Page 1

Table of Contents

Rotary Cutters

RCB6610 & RCBM6610 Series 2 S/N 944730+

30219

Operator’s Manual

Read the Operator’s Manual entirely. When you

see this symbol, the subsequent instructions and

warnings are serious - follow without exception.

!

Your life and the lives of others depend on it!

Cover photo may show optional equipment

not supplied with standard unit.

© Copyright 2015 Printed

330-584M

11 /11 /12

Page 2

Table of Contents

Table of Contents

Important Safety Information . . . . . . . . . . . . . 1

Safety at All Times . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Using This Manual . . . . . . . . . . . . . . . . . . . . . . . . . 11

Owner Assistance . . . . . . . . . . . . . . . . . . . . . . . . . 11

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Section 1: Assembly & Set-up . . . . . . . . . . . 12

Tractor Requirements . . . . . . . . . . . . . . . . . . . . . . 12

Horsepower . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Drawbar Set-up . . . . . . . . . . . . . . . . . . . . . . . . . 12

PTO Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Hydraulic Outlets . . . . . . . . . . . . . . . . . . . . . . . . 12

Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Torque Requirements . . . . . . . . . . . . . . . . . . . . . . 12

Hitch Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Hitch Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Park Jack Assembly . . . . . . . . . . . . . . . . . . . . . . . 14

Tractor Shutdown Procedure . . . . . . . . . . . . . . . . . 14

Standard Clevis Hitch Hook-up . . . . . . . . . . . . . . . 15

LP Performance Hitch Hook-up . . . . . . . . . . . . . . . 16

Bar-Tite Hitch Hook-up . . . . . . . . . . . . . . . . . . . . . 17

Hydraulic Plumbing . . . . . . . . . . . . . . . . . . . . . . . . 18

Hydraulic Hook-up . . . . . . . . . . . . . . . . . . . . . . . . . 18

Unfolding Wing Deck . . . . . . . . . . . . . . . . . . . . . . . 18

Driveline Installation . . . . . . . . . . . . . . . . . . . . . . . 20

Driveline Hook-up to Tractor PTO . . . . . . . . . . . . . 21

Adjust Driveline Hanger . . . . . . . . . . . . . . . . . . . . . 21

Driveline Clearance Check . . . . . . . . . . . . . . . . . . 21

Purge Hydraulic System . . . . . . . . . . . . . . . . . . . . 22

Lift Cylinder Mounting Position . . . . . . . . . . . . . . . 23

Rephase Lift Cylinders . . . . . . . . . . . . . . . . . . . . . 23

Slow Moving Vehicle Sign (SMV) . . . . . . . . . . . . . 23

Adjust Optional Light Kit . . . . . . . . . . . . . . . . . . . . 24

Remove Shipping Lugs . . . . . . . . . . . . . . . . . . . . . 24

Unhook Rotary Cutter . . . . . . . . . . . . . . . . . . . . . . 25

Section 2: Adjustments . . . . . . . . . . . . . . . . . 26

Park Jack Angle Alignment . . . . . . . . . . . . . . . . . . 26

Leveling Center Deck & Wing . . . . . . . . . . . . . . . . 26

Center Deck Leveling . . . . . . . . . . . . . . . . . . . . . 26

Cutting Height Adjustment . . . . . . . . . . . . . . . . . . . 28

LP Performance Hitch Hole Size . . . . . . . . . . . . . . 28

Section 3: Operating Instructions . . . . . . . . 29

Startup Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . 29

Avoid Extreme Turning Angles . . . . . . . . . . . . . . . 30

Tractor & Cutter Inspection . . . . . . . . . . . . . . . . . . 31

Blade Operation Inspection . . . . . . . . . . . . . . . . . . 31

Transport Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Road Side Cutting . . . . . . . . . . . . . . . . . . . . . . . . . 32

Field Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Inspect Field and Cutter Blades . . . . . . . . . . . . . 33

Lower Wing Down & Set Cutting Height . . . . . . . 33

Set Wing Lift Lever In Float Position . . . . . . . . . . 33

Rephasing Lift Cylinders . . . . . . . . . . . . . . . . . . . 34

Select Gear Range . . . . . . . . . . . . . . . . . . . . . . . 34

Engage Blades . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Disengage Blades . . . . . . . . . . . . . . . . . . . . . . . 34

General Operating Instructions . . . . . . . . . . . . . . . 35

Section 4: Options & Accessories . . . . . . . . 36

Light Kit Option (LED) . . . . . . . . . . . . . . . . . . . . . . 36

Tool Box Option . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Installation Instructions . . . . . . . . . . . . . . . . . . . . 37

Mechanical Wing Lift . . . . . . . . . . . . . . . . . . . . . . . 38

Installation Instructions . . . . . . . . . . . . . . . . . . . . 38

Operating Instructions . . . . . . . . . . . . . . . . . . . . 38

Safety Guard Options . . . . . . . . . . . . . . . . . . . . . . 39

Low Lift Blade Accessory . . . . . . . . . . . . . . . . . . . . 39

Tire & Axle Options . . . . . . . . . . . . . . . . . . . . . . . . 39

Hitch Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Selector Control Valve Kit . . . . . . . . . . . . . . . . . . . 39

Section 5: Maintenance & Lubrication . . . . . 40

General Maintenance Information . . . . . . . . . . . . . 40

Tractor Maintenance . . . . . . . . . . . . . . . . . . . . . . . 40

Skid Shoes & Side Skirt . . . . . . . . . . . . . . . . . . . . . 40

Center Skid Shoes . . . . . . . . . . . . . . . . . . . . . . . 40

Wing Skid Shoe . . . . . . . . . . . . . . . . . . . . . . . . . 40

Side Skirt With Skid Shoes Attached . . . . . . . . . 40

Weight Box Skid Shoe . . . . . . . . . . . . . . . . . . . . 41

Gearbox Shaft Guard . . . . . . . . . . . . . . . . . . . . . . 41

Cutter Blade Maintenance . . . . . . . . . . . . . . . . . . . 42

Drivelines With Slip Clutches . . . . . . . . . . . . . . . . . 44

Type A Clutches . . . . . . . . . . . . . . . . . . . . . . . . . 44

Type B Clutches . . . . . . . . . . . . . . . . . . . . . . . . . 46

Tire Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Long Term Storage . . . . . . . . . . . . . . . . . . . . . . . . 48

Ordering Replacement Parts . . . . . . . . . . . . . . . . . 48

Lubrication Points . . . . . . . . . . . . . . . . . . . . . . . . . 49

Section 6: Specifications & Capacities . . . . . 56

Section 7: Features & Benefits . . . . . . . . . . . 58

Section 8: Troubleshooting . . . . . . . . . . . . . . 60

Section 9: Torque & Tire Inflation Charts . . . 62

Section 10: Warranty . . . . . . . . . . . . . . . . . . . 63

© Copyright 2015 All rights Reserved

Land Pride provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the

preparation of this manual, Land Pride assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use

of the information contained herein. Land Pride reserves the right to revise and improve its products as it sees fit. This publication describes the state of this

product at the time of its publication, and may not reflect the product in the future.

Land Pride is a registered trademark.

All other brands and product names are trademarks or registered trademarks of their respective holders.

Printed in the United States of America.

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

11 /11 / 12

Page 3

Table of Contents

Important Safety Information

Important Safety Information

These are common practices that may or may not be applicable to the products described in

this manual.

Safety at All Times

Thoroughly read and understand

the instructions given in this

manual before operation. Refer to

the “Safety Label” section, read all

instructions noted on them.

Do not allow anyone to operate

this equipment who has not fully

read and comprehended this

manual and who has not been

properly trained in the safe

operation of the equipment.

▲ The operator must not use drugs

or alcohol as they can change the

alertness or coordination of that

person while operating equipment.

The operator should, if taking overthe-counter drugs, seek medical

advice on whether he/she can

safely operate the equipment.

▲ Operator should be familiar with all

functions of the unit.

▲ Operate controls from the driver’s

seat only. Never operate controls

from the ground.

▲ Make sure all guards and shields

are in place and secured before

operating implement.

▲ Keep all bystanders away from

equipment and work area.

▲ Do not leave tractor or implement

unattended with engine running.

▲ Dismounting from a moving tractor

can cause serious injury or death.

▲ Do not allow anyone to stand

between tractor and implement

while backing up to implement.

▲ Keep hands, feet, and clothing

away from power-driven parts.

▲ Watch out for fences, trees, rocks,

wires, etc., while operating and

transporting implement.

▲ Turning tractor too tight may cause

hitched machinery to ride up on

wheels. This could result in injury

or equipment damage.

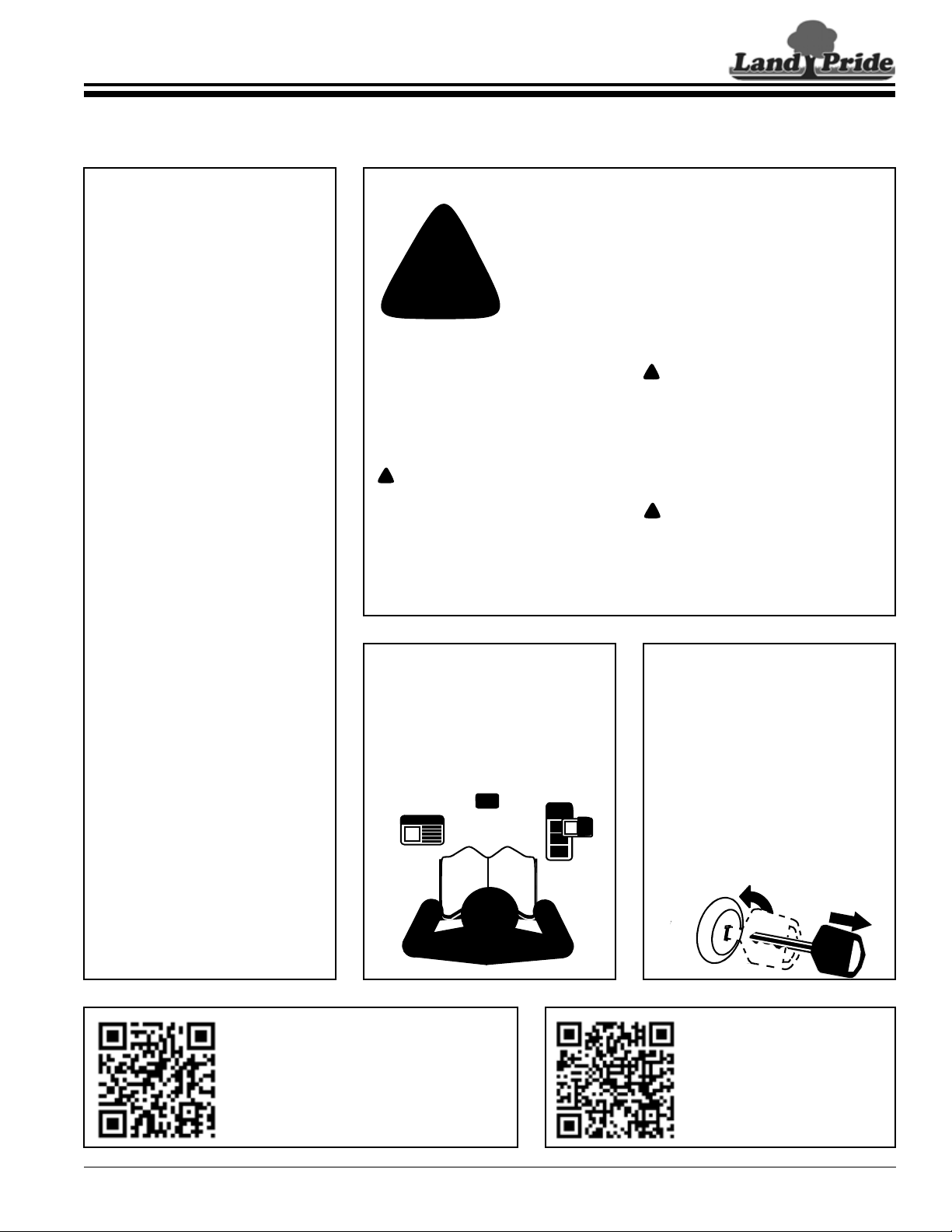

Look For The Safety Alert Symbol

The SAFETY ALERT SYMBOL indicates there is a

potential hazard to personal safety involved and extra

safety precaution must be taken. When you see this

symbol, be alert and carefully read the message that

follows it. In addition to design and configuration of

!

Be Aware of

Signal Words

A Signal word designates a degree or

level of hazard seriousness. The

signal words are:

!

DANGER

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury. This

signal word is limited to the most

extreme situations, typically for

machine components that, for

functional purposes, cannot be

guarded.

For Your Protection

▲ Thoroughly read and understand

the “Safety Label” section, read

all instructions noted on them.

equipment, hazard control, and accident prevention are

dependent upon the awareness, concern, prudence, and

proper training of personnel involved in the operation,

transport, maintenance, and storage of equipment.

!

WARNING

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury, and

includes hazards that are exposed

when guards are removed. It may also

be used to alert against unsafe

practices.

!

CAUTION

Indicates a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury. It

may also be used to alert against

unsafe practices.

Tractor Shutdown & Storage

▲ If engaged, disengage PTO.

▲ Lower attached implement to

ground, put tractor in park or set

park brake, turn off engine, and

remove switch key to prevent

unauthorized starting.

▲ Wait for all components to come to

a complete stop before leaving the

operator’s seat.

▲ Detach and store implement in an

area where children normally do

not play. Secure implement using

blocks and supports.

OFF

R

E

M

O

V

E

11 /11 / 12

Parts Manual QR Locator

The QR (Quick Reference) code on the

cover and to the left will take you to the

Parts Manual for this equipment.

Download the appropriate App on your

smart phone, open the App, point your

phone on the QR code and take a picture.

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

Dealer QR Locator

The QR code on the left will

link you to available dealers

for Land Pride products.

Refer to Parts Manual QR

Locator on this page for

detailed instructions.

1

Page 4

Table of Contents

Important Safety Information

These are common practices that may or may not be applicable to the products described in

this manual.

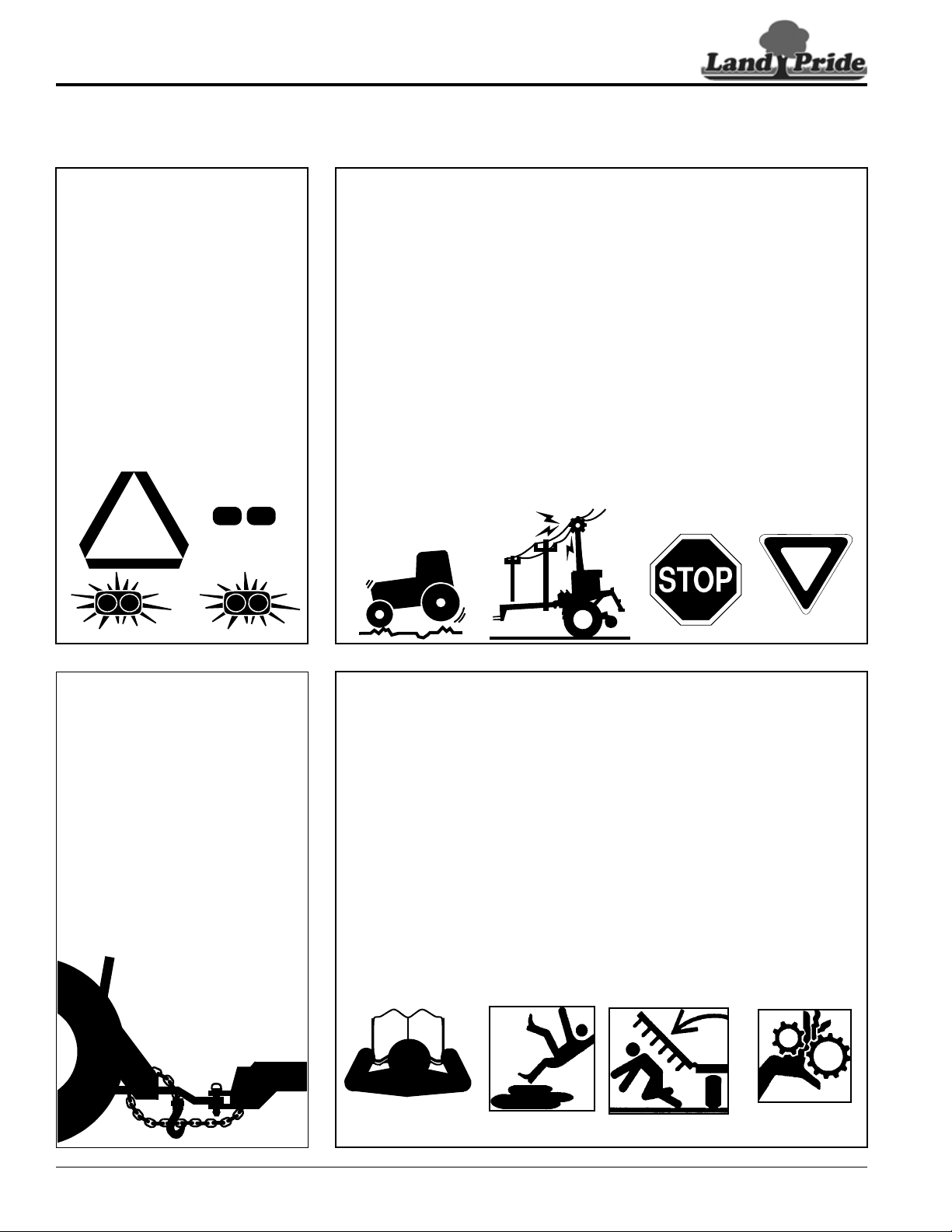

Use Safety

Lights and Devices

▲ Slow moving tractors,

self-propelled equipment, and

towed implements can create a

hazard when driven on public

roads. They are difficult to see,

especially at night.

