauge wheels per

“Gauge Wheels (Optional)” instructions on page 18.

To make this functional check, “ARM 1” and “ARM 2”

must extended about half way. The Rotary Cutter deck

should be resting on its gauge wheels.

1. Operate all three tractor console control levers and

lower gauge wheels to ground level.

2. Set only “ARM 2” and “DECK” control levers in float

position. Consult tractor manual if operator is unsure

of where float position is for the tractor control levers.

3. Retract “ARM 1” control lever. “ARM 2” and “Deck

Pivot” cylinders should float (change position)

allowingdeck gauge wheels to remain resting on the

ground.

4. Return control levers to center detent position to

regain full control of “ARM 2” and “Deck Pivot” pivot

cylinders.

Flow Control (Turtle/Rabbit Adjustments)

Flow control adjustments are made in the Adjustment

section. Refer to “Turtle/Rabbit Flow Control at the

Tractor” on page 28 for detailed instr uctions.

24616

Parallel Arm Movement

Figure 2-2

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

20

1/11/13

Page 23

Table of Contents

Section 2: Hydraulic Set-up Options

Solenoid Control

Hydraulic oil is supplied to the solenoid valve block

through two hydraulic lines connected to one of the

tractor’s remote duplex outlets. “ARM 1”, “ARM 2”, and

“Deck Pivot” hydraulic cylinders are plumbed to the

solenoid valve block and controlled from the tractor seat

with an electrically operated control stick. The speed at

whichthe cylindersextendand retractis controlled with a

flow control valve mounted on the cutter frame.

Flow Control Valve Plumbing

The tractor duplex outlet connected to the solenoid valve

block must be capable of continuous flow. An auxiliary

flow control valve on the cutter frame diverts excess oil

back to the tractor. This valve regulates volume flow of

hydraulicoil to the hydraulic cylinders and helps cool the

hydraulic oil by keeping back pressure down.

IMPORTANT: Damage to o-rings in the solenoid

valve and/or in the cylinders may occur if oil

becomes overheated. Make sure pressure & return

hoses are configured to match tractor rated GPMs.

See your tractor’smanual to determine its rated flow.

Tractors Rated 15 GPM and Under

Refer to Figure 2-3:

1. Pressureline #1 isplumbed from thelowerportin the

solenoid valve block to the port labeled “CF” in the

flow control valve.

2. Pressure line #2 is plumbed to the bottom port in the

flow control valve por t labeled “IN” and the opposite

end is fitted with a Pioneer-quick disconnect coupler.

3. Return line #1 is plumbed from the upper por t in the

solenoid valve block to the tee at the flow control

valve with a check valve between the tee and hose.

4. Return line #2 is plumbed to the tee at the flow

control valve and the opposite end is fitted with a

Pioneer-quick disconnect coupler.

5. Connect return line#2 and pressure line #2 to one of

thetractor’sduplexoutlets.Pioneer-quickdisconnect

hose couplings are supplied with each hose. Some

tractors use other types of quick couplers.

Tractors Rated 16 GPM and Above

Refer to Figure 2-4:

1. Return line #1 is plumbed to the upper port in the

solenoid valve block and the opposite end is fitted

with a Pioneer-quick disconnect coupler.

2. Pressureline #1 isplumbed from thelowerportin the

solenoid valve block to the port labeled “CF” in the

flow control valve.

3. Pressure line #2 is plumbed to the por t in the bottom

ofthe flowcontrolvalvelabeled “IN”and the opposite

end is fitted with a Pioneer-quick disconnect coupler.

4. Return line #2 is plumbed to the tee at the flow

control valve and the opposite end is plumbed to

either the tractor sump or deck motor return line.

Fittings to plumb to tractor sump or motor return line

are customer supplied.

5. The unused port on the tee must be plugged.

6. Connect return line#1 and pressure line #2 to one of

thetractor’sduplexoutlets.Pioneer-quickdisconnect

hose couplings are supplied with each hose. Some

tractors use other types of quick couplers.

22010

Plumbing for Tractors Rated 15 GPM & Under

Figure 2-3

22221

Plumbing for Tractors Rated 16 GPM & Above

Figure 2-4

Flow Control Valve Adjustments

Flow control valve adjustments are made after the

electrical controls have been installed. Detailed

instructions will be provided later on page 28 under the

heading “Hydraulic Flow Control”.

Skip to Solenoid Valve Block Functions on

page 22 to continue.

1/11/13

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

21

Page 24

Table of Contents

Section 2: Hydraulic Set-up Options

Independent Control

Withthe IndependentControl option, only the breakaway

cylinder is operated by tractor hydraulics. All other

hydraulicson the cutter are self contained using only the

oil in the reservoir to run the cylinders and deck motor.

Both, Independent and Solenoid Control options rely

upon the solenoid valve block to control “ARM 1”,

“ARM 2”, and “Deck Pivot” cylinders.

Solenoid Valve Block Functions

Refer to Figure 1-10 & Figure 2-1:

A solenoid valve block is included on cutters with

Independent Control and Solenoid Control. If Gauge

Wheel Option is included, the solenoid valveblock must

have two poppet valves on top to allow the deck to float

on its gauge wheels. See Figure 2-6 for illustration of

poppet valves.

