Page 1

Baffle and Shredder Kits

For RC(M)5020 Rotary Cutters

Before You Start

When you see this symbol, the subsequent

instructions and warnings are serious - follow

!

without exception. Your life and the lives of

others depend on it!

IMPORTANT: Before you begin, read these

instructions and check to be sure all parts and tools

are accounted for. Please retain these installation

instructions for future reference and parts ordering

information.

The Baffle Kit and Shredder Kit are exclusively designed

for your 20 foot Land Pride Rotary Cutter. Please read

these installation instructions and your Rotary Cutter

Operator’s Manual thoroughly before beginning.

Especially read information relating to safety concerns.

Also included in the Operator’s Manual is important

information on operation, adjustment, troubleshooting,

and maintenance for this attachment (some manual

sections do not apply to all accessories).

A separate Rotary Cutter Parts Manual is available free

of charge at www.landpride.com or can be purchased

from your nearest Land Pride dealer. Have the model

andserialnumbersofyourcutterhandywhenplacingan

order.

Manual Part Numbers:

• Operator’sManual . . . . . . . . . . . . . . . . . 318-474M

• Parts Manual . . . . . . . . . . . . . . . . . . . . . 318-474P

General Information

Manual No. 330-148M

Safety Information

!

Never work under equipment supported by hydraulics.

Hydraulics can drop equipment if controls are actuated or if

hydraulic lines burst. Either situation can drop the cutter

instantly even when power to the hydraulics is shut off.

Always disconnect main driveline from tractor PTO before

servicing the cutter deck. Cutter can be engaged if tractor is

started resulting in damage to the cutter, bodily injury and/or

death.

WARNING

!

DANGER

Baffle Assembly Instructions

A detailed listing of parts for the Baffle and Shredder Kits

is provided on page 6. Use the list as a checklist to

inventory parts received. Please contact your local Land

Pride dealer for any missing hardware.

IMPORTANT: Read “Safety Information” above

before installing baffle plates.

1. Lower cutter and wings to the lowest position.

2. Place tractorgear selector in par k and/or set brakes,

shut engine off and remove ignition key.