▲ Flashing warning lights and turn

signals are recommended

whenever driving on public roads.

Transport

Machinery Safely

▲ Comply with state and local laws.

▲ Use towing vehicle and trailer of

adequate size and capacity.

▲ Secure equipment towed on a

trailer with tie downs and chains.

▲ Sudden braking can cause a trailer

to swerve and upset. Reduce

speed if trailer is not equipped with

brakes.

▲ Avoid contact with any over head

utility lines or electrically charged

conductors.

▲ Engage parking brake when

stopped on an incline.

▲ Maximum transport speed for an

attached implement is 20 mph. DO

NOT EXCEED. Never travel at a

speed which does not allow

adequate control of steering and

stopping. Some rough terrains

require a slower speed.

▲ As a guideline, use the following

maximum speed weight ratios for

an attached implement:

20 mph when weight of attached

implement is less than or equal to

the weight of machine towing the

implement.

10 mph when weight of attached

implement exceeds weight of

machine towing implement but

not more than double the weight.

▲ IMPORTANT: Do not tow a load

that is more than double the weight

of the machine towing the load.

Use A Safety Chain

▲ A safety chain will help control

drawn machinery should it

separate from the tractor drawbar.

▲ Use a chain with the strength

rating equal to or greater than the

gross weight of the towed

machinery.

▲ Attach the chain to the tractor

drawbar support or other specified

anchor location. Allow only

enough slack in the chain to

permit turning.

▲ Do not use safety chain for towing.

Practice Safe Maintenance

▲ Understand procedure before doing

work. Use proper tools and

equipment, refer to Operator’s

Manual for additional information.

▲ Work in a clean dry area.

▲ Lower attached implement to the

ground, put tractor in park, turn off

engine, and remove key before

performing maintenance.

▲ Allow implement to cool before

working on it.

▲ Disconnect battery ground cable (-)

before servicing or adjusting

electrical systems or before welding

on implement.

▲ Do not grease or oil implement

while it is in operation.

▲ Inspect all parts. Make certain

parts are in good condition &

installed properly.

▲ Remove buildup of grease, oil, or

debris.

▲ Remove all tools and unused parts

from implement before operation.

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

2

11 /11 / 12

Page 5

Table of Contents

Important Safety Information

These are common practices that may or may not be applicable to the products described in

this manual.

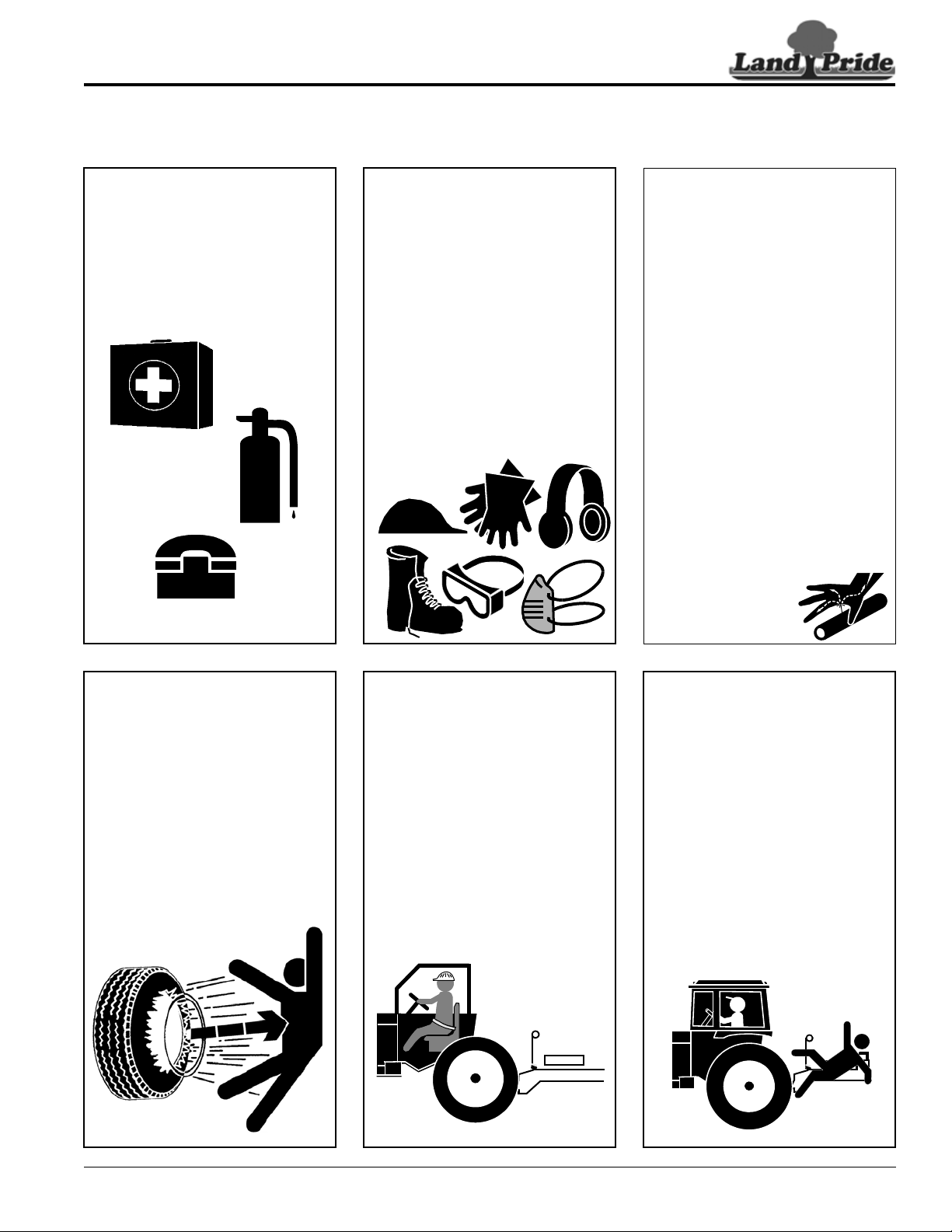

Prepare for Emergencies

▲ Be prepared if a fire starts.

▲ Keep a first aid kit and fire

extinguisher handy.

▲ Keep emergency numbers for

doctor, ambulance, hospital, and

fire department near phone.

911

Wear

Protective Equipment

▲ Wear protective clothing and

equipment appropriate for the job.

Clothing should be snug fitting

without fringes and pull strings to

avoid entanglement with moving

parts.

▲ Prolonged exposure to loud noise

can cause hearing impairment or

hearing loss. Wear suitable

hearing protection such as

earmuffs or earplugs.

▲ Operating equipment safely

requires the operator’s full

attention. Avoid wearing radio

headphones while operating

machinery.

Avoid High

Pressure Fluids Hazard

▲ Escaping fluid under pressure can

penetrate the skin causing serious

injury.

▲ Avoid the hazard by relieving

pressure before disconnecting

hydraulic lines or performing work

on the system.

▲ Make sure all hydraulic fluid

connections are tight and all

hydraulic hoses and lines are in

good condition before applying

pressure to the system.

▲ Use a piece of paper or

cardboard, NOT BODY PARTS, to

check for suspected leaks.

▲ Wear protective gloves and safety

glasses or goggles when working

with hydraulic systems.

▲ DO NOT DELAY. If an accident

occurs, see a doctor familiar with

this type of injury immediately. Any

fluid injected into the skin or eyes

must be treated within

a few hours or

gangrene may

result.

Tire Safety

▲ Tire changing can be dangerous

and should be preformed by

trained personnel using the

correct tools and equipment.

▲ When inflating tires, use a clip-on

chuck and extension hose long

enough to allow you to stand to

one side and NOT in front of or

over the tire assembly. Use a

safety cage if available.

▲ When removing and installing

wheels, use wheel handling

equipment adequate for the

weight involved.

Use Seat Belt and ROPS

▲ Operate only tractors equipped

with Roll-Over Protective

Structure (ROPS) and seat belt.

▲ Fasten seat belt snugly and

securely to help protect against

serious injury or death from falling

and tractor overturn.

▲ Wearing protective equipment

such as safety shoes, safety

glasses, hard hat, and ear plugs is

highly recommended.

Keep Riders Off

Machinery

▲ Never carry riders or use

machinery as a person lift.

▲ Riders obstruct operator’s view.

▲ Riders could be struck by foreign

objects or thrown from the

machine.

▲ Never allow children to operate

equipment.

11 /11 / 12

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

3

Page 6

Important Safety Information

37690

37690

37690

Table of Contents

Safety Labels

Your Rotary Cutter comes equipped with all safety labels in

place. They were designed to help you safely operate your

implement. Read and follow their directions.

1. Keep all safety labels clean and legible.

2. Refer to this section for proper label placement. Replace

all damaged or missing labels. Order new labels from your

nearest Land Pride dealer. To find your nearest dealer,

visit our dealer locator at www.landpride.com.

3. Some new equipment installed during repair requires

safety labels to be affixed to the replaced component as

specified by Land Pride. When ordering new components

make sure the correct safety labels are included in the

request.

4. Refer to this section for proper label placement.

To install new labels:

a. Clean surface area where label is to be placed.

b. Spray soapy water onto the cleaned area.

c. Peel backing from label and press label firmly onto the

surface.

d. Squeeze out air bubbles with edge of a credit card or

with a similar type of straight edge.

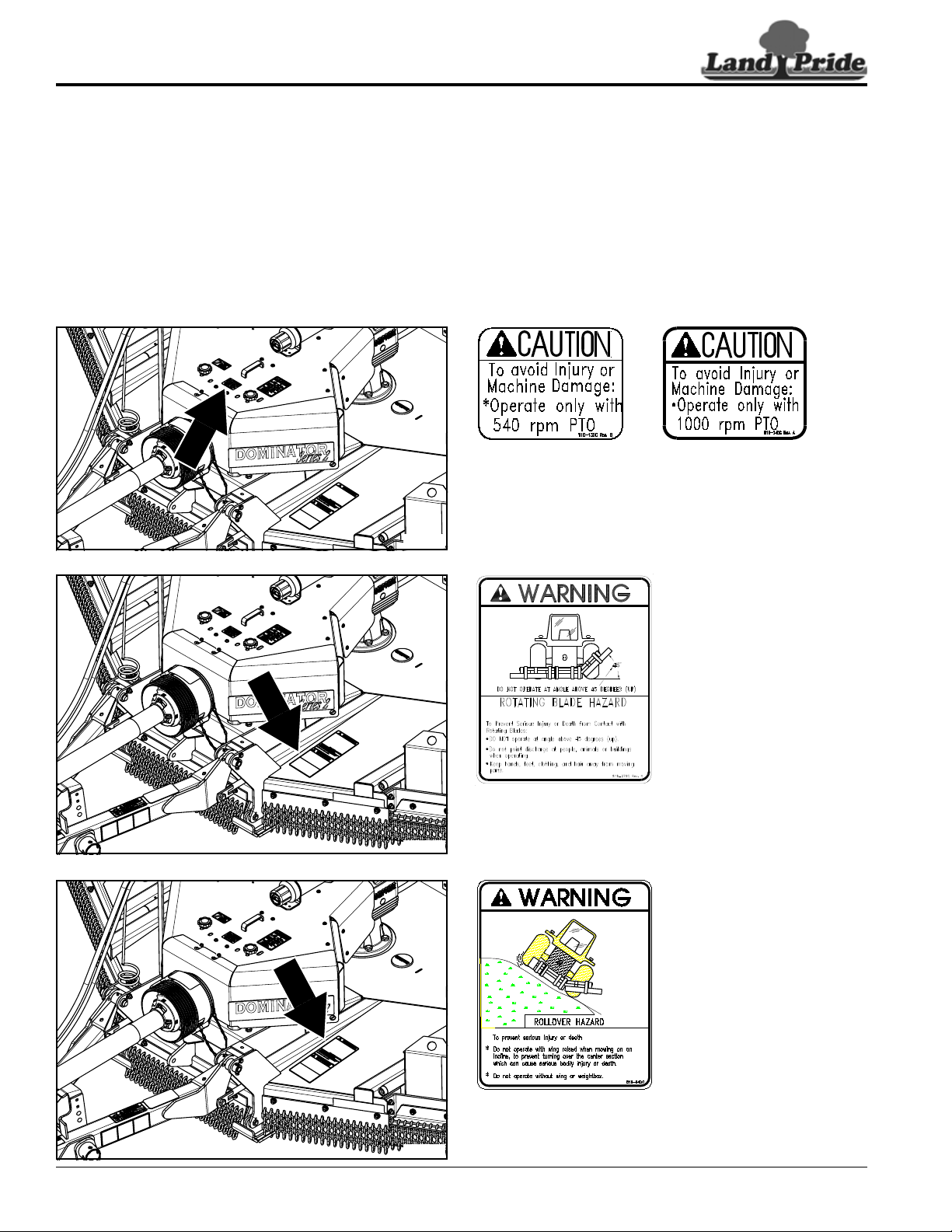

818-130C

Caution! Use 540 RPM PTO only (RC Series cutters)

818-240C

Caution! Use 1000 RPM PTO only (RCM Series cutters)