27970

Solenoid Valve Block Without Deck Float Capabilities

Figure 2-5

Poppet Valves

For Deck Floating

24637

Solenoid Valve Block With Deck Float Capabilities

Figure 2-6

Independent Control

Refer to Figure 2-1:

1. Set flow control valve on the solenoid valve block to

“OPEN” byturning the flow control knob “COUNTER

CLOCKWISE” until knob stops turning.

The Independent Control Option is designed to

produce the correct volume flow of hydraulic oil to

thehydraulic cylinders.The flowcontrol valve shown

in Figure 2-4 on page 21 is not needed.

Solenoid Control

1. Consult the tractor’smanual to determine the

tractor’shydraulic system (System A, B, or C below):

A. Closed Center System With PC & LS

PC = Pressure Compensating

LS = Load Sensing

IMPORTANT: Tractors with this system must

have variable flow control (turtle/rabbit control).

B. Closed Center System Without PC or LS

C. Open Center System

2. Remove plastic cover located at the rear of the

solenoid valve block.

3. Adjust flow control valve Knob at the solenoid valve

block and flow control valve on the 3-Point frame:

A. Closed Center System With PC & LS:

IMPORTANT: A tractor with this system

MUST HAVE VARIABLE FLOW CONTROL

(tur tle/rabbit control) at the duplex outlet. Using

a tractor without variableflow control will cause

the oil to over heat and damage seals in the

solenoid valve block.

Set flow control valve on the solenoid block to

“OPEN” by turning the flow control valve knob

“COUNTER CLOCKWISE” until knob stops

turning. (See Figure 2-5.)

See Figure 3-1 on page 28: Set flow control valve

knob on the 3-Point frame to the lowest possible

number to allow maximum oil flow.

Adjust hydraulic flow to the solenoid block using

“Turtle/Rabbit Flow Control at the Tractor”

instructions on page 28.

B. Closed Center System Without PC or LS:

Set flow control valve on the solenoid valve block

to “CLOSED” by turning knob “CLOCKWISE” until

it stops turning. (See Figure 2-5.)

If the tractor’s duplex outlet has turtle/rabbit

control, adjust hydraulic flow to the solenoid block

using “Turtle/Rabbit Flow Control at the

Tractor” instructions on page 28. Be sure to set

flow control valve knob on the 3-Point frame (See

Figure 3-1 on page 28) to the lowest possible

number.

If tractor does not have turtle/rabbit control, adjust

flowcontrolvalveknob using instructionsfor“Flow

Control Valve on the Rotary Cutter” on page 28.

C. Open Center System:

Set flow control valve on the solenoid valve block

to “OPEN” by turning knob “COUNTER

CLOCKWISE” until it stops. (See Figure 2-5.)

Adjust hydraulic flow to the solenoid block using

“Turtle/Rabbit Flow Control at the Tractor”

instructions on page 28. Besure to set flow control

valveknobon the3-Pointframe (See Figure3-1on

page 28) to the lowest possible number.

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

22

1/11/13

Page 25

Table of Contents

Section 2: Hydraulic Set-up Options

Control Sticks

There are four control stick arrangements. They are as

follows:

• Solenoid Control Without Gauge Wheels.

• Solenoid Control With Gauge Wheels.

• Independent Control Without Gauge Wheels.

• Independent Control With Gauge Wheels.

See Figure 2-14 on page 26 for illustration of “ARM 1”,

“ARM 2”, “Deck Pivot”& “Deck Motor”. The deck must be

equipped with gauge wheels before “Deck Float” is

included. “Deck Float” allows “ARM 2” and “Deck Pivot”

cylinders to float with the gauge wheels as they roll over

the ground surface. Make sure you have the correct

control stick for your particular set-up.

Solenoid Control Without Gauge Wheels

Refer to Figure 2-11:

This control stick includes the following push buttons:

• Two momentary push buttons for moving “ARM 1”.

• Two momentary push buttons for moving “ARM 2”.

• Two momentary push buttons for “Deck Pivot”.

Solenoid Control With Gauge Wheels

Refer to Figure 2-8:

This control stick includes the following push buttons:

• Two momentary push buttons for moving “ARM 1”.

• Two momentary push buttons for moving “ARM 2”.

• Two momentary push buttons for “Deck Pivot”.

• One “ON/OFF” float switch for “Deck Float”.

• One LED light Indicating float switch is “ON”.

30019

Solenoid Control Without Gauge Wheels

Figure 2-7

30019

Solenoid Control With Gauge Wheels

Figure 2-8

Independent Control Without Gauge Wheels

Refer to Figure 2-9:

This control stick includes the following push buttons:

• Two momentary push buttons for moving “ARM 1”.

• Two momentary push buttons for moving “ARM 2”.

• Two momentary push buttons for “Deck Pivot”.

• One “ON/OFF” lighted push button switch for

controlling “Deck Motor”. Light is on when running.

Independent Control With Gauge Wheels

Refer to Figure 2-10:

This control stick includes the following push buttons:

• Two momentary push buttons for moving “ARM 1”.