3. Disconnect main driveline from tractor PTO.

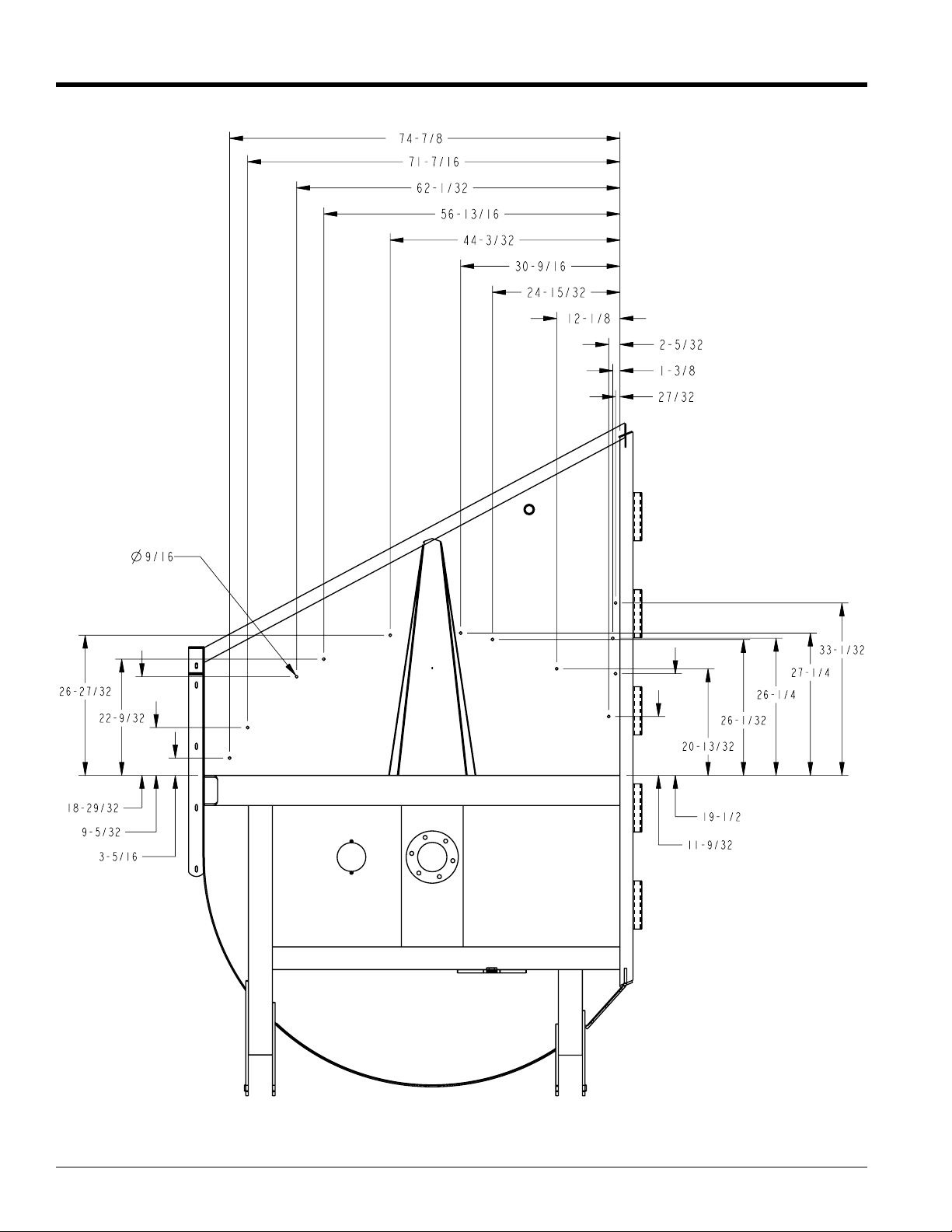

Refer to Figure 1 on page 2:

4. Locate and drill twelve 9/16" dia. holes on each wing

deck as shown in Figure 1.

These assembly instructions apply to the Baffle and

Shredder Kits listed below:

330-114A RC/RCM5020 BAFFLE KIT

318-958A RC/RCM5020 SHREDDER KIT

Tools required:

•

Safety Glasses

• Work Gloves

• Tape measure . . . . . . . . . . . . . . . . . . . .Baffle Kit Only

• Pencil . . . . . . . . . . . . . . . . . . . . . . . . . . .Baffle Kit Only

• Center Punch . . . . . . . . . . . . . . . . . . . . .Baffle Kit Only

• Hammer . . . . . . . . . . . . . . . . . . . . . . . . .Baffle Kit Only

• Drill with 9/16" Drill Bit . . . . . . . . . . . . . .Baffle Kit Only

• Extension Cord . . . . . . . . . . . . . . . . . . . . . . if required

• Two 3/4" wrenches . . . . . . . . . . . . . . . . .Baffle Kit Only

• Two 1 1/2" wrenches . . . . . . . . . . . . Shredder Kit Only

• One 55mm wrench . . . . . . . . . . . . . . Shredder Kit Only

© Copyright 2007 Printed

8/20/07

NOTE: Drilling holes is not necessary on models

manufactured after serial # 536743.

5. The wings can be raised and locked into position for

the remainder of the assembly.

Refer to Figure 2 on page 3:

6. Attach the four front baffles (#4) to each wing deck

with 1/2"-13 x 1 1/2" GR5 hex head bolts (#5), 1/2"

flat washers (#7) and 1/2" hex whiz nut (#6).

7. Torque nuts to 76 ft-lbs.

IMPORTANT: The rear baffle is installed with the

same bolts attaching the rear guard. Do not remove

rear guard.

8. Removenutssecuring the rear guard andattach rear

baffle plate (#1) to the inside of the rear deck plate

using existing hex whiz nuts. Do not remove rear

guard.

1

Page 2

Baffle Assembly Instructions

Land Pride

Bolt Hole Pattern (Left Wing Shown)

Figure 1

Manual No. 330-148M 8/20/07

2

■

Page 3

Baffle Assembly Instructions

Land Pride

9. Install 1/2"-13 x 1 1/2" GR5 round head square neck

bolt (#2) and 1/2" hex whiz nut (#6) as shown in

Figure 2.

10. Torque nuts to 76 ft-lbs.

8/20/07

24860

Baffle Installation (Left Wing Shown)

Figure 2

■

Manual No. 330-148M

3

Page 4

Shredder Assembly Instructions

Shredder Assembly Instructions

Land Pride

Adetailed listingof parts forthis accessory kitis provided

on page 6. Use the list as a checklist to inventory parts

received.Please contact your local Land Pridedealer for

any missing hardware.

IMPORTANT: Read “Safety Information” on page 1

before installing shredder blades.

Refer to Figure 3:

1. Remove all three existing blade carrier assemblies

from the gearbox output shafts (A & B). Keep flat

washers C), slotted hex nuts (D) and cotter pins (E)

for reuse.

Right Wing Shredder Assembly

Refer to Figure 3:

1. Attach right wing shredder assembly (#1) to gearbox

output shaft (A) with existing washer (C) and slotted

hex nut (D). Torqued slotted nut to 550 ft./lbs.

2. Install cotter pin (E) in the slotted nut with legs

securely bent around the nut.

Center Deck & Left Wing Shredder Assy

Refer to Figure 4:

1. Attach center deck and left wing shredder

assemblies (#2) to gearbox output shafts (B) with

existingwasher (C) and slotted hex nut (D). Torqued

slotted nut to 550 ft./lbs.

2. Install cotter pin (E) in the slotted nut with legs

securely bent around the nut.

Clockwise Rotation

Right Wing Shredder Assembly

Figure 3

Manual No. 330-148M 8/20/07

4

25601

Center Deck & Left Wing Shredder Assemblies

Counterclockwise Rotation

Figure 4

25601

■

Page 5

Shredder Assembly Instructions

Land Pride

Replacing Blade Spacers

Refer to Figure 5:

The cutting blades should not have more than 3/4" free

vertical movement at the blade tips. If vertical movement

exceeds 3/4", install or change to thicker spacers (#3)

following steps 1 through 5.