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

4

818-276C

Warning! Rotating Blade Hazard

1 - Place: Left side of center deck

818-840C

Danger: Rollover Hazard

1 - Place: Left side of center deck

11 /11 / 12

Page 7

Important Safety Information

30163

30163

35544

Table of Contents

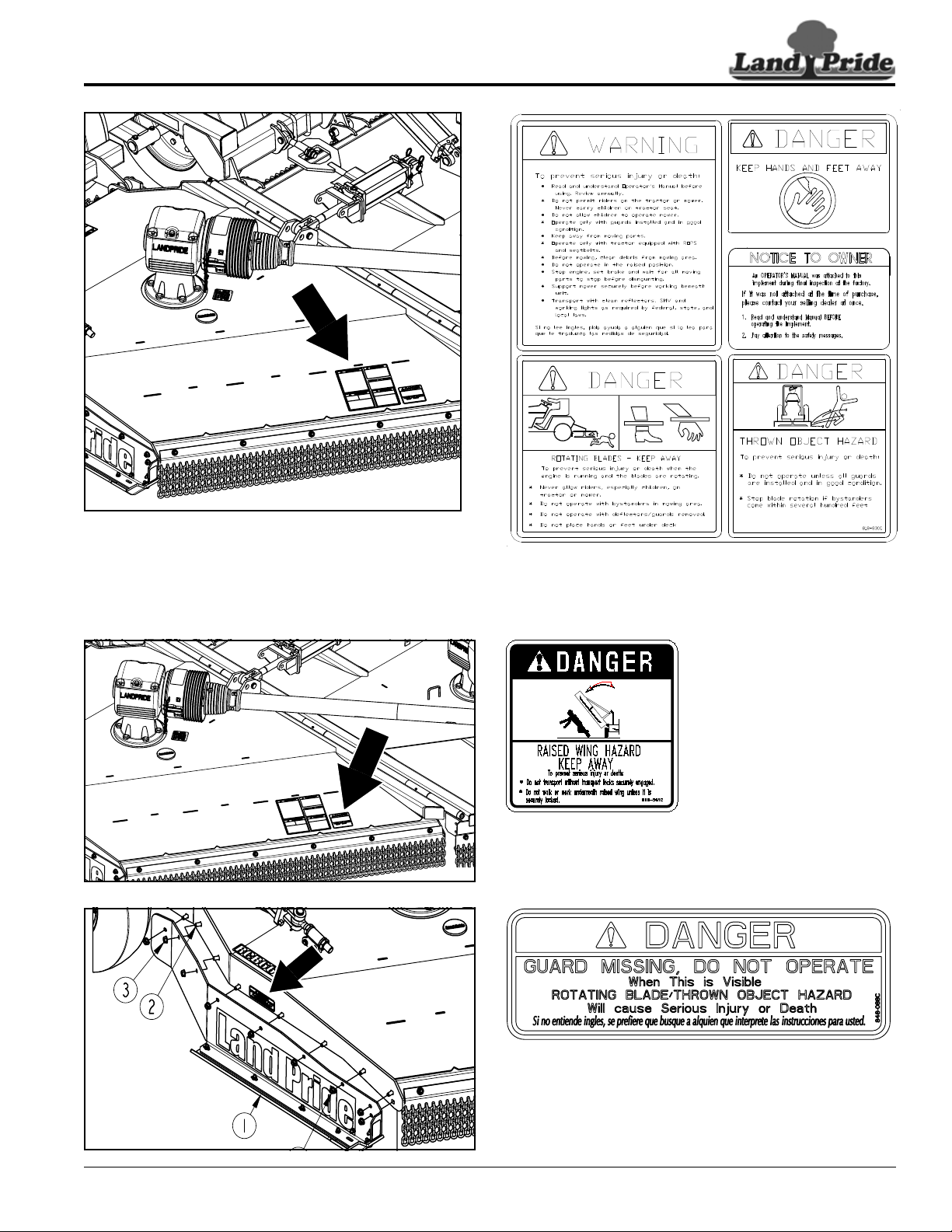

818-830C

Safety Combo

1 - Place: Front of right wing

818-561C

Danger! Raised Wing Hazard

1 - Place: Front of right wing

11 /11 / 12

848-088C

Danger! Guard Missing

1 - Place: Behind replaceable wing side skirt

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

5

Page 8

Important Safety Information

30164

30165

30165

30163

Table of Contents

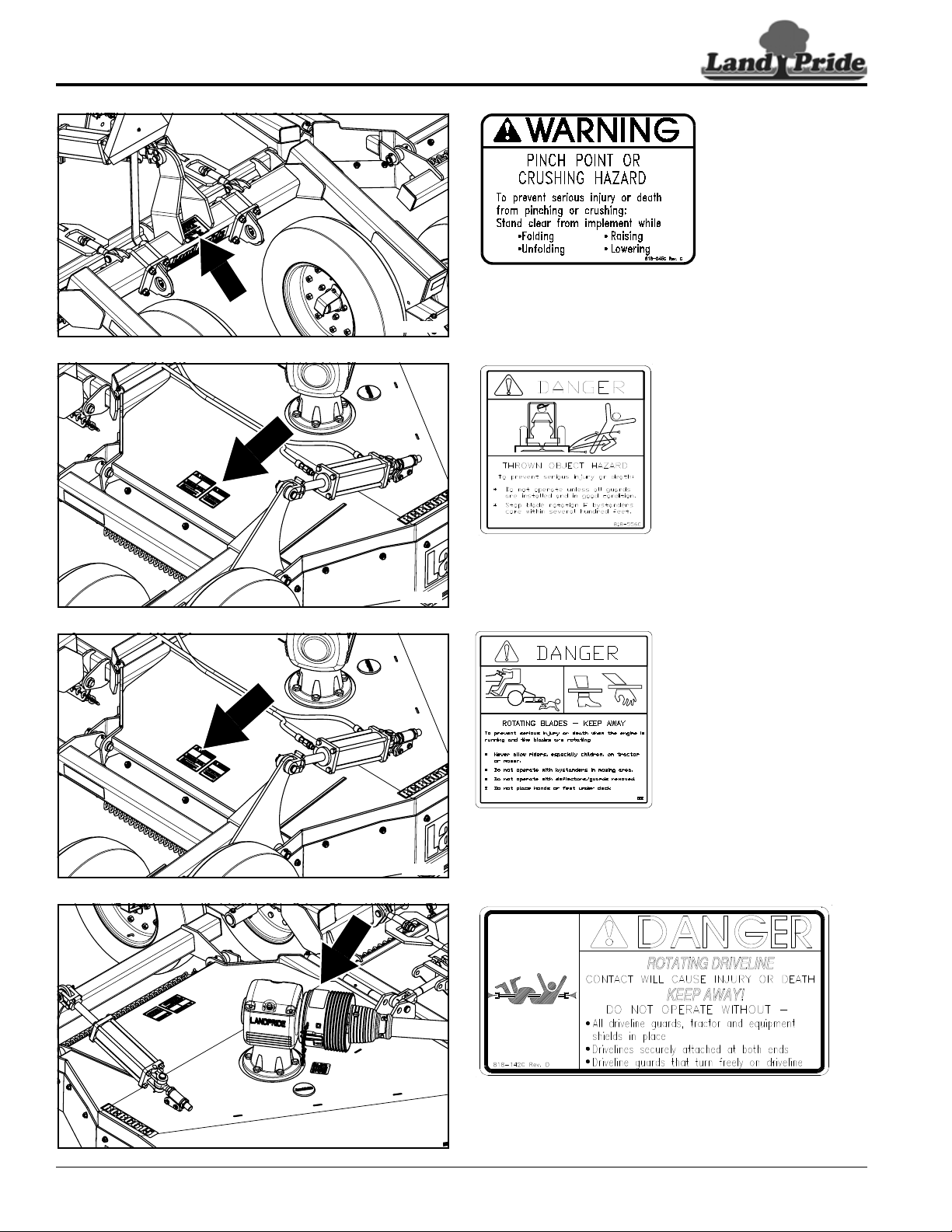

818-045C

Warning! Pinch Point

1 - Place: Top of rear center axle

818-556C

Danger! Thrown Object Hazard

1 - Place: Rear of the right wing

818-564C

Danger! Rotating Blade

1 - Place: Rear of the right wing

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

6

818-142C

Danger! Rotating Driveline - Keep Away

2 - Places: Top of wing gearbox shield and splitter

gearbox input shaft shield

11 /11 / 12

Page 9

Important Safety Information

30163

37609

37690

37614

37690

ROTATING DRIVELINE

KEEP AWAY!

Table of Contents

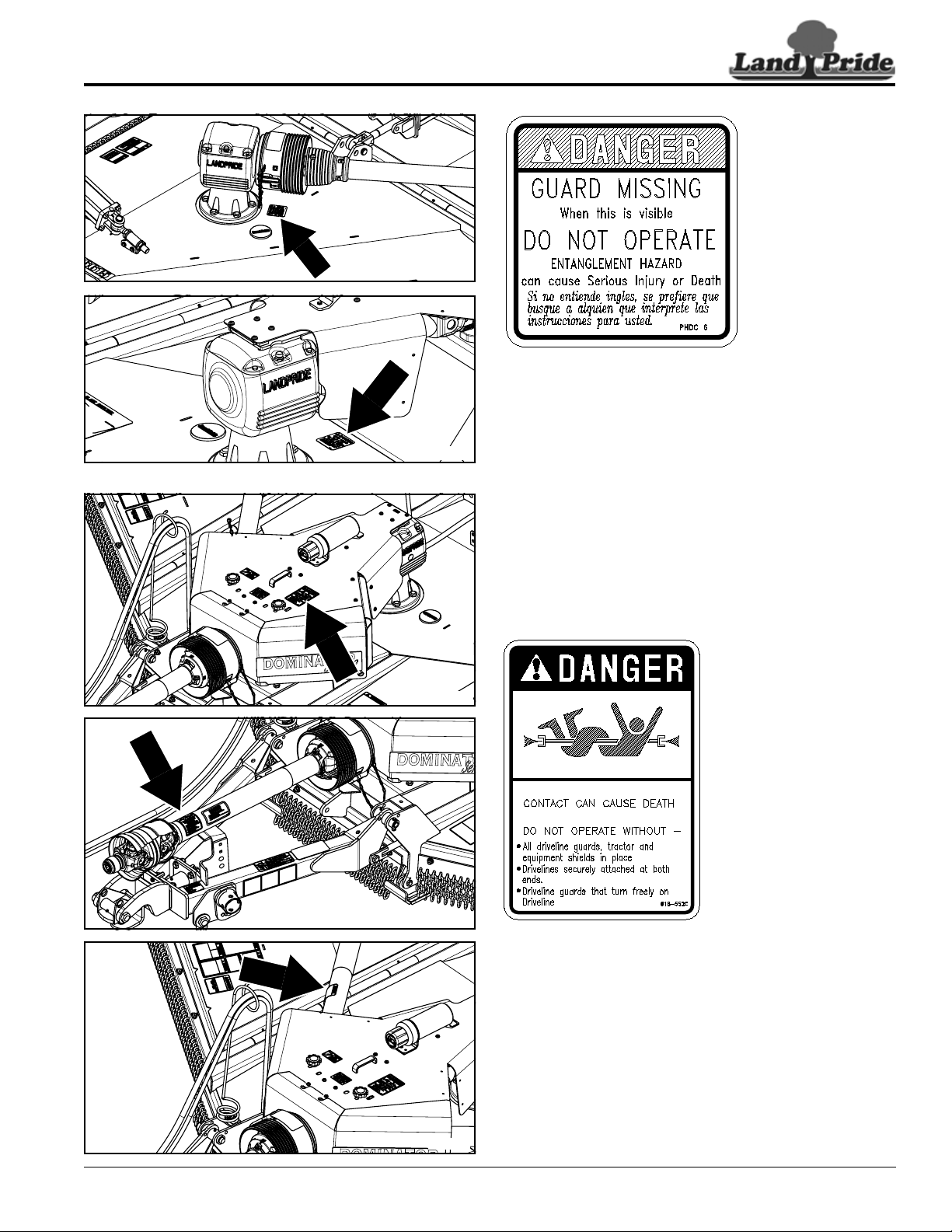

818-543C

Danger! Guard Missing - DO NOT Operate

2 - Places: Under spindle gearbox shields

11 /11 / 12

818-552C

Danger! Rotating Driveline - Keep Away

1 - Place: Top of splitter shield

2 - Places: Main driveline and wing driveline

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

7

Page 10

Important Safety Information

13313

37690

37690

37690

Table of Contents

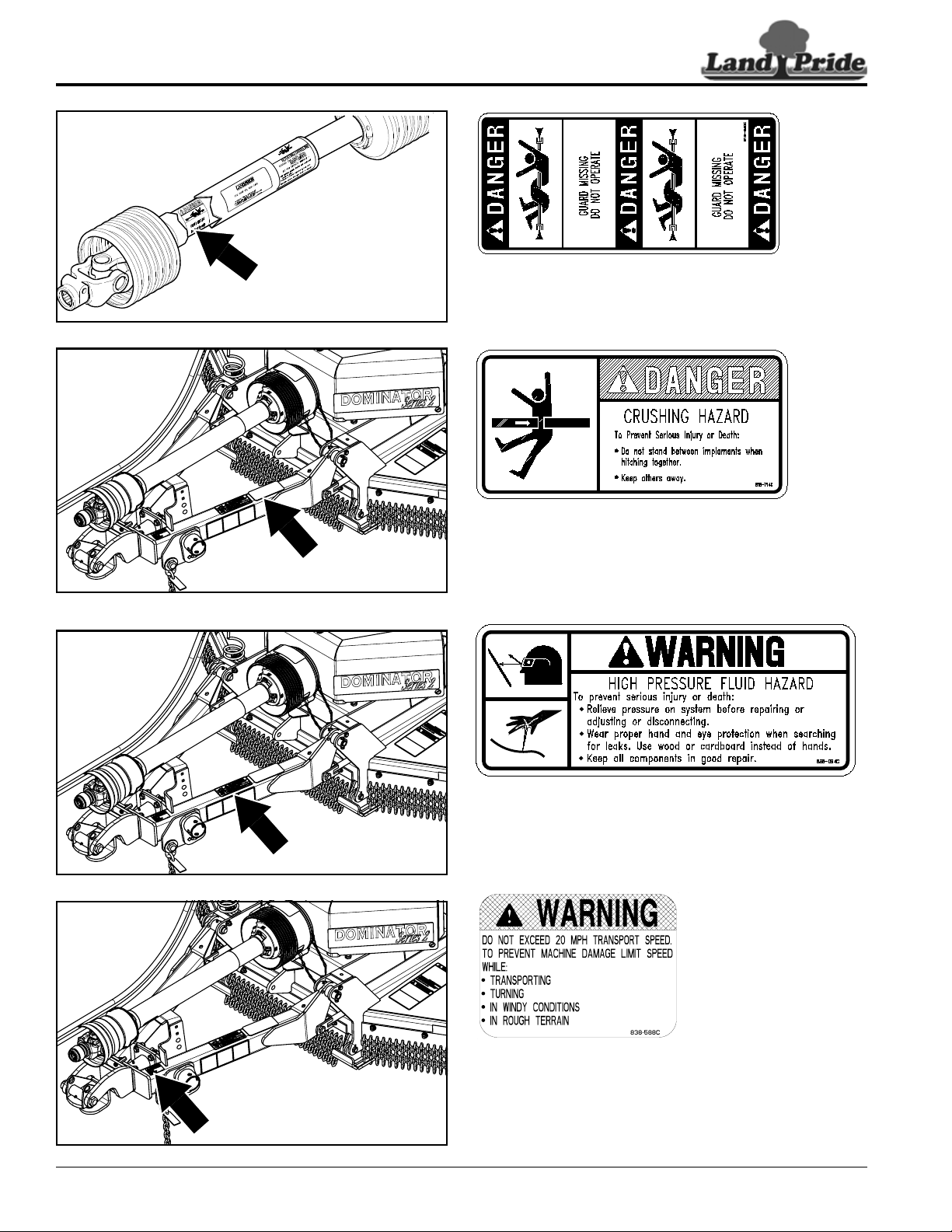

818-540C

Danger! Shield Missing - DO NOT Operate

2 - Places: On wing drive line and main driveline

818-714C

Danger! Crushing Hazard

1 - Place: Located on hitch frame

838-094C

Warning! High Pressure

1 - Place: Located on hitch frame

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

8

838-588C

Warning! Folding Cutter Speed Warning

1 - Place: Located on hitch frame

11 /11 / 12

Page 11

Important Safety Information

30222

37690

30222

30163

30163

Table of Contents

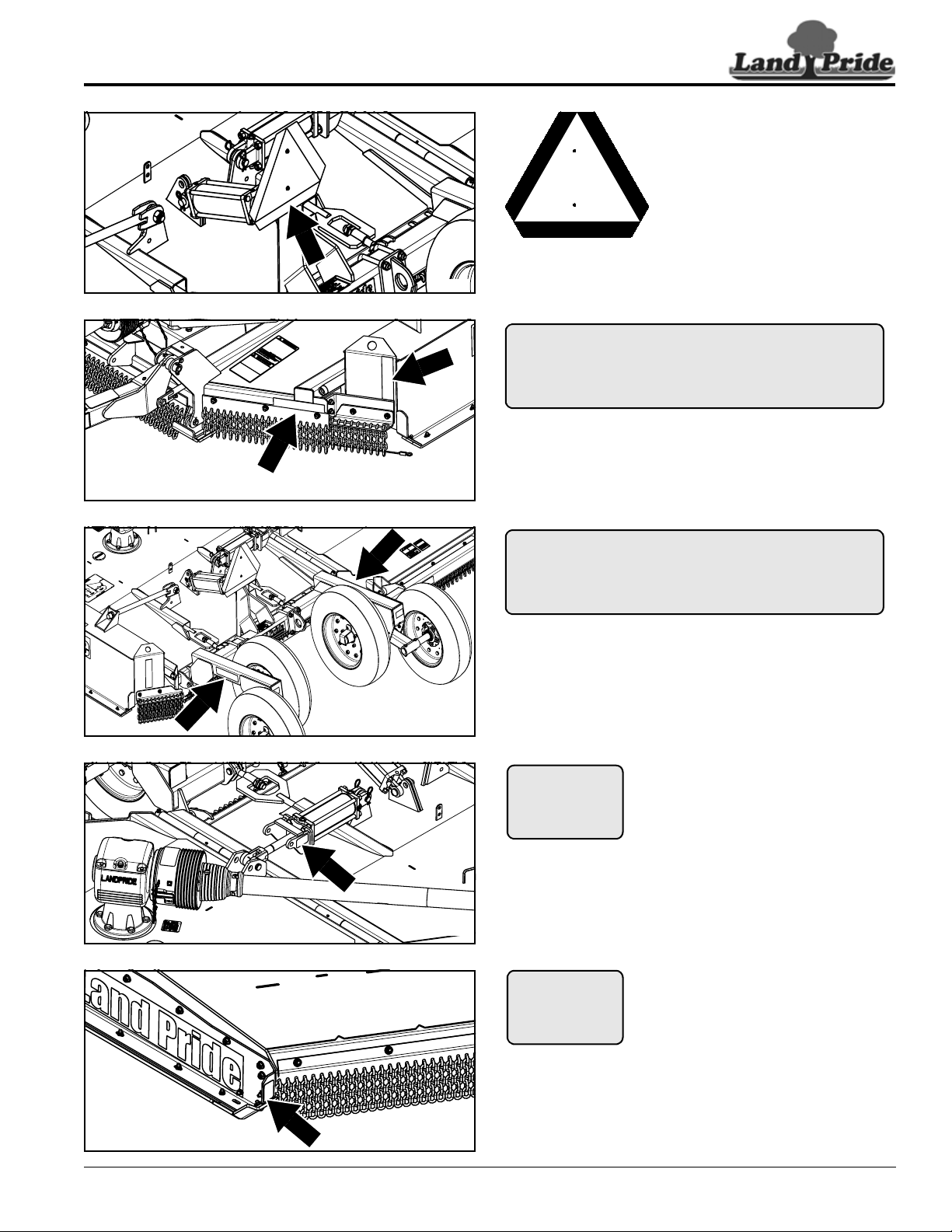

818-055C

Caution! Slow moving vehicle sign (SMV)

838-615C

2" x 9" Amber Reflector

2 - Places: Font left side of center deck and front left

side of weight box

838-615C

2" x 9" Amber Reflector

2 - Places: Left & right side of center deck rear axle.