• Two momentary push buttons for moving “ARM 2”.

• Two momentary push buttons for “Deck Pivot”.

• One “ON/OFF” lighted push button switch for

controlling “Deck Motor”. Light is on when running.

• One “ON/OFF” lighted push button switch for “Deck

Float”. Light is on when deck is floating.

1/11/13

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

30019

Independent Control Without Gauge Wheels

Without Deck Float

Figure 2-9

30019

Independent Control With Gauge Wheels

Figure 2-10

23

Page 26

Table of Contents

Section 2: Hydraulic Set-up Options

Control Stick Hook-up

Refer to Figure 2-11:

IMPORTANT: TheRCP is fully operational once the

control stick is hooked-up.To protect the PTO driven

pump, make sure the reser voir is full of hydraulic oil

and that the shut-off valve on the reservoir is turned

“ON” before hooking-up the control stick.

Always disconnect power cable from the tractor

battery or unplugthe controlswitchfrom the solenoid

control box and deck motor switch before turning

“OFF” the shut off valve. Never turn “OFF” shut off

valve when equipment is in operation.

Refer to Figure 2-12:

1. Route control cable from control stick to solenoid

control box on the cutter and connect to mating pin

connector.

2. Independent Control Only:

a. Wrap deck motor cable around 2" square tubing

once to keep cable from the PTO driveline.

b. Connect orange/black terminal to terminal on the

deck motor switch closest to the solenoid nut.

c. Connect black/white ter minal to terminal on the

deck motor switch far thest from solenoid nut.

3. Route power cable to the tractor’s power source or

circuit breaker panel. A 10 Amp or larger fuse/circuit

breaker source should be used.

a. Connect red lead to a 12 VDC positive power

source.

b. Connect black lead to negative 12 VDC power

source.

Make Sure Reservoir

Is Full Of Hydraulic Oil

Before Engaging PTO

Make Sure Shut Off

Valve Is Turned ON

Before Engaging PTO

30020

Hydraulic Reservoir & Shut Off Valve

Figure 2-11

27969

IMPORTANT: Connect power cable leads only to a

12 VDC power source. Connecting to 24 VDC or

larger will damage electrical system.

Check tractor’s manual to verify how to make a 12

volt hook-up if tractor is equipped with dual 6 volt

batteries. Arm and deck functions will be slow if

hooked-up to the dual 6 volt batteries incorrectly.

NOTE: The control stick wiring includes a 10 amp

fuse on the red power cable. If overheated, the fuse

willopen stopping allpower to the controls. Thefuse

must be replaced before power will resume.

Refer to Figure 2-13:

4. Find a suitable location to place control stick when

not in use.

a. A suitable location for the control stick is usually

close to the operator’s right-hand side on the

tractor fender or fender console. Exact location

should be convenient for the operator.

b. When in use, grip the control stick such that the

push button switches are easy to access.

RCP2660, RCPM2660, RCP3060 and RCPM3060 Parallel Arm Rotary Cutter 316-111M

24

Control Stick Hook-Up

Figure 2-12

25830

Control Stick (Shown with Float Switch)

Figure 2-13

1/11/13

Page 27

Table of Contents

Section 2: Hydraulic Set-up Options

Control Stick Operation

Refer to Figure 2-14 on page 26:

ARM 1 Control

“ARM 1 OUT/IN” push button switches extends and

retracts the inboard parallel arm. Pivot angle of the deck

remains unchanged while operating these two switches.

“ARM 1” push button switchesare always functional and

will operate with Float Switch turned “ON” or “OFF”.

1. Press and hold “ARM 1 OUT” push button to extend

inboard arm. Release switch to stop movement.

2. Press and hold “ARM 1 IN” push button to retract

inboard arm. Release switch to stop arm movement.

ARM 2 Control

“ARM 2 OUT/IN” push buttons extends and retracts the

outboard parallel arm. Pivot angle of the deck remains

unchanged while operating these two switches. “Deck

Float” switch and LED light must be “OFF” before

“ARM 2” switches will function.

1. Press and hold “ARM 2 OUT” push button to extend

outboard arm. Release switch to stop movement.

2. Press and hold “ARM 2 IN” push button to retract

outboard arm. Release switch to stop movement.

Deck Pivot Control

Refer to Figure 2-14 on page 26:

Operate “Deck Pivot UP/DOWN” push buttons to keep

deck parallel to the ground. “Deck Float” switch and LED

light must be “OFF” before “Deck Pivot” switches will

function.

1. Press and hold “DECK UP” push button to pivot end

of deck up. Release switch to stop movement.

2. Press and hold “DECK DOWN” push button to pivot

endof deck down. Releaseswitchto stop movement.

Deck Float Control

The control stick is equipped with a Float Switch and an

LED light if the cutter deck is equipped with gauge

wheels.

1. Press and release “Deck Float” push button to turn

floatfunction “ON” andto bypass“ARM 2”and “Deck

Pivot” controls.

2. Press and release the push buttonagain to turn float

function “OFF” and to regain control of “ARM 2” and

“Deck Pivot”.