Order spacers (#3) and locknuts (#7) from your nearest

Land Pride Dealer.

IMPORTANT: Read “Safety Information” on page 1

before disassembling the shredder blades.

IMPORTANT: Locknuts can lose their ability to lock

properly once removed. Always use a plain throw

away nut during pre-assembly of spacers.

IMPORTANT: Spacers (#3) are not required if

vertical movement at blade tip is 3/4" or less without

spacers. However, spacers are required if vertical

movement at blade tip is greater than 3/4".

25600

1.

Check blade deflection. If vertical deflection at the

blade tip is greater than 3/4", removeblade bolt (#6)

and reassemble using thicker spacers (#3). Select

spacer thickness based on deflection. The greater

the deflection, the thicker the spacer.

2.

Assemble blades by inserting 1"-8 x 4 1/2" GR8 hex

head bolt (#6) through blade bushing (#4), spacer

(#3), lower cutting blade (#8 or #10), blade carr ier

(#5), upper flat cutting blade (#9), spacer (#3) and

blade bushings (#4). Temporar y secure blade with a

plain hex nut (Plain hex nut furnished by customer.)

Draw nut up snug. Do not tighten.

3.

Check blade deflection. If deflection at the blade tips

are greater than 3/4", remove blade bolt and

reassemble as before except use thicker spacers.

4.

Once blade deflection is correct, replace plain nut

with supplied locknut (#7) & torque to 450 ft-lbs.

5. Repeat instr uctions for “Replacing Blade Spacers”

for the remaining shredder blade assemblies.

Blade

Cutting

Edge

Blade

Cutting

Edge

CW

Rotation

(#1) Right Wing Shredder Assembly

Clockwise Rotation

Position Beveled

Edges Down

CCW

Rotation

Blade Cutting Edges

Position Beveled Edges Up

(#2) Center Deck & Left Wing Shredder Assemblies

Counterclockwise Rotation

8/20/07

Figure 5

■

Manual No. 330-148M

5

Page 6

Listing of Parts

Kit No. 330-114A RC5020 BAFFLEASSEMBLY KIT

Item Qty. Part No. Part Description

Refer to Figure 2 on page 3:

1 330-148M BAFFLE KIT INSTALLATION MANUAL

1 2 318-769D PLATE, REAR BAFFLE

2 2 802-106C RHSNB 1/2-13X1 1/2 GR5

3 2 803-037C NUT HEX WHIZ 1/2-13 PLT

4 8 330-095H BAFFLE 5020

5 24 802-091C HHCS 1/2-13X1 1/2 GR5

6 24 803-037C NUT HEX WHIZ 1/2-13 PLT

7 24 804-016C WASHER FLAT 1/2 SAE PLT

Kit No. 318-958A RC5020 SHREDDER ASSEMBLY, COMER

Item Qty. Part No. Part Description

Land Pride

Refer to Figure 3 & Figure 4 on page 4:

1 330-148M BAFFLE KIT INSTALLATION MANUAL

1 1 318-859S ASSY. CW BLADE CARRIER 84"

2 2 318-860S ASSY. CCW BLADE CARRIER 84"

Refer to Figure 5 on page 5:

(#1) Components for 318-859S CW Blade Assembly (Quantities shown are for one Assembly)

3 4 312-075D BLADE SPACER 16 GA

3 4 312-082D BLADE SPACER 18 GA

3 4 312-089D BLADE SPACER 20 GA.

3 4 312-808D BLADE SPACER 24GA

4 4 318-309D BLADE BUSHING

5 1 330-209H BLADE BAR

6 2 802-680C HHCS 1-8 X 4 1/2 PLT GR8

7 2 803-168C NUT HEX TOP LOCK 1-8 PLT

9 2 820-216C CUTTER BLADE 1/2X4X28.5 FLAT

10 2 820-249C CUTTER BLADE 1/2X4X29 CW

A maximum of four spacers

are used per assembly.

Refer to Figure 5 on page 5:

(#2) Components for 318-860S CCW Blade Assembly (Quantities shown are for one Assembly)

3 4 312-075D BLADE SPACER 16 GA

3 4 312-082D BLADE SPACER 18 GA

3 4 312-089D BLADE SPACER 20 GA.

3 4 312-808D BLADE SPACER 24GA

4 4 318-309D BLADE BUSHING

5 1 330-209H BLADE BAR

6 2 802-680C HHCS 1-8 X 4 1/2 PLT GR8

7 2 803-168C NUT HEX TOP LOCK 1-8 PLT

8 2 820-168C CUTTER BLADE 1/2X4X29 CCW

9 2 820-216C CUTTER BLADE 1/2X4X28.5 FLAT

A maximum of four spacers

are used per assembly.

Corporate Office: P.O. Box 5060

Salina, Kansas 67402-5060 USA

www.landpride.com

6

Manual No. 330-148M 8/20/07

■

Loading...

Loading...