818-229C

1 3/4" x 2 3/4" Amber Reflector

1 - Place: Front side of right transport lock

818-229C

1 3/4" x 2 3/4" Amber Reflector

1 - Place: Front right corner of right-hand wing

11 /11 / 12

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

9

Page 12

Important Safety Information

30222

35938

27853

35938

3022

Table of Contents

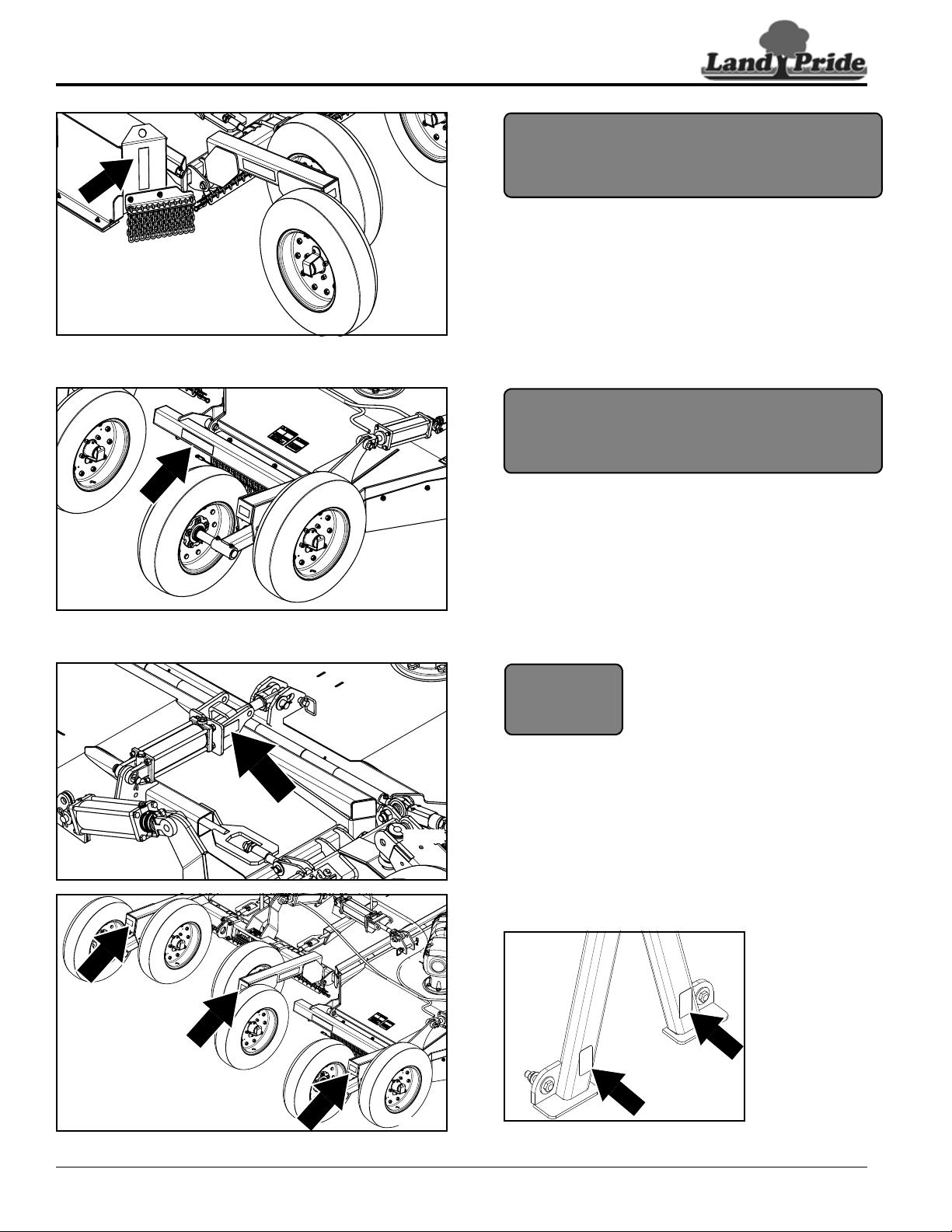

838-614C

2" x 9" Red Reflector

1 - place: Back face of weight box

838-614C

2" x 9" Red Reflector

1 - place: Back face of wing axle

818-230C

11/16" x 2 13/16" Red Reflector

8 possible places:

1 - place: Back face of transport lock

3 - places: Back face of wheel arms

2 - places: Back face of optional mechanical winch

2 - places: Back face of optional tool box

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

10

Mechanical winch & Tool Box Options

11 /11 / 12

Page 13

Table of Contents

30166

IMPORTANT: A special point of information related

to the following topic. Land Pride’s intention is this

information must be read & noted before continuing.

NOTE: A special point of information that the

operator should be aware of before continuing.

Introduction

Introduction

Land Pride welcomes you to the growing family of new

product owners. This Rotary Cutter has been designed

with care and built by skilled workers using quality

materials. Proper assembly, maintenance and safe

operating practices will help you get years of satisfactory

use from this machine.

Application

The RCB6610 & RCBM6610 Series 2 Rotary Cutters are

designed and built by Land Pride to provide excellent

cutting performance on gently sloping or slightly

contoured right-of-ways, roadsides, pastures, set-asideacres, or for residue in row crop fields. The 10’ cutting

width, 2" to 14" cutting height and ability to cut weeds and

brush up to 4 1/2" in diameter make them well suited for

these applications.

All listed models offer a pull-type, narrow A-frame hitch,

and Cat 5 conventional or Cat. 6 constant velocity main

driveline for attachment to 50-250 hp tractors. The

RCB6610 attaches to 540 RPM tractors and RCBM6610

attaches to 1000 RPM tractors.

They are also offered with various optional hitch types,

axle configurations, tires, safety guards, and deck rings

making them an excellent choice for agricultural, state,

and municipal mowing applications.

See “Specifications & Capacities” on page 56 and

“Features & Benefits” on page 58 for additional

information and performance enhancing options.

Owner Assistance

The Online Warranty Registration should be completed

by the dealer at the time of purchase. This information is

necessary to provide you with quality customer service.

The parts on your Rotary Cutter have been specially

designed by Land Pride and should only be replaced with

genuine Land Pride parts. Contact a Land Pride dealer if

customer service or repair parts are required. Your Land

Pride dealer has trained personnel, repair parts, and

equipment needed to service the implement.

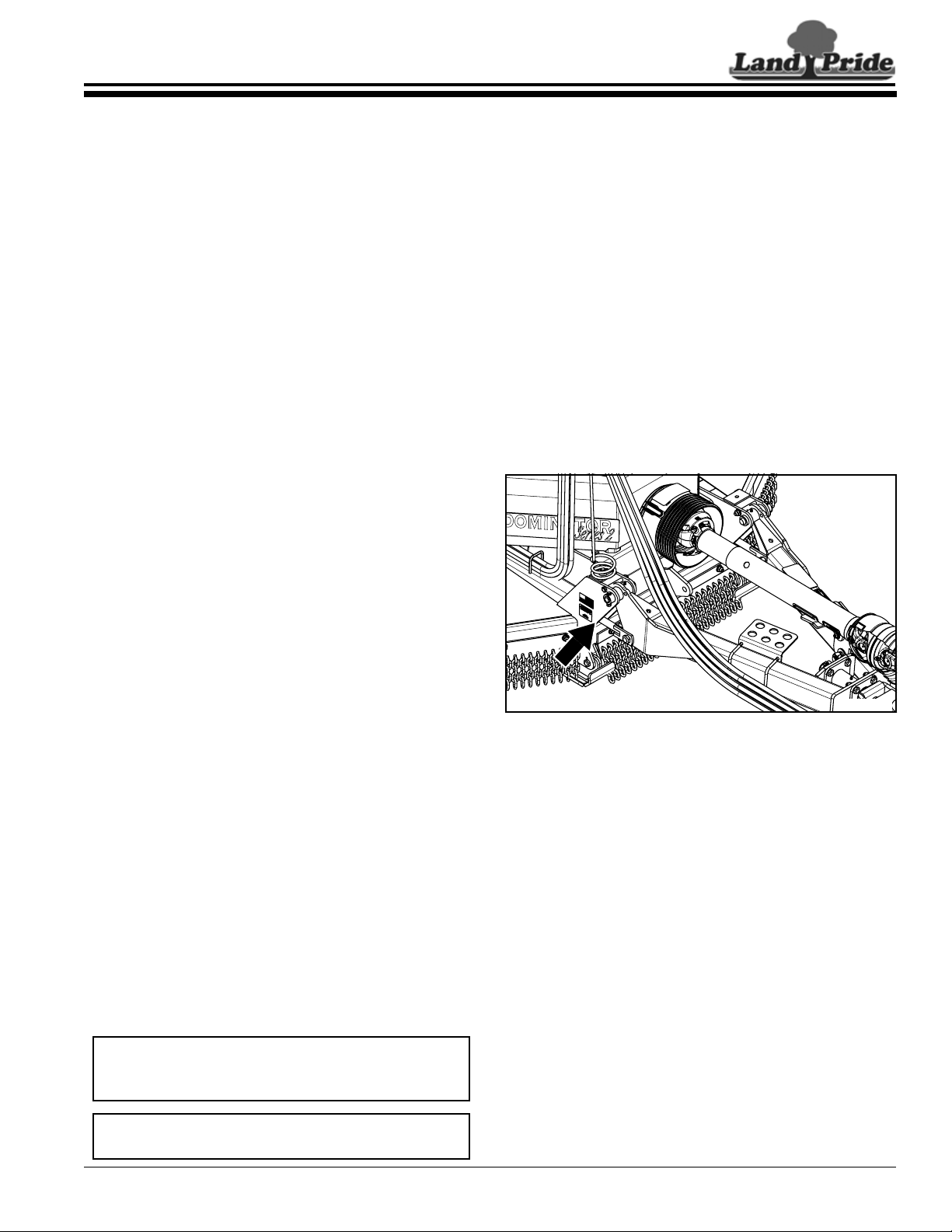

Serial Number

Model No. _____________Serial No. ______________

For quick reference and prompt service, record model

number and serial number in the spaces provided above

and again on warranty page 63. Always provide model

number and serial number when ordering parts and in all

correspondences with your Land Pride dealer. Refer to

Figure 1 for location of your serial number plate.

Using This Manual

•

This Operator’s Manual is designed to help familiarize

you with safety, assembly, operation, adjustments,

troubleshooting, and maintenance. Read this manual

and follow the recommendations to help ensure safe

and efficient operation.

• The information contained within this manual was

current at the time of printing. Some parts may change

slightly to assure you of the best performance.

• To order a new Operator’s or Parts Manual, contact

your authorized dealer. Manuals can also be

downloaded, free-of-charge, from our website at

www.landpride.com.

• Store this manual in the dry storage tube located on top

of the splitter guard.

Terminology

“Right” or “Left” as used in this manual is determined by

facing forward in the direction the machine will operate

while in use unless otherwise stated.

Definitions

Serial Number Plate Location

Figure 1

Further Assistance

Your dealer wants you to be satisfied with your new

cutter. If for any reason you do not understand any part of

this manual or are not satisfied with the service received,

the following actions are suggested:

1. Discuss the matter with your dealership service

manager making sure that person is aware of any

problems you may have and has had the opportunity

to assist you.

2. If you are still not satisfied, seek out the owner or

general manager of the dealership, explain the

problem, and request assistance.

3. For further assistance write to:

Land Pride Service Department

1525 East North Street

P.O. Box 5060

Salina, Ks. 67402-5060

11 /11 / 12

E-mail address

lpservicedept@landpride.com

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

11

Page 14

Section 1: Assembly & Set-up

!

WARNING

IMPORTANT: PTO damage may occur if distances

“A” and “B” are not properly maintained.

IMPORTANT: A PTO adaptor should not be used.

Using a PTO adaptor can damage the PTO.

22273

Table of Contents

Section 1: Assembly & Set-up

Tractor Requirements

Horsepower

Do not use too small a tractor. Tractors that are too small can

be pushed around and/or flipped over by the weight of the

cutter. Tractors that are too large can damage the cutter.

Tractor horsepower should be within the range noted

below. Tractors outside the range must not be used.

Horsepower Rating . . . . . . . . . . . . . . . . . .50-250 HP

Drawbar Set-up

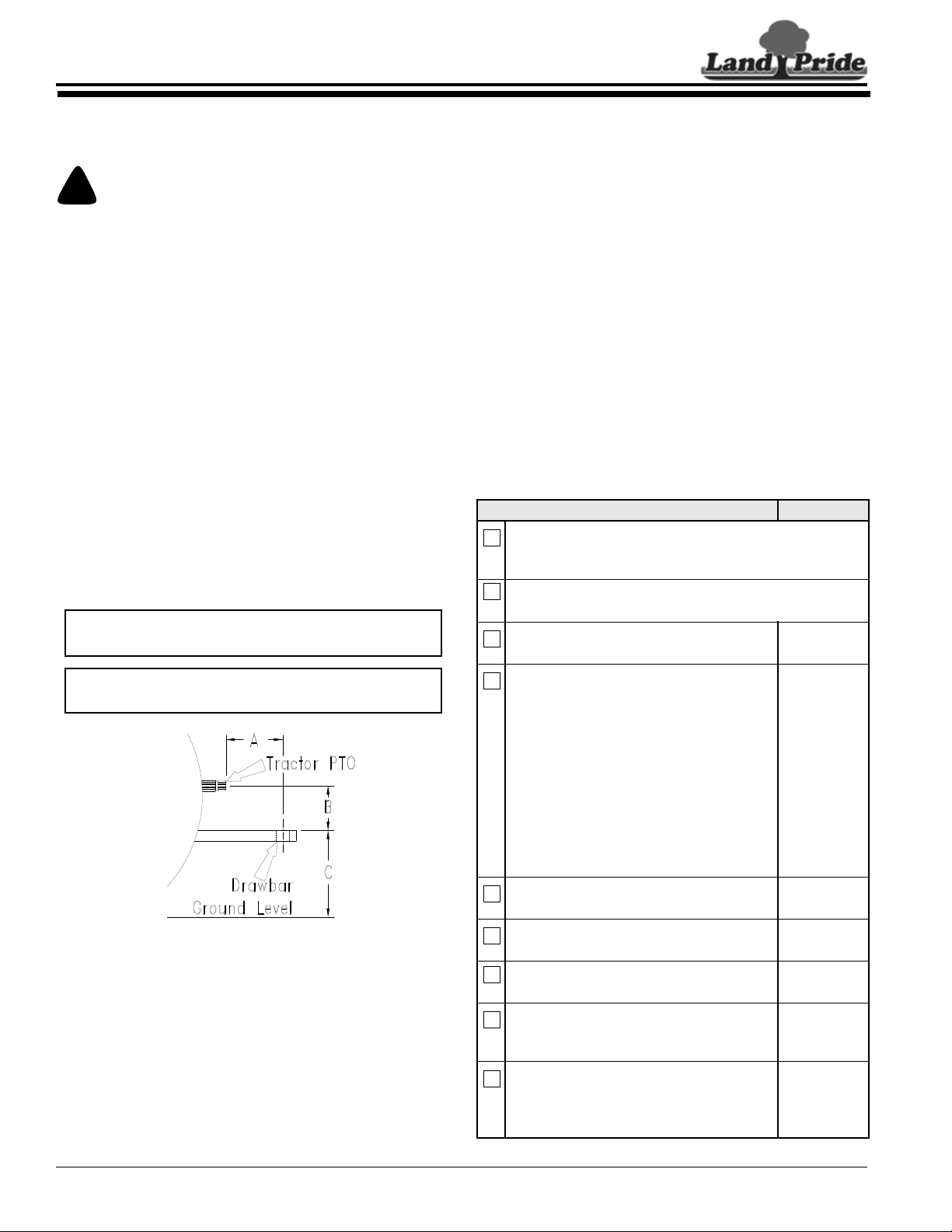

Refer to Figure 1-1:

Maintain proper distance, dimension A, between center

of drawbar hitch pin hole and end of tractor PTO shaft.

Hitch Type . . . . . . . . . . . . . . . . . . . . . . . . . . Draw Bar

540 RPM & 1 3/8", 1000 RPM Rear PTO Speed:

A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14"- 16"

B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8" - 10"

C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18" - 22"

1 3/4", 1000 RPM Rear PTO Speed:

A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18" - 20"

B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10" - 12"

C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18" - 22"

PTO to Drawbar Distance

Figure 1-1

PTO Speed

Rear PTO Speed:

Model RCB6610 . . . . . . . . . . . . . . . . . . . . 540 RPM

Model RCBM6610. . . . . . . . . . . . . . . . . . 1000 RPM

Hydraulic Outlets

Two duplex outlets are required. One to raise and lower

the cutter, and one to fold the wing. Float position is

highly recommended for the wing.

If your tractor is not equipped with two duplex outlets, an

optional control valve kit is available from your local Land

Pride dealer. See “Selector Control Valve Kit” on page

39 for information about the hydraulic kit.

Before You Start

Read and understand the operator’s manual for your

cutter. An understanding of how it works will aid in the

assembly and setup of your cutter.

It is best to go through the Assembly Checklist before

assembling the cutter. Speed up your assembly task and

make the job safer by having all needed parts and

equipment readily at hand.

Torque Requirements

See “Torque Values Chart” page 62 to determine

correct torque values when tightening hardware. See

“Additional Torque Values” at bottom of chart for

exceptions to common torque values.

Assembly Checklist

Check Reference

Have a fork lift or loader with properly sized chains and

safety stands capable of lifting and supporting the

equipment on hand.

Have a minimum of two people available during

assembly.

Make sure all major components and

loose parts are shipped with the machine.

Double check to make sure all parts,

fasteners, and pins are installed in the

correct location. Refer to the Parts

Manual if unsure. By double checking,

you will lessen the chance of using a bolt

incorrectly that may be needed later.

NOTE: All assembled hardware from the

factory has been installed in the correct

location. Remember location of a part or

fastener if removed during assembly.

Keep parts separated.

Make sure working parts move freely,

bolts are tight & cotter pins are spread.

Make sure all grease fittings are in place

and lubricated.

Make sure all safety labels are correctly

located and legible. Replace if damaged.

Make sure all red and amber reflectors

are correctly located and visible when

machine is in transport position.

Make sure all tires are inflated to the

specified psi air pressure and all wheel

bolts and axle nuts are tightened to the

specified torque.

Operator’s

Manual

Operator’s

Manual

330-584M

Par ts

Manual

334-071P

Operator’s

Manual

Page 49

Page 4

Page 10

Page 62

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

12

11 /11 / 12

Page 15

Table of Contents

26596

37590

26599

26600

26602

Section 1: Assembly & Set-up

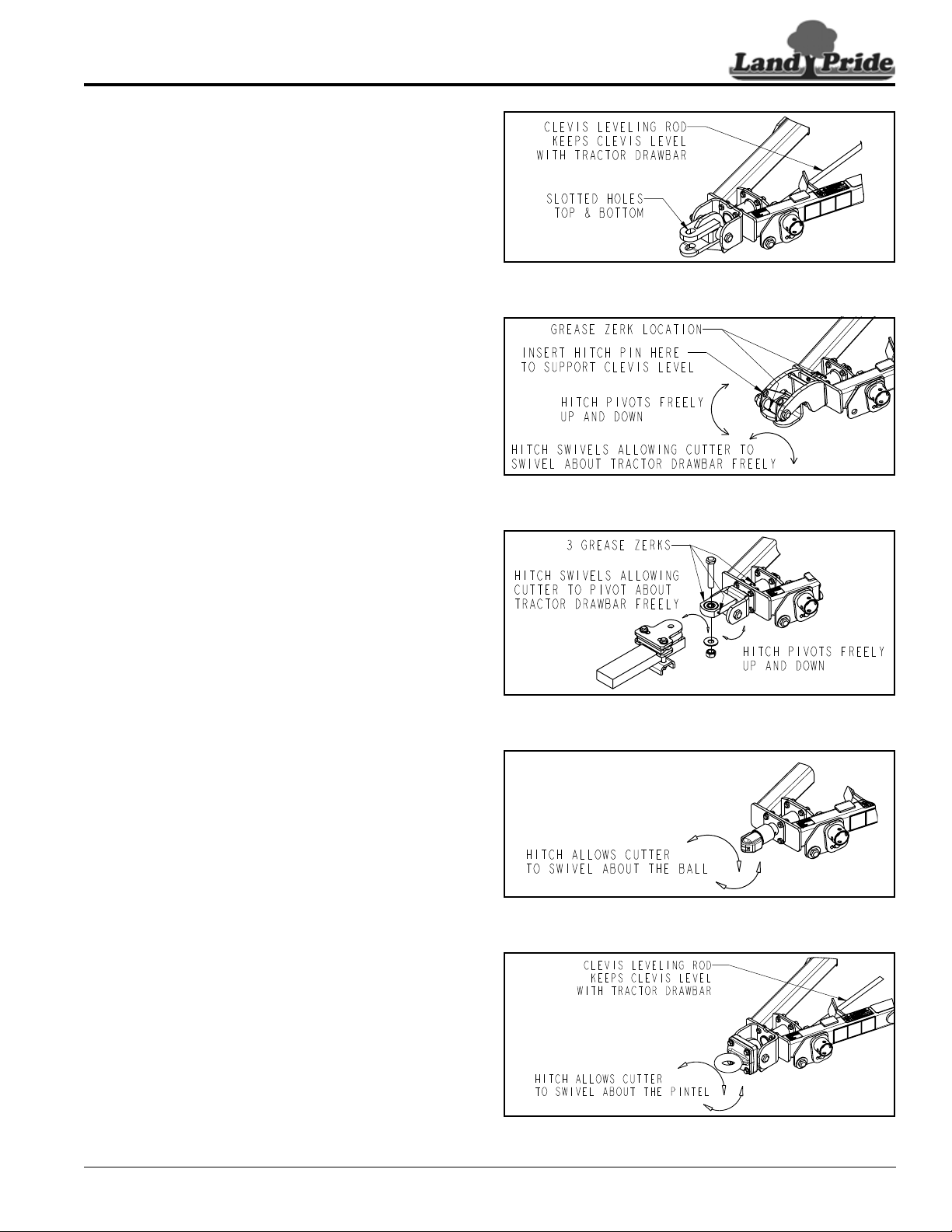

Hitch Types

The cutter is factory supplied with the standard clevis

hitch. Other optional hitches are available. They include

Land Pride Performance hitch, bar-tite hitch, ball hitch,

and pintle hitch. See your nearest Land Pride dealer

should you want to change your hitch set-up.

Standard Clevis Hitch

Refer to Figure 1-2:

A clevis leveling rod attached to the underside of the

clevis keeps the clevis parallel with tractor drawbar at all

cutting heights. Cutter rotation about the tractor drawbar

is limited to slots located in the clevis’ upper and lower

plates and drawbar hole size.

Land Pride Performance Hitch (Optional)

Refer to Figure 1-3:

The LP Performance Hitch is a drawbar friendly,

self-leveling hitch that pivots up and down and side-toside. It is held upright with customer-supplied hitch pin to

allow single-person hook-up.

Standard Clevis Hitch

Figure 1-2

LP Performance Hitch

Figure 1-3

Bar-Tite Hitch (Optional)

Refer to Figure 1-4:

The bar-tite hitch functions similar to LP Performance

hitch except it clamps directly to the drawbar. The bar-tite

hitch is sandwiched between hardened steel plates to

eliminate drawbar wear. It has a bushing in the tongue to

extend hitch life. Bushing and hitch swivel are greasable.

Ball Hitch (Optional)

Refer to Figure 1-5:

Cutter rotation about the tractor drawbar is limited to

swivel movement over the 2 5/16" tractor mounted ball.

Pintle Hitch (Optional)

Refer to Figure 1-6:

A leveling rod attached to the underside of the pintle hitch

keeps the pintle parallel with the tractor drawbar at all

cutting heights. Cutter rotation about the tractor drawbar

is limited to movement about the pintle connection. The

pintle hitch is ideal for a drawbar hammer strap.

Bar-Tite Hitch

Figure 1-4

Ball Hitch

Figure 1-5

11 /11 / 12

Pintle Hitch

Figure 1-6

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

13

Page 16

Section 1: Assembly & Set-up

IMPORTANT: Insert bolts (#7) from outside the hitch

frame. Inserting bolts from inside the hitch will result

in them interfering with tractor tires.

37612

Table of Contents

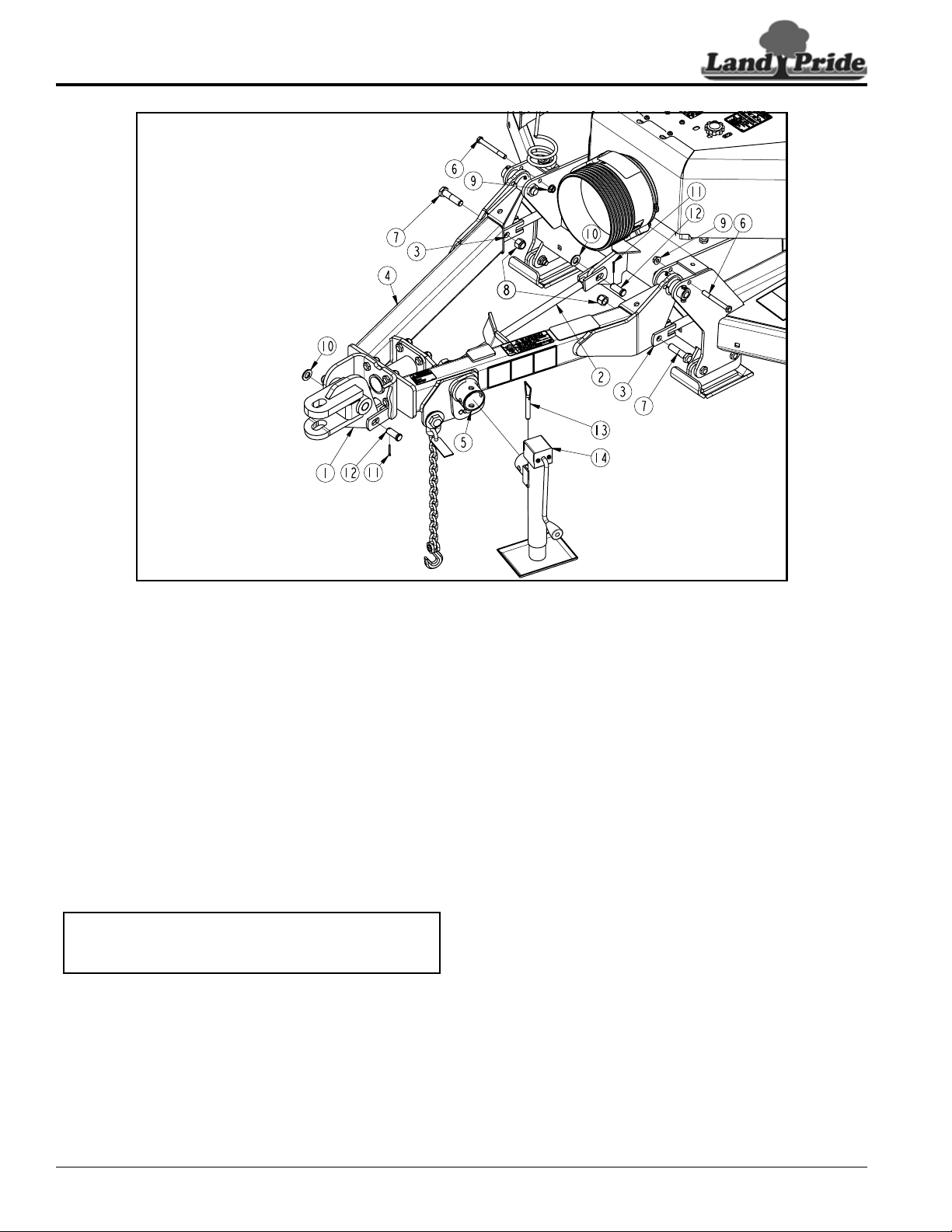

Hitch & Jack Assembly

Figure 1-7

Hitch Assembly

Refer to Figure 1-7:

1. Remove and discard 1/2" nuts (#9) and bolts (#6).

2. Rotate hitch (#4) down into pulling position as shown

in Figure 1-7.

3. Instructions “a” & “b” below are for cutters equipped

with standard clevis or pintle hitch. Skip to step 4 if

assembling LP Performance, bar-tite, or ball hitch.

a. Attach clevis level rod (#2) to center deck lug and

clevis hitch (#1) with clevis pins (#12), flat

washers (#10), and cotter pins (#11).

b. Secure cotter pins (#11) by bending one or more

legs of each pin.

4. Attach hitch frame (#4) to leveling rods (#3) by

inserting 3/4" x 3" lg. bolts (#7) through leveling rod’s

outside clevis plate, hitch frame (#4), and out through

leveling rod’s inside clevis plate. Secure bolts with

nylock nut (#8). Draw nuts up snug, do not tighten.

5. Leveling rod adjustment will be made after the cutter

is attached to the tractor.

Park Jack Assembly

Refer to Figure 1-7:

1. Attach park jack (#14) to jack mount (#5) and secure

with detent pin (#13).

2. If park jack is not vertical, adjust jack angle according

to “Park Jack Angle Alignment” on page 26.

3. Adjust jack up or down until clevis hitch (#1) is at

drawbar height.

Tractor Shutdown Procedure

The following is proper tractor shutdown procedures.

Always follows these procedures before dismounting

tractor.

1. If engaged, disengage PTO.

2. Lower attached implement to ground, put tractor in

park or set park brake, turn off engine, and remove

switch key to prevent unauthorized starting.

3. Wait for all cutter components to come to a complete

stop before leaving the operator’s seat.

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

14

11 /11 / 12

Page 17

Table of Contents

!

DANGER

IMPORTANT: Ball detent pin (#8) must be fully

inserted in park jack (#3) before working on or

around a cutter not hooked to a tractor drawbar.

NOTE: Hitch pin (#1) and hairpin cotter (#2) are

supplied by customer.

IMPORTANT: Protect park jack by attaching it to the

weight box before moving the cutter. Make sure jack

is stored with its base level or lower than the head to

prevent water and freeze damage.

35547

Section 1: Assembly & Set-up

Standard Clevis Hitch Hook-up

A Crushing Hazard exists when hooking-up equipment to a

tractor. Do not allow anyone to stand between tractor and

implement while backing-up to implement. Do not operate

hydraulic 3-Point lift controls while someone is directly

behind the tractor or near the implement.

Refer to Figure 1-8:

1. Make certain park jack (#3) is properly attached to

cutter hitch and secured with detent pin (#8). If park

jack is not vertical, refer to “Park Jack Angle

Alignment” on page 26.

2. Start tractor and raise 3-point arms fully up.

3. Carefully back tractor within close proximity of

clevis (#9).

4. Shut tractor down properly before dismounting. Refer

to “Tractor Shutdown Procedure” on page 14.

5. Verify tractor drawbar is adjusted correctly. Refer to

“Drawbar Set-up” dimensions on page 12.

6. Raise or lower park jack (#3) to align clevis (#9) with

tractor drawbar. Drawbar should fit between lower

and upper plates of clevis.

7. Restart tractor and continue to back tractor up to

cutter hitch until hitch holes in tractor drawbar and

clevis hitch (#9) are properly aligned.

8. Shut tractor down properly before dismounting.

Tractor Hook-up to Standard Clevis Hitch

Figure 1-8

9. Attach cutter to tractor drawbar with customer

supplied hitch pin (#1) and hairpin cotter (#2).

10. Lower park jack (#3) until hitch weight is supported

by drawbar.

11. Remove park jack (#3) from the hitch and attach it to

the weight box with detent pin (#8). Make sure jack

base is level or lower than the jack crank head. See

cover picture for correct positioning.

12. Attach hitch safety chain (#4) to the tractor. Adjust

chain length to remove all slack except what is

necessary to permit turning. Lock chain hook

securely to the safety chain.

13. Continue with “Hydraulic Plumbing” on page 18

and “Driveline Installation” on page 20.

11 /11 / 12

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

15

Page 18

Section 1: Assembly & Set-up

!

DANGER

IMPORTANT: Ball detent pin (#8) must be fully

inserted in park jack (#3) before working on or

around a cutter not hooked to a tractor drawbar.

NOTE: Hitch pin (#1) and hairpin cotter (#2) are

customer-supplied.

IMPORTANT: Protect park jack by attaching it to the

weight box before moving the cutter. Make sure jack

is stored with its base level or lower than the head to

prevent water and freeze damage.

37986

Table of Contents

Tractor Hookup to LP Performance Hitch

Figure 1-9

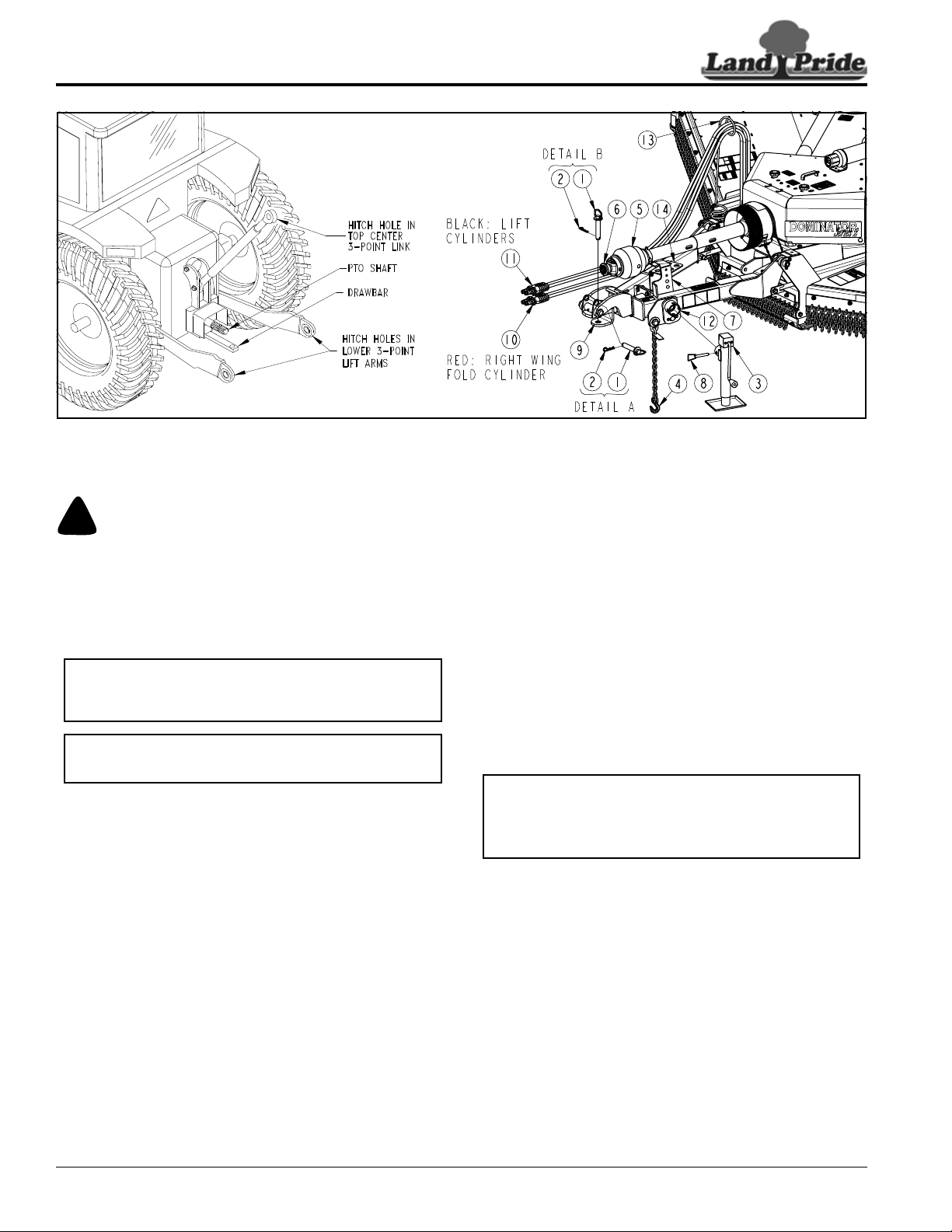

LP Performance Hitch Hook-up

A Crushing Hazard exists when hooking-up equipment to a

tractor. Do not allow anyone to stand between tractor and

implement while backing-up to implement. Do not operate

hydraulic 3-Point lift controls while someone is directly

behind the tractor or near the implement.

Refer to Figure 1-9:

1. Make certain park jack (#3) is properly attached to

jack mount (#15) and secured with attachment

pin (#8). If park jack is not vertical, refer to “Park

Jack Angle Alignment” on page 26.

2. If clevis (#9) is not already supported horizontal,

rotate clevis horizontal and insert customer-supplied

hitch pin (#1) through horizontal holes in clevis (#9)

as shown in detail A. Secure with hairpin cotter (#2).

3. Store center 3-point link in its storage hook.

4. Start tractor and raise 3-point arms fully up.

5. Carefully back tractor within close proximity of

clevis (#9).

6. Shut tractor down properly before dismounting. Refer

to “Tractor Shutdown Procedure” on page 14.

7. Verify tractor drawbar is adjusted correctly. Refer to

“Drawbar Set-up” dimensions on page 12.

8. Raise or lower park jack (#3) to align clevis (#9) with

tractor drawbar. Drawbar should fit between lower

and upper plates of clevis.

9. Restart tractor and continue to back tractor up to

cutter hitch until hitch holes in tractor drawbar and

hitch clevis (#9) are aligned.

10. Shut tractor down properly before dismounting.

11. Remove hairpin cotter (#2) and hitch pin (#1) from

clevis (#9) as shown in detail A.

12. Attach cutter to tractor drawbar with hitch pin (#1) and

hairpin cotter (#2) as shown in detail B.

13. Lower park jack (#3) until hitch weight is supported

by tractor drawbar.

14. Remove park jack (#3) from jack mount (#12) and

attach it to the weight box with detent pin (#8). Make

sure jack base is level or lower than the jack crank

head. See cover picture for correct positioning.

15. Attach hitch safety chain (#4) to the tractor. Adjust

chain length to remove all slack except what is

necessary to permit turning. Lock chain hook

securely to the safety chain.

16. Continue with “Hydraulic Plumbing” on page 18

and “Driveline Installation” on page 20.

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

16

11 /11 / 12

Page 19

Table of Contents

!

DANGER

IMPORTANT: Ball detent pin (#8) must be fully

inserted in park jack (#3) before working on or

around a cutter not hooked to a tractor drawbar.

22265

IMPORTANT: Protect park jack by attaching it to the

weight box before moving the cutter. Make sure jack

is stored with its base level or lower than the head to

prevent water and freeze damage.

35549

Section 1: Assembly & Set-up

Bar-Tite Hitch Hook-up

Refer to Figure 1-10:

Attach Bar-Tite Hitch to Tractor Drawbar

1. Insert 1" x 5 1/2" hex bolt (#1) through hitch top

plate (#2), hitch bushing (#3), hitch wear plate (#4),

tractor drawbar (#5), and washer (#6) as shown.

Secure with 1" lock nut (#7). Tighten 1" lock nut

snugly to remove all play and then back nut

one-quarter turn. Do Not torque 1" lock nut.

2. Insert two 3/4" x 6" GR5 hex bolts (#8) through,

3/4" flat washers (#9), hitch top plate (#2), hitch wear

plate (#4), and formed hitch support (#10) as shown.

Secure with 3/4" locknuts (#11).

3. Tighten 3/4" locknuts to correct torque.

4. Remove 1" x 6 1/2" GR5 hex bolt (#12) and 1" lock

nut (#13) from hitch bushing (#3). Keep bolt and lock

nut for reuse.

Attach Tractor to Rotary Cutter

A Crushing Hazard exists when hooking-up equipment to a

tractor. Do not allow anyone to stand between tractor and

implement while backing-up to implement. Do not operate

hydraulic 3-Point lift controls while someone is directly

behind the tractor or near the implement.

Refer to Figure 1-11:

1. Make certain park jack (#3) is properly attached to

cutter hitch and secured with detent pin (#8). If park

jack is not vertical, refer to “Park Jack Angle

Alignment” on page 26.

2. Store center 3-point link in the tractor storage hook.

3. Start tractor and raise 3-point arms fully up.

4. Carefully back tractor within close proximity of

clevis (#9).

5. Shut tractor down properly before dismounting. Refer

to “Tractor Shutdown Procedure” on page 14.

6. Verify tractor drawbar is adjusted correctly. Refer to

“Drawbar Set-up” dimensions on page 12.

7. Raise or lower park jack (#3) to align swivel

clevis (#9) with bolt hole in hitch bushing (#7).

8. Restart tractor and back tractor up to swivel

clevis (#9) until hole in hitch bushing (#10) aligns with

holes in swivel clevis (#9).

9. Shut tractor down properly before dismounting.

10. Insert 1" x 6 1/2" GR5 hex bolt (#1) through swivel

clevis (#9) and hitch bushing (#7). Secure hex bolt

with lock nut (#2). Tighten lock nut snugly to remove

all play. Do Not torque 1" lock nut.

11 /11 / 12

Bar-Tite Hitch Assembly to Tractor Tongue

Figure 1-10

11. Lower park jack (#3) until hitch weight is supported

by the drawbar.

12. Remove park jack (#3) from the hitch and attach it to

the weight box with detent pin (#8). Make sure jack

base is level or lower than the jack crank head. See

cover picture for correct positioning.

13. Attach hitch safety chain (#4) to the tractor. Adjust

chain length to remove all slack except what is

necessary to permit turning. Securely lock chain

hook to the safety chain.

14. Continue with “Hydraulic Plumbing” on page 18

and “Driveline Installation” on page 20.

Tractor Hookup to Bar-Tite Hitch

Figure 1-11

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

17

Page 20

Section 1: Assembly & Set-up

!

DANGER

Hand Grips with Cylinder Extension Symbol

Hand Grips with Cylinder Retraction Symbol

35553

!

CAUTION

!

DANGER

!

WARNING

37647

Table of Contents

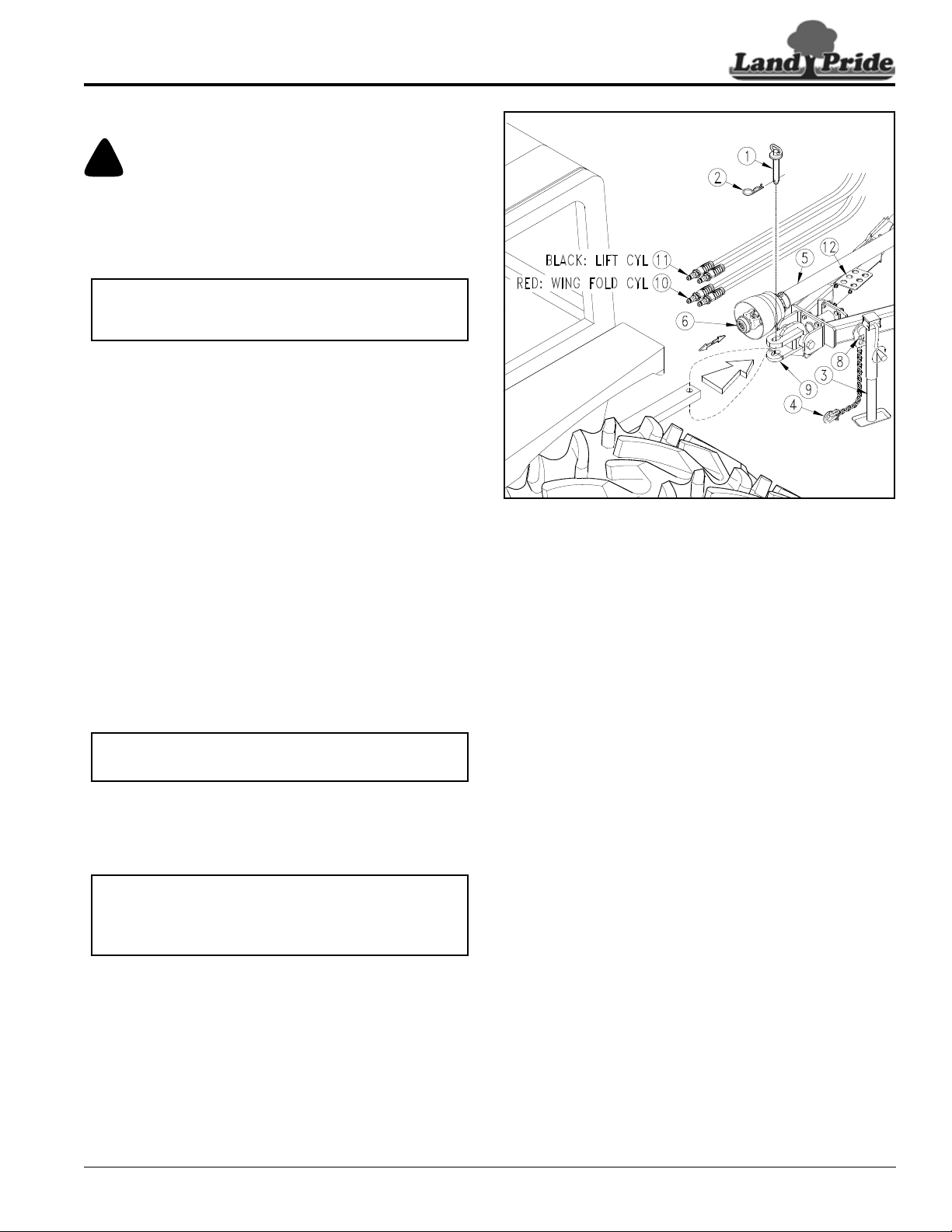

Hydraulic Plumbing

Hydraulic fluid under high pressure can penetrate skin. Wear

protective gloves and safety glasses or goggles when working

with hydraulic systems. Use a piece of cardboard or wood

rather than hands when searching for hydraulic leaks. If

hydraulic fluid is injected into the skin or eyes, it must be

treated by a doctor familiar with this type of injury within a

few hours or gangrene may result. DO NOT DELAY.

Refer to Figure 1-12:

Located on the hand grips are symbols indicating if the

cylinder will extend or retract when hydraulic pressure is

applied to that hose. Make sure hand grips are on the

correct hoses. Use hand grip colors and symbols to aid in

hook-up.

Hydraulic Hose Hand Grips

Figure 1-12

Unfolding Wing Deck

Metal shipping bands are under tension. Always wear eye

protection when cutting bands. Keep head, body, and body

extremities away from areas a band will recoil into when cut.

Keep everyone out of the area wher e the wing deck will unfold

into. A wing that falls suddenly on a person will cause serious

bodily injury or death.

The wing deck is shipped leaning in towards the center deck.

A person will need to manually push the wing deck out pass

vertical position before it will lower under its own weight.

Before pushing on the wing deck:

• Make certain no one is in the area where the deck will

lower down into as it is unfolded.

• Make certain your footing is secure and you are clear of

any possible pinch points.

• Make certain you are standing on the center deck behind

and away from hydraulic hoses, hydraulic cylinders,

gearboxes, and drivelines so that you do not become

entangled in them as they move while the decks are unfolding.

Refer to Figure 1-14 on page 19:

Refer to Figure 1-14 to verify wing folding cylinder is

plumbed correctly. Make sure couplings (#4) with red

hand grips (#5 & #6) are attached to the right wing folding

cylinder. It is best if the wing folding cylinder (#1) is

connected to a duplex outlet with float option to allow the

wing to float with the contour of the ground while cutting.

Refer to Figure 1-15 on page 19:

The cutting/transporting height is controlled by two

rephasing lift cylinders (#1 & #2) which are plumbed

together to operate in unison. The decks will not lift

properly if rephasing cylinders are plumbed incorrectly.

See Figure 1-15 to verify plumbing. Make sure

couplings (#5) with black hand grips (#9 & #10) are

attached to lift cylinders (#1 & #2).

Hydraulic Hook-up

Refer to Refer to Figure 1-9 on page 16:

1. Route right wing cylinder hoses (#10) with red hand

grips through hose support loop (#13) and connect to

a tractor duplex outlet with float option if available.

2. Route lift cylinder hoses (#11) with black hand grips

through hose support loop (#13) and connect to a

tractor duplex outlet.

Remove Shipping Bar

Figure 1-13

Refer to Figure 1-13:

1. Make sure cutter is parked on a level surface.

2. Place gear selector in park or set park brake, fully

retract wing hydraulic cylinder, shut tractor off, and

remove switch key before dismounting tractor.

3. Remove hex nylock nuts (#6 & #7), bolts (#4 & #5),

shipping strap (#1), and shipping tubes (#2 & #3).

Discard removed hardware (#1 thru #7).

4. See "DANGER" above. Cut and remove rear metal

shipping strap securing the wing deck wheel.

5. Set tractor control lever for the wing cylinder in float.

18

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

11 /11 / 12

Page 21

Table of Contents

30230

30229

Section 1: Assembly & Set-up

6. See "WARNING" on page 18. Once you are sure the

area is clear and you are safely positioned, manually

unfold the wing until it starts to fall on its own. The

wing should fall slowly as the hydraulic line is orificed

to control the fall.

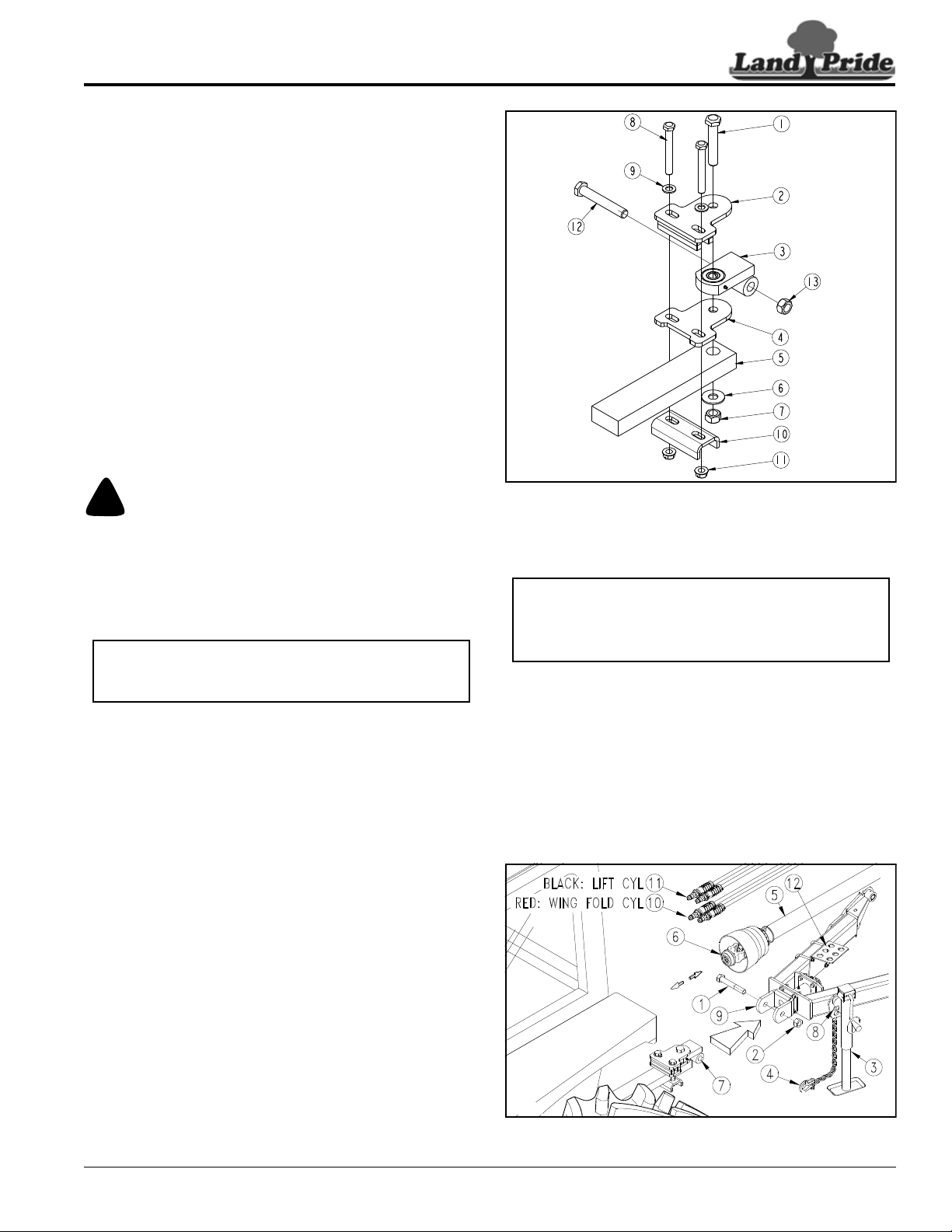

Wing Folding Cylinder & Plumbing

Refer to Figure 1-14:

1. Hydraulic cylinder 3 1/2" x 8" x 1 1/4" rod

2. Orifice elbow, 1/16" x 9/16" MJIC x 3/4" MORB

3. 3/8" Hydraulic hose, 189" long x 9/16" FJIC x 3/4" MORB

4. Quick disconnect poppet type coupling, 3/4" MORB male

5. Red hand grip for cylinder extension

6. Red hand grip for cylinder retraction

7. Hand grip adapter, 3/4MORB x 3/4FORB

Wing Folding Cylinder and Plumbing

Figure 1-14

Rephasing Cylinders & Plumbing

Refer to Figure 1-15:

1. Rephasing hydraulic cylinder 3 1/2" x 8" x 1 1/4" rod

2. Rephasing hydraulic cylinder 3 1/4" x 8" x 1 1/4" rod

3. Straight adapter 3/4 MORB x 3/4MJIC

4. Elbow, 3/4" MJIC x 3/4" MORB

5. Quick disconnect poppet type coupling, 3/4" MORB male

6. 3/8" Hydraulic hose, 168" long x 3/4" MORB x 3/4" FJIC

7. 3/8" Hydraulic hose, 84" long x 3/4" FJIC

8. 3/8" Hydraulic hose, 249" long x 3/4" FJIC x 3/4" MORB

9. Black hand grip for cylinder extension

10. Black hand grip for cylinder retraction

11. Hand grip adapter, 3/4MORB x 3/4FORB

11 /11 / 12

Re-phasing Deck Lift Cylinders and Plumbing

Figure 1-15

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

19

Page 22

Table of Contents

!

DANGER

!

WARNING

IMPORTANT: Do not attempt to operate a 540 rpm

driveline at 1,000 rpm or a 1,000 rpm driveline at 540

rpm. Many tractors provide both 540 and 1,000 rpm

PTO modes. Check your tractor’s manual to

determine its capabilities.

IMPORTANT: The driveline must be lubricated

before putting it into service. Refer to “Lubrication

Points” on page 49.

NOTE: Complete “Unfolding Wing Deck”

instructions on page 18 before removing driveline

from its shipping location.

37810

37960

Section 1: Assembly & Set-up

Driveline Installation

Do not engage tractor PTO while hooking-up and unhooking

driveline or while someone is standing near the driveline. A

person’s body and/or clothing can become entangled in the

driveline resulting in serious injury or death.

To avoid serious injury or death:

• Do not use PTO adapters. A PTO adapter will increase strain

on the tractor’s PTO shaft resulting in possible damage to

shaft and driveline. It will also defeat the purpose of the

tractor’s master shield.

• Always disengage PTO, place tractor in park or set park

brake, shut tractor engine off, r emove switch key , and wait for

blades to stop before dismounting from tractor.

• Make certain all driveline yokes are securely fastened at both

ends. A loose yoke can work free allowing the driveline to

rotate uncontrollably causing machine damage and bodily

injury or death to anyone nearby.

• Do not operate cutter above its rated PTO speed or machine

breakage may result.

Remove Main Driveline From Cutter

Figure 1-16

Refer to Figure 1-17:

6. Unsnap latches (#5) on both sides of gearbox

shield (#10) and remove shield.

7. Remove and discard rubber shaft protector (#7) from

splitter gearbox shaft (#8).

8. Remove locknuts (#1) and bolts (#2) from bolted

coupler end of driveline (#9).

9. Insert bolted coupler end of driveline (#9) through

gearbox shield (#10) and attach to gearbox input

shaft (#8) with removed bolts (#2) and locknuts (#1).

Tighten locknuts to the correct torque.

10. Collapse driveline (#9) by pushing tractor end of

driveline toward splitter gearbox (#8).

11. Rotate driveline hanger (#11) up and support

driveline (#9) on hanger. Final adjustments to hanger

will be made later after tractor hook-up.

12. Return gearbox shield (#10) to mounting plate (#4)

and secure with latches (#5).

13. Check safety chain (#3). Make sure it is latched to

mounting plate (#4) and gearbox shield (#10).

The main driveline may be either constant velocity type

or conventional type. Pull-collar coupler and retaining

bolts are used to connect the driveline to the tractor and

implement gearbox, respectively.

Refer to Figure 1-16:

1. Remove hex whiz nuts (#4A) and shipping

bracket (#2). Discard shipping bracket.

2. Slide driveline (#5) off end of shipping bracket (#1).

Set driveline aside for attaching to splitter box later.

3. Reattach hex whiz nuts (#4A) to carriage bolts (#3)

and tighten them to the correct torque.

4. Remove hex whiz nuts (#4B) and shipping

bracket (#1). Discard shipping bracket.

5. Reattach hex whiz nuts (#4B) to carriage bolts (#3)

and tighten them to the correct torque.

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

20

Driveline Installation

Figure 1-17

11 /11 / 12

Page 23

Table of Contents

IMPORTANT: Always rotate driveline hanger down

after hook-up to prevent driveline damage.

IMPORTANT: Always rotate driveline hanger down

after hook-up to prevent driveline damage.

26611

26611

37961

Section 1: Assembly & Set-up

Driveline Hook-up to Tractor PTO

Refer to Figure 1-19:

1. If needed, collapse driveline (#5) by pushing tractor

end of driveline against splitter gearbox.

2. Pull back on yoke locking collar (#6) and slide yoke

over tractor PTO shaft.

3. Release locking collar (#6) and continue to push

outer yoke onto tractor PTO shaft until locking collar

snaps in place.

4. Both yoke ends of driveline (#5) should be moved

back and forth to ensure they are secured. Reattach

yoke end if it is loose.

5. Rotate driveline hanger (#1) down.

6. If attached, remove park jack (#3) and store on

weight box. See steps 13 & 14 on page 16.

12. Rotate driveline hanger (#1) down.

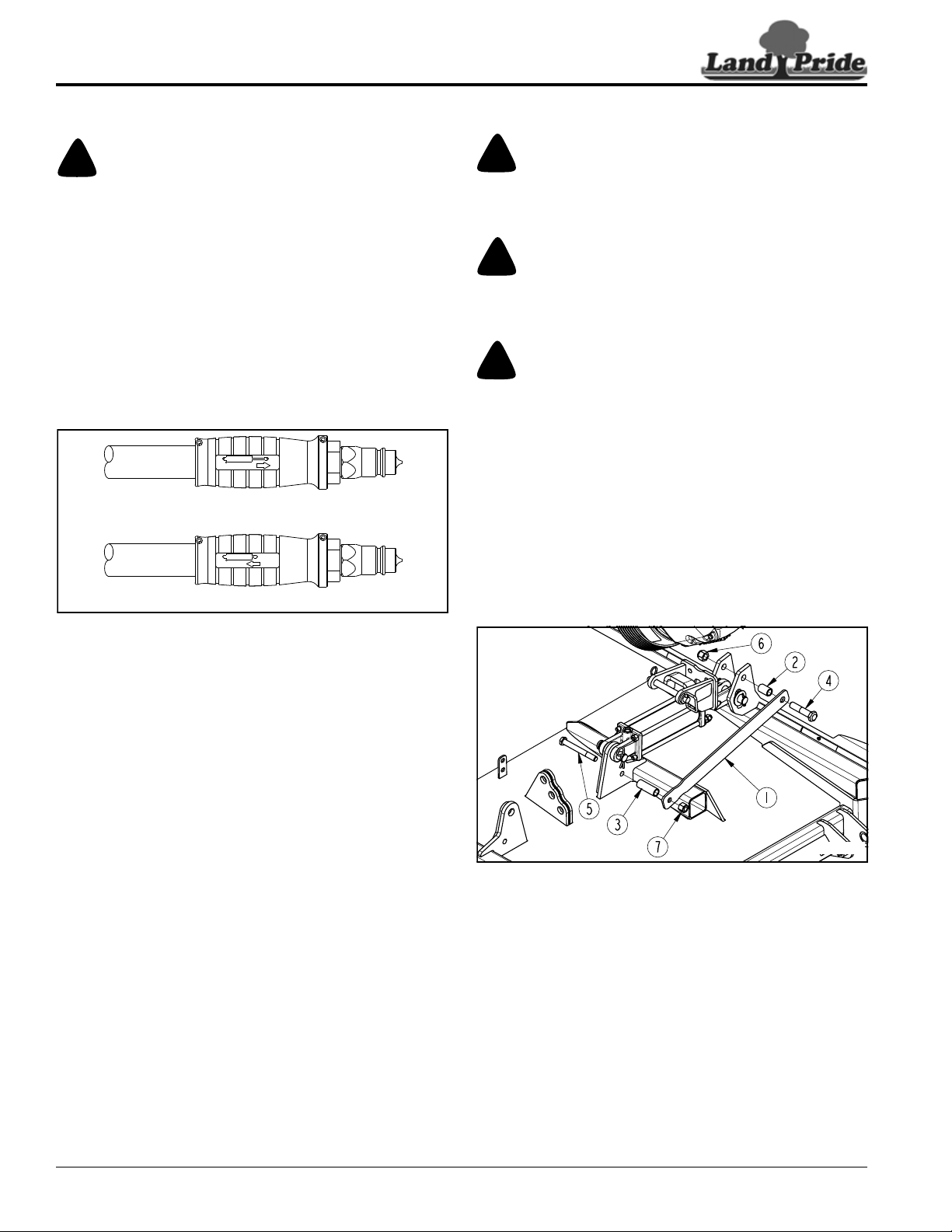

Driveline Clearance Check

Check driveline for adequate clearance under all ranges

of cutter height.

1. With driveline shaft attached to the tractor and all

stroke control spacers (#4 in Figure 1-18) removed

from hydraulic cylinder (#1), slowly raise and lower

cutter to its upper and lower limits while observing

clearances between hitch and driveline.

2. Adjust tractor drawbar height and/or length if

driveline interferes. See “Drawbar Set-up” on page

12 for correct drawbar dimensions.

3. Cycle cylinders back and forth several times to purge

cylinders and hydraulic lines of air. For additional

details, see “Purge Hydraulic System” on page 22.

Adjust Driveline Hanger

Refer to Figure 1-18:

1. Move tractor control lever to extend hydraulic lift

cylinder (#1) until pressure against stroke control

spacers (#4) is removed.

2. Shut tractor down properly before dismounting. Refer

to “Tractor Shutdown Procedure” on page 14.

3. Remove all stroke control spacers (#4) from center

hydraulic lift cylinder (#1) by spreading them apart at

the break line.

4. Start tractor and lower cutter until front skids are

resting on the ground or on support blocks.

5. Shut tractor down properly before dismounting.

6. Replace stroke control spacers (#4) as needed to

support wheels at this position.

Refer to Figure 1-19:

7. With driveline attached to tractor, rotate driveline

hanger (#1) up as shown.

8. Loosen nuts securing carriage bolts (#4) and adjust

driveline hanger (#1) up until there is a small gap

between driveline (#5) and hanger (#1).

9. If driveline hanger (#1) is adjusted fully up and needs

to adjust higher, remove carriage bolts (#4) and

reattach hanger to the upper two square holes (#2)

with existing flat washers, lock washers, hex nuts,

and carriage bolts (#4). Continue to adjust hanger to

underside of driveline.

10. Draw nuts securing carriage bolts (#4) up snug and

rotate driveline hanger (#1) down. If hanger makes

contact with driveline (#5), readjust hanger down

until it misses the driveline.

11. Tighten 3/8"-16 GR5 bolts (#4) to the correct torque.

Hydraulic Lift Cylinder With Stroke Control Spacers

Figure 1-18

Adjust Driveline Hanger Vertically

Figure 1-19

11 /11 / 12

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

21

Page 24

Section 1: Assembly & Set-up

!

DANGER

!

WARNING

39071

Table of Contents

Purge Hydraulic System

Figure 1-20

Purge Hydraulic System

Refer to Figure 1-20:

Never remove or install a folding wing cylinder with cylinder

rod r etracted and wing folded up. The wing is unstable without

its folding cylinder and can suddenly fall. Also, air trapped in

a new or repaired cylinder will drop the wing suddenly when

lowering the wing. Either situation can render the cutter

inoperable and cause serious bodily injury or death.

Be sure center and wing decks are lowered to the ground and

all hydraulic pressure is relieved before disconnecting any

hydraulic lines or fittings between the Rotary Cutter and

tractor hydraulic system.

Be sure tractor reservoir is filled properly before

operating hydraulic cylinders. If tractor reservoir is low on

hydraulic fluid, there is a chance of drawing air into the

system causing jerky or uneven cylinder movements.

The wing deck lift cylinder may be purged as follows:

Wing Fold Cylinders

1. Start tractor and lower center deck until it is

supported by stroke control spacers (#5) on hydraulic

cylinder (#1).

2. Lower wing deck until it is resting on the ground.

3. See “Tractor Shutdown Procedure” on page 14.

Shut tractor down properly and move wing control

levers back and forth to relieve all hydraulic pressure.

4. Slightly loosen hose fittings (#4) on wing folding

cylinder (#3).

5. Restart tractor and slowly activate tractor control

lever to extend/retract folding cylinder (#3), and to

purge trapped air from the hydraulic system.

6. Shut tractor down properly, dismount, and tighten

hose fittings (#4) on folding cylinder (#3).

Deck Lift Cylinders

Deck lift cylinders are rephasing cylinders and self purge

if tractor control lever is held in deck lift position for and

extended period.

1. Start tractor and slowly activate tractor control lift

lever to extend hydraulic cylinders (#1 & #2).

2. Once cylinders (#1 & #2) are fully extended, continue

to hold control lever in the deck lift position to allow

time for hydraulic oil and trapped air to make a

complete circuit through the hydraulic system.

3. With tractor control lever, lower and raise decks

several times to verify all trapped air is removed and

cylinders (#1 & #2) are operating smoothly.

4. If needed, repeat steps 1 thru 3 until deck left

cylinders operate smoothly.

22

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

11 /11 / 12

Page 25

Table of Contents

26611

26611

30727

Section 1: Assembly & Set-up

Lift Cylinder Mounting Position

Figure 1-21

Lift Cylinder Mounting Position

Refer to Figure 1-21:

Lift cylinder (#1) should be mounted in lower hole (A) if

cutter is equipped with 21" laminated tires or middle

hole (B) if cutter is supplied with 25.5" aircraft tires, or

upper hole (C) if 29" aircraft tires. Reposition lift cylinder

if it is not assembled in the correct hole.

1. Park tractor and cutter on a level surface and raise

center deck fully up.

2. Without lowering cutter, shut tractor down properly

before dismounting. Refer to “Tractor Shutdown

Procedure” on page 14.

3. Place sturdy support blocks or jack stands under the

four corners of the center deck.

4. Remove all stroke control spacers (#4) from the

hydraulic cylinder rod.

5. Start tractor and lower center deck onto the support

blocks until hydraulic cylinder hitch pin (#2) is loose.

6. Shut tractor down properly before dismounting.

7. Remove hairpin cotter (#3) and hitch pin (#2).

8. Reposition hydraulic cylinder to the correct mounting

hole (A, B, or C) and reinsert hitch pin (#2). Secure

hitch pin with hairpin cotter (#3).

9. Start tractor, raise deck fully up, and then shut tractor

down again before dismounting.

10. Replace stroke control spacers (#4) and remove

support blocks.

11. Start tractor and cycle hydraulic system by raising

and lowering center deck cylinder and wing folding

cylinders.

Rephase Lift Cylinders

The lift cylinders may be out of phase. See “Rephasing

Lift Cylinders” on page 34 for detailed instructions.

Slow Moving Vehicle Sign (SMV)

Refer to Figure 1-22:

Mounting blade (#7) is shipped from the factory bolted to

mounting socket (#8). The two should be separated and

reassembled as follows:

1. Remove hex flange nuts (#5), hex flange serrated

screws (#2) and SMV sign (#6) from mounting

blade (#7). Keep hardware for reuse.

SMV Sign Assembly

Figure 1-22

2. Remove hex whiz nuts (#4), carriage bolts (#3),

mounting blade (#7), and mounting socket (#8) from

bracket (#1). Keep hardware for reuse.

3. Attach mounting socket (#8) to bracket (#1) with

existing carriage bolts (#3) and hex whiz nuts (#4).

Tighten whiz nuts to the correct torque.

4. Attach SMV sign (#6) to mounting blade (#7) with

existing hex flange serrated screws (#2) and hex

flange nuts (#5). Tighten nuts to the correct torque.

5. Insert mounting blade (#7) into mounting socket (#8).

11 /11 / 12

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

23

Page 26

Table of Contents

39040

37658a

Section 1: Assembly & Set-up

Adjust Optional Light Kit

Refer to Figure 1-23:

The Light Kit will need to be adjusted when purchased

assembled to the cutter at the factory.

Adjust light kit as follows:

1. Shut tractor down properly before dismounting. Refer

to “Tractor Shutdown Procedure” on page 14.

2. On the right-hand wing, loosen hex lock nuts (#1). Do

not remove lock nuts.

3. Slide light assembly (#2) and mounting clamp (#3) as

far as possible toward the rod end of hydraulic

cylinder (#4).

4. Tighten each lock nut (#1) one-half turn in a crisscross pattern until all nuts are tightened to the correct

torque.

Optional Light Kit Adjustment

Figure 1-23

Remove Shipping Lugs

Figure 1-24

Remove Shipping Lugs

Refer to Figure 1-24:

Tie down lugs are installed to the cutter for shipping

purposes only. If included, they should be removed and

discarded before the cutter is put into use.

1. Remove and discard all four shipping lugs (#1) and

attaching hardware (#2 & #3).

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

24

11 /11 / 12

Page 27

Section 1: Assembly & Set-up

30173

37986

Table of Contents

Unhook Rotary Cutter

1. S e e “Long Term Storage” on page 48 if parking the

cutter for long periods and end of season.

2. Disengage PTO, park on a level hard surface. Place

tractor gear selector in park or set park brake.

3. Raise center deck fully up.

4. Wait for blades to come to a complete stop and then

fold wing up to transport position.

5. Shut tractor engine off and remove switch key before

dismounting from tractor.

Refer to Figure 1-25:

6. Place transport lock pin (#2) in transport lock

holes (B). Make sure pin is secured with hairpin

cotter (#3).

Refer to Figure 1-21 on page 23:

7. Remove stroke control spacers (#4) from center

hydraulic cylinder.

8. Start tractor and lower cutter until front skids are on

the ground.

9. Shut tractor engine off and remove switch key before

dismounting tractor.

10. Replace stroke control spacers (#4) on lift cylinder as

needed to support wheels at this height.

11. Return to the tractor seat. With no one around or near

the cutter, move cylinder lift levers back and forth to

release hydraulic line pressure.

Refer to Figure 1-26:

12. Remove park jack (#3) from weight box and attach to

jack mount (#12) as shown. Fully insert detent

pin (#8) in jack mount to secure park jack.

13. If needed, realign park jack (#3) to be vertical. Refer

to “Park Jack Angle Alignment” on page 26.

14. Unhook hydraulic hoses (#10 & #11) from tractor

duplex outlets. Store coupling ends in hose

holder (#14).

15. Unhook hitch safety chain (#4) from tractor.

16. Pull back on locking collar (#6) and pull driveline (#5)

from tractor PTO shaft.

17. Collapse driveline (#5) by pushing tractor end of

driveline toward the splitter gearbox.

18. Rotate driveline hanger (#7) up to position shown

and store driveline on hanger. If height of driveline

hanger needs readjusting, refer to “Adjust Driveline

Hanger” on page 21.

19. Adjust park jack (#3) to raise cutter up until all load is

removed from tractor drawbar.

20. Remove connecting hitch pin or bolt as follows:

a. Refer to Detail A in Figure 1-26: If unhooking

LP Performance hitch or standard clevis, remove

hairpin cotter (#2) and hitch pin (#1).

b. Refer to Figure 1-11 on page 17: If unhooking

bar-tite hitch, remove lock nut (#2) and bolt (#1).

21. Restart tractor and drive tractor slowly forward

several feet.

22. Shut tractor down properly before dismounting.

23. Lower park jack (#3) until skid shoes support cutter.

24. Replace connecting pin/bolt (#1) as follows:

a. Refer to Detail A in Figure 1-26:

If unhooking LP Performance hitch, insert hitch

pin (#1) in horizontal hitch holes to support clevis

level. Secure with hairpin cotter (#2)

b. Refer to Detail B in Figure 1-26:

If unhooking standard clevis, replace connecting

pin (#1) in clevis hitch pin holes and secure with

hair pin cotter (#2).

c. See Figure 1-11 on page 17:

If unhooking bar-tite hitch, remove hitch (#10)

from tractor and attach it to cutter hitch (#9) with

bolt (#1) and lock nut (#2) Screw lock nut on 4 or

5 full turns. Do not torque nut tight.

Wing Transport Lock

Figure 1-25

Unhook Rotary Cutter (LP Performance Hitch Shown)

Figure 1-26

11 /11 / 12

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

25

Page 28

Section 2: Adjustments

37576

NOTE: If cutter is not hitched securely to a tractor,

support blocks should be placed under the front

skid shoes to support cutter while aligning the park

jack vertically.

NOTE: Refer to decal (#6) and instructions below

for jack alignment and torque values.

NOTE: Loosening adjusting nuts (#5) will lengthen

leveling rods (#2) and lower front of cutter.

Tightening adjusting nuts (#5) will shorten leveling

rods (#2) and raise front of cutter.

Section 2: Adjustments

Park Jack Angle Alignment

Figure 2-1

Park Jack Angle Alignment

Refer to Figure 2-1:

The jack mount angle should be adjusted to position the

park jack vertical while supporting the cutter hitch. This

angle will vary depending on the number and size of

stroke control spacers placed on the lift cylinder rod.

1. With cutter hitched to a tractor, lower cutter to storage

height.

2. Shut tractor down properly before dismounting. Refer

to “Tractor Shutdown Procedure” on page 14.

3. Install park jack (#7). See “Park Jack Assembly” on

page 14. Check jack angle. If jack is not vertical,

proceed with step 4 below.

4. Remove 1/2" hex nut (#3), lock washer (#5) and

carriage bolt (#2).

5. Loosen 1" hex nut (#4). Do not remove.

6. Rotate jack mount (#1) to align park jack (#7) as near

vertical as possible.

7. Replace 1/2"-13 x 1 1/2" GR5 carriage bolt (#2) and

secure with lock washer (#5) and hex nut (#3).

Tighten hex nut to the correct torque.

8. Tighten 1" hex nut (#4) to 645 ft-lbs.

9. If moving cutter, skip to step 10. If unhooking cutter,

see “Unhook Rotary Cutter” on page 25 for detailed

instructions.

10. If cutter is to be moved, remove park jack (#7) from

hitch frame and attach it to the weight box storage

base.

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

26

Table of Contents

Leveling Center Deck & Wing

These adjustments should be made with your cutter

hooked to the tractor operating the unit or to a tractor

having the same drawbar height.

Center Deck Leveling

Refer to Figure 2-2 & Figure 2-3 on page 27:

1. Attach cutter to tractor and park on level ground.

2. Raise wing up and lock into position with transport

lock to keep wings from falling.

3. Using hydraulic lift, adjust center deck height so that

the front skids (#5) are 2 to 3 inches above ground.

4. Shut tractor down properly before dismounting. Refer

to “Tractor Shutdown Procedure” on page 14.

5. On both sides of the center deck are continuous

hinges (#1). Measure distance from bottom of hinges

to ground at the front and back. They should be equal

distance off the ground at the back and 1" closer to

the ground at the front than they are at the back.

If continuous hinges are too high at the front:

a. Loosen jam nuts (#3) several turns.

b. Unscrew adjusting nuts (#5) an equal amount to

lower front of cutter until both hinges are inclined

from front to back by 1" with the front being closer

to the ground than the back.

If continuous hinges are too low at the front:

a. Loosen jam nuts (#3).

b. Tighten adjusting nuts (#5) an equal amount to

raise front of cutter until both hinges are inclined

from front to back by 1" with the front being closer

to the ground than the back.

6. Be sure left and right leveling rods (#2) have equal

amounts of tension and then re-tighten jam nuts (#3)

against lock washers (#4) and adjusting nuts (#5).

11 /11 / 12

Page 29

Section 2: Adjustments

37616

Guard Removed for Clarity

30165

8

9

B

A

30233

Table of Contents

Center Deck Leveling

Figure 2-2

Wing Deck Leveling

Refer to Figure 2-2:

The wing section will need adjusting if its top is not level

with the center deck top when wing is unfolded.

1. With tractor hydraulics, raise wings fully up, remove

transport lock pin (#7) from holes "B", and store in

holes “A”. Be sure to secure transport lock pin with

hairpin cotter (#6).

2. Lower wing to ground position and pull cutter straight

forward six to ten feet to allow outer wing wheel to

properly align itself.

3. With tractor hydraulics, fully extend rephasing

cylinders ensuring all cylinders are fully extended.

Then lower cutter to approximate cutting height.

4. Shut tractor down properly before dismounting. Refer

to “Tractor Shutdown Procedure” on page 14.

5. Check wing top to see if it is level with top of center

deck. If outer edge of wing is higher or lower than the

center deck, then level wing as follows:

a. If the outer wing edge is higher than the center

deck, loosen adjusting nut (#9) to lower the outer

wing edge until wing is level. Tighten adjusting

nut (#10) to the correct torque when level.

b. If the outer wing edge is lower than the center

deck, loosen adjusting nut (#10) several turns and

tighten adjusting nut (#9) until wing is level.

Tighten adjusting nut (#10) to the correct torque

when level.

Front Skid Position

Figure 2-3

11 /11 / 12

RCB6610 & RCBM6610 Series 2 S/N 944730+ Rotary Cutters 330-584M

Leveling Wing Deck

Figure 2-4

27

Page 30

Table of Contents

NOTE: Make all cutting height adjustments in the

field using height of cut grass/material as a guide.

Do not measure blade height above ground as the

non-operating blade height will be different than the

operating blade height.

NOTE: Removing spacers lowers the cutting height

and adding spacers raises the cutting height.

26611

Section 2: Adjustments

Cutting Height Adjustment

Refer to Figure 2-5:

1. At the cutting site, unfold wings and raise center deck

fully up with lift cylinder (#1). See instructions for

“Unfolding Wing Deck” on page 18.

2. Shut tractor down properly before dismounting. Refer

to “Tractor Shutdown Procedure” on page 14.

3. Remove all stroke control spacers (#4) from center

hydraulic cylinder (#1) by spreading them apart at

the break line. Store spacers in a location they can be

retrieved.

4. Start tractor and engage blades. See instructions for

“Engage Blades” on page 34.